Waste edge removal device for soft bag and method for removing waste edge of soft bag thereof

A technology for rejecting devices and soft bags, which is applied in packaging, bag making operations, transportation and packaging, etc., can solve the problems of production environment damage, laminar flow damage, particles flying around, etc., so as to simplify the production process and reduce damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

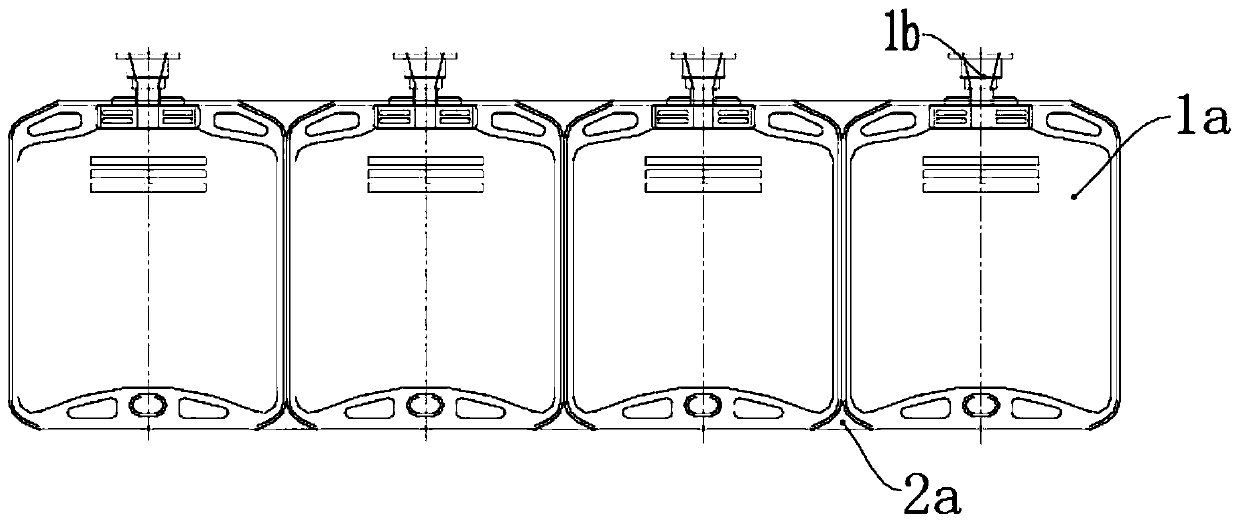

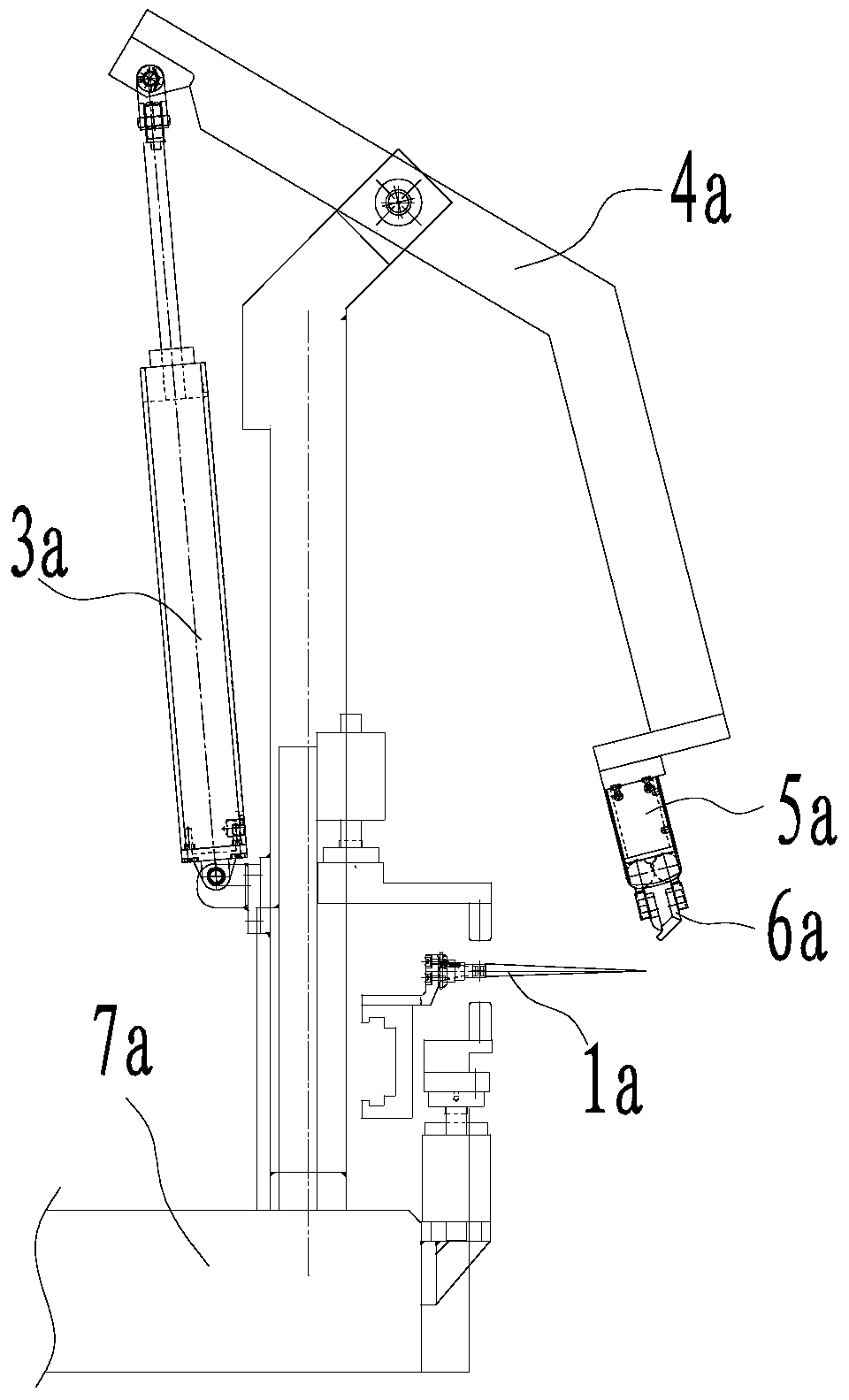

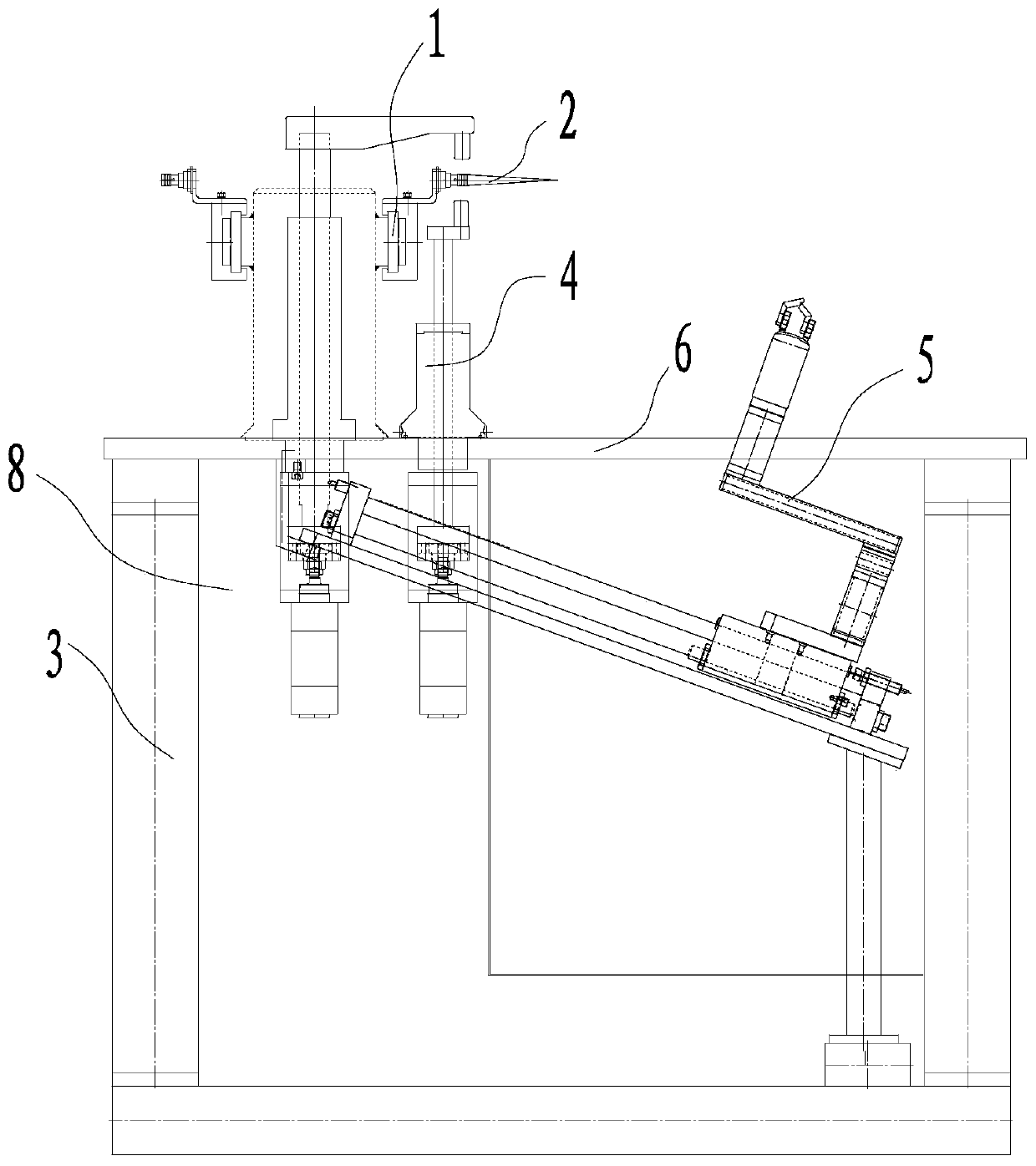

[0059] A device for removing waste edges of soft bags, used for removing waste edges of a group of four soft bags 2 on a conveyor belt 1, especially suitable for removing waste edges of large infusion soft bags containing traditional Chinese medicine, amino acids and other medicinal liquids in the medical field ,Such as Figure 3 to Figure 8 As shown, the waste edge removing device includes a base frame 3, an interface shaping assembly 4 and a waste edge removal assembly 5, and the base frame 3 is arranged on the conveyor belt 1 for shaping a group of four soft bags 2 with waste edges. station; the interface shaping assembly 4 is installed on the machine frame 3, and is used for clamping and fixing a group of four soft bags 2 with waste edges at the shaping station on the conveyor belt 1, and for four soft bags 2 Reshaping is carried out at the interface; the waste edge removal assembly 5 is installed on the underside of the top plate 6 of the machine base frame 33, and after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com