Patents

Literature

206results about How to "Prevent accumulation and clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

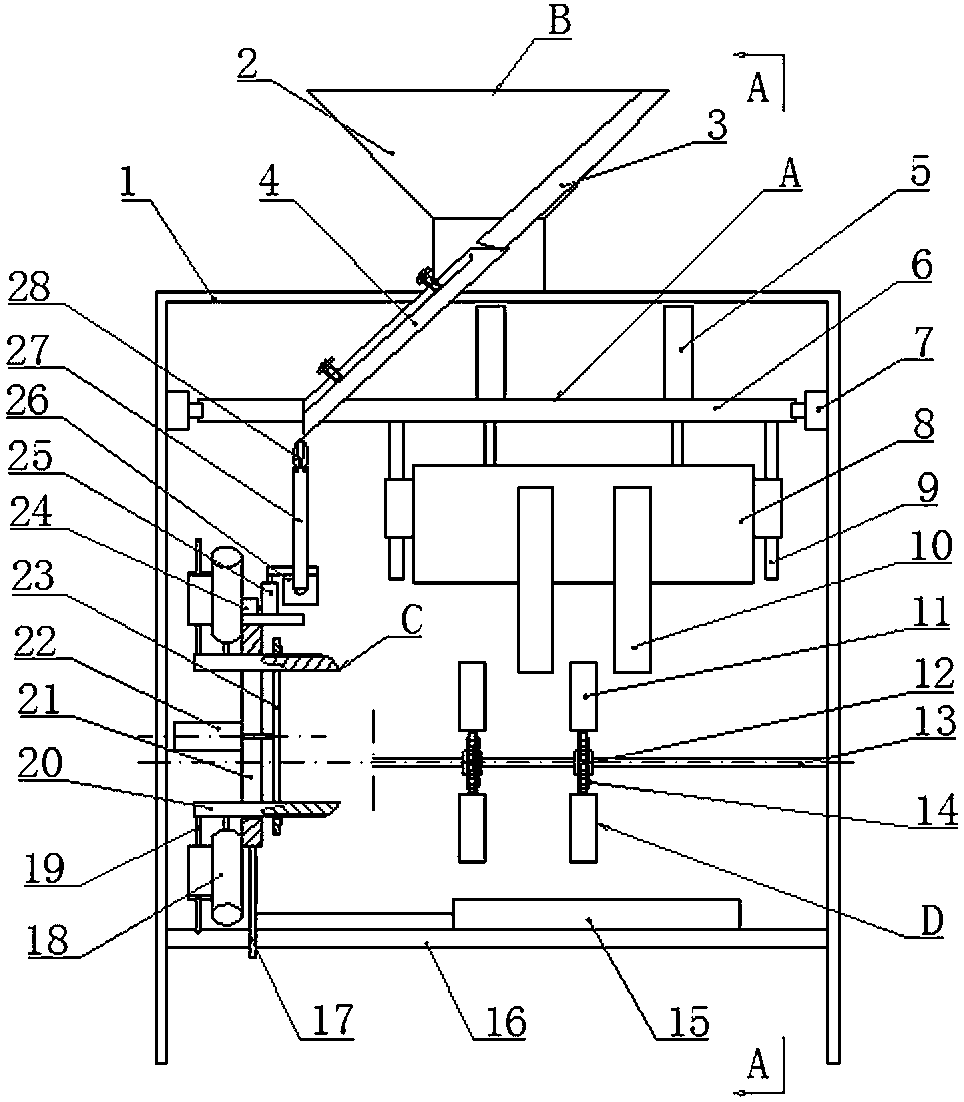

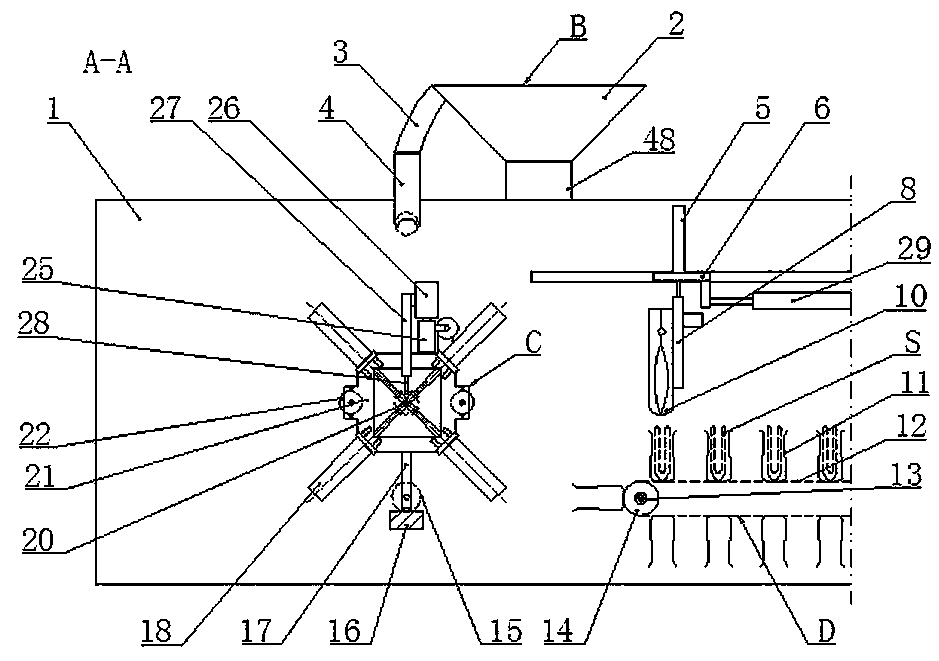

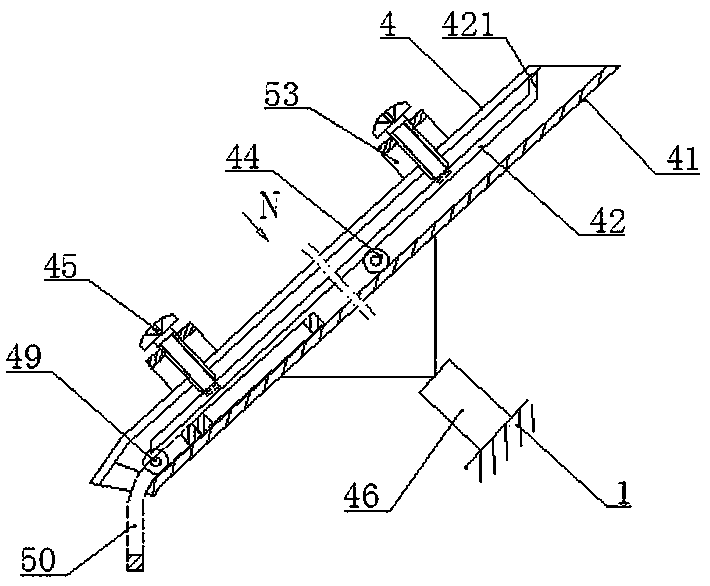

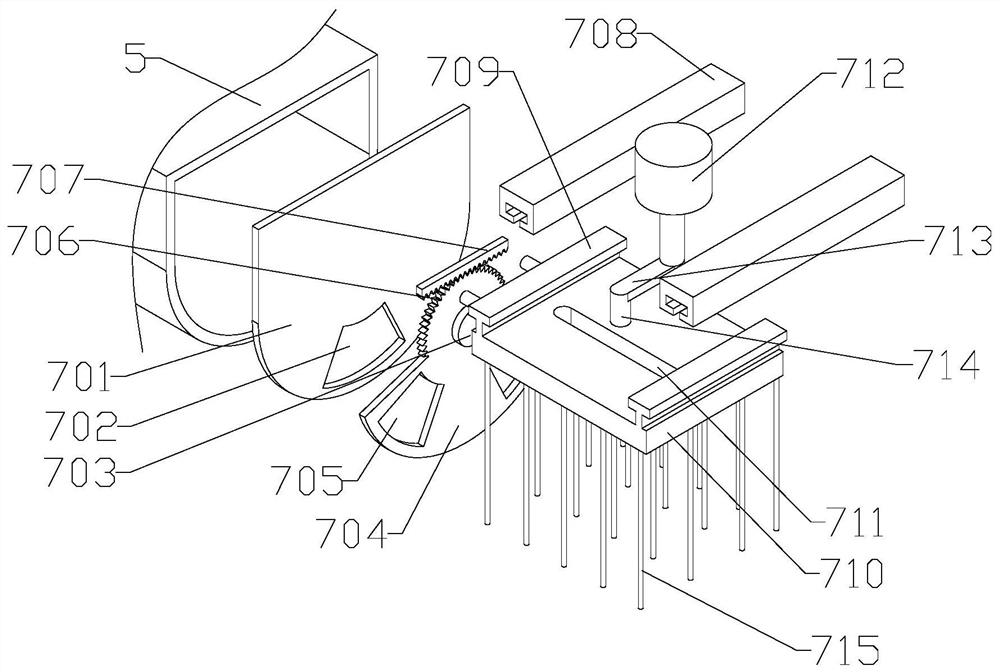

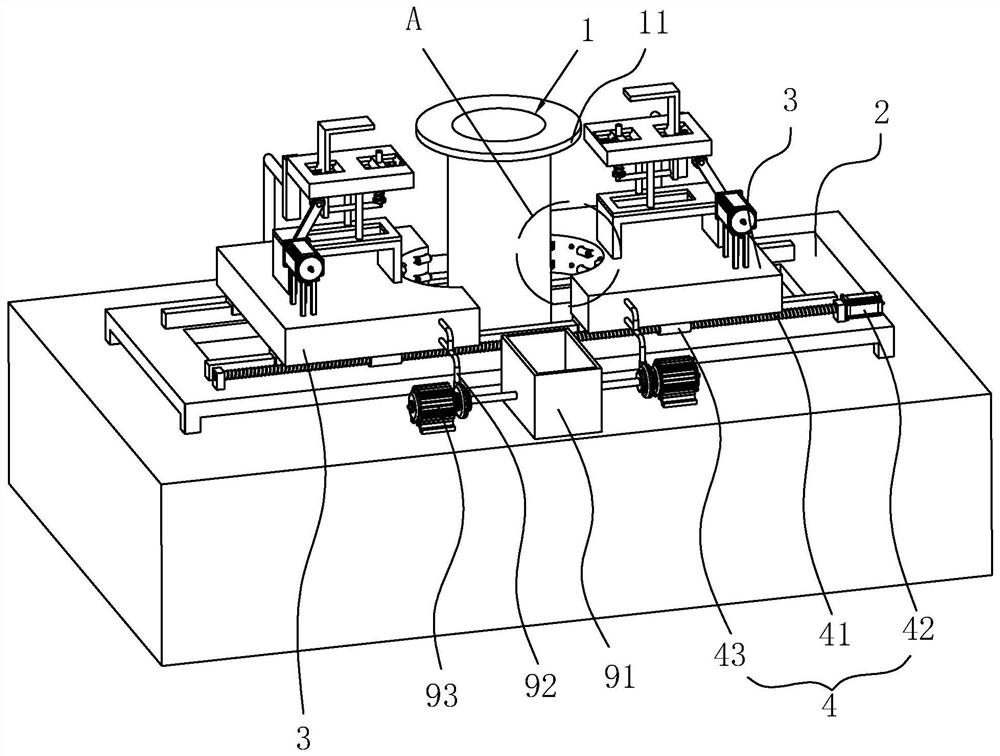

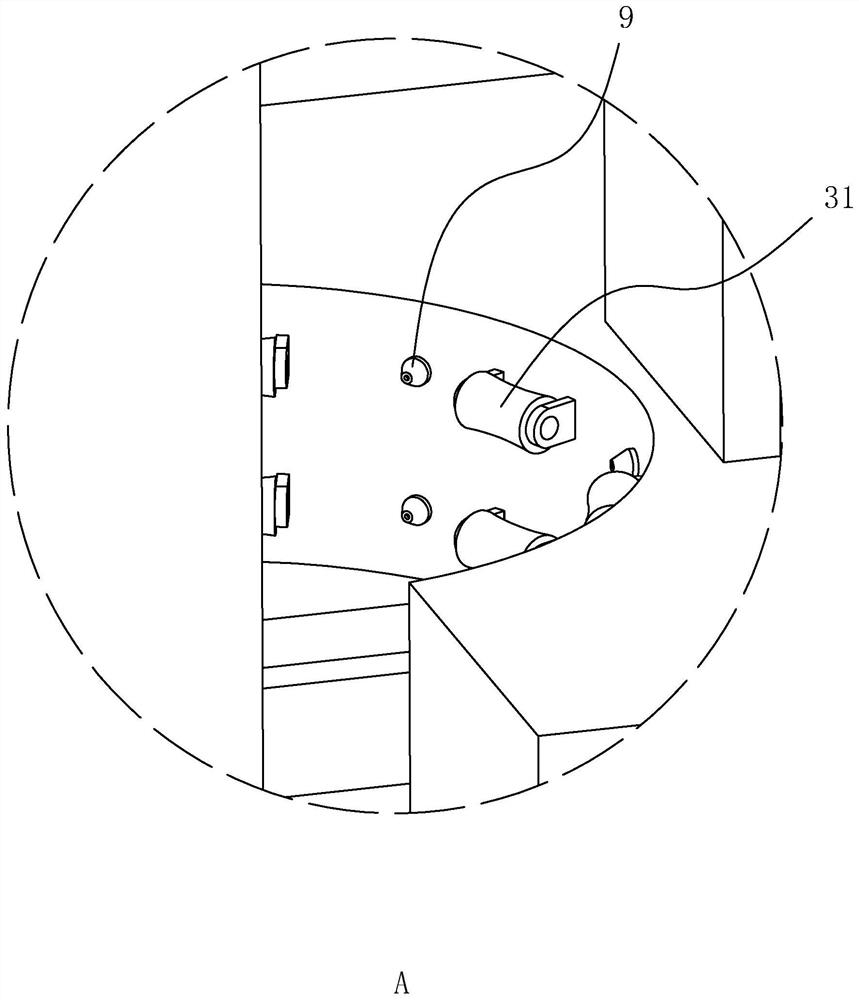

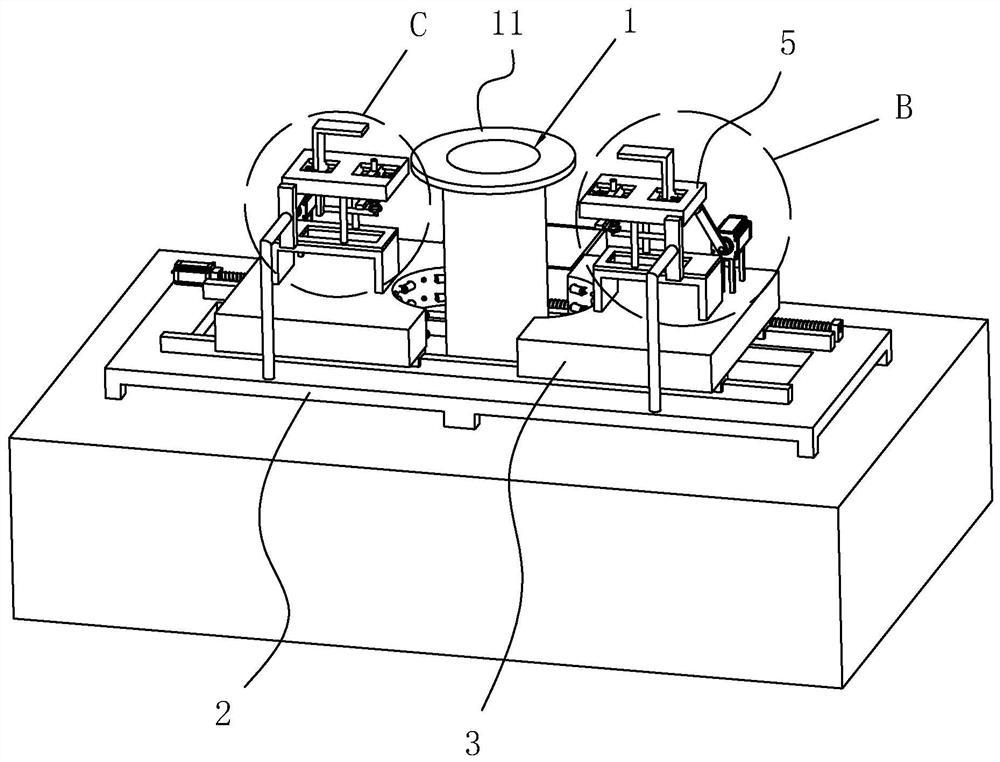

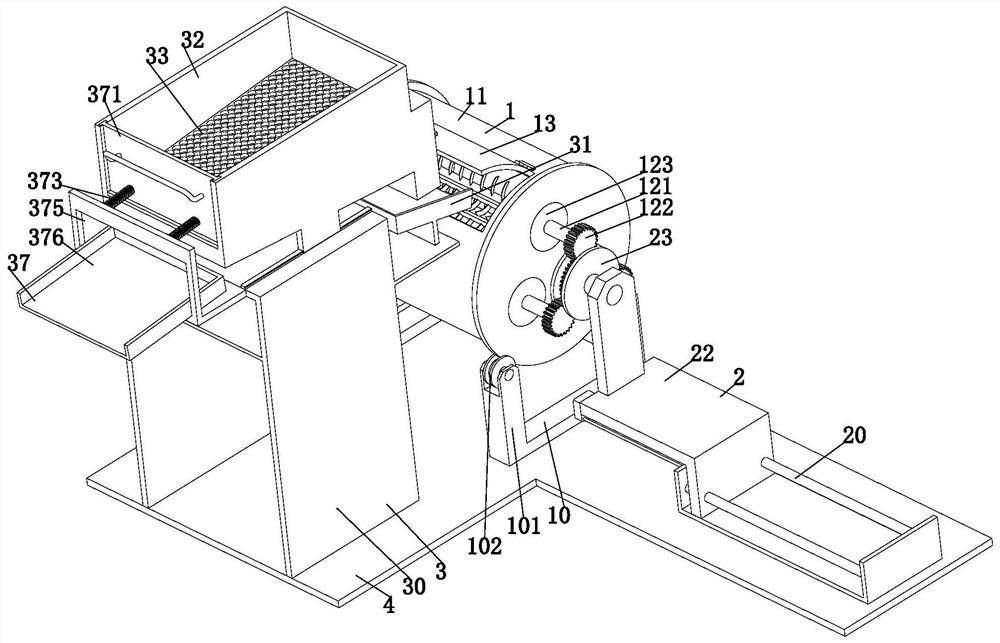

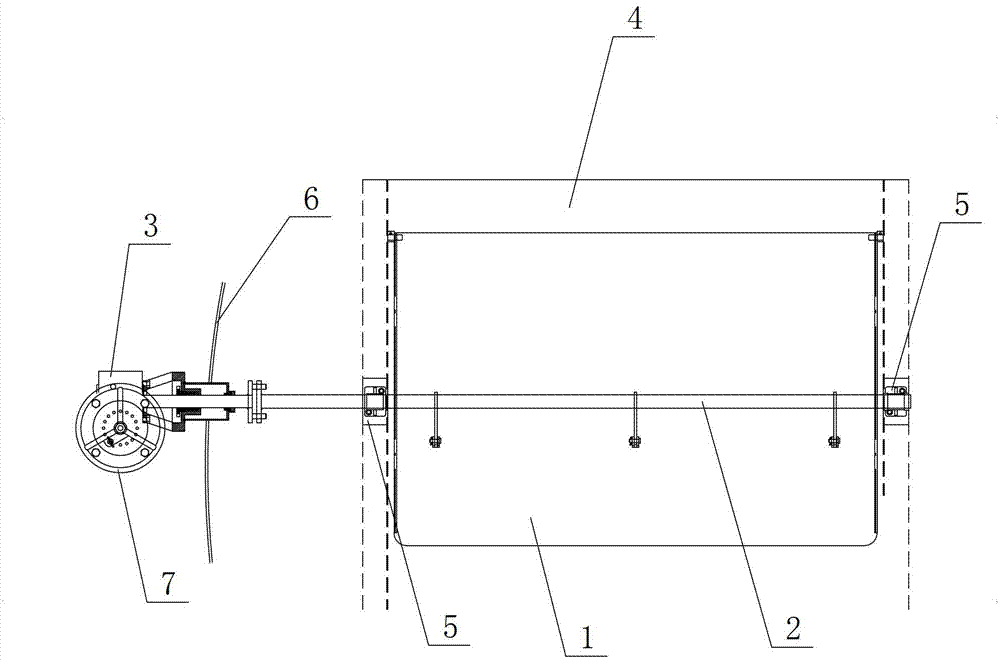

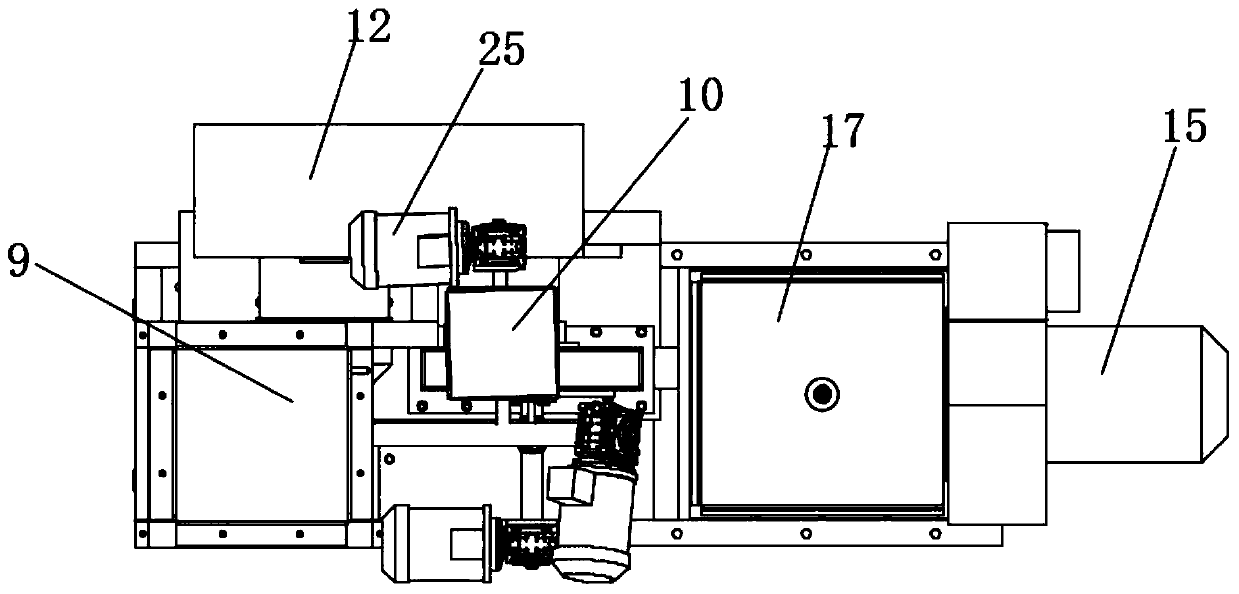

Automatic bundling device of plastic bag making machine

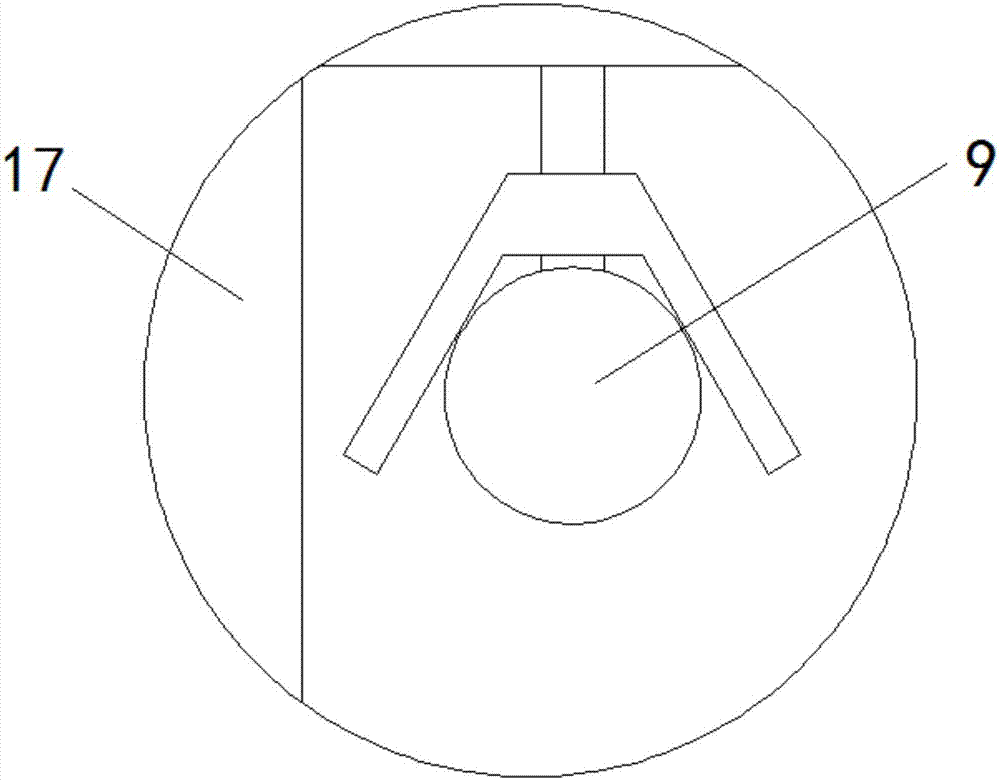

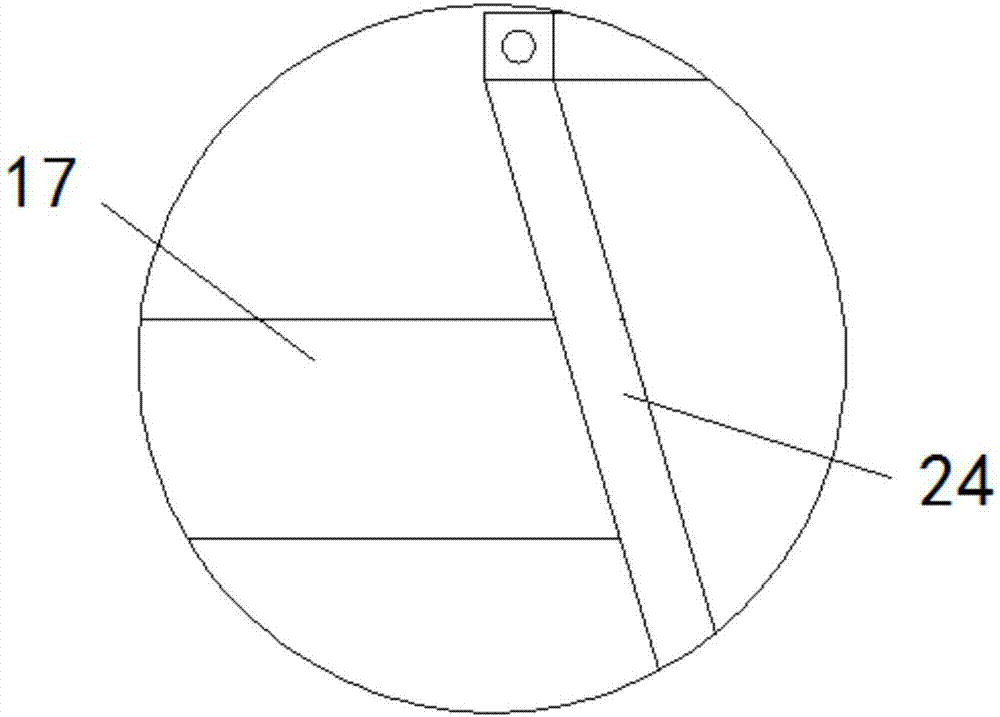

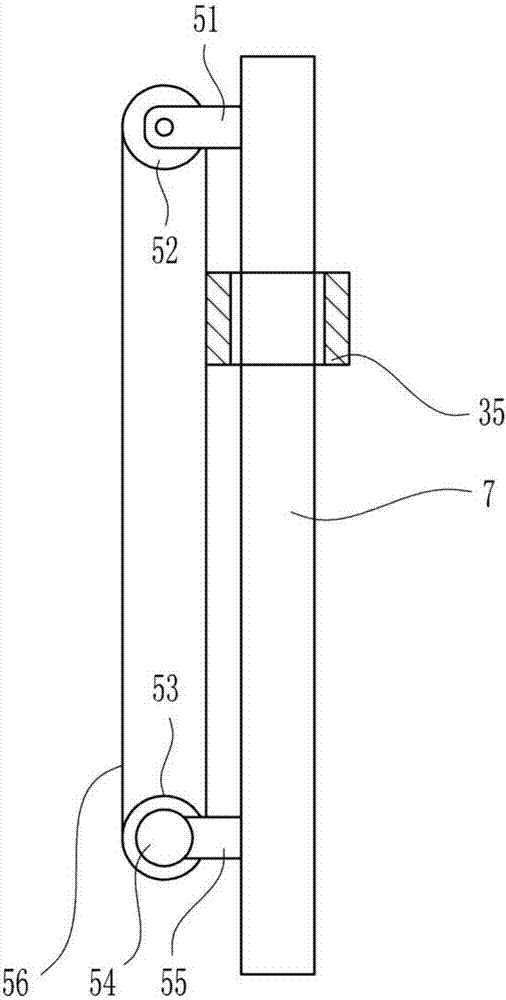

PendingCN108773518ARealize automatic strappingPrevent accumulation and cloggingPaper article packagingBinding material applicationEngineeringTransfer mechanism

The invention provides an automatic bundling device of a plastic bag making machine. The automatic bundling device comprises a plastic bag feeding mechanism, a rubber band arranging and output mechanism and a bundling mechanism. The bundling mechanism comprises an opening device and a rubber band transfer mechanism. The rubber band transfer mechanism is used for transferring rubber bands output bythe rubber band arranging and output mechanism to the opening device. The opening device is used for opening each rubber band and sleeving the rubber band onto a stack of plastic bags. The automaticbundling device has the advantages that the automatic bundling device can implement automatic bundling of soft thin film products and improves the working efficiency; through arranging of a lower rubber band output channel of the rubber band arranging and output mechanism, the rubber bands can be prevented from getting accumulated and blocked and can be conveyed smoothly; through the combination effect of band release convex heads of band release plates arranged on the outer side of a band release plate of the opening device and brace rod grooves formed in the circumferential surfaces of rubber band brace rods, the situation that rubber bands cannot be kept away from the rubber band brace rods can be effectively prevented, and the working reliability of band release is improved.

Owner:王根乐

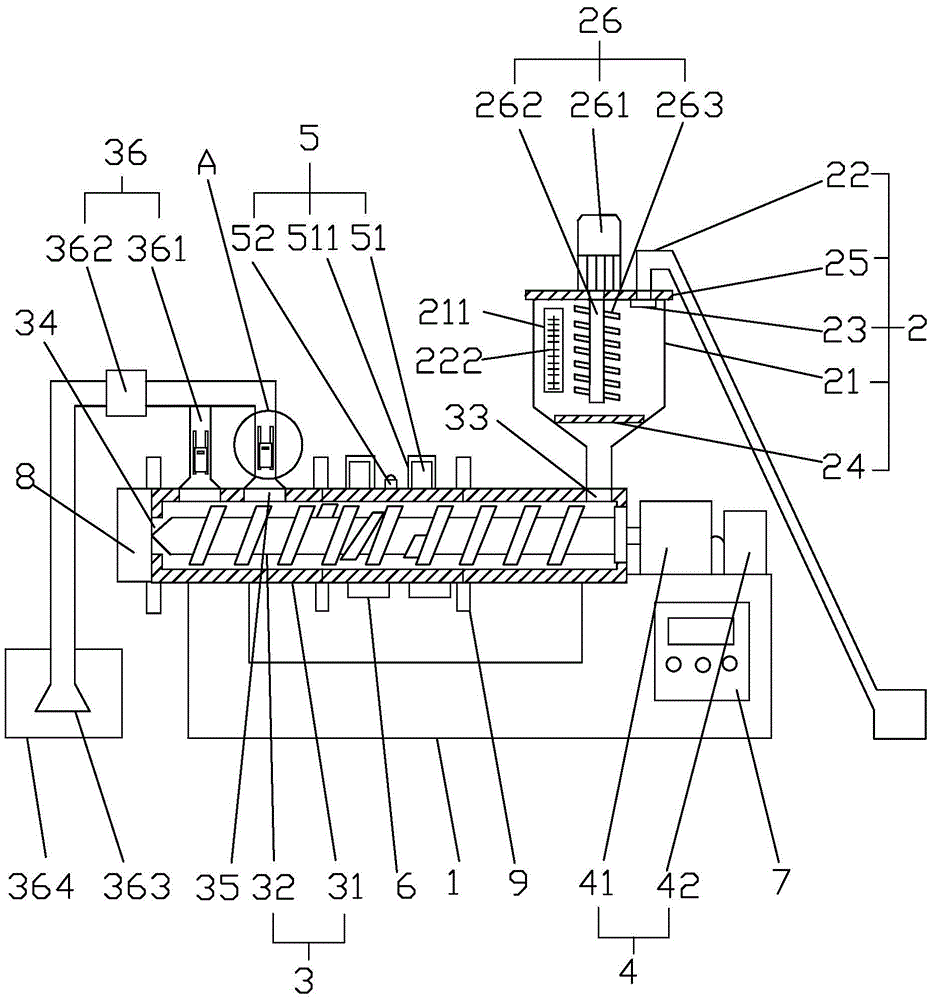

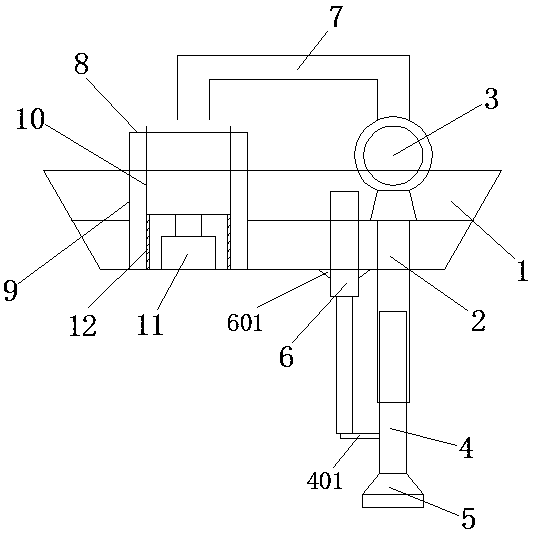

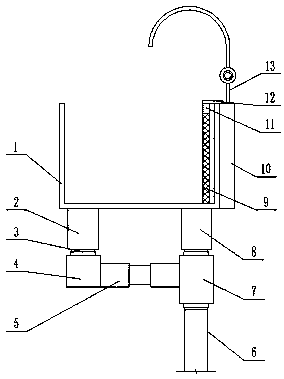

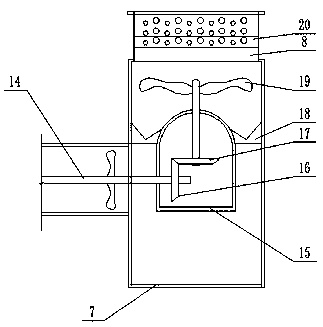

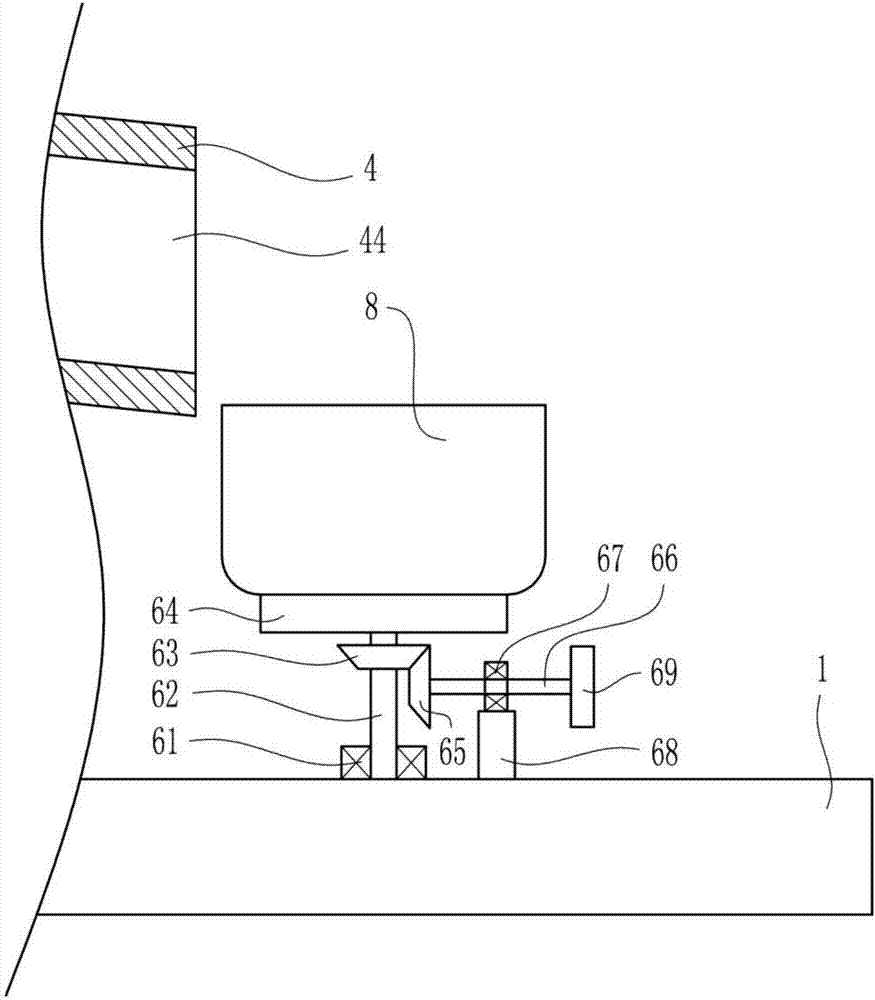

Extruding machine

InactiveCN105619742APrevent fallingPrevent accumulation and cloggingSievingScreeningEngineeringElectric control

The invention mainly discloses an extruding machine. According to the technical scheme, the extruding machine comprises a machine base, a feeding system, an extruding system, a transmission system, a heating system, a cooling system, an electric control system and a machine head. The feeding system comprises a hopper and a material conveying screw. A filtering net is arranged at the connecting position of the material conveying screw and the hopper. An opening and closing door is arranged at the bottom of the hopper. The extruding system comprises a machine cylinder and a separated type screw arranged in the machine cylinder. A feeding port, a discharging port and a smoke outlet are formed in the machine cylinder. An exhaust system is arranged at the position of the smoke outlet. The heating system and the cooling system are connected to the outer side of the machine cylinder. The material conveying screw can convey materials to the hopper automatically so that labor force can be saved; impurities can be filtered out through the filtering net; the opening and closing door is arranged at the bottom of the hopper so that feeding can be stopped and the feeding amount can be adjusted; a stirrer is arranged in the hopper for stirring the materials, and accumulating and blocking at the position of the feeding port of the machine cylinder are avoided; and the exhaust system can remove pollutants such as sulfur dioxide smoke and lampblack through purification, and therefore environment pollution in the production process is effectively avoided.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

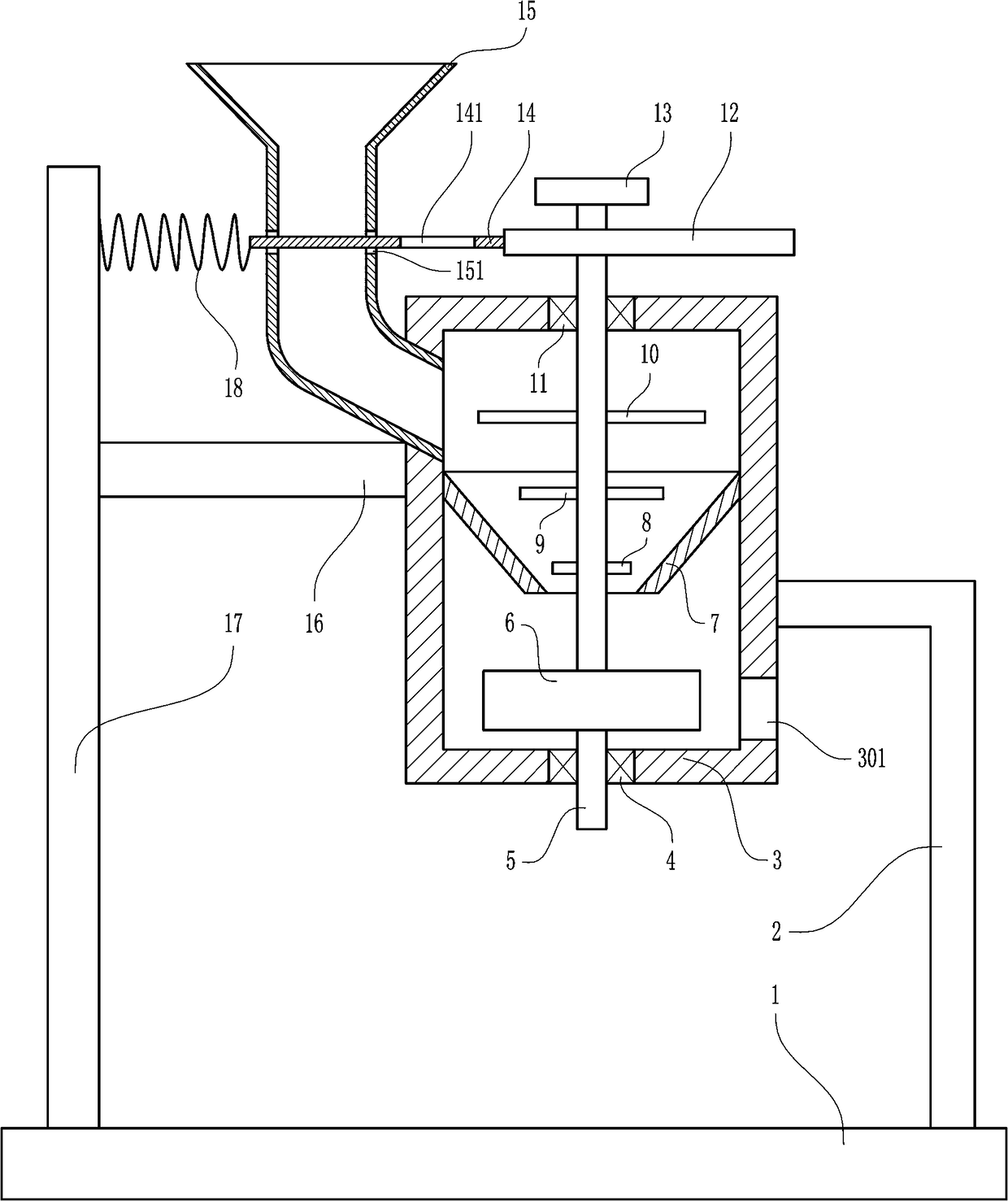

Water conservancy river channel silt removal device with silt and water separation function

InactiveCN107893440AEasy to collect and clean upPrevent accumulation and cloggingMechanical machines/dredgersSewageEngineering

Disclosed is a water conservancy river channel silt removal device with a silt and water separation function. The water conservancy river channel silt removal device with the silt and water separationfunction comprises a silt removal ship, a silt removal pipeline and a silt removal pump, wherein the silt removal pipeline is arranged at the bottom of the silt removal ship, and the silt removal pump communicates with the silt removal pipeline. An extension pipe is arranged at the bottom end of the silt removal pipeline in a sliding and sleeving mode, a silt removal suction disc is arranged at the bottom end of the extension pipe, and a fixing plate is arranged on the side wall of the portion, close to the bottom end, of the extension pipe. A telescopic cylinder is perpendicularly arranged on the side, adjacent to the silt removal pipeline, of the silt removal ship, and the telescopic rod end of the telescopic cylinder is connected with the fixing plate to drive the extension pipe to perpendicularly stretch out of and draw back to the silt removal pipeline. A sewage discharging pipe is arranged in the outlet formed in the top of the silt removal pump, and a filtering drum which is used for conducting silt and water separation is arranged on the silt removal ship and located on the lower side of the outlet of the sewage discharging pipe. The water conservancy river channel silt removal device with the silt and water separation function is adjustable in length of the silt removal pipeline, is suitable for silt removal operation of river channels with different water depths, cantimely conduct separation of pumped silt and water, and enables silt to be conveniently discharged.

Owner:HENAN ZHIAO ELECTROMECHANICAL EQUIP INSTALLATION ENG CO LTD

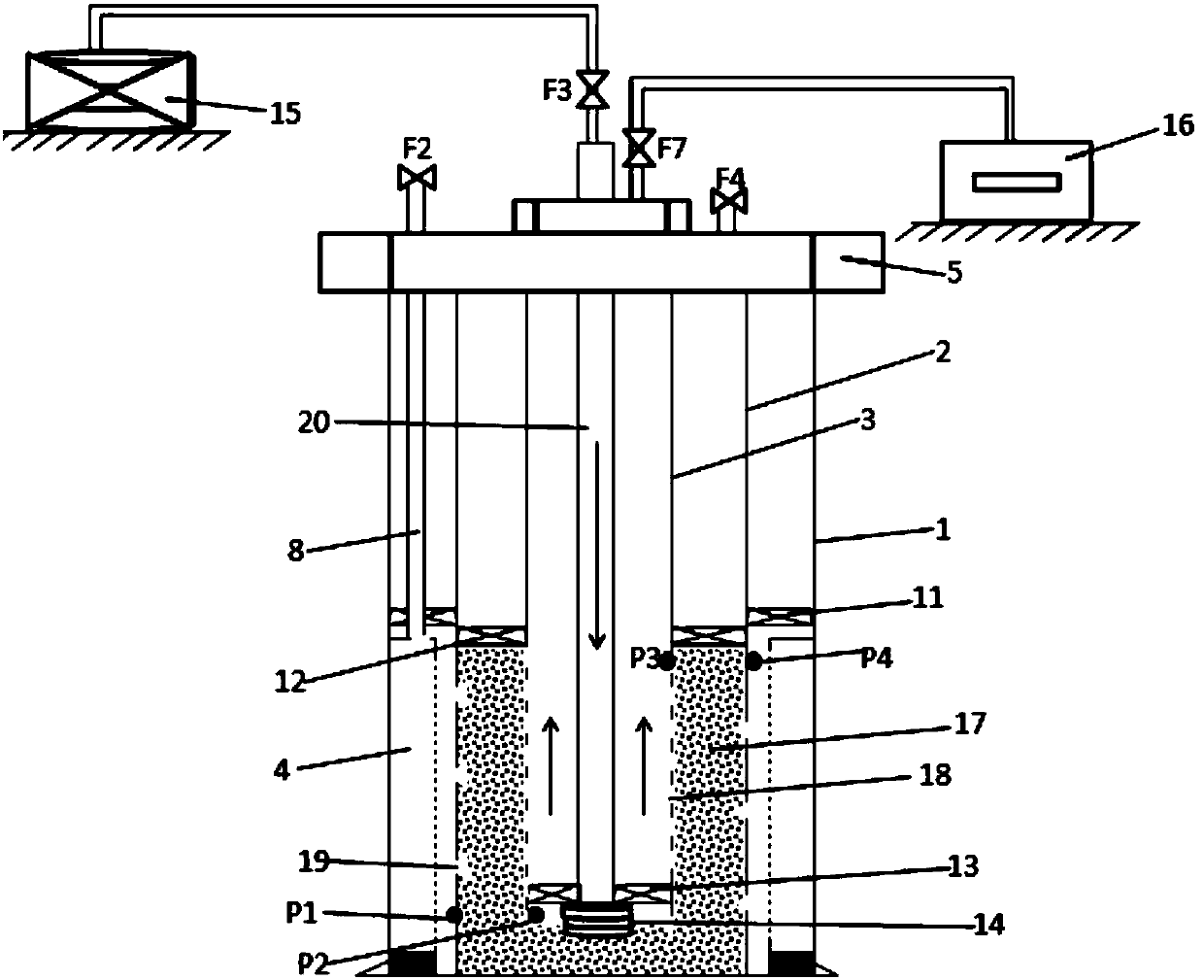

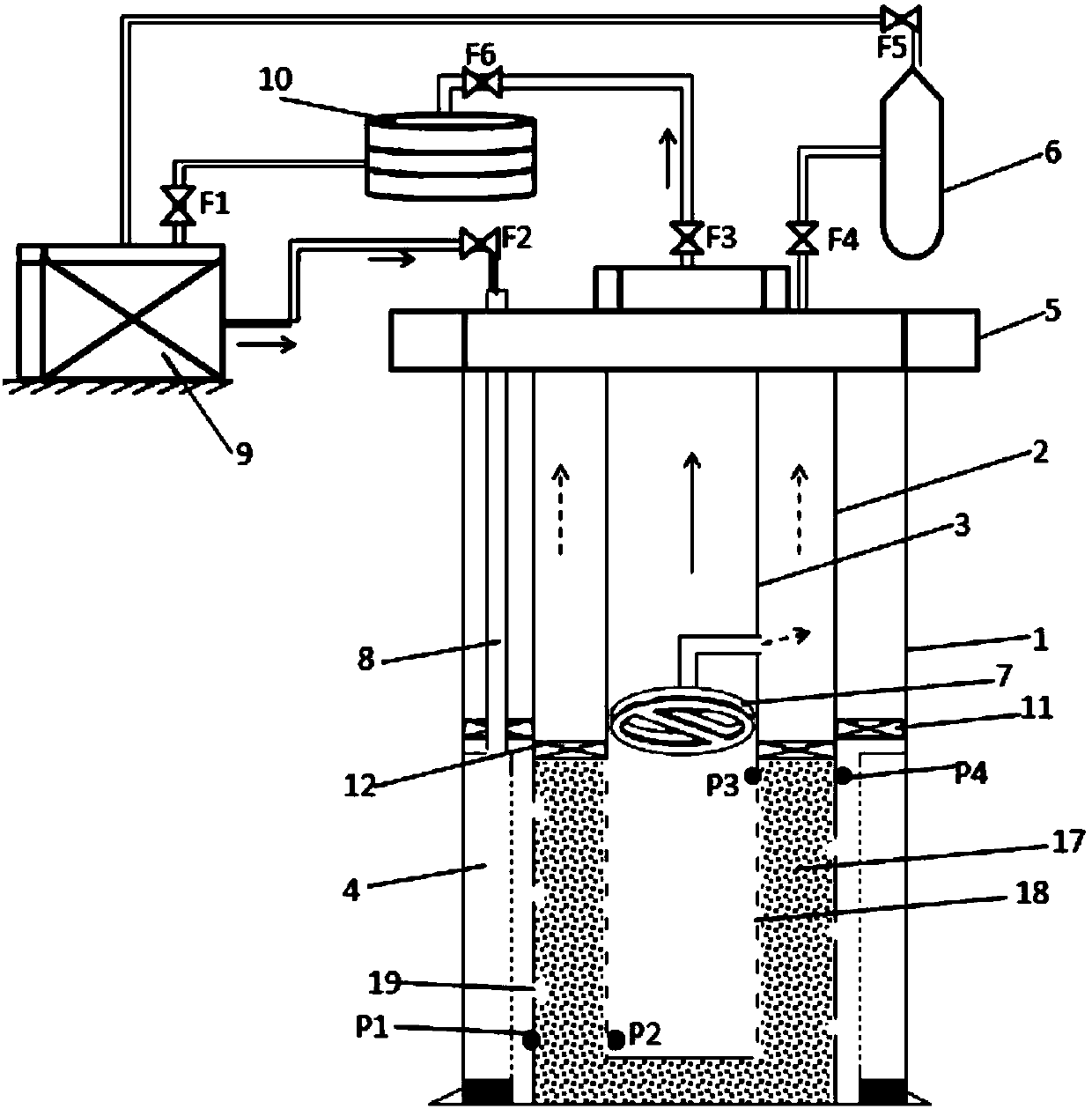

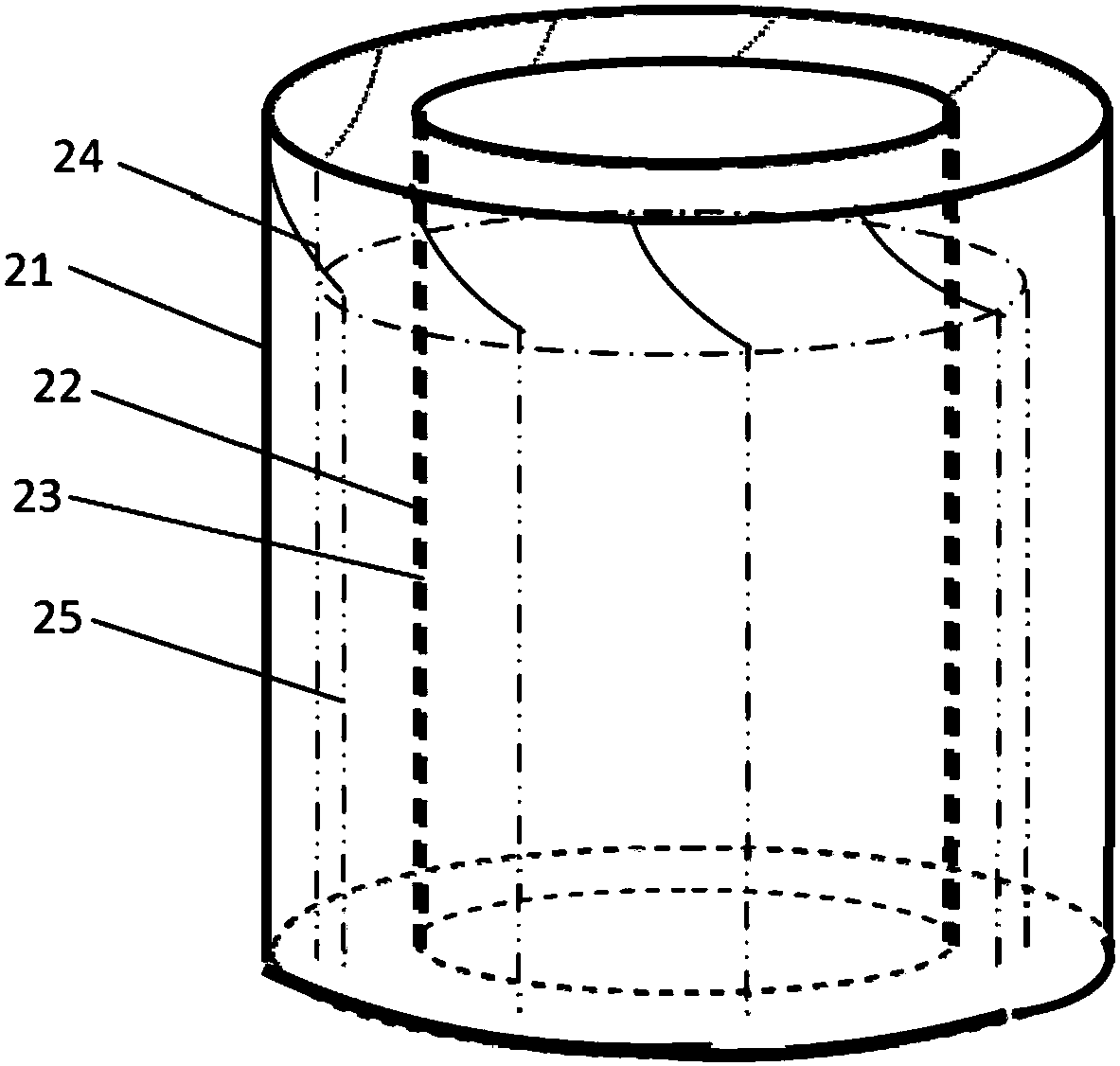

Gravel filling and simulation system and method in hydrate mining well pipe

ActiveCN107795303AOptimize construction parametersOptimizing Gravel SizeSurveyFluid removalWell loggingClassical mechanics

The invention discloses a gravel filling and simulation system and method in a hydrate mining well pipe. The simulation system includes a test well subsystem, a simulation and filling subsystem and afilling quality detecting subsystem. A wellhole pipe column is installed according to an actual well structure, and filling operation simulation and filling quality detecting are conducted; not only can be full-scale simulation conducted on characteristics of an actual gas hydrate mining well reservoir and in-pipe gravel filling operation under limitation of the well structure, but also whole-process monitoring and evaluating can be conducted on the construction quality of the filling operation and adaptation of the filling operation under a long-term hydrate formation condition, so that the aim of optimizing construction parameters and process design parameters is achieved. By combining the introduction of a radial-flow flow divider, a point piezometer and an acoustic imaging logging system, the measurement effect is true and credible, the simulation result is closer to the difference construction, the reference is high, and the gravel filling and simulation system and method is suitable for gravel filling processes in different well structures and effect monitoring simulation of gravel filling. The gravel filling and simulation system and method not only provides new ideas for adaptability evaluation of the gravel filling operation of a marine shallow gas hydrate mining well, but also provides gist for a best construction scheme and best technological parameters of the gravelfilling operation.

Owner:QINGDAO INST OF MARINE GEOLOGY

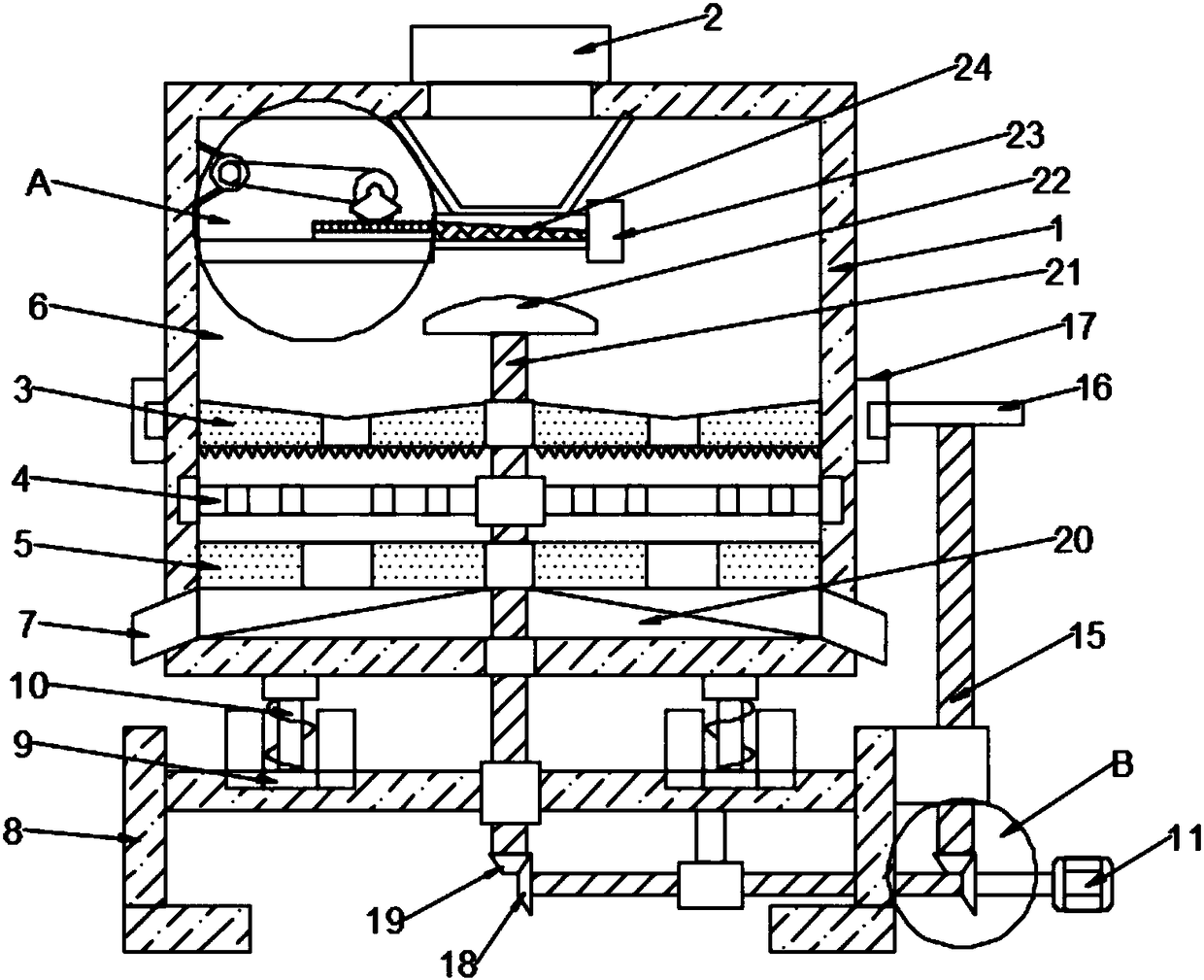

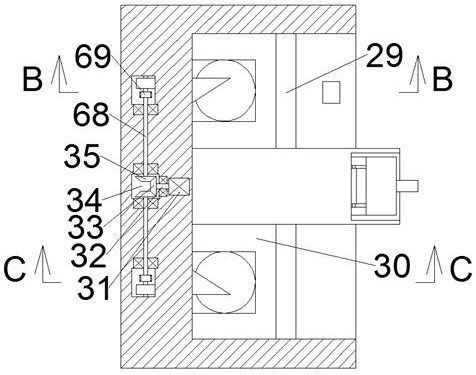

Health food material grinding device achieving complete grinding

The invention discloses a health food material grinding device achieving complete grinding. The health food material grinding device achieving complete grinding comprises a shell, a feeding hopper, agrinding cavity, discharging openings and a supporting base. The grinding cavity is arranged in the shell. The feeding hopper is arranged in the middle of the upper surface of the shell. The feeding hopper communicates with the grinding cavity. The discharging cavities are symmetrically formed in the bottom of the side wall of the shell. The grinding cavity communicates with the discharging openings. The supporting base is arranged at the bottom of the shell. The supporting base is rotationally connected with the shell. The health food material grinding device is characterized in that a servomotor is installed on the right side of the supporting base, a first rotating shaft is welded to the left side of an output shaft of the servo motor, a first bevel gear is fixedly installed on the left side of the first rotating shaft, and a second rotating shaft is vertically arranged above the first bevel gear. The health food material grinding device achieving complete grinding has the advantages of quantitative feeding, rapid grinding and time and effort saving. Meanwhile, raw material blockage of raw materials in the grinding process can be avoided, operation is easy, and the health foodmaterial grinding device achieving complete grinding is suitable for application and popularization.

Owner:山西华欣久泰科技有限公司

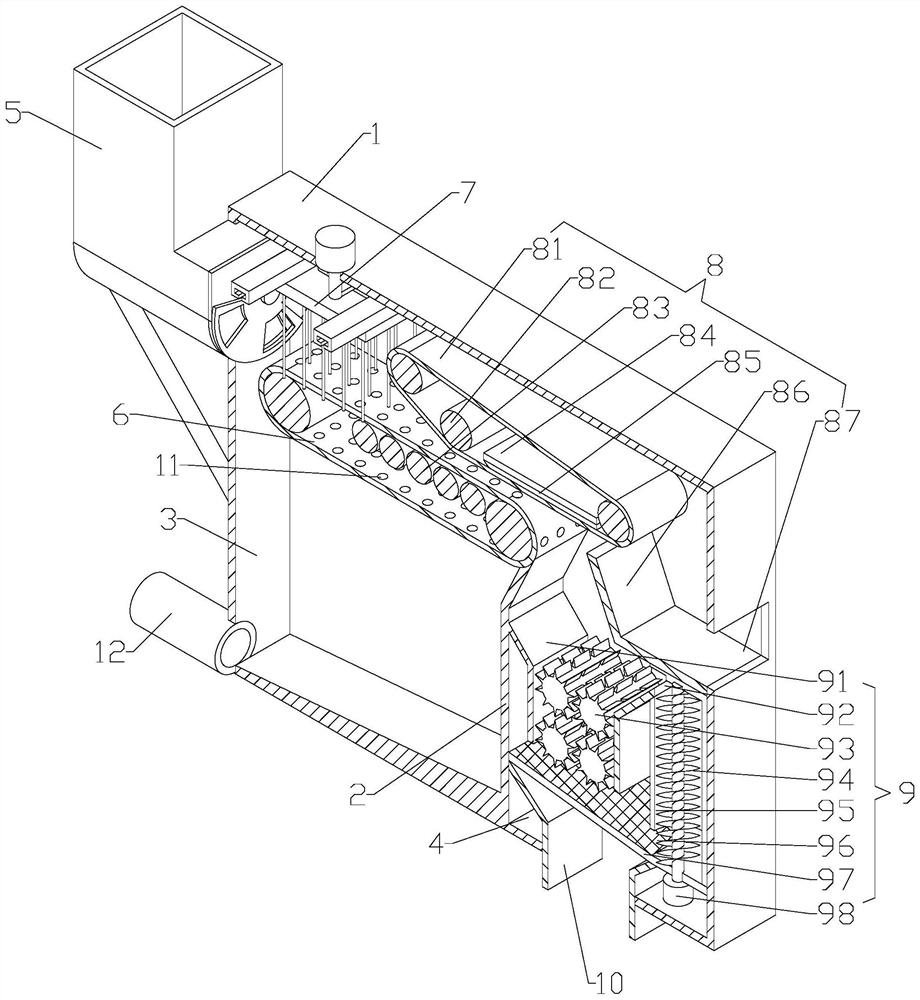

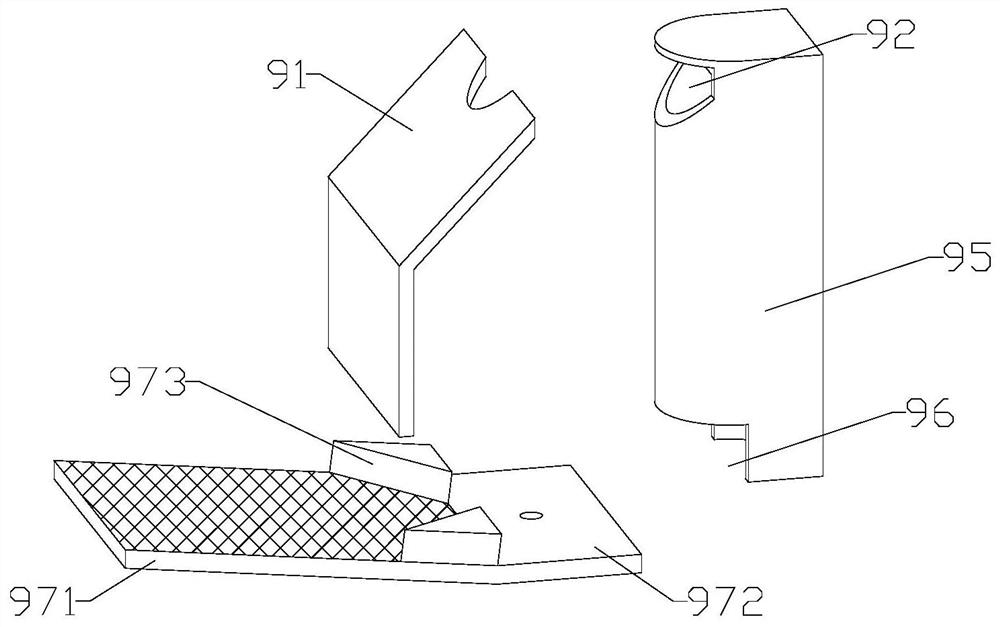

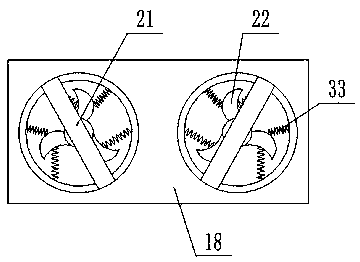

Industrial garbage solid-liquid crushing and separating device and operation method thereof

PendingCN112275771AConvey evenlyPrevent accumulation and cloggingSolid waste disposalTransportation and packagingWater filterMagnetic separator

The invention discloses an industrial garbage solid-liquid crushing and separating device and an operation method thereof. The industrial garbage solid-liquid crushing and separating device comprisesa treatment box, wherein the treatment box is divided into a water filtering cavity and a crushing cavity; a conveying belt is mounted at the top of the water filtering cavity; water filtering holes are formed in the conveying belt; a feeding hopper is mounted at the top of the side wall of the treatment box; a material spreading mechanism is mounted between the feeding hopper and the treatment box; a filter pressing magnetic separation mechanism is mounted between the conveying belt and the top of the crushing cavity; a crushing mechanism is mounted in the middle of an inner cavity of the crushing cavity; and a material falling opening is formed in the bottom of the crushing cavity. The material spreading mechanism enables garbage to be uniformly spread on the conveying belt, so that water in the garbage can be naturally filtered out through the water filtering holes, and the situation that a large amount of garbage is fed into the crushing mechanism at the same time to cause blockageis avoided; the filter pressing magnetic separation mechanism compacts the spread garbage to press out liquid in the garbage, so that a filter pressing effect is achieved; iron products in the garbage are removed through magnetic separation, so that the damage to the crushing mechanism by the iron products is avoided; the crushing mechanism performs cyclic crushing, so that the crushing is thorough; and solid-liquid separation and crushing are integrally designed, so that the efficiency is improved, and the cost is reduced.

Owner:沈洁

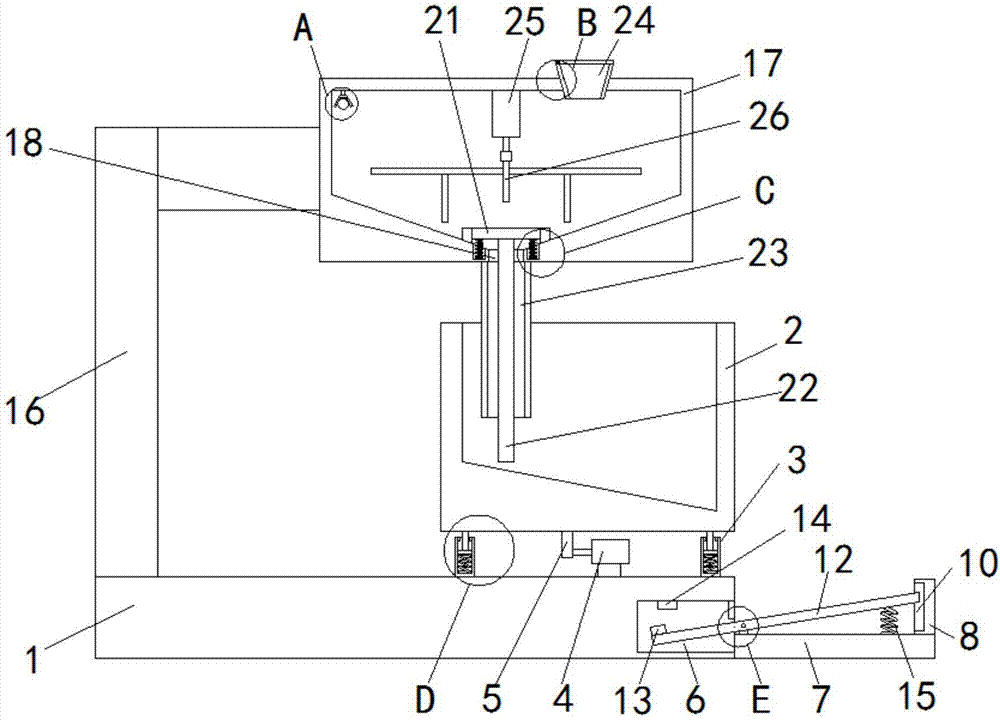

Domestic sewage pipe anti-blocking device

ActiveCN109208736APlay a role in fixing garbageAvoid entanglementSewer cleaningSewer pipelinesImpellerDrive shaft

The invention relates to a piping device, a domestic sewage pipe anti-blocking device include brackets, ring fence, Impeller knives, shafts and motors, a torque limiter is fixedly connected to the center of rotation of the annular fence, a limit bar is arranged on that annular fence, Bracket and fixed connection, shift lever is arranged on that bracket, a tension spring is connected between the bracket and the ring fence. The impeller cutter sleeve is fixedly connected with the transmission shaft, an overrunning clutch is arranged at the end of the transmission shaft along the water flow direction, a driven bevel gear is fixedly connected with the star wheel of the overrunning clutch, a motor is fixedly connected with a pipeline, and a driving bevel gear is fixedly connected with the shaftend of the motor, and the driving bevel gear is meshed with the driven bevel gear. The domestic sewage pipe anti-blocking device with the above structure intercepts the garbage together for centralized treatment, accelerates the flow velocity of the water while cutting the garbage, plays the role of scouring and cleaning the inner wall of the pipe, accelerates the garbage transportation, and prevents the garbage from accumulating again.

Owner:阜阳市世科智能设备有限公司

Automatic feeding forage tank for animal husbandry

InactiveCN107396843ASave manpower and material resourcesSmooth dischargeAnimal feeding devicesAnimal ForagingCam

The invention relates to the technical field of animal husbandry equipment, and discloses a feed trough for automatic feeding for animal husbandry, which includes a base. The telescopic rod is fixedly connected to the base, and a vibrating motor is fixedly connected to the upper surface of the base and corresponding to the main body of the feed trough. The feed trough with automatic feeding for animal husbandry can control the feed in the storage box through the first metal contact plate and the stirring rod, the stirring motor, the second metal contact plate, the rotating shaft, the pressure plate, the support spring, the vibration motor, and the cam. Stirring can also vibrate the feed in the feed trough body, so that the feed in the storage box can be discharged more smoothly, and the feed in the feed trough body can be concentrated on the right side inside the feed trough body, which is more convenient for animals to eat. It will not cause the accumulation of feed to deteriorate, ensuring the feeding of animals and the economic benefits of the farm.

Owner:李瑞蓉

Domestic anti-blocking vegetable washing sink

ActiveCN109138080AReduce resistanceImprove drainage efficiencyDomestic plumbingEngineeringLinkage concept

The invention belongs to the technical field of vegetable washing sinks, particularly relates to a domestic anti-blocking vegetable washing sink, and aims to solve the problem that the funnel and pipeline of a domestic vegetable washing sink are prone to blocking, and the use of the sink is affected. According to the technical scheme, the domestic anti-blocking vegetable washing sink comprises a vegetable washing sink body and pipe connection flange plates and is characterized in that a faucet fixing seat is fixed to the outer wall of one side of the vegetable washing sink body, a faucet is connected to the top outer wall of the faucet fixing seat in an inserted manner, ports are formed in two sides of the bottom outer wall of the vegetable washing sink body, a first funnel storage pipe and a second funnel storage pipe are respectively fixed to the inner walls of the two ports, and a first linkage pipe and a second linkage pipe are respectively fixed to the bottom outer walls of the first funnel storage pipe and the second funnel storage pipe through the pipe connection flange plates. The vegetable washing sink has the advantages that fan blades are driven to rotate through water flow so as to drive an anti-blocking seat to rotate to drive an anti-blocking rack to stir sundries such as vegetable leaves, the funnel is prevented from being blocked by the static sundries, an external power supply is not needed, manual sundry fishing is not needed, and clean and efficient sewage discharge is achieved.

Owner:六安科科达尔生物科技有限公司

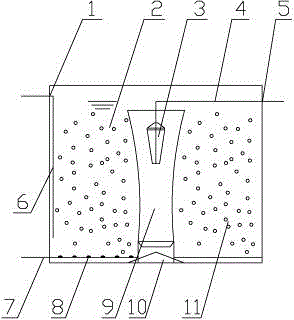

Moving bed bio-membrane reactor

ActiveCN104925939AImproved hydraulic flow propertiesImprove hydraulic conditionsSustainable biological treatmentBiological water/sewage treatmentMoving bed biofilm reactorBiochemical engineering

The invention relates to a moving bed bio-membrane reactor provided with a biochemical reaction pool. A water inlet hole and a water outlet hole are formed in the upper portions of any two side walls of the biochemical reaction pool respectively and connected with a water inlet pipe and a water outlet pipe respectively. Suspended filler is thrown in the biochemical reaction pool, a conical sliding table is arranged in the center at the bottom in the biochemical reaction pool, a flow guiding barrel is arranged over the conical sliding table, a water outlet screen is arranged at the upper portion in the flow guiding barrel, the upper end of the water outlet screen is communicated with the water outlet hole through the water outlet pipe, the bottom of the flow guiding barrel is connected with a water outlet grate support, and an aerator pipe is arranged on the part, located on the periphery of the flow guiding barrel, at the bottom of the biochemical reaction pool. The moving bed bio-membrane reactor is simple and novel in structural design, has very high application and popularization value and is mainly applied to the sewage treatment technology.

Owner:HUBEI QUANSHENG ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

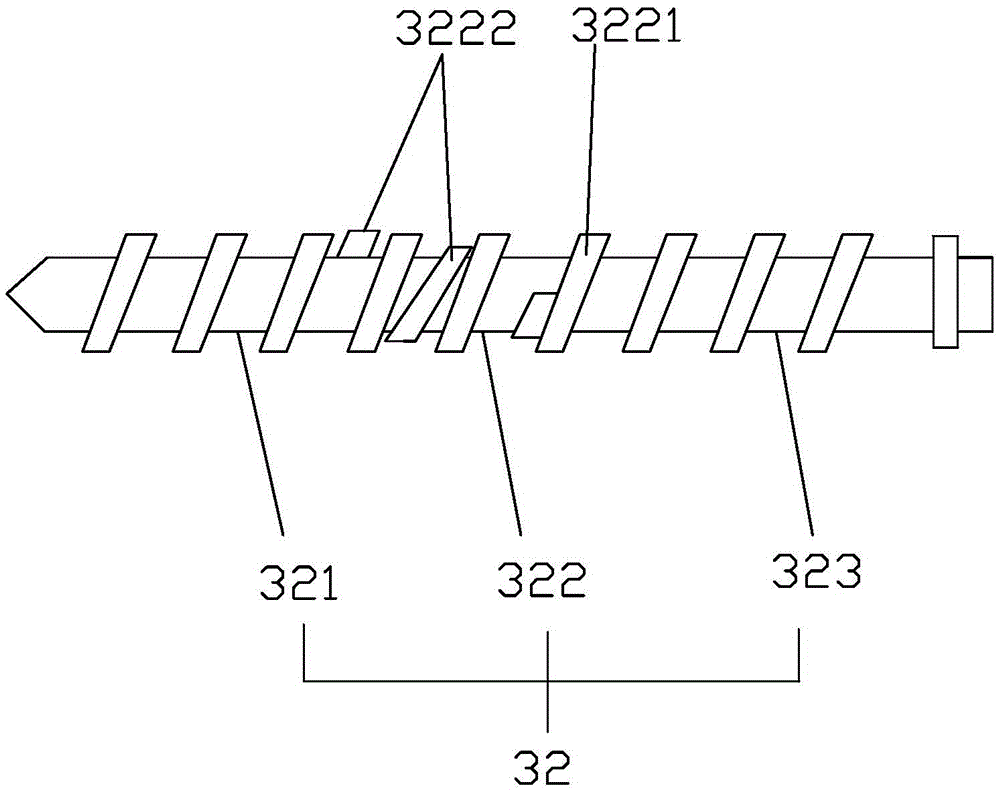

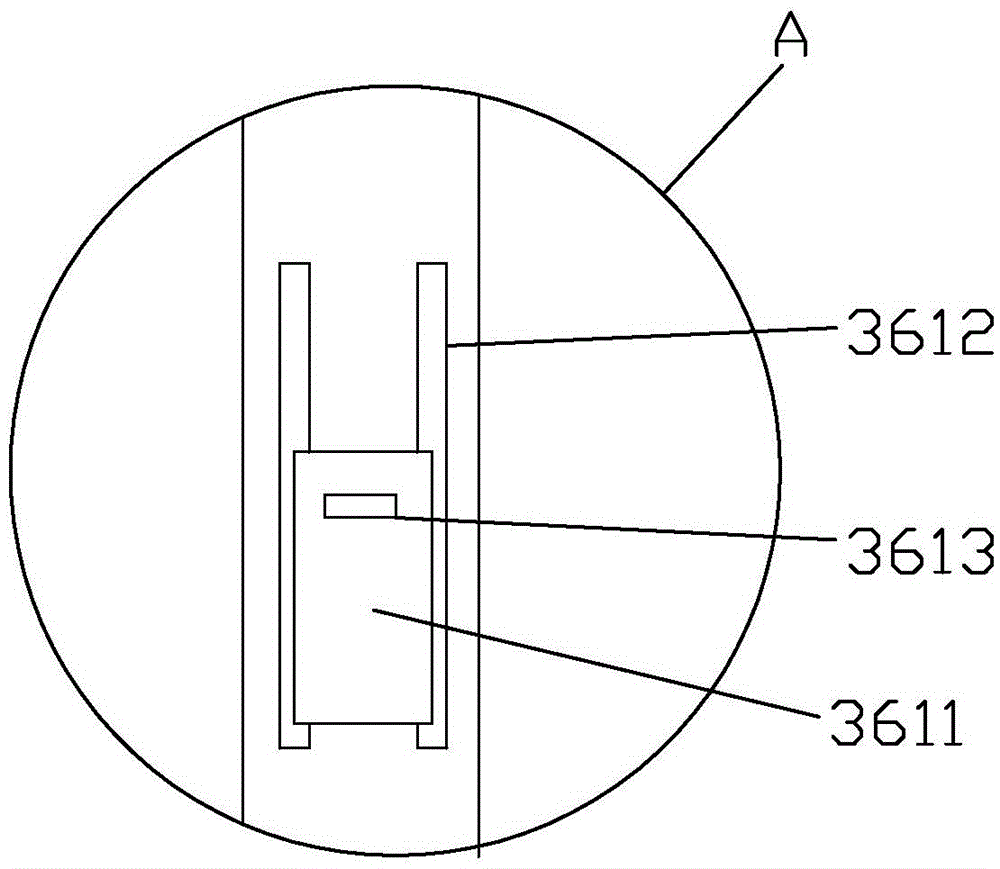

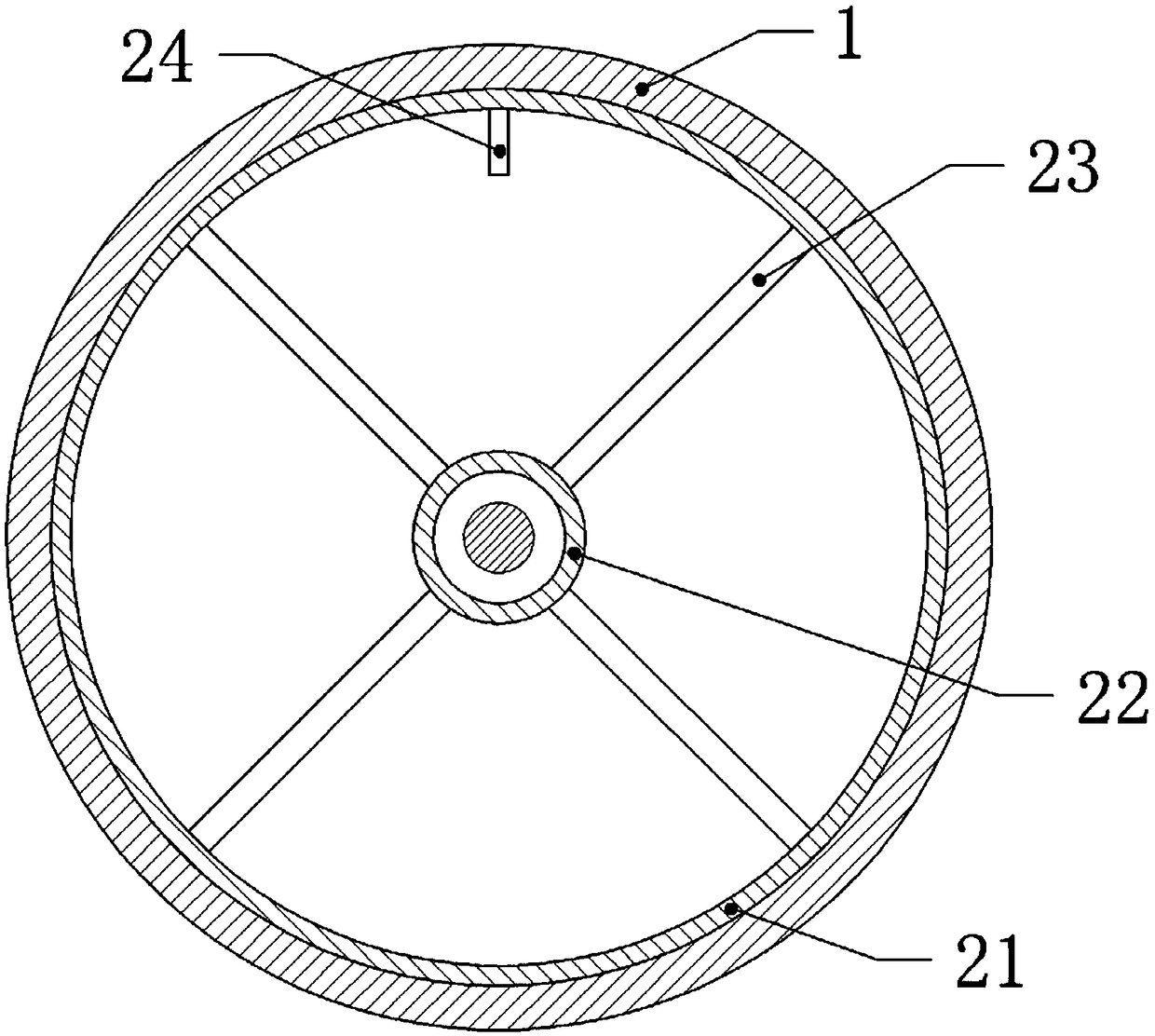

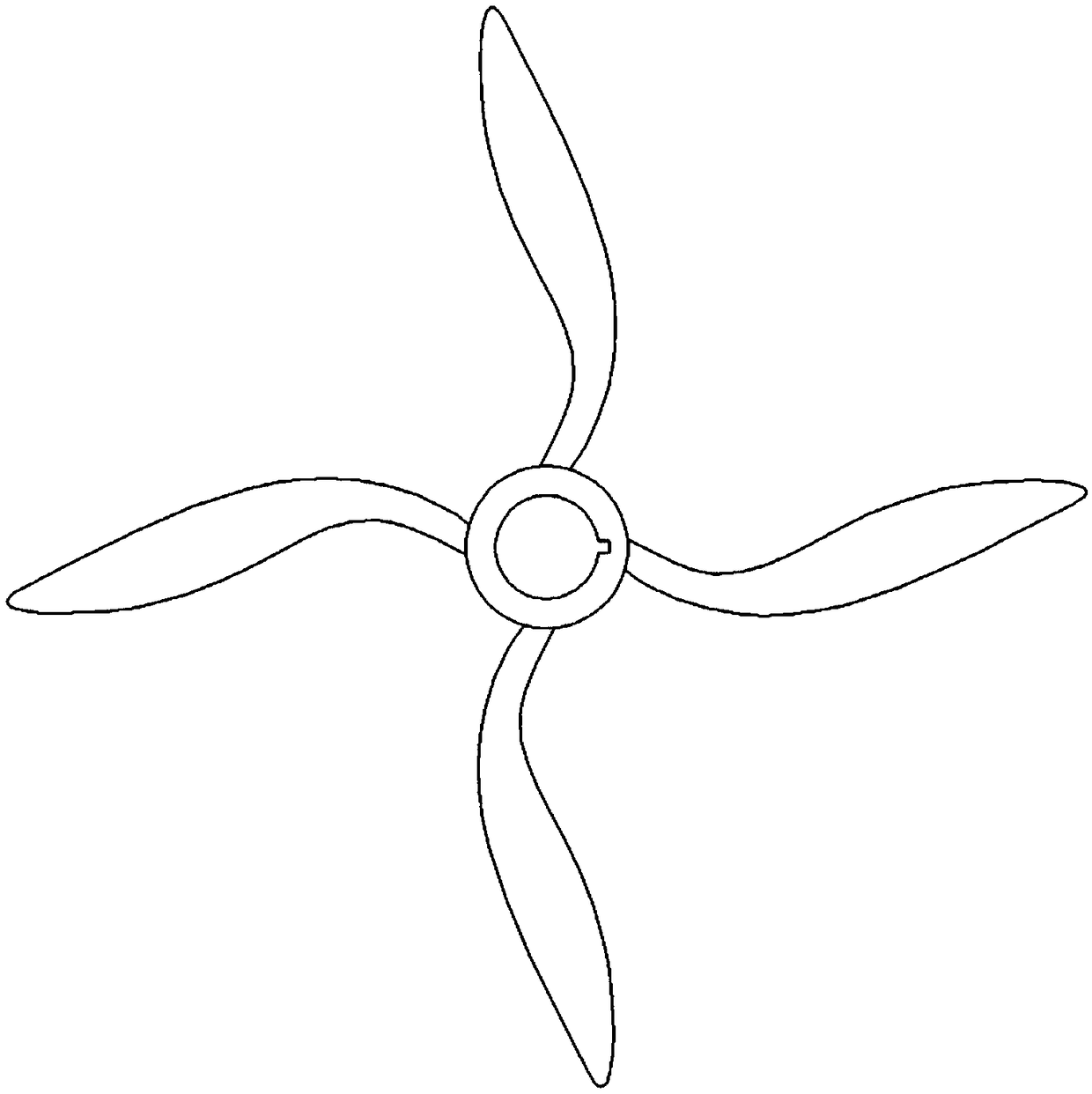

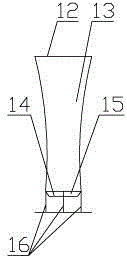

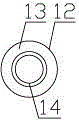

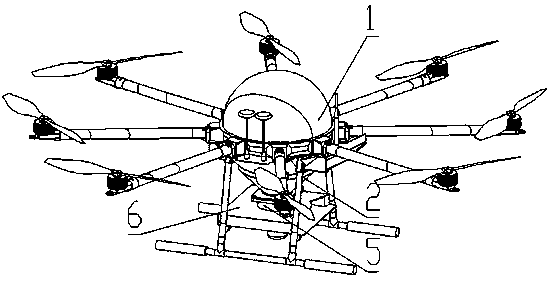

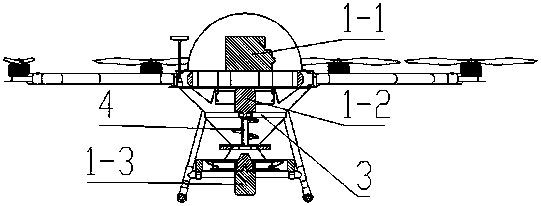

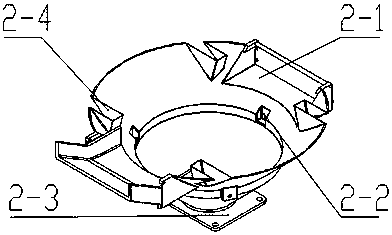

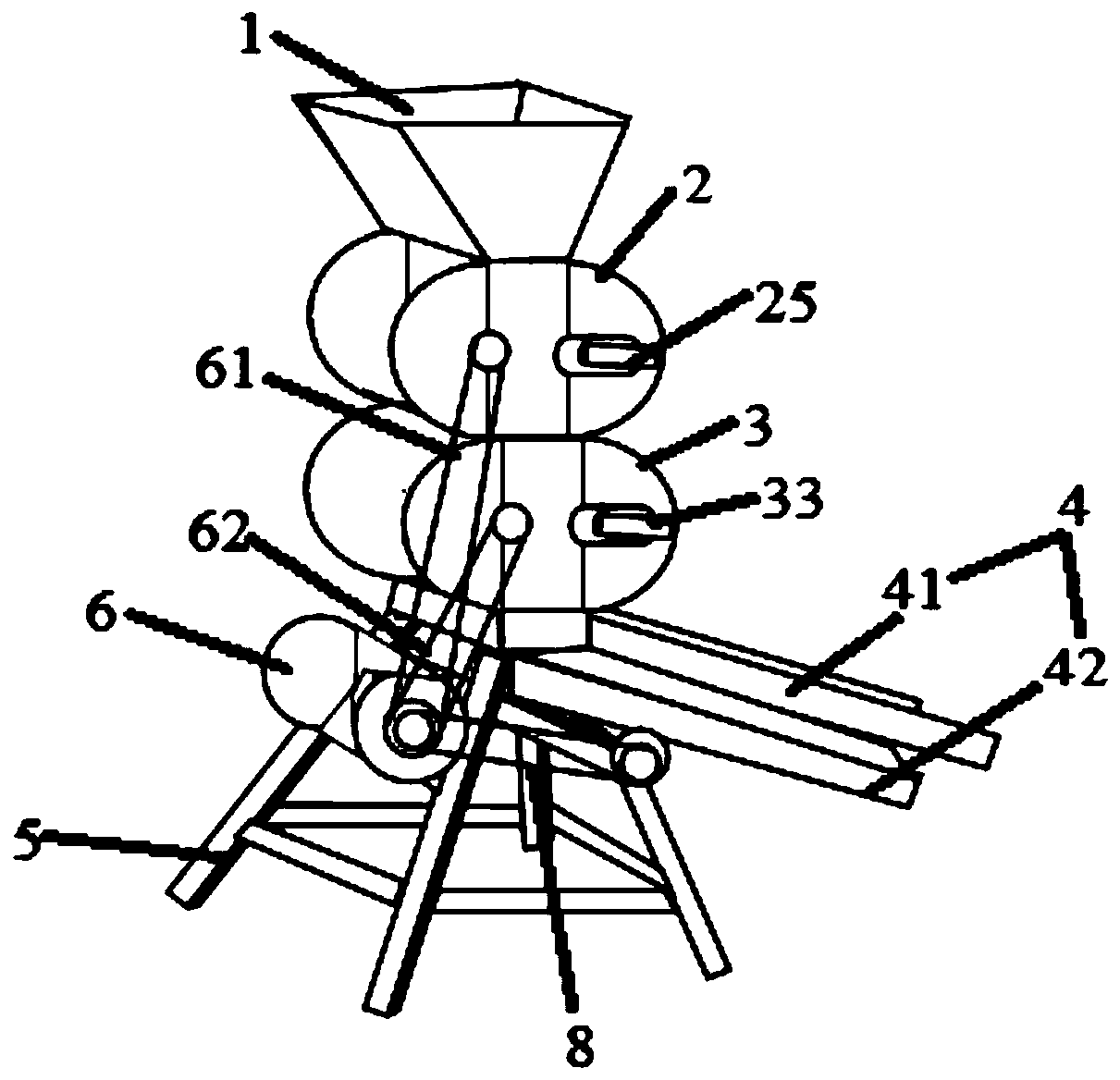

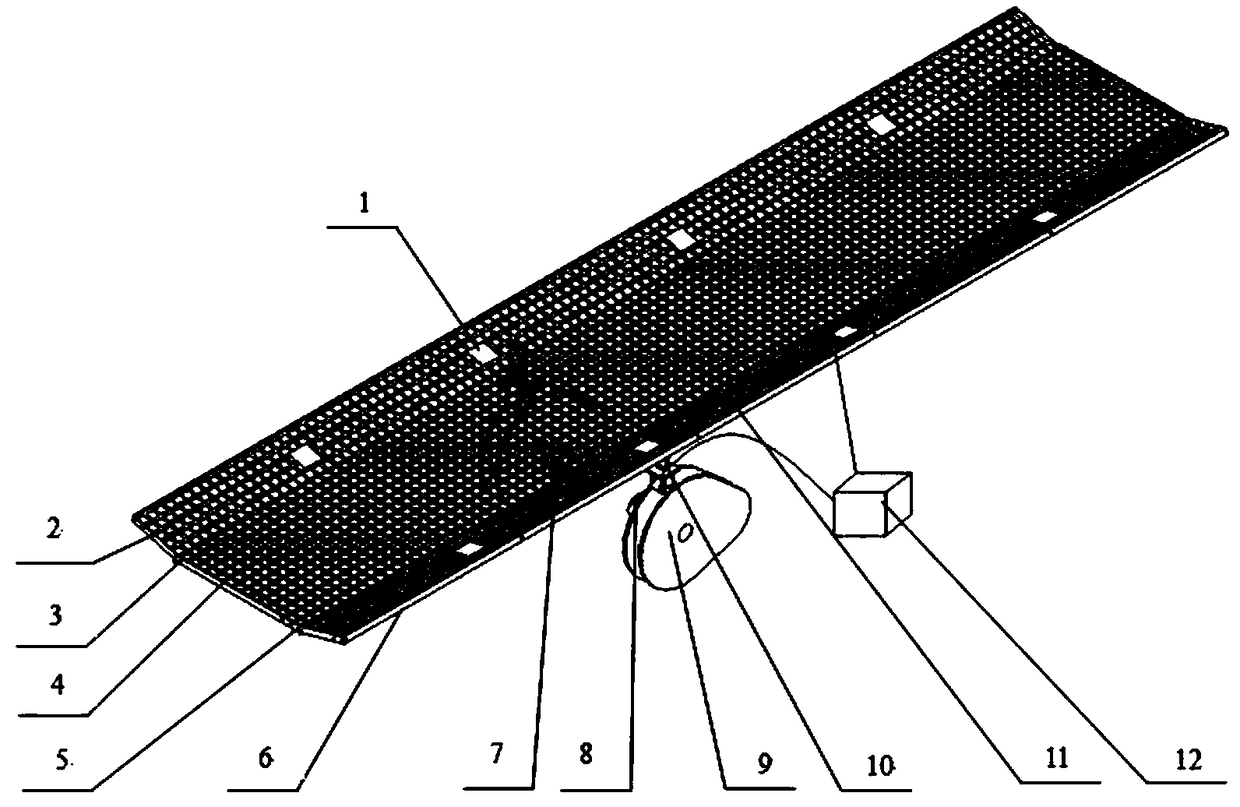

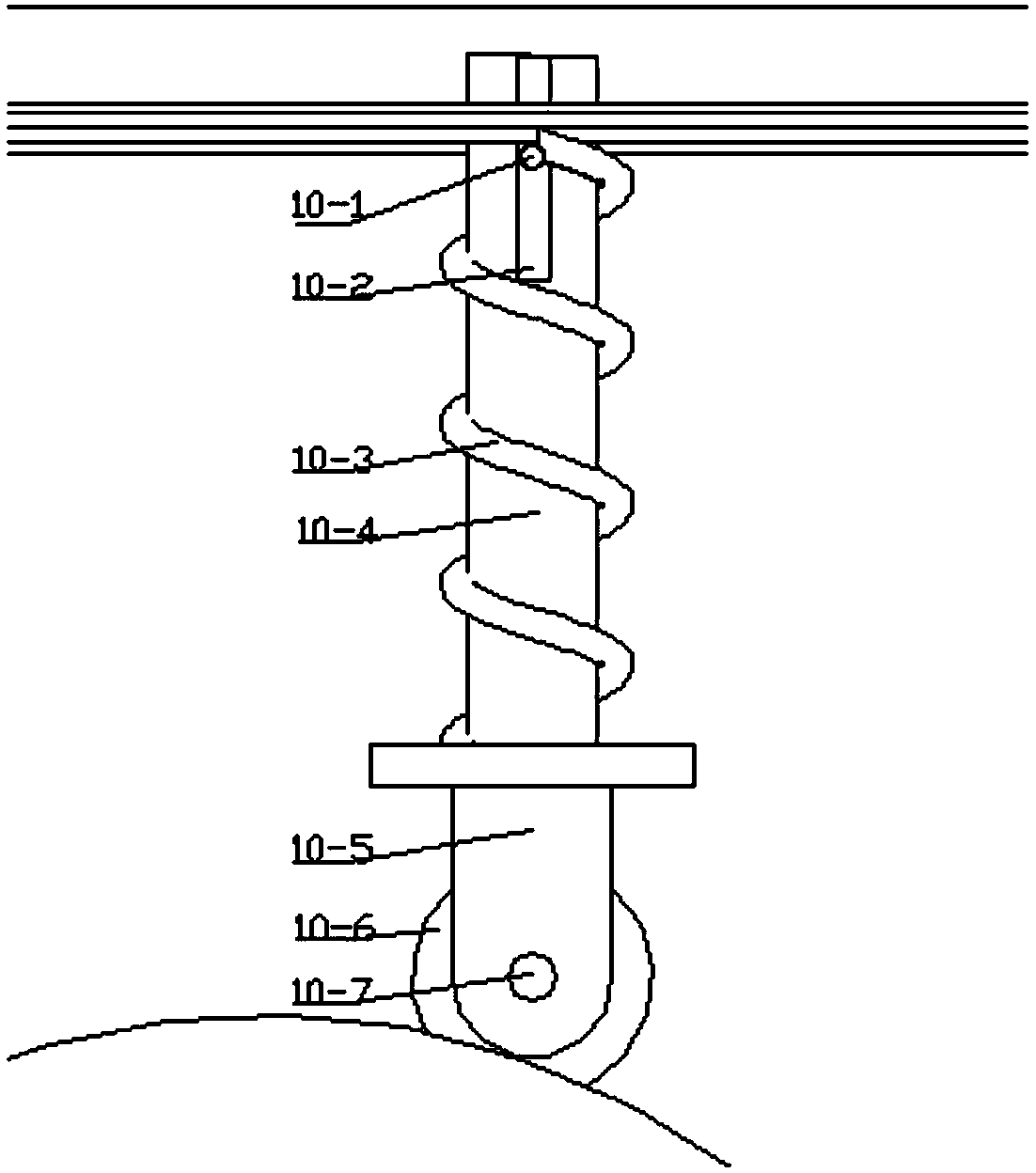

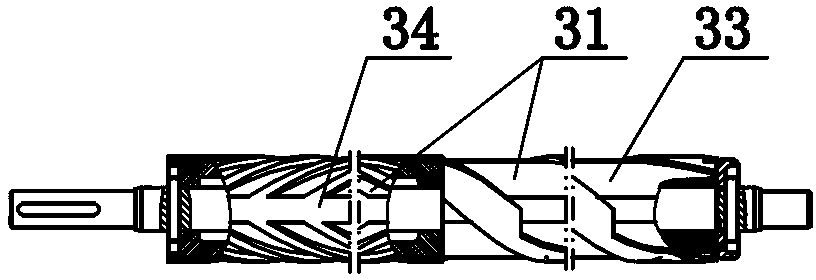

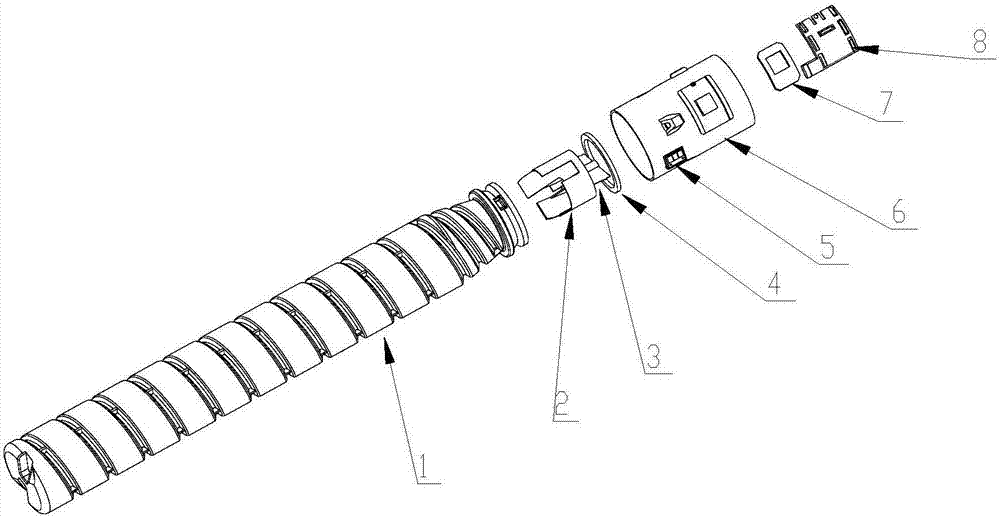

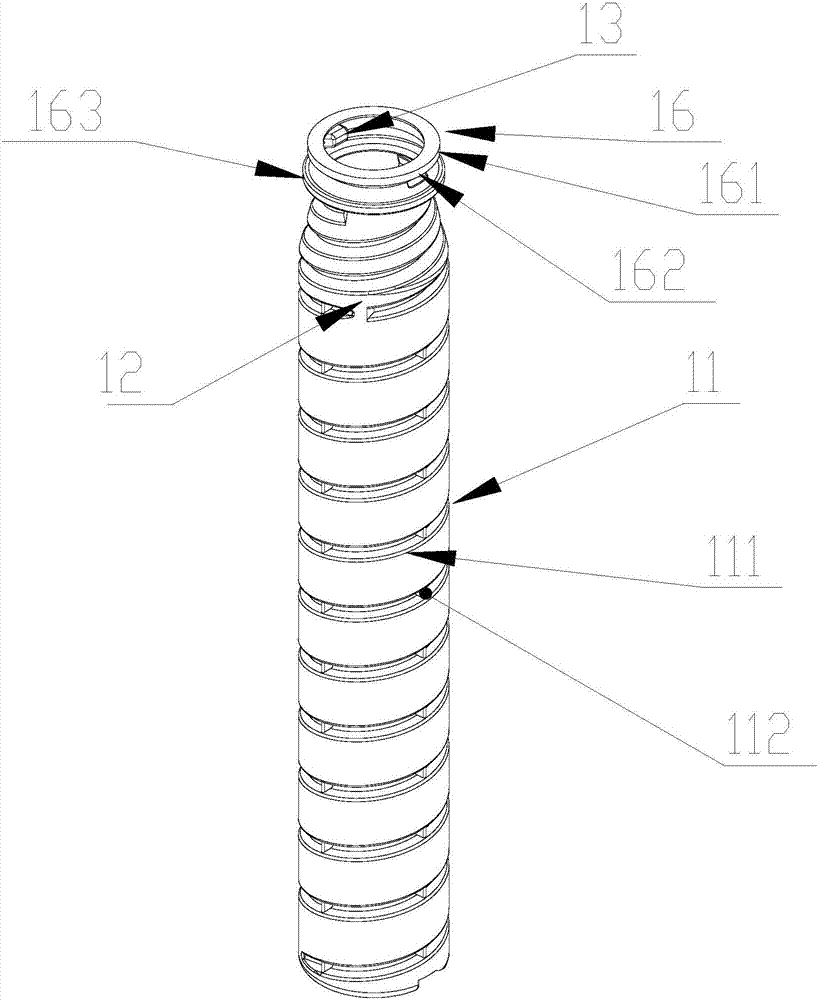

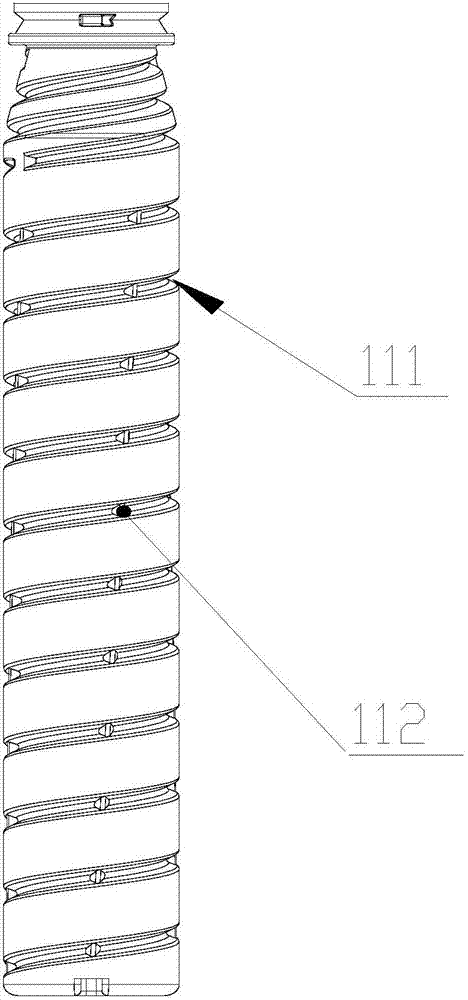

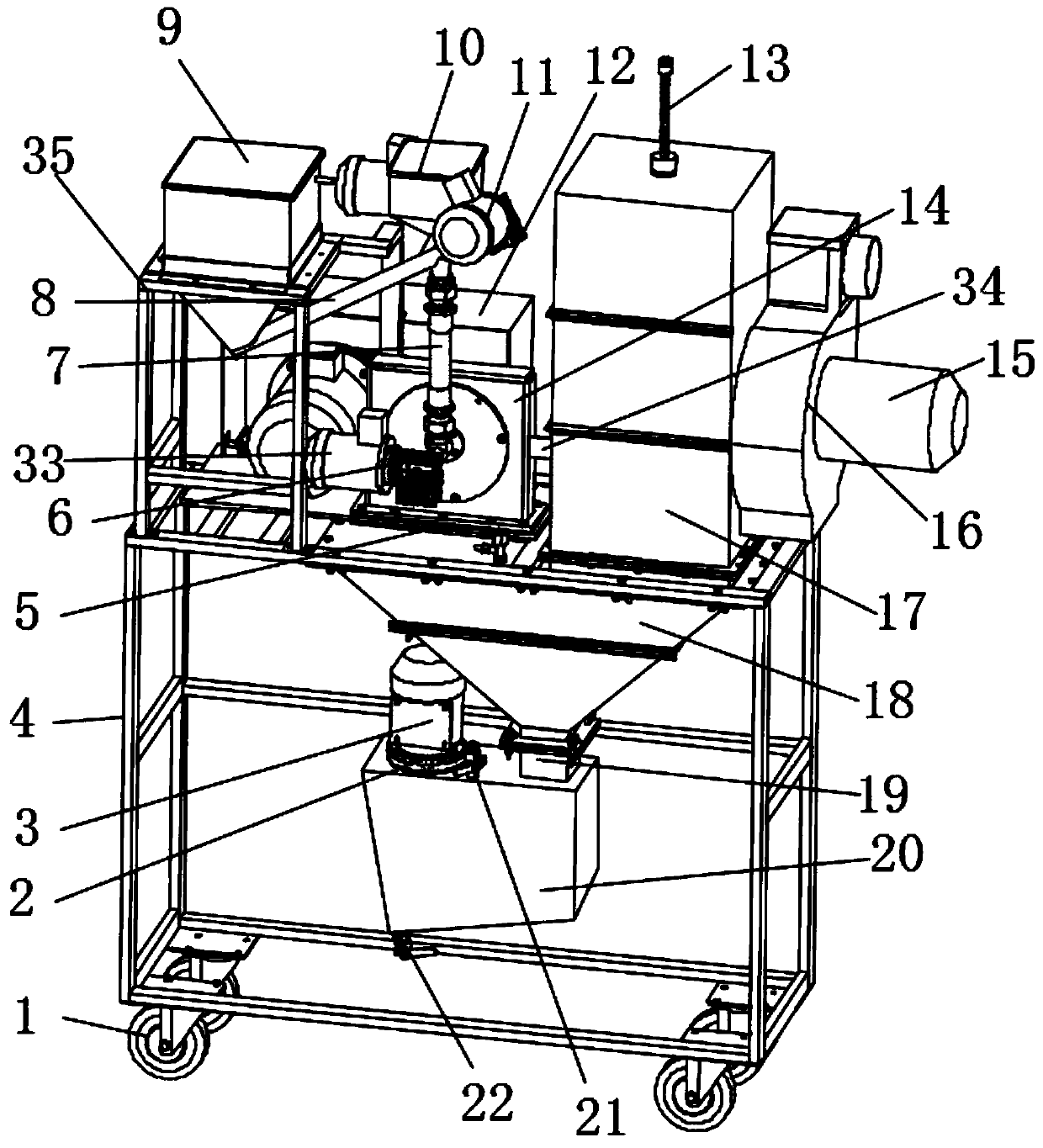

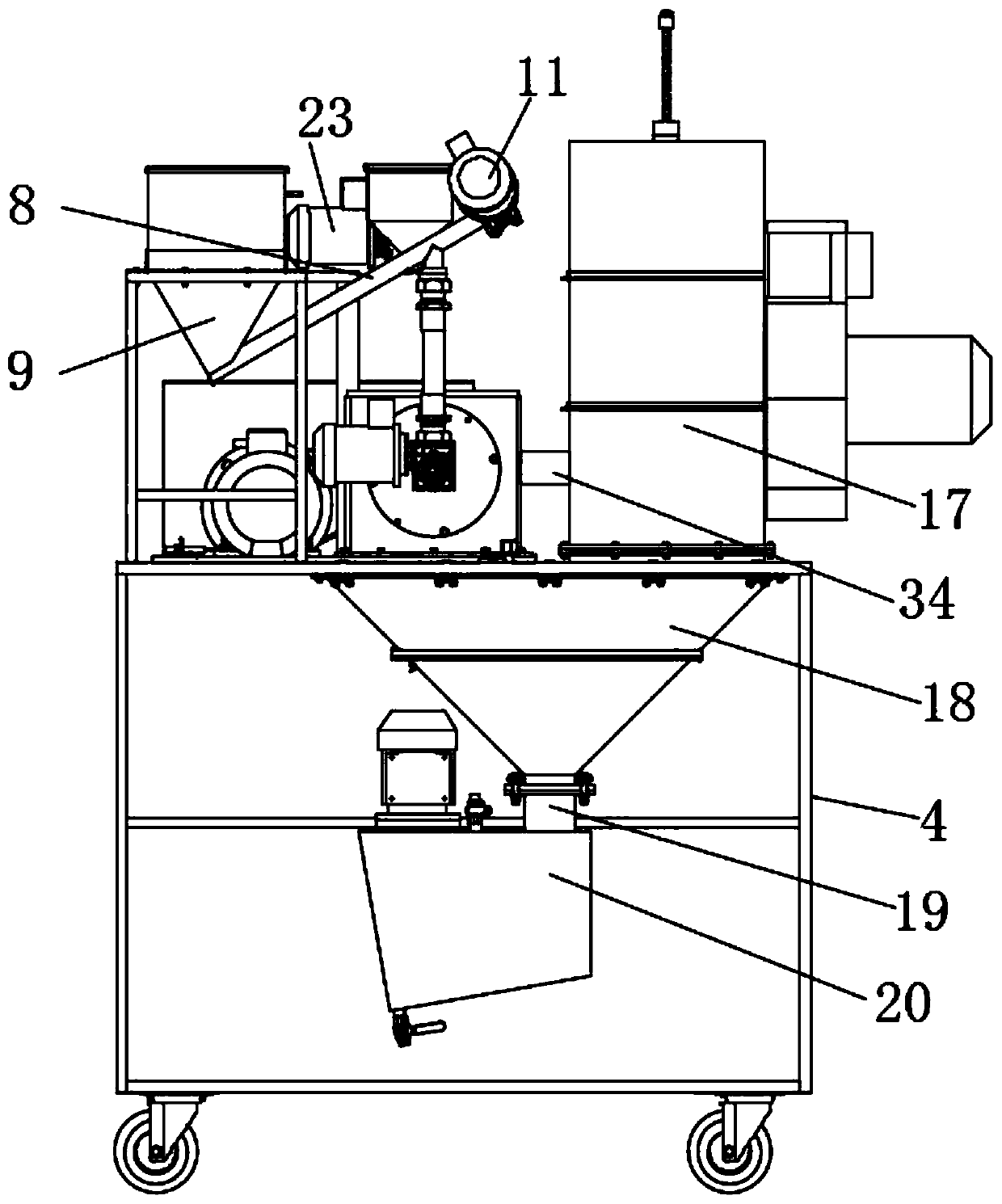

Helical uniform-seeding centrifugal disc type rice seeder matched with unmanned aerial vehicle

PendingCN108432430AAchieve continuous and precise adjustmentImprove uniformityAircraft componentsFertiliser distributersAgricultural engineeringFrustum

The invention belongs to the technical field of agricultural machinery unmanned aerial vehicle seeding and relates to a helical uniform-seeding centrifugal disc type rice seeder matched with an unmanned aerial vehicle. The rice seeder mainly comprises a multi-rotor unmanned aerial vehicle, a seed tank, a motor mounting spoke wheel, a disturbance quantitative conveying screw, a seed collection drum, a centrifugal disc seeding device and a transmission system. The seed tank is fixed to the upper side under the multi-rotor unmanned aerial vehicle through a clamping groove; the seed collection drum is mounted under the seed tank through a flange; the disturbance quantitative conveying screw is mounted in the middle of the seed tank and the seed collection drum; a rice seed guide uniform-seeding frustum is positioned under the disturbance quantitative conveying screw; the centrifugal disc seeding device is fixed to the lowest side of the multi-rotor unmanned aerial vehicle. The rice seederhas advantages that continuous and accurate adjustment of seeding quantity is realized, seeding uniformity is improved, and blockage and accumulation of seeds at an outlet of the seed tank are avoided.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

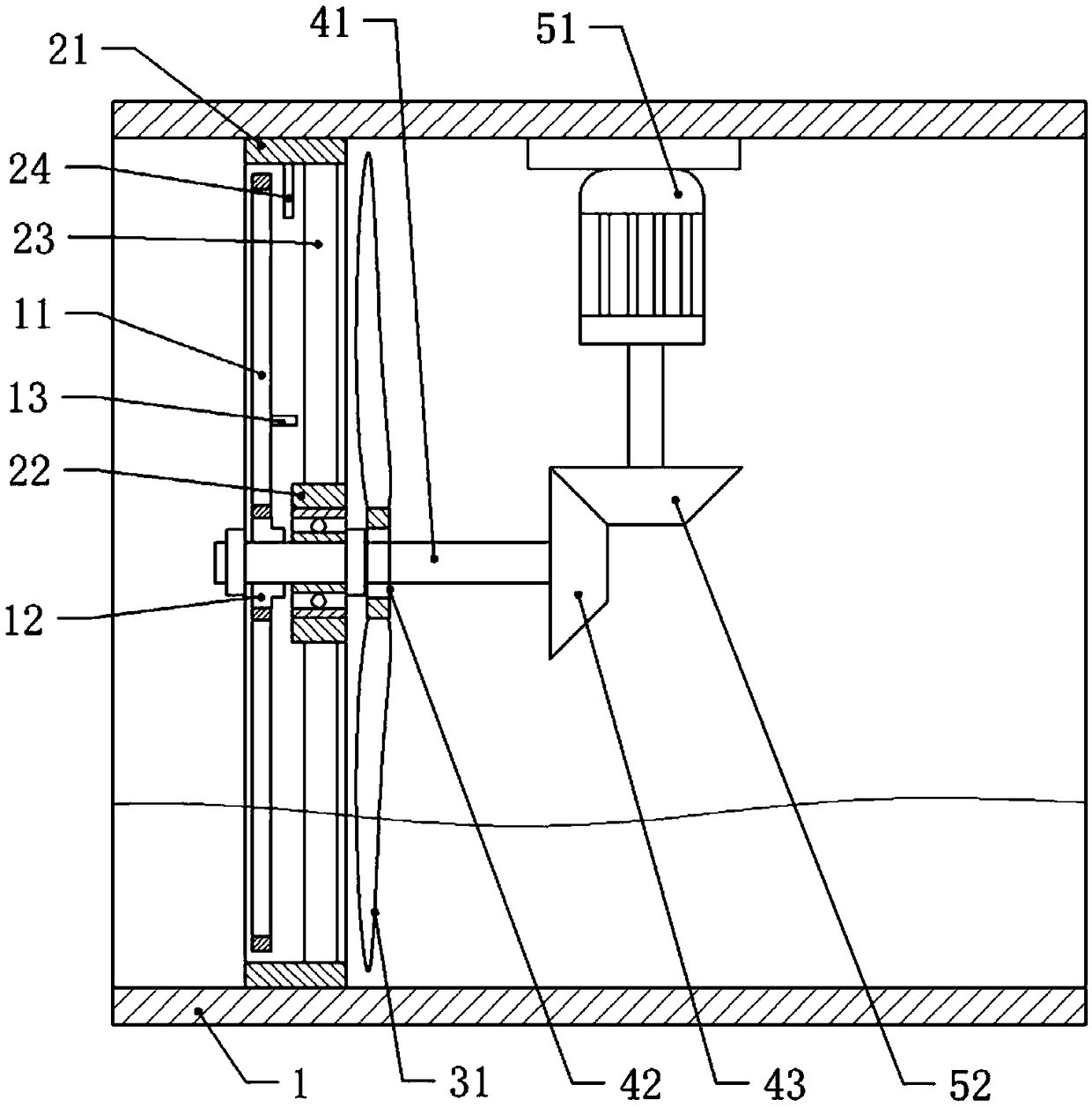

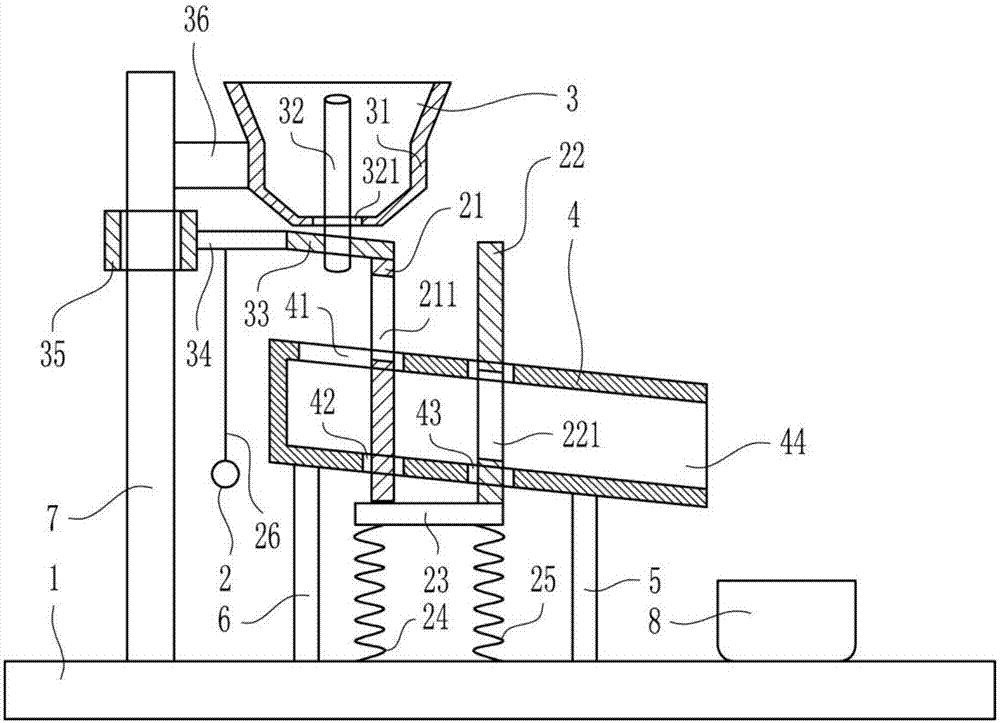

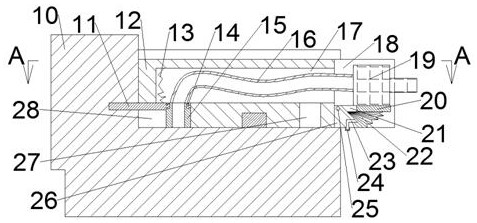

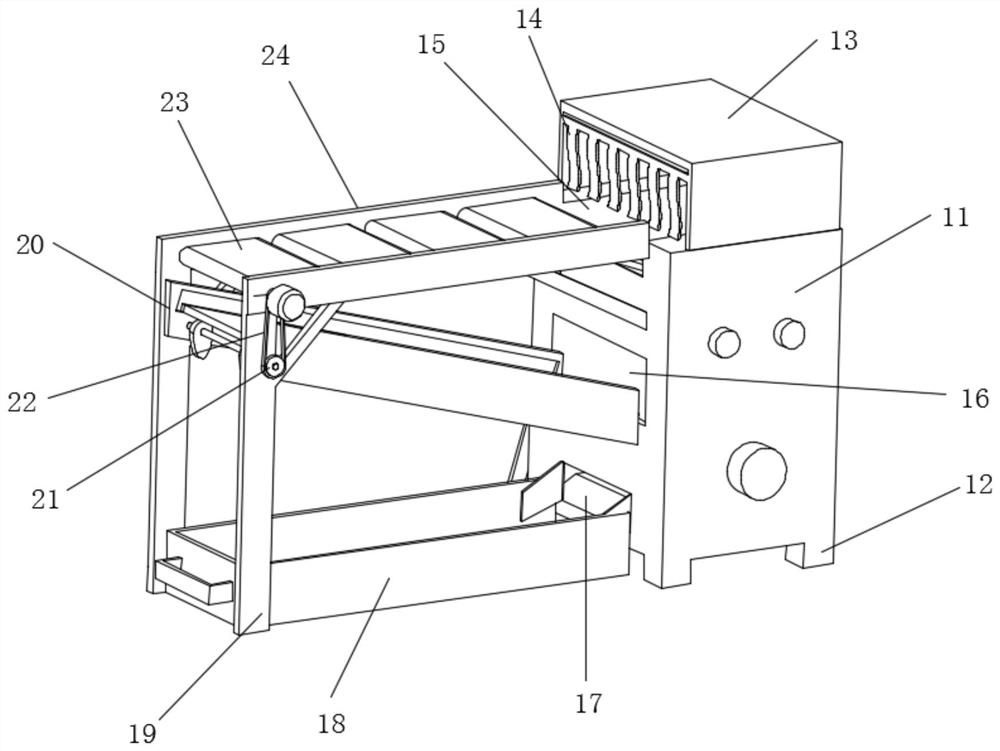

Intermittent feeding and cleaning device for potato starch raw materials

The invention relates to an intermittent feeding and cleaning device for starch raw materials, in particular to an intermittent feeding and cleaning device for potato starch raw materials. The invention technically aims to the intermittent feeding and cleaning device for the potato starch raw materials. According to the technical scheme, the invention provides the intermittent feeding and cleaningdevice for the potato starch raw materials. The intermittent feeding and cleaning device comprises a base, an intermittent device, a feeding device and so forth; the intermittent device is connectedto the base, and the feeding device is located above the intermittent device; the feeding device is connected to the intermittent device, and a feeding box is located below the feeding device, and connected to the intermittent device; the top of the feeding box is provided with a feeding port, and the bottom of the feeding box is provided with a first sliding chute. According to the intermittent feeding and cleaning device for the potato starch raw materials, the intermittent feeding of potatoes can be achieved through the intermittent device, so that the problem of stacking and blocking is solved; and smooth implementation of cleaning work is ensured, and the labor intensity of workers is reduced.

Owner:吴宇

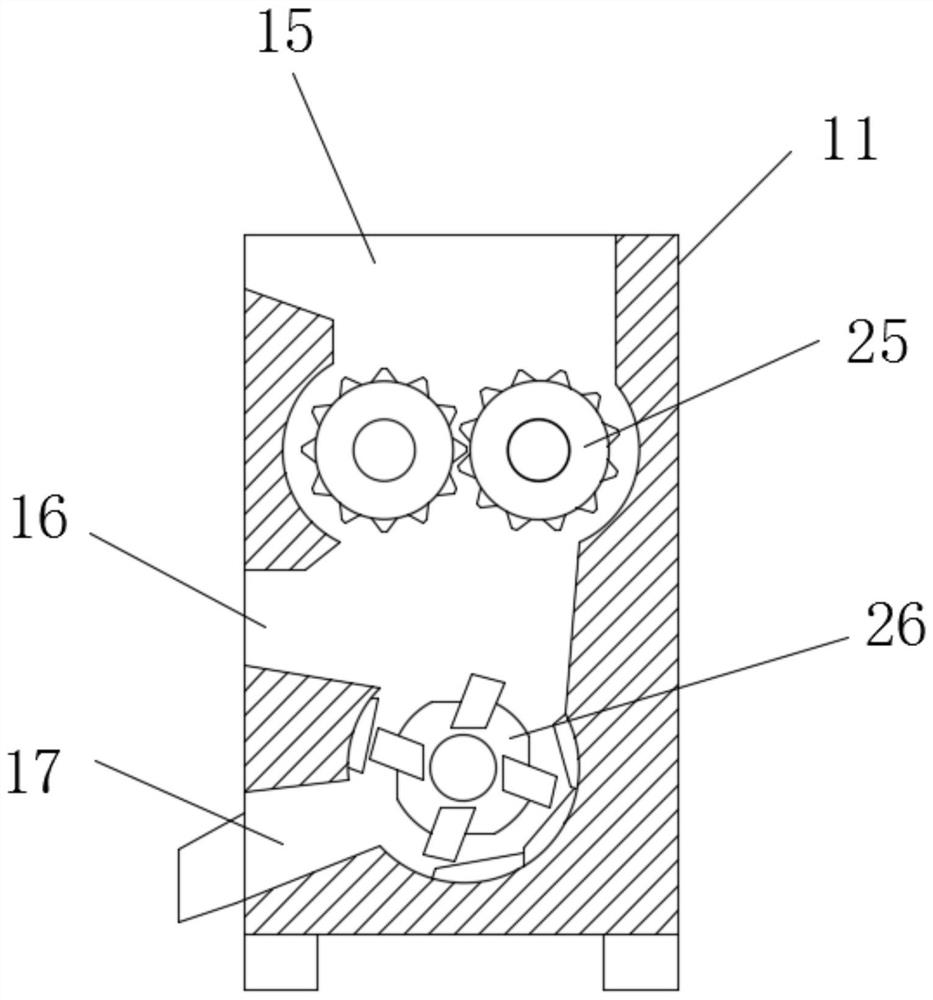

Crushing device for medical waste glass medicine bottles

InactiveCN108787041ACause some damagesImprove crushing effectGrain treatmentsMedical wasteMedical treatment

The invention relates to a crushing device for medical medicine bottles, in particular to the crushing device for the medical waste glass medicine bottles and aims to achieve the technical effect of providing the crushing device for the medical waste glass medicine bottles, wherein the crushing device is simple and convenient in operation, small in labor intensity, safe and reliable. According tothe technical implementation scheme, the crushing device for the medical waste glass medicine bottles comprises a base, an L-shaped supporting plate, a big barrel body, a first bearing, a big rotatingshaft, a stirring plate, a conical funnel, a first crushing rod, a second crushing rod, a third crushing rod and the like. The L-shaped supporting plate is located on the base and is connected with the base, and the big barrel body is located on the left side of the L-shaped supporting plate and is connected with the L-shaped supporting plate. The crushing device for the medical waste glass medicine bottles provided by the invention is simple and convenient in operation, small in labor intensity, safe and reliable in performance, time-labor saving, high in crushing efficiency, good in effect,simple in structure, easy to maintain and repair, low in maintenance and repair cost and easy to produce and manufacture.

Owner:HEBI CITY PEOPLES HOSPITAL

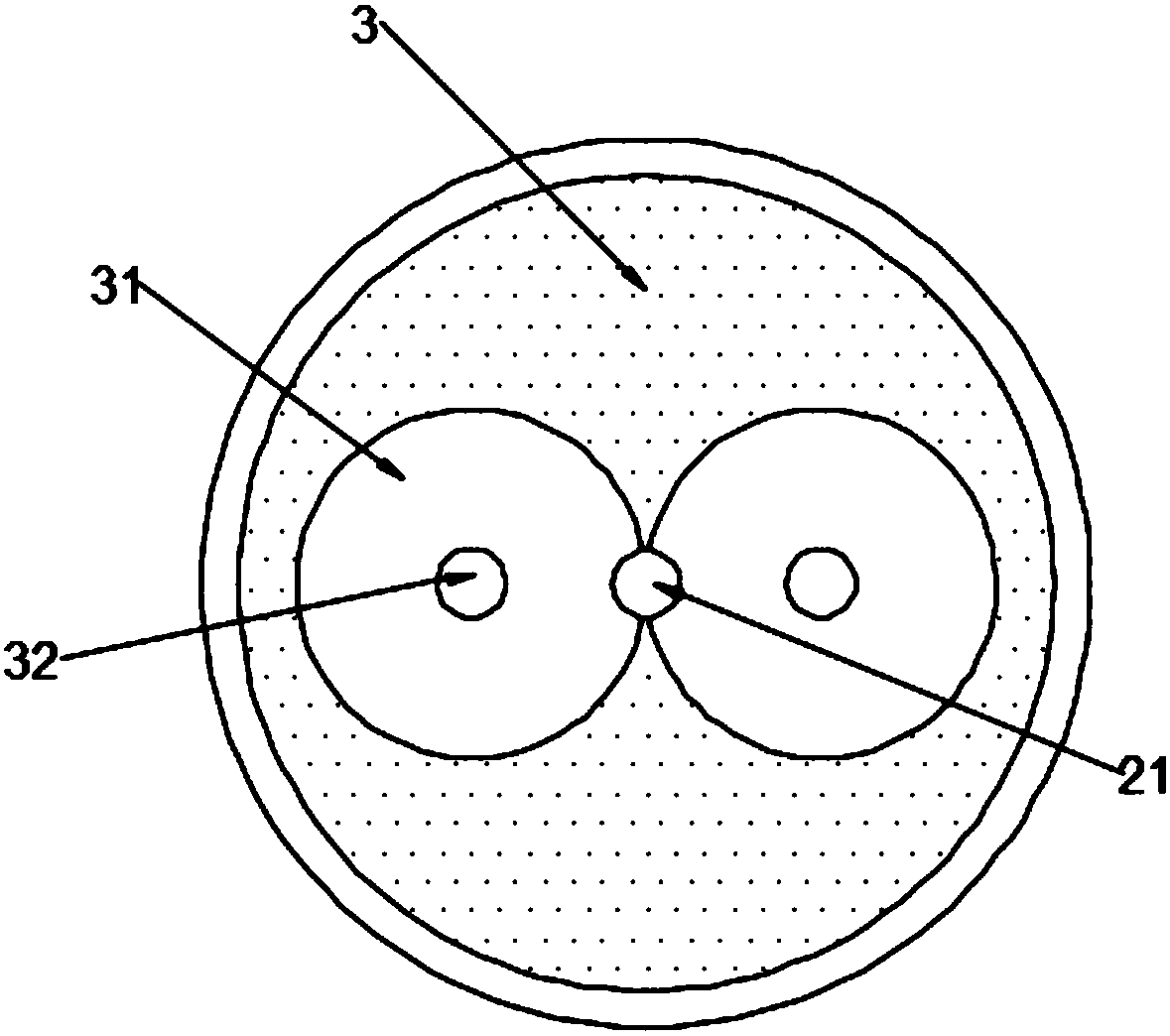

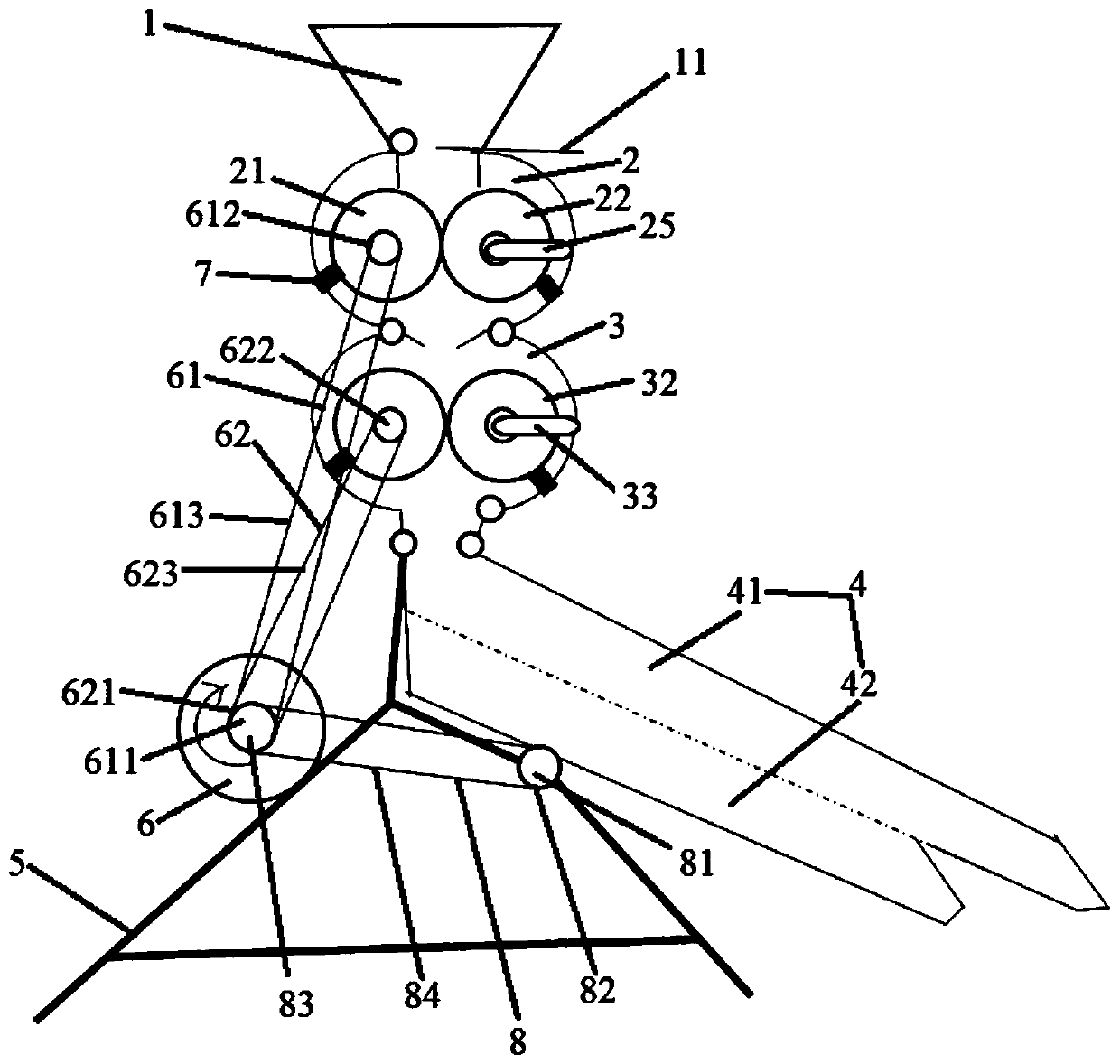

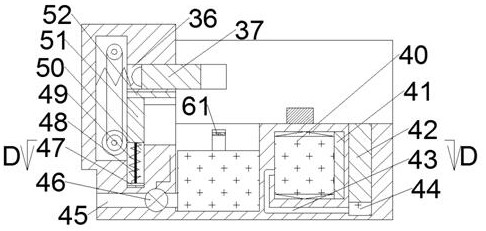

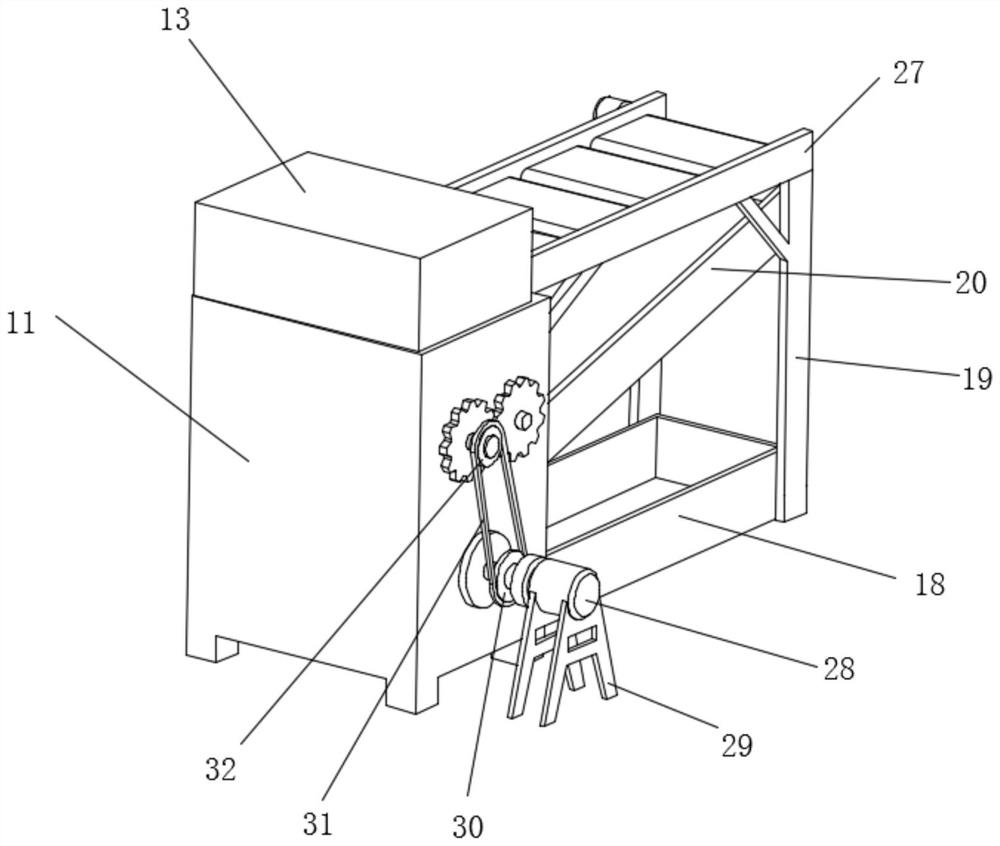

Soil grinding and crushing device and method

InactiveCN110743654AControllable grinding precisionHigh grinding efficiencyPreparing sample for investigationGrain treatmentsGrindingElectric machinery

The invention provides a soil grinding and crushing device and method. The soil grinding and crushing device comprise a feeding funnel, a coarse grinding cylinder, a fine grinding cylinder, a discharging device and a supporting frame which are arranged from top to bottom. The feeding funnel is of an up-and-down through chamfered platform structure, and a first coarse grinding roller and a second coarse grinding roller which are arranged side by side and have parallel axes are arranged in the coarse grinding cylinder. A first fine grinding roller and a second fine grinding roller which are arranged side by side and have parallel axes are arranged in the fine grinding cylinder. The discharging device comprises a first discharging box and a second discharging box which are arranged up and down, a grid screen is arranged at the bottom of the first discharging box, a discharging port is formed in the side surface of the bottom of the second discharging box, the supporting frame is fixed atthe bottom of the discharging device, a motor is mounted on the supporting frame, the motor drives the first coarse grinding roller to move through a first transmission device, and the motor drives the first fine grinding roller to move through a second transmission device. Air-dried soil needs to be ground and crushed before remolded soil samples are prepared in geotechnical tests.

Owner:WUHAN UNIV OF SCI & TECH

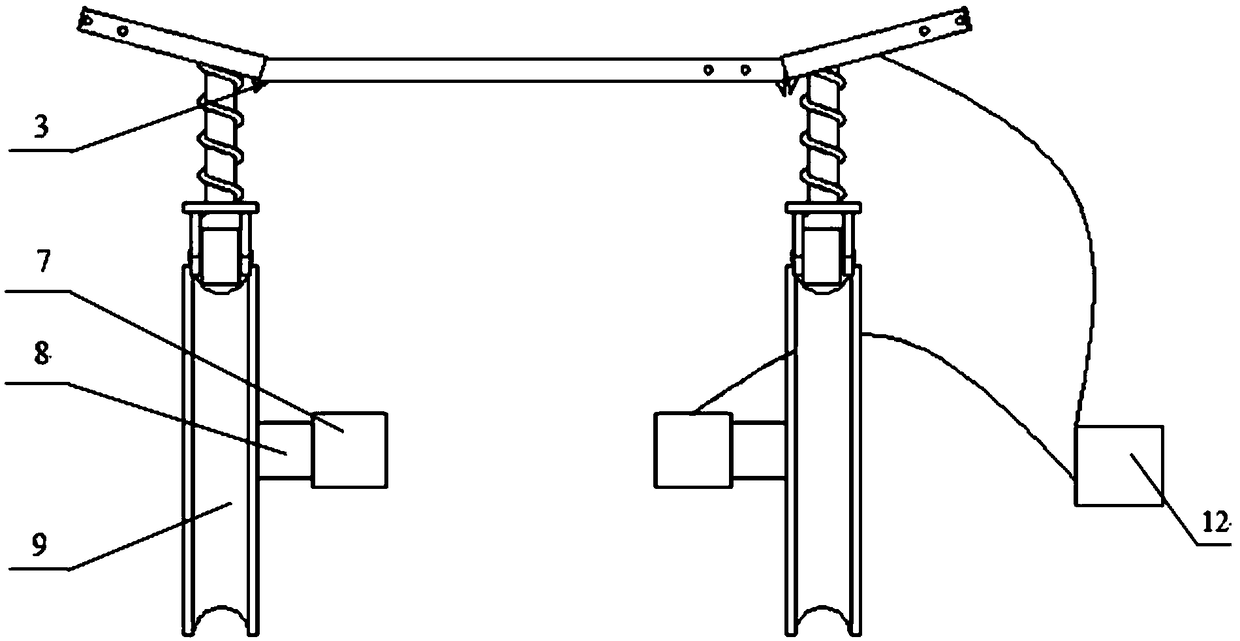

Cast-in-situ bored pile grouting device and construction method thereof

ActiveCN112227375APrevent accumulation and cloggingAvoid problemsBulkheads/pilesArchitectural engineeringLap joint

The invention relates to a cast-in-situ bored pile grouting device and a construction method thereof. The cast-in-situ bored pile grouting device comprises a rack arranged at an orifice of a foundation pile, two sliding seats symmetrically sliding in the radial direction of the orifice on the rack, guide rollers rotationally arranged on the side walls, close to the orifice, of the sliding seats, and a driving device for driving the two sliding seats to synchronously and reversely slide are arranged on the rack; the cast-in-situ bored pile grouting device further comprises lap-joint lugs whichare fixedly connected to the outer walls of the two ends of a pipe section, a lap-joint table is arranged on the sliding seats in a lifting mode in the vertical direction, and a lifting device used for driving the lap-joint table to ascend and descend in a reciprocating mode is arranged on the sliding seats; and when concrete is poured, the spliced pipe section is inserted into the orifice, the two sliding seats are driven to synchronously get close to each other and clamp a grouting pipe, the guide rollers play a role in guiding and correcting the grouting pipe, then the lap-joint lugs on thegrouting pipe are in lap joint with the lap-joint table, then the lap-joint table is driven to ascend and descend up and down in a reciprocating mode, and smooth flowing of the concrete in the grouting pipe is guaranteed. The cast-in-situ bored pile grouting device and the construction method thereof have the effects of improving the quality of the foundation pile and saving manpower.

Owner:飞帆集团有限公司

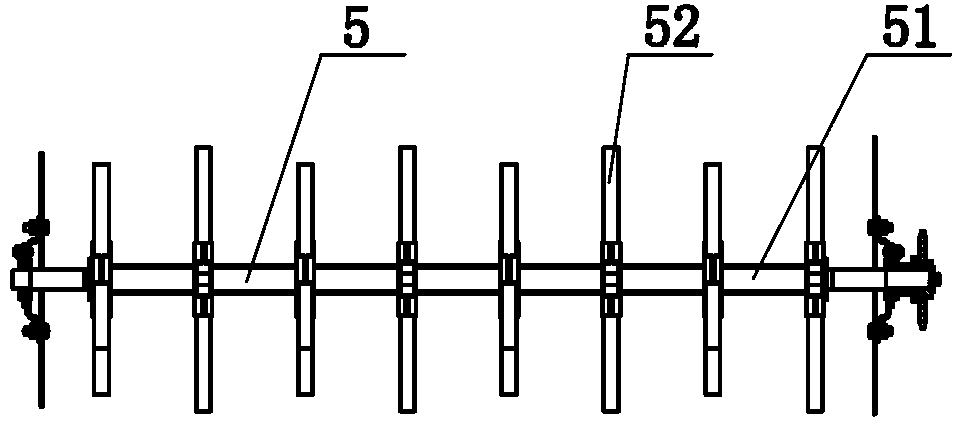

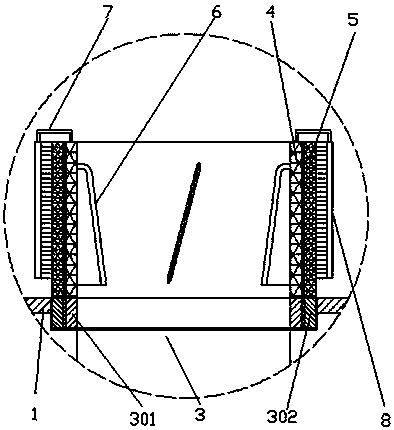

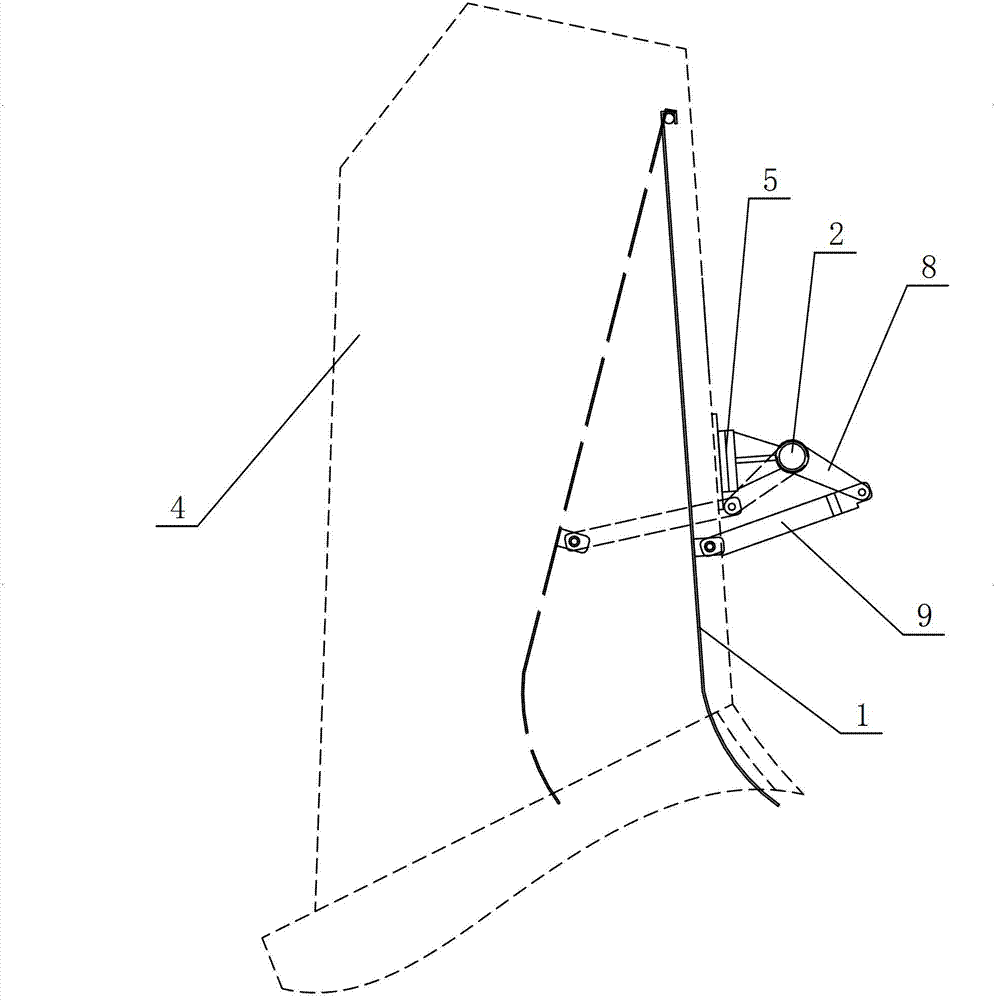

Segmented anti-blocking cleaning device with variable roll angle and control method thereof

ActiveCN108811695AImprove screening efficiencyPrevents cam and roller separationMowersThreshersRolling angleEngineering

The invention provides a segmented anti-blocking cleaning device with variable roll angle and a control method thereof. The cleaning device comprises weighing sensors, a left sieve plate, a main sieveplate, a motor, cams, roller push rod combination structures, a right sieve plate and a controller. The left sieve plate and the right sieve plate are rotatable relative to the main sieve plate. Thetwo roller push rod combination structures are respectively disposed under the left sieve plate and the right sieve plate, and the two cams are respectively driven by one motor. Rollers under push rods are in contact with the cams through the arc surfaces. The left sieve plate and the right sieve plate are respectively provided with a weighing sensor connected with the controller, and the controller controls start and stop of the two motors according to detection data of the weighing sensors. By means of the cleaning device and the control method, a combined harvester can be effectively prevented from tilting left and right during the slope operation, so that the blockage of materials on one side of a sieve can be avoided. The screening efficiency and the screening effect are improved, andthe cleaning efficiency is improved.

Owner:JIANGSU UNIV

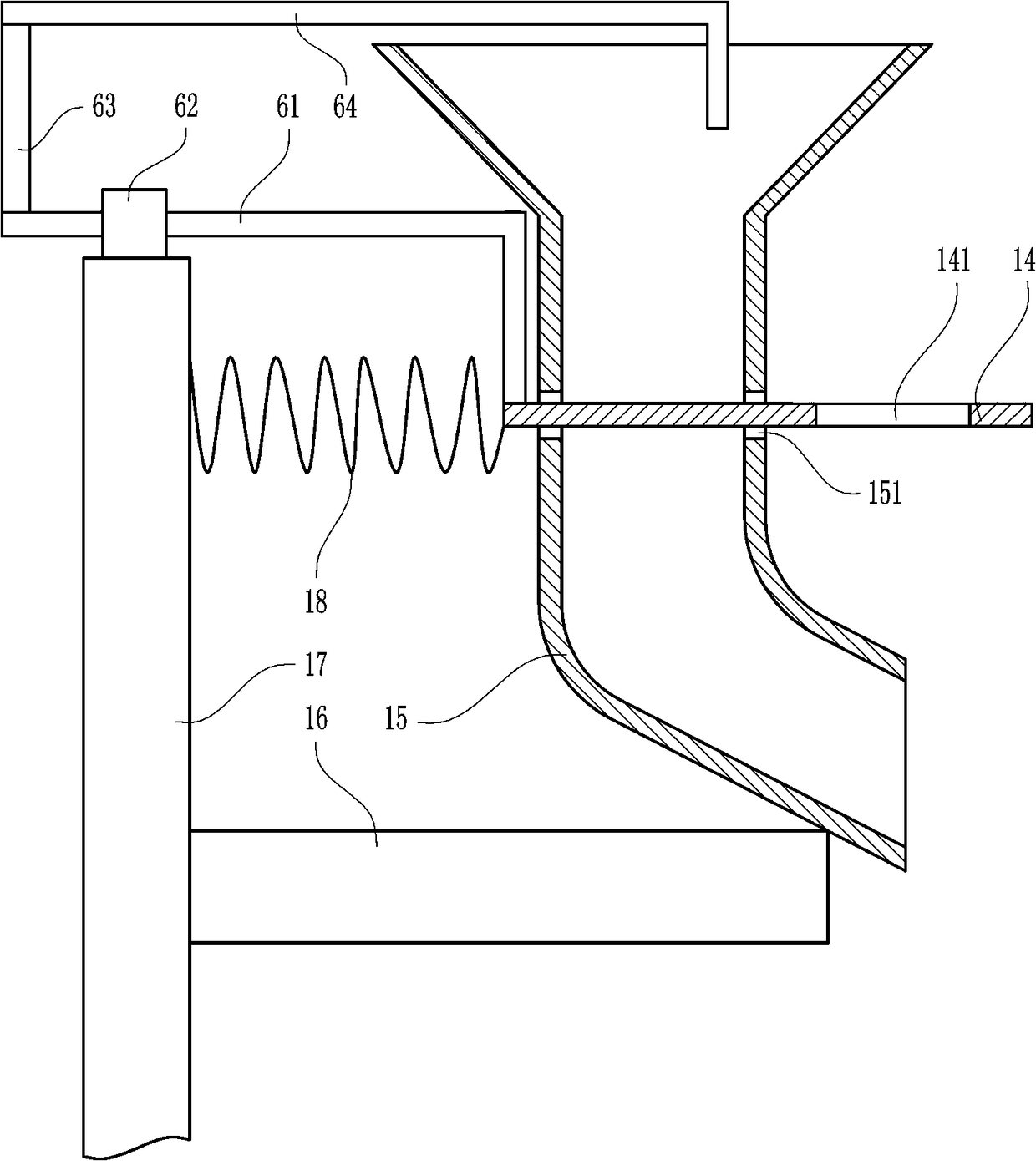

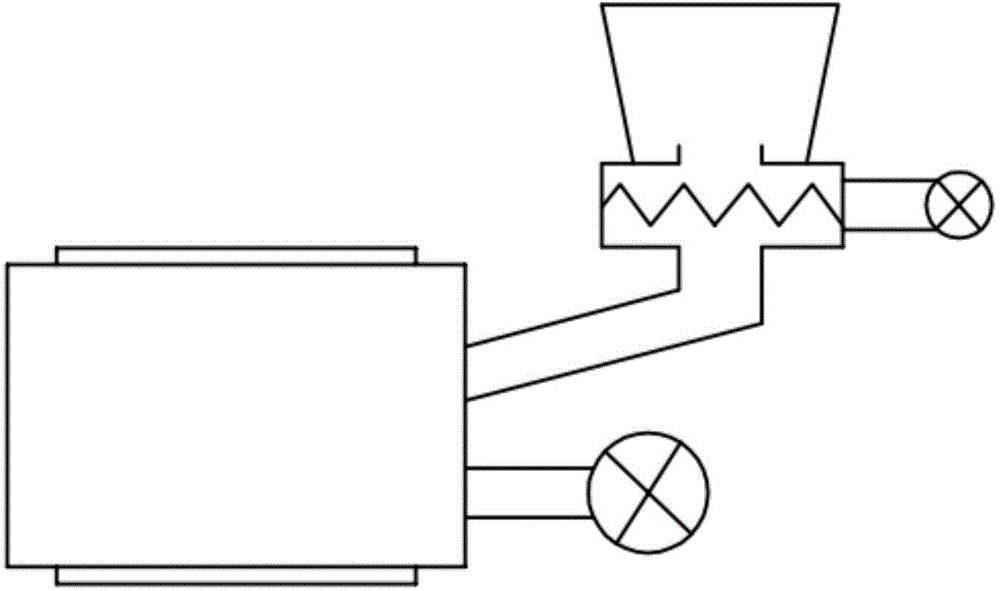

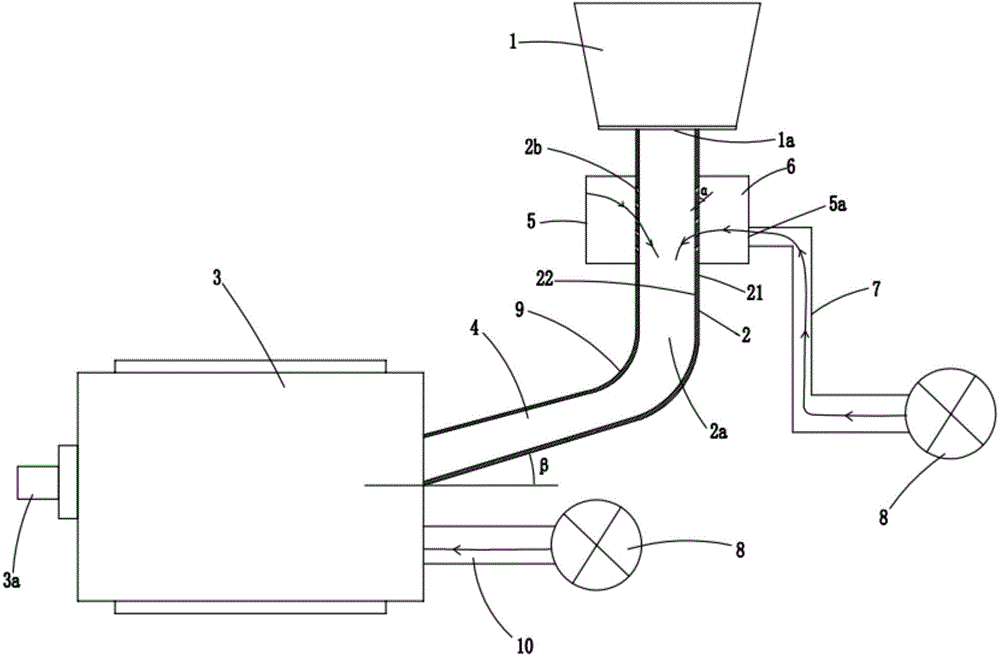

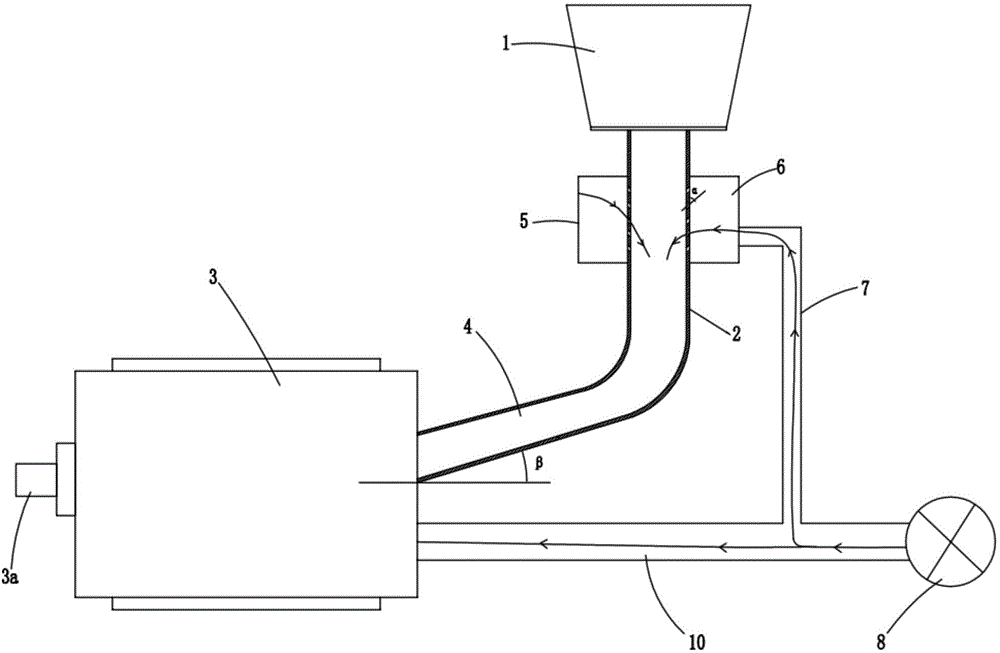

Feeding mechanism and biomass burner applying same

ActiveCN104832942AImprove liquidityBurn fullySolid fuel combustionLump/pulverulent fuel feeder/distributionCombustion chamberEngineering

The invention relates to a feeding mechanism and a biomass burner applying the same. The feeding mechanism comprises a stock bin, wherein a discharge hole of the stock bin is communicated with a material conveying passage; a passage outlet formed in the bottom of the material conveying passage is communicated with a feeding passage; one end of the feeding passage is communicated with the interior of a combustion chamber, and the feeding passage is obliquely arranged; the exterior of the material conveying passage is provided with a sleeve; a sealed annular cavity is formed between the inner wall of the sleeve and the outer wall of the material conveying passage; the side wall of the material conveying passage positioned in the annular cavity is provided with a plurality of through holes which penetrate through the outer wall and the inner wall; <0}{0><}0{>an air inlet of the sleeve is communicated with an air pipe; the end part of the air pipe is provided with a blower; gas is introduced into the annular cavity through the air pipe by virtue of the blower, and enters into the material conveying passage through an inclined hole. The feeding mechanism has the advantages of being good in anti-clogging performance, high in material conveying efficiency, relatively full in biomass particle combustion, simplified in structure, reduced in production cost, and the like.

Owner:HAIYAN DABEIR NEW BUILDING MATERIALS

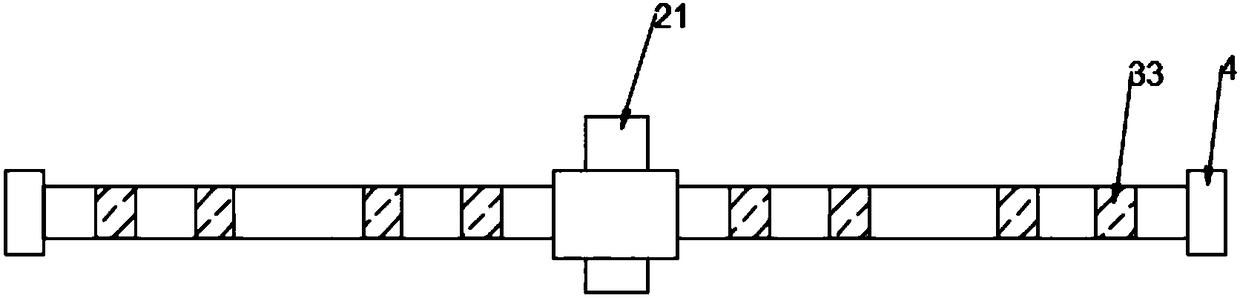

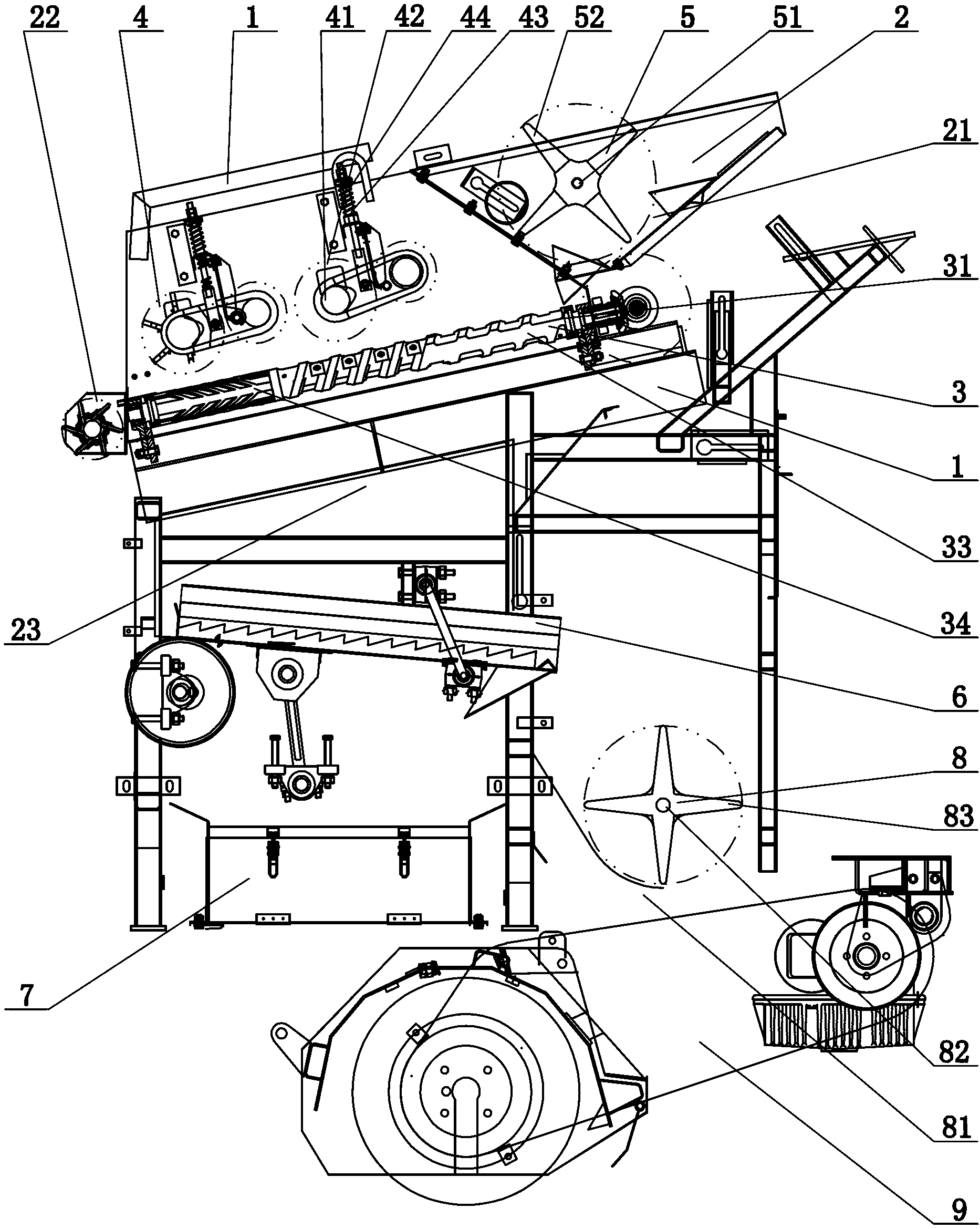

Peeling device for corn harvester

ActiveCN103004362AHigh stripping rateAvoid build-up cloggingHarvestersThreshersEngineeringDistributor

The invention discloses a peeling device for a corn harvester, and belongs to the technical field of corn harvesters. The peeling device comprises a peeling box arranged on a machine frame, wherein a plurality of peeling roller groups which are driven by a power device and are arranged in a groove shape are rotatably arranged in the peeling box; at least one pressing device which is driven by the power device is rotatably arranged above the peeling roller groups; a distributor is rotatably arranged on the peeling box at a fruit cluster entrance; the distributor is connected with the pressing device in a transmission way; and the distributor comprises a shifting wheel shaft and a plurality of cross shifting wheels which are fixedly arranged on the shifting wheel shaft. Because the distributor is arranged at the fruit cluster entrance, fruit clusters are uniformly distributed in the peeling roller groups by the distributor when the fruit clusters enter the peeling device from a lifting device; the distribution of the fruit clusters on the peeling roller groups is improved remarkably; the peeling rate of subtending leaves is improved; and moreover, the service life of the peeling roller groups is prolonged.

Owner:GAOMI CHUNYU MACHINERY

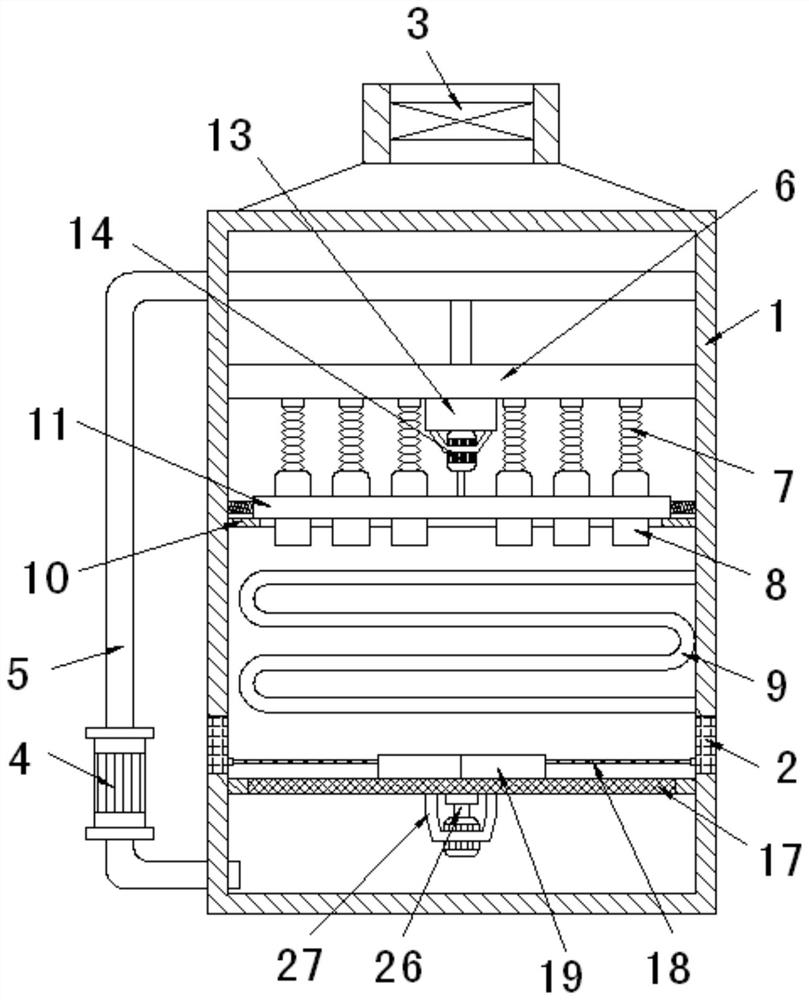

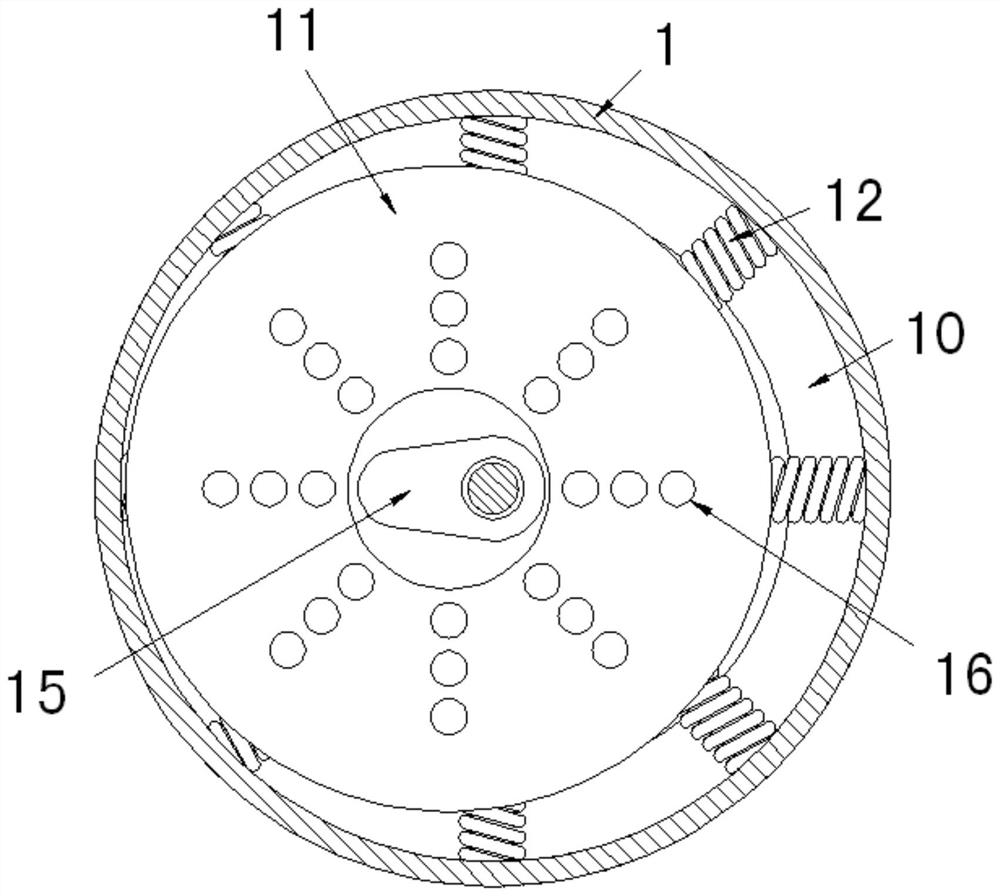

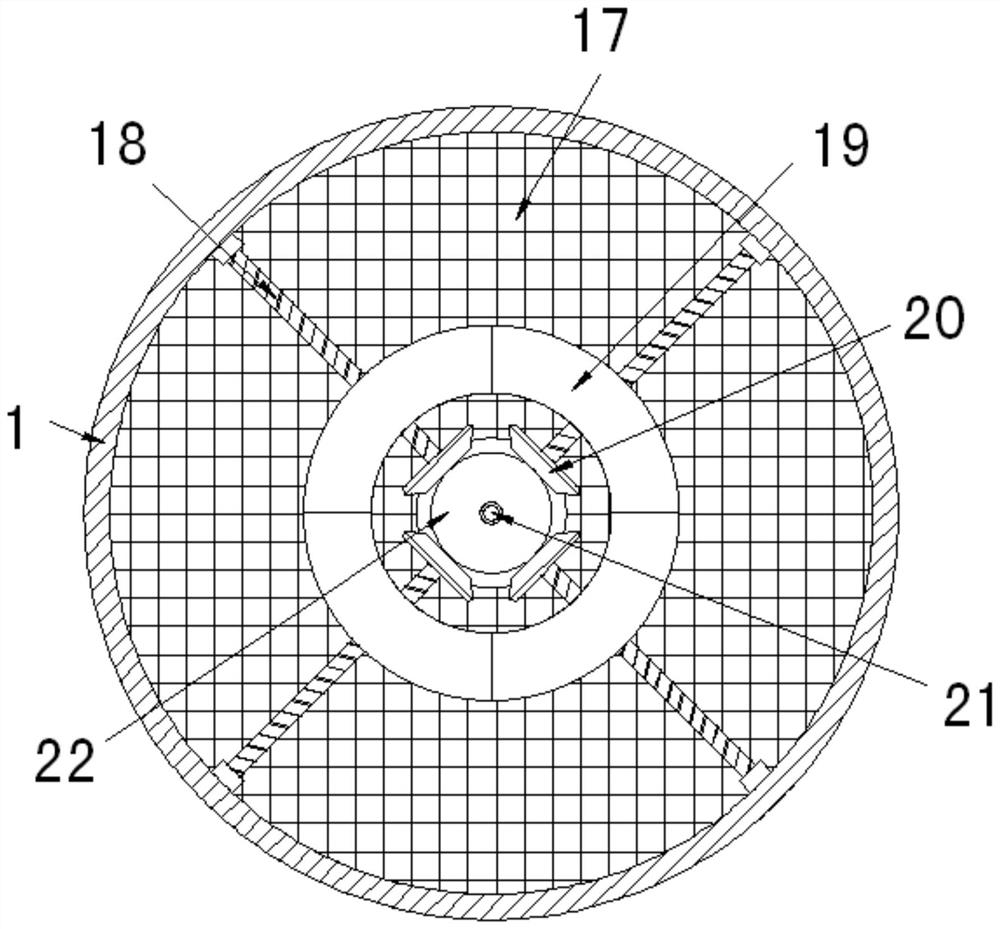

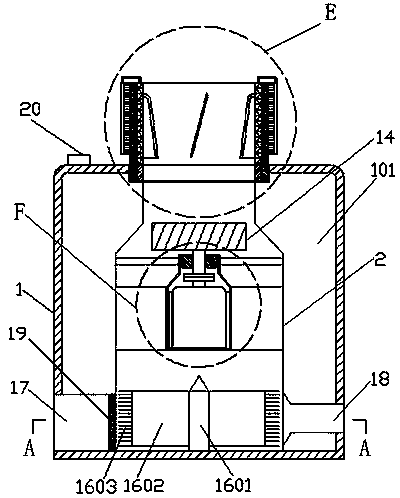

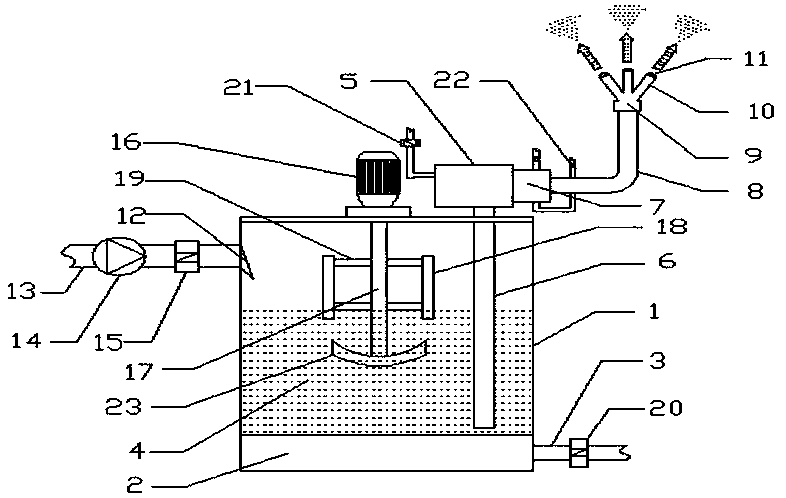

Closed cooling tower with spraying angle convenient to adjust

ActiveCN112393624AEasy to adjust spray angleSpray fully and evenlyTrickle coolersNon-rotary device cleaningCooling towerWater circulation

The invention relates to the technical field of cooling towers, and discloses a closed cooling tower with a spraying angle convenient to adjust. The closed cooling tower comprises a tower body and a fan, air inlet grids are fixedly arranged on both sides of the lower end of the tower body, the fan is fixedly arranged at the top end of the interior of the tower body, and a water pump is arranged onthe left side of the tower body; a water inlet and a water outlet of the water pump communicate with the lower end and the upper end of the interior of the corresponding tower body through water pipes, a hollow plate is fixedly arranged at the upper end of the interior of the tower body, the water pipe at the upper end communicates with the hollow plate, and the lower end of the hollow plate communicates with a plurality of spray heads through a plurality of corrugated pipes; and a push plate is arranged in the middle of the tower body, a plurality of springs are fixedly arranged on the outerside of the push plate, and one end of the outer side of each spring is fixedly connected with the side wall of the tower body. According to the closed cooling tower with the spraying angle convenient to adjust, the spraying angles of the multiple spraying heads can be adjusted at the same time, spraying can be more uniform and sufficient, and water can be recycled.

Owner:FUYANG ANGU BOILER PRESSURE VESSEL MFG

Floating water pump

ActiveCN111561452APrevent affecting drainage efficiencyPrevent accumulation and cloggingWaterborne vesselsPump componentsImpellerWater flow

The invention discloses a floating water pump, and belongs to the technical field of water pump equipment. An inner filtering screen barrel and an outer filtering screen barrel which are nested with each other are connected to a bearing ring arranged at the top end of a through-flow pipe, the inner filtering screen barrel is rotatably connected with a bearing inner ring, dispersing impellers are arranged on the inner wall of the inner filtering screen barrel, so that passing water flow drives the inner filtering screen barrel to rotate, a strip brush fixedly connected with the inner filteringscreen barrel is driven to slide along the outer side surface of the outer filtering screen barrel, large sundries attached to the surface of the outer filtering screen barrel are cleaned, accumulation and blocking are prevented, a filter screen is arranged at the connecting position of a drainage opening in the device and the through-flow pipe, a driven impeller is arranged at a same horizontal position of the interior of the through-flow pipe and the drainage opening, the water flow flowing from top to bottom drives the driven impeller to rotate, the strip brush at the outer end sweeps the filter screen surface, and the scraped sundries can be discharged to the outer end with water flow branch flow when rotate to a sundry-discharging opening of the right end of the through-flow pipe withthe strip brush; and the situation that the drainage efficiency is affected by sundry blocking is prevented, and the cleanliness of water pumping can further be improved.

Owner:江苏博利源机械有限公司

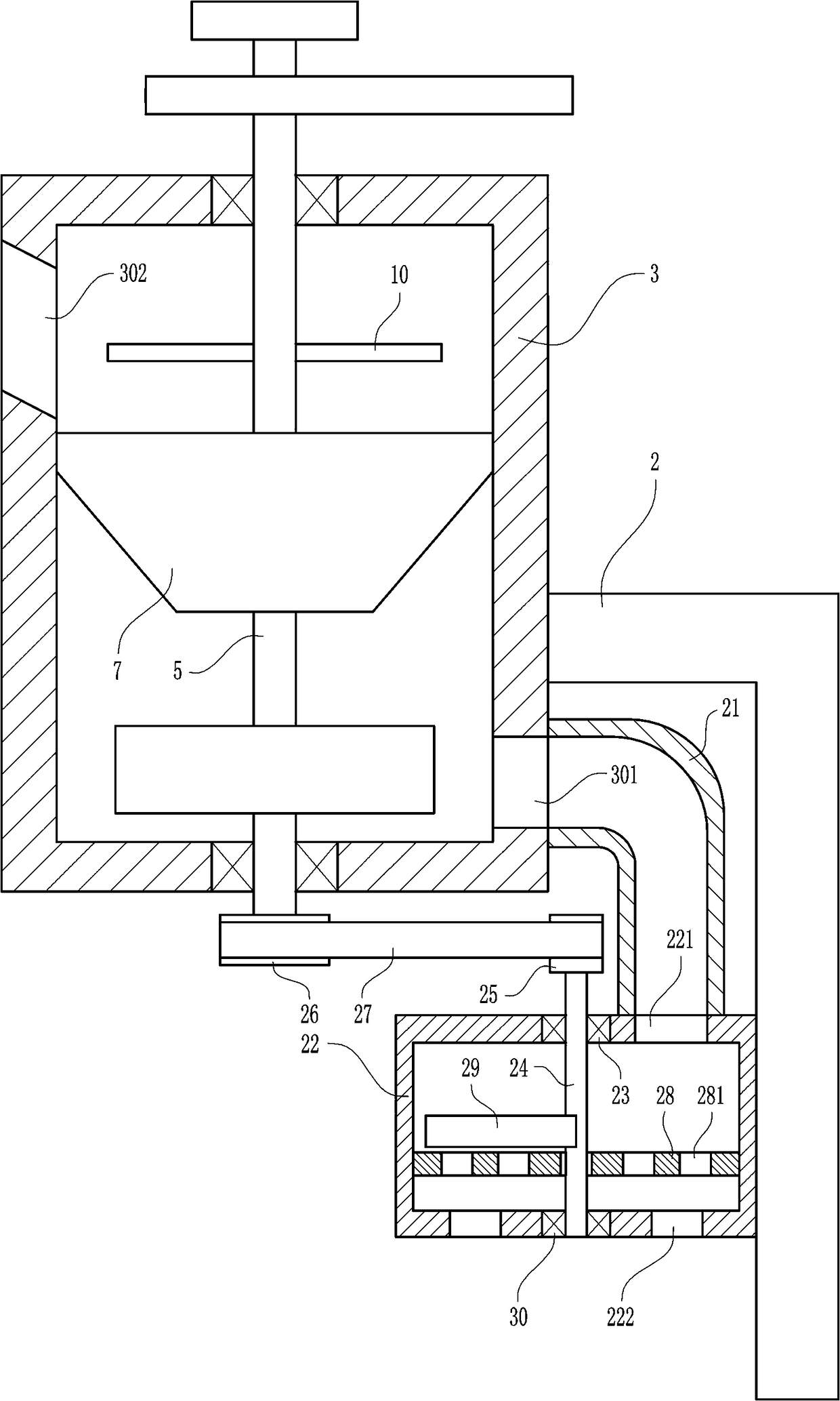

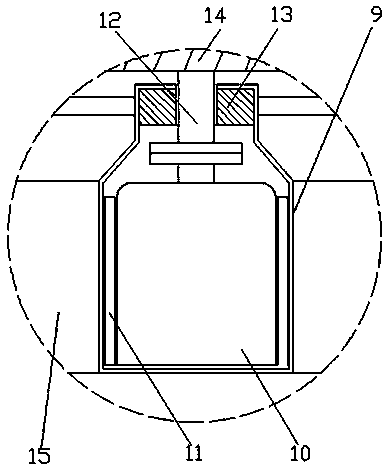

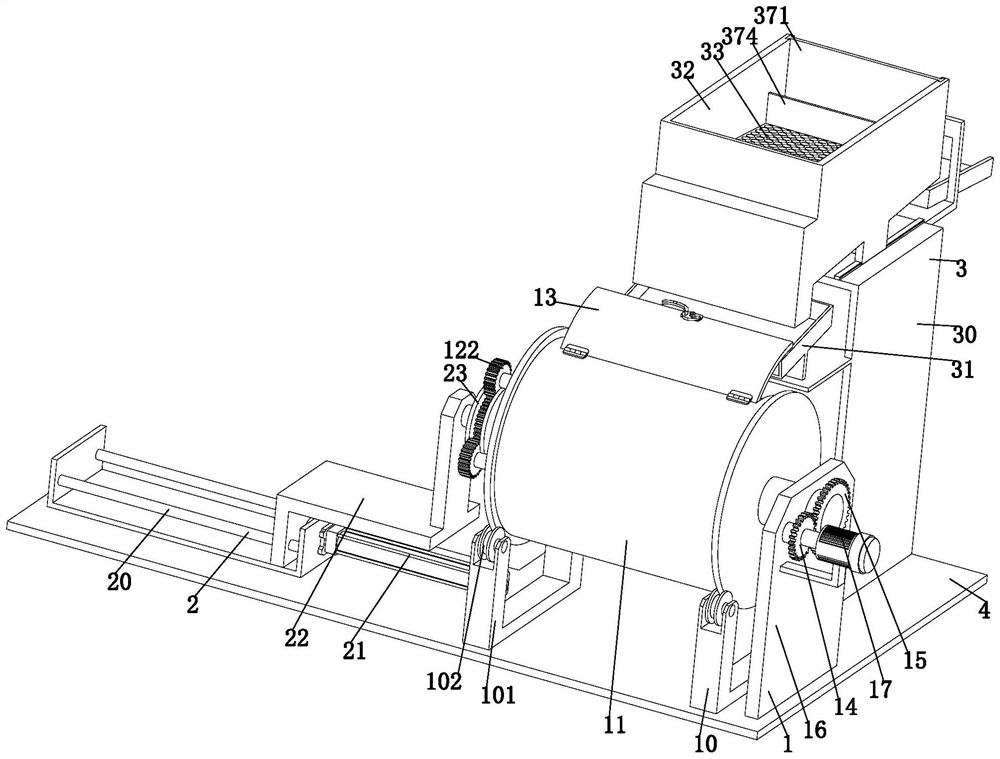

Preparation method of high-permeability emulsified asphalt concrete

InactiveCN113174810AIncrease linkageQuality improvementRoads maintainenceBitumen emulsionStructural engineering

The invention provides a preparation method of high-permeability emulsified asphalt concrete. A stirring mechanism, a guiding auxiliary mechanism, a screening mechanism and a bottom plate are included; the stirring mechanism and the screening mechanism are respectively mounted on the bottom plate, the guiding auxiliary mechanism is arranged on the opposite side of the stirring mechanism, and the guiding auxiliary mechanism is mounted on the bottom plate. The problems that a stirring device is difficult to clean during preparation and stirring of existing asphalt concrete, the asphalt concrete exists on the surface of the stirring device, the heavy and dry asphalt concrete exists on the surface after repeated use, the mechanical property of stirring is reduced, the prepared asphalt concrete material cannot be fully mixed, the preparation quality of the asphalt concrete is influenced, and stones for preparing the asphalt concrete are not screened, so that large-grain stones are inevitably doped in the stones, and the preparation quality of the asphalt concrete is influenced are solved.

Owner:李文海

Spraying device for preventing liquid from adhering to pipe walls for long time

InactiveCN111871670AReduce attachmentClean up in timeLiquid spraying apparatusStructural engineeringPipe

The invention discloses a spraying device for preventing liquid from adhering to pipe walls for a long time. The spraying device comprises a box body, an electric sliding block sliding groove with a leftward opening is formed in the top surface of the box body, an electric guide rail is fixedly arranged on the bottom surface of the electric sliding block sliding groove, and the electric guide railis in power sliding connection with an electric sliding block; the right end of the electric sliding block is provided with an angle adjusting groove which is through up and down and provided with aleftward opening, and the left end wall of the bottom end of the angle adjusting groove is fixedly provided with a slope supporting block, the bottom end of the slope supporting block is fixedly provided with a rotating plate shaft, and the front and rear ends of the rotating plate shaft are rotatably connected with the left end of a rotating supporting plate; and an angle adjusting air bag is fixedly connected between the bottom face of the rotating supporting plate and a top end slope of the slope supporting block, a spraying head device is fixedly arranged on the top face of the rotating supporting plate, and two inclined block sliding grooves with rightward openings are formed in the left end wall of the electric sliding block sliding groove in a front-back symmetry manner. Residual liquid in a used infusion tube can be automatically collected in time through the pressure difference, and the spraying angle can be freely adjusted.

Owner:SHAOXING FANGDAN TECH CO LTD

Novel glass powder sprayer and working method thereof

PendingCN109678355APrevent accumulation and cloggingPlay the role of self-cleaningEngineeringDistributor

The invention provides a novel glass powder sprayer which comprises a rack and further comprises a fluidization device, a vacuum generator and a powder distributor that are fixedly arranged on the rack, wherein the fluidization device comprises a fluidization powder storage box and a base arranged below the fluidization powder storage box; the base is internally provided with a fluidization compression pipeline; the fluidization compression pipeline is connected with an external compressed air pipeline; the fluidization compression pipeline is communicated with the fluidization powder storagebox; glass mold-proof partitioning powder is stored in the fluidization powder storage box; and a suction connector is arranged at the lower end of the vacuum generator and connected with a powder suction pipe in a sleeving manner. The invention further provides a working method of the novel glass powder sprayer, which particularly comprises the following steps: S1, opening a fluidization valve for fluidization treatment, and S2, turning on the vacuum generator, and conveying the fluidization powder storage box into the vacuum generator. The novel glass powder sprayer uniformly sprays atomizedpowder to the surface of glass through spray heads, is uniform in powder spraying, stable and reliable and reduces cost.

Owner:NANTONG VOCATIONAL COLLEGE

Toner supply supplementing container

PendingCN106873330AReduce and avoid agglutinationPrevent accumulation and cloggingElectrographic process apparatusMechanical engineeringComposite material

The invention discloses a toner supply supplementing container, which comprises a powder container, an auxiliary powder feeding frame, a stirring blade and a container cover, wherein the stirring blade is arranged in the auxiliary powder feeding frame which is clamped on the inner side of a container opening of the powder container, the outer side of the container opening of the powder container is covered and connected with the container cover through a buckle structure, a sponge sealing ring is arranged between a powder outlet cover and a powder outlet, the powder outlet is formed in the container cover, the powder outlet cover is arranged at the powder outlet, and powder outlet sponge is arranged between the powder outlet cover and the powder outlet. By all-point full contact and stirring of the stirring blade and the periphery, powder at the powder outlet part can be enabled to be fully transmitted for supply without any dead angle, and the inner wall is simultaneously cleaned, so that long-term accumulation and adhesion is prevented, and the flowability can also be improved. In addition, the powder discharge rate and the utilization rate are increased.

Owner:ZHUHAI CHINAMATE TECH

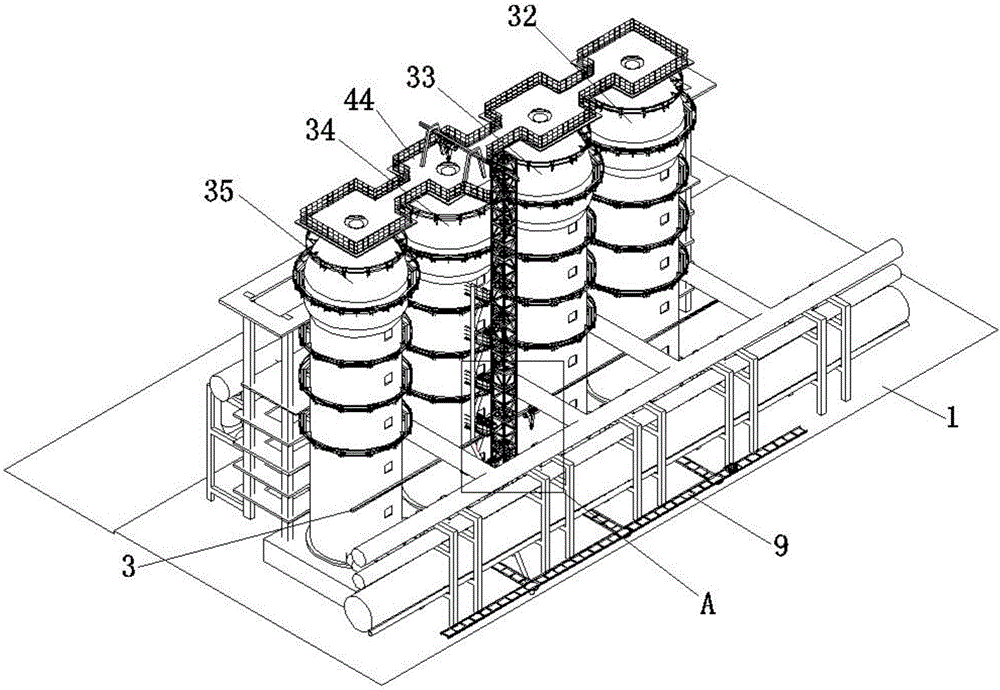

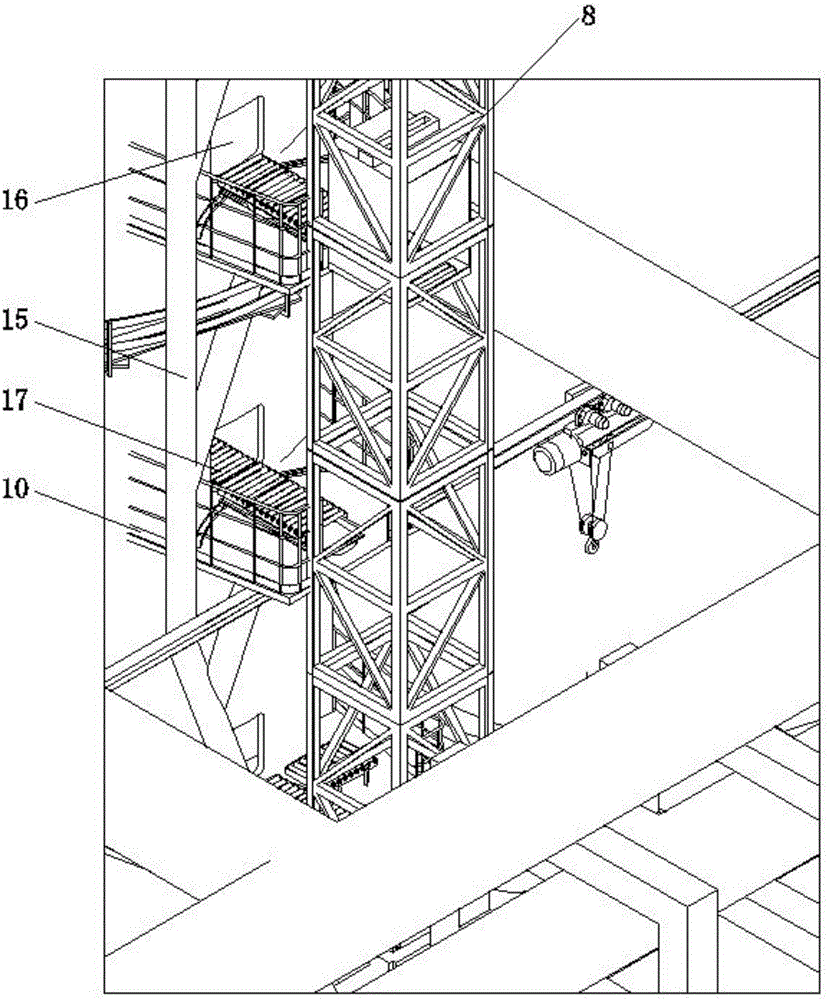

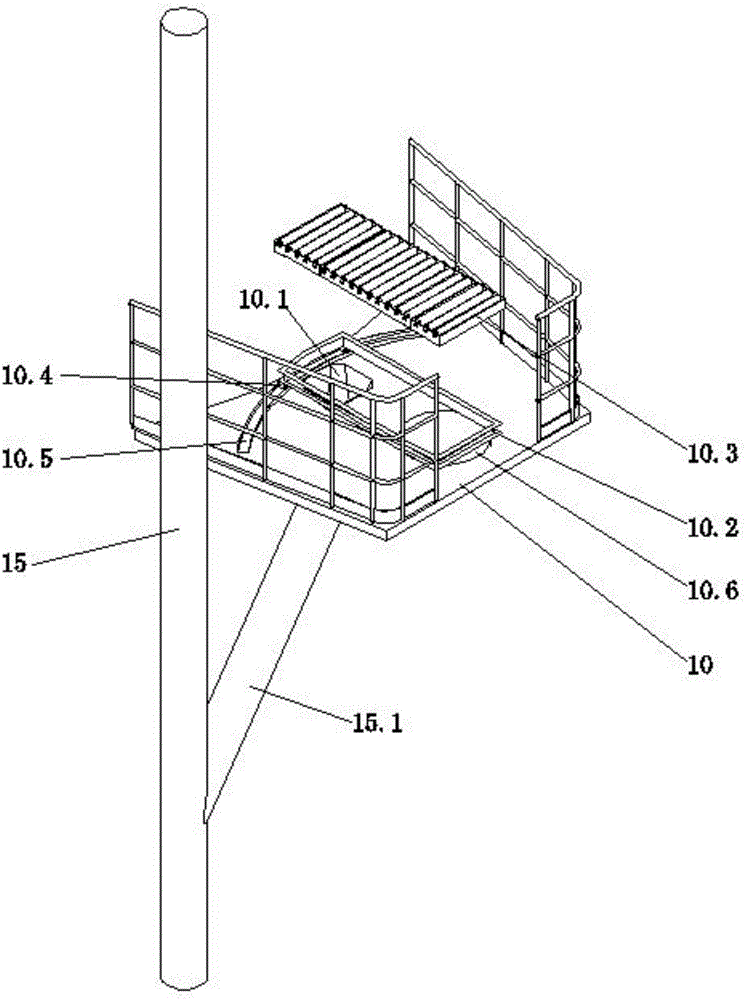

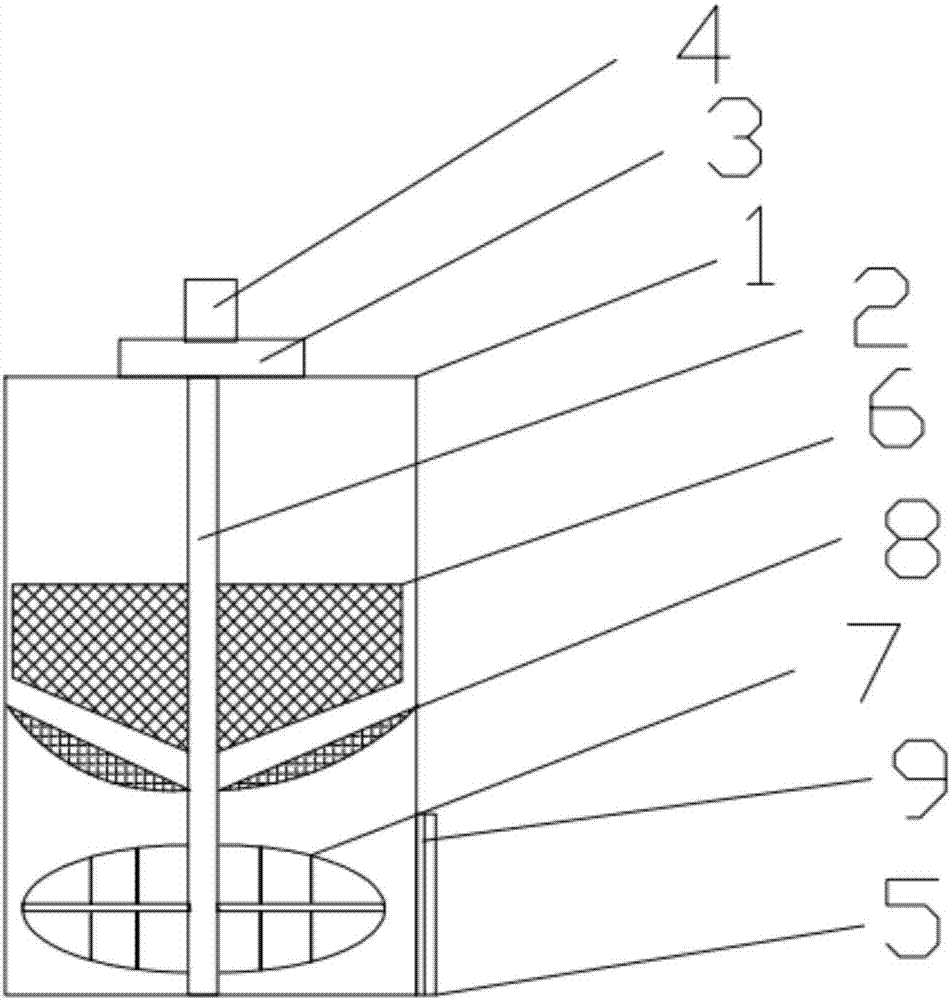

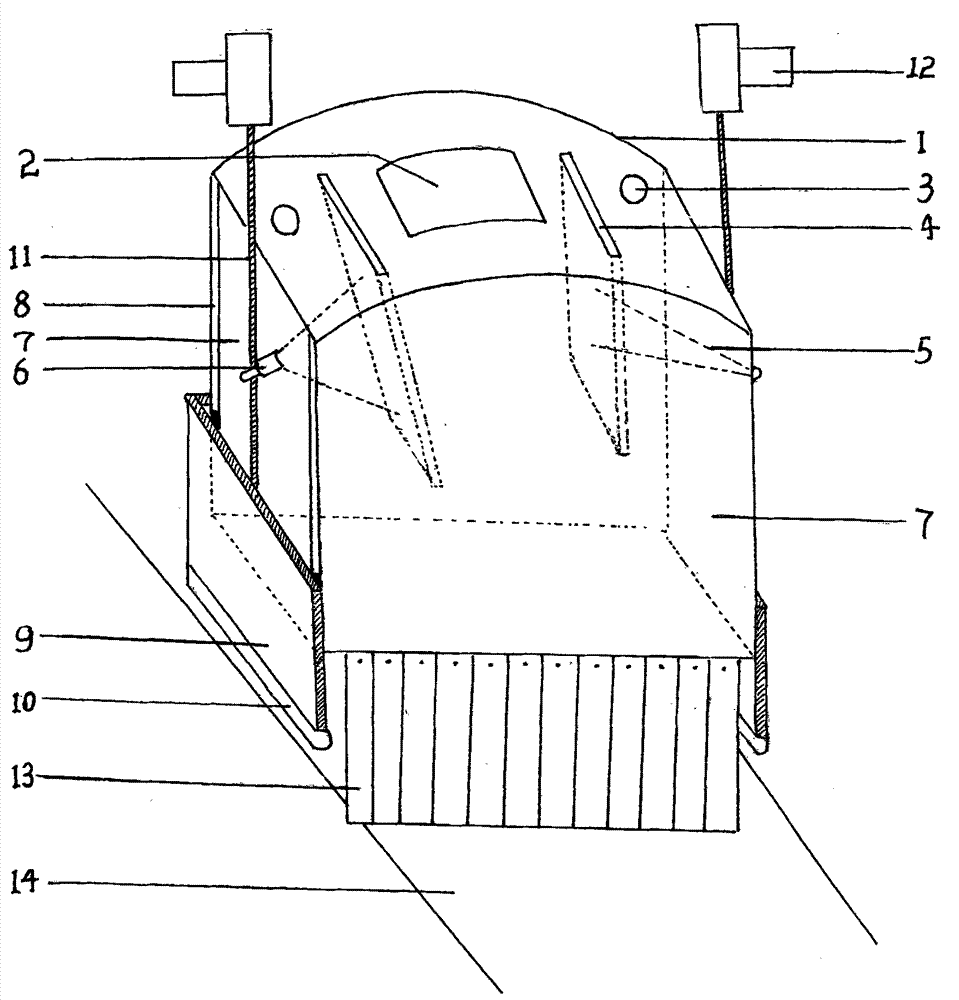

Online overhaul and refractory material transportation system for independent hot blast furnace and overhaul method

ActiveCN106766929AReduce maintenance costsImprove construction progressLinings repairRefractoryCold blast

The invention discloses an online overhaul and refractory material transportation system for an independent hot blast furnace. The online overhaul and refractory material transportation system comprises a furnace external transportation device located outside the hot blast furnace and a furnace internal hoisting device located inside the hot blast furnace; the furnace external transportation device mainly comprises a one-layer construction plane, construction platforms, an auxiliary vertical transportation mechanism and a vertical transportation mechanism; the construction platforms are built at the outer side of a construction hole of the hot blast furnace; a turnover platform is built below the construction platform at the bottom layer; the auxiliary vertical transportation mechanism is mounted above the turnover platform and is used for hoisting and transporting a refractory material on the one-layer construction plane to the turnover platform; and the vertical transportation mechanism is mounted at the outer sides of the construction platforms, the bottom of the vertical transportation mechanism is erected above a cold blast elbow pipe of the hot blast furnace, and an outlet / inlet at the lower part of the vertical transportation mechanism is located at the turnover platform. The invention also discloses an online overhaul method for an independent hot blast furnace. The online overhaul and refractory material transportation system has the beneficial effects that the furnace external transportation device is kept away from pipeline equipment at the lower part of the hot blast furnace, and furnace internal overhaul can be realized without dismounting the equipment of the hot blast furnace, so that the overhaul cost is reduced, meanwhile, the construction progress can be accelerated, and the production efficiency is increased.

Owner:CHINA FIRST METALLURGICAL GROUP

Stirring and mixing device for concrete process

InactiveCN108000714ASolve the problem of poor mixing effect and uneven mixingStir wellCement mixing apparatusSold ingredients supply apparatusEngineering

Owner:苏州卡斯迈金属科技有限公司

Anti-blocking adjustment device for net cage of dyeing machine

InactiveCN102899830AGuaranteed uptimePrevent accumulation and cloggingTextile treatment machine partsAgricultural engineeringDyeing

The invention discloses an anti-blocking adjustment device for a net cage of a dyeing machine. The anti-blocking adjustment device comprises an adjustment plate, an adjustment shaft and an adjuster. One end of the adjustment plate is hinged into the net cage of the dyeing machine, and the adjustment plate is connected with the adjustment shaft through at least one set of transmission parts. The adjustment shaft is rotatably arranged on the net cage of the dyeing machine, the adjuster is arranged at one end of the adjustment shaft and disposed outside a barrel of the dyeing machine, and an adjustment hand wheel is arranged on the adjuster. When the anti-blocking adjustment device for the net cage of the dyeing machine is needed, the adjustment hand wheel of the adjuster is rotated to drive the adjustment shaft to rotate, accordingly fabrics in the net cage of the dyeing machine are led to move smoothly by pushing the adjustment plate through a first connection rod and a second connection rod, and the anti-blocking adjustment device is convenient to operate and avoids fabric stacking and blocking in the net cage of the dyeing machine.

Owner:WUXI XINDA DYEING MACHINE FACTORY

Lifting type sealing and anti-blocking guide chute

InactiveCN103482336APrevent accumulation and cloggingEasy to set upConveyor partsChinese charactersPulp and paper industry

The invention discloses a lifting type sealing and anti-blocking guide chute which comprises a chute body, a material discharging port, a spray nozzle, a buffer board, an adjusting rod, an adjusting bolt, fixing baffles, sliding rails, a movable chute body, a sealing strip, a pull rod, a driving device, a dustproof curtain and a material receiving belt. The top cover of the chute body is of an arc shape, the material discharging port, the spay nozzle and the buffer board are arranged on the top cover of the chute body, the buffer board is supported through the adjusting rod, the adjusting bolt is arranged on the side wall of the chute body, the inclination of the adjusting rod is adjusted through the adjusting bolt to enable materials to be buffered and drop in correct positions, the sliding rails are arranged on the two sides of the chute body, the movable chute body is arranged on the lower portion of the chute body, the movable chute is shaped like a Chinese character 'ji' and formed by the baffles arranged on the two sides and the rear side of the chute body, the pull rod is arranged on the movable chute body, the sealing strip is arranged on the bottom of the movable chute body, and the pull rod is provided with the driving device. The lifting type sealing and anti-blocking guide chute prevents materials from stacking and blocking, is easy and convenient to set, and reduces dust and splashed material dregs brought by falling of materials.

Owner:山西永皓煤矸石发电有限公司

Waste plastic crushing and recycling device and method

PendingCN113334634APrevent accumulation and cloggingPrevent from causingPlastic recyclingMechanical material recoveryProcess engineeringMechanical engineering

The invention discloses a waste plastic crushing and recycling device and a method. The device comprises a crushing box, wherein a first-stage crushing cavity and a second-stage crushing cavity are formed in the crushing box, a first feeding opening is formed in one side of the first-stage crushing cavity, a second feeding opening is formed in one side of the second-stage crushing cavity, a discharging opening is formed in the side, close to the second feeding opening, of the bottom of the second-stage crushing cavity, and four supporting legs are connected to the bottom of the crushing box. According to the device, when a conveying assembly conveys waste plastics and large-size materials are conveyed on a conveying belt, small-size materials can fall on a sieve plate from material leakage gaps, excessive dust raising caused by excessive smashing of the small-size materials is prevented, a transmission part drives the conveying belt to work and meanwhile drives a shaking part to work, the sieve plate is shaken, accumulation and jam of the materials are prevented, the materials on the sieve plate enter the second-stage crushing cavity to be crushed, part of the materials fall into a recycling box from meshes of the sieve plate to be recycled, and the materials with smaller sizes are prevented from being excessively crushed.

Owner:HENAN VOCATIONAL COLLEGE OF APPLIED TECH

Automatic garbage recovery device and recovery method thereof

InactiveCN110813978ATo removeEasy to crush in cold zoneSolid waste disposalGrain treatmentsElectric machineryGarbage collection

The invention discloses an automatic garbage recovery device. The automatic garbage recovery device comprises a base, a feed box and a crushing box. A mounting rack is fixedly arranged at one end of the top of the base. The feed box is arranged on the top of the mounting rack. The bottom of the feed box is provided with a feed pipe. A cover plate is arranged in the position, on one side of the mounting rack, of the top of the base. The top of the cover plate is fixedly provided with supporting columns. Crushed garbage is fed into a collection box from the bottom of the crushing box and goes into a storage box through a transition pipe. The bottom surface of the storage box is an inclined plane, and a discharge port is arranged at the bottom of the inclined plane, so that the crushed garbage slides to the discharge port under the action of gravity and is discharged from the discharge port. Meanwhile, the output end of an unchoking motor drives an unchoking shaft to rotate, and unchokingblades on the unchoking shaft rotate to stir the crushed garbage to move, so that the crushed garbage can be discharged from the discharge port. The automatic garbage recovery device achieves the crushed garbage unchoking effect to protect materials against accumulation and blockage.

Owner:苏州德君环卫服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com