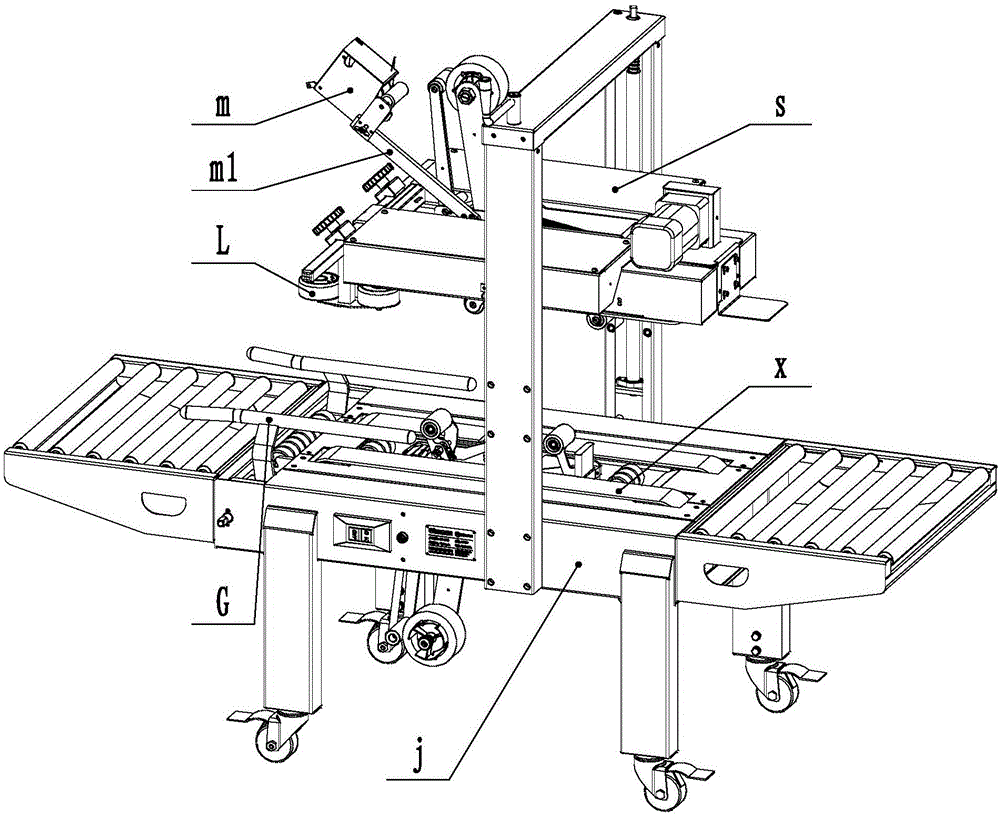

Box sealing machine

A box sealing machine and box sealing technology, which is applied in the directions of packaging sealing/fastening, external support, transportation packaging, etc. It can solve the problems of affecting packaging efficiency, tape paper cannot be accurately attached to the packaging box, and easy to flutter a lot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

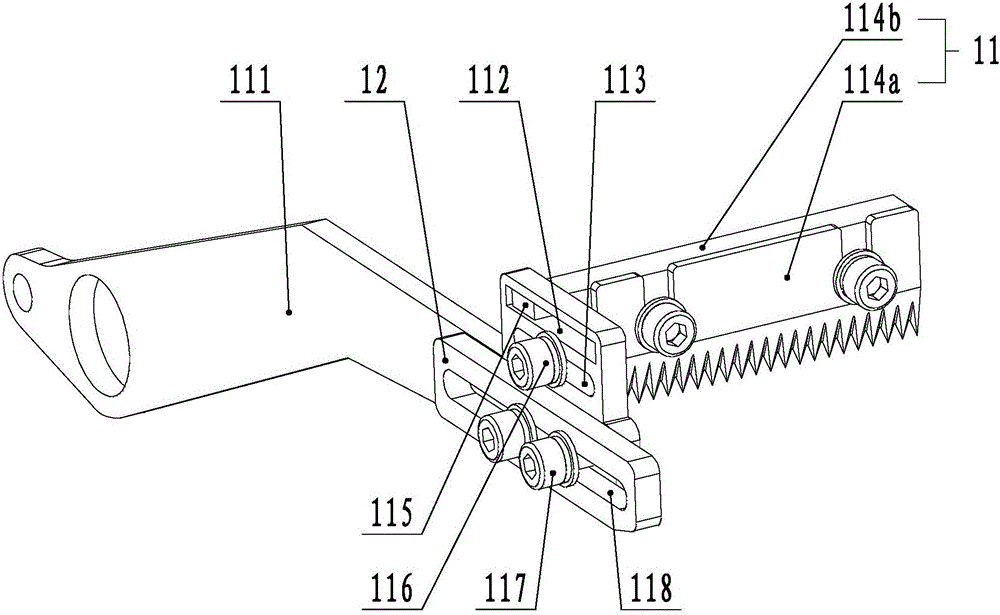

[0101] As an improved specific embodiment, the cutter 11 includes

[0102] The fixed block 114b is connected with the knife rest 111, and the protrusion 115 is arranged on the fixed block 114b;

[0103] The blade 114a is installed on the fixed block 114b, and one end thereof is provided with an installation opening, and a fixing bolt is arranged in the installation opening, and the fixing bolt passes through the installation opening and is threadedly connected with the fixing block 114b, so that the blade 114a is fixed on the fixing block 114b superior. This design facilitates the manufacture of the blade 114a, and can be made of higher strength material to make the blade 114a more durable, while the fixing block 114b is made of relatively cheap material to save cost.

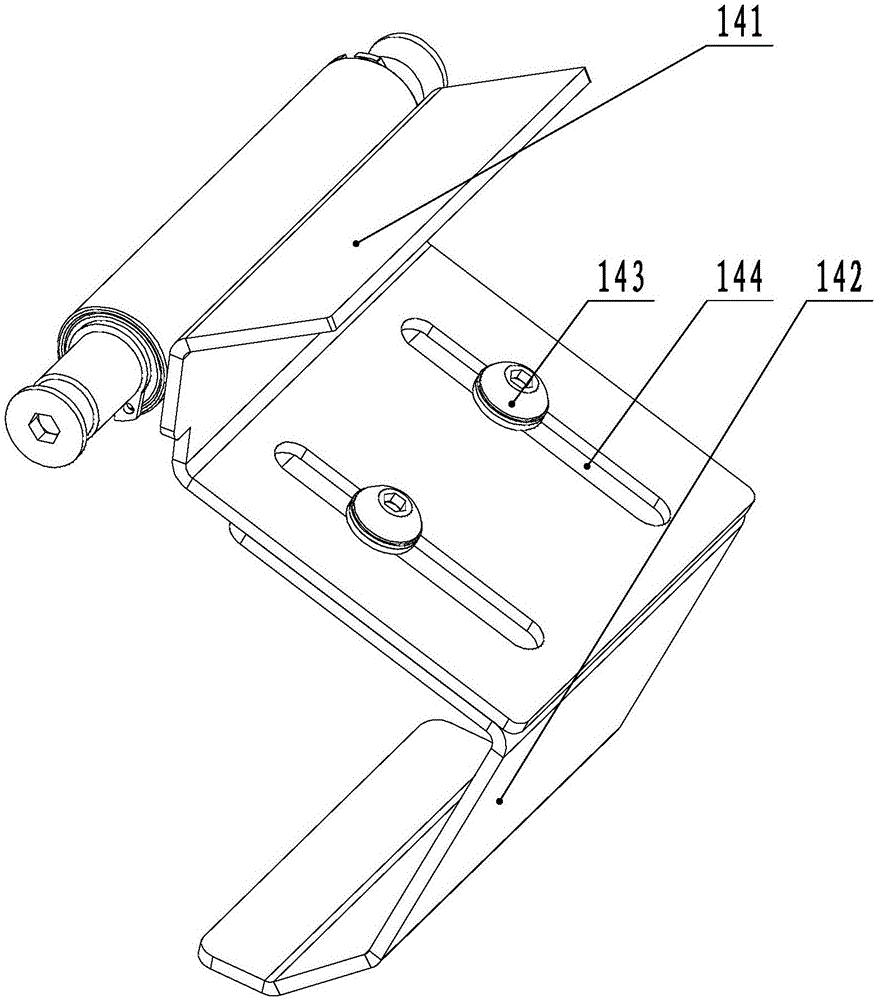

[0104] As an improved specific embodiment, the guard plate 14 includes

[0105] The hinged plate 141 is hinged on the fixed frame g, and a fourth waist-shaped hole 144 is opened on it;

[0106] Shielding pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com