Patents

Literature

615results about How to "Fast pack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fiber reinforced thermolplastic plastic preparation method

The invention provides a fiber reinforced thermolplastic plastic preparation method, which is obtained by mixing thermoplastic resin, fortifying fiber and auxiliary substance with exhaust type single screw-spindle extrusion machine, and extruding them, the extrusion temperature being 190-350 deg. C, the screw-spindle rotate speed being 20-120 r / min.

Owner:安善兴

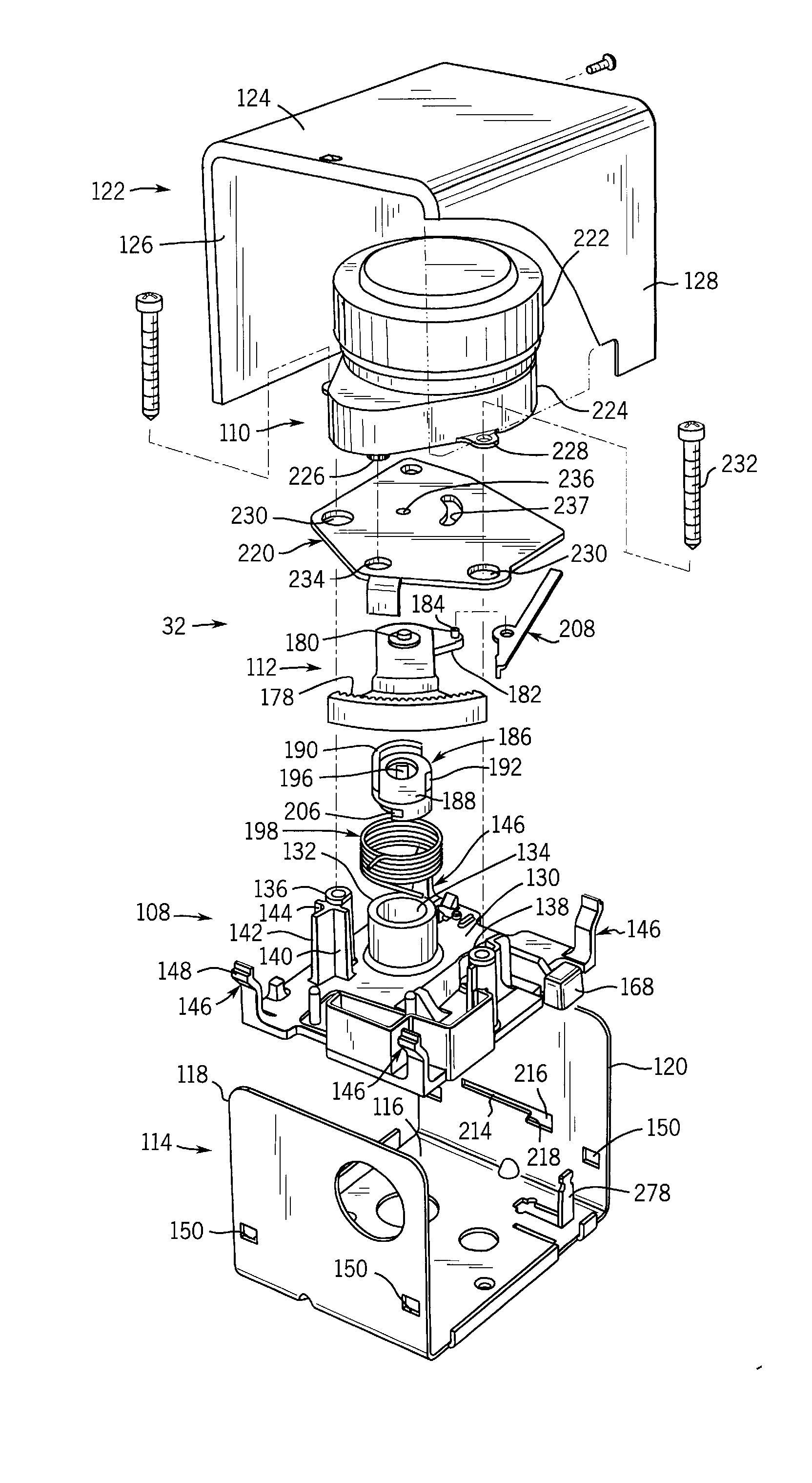

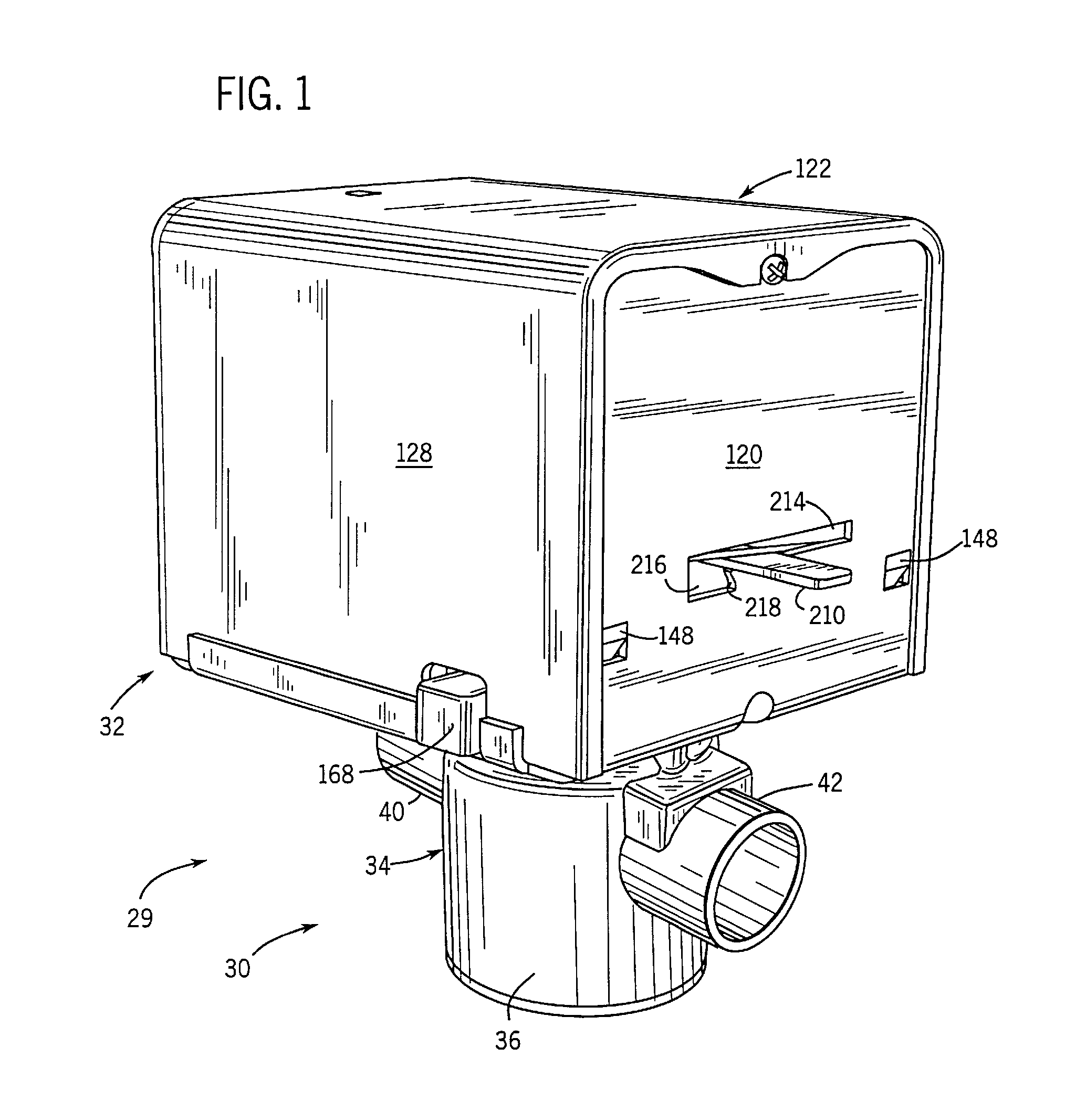

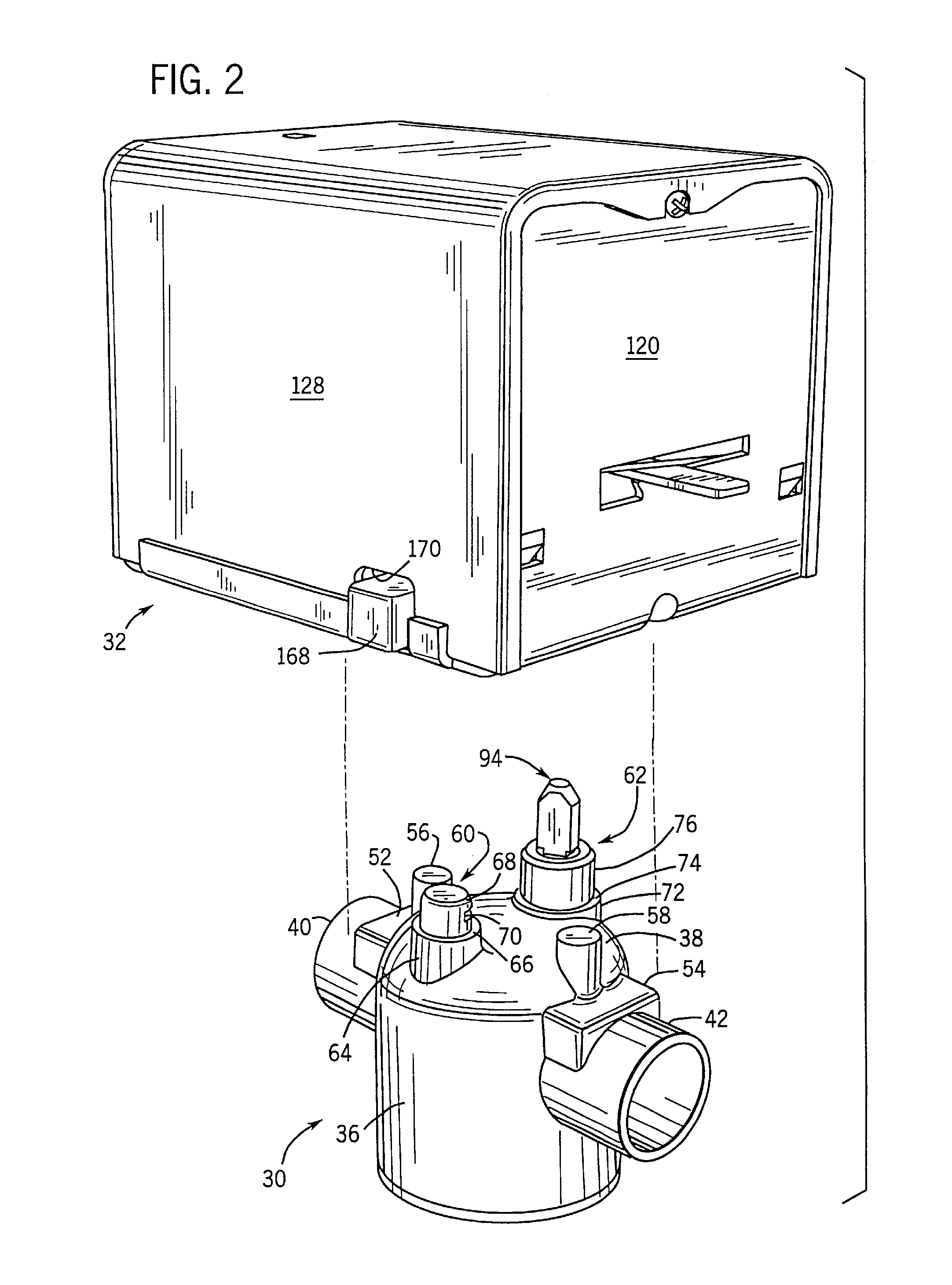

Valve Actuator Having Synchronous Motor Having Plastic Bushings

InactiveUS20110240893A1Avoid corrosionReduce failureOperating means/releasing devices for valvesSynchronous motorsSynchronous motorValve actuator

A synchronous motor and a valve having a valve actuator and valve assembly is provided. The valve actuator includes the synchronous motor. The synchronous motor utilizes a magnetic coil, a stator and a rotor to generate rotational movement to drive the valve member for the valve assembly. The valve has a normal state in which the valve is maintained when power is not supplied to the motor. The valve has a non-normal actuated state when power is supplied to the motor. The motor is stalled in the non-normal state to maintain the valve in that state. The rotor includes a rotor shaft that passes through a magnetic hub of the stator. The rotor shaft is supported by a plurality of plastic and / or nylon bearings to prevent corrosion therebetween when the rotor shaft and bearings remain in a substantially fixed orientation for an extended period of time.

Owner:SCHNEIDER ELECTRIC BUILDINGS LLC

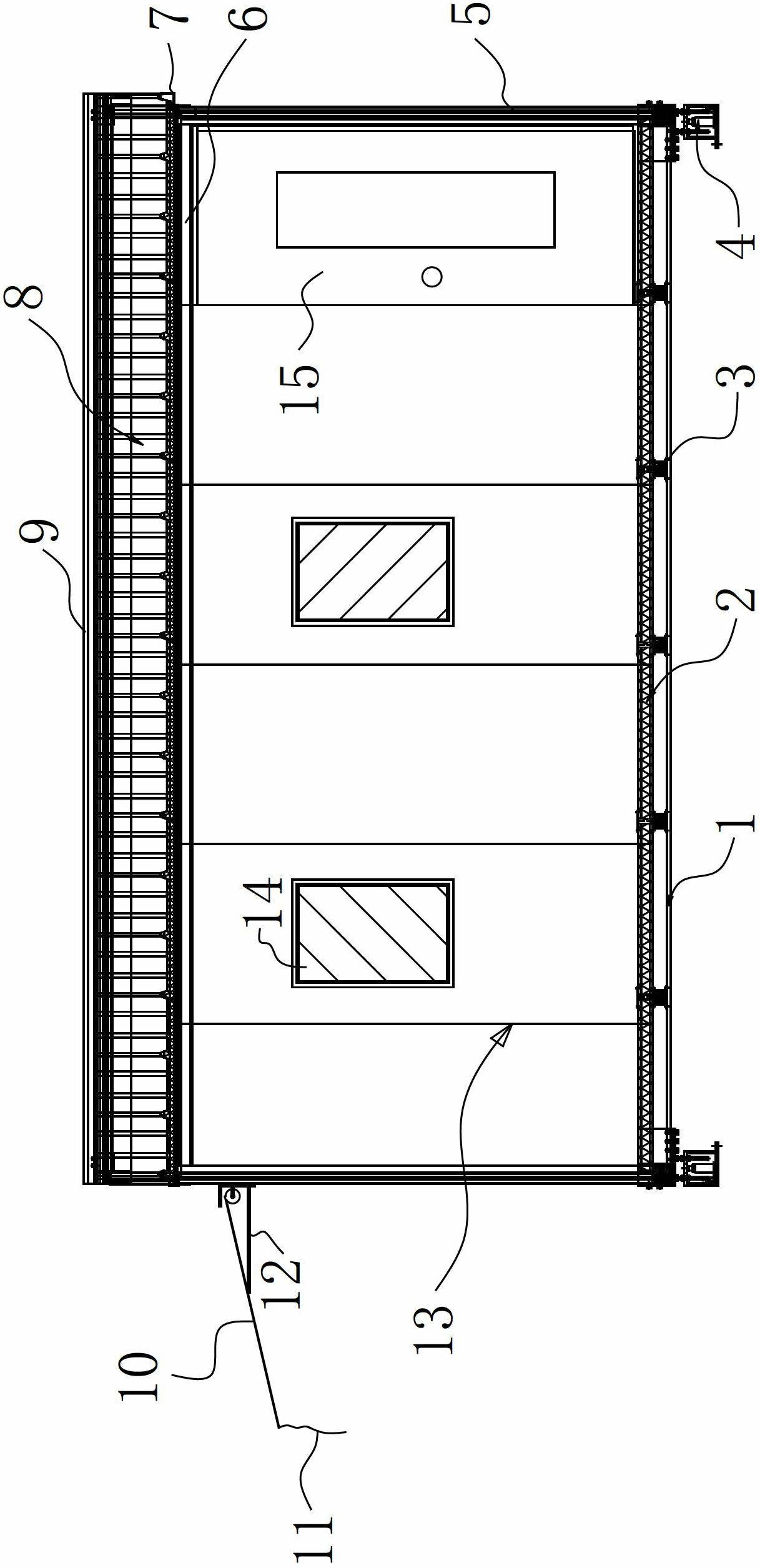

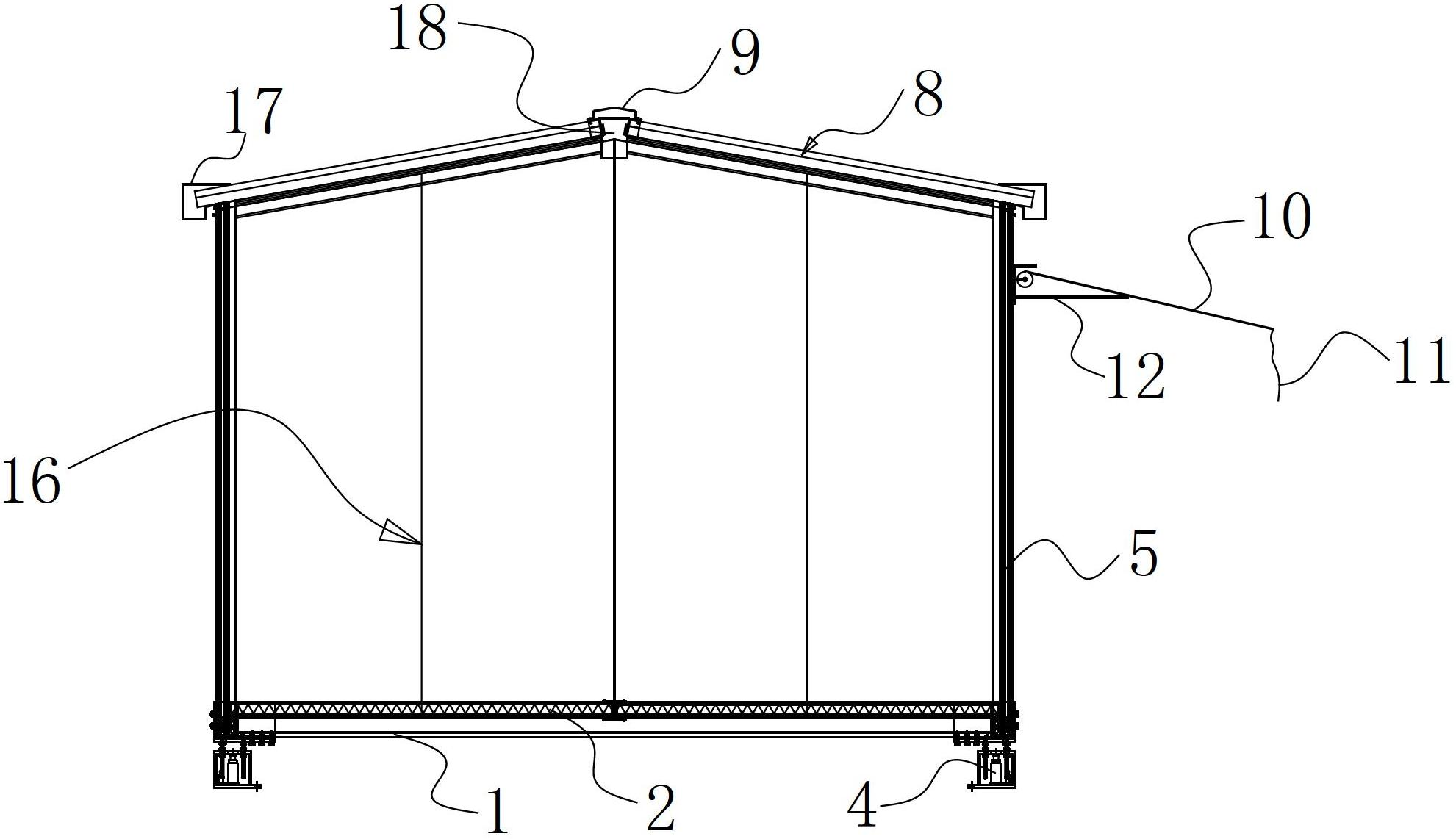

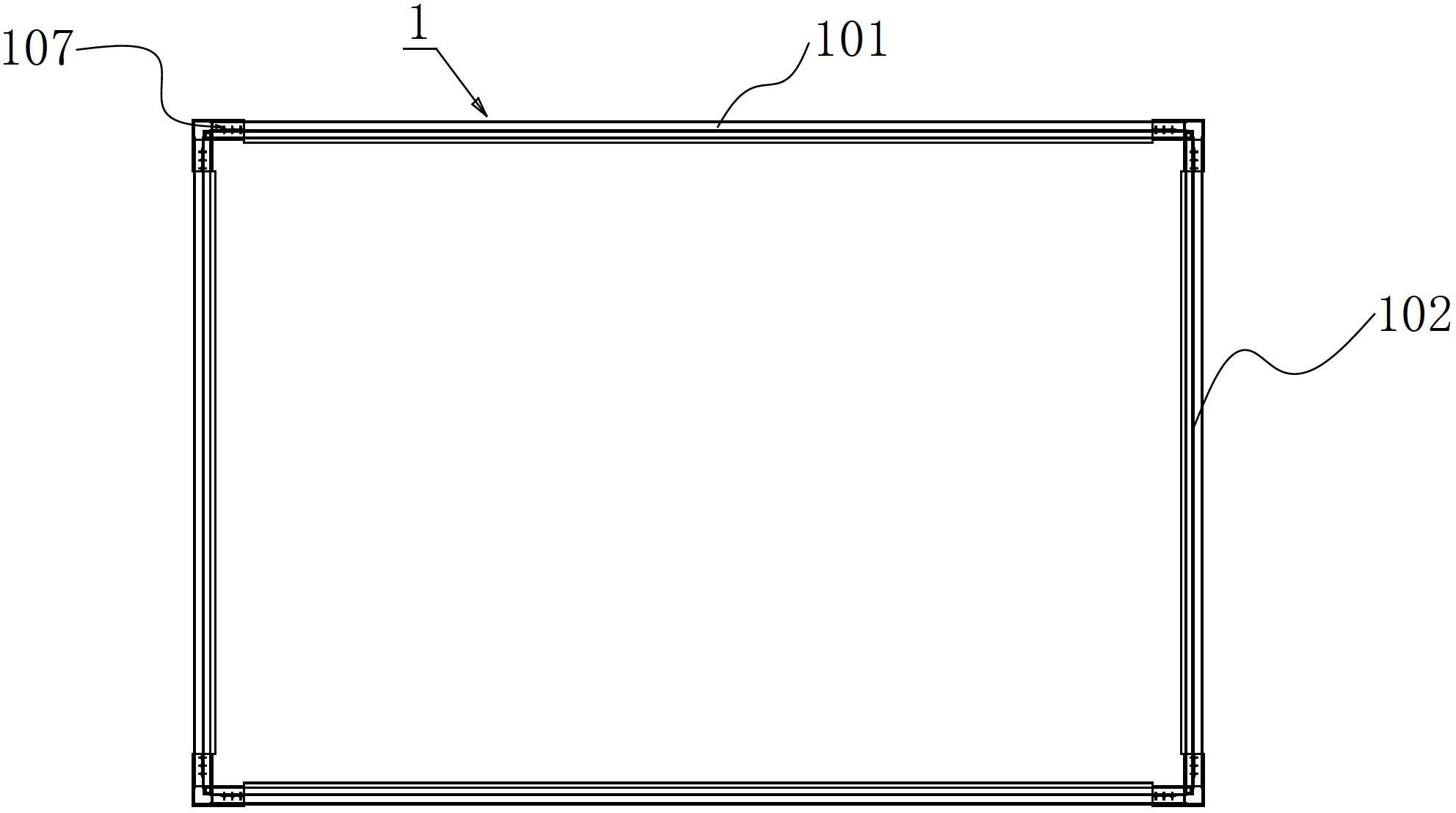

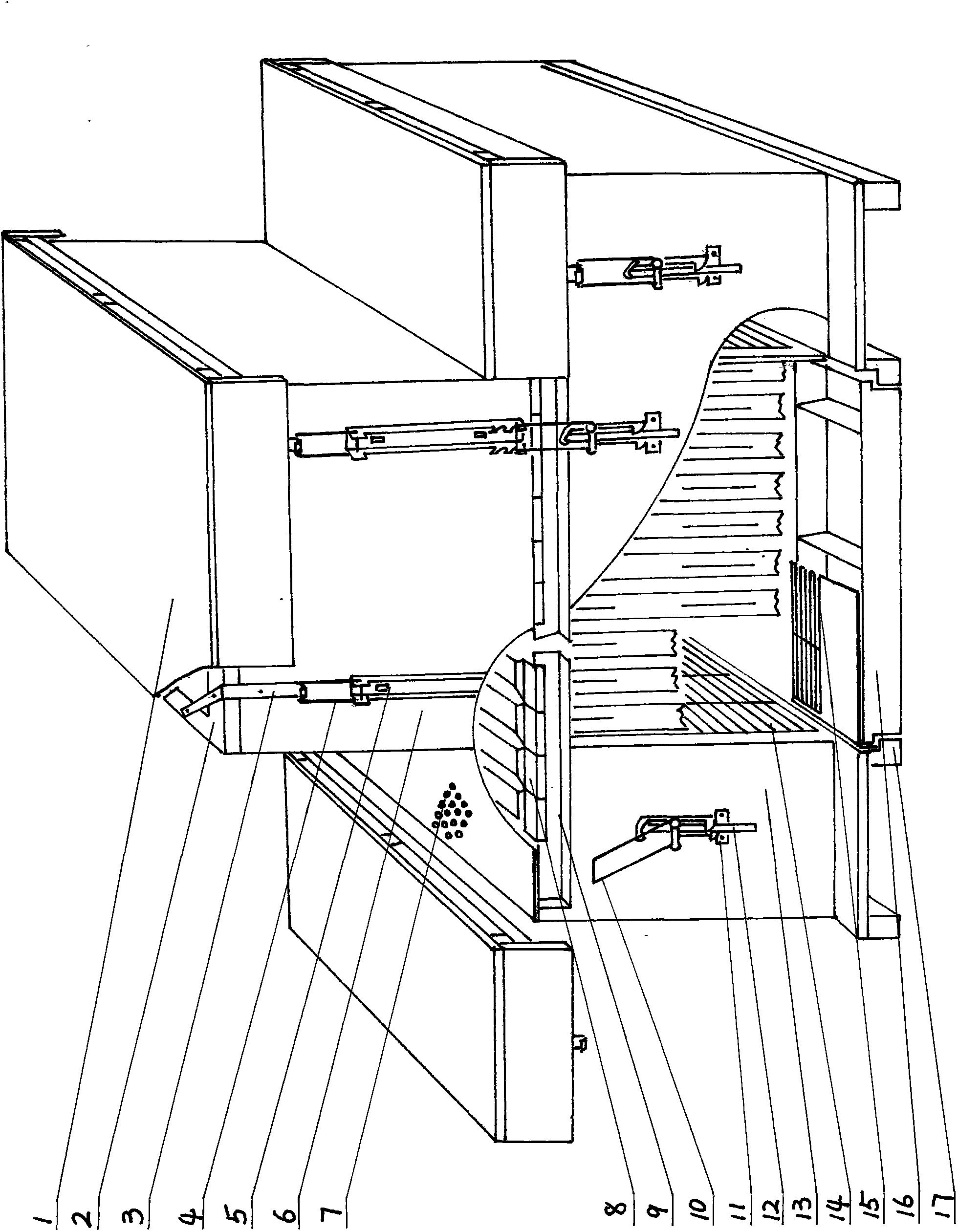

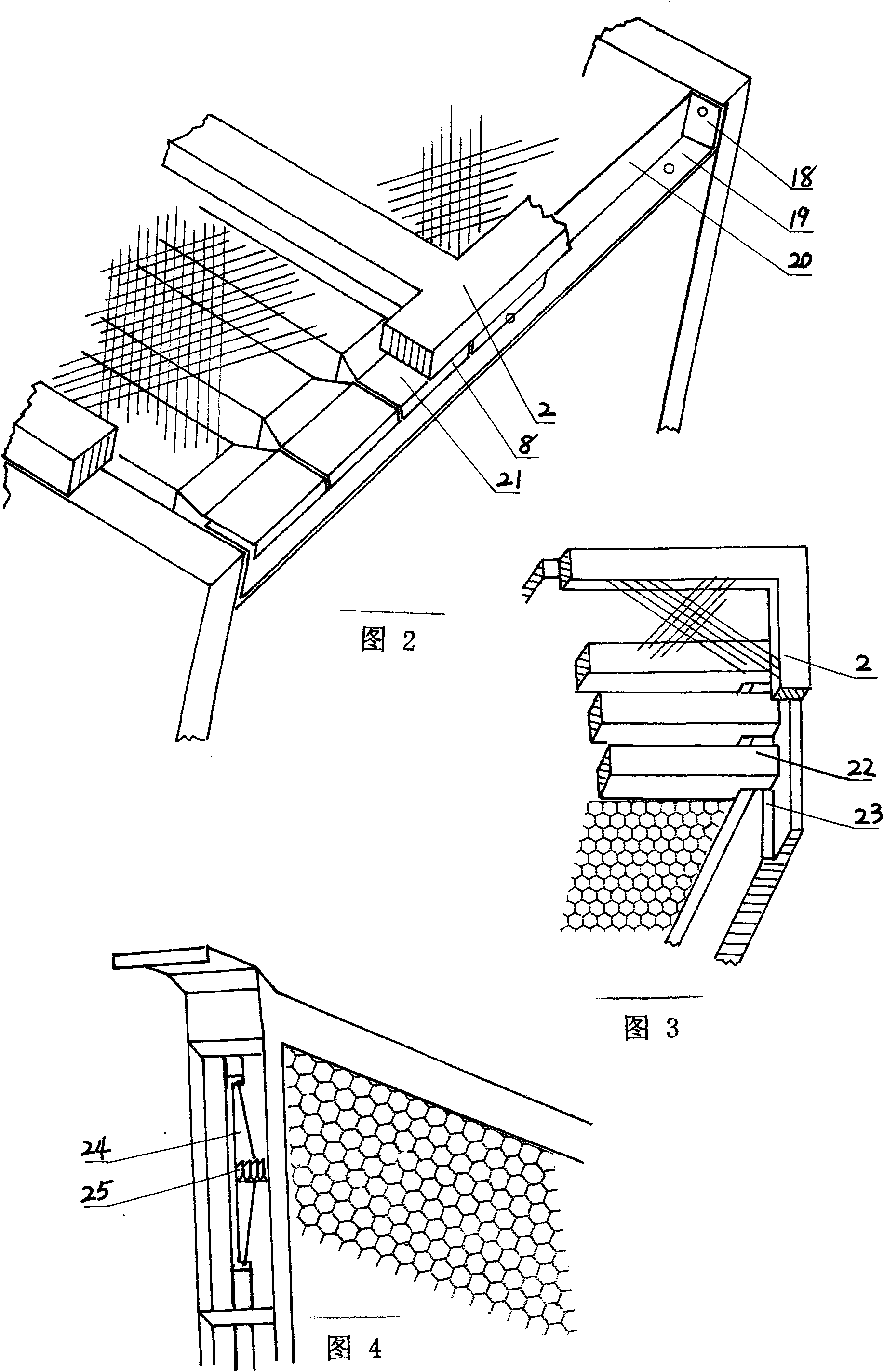

Modular integrated house

InactiveCN102691352AAvoid environmental problemsAvoid noise pollutionBuilding constructionsModularityBuilding construction

The invention discloses an industrialized, large-scale and factorized modular integrated house, which has the advantages of quick construction, firmness, durability, wind resistance, shock absorption, convenience in secondary disassembly and assembly and the like, is beneficial to warehousing and transportation, is not required to be installed by professionals and realizes industrialized and large-scale production and free house combination. The modular integrated house comprises ground beams which form a frame-type structure through connecting profiles; a plurality of floor units are detachably connected into a whole, and the integral edge of the floor units is lapped on a floor on the upper part of the inner side of the frame-type structure of the ground beams; a plurality of wall panels are detachably connected into transverse and longitudinal wall panels, an upright post is fixedly arranged on each corner of the ground beams, the lateral surfaces and the bottoms of the transverse and longitudinal wall panels are correspondingly detachably arranged on the upright posts and the ground beams to form an integral wall of the integrated house, and doors and windows are formed on the wall panels; and transverse and longitudinal collecting edges arranged on the tops of the wall panels and a ridge are positioned on the roof of the integrated house to form a roof slab.

Owner:CHONGQING QICHI TECH

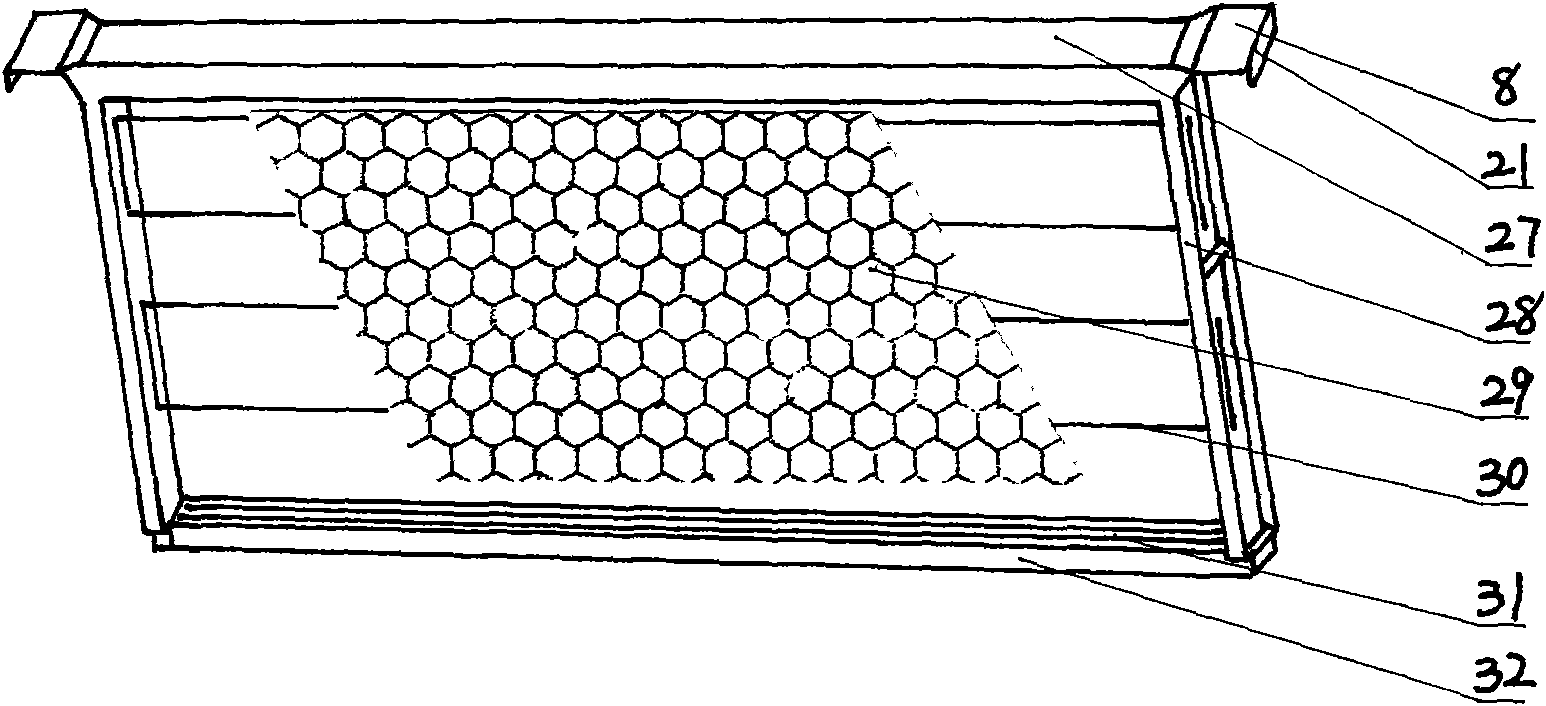

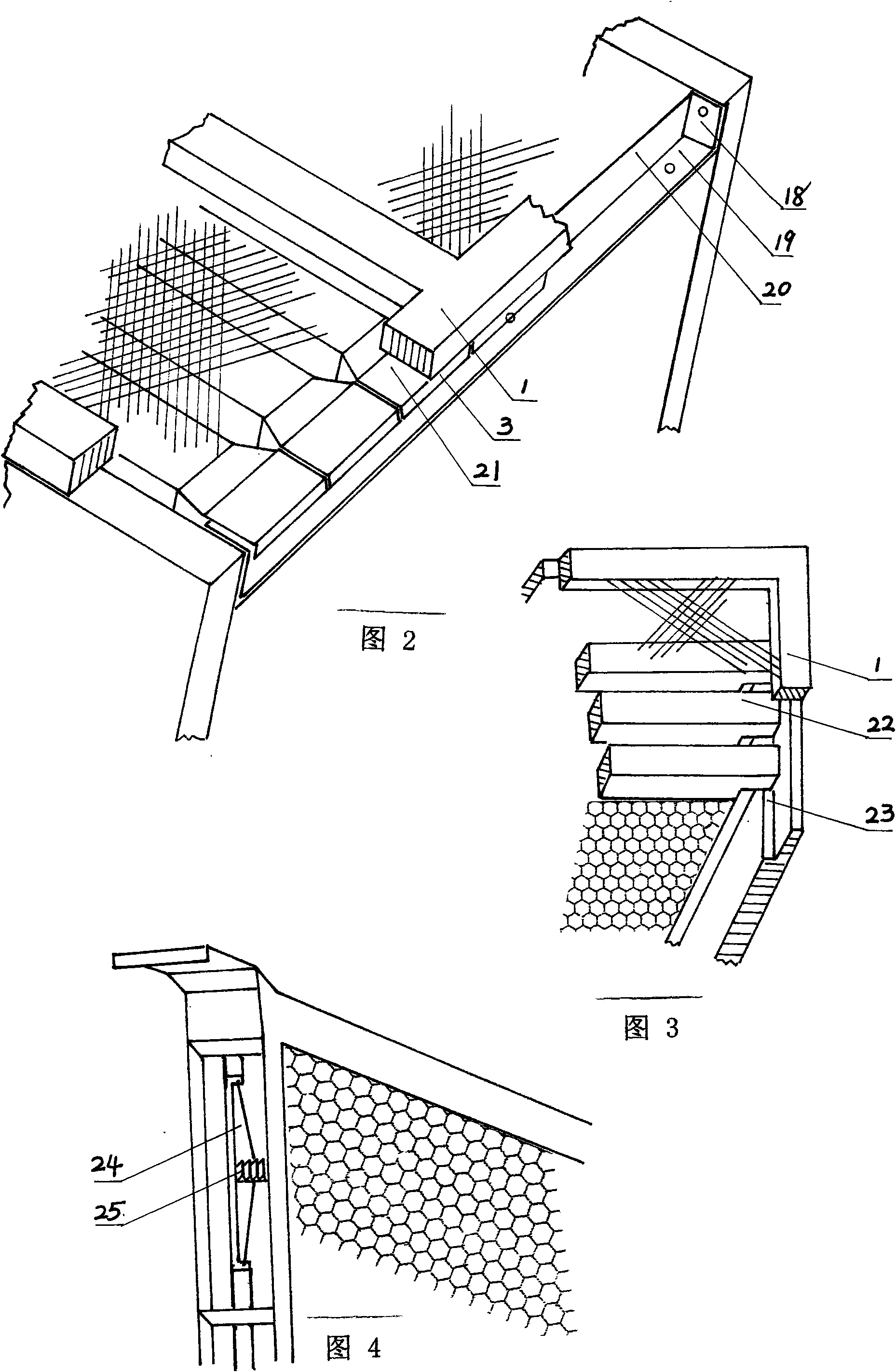

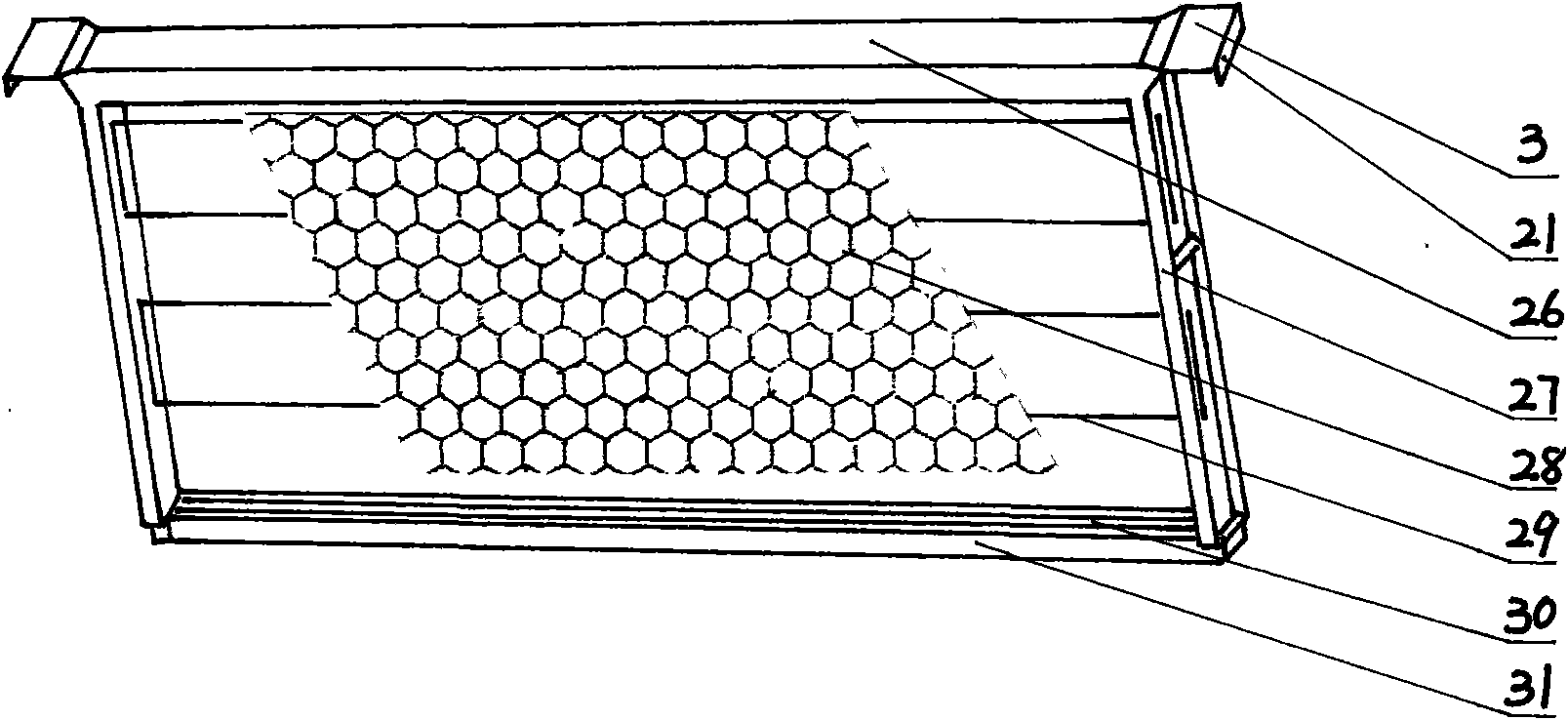

Horizontal and super combined beehive

InactiveCN101897300AImprove work efficiencyIncrease productionBeehivesHoney collectionWaxEngineering

A horizontal and super combined beehive comprises a wide-comb box, a frame support, a powder-releasing cover, a pollen box, a connector, a degummed drape, an inserted frame, an integrated frame and a wax comb foundation with suspension loops. The wide-comb box is characterized in that the both ends of the box are used as the breeding areas for two swarms of bees, a super is supported above the middle production area, frame queen excluders are used to form a working bee centralized production area, the areas are covered; the powder-releasing cover is bottomless, pollens and honey on a powder-leaking railing pedal with anti-theft gantry boxes on both sides directly leak in the pollen box at the bottom; the connected box is coarsely adjusted by a multi-teeth hook and finely adjusted and connected firmly by a screw crow bar through screws; the laps and edgings of the inserted frame are integrated, an upper beam and a lower beam are inserted in the upper and lower grooves of two edgings to integrate, the upper beam is thin, the lower beam and the edgings are provided with grooves to be inserted in the comb foundation; a wide hook with the same width and an adjuster are hung on the wax comb foundation for tightening; the laps are integrated with a frame-distance clip and connected with the upper beam through a downward slope, the tops of comb-forming frame supports are butted to each other and are tightly pressed by the degummed drape and the inner frame of the box cover, the distance of the frames is standard so that people can not stung by bees; and the top of each lap is provided with a handle, thus the laps can be fast gripped outside the box. The wide-comb box can be used to multiply the efficiency, thus being suitable to be used for beekeeping around the world.

Owner:汪修建

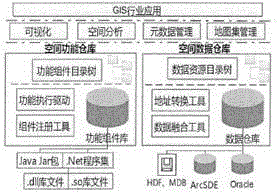

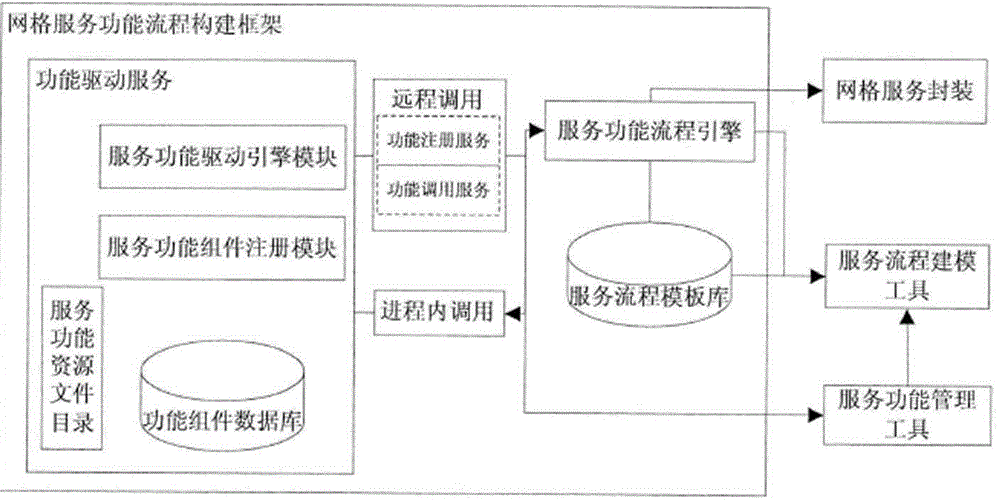

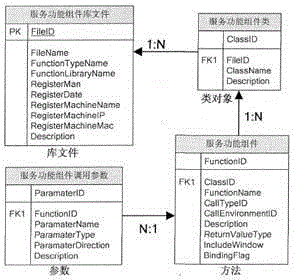

Construction method for geospatial information workflow service function flow templates

InactiveCN104572062ARealize visual modelingRapid scalabilityResourcesSpecific program execution arrangementsService flowSpatial function

The invention relates to a construction method for geospatial information workflow service function flow templates. The method is characterized in that a framework is constructed on the basis of a service function flow template of a spatial function warehouse architecture, and by sufficiently utilizing the advantages of scalability and easy construction of the spatial function warehouse, the rapid extension and packaging of spatial function services is provided. The core component of the framework mainly comprises two parts, i.e. a function drive service module and a service function flow execution engine. The function drive service function for driving services serves which serves as an important part of the function warehouse of a geospatial information kernel provides a function of discovering and registering various heterogeneous GIS (Geographic Information System) function component resources on spatial information nodes, and after the warehouse registration and clearing of the function components, all the issued functional resources declare resource services to the outside according to a unified interface specification. The service function flow execution engine which serves as a carrier for the logic execution of the lower-layer functions of the spatial information grid services can instantiate a service function processing flow by parsing service flow templates in a service function flow template library and call and execute a function drive service for a spatial function component associated with a function flow object.

Owner:武汉中地数码科技有限公司 +1

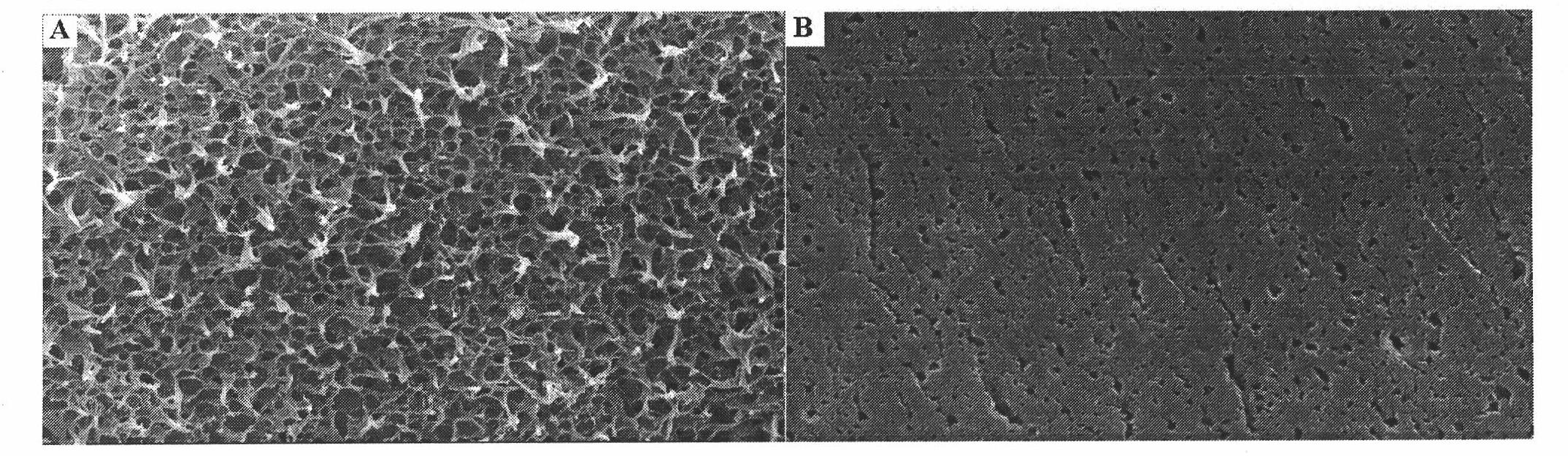

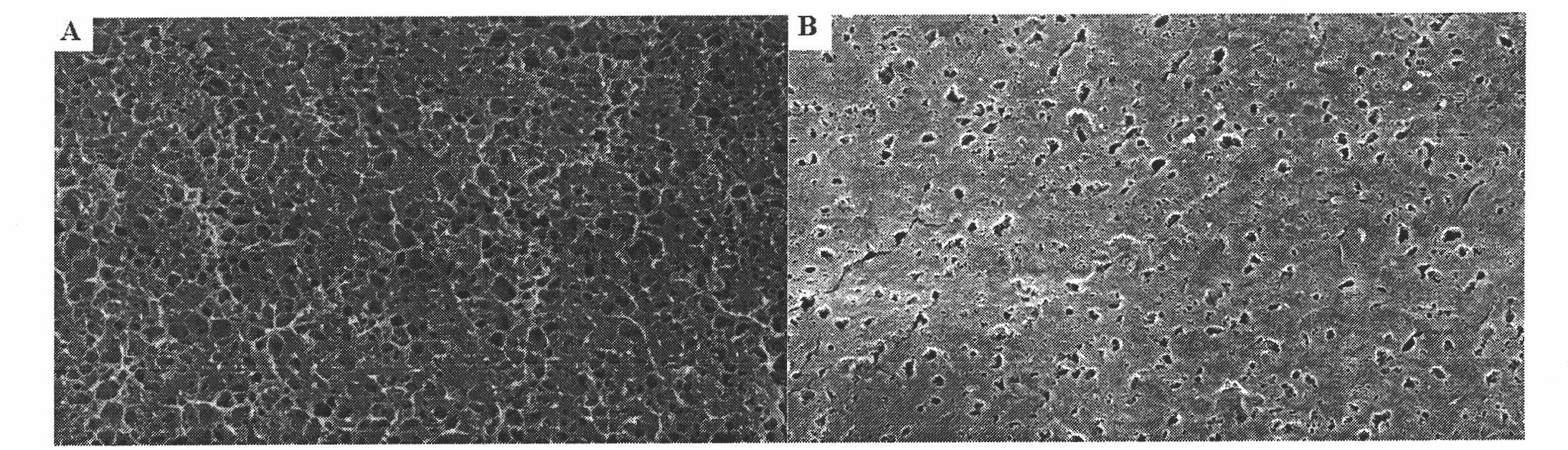

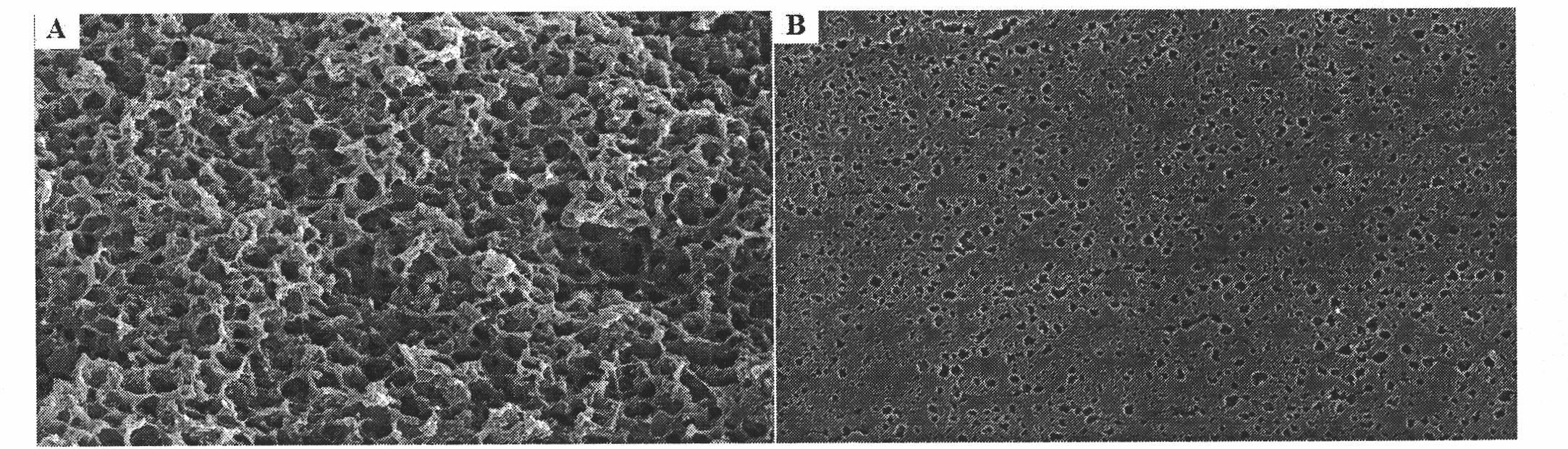

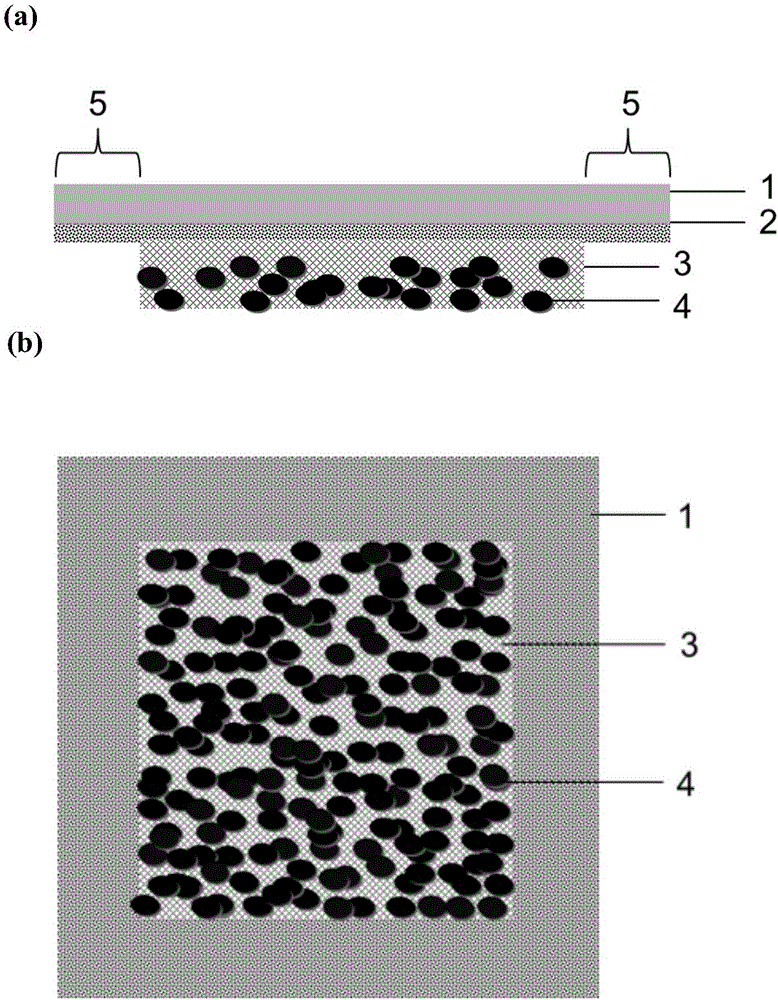

Polyester flat microporous membrane and preparation method thereof

InactiveCN101985085AAchieve hydrophilicAchieve hydrophilizationSemi-permeable membranesCell seperators/membranes/diaphragms/spacersPolyesterMicrometer

The invention discloses a polyester flat microporous membrane and a preparation method thereof. The microporous membrane comprises the following materials in percentage by mass: 60-99.9% of polyester and 0.1-40% of modifier; or 20-40% of non-woven fabric, 60-79.9% of polyester and 0.1-30% of modifier. The preparation method is realized on the basis of a thermally induced phase separation process and comprises the following steps: mixing the polyester, the modifier and diluter into a homogeneous solution at high temperature; scraping the homogeneous solution into a liquid membrane, cooling andcuring into a membrane so as to form a precursor membrane subject to microphase separation, and extracting to obtain a flat microporous membrane. The prepared polyester flat microporous membrane is in a spongeous structure with the pore diameter of 0.05-5.0 micrometers and the porosity of 30-80%, and has the advantages of narrow pore diameter distribution, uniform pore size, easily controlled pore size, high strength, symmetrical structure and the like, thereby being a filter membrane material for water treatment and a lithium ion battery diaphragm material with high performance, low cost andlong life.

Owner:ZHEJIANG UNIV

Convenient beehive

The invention comprises a convenient beehive consisting of a nest frame support, degummed covering cloth, a powder-removing cover, a pollen box, a connector, a plug-in nest frame, an integrated nest frame and a wax nest foundation with hanging rings, and is characterized in that the powder-removing cover is erected on a box leak powder grate pedal, and pollen and honey water are leaked into the pollen box at the bottom part via a powder grate; the beehive is connected in a multi-tooth hook group for rough adjustment, and a thread of a spiral crowbar is used for fine adjustment and tight prying; the nest frame is integrally formed, laps of the plug-in nest frame are integrated with edge strips, the upper and the lower hanging rings at two ends of the was nest foundation are hung on wide hanging hooks in two edge strip bare cover type mouths, an upper beam and a lower beam are also tightened when being inserted in an upper groove and a lower groove of two edge strips, and a regulating buckle which is not tightened is buckled in the group; the upper beam is thin, the grooves are formed on the edge strips and the lower beam for mounting a plastic nest foundation; the laps are integrated with a frame distance clamp, a lower slope is connected with the upper beam, a frame and the top part of the nest frame support push against each other and compressed by a bee separating plate and a cover frame without gaps, and the frame distance is standard and difficult to kill bees due to extrusion and avoid the bees from stinging people; pull handles are arranged at the top ends of the laps, thereby being convenient to grab outside the beehive; and the degummed covering cloth with holes is used for covering the bees, thereby collecting more gum and realizing fast degumming. The convenient beehive can improve the effectiveness by a plurality of times and is applicable to world beekeeping.

Owner:汪修建

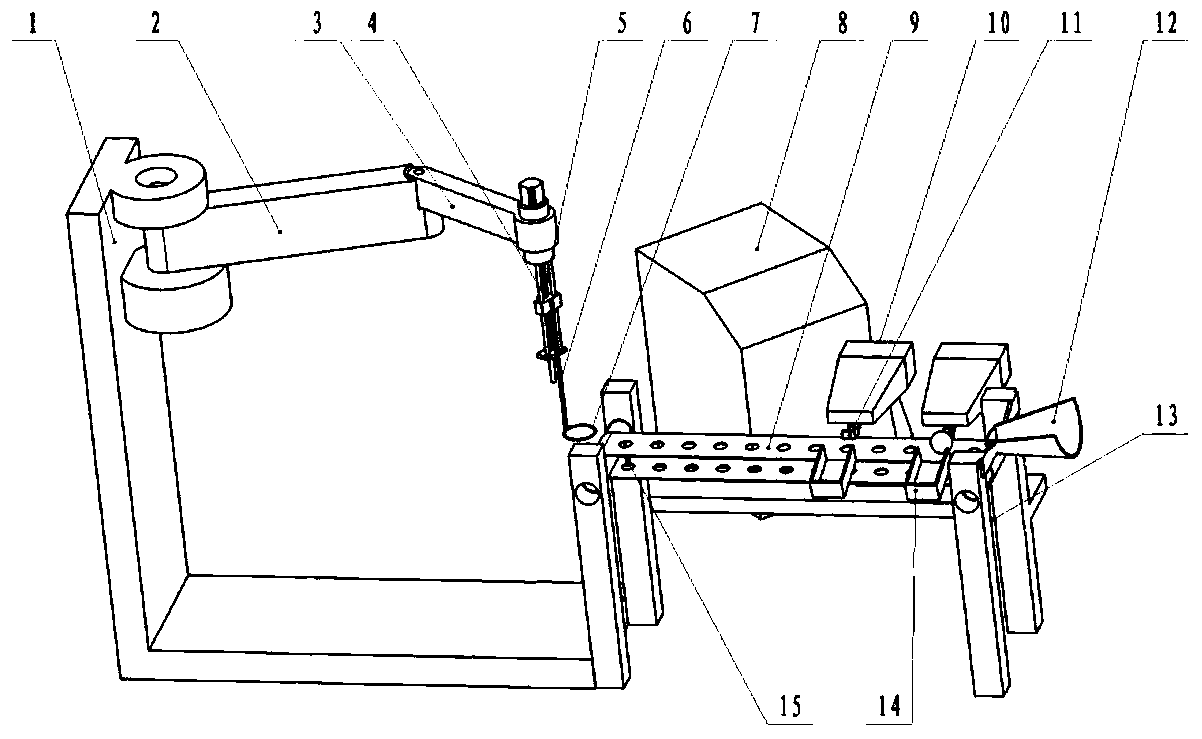

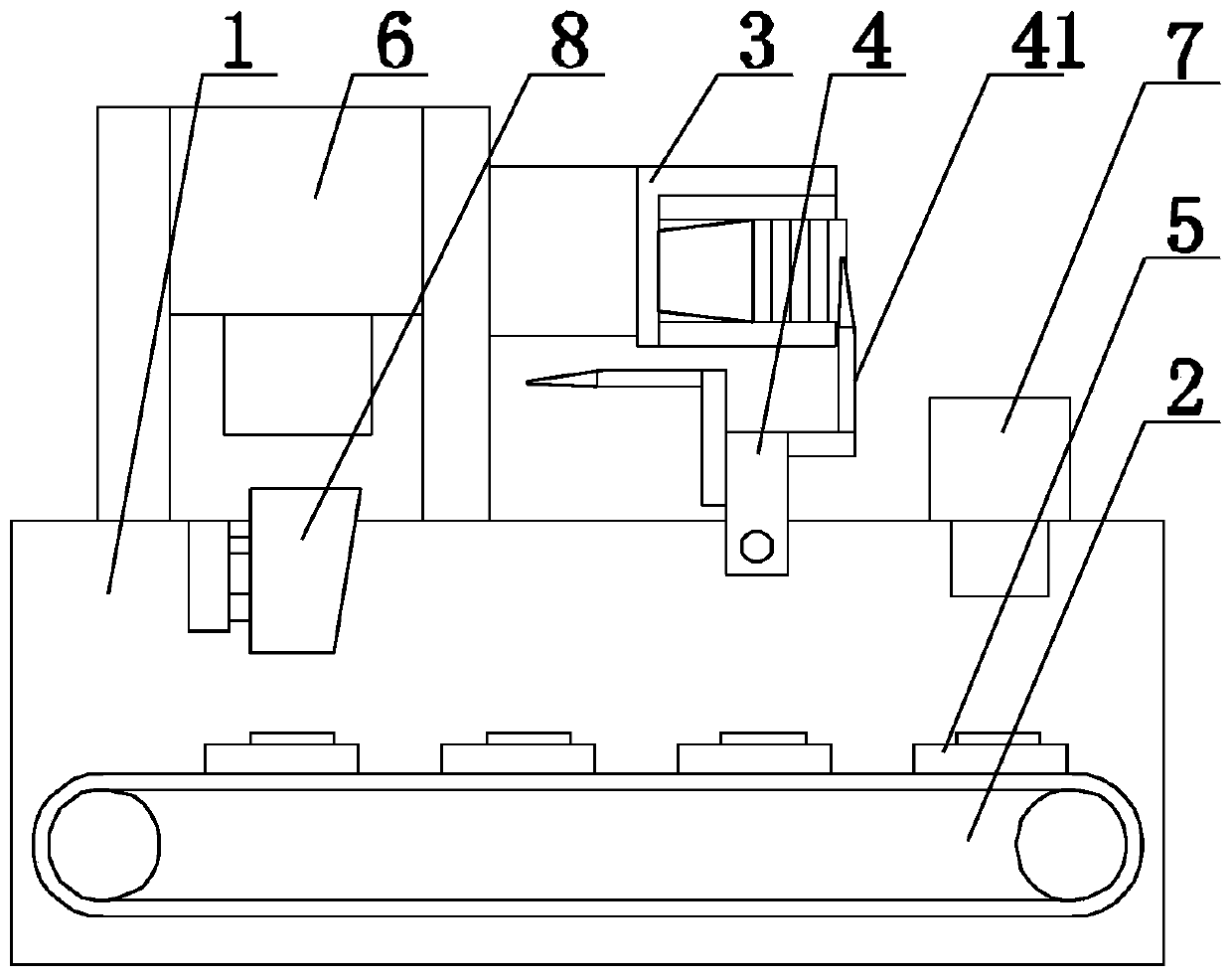

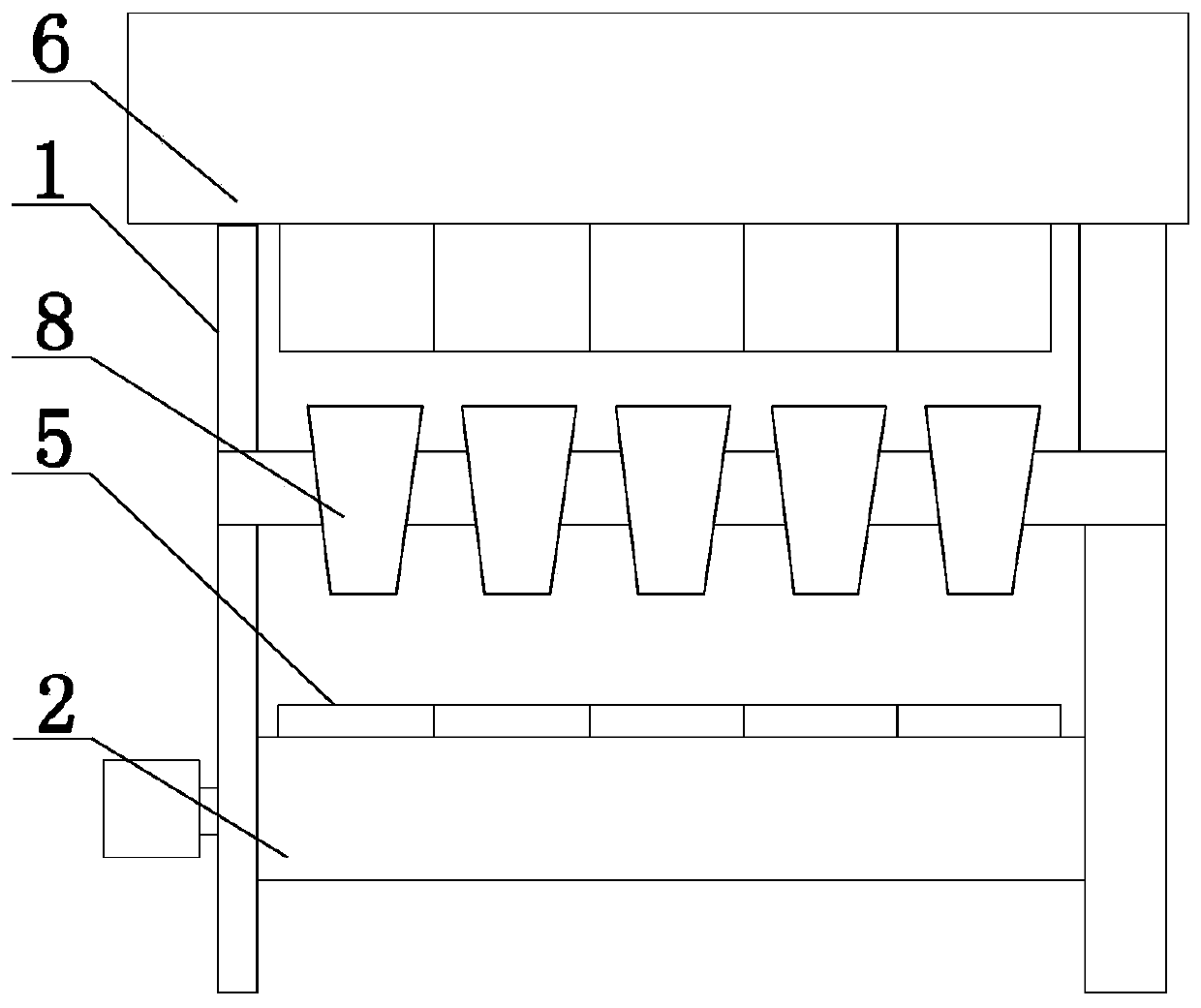

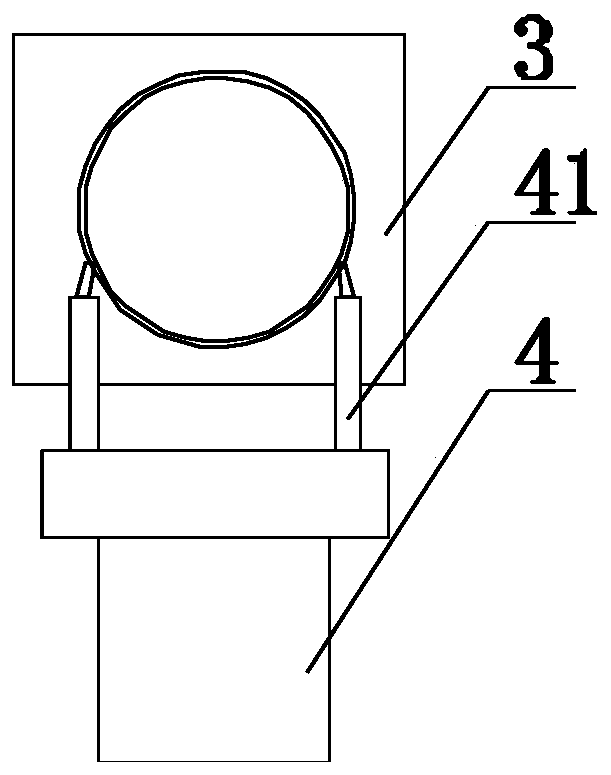

Automatic fruit screening and casing device

The invention relates to an automatic fruit screening and casing device, which is composed of a bottom plate, a movable arm, an adjustment arm, guide rails, a leading screw, a connecting frame, an air bag expansion hand, a control cabinet, a conveyor belt, infrared units, push rods, a fruit conveying tray, a stand, catching trays, and a photoelectric sensor. The movable arm is mounted over the bottom plate, the adjustment arm and the movable arm are connected together, the guide rails are fixed below the adjustment arm, and the leading screw is fixed in an end hole of the adjustment arm. One end of the connecting frame is sleeved on the two guide rails, and the other end is connected to the air bag expansion hand. The control cabinet is positioned behind the whole device. The conveyor belt is sleeved on the stand. The infrared units are fixed on the stand, and the detection part is over against the upper part of the conveyor belt. The push rods are below the infrared units. The fruit conveying tray is positioned at the stand end. The catching trays are fixed on the stand and are opposite to the push rods. The photoelectric sensor is fixed at one stand end close to the air bag expansion hand and is below the conveyor belt end. The device can separate damaged fruits, accurately screens fruits of different grades, and realizes quick casing.

Owner:于礼英

Fly ash solidification foamed material for preventing coal spontaneous combustion and preparation method thereof

ActiveCN103387410AEvenly dispersedEvenly suspendedSolid waste managementCeramicwareCoal spontaneous combustionCompressive strength

A fly ash solidification foamed material for preventing coal spontaneous combustion and a preparation method thereof. The fly ash solidification foamed material comprises the following ingredients, by weight: 40-60 parts of water, 100 parts of fly ash, 25 parts of complex powder for chemically self-producing gas, 1-5 parts of an accelerator, 1-4 parts of an activator, 0.6-1.5 parts of a water reducer, and 0.5-1 parts of a foam stabilizer. The preparing method comprises: adding the foam stabilizer in water and stirring to form a uniform foam solution; adding the fly ash, the complex powder for chemically self-producing gas, the accelerator, the activator, and the water reducer in a dry-blending mixer to form a blended powder; and finally adding the blended powder into the uniform foam solution to obtain the fly ash solidification foamed material. The material of the invention is light in weight, safe and low in costs, and has strong crack penetration capability, adjustable solidification time, great compressive strength, low heat conductivity coefficient, and a good heat insulation effect; foam fluid can uniformly cover loose coal-rock mass; carbon dioxide is released during a foaming reaction process to well dilute the oxygen concentration in residual coal space; and the operation technique is simple.

Owner:CHINA UNIV OF MINING & TECH

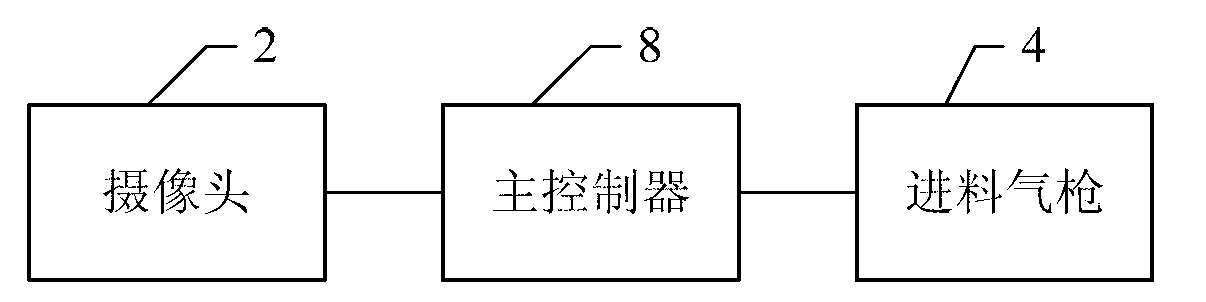

System used for automatically detecting and sorting work pieces

The invention provides a system used for automatically detecting and sorting work pieces. The system comprises a conveying device, a video device, a plurality of qualified product collecting boxes, a plurality of feed pneumatic runners and a processor. The video device is arranged at the position of a feed port of the conveying device and used for shooting the work pieces, the qualified product collecting boxes are arranged on one side of the conveying device at intervals from the video device and along the discharge direction of the conveying device, the feed pneumatic runners are arranged on the other side of the conveying device and correspond to the collecting boxes, and according to image information output by the video device, the processor controls the corresponding feed pneumatic runners to blow the work pieces into the corresponding collecting boxes. By means of the system, the work pieces can be automatically, accurately and quickly detected and sorted, and therefore manual labor is saved, and production efficiency is improved.

Owner:汉升密封科技(上海)有限公司

Low-temperature heat-seal acrylic emulsion for coating and preparation method thereof

The invention relates to a low-temperature heat-seal acrylic emulsion for coating and a preparation method thereof. The paint is prepared from the following raw materials in percentage by mass: 85-95% of modified acrylic emulsion and 5-15% of ethylene-acrylic acid copolymer emulsion (EAA emulsion for short). The modified acrylic emulsion is prepared from the following raw materials in percentage by mass: 11-18% of methacrylate, 3-6% of acrylate, 0.1-1% of acrylic acid, 0.01-0.2% of emulsifier, 0.01-0.1% of electrolyte, 0.4-0.6% of initiator, 1-4% of neutralizer, 72-80% of deionized water and 0.05-0.3% of bactericide. The emulsion can be coated on a biaxially-oriented polypropylene (BOPP) film to prepare a coating film for low-temperature heat seal, wherein the initial seal temperature can be lowered to 80 DEG C, and the heat-seal strength is 1.8-2.2N / 15mm (the heat-seal conditions are 80 DEG C, 0.14 MPa and 0.75s). The low-temperature heat-seal acrylic emulsion can be used for quickly packaging some candy products of which the packaging temperature is controlled at 85 DEG C below.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

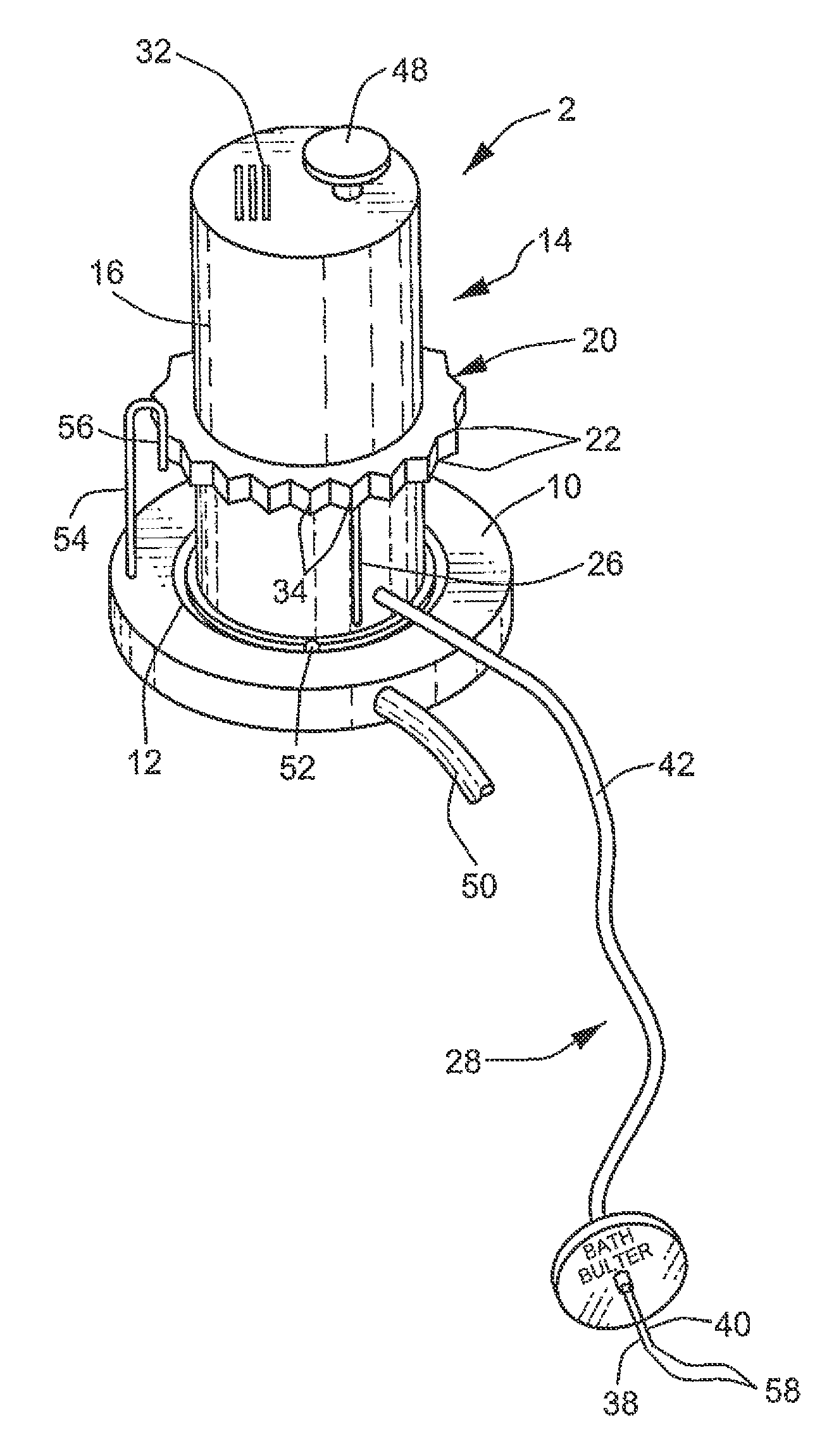

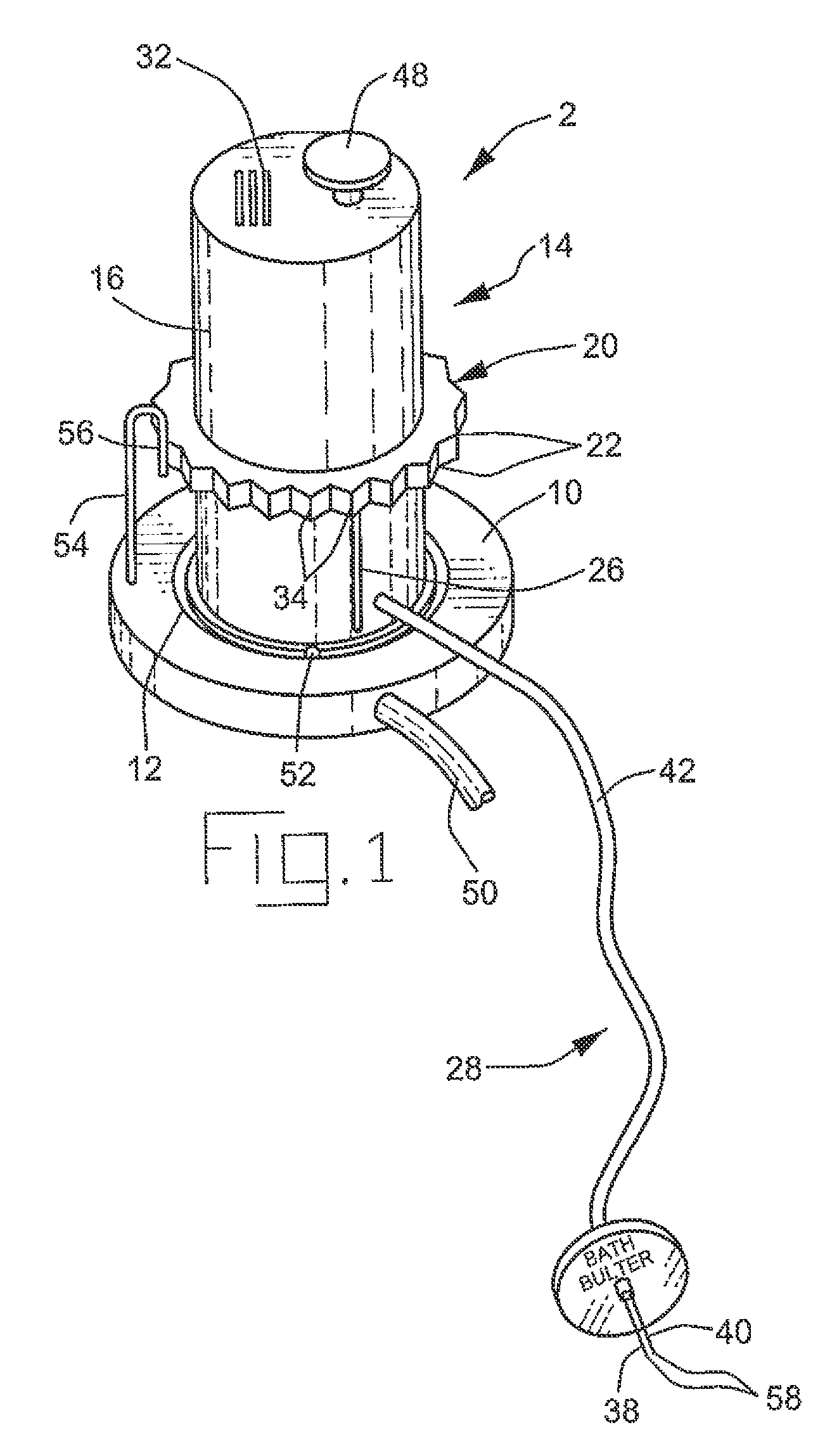

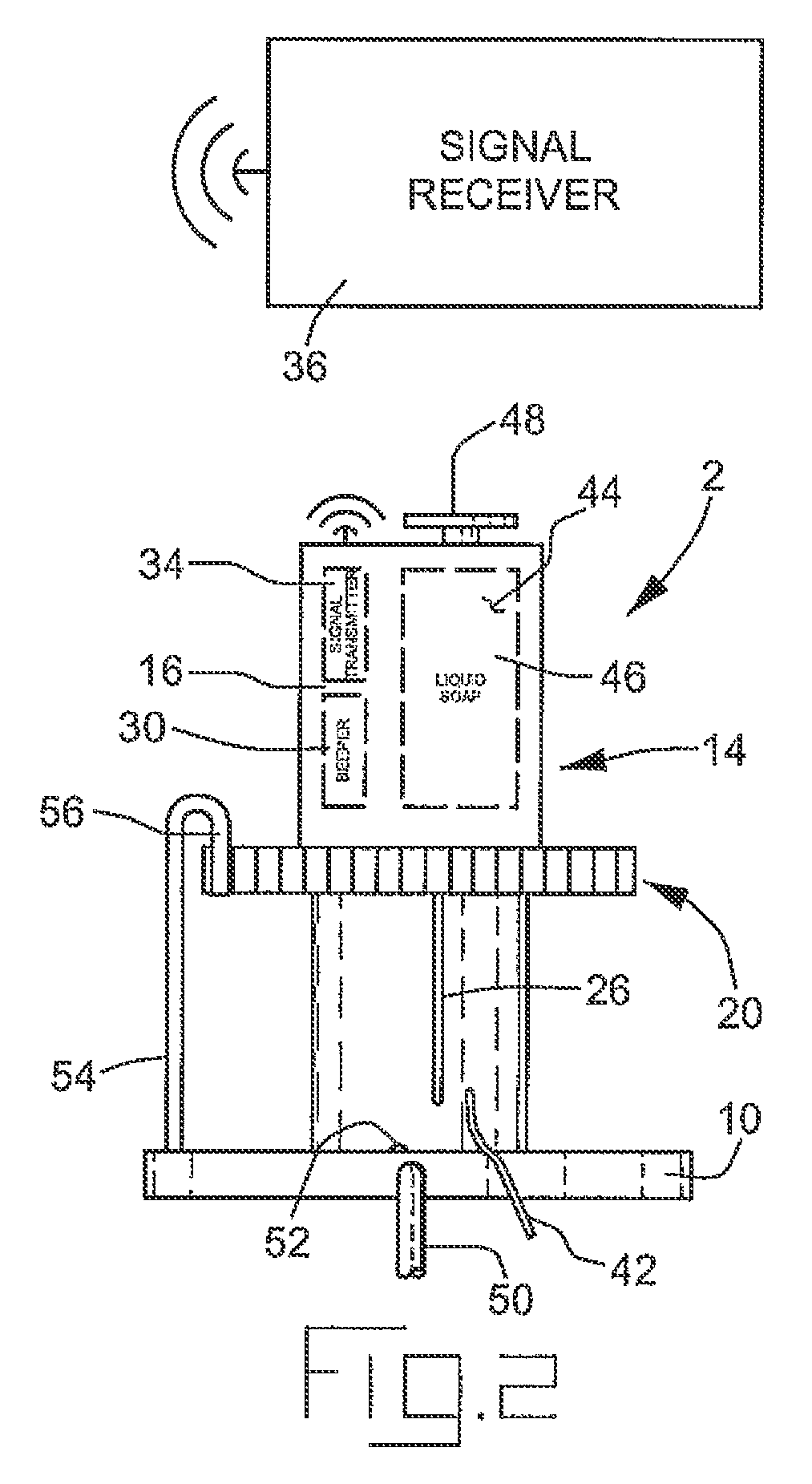

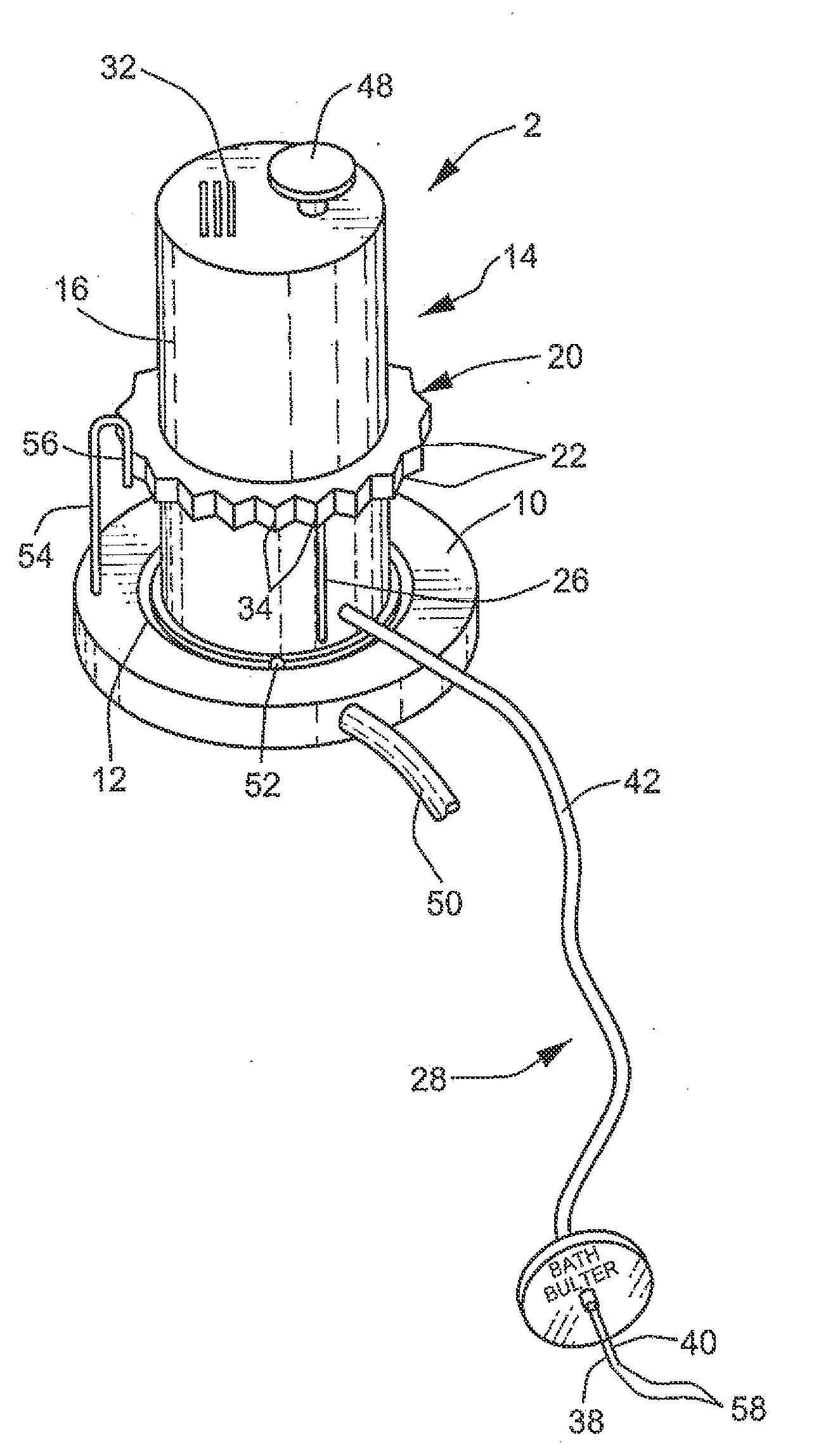

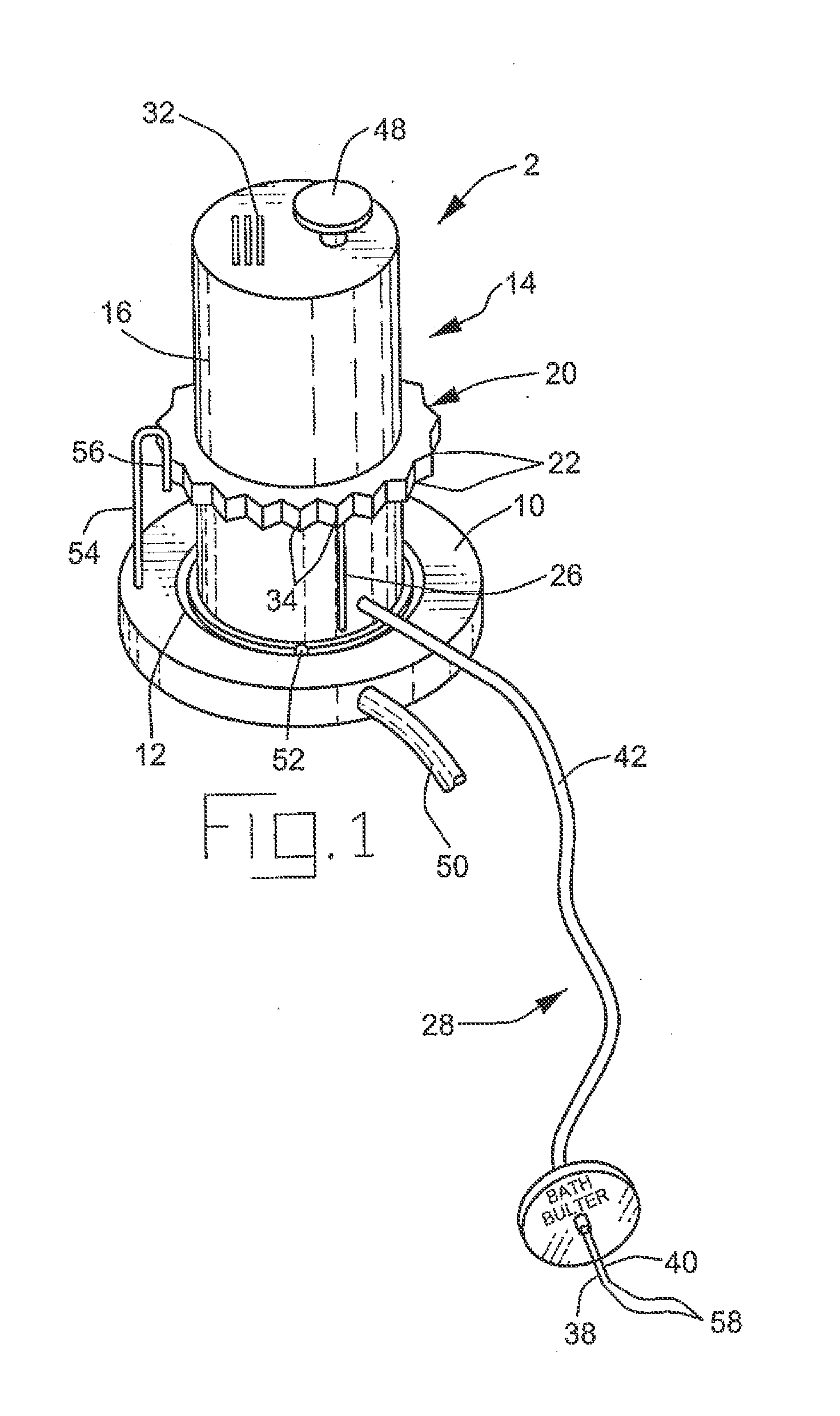

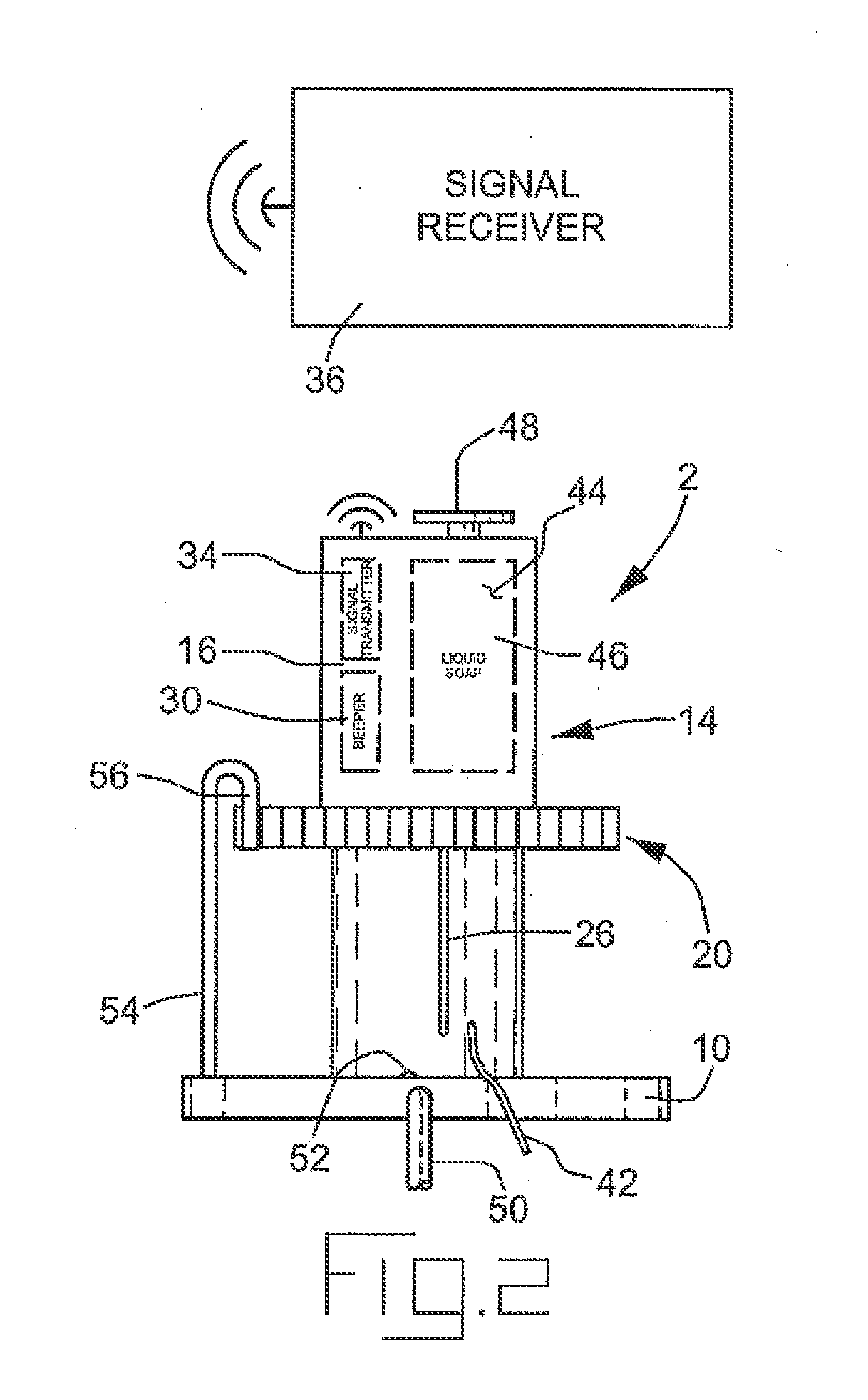

Adjustable sensor for sensing a level of liquid

A liquid level sensing device for sensing liquid in a container. The liquid level sensing device has a base and a rotatable member which extends from and is rotatable relative to the base. A cord extends from the rotatable member and has a sensor provided at a free end thereof. The sensor may be accurately positioned at various heights relative to a bottom of the container to allow a user to fill the container with the liquid to the desired level. An alarm and a signal transmitter are provided in electrical communication with the sensor, such that as a liquid is introduced to the container, the alarm and the signal transmitter will be activated when the level of the liquid reaches the sensor.

Owner:SHERRON MARK

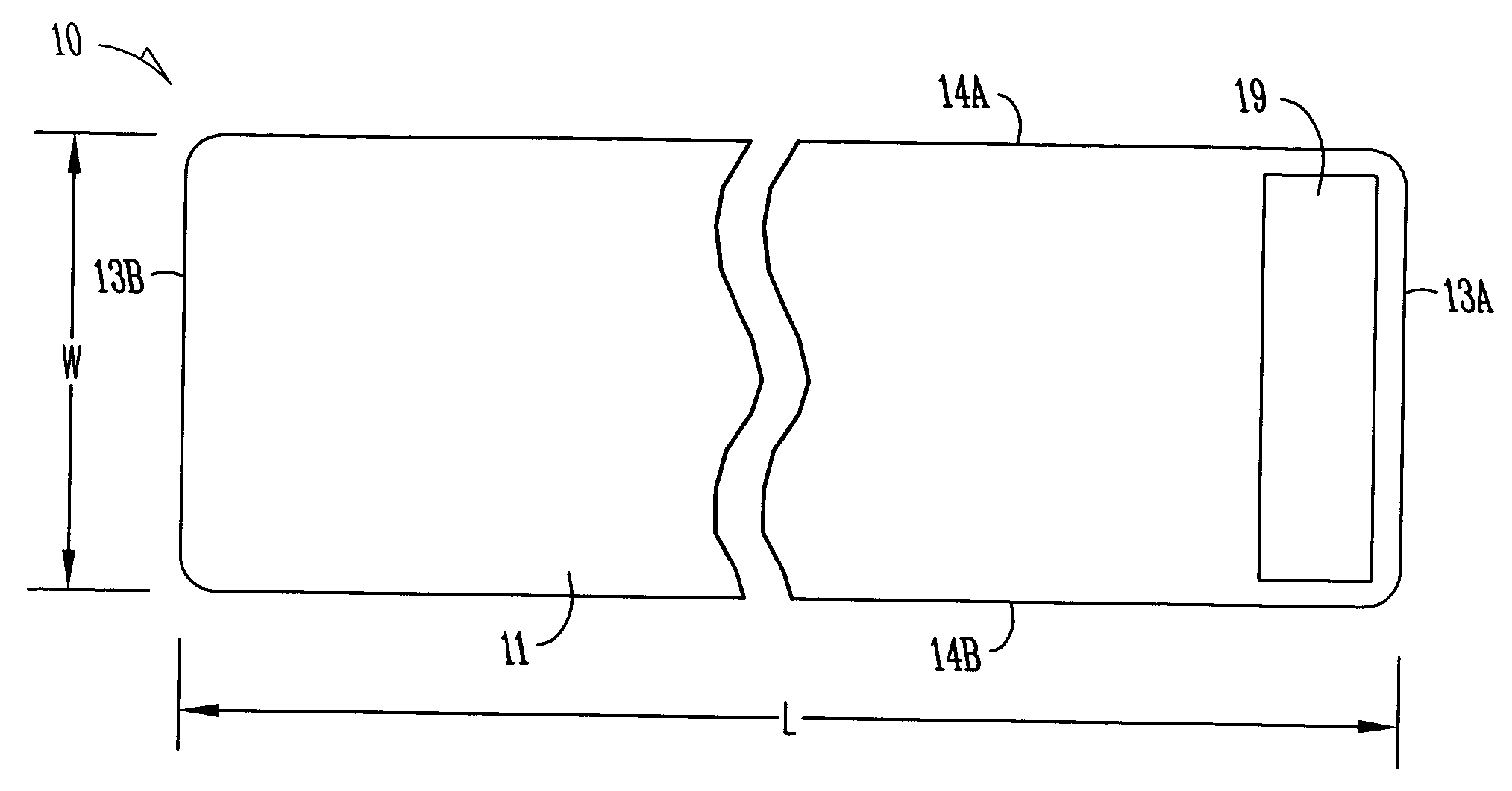

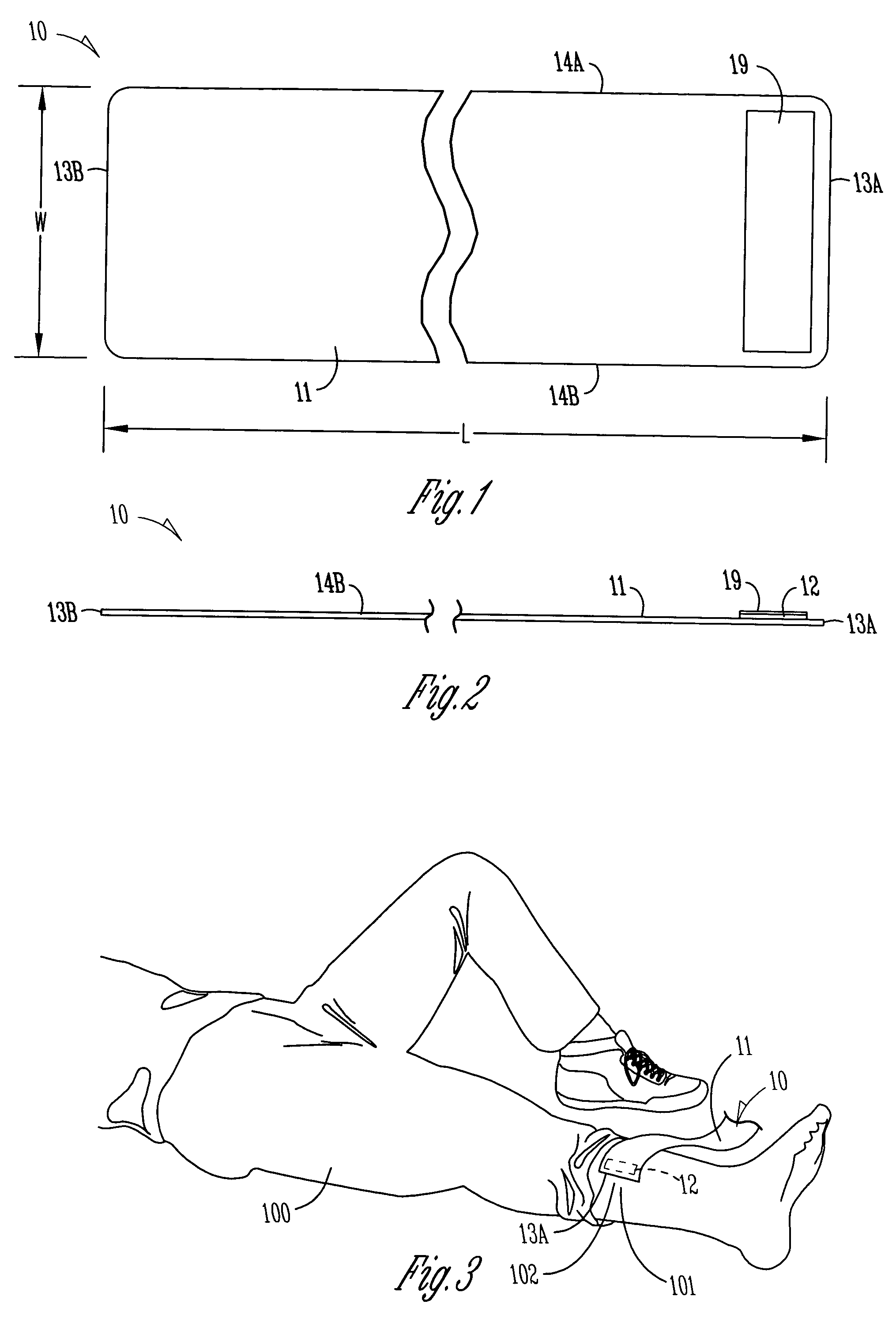

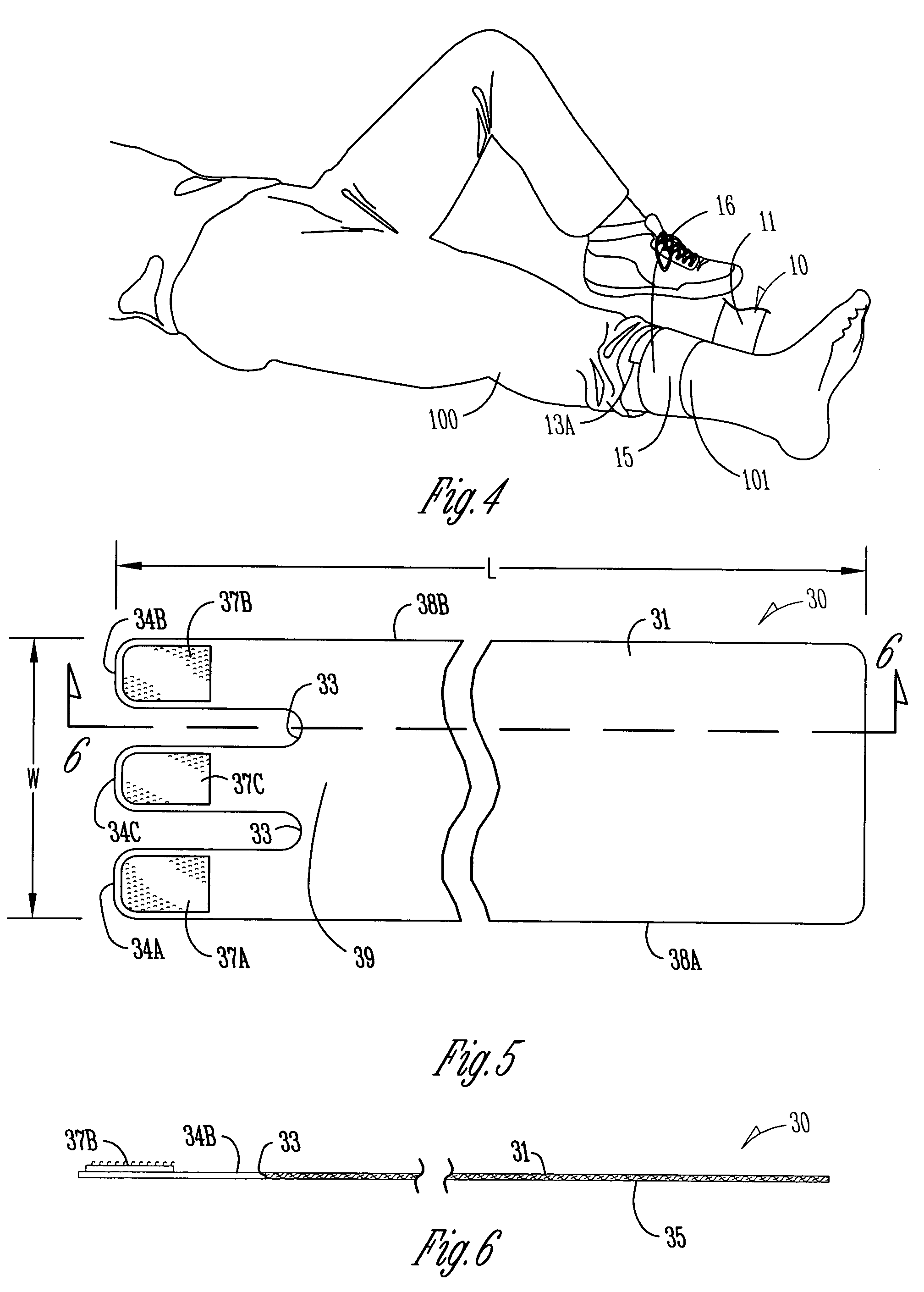

Flexible wrap for supporting a portion of a body

InactiveUS20050049537A1Easy to manufactureQuickly wrapped around injured areaBreast bandagesFeet bandagesAdhesiveEngineering

A flexible wrap and method for supporting a portion of a body. The flexible wrap includes an elastic band and an adhesive mounted on the elastic band near an end of the elastic band. The adhesive secures the elastic band to a body and is adapted to be detachably mounted to the body. In another form, the flexible wrap includes an elastic band and a plurality of fingers that extend from an end of the elastic band. Each of the plurality of fingers is secured to an exposed section of the elastic band when the flexible wrap is attached to the body. In still another form, the flexible wrap includes an elastic band and a pack having a midsection. The flexible wrap further includes a fastener, such as an adhesive, that extends along the midsection of the pack and secures the pack to the elastic band.

Owner:KIMBERLY-CLARK WORLDWIDE INC

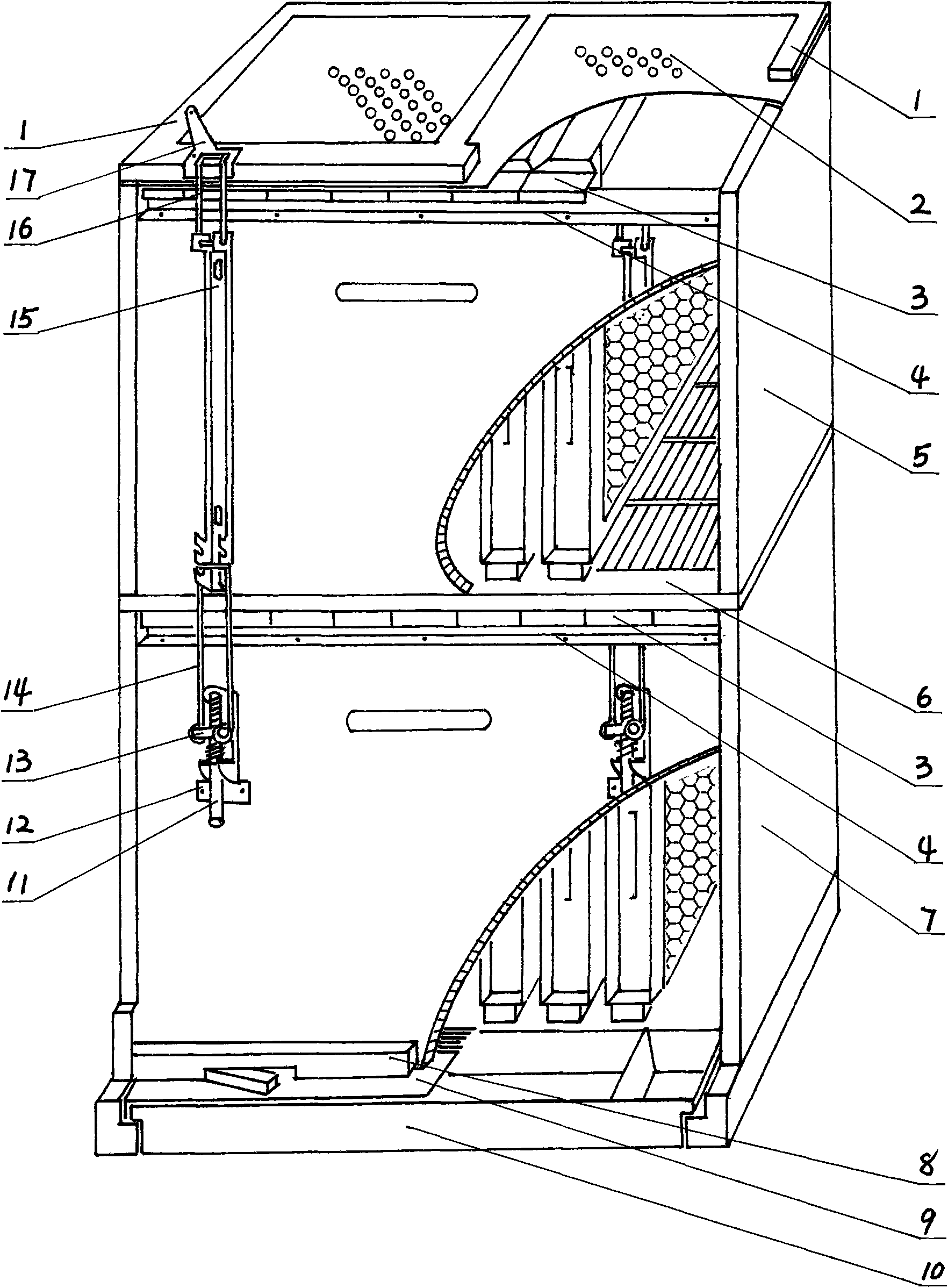

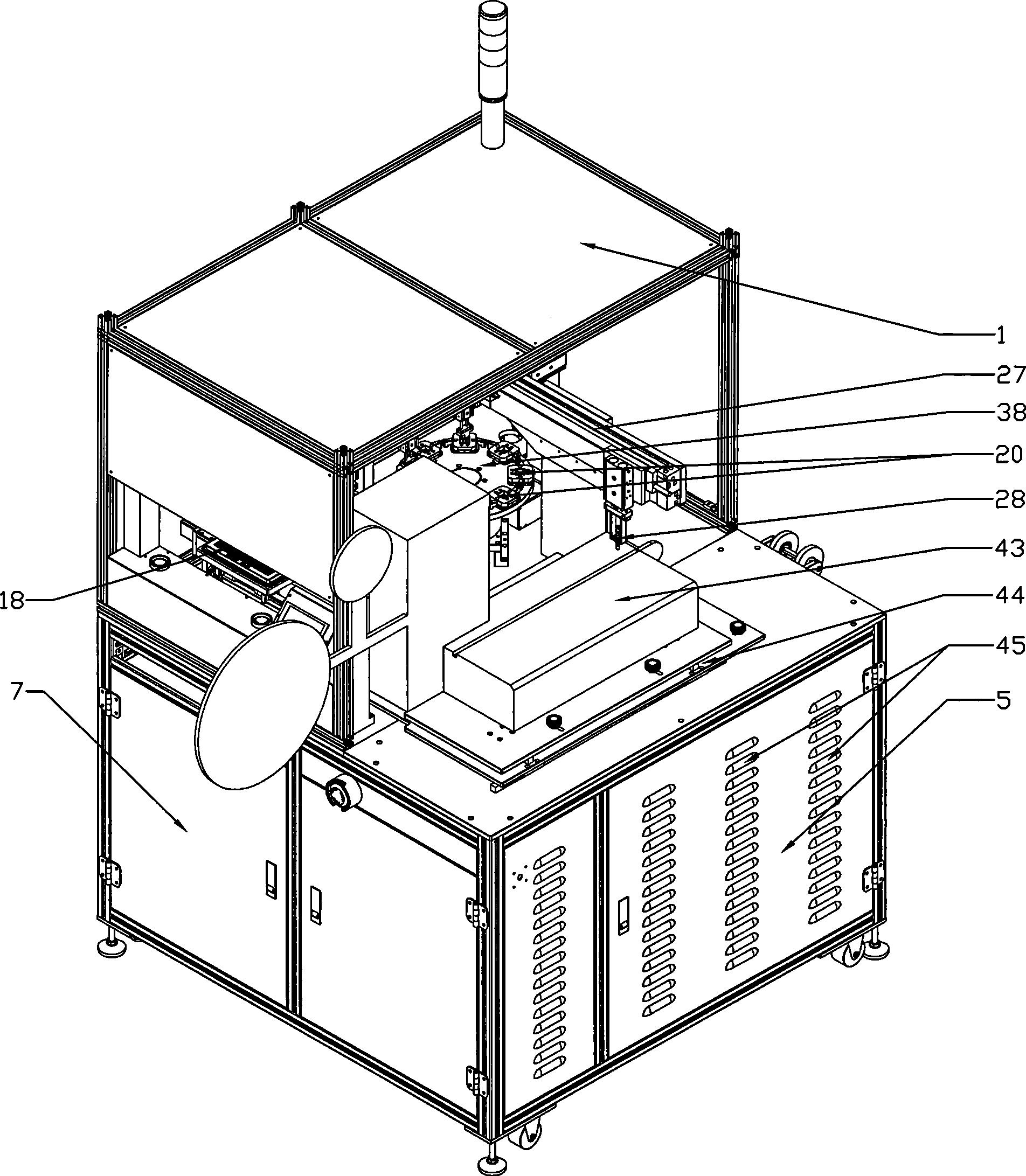

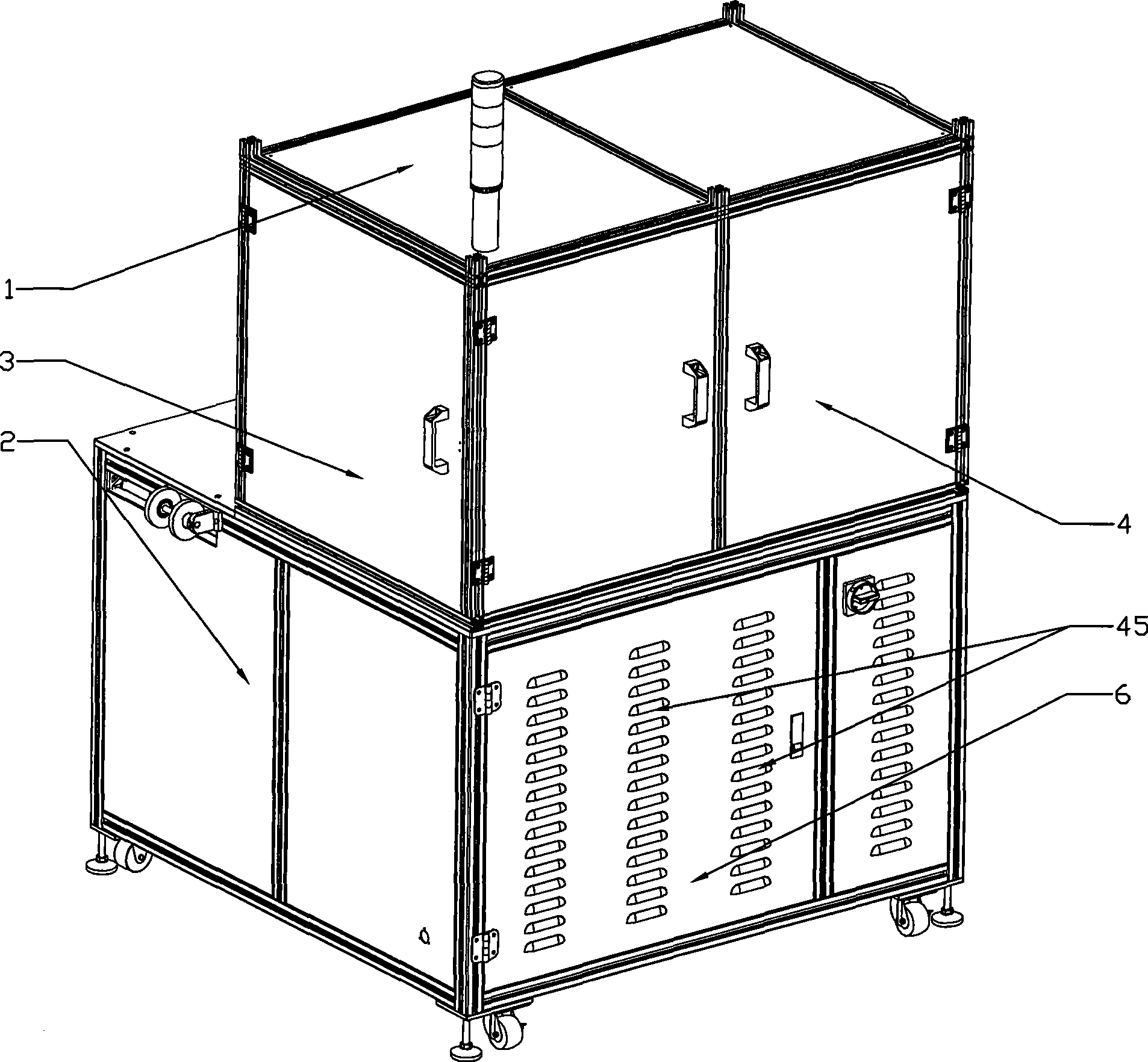

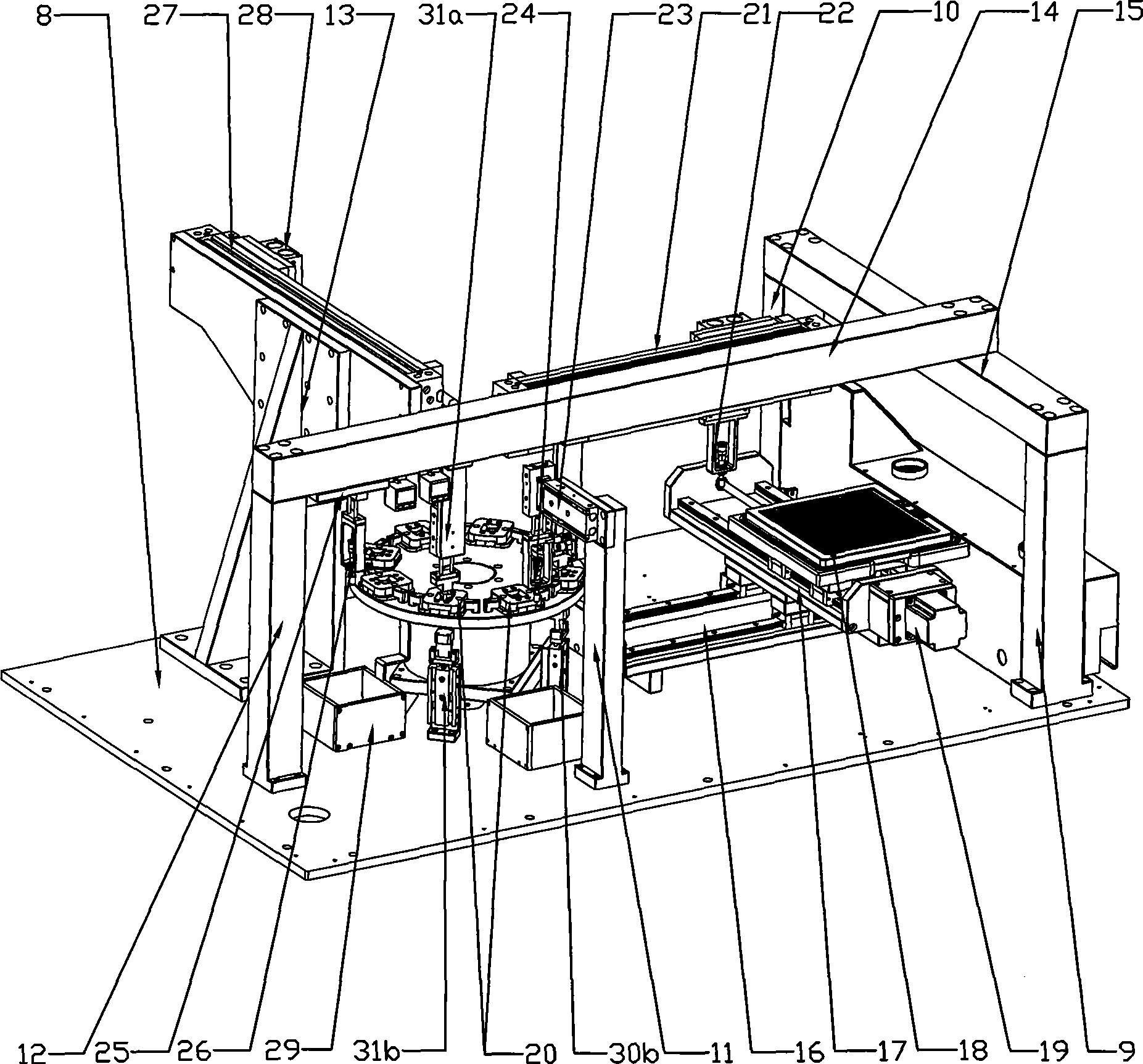

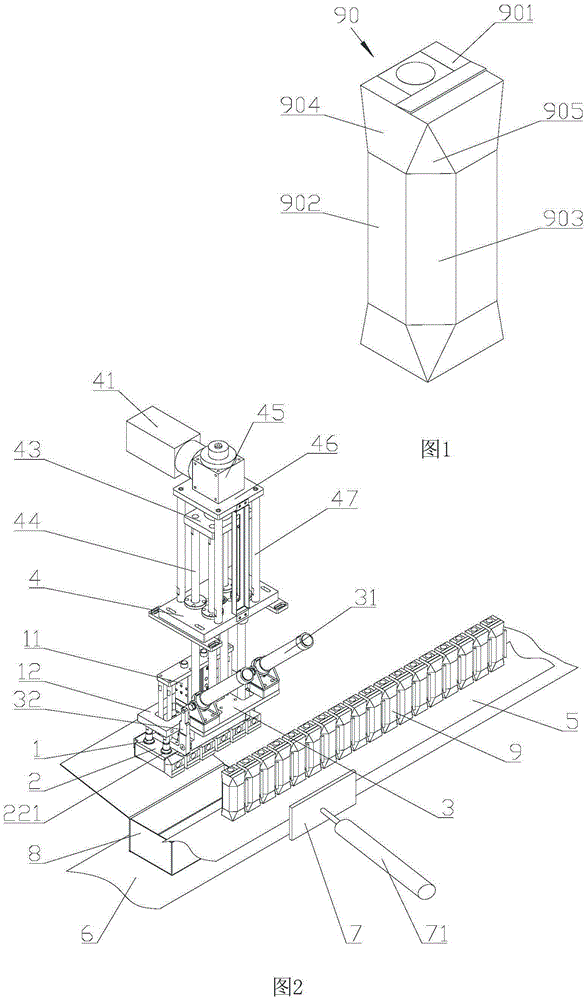

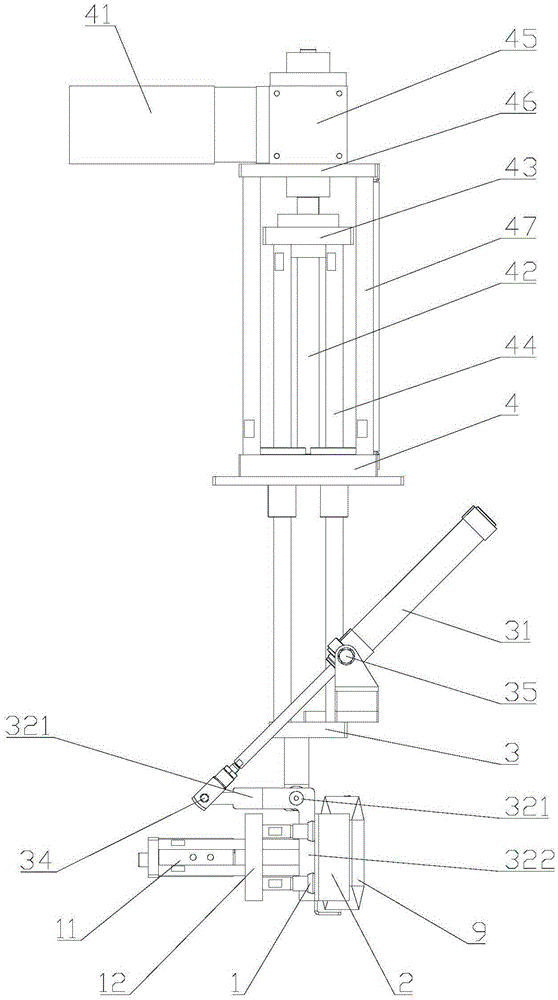

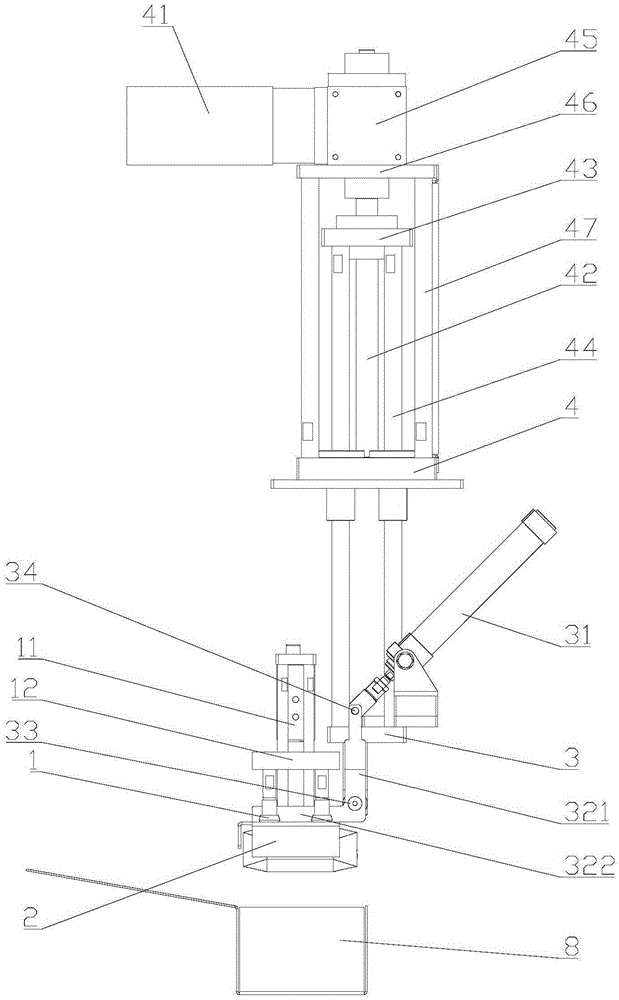

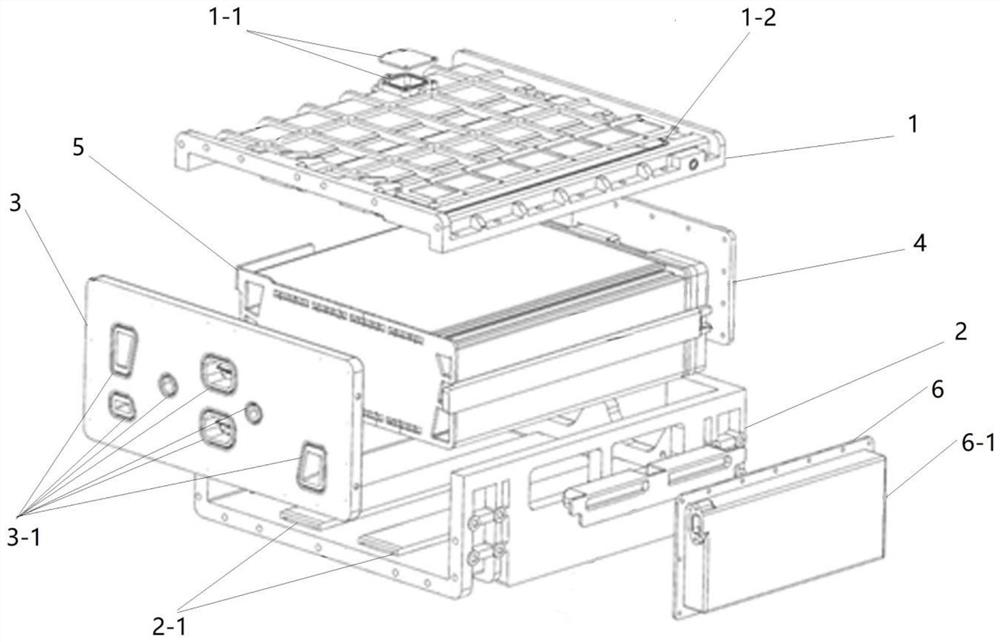

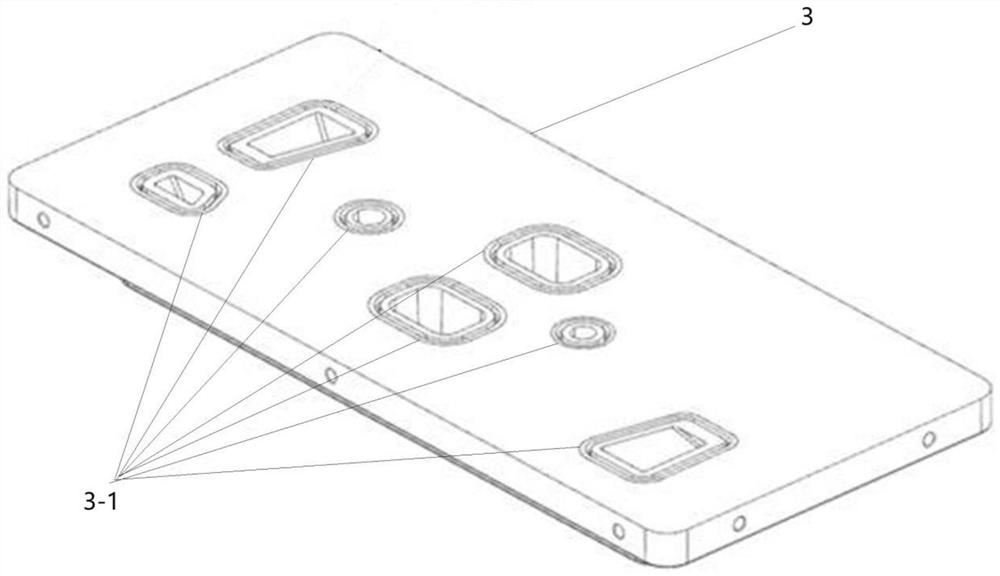

Automatic test packing machine for electronic component

ActiveCN101503125AGuarantee product qualityMeet needsSortingIndividual articlesEngineeringElectronic component

The invention discloses a machine for automatic testing and packing of electronic devices and components, which features high degree of automation and efficiency as well as compact structure. The machine comprises a protective cabinet (1) and an electric cabinet (2), wherein, the upper end surface of the protective cabinet (1) is provided with an automatic testing device and a finished product packing device which are used for carrying out the work procedures such as testing, processing unqualified products, packing finished products and the like on the electronic devices and components; the work procedures are tight and ordered, and have the advantages of high degree of automation and efficiency as well as rapid package. The machine can be widely applied to the field of testing and packing of the electronic devices and components.

Owner:珠海市运泰利自动化设备有限公司

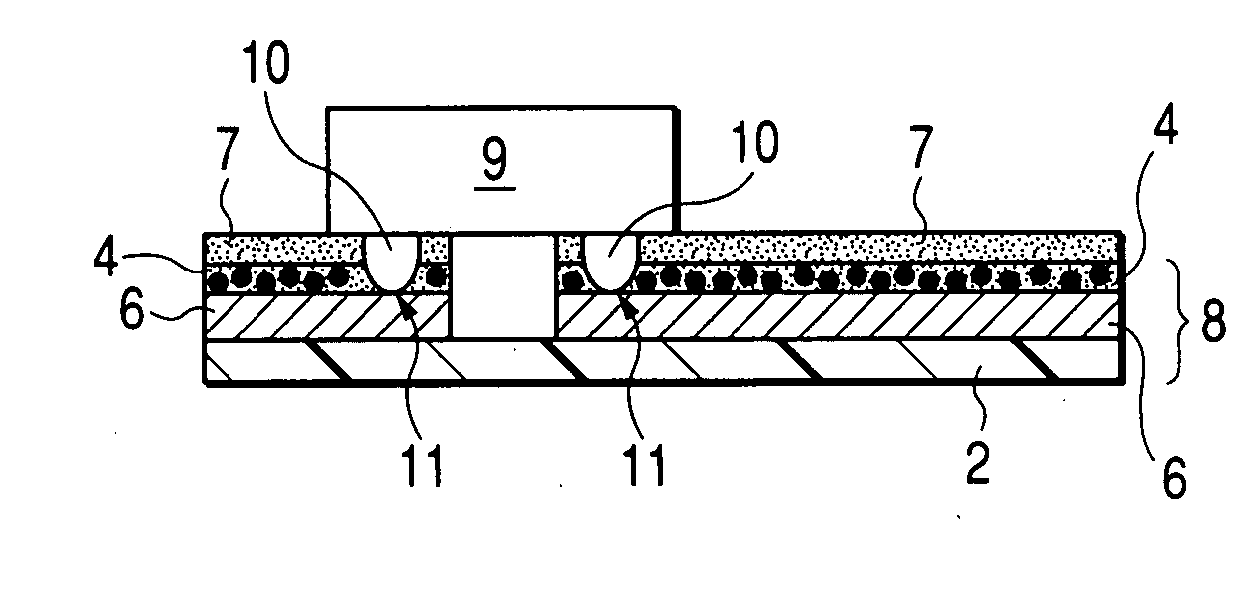

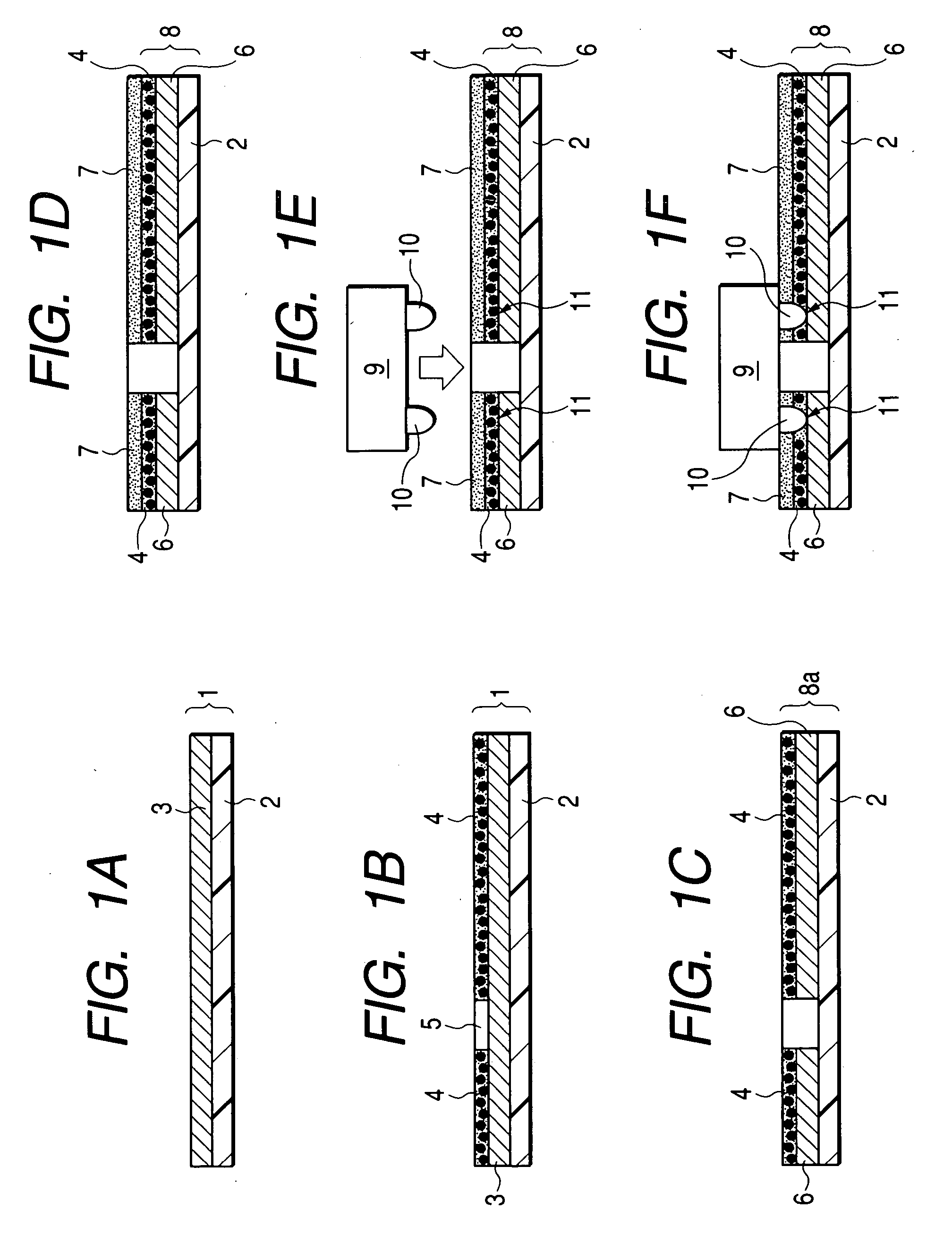

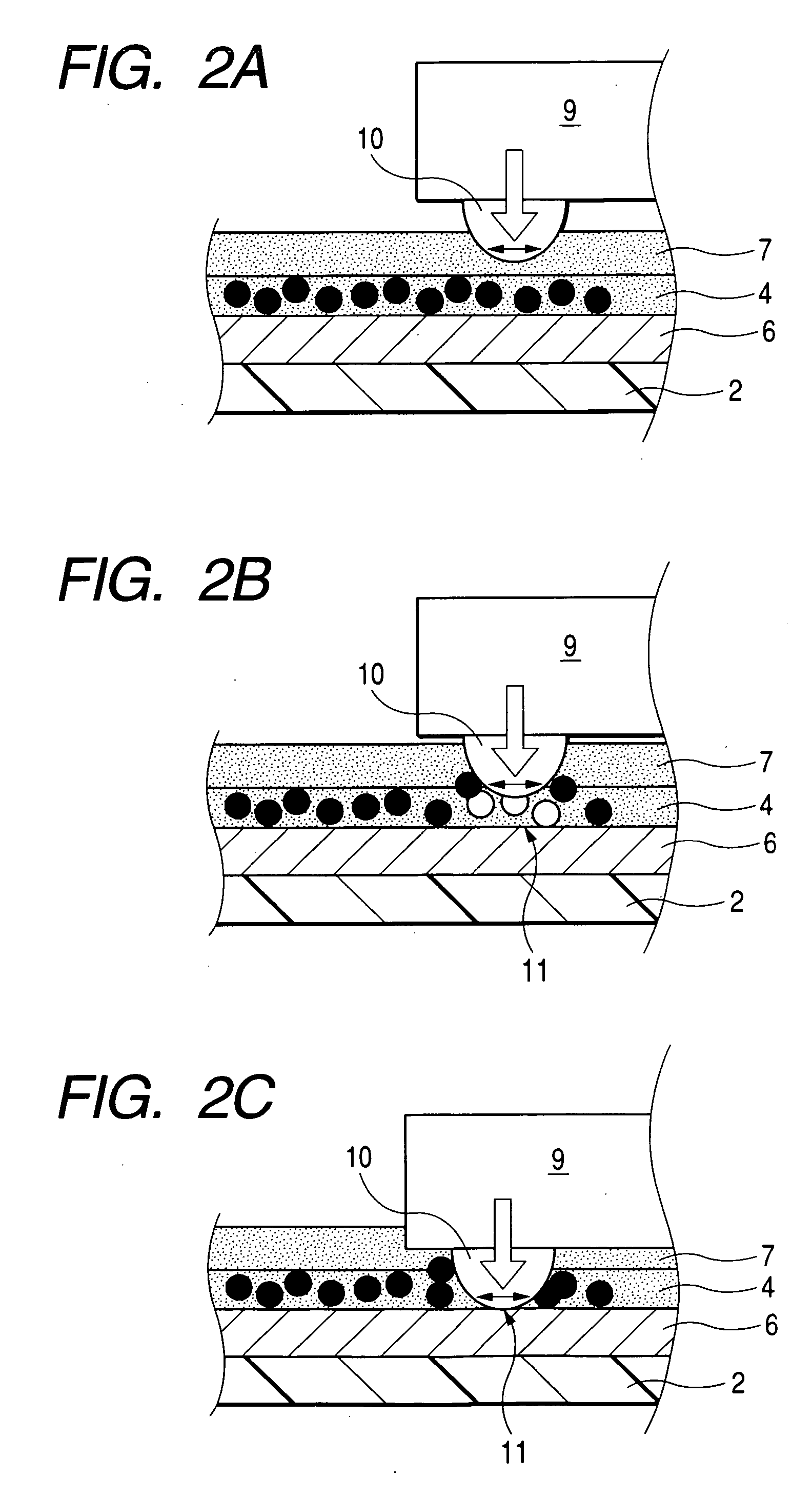

Manufacturing method for electronic component module and electromagnetically readable data carrier

InactiveUS20040112636A1Low costPrevent a short-circuit from occurringPrinted circuit assemblingSemiconductor/solid-state device detailsThermoplasticComputer module

A semiconductor bear chip having a bump subjected to high temperatures is pressed, from the upper side, onto a wiring board including a wiring pattern, a thermosetting resin film covering an electrode area on the wiring pattern and having insulating particles dispersed and included and a thermoplastic resin film covering the thermosetting resin film, while applying a ultrasonic wave, thereby inserting the bumps of the semiconductor bear chip through the thermoplastic resin film and the thermosetting resin film to bond the top end portion of the bump with the electrode area.

Owner:ORMON CORP

Product conveying and carrying device

ActiveCN105416634AGuaranteed adsorption effectImprove efficiencyIndividual articlesReciprocating motionDiamond

The invention discloses a product conveying and carrying device, belongs to the field of packing machinery, and solves the problem of manual container loading and transportation of diamond package products in the prior art. The product conveying and carrying device mainly comprises a conveying mechanism and a carrying mechanism; the conveying mechanism includes a product conveying line; the carrying mechanism is positioned at one side of the product conveying line, and includes a lifting part, a turnover part and a package sucking part; the turnover part is connected with a moving end of the lifting part; the package sucking part includes a sucker and a sucker drive; the sucker drive is fixed at an output end of the turnover part; the sucker is fixed at an output end of the sucker drive; the sucker drive drives the sucker to perform a linear reciprocating motion perpendicular to the conveying direction of the production conveying line; and the linear reciprocating motion range of the sucker is intersected with the operation range of the product conveying line. The product conveying and carrying device is mainly applied to automatic transportation and container loading of the diamond package products.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

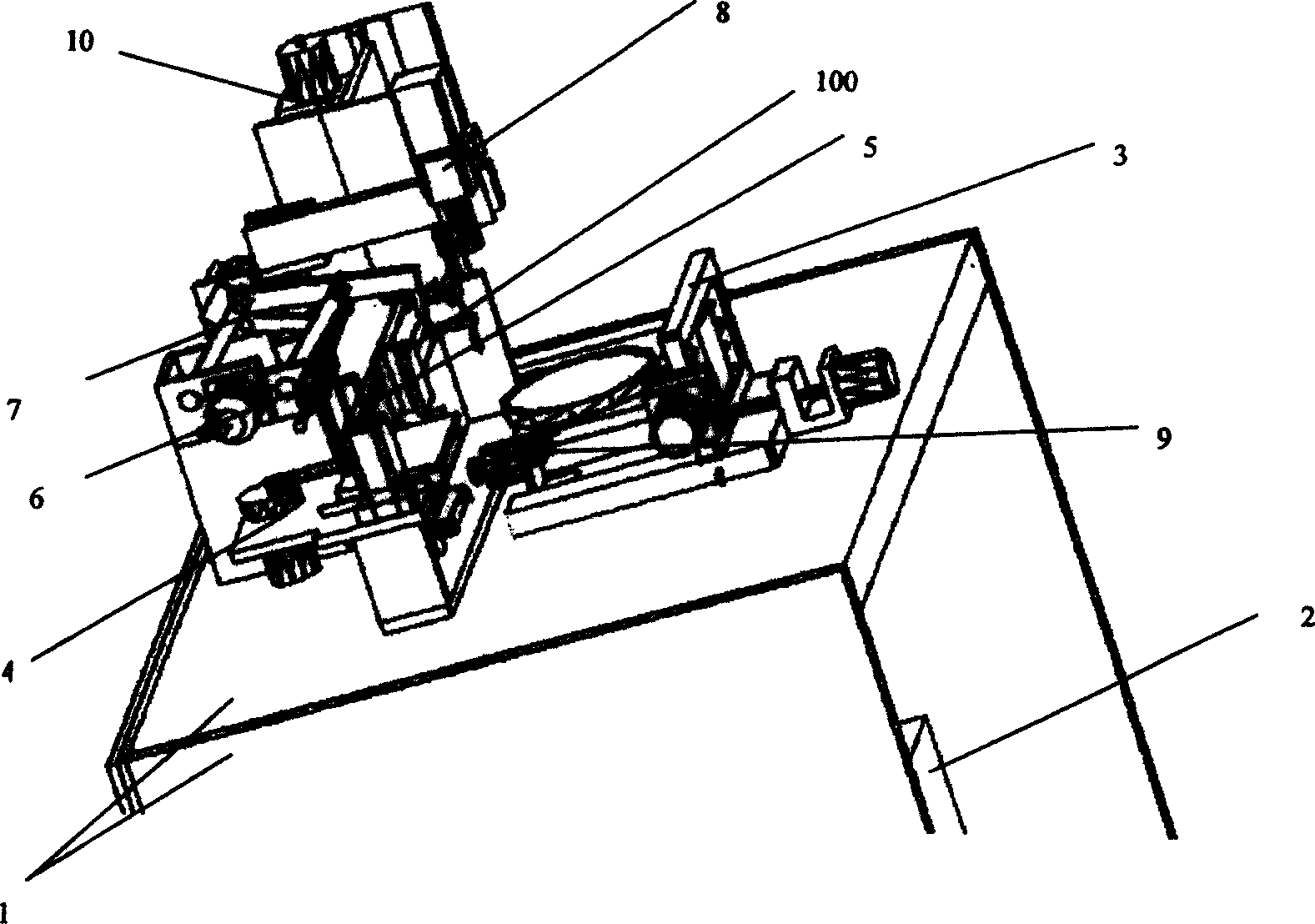

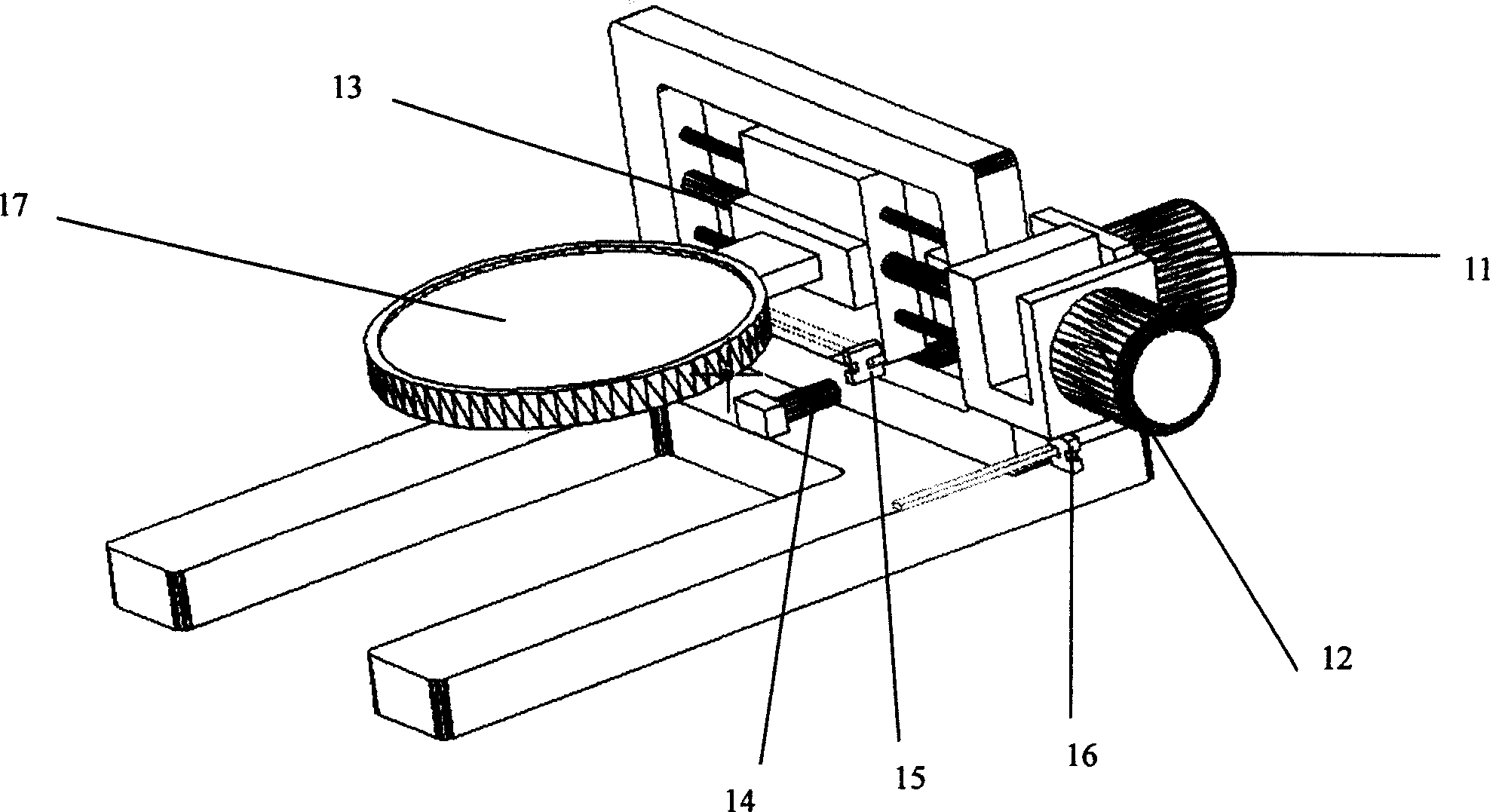

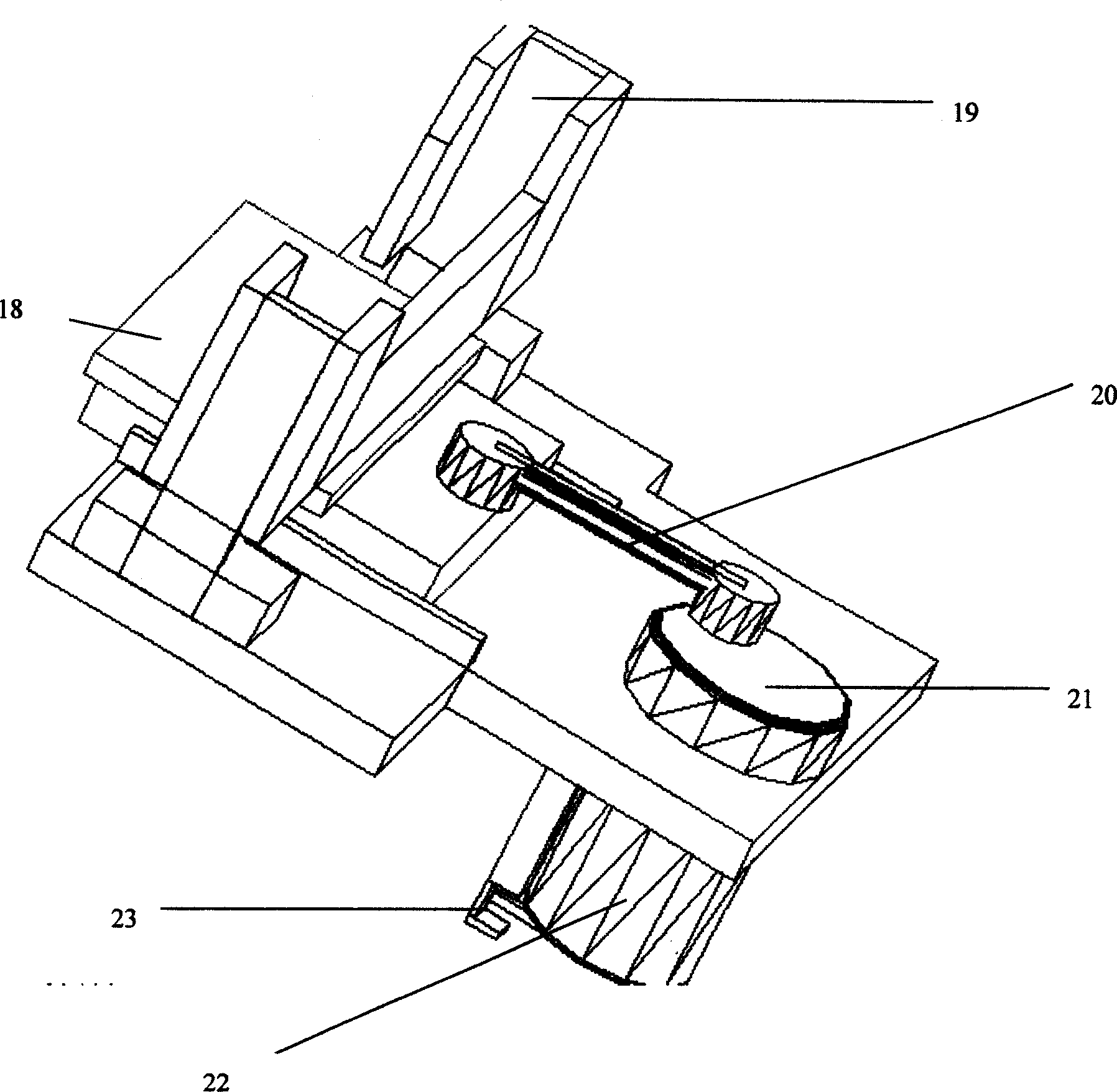

Automatic chip feeder and control thereof

InactiveCN1747142AAvoid stabilitySpeed blockSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingControl systemAgricultural engineering

The die bonder includes a machine frame. A control box is located at lower end of machine frame, and wafer bed and chute feeder are located on top of it. Under the wafer bed, the thimble is mounted. At the both ends of chute feeder, the loader and lay off machine are separately connected, and the claw and welding arm are also connected. The image collection device is located above it, and a heater is located under it. The image collection device is connected with the control circuit in the control box.

Owner:SOUTH CHINA UNIV OF TECH

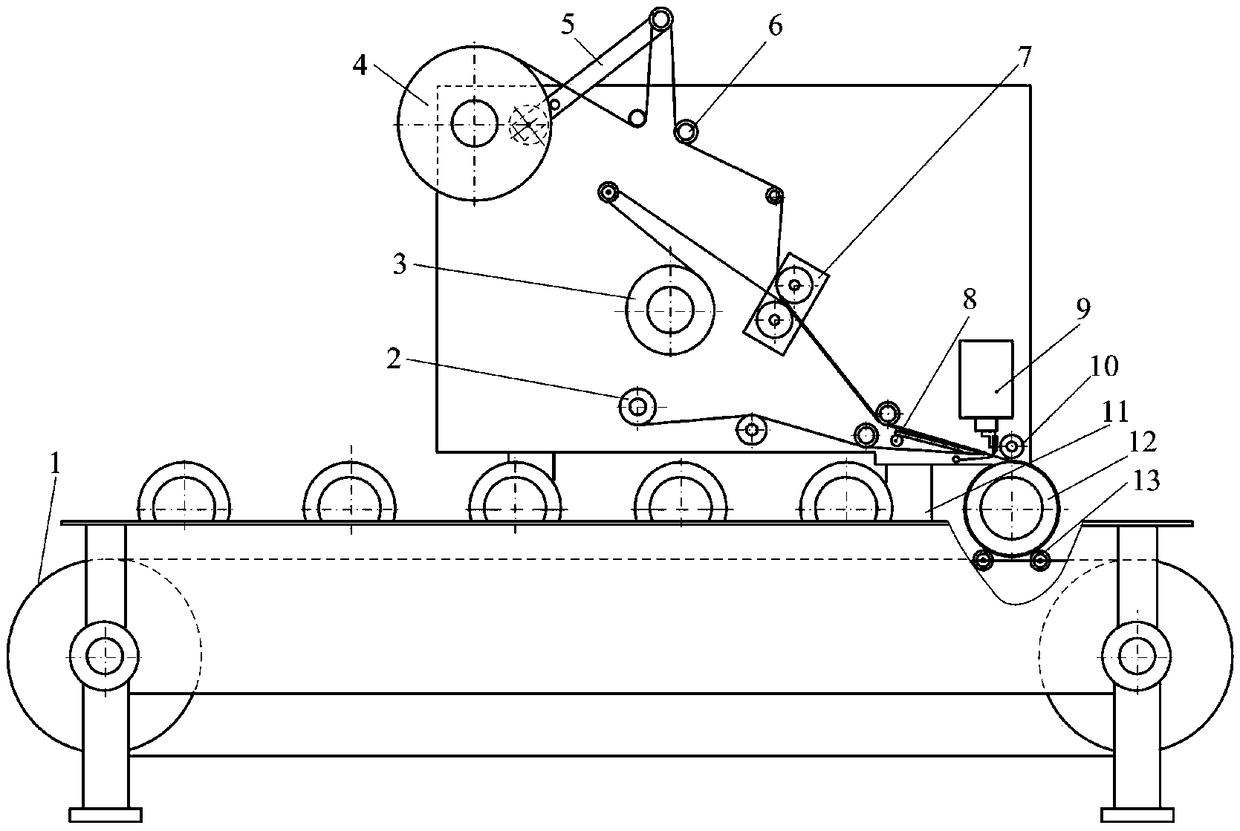

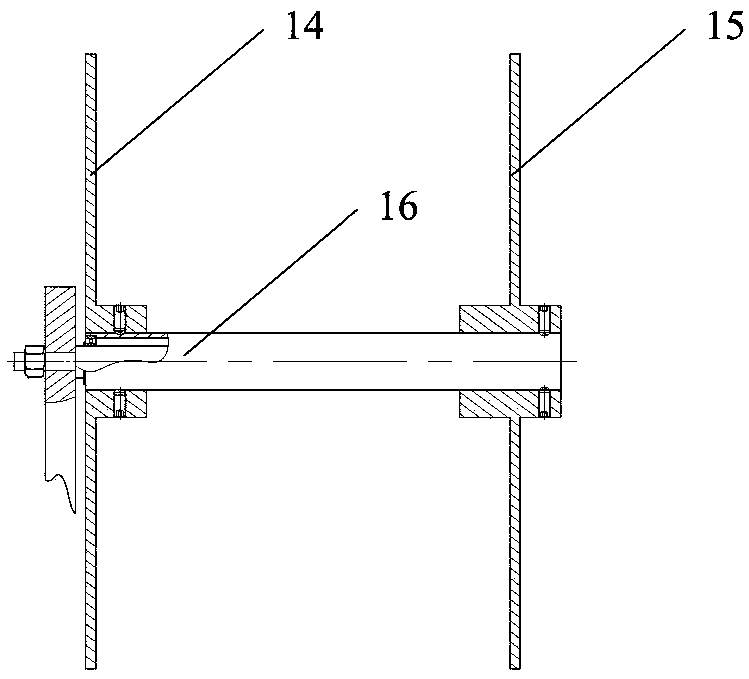

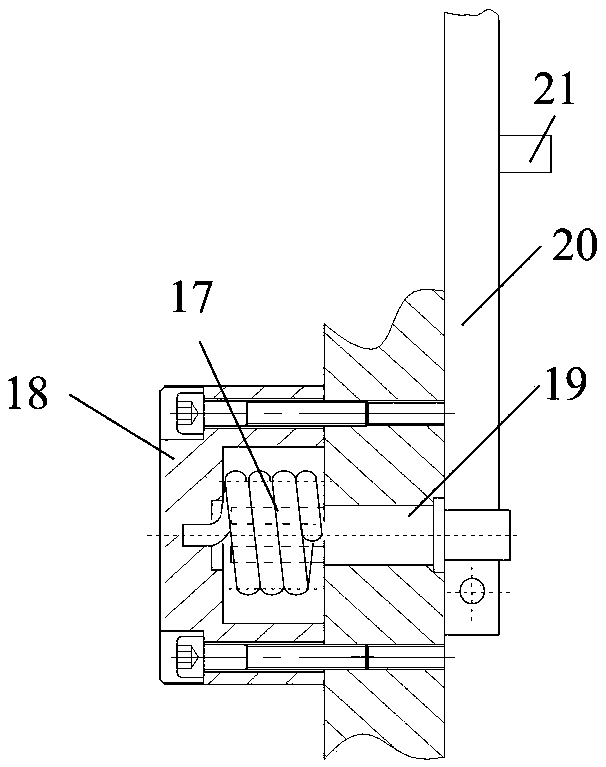

Waterproof coil winding and cutting process system capable of realizing effective alignment

InactiveCN105858303ACorrect deviationImprove packaging qualityWebs handlingProcess systemsEngineering

The invention relates to the field of waterproof coiled material production, in particular to an effectively aligned waterproof coiled material winding and cutting process system, including a deviation correcting device and a winding and cutting device arranged at the rear end of the deviation correcting device. Deviation correction device, through the cooperation of coarse adjustment screw and fine adjustment screw, the deviation correction device can realize accurate deviation correction of waterproof coiled material. The winding and cutting device can accurately control the winding length. Tape-encapsulate the coiled material quickly while rewinding, with a high degree of automation, which improves the packaging quality of the coiled material and improves production efficiency.

Owner:TIANJIN YUSHEN BUILDING WATERPROOF MATERIAL

Environment-friendly type water-based pickling agent

The invention discloses an environment-friendly type water-based pickling agent. The environment-friendly type water-based pickling agent is characterized by comprising the following raw materials including, by weight percentage, 50%-80% of pure water, 15%-49% of organic acid and 1%-5% of surface active agent. According to the environment-friendly water-based pickling agent, the formula is simple, and the environment-friendly type water-based pickling agent is compounded from the organic acid and the biodegradable surface active agent; after use, an appropriate amount of alkali can be added to the environment-friendly type water-based pickling agent so that the environment-friendly type water-based pickling agent can be neutralized to be neutral, and then the environment-friendly type water-based pickling agent is directly discharged to a sewer; and in this way, bio-concentration, the increase of COD and other hazards are avoided, the water-based pickling agent is environmentally friendly and does not need independent treatment, and the use cost of an enterprise is reduced.

Owner:TIANJIN PRIMETECH CHEM

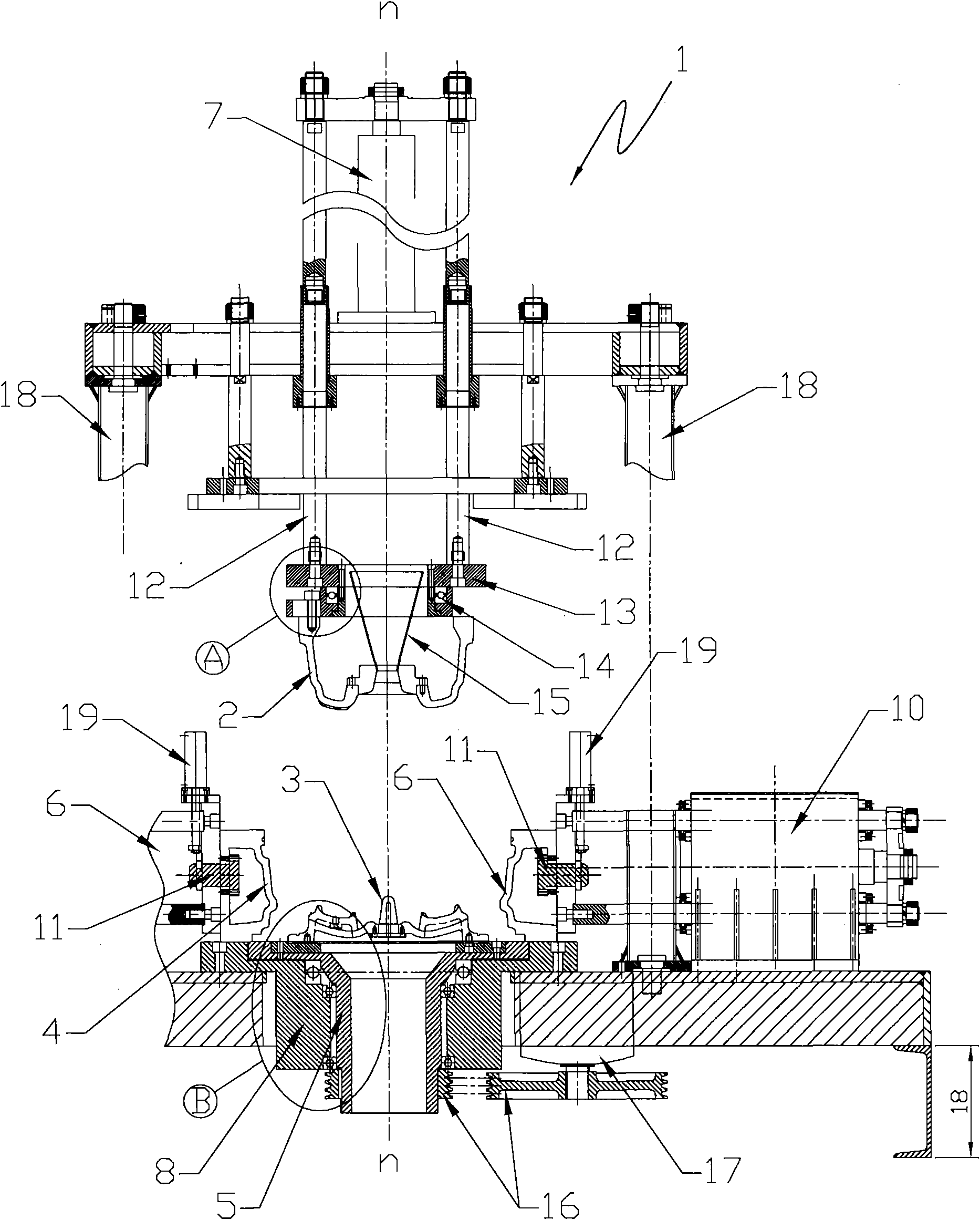

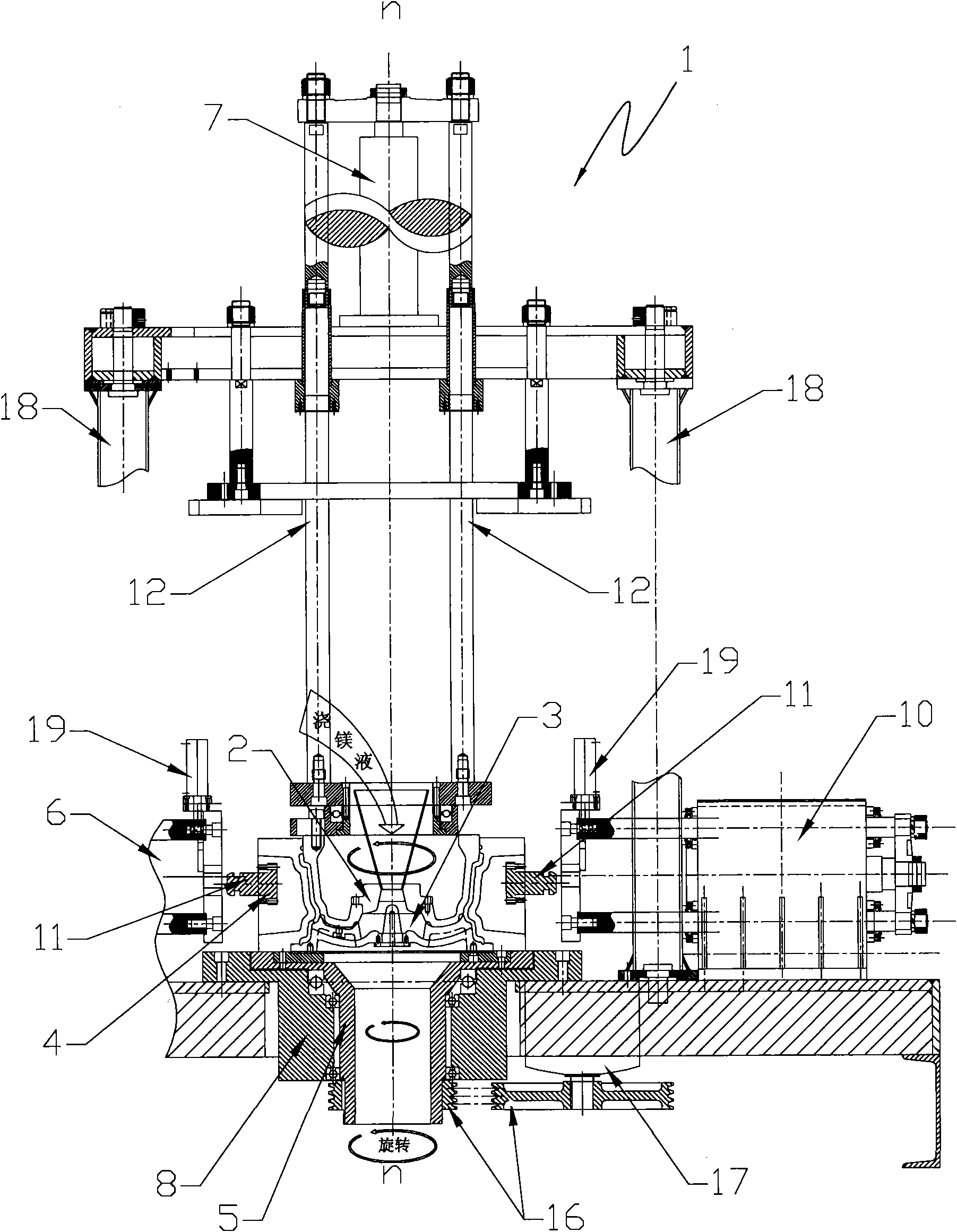

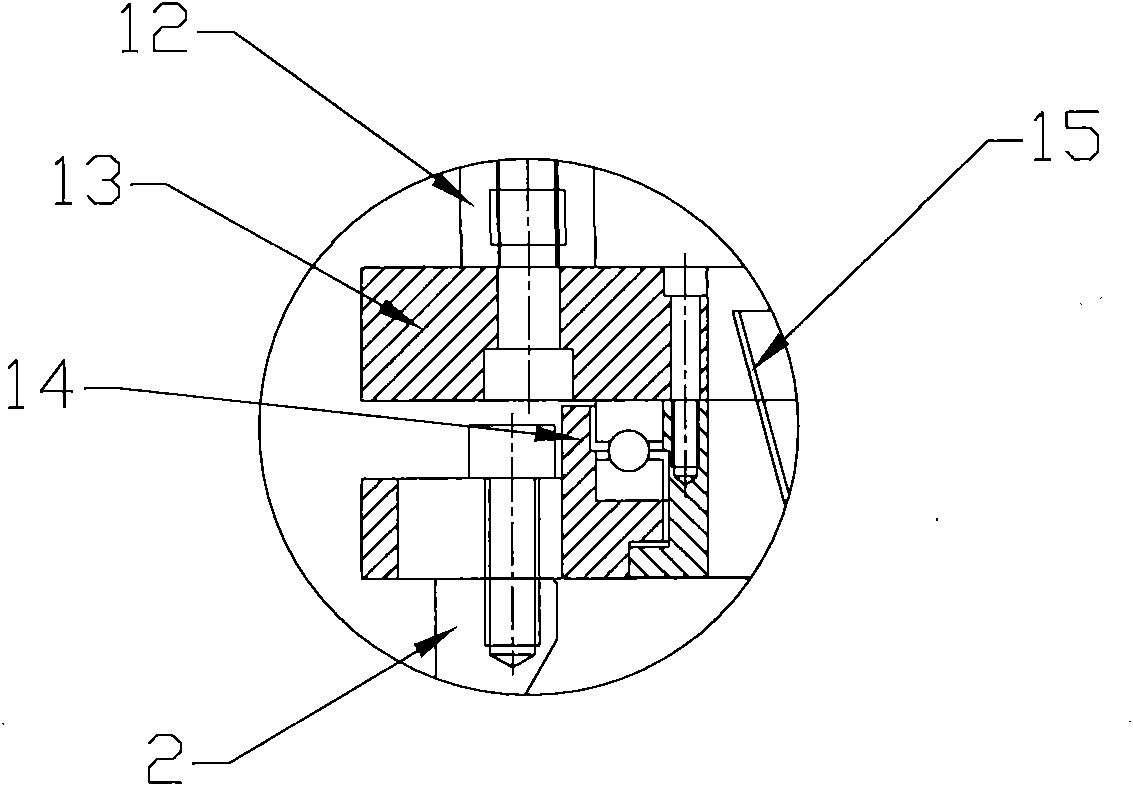

Centrifugal casting method and device of magnesium alloy hub

The invention relates to a centrifugal casting method of a magnesium alloy hub, which belongs to the technical field of casting. The prior gravity and low-pressure casting method for casting the magnesium alloy hub exists the easily occurred casting defects of incompleteness of mould filling, shrinkage cavity, cold shut, hot cracking, shrinkage cracking, and the like. An upper die, a side die and a lower die of a die are matched and then held into a whole, then gravity center casting is carried out for the matched die, the die is enabled to rotate around the axes thereof for a set time and then stop before cast magnesium melt solidifies, the cast mode can be divided into casting before die rotating and casting after die rotating according to the technological requirements of concrete products, and the die is opened to take out a cast after the magnesium alloy melt solidifies. With the method, the magnesium melt in the die can rapidly fill shrinkage towards peripheral parts under the action of centrifugal force to enable cast products to be full and compact, and the method has the advantages of low production rejection rate, compact structure of casts, improvement of quality of workpieces, and the like.

Owner:SHANGHAI MERIDIAN MAGNESIUM PROD CO LTD

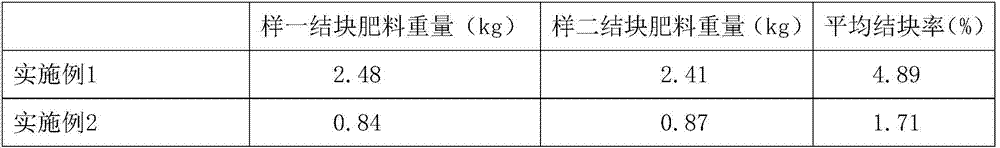

Method for preventing fertilizer agglomeration

InactiveCN107151186ALow costGood anti-knot effectLayered/coated fertilisersFertilizer mixturesFertilizerChemistry

The invention relates to a method for preventing fertilizer agglomeration. A paste fertilizer agglomeration prevention agent is added into a dissolution groove to be dissolved; the dissolved paste fertilizer agglomeration prevention agent is sprayed onto the surface of the fertilizer after the atomization; after the uniform coating, insert powder is added. The treated fertilizer can be stored for 4 to 6 months without agglomeration.

Owner:烟台市昊星晟信息技术有限公司

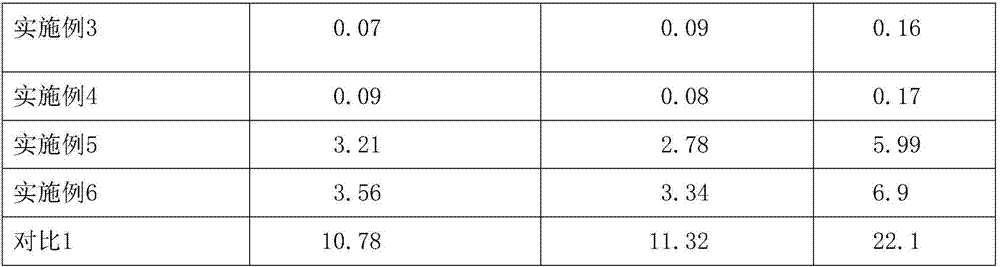

Rapidly packaged double-sided soft lithium-air battery and preparation method thereof

ActiveCN106784422AQuick sealGood sealingFuel and secondary cellsElectrode carriers/collectorsLithium–air batteryPressure sensitive

The invention discloses a rapidly packaged double-sided soft lithium-air battery and a preparation method thereof. An upper gas-permeable membrane, an upper pressure sensitive adhesive layer, an upper anode current collector, a first anode material, a first diaphragm, a lithium cathode, a second diaphragm, a second anode material, a lower anode current collector, a lower pressure sensitive adhesive layer and a lower gas-permeable membrane are sequentially laminated, filled with electrolyte and packaged to form the battery. Compared with the prior art, the battery is rapidly packaged by directly adhering the edge of the upper pressure sensitive adhesive layer with the edge of the lower pressure sensitive adhesive layer without heat sealing. In addition, the gas-permeable membranes and the anode current collectors are closely fitted together, so that the lithium-air battery has the advantages of uniform reaction, high specific energy, good consistency and the like.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Adjustable sensor for sensing a level of liquid

A liquid level sensing device for sensing liquid in a container. The liquid level sensing device has a base and a rotatable member which extends from and is rotatable relative to the base. A cord extends from the rotatable member and has a sensor provided at a free end thereof. The sensor may be accurately positioned at various heights relative to a bottom of the container to allow a user to fill the container with the liquid to the desired level. An alarm and a signal transmitter are provided in electrical communication with the sensor, such that as a liquid is introduced to the container, the alarm and the signal transmitter will be activated when the level of the liquid reaches the sensor.

Owner:SHERRON MARK

High-pressure hub casting mold and casting method thereof

PendingCN108543914AIncrease profitIncrease productivityFoundry mouldsFoundry coresCasting moldHigh pressure

The invention provides a high-pressure hub casting mold. The high-pressure hub casting mold comprises an upper mold body, a side mold body, a bottom mold body and a gas pressurization system, whereinthe upper mold body, the side mold body and the bottom mold body form a casting cavity for a hub to be cast after being assembled; the center of the upper mold body is connected with a liquid storagehopper; a metal liquid storage chamber communicating with the casting cavity is formed in the liquid storage hopper; the gas pressurization system is connected with the liquid storage hopper through aventilation pipe and communicates with the metal liquid storage chamber; the side mold body is provided with a runner, and a pouring gate is arranged at the outer end of the runner; and after metal liquid is poured into the casting cavity, the gas pressurization system is used for applying high pressure to the metal liquid in the metal liquid storage chamber, and the metal liquid in the metal liquid storage chamber carries out feeding on a hub casting in the casting cavity under the high pressure applied by the gas pressurization system. The high-pressure hub casting mold further comprises aheating system, a cooling system and a demolding system used for demolding the formed hub casting. According to the high-pressure hub casting mold, a working allowance is reserved for the casting, thedeformation amount of the casting is reduced, the production efficiency is improved, and the rejection rate is low.

Owner:田平康

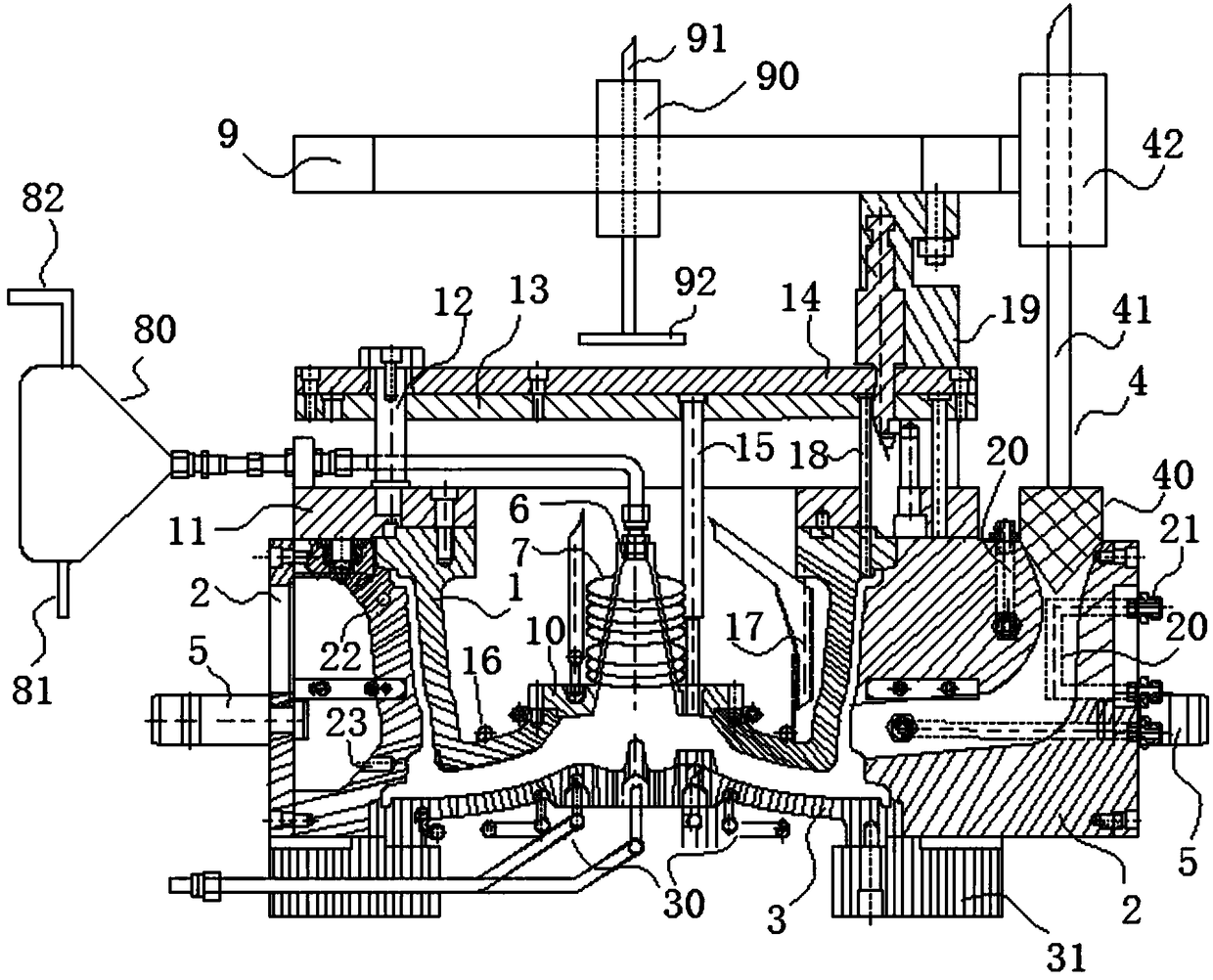

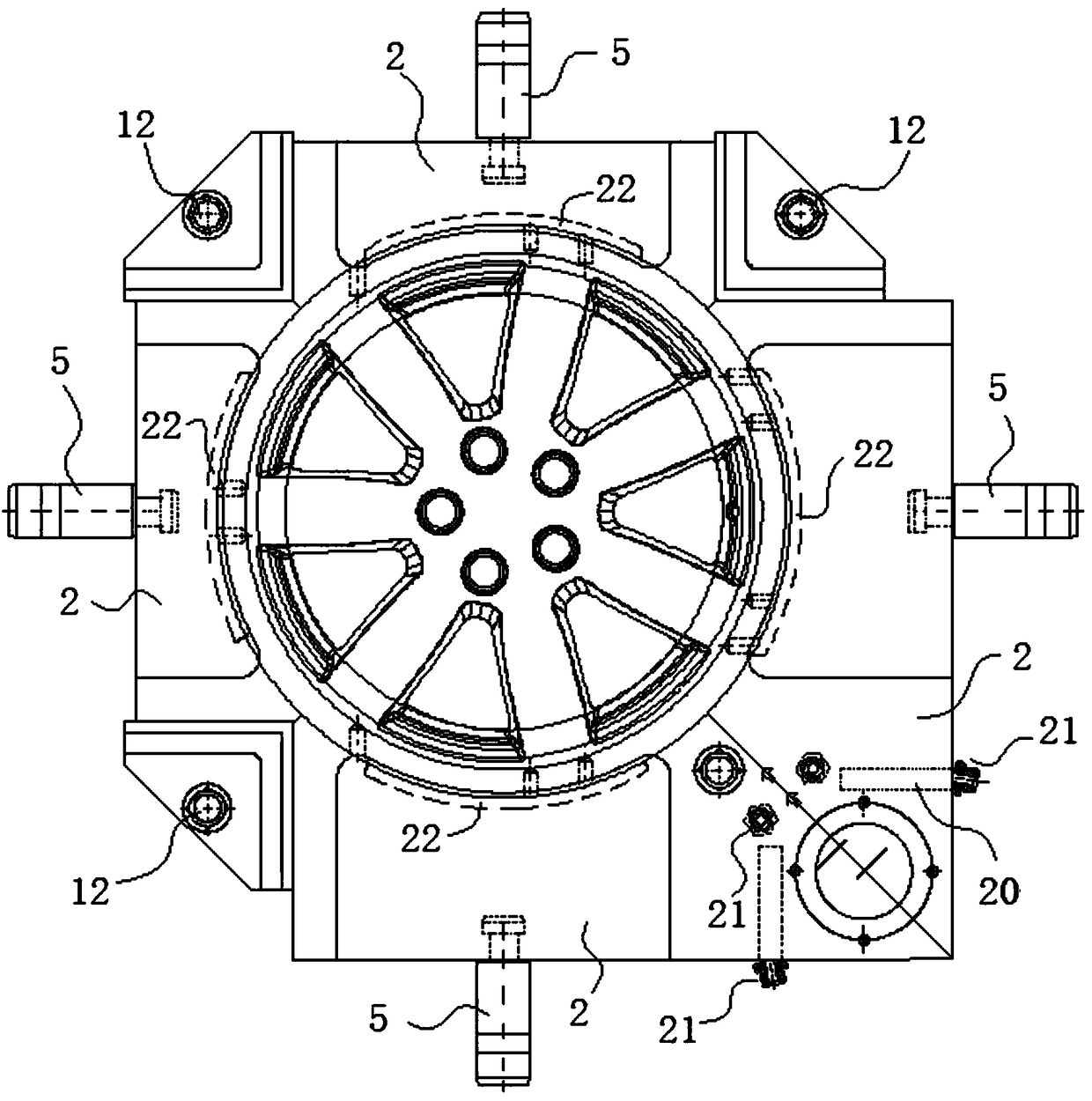

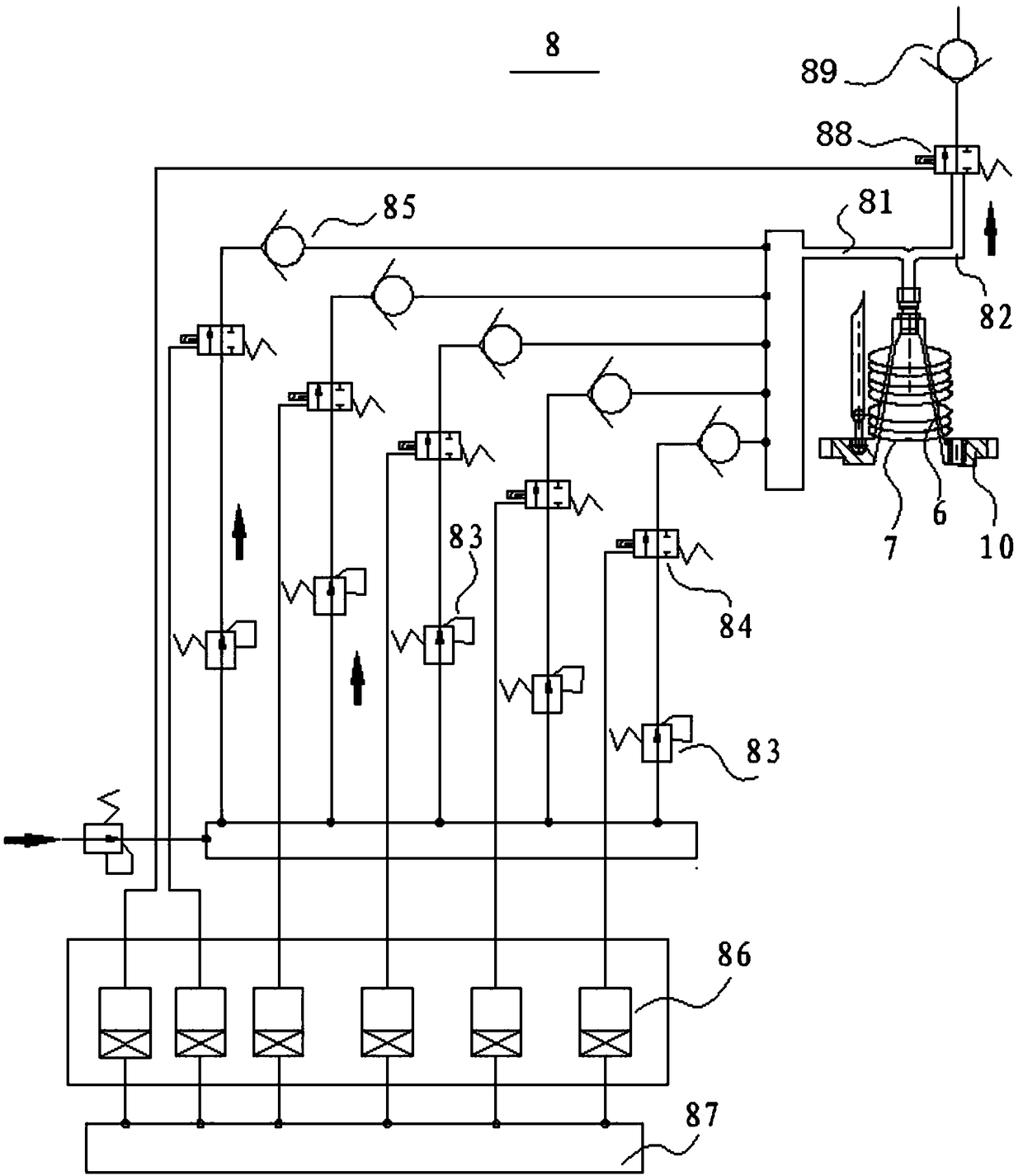

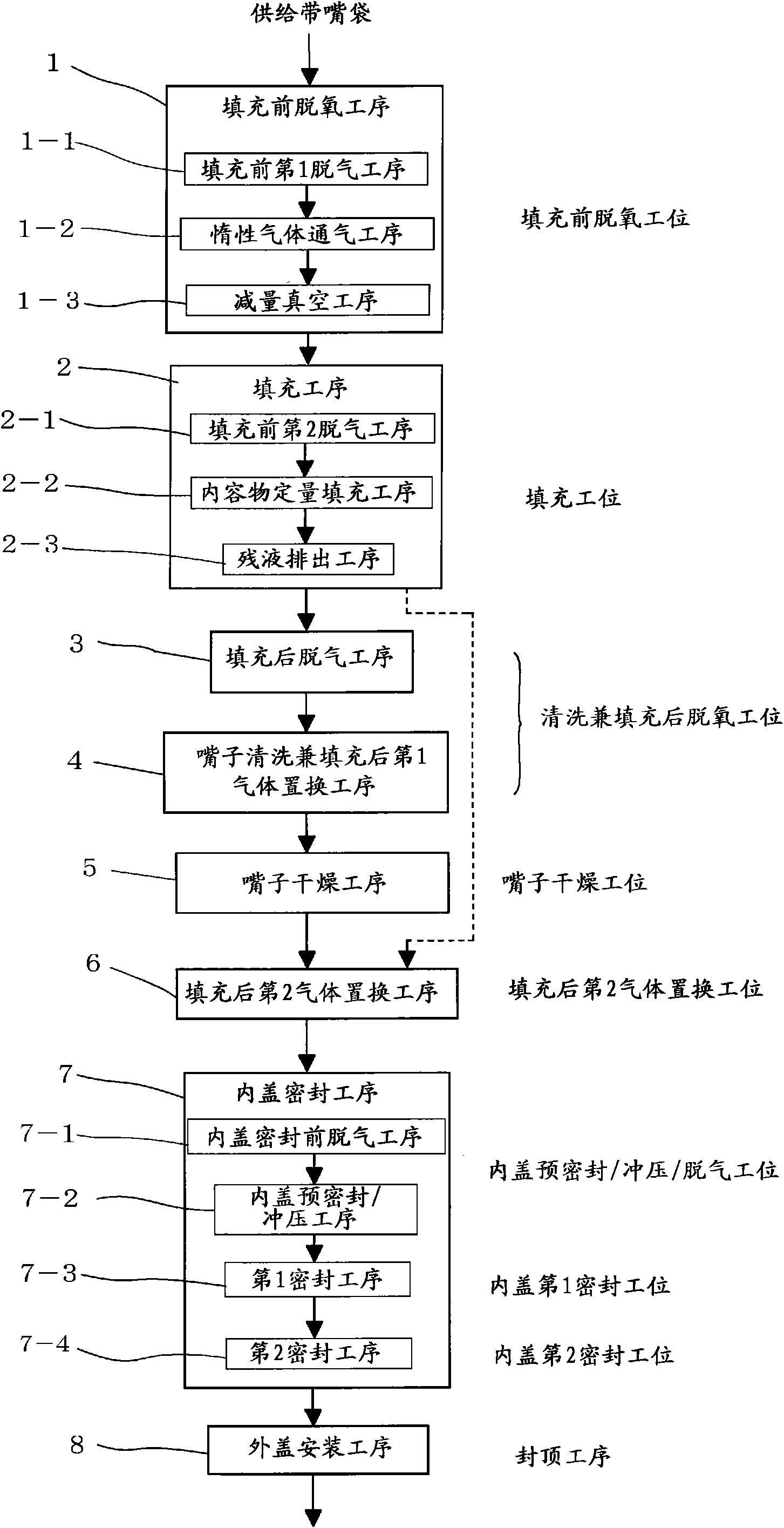

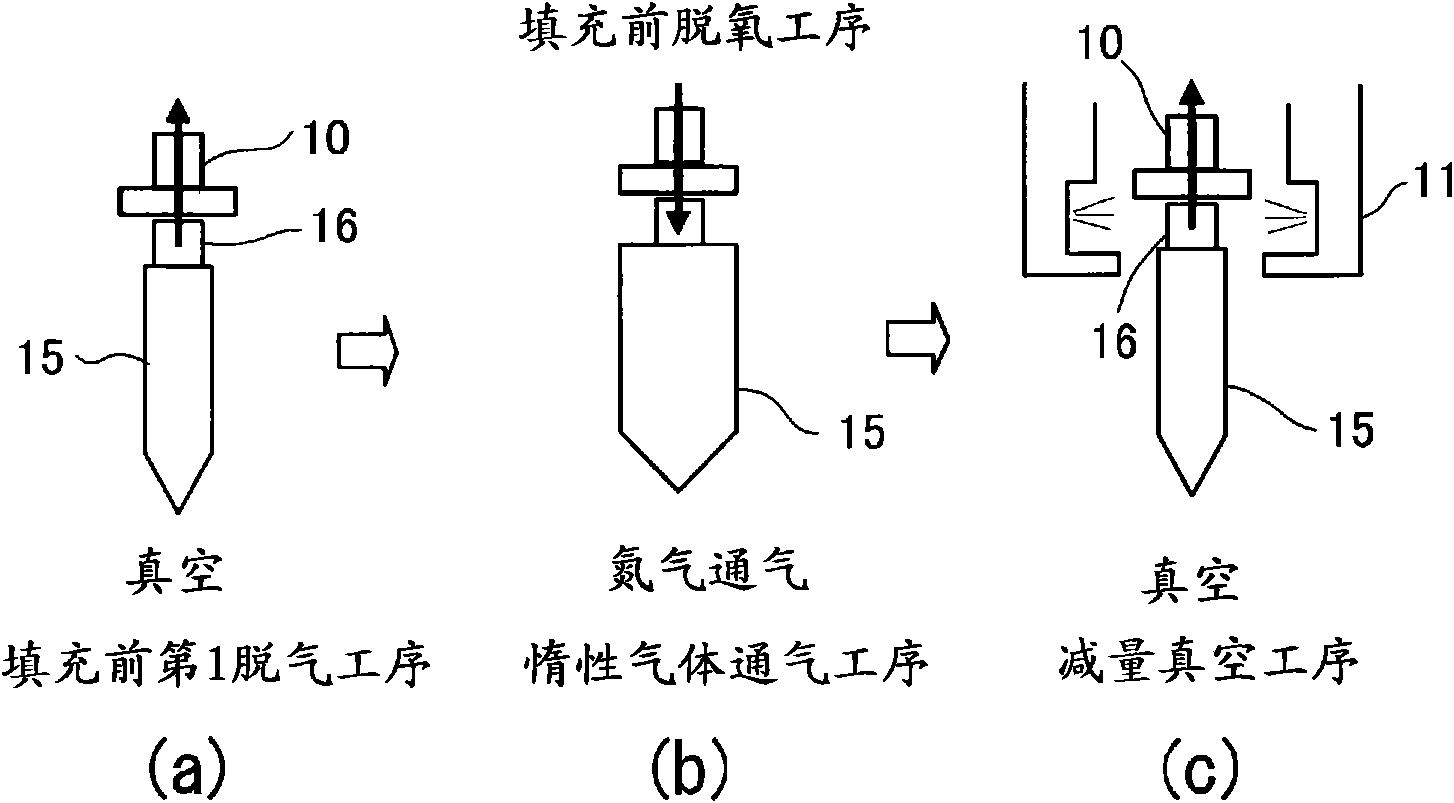

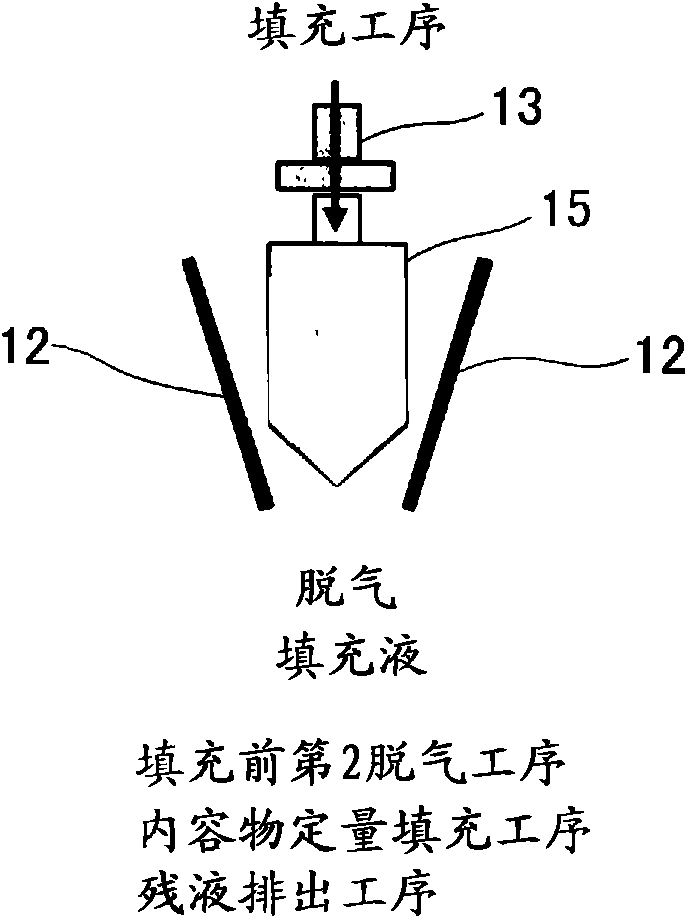

Method of packing liquid filling into spouted pouch and sealing the pouch and apparatus therefor

InactiveCN101588968AImprove qualityHigh deoxygenation ratePackaging by pressurising/gasifyingPackaging protectionLiquid stateProduct gas

To obtain a spouted-pouch package having a high degree of deoxidation by a method in which even a liquid filling which readily lathers can be packed while being inhibited from lathering. [MEANS FOR SOLVING PROBLEMS] A before-packing deoxidation step (1) is performed before a liquid filling is packed into a pouch. The step (1) comprises: a vacuum step (1-1) in which the pouch is evacuated under vacuum; an inert-gas blow step (1-2) in which an inert gas is blown into the pouch after the vacuum step; and a gas-diminishing vacuum step (1-3) in which the gas in the pouch after the inert-gas blow step is discharged under vacuum to diminish the gas in the pouch to a given amount. Thereafter, the pouch is evacuated in a second before-packing evacuation step (2-1) and then packed with the filling. After the packing, gas replacement is conducted.

Owner:TOYO SEIKAN KAISHA LTD

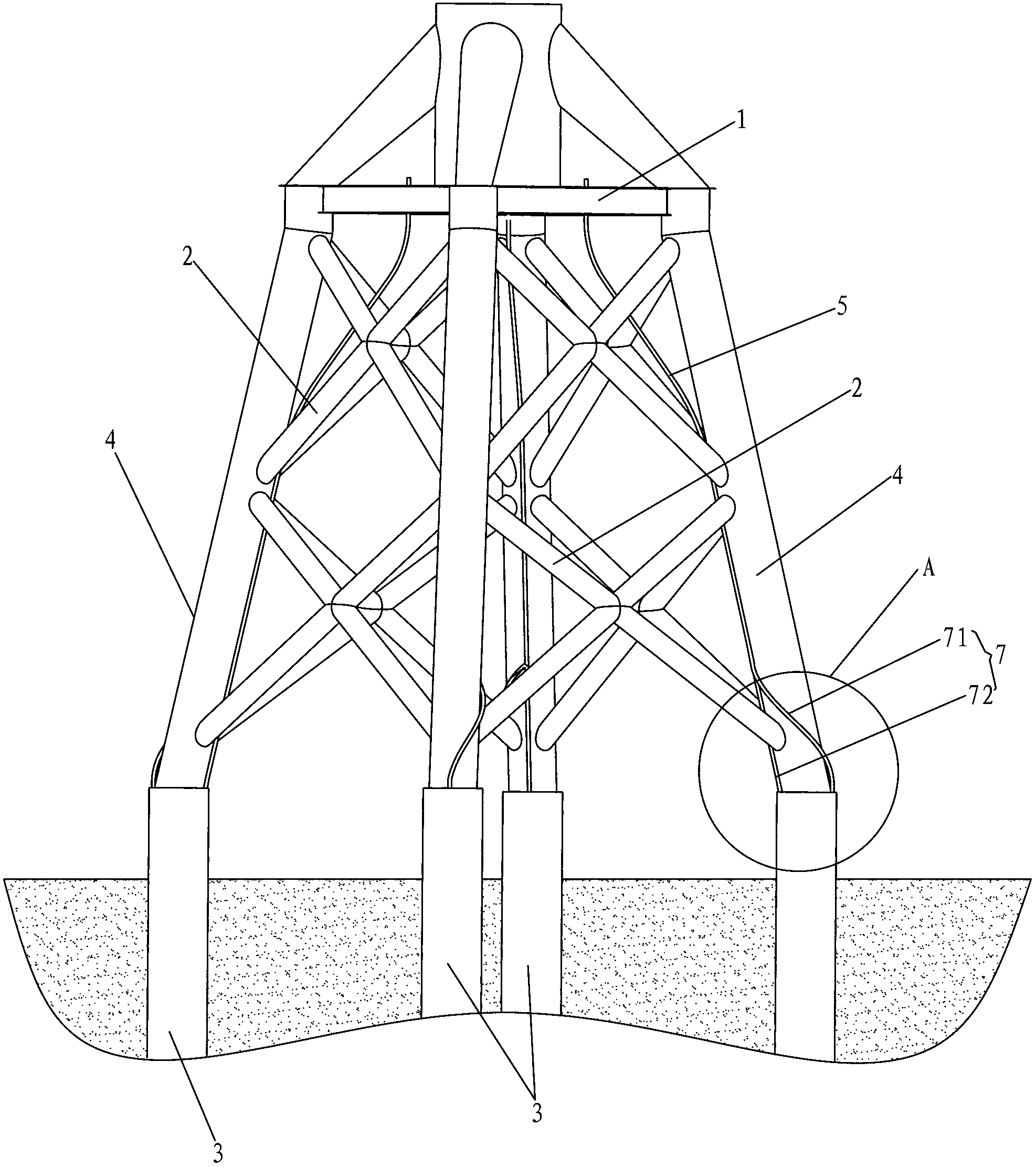

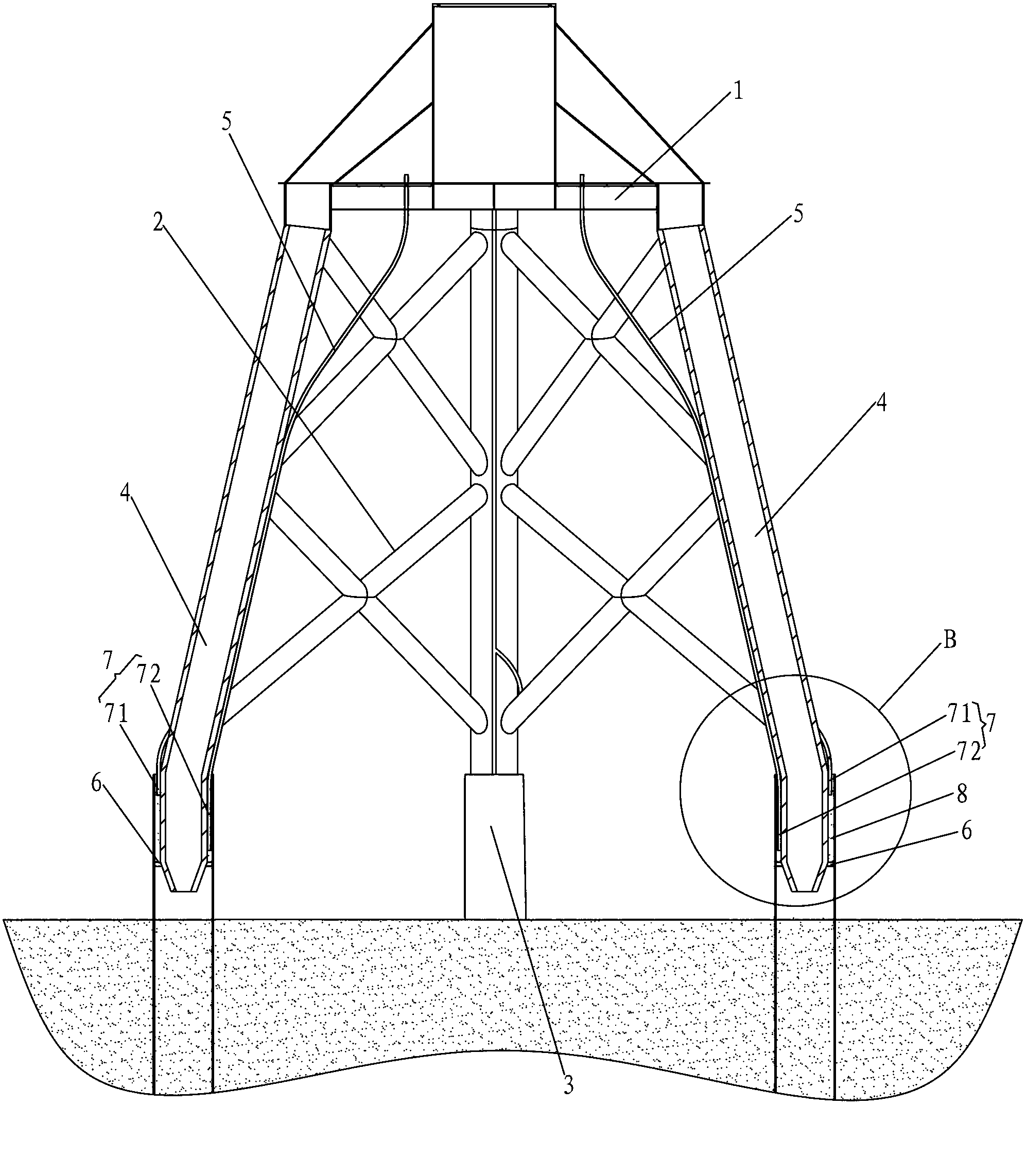

Jacket support structure capable of being connected through grouting

ActiveCN103233481ALess materialFirmly connectedArtificial islandsUnderwater structuresSlurryBuilding construction

The invention discloses a jacket support structure capable of being connected through grouting. A plurality of hollow steel piles are driven into a sea floor and fixed, grouting guide pipes are welded on jacket support legs, the upper end of the grouting guide pipe is arranged on a jacket platform, tail ends of jacket support legs are inserted in ports at the upper ends of the steel piles to form connection gaps, tail ends of grouting guide pipes are inserted into the connection gaps, constructors can guide concrete slurry into the connection gaps of the jacket support legs and the steel piles on the jacket platform by using the grouting guide pipes, reliable connection of the jacket support legs with the steel piles can be guaranteed, and the jacket support structure has the advantages of being low in construction cost, low in construction difficulty and convenient to operate.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

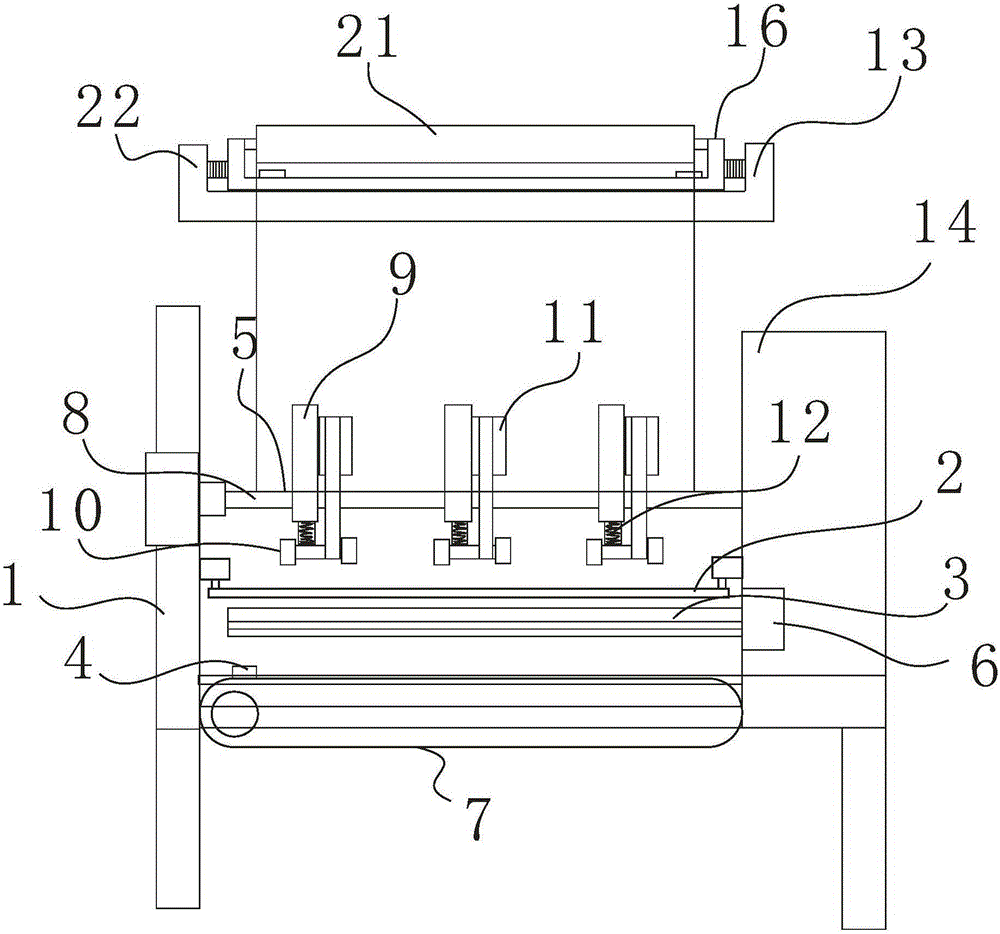

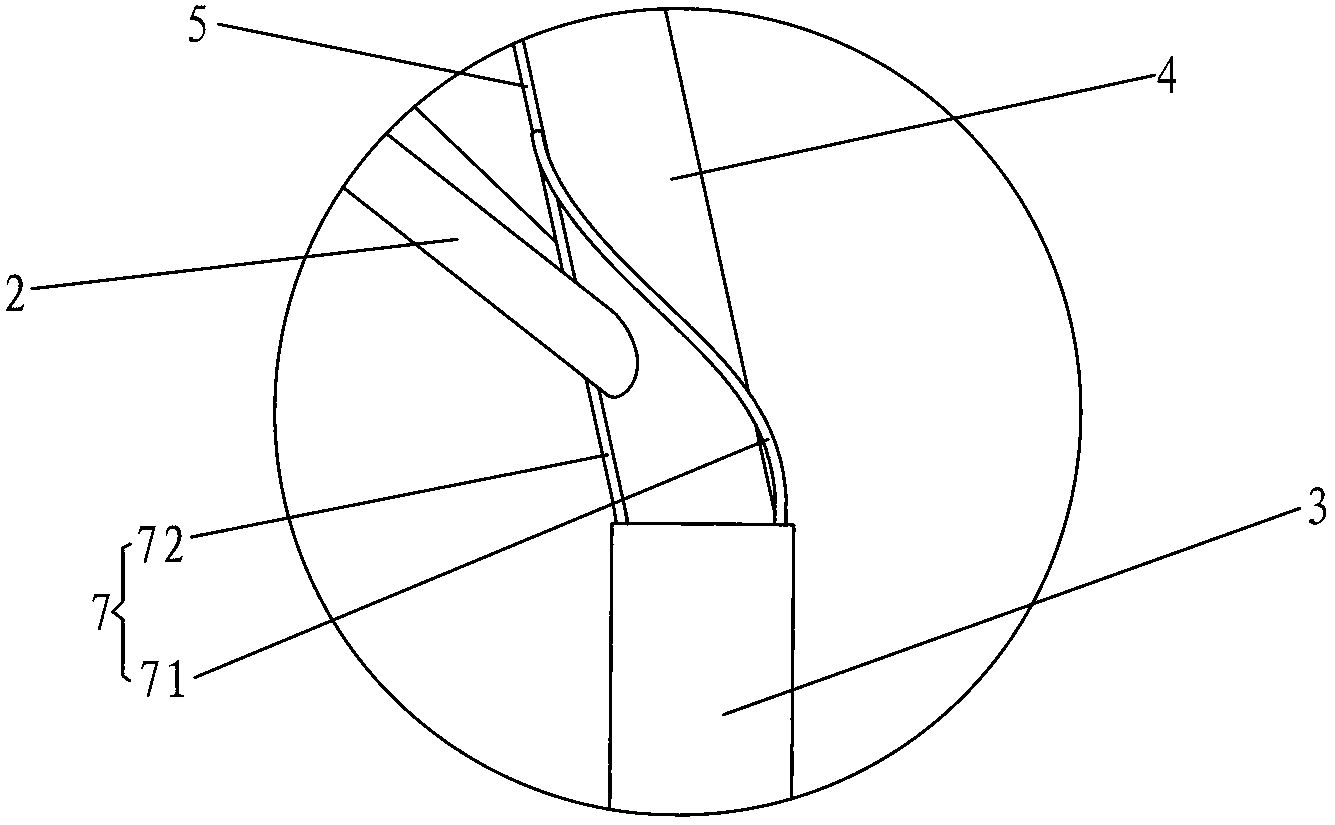

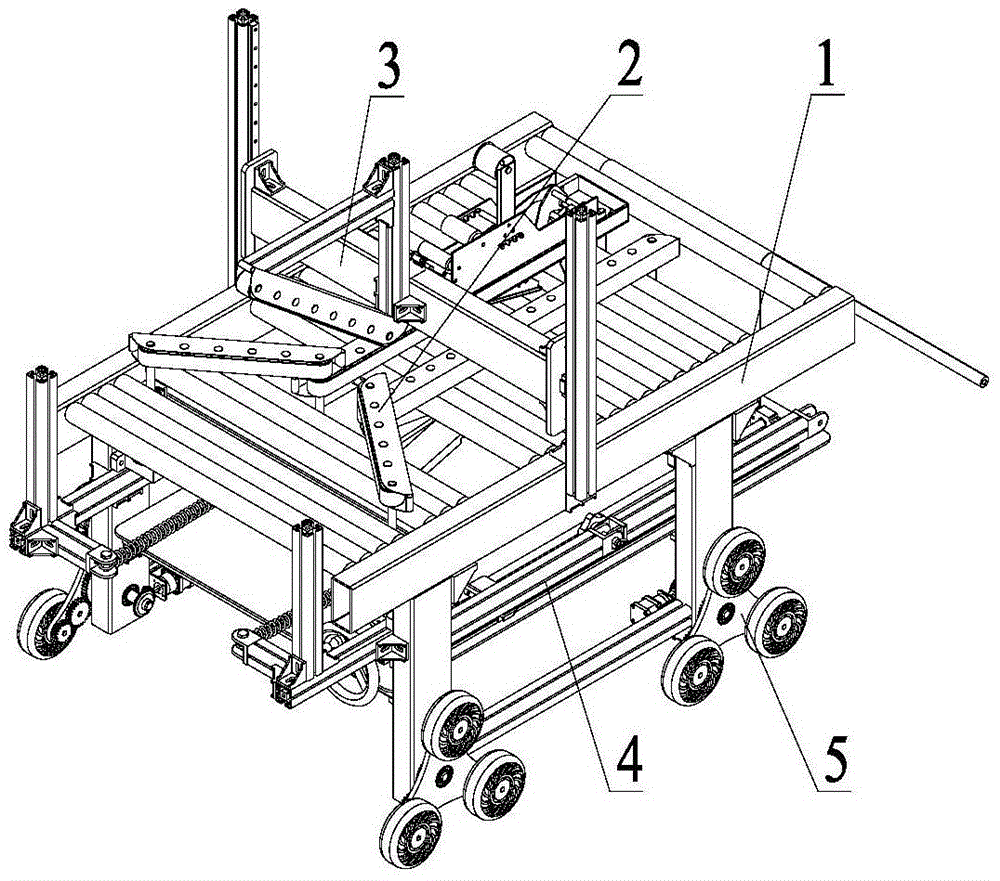

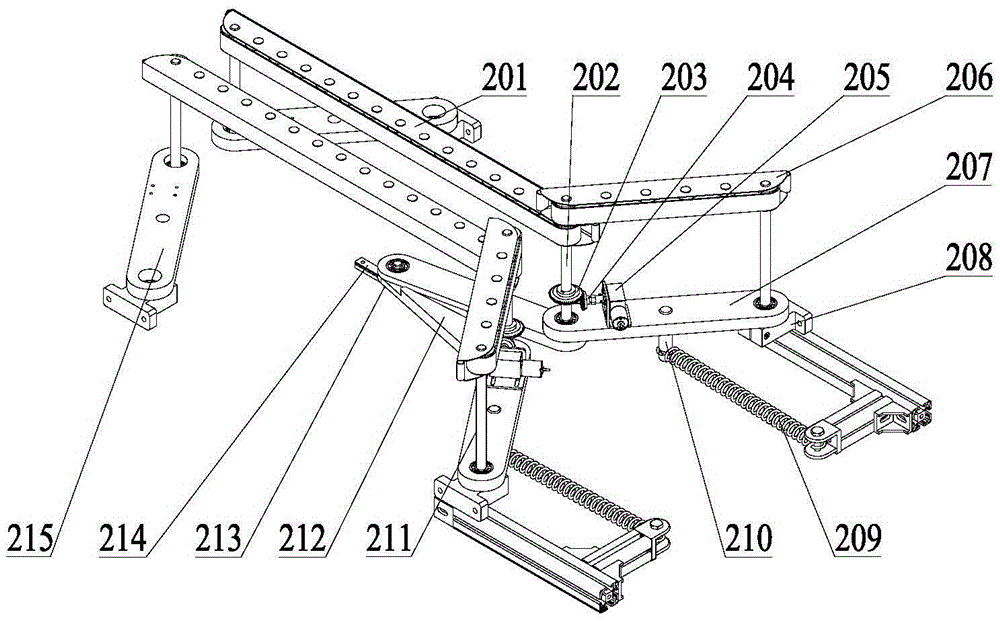

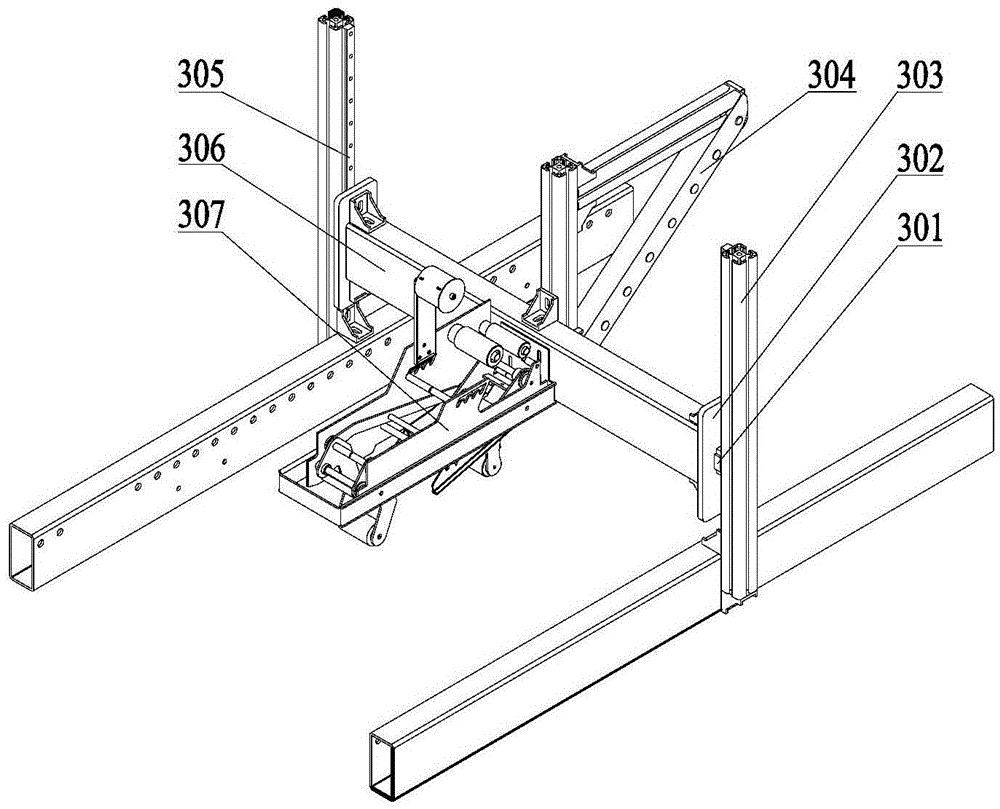

Self-adaptation follow-up carton packaging machine

The invention discloses a self-adaptation follow-up carton packaging machine, belongs to the technical field of manufacture and automation and aims at solving the problems that a carton packaging machine existing in the prior art cannot be used for packaging cartons different in size rapidly at any time and cannot work conveniently at different sites. The self-adaptation follow-up carton packaging machine comprises a truss type platform, two sets of follow-up parallelogram mechanisms symmetrically arranged on rollers of the truss type platform, and a blocking rod frame fixed to the truss type platform, wherein the rollers in a row are arranged on the truss type platform; two guide rail II supporting frames of the blocking rod frame are fixed to the truss type platform; a guide rail II is vertically arranged on the inner side of each guide rail II supporting frame; each of the two ends of a supporting beam is connected with a sliding block II through a sliding block II connecting block; one sliding block is matched with one guide rail II, and the other sliding block is matched with the other guide rail II; an adhesive tape winding mechanism is fixedly connected with the supporting beam and is parallel to the walking direction of cartons; a blocking rod is fixedly connected with the other side of the supporting beam which is obliquely arranged; and the end, fixed to the supporting beam, of the blocking rod is a low end.

Owner:CHANGCHUN UNIV OF SCI & TECH

Food automatic packaging equipment

The present invention discloses food automatic packaging equipment. A food feeding mechanism and a packaging mechanism are located above the feeding end of a conveying belt and are installed on a machine frame, the packaging mechanism is located on one side, away from the discharging end of the conveying belt, of the food feeding mechanism, a material taking opening is formed in one side, away from the food feeding mechanism, of a packaging storage box, a material taking assembly is provided with a horizontally arranged material taking rotating shaft and is rotatably mounted on the machine frame through the material taking rotating shaft, and a material taking hand is arranged at one end, away from the material taking rotating shaft, of a L-shaped material taking swing arm of the materialtaking assembly. According to the food automatic packaging equipment with the optimized design, food to be packaged is fed to a weighing table through the feeding mechanism, when the weighing table moves to the position below the packaging mechanism along with the movement of the conveying belt, the material taking assembly is turned over to remove a packaging box in a storage box, the food on theweighing table is covered, and rapid packaging is realized.

Owner:宣城市水阳三宝食品有限公司

Automatic columnar product protection layer wrapping device

ActiveCN109110229AFast automatic windingFast packWrapping material feeding apparatusWrapping with article rotationTectorial membraneEngineering

The invention discloses an automatic columnar product protection layer wrapping device. The automatic columnar product protection layer wrapping device is composed of a blank conveying mechanism, a protection film supply mechanism, a double faced adhesive tape supply and conveying mechanism, a protection film glue coating mechanism, a glue peeling mechanism, a winding mechanism, a shearing mechanism, a supporting mechanism and the like. After a low-tension protection film roll and a double faced adhesive tape roll pass through the glue coating mechanism under the action of respective supply traction force, a glue layer is bonded to the inner side of the protection film, and body paper is still left on the outer side of the glue layer, wherein the glue coating mechanism is composed of double rollers. After the protection film continuously passes through the glue peeling mechanism and the body paper is peeled, protection film rolling wrapping is conducted. According to the automatic columnar product protection layer wrapping device, rapid and automatic winding of a low-tension protection film on a columnar product can be achieved; the product packaging and delivery efficiency is improved in a mechanical and standard manner, and the production cost is reduced; and the wrapping quality is reliable, performance is stable, and the production efficiency is effectively improved.

Owner:YANSHAN UNIV

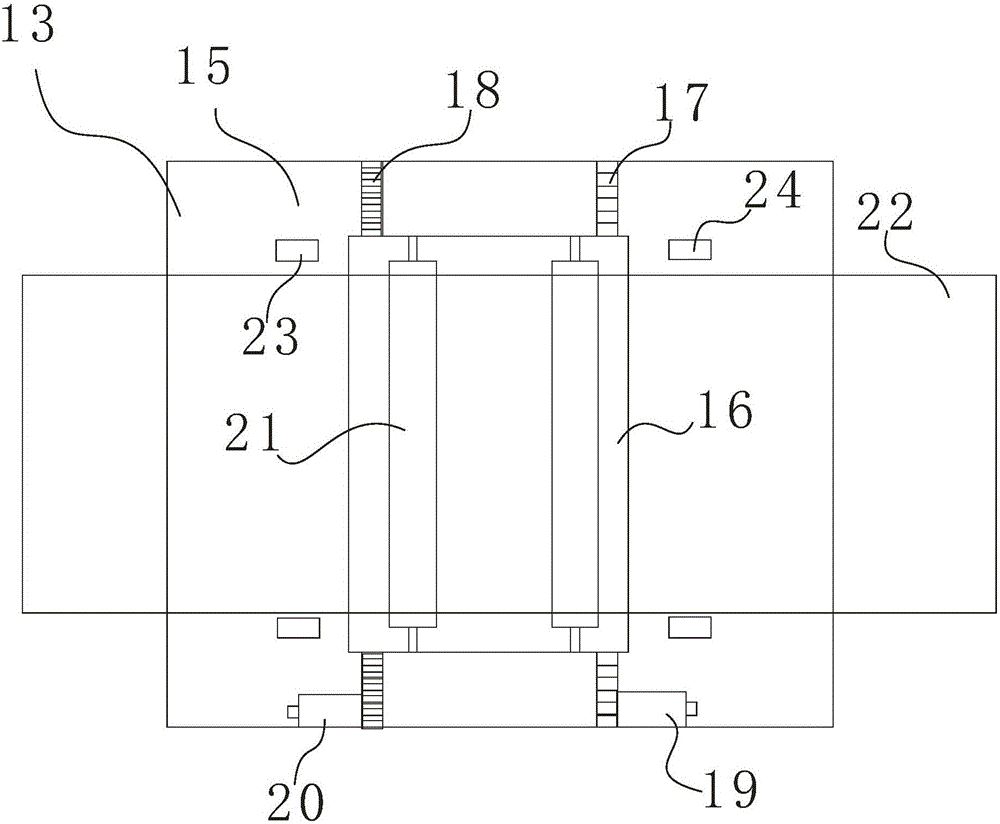

Packaging structure of integrated fuel cell stack and assembling method thereof

PendingCN111785999AImprove seismic performanceImprove insulation performanceFuel cellsFuel cellsStructural engineering

The invention provides a packaging structure of an integrated fuel cell stack and an assembling method of the packaging structure. The packaging structure of the fuel cell stack comprises a front endplate, an upper shell, a lower shell, a reactor core structure and a rear cover plate; the upper end plate is provided with a common pipeline which is communicated with a reactor core of the electricpile to form a flow channel for providing reaction gas and cooling liquid; and the upper shell and the lower shell are provided with anti-collapse structural components which are tightly attached to the reactor core. According to the packaging structure of the integrated fuel cell stack, the performance of the fuel cell stack is greatly improved, the size and the weight of the fuel cell stack areeffectively reduced, and the overall integration degree of the fuel cell stack is greatly improved; meanwhile, the vibration resistance and the insulativity of the fuel cell stack are further improved. Meanwhile, the integrated packaging structure can achieve rapid assembly and assembly line work.

Owner:上海氢晨新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com