Cloth dust cleaning and arranging equipment

A dust and cloth technology, applied in the field of cloth dust cleaning and arranging equipment, can solve the problems of inconvenient cloth finishing and change in the shape of the cloth, and achieve the effect of convenient collection and cleaning, preventing scattering and improving cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

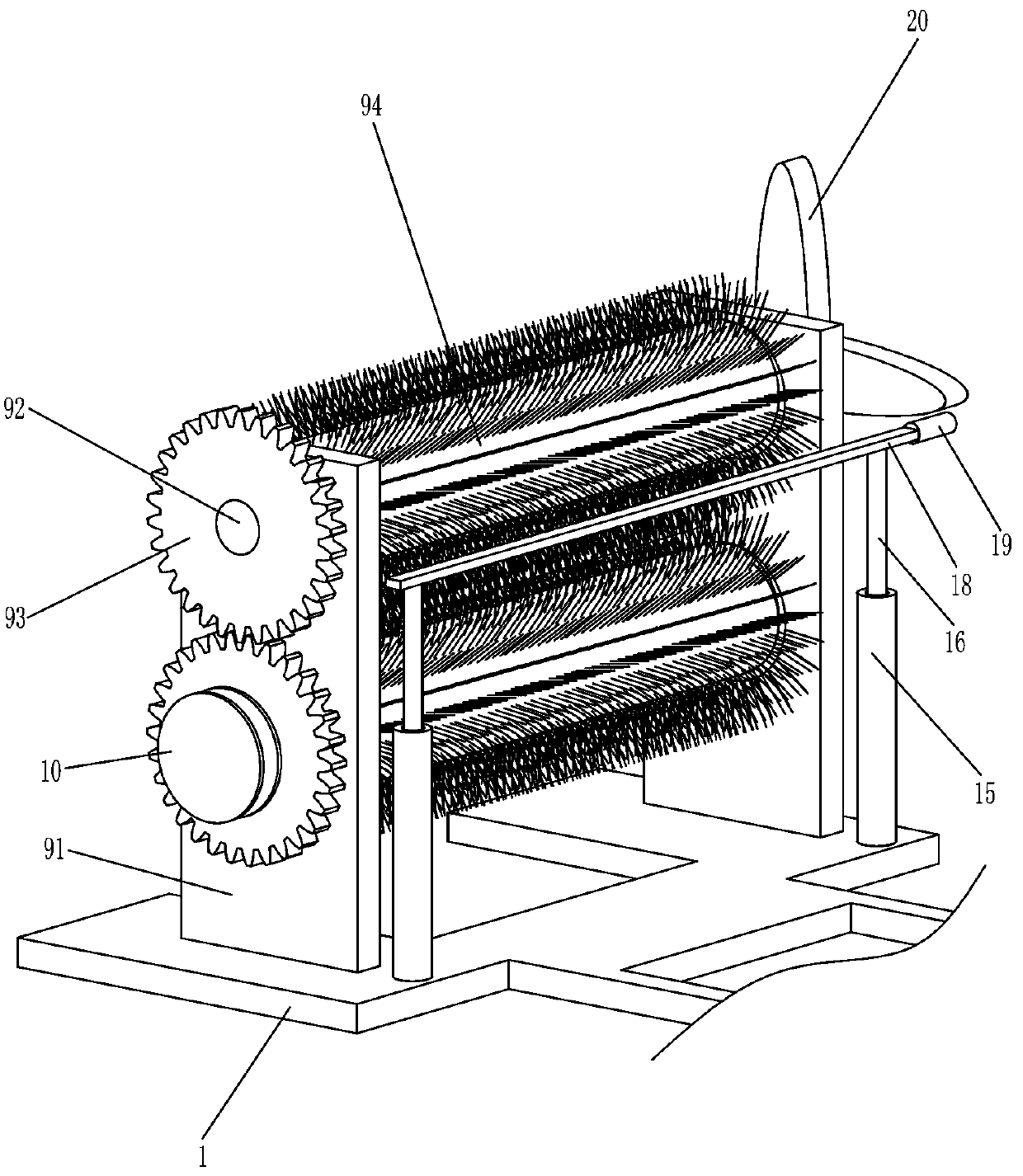

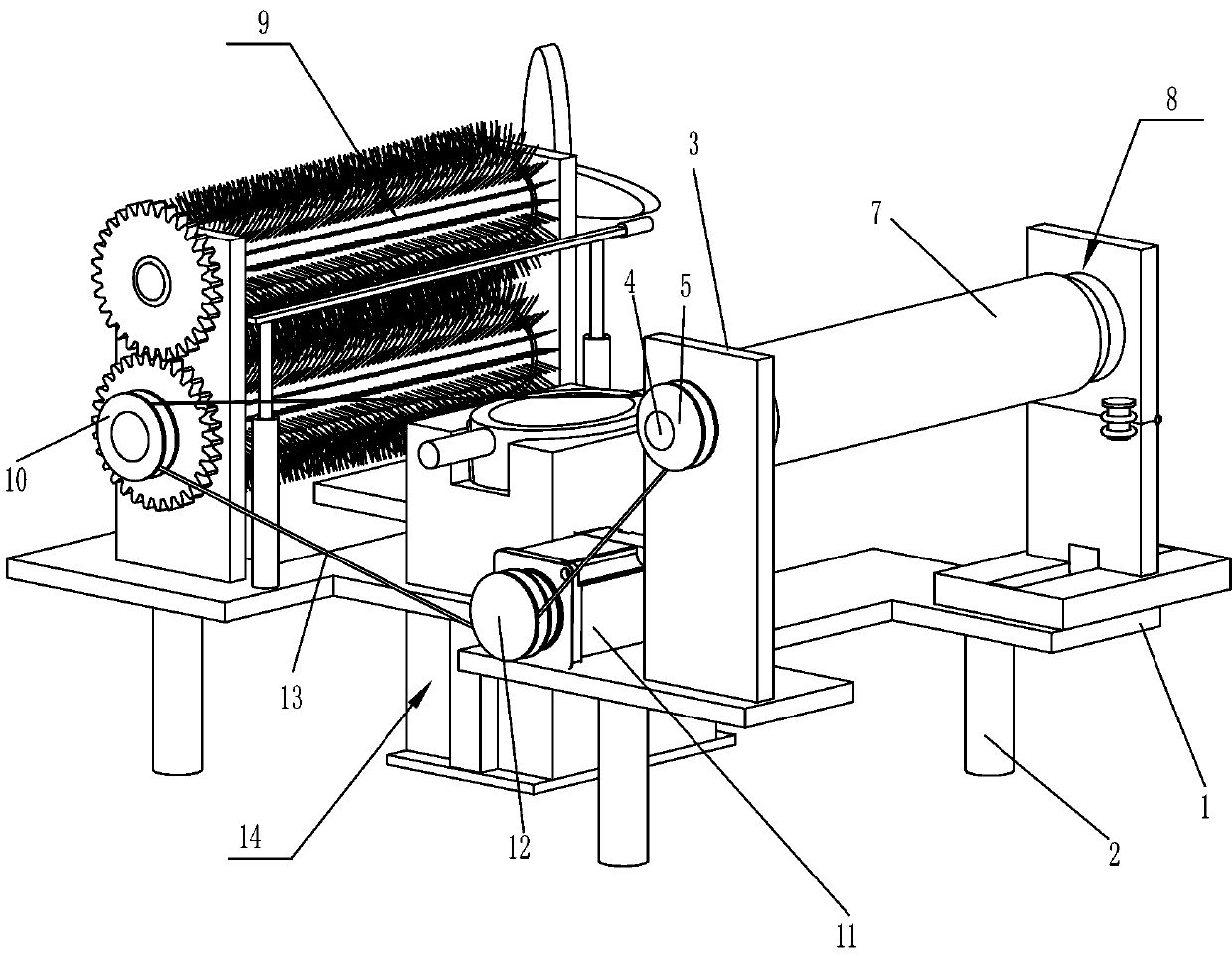

[0025] A cloth dust cleaning and finishing equipment, such as figure 1 and figure 2 As shown, it includes a workbench 1, a pole 2, a vertical plate 3, a rotating shaft 4, a block 401, a first pulley 5, a chuck 6, a roll 7, a clamping mechanism 8, a cleaning mechanism 9, a second belt Wheel 10, deceleration motor 11, third pulley 12 and belt 13, four poles 2 are connected to the bottom of workbench 1, riser 3 is fixedly connected to the top right side of workbench 1, and the upper part of riser 3 is rotatable Connected with a rotating shaft 4, the rear end of the rotating shaft 4 is connected with a block 401, the front end of the rotating shaft 4 is provided with a first pulley 5, the front portion of the rotating shaft 4 is equipped with a chuck 6, and the chuck 6 is covered with a winding roller 7. A clamping mechanism 8 is installed on the workbench 1 at the rear side of the plate 3, and a cleaning mechanism 9 is installed on the left side of the top of the workbench 1. T...

Embodiment 2

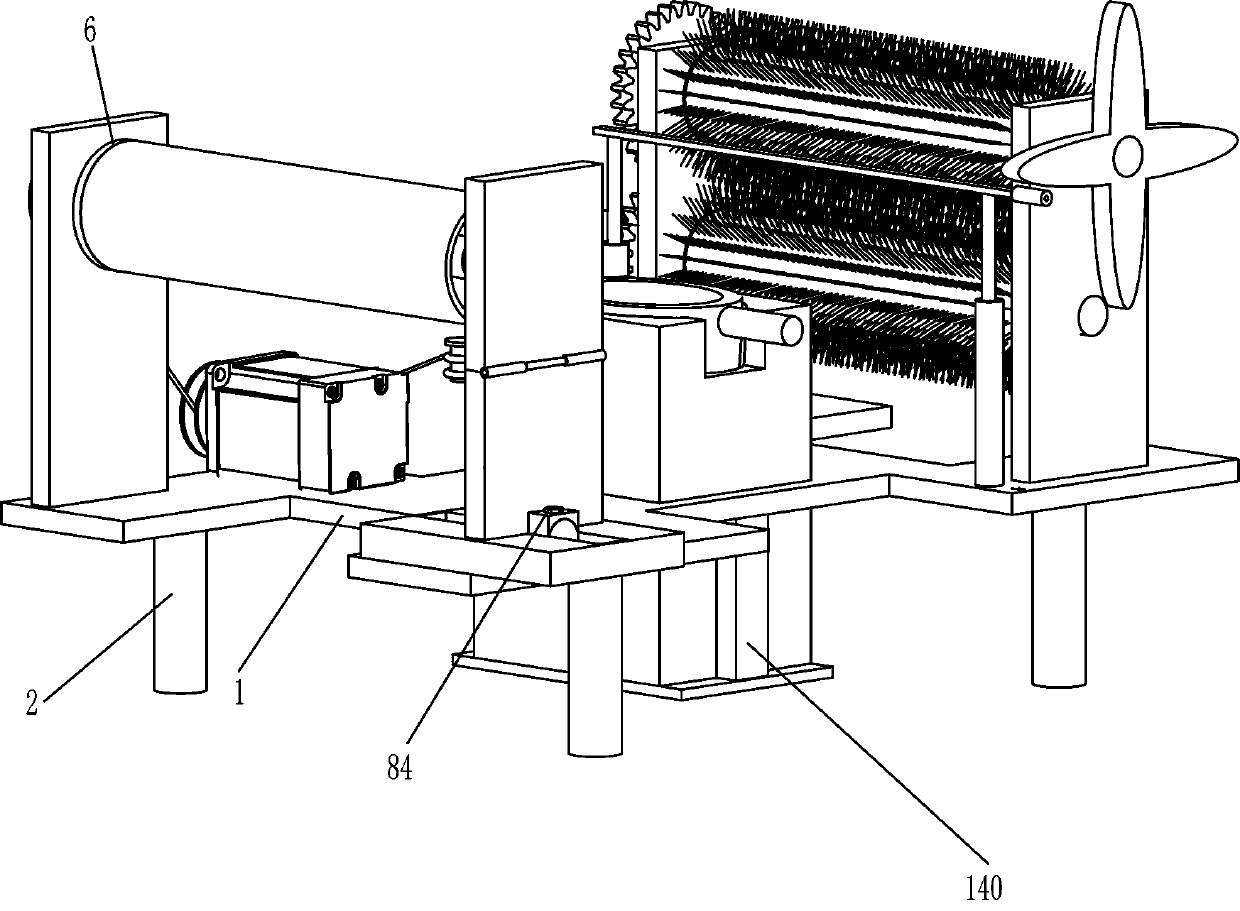

[0032] On the basis of Example 1, such as figure 2 and Figure 5 Shown, also comprise dust suction mechanism 14, dust suction mechanism 14 includes support plate 140, connecting plate 141, placement frame 142, dustproof bag 145, connecting rod 146, rotating motor 148 and fan blade 149, the workbench 1 Two support plates 140 are arranged in the middle of the bottom, and a connection plate 141 is fixedly connected between the bottoms of the two support plates 140. The connection plate 141 is provided with a placement frame 142, and a U-shaped cavity 143 is provided on the placement frame 142. The placement frame 142 There are two grooves 144 on the upper part of the U-shaped cavity 143, and a dustproof bag 145 is provided in the U-shaped cavity 143. Two connecting rods 146 are fixedly connected to the dustproof bag 145. The connecting rods 146 are located in the corresponding grooves 144, and the placement frame 142 There is a cavity 147 at the bottom of the bottom, and the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com