Spliced wood board grooving machine

A technology for slotting machines and wood boards, which is applied to slotting machines, mortising machines, wood processing appliances, etc., can solve the problems of easy to cause discomfort, reduce the efficiency of slotting, and obstruct the sight line, so as to reduce the workload and improve the Slotting efficiency, the effect of protecting health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

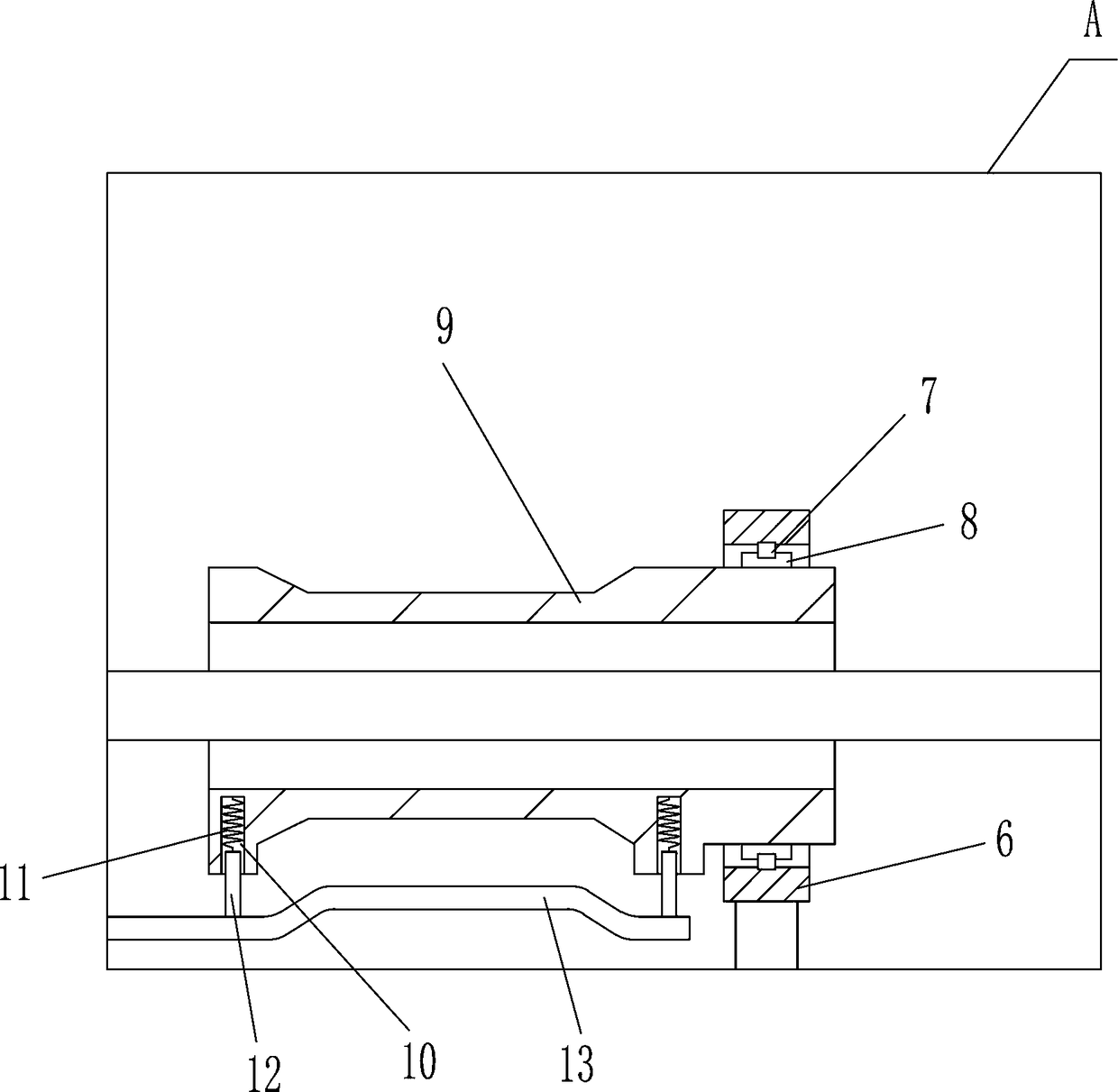

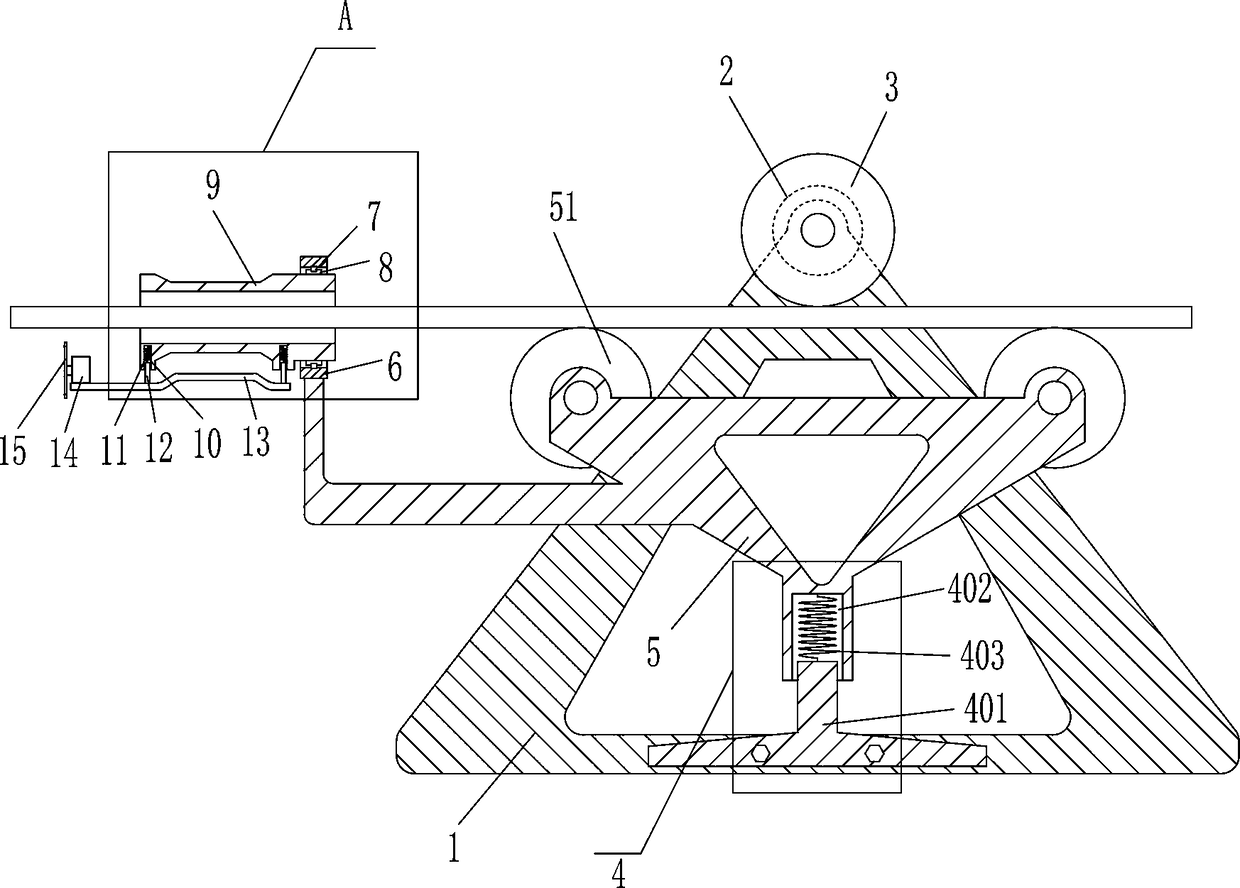

[0019] A spliced plank slotting machine, such as Figure 1-2 As shown, it includes a support 1, a transmission motor 2, a transmission wheel 3, a telescopic device 4, a first bracket 5, a first roller 51, a first hollow sleeve 6, an arc-shaped slider 7, an arc-shaped slide rail 8, and a guide Cover 9, second spring 11, second slide bar 12, grip bar 13, cutting motor 14 and cutting wheel 15, the transmission motor 2 that can drive the transmission wheel 3 to rotate is installed on the top of the support 1, and the transmission motor 2 is connected by bolts It is connected with the support 1 in the same way, the output shaft of the transmission motor 2 is fixed with the transmission wheel 3 that can transport the plank, the expansion device 4 that can fix the plank is installed on the lower part of the front side of the support 1, and the first support 5 is installed on the On the telescopic device 4, first rollers 51 are arranged on the left and right sides of the rear side o...

Embodiment 2

[0021] A spliced plank slotting machine, such as Figure 1-2 As shown, it includes a support 1, a transmission motor 2, a transmission wheel 3, a telescopic device 4, a first bracket 5, a first roller 51, a first hollow sleeve 6, an arc-shaped slider 7, an arc-shaped slide rail 8, and a guide Cover 9, second spring 11, second slide bar 12, grip bar 13, cutting motor 14 and cutting wheel 15, the transmission motor 2 that can drive the transmission wheel 3 to rotate is installed on the top of the support 1, the output shaft of the transmission motor 2 The transmission wheel 3 that can transport the plank is fixed on the top, the telescopic device 4 that can be fixed to the plank is installed on the lower part of the front side of the support 1, the first support 5 is installed on the telescopic device 4, the left and right sides of the rear side of the first support 5 The upper part is provided with the first roller 51, and the first hollow sleeve 6 is arranged on the left sid...

Embodiment 3

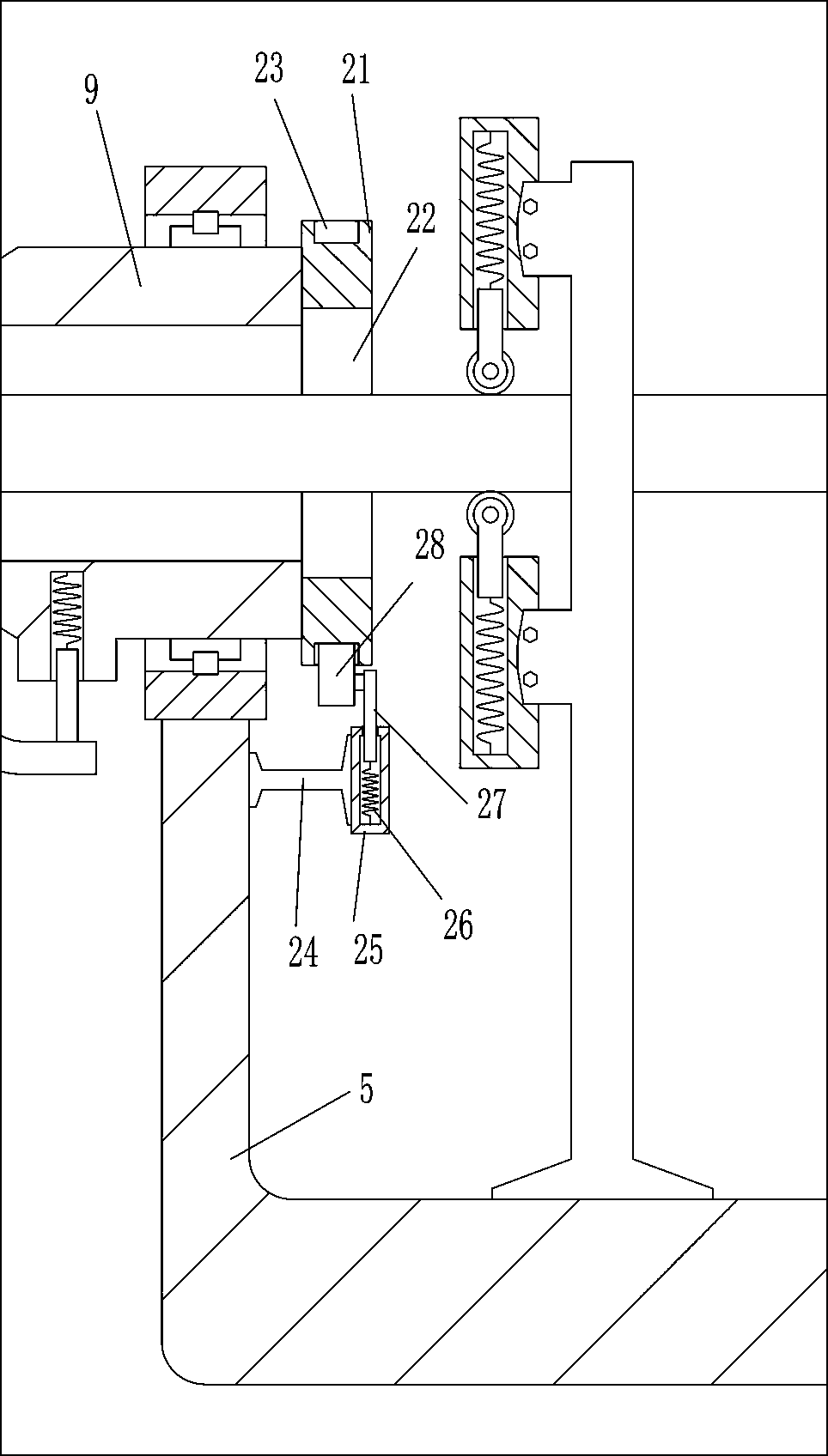

[0024] A spliced plank slotting machine, such as Figure 1-3As shown, it includes a support 1, a transmission motor 2, a transmission wheel 3, a telescopic device 4, a first bracket 5, a first roller 51, a first hollow sleeve 6, an arc-shaped slider 7, an arc-shaped slide rail 8, and a guide Cover 9, second spring 11, second slide bar 12, grip bar 13, cutting motor 14 and cutting wheel 15, the transmission motor 2 that can drive the transmission wheel 3 to rotate is installed on the top of the support 1, the output shaft of the transmission motor 2 The transmission wheel 3 that can transport the plank is fixed on the top, the telescopic device 4 that can be fixed to the plank is installed on the lower part of the front side of the support 1, the first support 5 is installed on the telescopic device 4, the left and right sides of the rear side of the first support 5 The upper part is provided with the first roller 51, and the first hollow sleeve 6 is arranged on the left side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com