Direct-injection gas injector with elastomer seat and sealing edge

A gas injector and sealing seat technology, which is applied in fuel injection devices, machines/engines, mechanical equipment, etc., can solve the problems of high temperature stability and easy wear, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

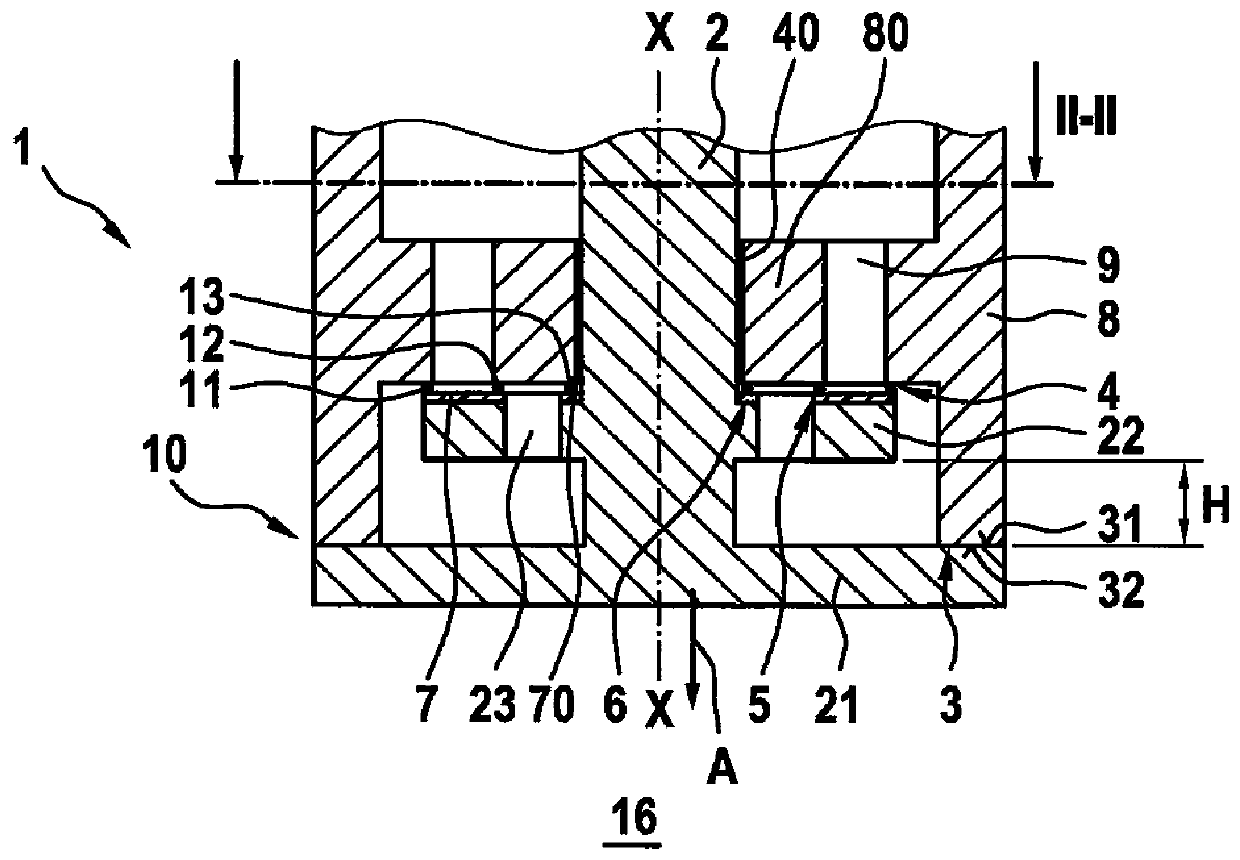

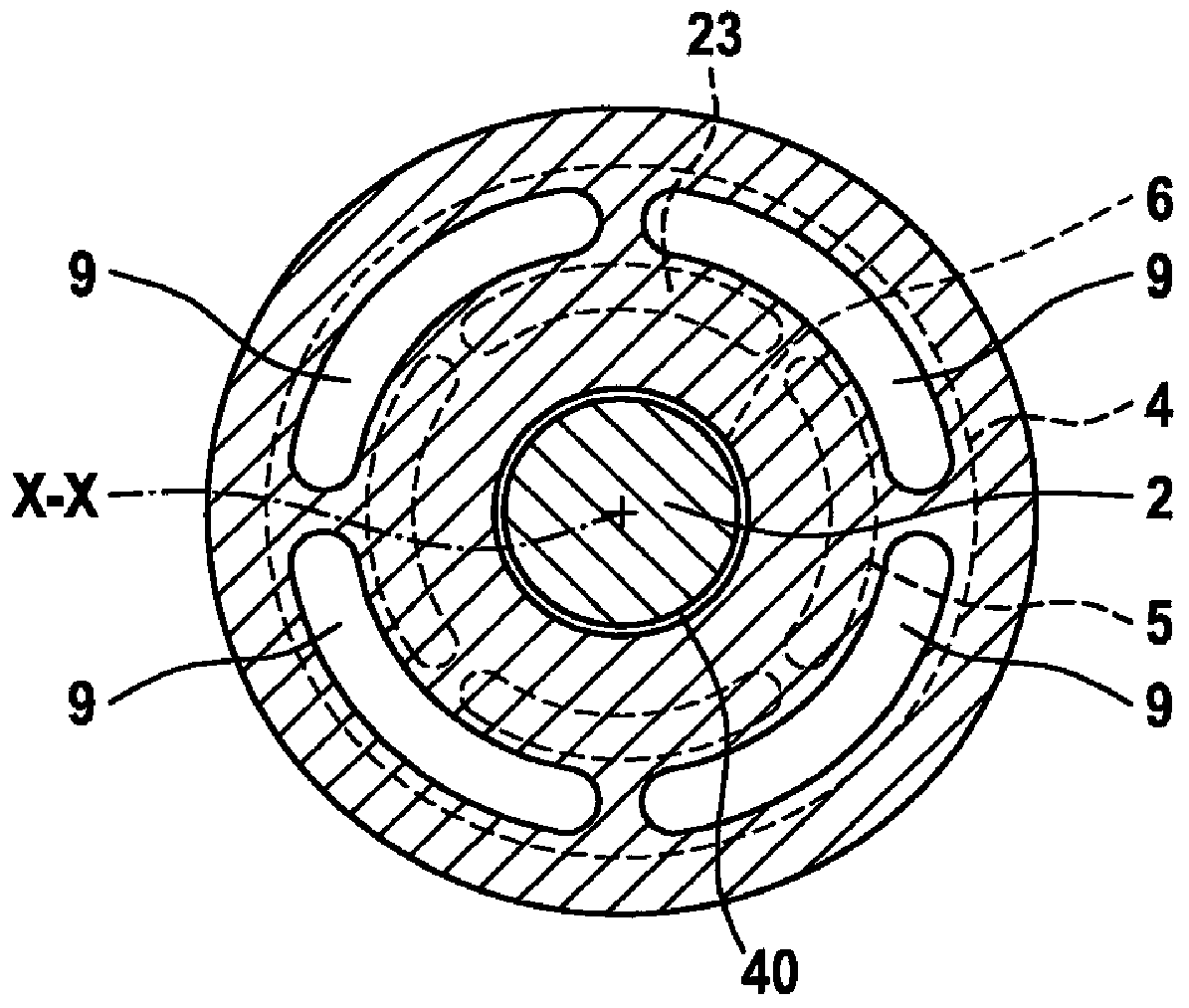

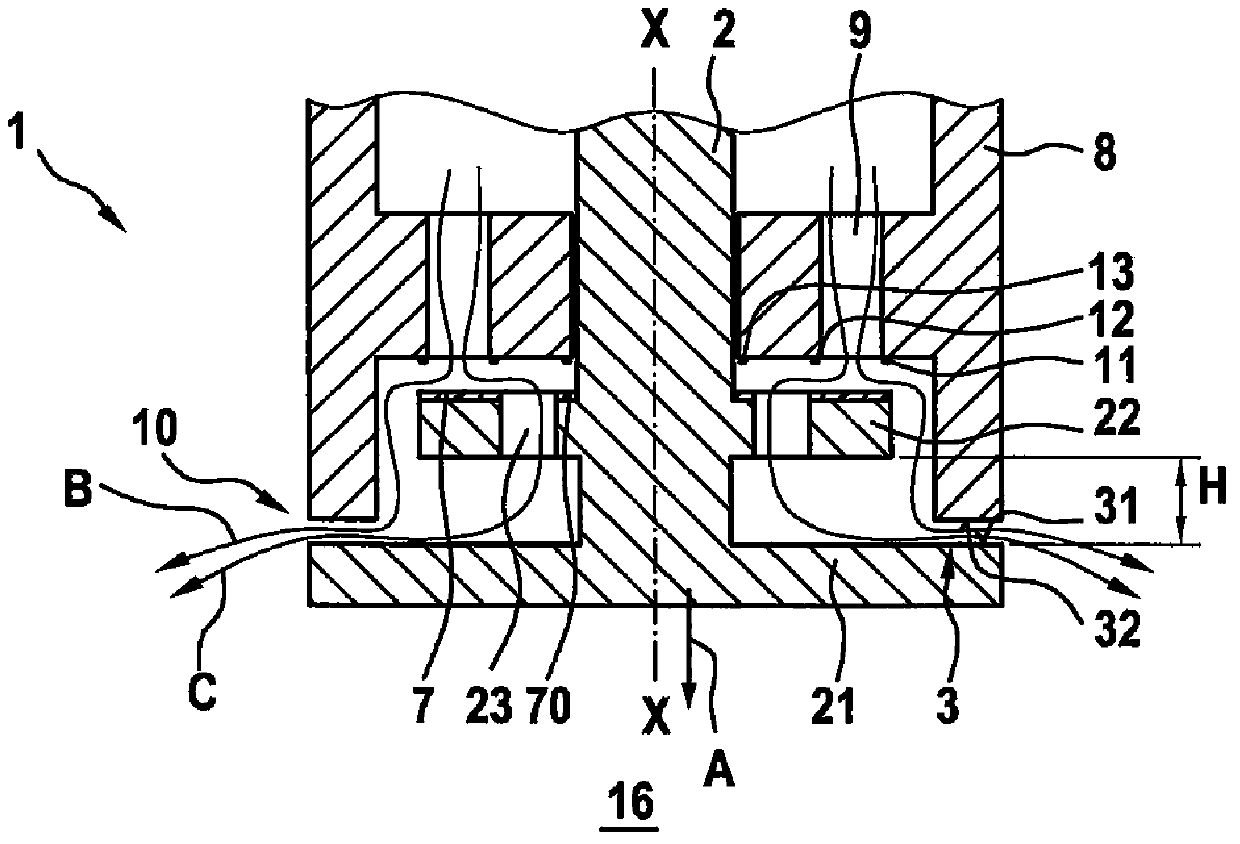

[0024] Refer to the attached Figures 1 to 3 A gas injector 1 according to a first preferred embodiment of the present invention will be described in detail.

[0025] as from figure 1 As can be seen, the gas injector 1 comprises a valve closing element 2 which in this embodiment is a valve needle with a cylindrical body. X-X here indicates the axial direction of the gas injector. The valve closing element 2 here releases or closes the passage opening 10 to the combustion chamber 16 . figure 1 The closed state of the gas injector is shown. The gas injector 1 is here a gas injector that opens outwards, as in figure 1 as indicated by arrow A.

[0026] The gas injector 1 also includes a plurality of sealing seats which are arranged between the valve closing element 2 and the valve body 8 . More precisely, the gas injector 1 comprises a first sealing seat 3 realized in two metal sealing counterparts 31 , 32 . In this case, the first metallic sealing counterpart 31 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com