Patents

Literature

279results about How to "Easy to collect and clean up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water conservancy river channel silt removal device with silt and water separation function

InactiveCN107893440AEasy to collect and clean upPrevent accumulation and cloggingMechanical machines/dredgersSewageEngineering

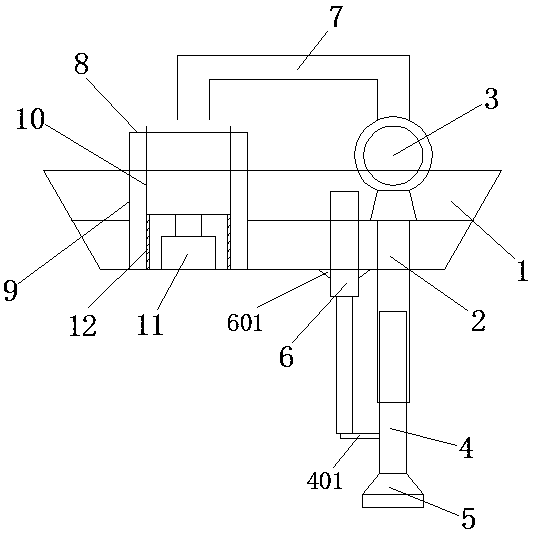

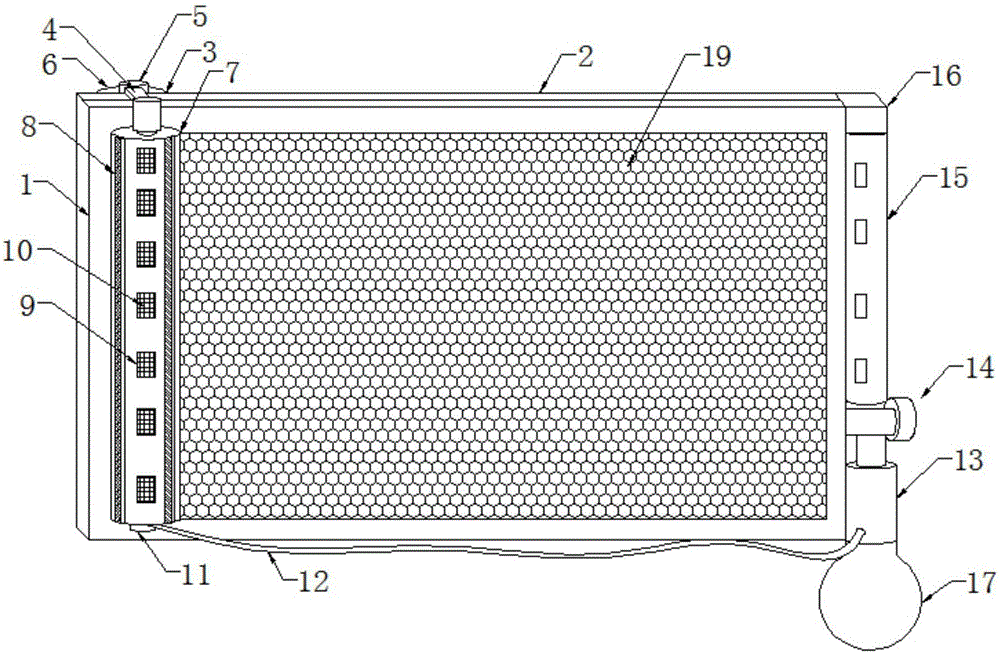

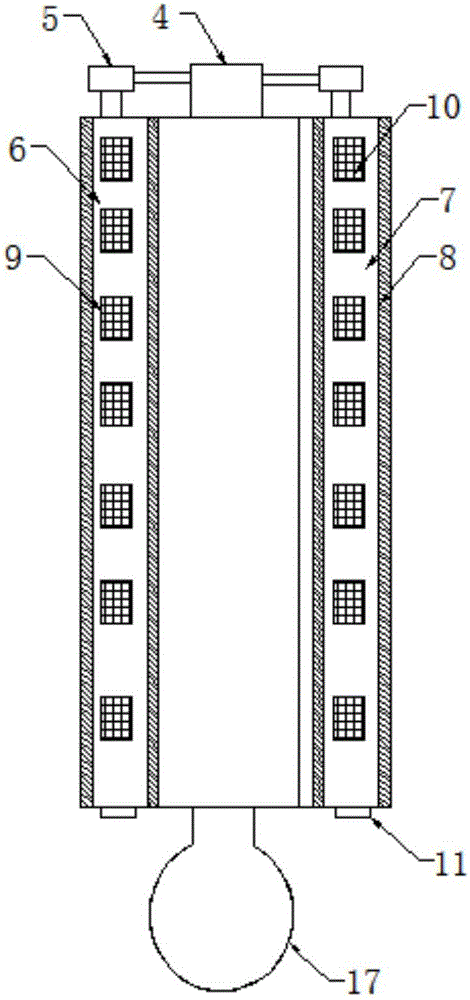

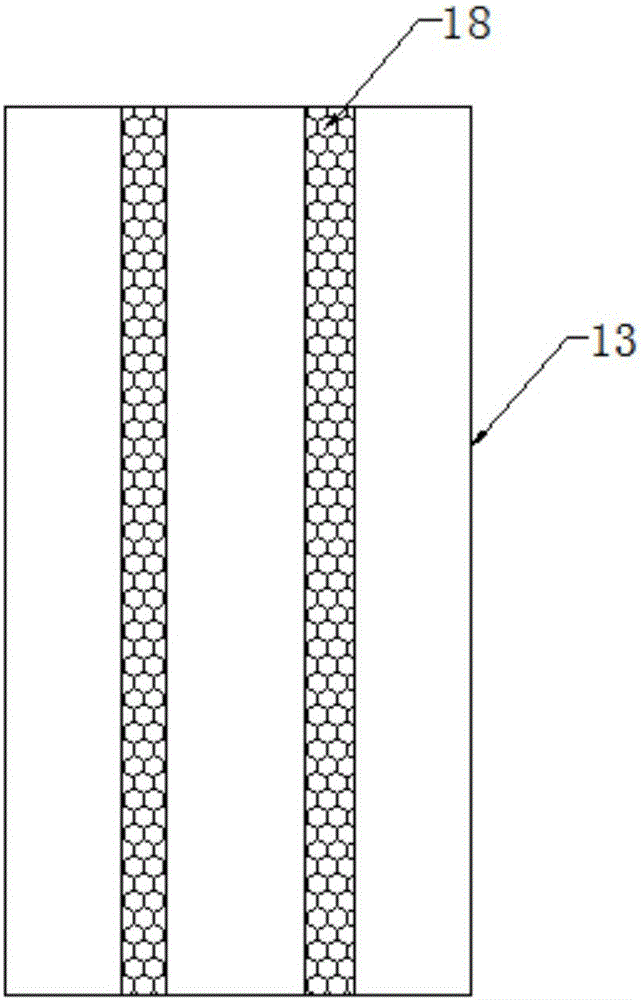

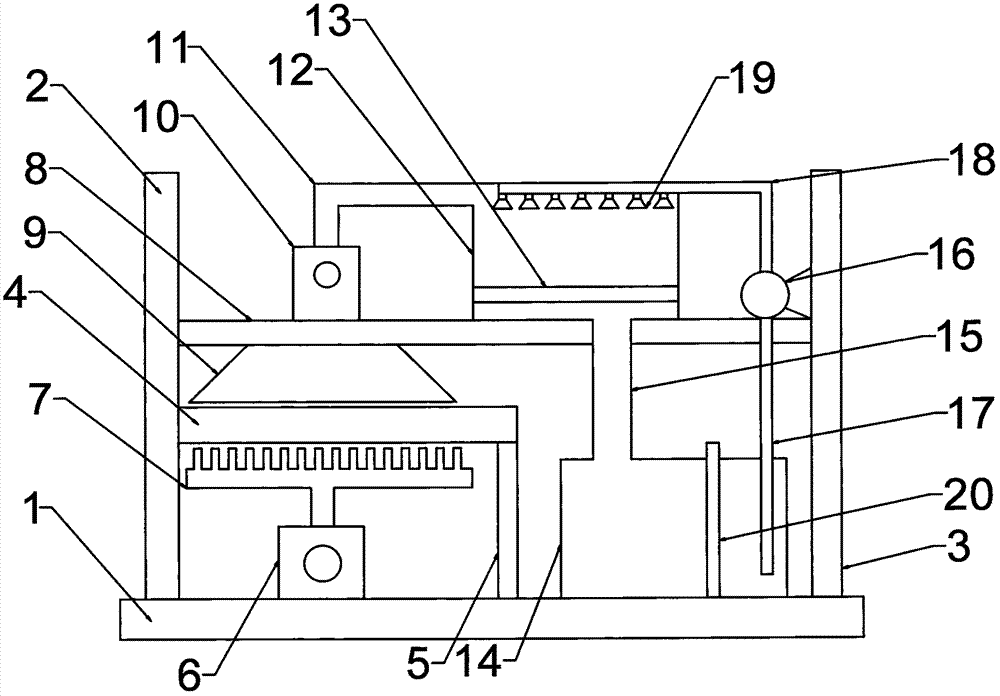

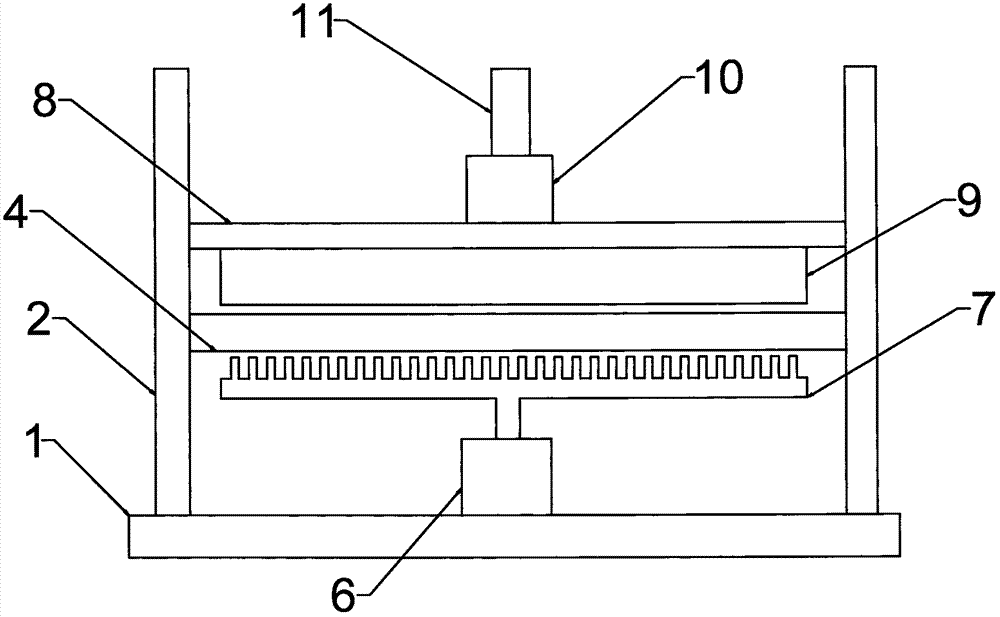

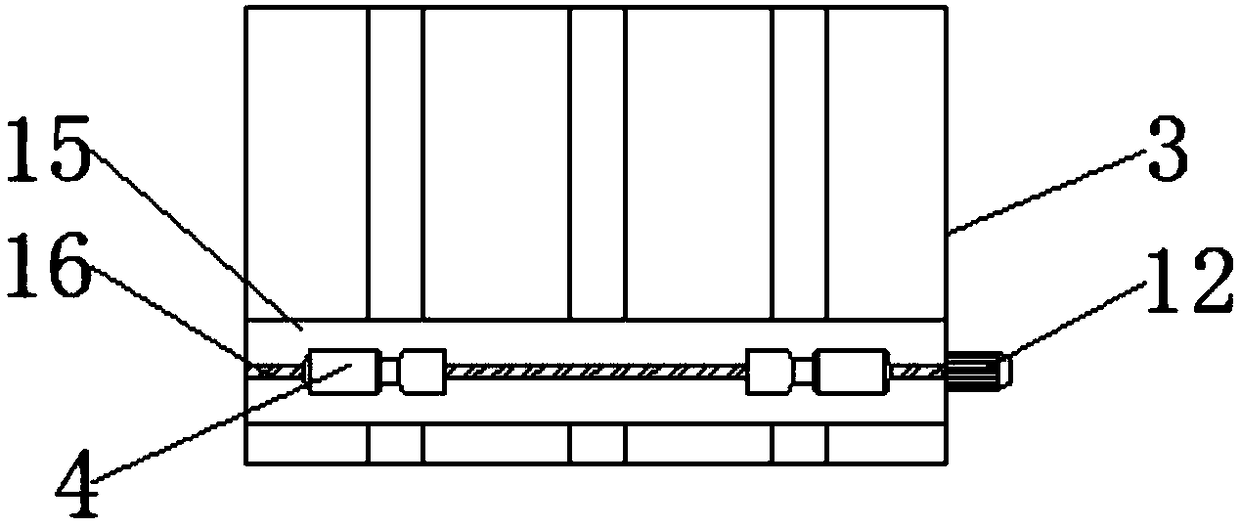

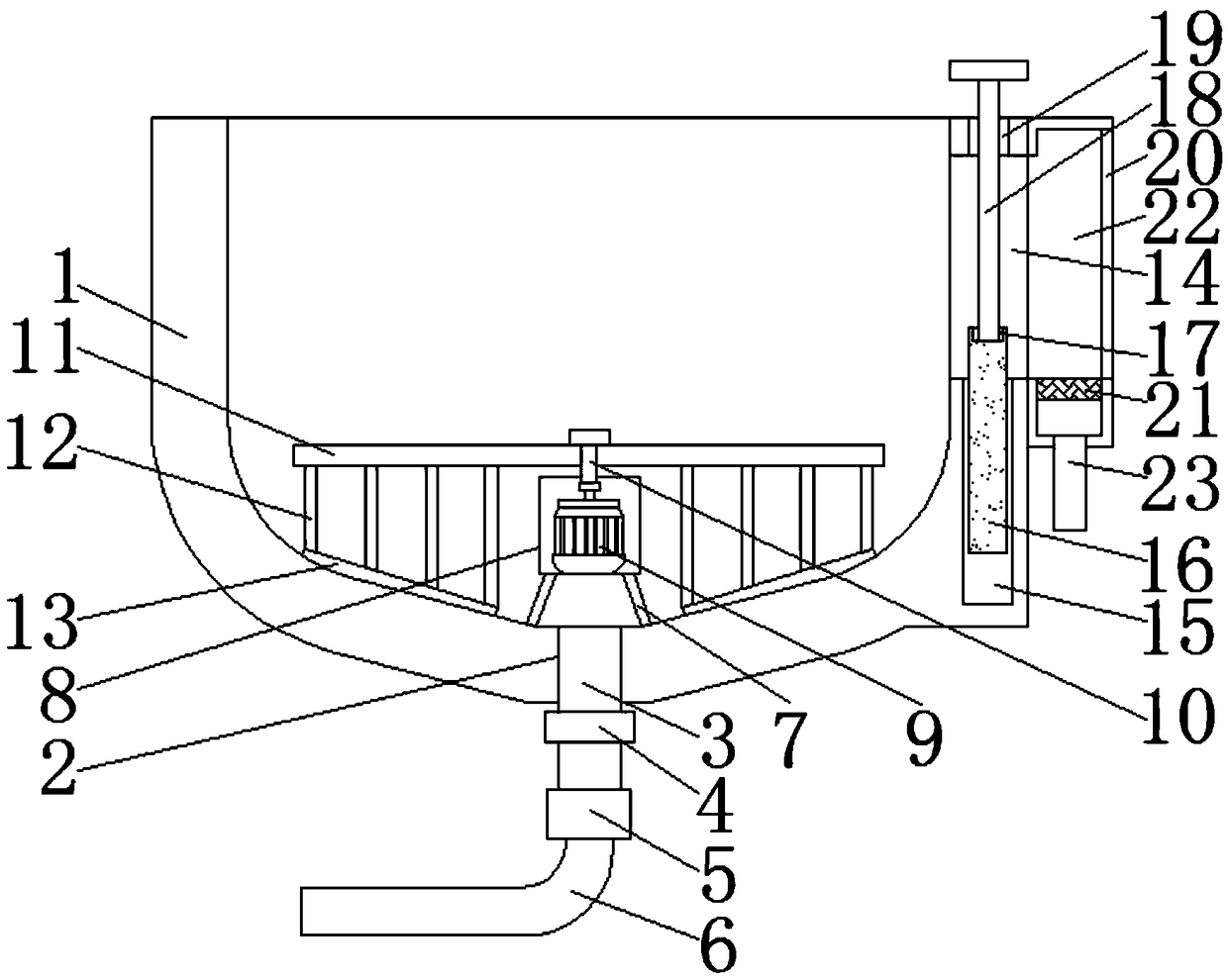

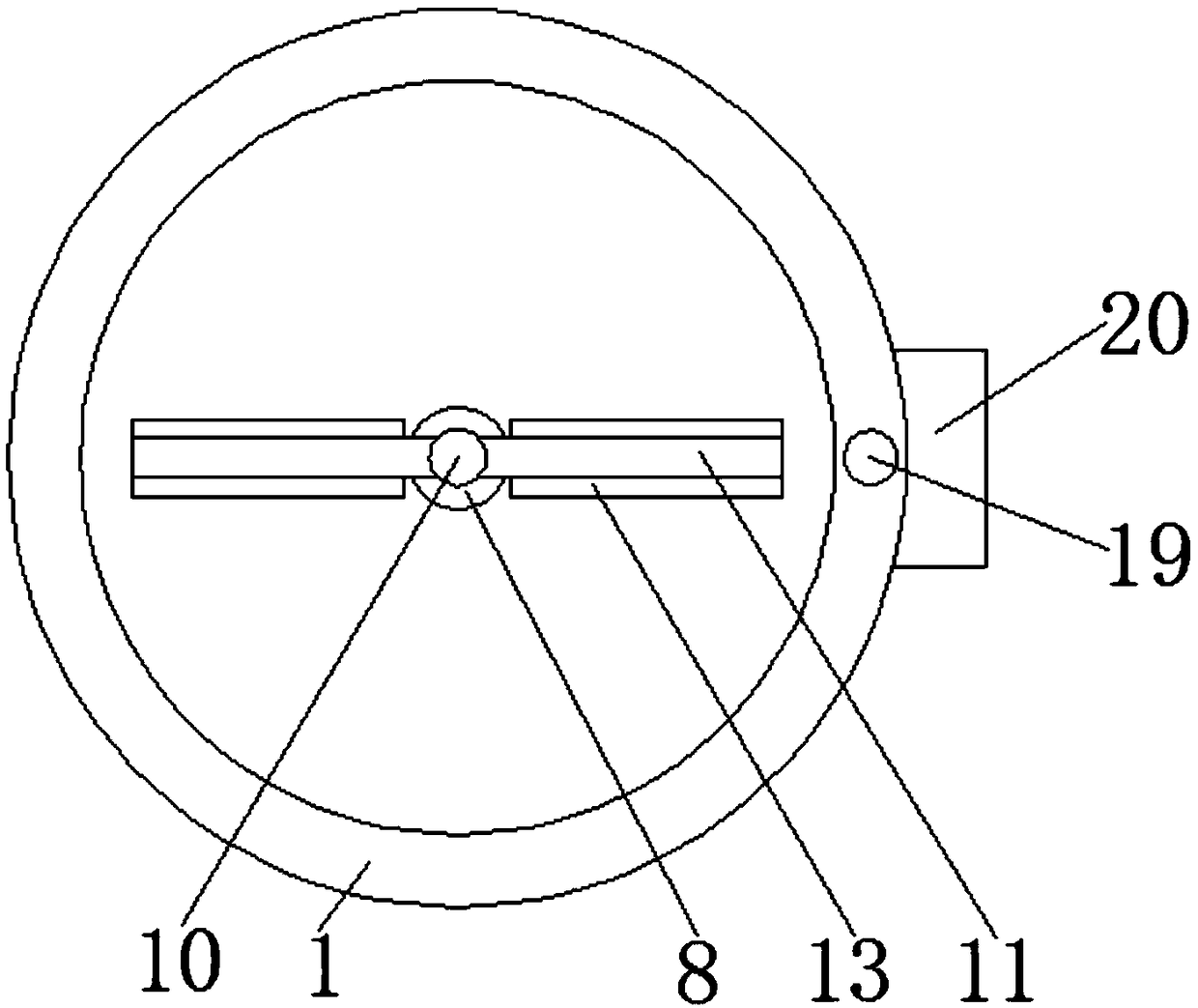

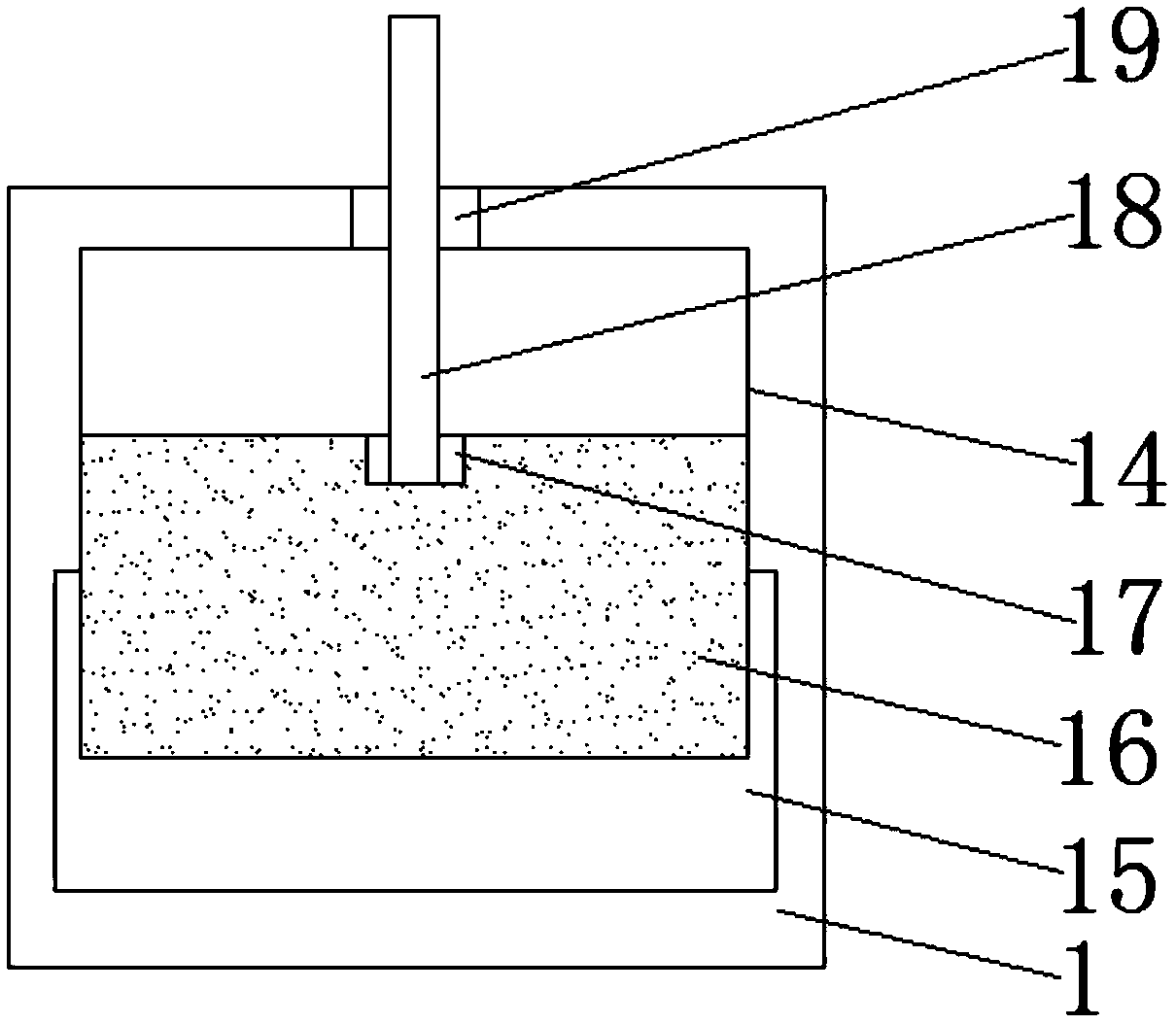

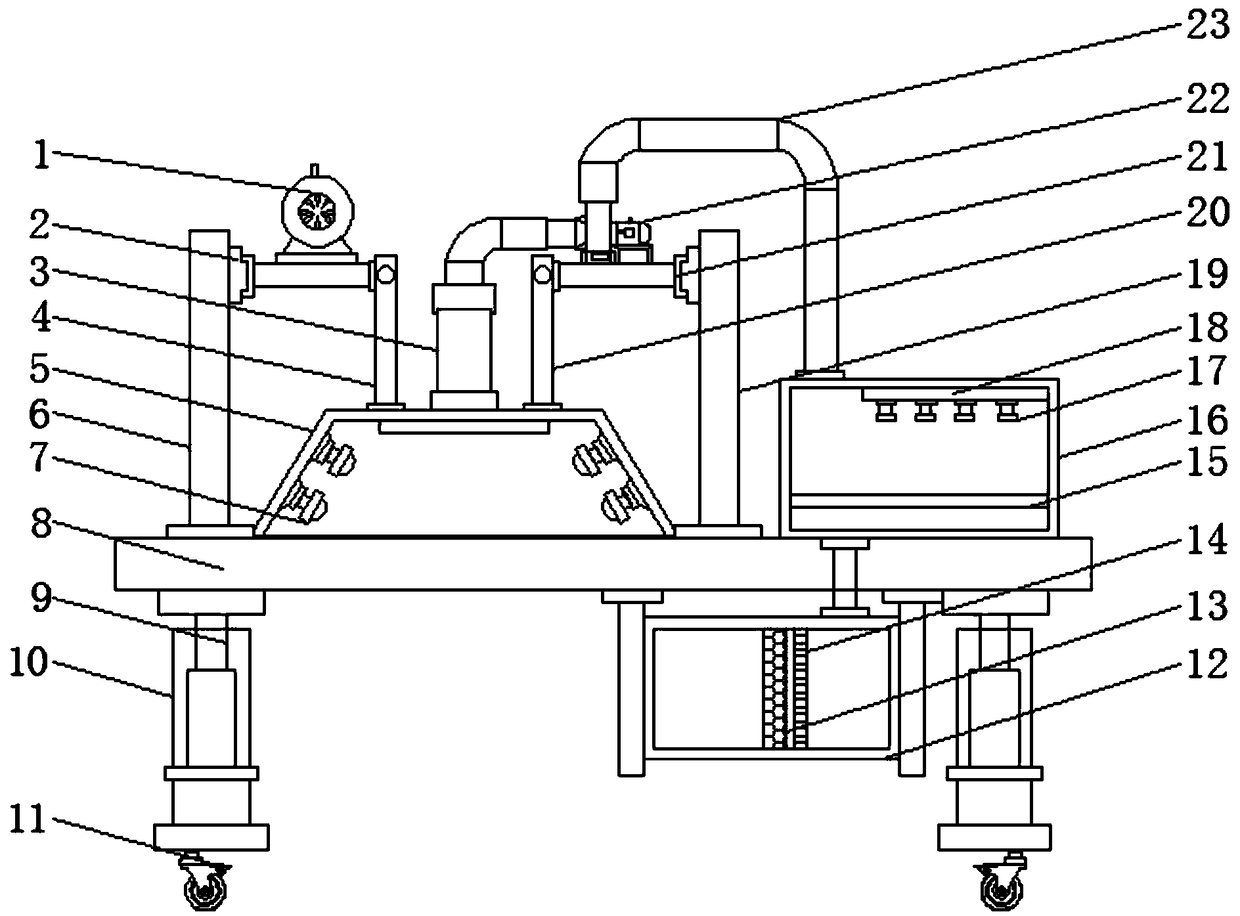

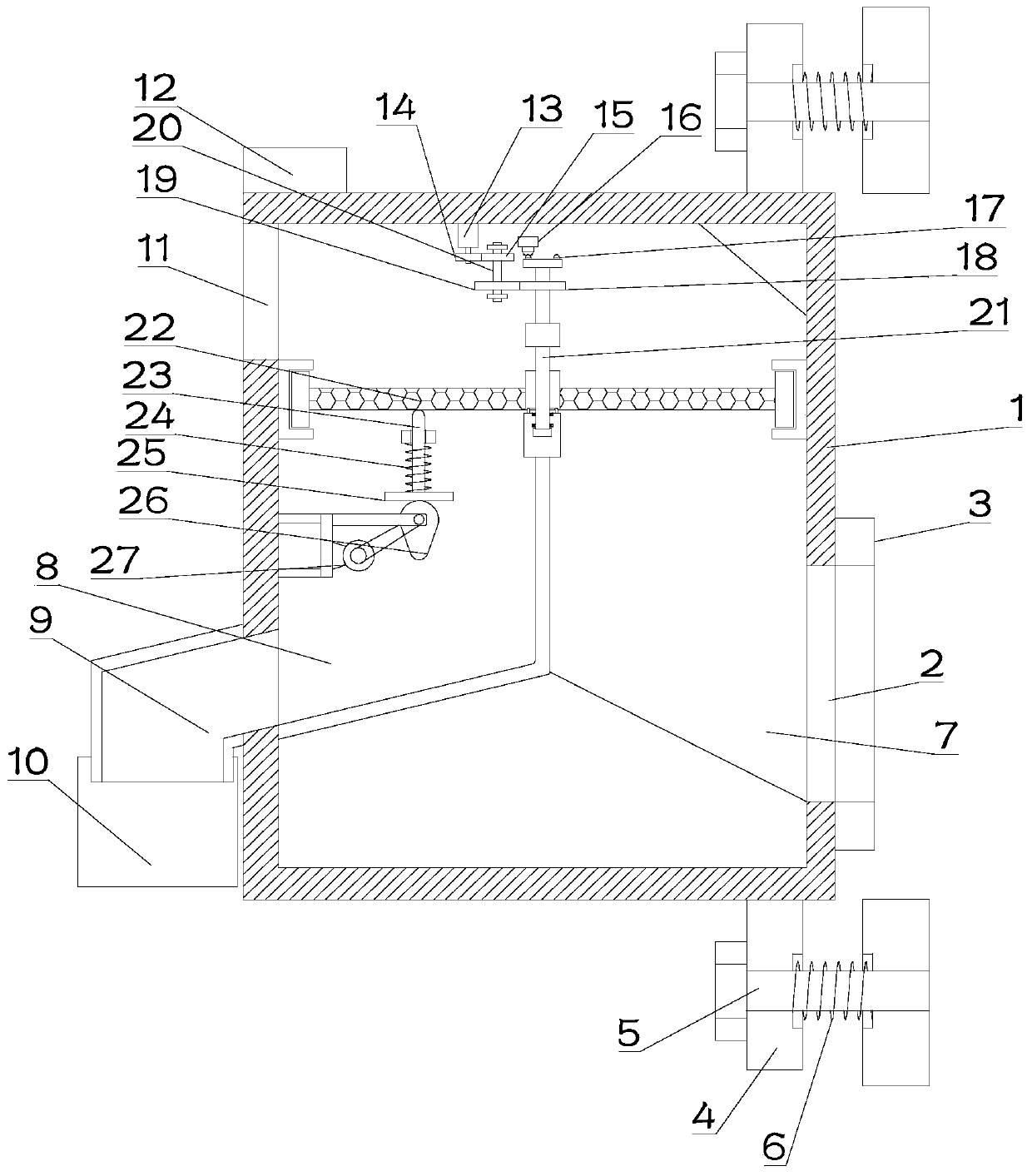

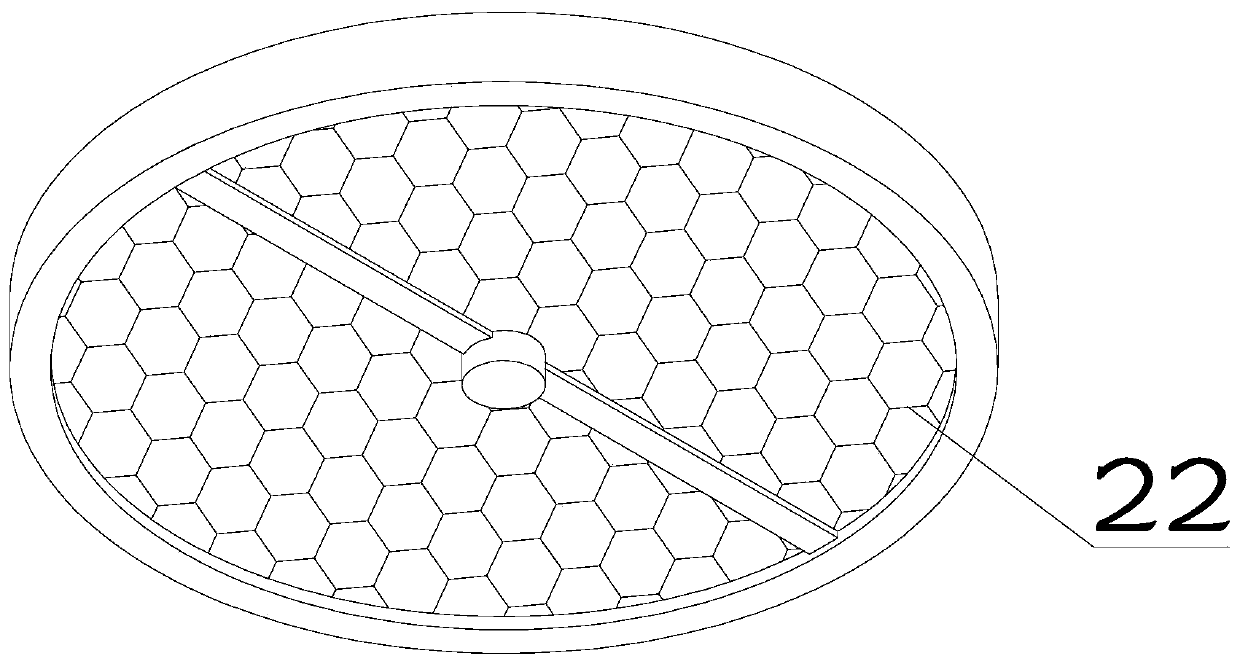

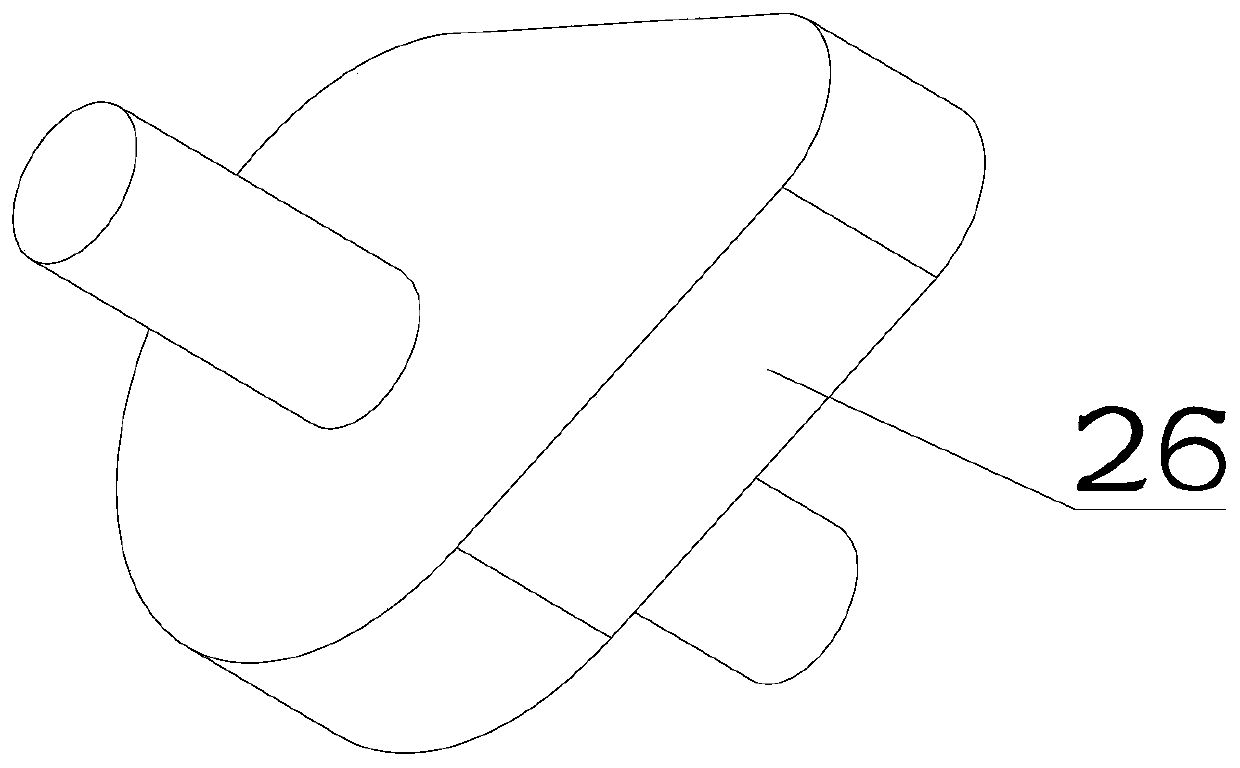

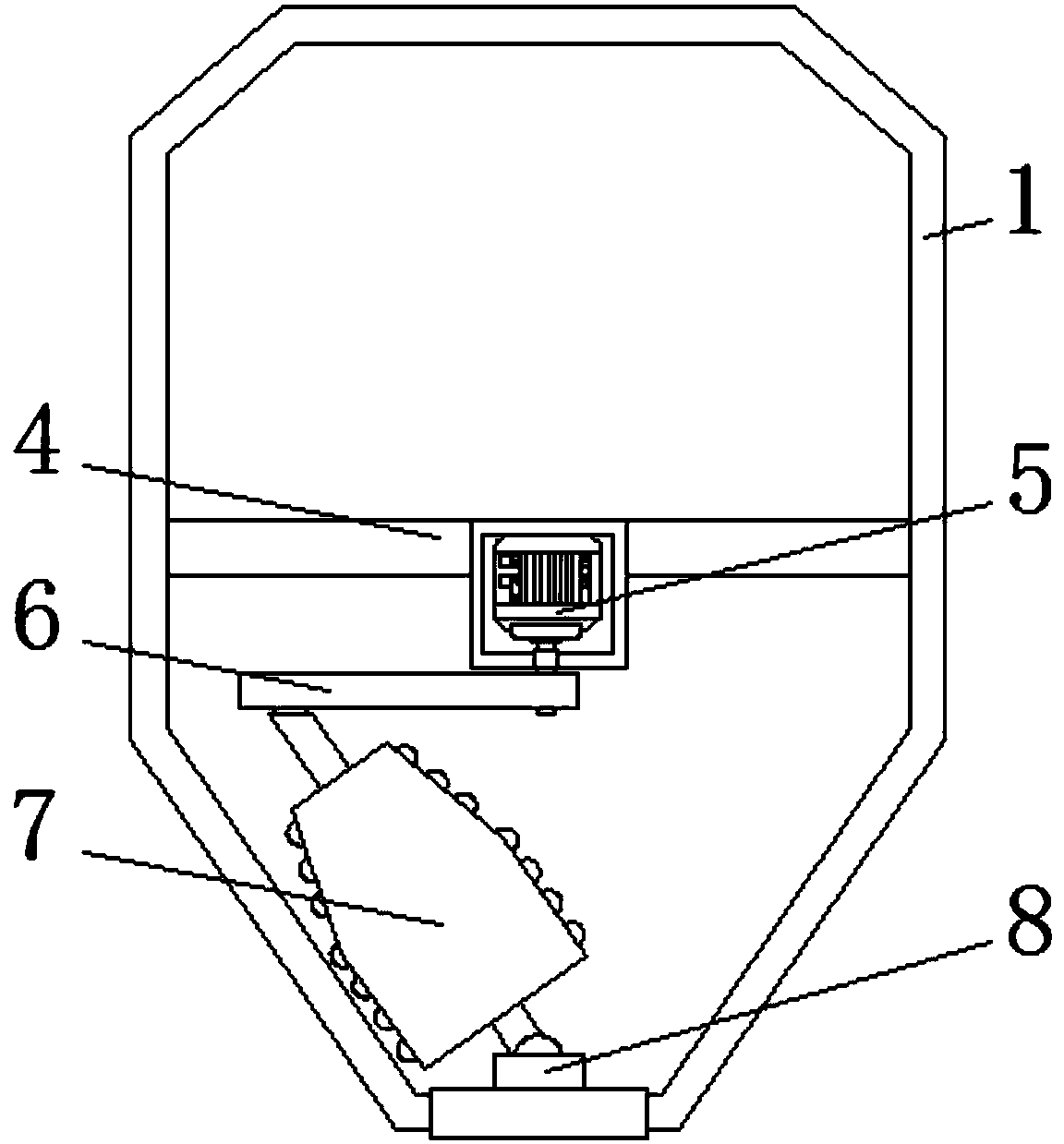

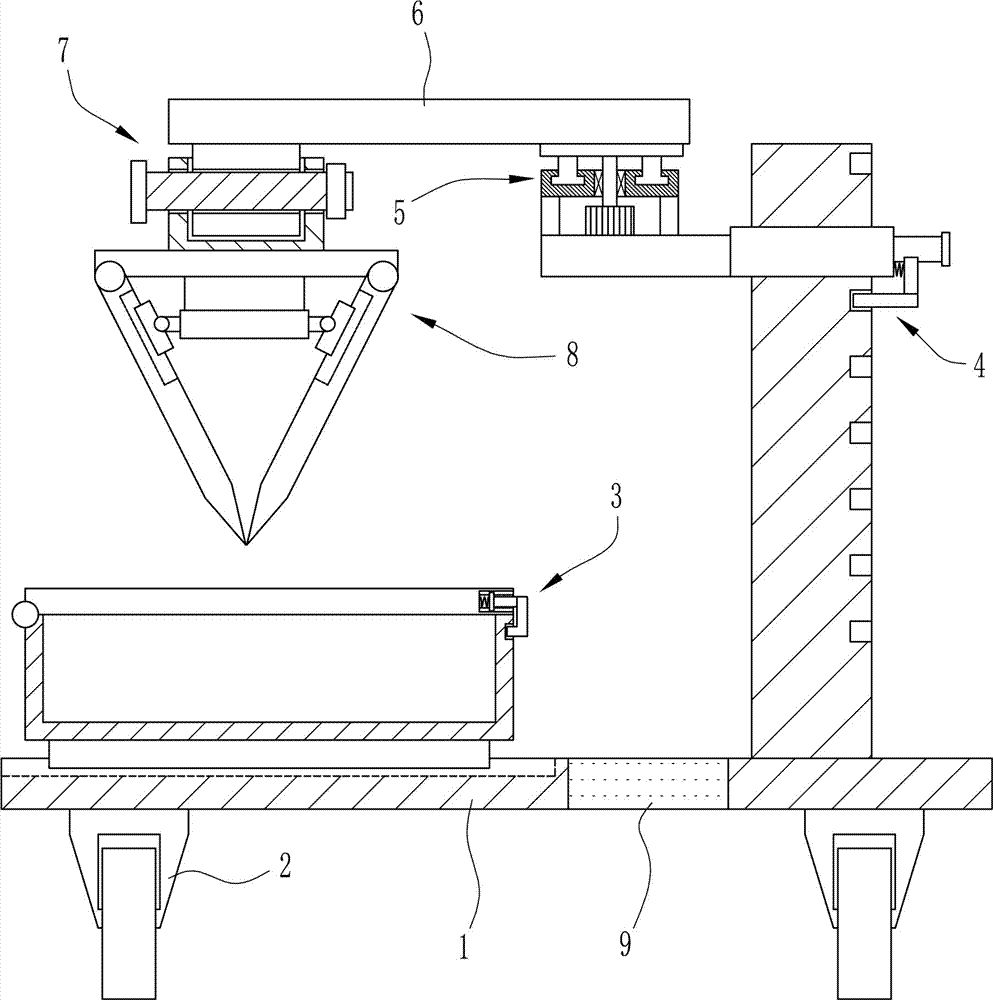

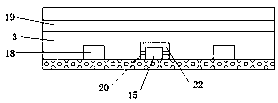

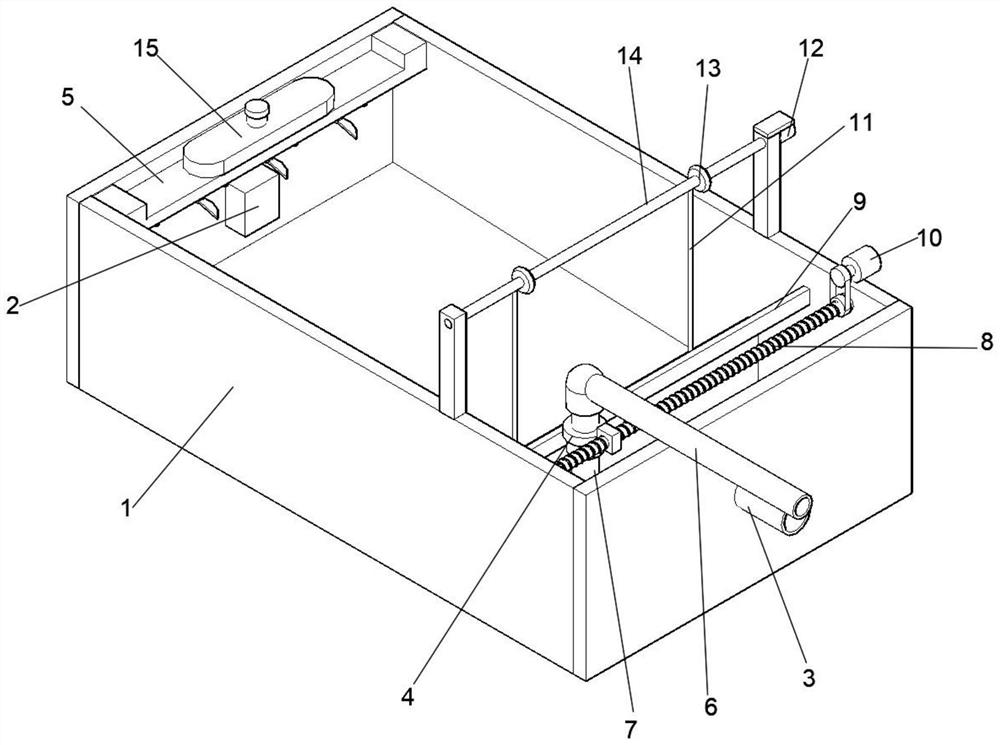

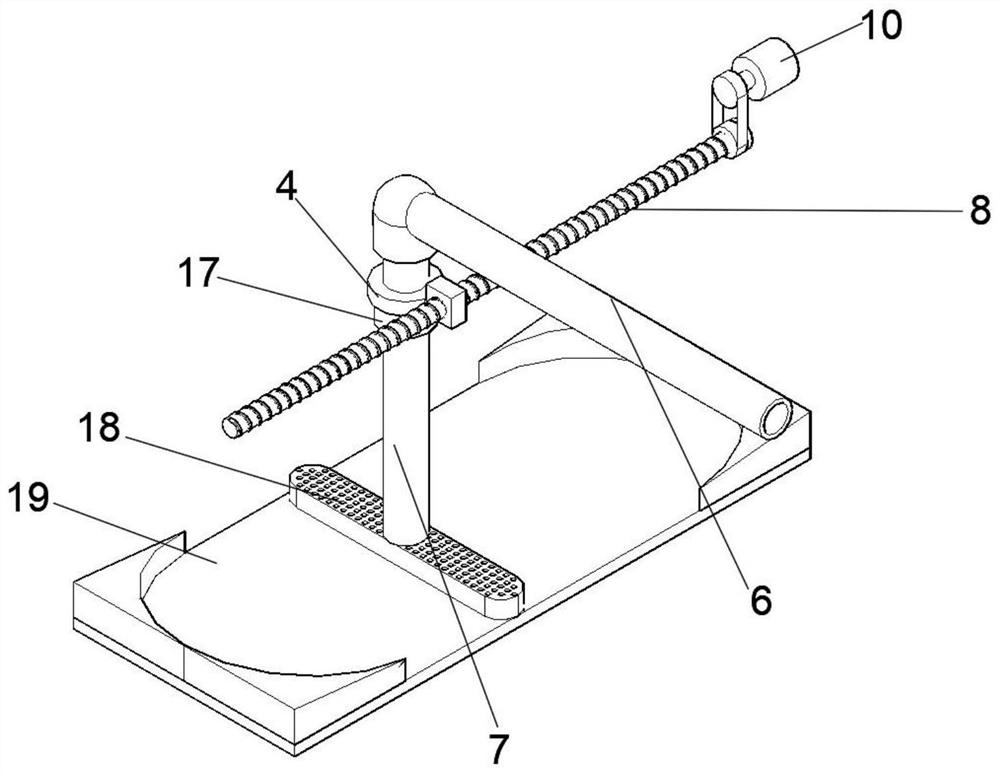

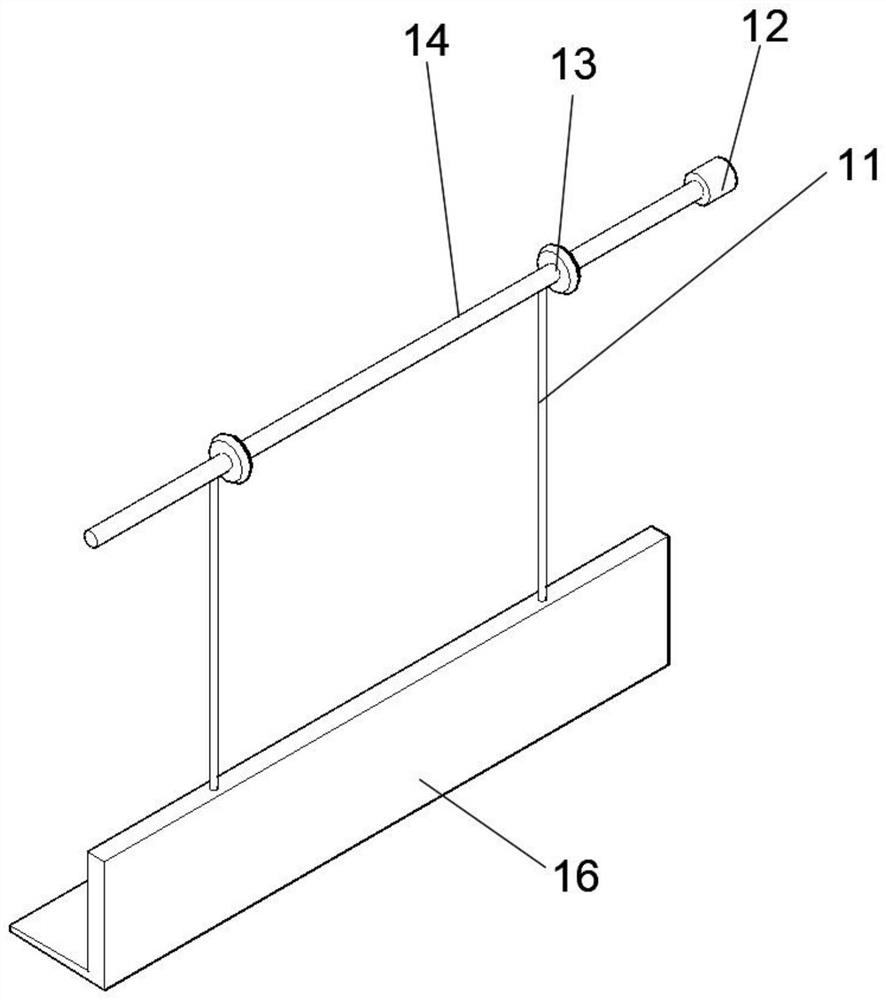

Disclosed is a water conservancy river channel silt removal device with a silt and water separation function. The water conservancy river channel silt removal device with the silt and water separationfunction comprises a silt removal ship, a silt removal pipeline and a silt removal pump, wherein the silt removal pipeline is arranged at the bottom of the silt removal ship, and the silt removal pump communicates with the silt removal pipeline. An extension pipe is arranged at the bottom end of the silt removal pipeline in a sliding and sleeving mode, a silt removal suction disc is arranged at the bottom end of the extension pipe, and a fixing plate is arranged on the side wall of the portion, close to the bottom end, of the extension pipe. A telescopic cylinder is perpendicularly arranged on the side, adjacent to the silt removal pipeline, of the silt removal ship, and the telescopic rod end of the telescopic cylinder is connected with the fixing plate to drive the extension pipe to perpendicularly stretch out of and draw back to the silt removal pipeline. A sewage discharging pipe is arranged in the outlet formed in the top of the silt removal pump, and a filtering drum which is used for conducting silt and water separation is arranged on the silt removal ship and located on the lower side of the outlet of the sewage discharging pipe. The water conservancy river channel silt removal device with the silt and water separation function is adjustable in length of the silt removal pipeline, is suitable for silt removal operation of river channels with different water depths, cantimely conduct separation of pumped silt and water, and enables silt to be conveniently discharged.

Owner:HENAN ZHIAO ELECTROMECHANICAL EQUIP INSTALLATION ENG CO LTD

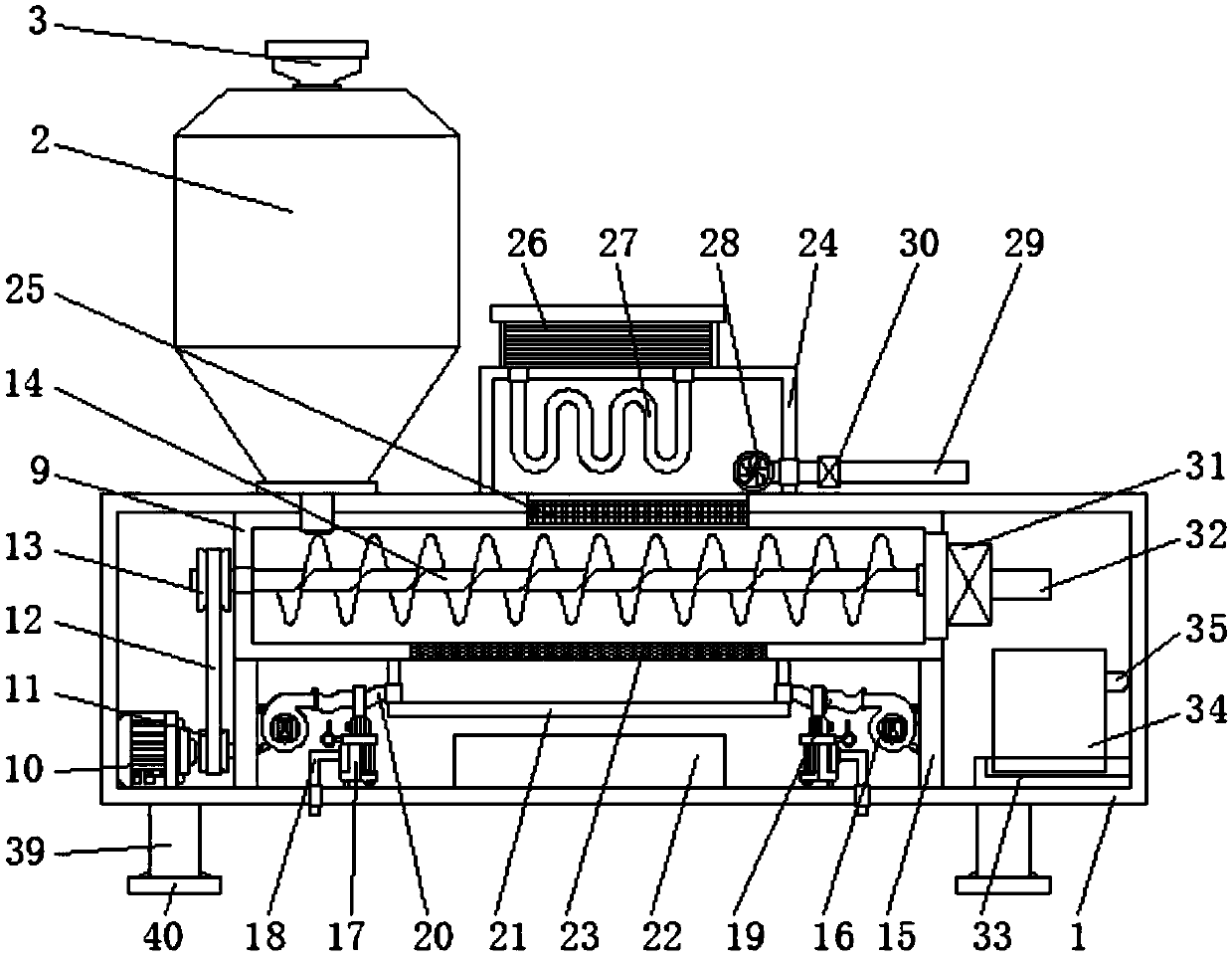

Low-temperature vehicle-mounted oil drilling fluid purifying system during drilling and repairing

ActiveCN101949271ACompact layoutFacilitate waste solid phase collection and disposalFlushingSolid phasesOil drilling

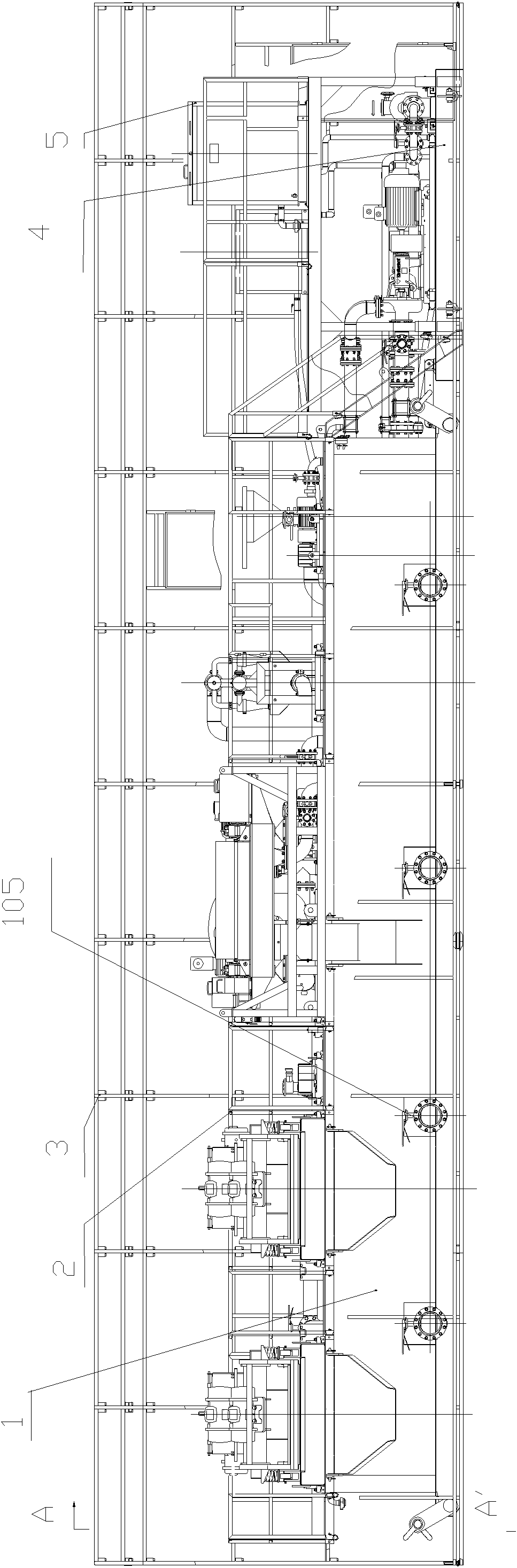

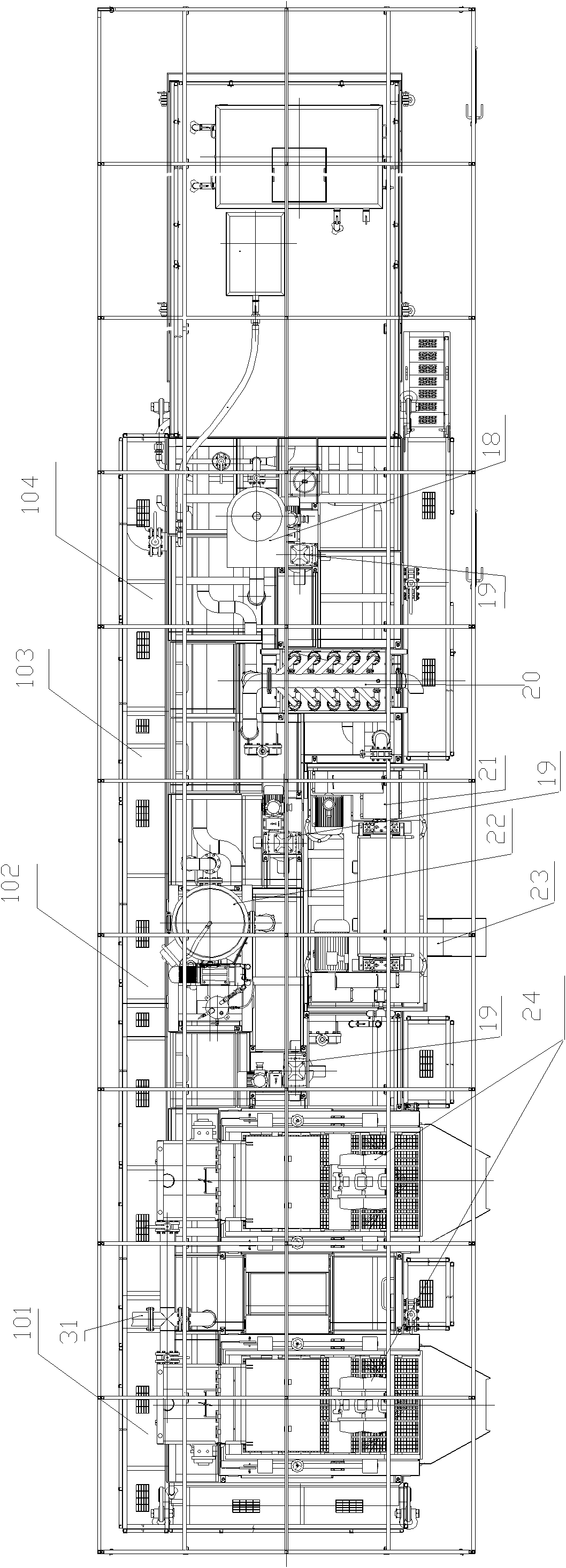

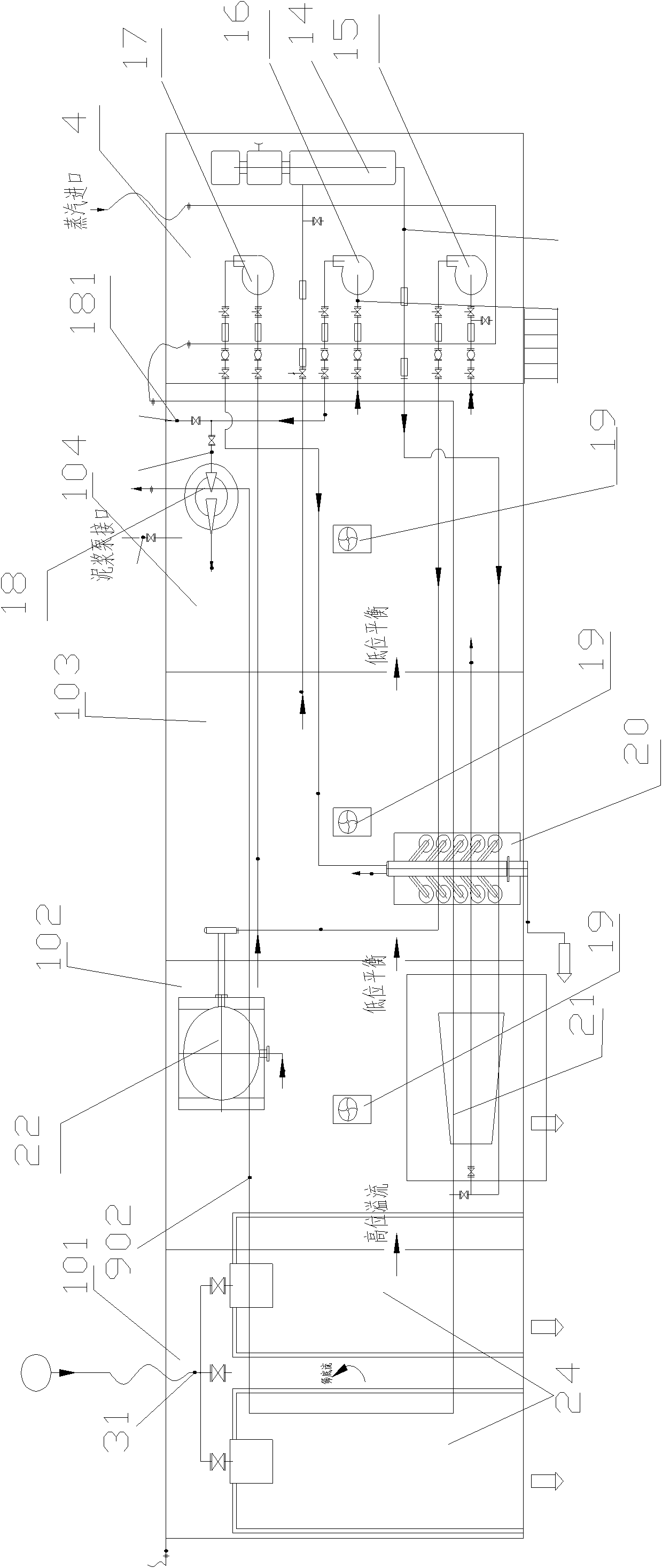

The invention discloses a low-temperature vehicle-mounted oil drilling fluid purifying system during drilling and repairing, which comprises a mud tank, a pump pry, solids control equipment, an equipment communicating pipeline, a cleaning hot water tank, a feeding tank and a steam heating pipeline, wherein a sand setting bin is communicated with a degassing bin through a high-level overflow; the degassing bin is communicated with a centrifuge bin and the centrifuge bin is communicated with a mixing bin respectively low-level overflow, communicating ports of all bins are provided with valves which can be closed, a degassing device and a high-speed centrifuge are arranged on the tops of the degassing bin and the centrifuge bin, the high-speed centrifuge is close to one side of the mud tank discharging the solid phase, and the degassing device is arranged on the tank surface the mud tank with far away from one side discharging the solid phase; a mud remover is arranged at the top of the centrifuge bin and one side closes to the degassing bin and is close to the high-speed centrifuge in parallel. The invention has the advantages of integration, compact layout, convenient and rapid disassembly and assembly, rapid movement and concentrated residual removal; and in order to adapt to the cold environment, steam heating pipelines are arranged at the bottom of the mud tank, and on a water tank and the pump pry.

Owner:CHENGDU WEST PETROLEUM EQUIP

Automatic cleaning device for filter screen of air conditioner

InactiveCN106839186AEasy to clean automaticallyImprove cleaning efficiencyMechanical apparatusDispersed particle filtrationEngineeringHigh pressure

Owner:SHENZHEN WOHAISEN TECH CO LTD

Cross-linked polyethylene insulated low-smoke halogen-free flame-retardant power cable special for rail transit

ActiveCN111864652AWon't breakEasy to collect and clean upPower cables with screens/conductive layersInsulated cablesLow smoke zero halogenPower cable

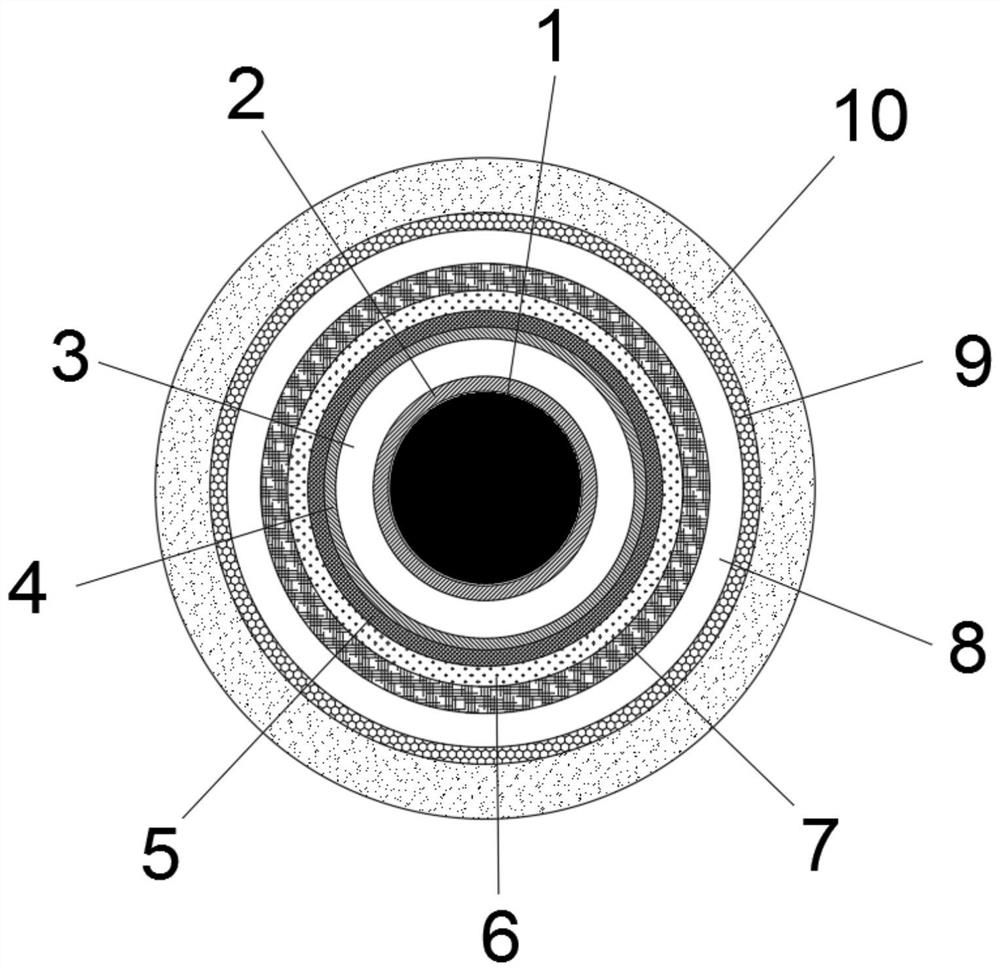

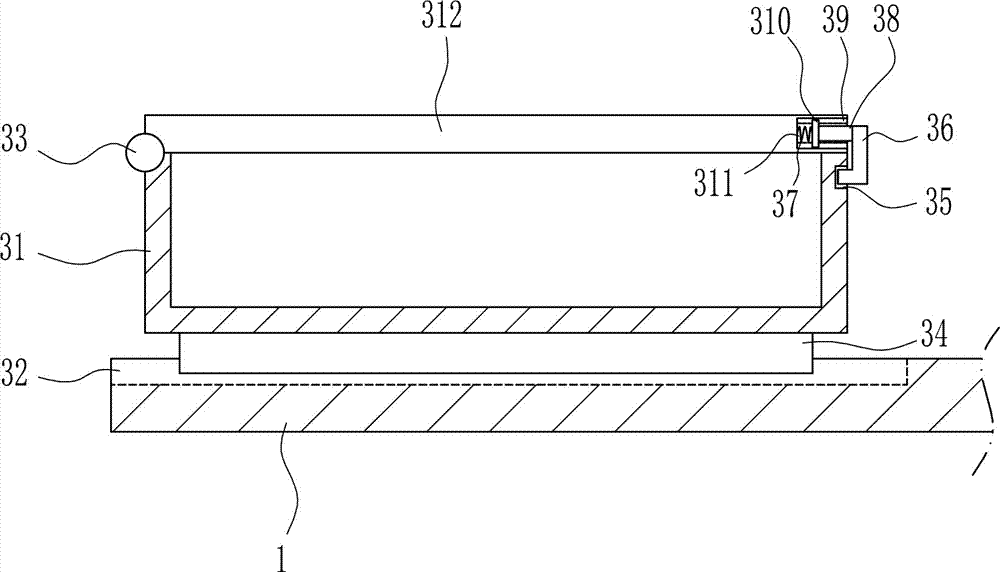

The invention discloses a cross-linked polyethylene insulated low-smoke halogen-free flame-retardant power cable special for rail transit. The power cable comprises a conductor, and a conductor shielding layer, an insulating layer, an insulating shielding layer, a metal shielding layer, a water blocking layer, an aluminum-plastic composite belt, an inner protective layer, a steel wire armor layerand an outer protective layer are sequentially wrapped on the outer side of the conductor. By arranging a skin prying plate and rolling wheels, one end of the outer protective layer is clamped and fixed through one-way rotation of the rolling wheels, the outer protective layer is torn and separated in the cutting process, the outer protective layer cannot be broken in the tearing and separating process, and collection and cleaning are easy; an adjusting sliding block and a threaded rod are arranged; the threaded rod is used for adjusting the adjusting sliding block; the adjusting sliding blockmoves in the adjusting sliding groove which is obliquely formed, then the cutting depth of the cutting blade is controlled, it is avoided that due to the fact that a notch is too shallow, the outer protective layer is inconvenient to strip or the internal structure of a cable is damaged due to the fact that the notch is too deep, the stripping time of the outer protective layer of the cable is greatly saved, and meanwhile the risk that workers are injured is reduced.

Owner:ANHUI HANGTIAN CABLE GROUP

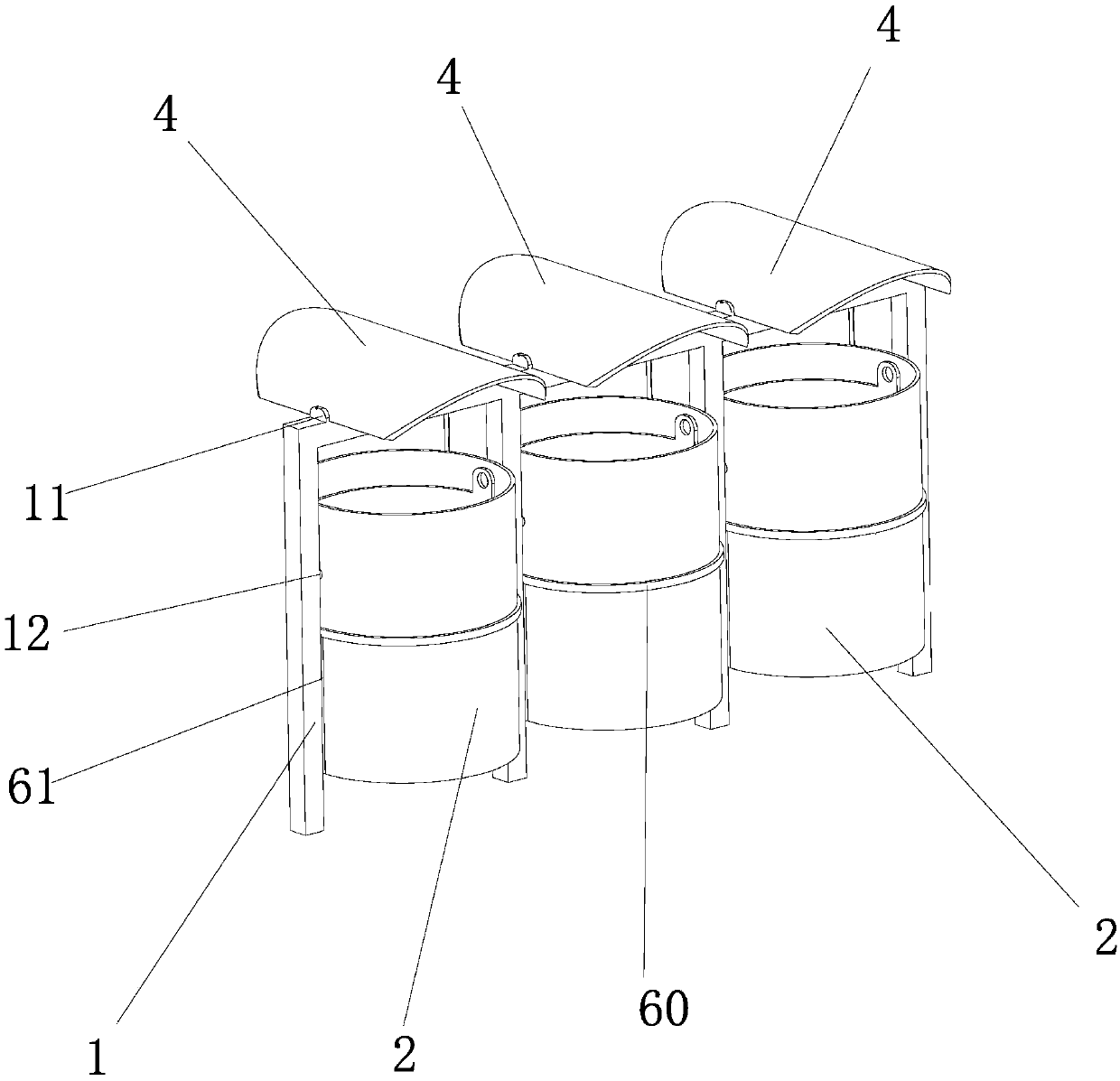

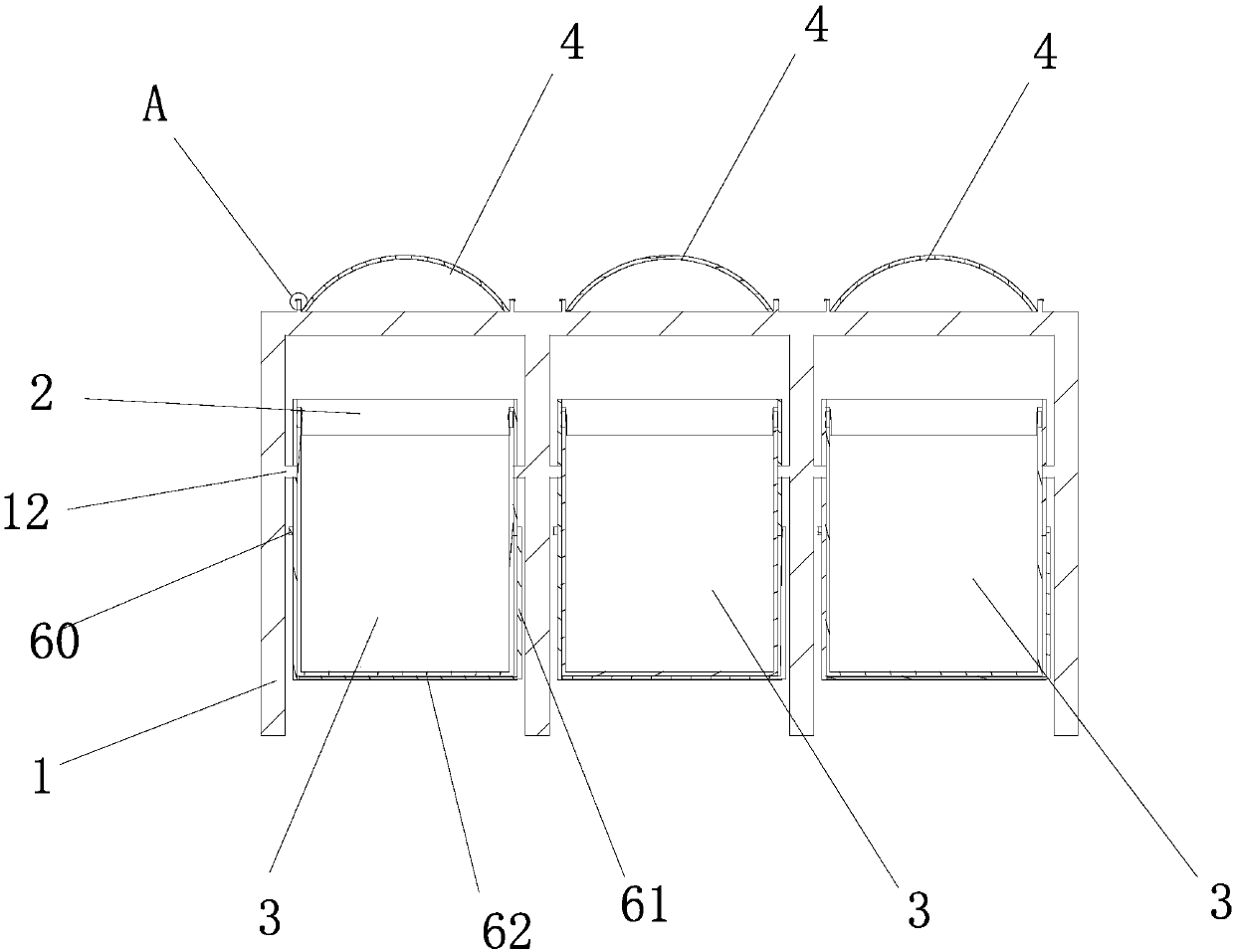

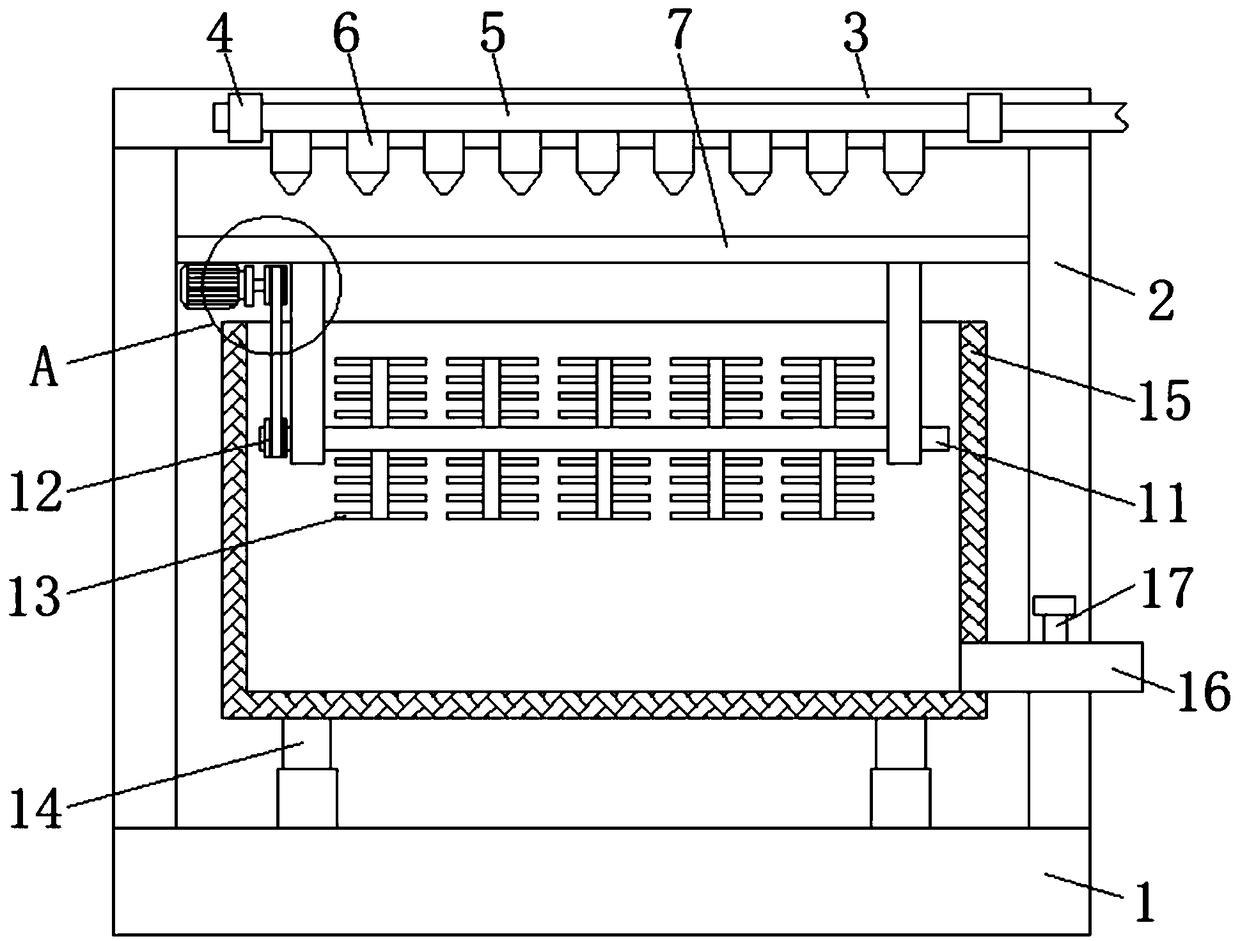

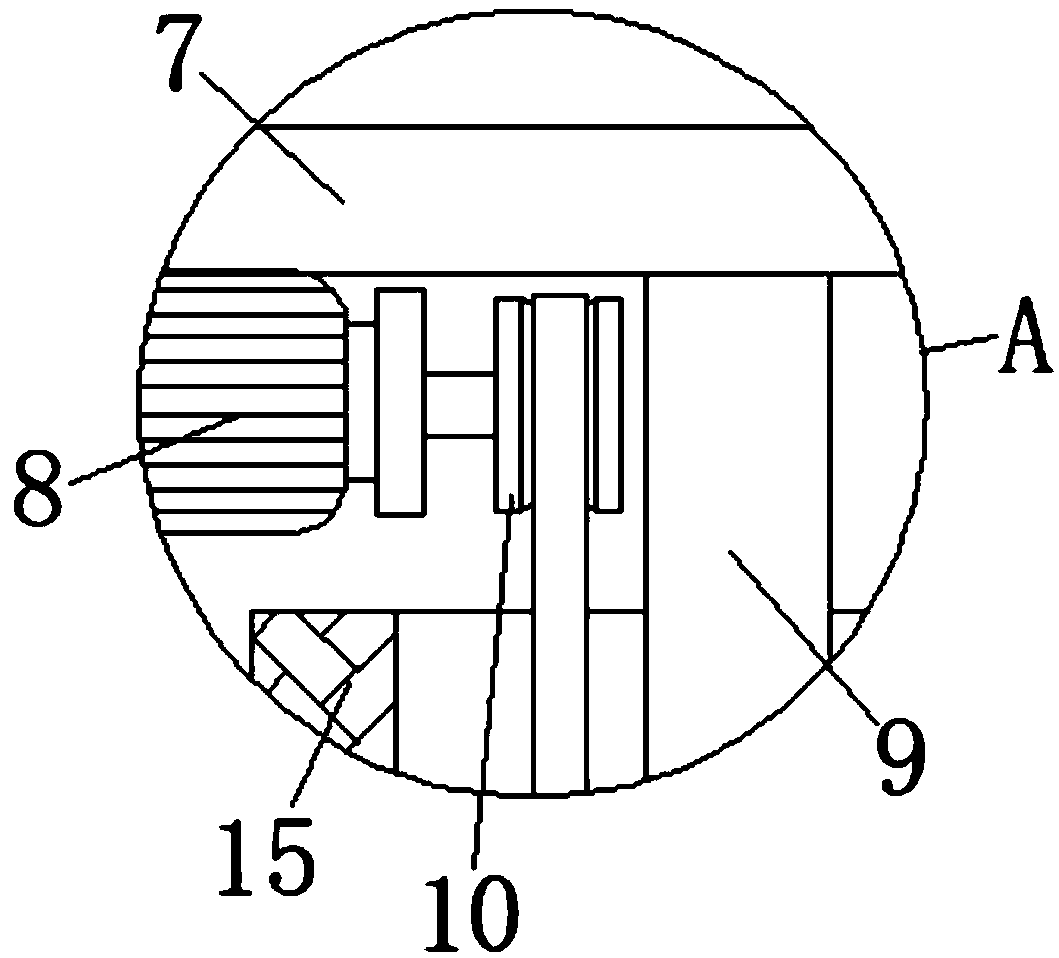

Aluminum product continuous punching mechanism

InactiveCN108787856AEasy to assemble and disassembleReasonable structural designMetal-working feeding devicesStripping-off devicesPunchingEngineering

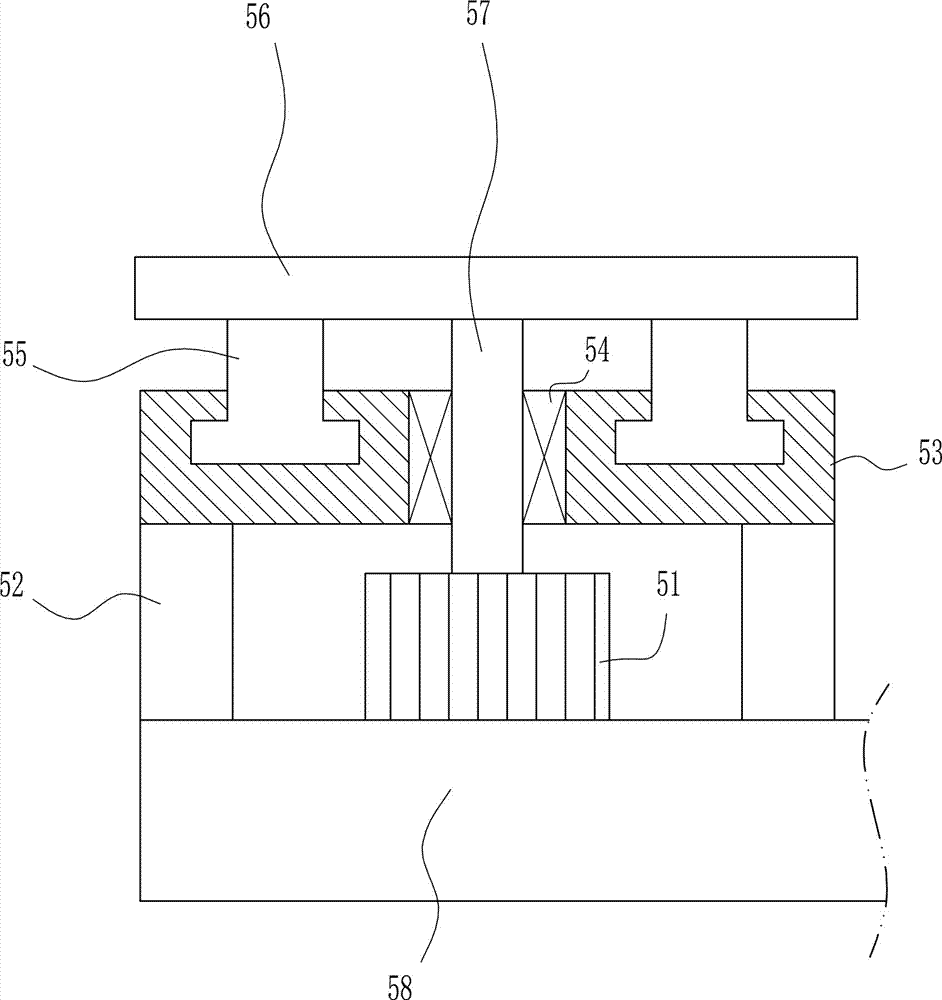

The invention discloses an aluminum product continuous punching mechanism and belongs to the field of sectional material machining equipment. Rotating roller brackets on the two sides of a space belowa material conveying bracket are rotationally connected with material guide rotating rollers; a plurality of punching brackets are arranged on a horizontal movement guide rod in a sliding manner in the horizontal direction; punching pressure rods are vertically and fixedly arranged at the middle parts of the lower sides of adjusting guide plates; a punching pressure plate is horizontally and fixedly arranged on the lower side of a lifting pressure plate; rotating pressure rods are correspondingly and vertically arranged at the parts, on the two sides of a space above the lifting pressure plate, on the material conveying bracket; pushing rod cams are arranged at the parts, on one sides of the rotating pressure rods, on the material conveying bracket; and the output end of a rotary electromagnet is in transmission connection with the pushing rod cam on one side of the material conveying bracket by a punching belt. The structural design is reasonable, aluminum products can be subjected to punching machining conveniently, rapidly, stably and efficiently in the conveying process according to the requirement, scratched marks on the surfaces of the aluminum products in the machining process can be avoided, the punching machining efficiency and the punching machining quality of the aluminum products are improved, and the machining and using requirements are met.

Owner:蔡燕

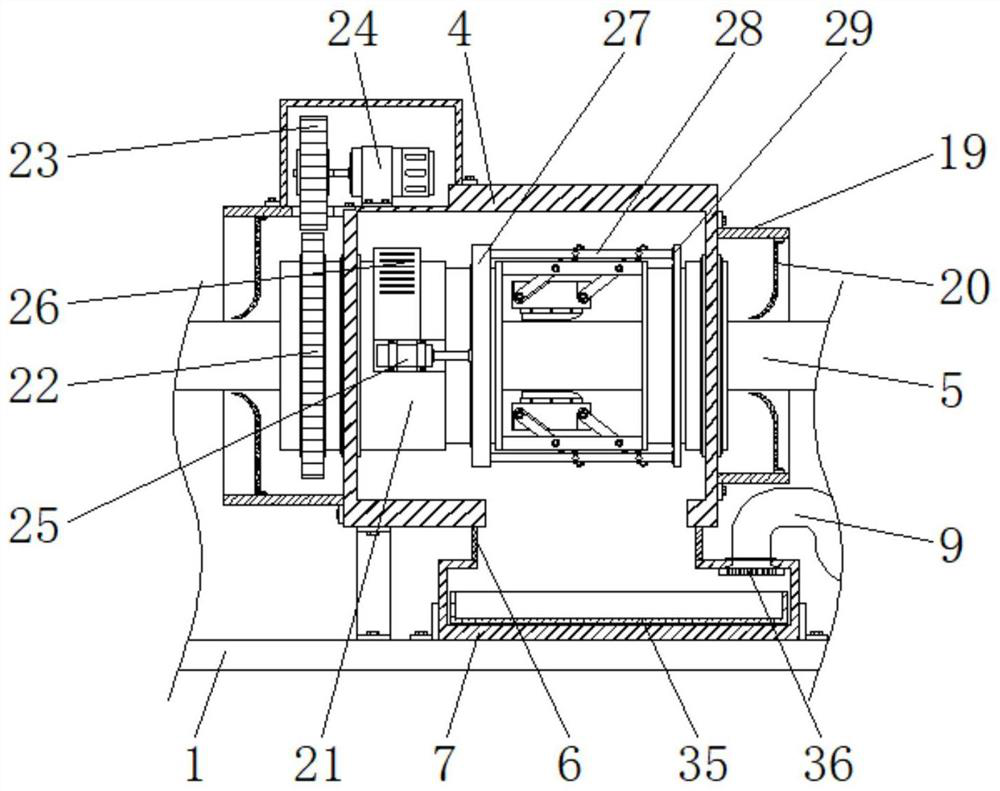

Mechanical device applied to sewage treatment

ActiveCN110368735AReduce stepsEasy to take outTableware washing/rinsing machine detailsMoving filtering element filtersEngineeringSewage

The invention relates to the field of sewage treatment, specifically to a mechanical device applied to sewage treatment. The mechanical device comprises a main body mechanism, a driving mechanism, a cleaning mechanism, a dust scraping mechanism, a linkage mechanism, a filtering mechanism and a backwashing mechanism. When the mechanical device is in use, the cleaning mechanism is arranged on the inner side wall of the main body mechanism, and the driving mechanism is connected with the top part of the main body mechanism, so the cleaning mechanism is driven by the driving mechanism to automatically clean a cookware positioned on the cleaning mechanism, and use is more convenient; meanwhile, the linkage mechanism positioned in the interior of the dust scraping mechanism is powered by a powersupply to drive the dust scraping mechanism and the filtering mechanism, and the dust scraping mechanism automatically cleans the bottom part of the cookware, so use is further convenient; and when sewage enters the filtering mechanism, the filtering mechanism is driven by the linkage mechanism to rotate, and filtered residual dirts are thrown into a storage unit located on the main body mechanism under the action of a centrifugal force to be conveniently taken out, so reduction of steps and improvement of work efficiency are realized, and use is further convenient.

Owner:广东德通水务有限公司

Textile mechanical dust removal device

InactiveCN106994275AImprove production qualityGood for collection and cleaningGas treatmentUsing liquid separation agentAerospace engineeringWater tanks

The invention discloses a textile mechanical dust removal device which comprises a base, a left upright column, a right upright column, a textile workbench, a horizontal platform and a water pump; a supporting column is arranged at the lower part of the right end of the textile workbench; an air blower is arranged on the left side of the upper part of the base; a blowhole platform is arranged at the upper part of the air blower; an air suction opening is formed in the left side of the lower end of the horizontal platform; an exhaust fan is arranged on the left side of the upper end of the horizontal platform; a ventilation pipe is arranged at the air outlet end of the upper end of the exhaust fan; the right end of the ventilation pipe is provided with a dust accumulation tank in a connecting manner; a filter screen is arranged at the lower part in the dust accumulation tank; a water tank is arranged on the right side of the upper part of the base; and a double-layer filter plate is vertically arranged in the water tank. According to the textile mechanical dust removal device, by matching densely distributed air blowing pipelines with the exhaust fan at the upper end, thread ends, fluffs and dust generated in the textile process can be rapidly and effectively eliminated, and the quality of production can be effectively improved.

Owner:杨露萍

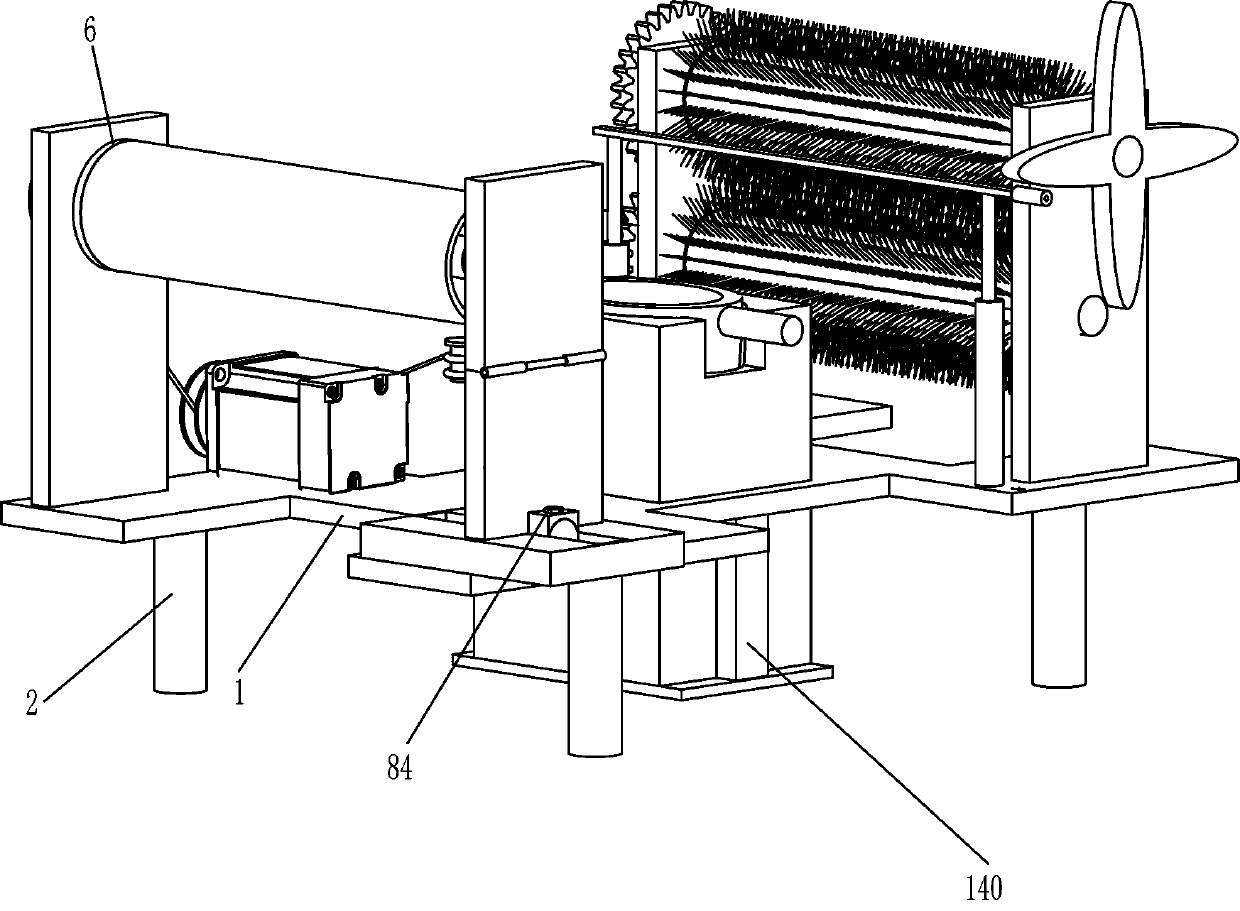

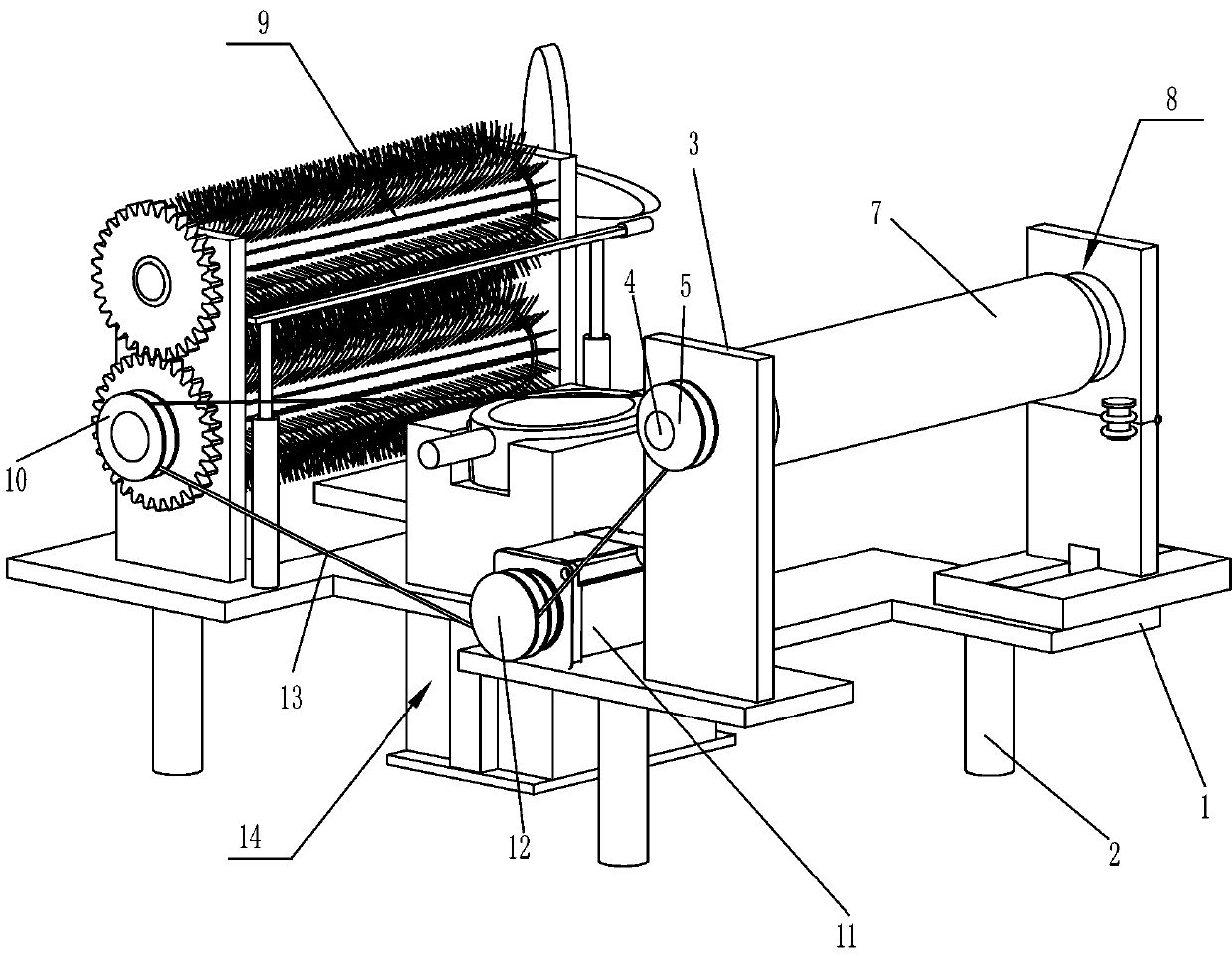

Cloth dust cleaning and arranging equipment

The invention relates to cleaning and arranging equipment, in particular to cloth dust cleaning and arranging equipment. The technical problem is how to provide cloth dust cleaning and arranging equipment which is capable of improving the cleaning efficiency and is convenient to arrange. Cloth dust cleaning and arranging equipment comprises a workbench, support rods, a vertical plate, a rotating shaft, a clamping block, a first belt wheel, a chuck and a winding roller. The bottom of the workbench is connected with four support rods, the vertical plate is fixedly connected to the top of the workbench, the rotating shaft is rotationally connected to the upper part of the vertical plate, the clamping block is connected to one end of the rotating shaft, the first belt wheel is arranged at theother end of the rotating shaft, the chuck is installed on the rotating shaft close to the vertical plate, and the winding roller is arranged on the chuck in a sleeving mode. The winding roller can befixed through a clamping mechanism, so that the winding roller can be prevented from rotating automatically and resulting in inconvenience of cleaning the dust on the cloth surface.

Owner:龚玉奖

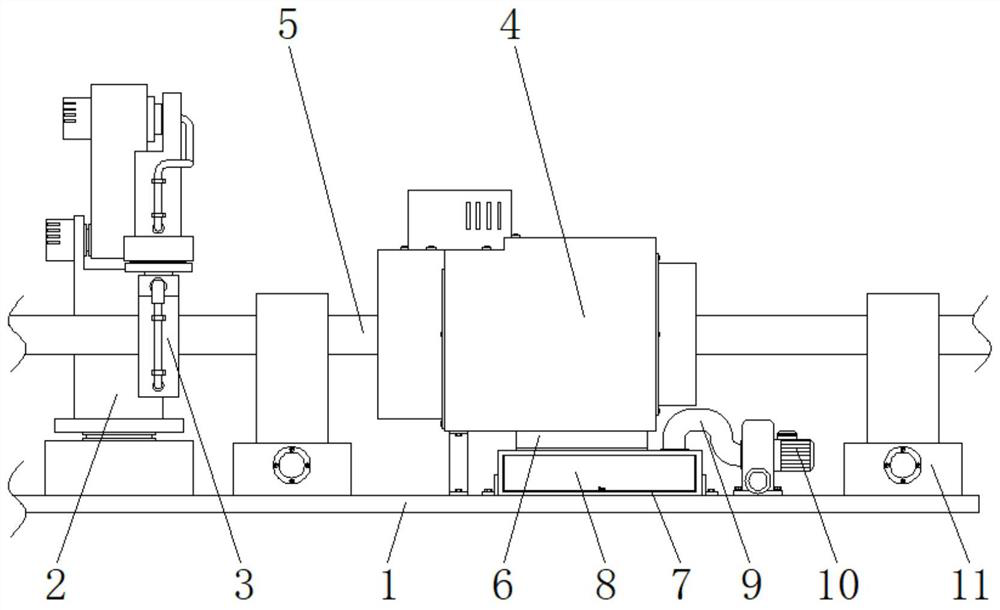

Double-sided toothed blade grinding tool

InactiveCN108422271AQuick changeEasy to replaceGrinding carriagesGrinding drivesWorking environmentEngineering

The invention discloses a double-sided toothed blade grinding tool, comprising a body base. Support legs are arranged on the top of the body base and fixedly connected with the body base, a waste binis arranged at the inner sides of the support legs and fixedly engaged with the body base, and a workbench is arranged on the tops of the support legs. Waste generated when a blade is ground can be drawn into the waste bin through an exhaust fan, so as to be collected and cleaned conveniently, which brings convenience for workers to clean the working environment and reduces the workload of the workers. A screw sliding table is arranged on the workbench, and can drive a fixed clip sliding seat on a screw at the inner side of the screw sliding table under the driving of a stepping motor, so thatthe blade can be moved when being ground, grinding rollers can grind different parts of the blade, and the angle adjustment of the blade can be more convenient.

Owner:佛山市远怀数控科技有限公司

Mechanical stirring and clarifying pond

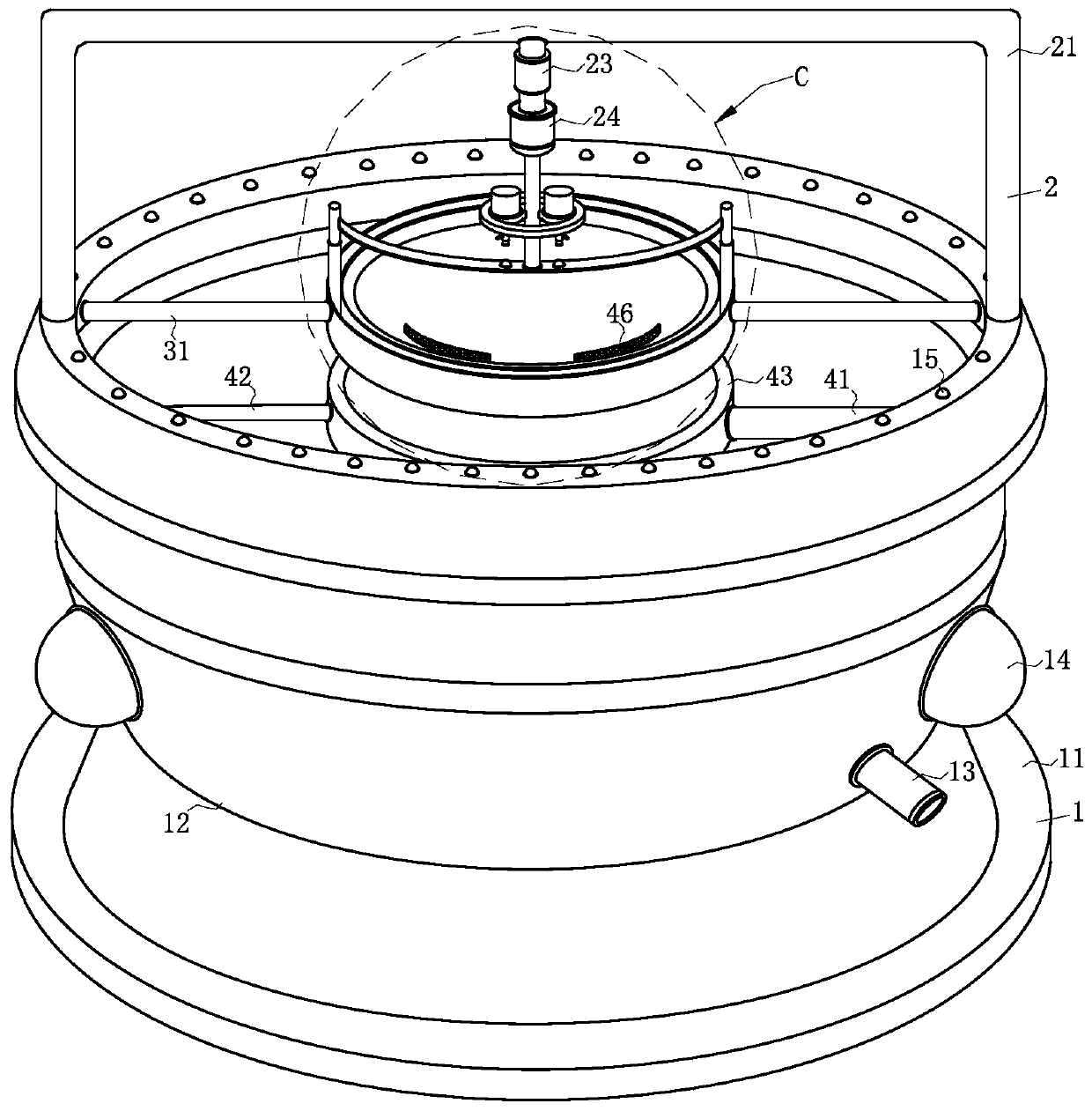

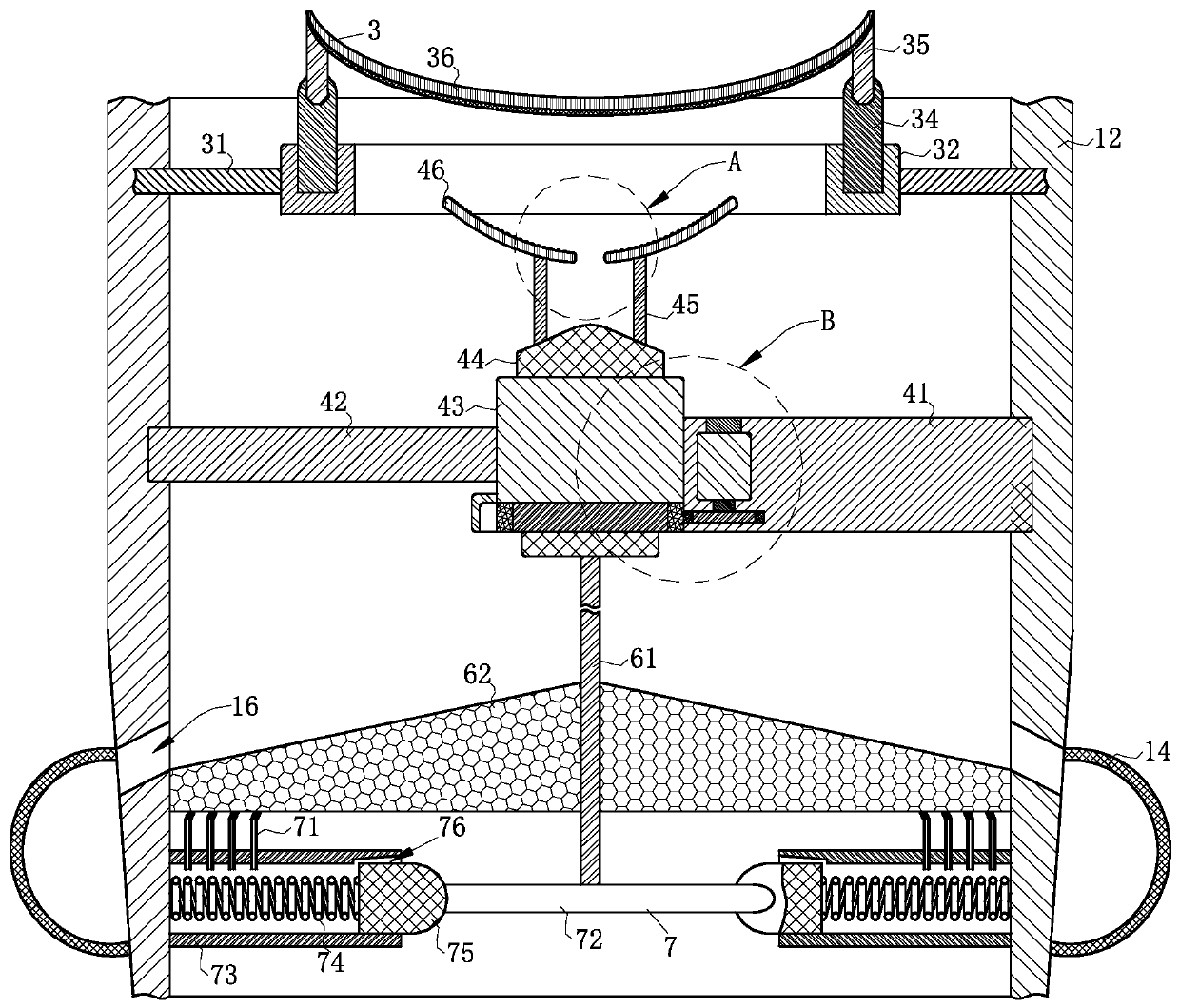

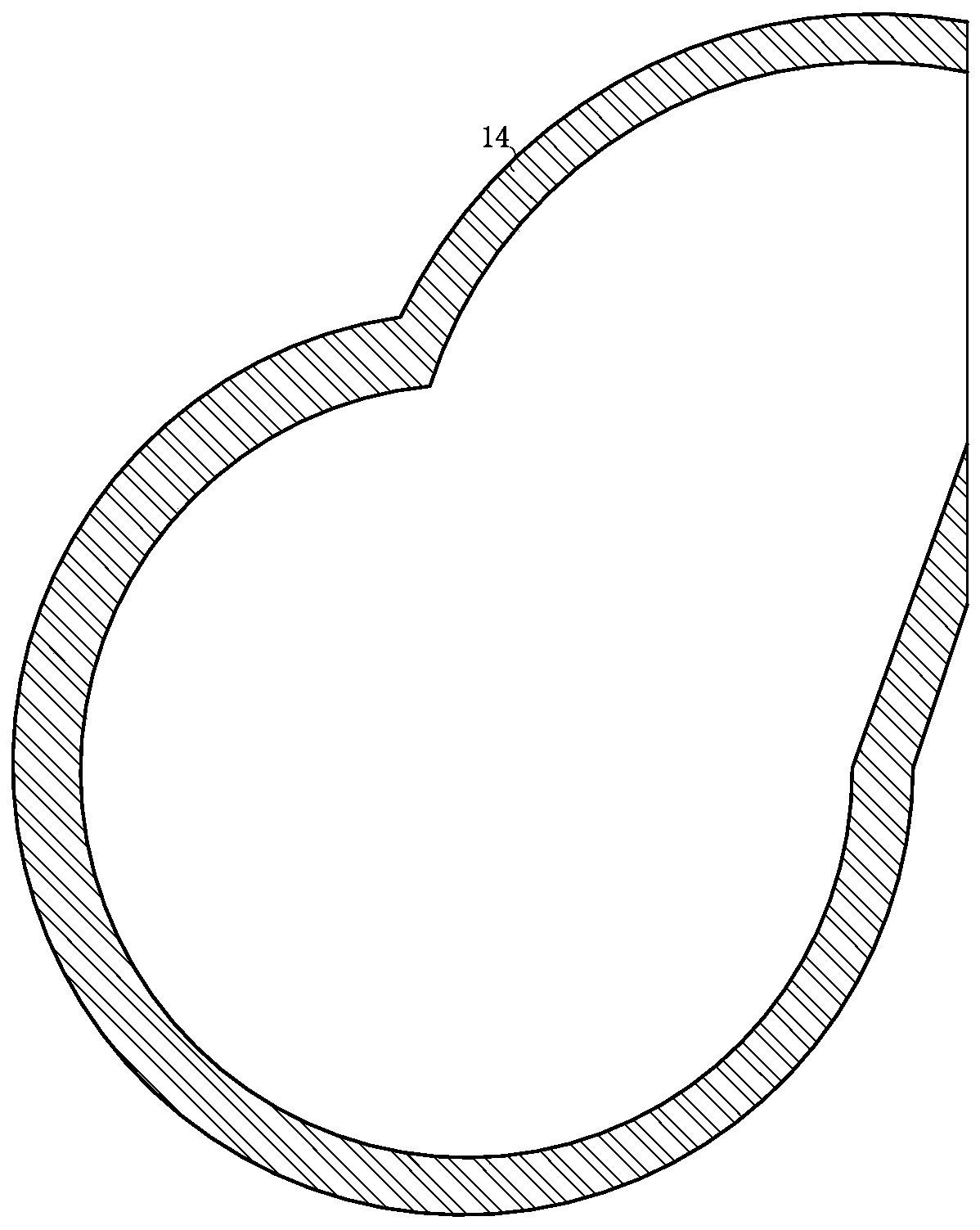

InactiveCN108992977AEasy to cleanPromote circulationSpecific water treatment objectivesSettling tanks feed/dischargeSludgeWater flow

The invention discloses a mechanical stirring and clarifying pond. The mechanical stirring and clarifying pond comprises a clarifying pond, wherein a residue collecting hole is formed in the bottom ofthe inner wall of the clarifying pond; a residue collecting pipe is fixedly connected to the inner part of the residue collecting hole; a valve is fixedly connected to the outer wall of the residue collecting pipe; a suction pump is fixedly connected to the bottom of the residue collecting pipe; a mud discharging pipe is fixedly connected to the top of the suction pump; supporting rods are fixedly connected to the bottom of the inner wall of the clarifying pond; and a motor tank is fixedly connected to the tops of the supporting rods. According to the mechanical stirring and clarifying pond disclosed by the invention, a scraping plate is arranged at the bottoms of the stirring rods, so that water currents can be effectively stirred, and mud and residues are promoted to circulate; solid impurities in water and the formed mud and the formed residues are in contact to flocculate to be separated and precipitated; and when the water currents are clarified and upper-layer clean water currents are drained through a through groove, the scraping plate is used for scraping sludge precipitated at the bottom of the inner wall of the clarifying pond, and the sludge is collected into the residue collecting hole, so that the cleaning of the clarifying pond is simple and convenient, and human resources and financial resources are saved.

Owner:浙江同成环境科技有限公司

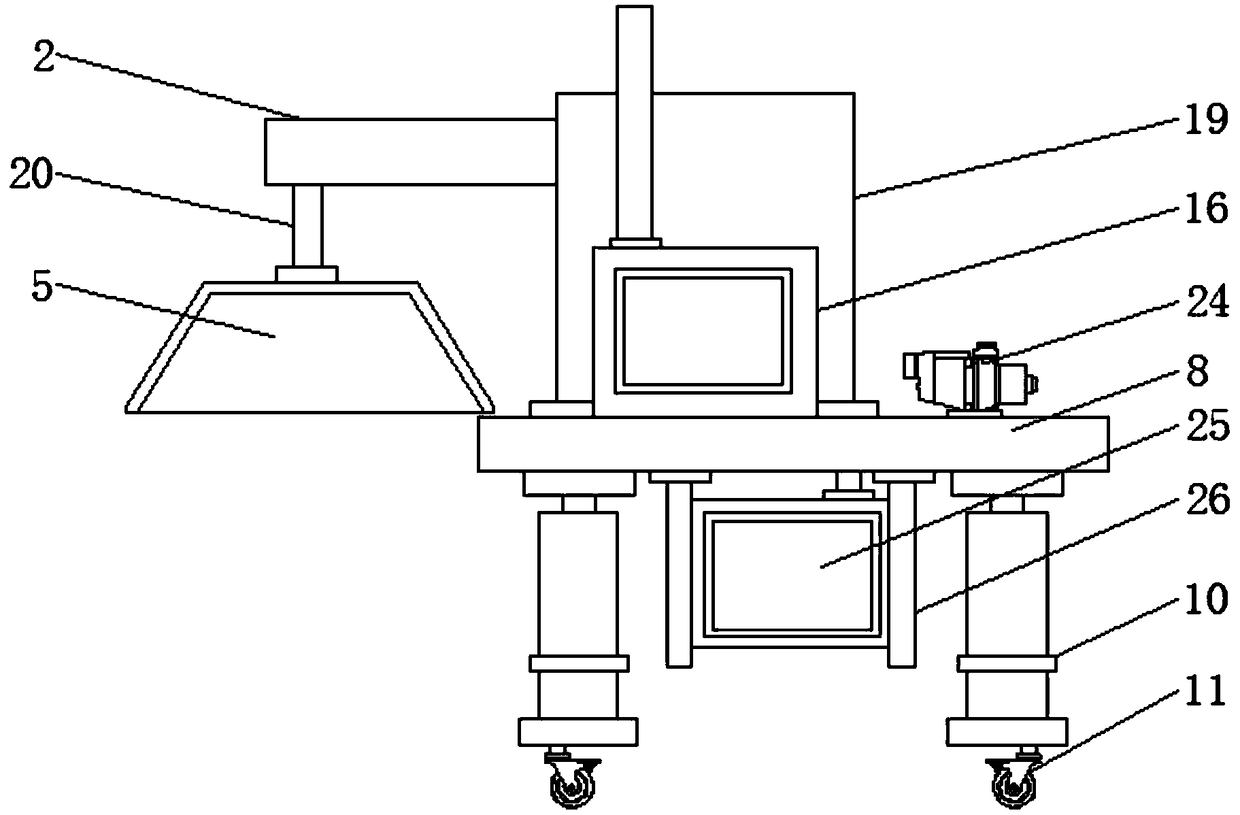

Dust blowing device for spinning machine

InactiveCN108607854AImprove production qualityGood for collection and cleaningUsing liquid separation agentTreatment involving filtrationEngineeringWater tanks

The invention discloses a dust blowing device for a spinning machine. The dust blowing device comprises a dust blowing cover, supporting stand columns, a circulation water tank and a dust collecting box. The output ends of hydraulic telescopic rods penetrate the top ends of the supporting stand columns and are horizontally provided with an installing platform. An installing frame is arranged at one end of the bottom end of the installing platform. The circulation water tank is arranged in the installing frame. The end, away from the installing frame, of the top end of the installing platform is vertically provided with a first vertical plate 6. The dust blowing cover is arranged at the bottom ends of a second installing frame and a first installing frame. Two dust blowing sprayers are arranged on the inner wall of each of the two sides of the dust blowing cover. The dust collecting box is arranged at the top end of the installing platform part on the side, away from the first verticalplate 6, of a first vertical plate 19. According to the dust blowing device, rapid dust blowing can be achieved, meanwhile, flying dust is collected in an air pumping manner, thread residues, flock and dust generated in the spinning process can be rapidly and effectively removed, and the production quality can be effectively improved.

Owner:JIANGSU BEILIN TEXTILE CO LTD

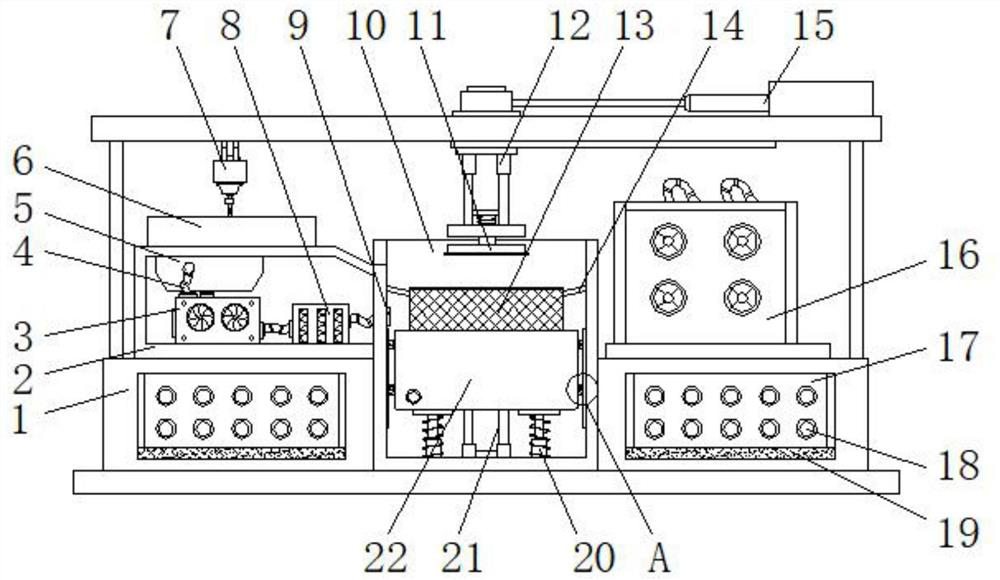

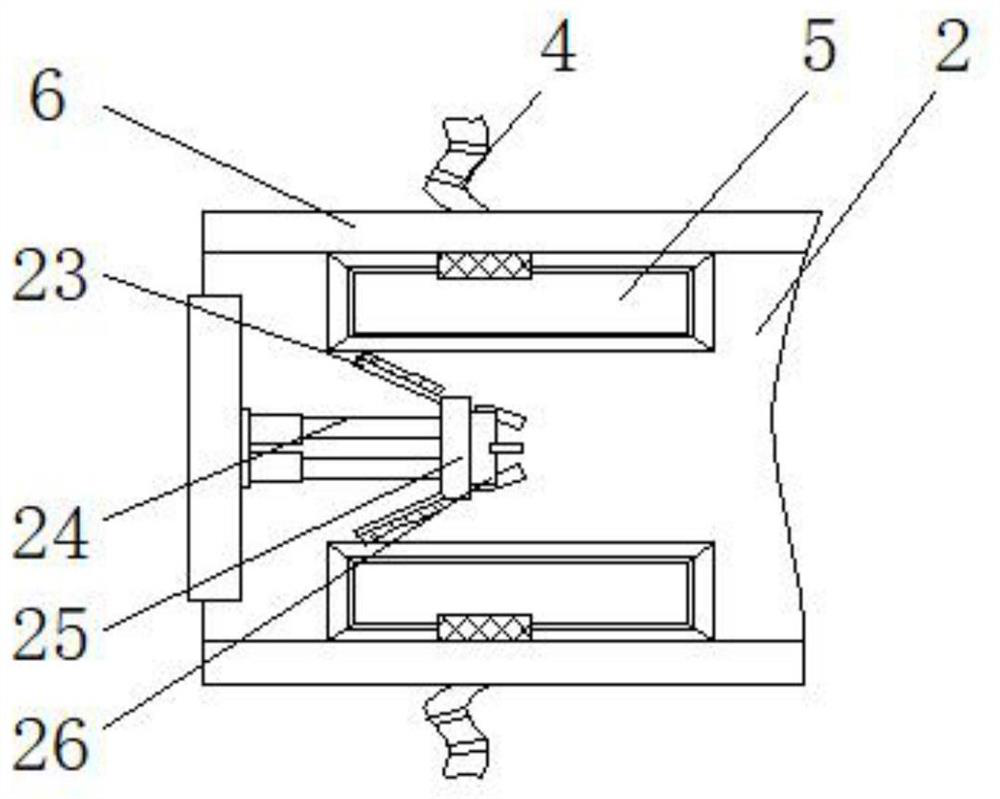

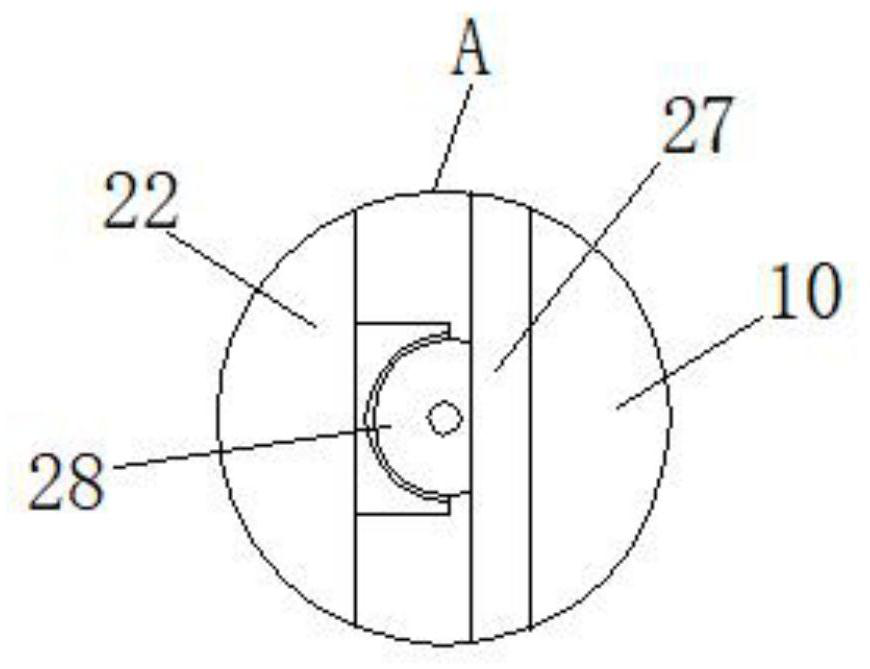

Robot spraying equipment capable of pretreating spraying surface

PendingCN111673577AEasy to collect and clean upImprove practicalityGrinding drivesGrinding machinesGrindingEngineering

The invention discloses robot spraying equipment capable of pretreating a spraying surface. The robot spraying equipment capable of pretreating the spraying surface comprises a bottom plate, a robot arm body and a spraying device. The left end of the upper surface of the bottom plate is fixedly connected with the robot arm body, and a forearm of the robot arm body is provided with the spraying device. A grinding box is fixedly connected to the middle of the upper surface of the bottom plate. The grinding box is connected with a pipe body in a penetrating mode. A blanking cover is welded on anopening on the lower side of the grinding box. A dust collection box is welded on the lower end of the blanking cover. The front side wall of the dust collection box is connected with a box door through a hinge. The right end of an exhaust pipe is fixedly connected with an air inlet of an exhaust fan, and the left and right sides of the grinding box are provided with bases. The robot spraying equipment capable of pretreating the spraying surface is convenient for grinding and pretreating the spraying surface, is convenient for collecting and cleaning grinded waste, improves the practicability,is also convenient for adjusting, and improves the scope of application.

Owner:福建众辉环保设备有限公司

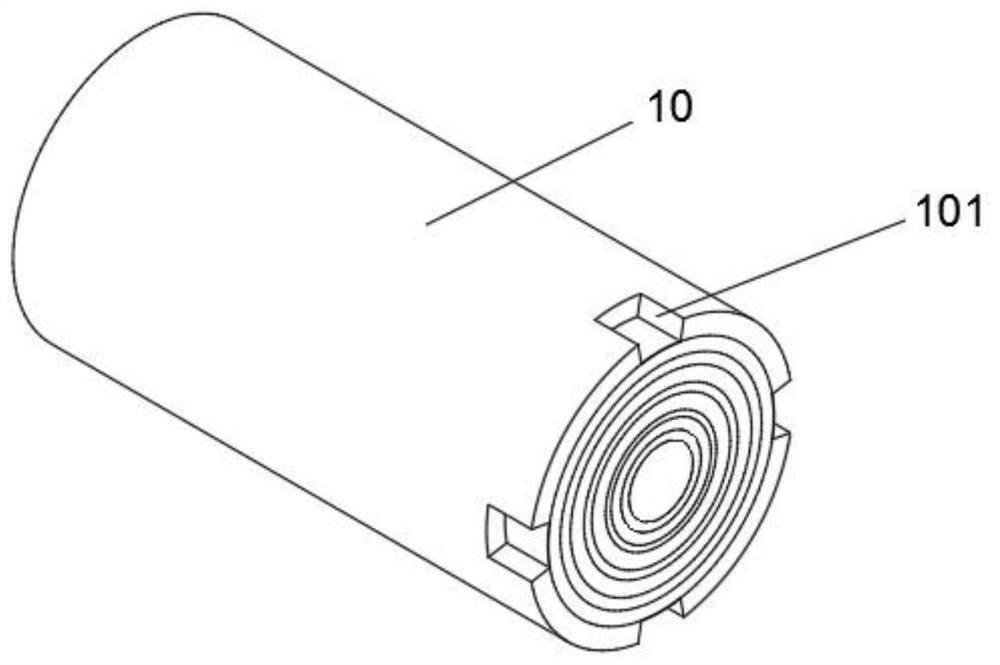

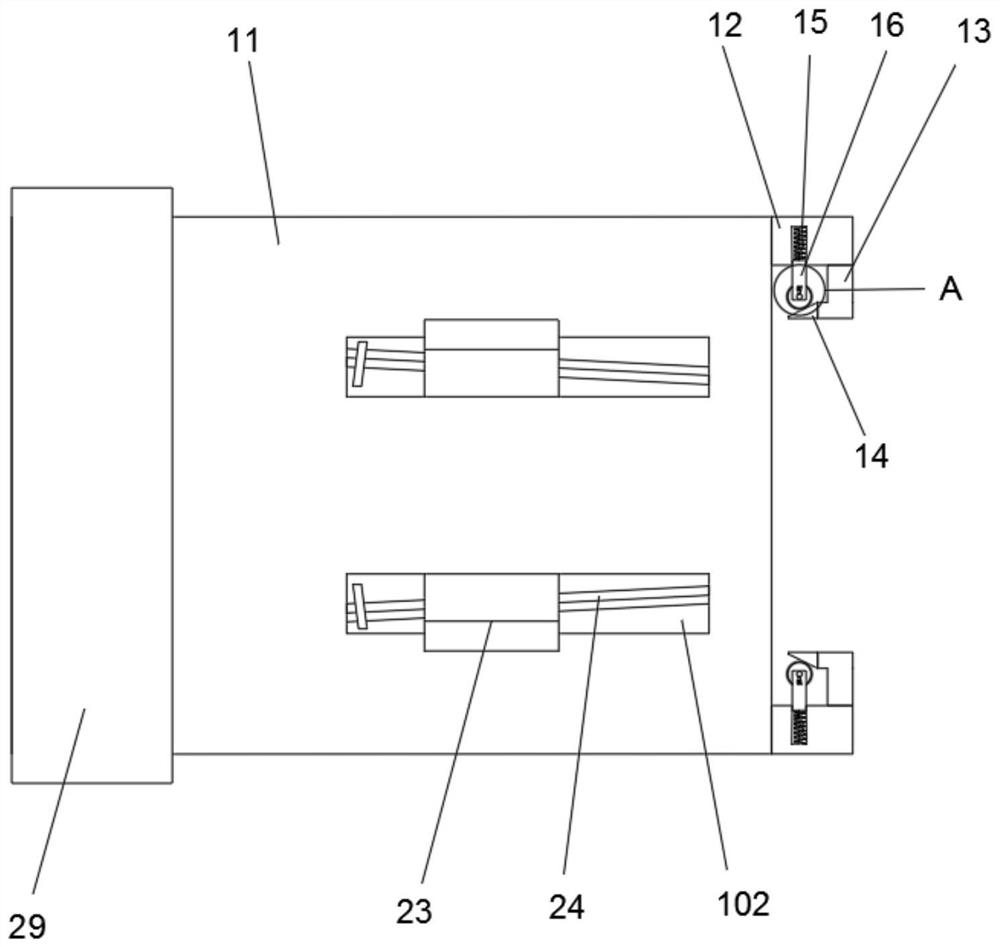

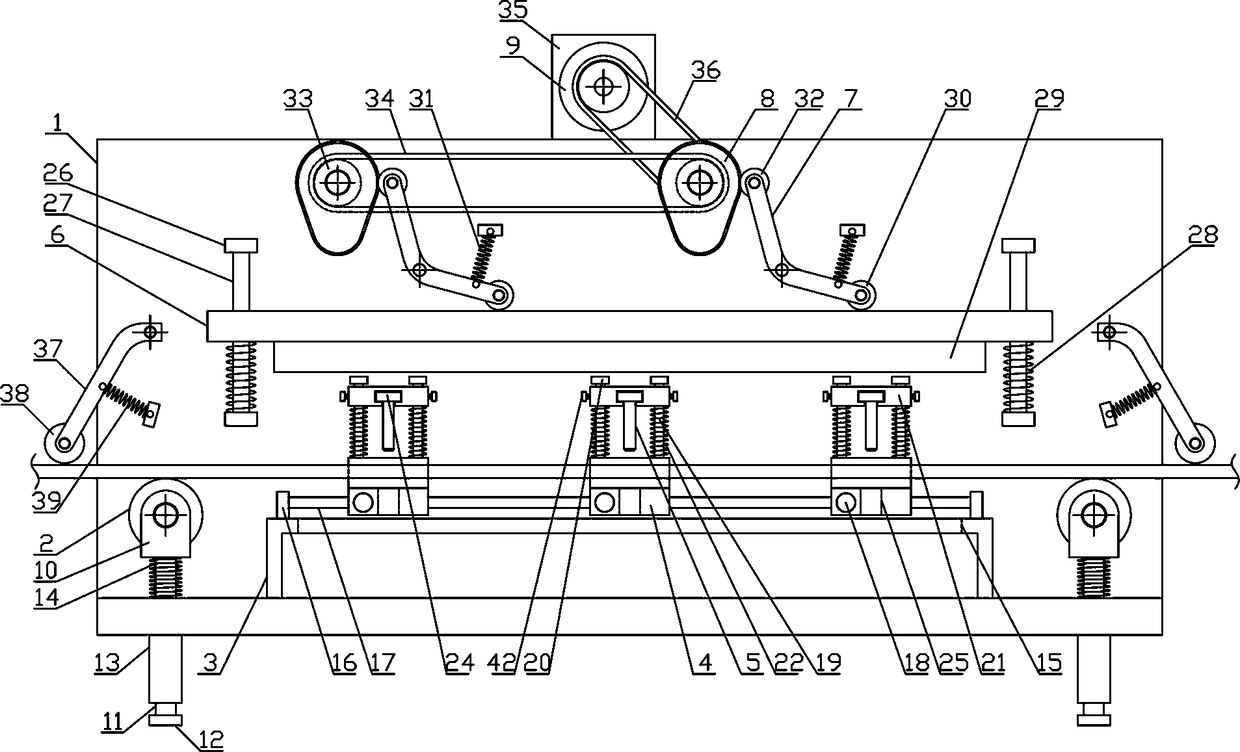

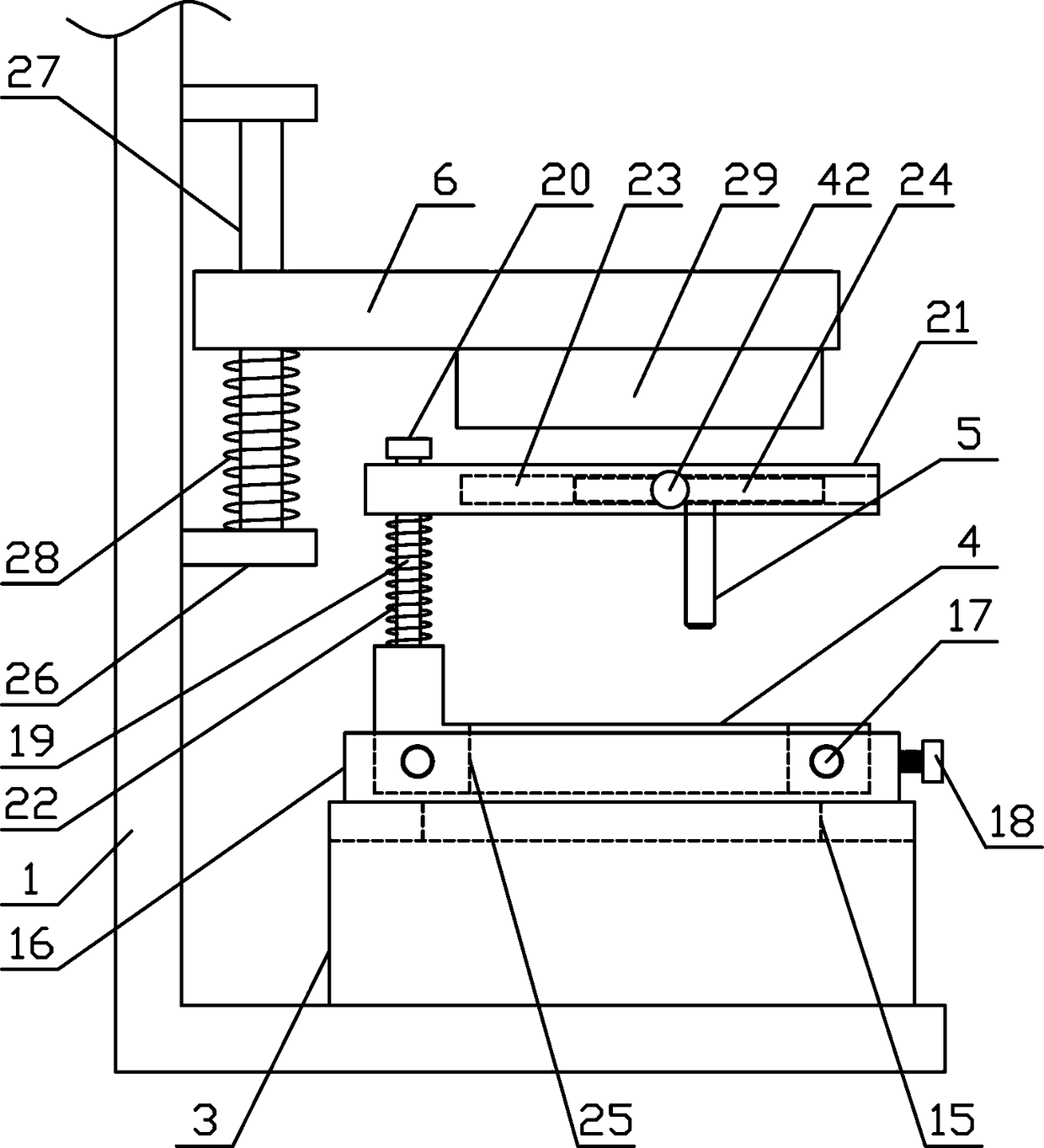

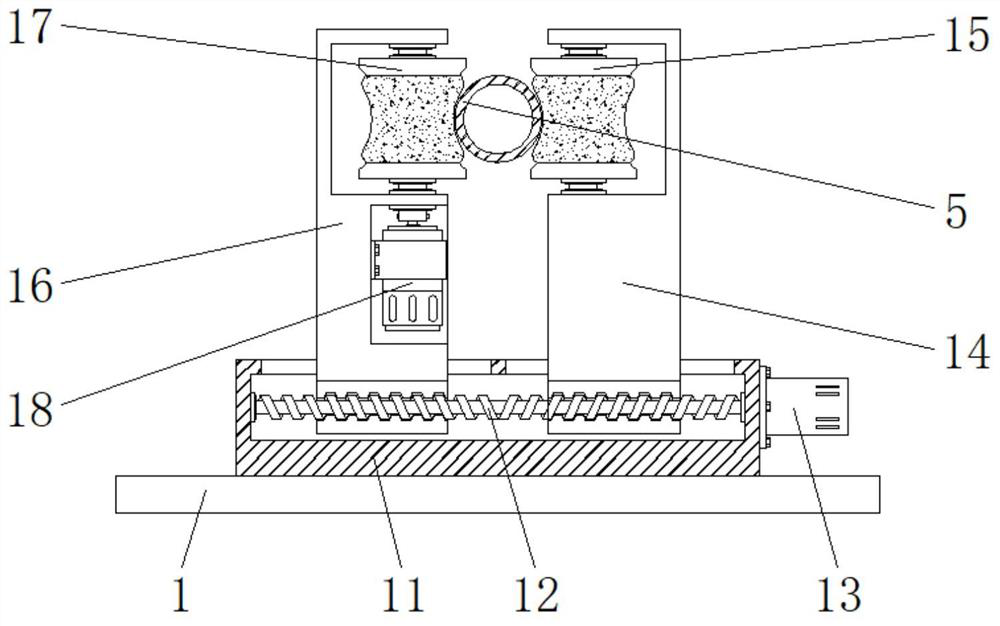

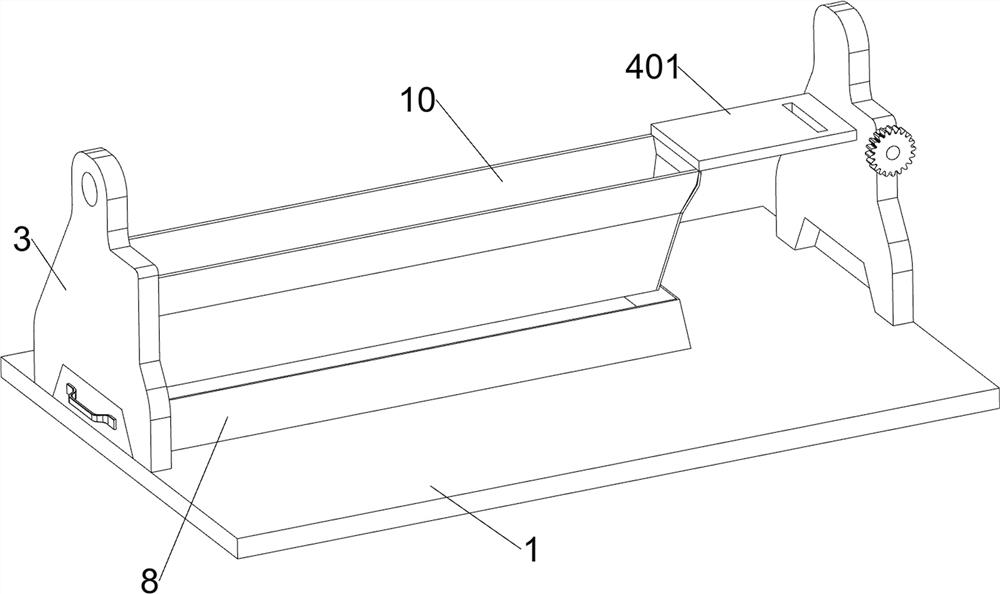

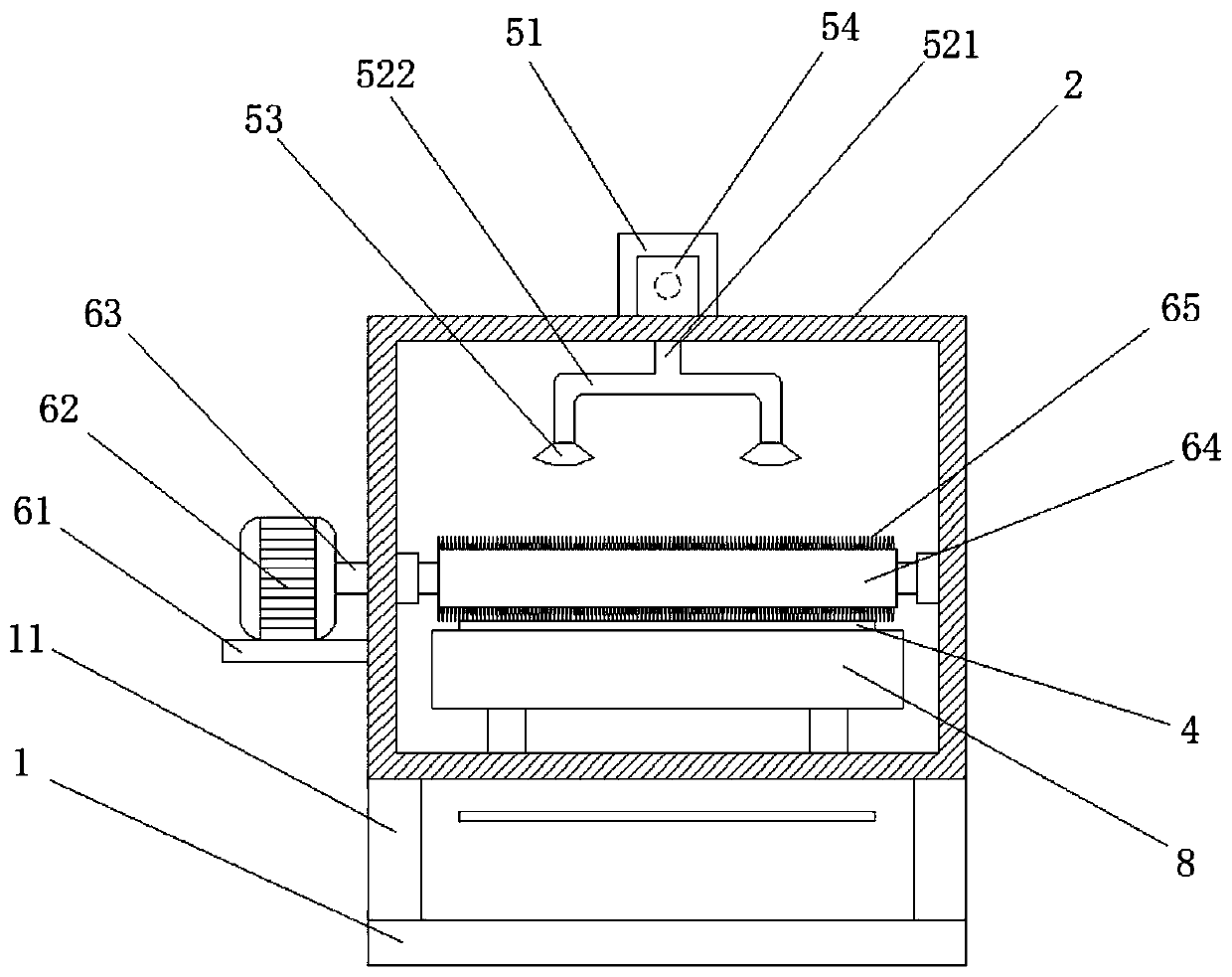

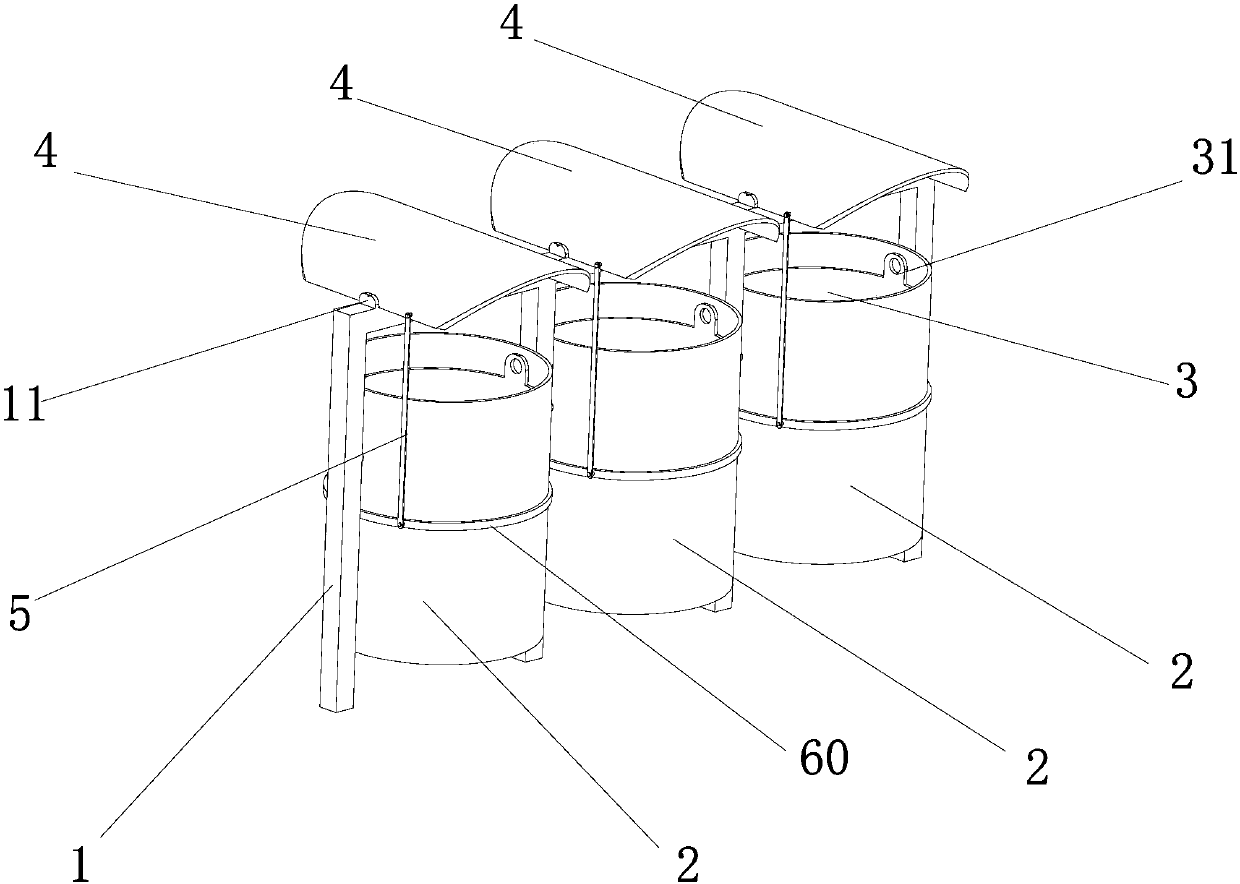

Solid wood cylinder polishing equipment for furniture production

PendingCN112247820AGood collection clean upEasy to fixEdge grinding machinesPolishing machinesSolid woodManufacturing engineering

The invention relates to polishing equipment, in particular to solid wood cylinder polishing equipment for furniture production, and provides the solid wood cylinder polishing equipment which is usedfor furniture production and can polish the surface of a wood plate smoothly and remove burrs completely without manual polishing. The solid wood cylinder polishing equipment for furniture productioncomprises a bottom plate, a double-shaft servo motor, supports, rotating assemblies, clamping assemblies, a moving assembly and a polishing assembly; the bottom plate is a carrier of the equipment; the double-shaft servo motor is arranged on one side of the top of the bottom plate; the supports are symmetrically arranged at the top of the bottom plate; the rotating assemblies arranged on the two supports and an output shaft of the double-shaft servo motor; the clamping assemblies are arranged on the two supports; the moving assembly is arranged between the output shaft of the double-shaft servo motor and the top of the bottom plate; and the polishing assembly is arranged between the two supports. Through the rotating assemblies and the clamping assemblies, the cylinder can be more stably fixed to the equipment and can be uniformly polished by the polishing assembly.

Owner:HEBEI JIRONG FURNITURE

Continuous dust removal device for communication base station

InactiveCN111195451AContinuous cleaningAvoid cleaningDispersed particle filtrationTransportation and packagingDust controlEngineering

The invention discloses a continuous dust removal device for a communication base station, which relates to the technical field of communication equipment. The device comprises a dust removal body, and a cavity is formed in the dust removal body and is divided into a filtering cavity and a cleaning cavity through a partition plate; an air inlet is formed in one side of the filter cavity, a filterscreen is rotationally arranged at a communicating opening in the upper ends of the filtering cavity and the cleaning cavity, an exhaust port is further formed in the dust removal body, the air inletand the exhaust port are formed in the upper portion and the lower portion of the filtering screen respectively, and the filtering screen is of a circular structure and is equally divided into two parts, a vibrating mechanism for driving the filtering screen part arranged at the communicating opening in the upper end of the cleaning cavity to vibrate up and down is arranged in the cleaning cavity,the middle of the filtering screen is fixedly mounted on a rotating shaft, the rotating shaft is rotationally mounted in the dust removal body, and an intermittent rotating mechanism for driving therotating shaft to drive the filtering screen to rotate is arranged in the dust removal body. Air is continuously filtered, and a filtering screen can be prevented from being manually and regularly cleaned.

Owner:钱丰

Ironing device with air suction and dust removal functions

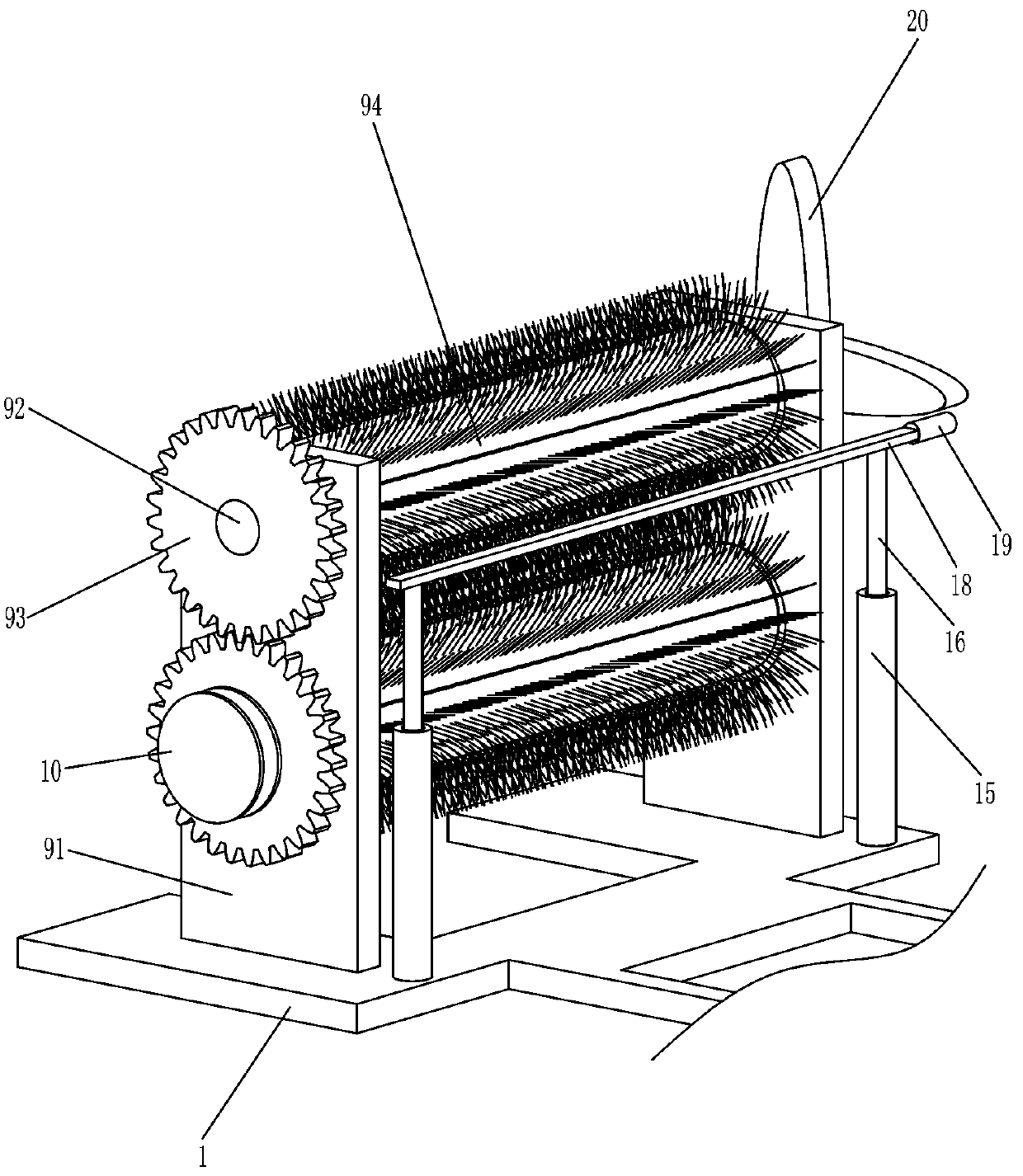

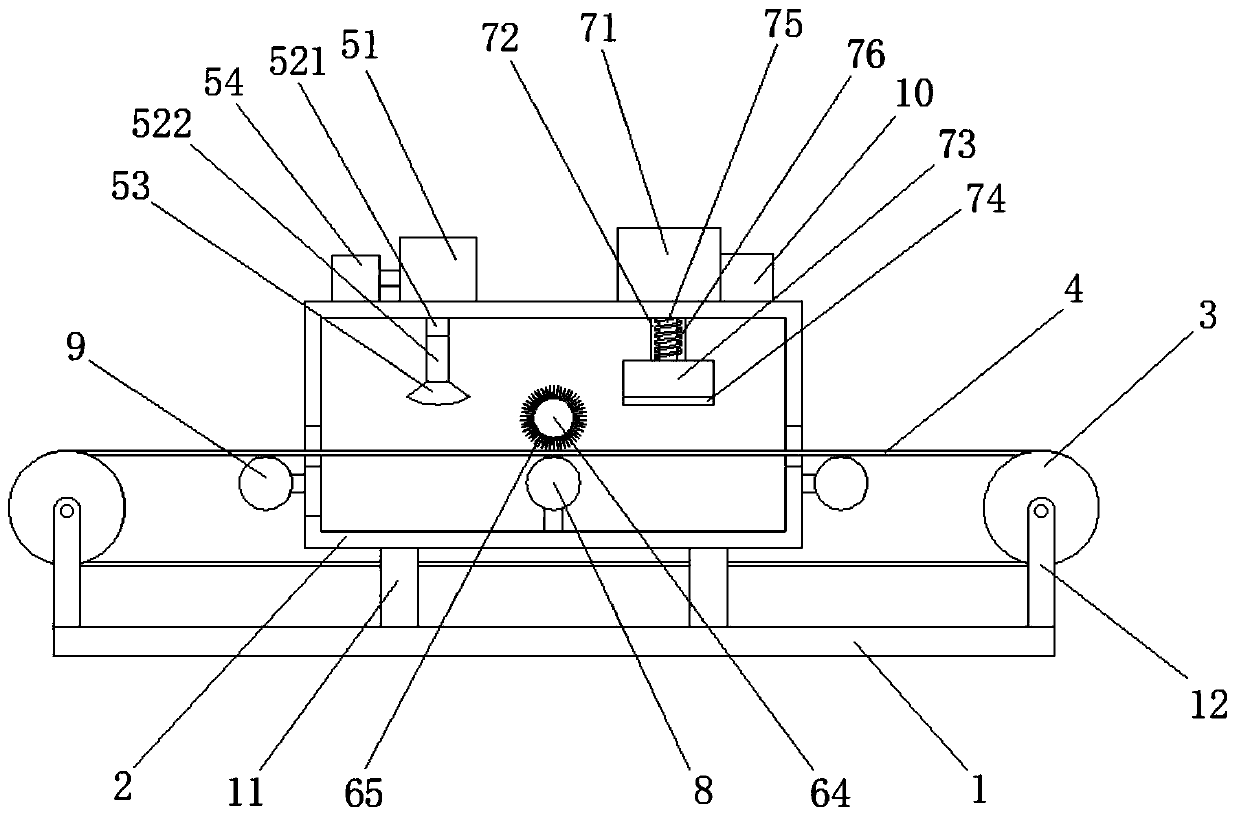

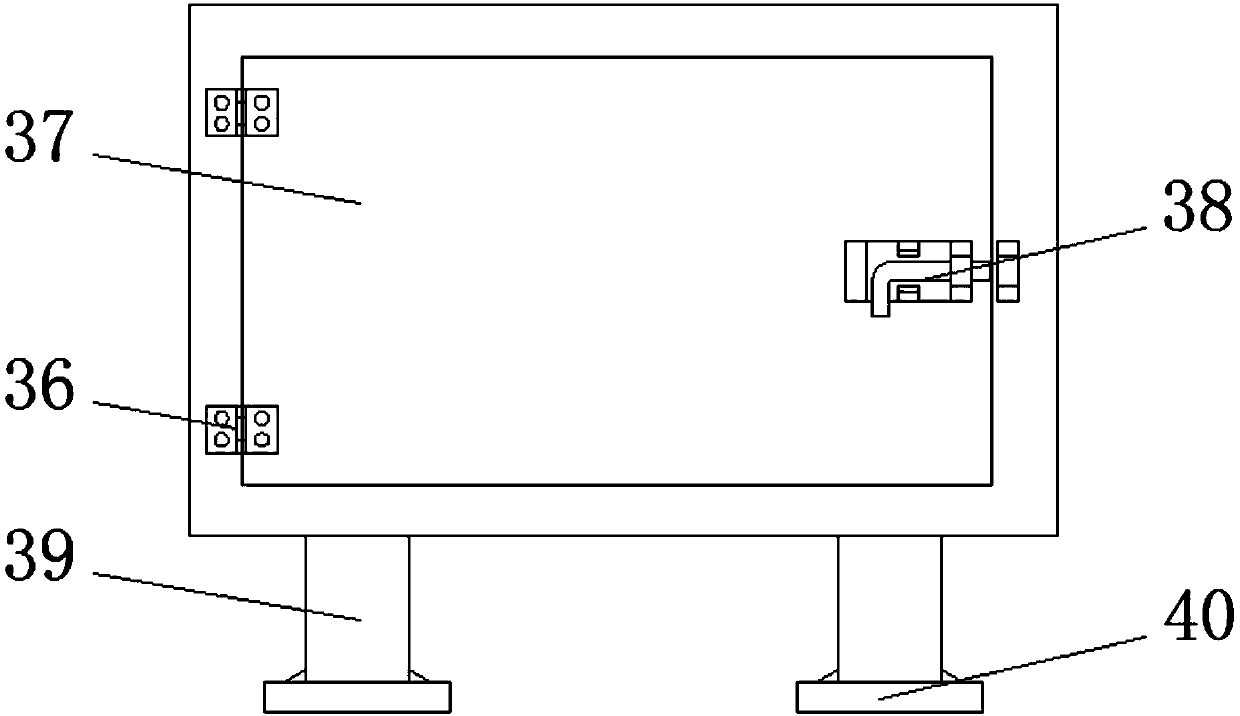

InactiveCN110172811AImprove cleanlinessEasy ironingMechanical cleaningPressure cleaningBristlePulp and paper industry

The invention discloses an ironing device with an air suction and dust removal functions. The ironing device comprises a base; a plurality of fixing columns are arranged in the middle of the base; a working box is arranged on the fixing columns; roller brackets are arranged at two ends of the base; rollers are erected on the roller brackets; conveyor belts are arranged on the rollers, and pass through the working box in the transverse direction; an air suction device, a bristle device and an ironing device body are sequentially arranged at parts, above the conveyor belt, in the working box inthe feeding direction; the air suction device comprises an induced draft fan, a dust removal pipeline, an air suction opening and a dust collection chamber; the bristle device comprises a bottom plate, a motor, a rotating shaft, a bristle roller and bristles; and the ironing device comprises an air cylinder, a piston rod, a steam chamber, an ironing board, a telescopic rod and a reset spring. Theironing device can be convenient for clearing and collecting dust on the surface of clothing, keeps clothing clean, is convenient for ironing of clothing, further keeps fabric smooth, improves the recovery effect, improves the operation stability and the safety, is high in ironing efficiency, and is suitable for batch production.

Owner:HAIYAN WEIBOYA KNITTING CLOTHING

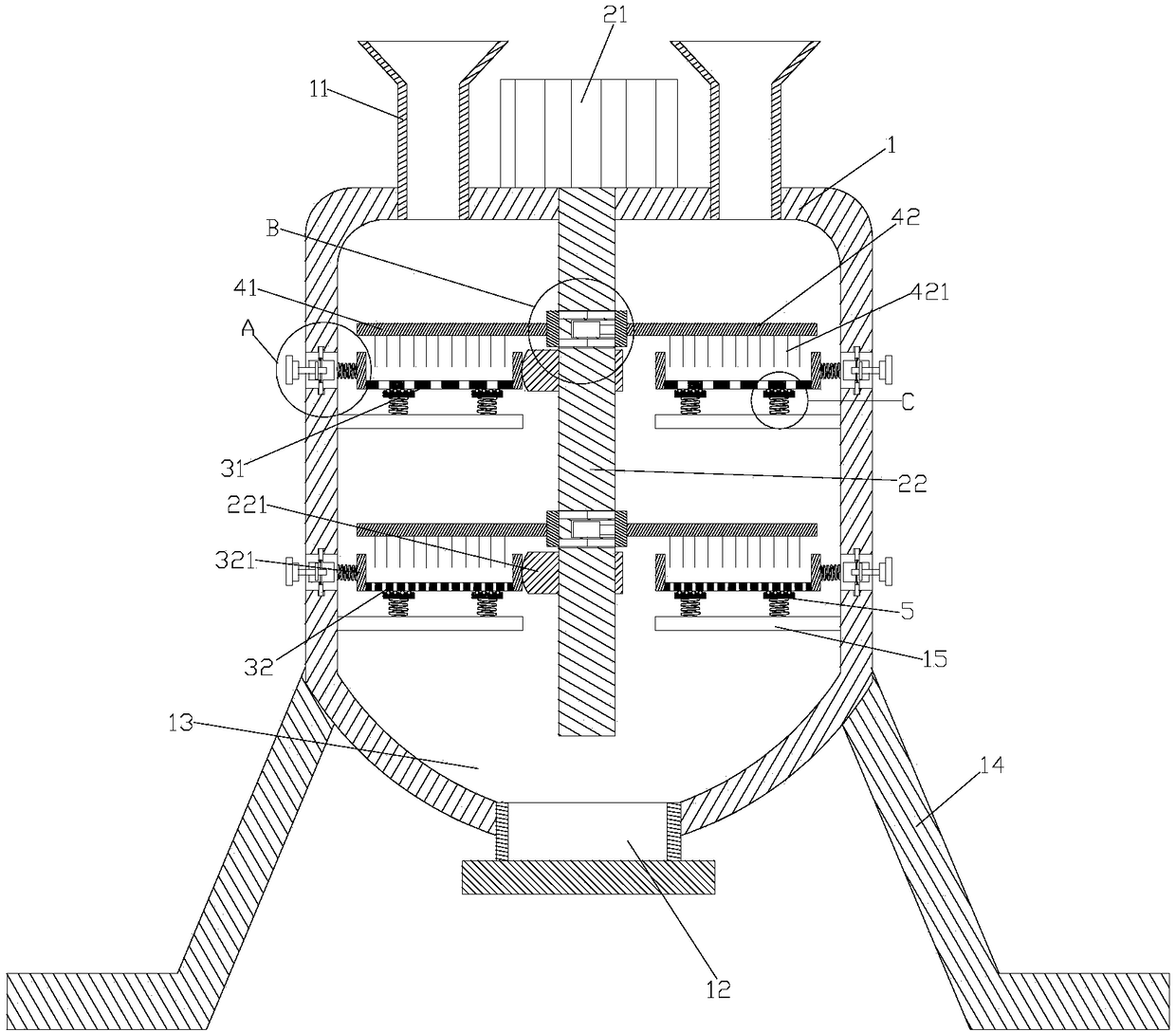

Plastic particle screening device

The invention discloses a plastic particle screening device comprising a box body, a first filter layer disposed in the box body, a second filter layer disposed under the first filter layer and a support for supporting the box body. The pore diameter of the first filter layer is smaller than that of the second filter layer. The top of the box body is provided with a feed port disposed above the first filter layer. The bottom of the box body is provided with a storage chamber, and the bottom of the storage chamber is provided with a discharge port. The first filter layer and the second filter layer are detachably connected with the box body. The plastic particle screening device further includes a shaking device for causing the first filter layer and the second filter layer to shake. When the plastic particle screening device is used for screening plastics, the filter layers can shake to improve the screening effect. By means of the detachable connection of the filter layers, materialson the filter layers can be cleaned conveniently, the filter layers can be replaced and dredged conveniently, and the service life of the filter layers is prolonged.

Owner:杭州大橙知一科技有限公司

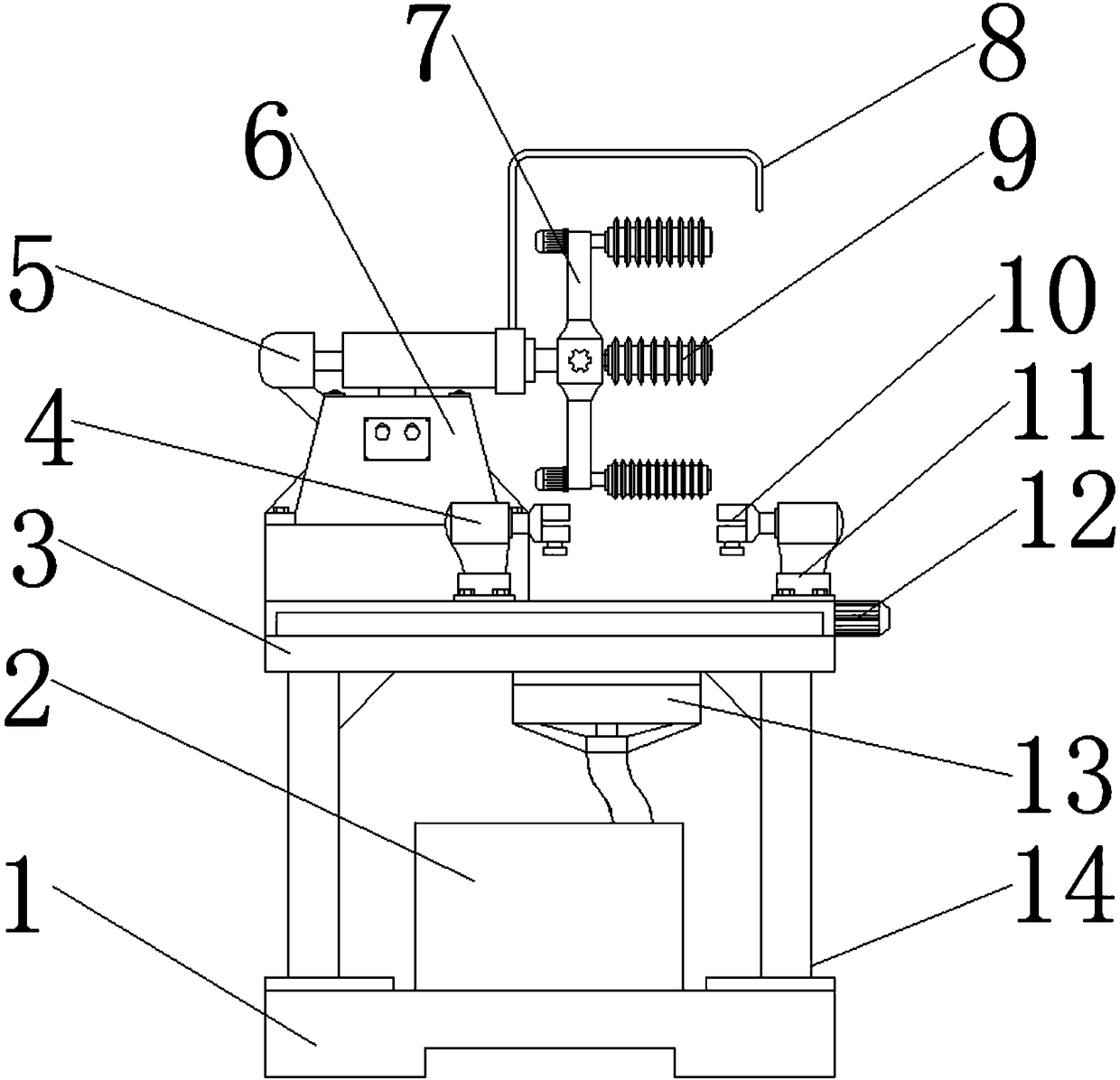

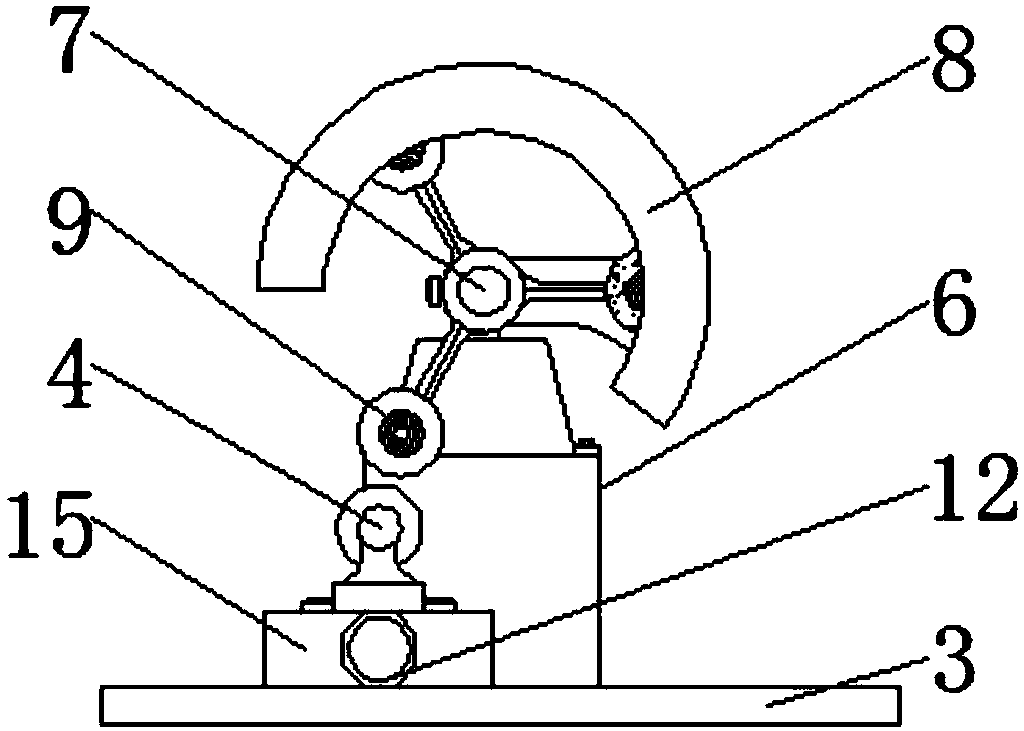

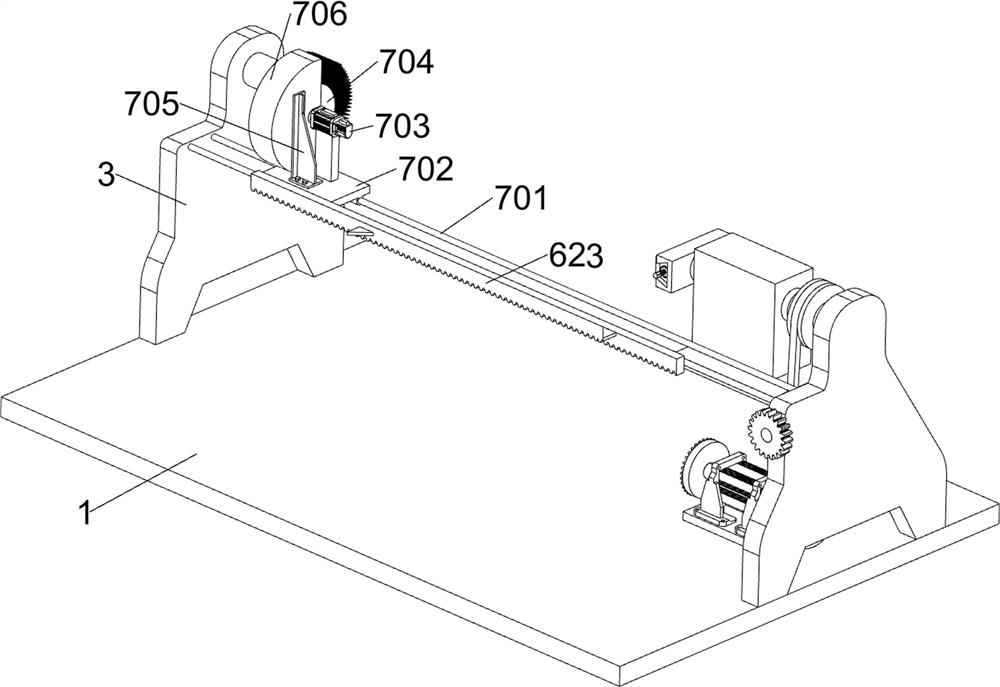

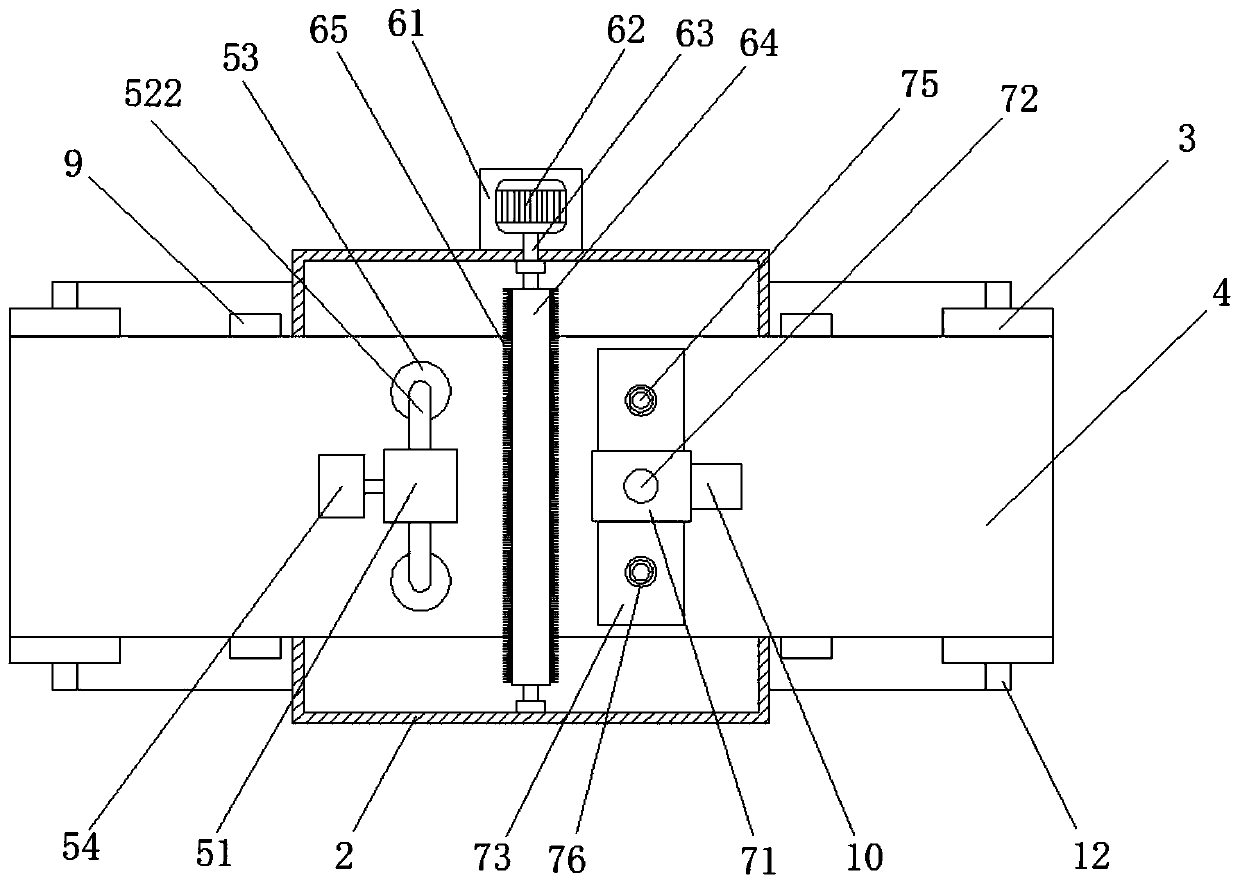

Cutting device for heat exchange tube of chemical heat exchanger

InactiveCN108213590AEasy to collect and clean upSimple structurePositioning apparatusMetal-working holdersEngineeringHeat exchanger

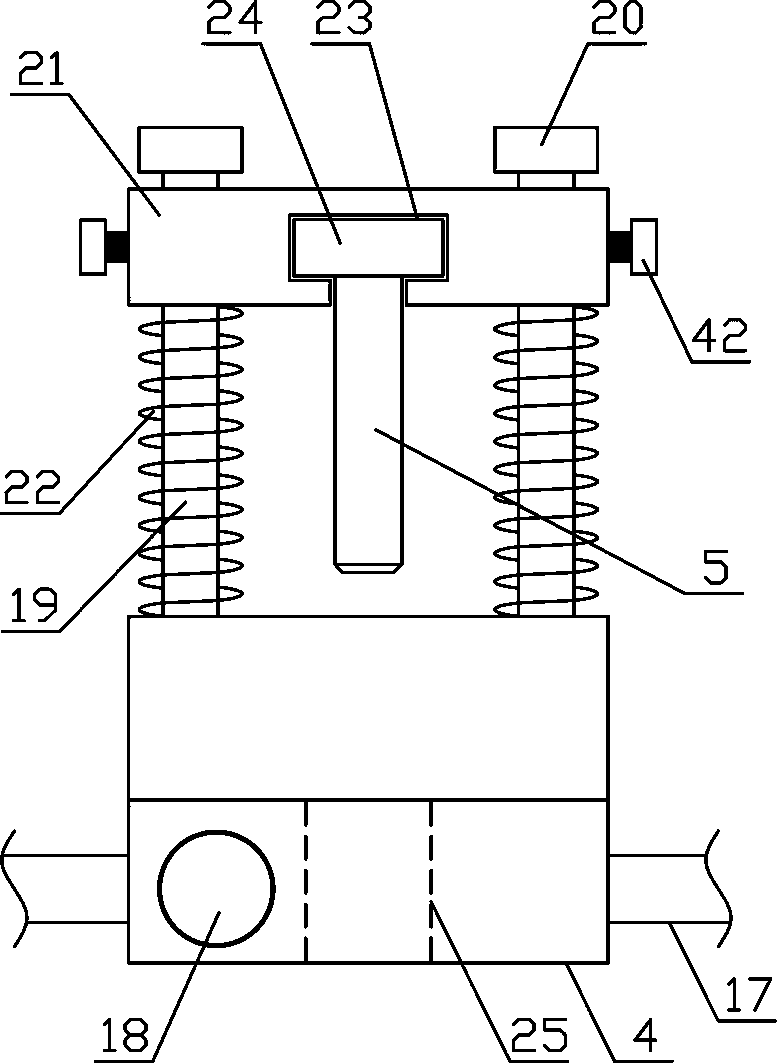

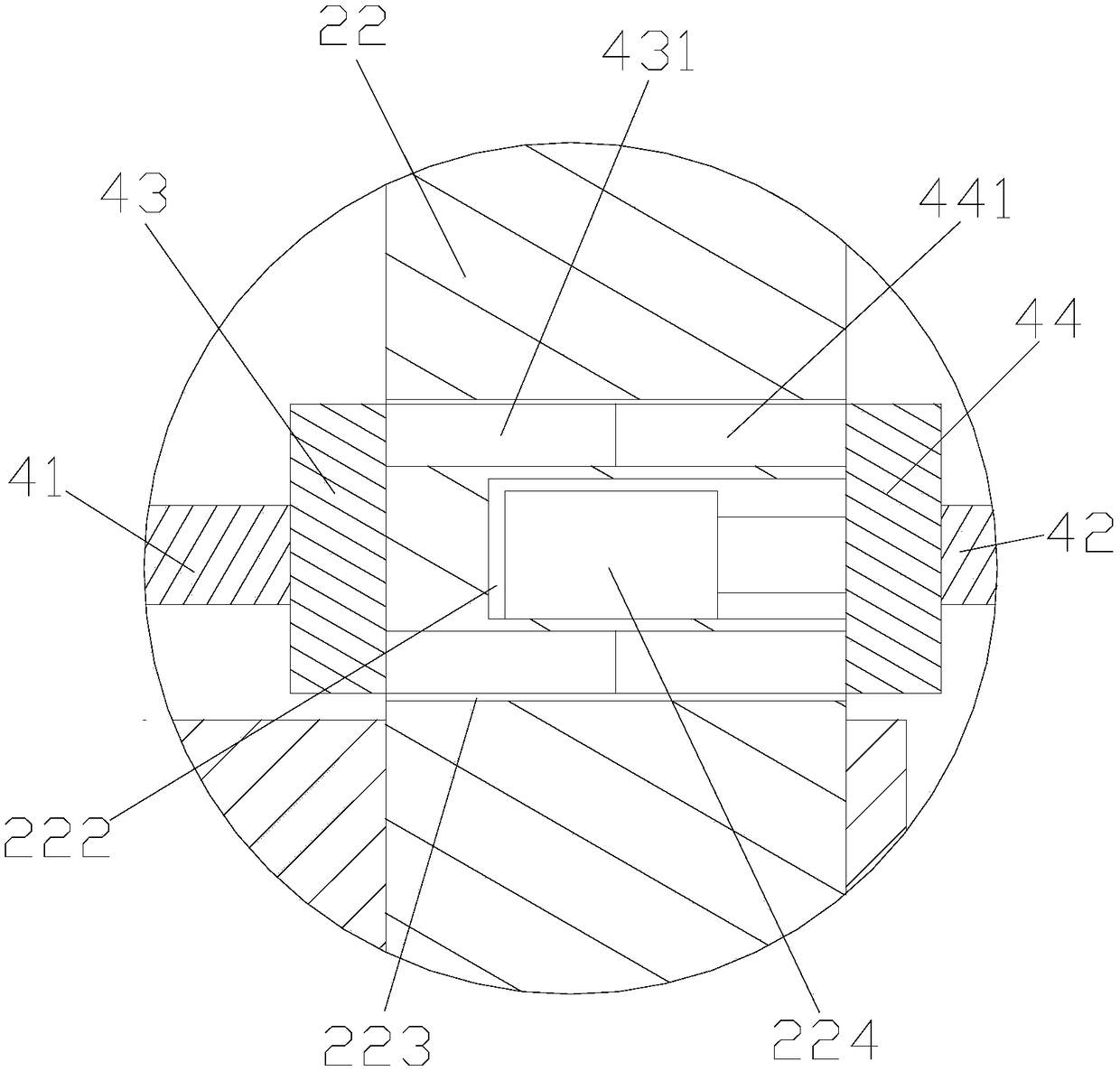

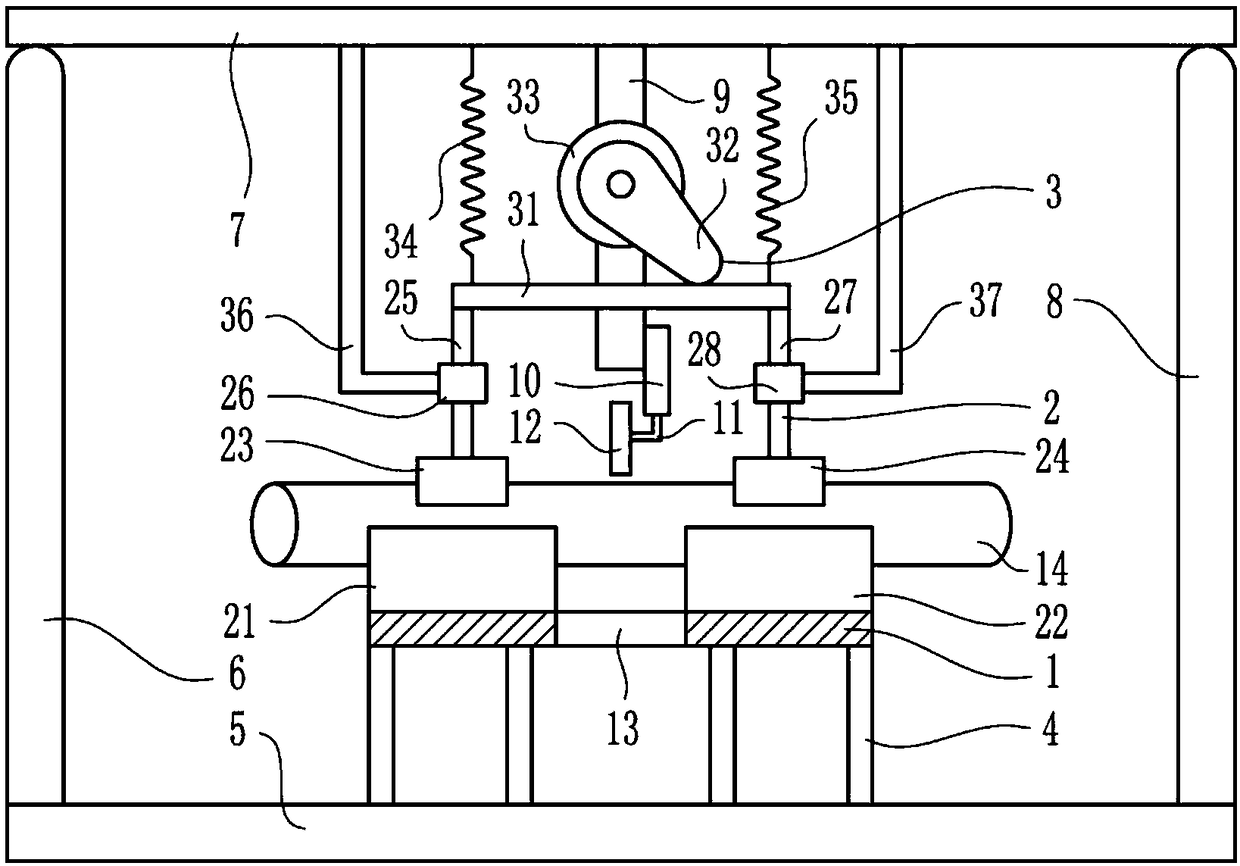

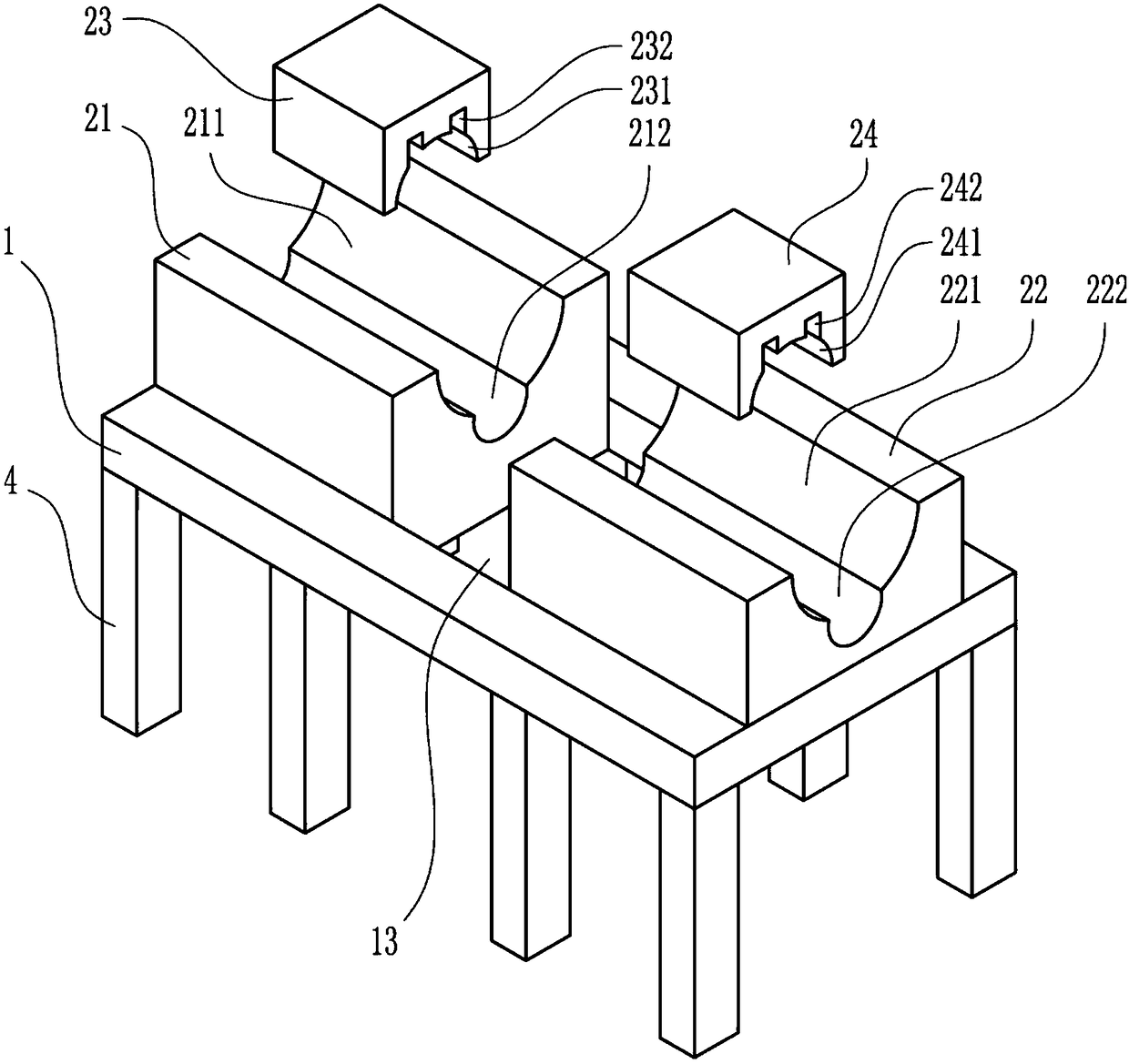

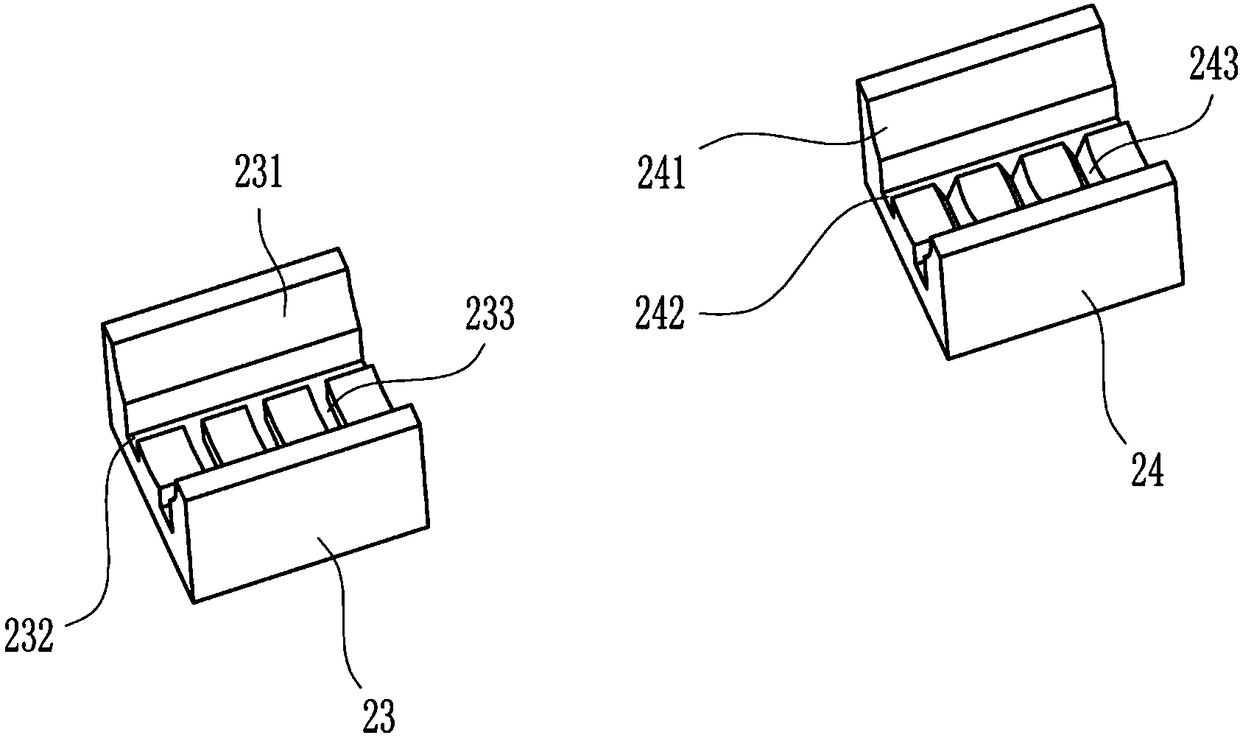

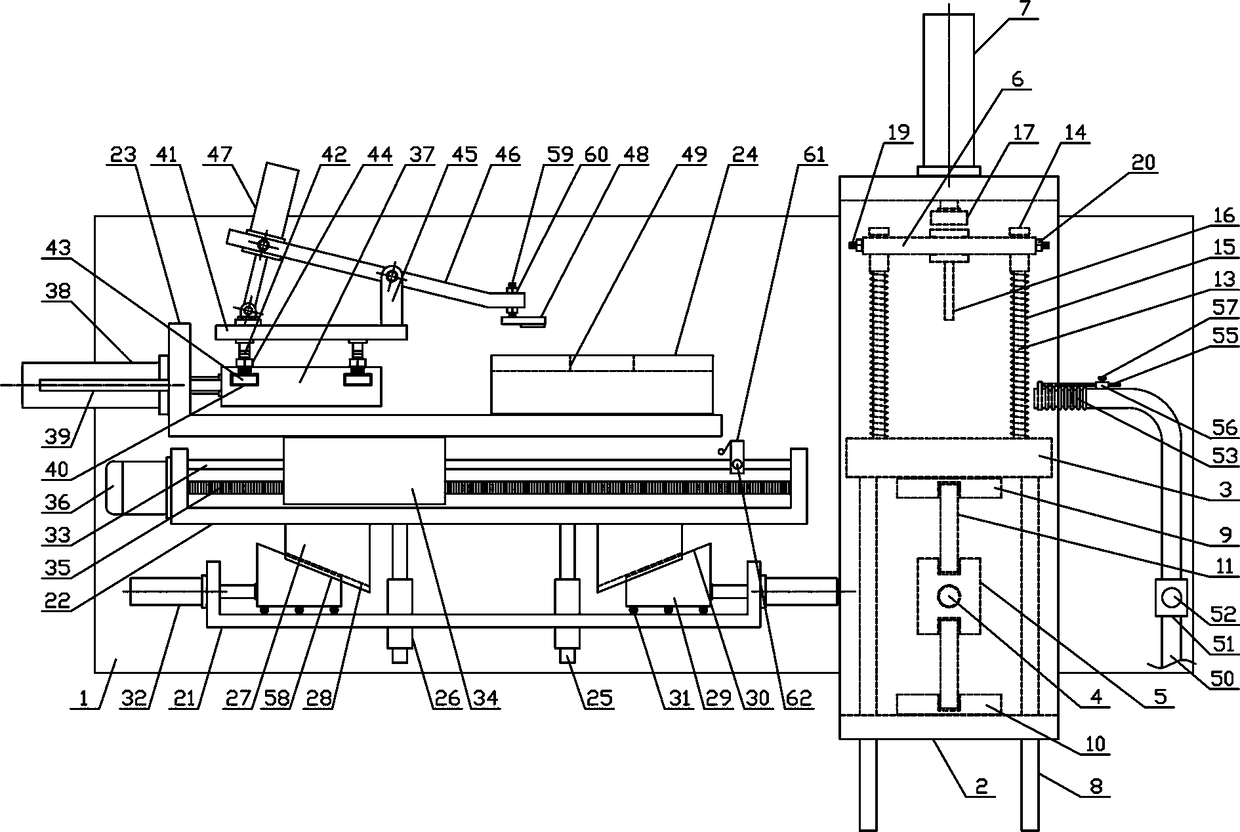

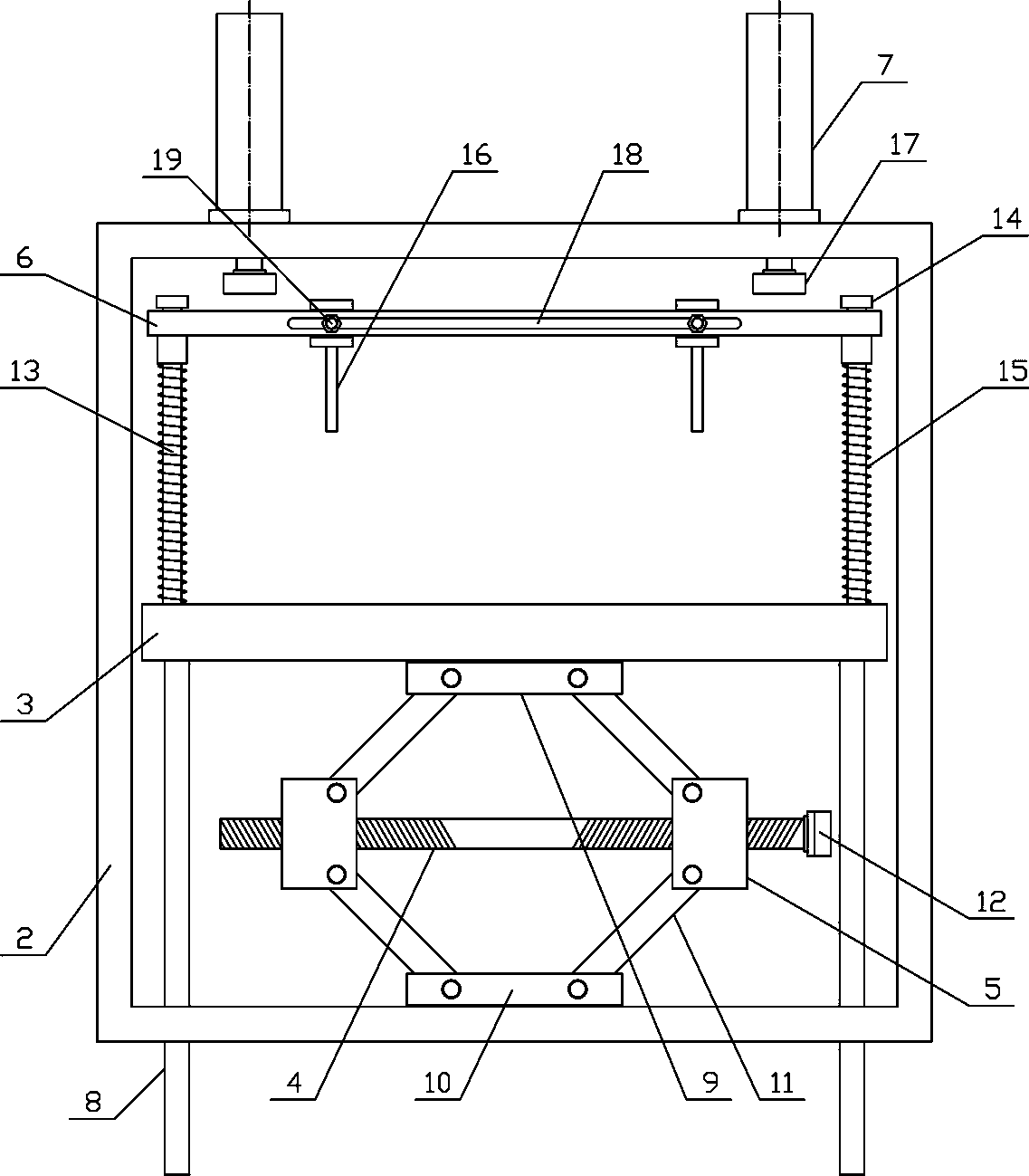

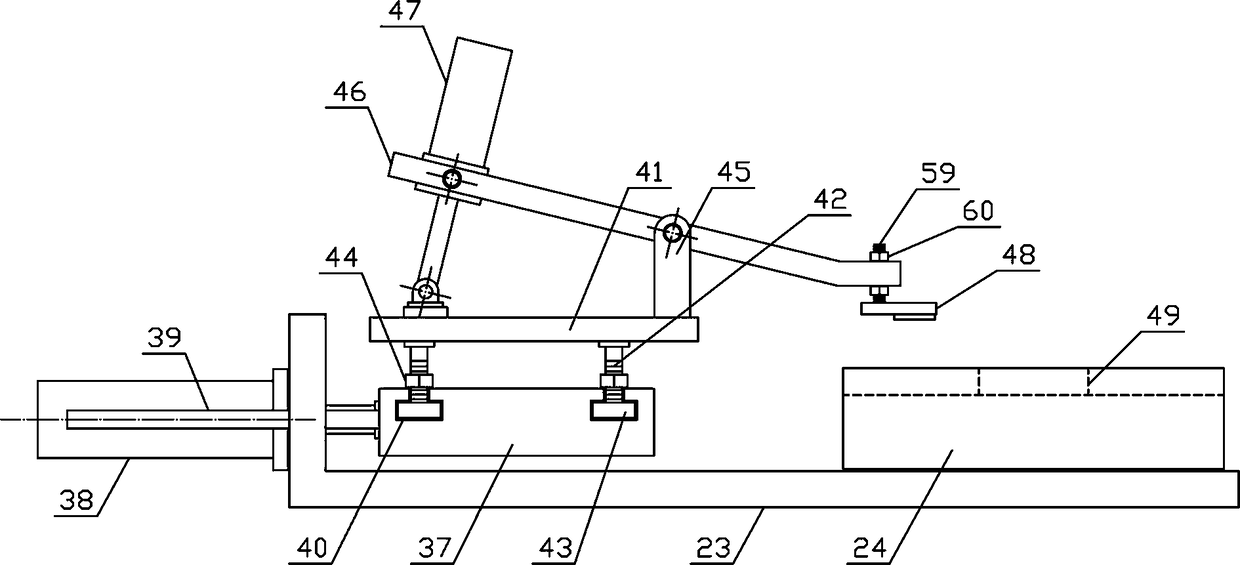

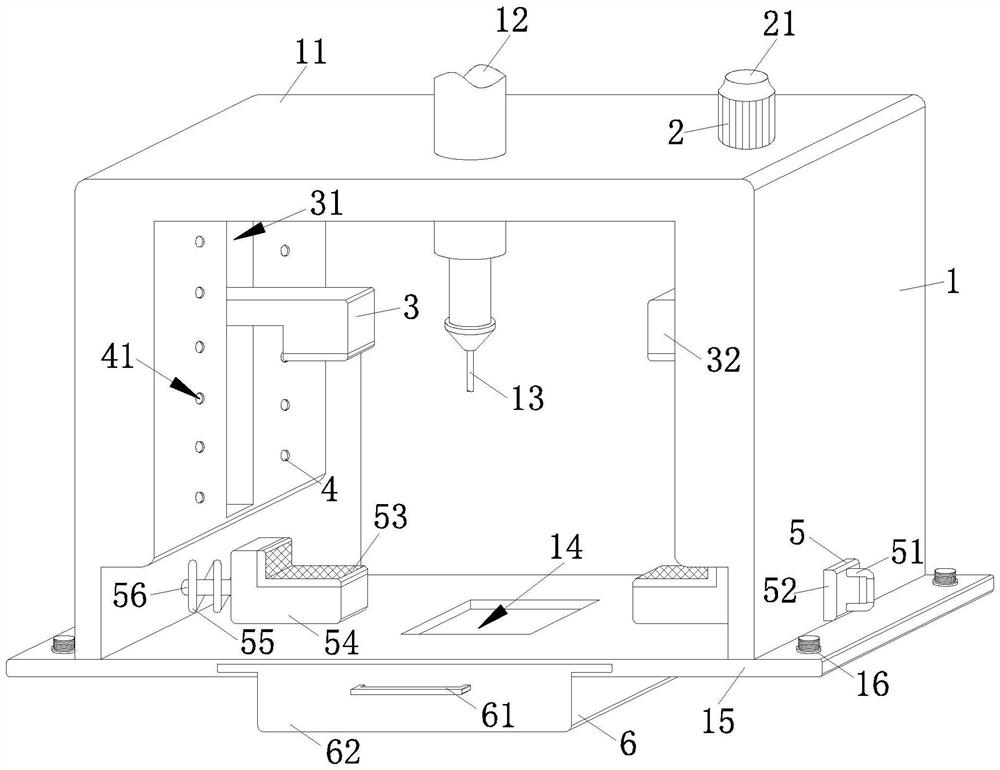

The invention relates to a cutting device of a heat exchange tube of a heat exchanger, in particular to a cutting device for a heat exchange tube of a chemical heat exchanger. The cutting device for the heat exchange tube of the chemical heat exchanger comprises a workbench and the like, wherein a clamping device and a driving device are arranged on the workbench, and the clamping device is connected with the driving device; and supports are located under the workbench, the supports are connected with the workbench through welding, and the plurality of supports are arranged. According to the cutting device for the heat exchange tube of the chemical heat exchanger, the clamping device and the driving device are arranged, so that the heat exchange tube can be fixed through the clamping device and the driving device, and a cutting machine can carry out accurate cutting on the heat exchange tube; and adopted parts are a few, the structure is simple, operation is convenient, performance issafe and reliable, and maintenance and repair are easy.

Owner:钟清

Intelligent dining table capable of being automatically cleaned

InactiveCN111329239AEasy to clean automaticallyEasy to pour automaticallyCarpet cleanersFloor cleanersStructural engineeringGarbage collection

The invention discloses an intelligent dining table capable of being automatically cleaned. The table comprises a bottom plate, a box and a tabletop body, wherein the upper surface of the bottom plateis fixedly connected with a box body; table top bodies are hinged to the upper ends of the left and right side walls of the box body; a heating plate is arranged on the inner side of the tabletop body; the side wall of the box body is rotationally connected with a supporting plate. The upper end of the supporting plate is rotationally connected to the side wall of the mobile frame. A threaded rodis rotatably connected to the interior of the front side wall of the rail frame, the auxiliary rod is fixedly connected to the interior of the rear side wall of the rail frame, the lower end of a connecting rod is connected with a scraper in a penetrating mode, a box door is hinged to the middle of the front side wall of the box body, and a spraying device is arranged on the outer side of a carrying block. According to the intelligent dining table capable of being automatically cleaned, the tabletop can be conveniently and automatically cleaned, the cleaning efficiency is improved, in addition, garbage can be conveniently and automatically dumped, subsequent garbage collection and cleaning are facilitated, and the practicability is improved.

Owner:赵建勋

Spice production device with high extraction rate

InactiveCN108034496AHigh extraction rateIncrease productivityEssential-oils/perfumesHeating timeSteam distillation

The invention discloses a spice production device with a high extraction rate. The spice production device comprises a fixing tank, wherein a squeezing tower is fixedly connected with one side of thetop of the fixing tank; a feeding funnel is communicated with the top of the squeezing tower; a fixing rack is fixedly connected between two sides of the inner wall of the squeezing tower; a first electromotor is fixedly connected with the surface of the fixing rack; the output shaft of the first electromotor is fixedly connected with a rotating rod; one end of the rotating rod is rotationally connected with an extrusion roller through a moveable part; a universal connector is rotationally connected with the bottom of the extrusion roller; the bottom of the universal connector is fixedly connected with the squeezing tower. The invention relates to the technical field of spice production. The spice production device with the high extraction rate adopts two extraction methods of physical squeezing and steam distillation, is relatively short in heating time, relatively low in electric consumption, high in production efficiency, small in floor space, rapid in production speed and wide in application range, and the extraction rate of spices is greatly increased.

Owner:梁林燕

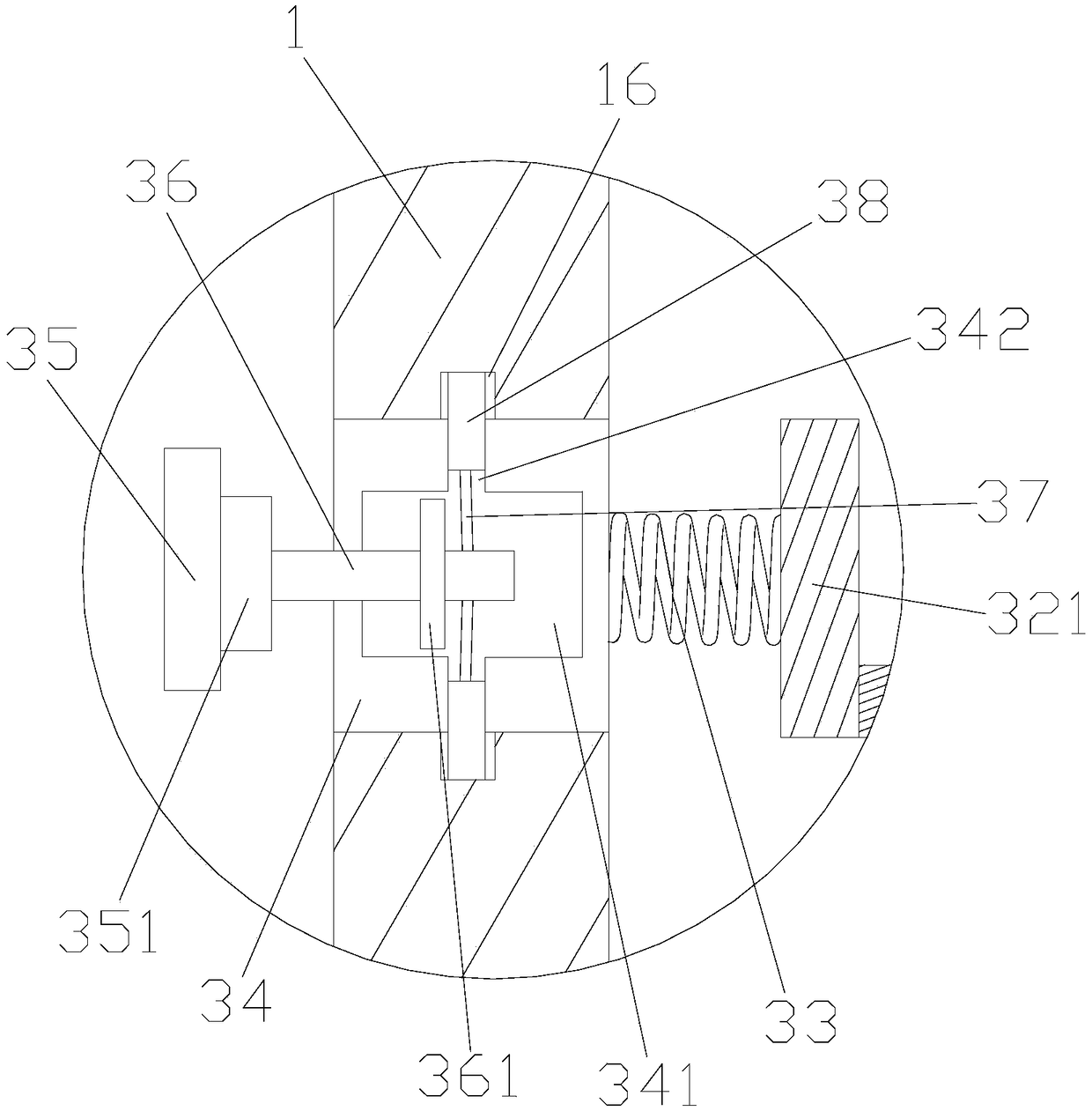

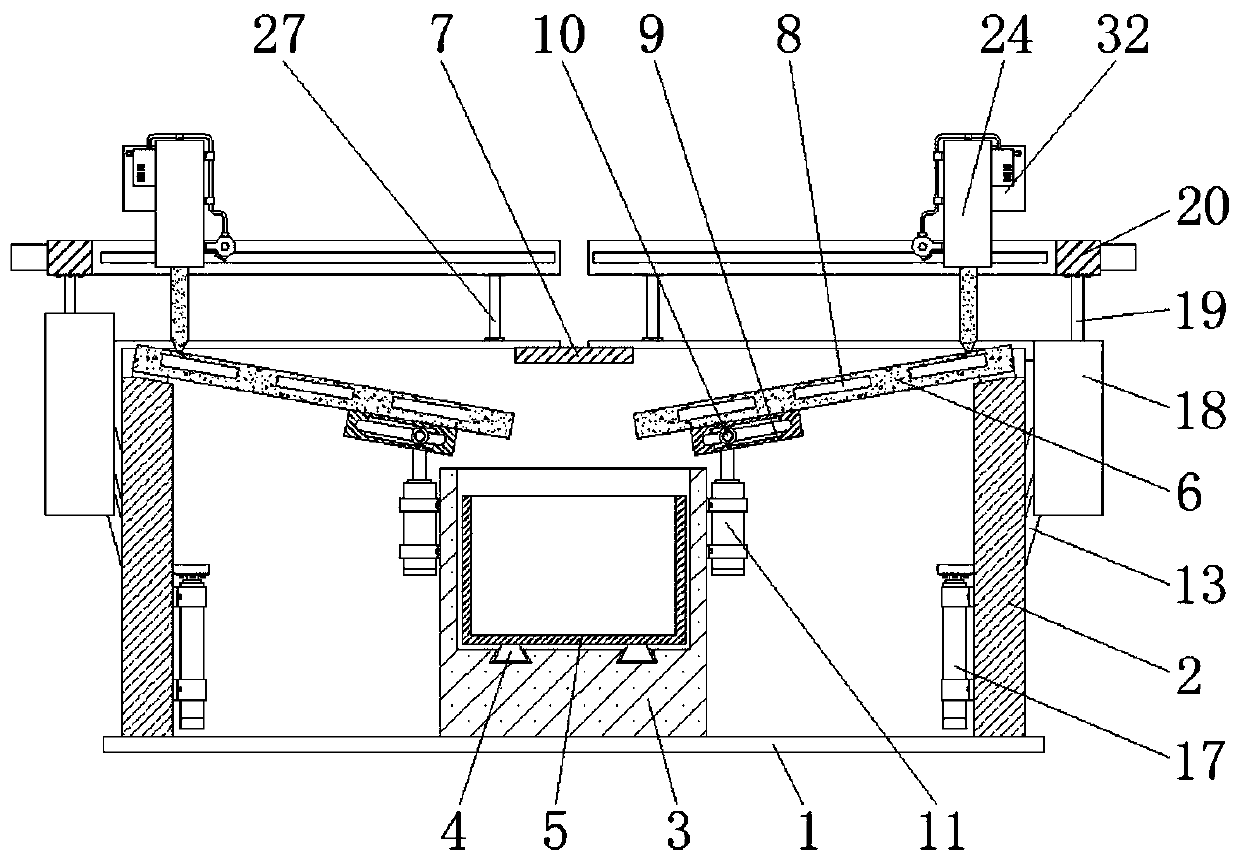

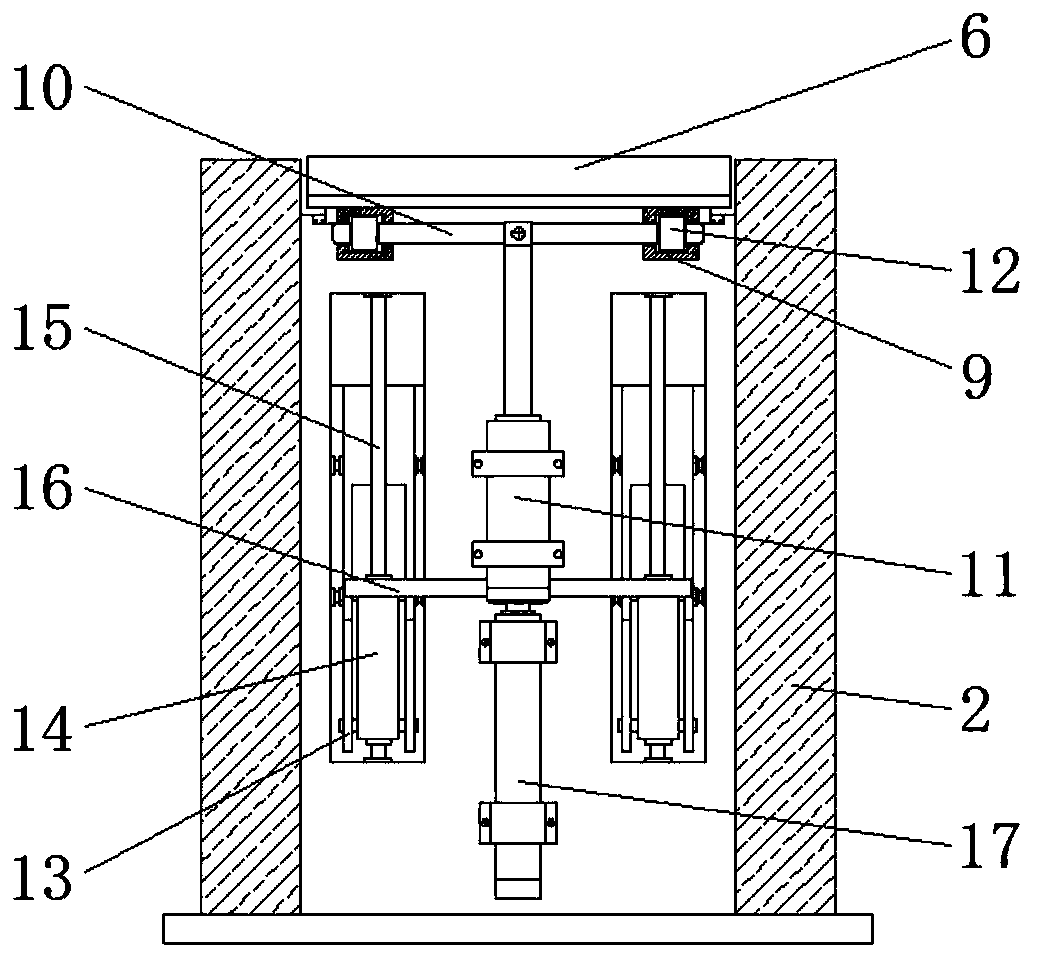

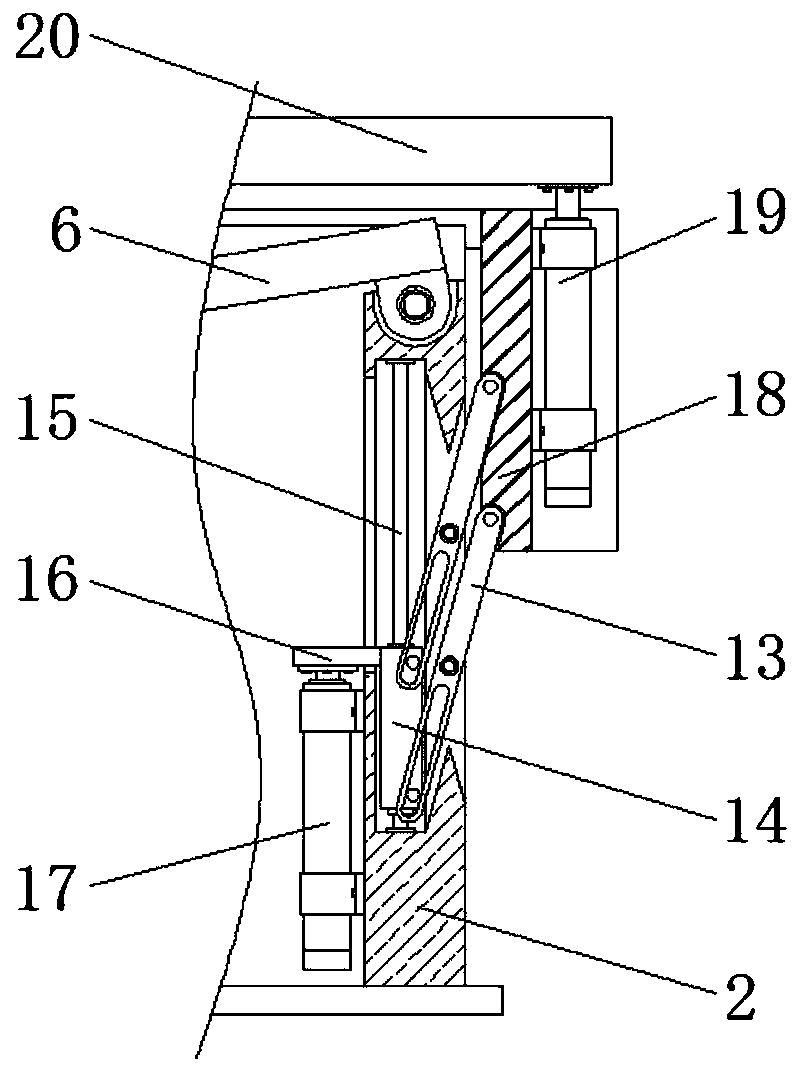

Garbage cleaning vehicle for interception ditch of bridge

InactiveCN107975088AAvoid cloggingEasy to collectSoil-shifting machines/dredgersEngineeringVertical displacement

The invention relates to a cleaning vehicle, in particular to a garbage cleaning vehicle for an interception ditch of a bridge. The invention aims to provide the garbage cleaning vehicle for the interception ditch of the bridge, wherein garbage can be effectively prevented from blocking the interception ditch and is collected and cleaned conveniently. In order to solve the technical problem, the garbage cleaning vehicle for the interception ditch of the bridge comprises a mounting plate, moving wheels, a collecting part, a vertical displacement part, a rotating part, a bearing plate, a connecting part and a clamping part, wherein the moving wheels are fixedly connected to the bottom surface of the mounting plate; the collecting part and the vertical displacement part are fixedly connectedto the top surface of the mounting plate, successively; the rotating part is in transmission connection to the output end of the vertical displacement part, and the bearing plate is in transmission connection to the output end of the rotating part; and the connecting part is fixedly connected to the bottom surface of the bearing plate. The garbage cleaning vehicle provided by the invention achieves the effects of preventing the garbage from blocking the interception ditch effectively and collecting and cleaning the garbage conveniently.

Owner:于德泉

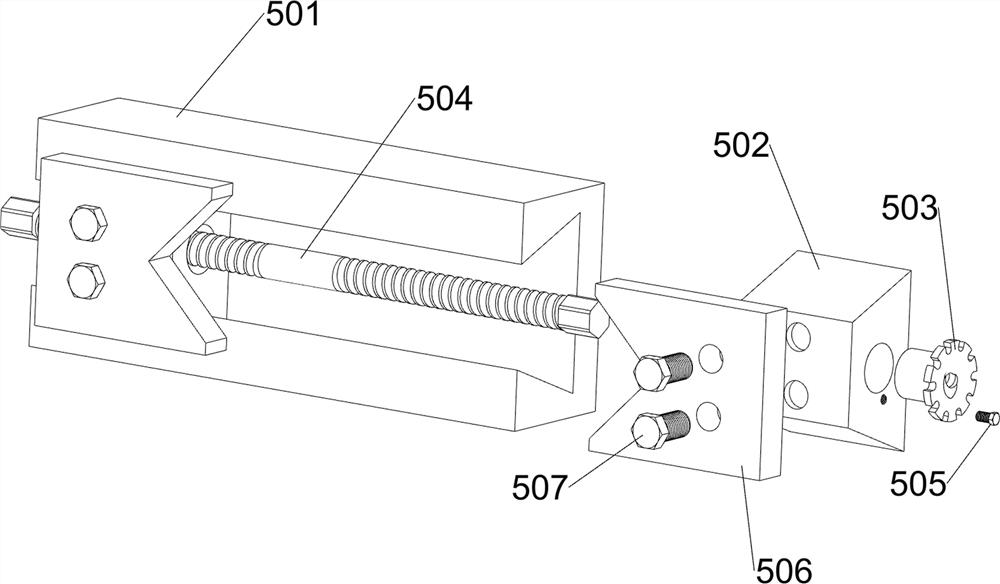

Flange-short pipe welding device and method

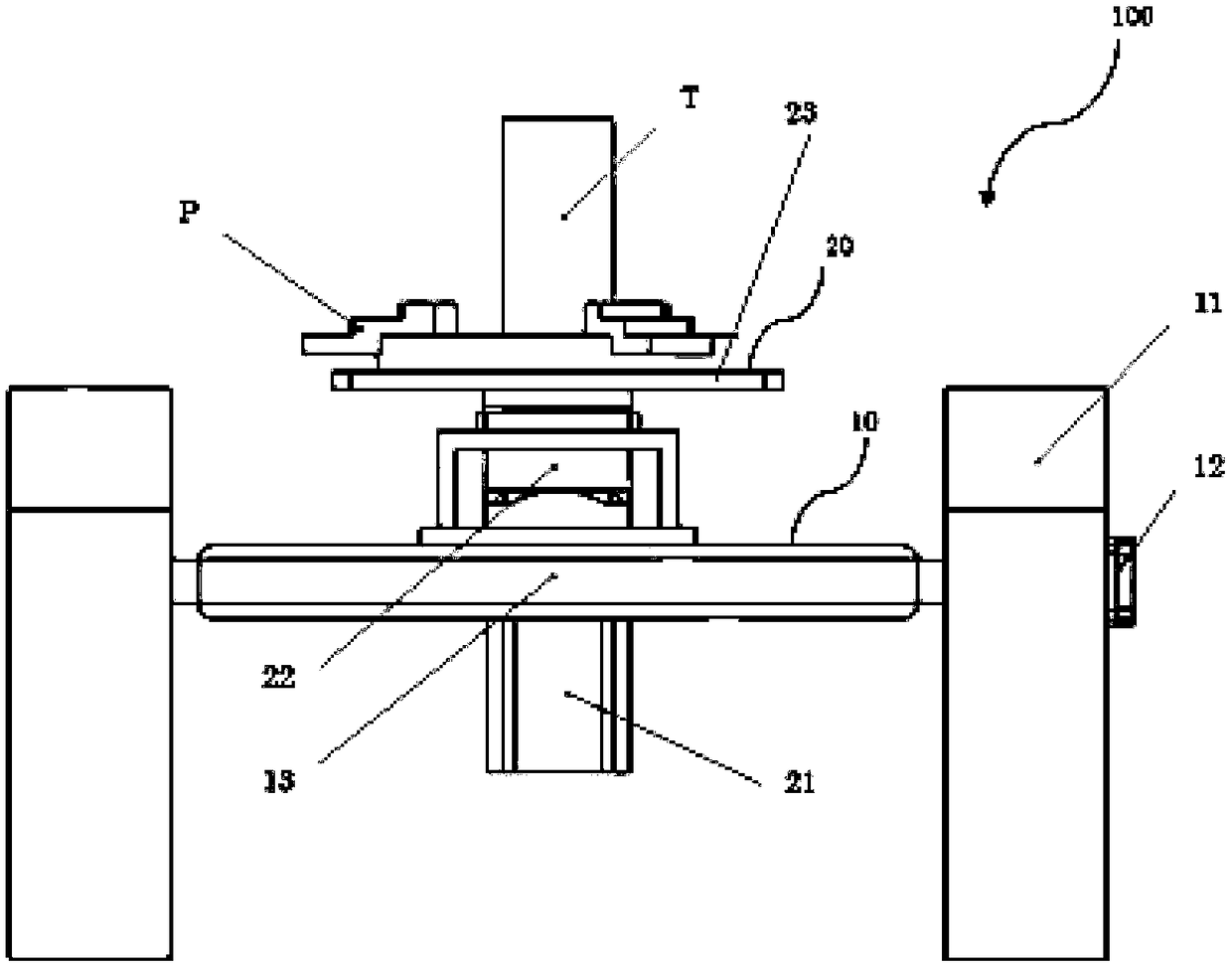

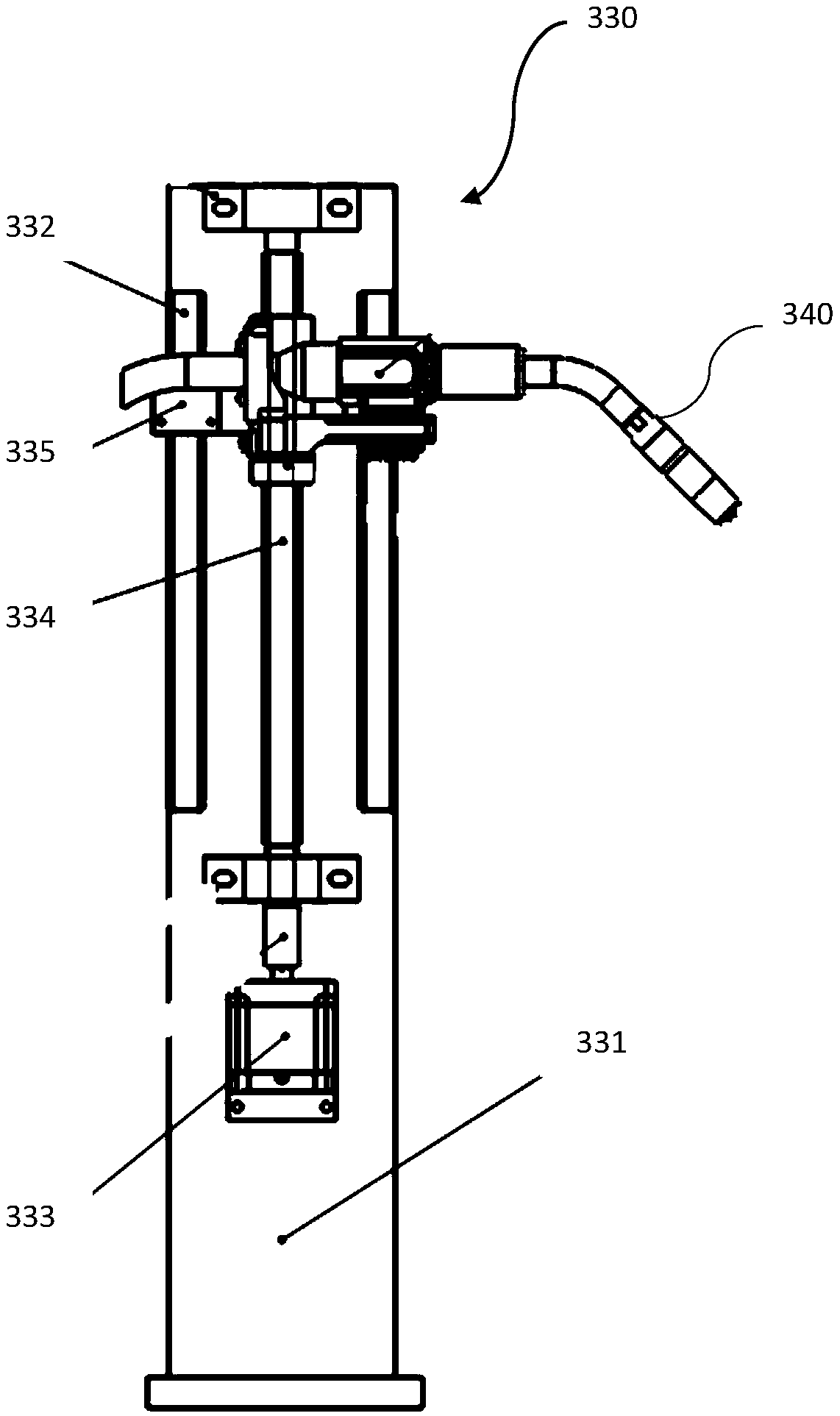

InactiveCN109483115AGuaranteed static workGuarantee and control of static workWelding/cutting auxillary devicesAuxillary welding devicesMotor driveEngineering

The invention relates to a flange-short pipe welding device and method. The device comprises a supporting portion, a welding execution portion and a welding gun portion, wherein the supporting portioncomprises supporting blocks, a first motor and a supporting frame, and the first motor drives the supporting frame to rotate; the welding execution portion comprises a second motor, a reduction box and a square rotary table, the second motor drives the square rotary table to rotate through the reduction box, and a plurality of groups of bolt holes used for fixing multiple types of flanges of predetermined specifications and multiple types of welding clamps are formed in the rotary table; and the welding gun portion comprises a first lead screw transmission assembly, a second lead screw transmission assembly, a third lead screw transmission assembly and a welding gun and used for performing fixed-point welding above the welding execution portion. Thus, the flange-short pipe welding deviceprovided by the invention is easy to operate, only simple learning is needed before skilled workers participate in production, in addition, the welding specialization degree is higher, the technological reproducibility is good, the product forming attractiveness is effectively guaranteed and controlled, and bulk duplicating of welding production is facilitated.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

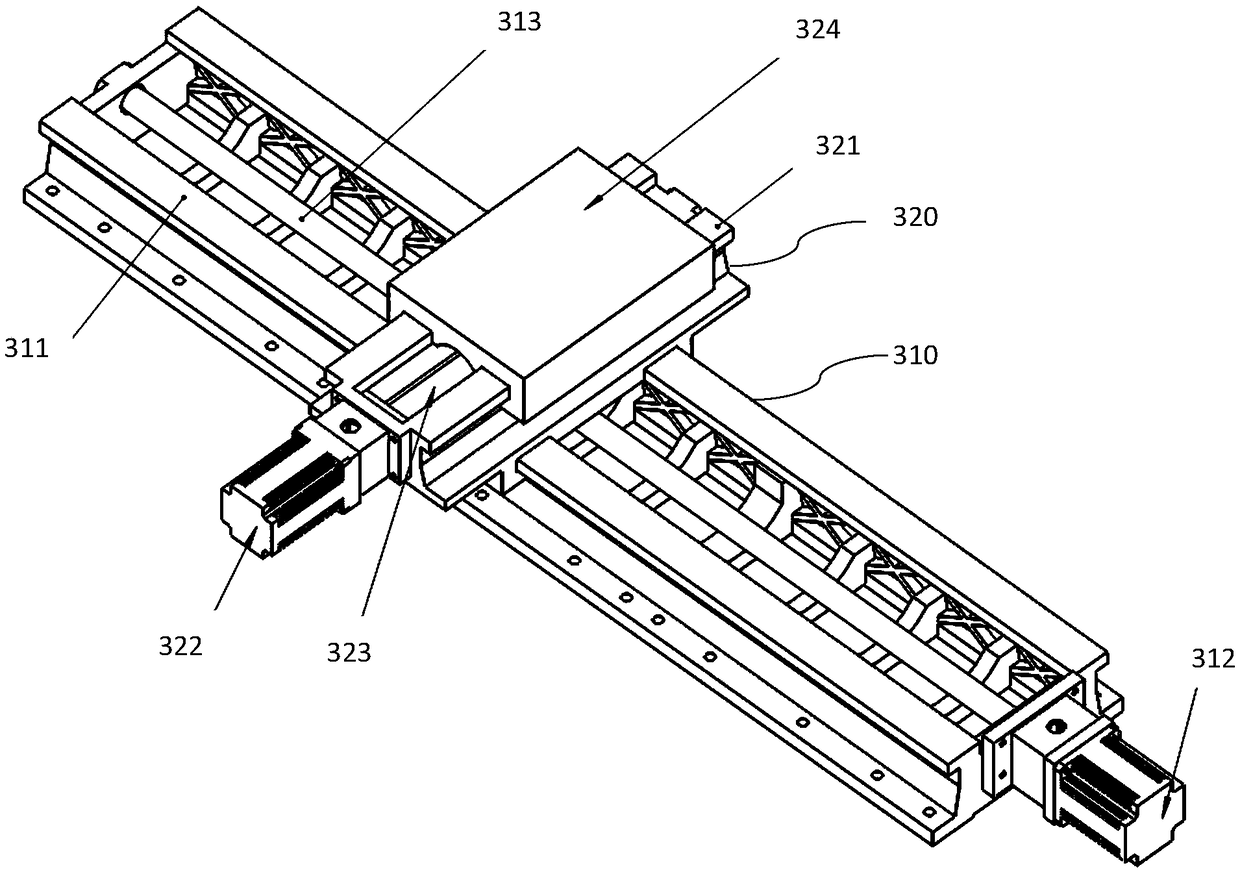

Profile translation perforating mechanism

InactiveCN108480467APunch fullyNo offset shakingPerforating toolsMetal-working feeding devicesMechanical equipmentGuide tube

The invention discloses a profile translation perforating mechanism, and belongs to the field of building material machining mechanical equipment. According to the profile translation perforating mechanism, a translation pushing mechanism is horizontally arranged on one side of a fixed support; a perforating mechanism is vertically arranged at the position, on one side of the translation pushing mechanism, of the fixed support; a lifting bearing plate is horizontally arranged in the middle of a perforating support; a perforating pressing plate slides in the vertical direction to be arranged onperforating guide rods; a lifting pressing plate is fixedly arranged at the output ends of perforating air cylinders; a clamping base is horizontally arranged on the upper side of a pushing support of the translation pushing mechanism; the output end of an adjusting air cylinder on one side of the pushing support is fixedly connected with the middle of one side of the clamping base; a clamping air cylinder is arranged at the upper end of a clamping pressing rod by inclining downwards; and a sundry suction guide pipe is vertically arranged on one side of the fixed support. The profile translation perforating mechanism is reasonable in structural design, profiles of multiple dimensions can be fast and efficiently subjected to section-by-section accurate translation feeding for perforating machining, the profile machining efficiency and quality can be improved, and the machining use requirement can be met.

Owner:沈洁

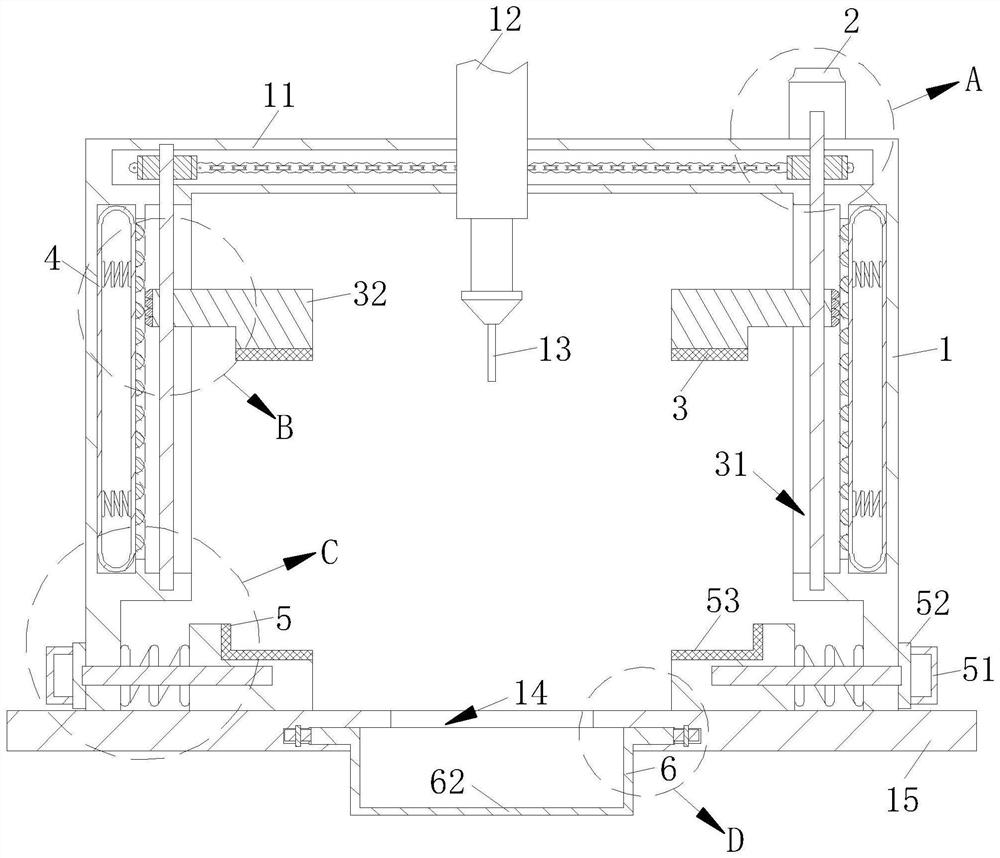

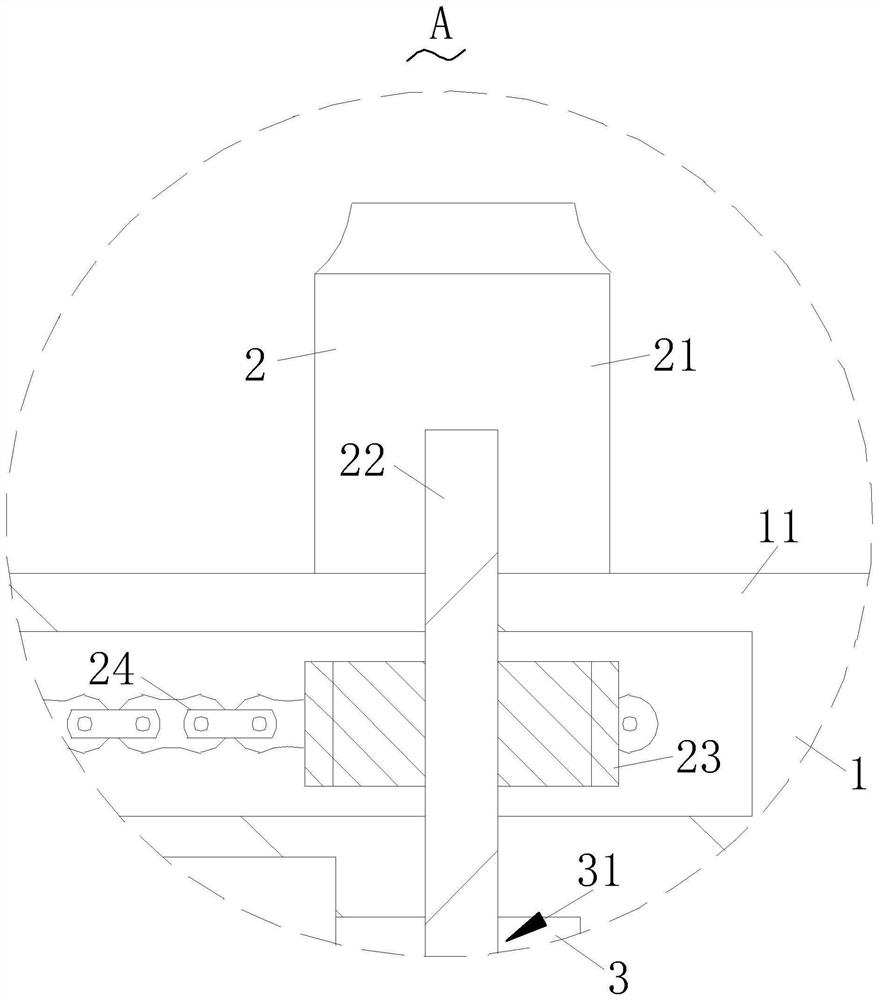

Environment-friendly punching device with precise positioning function

The invention relates to the field of environment-friendly punching devices with a precise positioning function, in particular to an environment-friendly punching device with a precise positioning function. The device comprises a main body mechanism, a driving mechanism, a sliding mechanism, a cleaning mechanism, a fixing mechanism and a storage mechanism. An operator pulls the fixing mechanism to conveniently clamp and position the side wall of a material needing to be punched, and when the driving mechanism rotates, the sliding mechanism fixes the top end of the material when sliding in the main body mechanism. Therefore, the situation that the punching position deviates due to the fact that the position of the material moves when the material is subjected to impact force during punching is prevented; when the sliding mechanism slides, the sliding mechanism abuts against the side wall of the cleaning mechanism, so that when the cleaning mechanism is extruded, internal gas is exhausted into the main body mechanism, chippings on the side wall of the device are blown off, and then the situation that the chippings affect the punching effect of the device is advantageously prevented; and when the device is used for punching the material, waste falls into the storage mechanism through the main body mechanism, so that an operator can conveniently collect and clean the waste.

Owner:邯郸市强合五金制品制造有限公司

Chipping arranging platform for mechanical part machining

InactiveCN108688695AEasy to cleanEasy to pourCell component detailsHand carts with multiple axesHydraulic cylinderEngineering

The invention relates to a chipping arranging platform for mechanical part machining. The chipping arranging platform comprises a battery box. A chipping collecting box is further fixedly connected tothe left side of the battery box, and a first baffle is fixedly connected to the top of the chipping collecting box. A second baffle is arranged on the rear side of the first baffle, and a third baffle is fixedly connected to the left end of the second baffle. The second baffle and the third baffle are both arranged at the top of the chipping collecting box, a first chipping net is movably connected to the first baffle, and a second chipping net is movably connected to the second baffle. The first chipping net and the second chipping net are movably connected to the first baffle and the second baffle through hinges correspondingly. A chipping scraping mechanism is further arranged between the first baffle and the second baffle and is composed of a hydraulic cylinder, a hydraulic telescopic rod and a hanging plate. The hydraulic cylinder is fixedly connected to the top of the battery box. The overall structure is simple, using is convenient, safety and sanitation are achieved, waste chippings generated in machining are conveniently collected and cleared, and meanwhile the waste chippings are convenient to dump and treat.

Owner:张芹

Water purification device for organic culture of mandarin fish

The invention discloses a water purification device for organic culture of mandarin fish. The water purification device comprises a pond body, the bottom of the pond body is obliquely arranged, and a sludge discharge mechanism and an impurity discharge mechanism are arranged in the pond body; the sludge discharging mechanism comprises a collecting groove, the collecting groove is formed in the lower end of the bottom of the pool body, a collecting pipe is arranged in the collecting groove, a plurality of sludge suction openings are formed in the collecting pipe, and the upper end of a control rod is rotationally connected with a rack through a fluted disc; and the residue discharge mechanism comprises a collecting frame, the collecting frame is of an L-shaped structure, the collecting frame is in a grid shape, the collecting frame is arranged on the side, close to the collecting groove, of the bottom of the pond body, and a lifting mechanism is arranged on the collecting frame. By arranging the collecting frame, some sundries are filtered, blockage is avoided, the sundries are discharged by lifting the collecting frame, cleaning and collecting are facilitated, sludge in the pond body can be collected and cleaned at any time, and efficiency is high.

Owner:安徽益丰生态农业开发有限公司

Conveniently-used bottom board cleaning device used for decoration construction team

InactiveCN108903836ASave electricityCheap to manufactureCarpet cleanersFloor cleanersEngineeringBrush device

The invention relates to the technical field of decoration devices, in particular to a conveniently-used bottom board cleaning device used for a decoration construction team. The technical problem that paint stains on a bottom board is inconvenient to clean after decoration is resolved. In order to resolve the above technical problem, the invention brings forward a conveniently-used bottom board cleaning device used for the decoration construction team. The device comprises a housing. The interior of the housing is equipped with a kinetic energy transmission device, a hammering device, a ground-brushing device and paint removal device. A rotary shaft is arranged in the housing. Two ends of the rotary shaft are welded with large movable wheels. The conveniently-used bottom board cleaning device used for the decoration construction team can clean dust on the floor and remove paint stains on the floor. During the process of cleaning paint stains, traces can be removed. Therefore, the floor looks more attractive and cleaner, wining more favorable comments. Therefore, the possibility at which the decoration construction team receives orders next time is greatly increased.

Owner:刘小亮

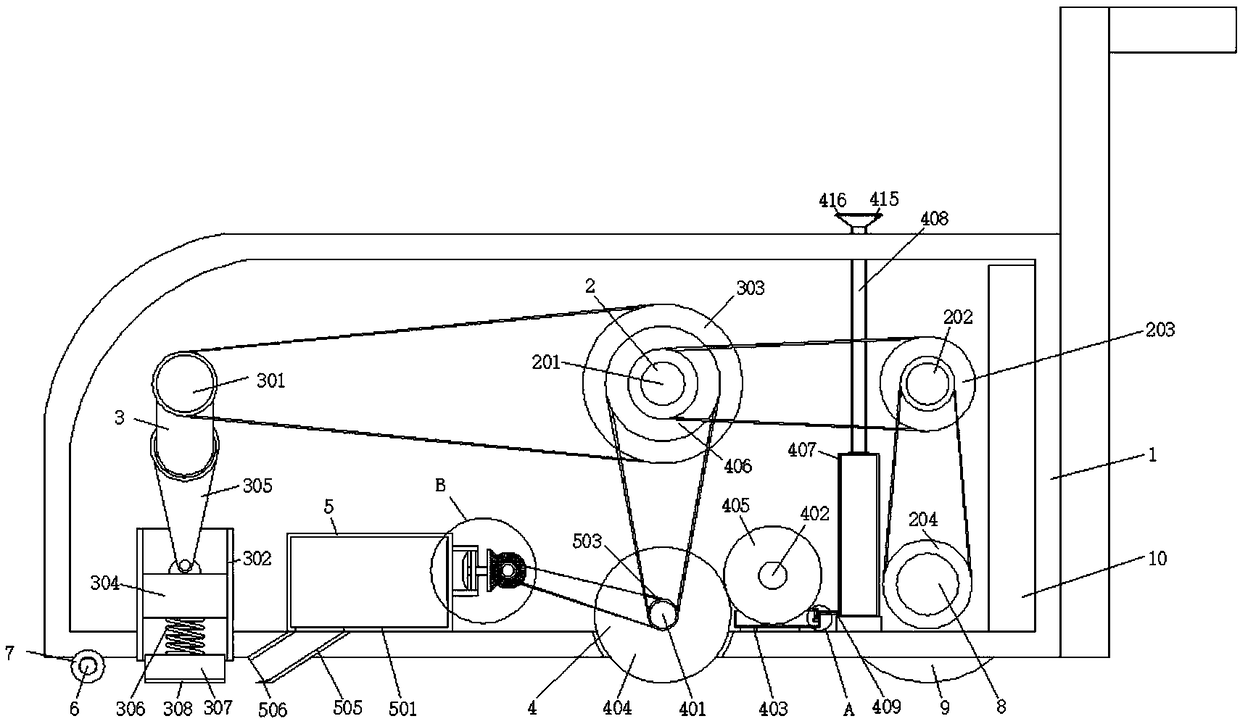

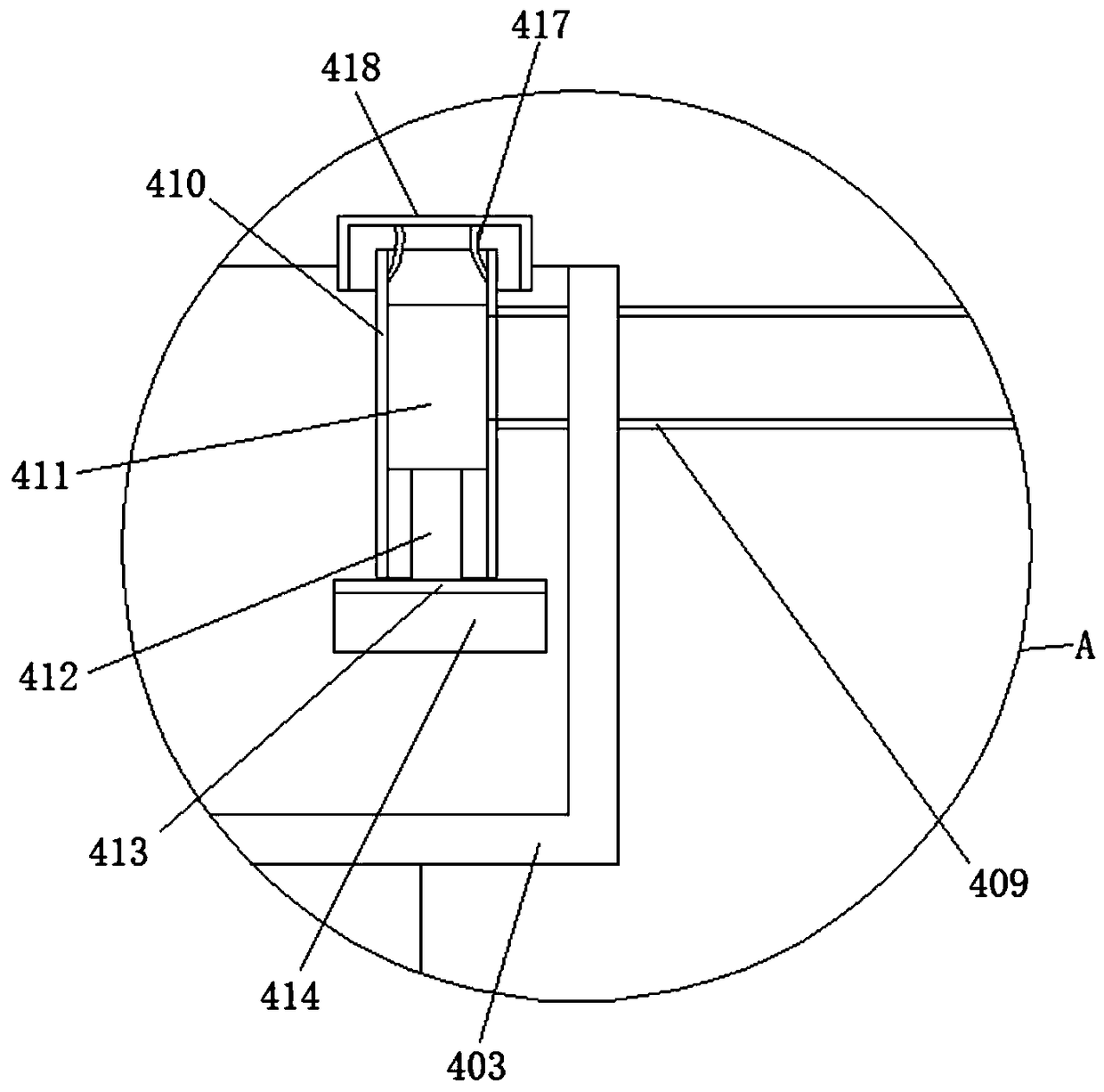

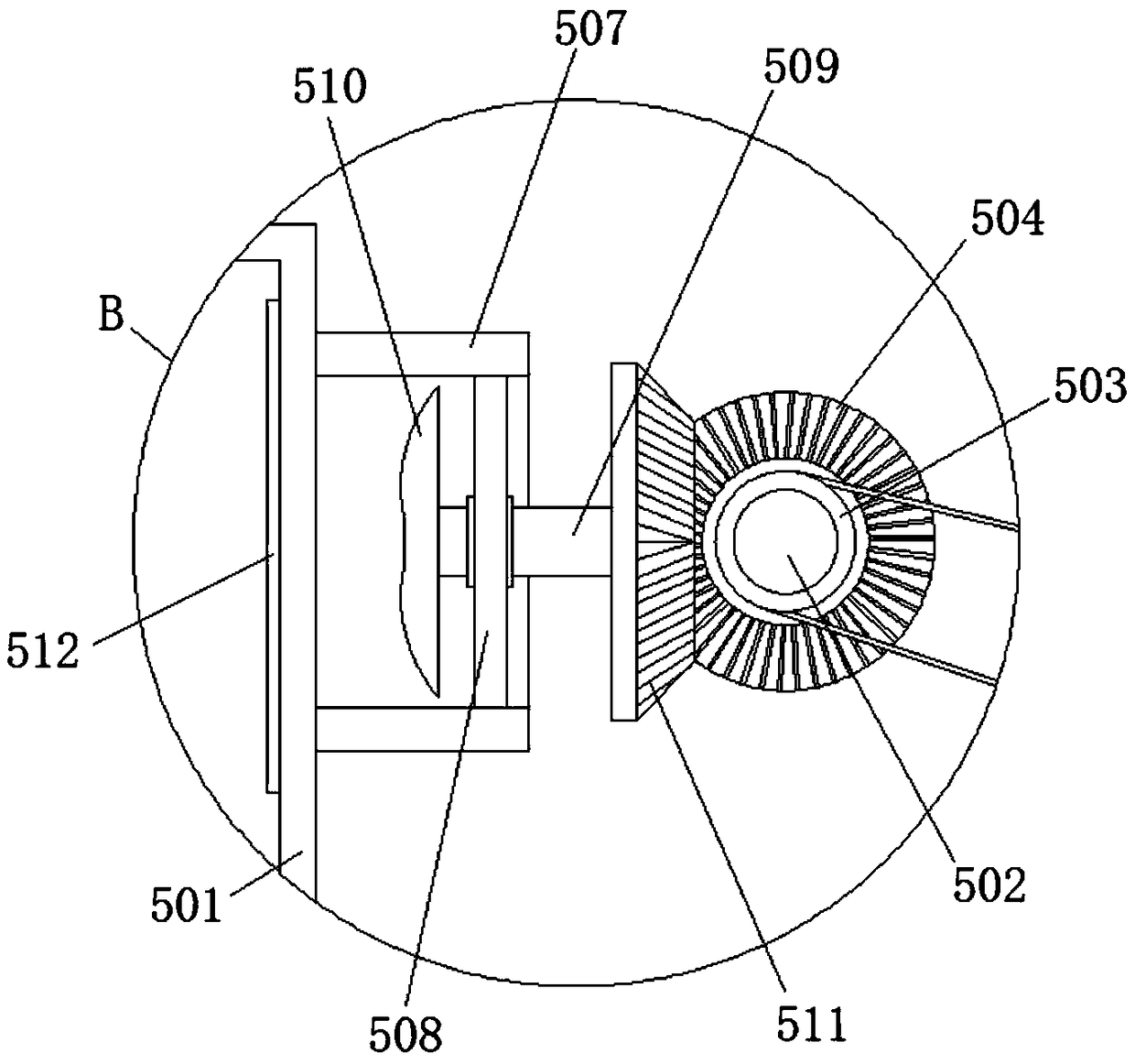

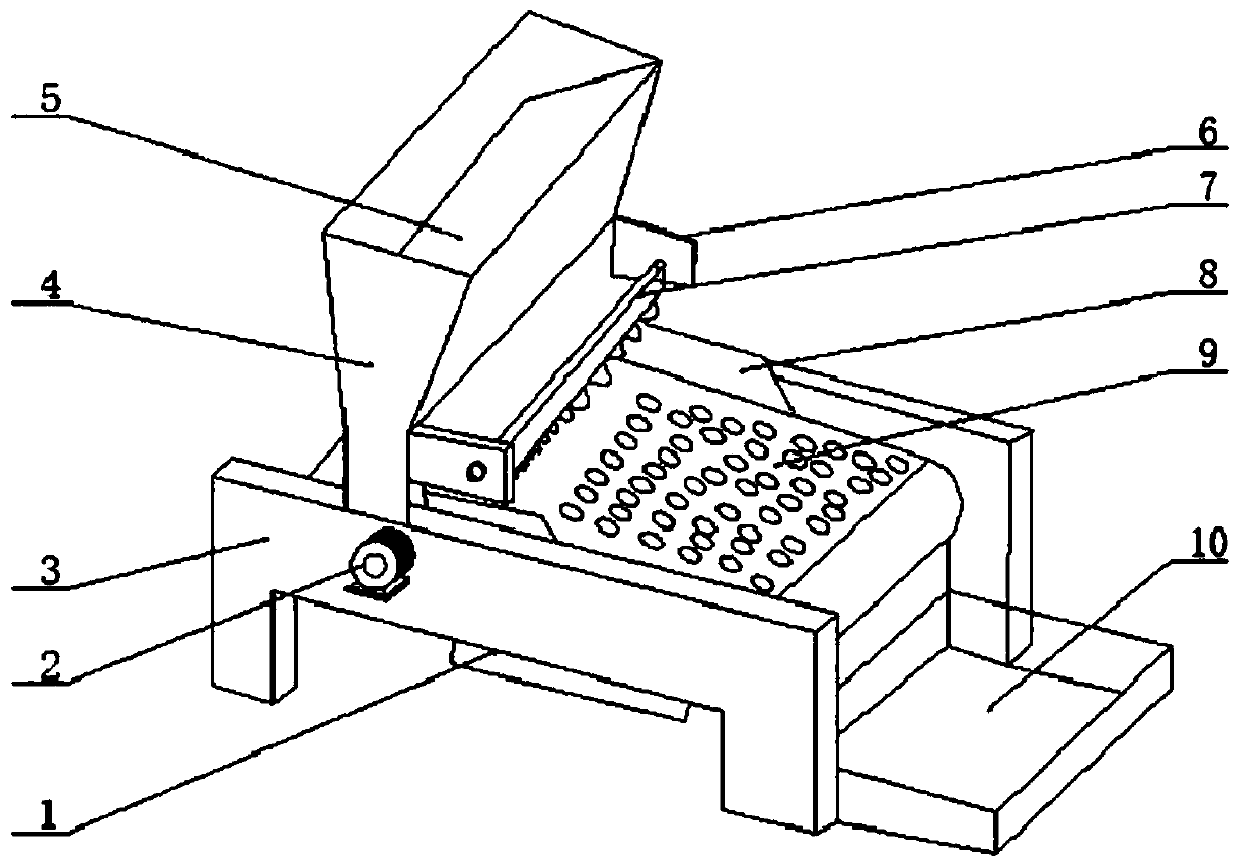

Screen type tea leaf sorting machine

InactiveCN110420829ASimple structureEasy to operateSievingPre-extraction tea treatmentPulp and paper industryTea leaf

The invention discloses a screen type tea leaf sorting machine. The screen type tea leaf sorting machine comprises a machine frame, wherein a conveying mechanism is arranged on the machine frame, anda brush plate is arranged at one end of the machine frame; and the conveying mechanism comprises a motor fixed on the machine frame, a first roller, a second roller, and a conveying belt connecting the first roller with the second roller, the first roller and the second roller are rotationally arranged on the machine frame correspondingly, a plurality of through filtering holes are formed in the surface of the conveying belt, a rotating head of the motor is coaxially connected with the first roller so that the motor can drive the first roller to rotate, and the brush plate is positioned abovethe conveying belt. According to the screen type tea leaf sorting machine, the problems that tea leaves are and tea stems can be quite difficultly separated through a traditional sorting machine, andthe separation efficiency is low are solved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Multi-stage processing device for high-speed train seat parts

InactiveCN111823020AEasy to dryEasy to moveDrying gas arrangementsCleaning using toolsWater storageWater storage tank

The invention discloses a multi-stage processing device for high-speed train seat parts, and belongs to the technical field of high-speed train seat production. The device comprises a device main body, a drilling table is fixedly connected to the lower surface of the inner wall of the device main body, and an exhaust fan is fixedly connected to the lower surface of the inner wall of the drilling table. According to the multi-stage processing device for the high-speed train seat parts, a heating mechanism, an electromagnet, a first hydraulic rod, a mesh box, a second hydraulic rod, a third hydraulic rod and a water storage box are arranged; through the cooperation of the mesh box and the water storage box, the parts can be directly cleaned after being drilled; through cooperation of the exhaust fan and the heating mechanism, the parts are directly dried after being cleaned; and through the cooperation of the electromagnet, the first hydraulic rod and the second hydraulic rod, the partscan be adsorbed and conveniently and directly moved into a spraying mechanism for spraying, so that the tedious process can be effectively reduced, the operation is convenient, and the processing efficiency is improved.

Owner:HUBEI DERUI SITONG TECH

Street garbage can convenient to pour

InactiveCN107814105ASimple structureEasy to useRefuse receptaclesFixed frameArchitectural engineering

The invention discloses a street garbage can convenient to pour. The street garbage can convenient to pour comprises a fixed frame and a garbage outer can; the fixed frame penetrates through the garbage outer can through valve rods on two sides of an inner rod, so that the garbage outer can is fixed on the fixed frame; semicircular fixed bases are arranged on the fixed frame corresponding to two sides of the garbage outer can; annular chutes surrounding the fixed bases are formed in the inner sides of the fixed bases; shielding semi-cylindrical plates capable of achieving an effect of shielding the garbage can below the fixed frame are slidingly arranged in the annular chutes; fixed convex columns are arranged on the side surfaces of one ends of the shielding semi-cylindrical plates, and sleeve downward transmission rods; a slow lifting mechanism is connected below the transmission rods; the slow lifting mechanism sleeves the outer wall of the garbage outer can, and penetrates throughthe bottom of the garbage outer can; and a garbage inner can is arranged in the garbage outer can, and is connected with a bottom slow lifting mechanism. The street garbage can convenient to pour overcomes the defects in the prior art, and adopts a linkage design.

Owner:中山市通发自动化设备有限公司

Seed screening and water separating device

InactiveCN109013042AAgitation worksEffective settlementSeed and root treatmentCleaning using liquidsScreening effectSurface mounting

The invention relates to the technical field of seed water separation and screening and discloses a seed screening and water separating device. The device comprises a base, and top of the base is fixedly connected with two symmetric supporting frames. A supporting plate is fixedly connected between the top ends of the two supporting frames, and the front face of the supporting plate is fixedly connected with two symmetric fixed sleeves. A water inlet pipe is sleeved between the inner rings of the two fixed sleeves, and spray heads are mounted on the outer surface of the water inlet pipe at equal intervals. A fixed plate is fixedly connected between the opposite side faces of the two supporting frames. The bottom of the fixed plate is fixedly connected with a motor and two supports. An output shaft of the motor is fixedly connected with a first belt wheel through a rotary shaft, and a rotary rod is movably connected between the side faces of the two supports. The seed screening and water separating device solves the problems that an existing seed water separation device is not high in work efficiency, seed separation is not thorough, trouble is caused, and labor is wasted, and has the beneficial effects of being high in work efficiency and good in screening effect and saving trouble and labor.

Owner:合肥安农源生物工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com