A kind of processing method of physically modified starch

A technology of modified starch and processing method, applied in the field of modified starch processing, can solve the problems of incomplete sterilization function, unfavorable cleaning, high power consumption, improve texture stability and freeze-thaw stability, broad application prospects and market competition The effect of strength, water absorption and gelatinization ability enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

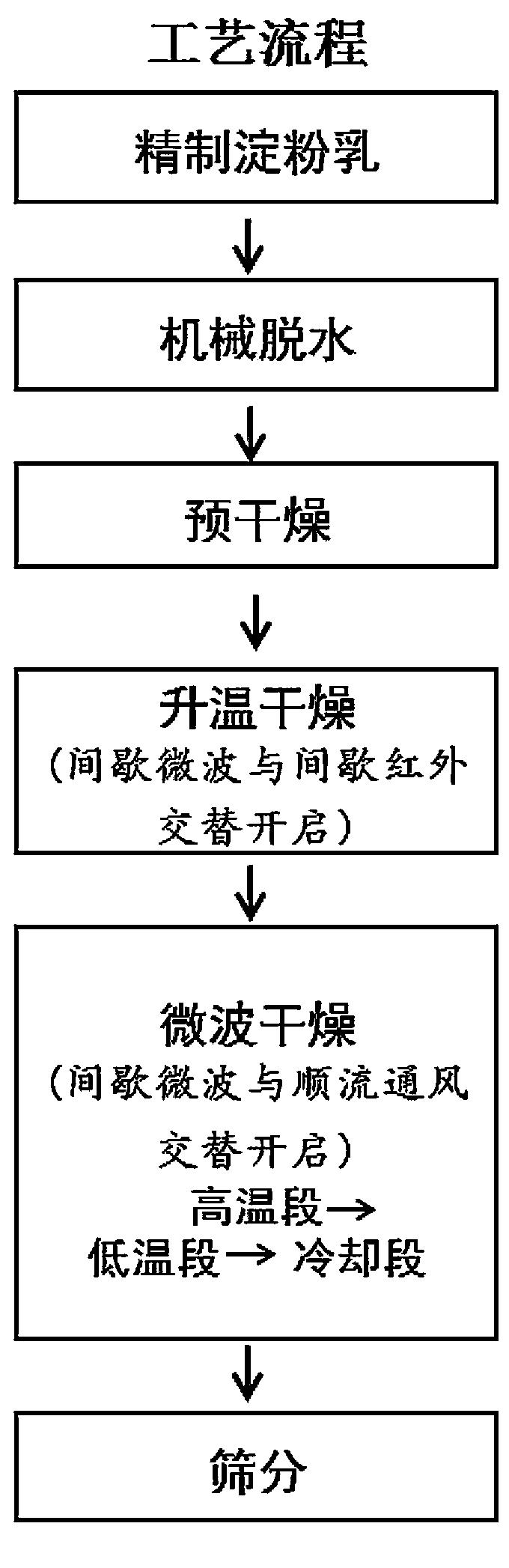

Image

Examples

Embodiment 1

[0047] Step 1. Refined starch milk: cassava is washed, crushed, separated, and purified to obtain refined starch milk with a concentration of 21.7°Bé, a protein content of 0.06% (dry basis), and a fat content of 0.04% (dry basis);

[0048] Step 2. Mechanical dehydration: use a horizontal scraper discharge centrifuge to mechanically dehydrate the refined starch milk, and the moisture content is reduced to 34.3%;

[0049] Step 3. Pre-drying: Use one airflow drying to reduce the moisture to 22.7%; the parameters used for airflow drying are wind speed 20m / s, air volume 3500m3 / h, inlet air temperature 100°C, drying time 1s, and discharge temperature 62.5°C ;

[0050] Step 4, heating and drying: the pre-dried starch is spread into a thin layer with a thickness of 2 cm through the cloth, and sent to the cavity of the intermittent microwave and intermittent infrared alternate heater for drying for 1 min. The temperature of the starch center is 80-84 ° C; in the cavity The microwave f...

Embodiment 2

[0054] Step 1. Refined starch milk: Potatoes are washed, crushed, separated, and purified to obtain refined starch milk with a concentration of 24.1°Bé, a protein content of 0.03% (dry basis), and a fat content of 0.05% (dry basis);

[0055] Step 2. Mechanical dehydration: use a horizontal scraper discharge centrifuge to mechanically dehydrate the refined starch milk, and the moisture content is reduced to 38.5%;

[0056] Step 3. Pre-drying: Use one airflow drying to reduce the moisture to 24.6%; the parameters used for airflow drying are wind speed 25m / s, air volume 4000m 3 / h, the inlet air temperature is 105°C, the drying time is 0.5s, and the discharge temperature is 67.8°C;

[0057] Step 4. Heating and drying: the pre-dried starch is spread into a thin layer with a thickness of 1.5 cm through the cloth, and then sent to the cavity of an intermittent microwave and intermittent infrared heater for drying for 0.5 min. The temperature of the starch center is 85-87 °C. The mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com