System and method for driving multiple pumps electrically with a single prime mover

a technology of prime mover and electrical drive, which is applied in the direction of pump control, positive displacement liquid engine, pump, etc., can solve the problems of busy and crowded pumping structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]The embodiments described herein are directed to control of motor-driven pumps in applications that are operating independently of a utility power grid, and combine the control of a single prime mover and one or more AC or DC generators to provide electric power to a plurality of motor-driven pumps in a manner that reduces system complexity, cost and footprint size. Such embodiments are particularly useful in the gas fracking industry where the usual control objective is to regulate wellhead pressures and / or flow rates.

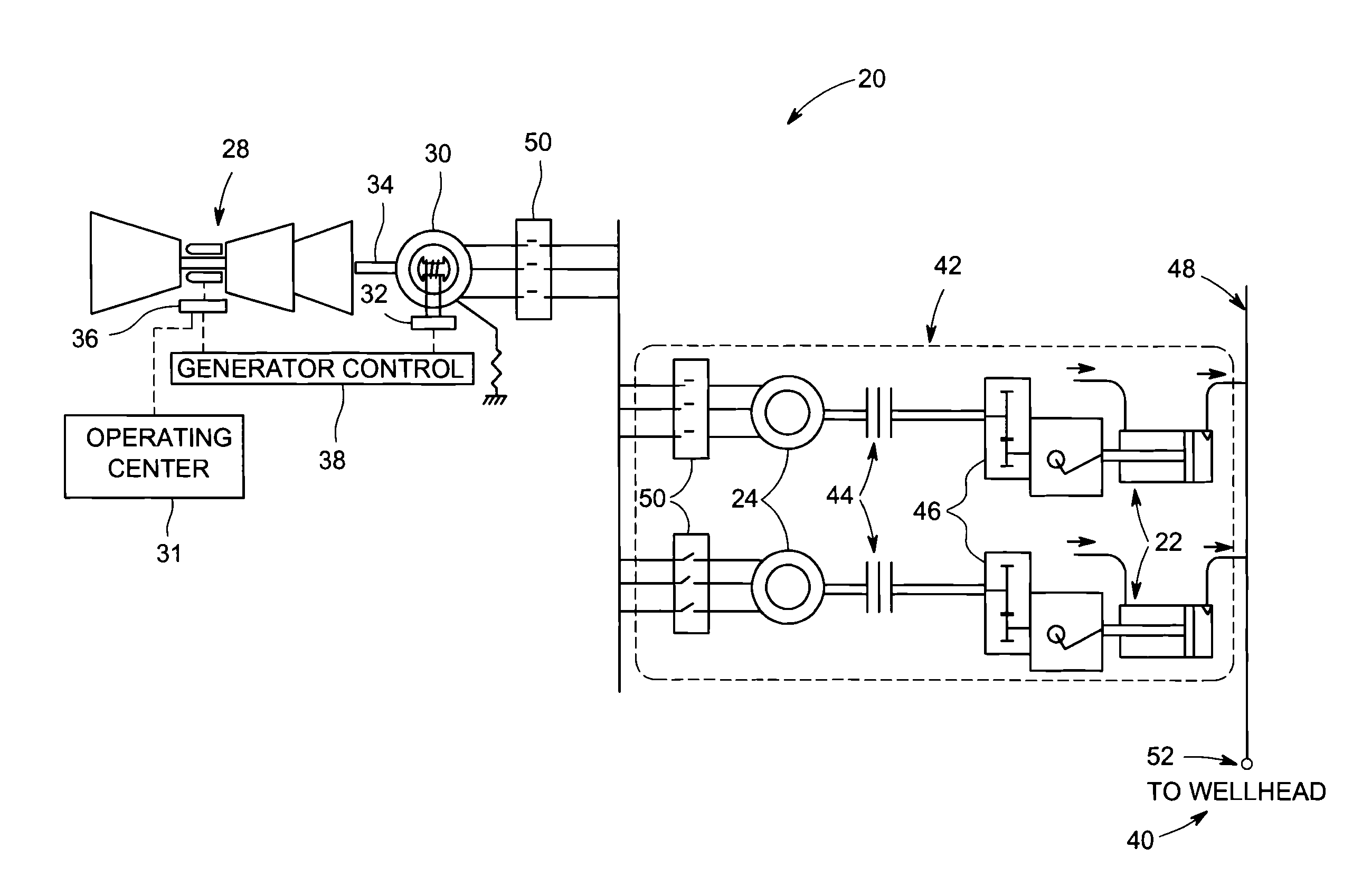

[0025]FIG. 3 is a motor-driven pumping system 20 illustrating a plurality of motor-driven pumps 22, according to one embodiment. Each pump 22 is driven by a corresponding electric motor 24. The electric motors 24 are powered from a shared electrical bus 26 that is supplied by a single prime mover 28 mechanically coupled to one or more electric generators 30. Although shown as an AC powered system, the principles described herein are just as easily applied to a D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com