Self-cleaning UV light-cured ink not easy to yellow and preparation method thereof

A light-curing ink and self-cleaning technology, which is applied in ink, household utensils, applications, etc., can solve the problems of unevenness, ink cannot be used and mixed, and yellowing is not easy, so as to improve waterproof ability, anti-yellowing ability, good mix effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

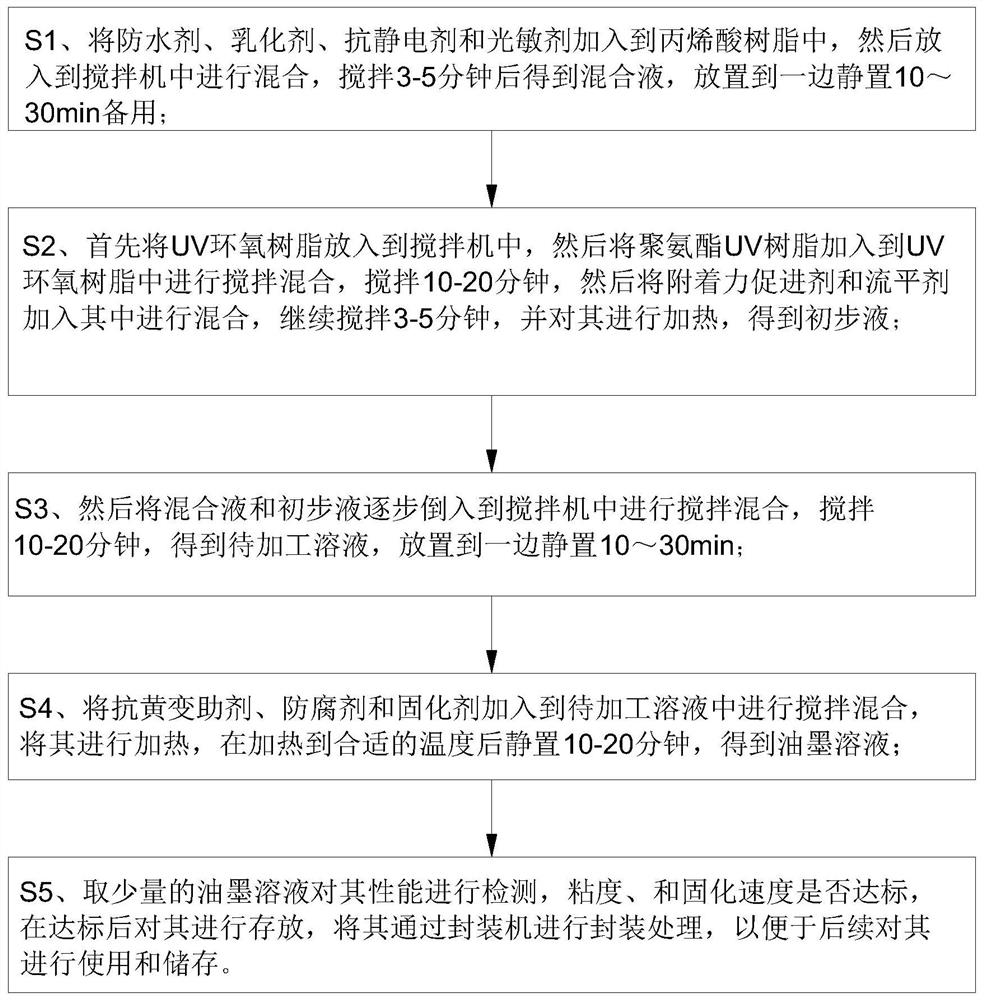

[0029] see figure 1 , the present invention provides the following technical solutions: a self-cleaning UV photocurable ink that is not easy to yellow, including the following raw materials in parts by weight, 50 parts of UV epoxy resin, 20 parts of polyurethane UV resin, 10 parts of acrylic resin, 5 parts of strength accelerator, 5 parts of leveling agent, 5 parts of photosensitizer, 6 parts of curing agent, 1 part of emulsifier, 1 part of antistatic agent, 1 part of waterproofing agent, 5 parts of flame retardant synergist, 1 part of preservative , 5 parts of anti-yellowing additives.

[0030] Specifically, the emulsifier is a white oil emulsifier.

[0031] Specifically, the waterproofing agent is a nano waterproofing agent.

[0032] Specifically, the adhesion promoter is an ink adhesion promoter.

[0033] The present invention also provides a kind of non-yellowing self-cleaning UV photocurable ink and its preparation method, comprising the following steps:

[0034] S1. ...

Embodiment 2

[0044] see figure 1 , the present invention provides the following technical solutions: a self-cleaning UV photocurable ink that is not easy to yellow, including the following raw materials in parts by weight, 100 parts of UV epoxy resin, 40 parts of polyurethane UV resin, 20 parts of acrylic resin, and 6 parts of focus accelerator, 6 parts of leveling agent, 6 parts of photosensitizer, 8 parts of curing agent, 2 parts of emulsifier, 2 parts of antistatic agent, 2 parts of waterproofing agent, 6 parts of flame retardant synergist, 2 parts of preservative , 6 parts of anti-yellowing additives.

[0045] Specifically, the emulsifier is a white oil emulsifier.

[0046] Specifically, the waterproofing agent is a nano waterproofing agent.

[0047] Specifically, the adhesion promoter is an ink adhesion promoter.

[0048] The present invention also provides a kind of non-yellowing self-cleaning UV photocurable ink and its preparation method, comprising the following steps:

[0049...

Embodiment 3

[0059] see figure 1 , the present invention provides the following technical solutions: a self-cleaning UV photocurable ink that is not easy to yellow, including the following raw materials in parts by weight, 150 parts of UV epoxy resin, 60 parts of polyurethane UV resin, 30 parts of acrylic resin, and 7 parts of focus accelerator, 7 parts of leveling agent, 7 parts of photosensitizer, 10 parts of curing agent, 3 parts of emulsifier, 3 parts of antistatic agent, 3 parts of waterproofing agent, 7 parts of flame retardant synergist, 3 parts of preservative , 7 parts of anti-yellowing additives.

[0060] Specifically, the emulsifier is a white oil emulsifier.

[0061] Specifically, the waterproofing agent is a nano waterproofing agent.

[0062] Specifically, the adhesion promoter is an ink adhesion promoter.

[0063] The present invention also provides a kind of non-yellowing self-cleaning UV photocurable ink and its preparation method, comprising the following steps:

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com