Patents

Literature

746results about "Bags opening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

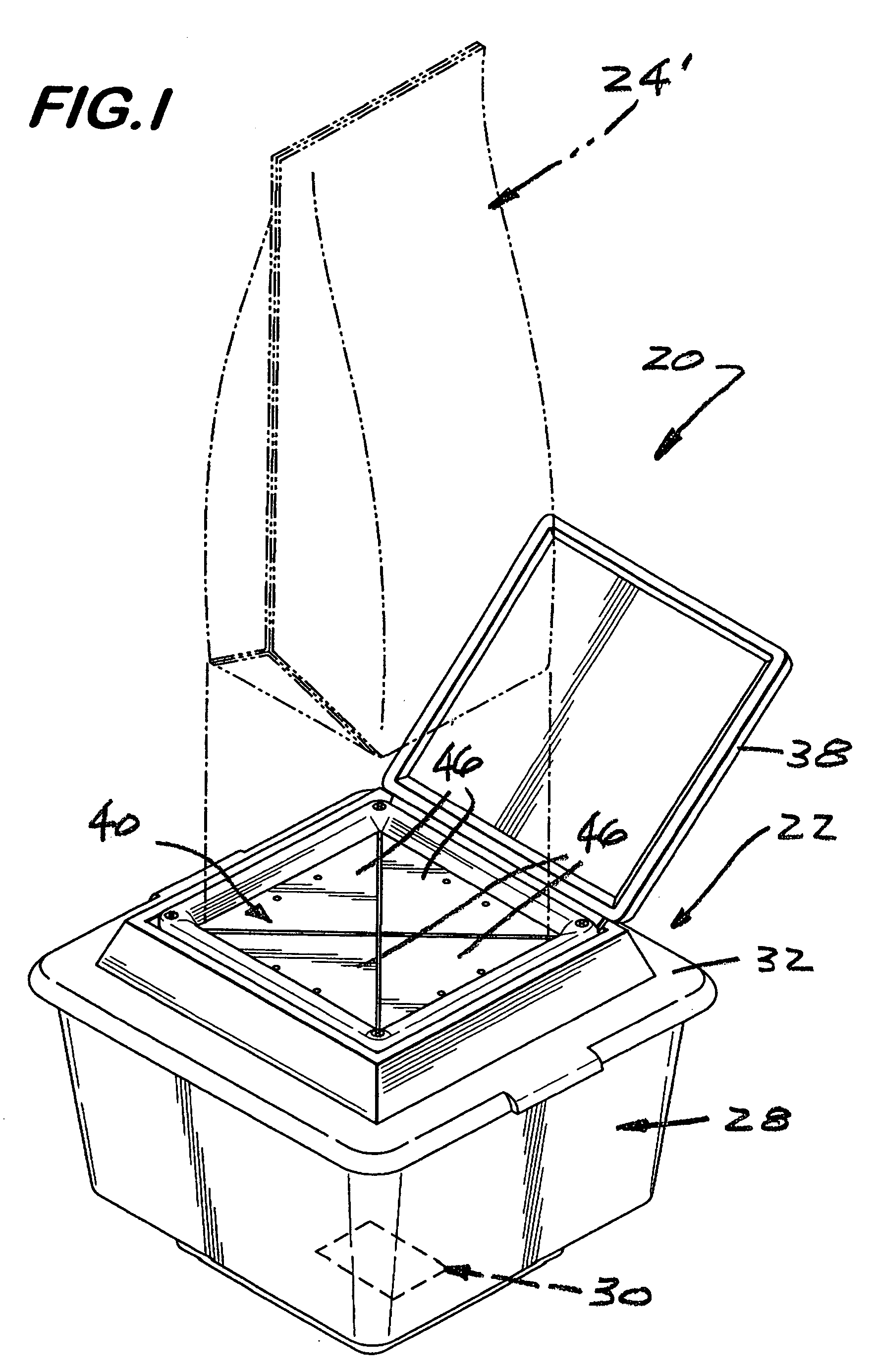

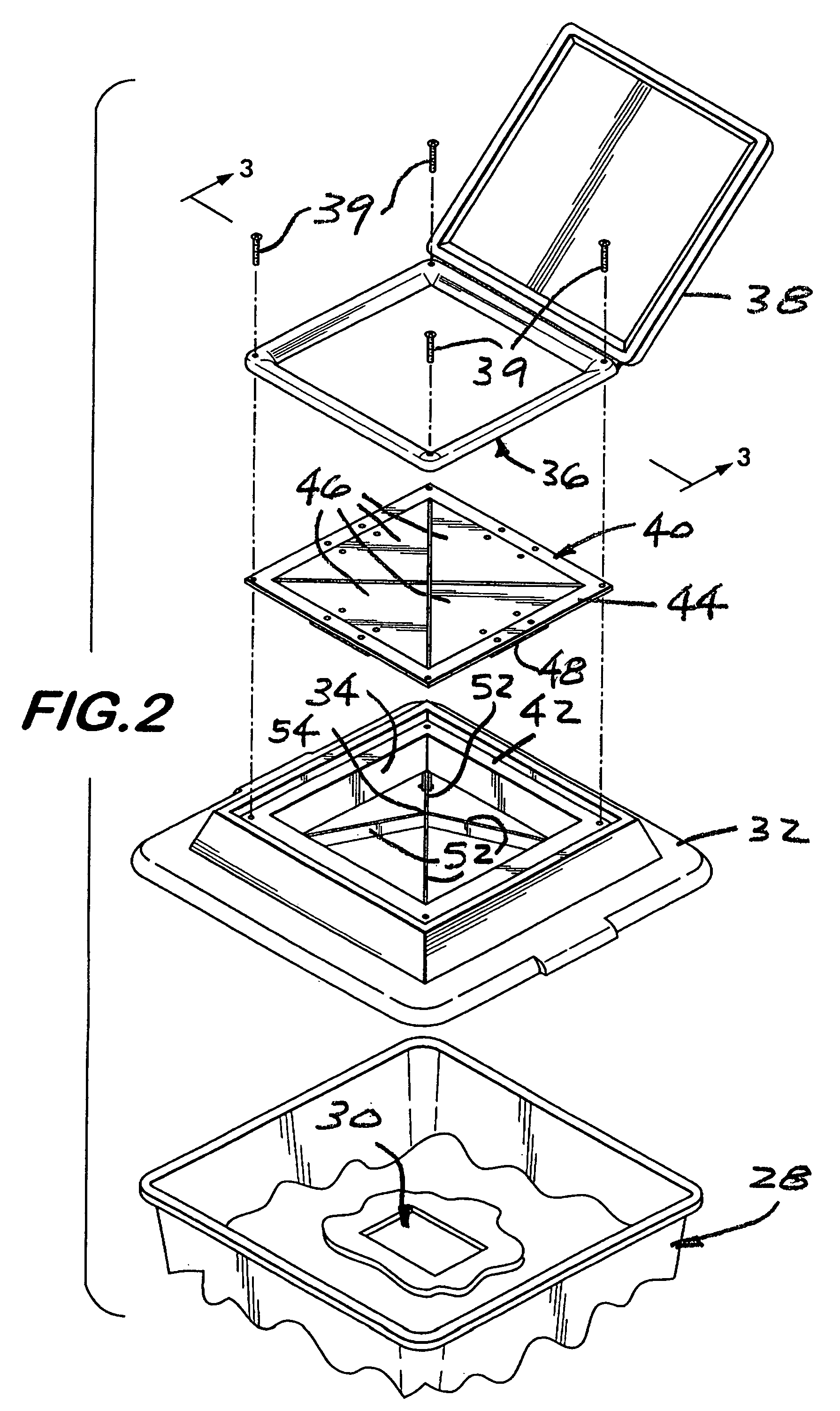

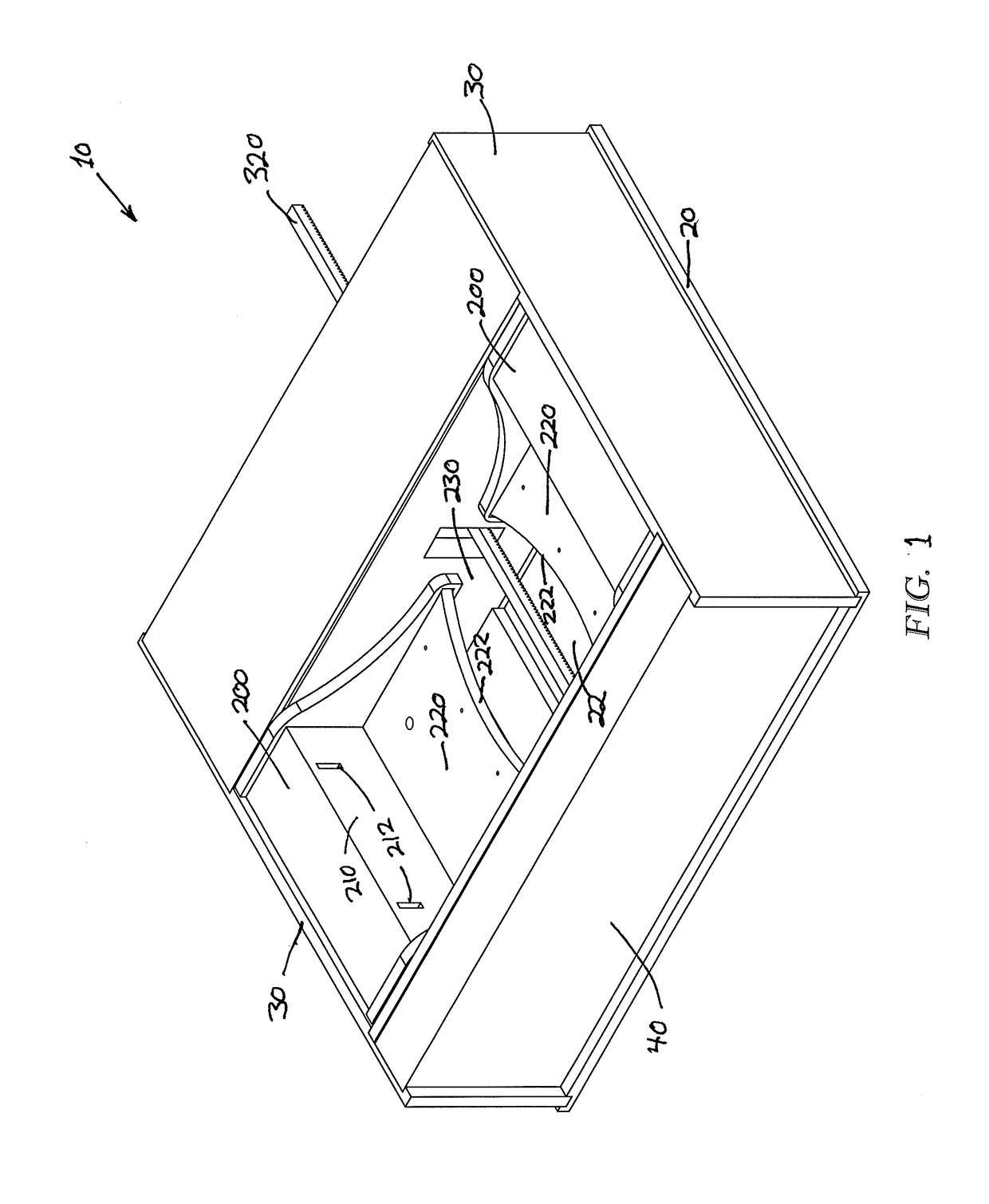

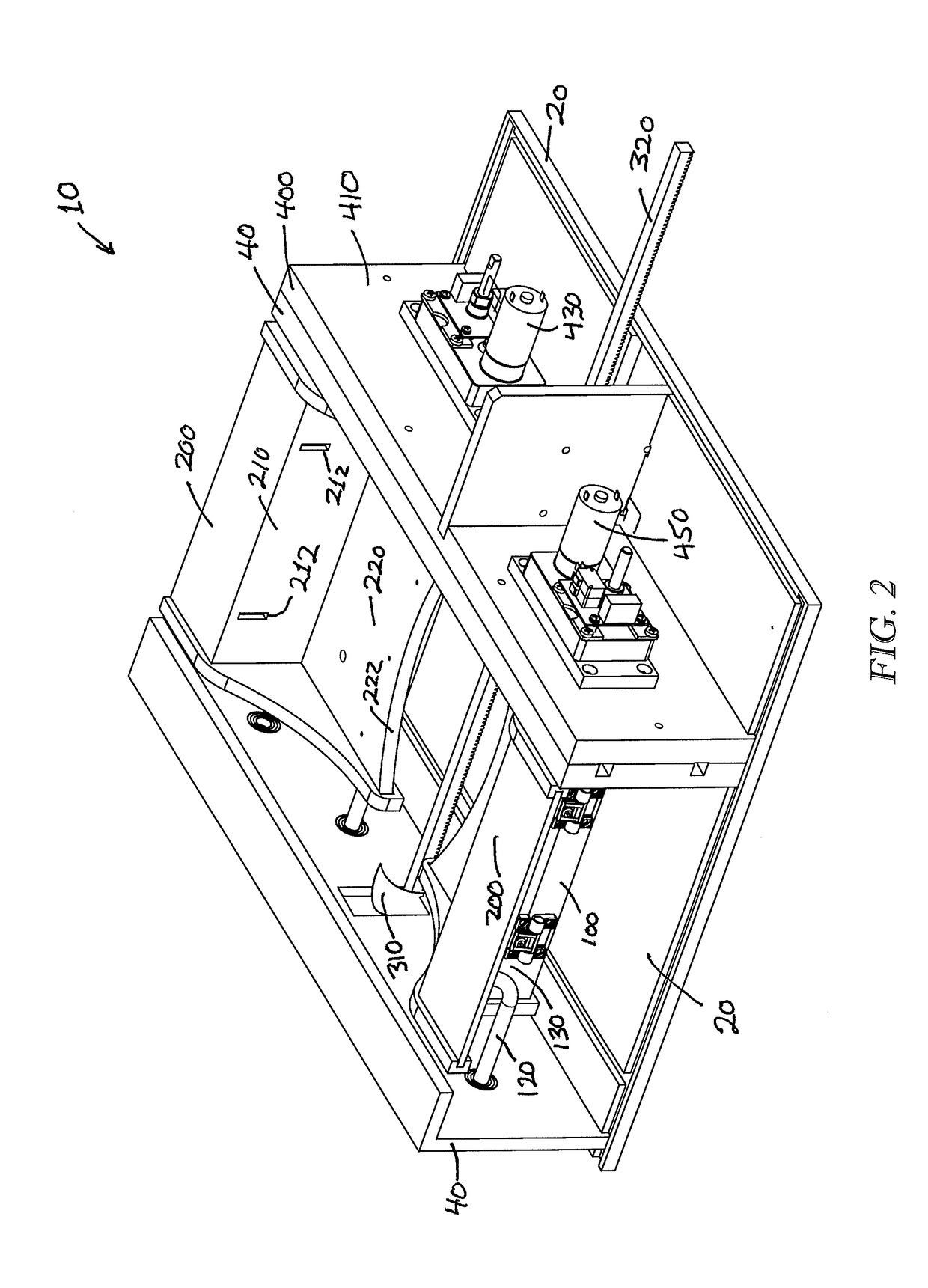

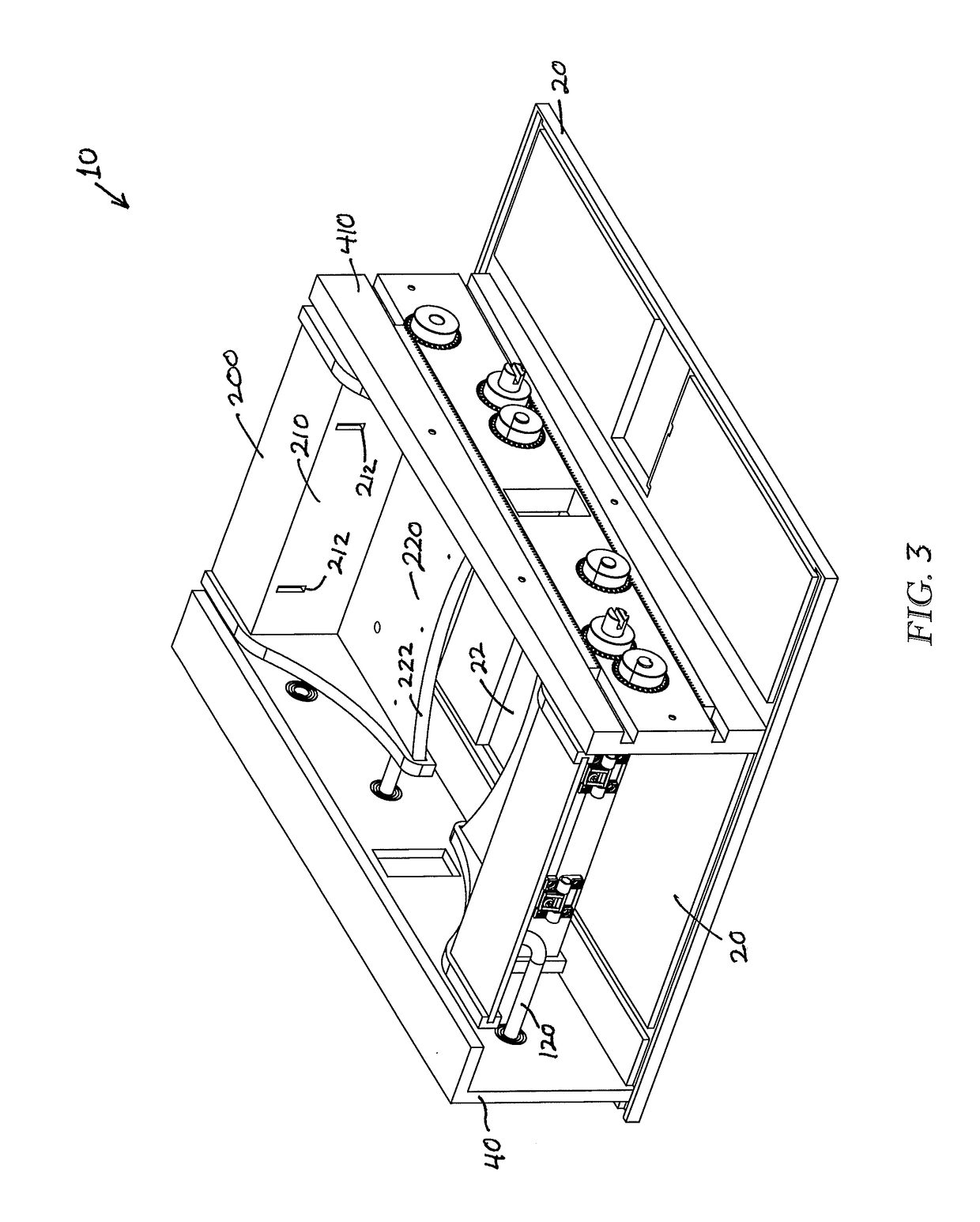

Packages for dispensing flowable materials and dispensing systems using such packages

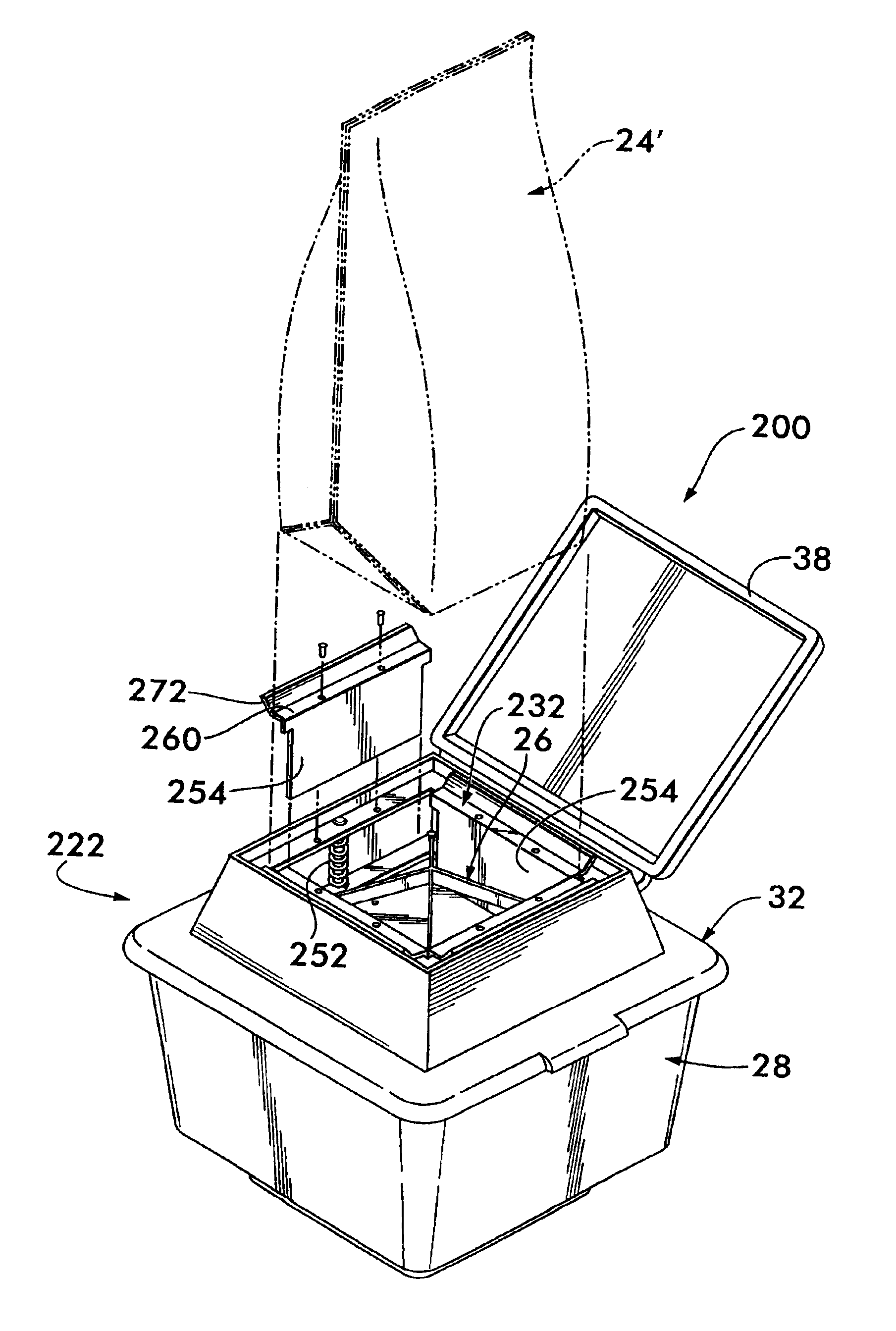

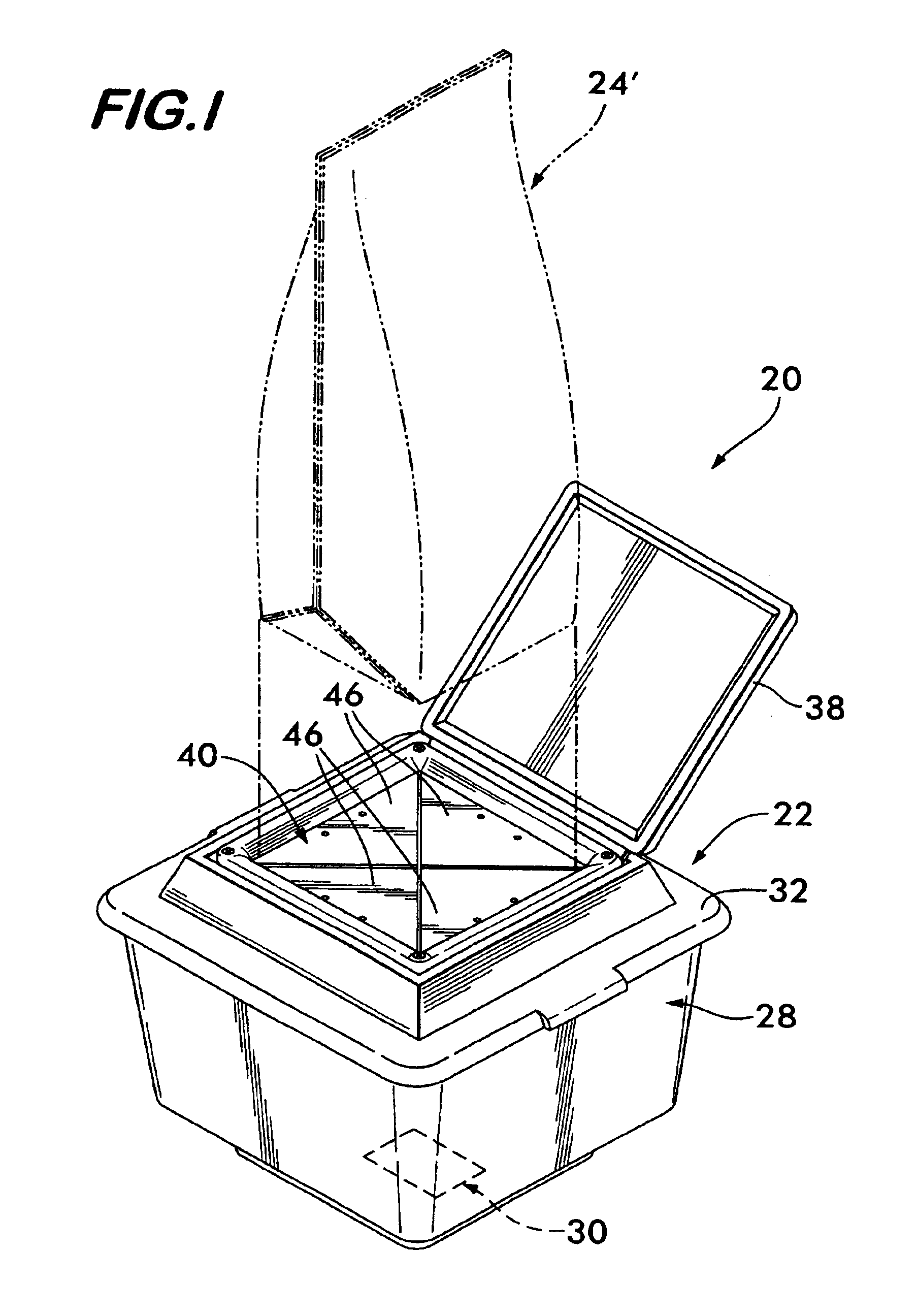

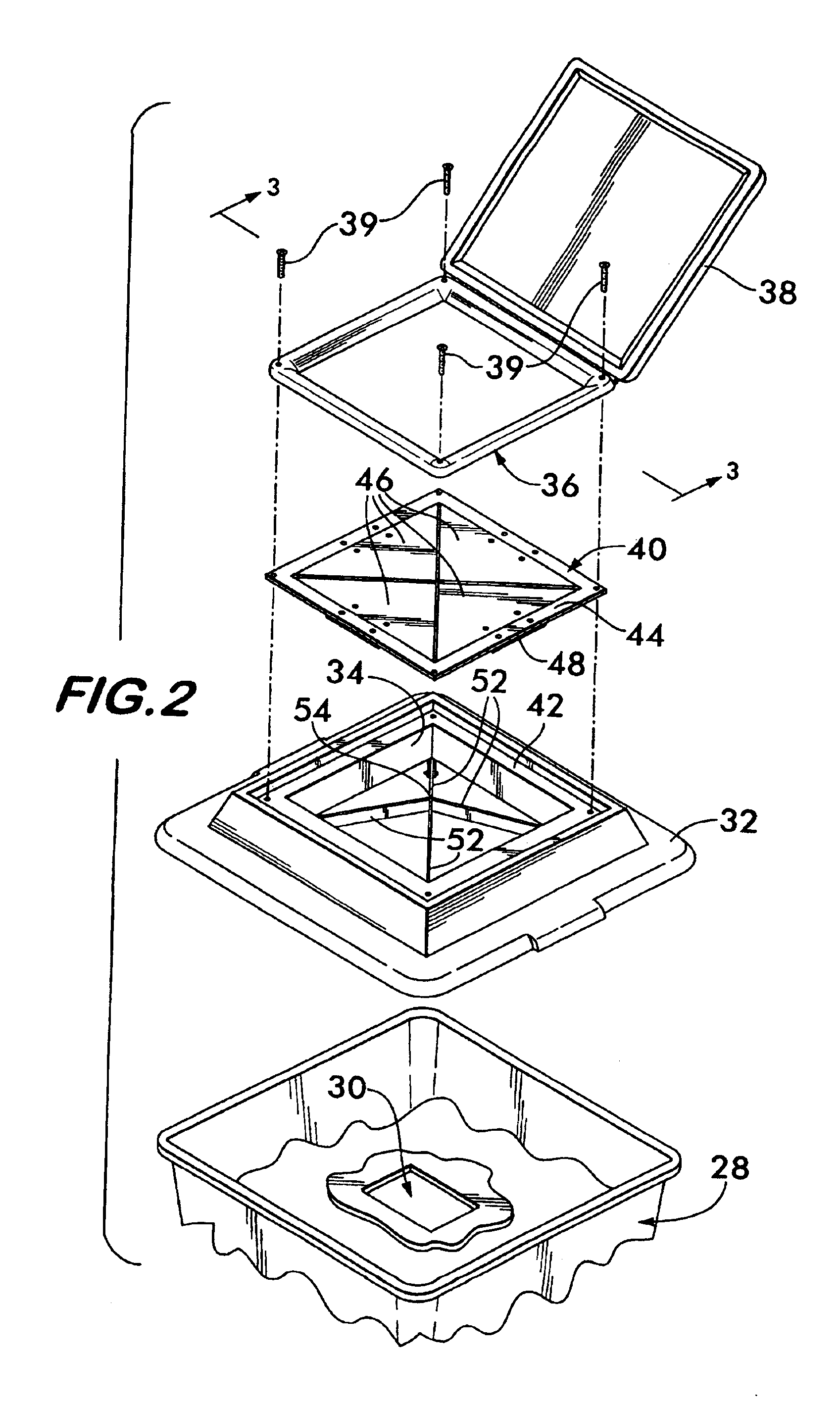

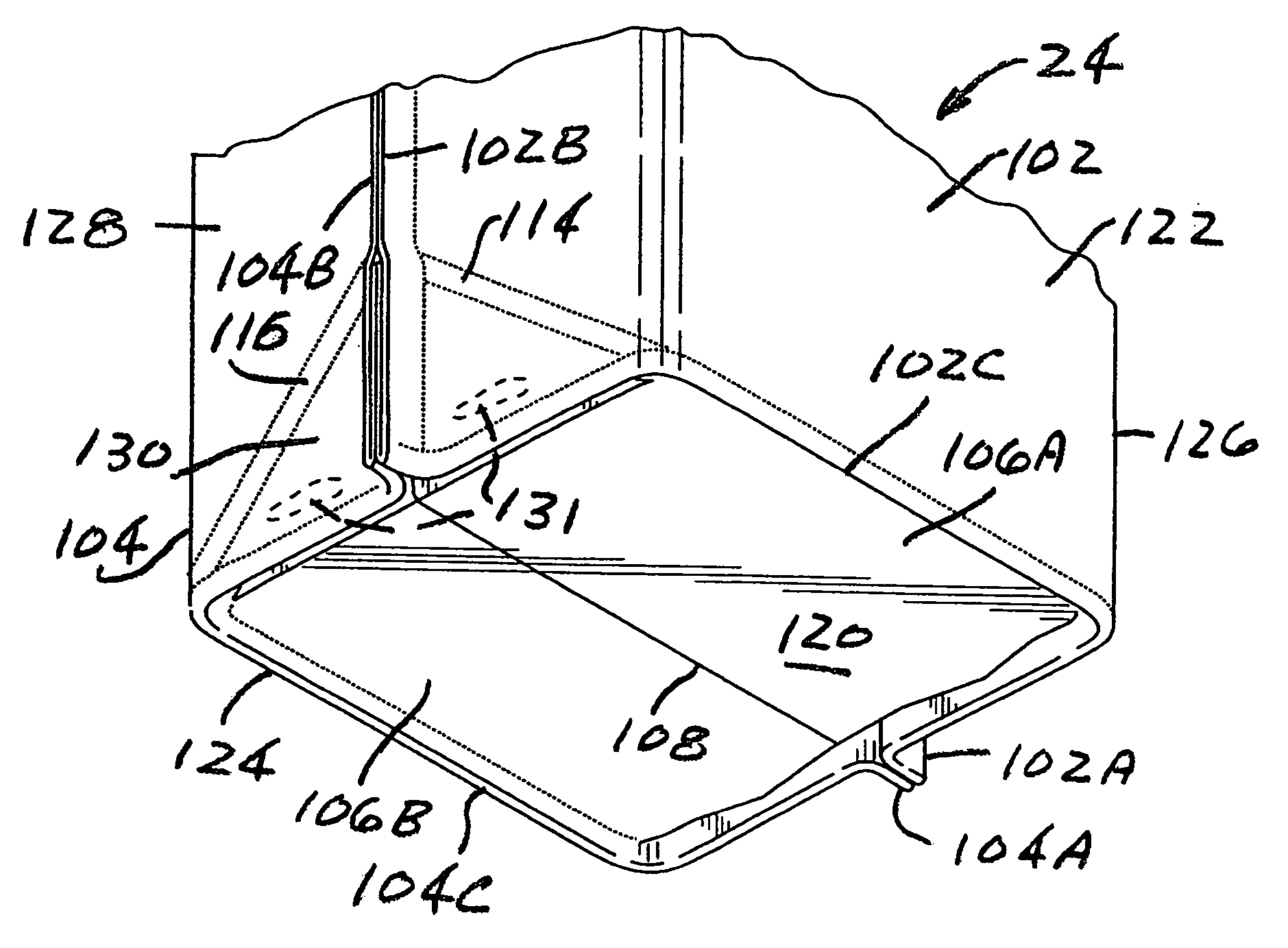

A system for dispensing flowable materials from a package. The system basically comprises the package and a receiver apparatus. The receiver apparatus includes a hollow interior chamber, e.g., a hopper, a penetrating assembly e.g., plural blades, fixedly mounted with respect to the chamber, and an outlet. The package, e.g., a flexible package, has a handle and a hollow interior in which the flowable material is located and includes at least one wall portion, e.g., a bottom wall, arranged to be penetrated by the penetrating assembly, whereupon the flowable material is enabled to flow out of the package for ultimate dispensing out of an outlet of the chamber. The flexible package may include an outer carton.

Owner:FRES SYST USA

System and package for dispensing flowable material and method for product dispensing

Owner:FRES SYST USA

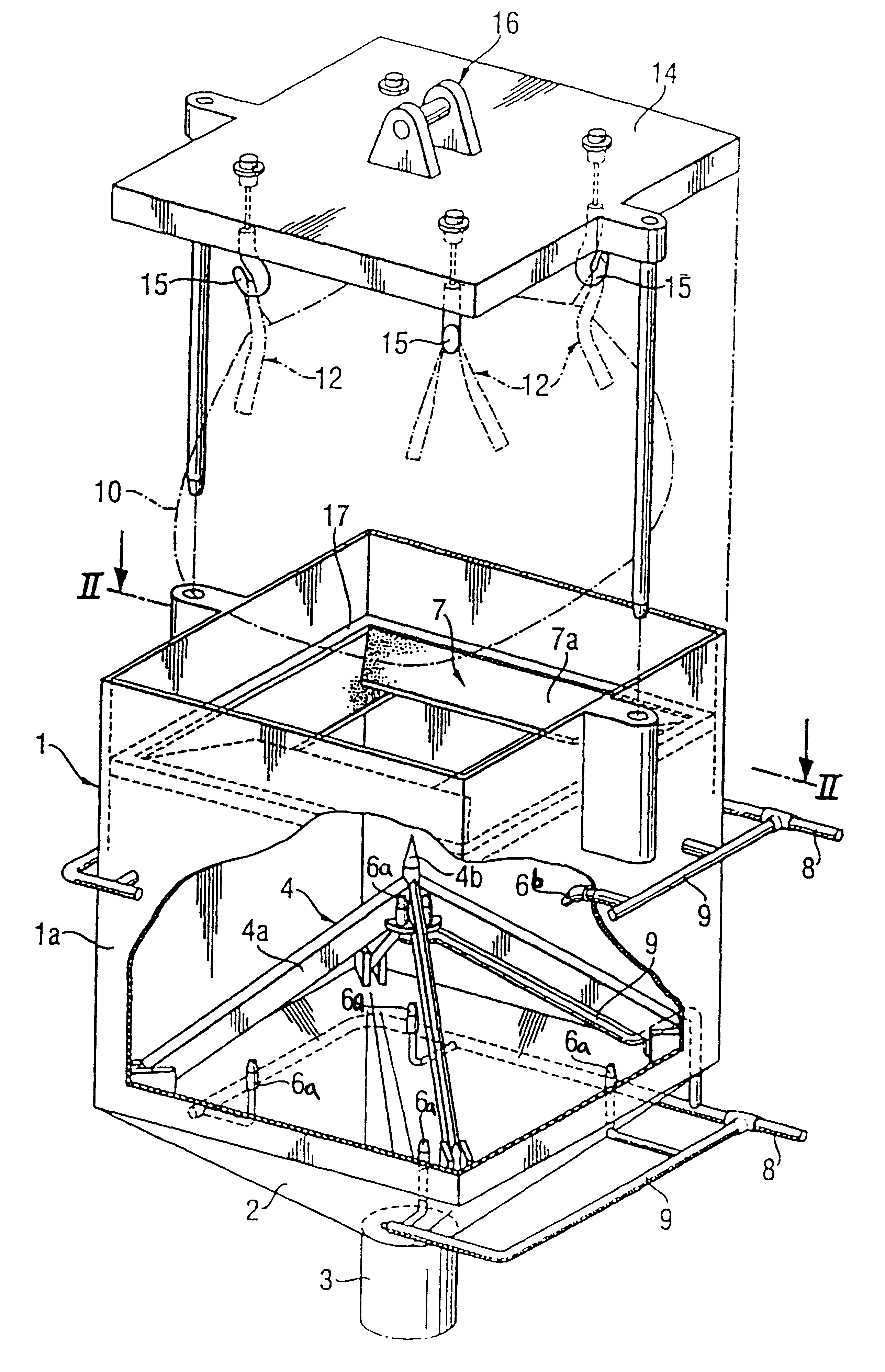

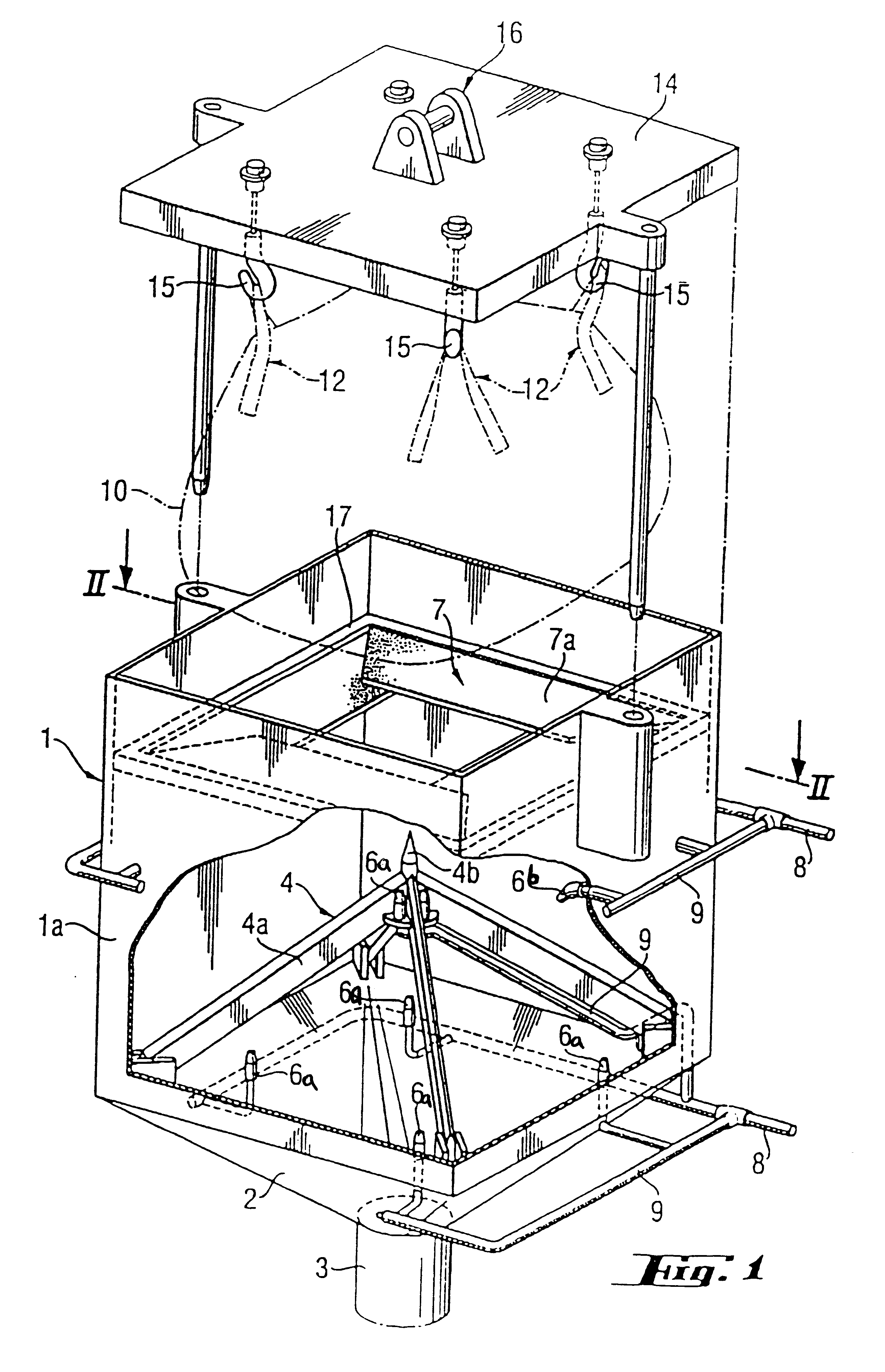

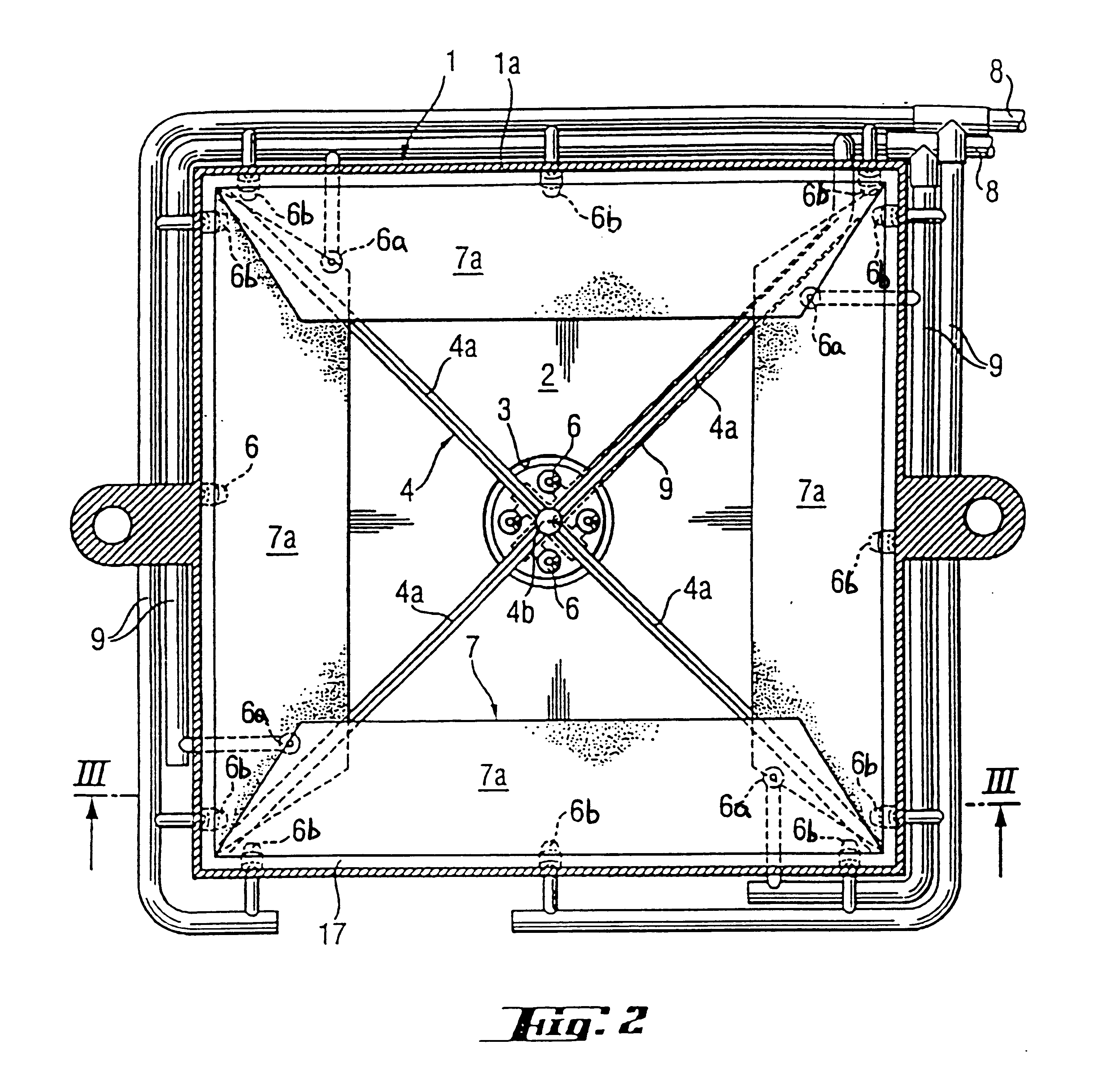

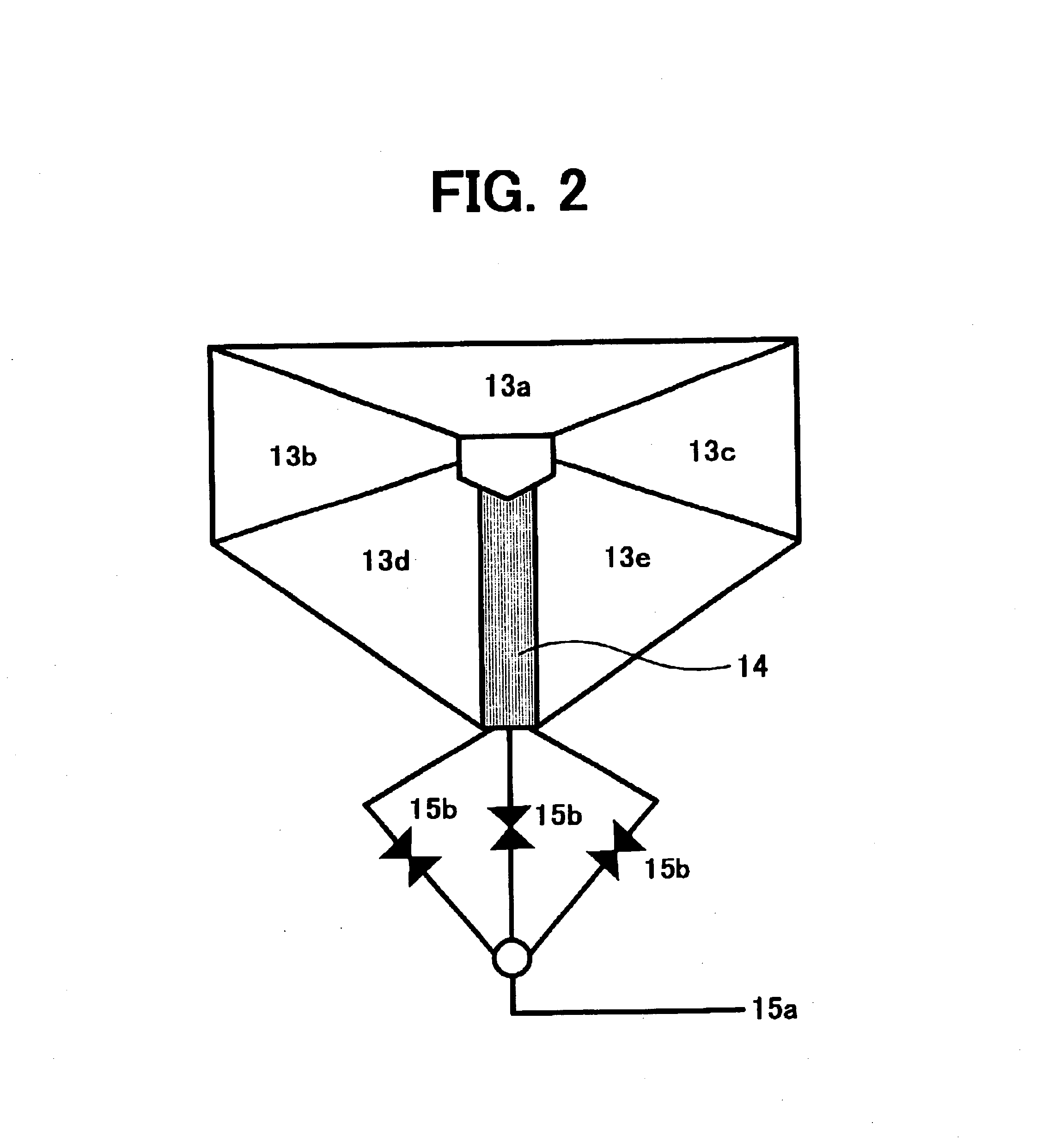

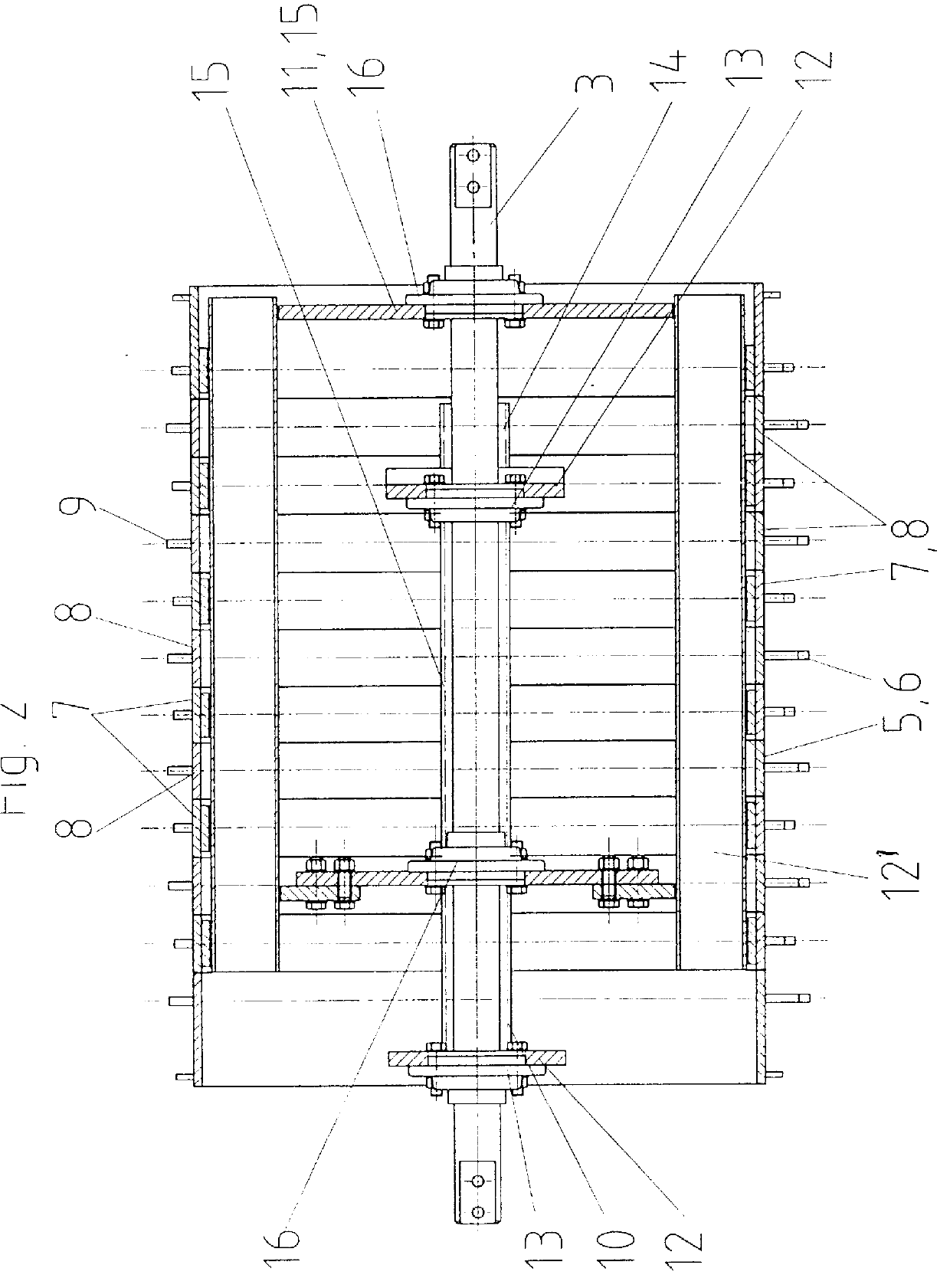

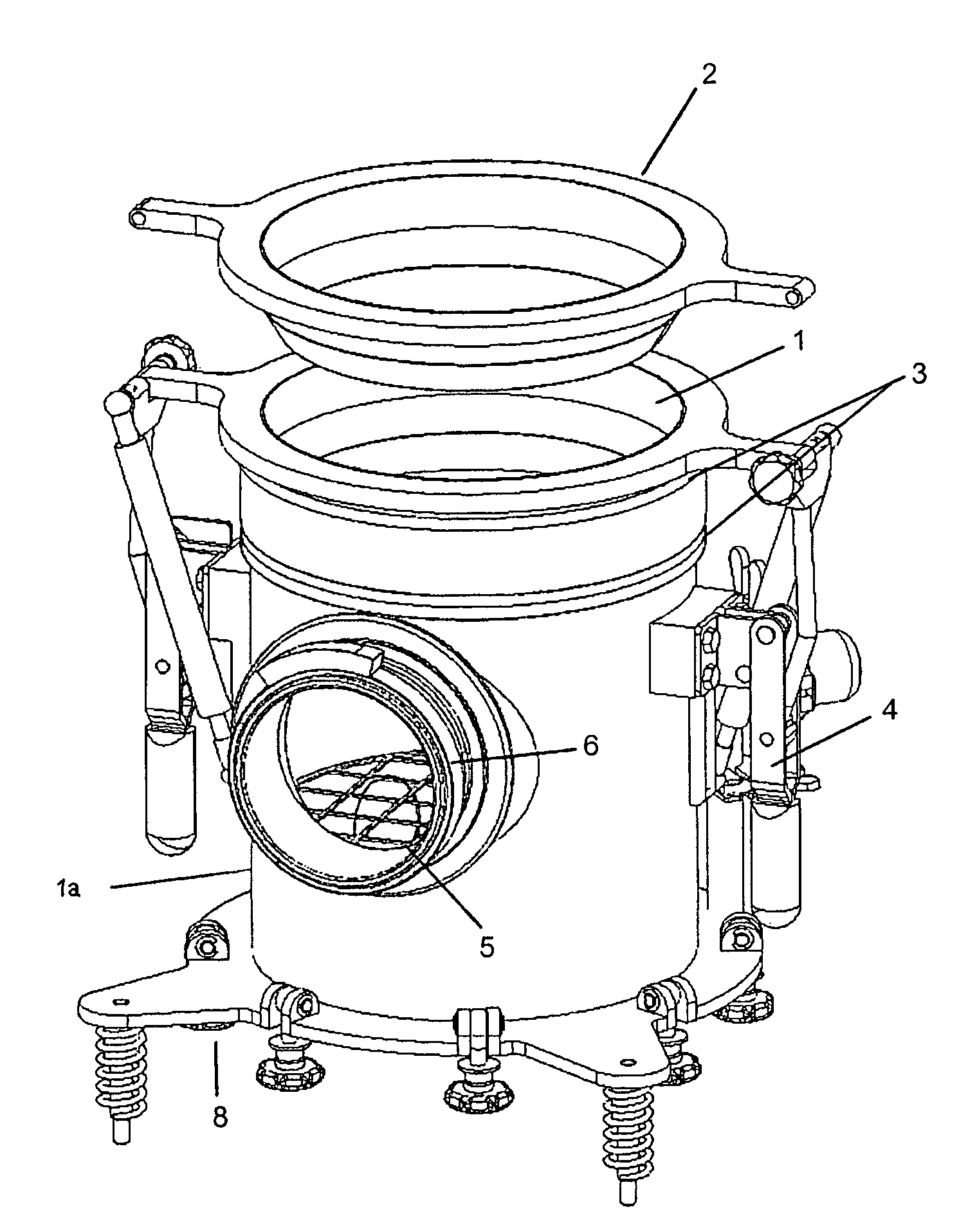

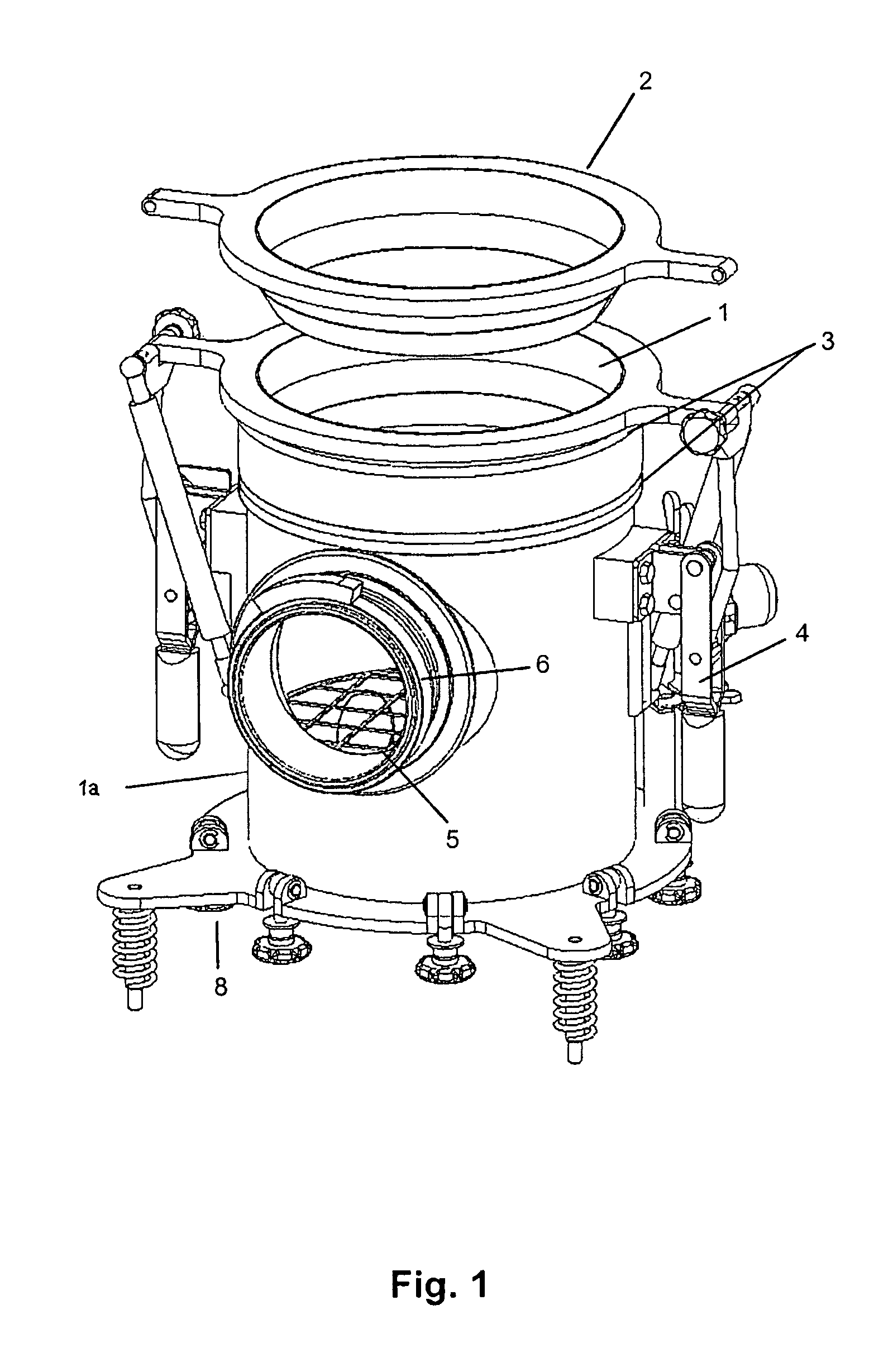

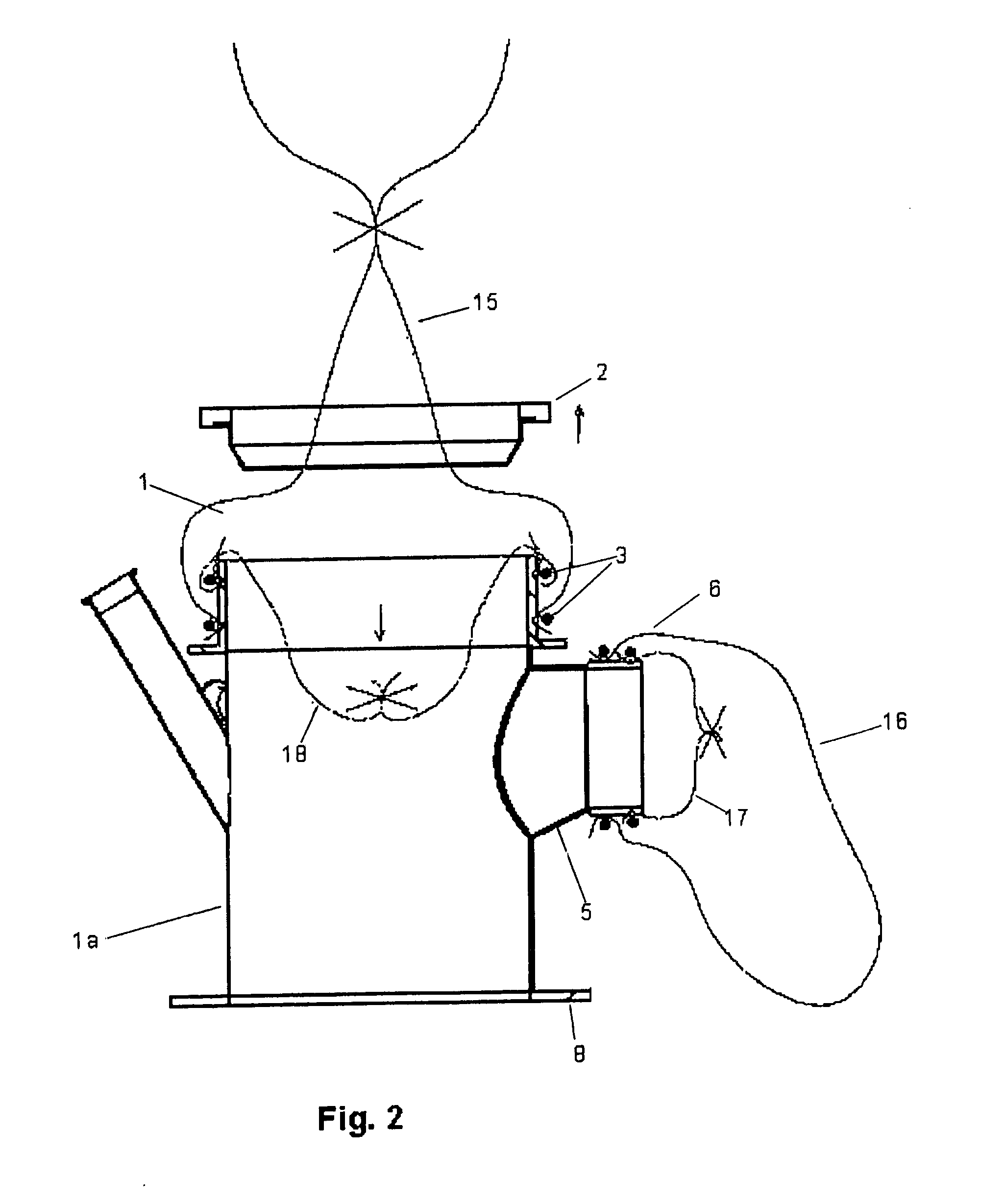

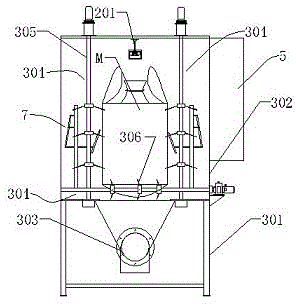

Emptying station for bulk bags, and process of emptying bulk bags in the station

This emptying station is suited for emptying contents from bulk bags, especially bulk bags containing particulate hazardous materials as their contents. The emptying station includes a bulk-bag receptacle body having a top opening and bottom outlet, a bulk-bag cutting subassembly in the receptacle body, a raisable and lowerable top closure, and a sealing structure. The cutting subassembly includes at least three cutters each having an associated blade facing upwards, with the cutters collectively arranged to define a pyramid having an apex, and puncture pin positioned at the apex to point upwardly. In operation, a bulk bag is suspended from the top closure, then lowered with the top closure to pass the bulk bag into the receptacle body and cause the substantially flat bottom of the bulk bag to be pieced by the puncture pin and cut by the blades of the cutters to start emptying contents from the bulk bags to the bottom outlet. The sealing structure seals gaps formed between inner surfaces of the side walls and the bulk bag to prevent dust from escaping through the top opening. As the bulk bag is emptied, the top closure continues to lower until the top closure is positioned in a closed state in the top opening. Spray nozzles are preferably arranged in the receptacle body for external and / or internal rinsing of the emptied bulk bag.

Owner:DEGUSSA AG

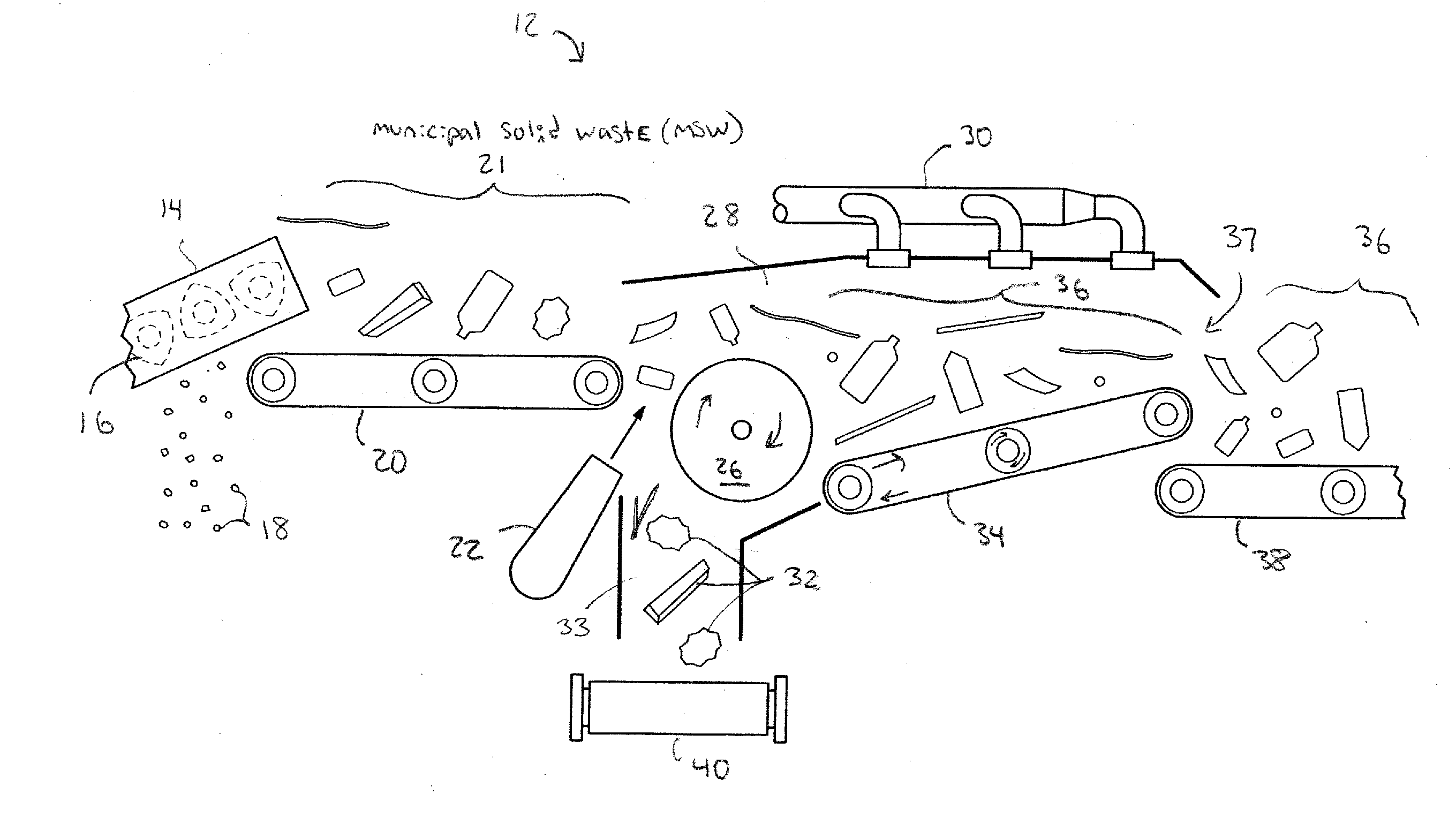

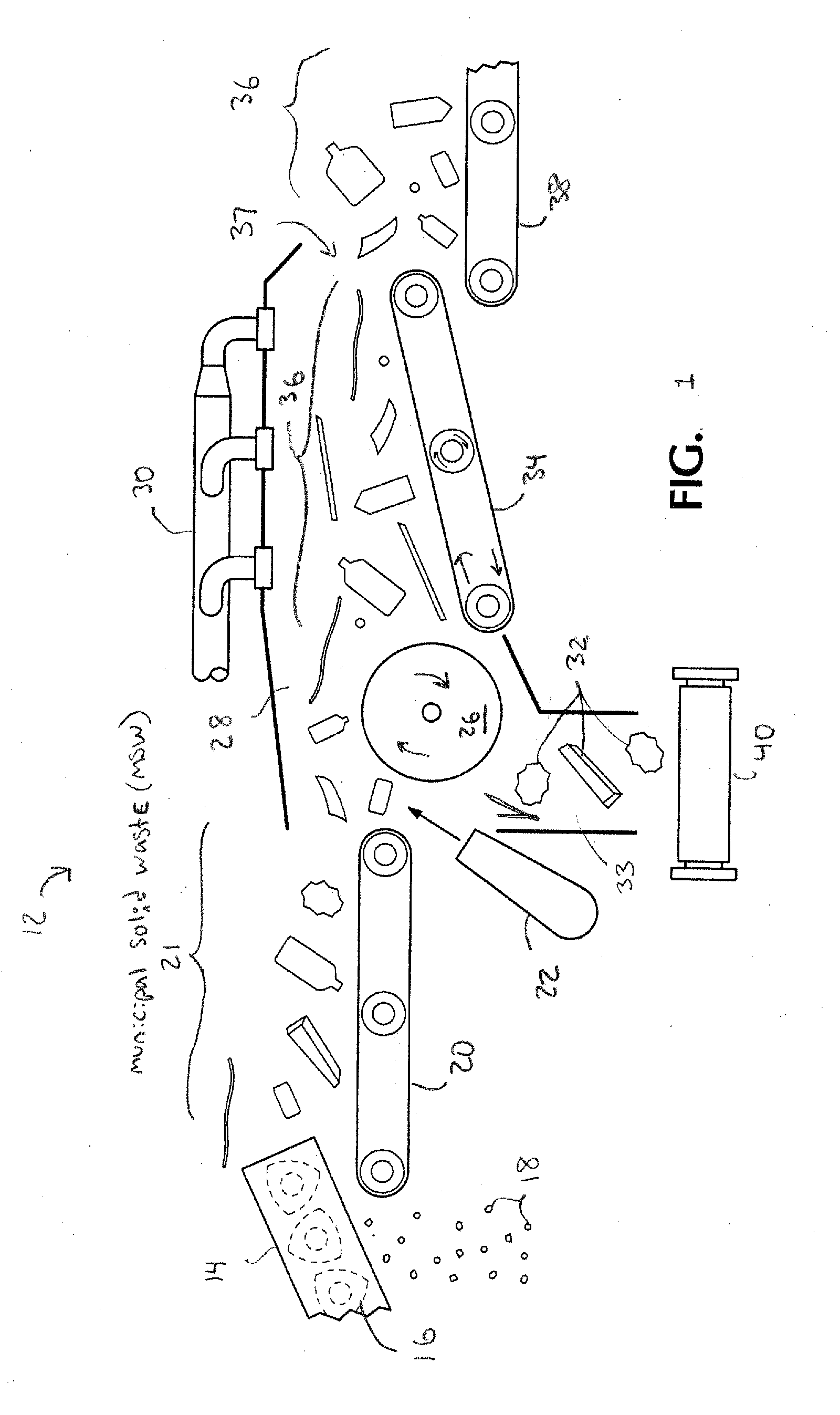

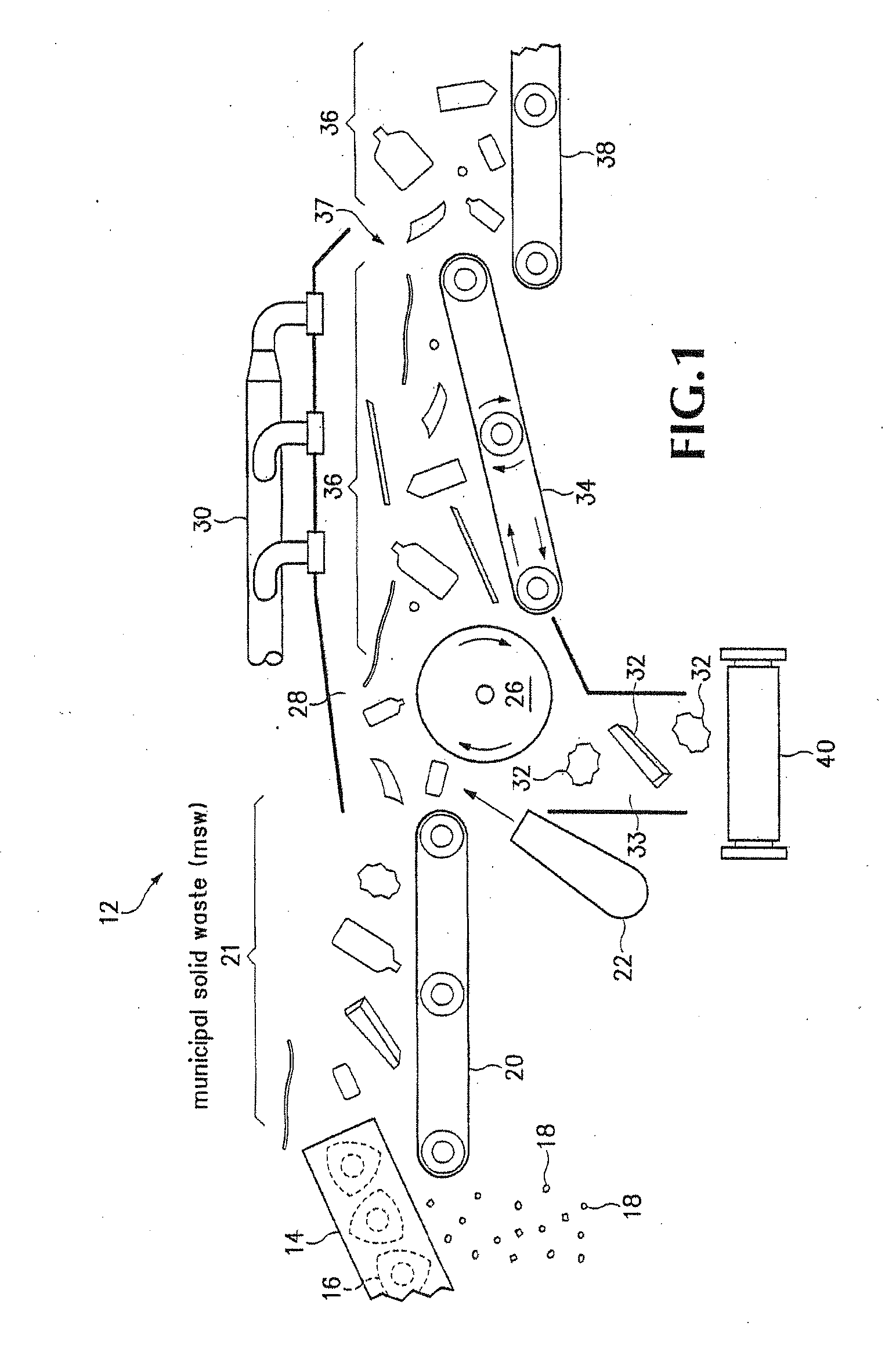

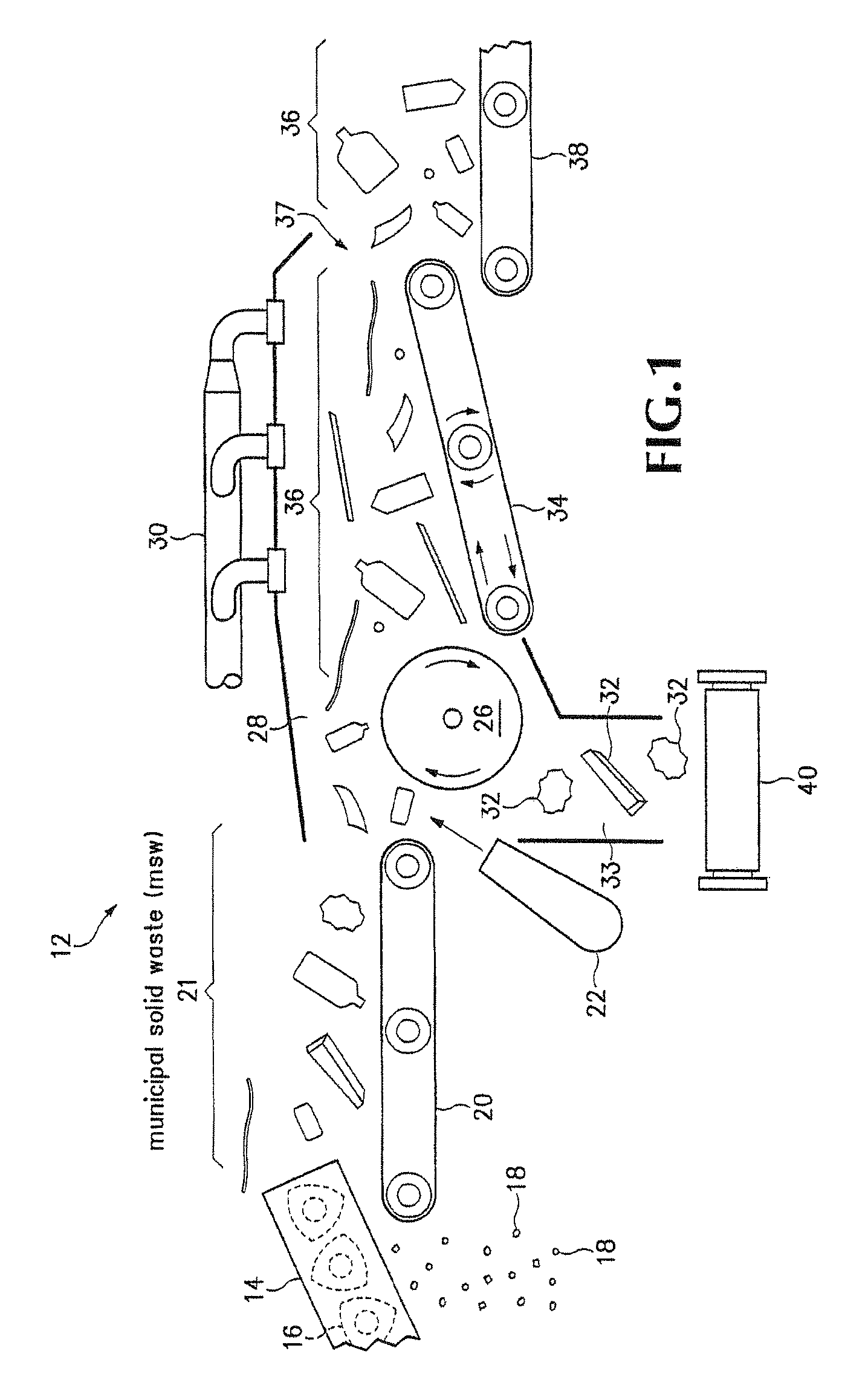

Air separation of recyclable material

A separation system includes an air separator that in one embodiment primarily receives Municipal Solid Waste (MSW) containing relatively light MSW recyclable materials such as paper, cardboard, plastic containers, and / or metal containers. The air separator blows the relatively light MSW recyclable materials up though a chamber and onto a first conveyer while the other relatively heavy MSW material drops down a chute onto a second conveyer. A separation screen receives the relatively light MSW recyclable materials from the air separator and separates the relatively flat paper and cardboard from the plastic and metal containers.

Owner:EMERGING ACQUISITIONS

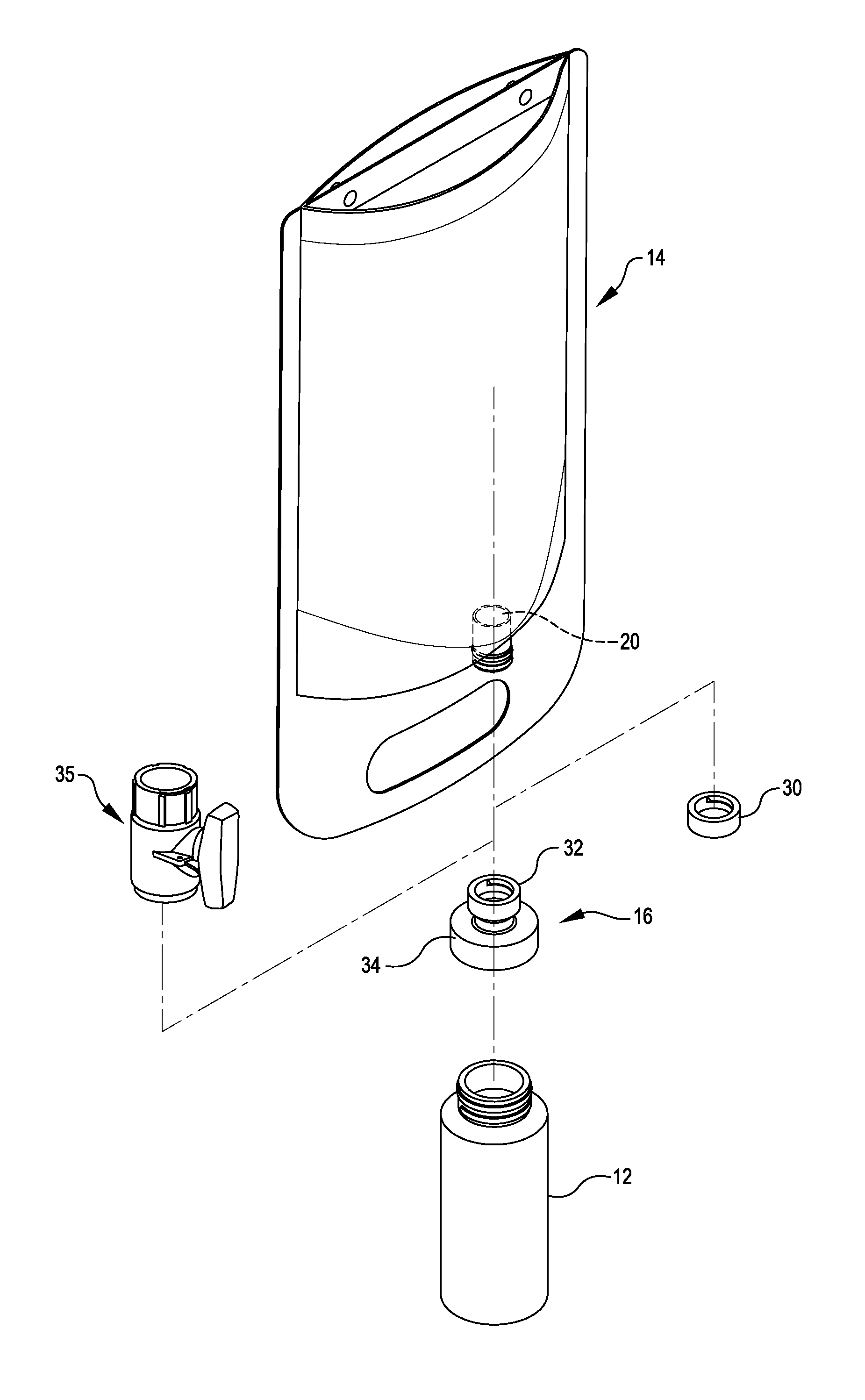

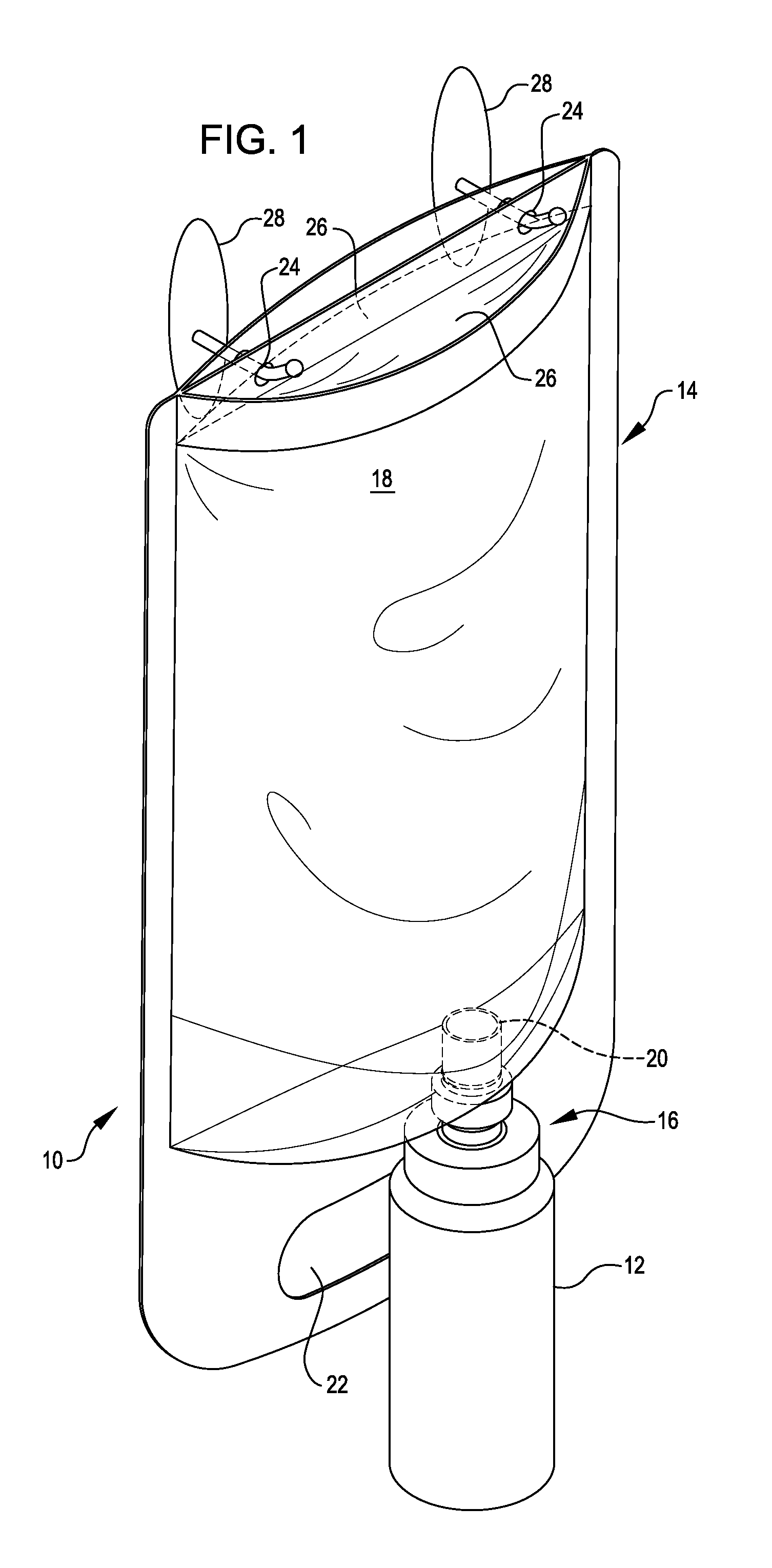

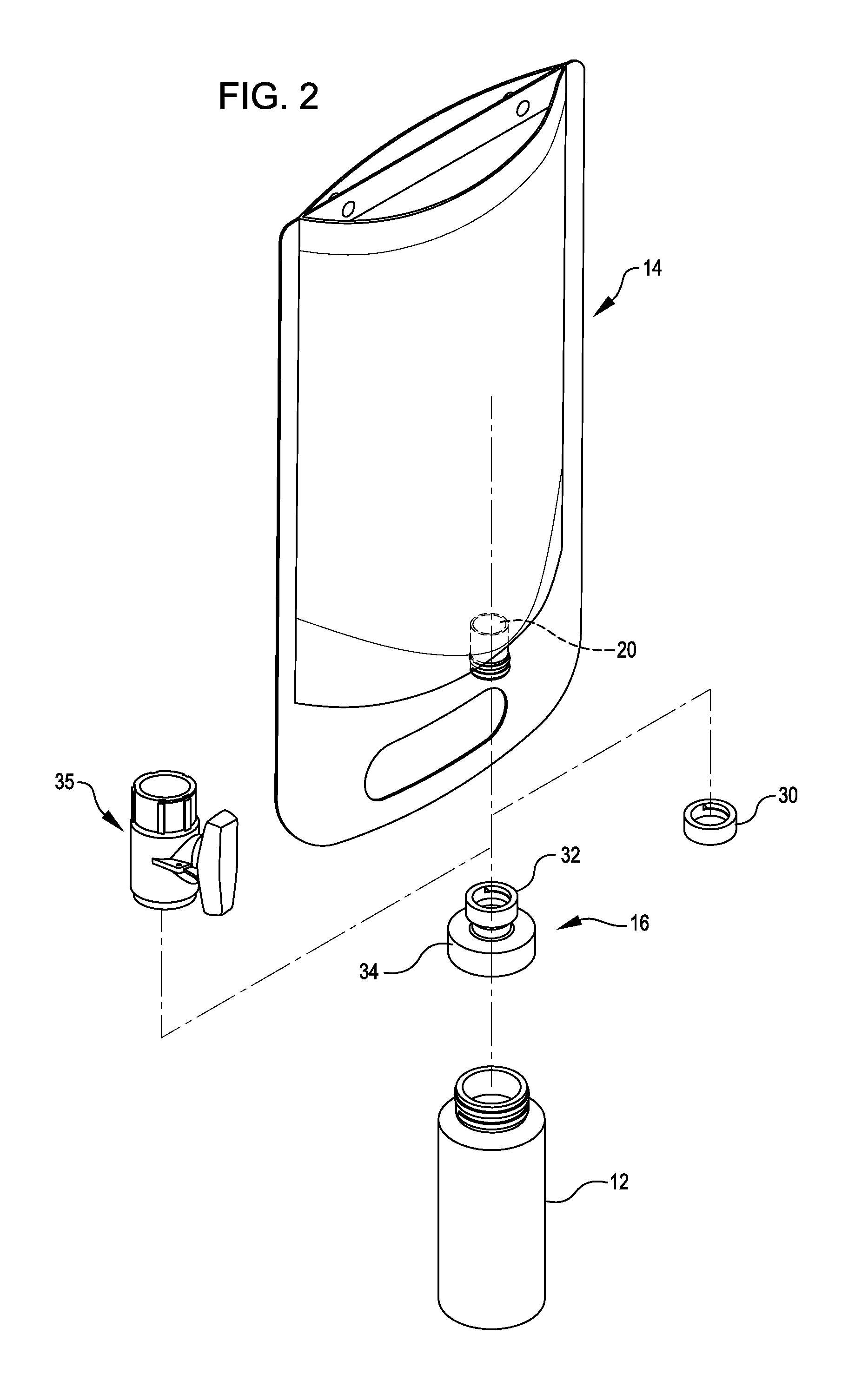

Adaptor for connecting a fluid package to a dispenser bottle

Adapters, systems, and methods are provided that can be used to refill a fluid dispenser bottle. An adapter is used to connect a fluid package to a dispenser bottle. The adapter includes a duct configured to convey a fluid being transferred from the fluid package to the dispenser bottle; a fluid package coupler coupled with the duct and configured to couple with the fluid package so as to place the duct in fluid communication with the fluid package; a dispenser bottle coupler coupled with the duct and configured to couple with the dispenser bottle so as to place the duct in fluid communication with the dispenser bottle; and at least one orifice disposed offset from the duct for venting the dispenser bottle when fluid is transferred from the fluid package to the dispenser bottle.

Owner:PARKER LAB

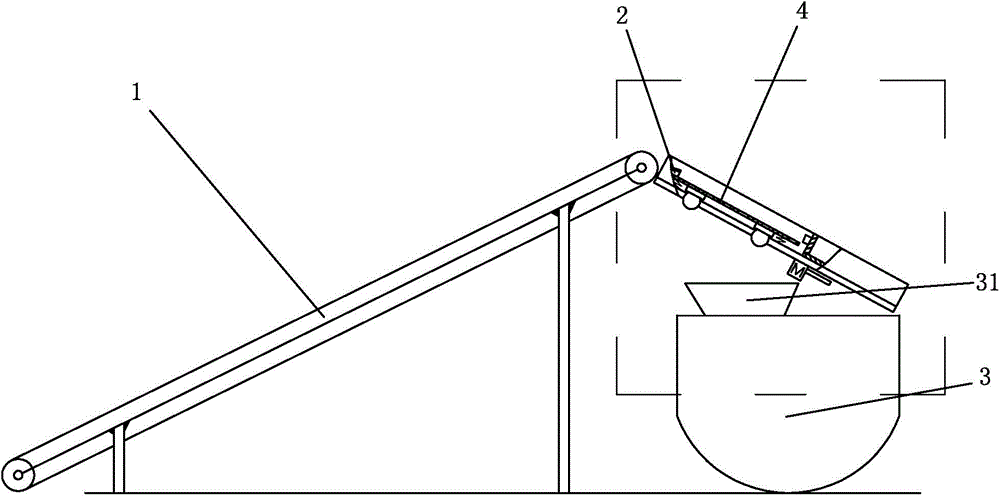

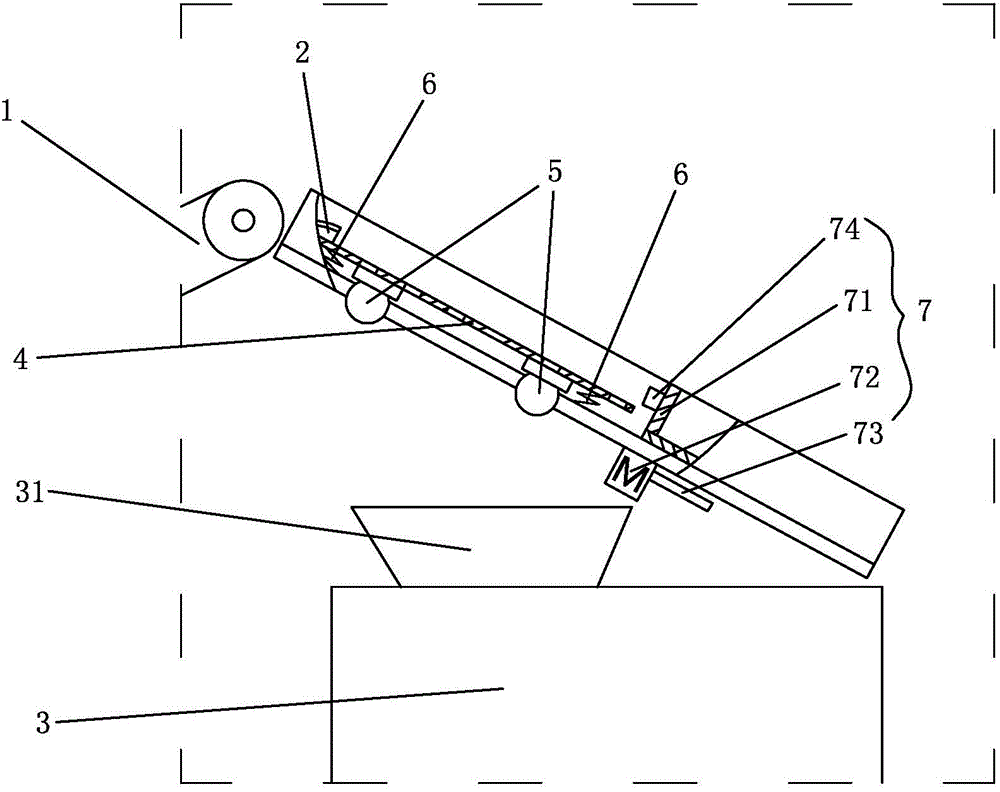

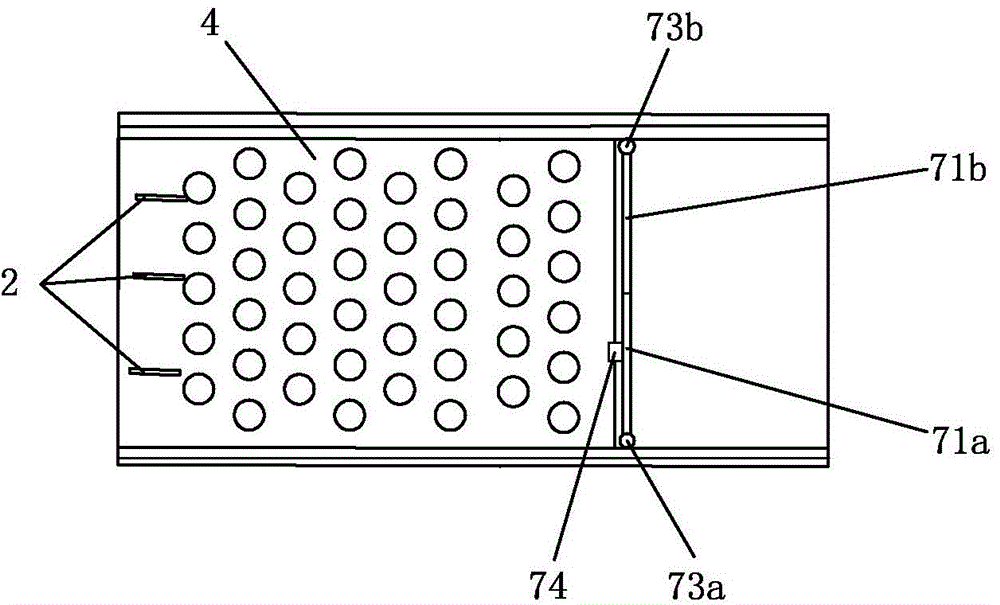

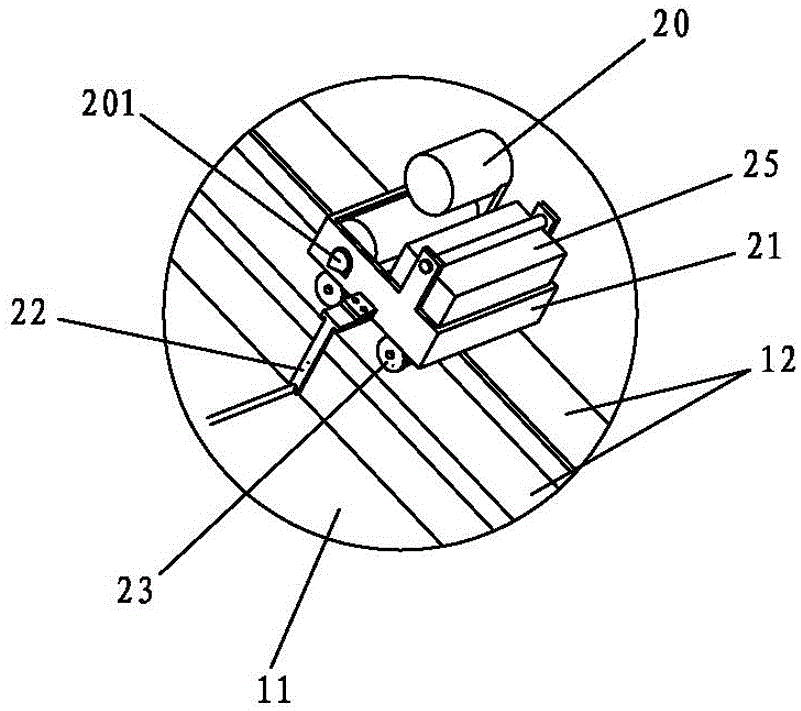

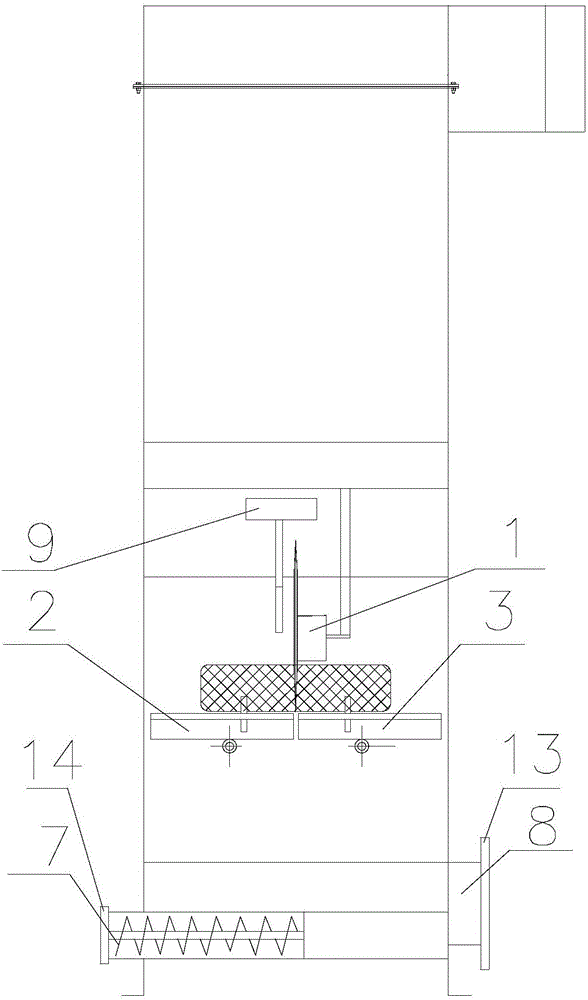

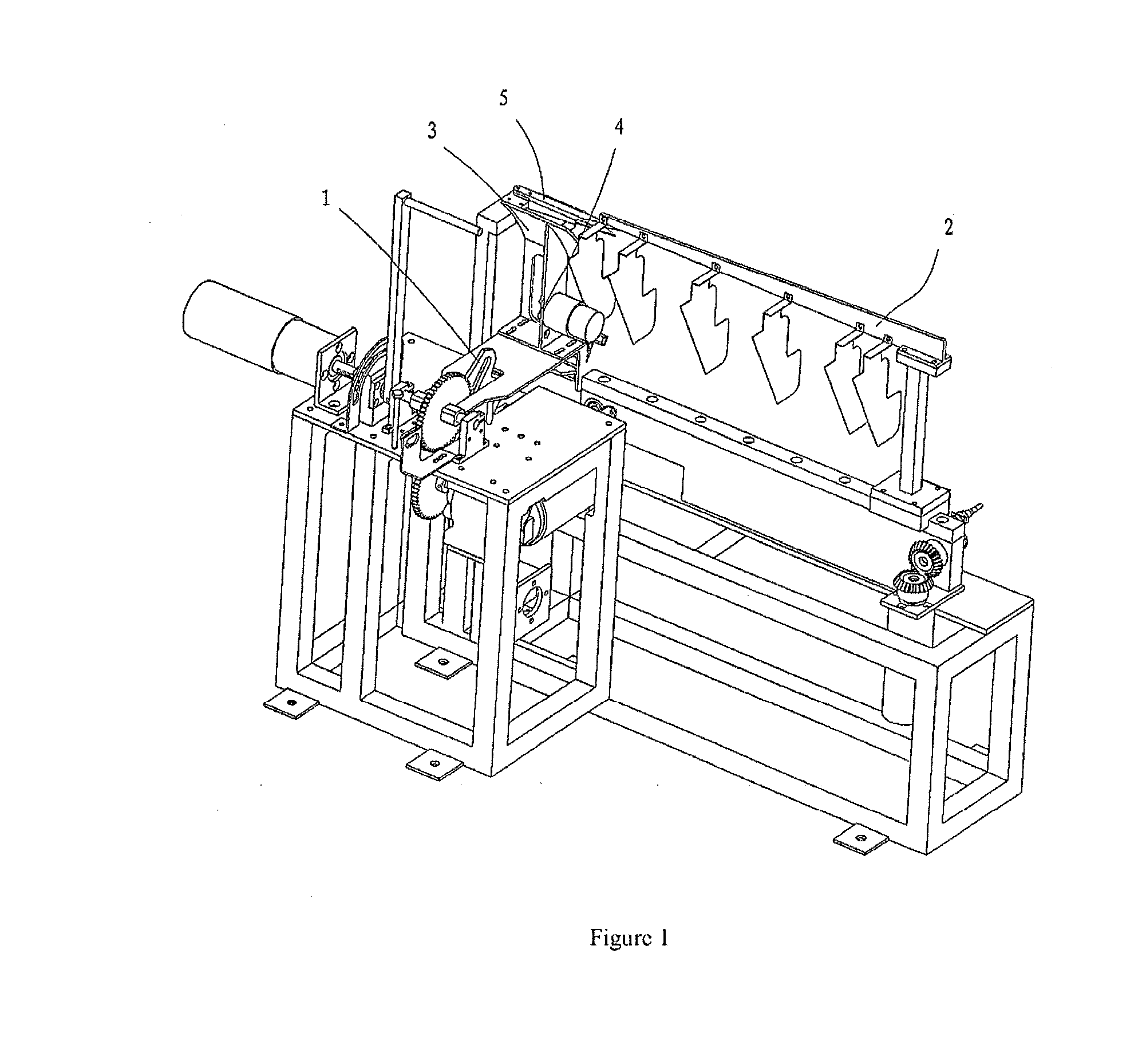

Automatic unpacking and blanking device

ActiveCN104828342AReduce exposureImprove working environmentBags openingWorking environmentEngineering

The invention discloses an automatic unpacking and blanking device comprising a conveying mechanism, a cutting mechanism and a storage bin. Bagged solid raw material is conveyed from one end to the other end of the conveying mechanism, and the conveying mechanism drives the bagged solid raw material to pass through the cutting mechanism to enable the bagged solid raw material to enter the storage bin after a packing bag is broken. The automatic unpacking and blanking device further comprises a sieve plate. The other end of the conveying mechanism is adjacent to one end of the sieve plate to enable the bagged solid raw material to enter one end of the sieve plate through one end of the conveying mechanism. The cutting mechanism is arranged at one end of the sieve plate to break the packing bag of the bagged solid raw material, and the bagged solid raw material drops into the storage bin via the meshes of the sieve plate. Automatic unpacking and blanking of bagged solid raw material is realized, the manual input in the production field is reduced, and the work environment of operators is improved.

Owner:南安华大石材产业技术研究院

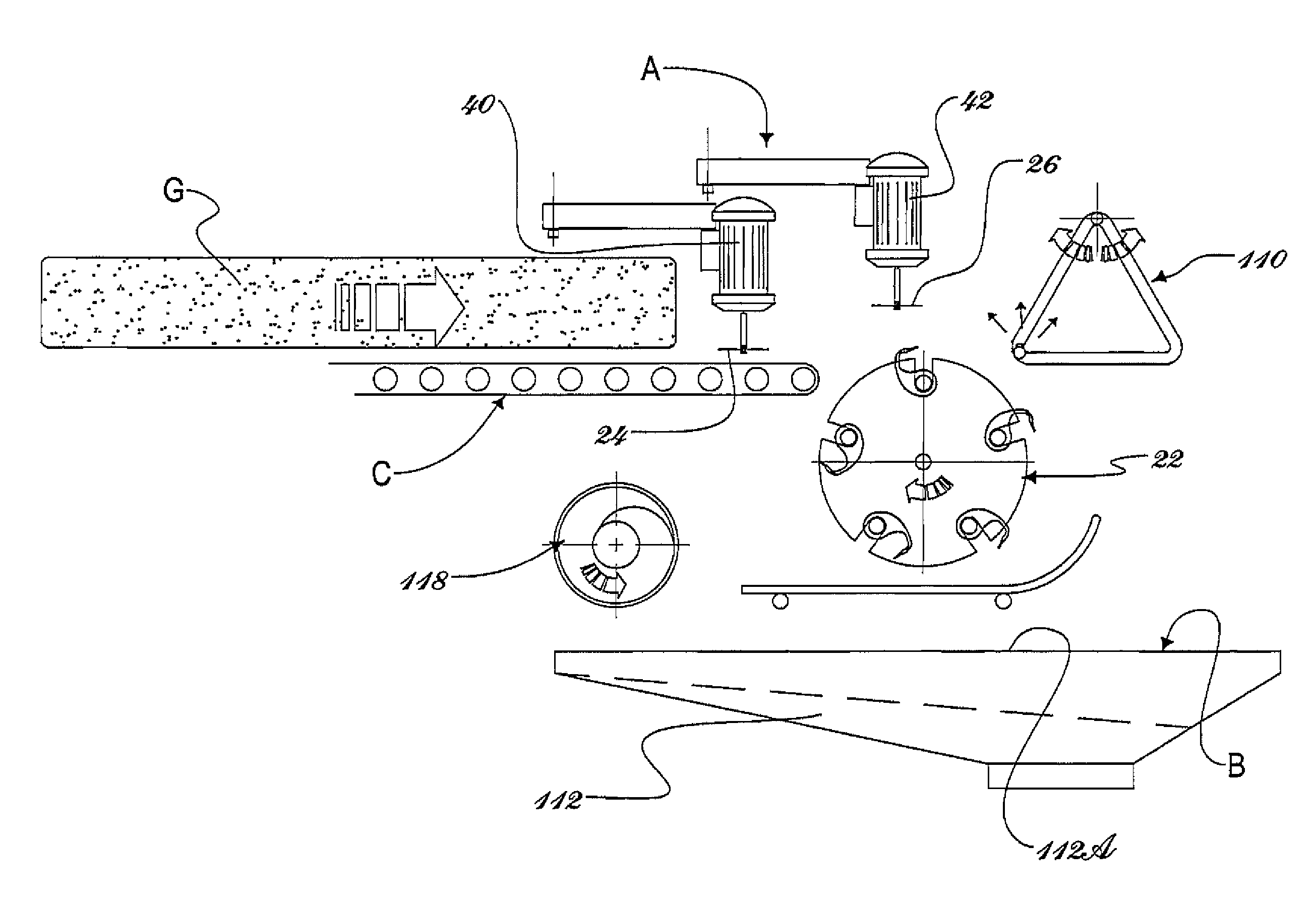

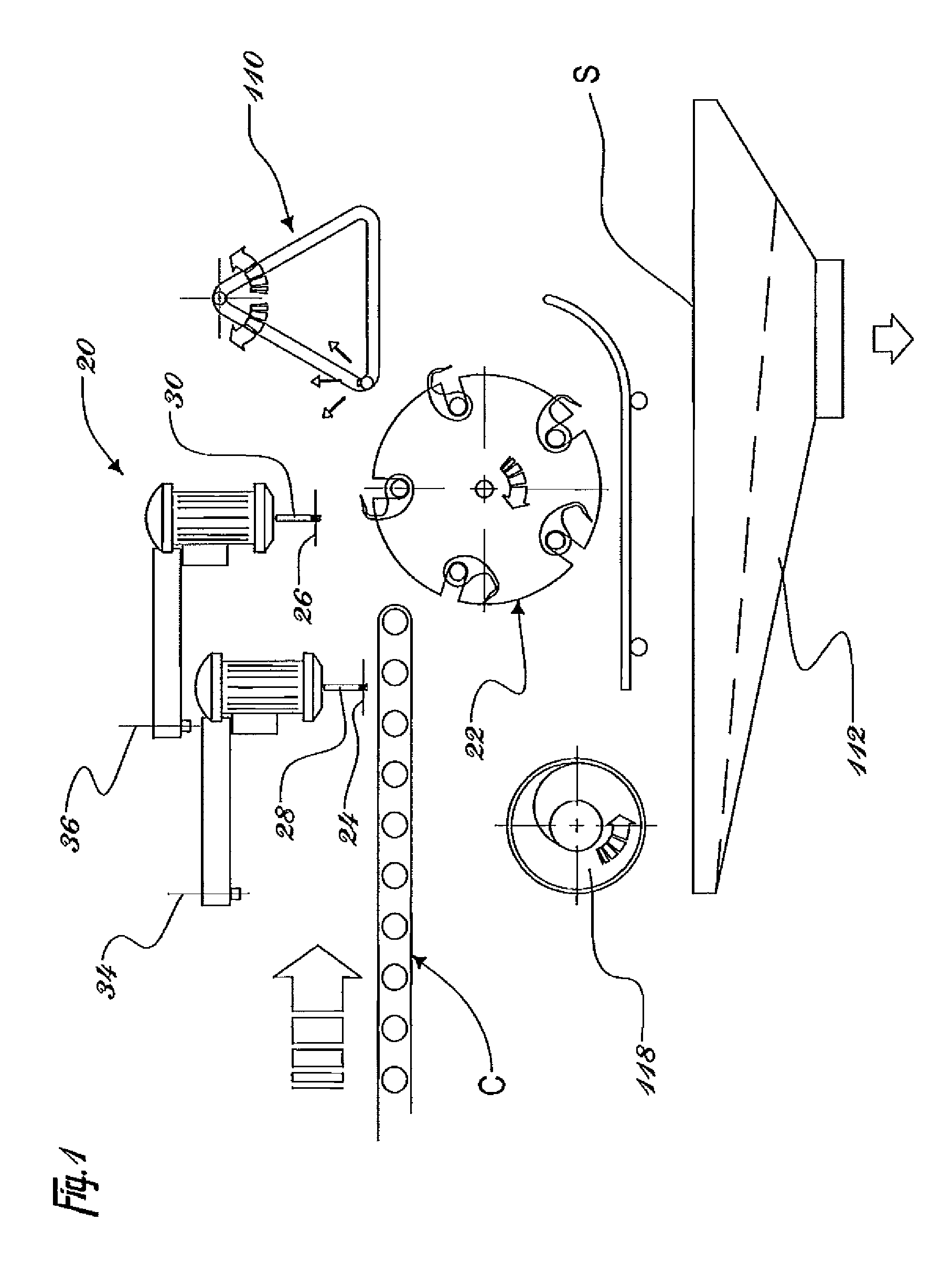

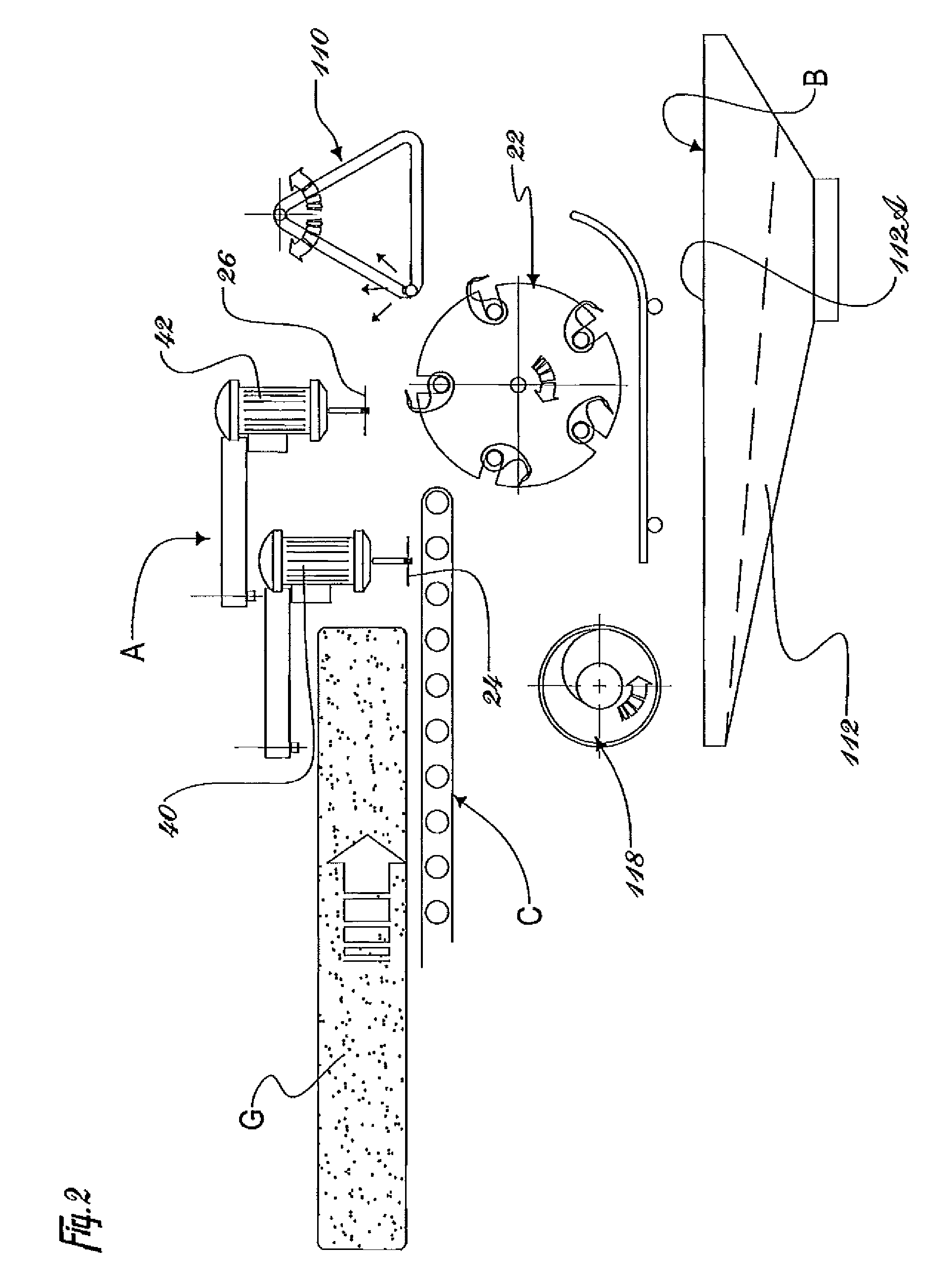

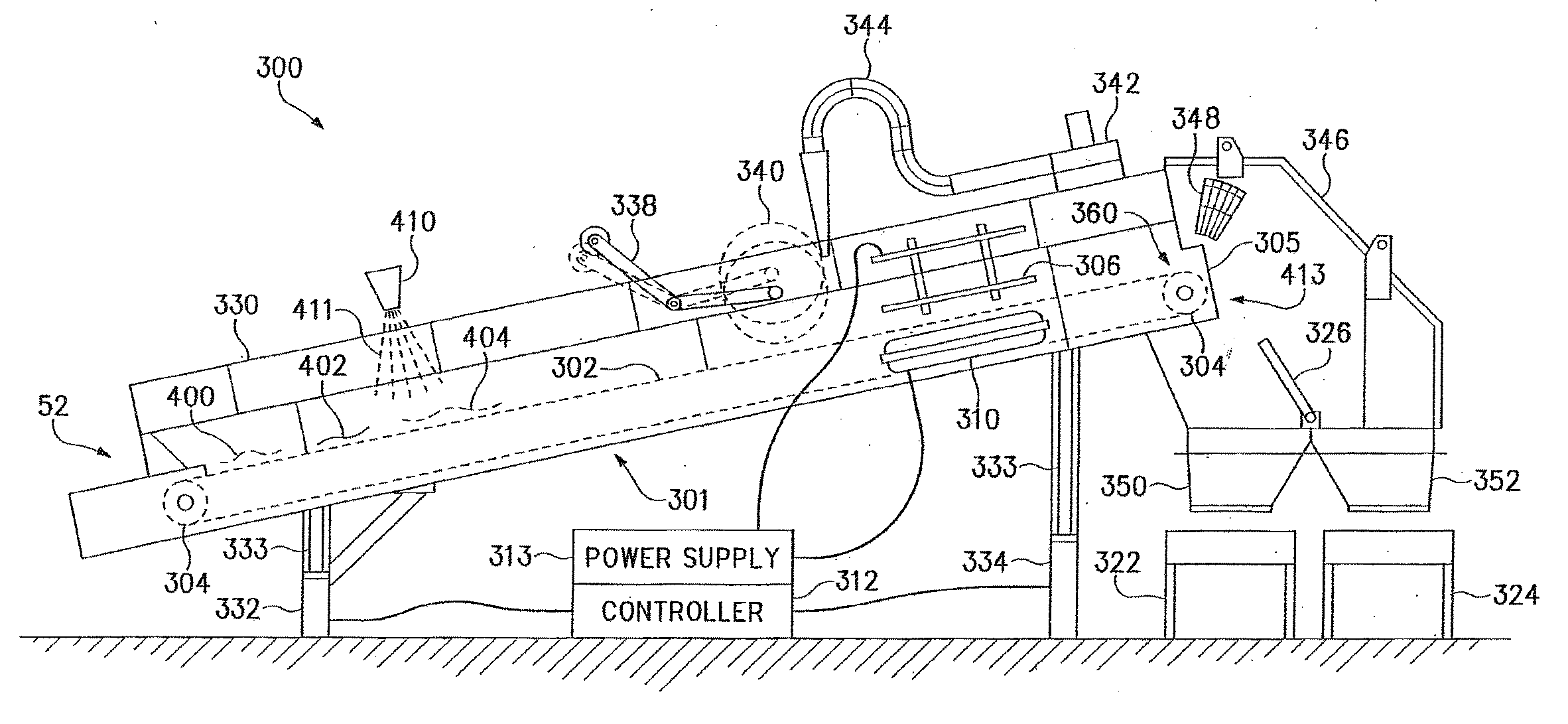

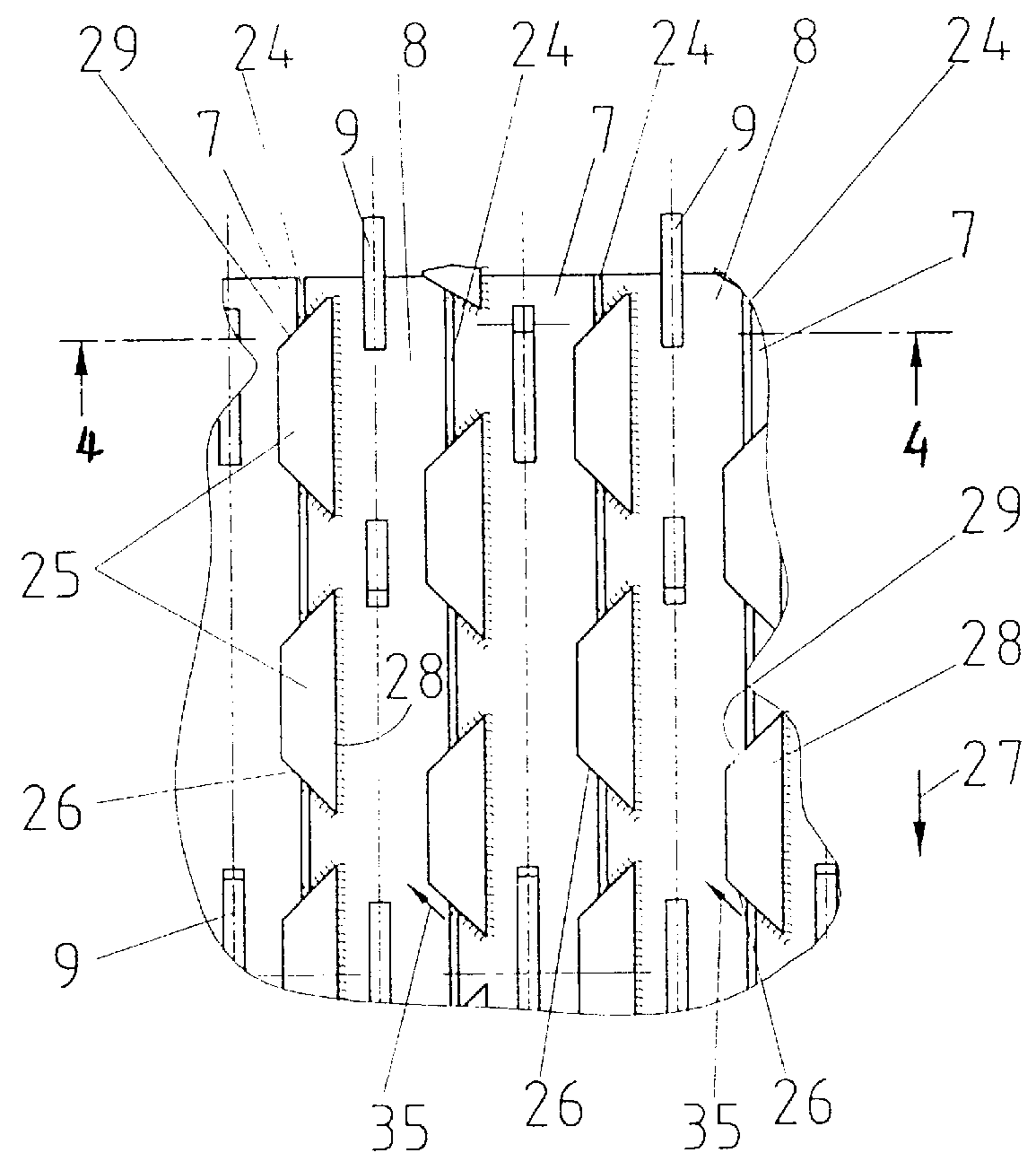

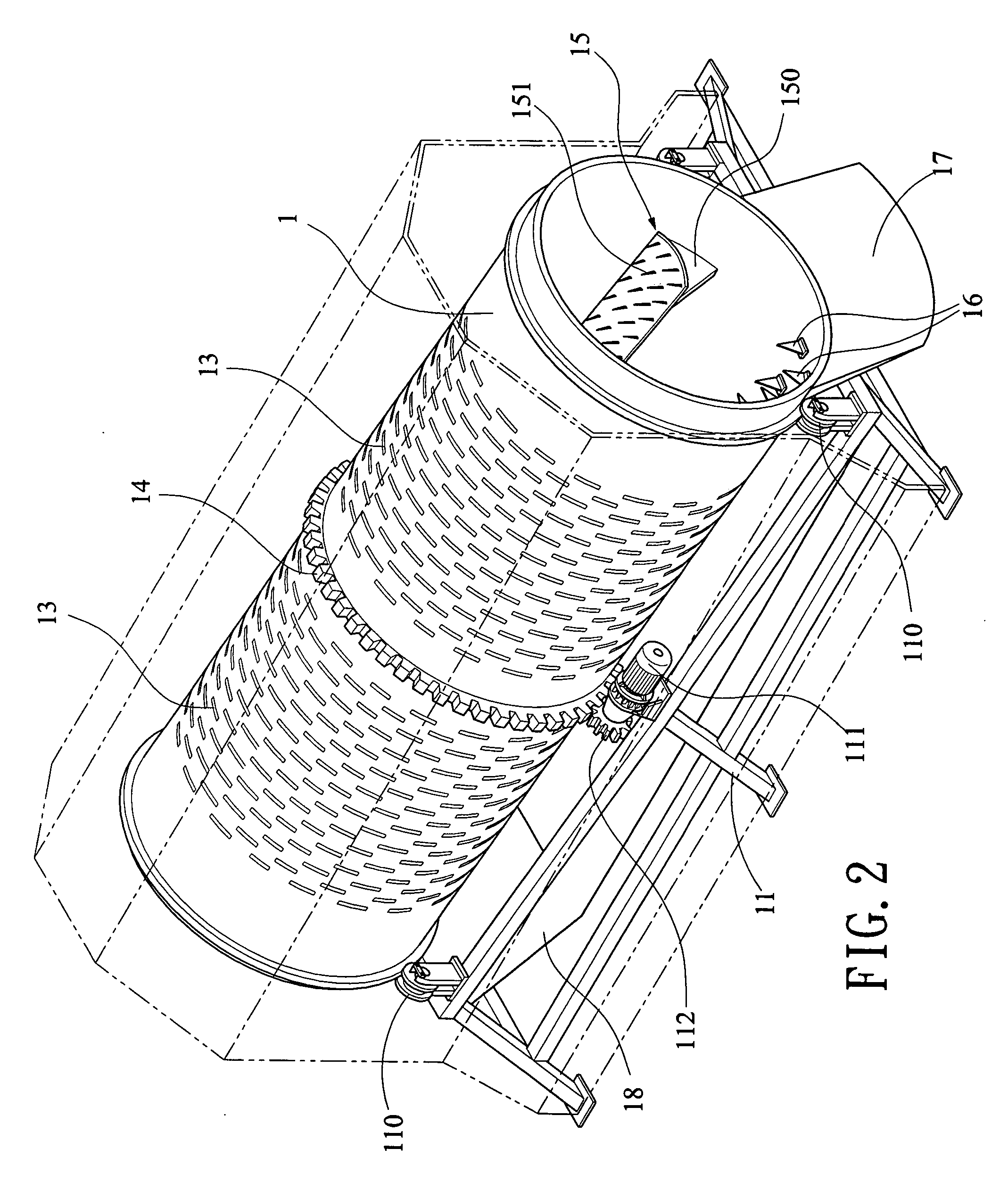

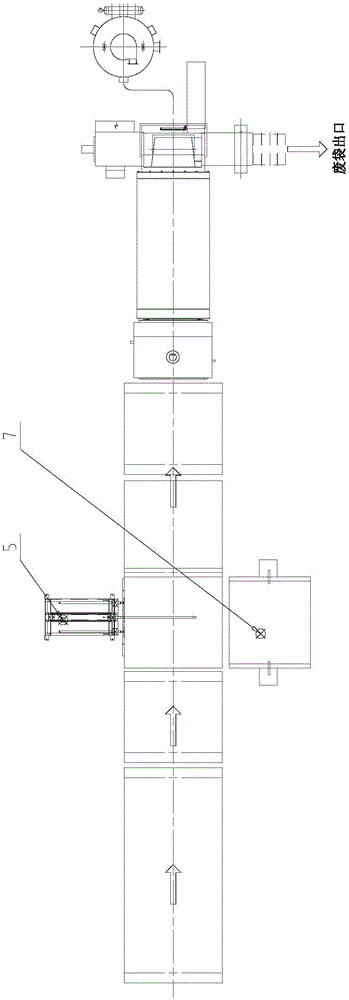

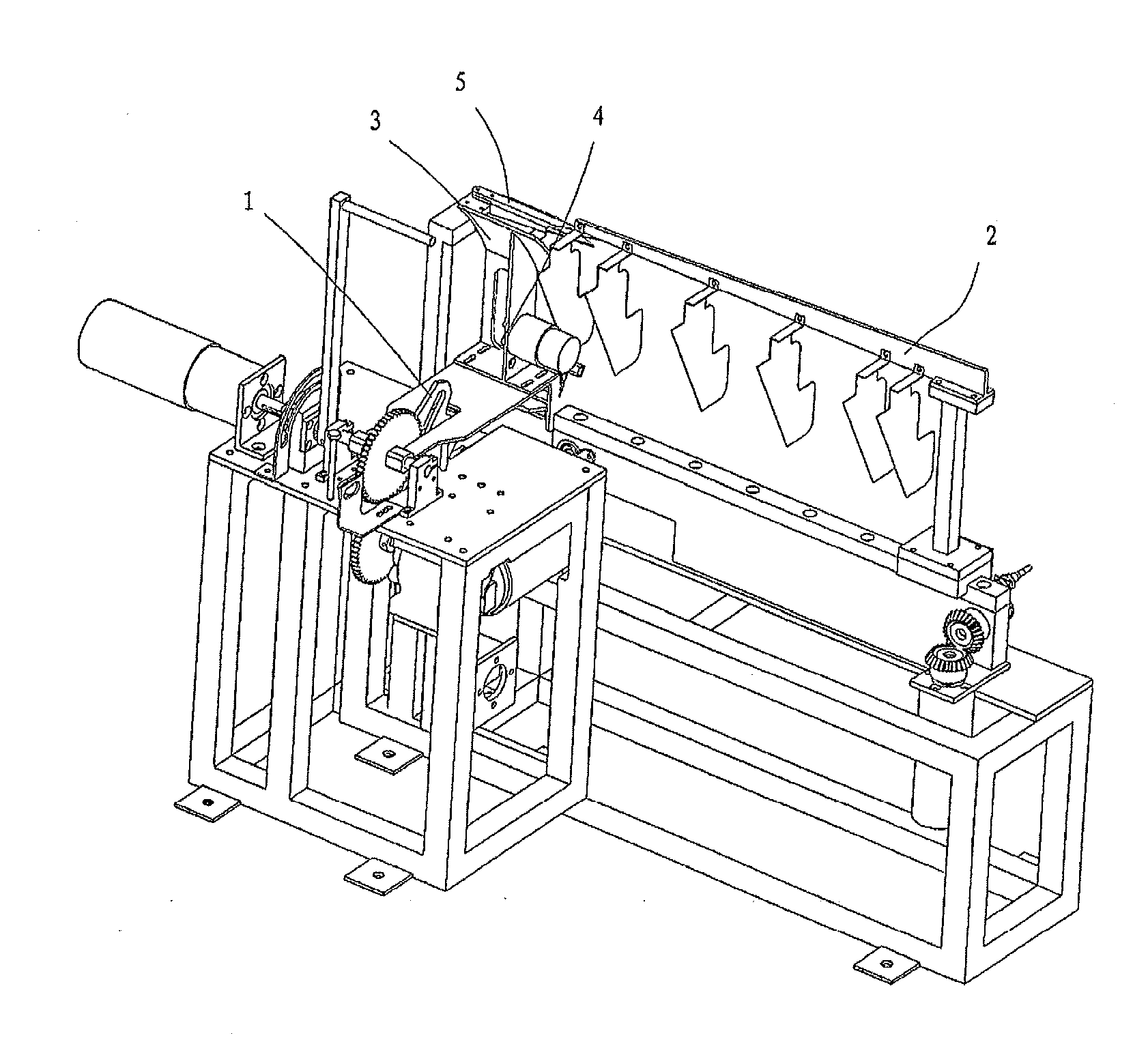

Automatic bag slitter, and method of use thereof

ActiveUS8197174B1Easy maintenanceEnhancing bag separationBags openingPackaging bottlesLitterEngineering

The automatic bag opening and slitting machine has a spike star wheels assembly comprising either of one or a combination of star wheels or cylindroid drum like object. The star wheels assembly is provided with spikes which convey a bag, impaled on the spikes when in an extended position, and extends beneath rotary cutting disks driven by two independent pneumatic or electric motors, that may make a continuous cut around three sides of the bag, so that after cutting thereof, the bag comprises two halves joined only at the rear or trailing side of the bag. These two bag halves are unfolded as one half of the bag engaged by the spikes is drawn around the upstream end of the star wheels assembly, while the other half slides over the rocker arm / bag separation bar / slide guide bar, thus emptying the powder / granular content of the bag into a hopper and releasing the emptied bag by retraction of the spikes from the bag for collection therebelow into a chute, for disposal into an endless screw which extrudes the bag into a compaction tube. The compacted bags are thereafter pushed into a waste plastic bag for refuse disposal.

Owner:LUXME HLDG

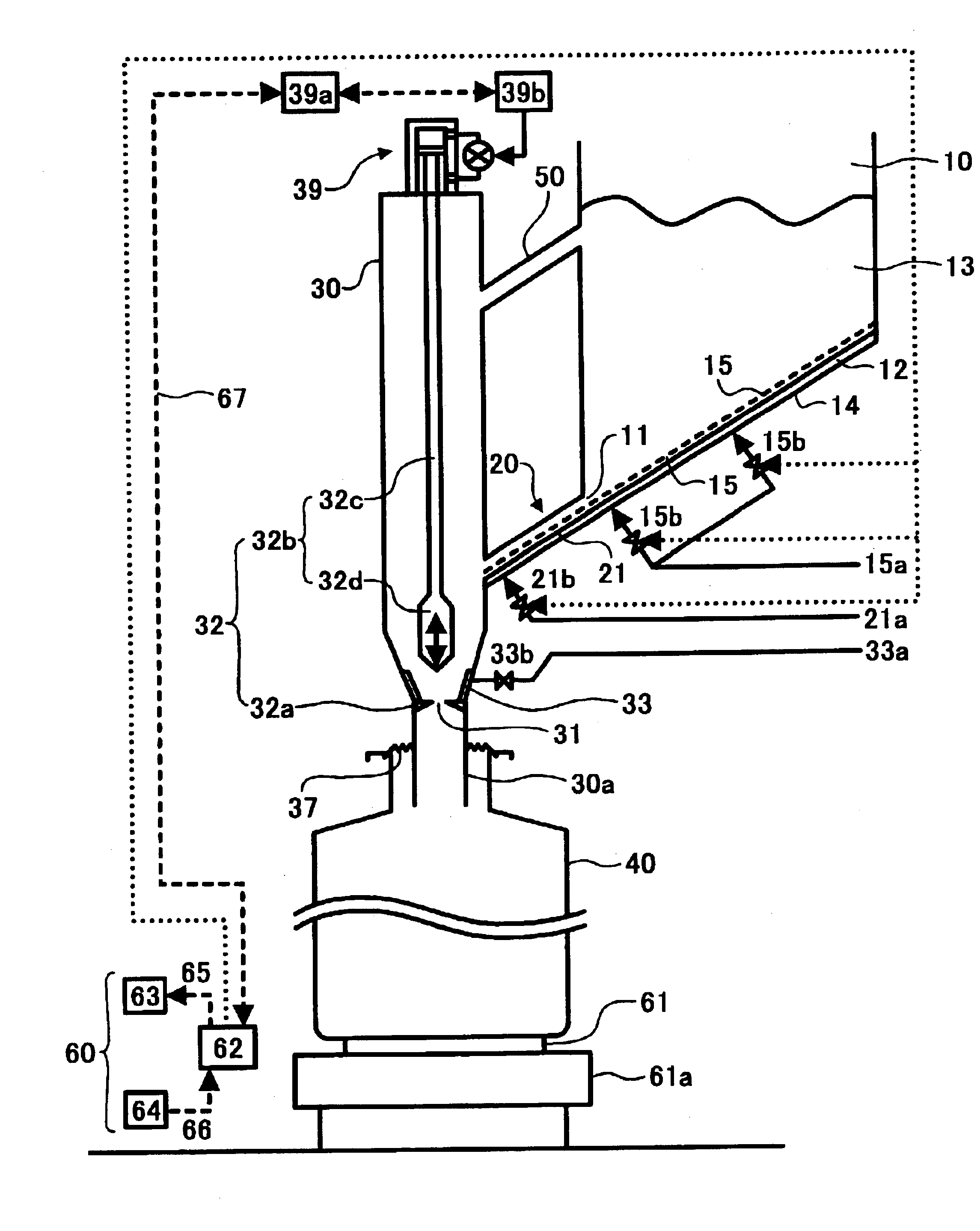

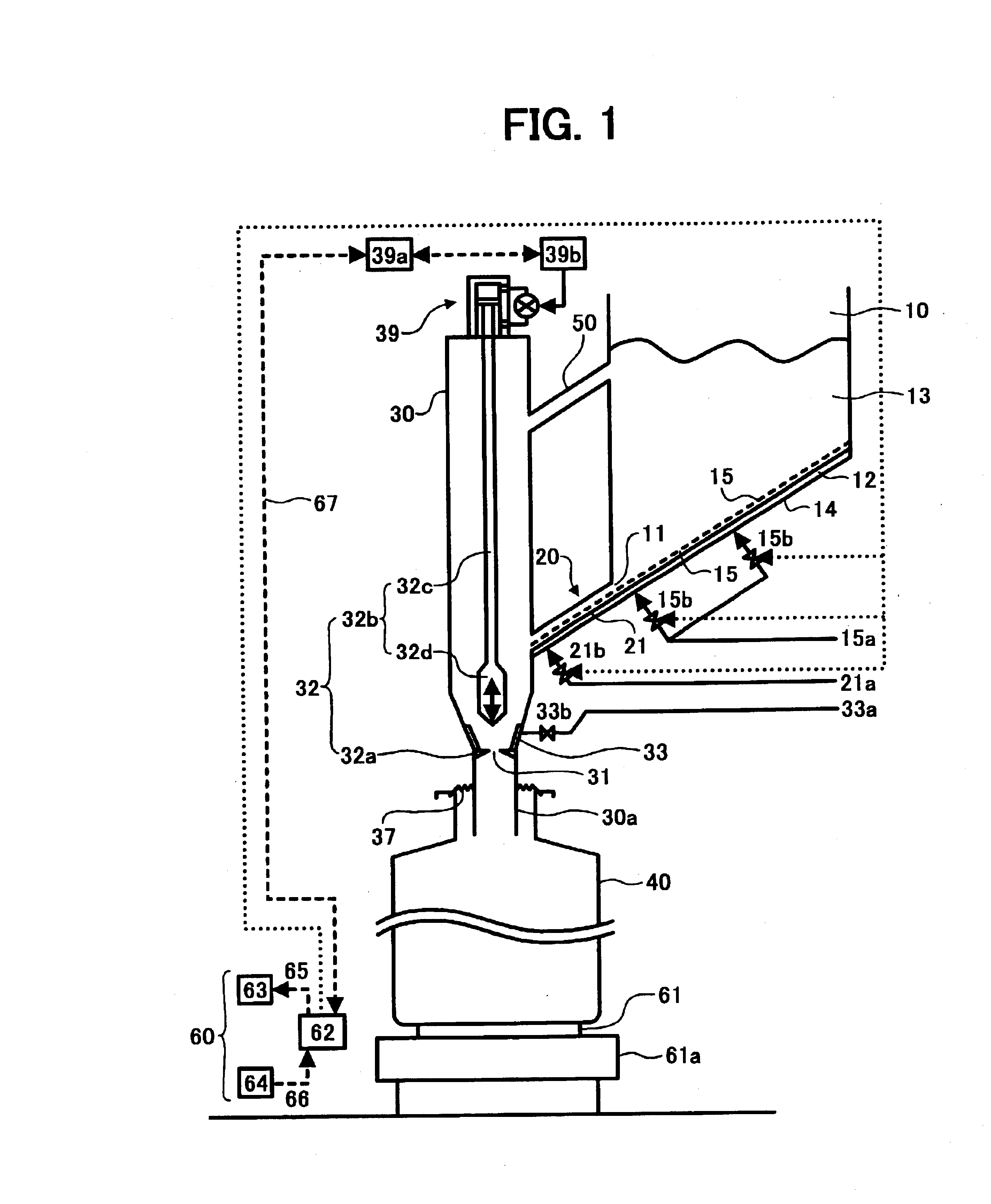

Apparatus and method of filling microscopic powder

InactiveUS6854493B2Fast fillExposed to dangerLiquid fillingLiquid transferring devicesEngineeringMechanical engineering

A powder filling apparatus includes a first container configured to contain a powder. A weighing tank is configured to receive the powder from the first container and discharge a predetermined amount of the powder to a second container, which includes an opening configured to discharge the powder into the second container and a regulator configured to open and close the opening to discharge the predetermined amount of the powder into the second container. A connector is configured to feed the powder from the first container into the weighing tank.

Owner:RICOH KK

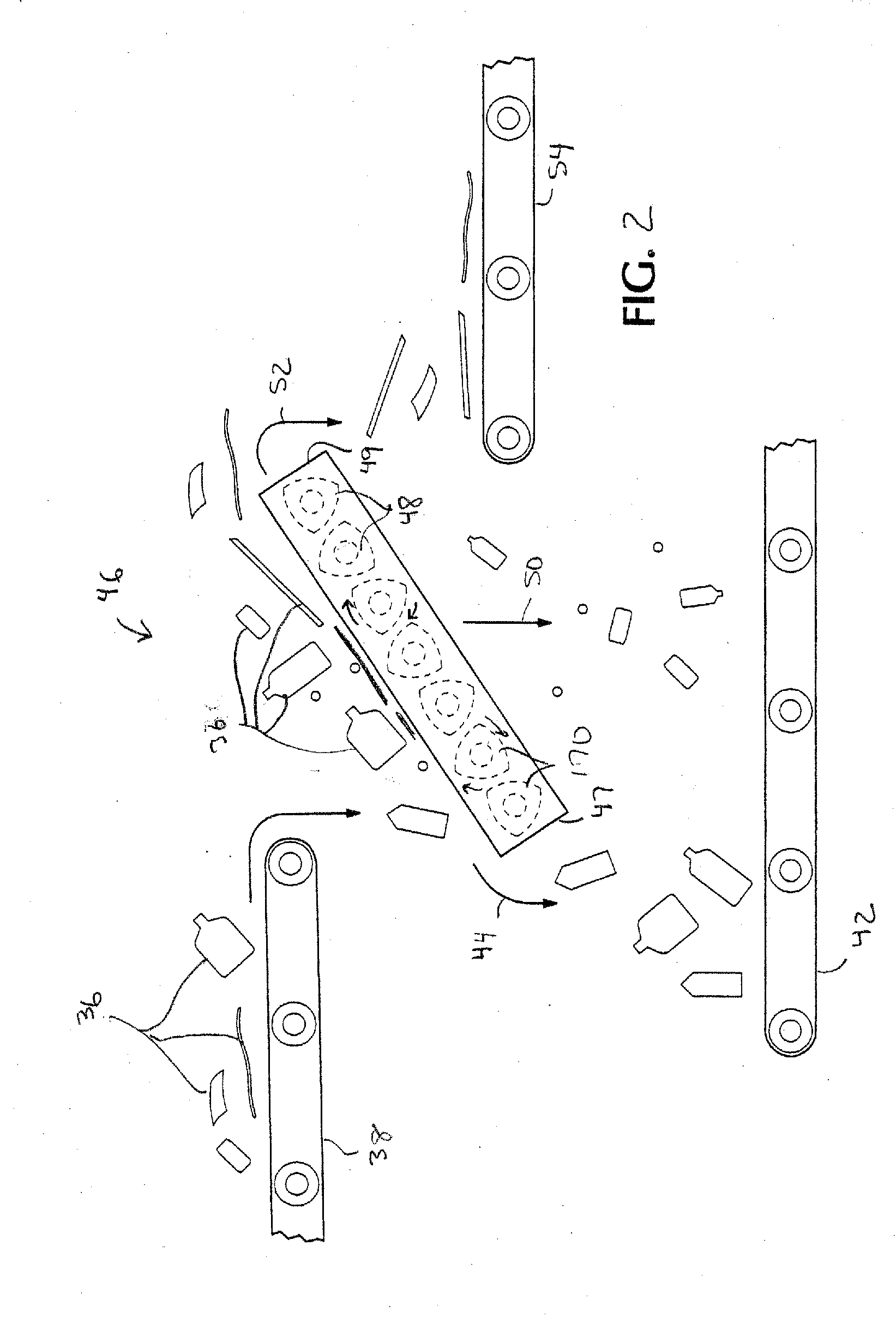

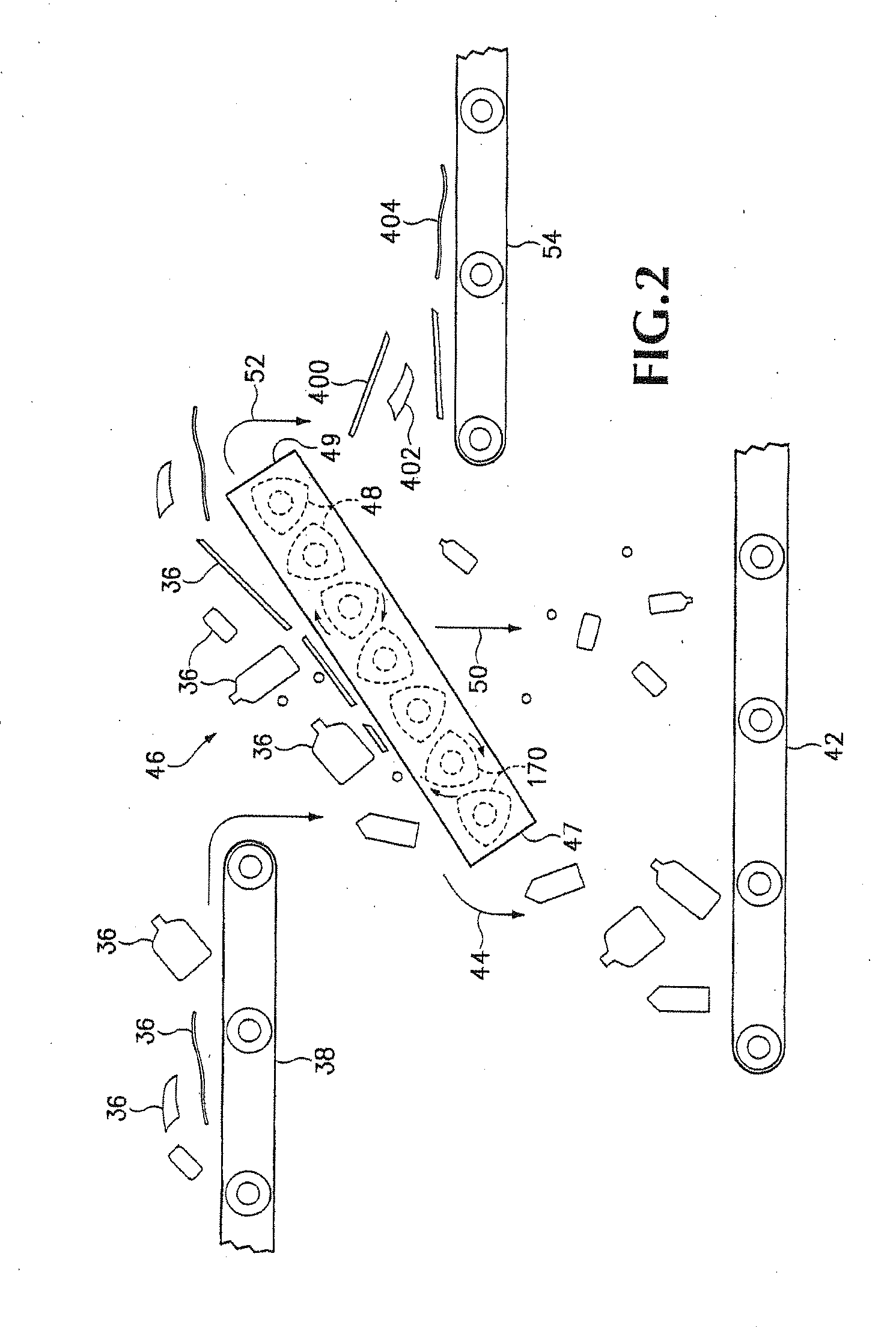

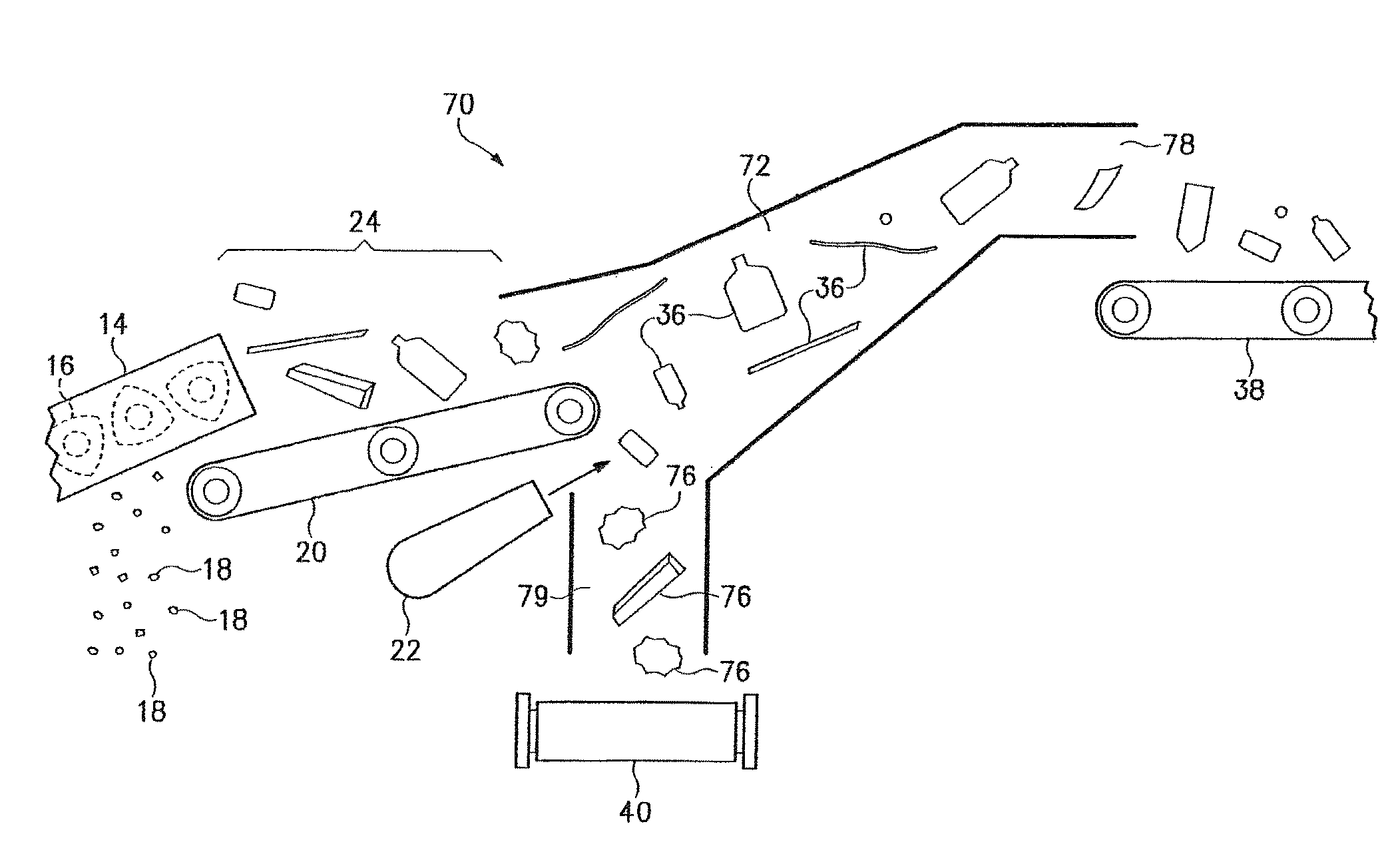

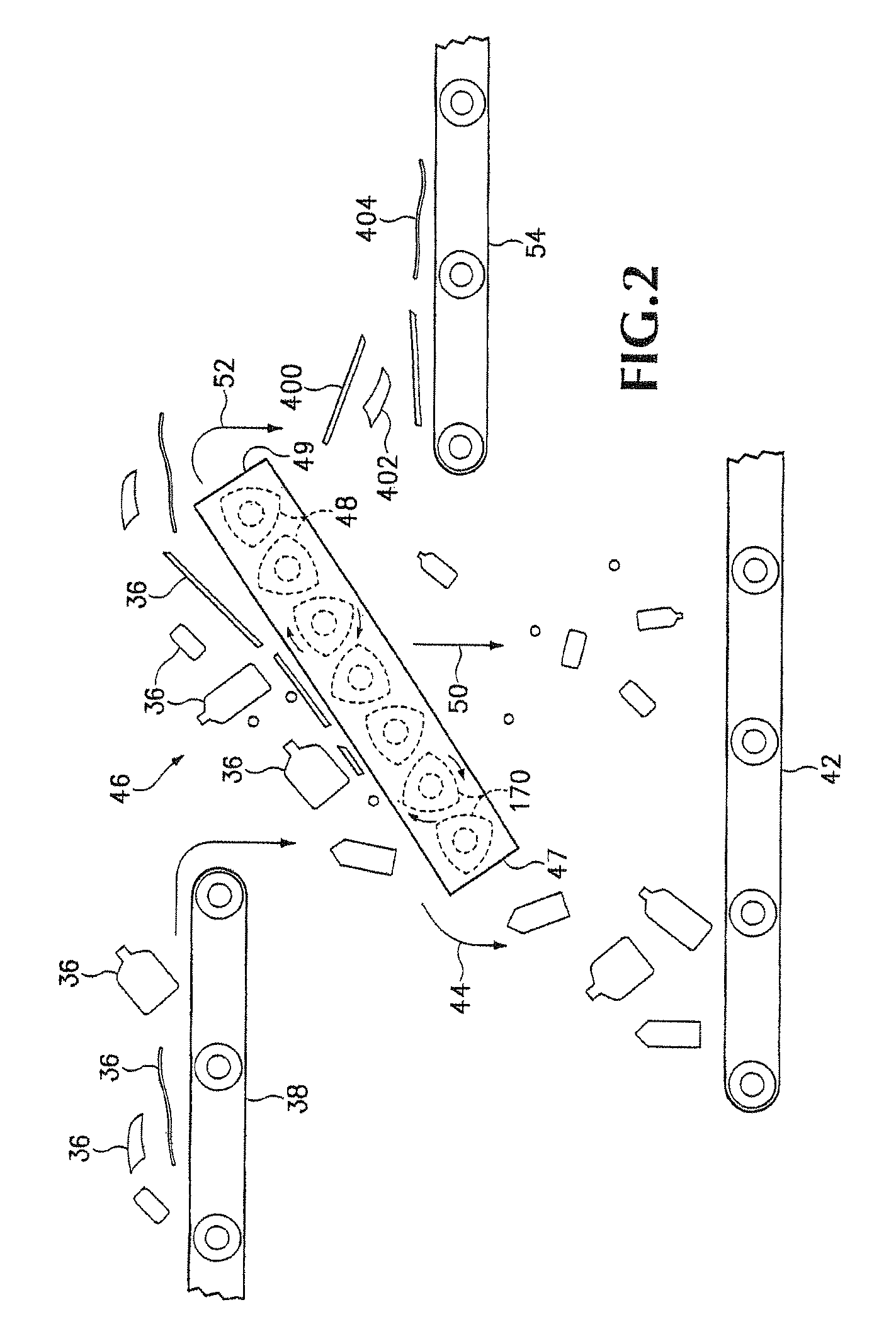

Electrostatic material separator

A separation system includes an air separator that, in one embodiment, primarily receives Municipal Solid Waste (MSW) containing a mixture of relatively light MSW recyclable materials such as plastic, paper, cardboard, plastic containers, and / or metal containers and relatively heavy MSW such as textiles, food waste, yard debris, etc. The air separator blows the relatively light MSW recyclable materials up though a chamber and onto a first conveyor while the other relatively heavy MSW material drops down a chute onto a second conveyor. A separation screen receives the relatively light MSW recyclable materials from the air separator and separates the relatively flat fiber and plastic film materials from the other paper, plastic and metal containers. In another separation stage, an electrostatic emitter is positioned adjacent to a conveyor for applying an electrostatic charge to faciliate separation of the MSW recyclable materials. An optical identification system is configured to distinguish different types of recyclable materials.

Owner:EMERGING ACQUISITIONS

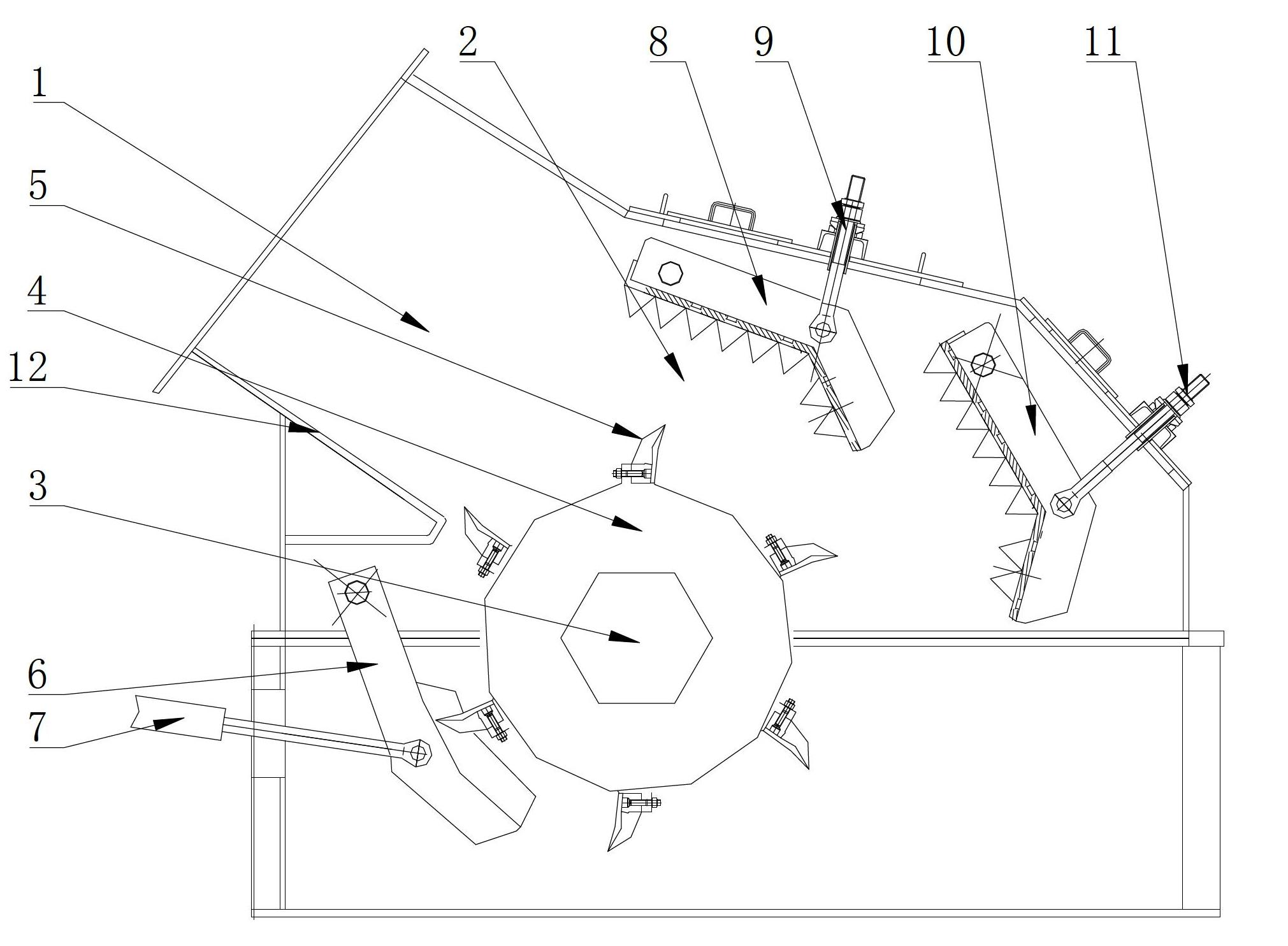

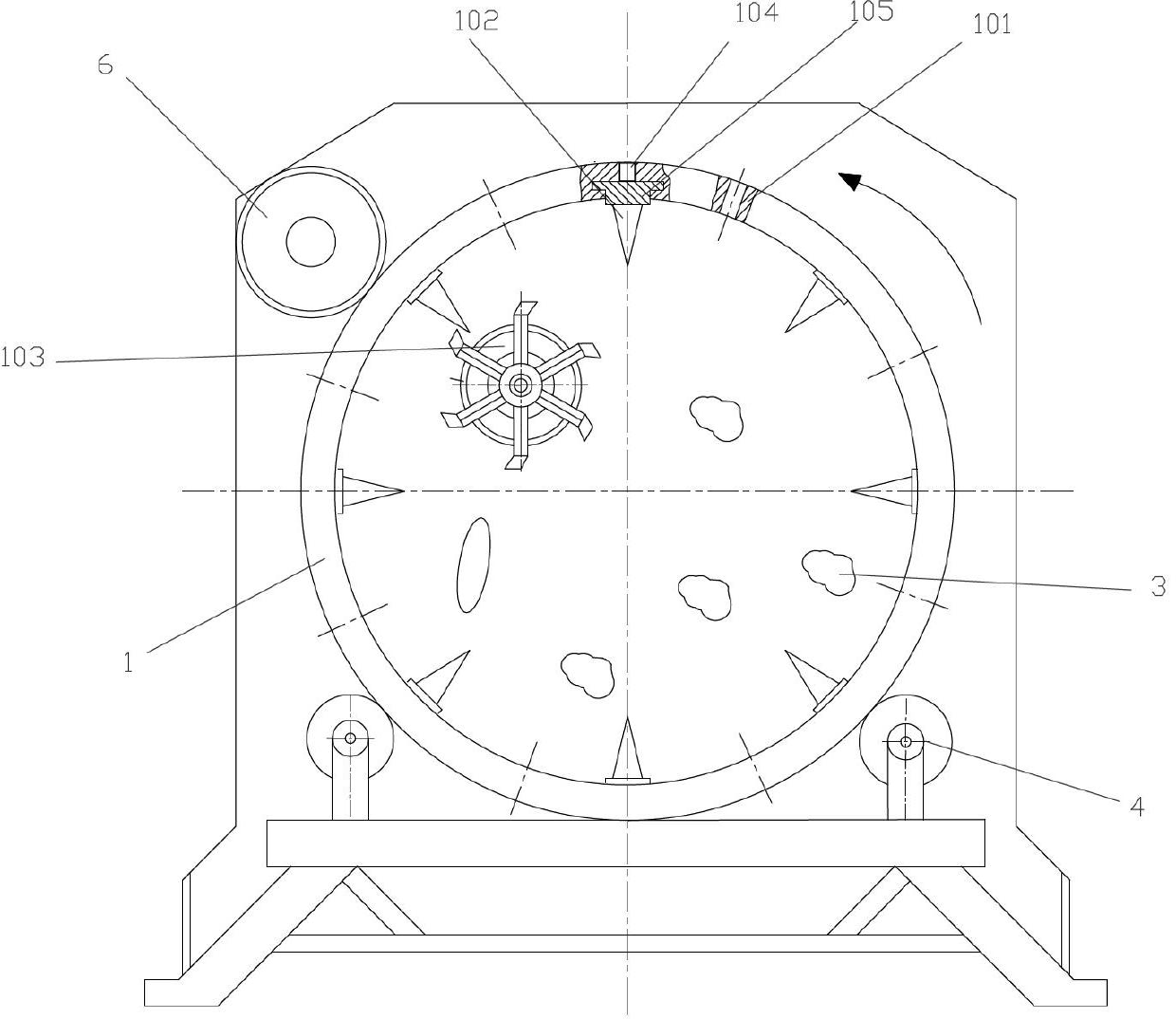

Urban garbage bag-breaking crushing device with knife cleaning function

InactiveCN102671745APrevent accumulation and cloggingQuick break bagBags openingGrain treatmentsResource utilizationEngineering

The invention discloses an urban garbage bag-breaking crushing device with a knife cleaning function. The urban garbage bag-crushing crushing device is characterized by comprising a shell and a crushing chamber located in the shell, wherein a rotating shaft is arranged in the crushing chamber; a roller is fixedly mounted on the rotating shaft; a plurality of five-edge sharp knife heads are distributed on the roller; a knife cleaning device matched with the five-edge sharp knife heads is further arranged in the crushing chamber; the knife cleaning device is connected with a hydraulic device for controlling the knife cleaning device to open and close; a tooth board which is matched with the five-edge sharp knife heads to crush materials is further arranged in the crushing chamber; and teeth are welded on the tooth board. The crushing device can well realize a pretreatment technique for garbage resource utilization. The crushing device can effectively treat various hard materials and flexible materials, has functions of preventing winding, breaking a large piece and breaking a large bag, and improves the crushing efficiency in garbage treatment.

Owner:四川川润环保能源科技有限公司 +1

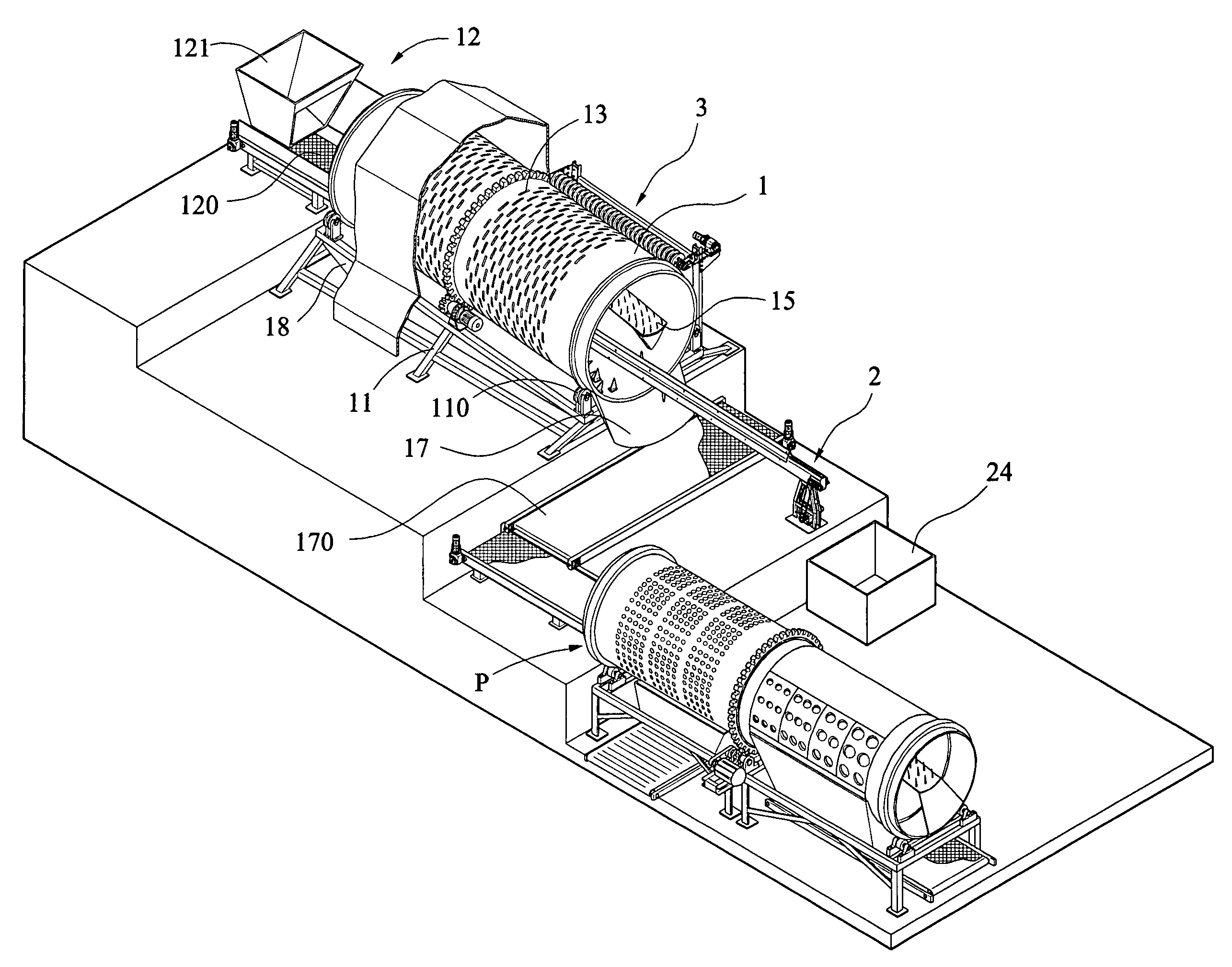

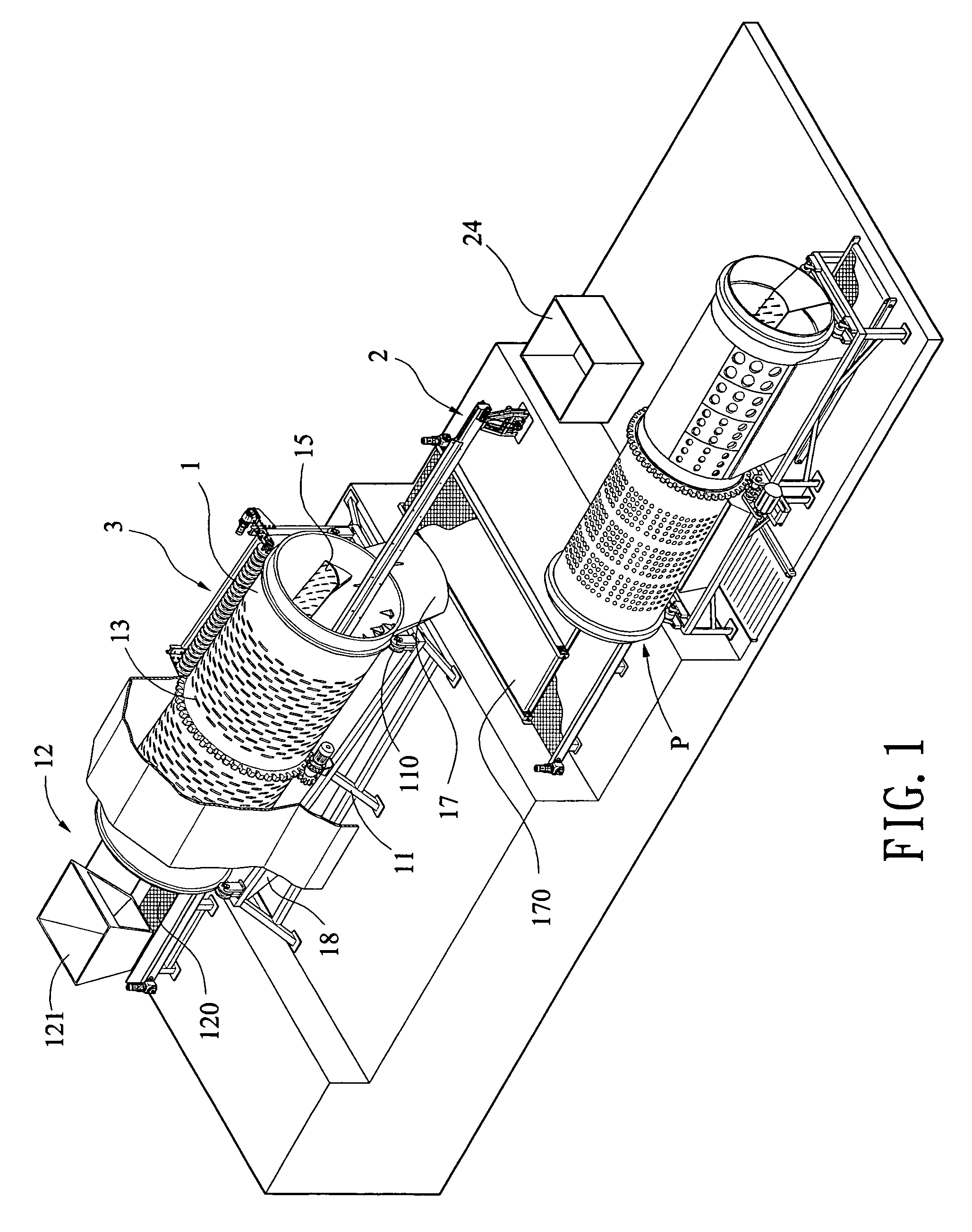

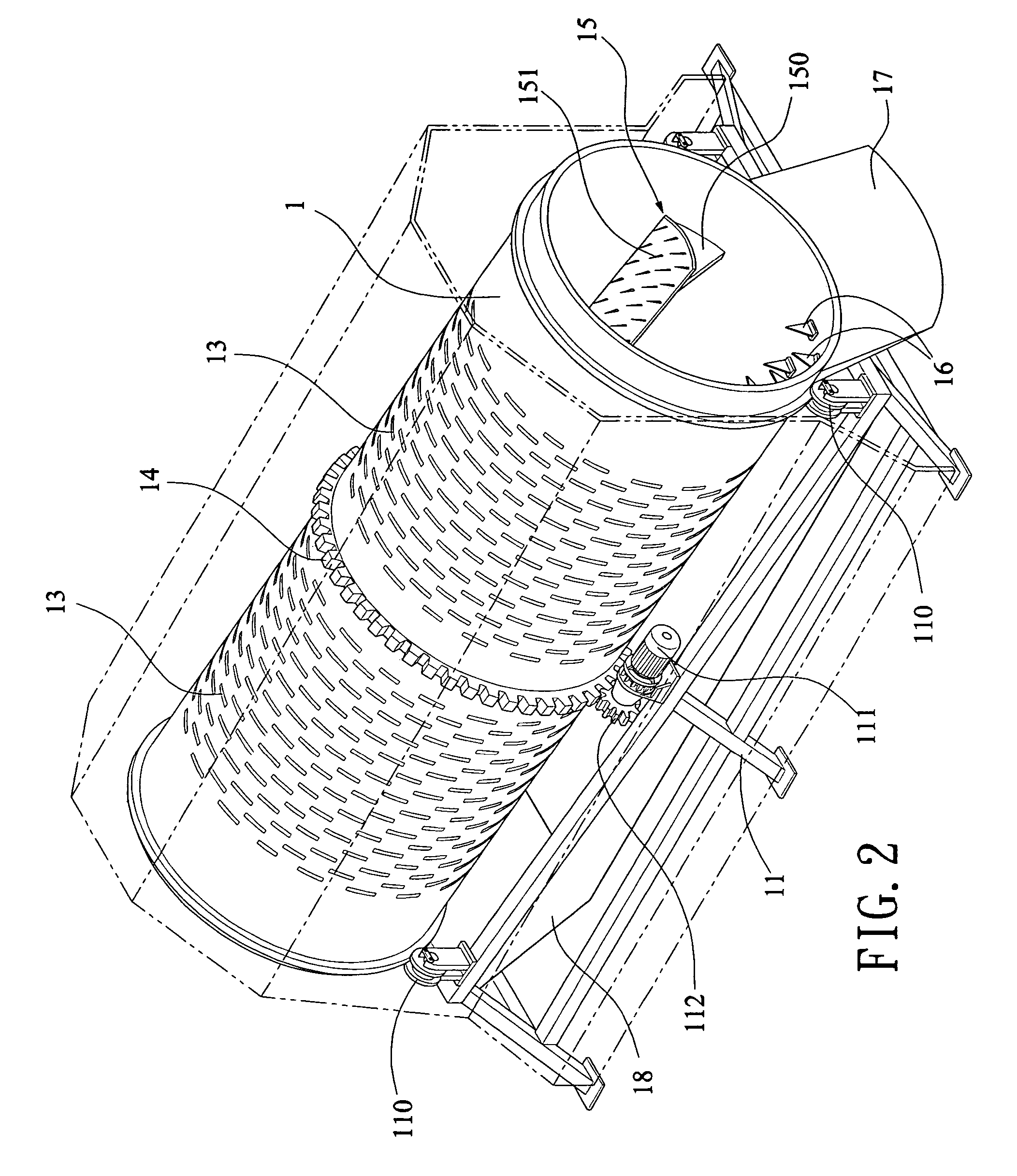

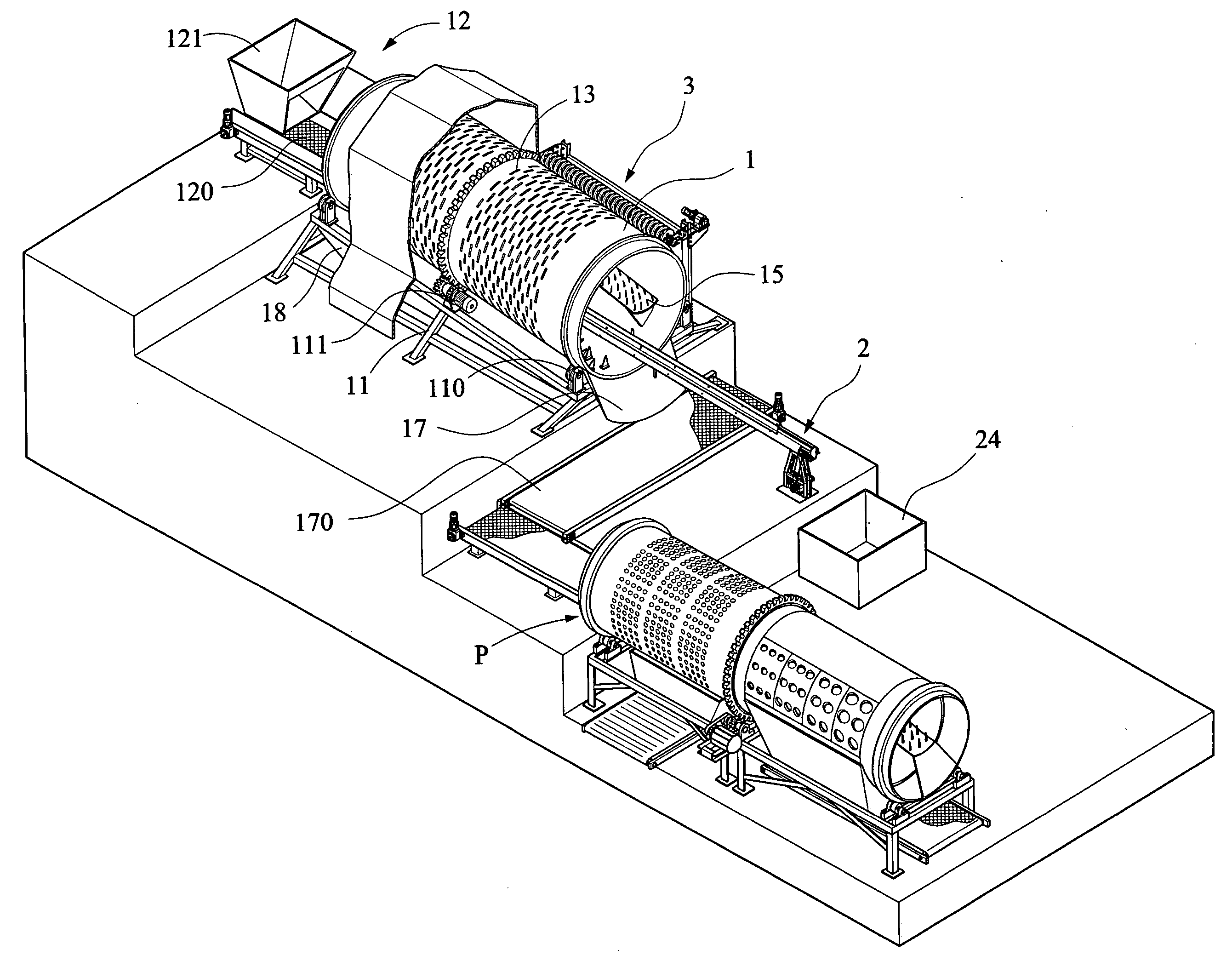

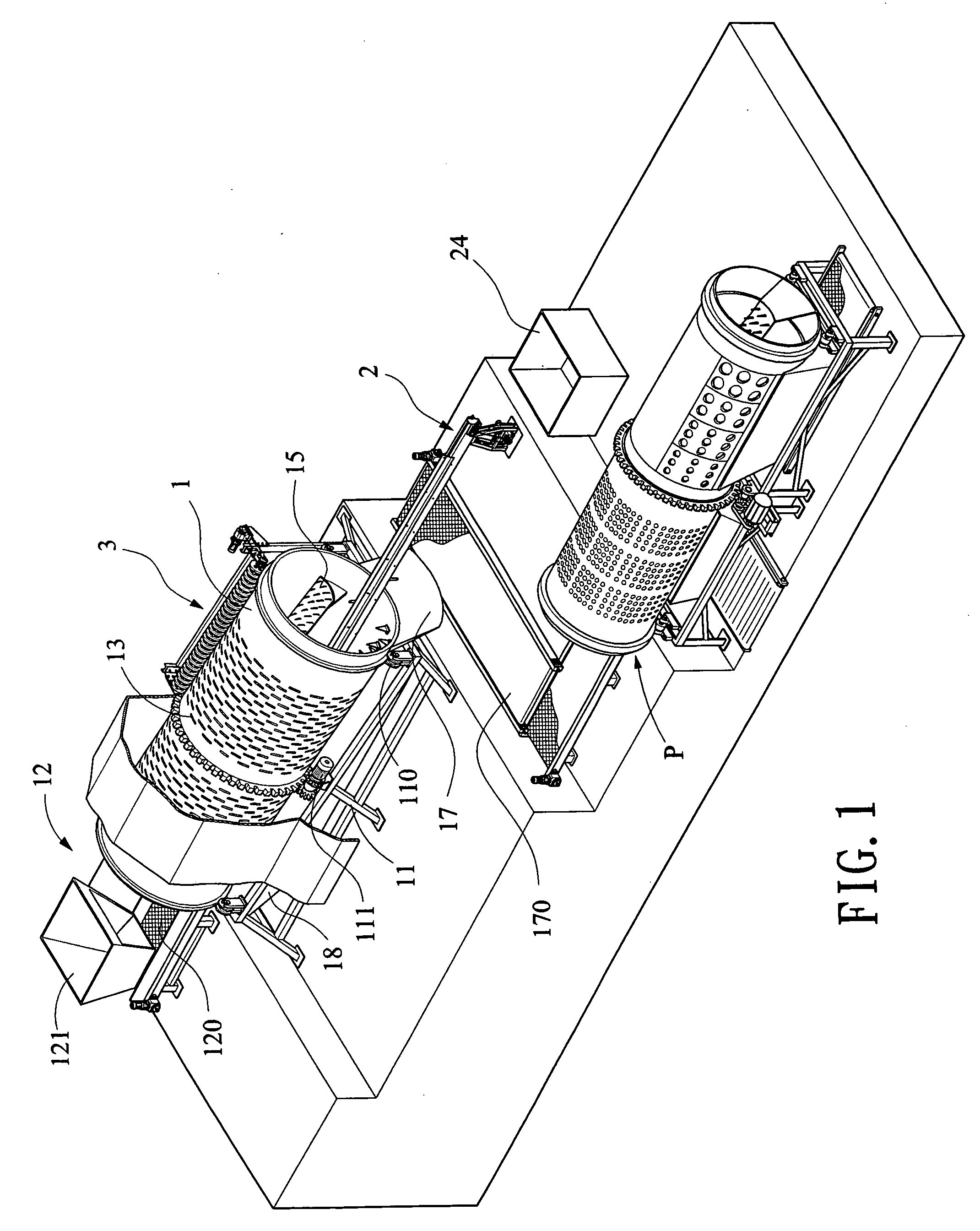

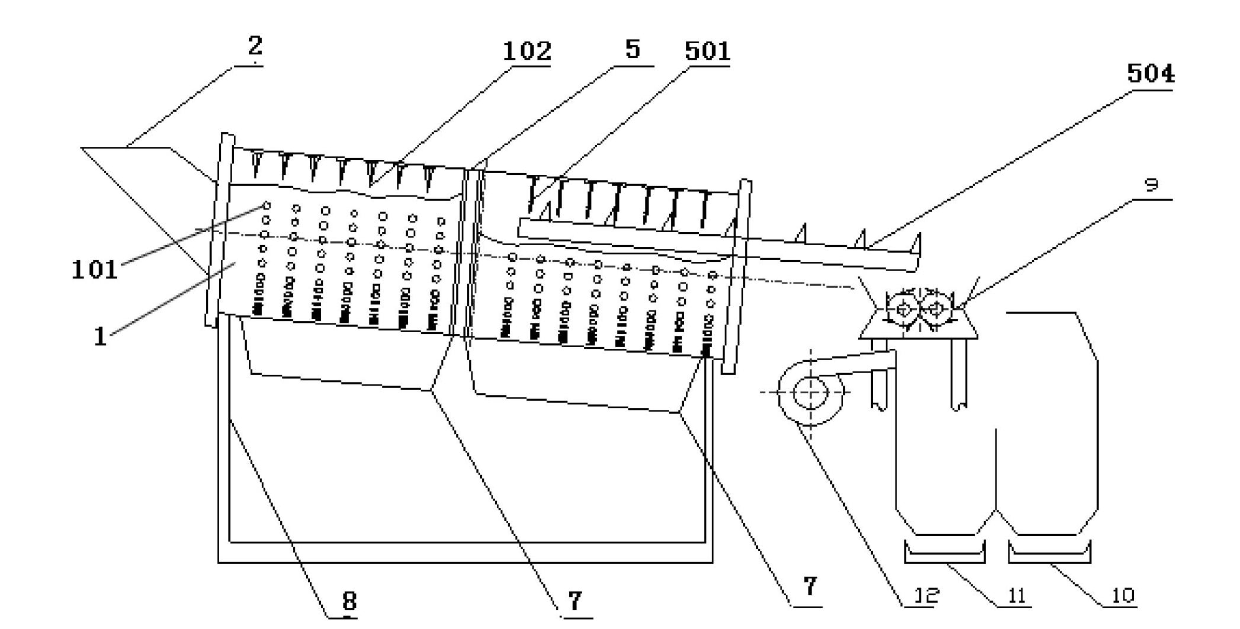

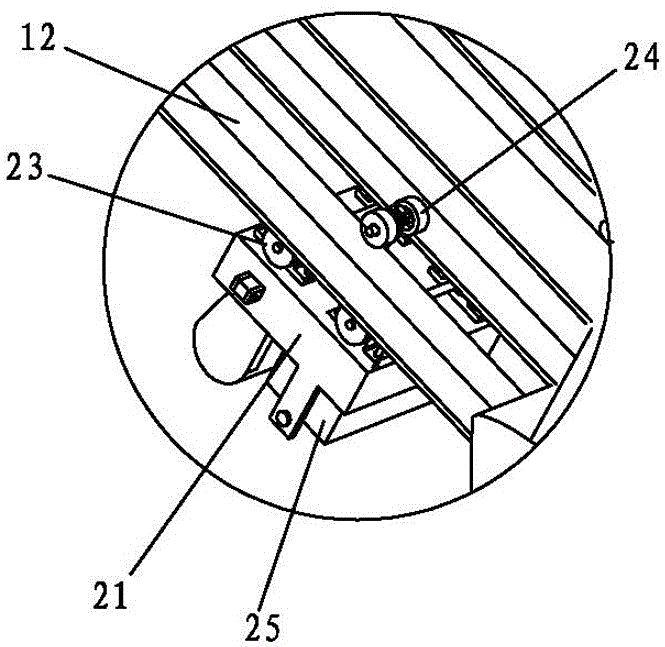

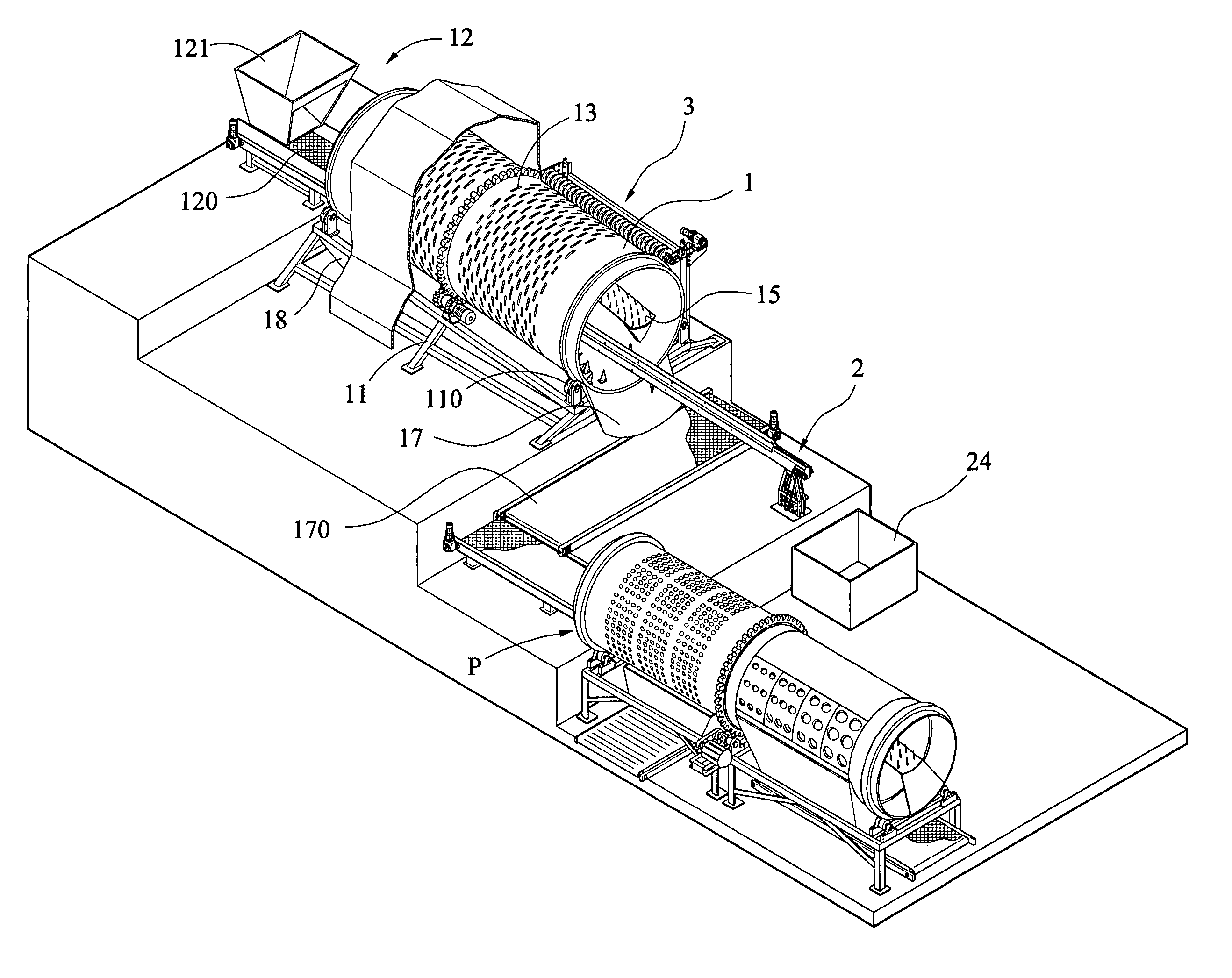

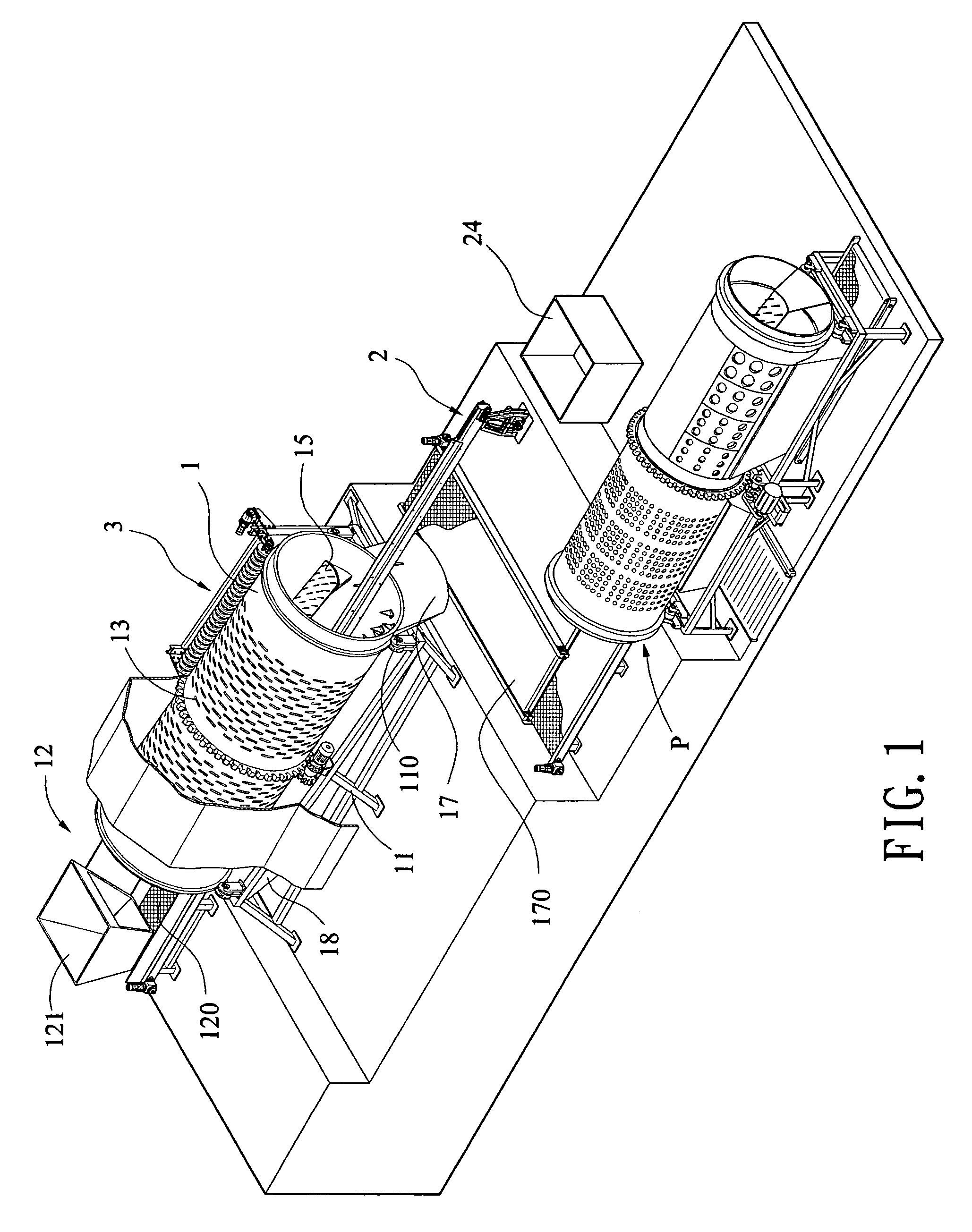

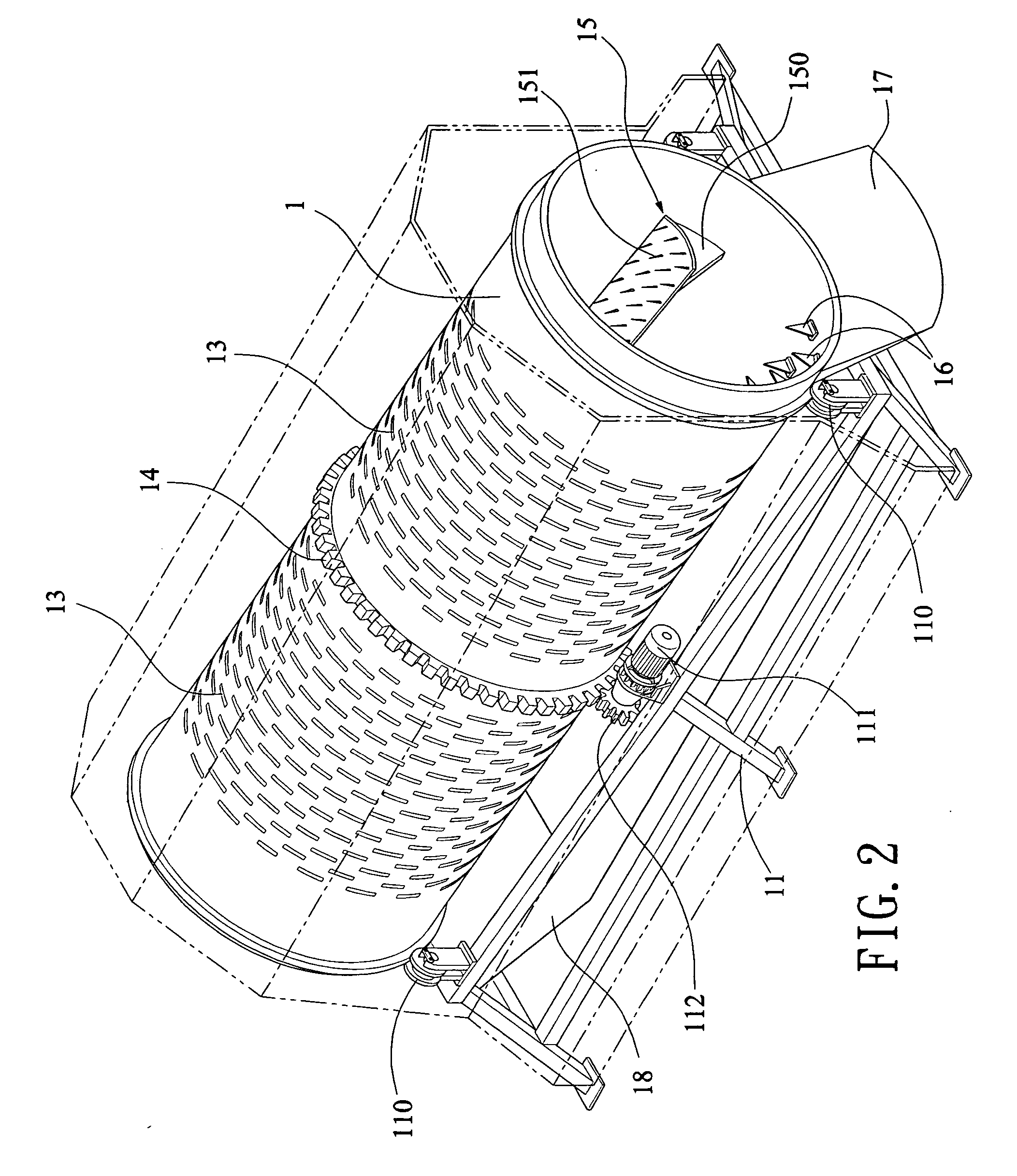

Apparatus for piercing garbage bags, washing materials released from the pierced garbage bags, and collecting nonrigid, elongate objects and powder

An apparatus for disposing garbage bags in one embodiment includes a screen assembly including a first conveyor for conveying garbage bags from a feeding device to a hollow screening cylinder for piercing, and a second conveyor mounted below a rear discharge opening of the cylinder for conveying materials released from the pierced bags to a subsequent station; a nonrigid, elongate object collection assembly extended from within the cylinder to a place rearward of the cylinder, a gable roof mounted on an elongate housing, a lengthwise gap formed on a top of the gable roof, and a second container mounted below a rear end of the object collection assembly for collecting nonrigid, elongate objects dropped therefrom; and a washing assembly including one or more sets of pump and pipe having nozzles terminated within the cylinder for washing the released materials.

Owner:WST INT HLDG

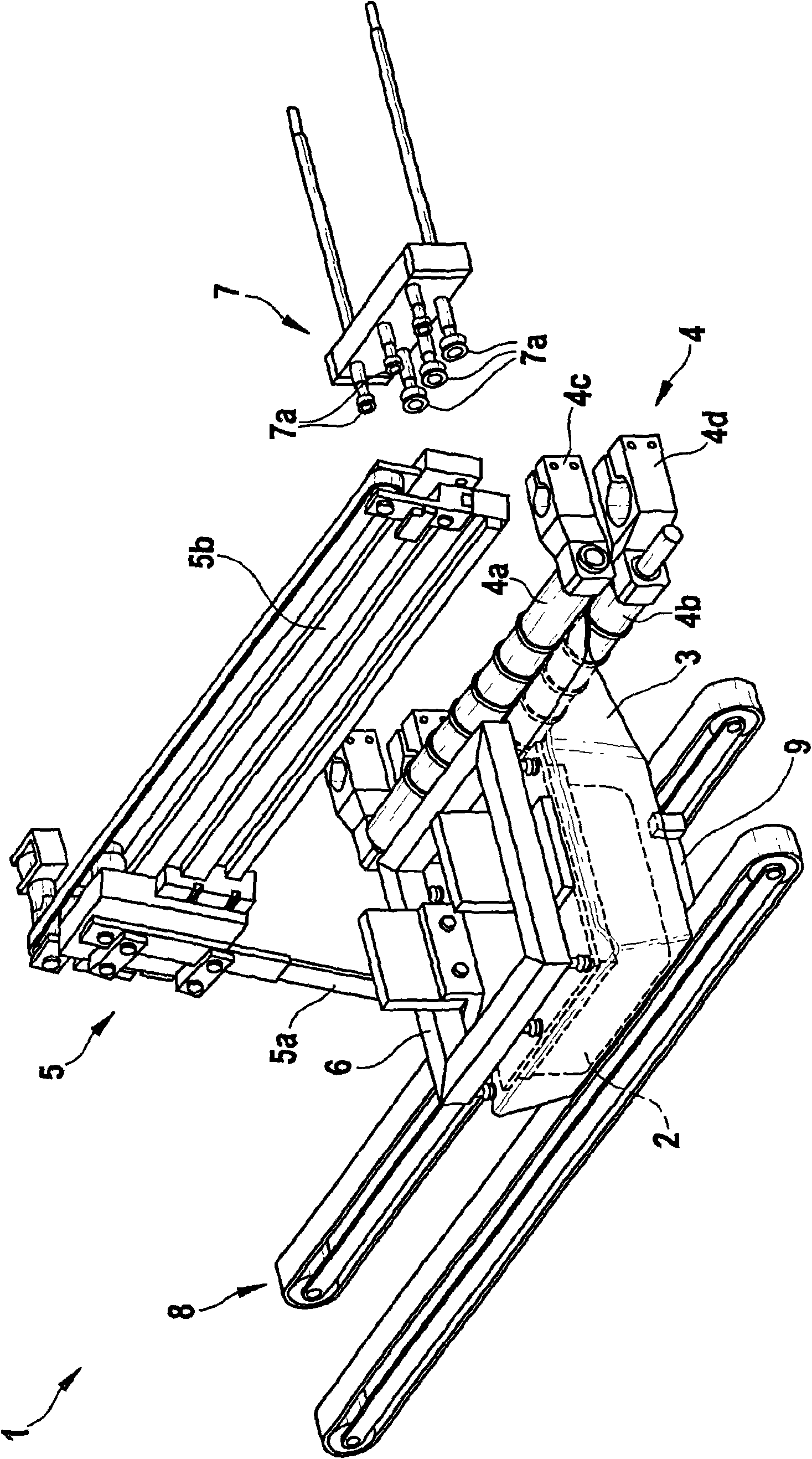

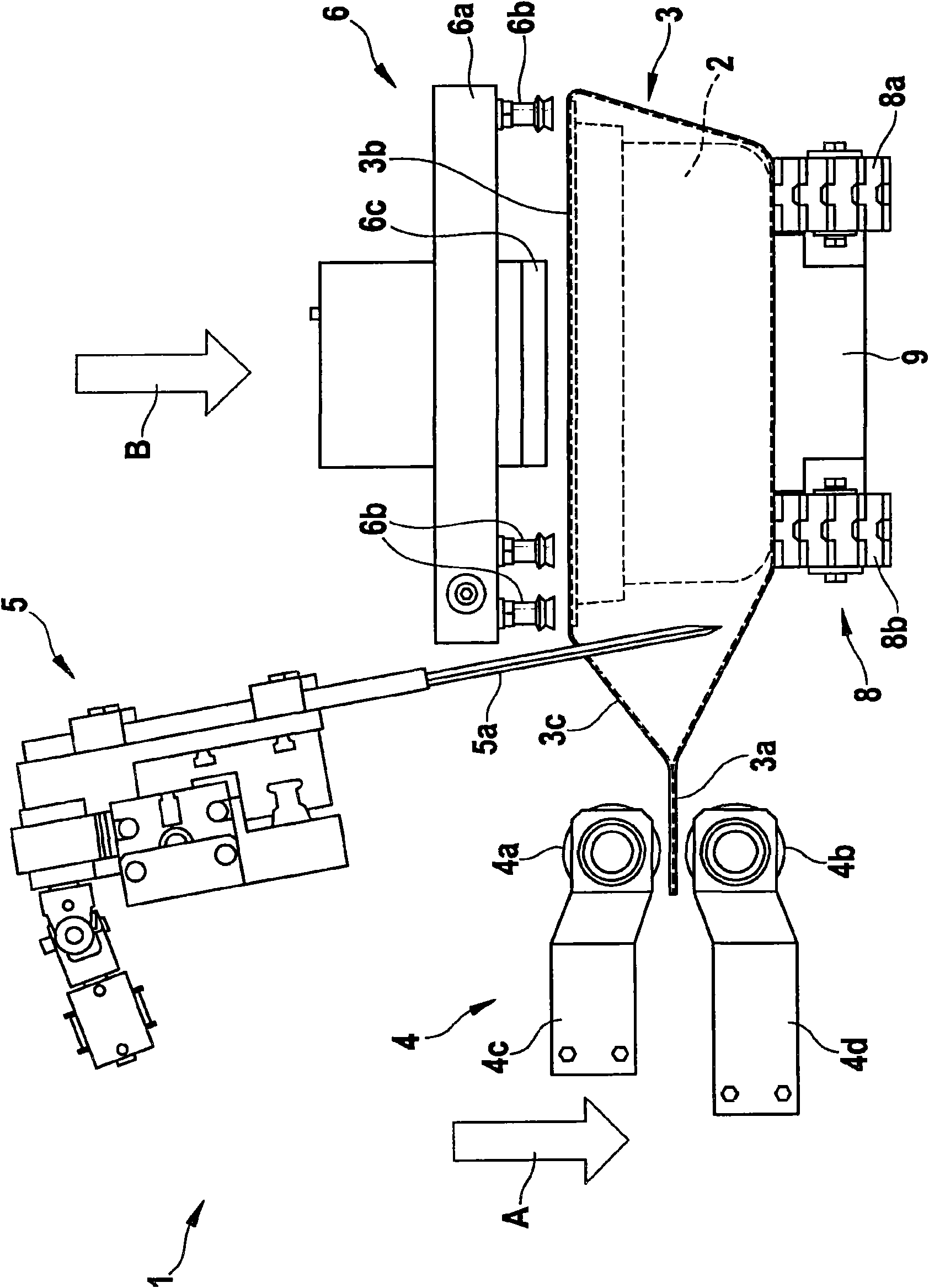

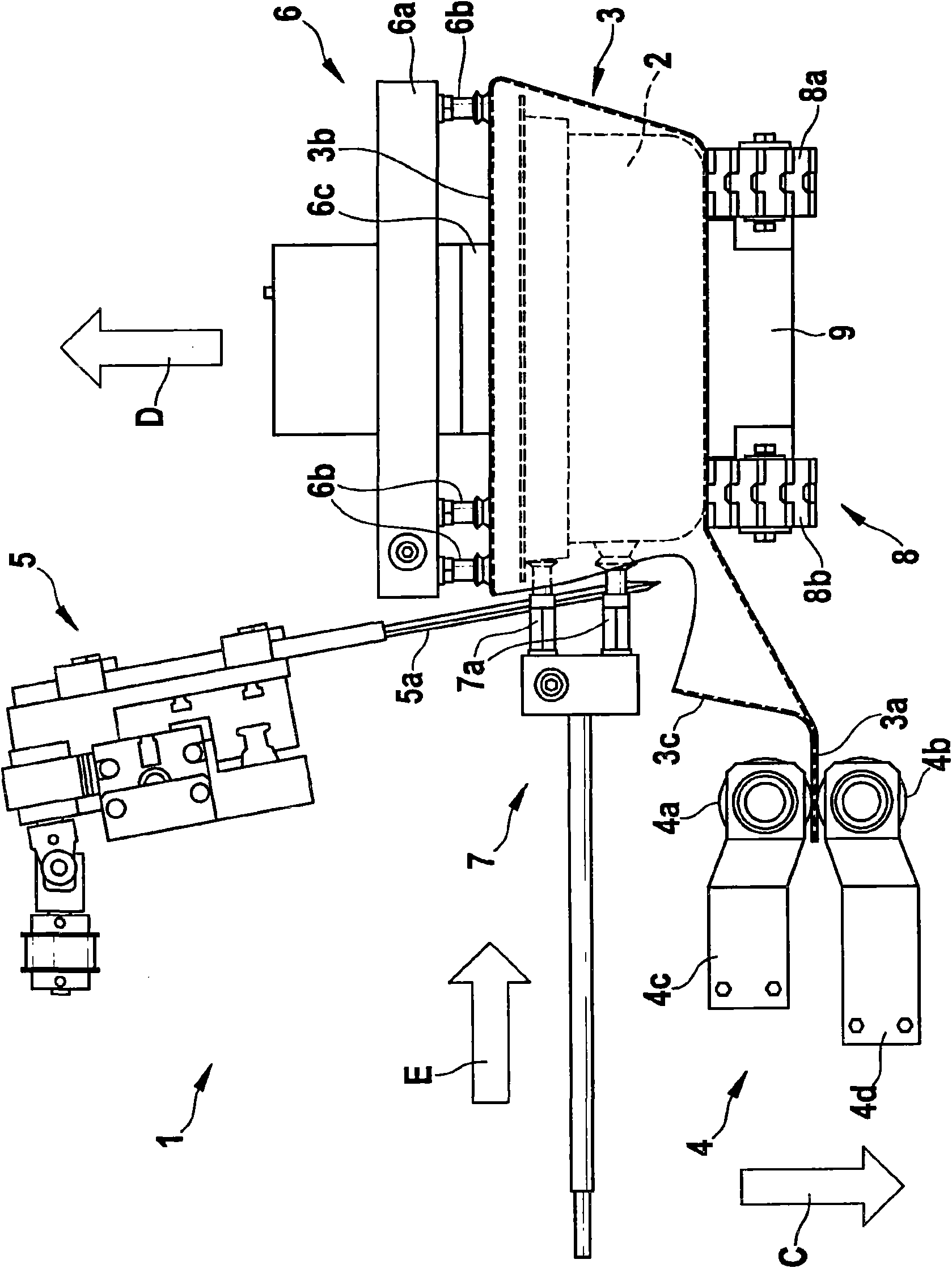

Device and method for removing a sterile object from a sterile packaging

ActiveCN101687559APreferred extension constructFast and reliable clampingBags openingUnpacking by cuttingEngineeringMechanical engineering

The invention relates to a device for removing a sterile object (2) from a sterile packaging (3), having a clamp device (4) which clamps a first subarea (3a) of the sterile packaging (3), a cutting device (5) for cutting the sterile packaging (3) in such a manner that a slit is produced in the sterile packaging (3), a holding device (6) which holds a second subarea (3b) of the sterile packaging (3), and a removal device (7) to remove the object (2) from the sterile packaging (3) through the slit. The invention also relates to a method for removing a sterile object.

Owner:SYNTEGON TECHNOLOGY GMBH

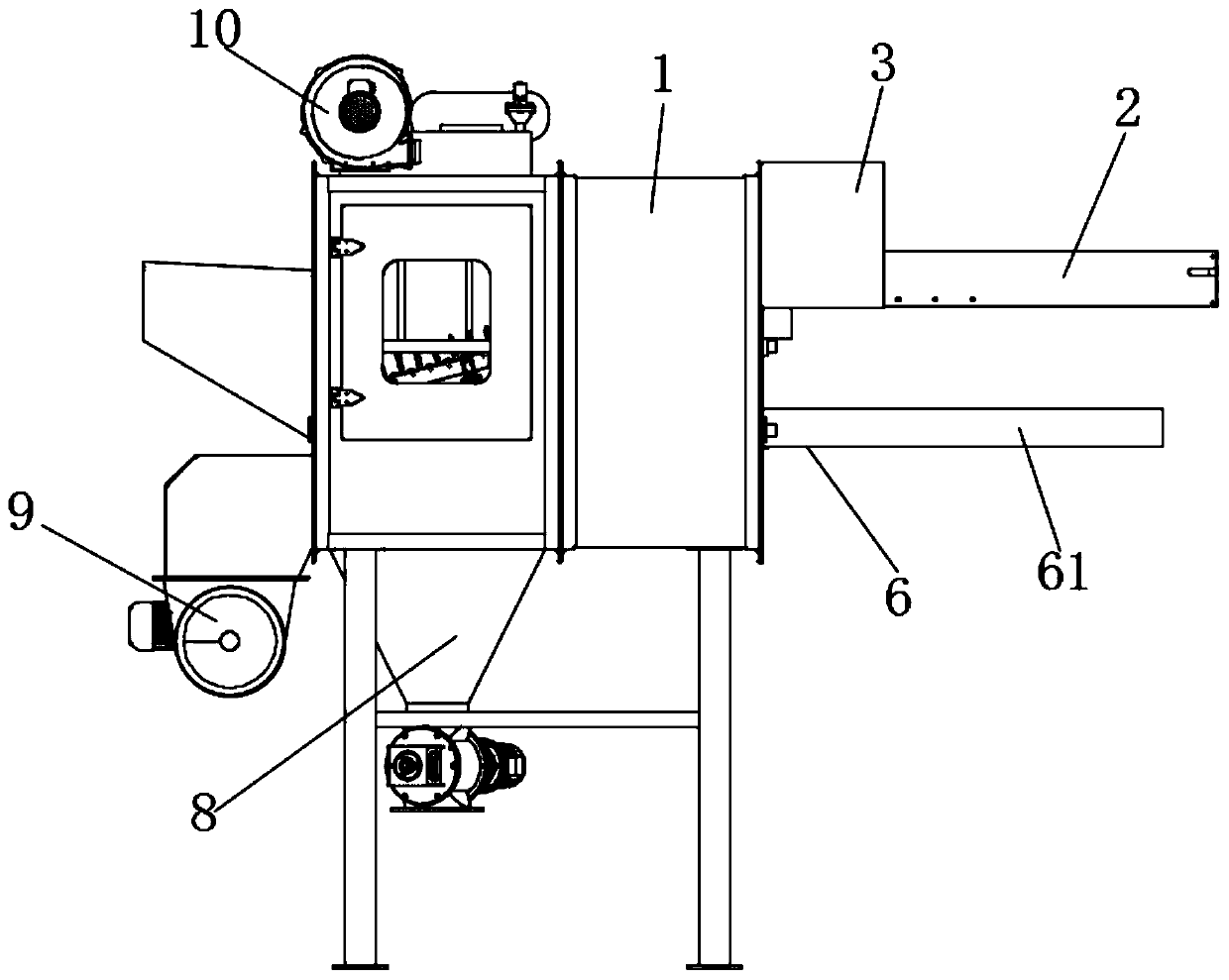

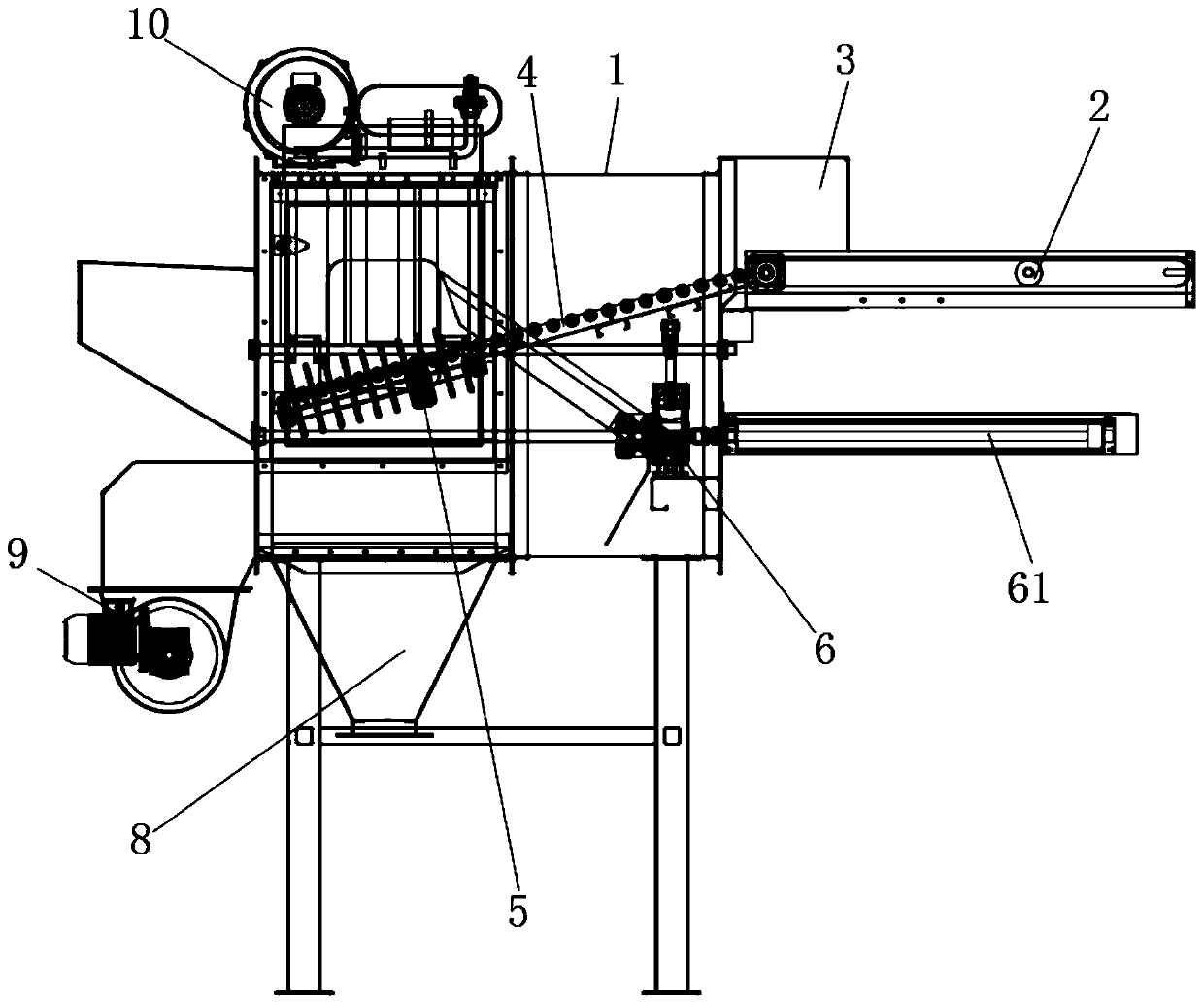

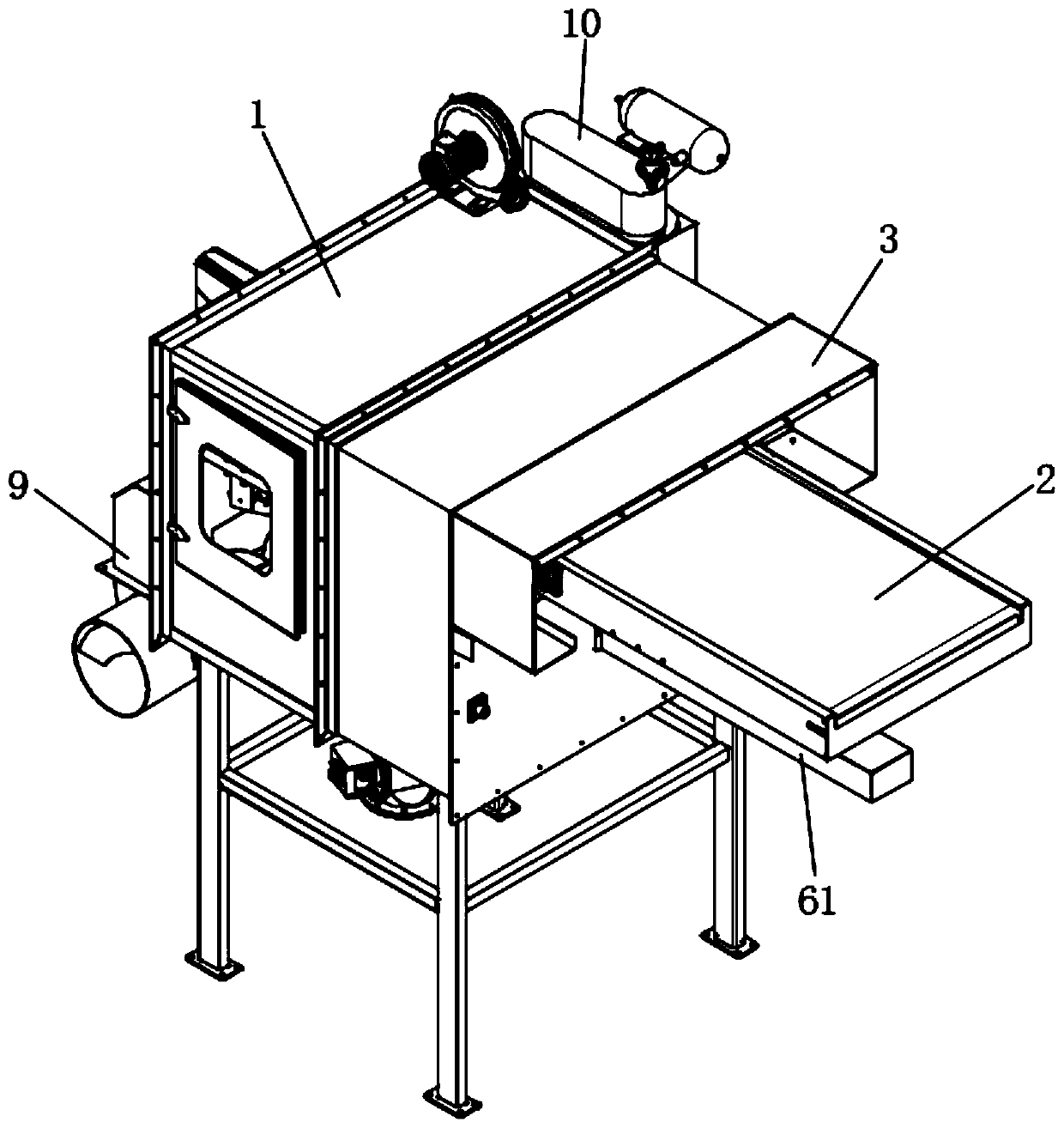

Clean full-automatic bale breaking method and structure

The invention discloses a clean full-automatic bale breaking method and structure, and belongs to the field of bale breakers. The clean full-automatic bale breaking structure comprises a bale breakerhousing bracket, a bag feeding belt conveyor and a bag feeding guide shell, wherein the bag feeding belt conveyor is arranged on the right side of the bale breaker housing bracket. Through the bag feeding belt conveyor, a sliding conveyor and the bag feeding guide shell, a material bag which requires bale breaking is conveyed to the interior of the bale breaker housing bracket; through the interaction between a swinging mechanism as well as a bag breaking and waste bag pushing mechanism, the original material bag is broken and separated; through a separating grid, a pure material drops into acollecting silo, so that the material wasting phenomenon can be avoided; the broken bag enters a waste bag collecting device; through a dust removing system, no dust leaks during the bag breaking process and the material separating process; the structure is simple, the operation is simple and the occupied area is small; during the bale breaking process, only one person is needed to put the material bag on the belt conveyor; the degree of automation is high; and the circumstance of dust leakage is prevented during the bale breaking process.

Owner:常州沃斯曼自动化科技有限公司

Bag breaking device of intelligent household garbage classification system

PendingCN111517039ARemove automaticallyWaste collection and transferRefuse receptaclesProcess engineeringBin bag

The invention discloses a bag breaking device of an intelligent household garbage classification system. The bag breaking device comprises a garbage can storage space arranged at the bottom in a case,a feeding inlet formed in one side of the upper portion of the case, a bag tearing mechanism arranged on the inner side of the feeding inlet, a bag falling mechanism arranged on the outer side of thegarbage can storage space on the opposite side of the feeding inlet, a conveying mechanism arranged at the top in the case, and a grabbing mechanism connected to the lower portion of the conveying mechanism and capable of being driven by the conveying mechanism to reciprocate between the feeding inlet and a garbage bag collecting box along the conveying mechanism, wherein the position of the feeding inlet is higher than the garbage can storage space, and a feeding inlet door is arranged on the feeding inlet; the garbage bag collecting box is installed below the bag falling mechanism; and theconveying mechanism is located above the garbage can storage space and arranged between the feeding inlet and the garbage bag collecting box. The bag breaking device can achieve bag breaking of garbage bags put into garbage cans, garbage and empty garbage bags are recycled respectively, and the requirement for garbage classification is met.

Owner:北京弘控生态环境有限公司

Automatic opening method and device for cigarette box

The invention discloses an automatic opening device and method for a cigarette box. The device comprises a conveying track, wherein the conveying track conveys cigarette packet cartons; an inner plastic bag cutting machine is arranged on the middle section of the conveying track; four cutting knives are arranged on the inner plastic bag cutting machine and are respectively mounted on four knife holders; the cutting knives are driven by a rotating cylinder; a static weighing device is arranged at the tail end of the conveying track; and a cigarette packet removing device is arranged on one side of the static weighing device. The inner plastic bag cutting machine is added to cut and grab plastic bags of liners, so that a whole box opening process is perfect; and after unpacking is finished, the static weighing device is added to detect measures of cigarette packets, unqualified cigarette packets are removed, production quality of the cigarette packets is guaranteed, and quality control level is improved.

Owner:CHINA TOBACCO ZHEJIANG IND

Device for ripping and tearing bags open

InactiveUS6089814AGood cleaning effectGood stripping effectSolid waste disposalBags openingEngineeringConductor Coil

Owner:BAYER MANFRED

Apparatus for piercing garbage bags and collecting nonrigid, elongate objects and powder

Provided is an apparatus comprising a screen assembly for sifting powder including a rear feeding device, a first conveyor adapted to convey garbage bags from the feeding device to the screen assembly, an inclined board extended downwardly from a front end of the screen assembly, and a second conveyor provided below the board, the second conveyor being adapted to convey materials leaving the screen assembly to a subsequent station for processing; and a nonrigid, elongate object collection assembly extended from the rear of the screen assembly through the screen assembly to a point in front of the screen assembly, the object collection assembly including an elongate housing of rectangular section, a gable roof provided on the housing, a lengthwise gap provided on a top of the gable roof, and a container provided below a front end thereof for collecting nonrigid, elongate objects dropped therefrom.

Owner:WST INT HLDG

Liner connecting device and liner filling device

InactiveUS20080145198A1Wrapping material feeding apparatusFlexible bulk container emptying systemsEngineeringAccess port

A liner emptying device and a liner filling device as well as methods using them for contamination-free filling and emptying of a liner. This contamination-free filling and emptying prevents any danger to the health of the people working with the packaged substances. Both the liner emptying device and the liner filling device are connected to the liner via a fastening device and the residual films sealing off the device can be removed via an access port, whereby the liner can be filled or emptied without contaminating the surroundings.

Owner:HECHT ANLAGENBAU GMBH

Novel powder bale breaker

InactiveCN105173276ANo manual operationImprove work efficiencyBags openingEngineeringMechanical engineering

The embodiment of the invention discloses a novel powder bale breaker. The bale breaker is used for solving the problems that existing manual bale breaking is large in labor intensity and low in working efficiency. The novel powder bale breaker comprises a conveyor, a bag grabbing deice, a station moving device, a material box and a bag discharging device. The novel powder bale breaker is provided with a bag grabbing station, a material pouring station and a bag discharging station; the conveyor is used for conveying a material bag to the bag grabbing station; the material box is mounted on the material pouring station, a cutting device is mounted on the material pouring station and used for cutting the material bag reaching the material pouring station to be open; the bag discharging device is mounted on the bag discharging station and used for recycling the material bag obtained after material pouring; and the station moving device is used for driving the bag grabbing device to move among the bag grabbing station, the material pouring station and the bag discharging station.

Owner:FOSHAN GOLD SILVER RIVER INTELLIGENT EQUIP CO LTD

Electrostatic material separator

A separation system includes an air separator that, in one embodiment, primarily receives Municipal Solid Waste (MSW) containing a mixture of relatively light MSW recyclable materials such as plastic, paper, cardboard, plastic containers, and / or metal containers and relatively heavy MSW such as textiles, food waste, yard debris, etc. The air separator blows the relatively light MSW recyclable materials up though a chamber and onto a first conveyor while the other relatively heavy MSW material drops down a chute onto a second conveyor. A separation screen receives the relatively light MSW recyclable materials from the air separator and separates the relatively flat fiber and plastic film materials from the other paper, plastic and metal containers. In another separation stage, an electrostatic emitter is positioned adjacent to a conveyor for applying an electrostatic charge to faciliate separation of the MSW recyclable materials. An optical identification system is configured to distinguish different types of recyclable materials.

Owner:EMERGING ACQUISITIONS

Sorting and separation system for long-strip articles in urban domestic garbage

InactiveCN102671861AEfficient sortingEfficient separationSievingGas current separationFixed frameEngineering

The invention discloses a sorting and separation system for long-strip articles in urban domestic garbage, which comprises a two-sectional drum screen, a double-shaft shearing crusher, an air-blower, a collection device for fabrics and a collection device for plastics; the two-sectional drum screen comprises a fixed frame and a drum screen arranged on the fixed frame, and the drum screen comprises an entrance section of the drum screen and an exit section of the drum screen; a plurality of bag-breaking cutters are arranged on the inner wall of the entrance section of the drum screen; and a plurality long-strip article hanging devices are arranged in the exit section of the drum screen, a long-strip article collection device is arranged in the exit section of the drum screen, a rear end of the long-strip article collection device extends out of the exit section of the drum screen and extends to a feeding part on the upper end of the double-shaft shearing crusher, the air-blower is arranged on the discharging part of the double-shaft shearing crusher, and the collection device for fabrics and the collection device for plastics are arranged in the lower part of the double-shaft shearing crusher. According to the system, long-strip articles in garbage can be effectively selected for separation, and the system has reliable selection and high accuracy of separation.

Owner:四川川润环保能源科技有限公司 +1

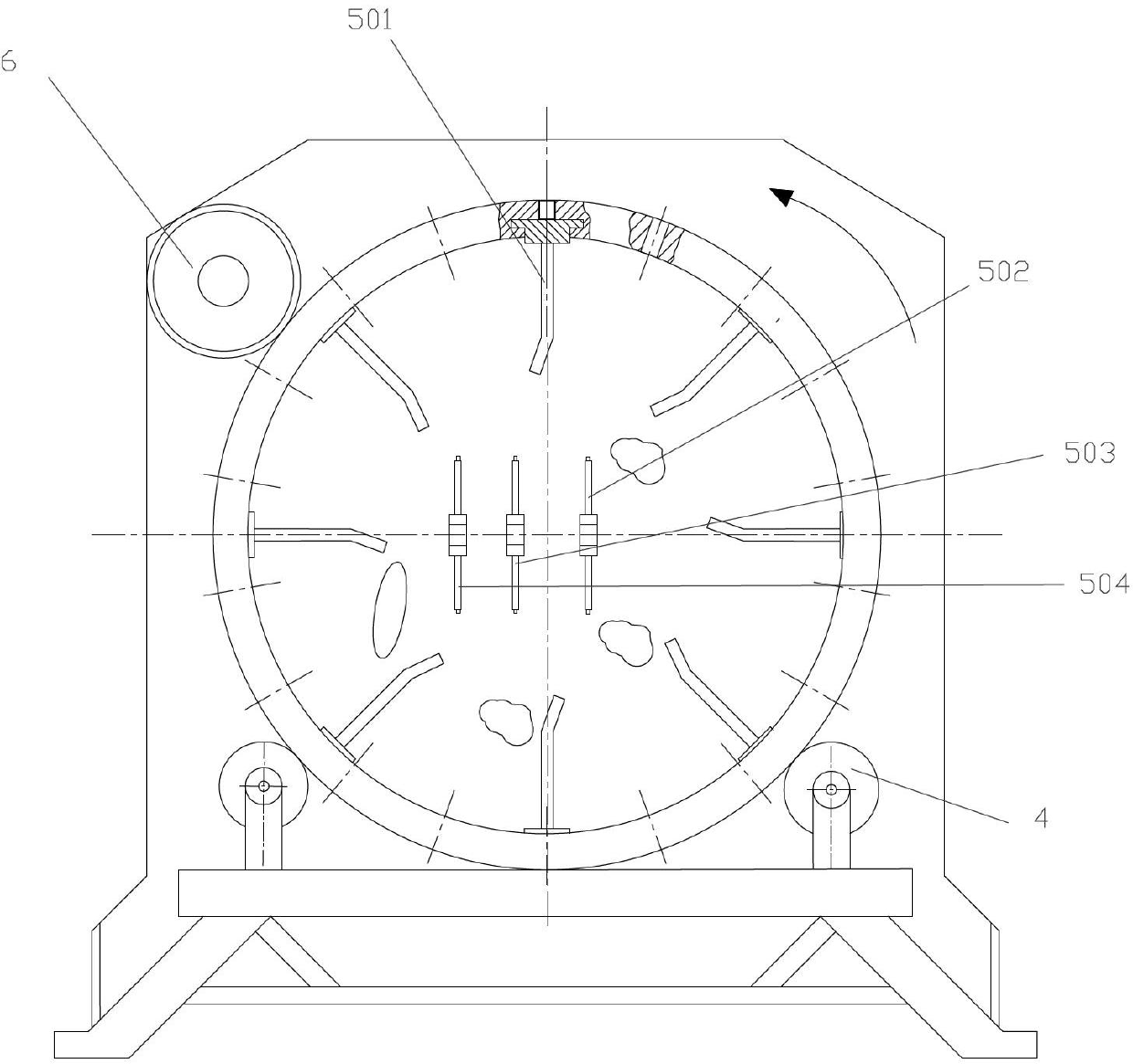

Intelligent full-automatic unpacking machine

ActiveCN105035440AScientific and reasonable structure designEasy to operateBags openingMechanical engineeringEngineering

The invention discloses an intelligent full-automatic unpacking machine which comprises an upward conveying device, an empty bag recycling device, an unpacking device and a material collecting device. The upward conveying device is provided with an upward conveying belt. The empty bag recycling device is arranged beside the upward conveying belt and moves along with the upward conveying belt, and the empty bag recycling device is provided with a barbed electric push rod. The unpacking device is arranged behind the tail end of the upward conveying belt and provided with a knife. The material collecting device is arranged below the unpacking device, and a feeding opening of the material collecting device is correspondingly located under the tail end of the upward conveying belt. The intelligent full-automatic unpacking machine is scientific and reasonable in structural design and easy to operate; gravity is ingeniously utilized, the knife is intelligently controlled in a full-automatic manner, blanking is accurate by combining the conveying belt and the action of gravity, and the machine can be suitable for being applied to different unpacking environments; the unpacking effect is good, the bag opening breaking speed is high, and few chippings exist; and compared with previous unpacking machines, the contamination of the chippings of material bags to materials is reduced to a large degree.

Owner:XIAMEN UNIV OF TECH

Apparatus for piercing garbage bags, washing materials released from the pierced garbage bags, and collecting nonrigid, elongate objects and powder

An apparatus for disposing garbage bags in one embodiment includes a screen assembly including a first conveyor for conveying garbage bags from a feeding device to a hollow screening cylinder for piercing, and a second conveyor mounted below a rear discharge opening of the cylinder for conveying materials released from the pierced bags to a subsequent station; a nonrigid, elongate object collection assembly extended from within the cylinder to a place rearward of the cylinder, a gable roof mounted on an elongate housing, a lengthwise gap formed on a top of the gable roof, and a second container mounted below a rear end of the object collection assembly for collecting nonrigid, elongate objects dropped therefrom; and a washing assembly including one or more sets of pump and pipe having nozzles terminated within the cylinder for washing the released materials.

Owner:WST INT HLDG

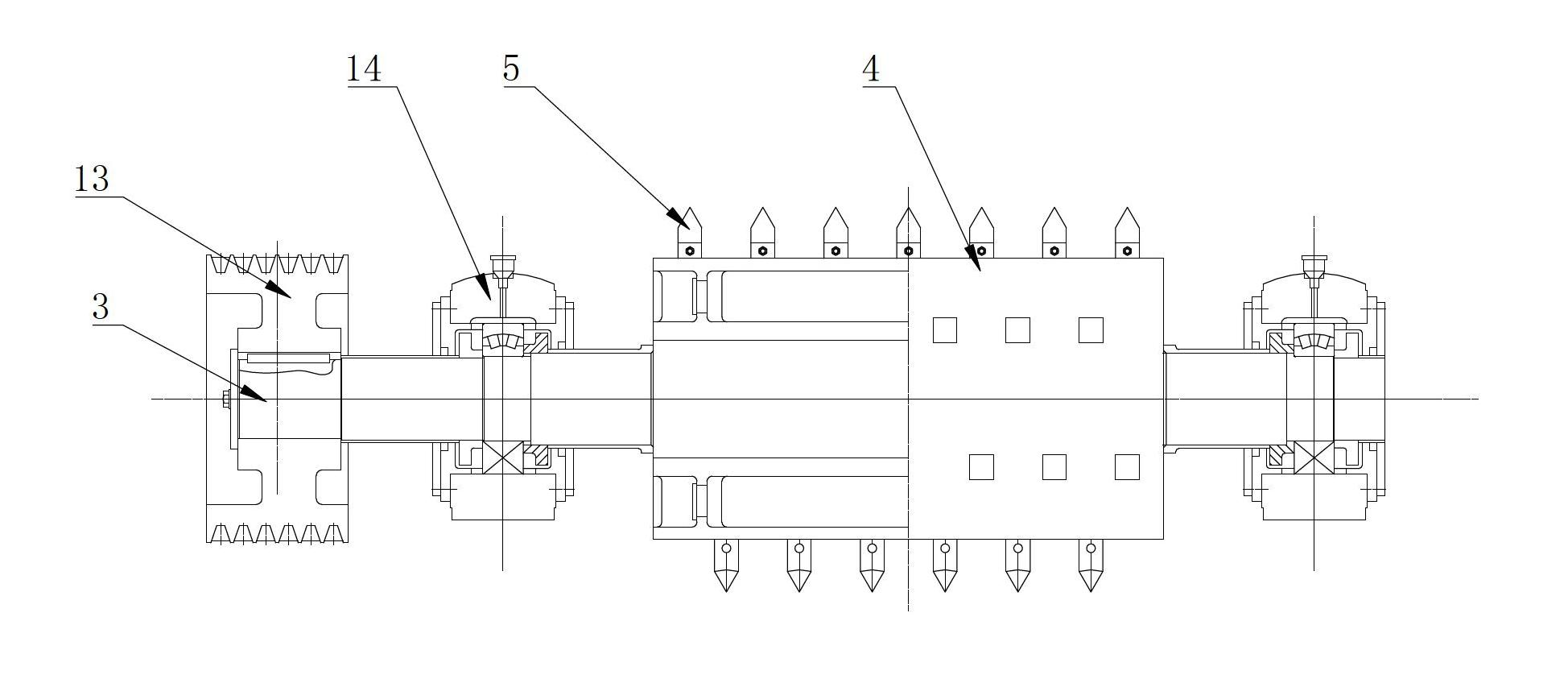

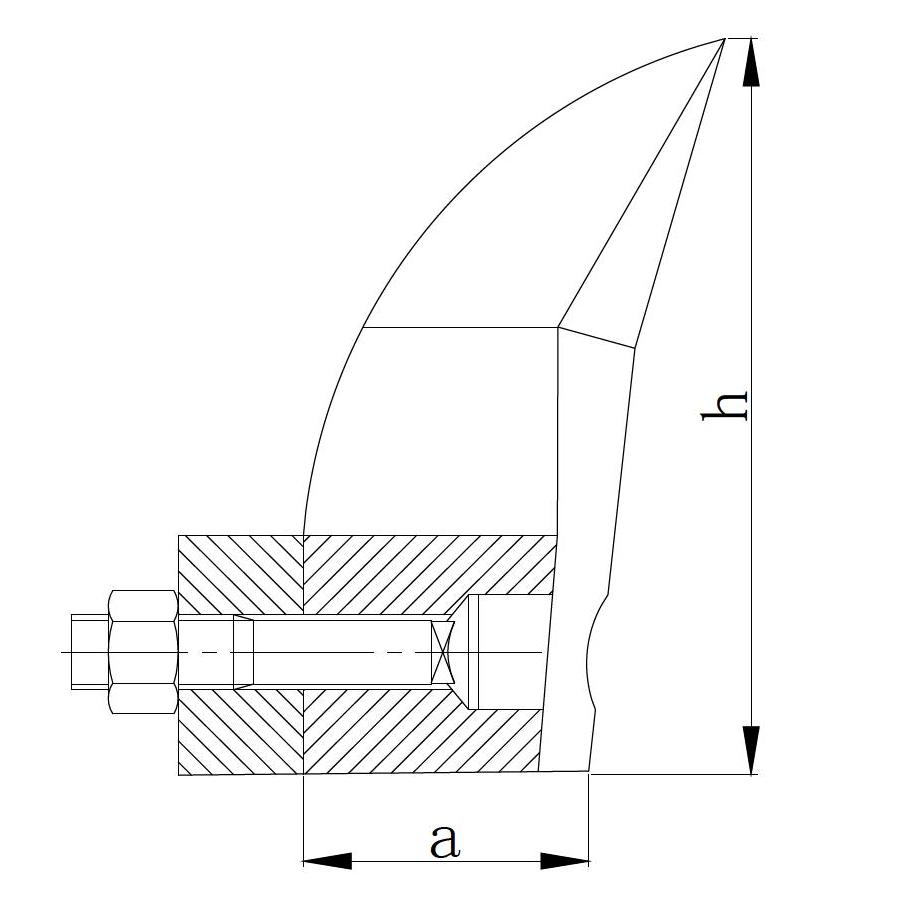

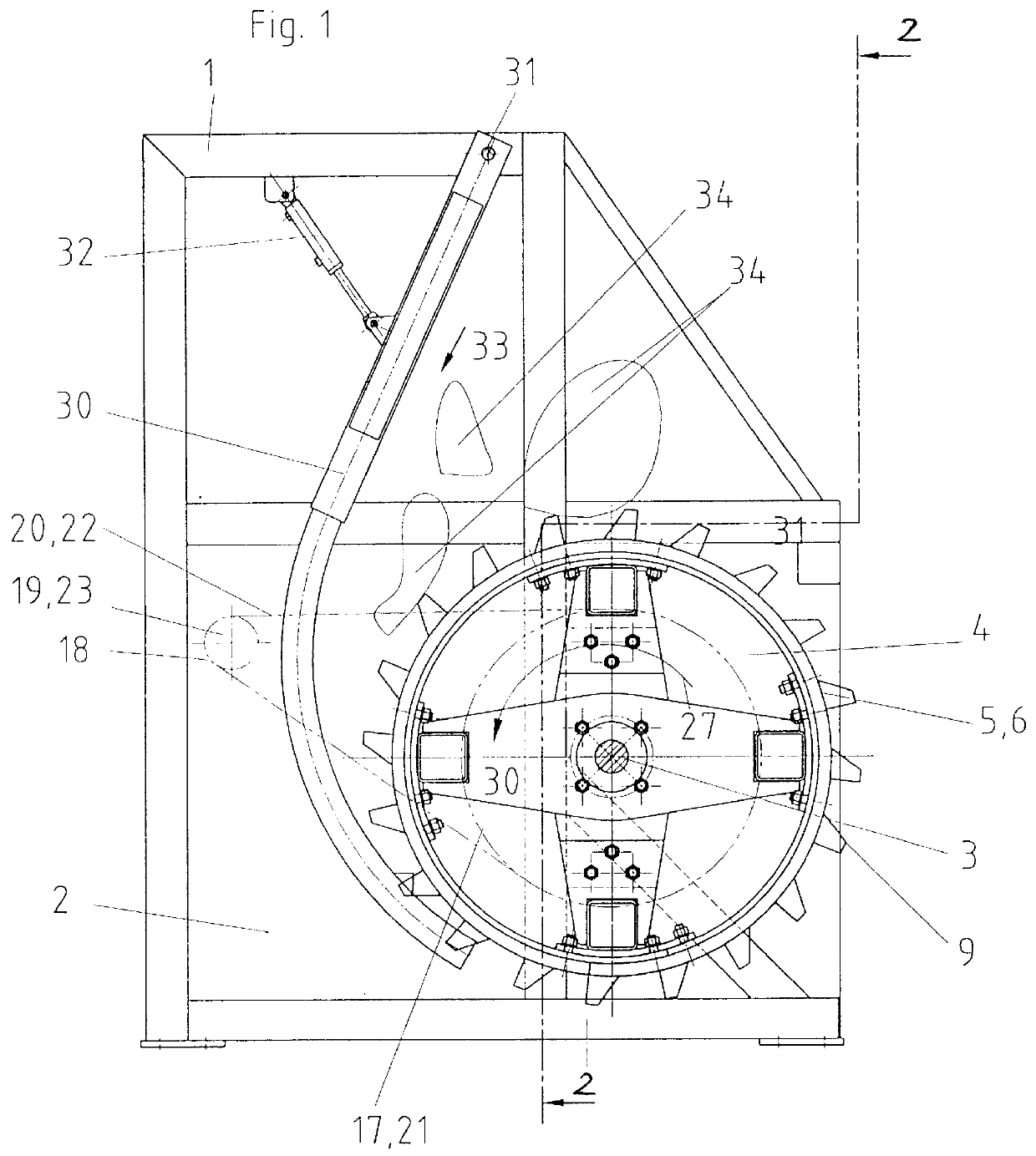

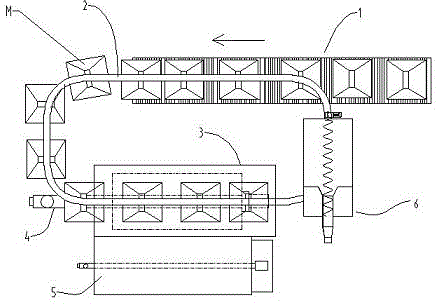

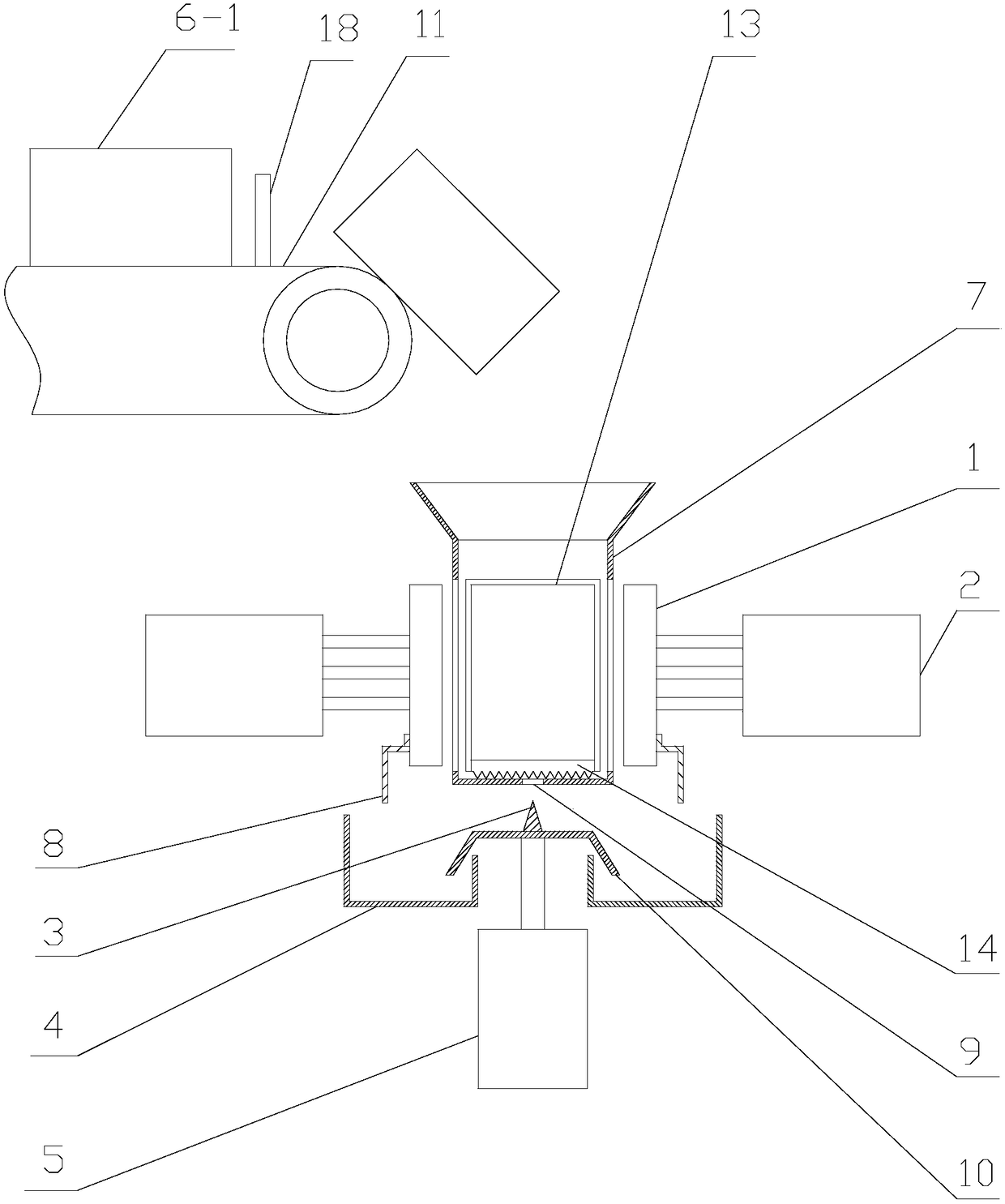

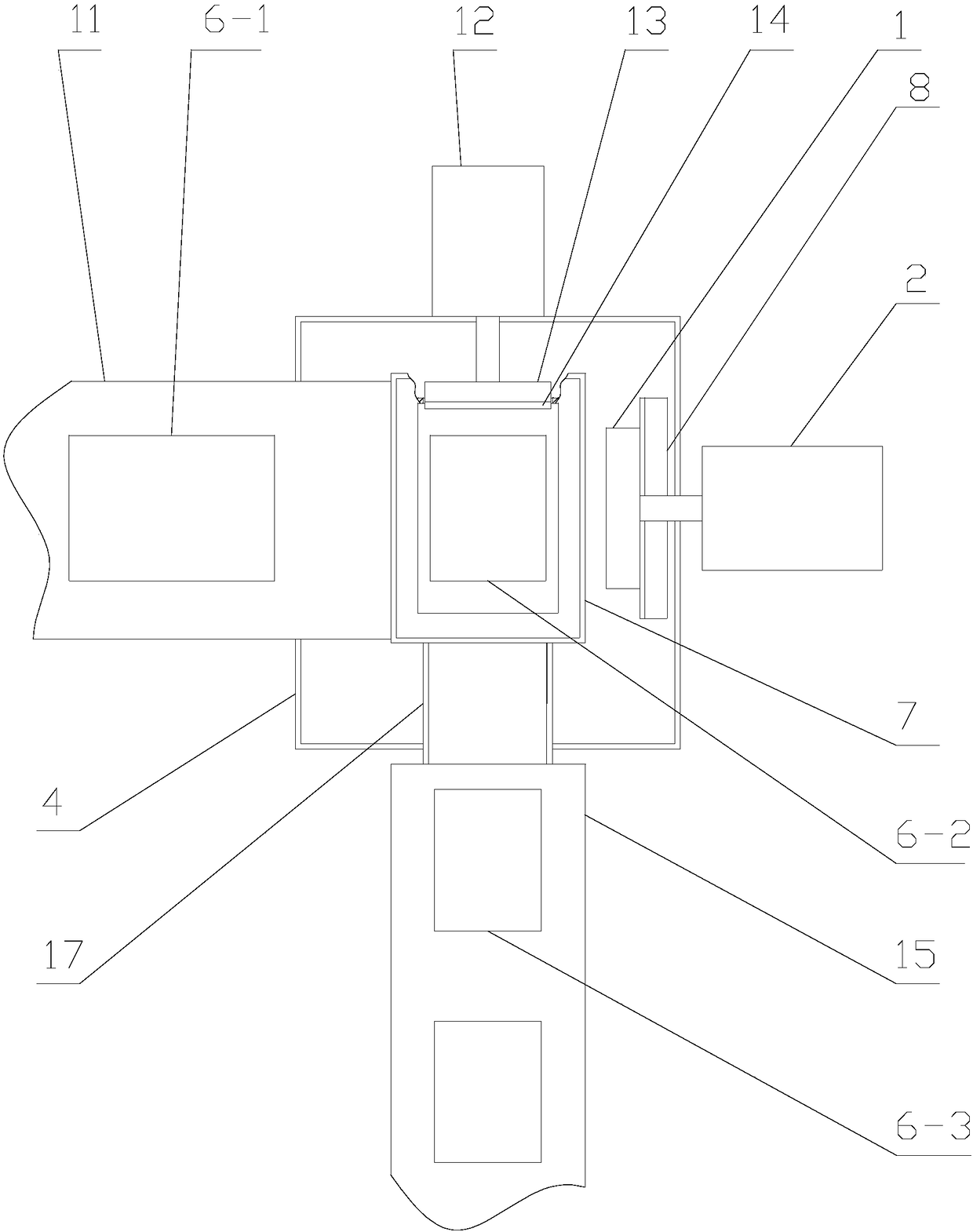

Bag opening machine for large bag

InactiveCN104528080AReduce pollutionReduce labor intensityBags openingEngineeringProcess engineering

The invention discloses a bag opening machine for a large bag. The bag opening machine comprises an annular conveying mechanism. A bag feeding conveying mechanism is arranged below the annular conveying mechanism, and used for guiding a packaging bag with materials into the annular conveying mechanism, the packaging bag is driven by the annular conveying mechanism to do annular motion, and a bag opening mechanism for opening the packaging bag is arranged on the annular conveying mechanism. According to the technical scheme, bag feeding, conveying, bag opening, bag cleaning, dust collecting, temporary storage, collecting and discharging and empty bag recycling are integrated, labor intensity is lowered, energy consumption is reduced, environmental pollution is reduced, the automation degree is high, use performance is stable, and production capacity is greatly improved. The bag opening machine can be used for opening various large-bag packaging materials, such as powder, particles, blocks and paste, and the superiority can be reflected better in the industries of chemical engineering, food, building materials, mineral powder, micro powder and the like.

Owner:ANQIU BOYANG MACHINERY MFR

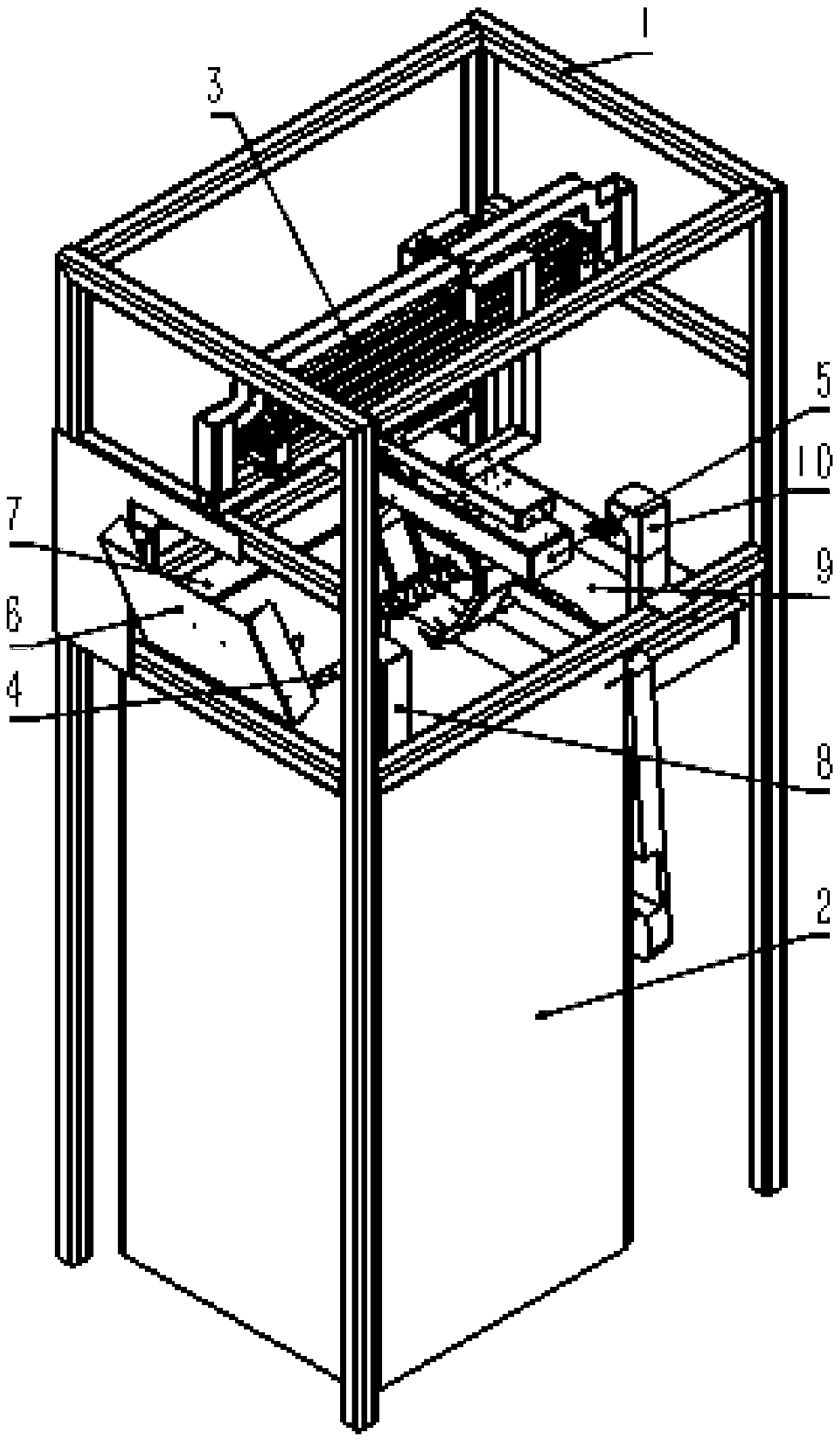

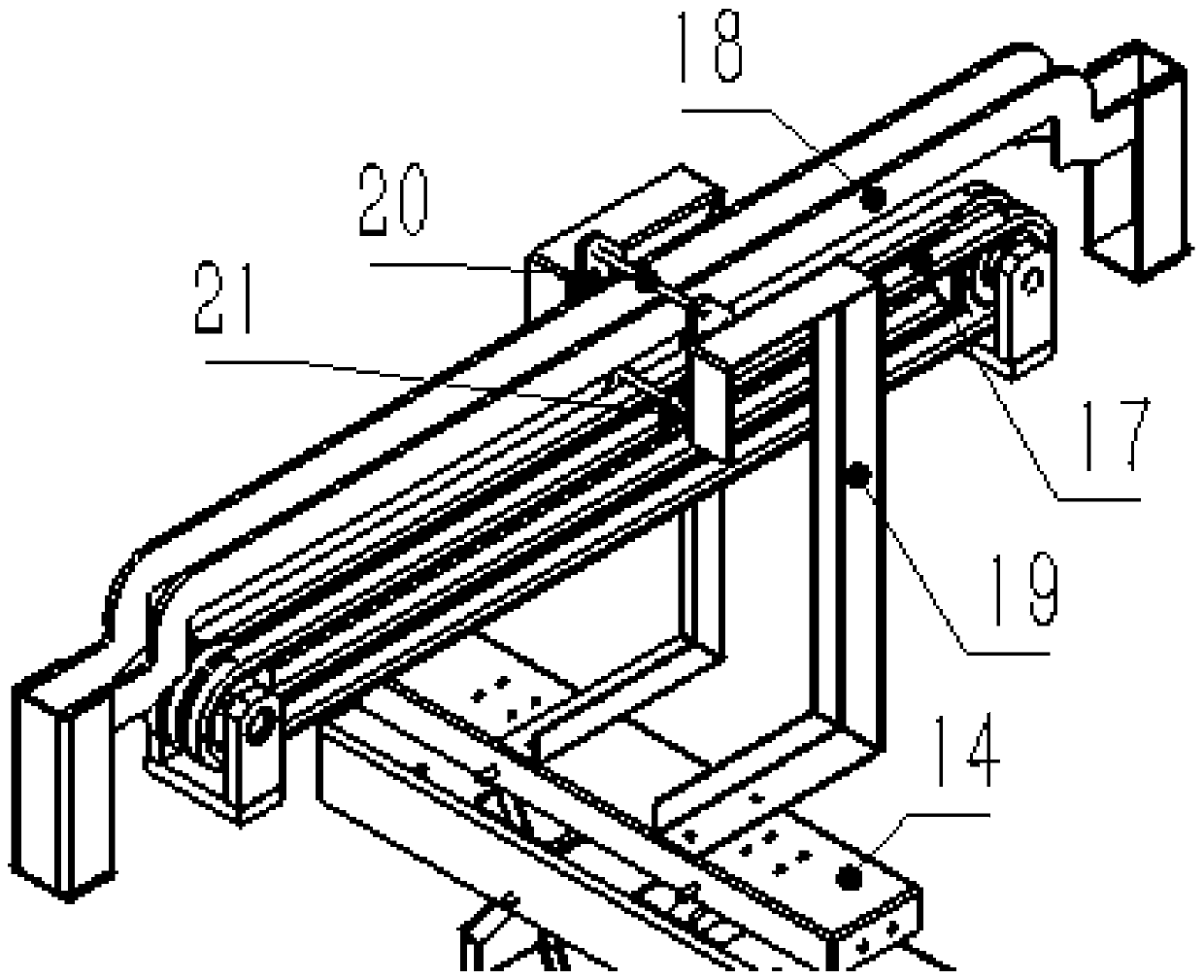

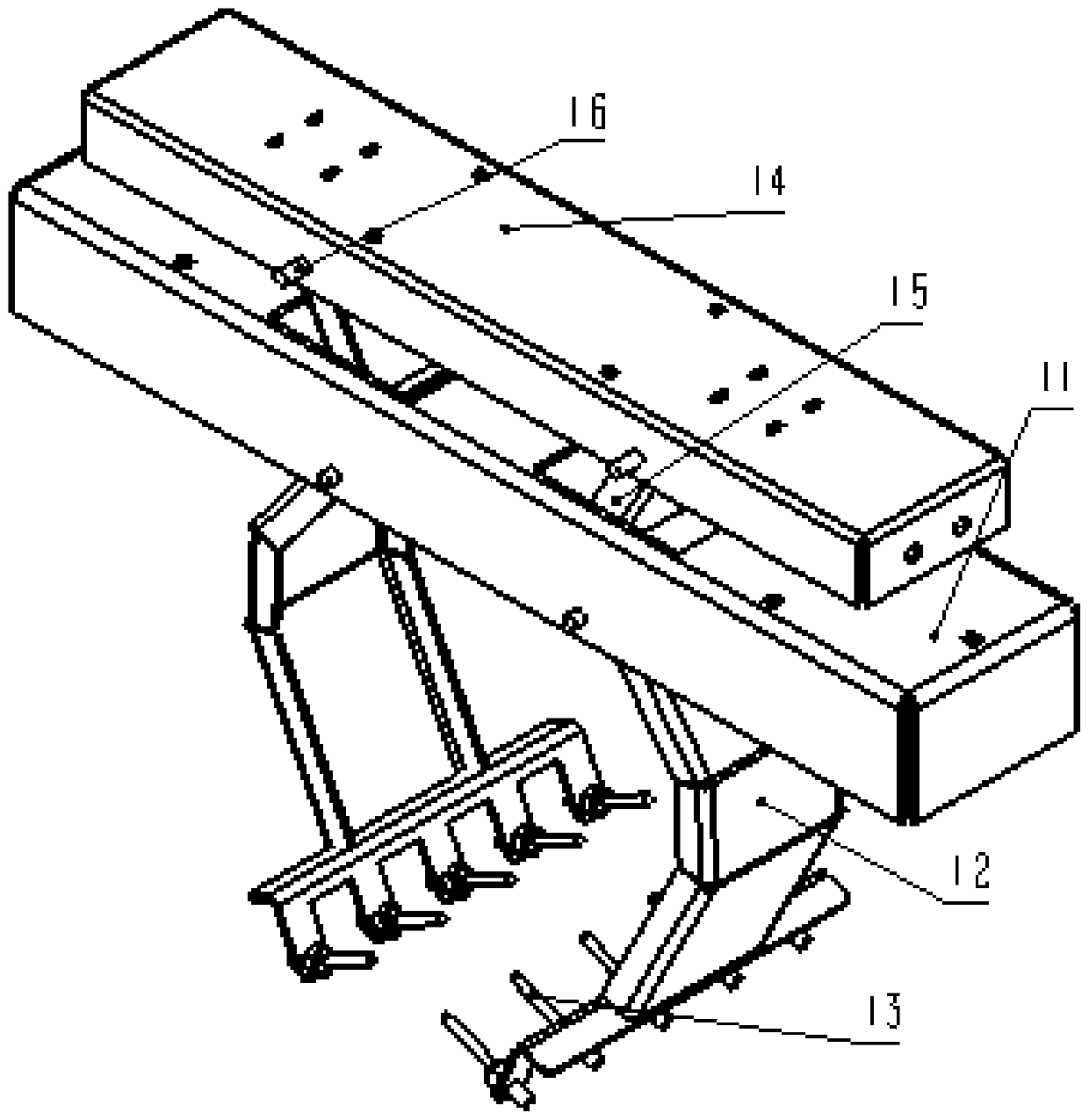

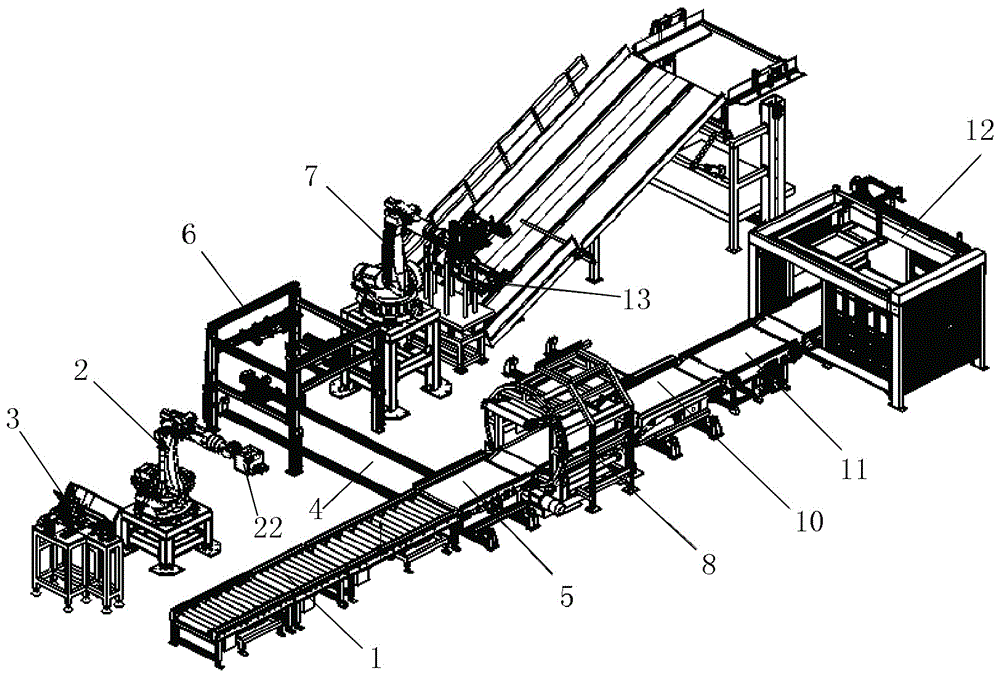

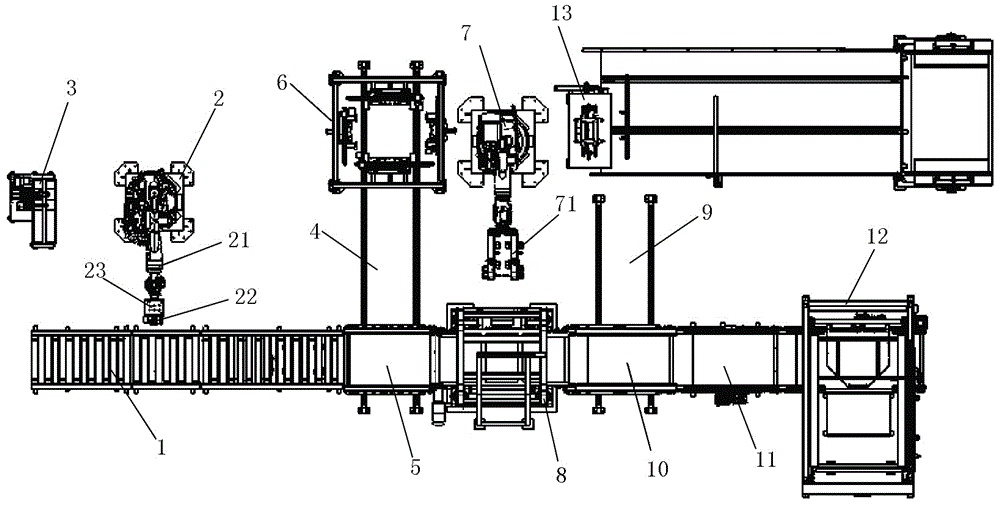

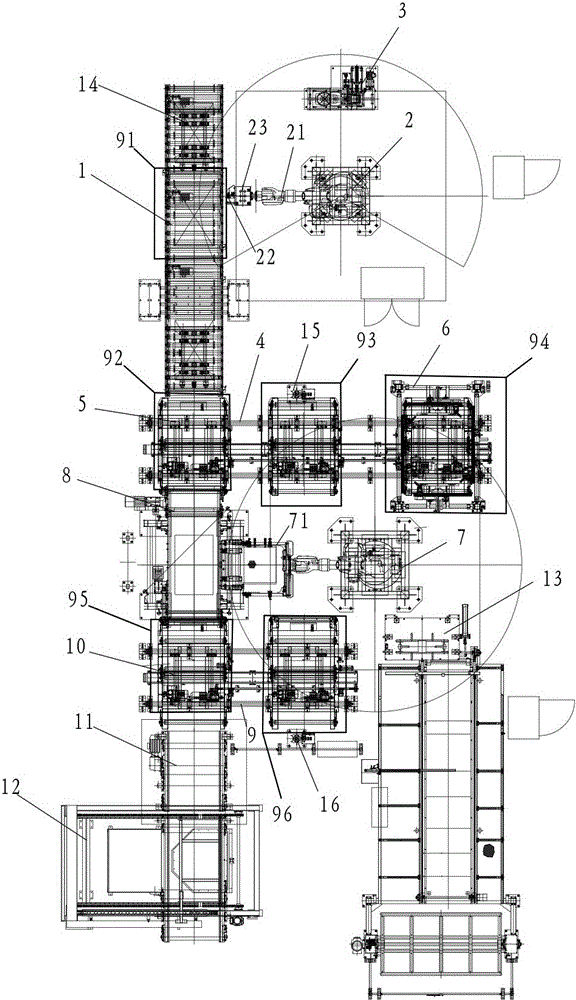

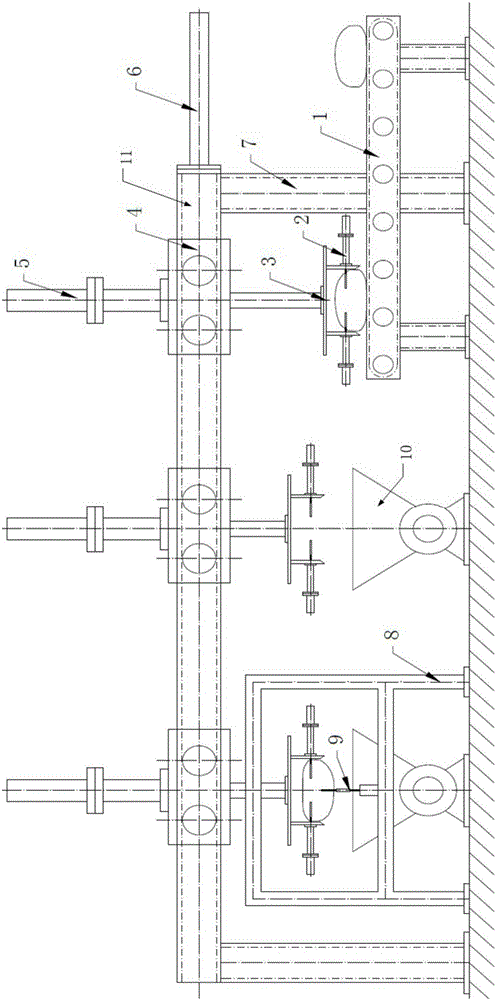

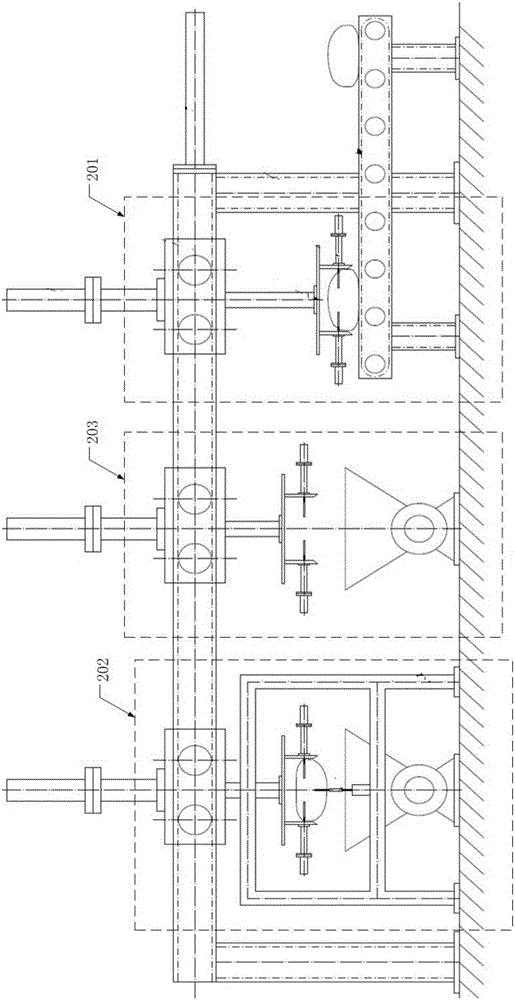

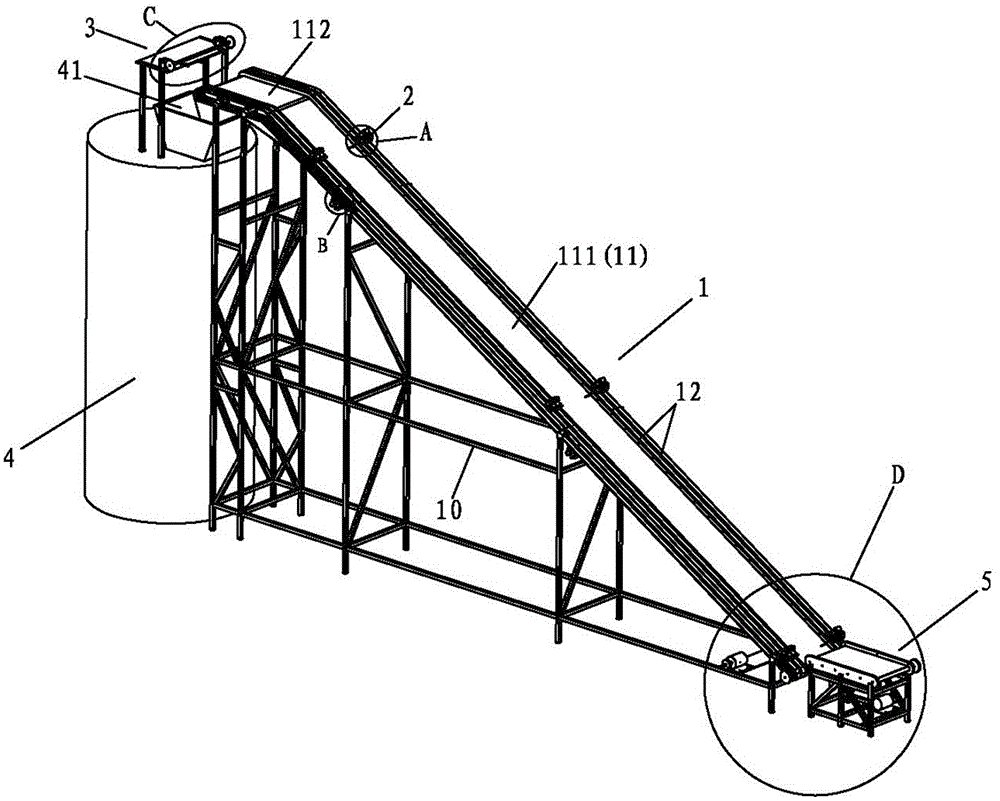

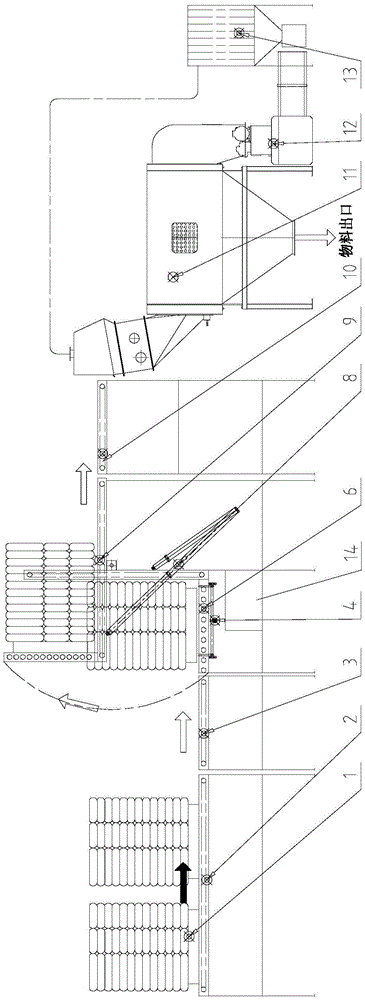

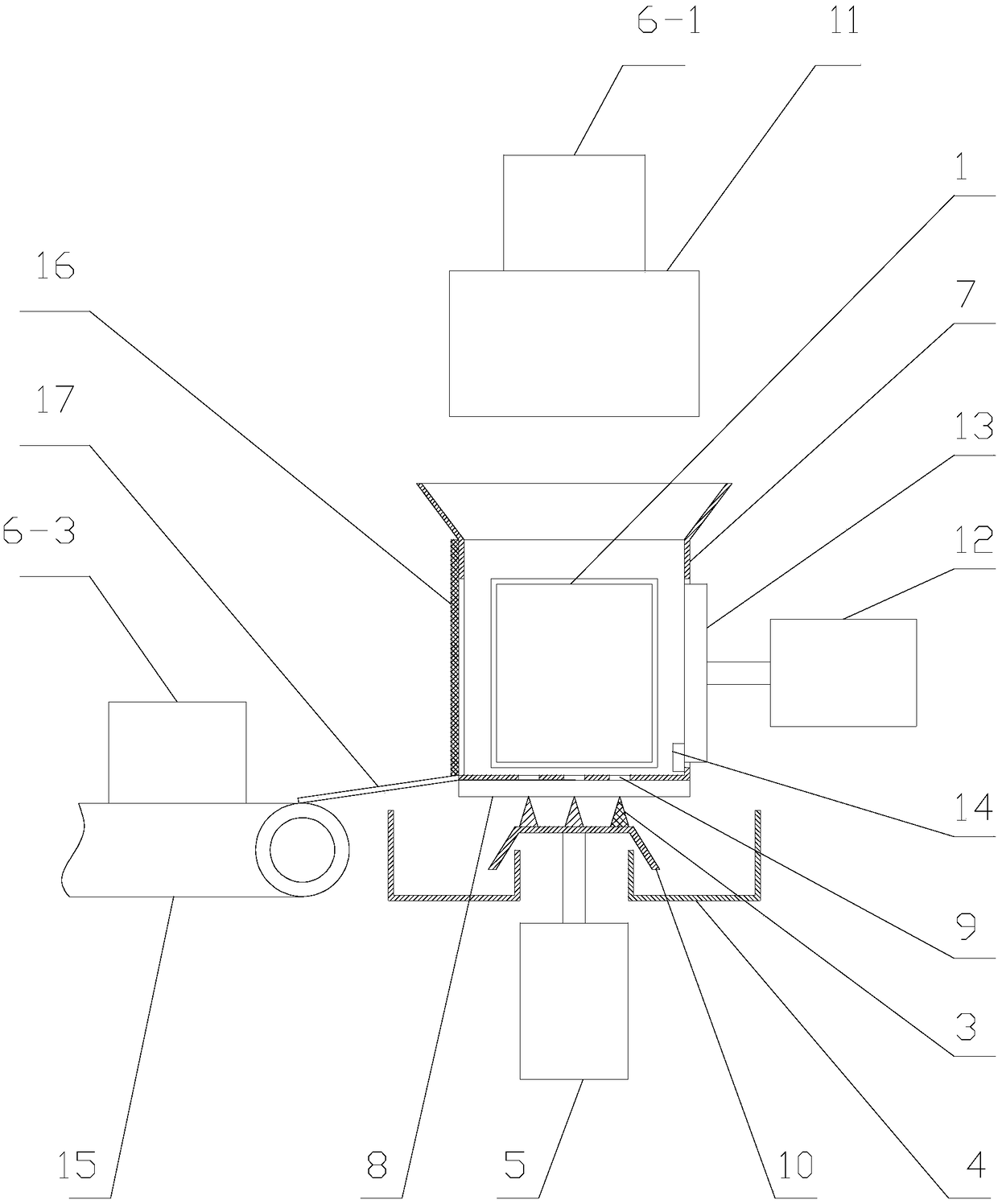

Full-automatic unstacking and unpacking system

ActiveCN105668197AAchieve staff reduction and increase efficiencyFully automatedBags openingConveyor partsEngineeringAutomatic testing

The invention relates to a full-automatic unstacking and unpacking system. The system comprises a chain plate type conveyor, a hydraulic turnover unstacking device, a packing bag conveyor (10), a full-automatic unpacking machine (11), a full-automatic packing machine (12) and a pulse dust remover (13); the output end of the chain plate type conveyor is connected with the input end of the hydraulic turnover unstacking device, and the output end of the hydraulic turnover unstacking device is connected with the input end of the packing bag conveyor (10); the packing bag conveyor (10) is connected to a supporting frame of the hydraulic turnover unstacking device, and the output end of the packing bag conveyor (10) is connected with the full-automatic unpacking machine (11); a material outlet is formed in the bottom end of the full-automatic unpacking machine (11), and the bag outlet end of the full-automatic unpacking machine (11) is connected with the full-automatic packing machine (12); and the full-automatic unpacking machine (11) is connected with the pulse dust remover (13) through a ventilation network pipeline. The full-automatic unstacking and unpacking system has the beneficial effects that the efficiency is high, continuity and full automation are achieved, the unstacking and unpacking environment is optimized, material losses are reduced, unnecessary pollution is prevented, and labor force is saved.

Owner:HANRUI PUZER BULK HANDLING TECH SHANGHAI

Beverage packaging bag recycling and processing system

InactiveCN108247896APrevent overflowIncrease profitPlastic recyclingBags openingSurface mountingEngineering

The invention discloses a beverage packaging bag recycling and processing system. The beverage packaging bag recycling and processing system comprises a recycling platform, a left extrusion unit, a right extrusion unit, a puncturing unit, a liquid collecting tank and a pushing-out unit; the recycling platform is provided with a chassis with sieve holes; a front enclosing plate, a rear enclosing plate, a left enclosing plate and a right enclosing plate are arranged on the four sides of the chassis; the left extrusion unit and the right extrusion unit are located on the left side and the right side of the recycling platform, and each of the left extrusion unit and the right extrusion unit comprises an extrusion air cylinder and an extrusion plate, wherein the extrusion plate is driven by theextrusion air cylinder; holes I allowing the extrusion plates to pass through are formed in the left enclosing plate and the right enclosing plate; the puncturing unit is located below the recyclingplatform and comprises a puncturing air cylinder and a flow guide plate, wherein the flow guide plate is driven by the puncturing air cylinder; thorn parts are arranged on the upper surface of the flow guide plate and upwards pass through the sieve holes to puncture a beverage packaging bag; the liquid collecting tank is positioned below the periphery of the flow guide plate; the pushing-out unitis positioned in front of the recycling platform and comprises a push-out air cylinder and a push-out plate, wherein the push-out plate is driven by the push-out air cylinder; holes II allowing the push-out plate to pass through are formed in the front enclosing plate and the rear enclosing plate; and the hole located in the rear enclosing plate is a discharge port. According to the beverage packaging bag recycling and processing system, beverage in the packaging bag and the packaging bag can be recycled and processed, and the structure is simple.

Owner:TIANJIN SHANDAO PACKAGING EQUIP TRADE CO LTD

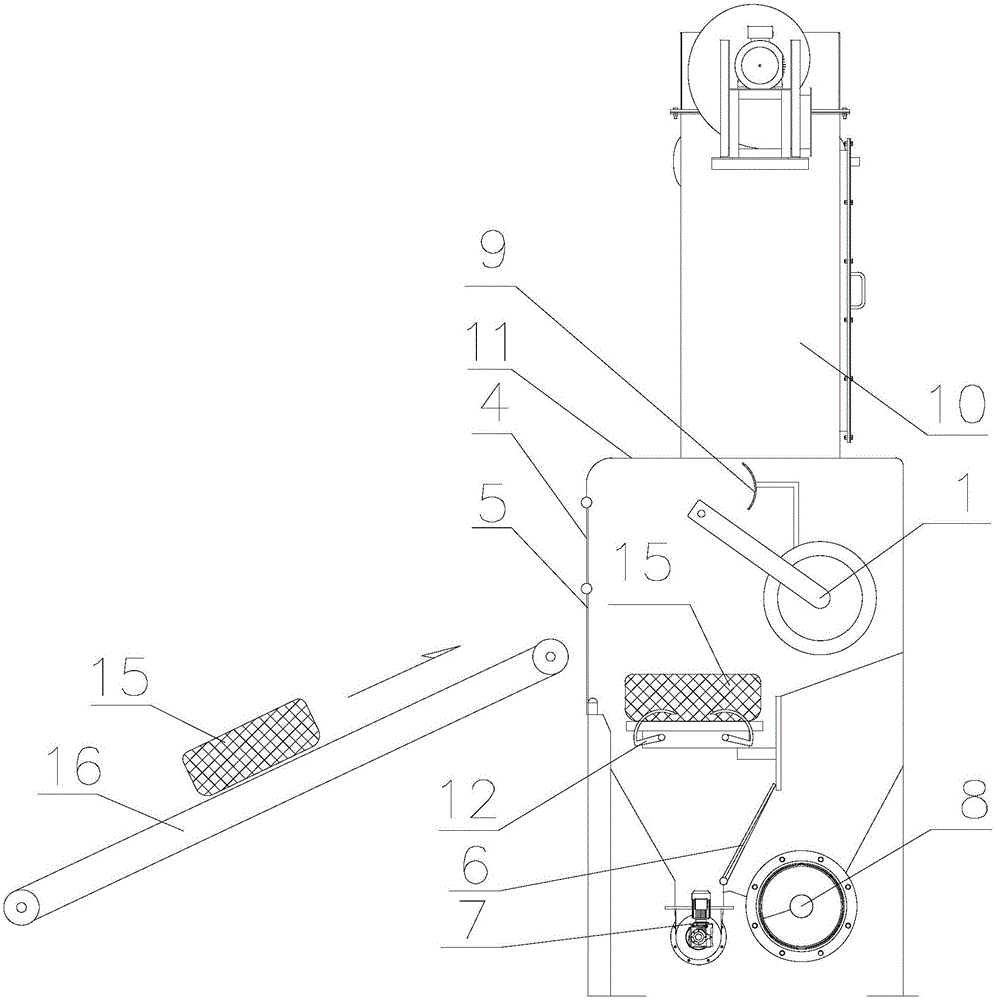

Small-sized intelligent automatic unpacking system

The invention relates to a small-sized intelligent automatic unpacking system. The small-sized intelligent automatic unpacking system comprises a box body and a PLC system, wherein a bag-in opening is formed in the box body; a waste bag opening and a discharge opening are formed in the bottom of the box body; a safety door mechanism is mounted at the bag-in opening; a turnover pouring mechanism is arranged in the position, below the bag-in opening, in the box body; a gripper mechanism is arranged under the turnover pouring mechanism; a bag cutting mechanism is arranged above one side of the turnover pouring mechanism; a falling / waste bag switching mechanism is arranged below the turnover pouring mechanism; a waste bag spiral conveying mechanism is arranged below one side of the falling / waste bag switching mechanism, and a powdery and granular material spiral conveying mechanism is arranged below the other side of the falling / waste bag switching mechanism; the falling / waste bag switching mechanism is used for switching the output end of the turnover pouring mechanism to the input end of the waste bag spiral conveying mechanism or the powdery and granular material spiral conveying mechanism; the waste bag spiral conveying mechanism is connected with the waste bag opening; and the powdery and granular material spiral conveying mechanism is connected with the discharge opening. The small-sized intelligent automatic unpacking system has the advantages that the unpacking process is closed, the size is small, the degree of automation is high, both time and labor are saved, and harm to workers and the environment is reduced to the maximum extent.

Owner:HANRUI PUZER BULK HANDLING TECH SHANGHAI

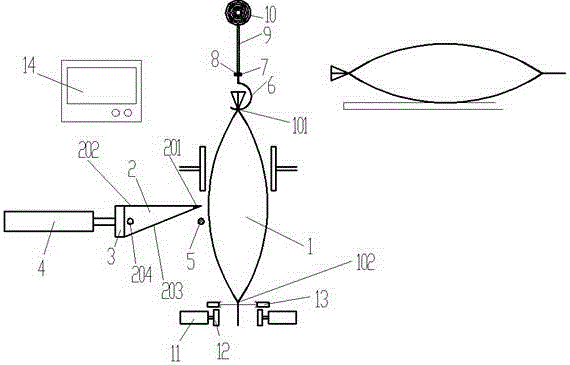

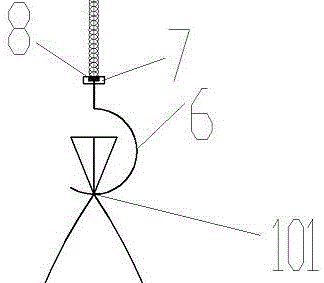

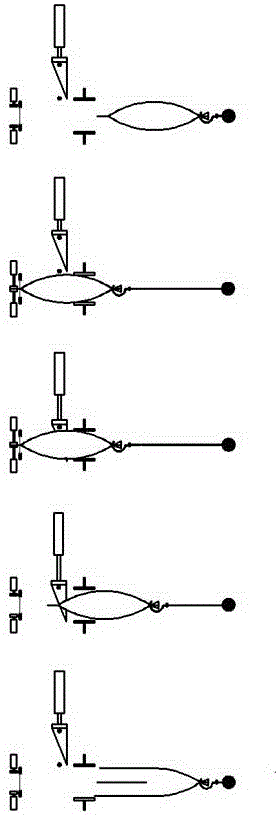

Full-automatic powder bag stabbing and cutting machine and control method thereof

ActiveCN105857792AEasy to cleanImprove work efficiencyPackaging automatic controlBags openingMechanical engineering

The invention relates to the technical field of unpacking and unloading, and particularly discloses a full-automatic powder bag stabbing and cutting machine and a control method thereof. The full-automatic powder bag stabbing and cutting machine comprises a hoisting part, a cutting tool part, a clamping plate part and a controller, and is characterized in that the hoisting part comprises a hoisting hook used for hoisting a bag opening, the hoisting hook is connected to a lifting plate, and the lifting plate is provided with a vibrator and is connected with a reel through a hoisting chain; the cutting tool part comprises a cutting tool directly facing the side face of a bag body, the cutting tool is provided with an induction point and is installed on a fixing plate, a first sensor is installed beside a stabbing-in path of the cutting tool, and the fixing plate is connected with a first driving device; and the clamping plate part comprises clamping plates and second sensors, the clamping plates are symmetrically located on the two sides of a bag tail, the second sensors are symmetrically located on the two sides of the bag tail, and the clamping plates are connected with second driving devices correspondingly. Compared with the prior art, the structure is novel and simple, and design is reasonable; and due to the fact that the cutting tool capable of stabbing in and cutting the bag is designed, only the cutting function is achieved on the powder packing bag, and no fragment is produced.

Owner:SHANDONG INST FOR PROD QUALITY INSPECTION

Bag Opening System

ActiveUS20180361047A1Securely holdEasy to useFlexible bulk container emptying systemsDialysis systemsLinear motionEngineering

A system and apparatus for opening and emptying a bag of material includes a base having a pair of opposed sides and a central aperture through which material may flow. The system includes a pair of opposed doors rotatably mounted on a pair of door shafts, the edges of the pair of opposed doors forming an opening and a plurality of piercing blades pivotally mounted to the base on a pivot rod, the blades capable of pivoting to pierce said bag. The system further includes a cutting blade mounted transversely below the opening of the opposed doors, the cutting blade capable of linear motion across the opening.

Owner:ISOPURE CORP

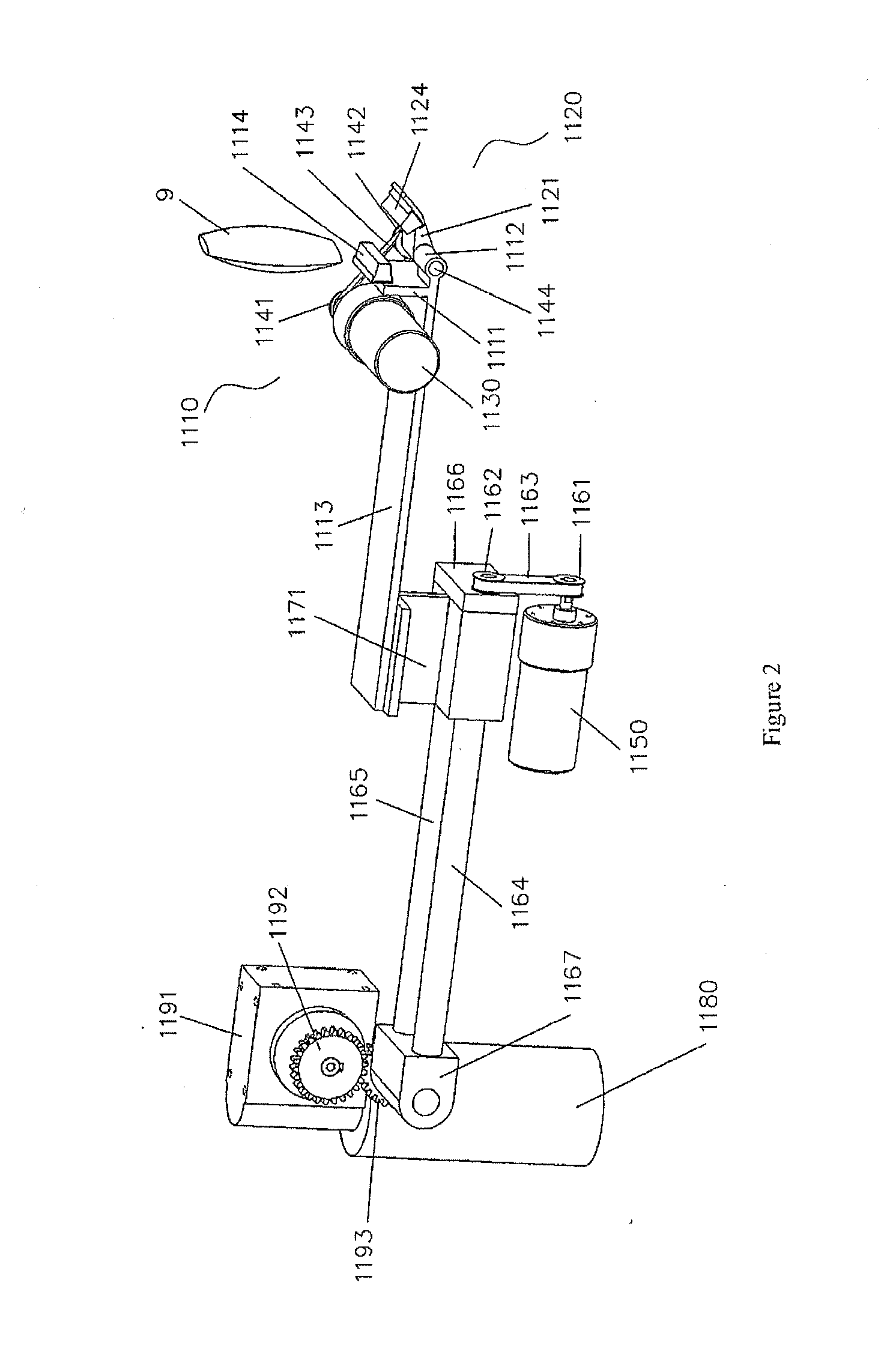

Cooking material dispensing method and dispensing system

ActiveUS20150128536A1Convenient and swift and simplified cooking processMove preciselyOpening closed containersBottle/container closureEngineeringCooking process

Disclosed are a cooking material dispensing system and dispensing method. The dispensing method comprises the following steps: setting a material bag (9) clamping station in a position near a cooking pot opening but outside the range of the pot opening, and clamping the material bag (9) containing a cooking material at the material bag (9) clamping station; confining the material bag (9), such that the material bag (9) is kept in a clamped state to control the deformation thereof during the dispensing procedure; flipping and / or tipping the material bag (9), and when in a position near the cooking pot opening, dispensing the cooking material in the material bag (9) into the cooking pot; and once the cooking material has been dispensed, shifting the material bag (9) from the range of the cooking pot opening and releasing the clamping of the material bag (9). The cooking material dispensing system comprises a dispensing device capable of clamping, confining, and transferring the material bag (9) and flipping the opened material bag and / or tipping the cooking material into the cooking pot. The dispensing system and dispensing method take a material packaged in the material bag (9) and can accurately move the material bag (9) into the dispensing position, making the cooking process convenient, fast and simple, and the entire process will not be contaminated.

Owner:LIU XINYU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com