Patents

Literature

129results about How to "Avoid floating around" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

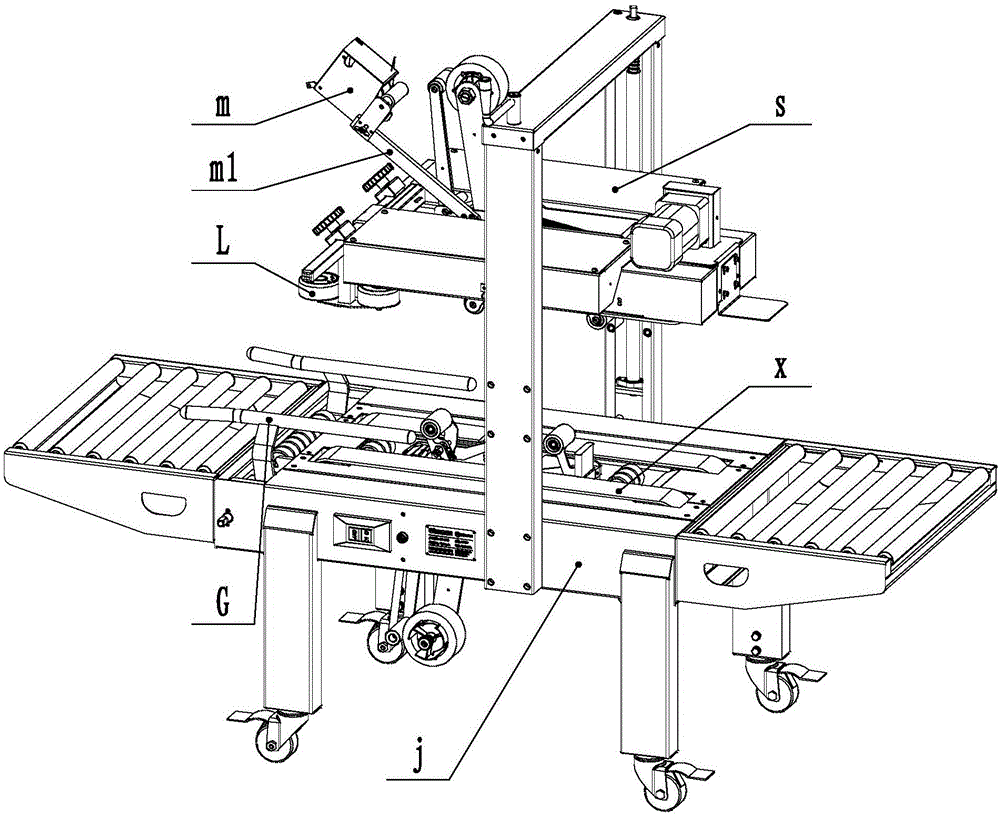

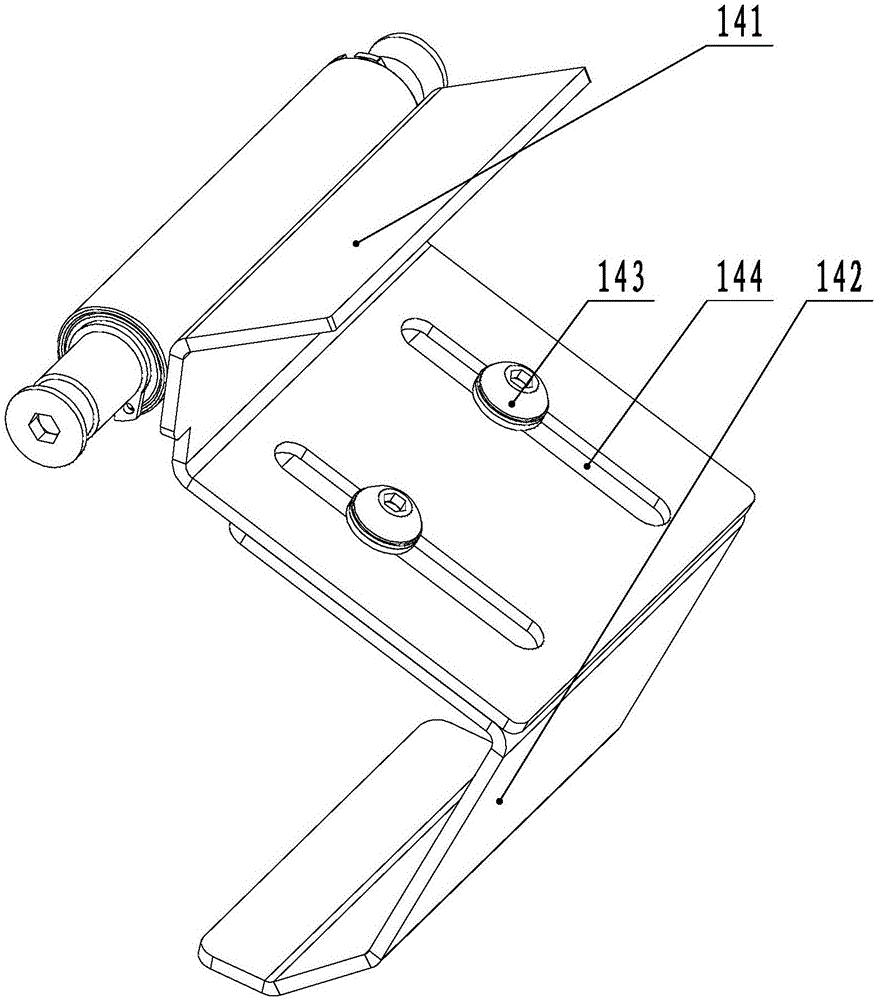

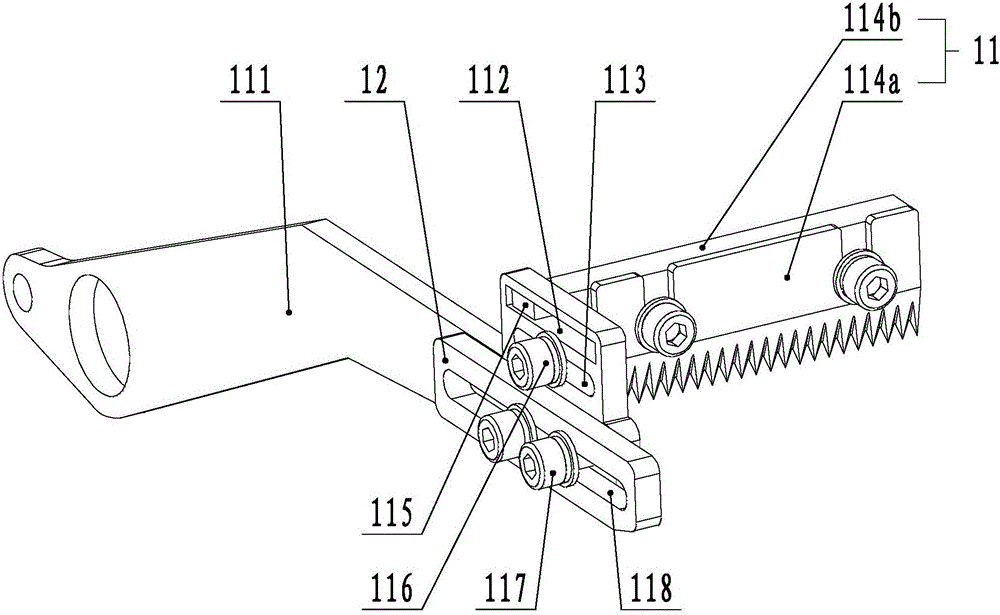

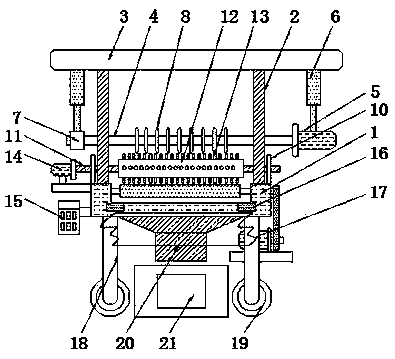

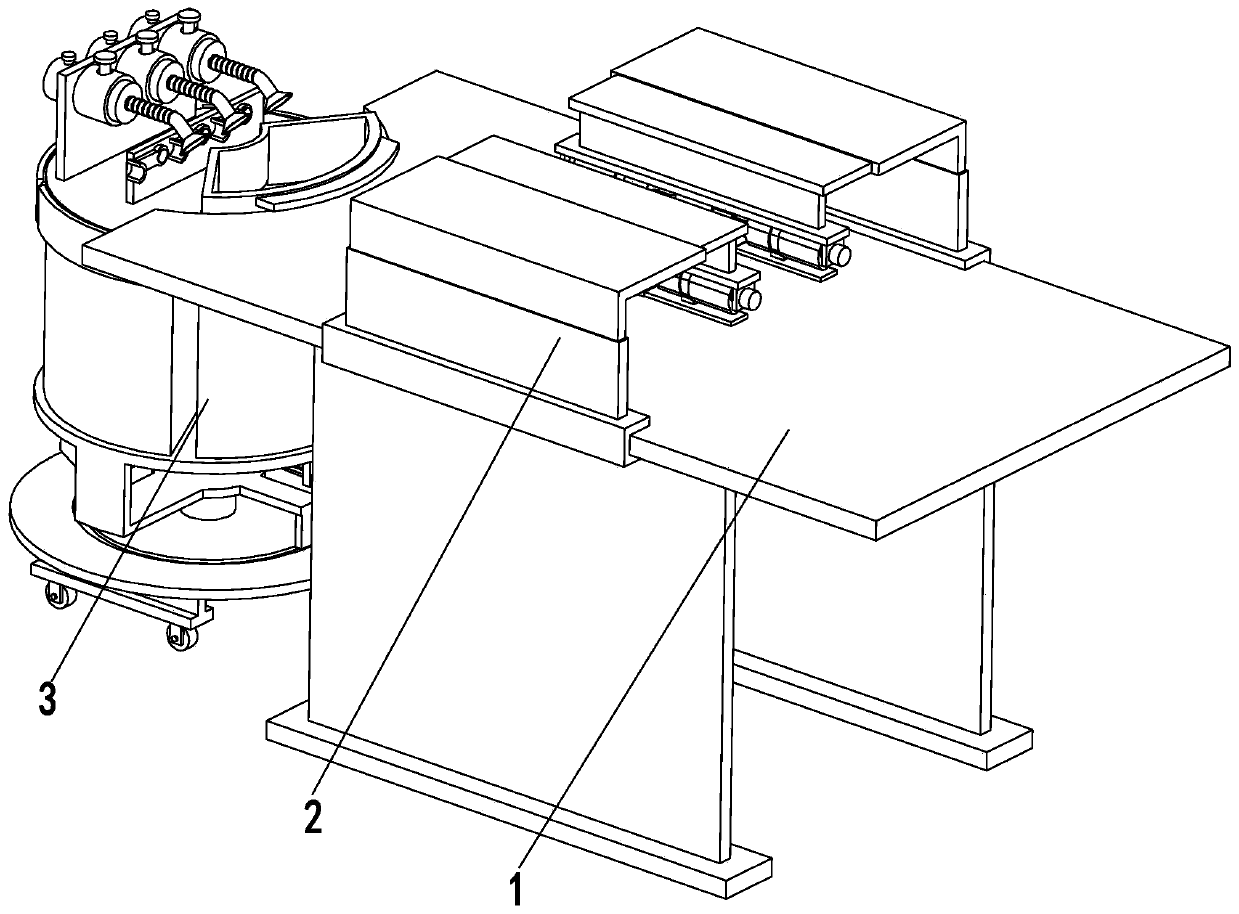

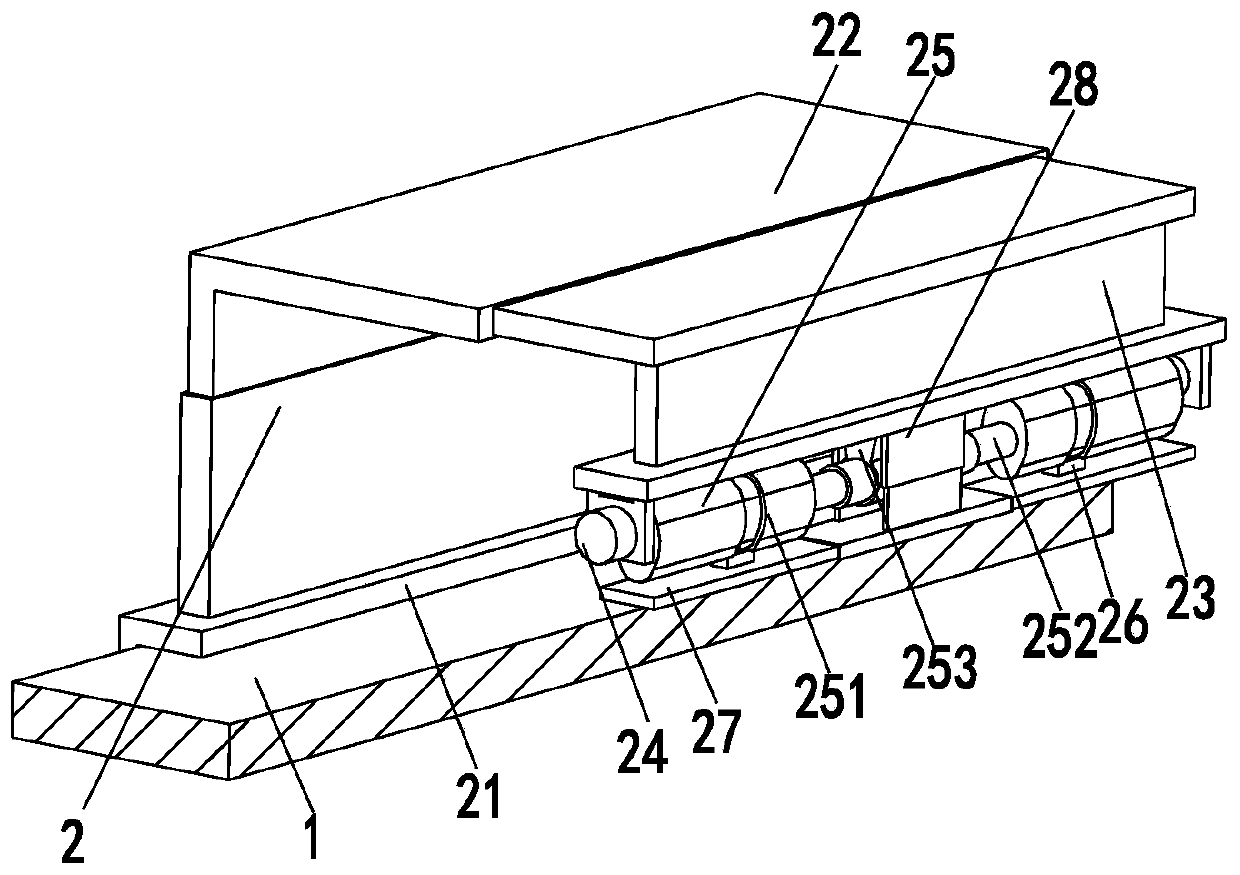

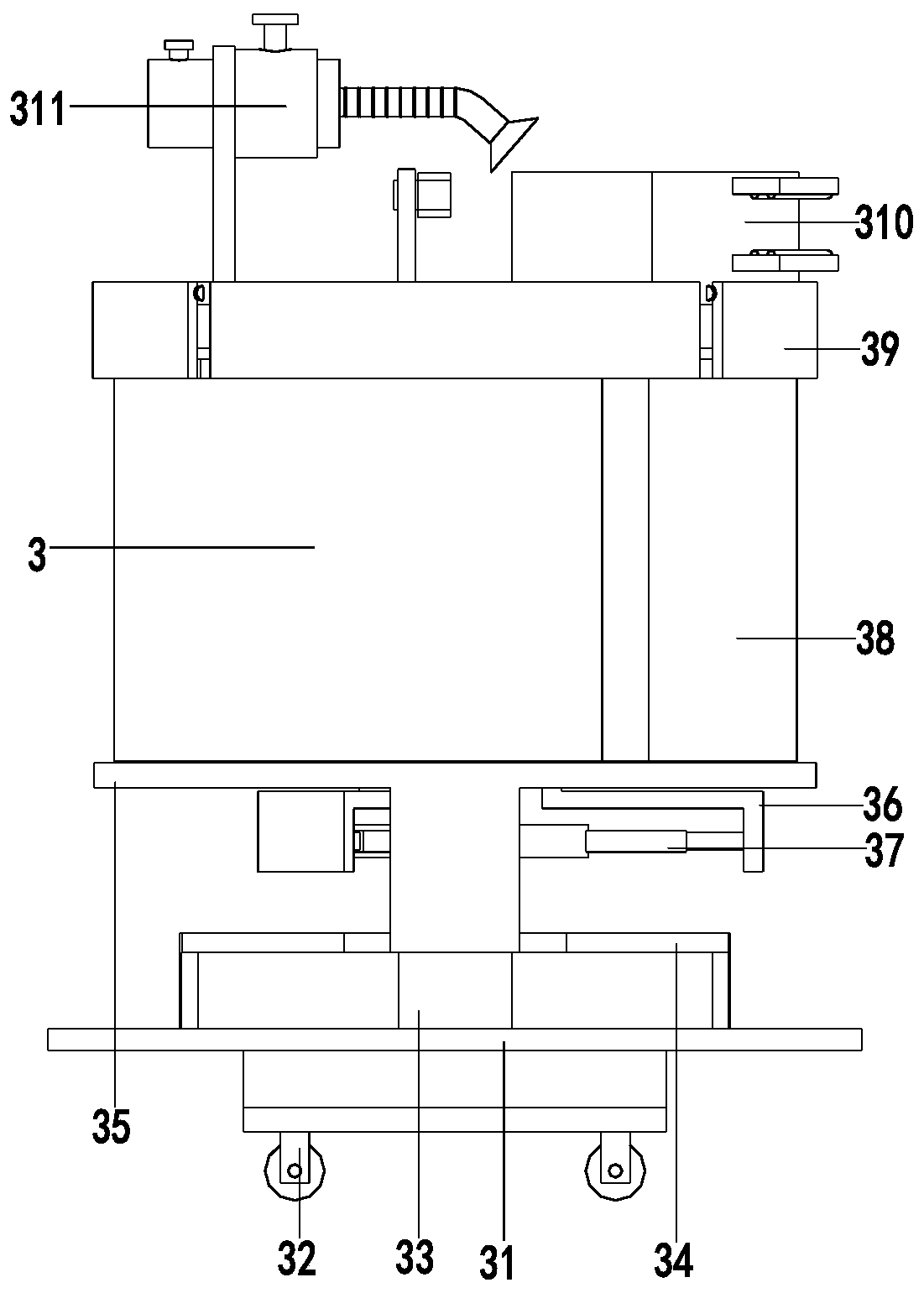

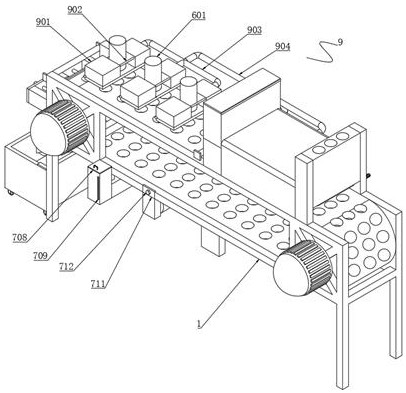

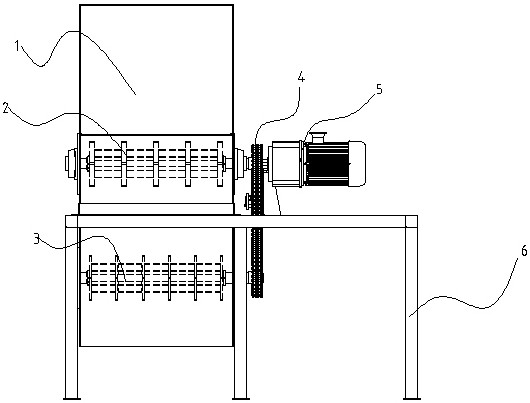

Box sealing machine

ActiveCN106516279AAvoid floating aroundAvoid pullingWrapper twisting/gatheringArticle deliveryEngineeringMechanical engineering

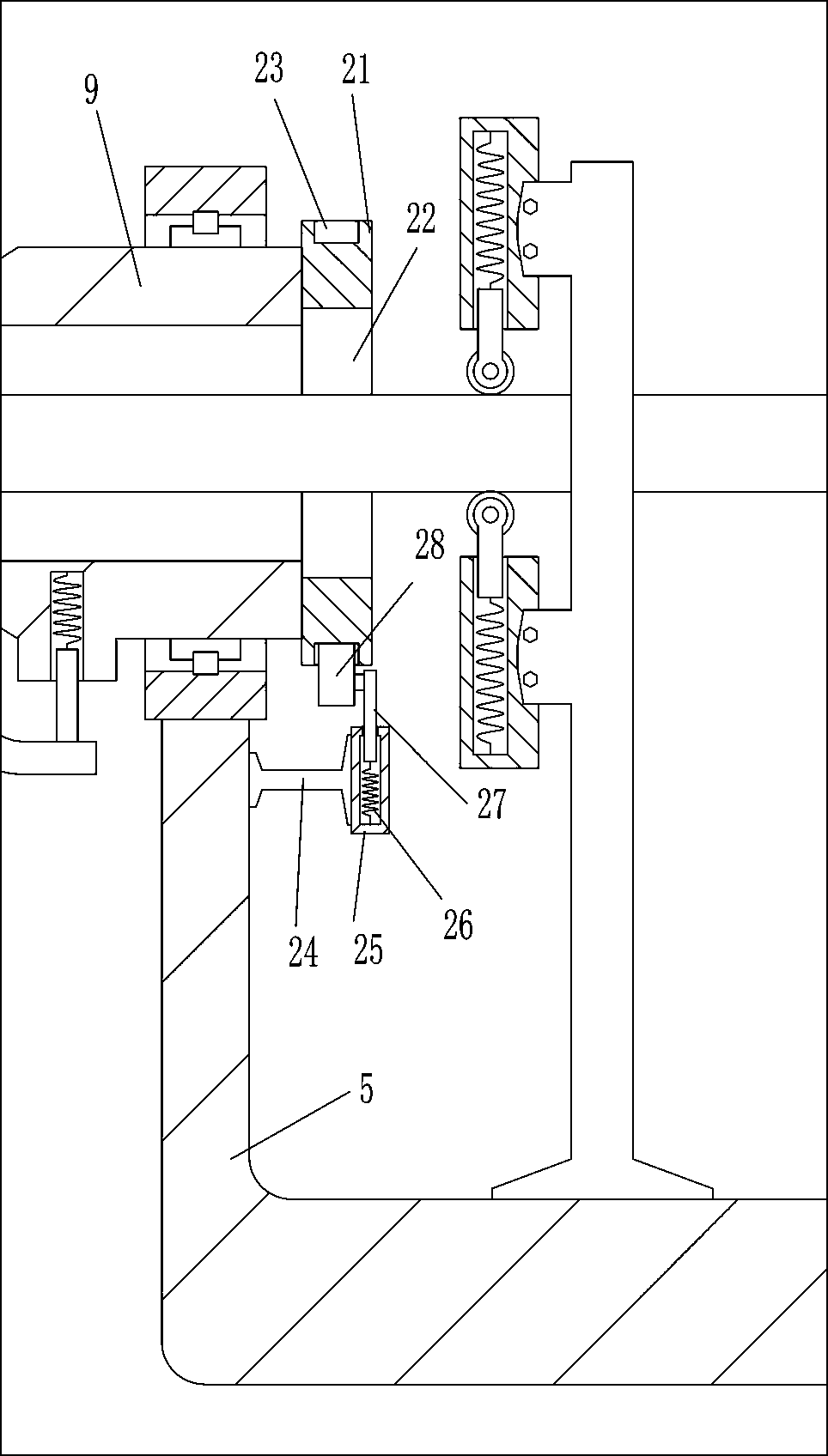

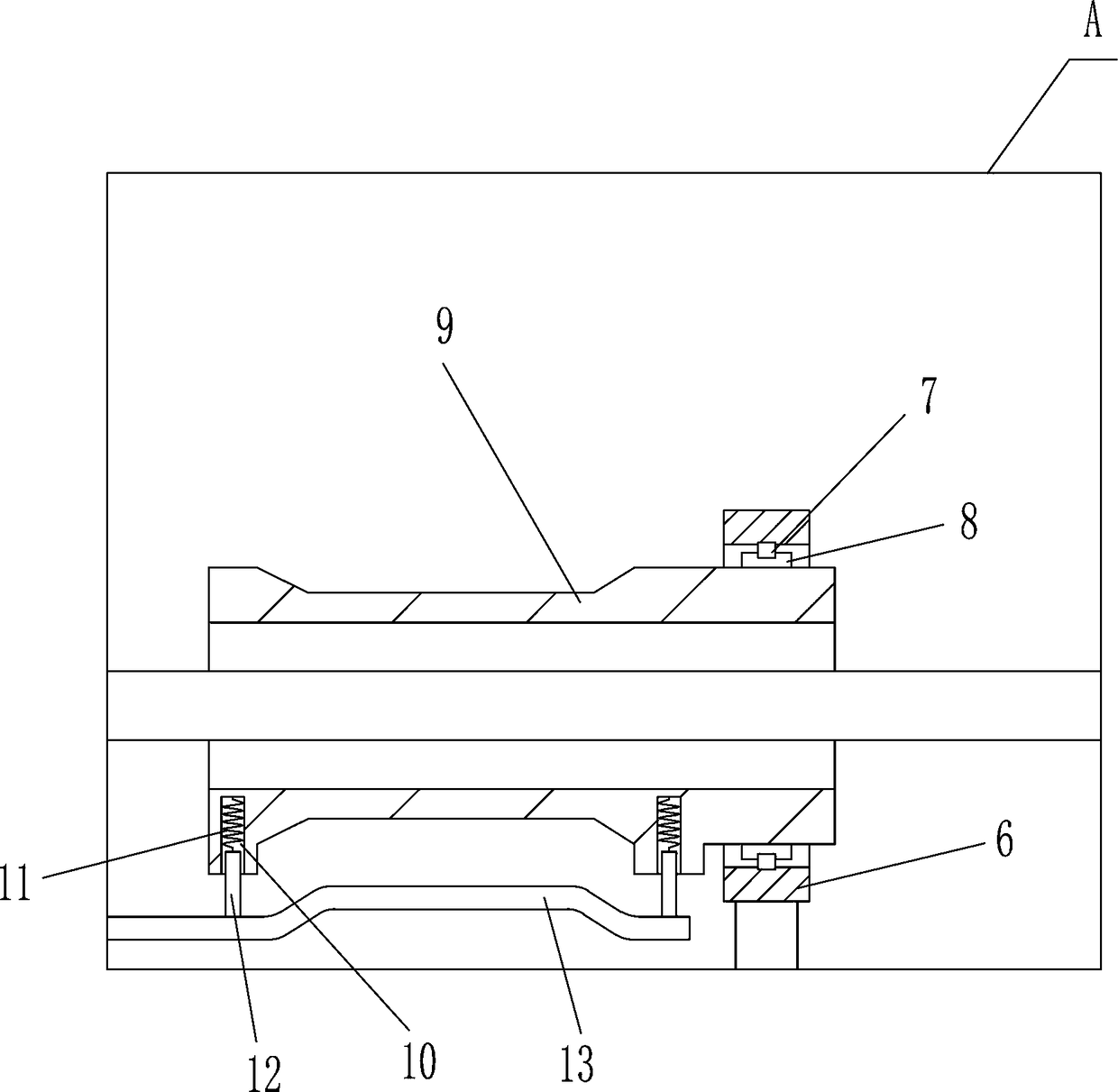

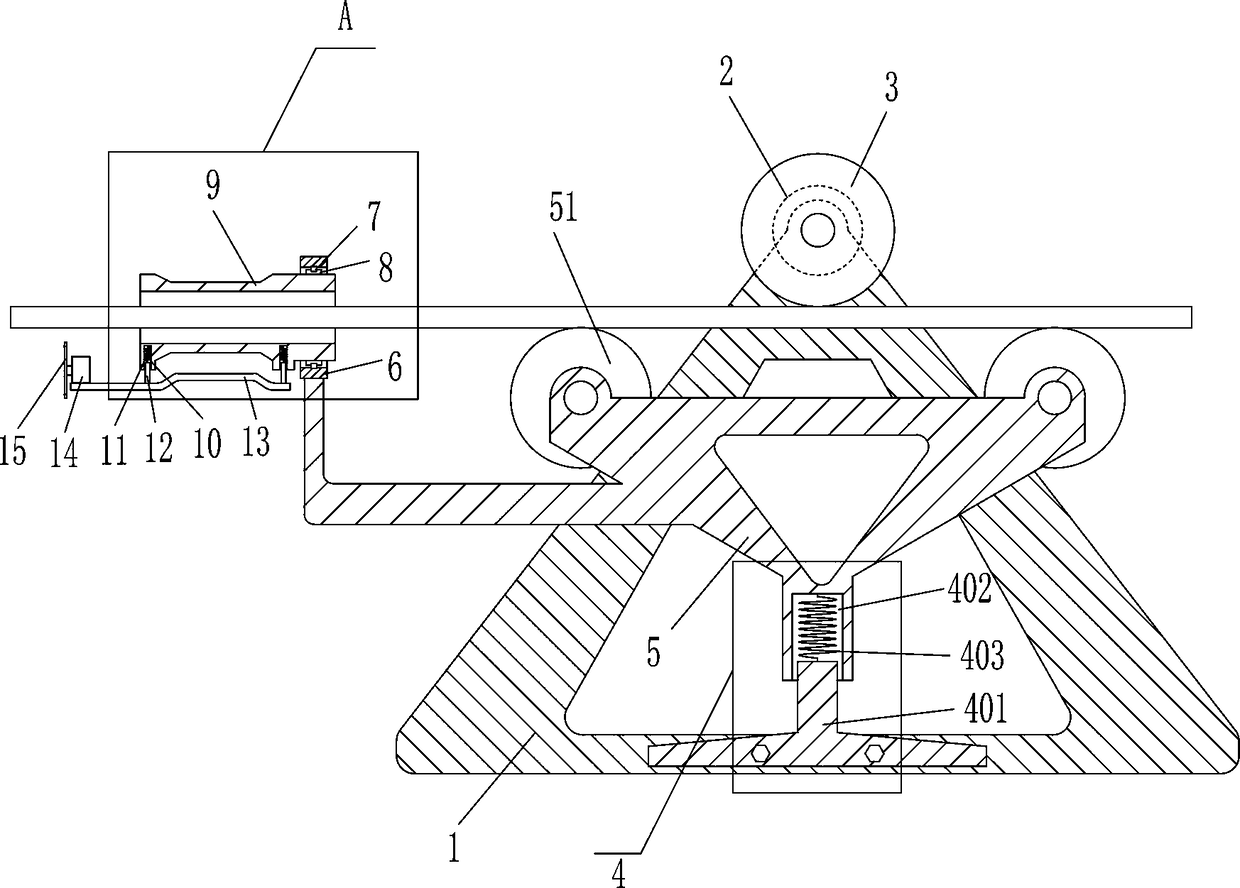

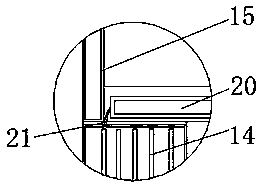

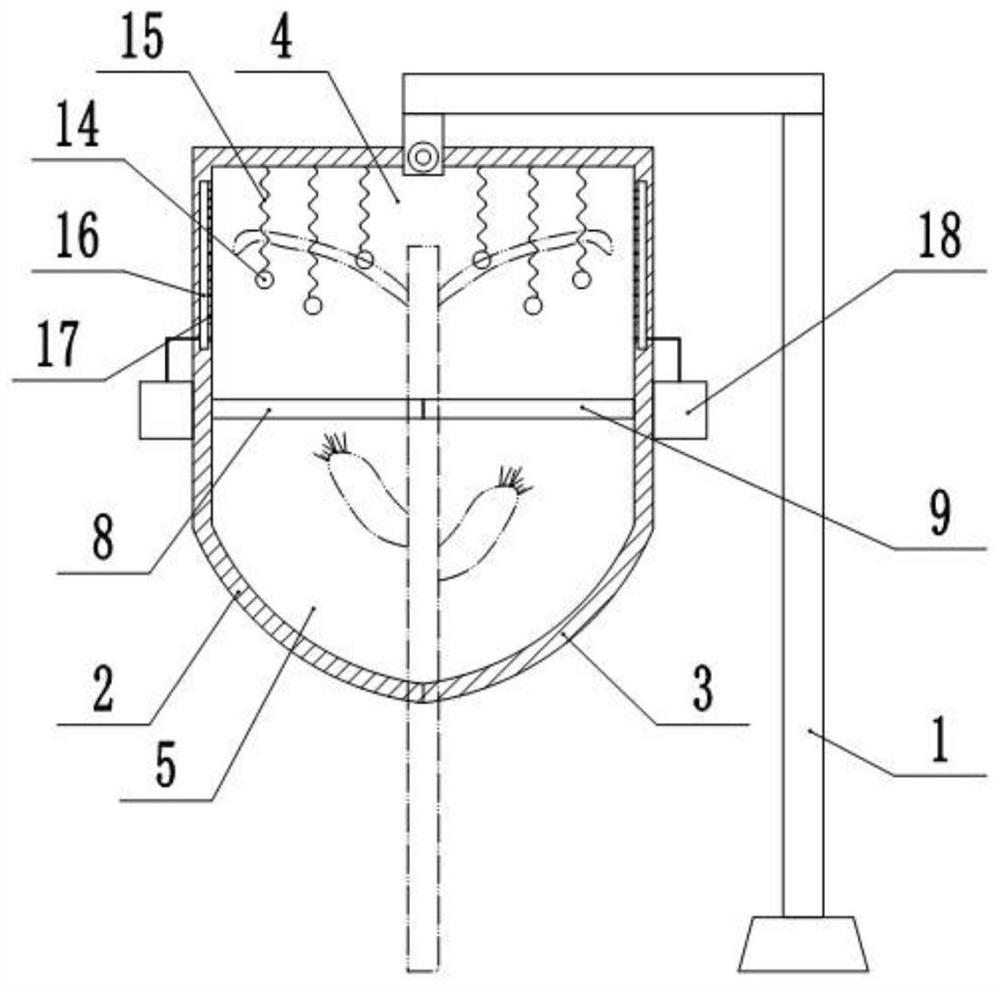

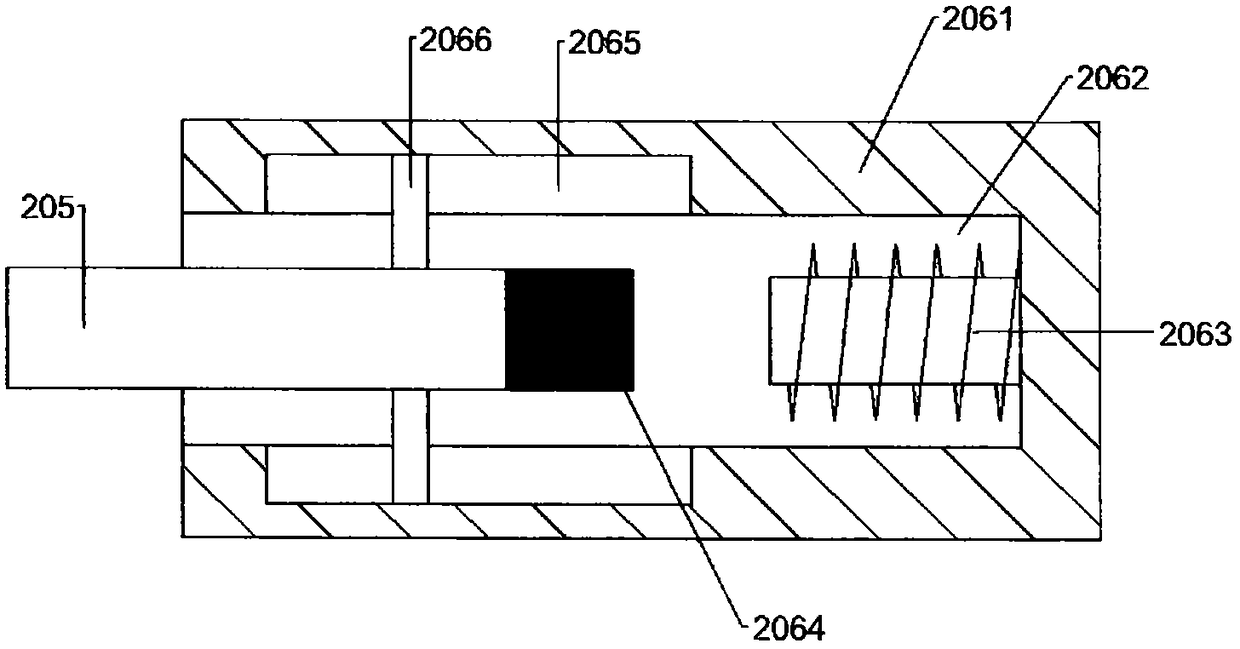

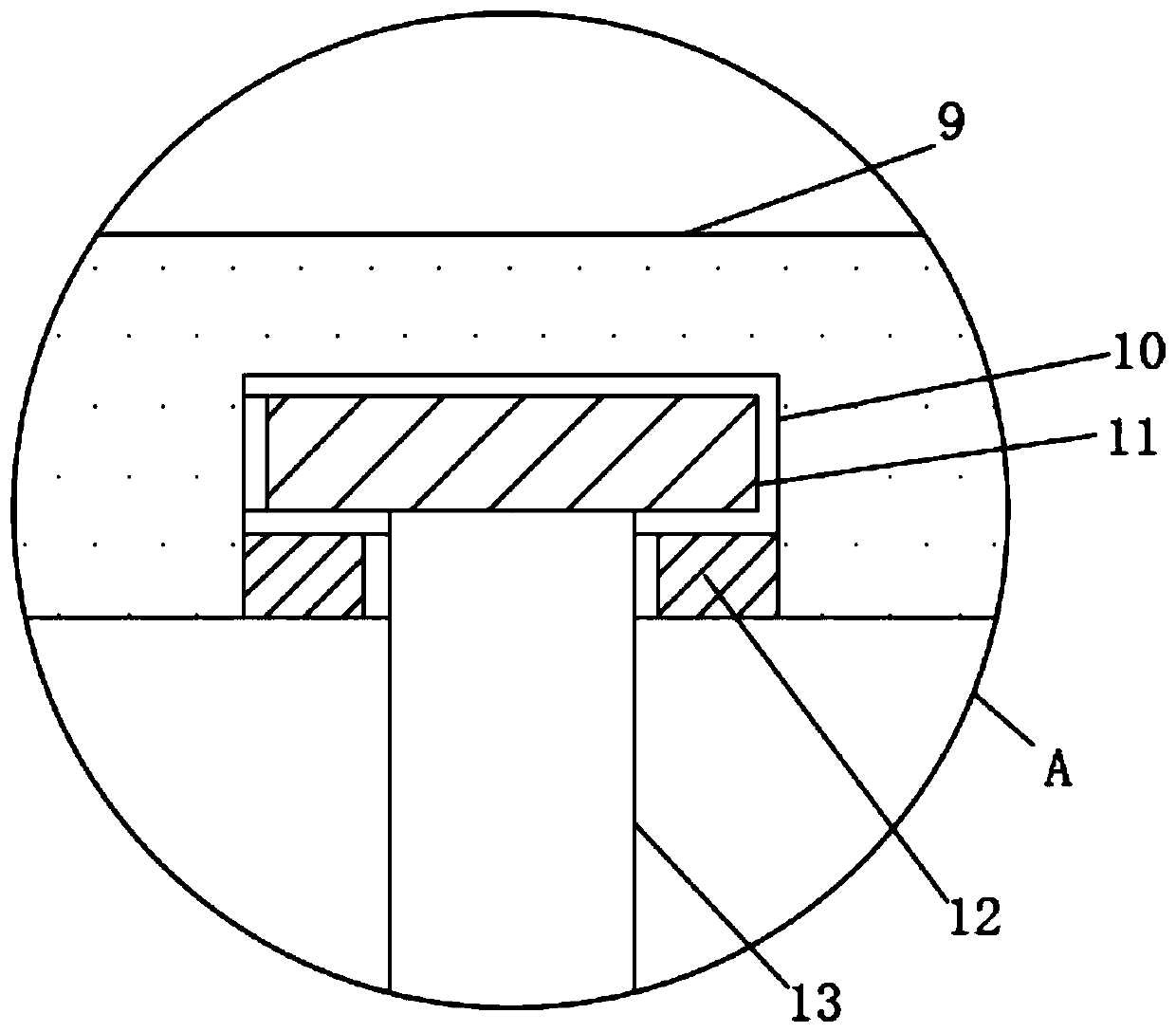

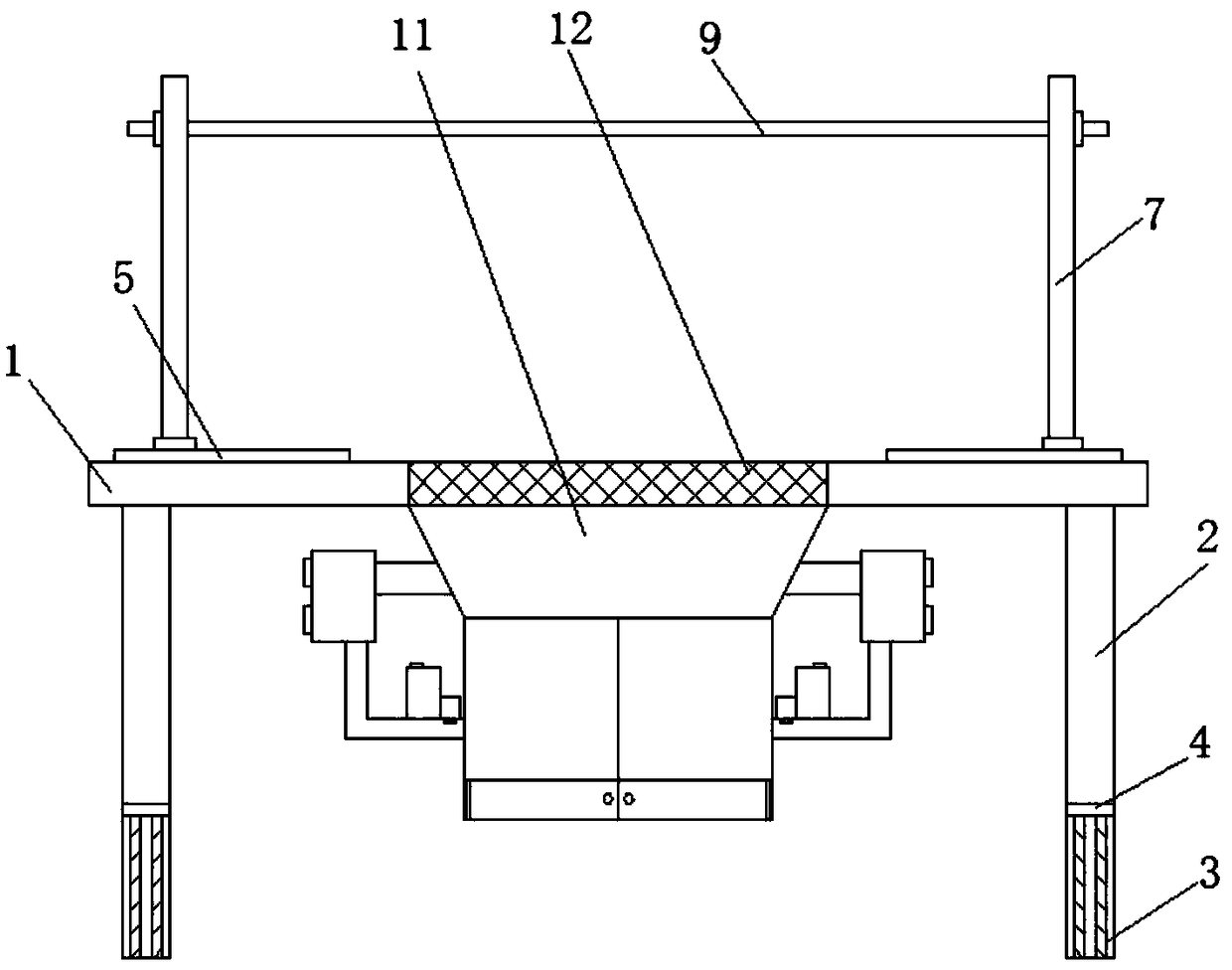

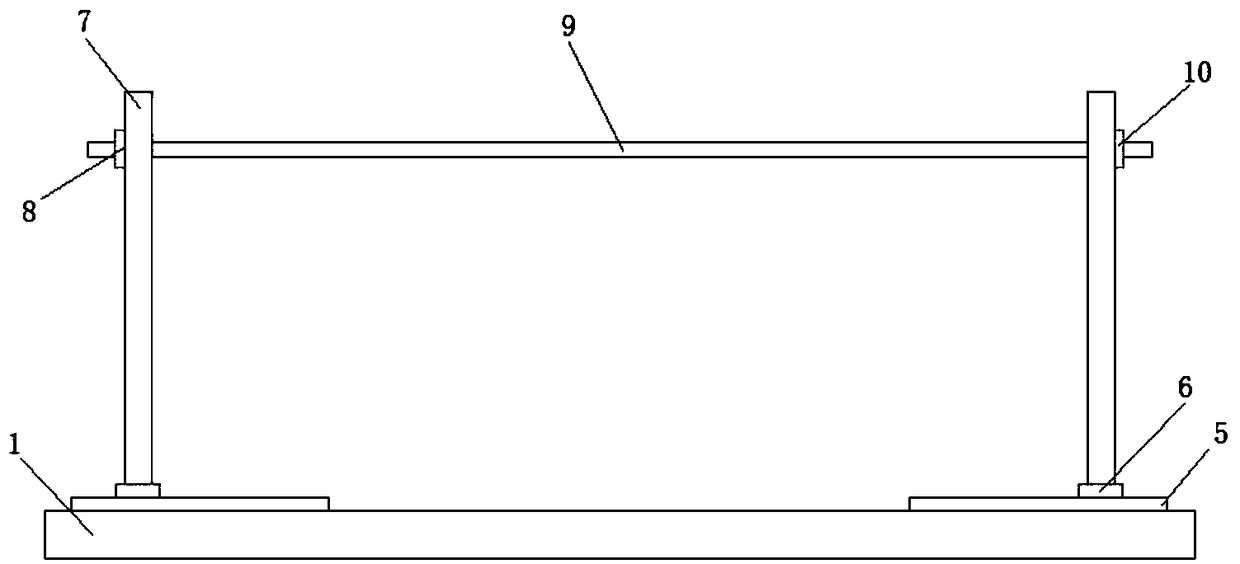

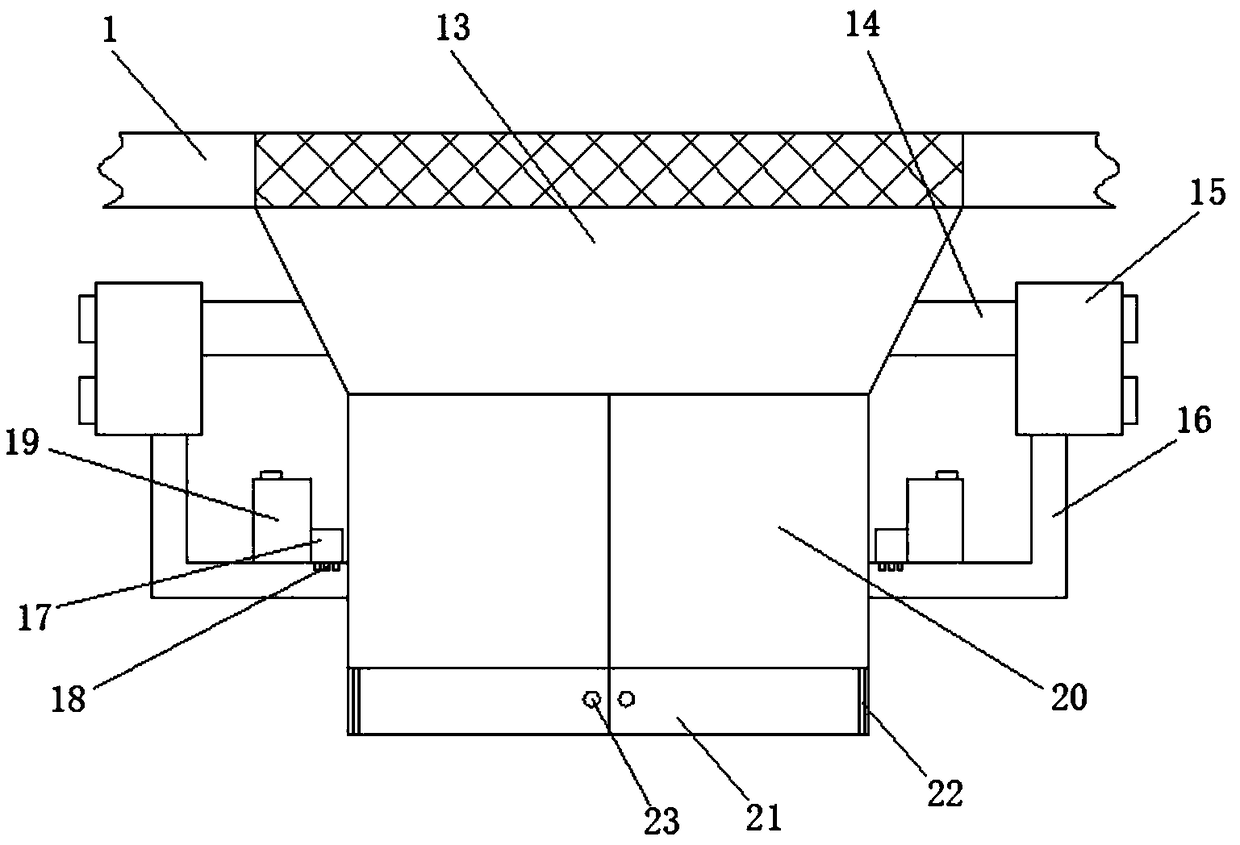

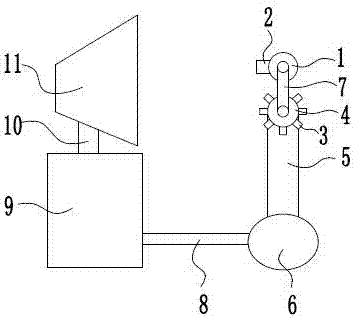

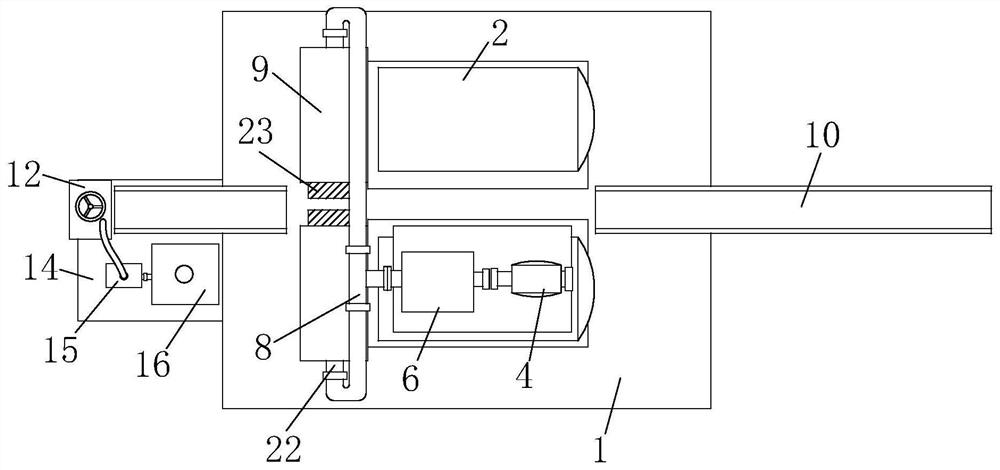

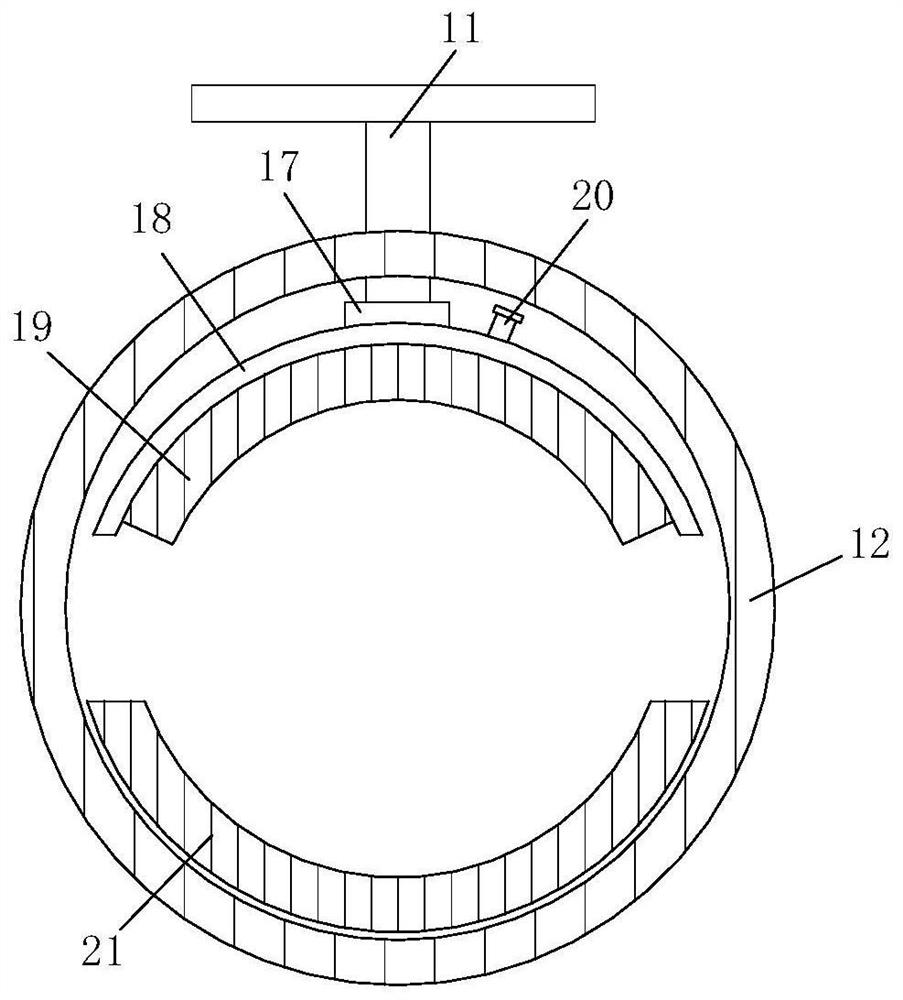

The invention discloses a box sealing machine. An adhesive tape roll is installed on a rolling frame. The two sides of adhesive tape paper are clamped between an outer clamping plate and an inner clamping plate, and adhesive tape is prevented from waving around in the operation process of the box sealing machine. A conveying belt drives a packaging box to move towards a front pressing frame. The adhesive tape is pushed to the front pressing frame through the packaging box. The adhesive tape paper is attached to the side face of the packaging box. A front roller shaft rolls along the surface of the box to flatly attach the adhesive tape paper to the packaging box. The front pressing frame drives a connection frame to rotate so as to drive a rear pressing frame to rotate, and at the moment, a first tension spring is stretched. When the box passes through an abutting plate, the abutting plate is rotated, a cutter is upraised, and at the moment, a second tension spring is upraised. When the abutting plate leaves from the packaging box, the second tension spring pulls the cutter to return to cut off the tensioned adhesive tape paper. When the packaging box is disengaged from contact with a rear roller shaft, the first tension spring pulls the rear pressing frame and the front pressing frame to return, the rear roller shaft rolls along the rear side face of the packaging box, and the adhesive tape paper is attached to the rear side face of the packaging box.

Owner:ZHEJIANG DINGYE MACHINERY

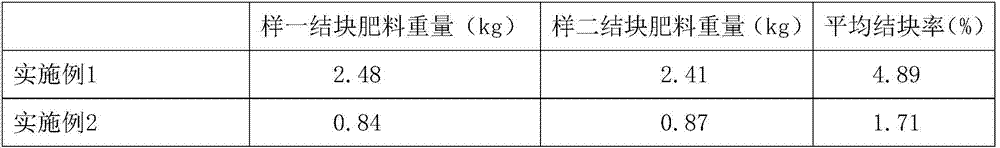

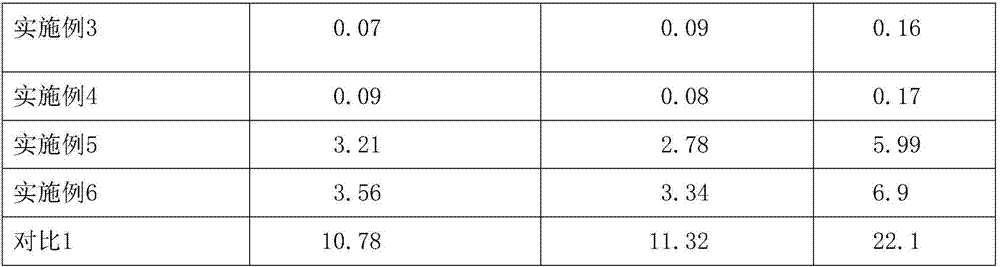

Method for preventing fertilizer agglomeration

InactiveCN107151186ALow costGood anti-knot effectLayered/coated fertilisersFertilizer mixturesFertilizerChemistry

The invention relates to a method for preventing fertilizer agglomeration. A paste fertilizer agglomeration prevention agent is added into a dissolution groove to be dissolved; the dissolved paste fertilizer agglomeration prevention agent is sprayed onto the surface of the fertilizer after the atomization; after the uniform coating, insert powder is added. The treated fertilizer can be stored for 4 to 6 months without agglomeration.

Owner:烟台市昊星晟信息技术有限公司

Stone crusher

InactiveCN111013720ASpeed up crushingAvoid cloggingUsing liquid separation agentDirt cleaningCrushed stoneEngineering

The invention relates to the technical field of stone treatment equipment, in particular to a stone crusher which comprises a shell, a crushing roller, a fixing rod, extrusion plates, an upper baffle,a lower baffle and a dust collection box. The stone crusher can cut and crush stone large in size, crushing of edge materials is improved through auxiliary crushing teeth on the inner wall, and the crushing efficiency is improved. A discharge elastic plate prevents a discharging port from being blocked, a supporting column and a damper improve the damping effect of the device, and therefore the high using effect is achieved; in the crushing process, dust can be effectively prevented from drifting out from the top end of the position between the extrusion plates, then the dust can be preventedfrom drifting out, meanwhile, the dust enters the dust collection box through a communication pipe in the extrusion crushing process, and therefore the dust can be effectively collected and preventedfrom drifting around, the body health of people is guaranteed, and high practicability is achieved.

Owner:福建省磊鑫环保科技有限公司

Preparation method for single-layer graphene dispersion liquid

ActiveCN107857257AGood electrical and thermal conductivityAvoid reunionSingle layer grapheneSlurrySingle layer graphene

The invention provides a preparation method for single-layer graphene dispersion liquid. The preparation method comprises the following steps: providing natural crystalline flake graphite, carrying out oxidation treatment, and preparing oxide graphite slurry; adding deionized water into the oxide graphite slurry, breaking and stripping through a high-pressure homogenizer until graphene oxide of which the average thickness is 0.4-0.7nm and the average sheet diameter is 0.8-10mu m is obtained; after the graphene oxide is subjected to freeze drying, introducing nitrogen and hydrogen mixed gas tobe subjected to program temperature rise treatment, and then, cooling to room temperature to obtain single-layer graphene powder; putting the single-layer graphene powder in an atomizing stirrer, taking ethanol solution which contains dispersing agent as spray, carrying out spraying drying under the conditions that revolving speed is 300-1000rpm and temperature is 70-100 DEG C, and continuously stirring to obtain the modified single-layer graphene powder after the spraying drying is finished; dissolving the modified single-layer graphene powder into organic solvent to be subjected to ultrasonic dispersion treatment to obtain the single-layer graphene dispersion liquid.

Owner:YAHAM OPTOELECTRONICS CO LTD

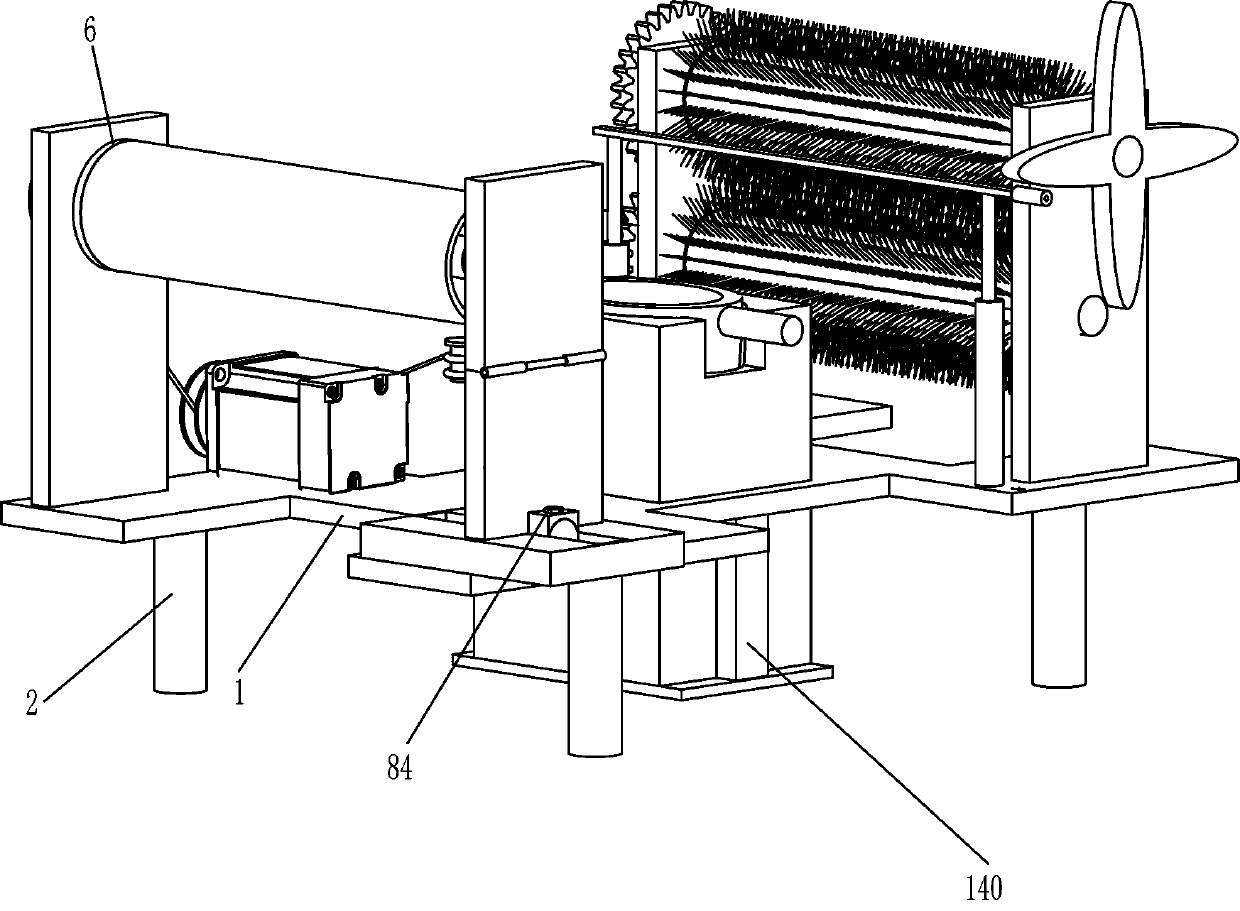

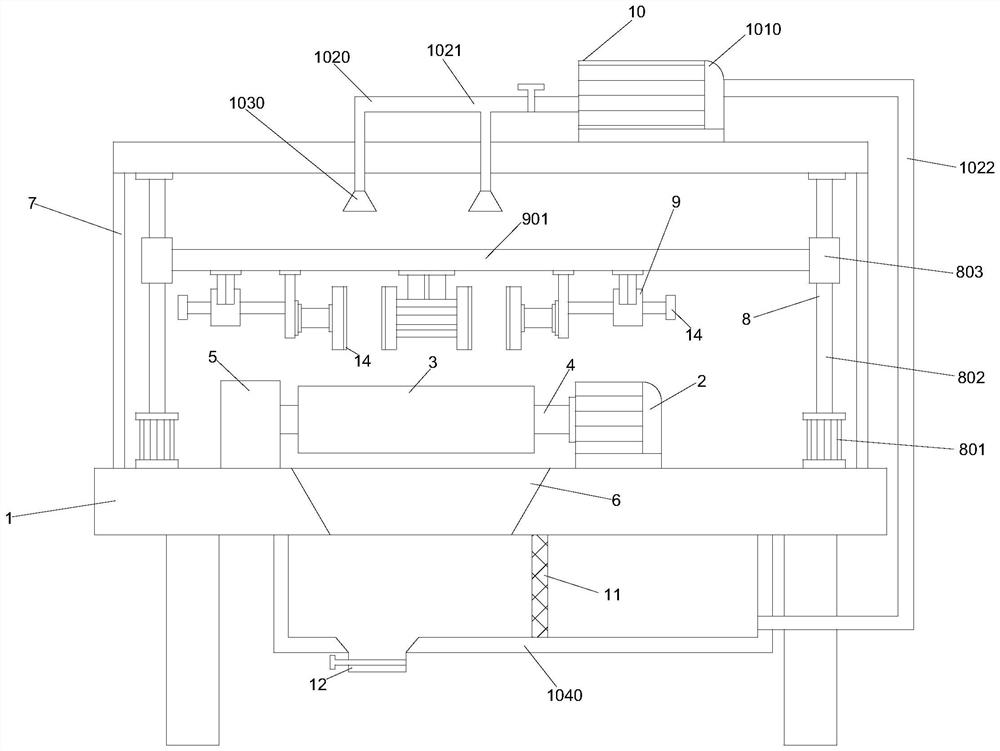

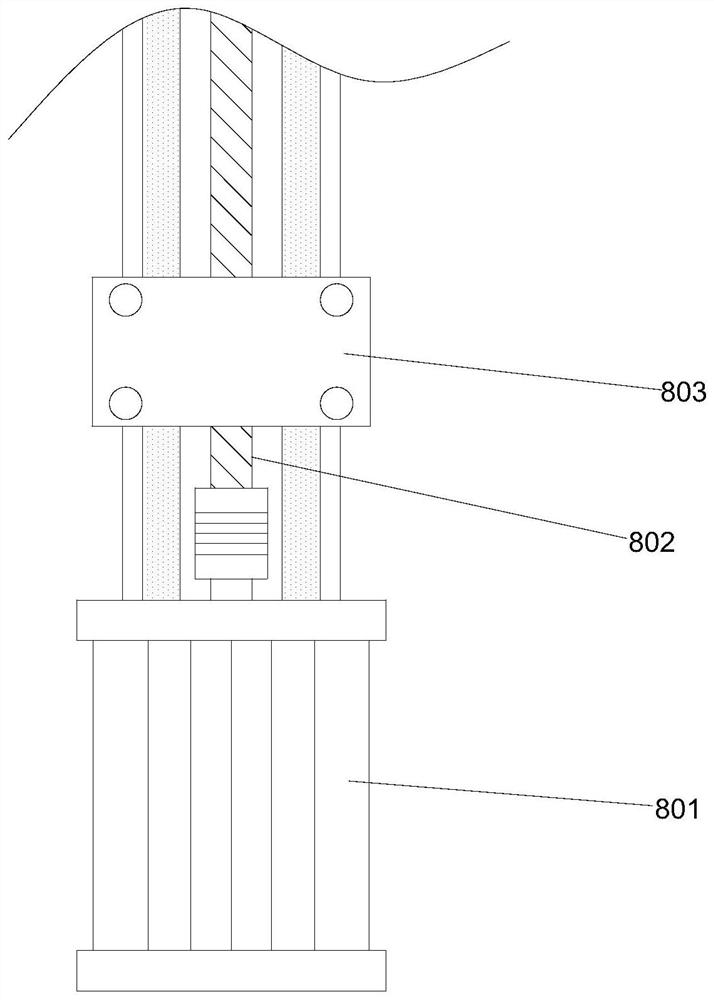

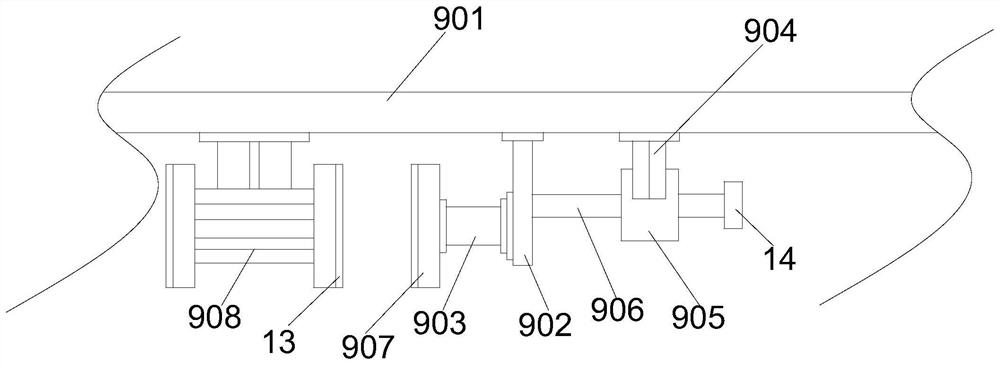

Spliced wood board grooving machine

ActiveCN109434976AConvenience to the leftReduce workloadWood mortising machinesBark-zones/chip/dust/waste removalPhysical healthPulp and paper industry

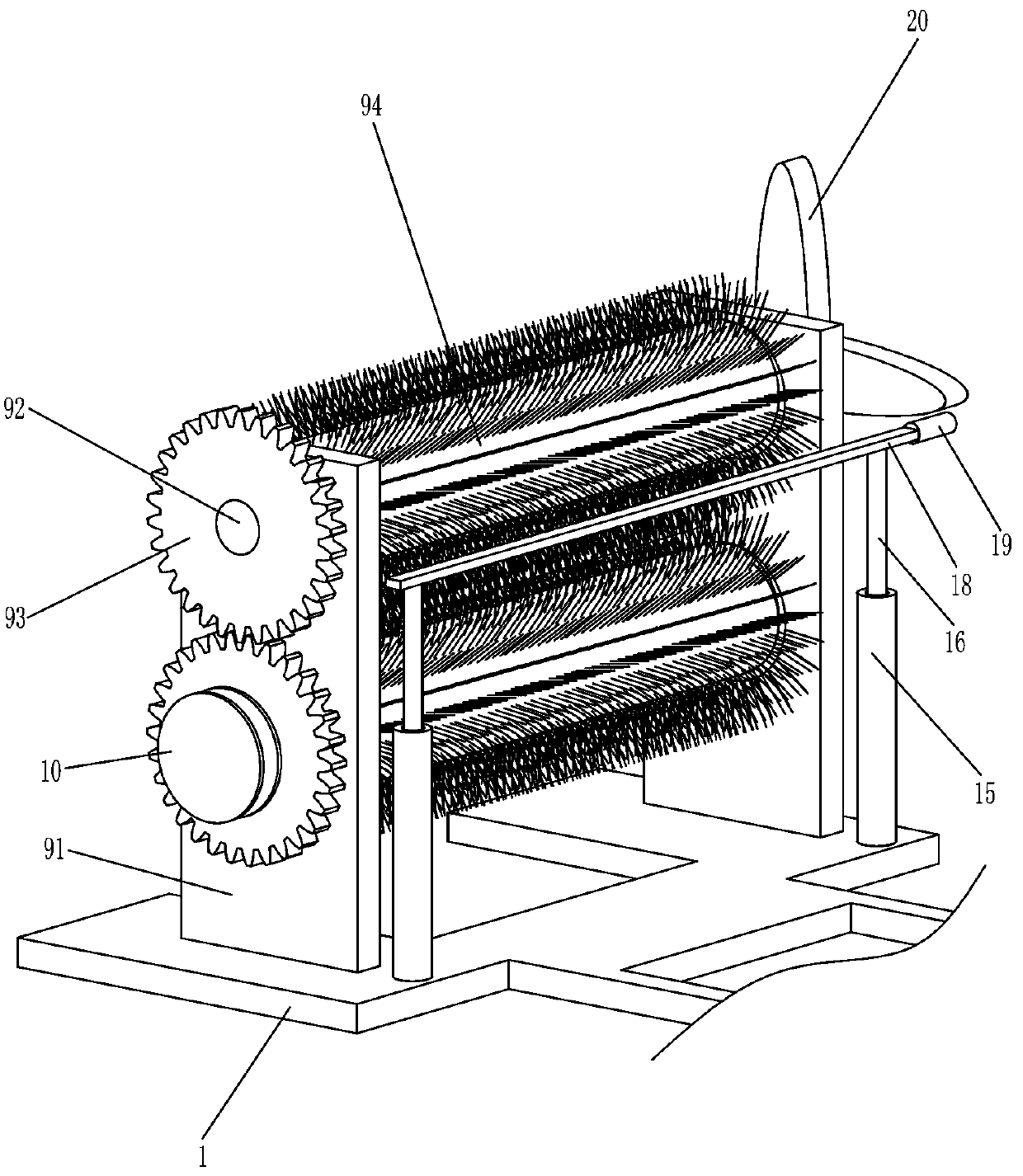

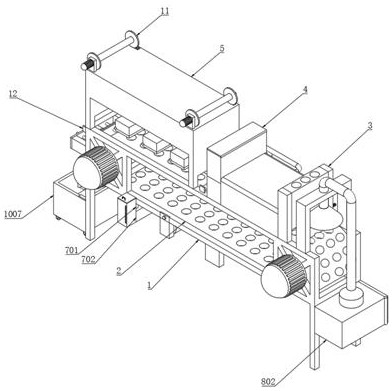

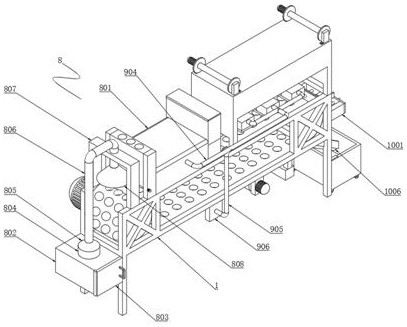

The invention relates to a grooving machine, in particular to a spliced wood board grooving machine. The spliced wood board grooving machine aims at achieving the technical effects that the physical health can be protected, and grooving efficiency can be improved. According to the technical scheme, the spliced wood board grooving machine comprises a holder, a delivery motor, a delivery wheel, an extending-and-contracting device, a first support, first rolling wheels, a first hollow sleeve, an arc-shaped sliding block and the like. The delivery motor which can drive the delivery wheel to rotateis mounted at the top of the holder. The delivery wheel is fixed to an output shaft of the delivery motor, wherein wood boards can be conveyed through the delivery wheel. The extending-and-contracting device capable of fixing the wood boards is mounted on the lower portion of the front side face of the holder. According to the spliced wood board grooving machine, by means of the extending-and-contracting device, a user can groove the wood boards of different thicknesses conveniently; a cutting wheel rotates, and the wood boards are conveyed leftwards, so that the wood boards can be grooved; by means of a rotating guide sleeve, grooving can be conducted on different positions of the wood boards, and thus, the grooving efficiency can be improved; and the work amount of the user can be reduced.

Owner:湖南高鹏木艺有限公司

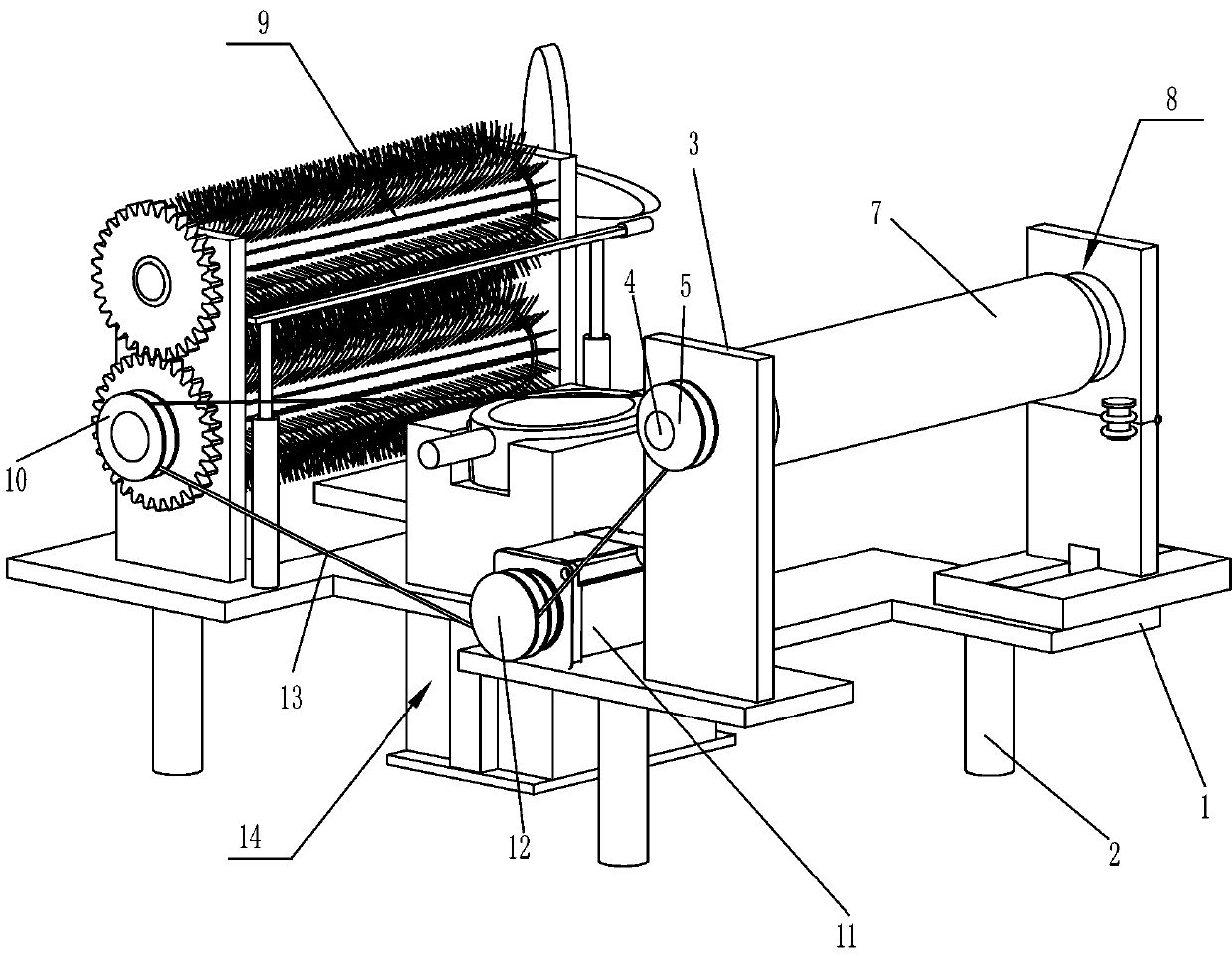

Cloth dust cleaning and arranging equipment

The invention relates to cleaning and arranging equipment, in particular to cloth dust cleaning and arranging equipment. The technical problem is how to provide cloth dust cleaning and arranging equipment which is capable of improving the cleaning efficiency and is convenient to arrange. Cloth dust cleaning and arranging equipment comprises a workbench, support rods, a vertical plate, a rotating shaft, a clamping block, a first belt wheel, a chuck and a winding roller. The bottom of the workbench is connected with four support rods, the vertical plate is fixedly connected to the top of the workbench, the rotating shaft is rotationally connected to the upper part of the vertical plate, the clamping block is connected to one end of the rotating shaft, the first belt wheel is arranged at theother end of the rotating shaft, the chuck is installed on the rotating shaft close to the vertical plate, and the winding roller is arranged on the chuck in a sleeving mode. The winding roller can befixed through a clamping mechanism, so that the winding roller can be prevented from rotating automatically and resulting in inconvenience of cleaning the dust on the cloth surface.

Owner:龚玉奖

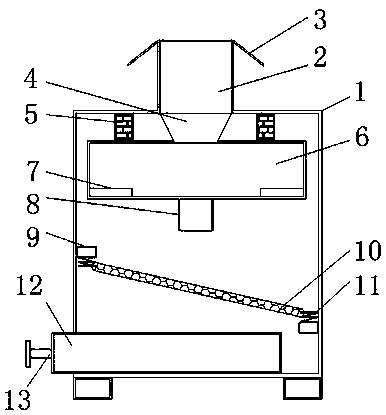

Integral vibration type down screening machine for down processing

InactiveCN108221092AImprove bulkImprove processing efficiencyFibre separationDrive motorPulp and paper industry

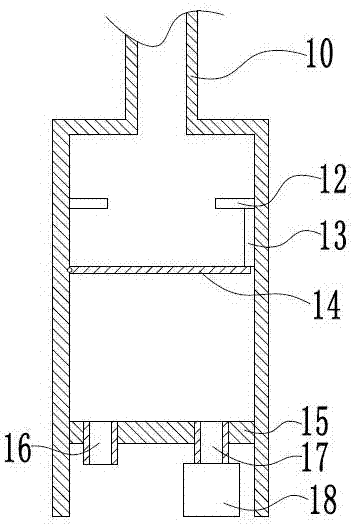

The invention discloses an integral vibration type down screening machine for down processing. The machine comprises a screening machine main body, a connecting rubber tube, a first fixed block, a second fixed block, a filter screen, a pull handle, a driving motor, a connecting wire and a moving groove; a feed inlet is formed in the screening machine main body, feed bin doors are arranged at the two ends of the feed inlet, the connecting rubber tube is arranged at the bottom of the feed inlet, a stirring box is arranged at the bottom of the connecting rubber tube, the screening machine main body and the stirring box are welded to the two ends of the first fixed block respectively, a discharge through hole is formed in the stirring box, a driving box is arranged at the bottom of the stirring box, the second fixed block is arranged in the screening machine main body, fixed springs are fixed to the bottom of the second fixed block through welding, and the fixed springs are fixed to the two ends of the filter screen through binding connection. The integral vibration type down screening machine for down processing is provided with the feed bin doors, the overall tightness of the devicecan be improved, and the raw material processing efficiency is effectively improved.

Owner:ZHANJIANG ZIJIN DOWN PROD

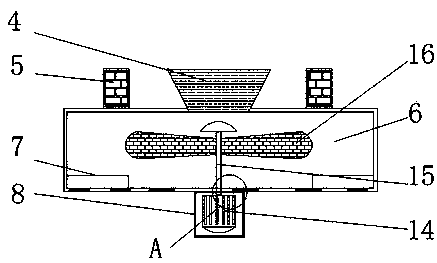

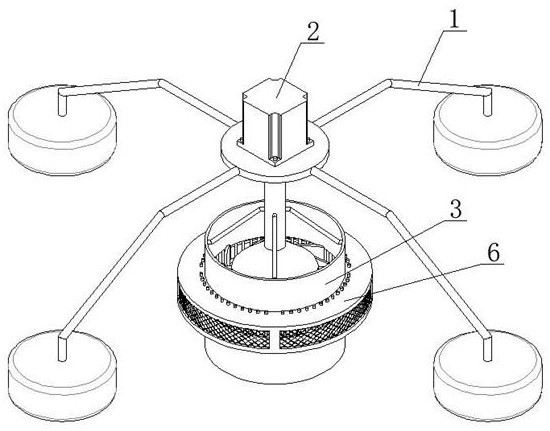

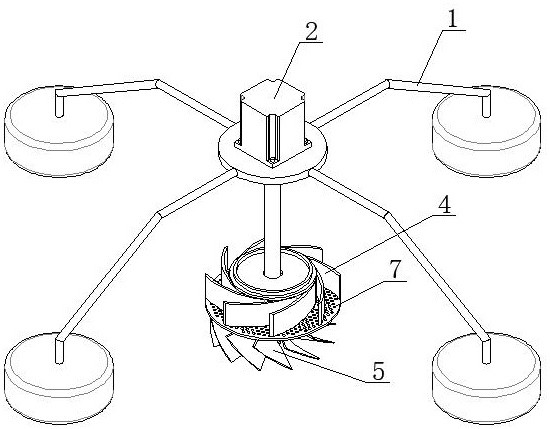

Artificial corn pollinator

ActiveCN113383704AIncrease productionFully pollinatedAgriculturePlant genotype modificationBiotechnologyPlant stalk

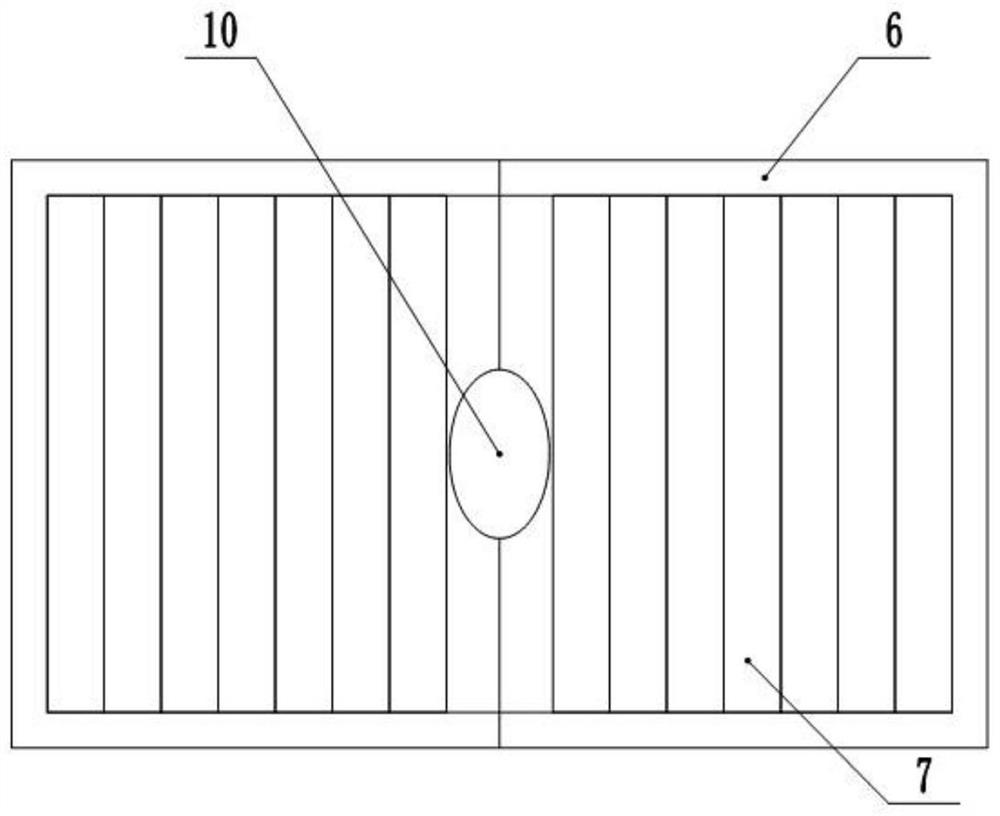

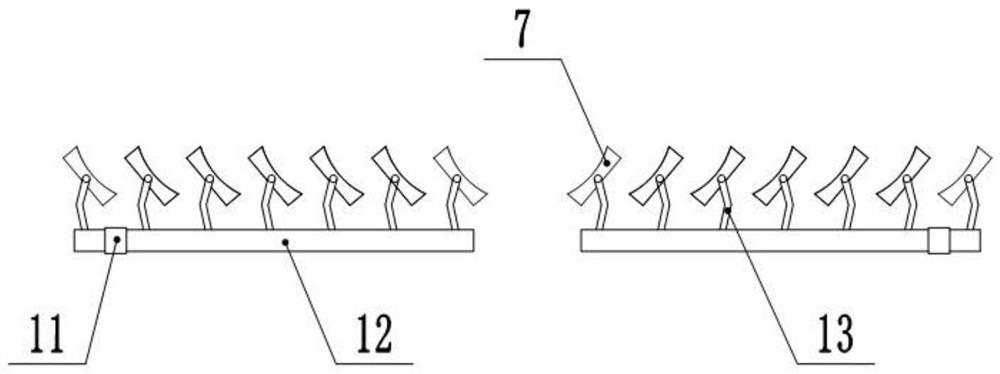

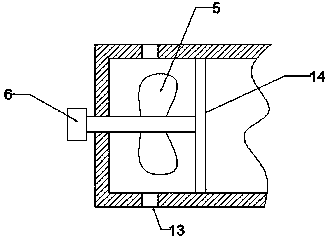

The invention relates to the technical field of crop cultivation, and discloses an artificial corn pollinator which comprises a support, a pollination cover is arranged on the support, the pollination cover is used for covering male ears and female ears, and the pollination cover comprises a left half cover and a right half cover; and a partition plate is arranged in the pollination cover and divides the pollination cover into an upper cavity and a lower cavity, a pollen shaking mechanism is arranged in the upper cavity and used for assisting pollen on tassels to shake off, the partition plate is composed of a plate frame and a plurality of battens rotationally connected to the plate frame, the battens are used for receiving the tassel pollen when being horizontal, a power mechanism for driving the battens to rotate is arranged on the pollination cover, the partition plate comprises a left half plate arranged on the left half cover and a right half plate arranged on the right half cover, and a through hole for corn plant stalks to pass through is formed in the joint of the left half cover and the right half cover. The artificial corn pollinator can solve the problems of low efficiency and poor pollination quality of manual pollen collection and pollination.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

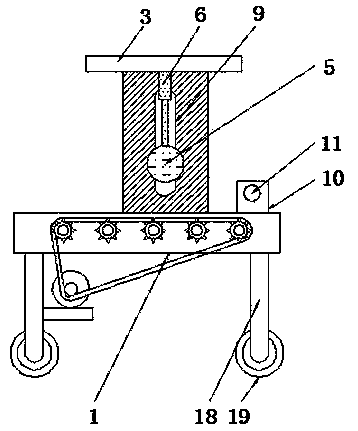

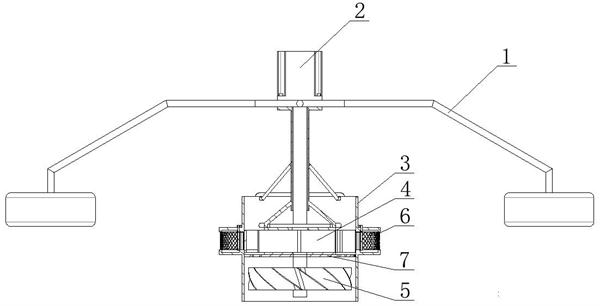

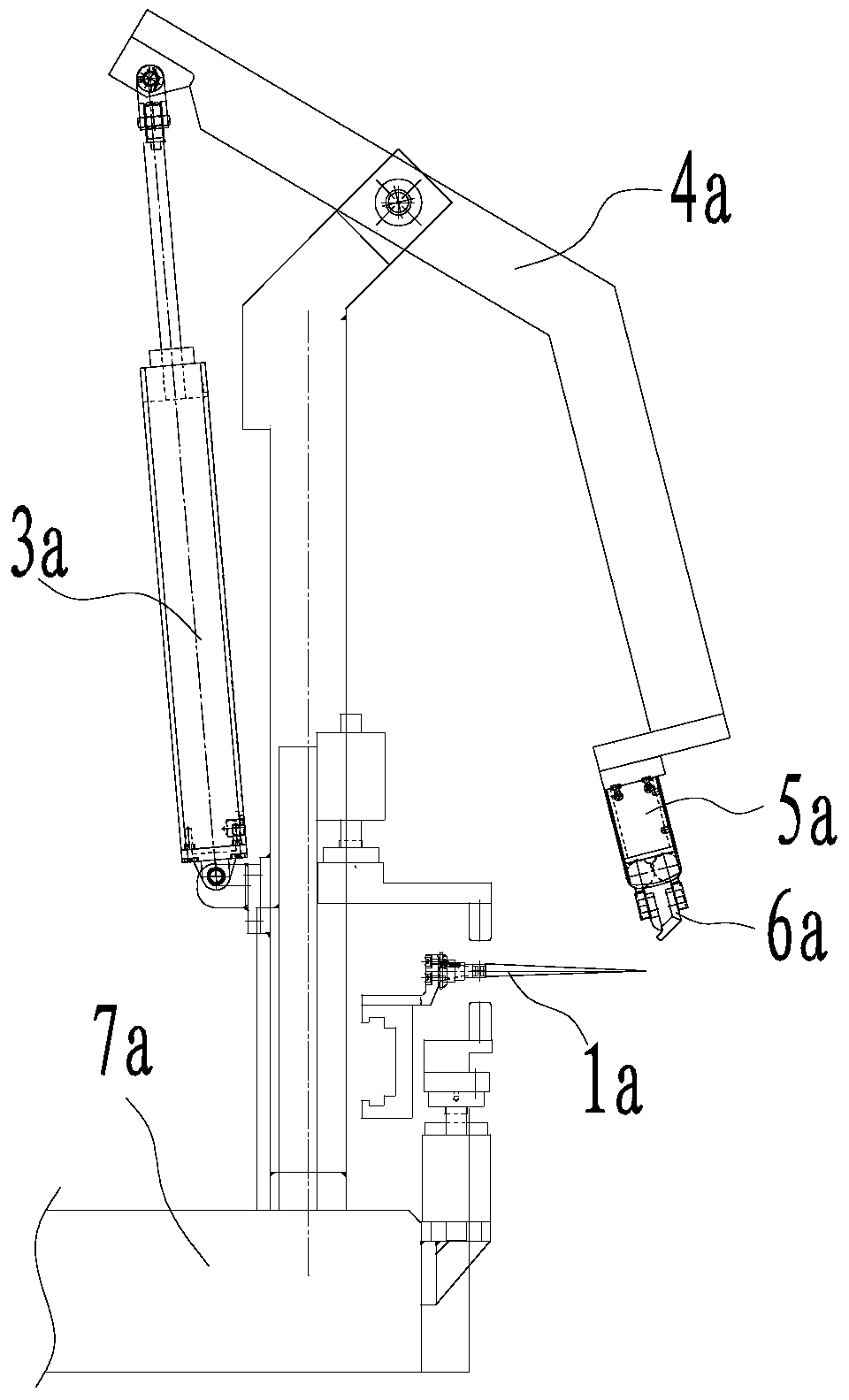

Wood slotting robot with depth adjusting function

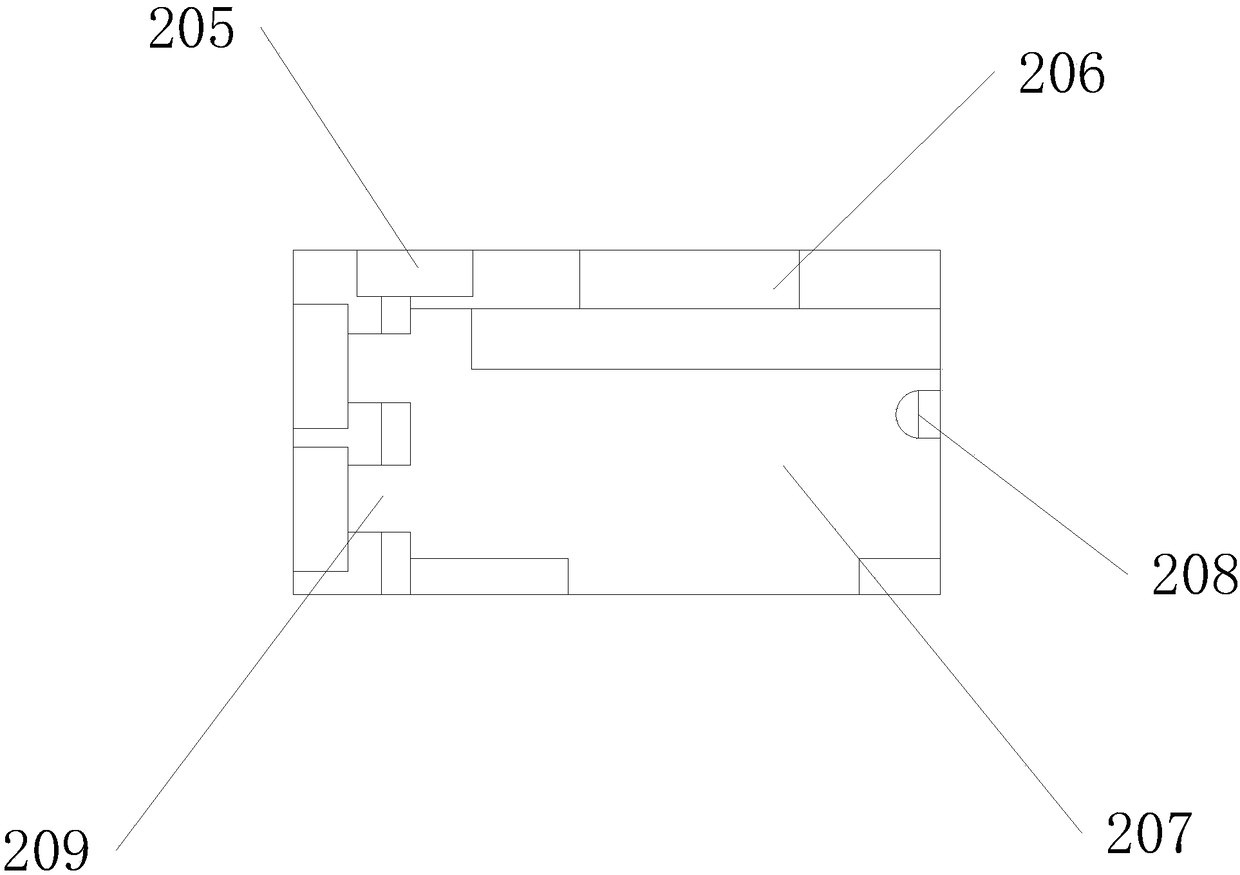

InactiveCN107685371AFreely adjustable depthAvoid floating aroundWood mortising machinesBark-zones/chip/dust/waste removalHydraulic motorPulp and paper industry

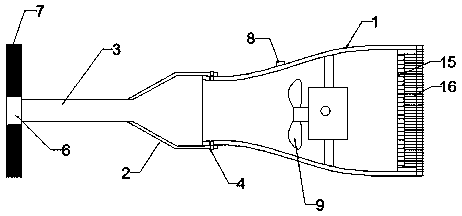

The invention discloses a wood grooving robot with adjustable depth, which includes a workbench, an installation frame is installed above the workbench, a horizontal plate is installed on the top of the installation frame, and a perforation is opened inside the installation frame. The inside of the perforation is installed with a first roller, one end of the first roller is installed with a bearing, the outside of the first roller is covered with a blade, and the other end of the first roller is installed with a first motor , a hydraulic rod is installed above the first motor. The invention is scientific and reasonable in structure, safe and convenient to use, equipped with a hydraulic rod, which can freely adjust the depth of the slot opened by the slotting machine, and equipped with a roller and a brush, which can remove the residual sawdust on the surface of the wood after slotting, and is equipped with a funnel And the ash collection box can collect wood chips for secondary use. Velcro and protective curtains are installed to prevent wood chips from floating around and causing pollution to users and the environment.

Owner:北海南坡腕网络技术有限公司

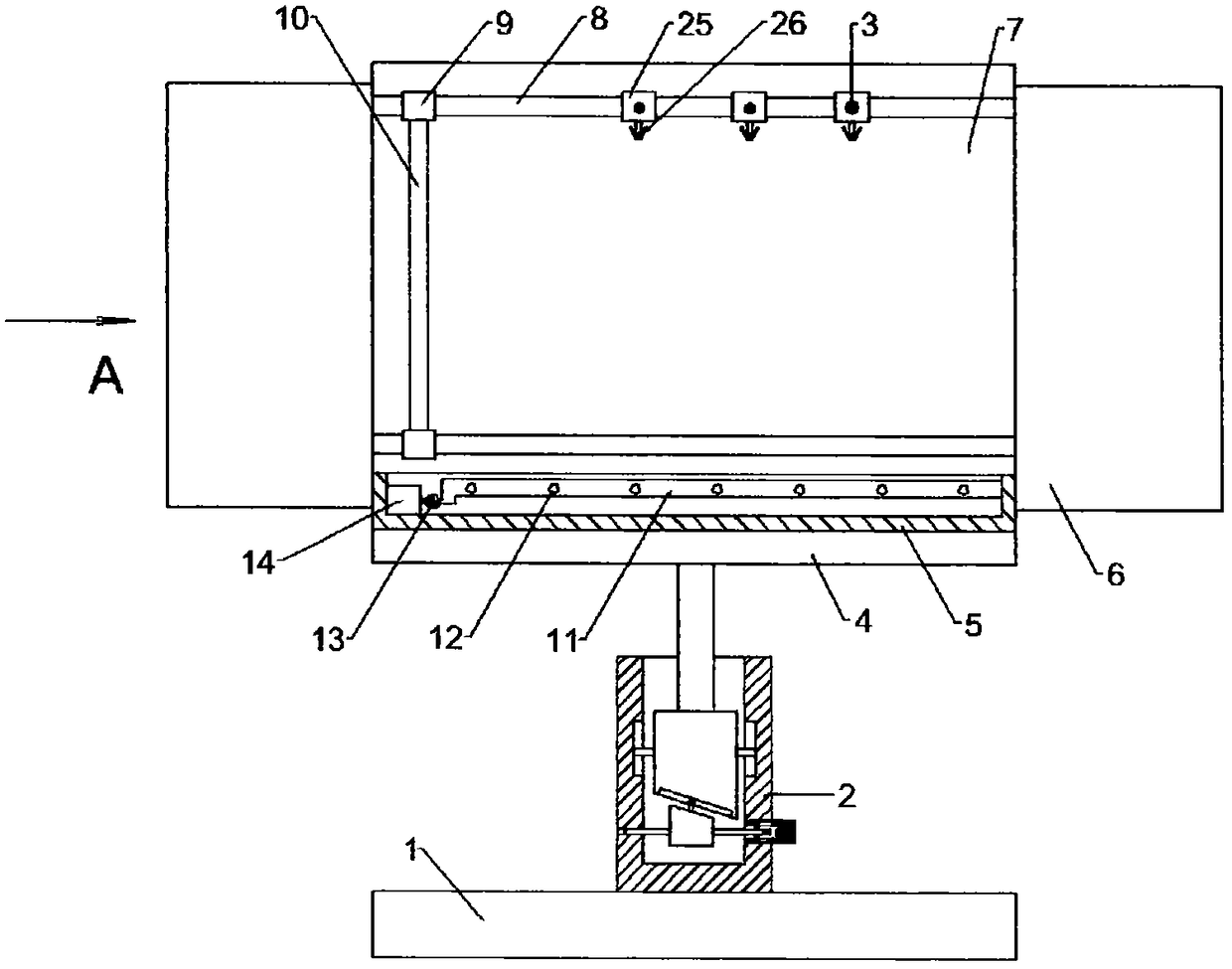

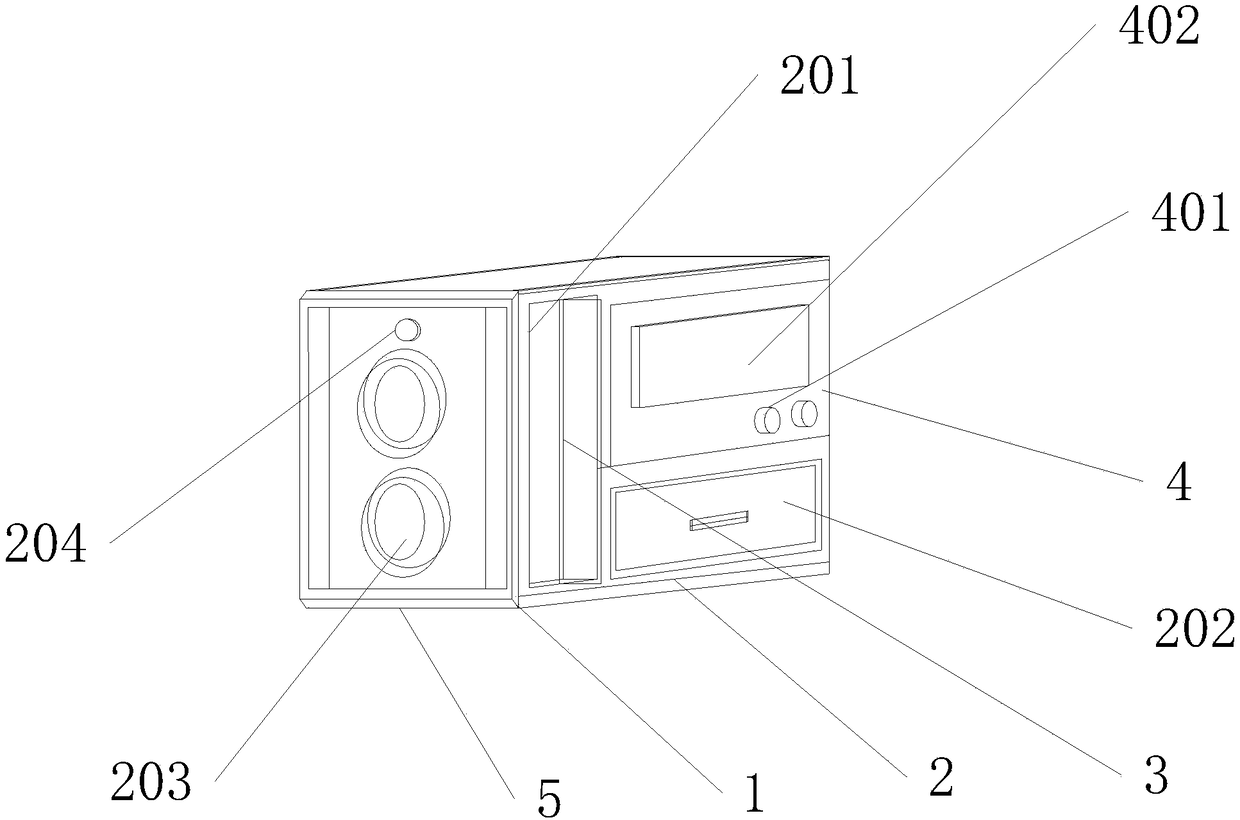

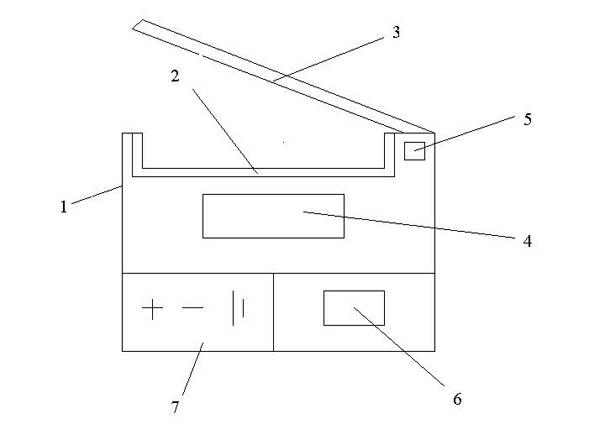

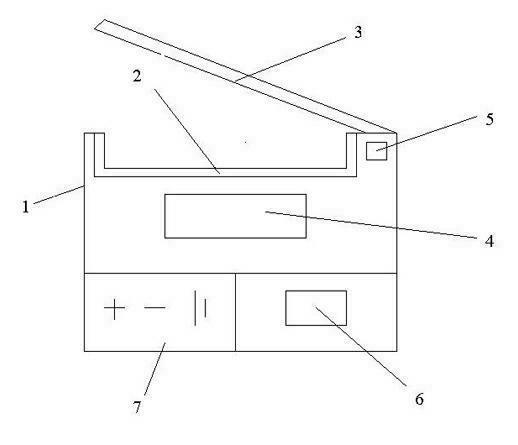

Mathematics teaching board with dust collection function

InactiveCN108597305AAchieve reductionChange inclinationBoard cleaning devicesWriting boardsEngineeringRight trapezoid

The invention provides a mathematics teaching board with a dust collection function. The mathematics teaching board comprises a support plate, wherein a height adjusting device is arranged at the lower side of the support plate, the height adjusting device comprises a support post, the bottom end of the support post is fixedly connected with the upper side of a base, a groove with an upward opening is formed in the support post, a lower movable block is arranged in the groove, the section of the lower movable block is in the shape of a right trapezoid, the oblique plane of the lower movable block faces the upward direction, movable rods are fixedly connected to two sides of the lower movable block, a movable through hole is formed in the left side of the support post, the movable rod on the left side is positioned inside the movable through hole, and the movable rod on the right side is connected with a drive device. The mathematics teaching board has the beneficial effects that the drive device drives the lower movable block to move towards the right side, the lower movable block enables an upper movable block to move upwards through a rolling wheel and a rolling wheel bracket, and thus a fixing post drives the increase of the height of the support plate; when the drive device enables the lower movable block to move towards the left side, the fall of the upper movable block isrealized.

Owner:XIAN UNIV OF SCI & TECH

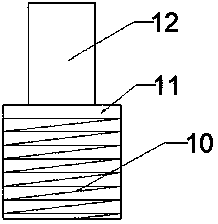

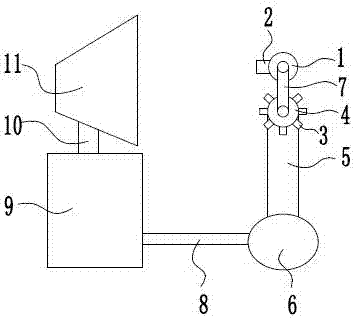

Dust removal device for computer hardware

InactiveCN110270522AAvoid accumulationAvoid floating aroundDispersed particle filtrationCleaning using toolsEngineeringWind power

The invention discloses a dust removal device for a computer hardware. The dust removal device comprises a machine shell, a conical sleeve, an air blowing pipe, a locking device, fan blades, a connecting block, a vertical brush, a switch, an electric fan, a compression spring, a limiting plate, a locking column, an air blowing hole, a fixed rod, a filter screen, an end cover, a cleaning sponge, a storage box, a spare cleaning head, a small cleaning brush and a rubber cleaning head; the machine shell is of a circular-tube-shaped structure, the left end of the machine shell is fine, the right end of the machine shell is thick, and the storage box is fixedly arranged at the bottom of the machine shell. According to the dust removal device, the switch of the electric fan is opened through the cooperation of the elongated air blowing pipe and the vertical brush, the wind power blows the fan blades to rotate so as to drive the vertical brush to rotate, the residual wind power can also be blown out of the air blowing hole, and dust in the corner of a case is cleared away; and the air blowing pipe can be detached through the locking device, and the dust which is easy to clean on the surface is directly cleaned by the electric fan.

Owner:西安哈希码信息技术有限公司

Horizontal child vomiting caring device

InactiveCN109700665AAvoid floating aroundRelieve discomfortSpittle receiving devicesBogieWater storage tank

The invention relates to a horizontal child vomiting caring device, which comprises a bed body, back-slapping mechanisms and a cleaning mechanism. The bed body is symmetrically mounted with the back-flapping mechanisms on the front and rear sides, the cleaning mechanism is arranged at the left end of the bed body, the left end of the bed body has a semicircular opening. The cleaning mechanism includes a base, a moving wheel, a steering motor, a steering frame, a support plate, a moving frame, an adjustment plate, a receiving groove, a shielding frame, a receiving frame and a cleaning branch chain. The cleaning branch chain includes a working plate, a support groove, a pressing rod, a water storage tank, a water supply pipe, an auxiliary plate and a support bracket, The back-slapping mechanism includes a sliding frame, an adjusting frame, a mounting frame, a rotating motor, a rotating rod, a sliding block, a back-slapping plate and a connecting plate. The device can solve the problems of high artificial dependence, emotional instability of the child, odor of the vomit on the surrounding environment and inconvenient cleaning of the vomit in the existing vomiting caring for children.

Owner:THE FIRST AFFILIATED HOSPITAL OF SHANTOU UNIV MEDICAL COLLEGE

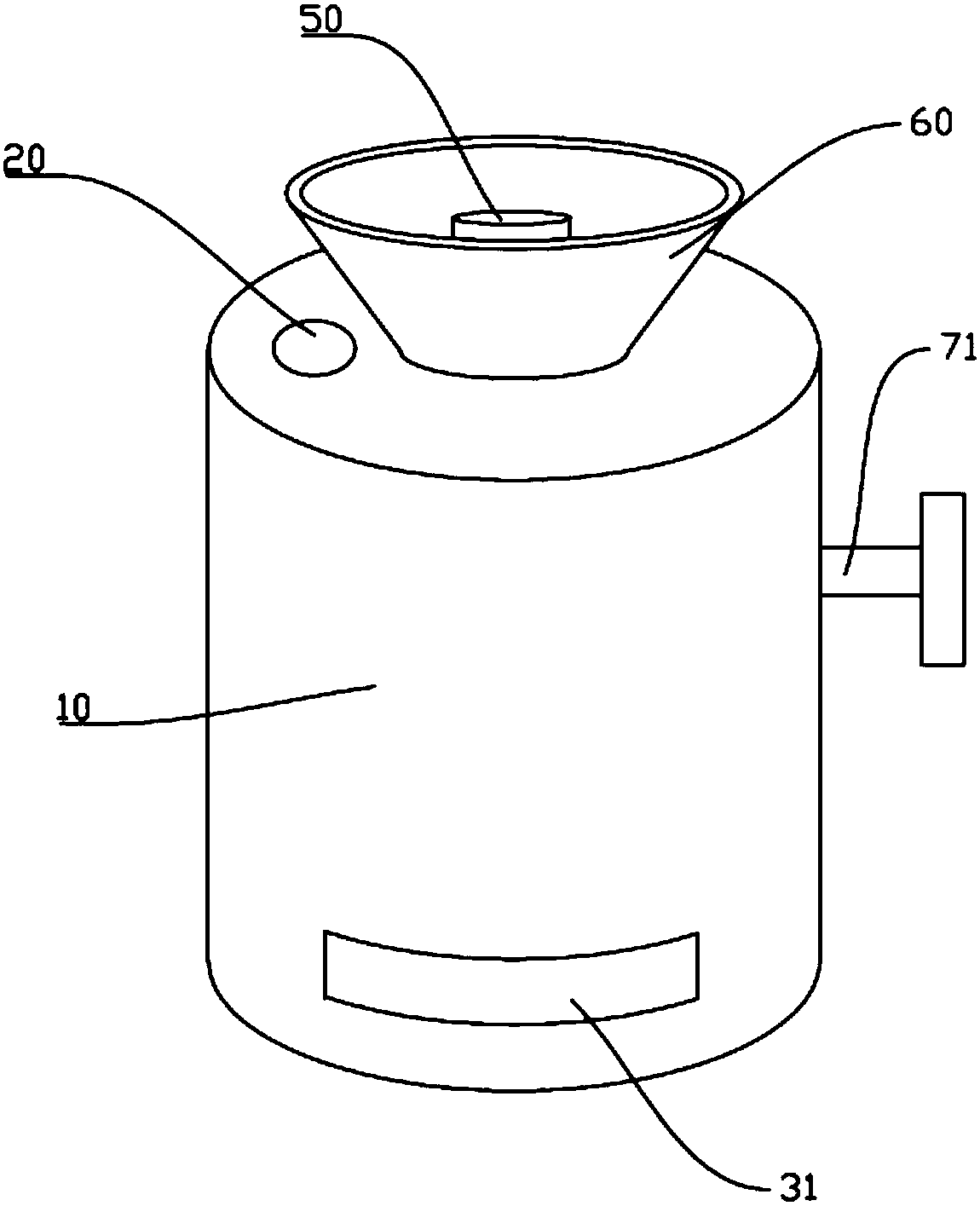

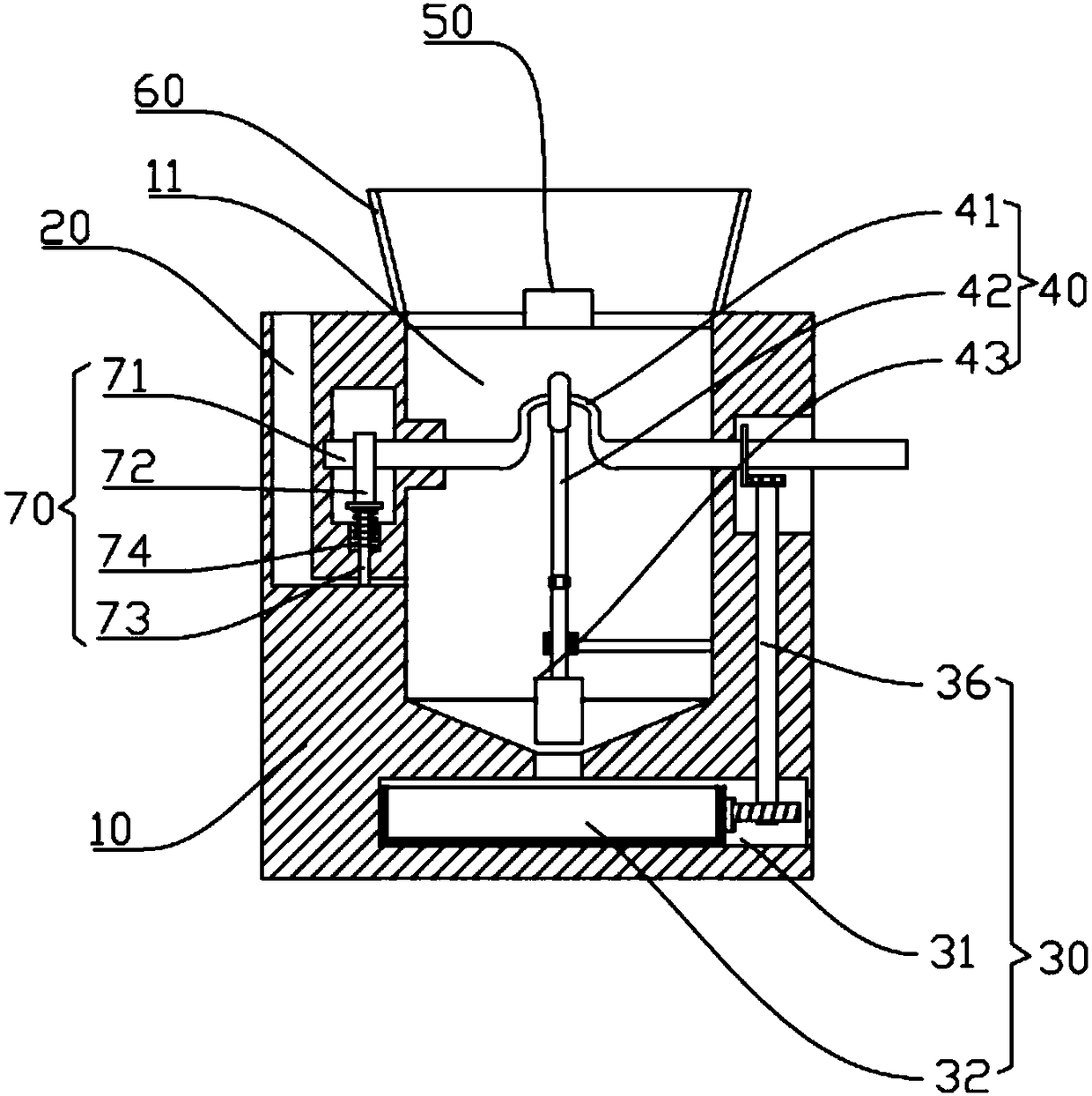

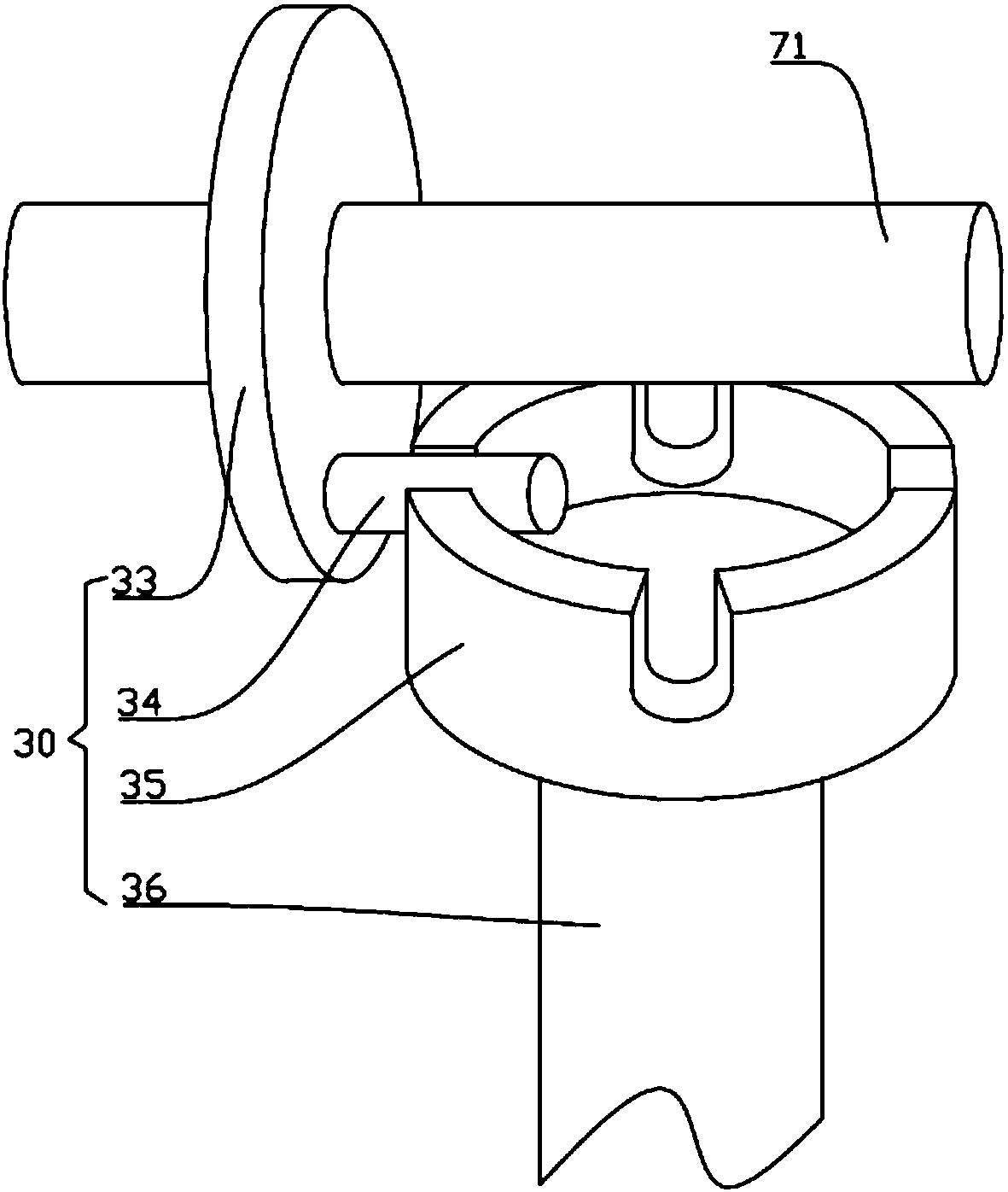

Incense burner capable of recycling and processing incense ash

InactiveCN108244972AAvoid floating aroundIncrease added valueReligious equipmentInjection deviceMaterial storage

The invention discloses an incense burner capable of recycling and processing incense ash, and belongs to the technical field of incense burners. The incense burner comprises a burner body, a glue injection device, a material storage device and a material smashing device, wherein an ash discharging channel is arranged in the burner body, an incense inserting base is arranged on the burner body, the incense inserting base is arranged above the ash discharging channel, and the glue injection device is arranged on the burner body; the output end of the glue injection device is communicated with the ash discharging channel, and the material storage device is arranged on the burner body and is used for receiving a mixture of the incense ash and glue falling off the ash discharging channel; thematerial smashing device is arranged on the burner body and is used for smashing the mixture of the incense ash and the glue in the ash discharging channel into the storage device and carrying out compaction.

Owner:吴依然

Novel environment-friendly electronic waste processing equipment

ActiveCN111282641AReasonable structureFunctionalUsing liquid separation agentCocoaWaste processingSewage outfall

The invention relates to the technical field of electronic waste processing equipment, in particular to novel environment-friendly electronic waste processing equipment. The novel environment-friendlyelectronic waste processing equipment comprises a crushing box, a material putting hopper is arranged on a top plate of the crushing box, the outer side of the material putting hopper is sleeved witha first gas collecting frame, first axial flow fans are arranged in the first gas collecting frame, first gas delivery pipes are inserted into side plates of the first gas collecting frame, and the other ends of the first gas delivery pipes are inserted into a dust fall water tank; and a crushing base is arranged on the bottom face of the top plate of the crushing box, crushing rolls are rotatably connected to the interior of the crushing box, a carrying plate is arranged on the surface of the crushing box, the bottom face of the carrying plate is provided with rotating grooves, rotating plates are arranged in the rotating grooves, and baffles are arranged on the lower portions of the rotating plates. The novel environment-friendly electronic waste processing equipment has the beneficialeffects that the gas collecting frame is additionally arranged on the outer side of the material putting hopper and the crushing box, dust is sucked into the dust fall water tank through the axial flow fans, the dust is mixed with water and discharged through a sewage draining port, and the condition that the dust generated in the crushing process drifts around is avoided.

Owner:新昌县维利机械有限公司

Plate cutting dust recovery device

The invention discloses a plate cutting dust recovery device. The plate cutting dust recovery device comprises a worktable, a damping spring column, the clamping rods, a dust absorbing module and a dust integration box; the bottom of the worktable is fixedly connected with a bracket; the damping spring column is arranged in the bracket; slide rails are averagely distributed above the worktable; slide blocks are arranged above the slide rails, and are fixedly connected with the clamping rods; a thread rod is arranged in middle of the clamping rods; a metal grid plate is arranged in middle of the worktable; the dust absorbing module is arranged under the worktable; and the dust absorbing module comprises an acquisition box, a suction pipe, a dust absorber, a discharge pipe, the dust integration box and an overturning cover. The plate cutting dust recovery device is provided with the dust absorbing module under the worktable for collecting dust generated in the cutting process to preventthe plate dust from being splashed anywhere and sucked into bodies of operators; and the plate cutting dust recovery device is simple in overall structure and higher in practicability.

Owner:ZHUHAI SHENGXIYUAN MECHANICAL & ELECTRICAL EQUIP CO LTD

Spinning cleaning device

The invention belongs to the field of spinning machinery, and discloses a spinning cleaning device. The device includes a pulling device used for being connected to a stator and rotating along with the rotator, a cleaning head used for being pulled and opened by the pulling device and spraying water to the stator, a water pump used for conveying water to the cleaning head, a dust collector used for adsorbing short fibers which are cleaned out, and a collecting box used for collecting the short fibers from the dust collector. The collecting box is internally provided with a vacuum pump for generating negative pressure inside the collecting box and the dust collector communicated with the collecting box.

Owner:余庆县鸿祥棉纺有限责任公司

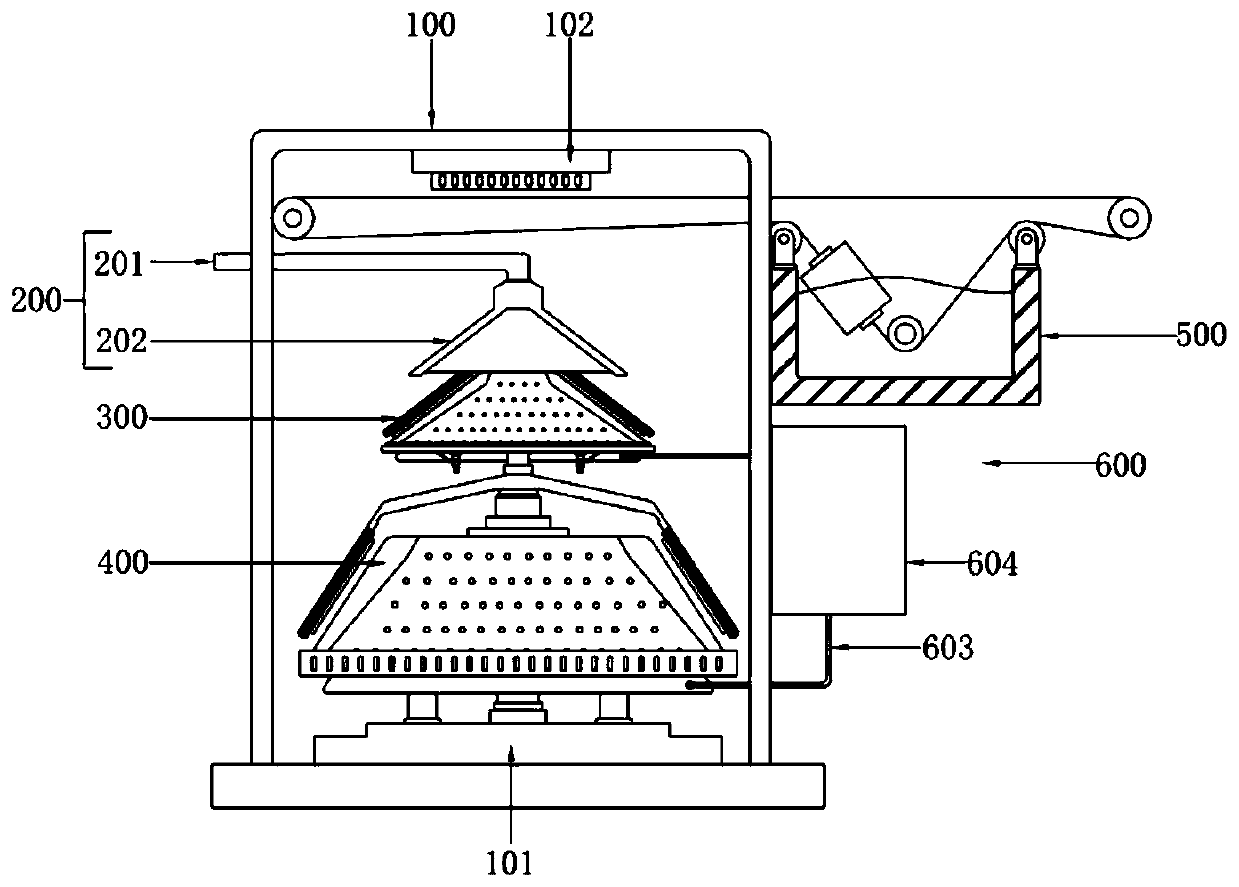

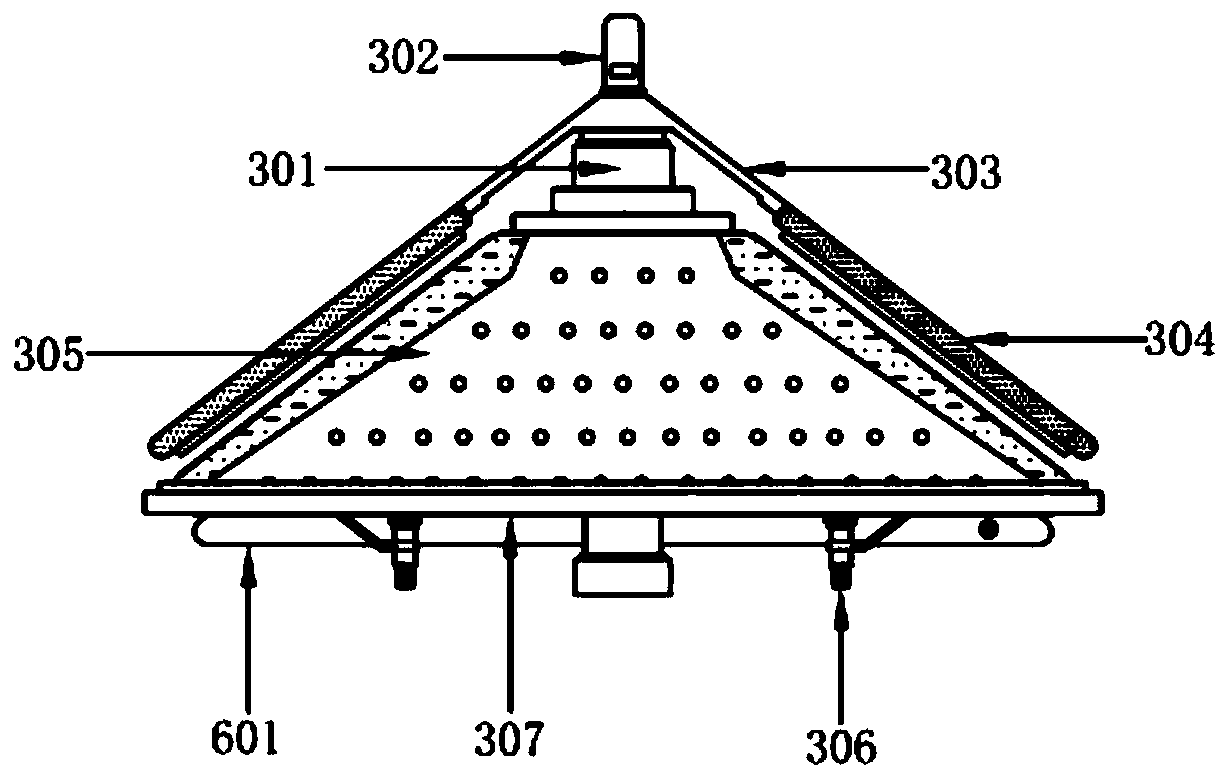

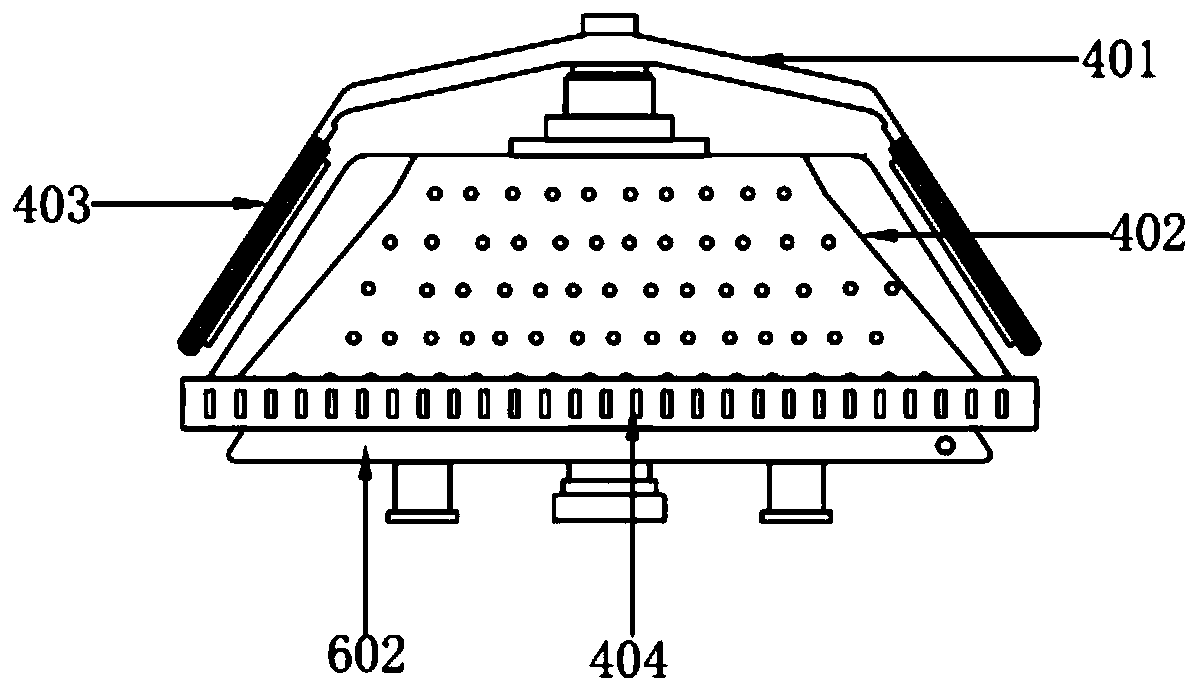

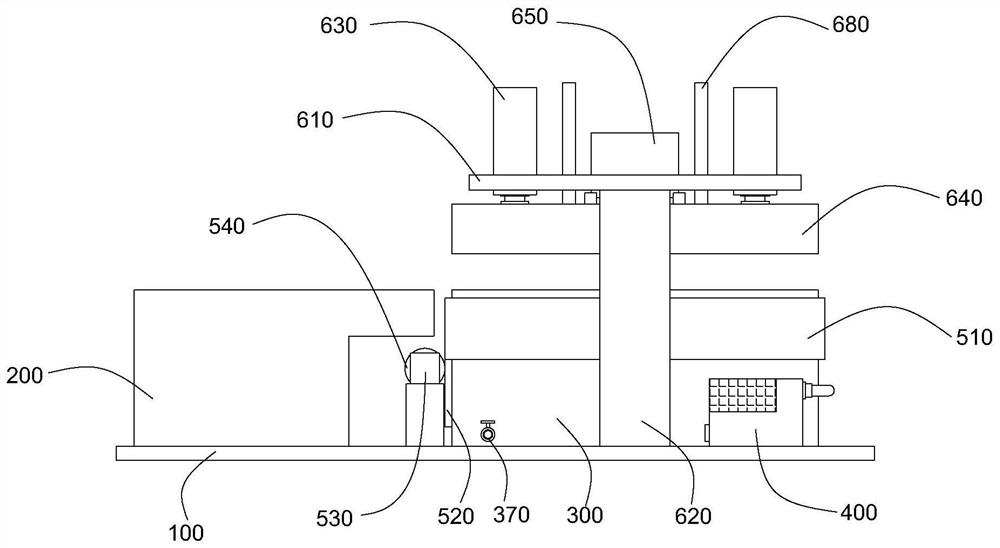

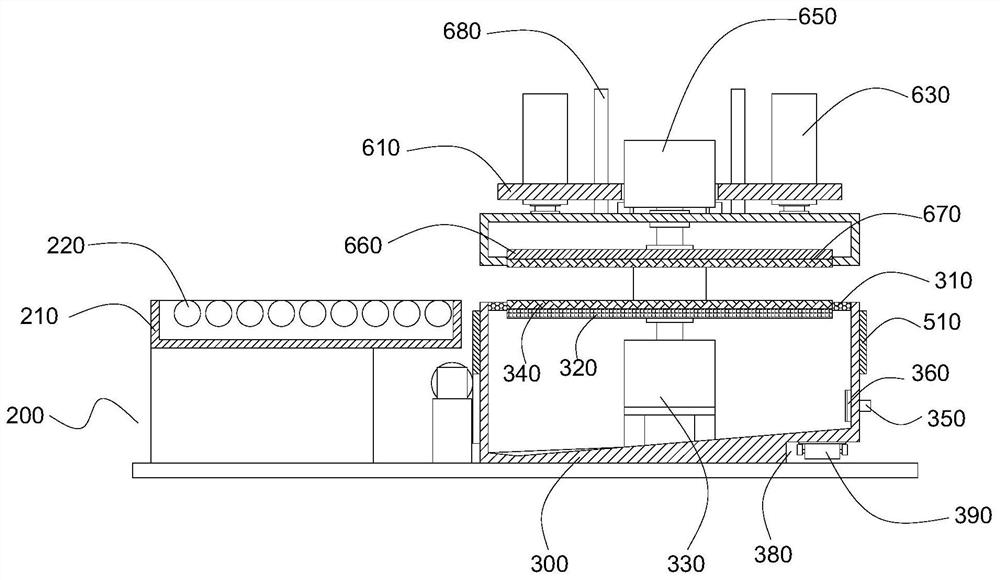

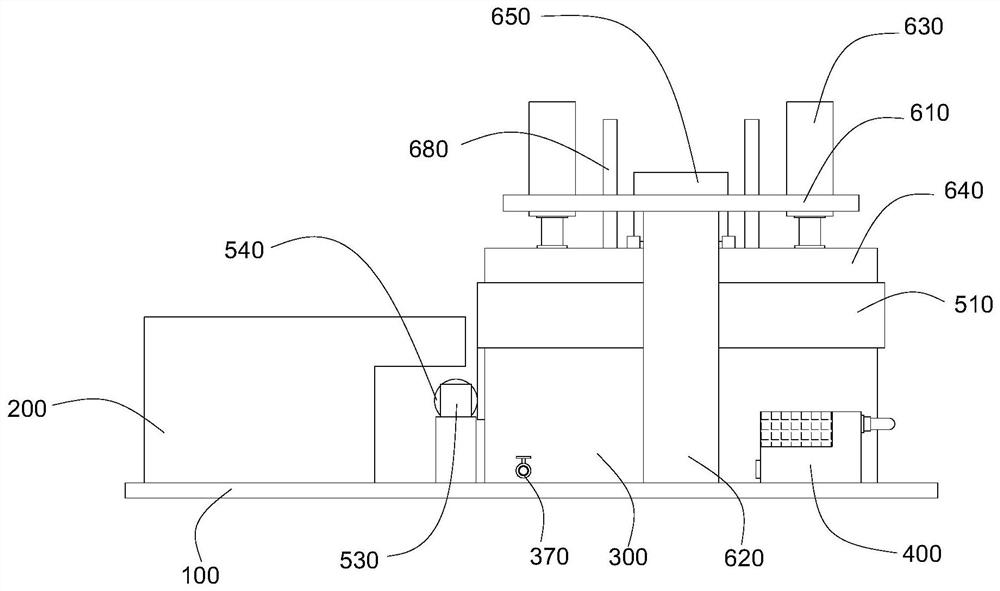

Uniform heat conduction system for jelly sealing machine and temperature control method

ActiveCN111846318AEasy extractionEasy to filterCleaningPackaging protectionTemperature controlHydraulic cylinder

The invention discloses a uniform heat conduction system for a jelly sealing machine and a temperature control method. The uniform heat conduction system comprises a fixing frame. A conveying belt isfixedly arranged on one side of the fixing frame. The edge portion of the top end of the fixing frame is provided with a shell placing block. A feeding groove is formed in a position, corresponding toone side of the shell placing block, of the top end of the fixing frame. The edge portion of top end of the fixing frame is provided with a sealing block. A heat conducting mechanism is fixedly arranged at the bottom end of the sealing block and comprises a hydraulic cylinder, a pressing plate, an oil outlet pipe, an oil via pipe, an oil pump, a through pipe, an oil pipe and a filtering box. According to the uniform heat conduction system for the jelly sealing machine and the temperature control method, through cooperation of the heat conducting mechanism, a cleaning mechanism, a dustproof mechanism and an energy-saving mechanism, optimization is conducted on the pressing plate and pressing block uniform heat conducting process, the heat recycling process and the sterilization process; and meanwhile, through a material collecting mechanism, the difficulty of collecting jelly products by workers is reduced, the sealing efficiency of the jelly sealing machine is effectively improved, and the jelly sealing machine is more efficient and energy-saving.

Owner:LABIXIAOXIN (FUJIAN) FOOD INDUSTRY CO LTD

Lens edging machine

InactiveCN112264862AImprove qualityAchieve recyclingEdge grinding machinesGrinding carriagesElectric machineryGrinding wheel

The invention provides a lens edging machine. The lens edging machine comprises a workbench, a first motor, a grinding wheel, a bearing and a fixed block, and further comprises a protective cover, anelectric lead screw device, a clamping device and a cooling device, wherein the first motor, the grinding wheel, the bearing and the fixed block are positioned on the top of the workbench; the grinding wheel is positioned on the bearing; one end of the bearing is connected to the first motor, and the other end of the bearing is connected to the fixed block; a water collecting hopper is arranged inside the workbench; the protective cover is a movable type protective cover, and is positioned on the top of the workbench; and the electric lead screw device, the clamping device and the cooling device are positioned inside the protective cover. The lens edging machine provided by the invention is equipped with dual stations, so that left and right lenses can be automatically edged at the same time, and thus, processing efficiency is improved, and working time is saved; a cooling device is arranged, and a water-cooling way is adopted for cooling the to-be-edged lenses, so that edging qualityof the lenses is improved; and meanwhile, cyclic utilization of water resources is realized through a water pump, a water tube and a filter screen.

Owner:江西中奥塑胶有限公司

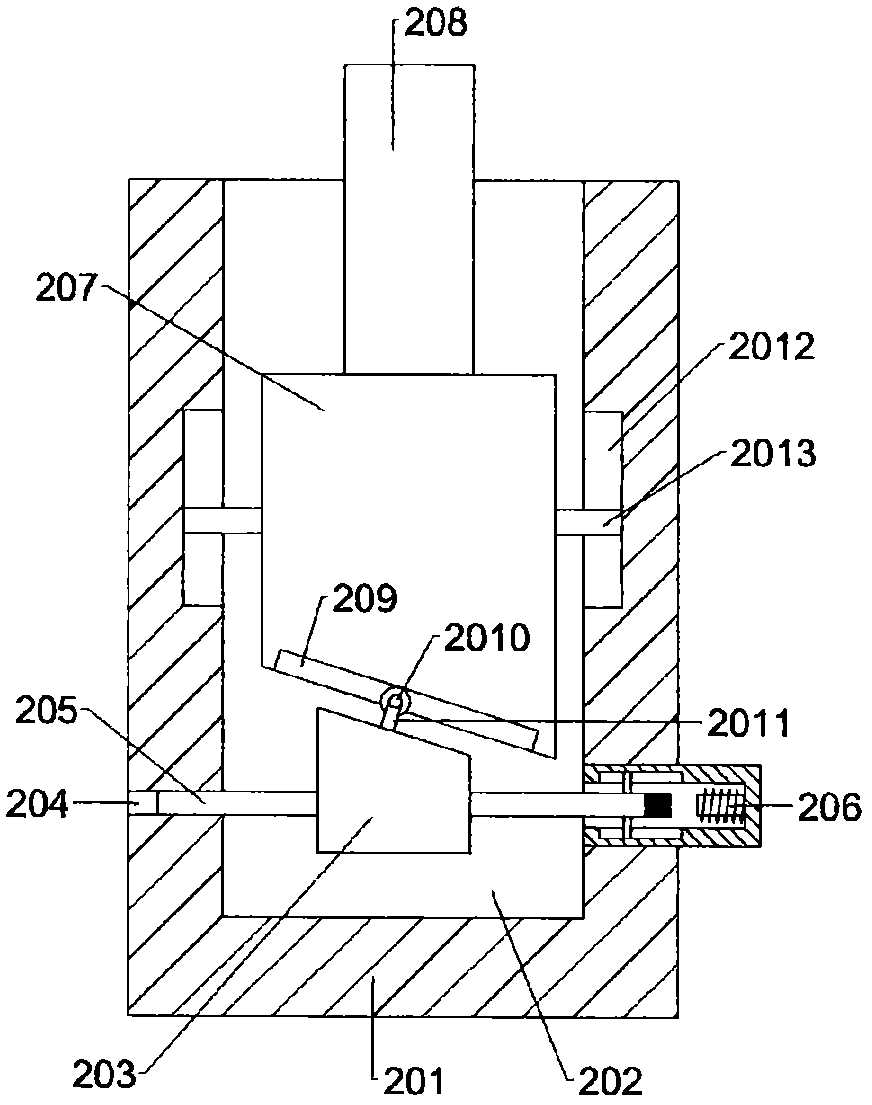

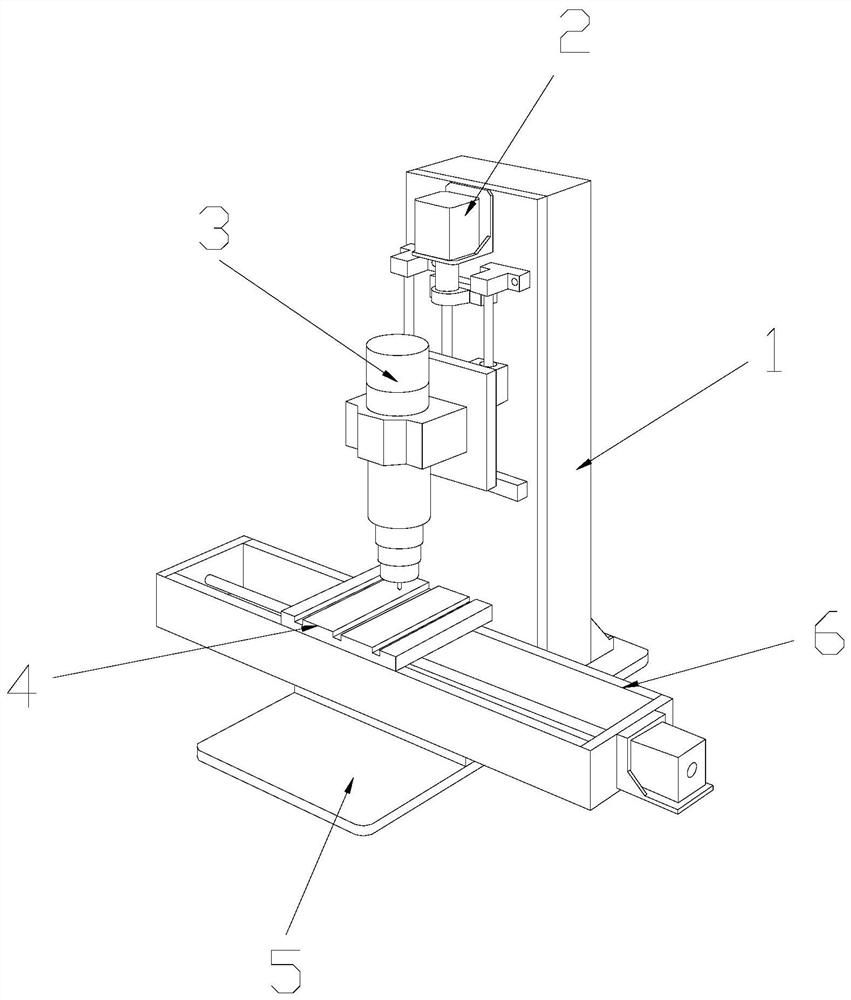

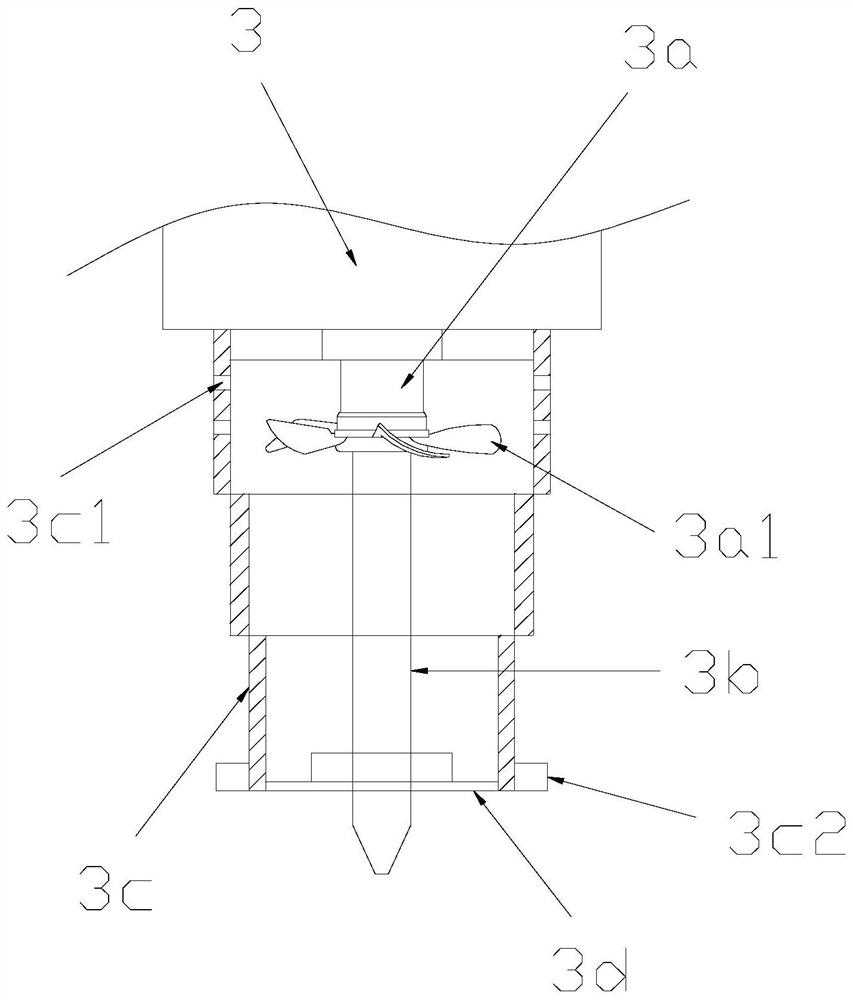

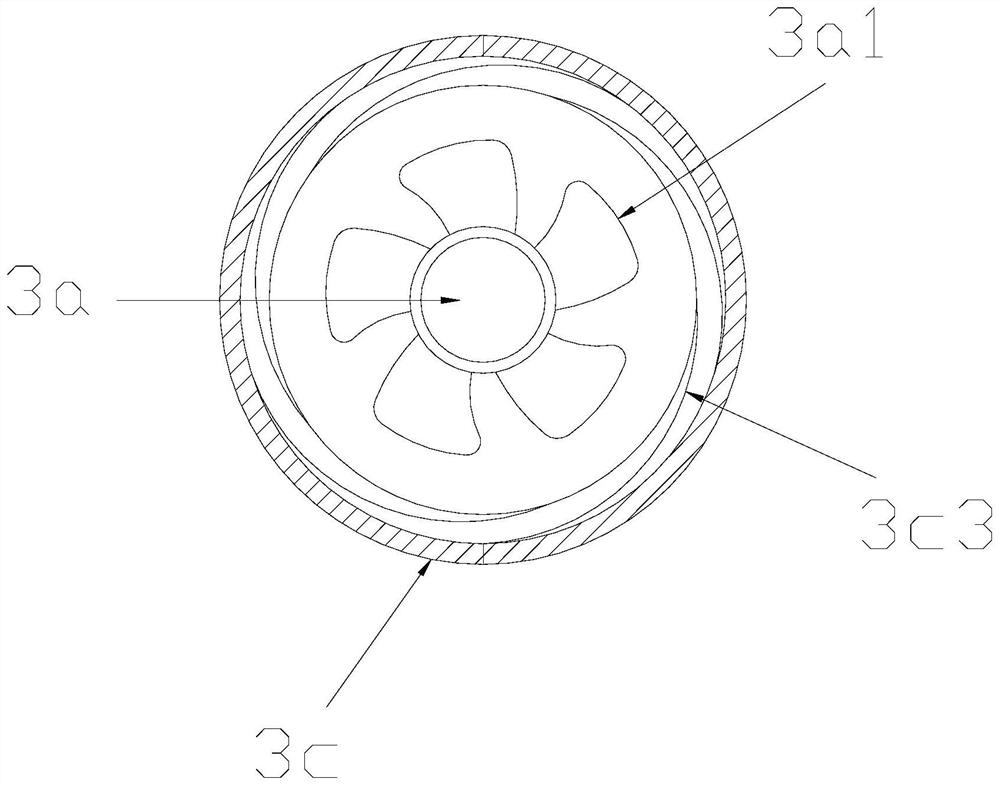

Drilling machine

ActiveCN111805244AAvoid harmAvoid floating aroundOther manufacturing equipments/toolsPositioning apparatusThermodynamicsDrilling machines

The invention discloses a drilling machine. The drilling machine structurally comprises a rack, a vertical sliding device, a drilling machine body, a working plate, a support and a sliding rail table,wherein the drilling machine further comprises a driving shaft, a drill bit, a telescopic folding protection cylinder and a drill bit balance mechanism. According to the drilling machine, the drill bit is used for driving a drill bit clamping piece, a drilling grinding layer is driven to grind the edge of a hole opening when an arc-shaped piece body rotates, and the damage of the edge of the holeopening to a contact person is avoided. The design of the drill bit clamping piece is used for assisting in balancing the rotation stability of the drill bit and grinding the edge of the hole opening, negative pressure attraction force is generated through rotation of a negative pressure fan, chippings are concentrated in the telescopic folding protection cylinder, the chippings are prevented from drifting away, the drill bit can be cooled, and the heat loss of the drill bit is reduced.

Owner:浏阳市旭驰五金制品有限公司

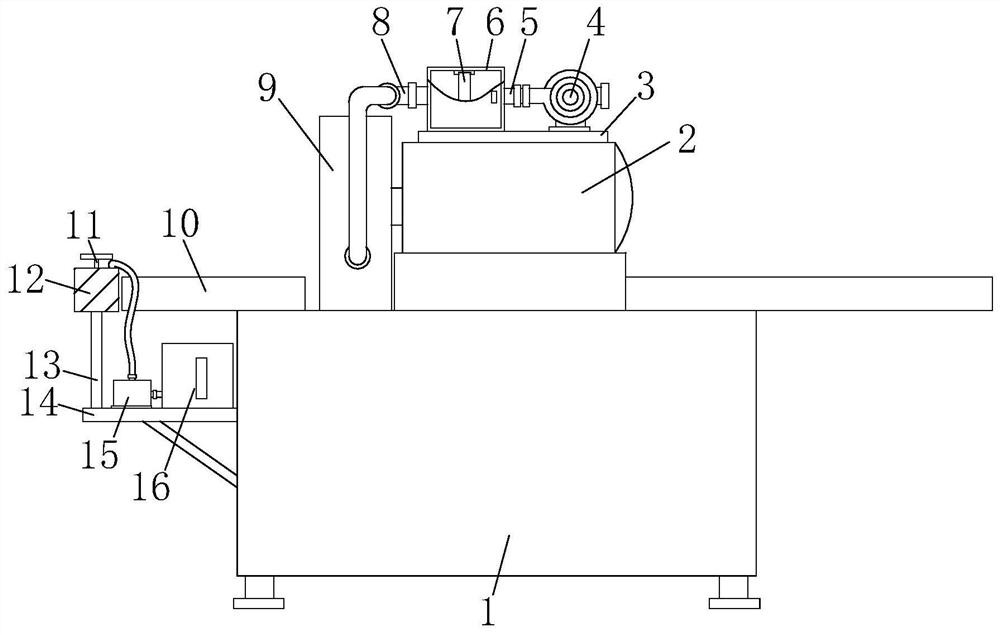

External-circle grinding machine

InactiveCN111823069AEasy to collectAvoid floating aroundRevolution surface grinding machinesDispersed particle filtrationElectric machineryWorking environment

The invention relates to the technical field of grinding machines, in particular to an external-circle grinding machine. The external-circle grinding machine comprises a machine body, a barreling motor, a mounting plate, a fan, a connector, a dust storage box, a filtering net, a three-way pipe, a cover, a U-shaped limiting piece, a threaded column, a cleaning barrel, a column body, a transverse plate, a water pump, a water tank, a bearing, an arc-shaped plate, first cleaning cotton, second cleaning cotton, a dust outlet joint and a grinding wheel. According to the external-circle grinding machine, under the action of the fan of a dust suction mechanism, grinding dust can be pumped into the dust storage box, under the action of the filtering net inside the dust storage box, the grinding dust is stored in the dust storage box, collection of the grinding dust is facilitated, the condition that the grinding dust drifts around can be avoided conveniently, the quality of the working environment can be improved, when a columnar piece is rounded and then passes through the cleaning barrel of a cleaning mechanism, under the action of the first cleaning cotton inside the cleaning barrel andthe dust outlet joint, dust on the outer surface of the columnar piece is cleaned, cleaning of the columnar piece after rounding is facilitated, and the cleanliness of the columnar piece after rounding can be improved conveniently.

Owner:张跃

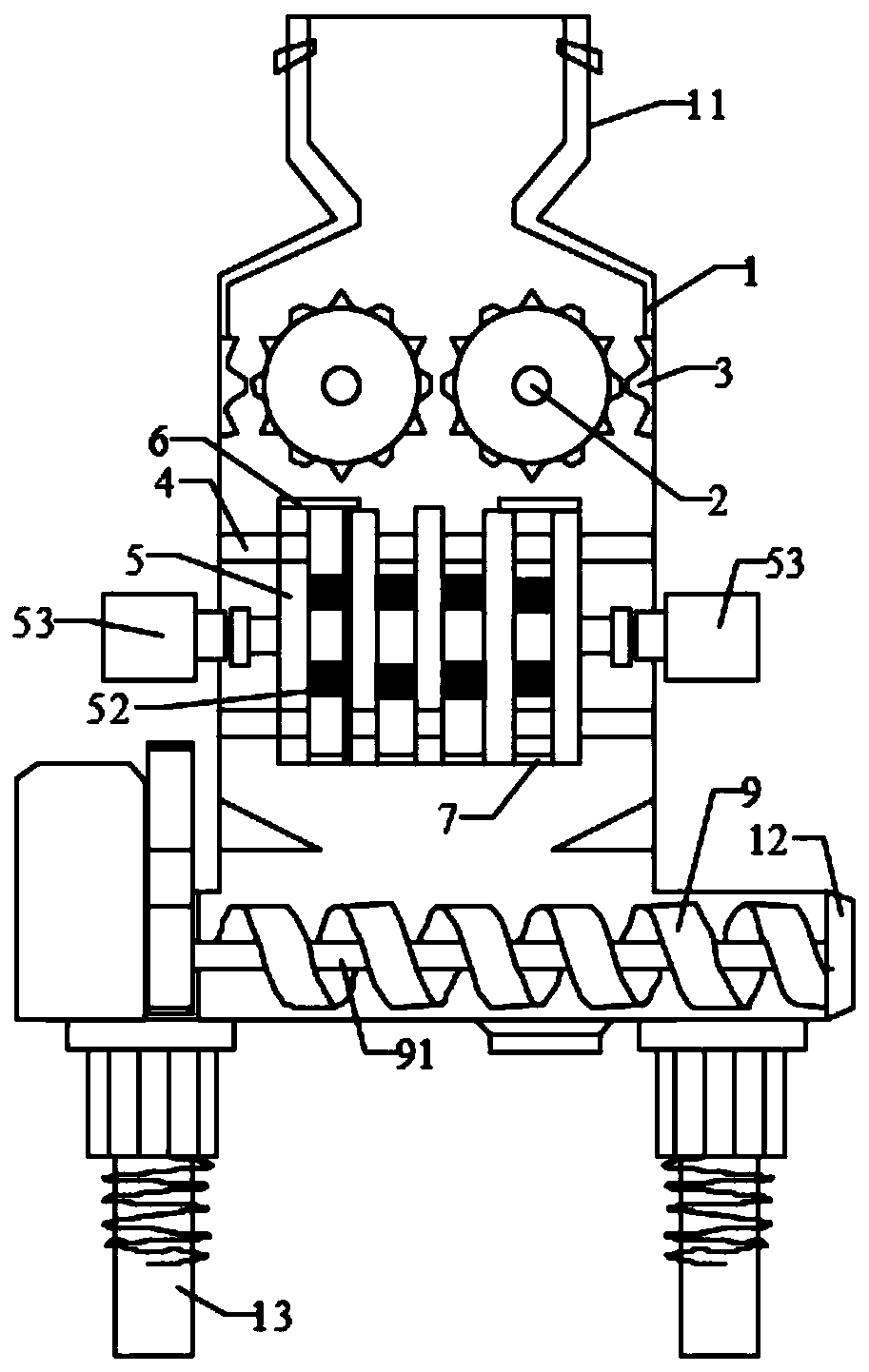

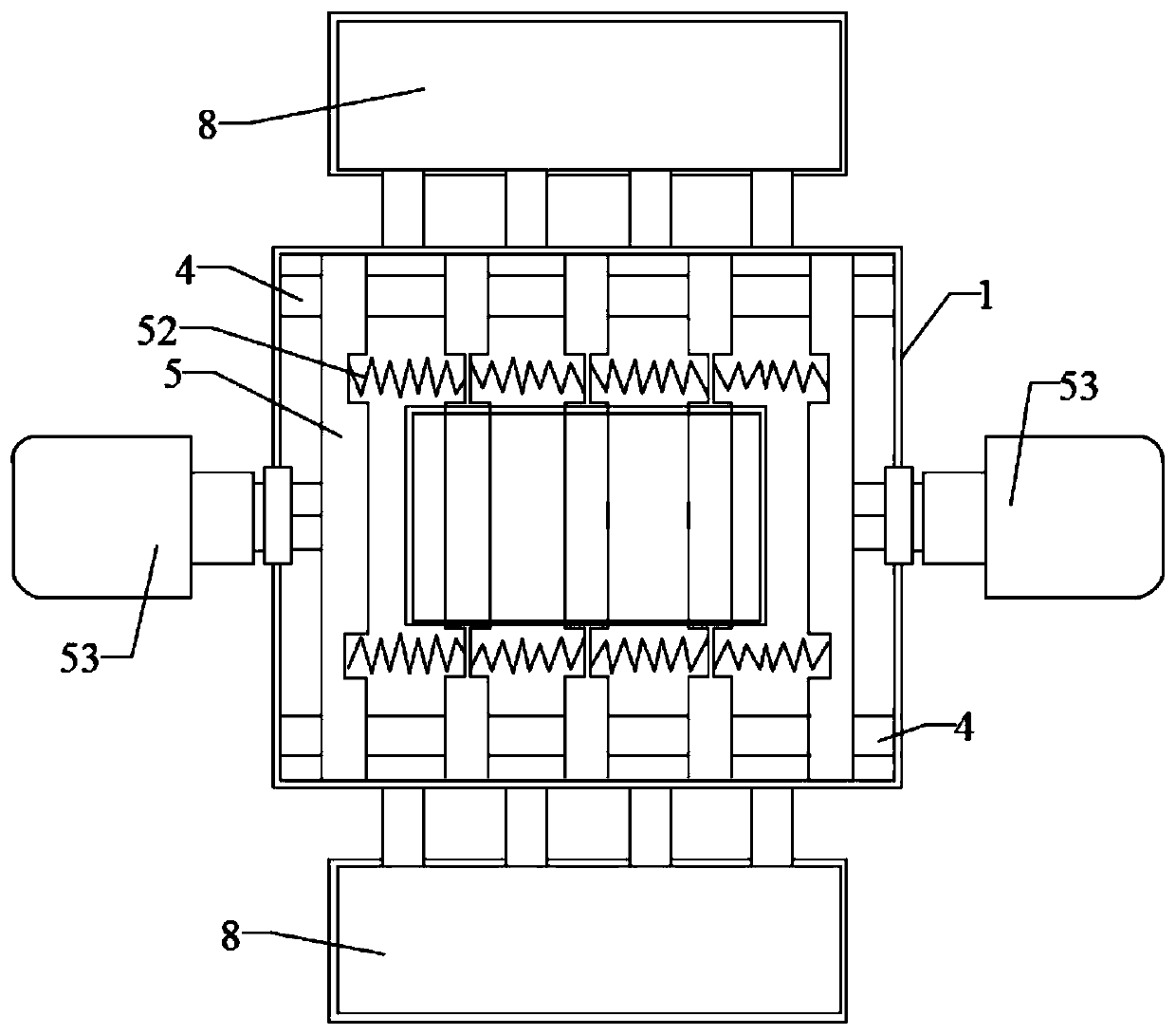

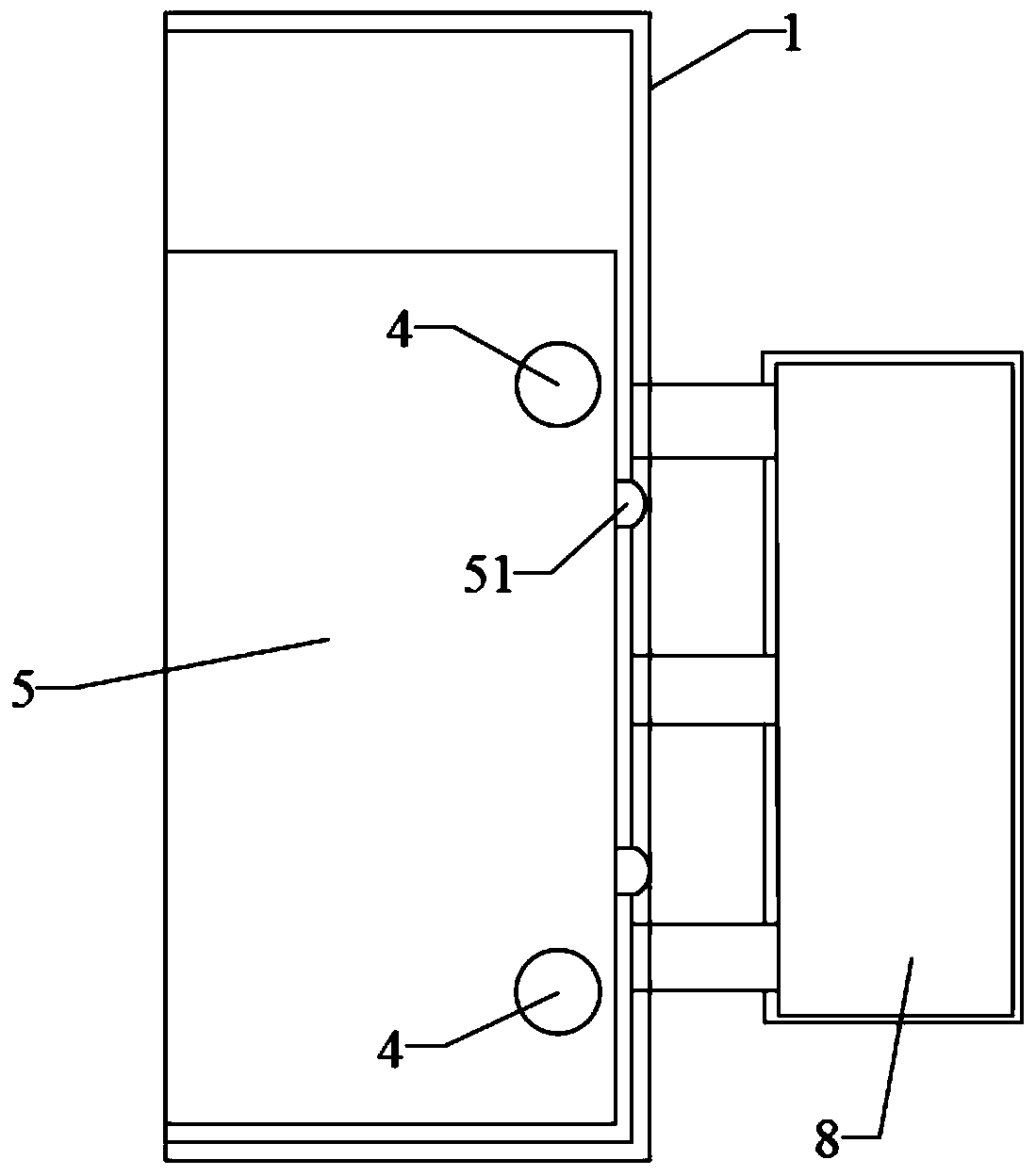

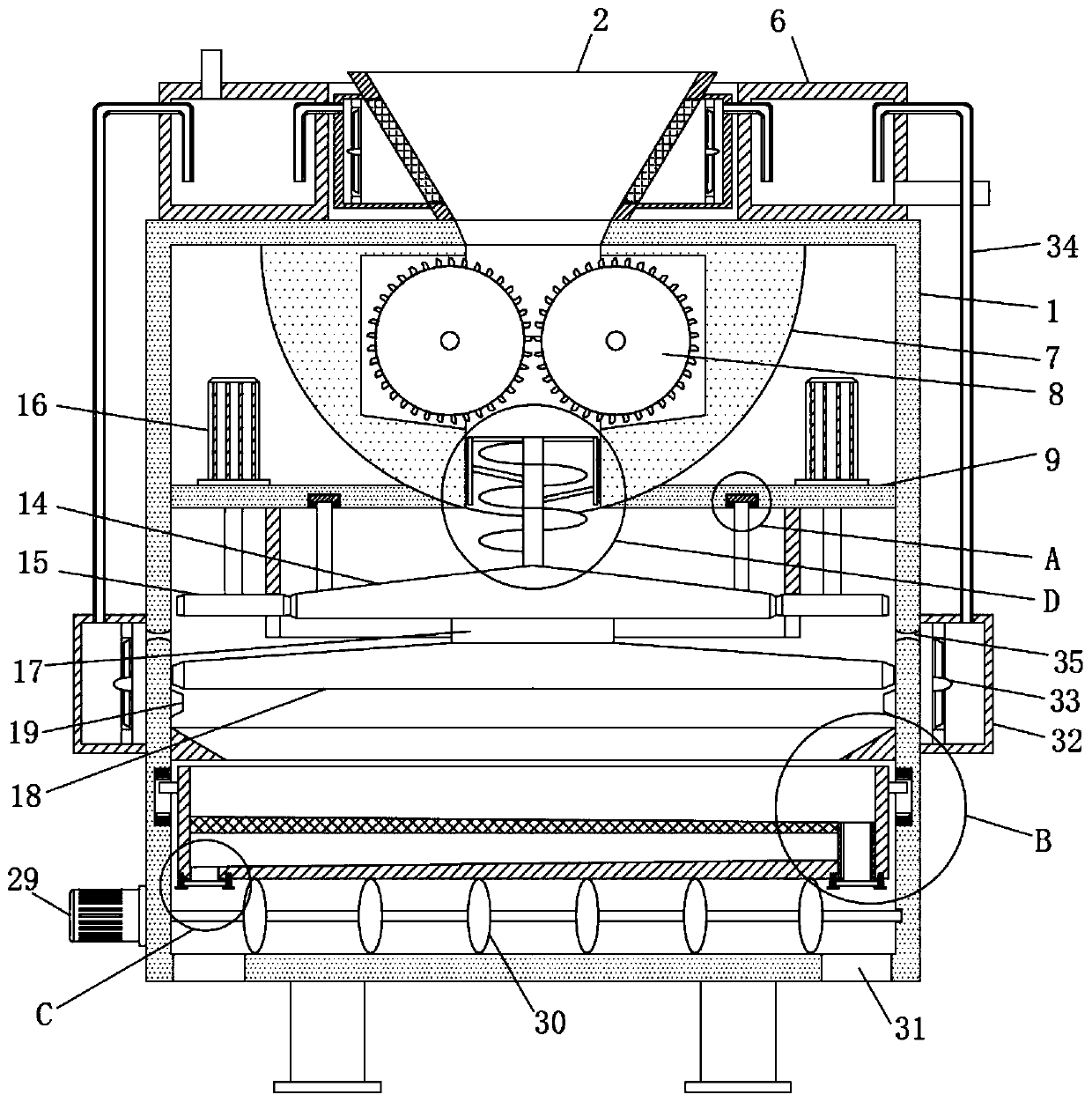

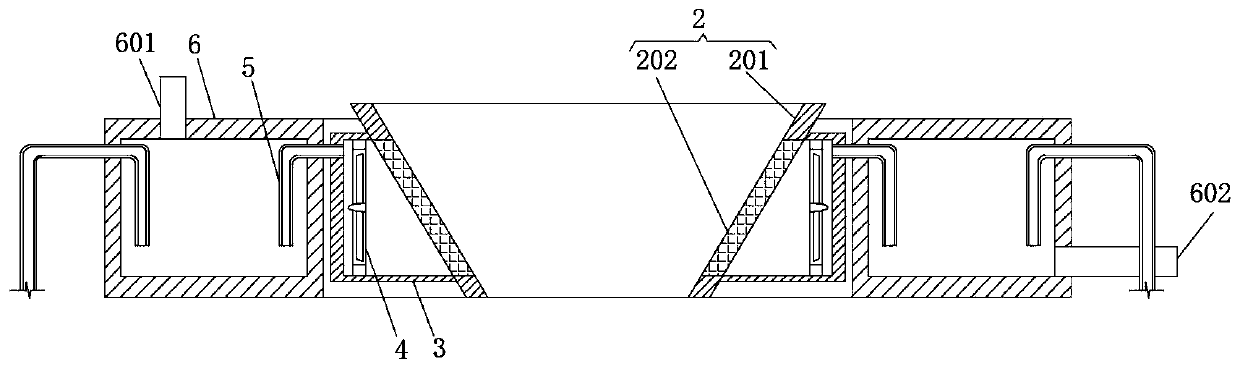

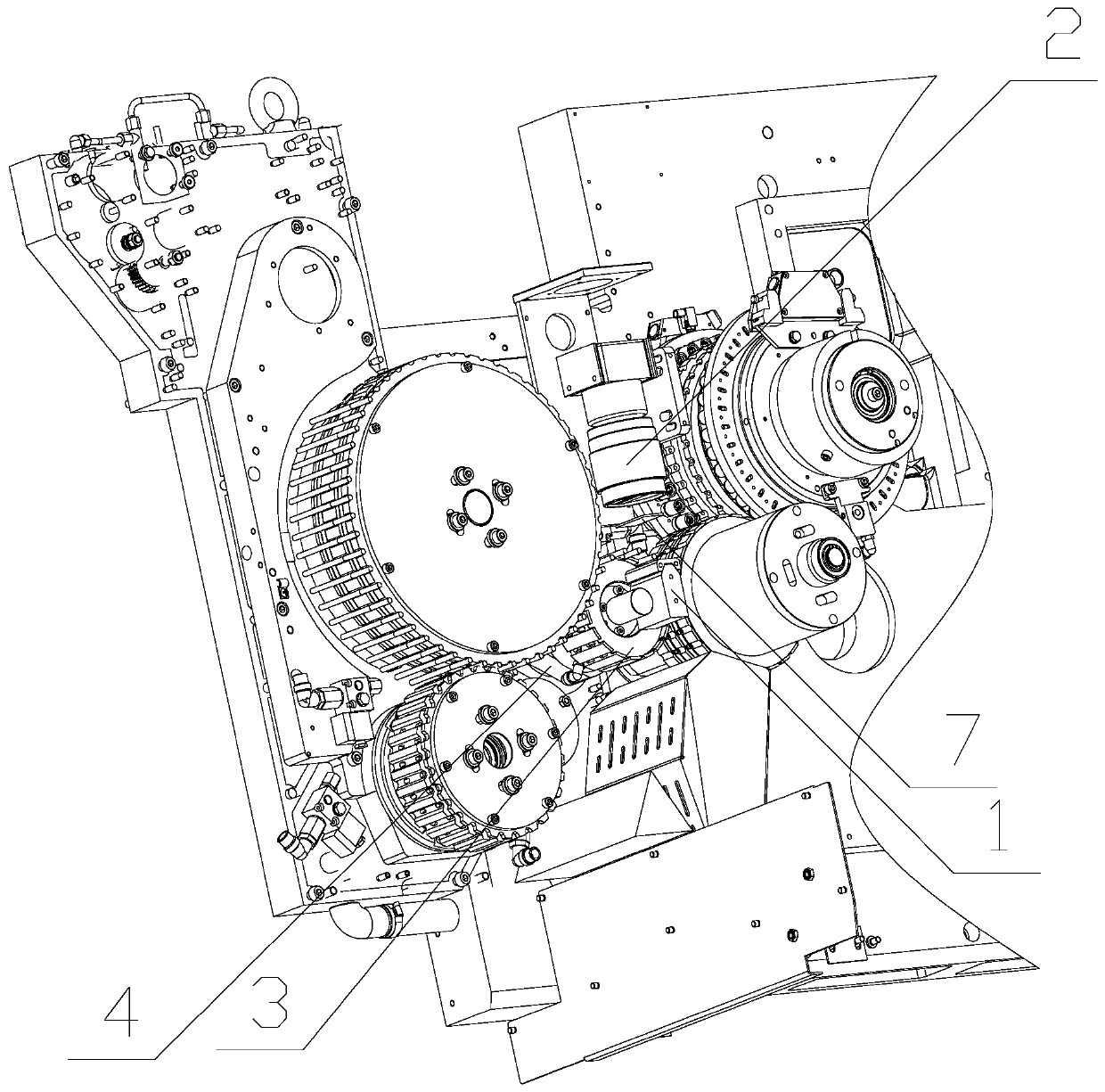

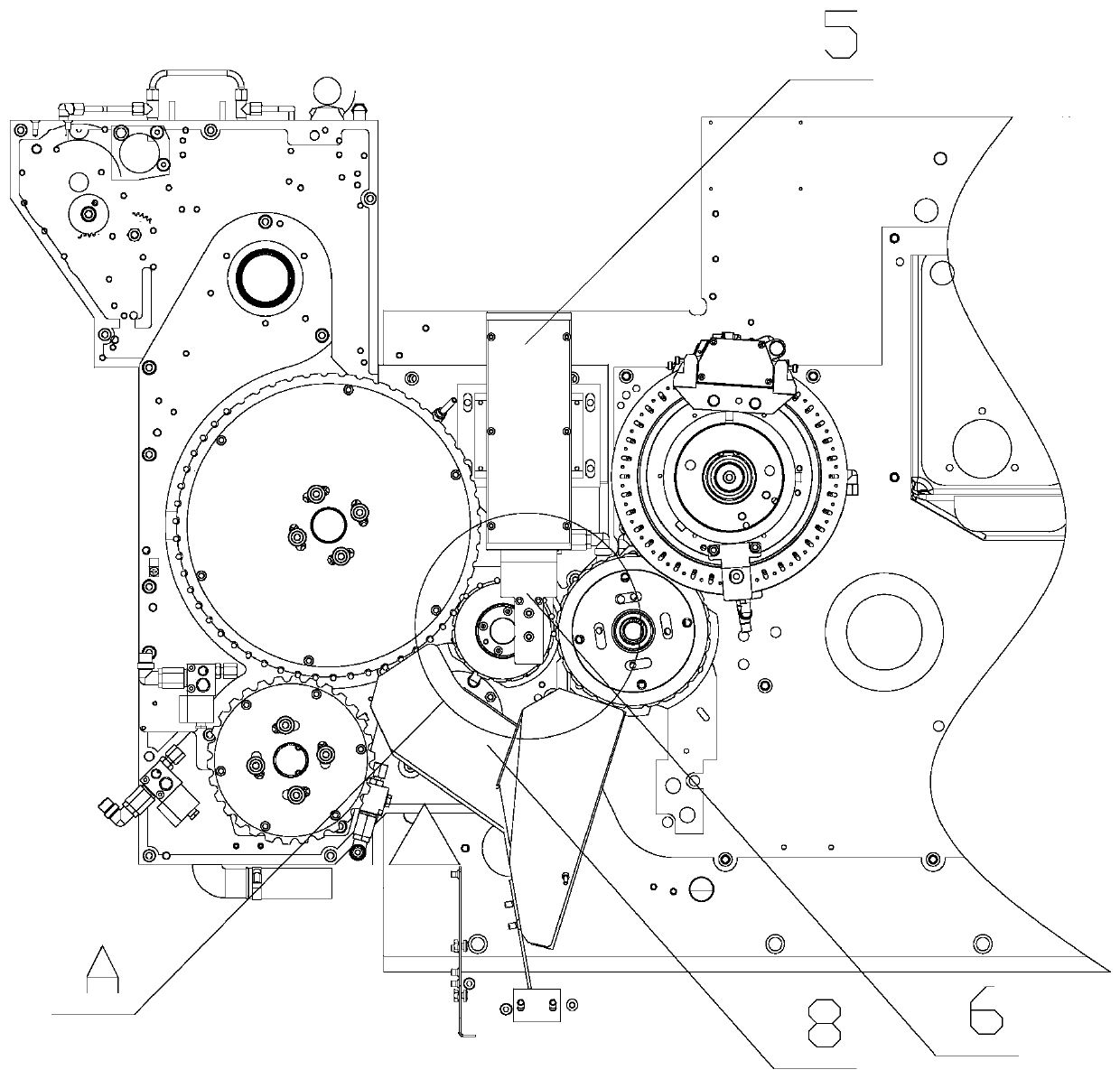

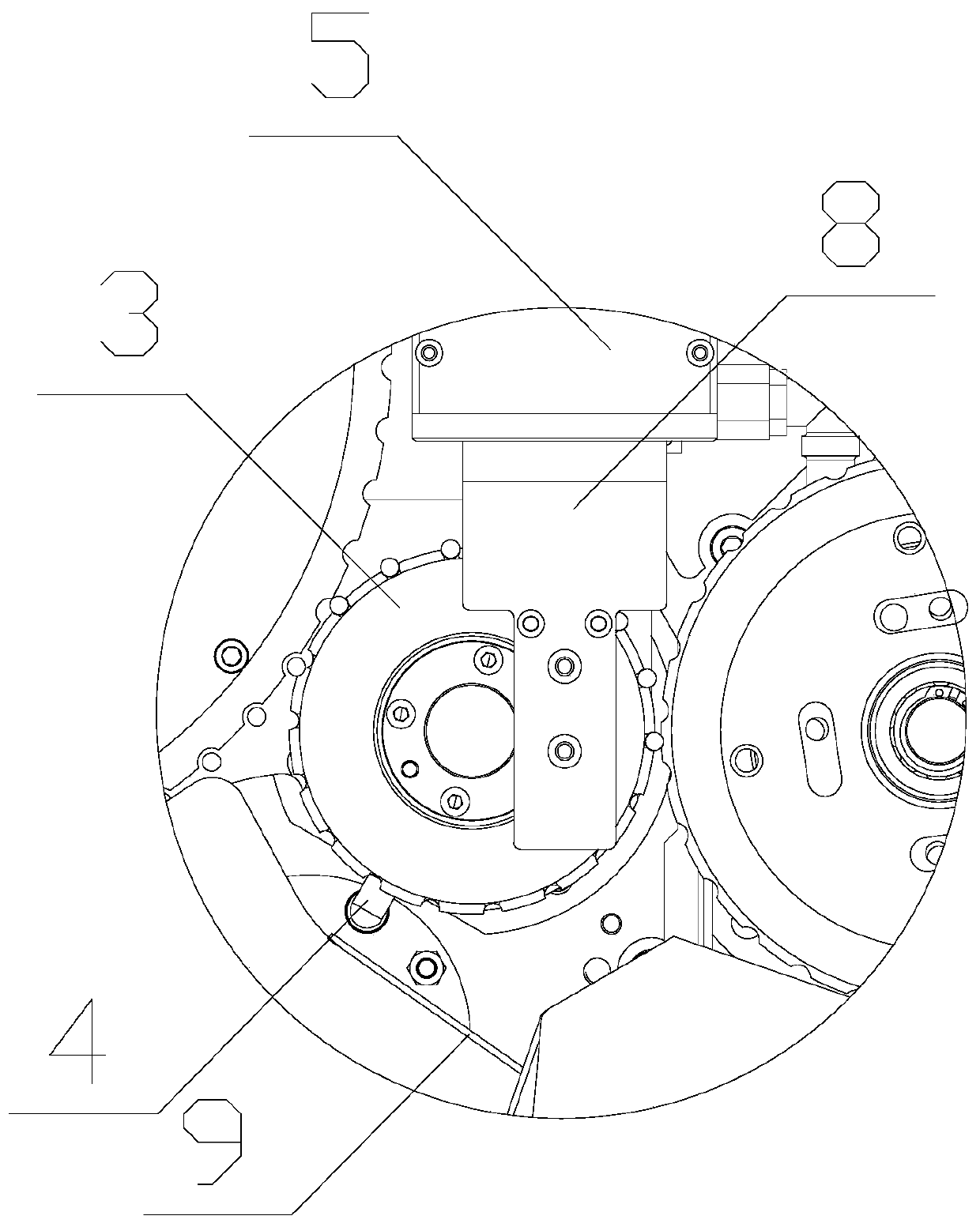

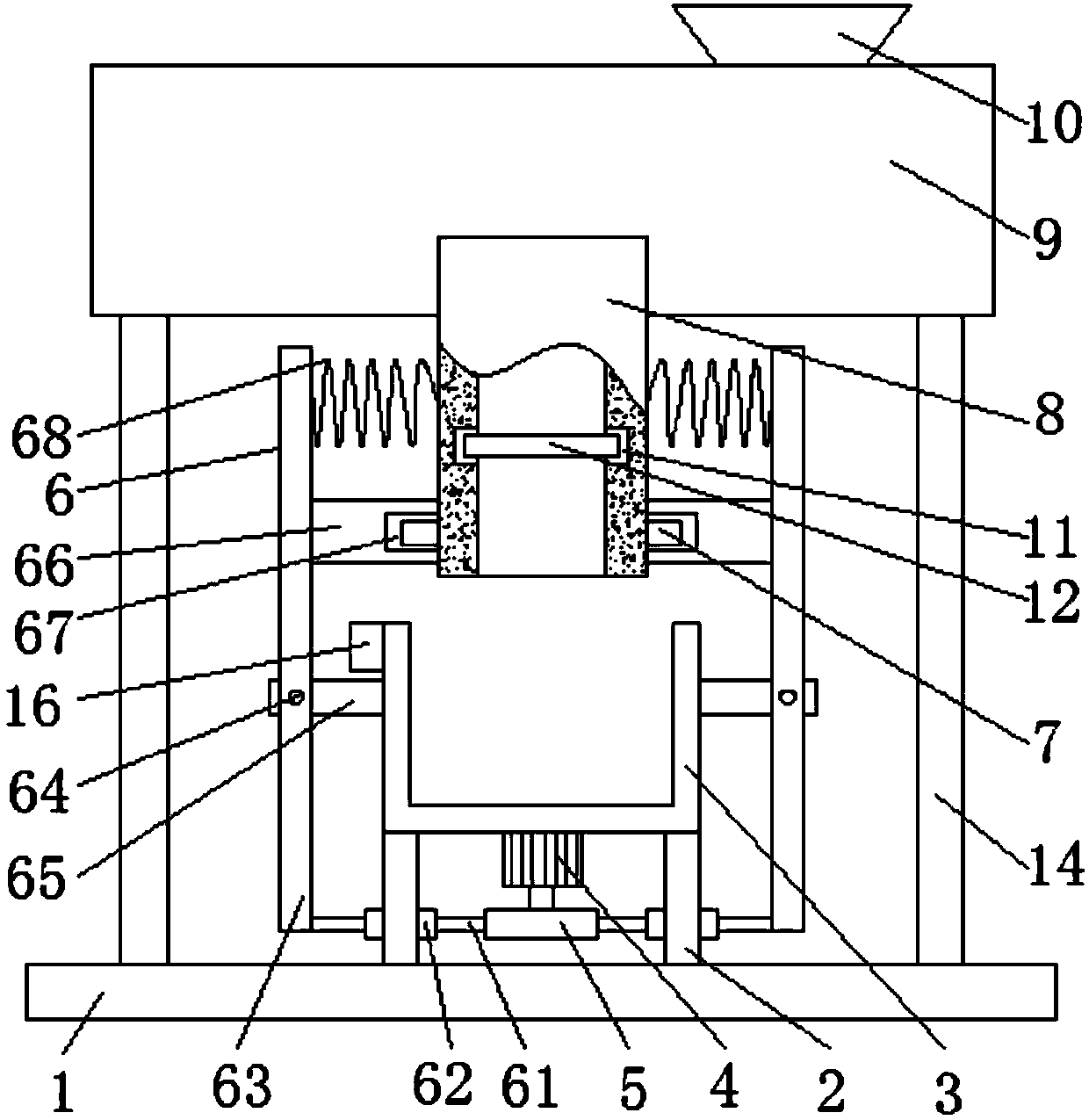

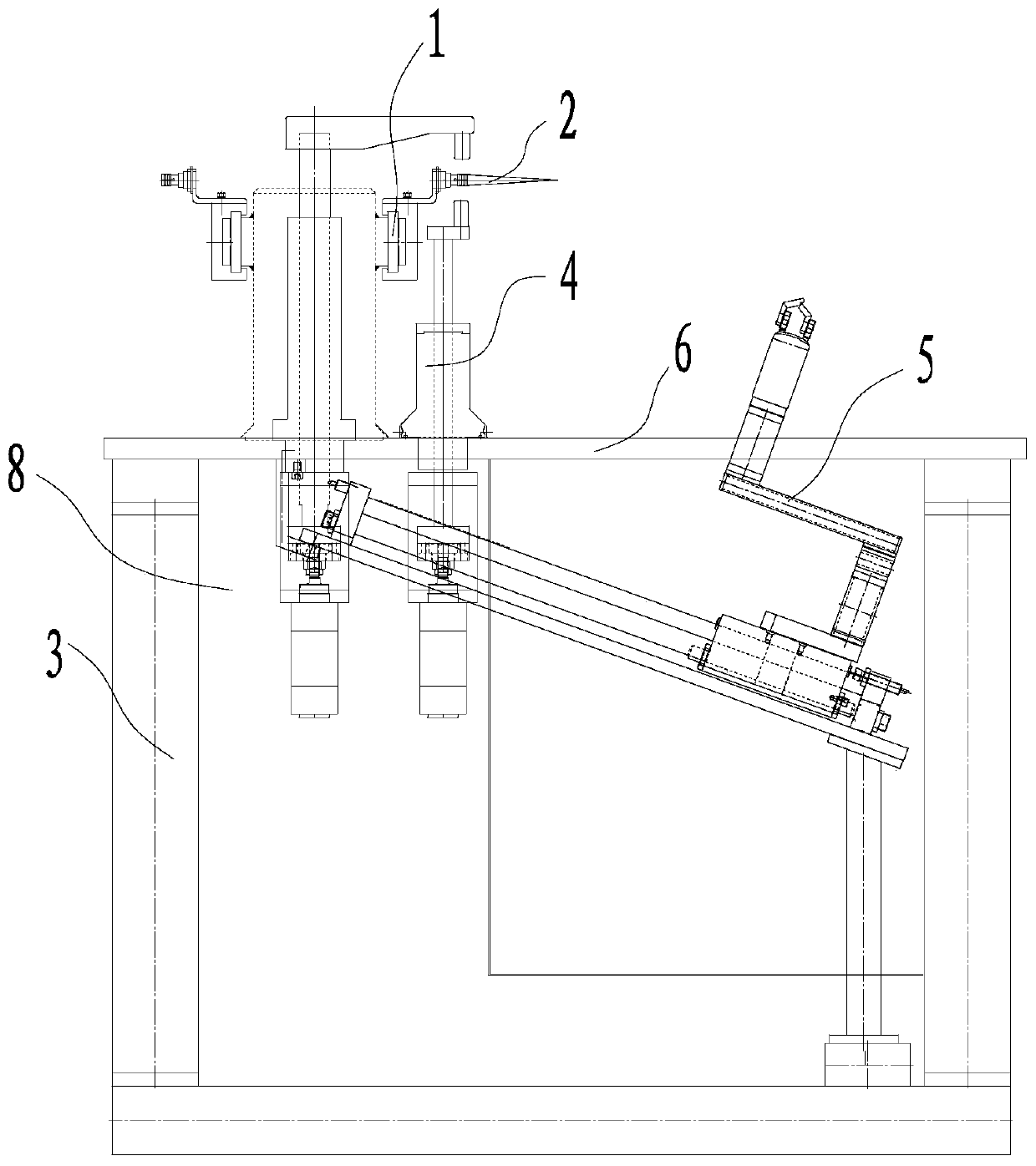

Waste paper bale breaking system based on vertical bale breaking machine

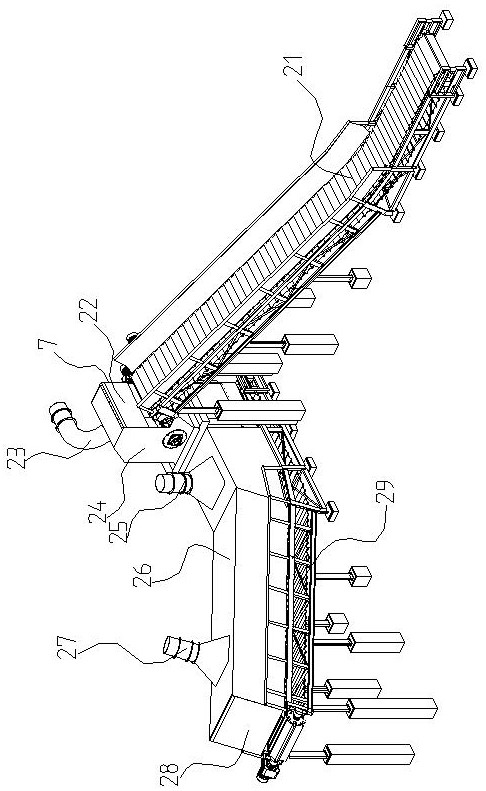

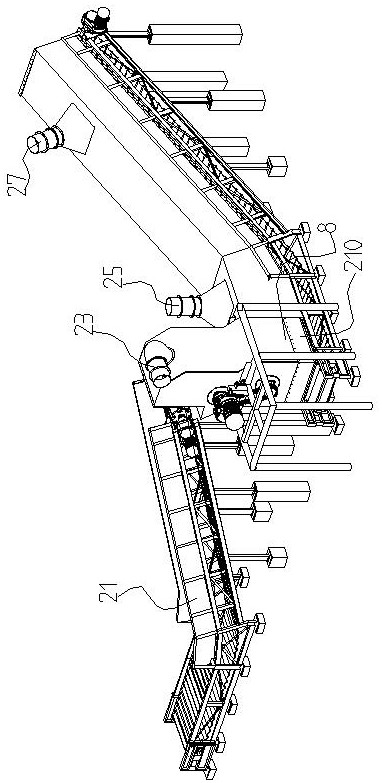

ActiveCN112278477ASpread out fastSimple structureUnpacking by cuttingDust controlProcess engineering

The invention discloses a waste paper bale breaking system based on a vertical bale breaking machine. The waste paper bale breaking system comprises the vertical bale breaking machine. The vertical bale breaking machine is mainly composed of a shell and paper breaking rollers arranged in the shell. The paper breaking rollers include the upper paper breaking rollers and the lower paper breaking rollers which are arranged in the shell in parallel up and down, the upper paper breaking rollers and the lower paper breaking rollers are connected through a transmission chain to rotate in the same direction, and the upper paper breaking rollers and the lower paper breaking rollers are each provided with a bale breaking fly-cutter structure. A feeding port is formed in the upper portion of the shell and connected with a feeding conveyor, the feeding end of the feeding conveyor is connected with an iron wire removing conveyor, waste paper on the iron wire removing conveyor is longitudinally stacked and baled, and a waste paper bale breaker is arranged between the feeding conveyor and the iron wire removing conveyor. A discharging port is formed in the bottom of the shell and is connected with a discharging conveyor. By optimizing the bale breaking machine and the aspects of feeding, dust removal and the like, the bale breaking efficiency is greatly improved, the service life of equipmentis prolonged, and the field operation environment is improved.

Owner:ZHENGZHOU LEIZHAN TECH PAPER MACHINERY

Online detecting and removing system and method for blasting bead cigarette

InactiveCN110252687AGuaranteed experienceRealize automatic eliminationSortingEngineeringMechanical engineering

The invention relates to an online detecting and removing system and method for a blasting bead cigarette. The system comprises a light source assembly, a CCD imaging assembly, a background handling terminal and a pneumatic removing assembly, wherein the light source assembly and the CCD imaging assembly are correspondingly oppositely arranged at intervals at one side of a cigarette distribution wheel in the radial direction of the cigarette distribution wheel in a cigarette making machine; a plurality of cigarette grooves are formed at uniform intervals in the outer circumferential sidewall of the cigarette distribution wheel; one end of a cigarette holder of the blasting bead cigarette extends close to one side of the cigarette distribution wheel and extends out of the corresponding cigarette groove; when the cigarette distribution wheel rotates, the cigarette holders of all blasting bead cigarettes sequentially penetrate through an area between the light source assembly and the CCD imaging assembly; and air outlet end of the pneumatic removing assembly extends into the inner wall of the cigarette distribution wheel. According to the system, the CCD imaging assembly is matched with the light source assembly to obtain the image information of the cigarette holder of the blasting bead cigarette; the background handling terminal determines whether a blasting bead in the cigarette holder of the blasting bead cigarette is qualified; the pneumatic removing assembly is controlled to remove the blasting bead cigarette containing unqualified blasting bead in case of unqualified blasting bead, and thus the qualified blasting bead cigarette can be automatically removed; the efficiency is high; and the product consistency is improved.

Owner:WUHAN MICROPOWER ROBOT TECH CO LTD

Coal ash screening device and method capable of avoiding raising dust

ActiveCN111545442AReduce pollutionAvoid floating aroundSievingDispersed particle filtrationProcess engineeringMechanical engineering

The invention discloses a coal ash screening device and method capable of avoiding raising dust, which belongs to the technical field of coal ash processing. A supporting table is arranged on the bottom of the inner cavity of a box body; an air inducing fan is arranged on the top of the inner cavity of the box body; a charging assembly is arranged below the air inducing fan; a first sorting assembly is arranged below the charging assembly; a second sorting assembly is arranged below the first sorting assembly; the side wall of the box body is provided with a raising dust preventing assembly; and a material collecting assembly is arranged below the raising dust preventing assembly. A conventional vibration type screening structure is changed, a sorting filter ring of an inner hollow circular table shaped structure is matched with a sweeping brush capable of continuously rotating along the surface of the sorting filter ring to realize sorting operation, so that dust amount raised by materials during vibration is reduced; and through stage-by-stage sorting operation, sorting quality is improved; and moreover, amount of raised dust is smaller, and raised dust is collected through dustcollecting cloth capable of rotating in a circulating mode, so that the coal ash screening device is high in environment friendliness, and is good in using effect.

Owner:山西昌靖环保科技有限公司

Intelligent fodder discharging system with function of preventing dust from drifting away

The invention discloses an intelligent fodder discharging system with a function of preventing dust from drifting away. The system comprises a baseboard, a U-shaped board is fixedly connected to the upper surface of the baseboard through two supporting boards, a motor is fixedly connected to the lower surface of the U-shaped board and located between the two supporting boards, a coil is fixedly connected to the output shaft of the motor, clamping devices are fixedly connected to both side surfaces of the coil, and the clamping devices comprise pull roes. According to the intelligent fodder discharging system with the function of preventing the dust from drifting away, the motor is controlled to rotate in the backward direction to make the pull ropes loose, so that a rectangular clamping block is connected into a first sliding groove in a clamping mode, and then an opening of a fodder bag is closely attached to the outer surface of a fodder discharging cylinder; a sliding board is pulled forward through a handle, so that fodder falls into the fodder bag through the fodder discharging cylinder; due to the fact that the fodder discharging cylinder is wrapped and closed by the openingof the fodder bag, it is avoided that the dust drifts away everywhere in the falling process of the fodder, so that damage to a worker of the dust is avoided, and work of the worker is promoted.

Owner:陈佳

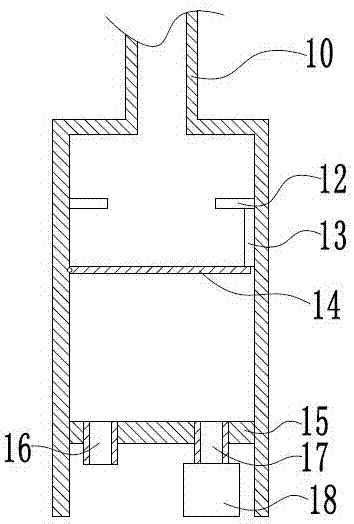

Environment-friendly activated carbon waste gas disposal box

InactiveCN108554113AFully absorbedAvoid floating aroundGas treatmentDispersed particle separationActivated carbonEngineering

The invention discloses an environment-friendly activated carbon waste gas disposal box. The environment-friendly activated carbon waste gas disposal box includes a disposal box body, a housing positioned on the outer surface of the disposal box body, a control panel positioned on the surface of the housing and an activated carbon filtering net contained in the disposal box body; the housing includes a groove, a clamping groove contained in the groove, an information processor positioned on the right side of the clamping groove, a purifying cavity positioned in the lower portion of the information processor, a pipe positioned on the left side of the purifying cavity and a rubber pad positioned at the bottom of the housing. The environment-friendly activated carbon waste gas disposal box can remove irritant smell in waste gas, absorption holes arrayed periodically can absorb the waste gas which is purified preliminarily, and the waste gas can be completely absorbed by activated carbon particles adhering the absorption holes. Moreover, since the absorption holes are arrayed periodically, the waste gas can be prevented from drifting all around and can be fully absorbed, and the practicability of the disposal box is improved.

Owner:肇庆益晟商贸有限公司

Electrostatic attraction-type ashtray

The invention relates to an ashtray, in particular to an electrostatic attraction-type ashtray. The electrostatic attraction-type ashtray comprises an ashtray body, and an ashtray lid connected with the ashtray body through a hinge device, wherein the ashtray body is an embedded ashtray in a hollow structure; an electrostatic attraction device is mounted on the lower layer; a battery box and a power switch are mounted on the bottom layer; and the electrostatic attraction device, a normally-open switch, the battery box, and the power switch are connected through wires to form a series circuit. The electrostatic attraction-type ashtray can effectively prevent cigarette ash diffusion so as not to influence the environment and body health. In addition, the electrostatic attraction-type ashtray with the advantages of energy conservation and environmental protection and handsome appearance is suitable for various kinds of occasions, and has wide market prospect.

Owner:张舒然

Guide cylinder and water surface garbage cleaning device with guide cylinder

The invention discloses a guide cylinder and a water surface garbage cleaning device with the guide cylinder, and belongs to the technical field of water surface decontamination. The guide cylinder comprises a fixed cylinder, a connecting rod and a guide cylinder body, wherein the water surface garbage cleaning device comprises a floating body, a driving piece, the guide cylinder, a radial flow turbine, an axial flow turbine, a collecting tank and a filter plate; the driving piece is fixedly connected to the middle part of the floating body, and is connected with a main shaft downwards extending from the floating body to the underwater; the radial flow turbine and the axial flow turbine are connected to the main shaft in sequence from top to bottom; the guide cylinder sleeves the outer sides of the radial flow turbine and the axial flow turbine; the collecting tank is buckled on the guide cylinder; the filter plate is arranged between the radial flow turbine and the axial flow turbine; vortexes are formed on the water surface to attract floating objects to flow into the guide cylinder; the radial flow turbine rotates to push the sucked floating objects to the side wall of the guide cylinder to enter the collecting tank; the manual ship driving for fishing is not needed, so that the risk is reduced; and garbage is sucked to prevent floating all around, so that the fishing is convenient.

Owner:马俊

Cleaning method used for spinning machine

The invention belongs to the field of textile manufacturing machines, and discloses a cleaning method used for a spinning machine. The method comprises the steps that firstly, a toggling device is installed on a stator, and a vacuum pump and a water pump are started; secondly, the spinning machine is started, the toggling device rotates along with the stator and squeezes a cleaning head, the cleaning head receives the water from the water pump and sprays the water to the stator, and short fibers on the stator is impacted through the cleaning head and leaves from the stator; thirdly, the short fibers are drawn in a suction machine through the negative pressure generated by the vacuum pump and conveyed to a collection box.

Owner:余庆县鸿祥棉纺有限责任公司

Dustless glass polishing equipment

InactiveCN111791123ANovel structureAvoid floating aroundGrinding carriagesGrinding drivesHydraulic cylinderPolishing

The invention provides dustless glass polishing equipment. The dustless glass polishing equipment comprises a feeding table and a polishing device, wherein the polishing device comprises a bearing box, a first circular plate of a grid plate structure is arranged at the top of the bearing box, the first circular plate is driven by a first motor, and a first polishing brush is arranged on the top surface of the first circular plate; an exhaust pipe and a filter cover are arranged on the side wall of the bearing box, and an air inlet of an exhaust pump is communicated with the end part of the exhaust pipe; the outer side of the bearing box is sleeved with a sealing frame, and the sealing frame is driven by a third motor to vertically move along the outer wall of the bearing box; an installation box is arranged above the bearing box, the installation box is driven by a hydraulic cylinder to move vertically, the installation box corresponds to the bearing box in position and is matched withthe outer contour, a second circular plate is arranged at the bottom of the installation box, the second circular plate is driven by a second motor, and a second polishing brush is arranged on the bottom surface of the second circular plate; and double-sided grinding and polishing can be carried out on glass, the grinding process is carried out in a closed space, powder can be sucked and collected, the powder is effectively prevented from floating around, and pollution is reduced.

Owner:清远市志豪兴工程玻璃有限公司

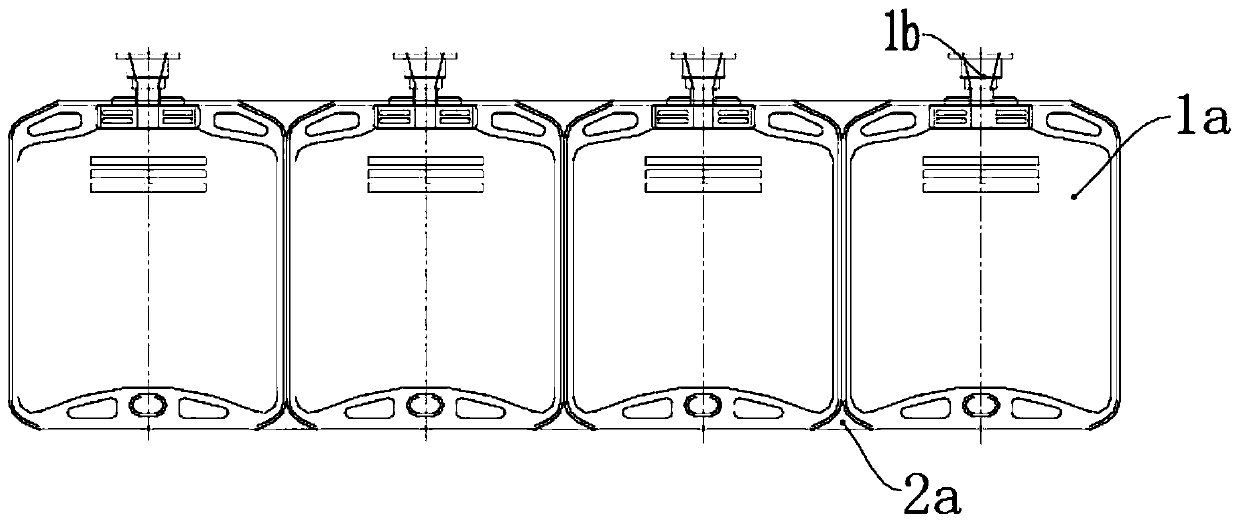

Waste edge removal device for soft bag and method for removing waste edge of soft bag thereof

The invention provides a waste edge removal device for a soft bag, which is used for removing the waste edge of the soft bag. The waste edge removal device comprises a base frame, a seam shaping component and a waste edge removing component, wherein the base frame is arranged at a shaping station of the soft bag with the waste edge; the seam shaping component is arranged on the base frame and is used for clamping and fixing the soft bag with the waste edge at the shaping station and shaping the seam of the soft bag; and the waste edge removing component is positioned below of the side of the seam shaping component and moves down to remove the waste edge of the soft bag. The whole waste edge removal device adopts relative isolation of a driving part and an execution part, and part of the structure above the top of the base frame adopts an easy cleaning mode without a dead angle, so that the aseptic production requirement can be met in the production process, and terminal products do notneed sterilization and can be instructed to the market after only outer packing. The invention further provides a method for removing the waste edge of the soft bag of the waste edge removal device for the soft bag.

Owner:LI MIN PHARM FAB OF LIVZON PHARM GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com