Flange-short pipe welding device and method

A welding device and short pipe technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of increasing production costs, routine maintenance, and maintenance costs of enterprises, achieve beautiful appearance, and facilitate collection and cleaning. good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments illustrate the flange and short pipe welding device of the present invention in detail in conjunction with the accompanying drawings.

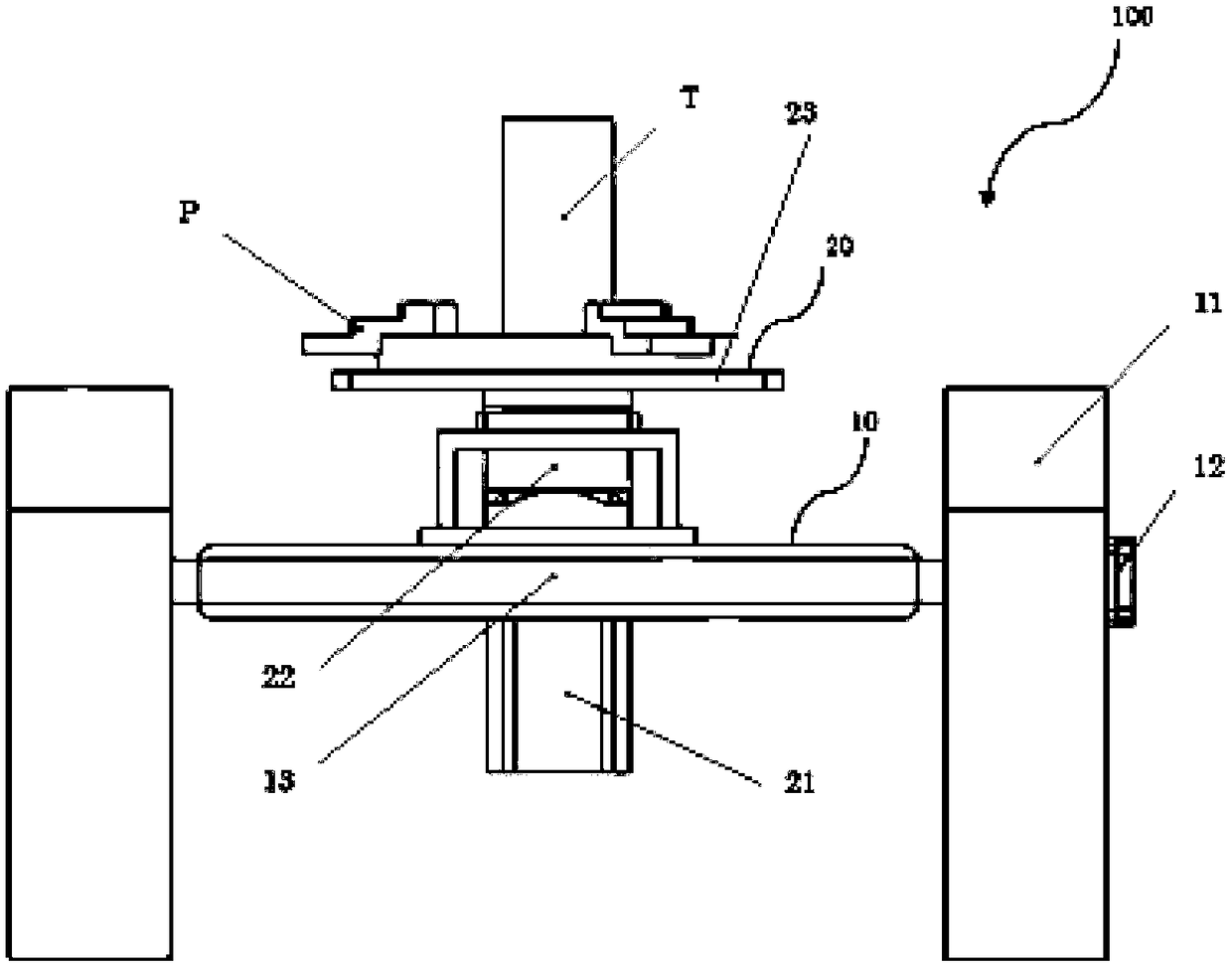

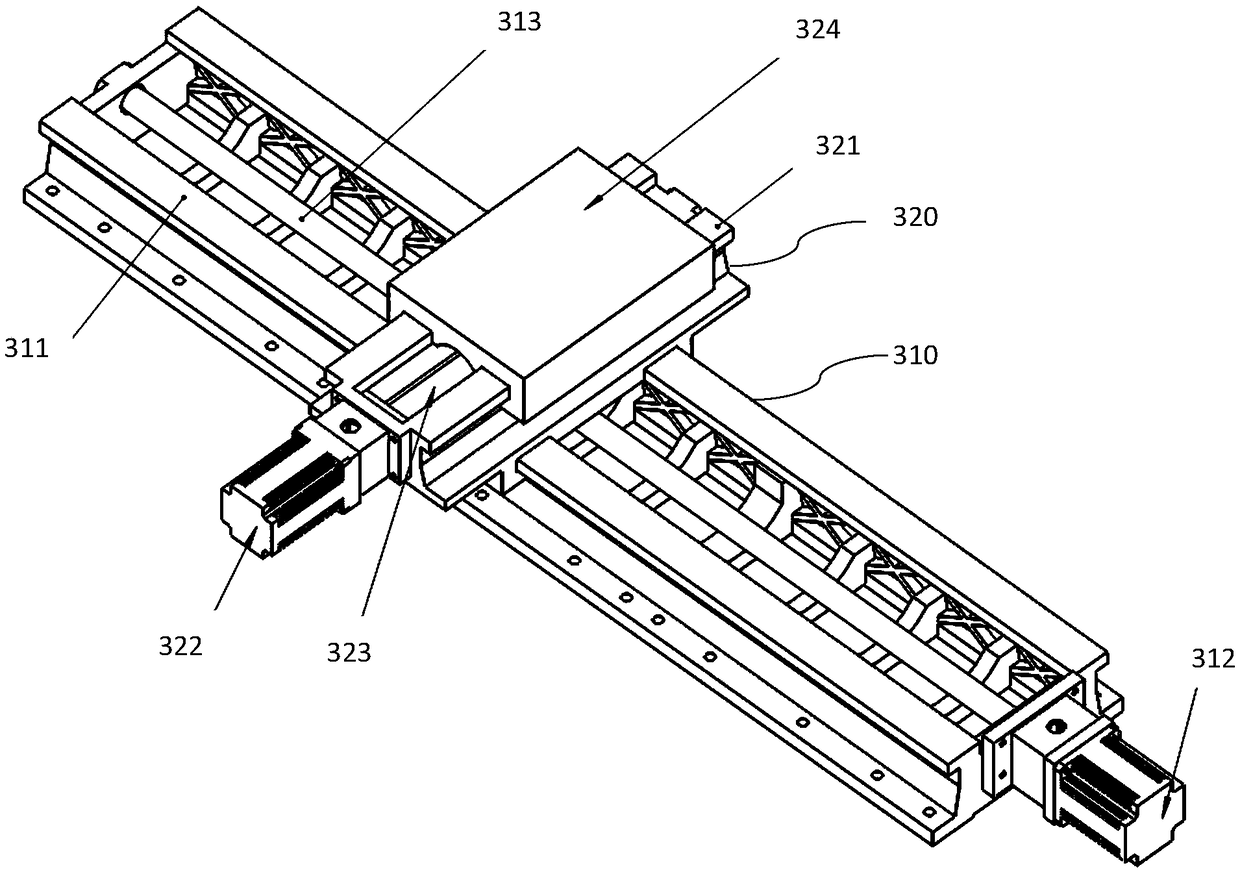

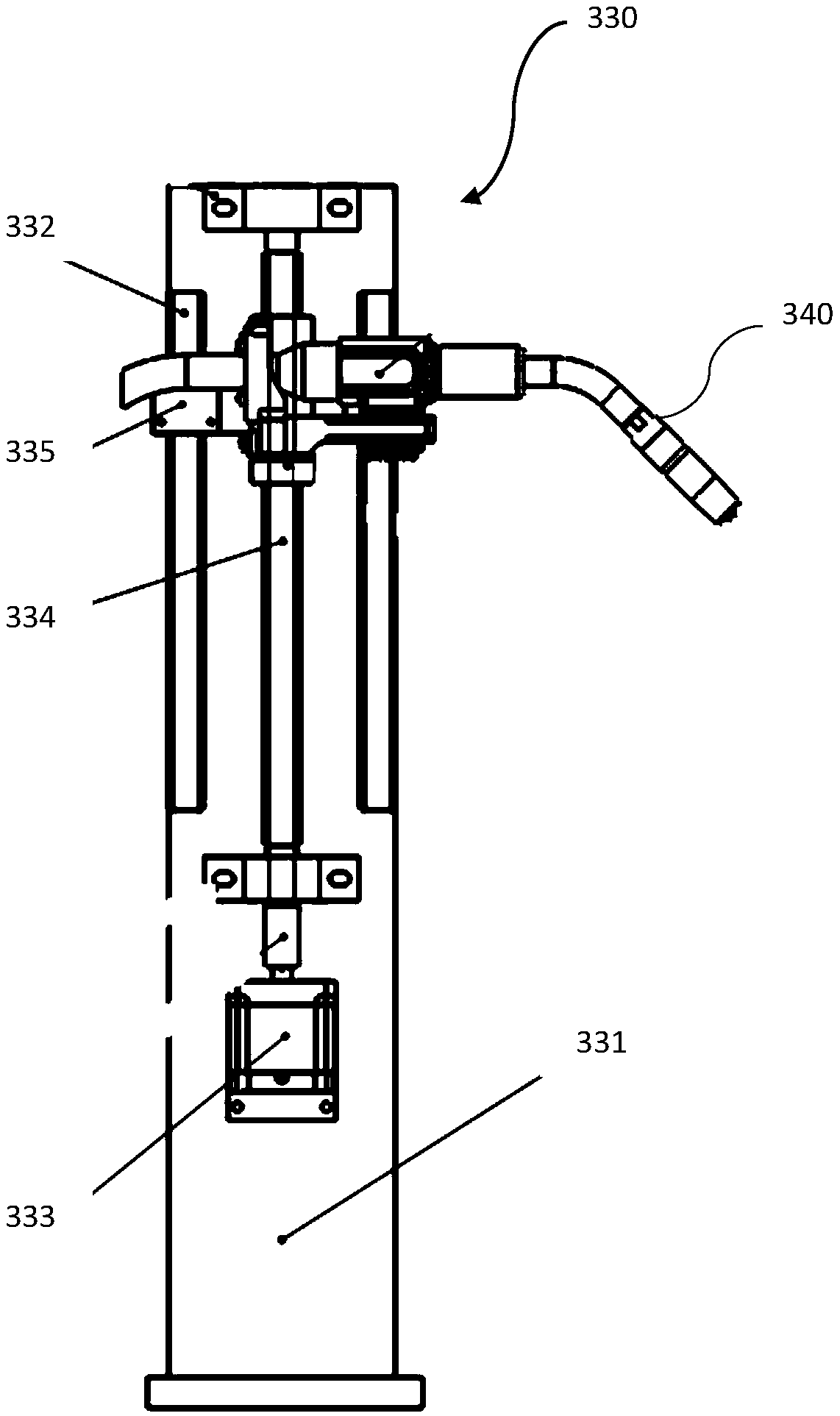

[0043] Such as figure 1 , Figure 4 As shown, a flange and short pipe welding device 100 includes a support part 10 , a welding execution part 20 and a welding torch part 30 .

[0044] The support part 10 includes a support block 11, a first motor 12 and a support frame 13,

[0045] There are two supporting blocks 11 arranged in parallel, placed on a horizontal plane steadily, and a first motor 12 is arranged on one of the supporting blocks 11 .

[0046] The support frame 13 is a metal square frame, located between the two support blocks 11 and parallel to the horizontal plane. The output shaft of the first motor 12 is connected to the midpoint on one side of the support frame 13. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com