Convenient beehive

An integrated, nest-frame technology, applied in beehives, beekeeping, honey collection, etc., can solve the problems of high labor intensity, unfavorable heat preservation, and more pollution, so as to reduce labor intensity, facilitate honey water feeding, and high powder removal output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

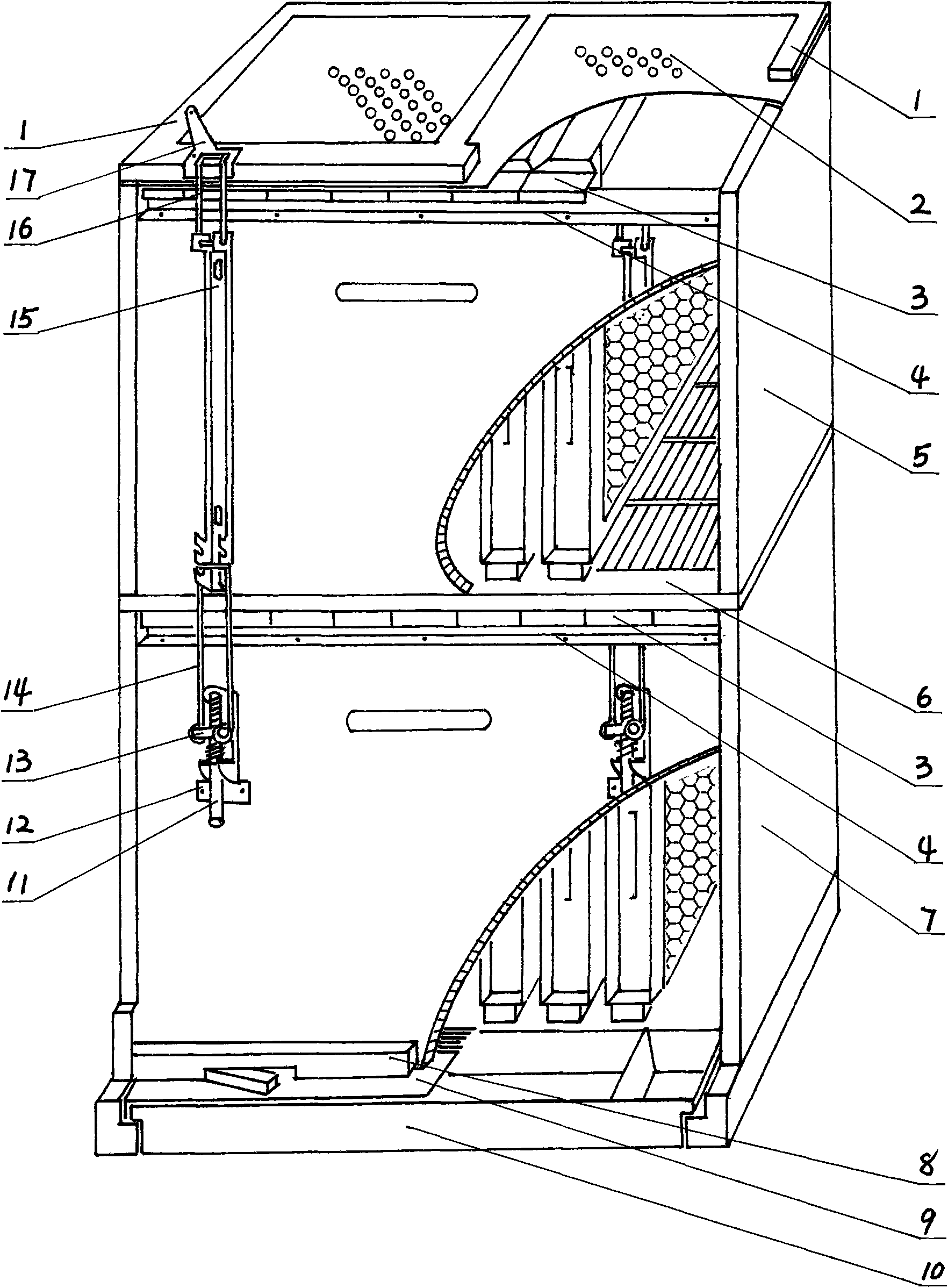

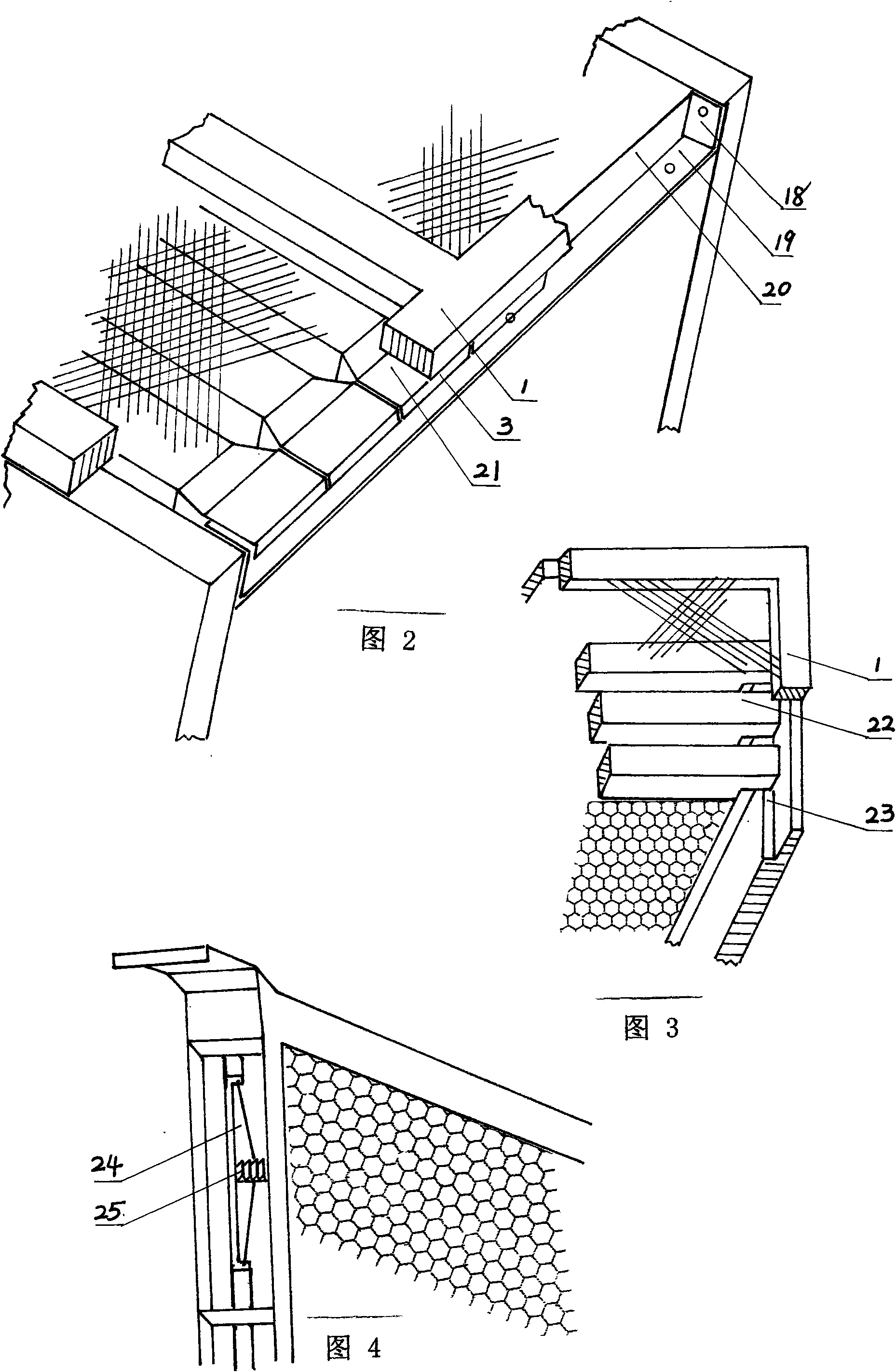

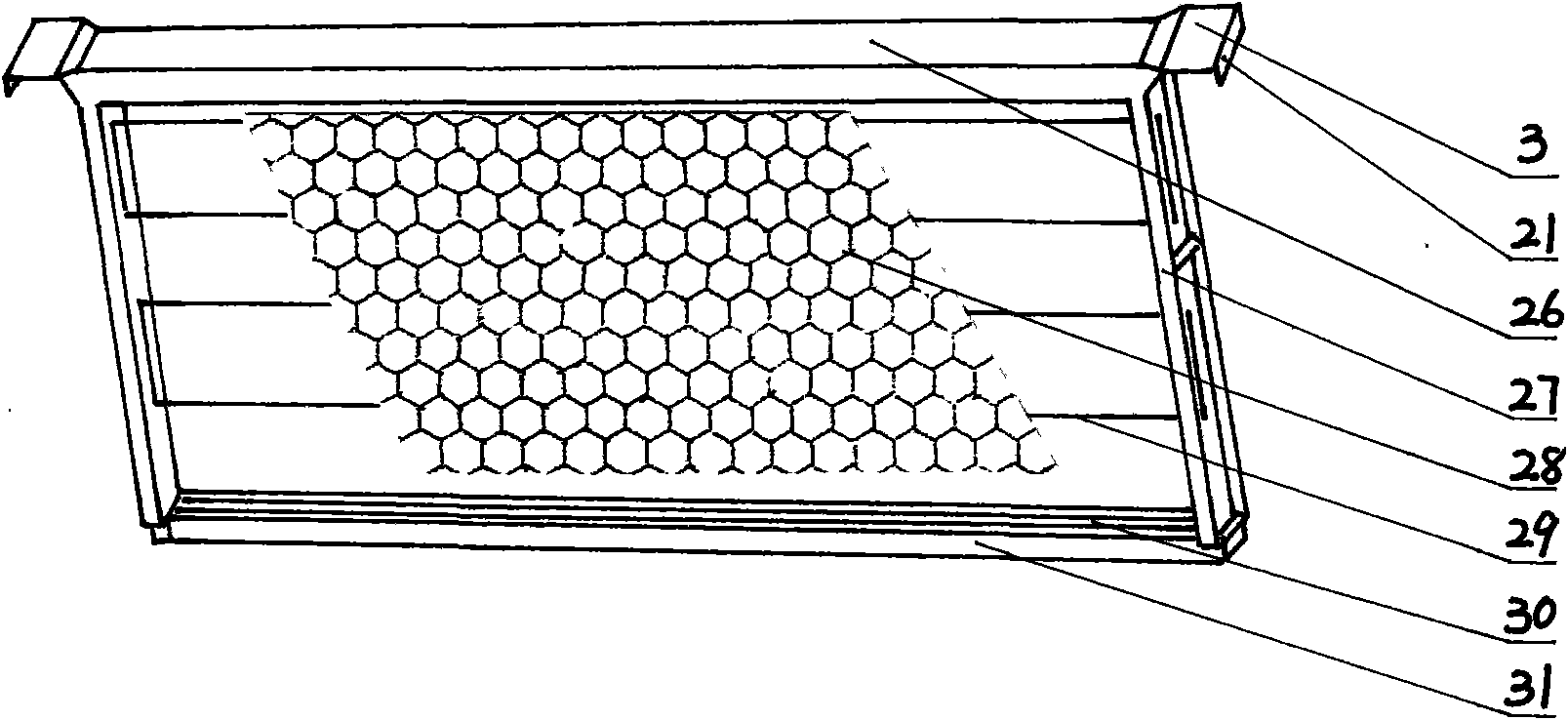

Embodiment 1

[0032] Example 1. Cover frame, 2. Degummed covering cloth, 3. Head plane, 4. Nest frame support, 5. Successor box, 6. King partition, 7. Nest box, 8. Powder removal cover, 9. Front Bottom plate, 10. Pollen box, 11. Screw crowbar, 12. Base, 13. Biaxial nut, 14. Pull-down ring, 15. Pull bar multi-tooth hook, 16. Upper pull ring, 17. Angle iron hook, 18. Connection surface, 19. Base, 20. Facade, 21. Handle, 22. Wooden nest frame head, 23. Beehive slot, 24. Wide hook, 25. Adjusting buckle group, 26. Upper beam, 27. Side Strip, 28. Wax nest base sheet, 29. Hanging ring, 30. Lower beam groove, 31. Lower beam, 32. Upper slot, 33. Side bar nest base nest, 34. Lower slot, 35. Top hole, 36. spring, 37. lock card, 38. lock bolt.

[0033] figure 1 : The two ends of the front bottom plate (9) of the beehive are bent down and the bottom of the box is flat with the bottom of the fixed box at the middle and rear; The box (10) is covered with a mask, and the outer box mouth of the nest door...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com