Patents

Literature

153results about How to "Not easy to squeeze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

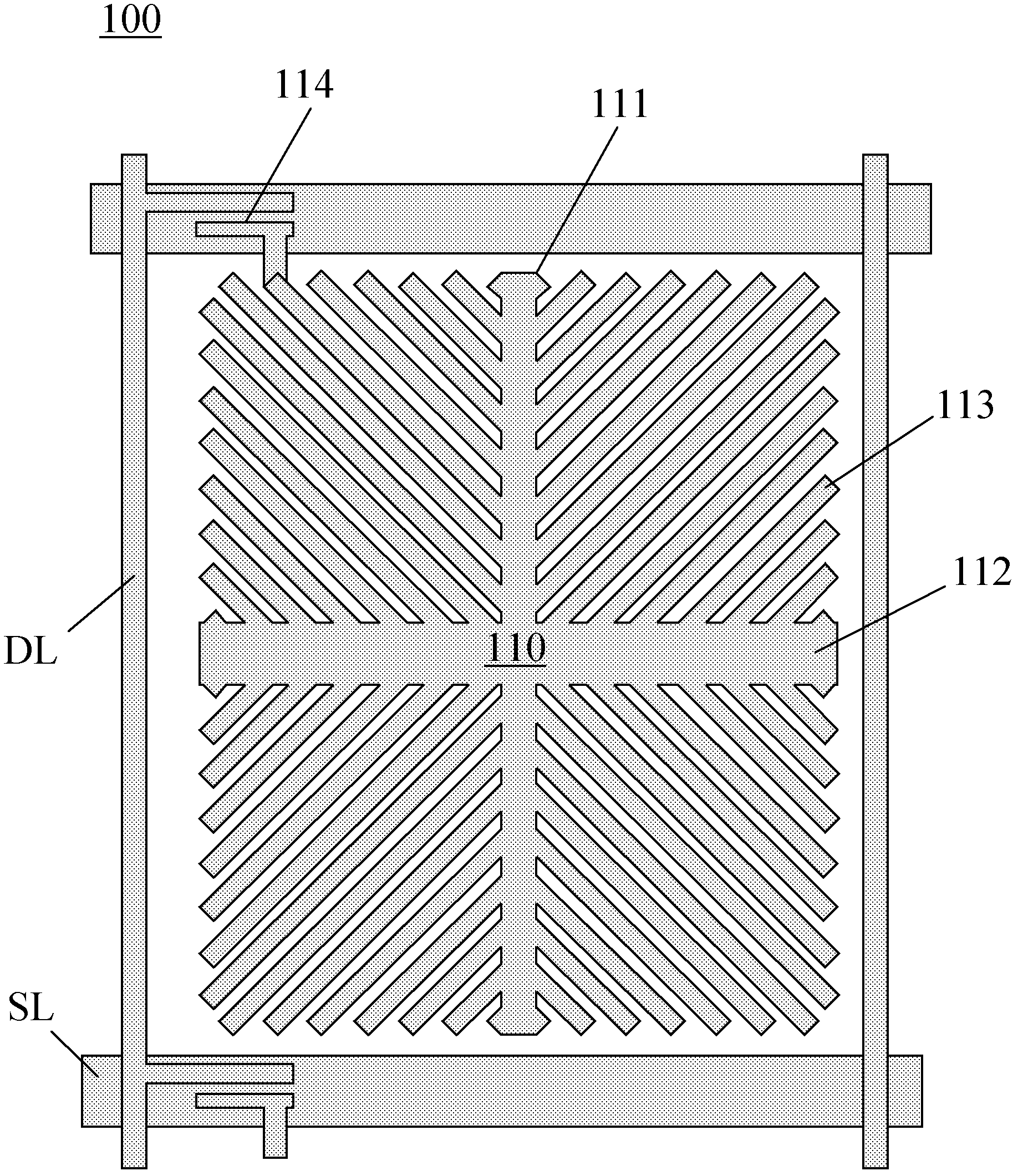

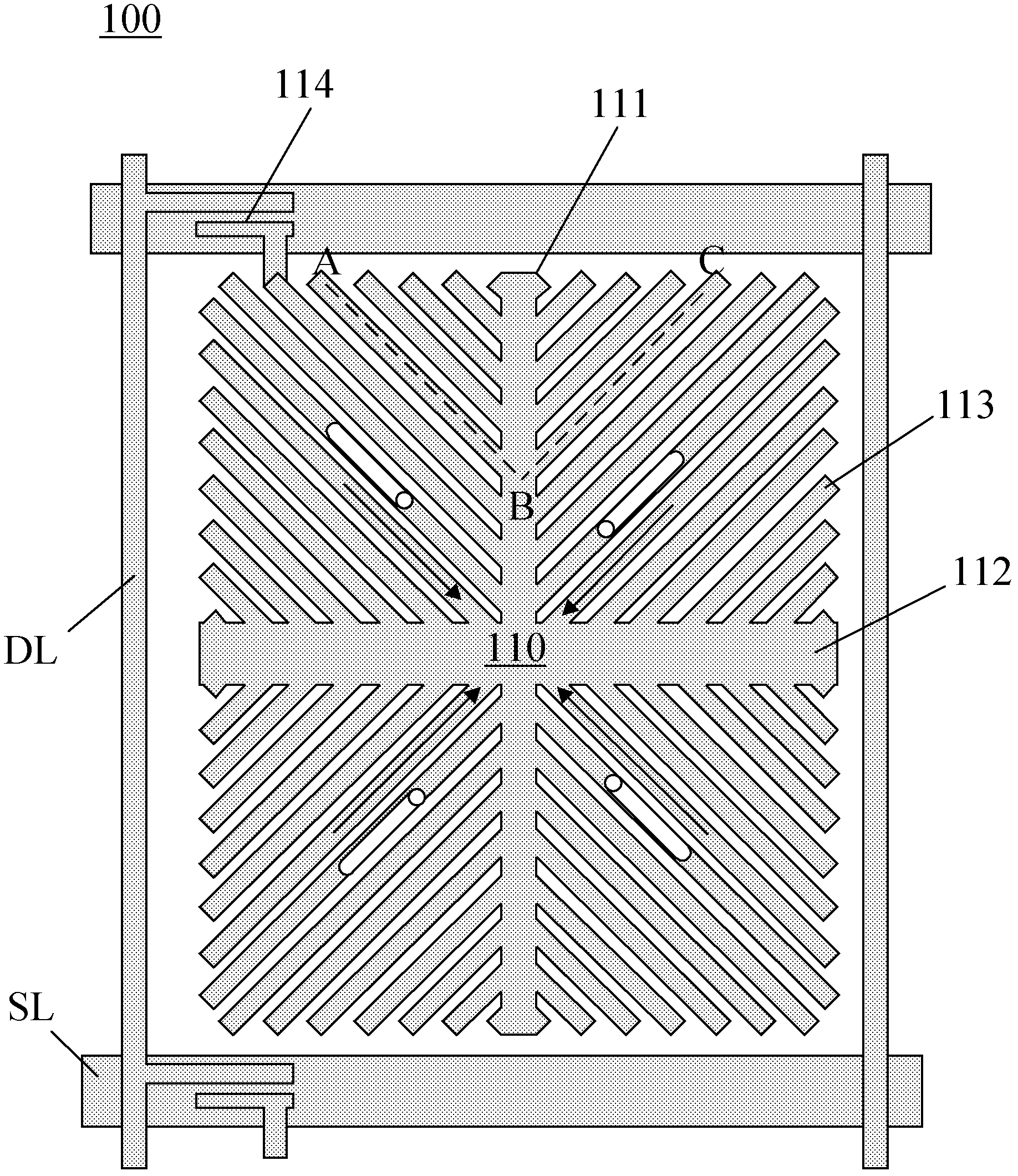

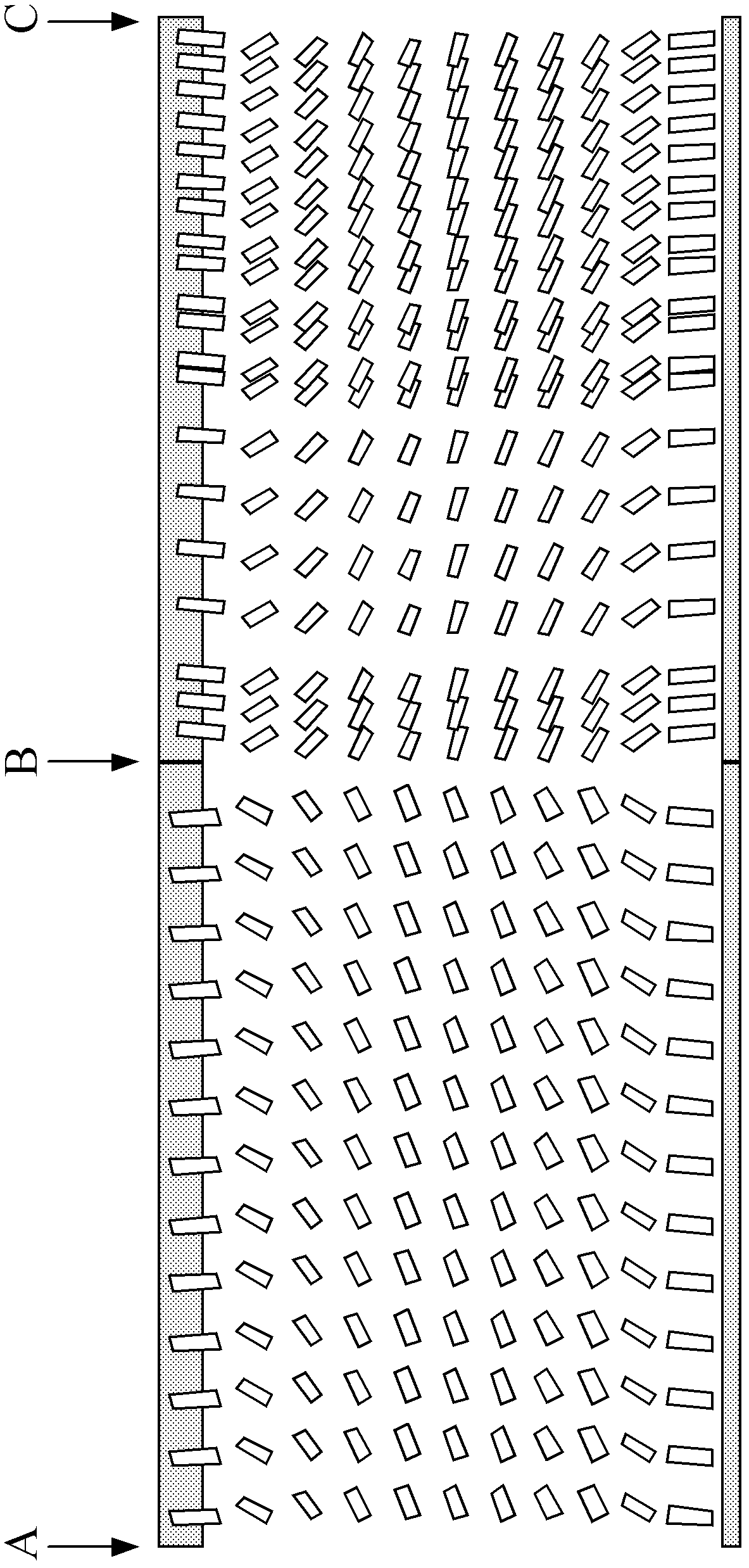

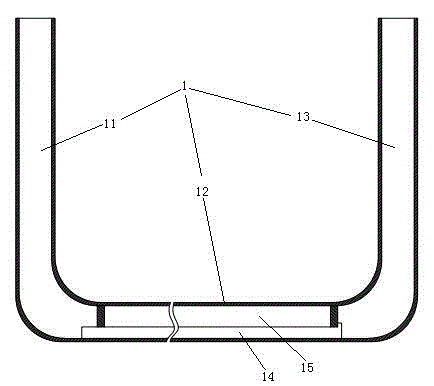

Liquid display panel and pixel electrode thereof

InactiveCN102662280ASolve the problem of discontinuous linesIncrease opening ratioNon-linear opticsComputer scienceElectrode

The invention discloses a pixel electrode of a liquid display panel; the pixel electrode is provided with a special pattern consisting of a surrounding part and a branch part; an opening is left in the surrounding part; and the width of a part of the branch part which is connected with the surrounding part is less than that of other parts of the branch part. According to the pixel electrode, the opening rate of the panel can be improved, and the discontinuous lines in the center of the pixel electrode can be suppressed.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

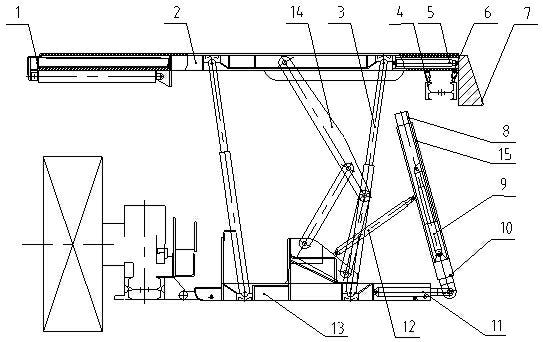

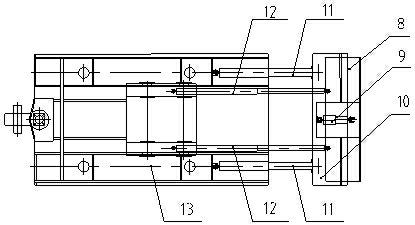

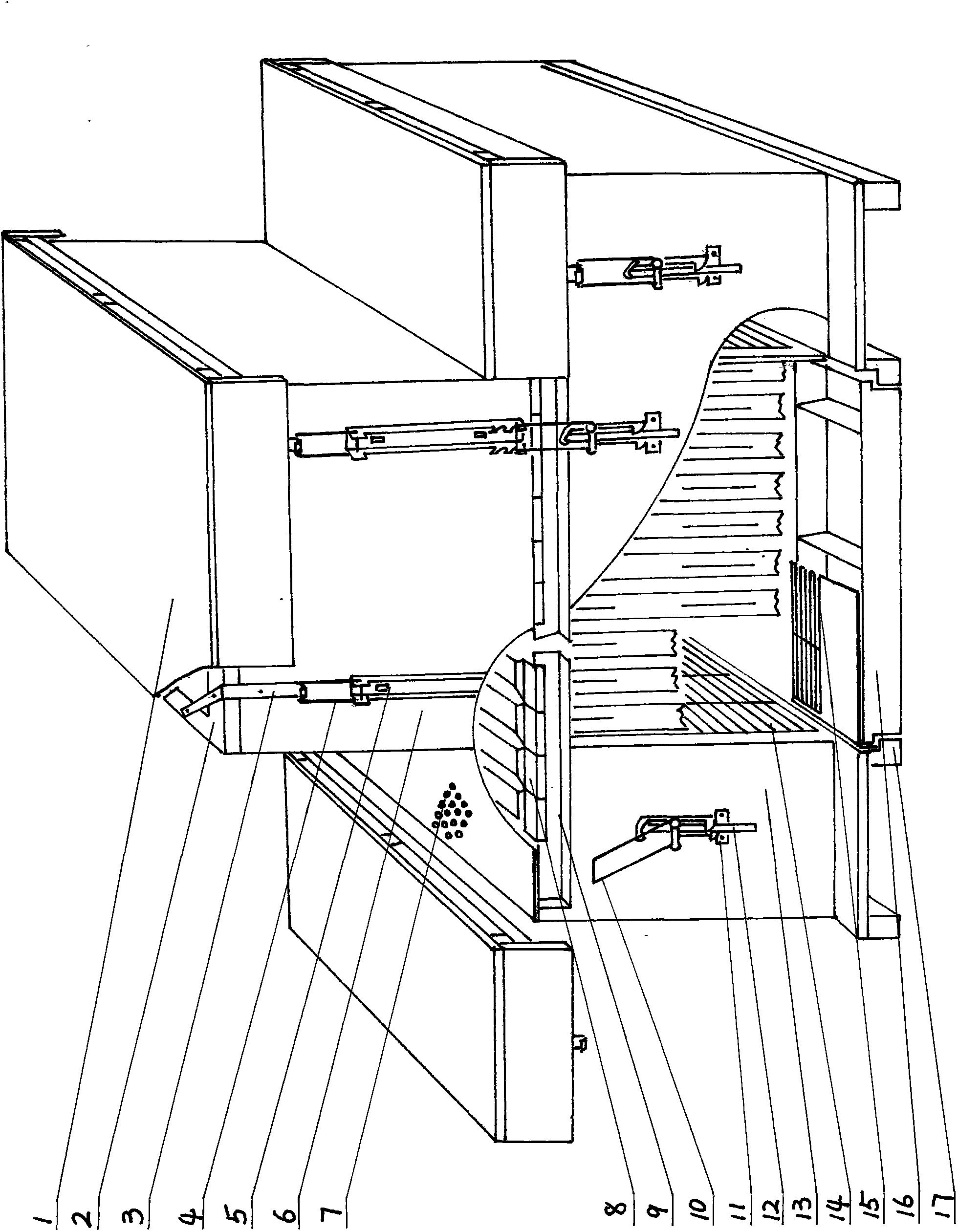

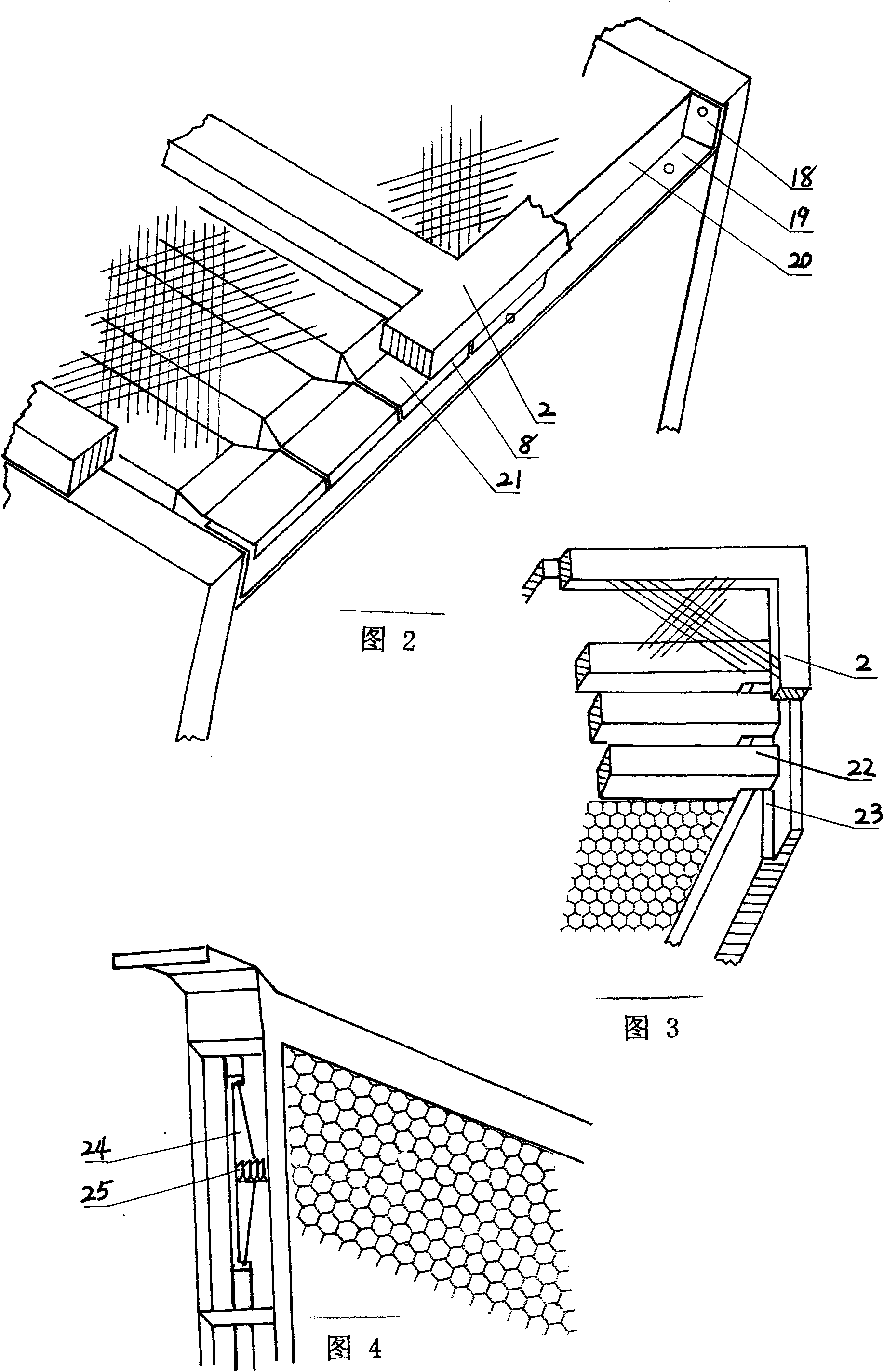

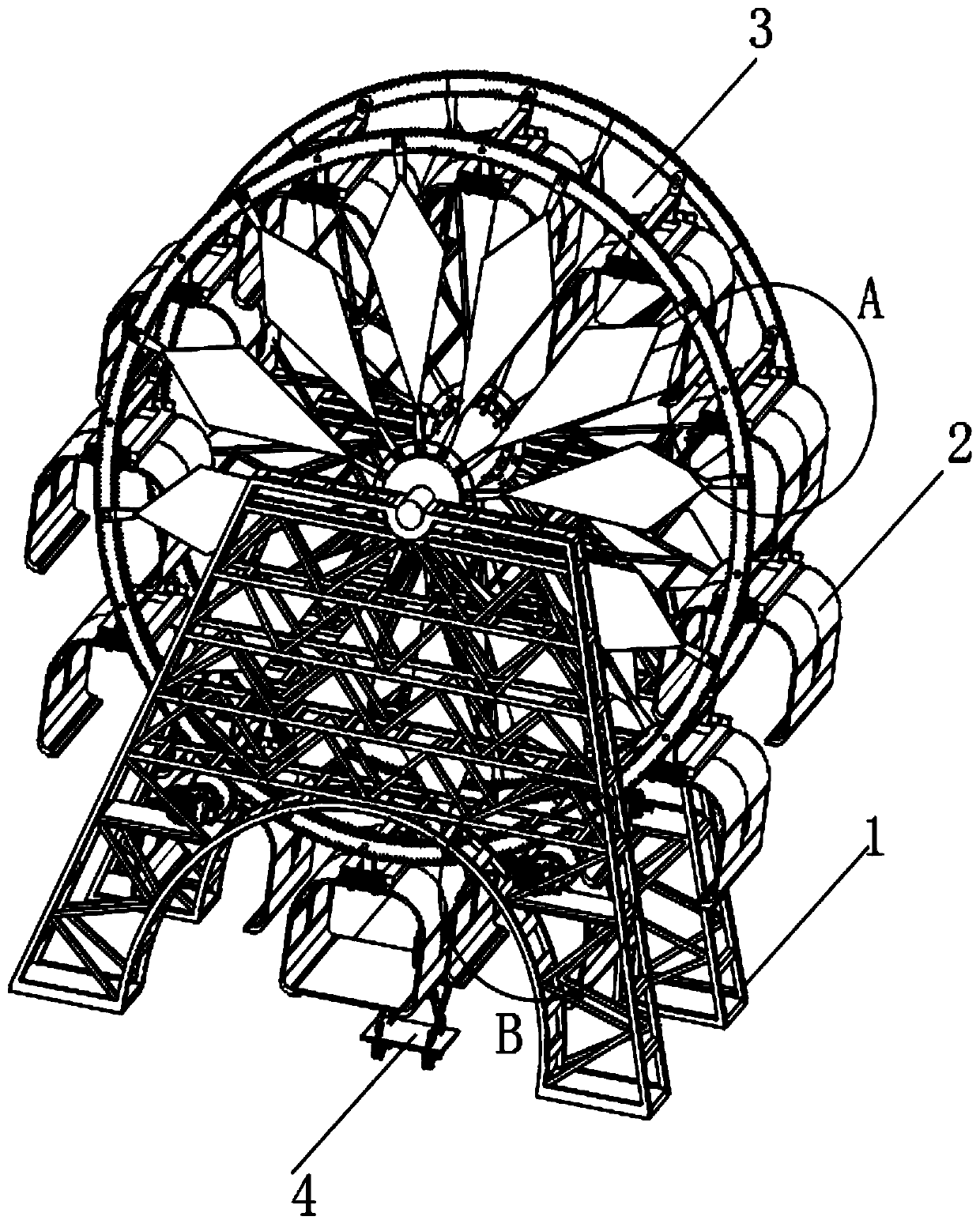

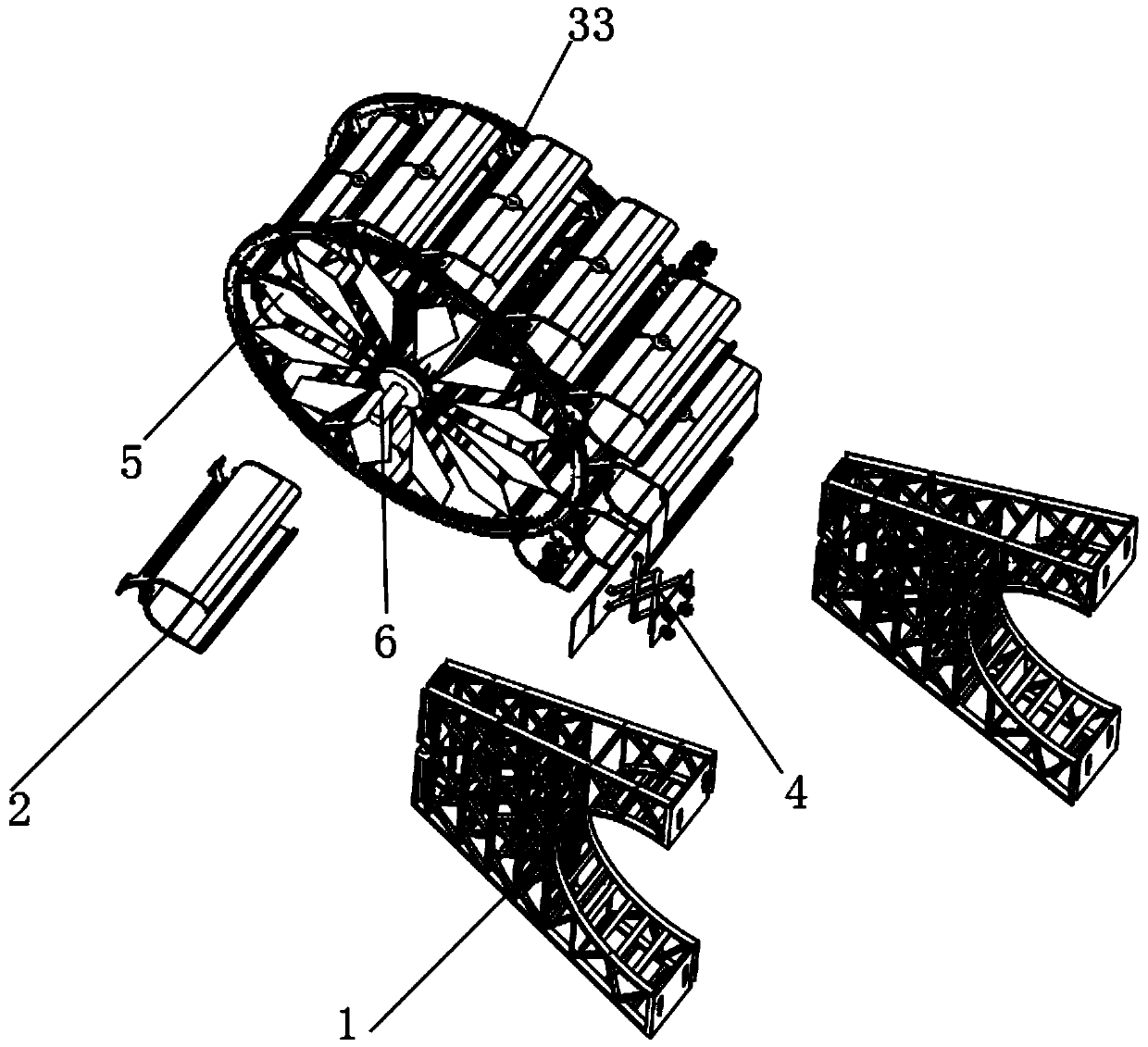

Automatic tamper type waste filling hydraulic support

InactiveCN102135006AGood topping effectSmooth connectionMaterial fill-upMine roof supportsGround subsidenceCut and fill

The invention discloses an automatic tamper type waste filling hydraulic support which comprises a base and a top beam, wherein the base and the top beam are connected by uprights, the front end of the top beam is provided with a forepole, the rear end of the top beam is provided with a scraper conveyor and further connected with an internally-telescopic extrusion scraping plate by a retractable jack which is arranged horizontally; the rear side of the base is provided with the extrusion scraping plate by a first and a second extrusion jacks, and the first extrusion jack is horizontally arranged. The automatic tamper type waste filling hydraulic support solves the problems that conventional cut and fill hydraulic support equipment can not ensure top filling of filler and has poor tamper intensity; in addition, the automatic tamper type waste filling hydraulic support realizes the high-strength supporting for a gob roof by virtue of waste fillers, effectively eliminates the defect of ground subsidence, realizes safe recovery for part of permanent coal pillars, corner coals and coal under buildings on the premise of not destroying factories and relocating villages, and improves the recovery of the coal resources. The invention is also suitable for various solid fillers such as coal ash, river sand, loess and the like.

Owner:HENAN POLYTECHNIC UNIV

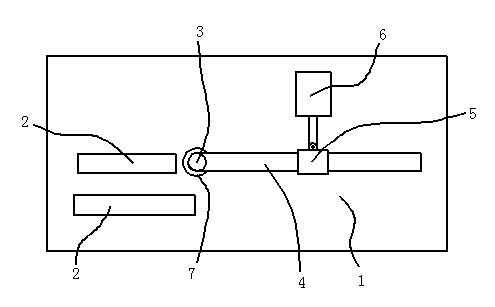

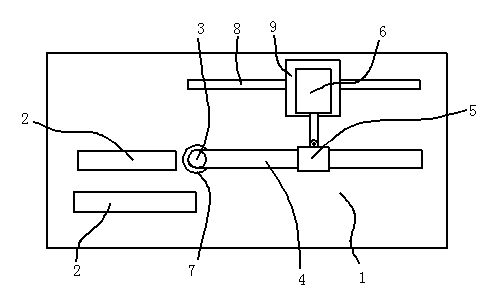

Metal sheet bending machine

The invention discloses a metal sheet bending machine which comprises a base seat. At least two fixing blocks and a rotating shaft are arranged on the base seat, a long rod is connected with the rotating shaft, a sliding sleeve is arranged on the long rod in a sleeved mode and connected with a power device in a rotatable mode, and the power device is fixedly arranged on the base seat. No matter what angle a metal sheet needs to be bent, the bent angle of the metal sheet can be controlled through the rotating angle of the rotating shaft, the bending machine does not need to be dismantled, and therefore the metal sheet bending machine is more convenient to use. In addition, when the metal sheet bending machine is used, fingers are not prone to be squeezed, and therefore the safety performance of the metal sheet bending machine is also improved.

Owner:NINGBO HENGSHENG ELECTRIC

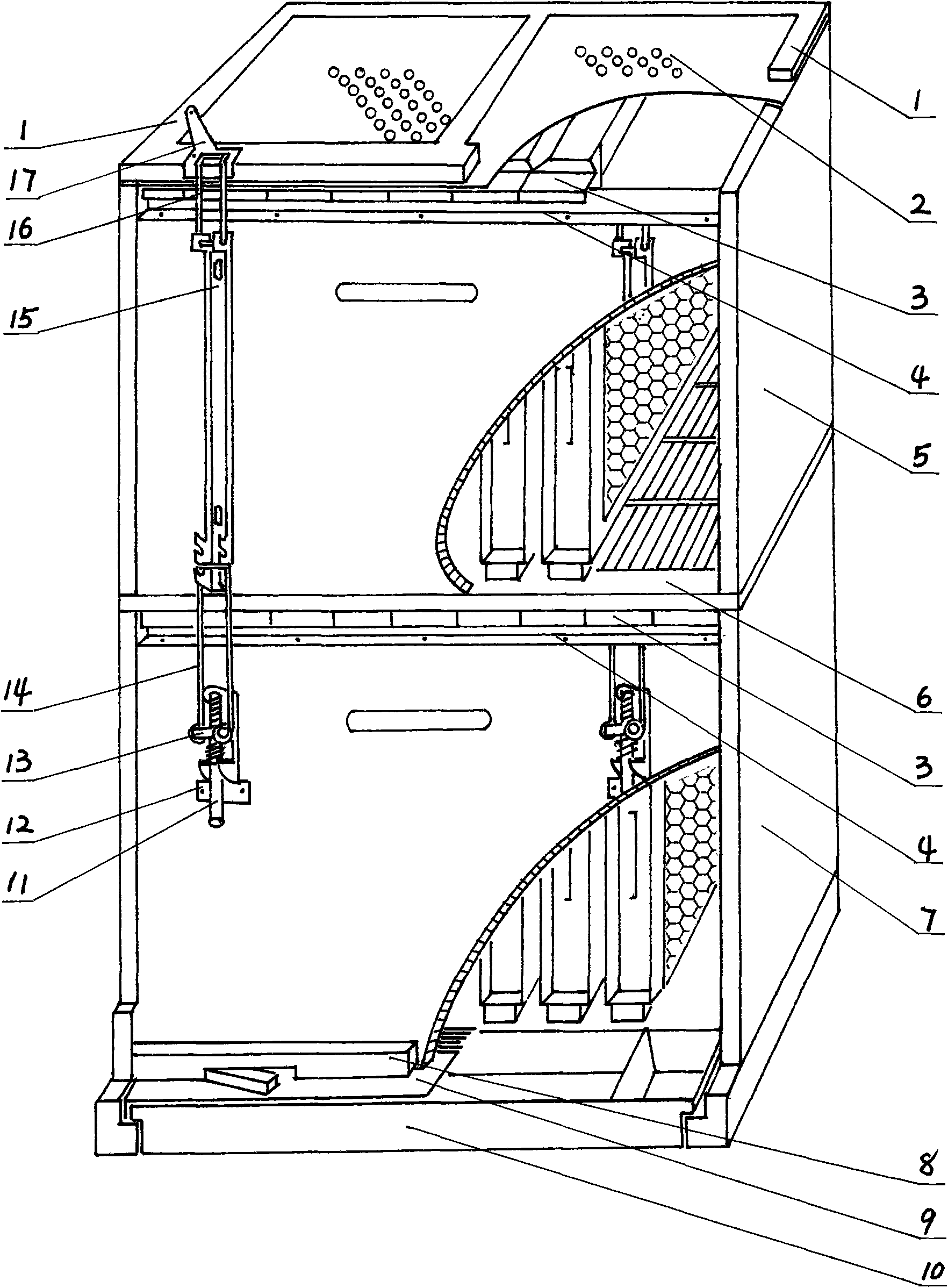

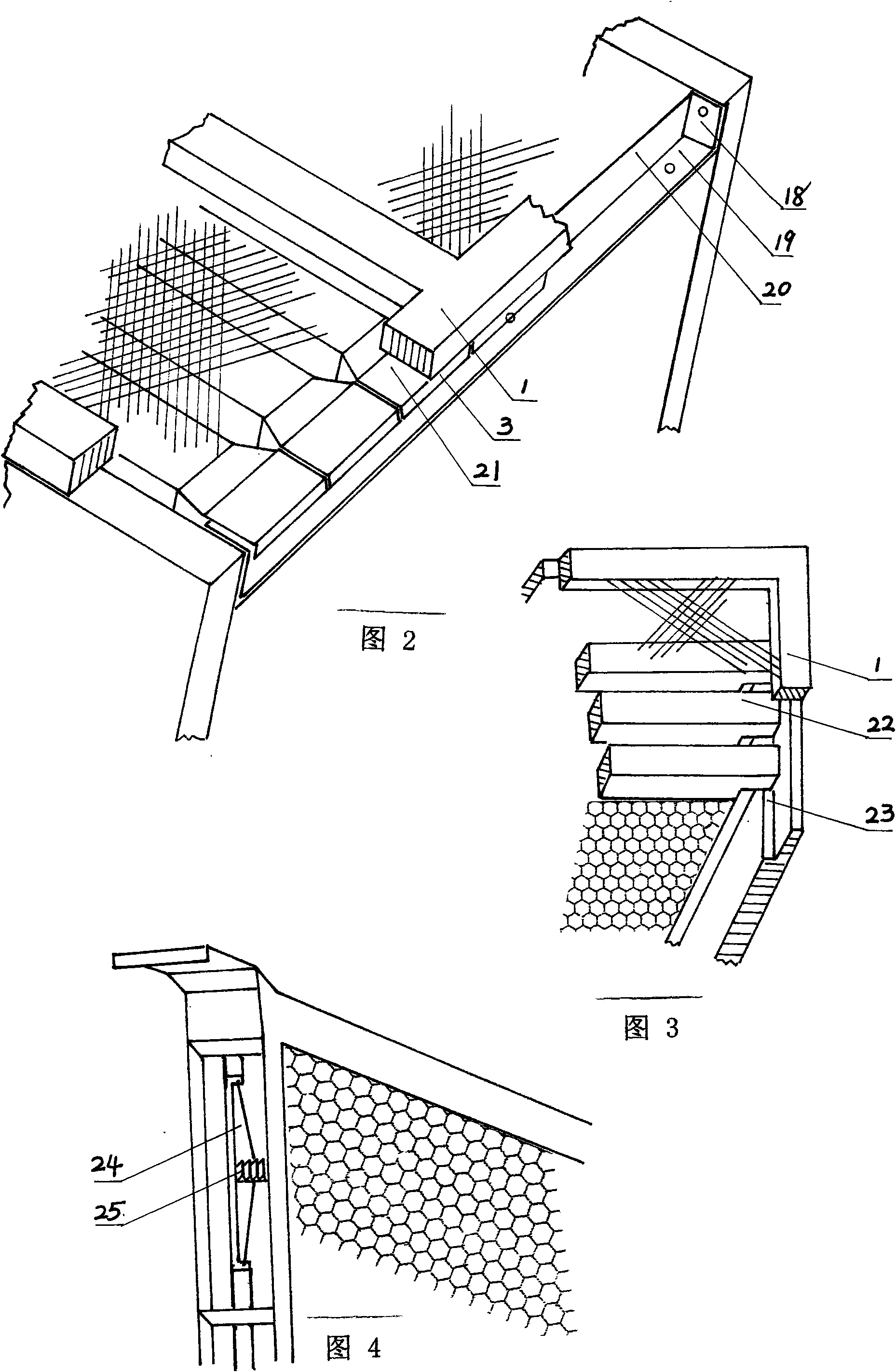

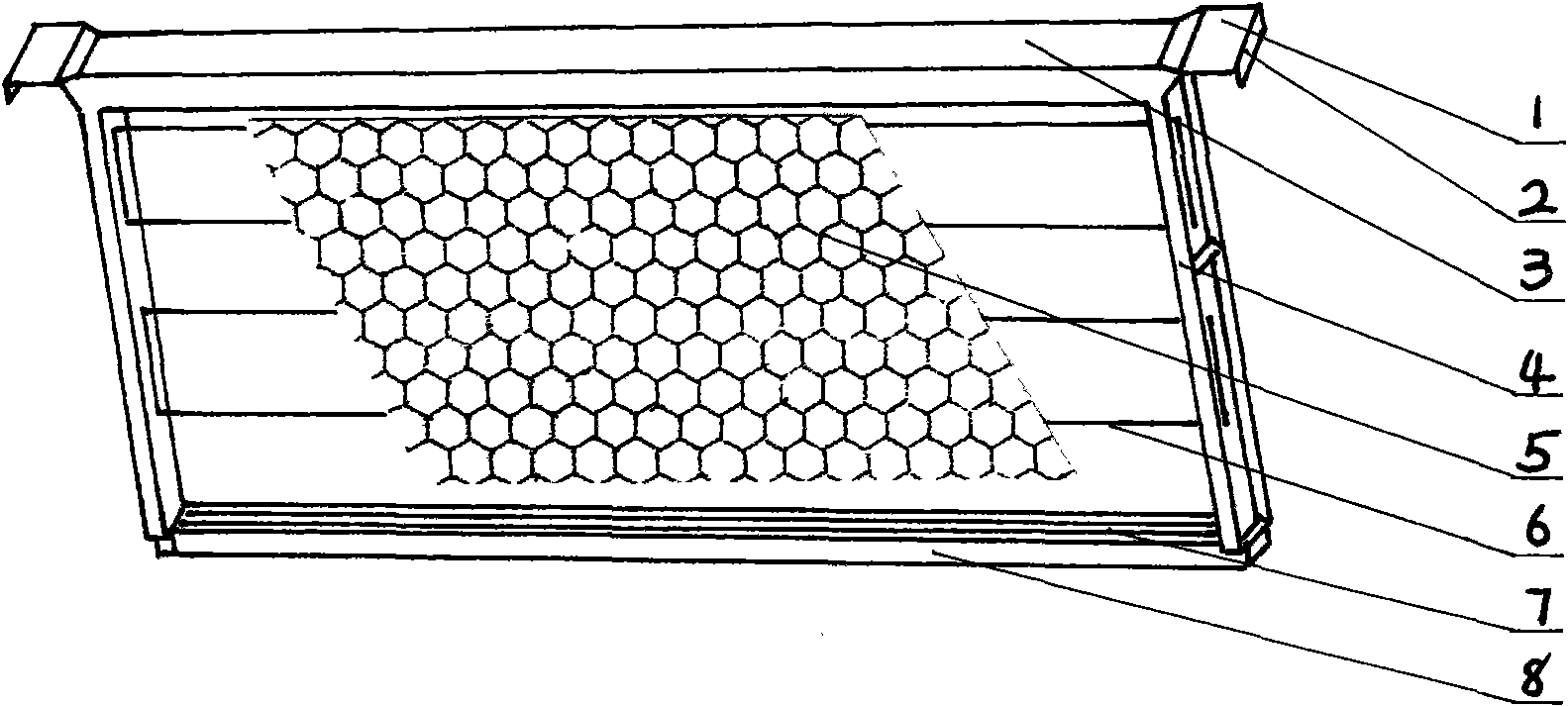

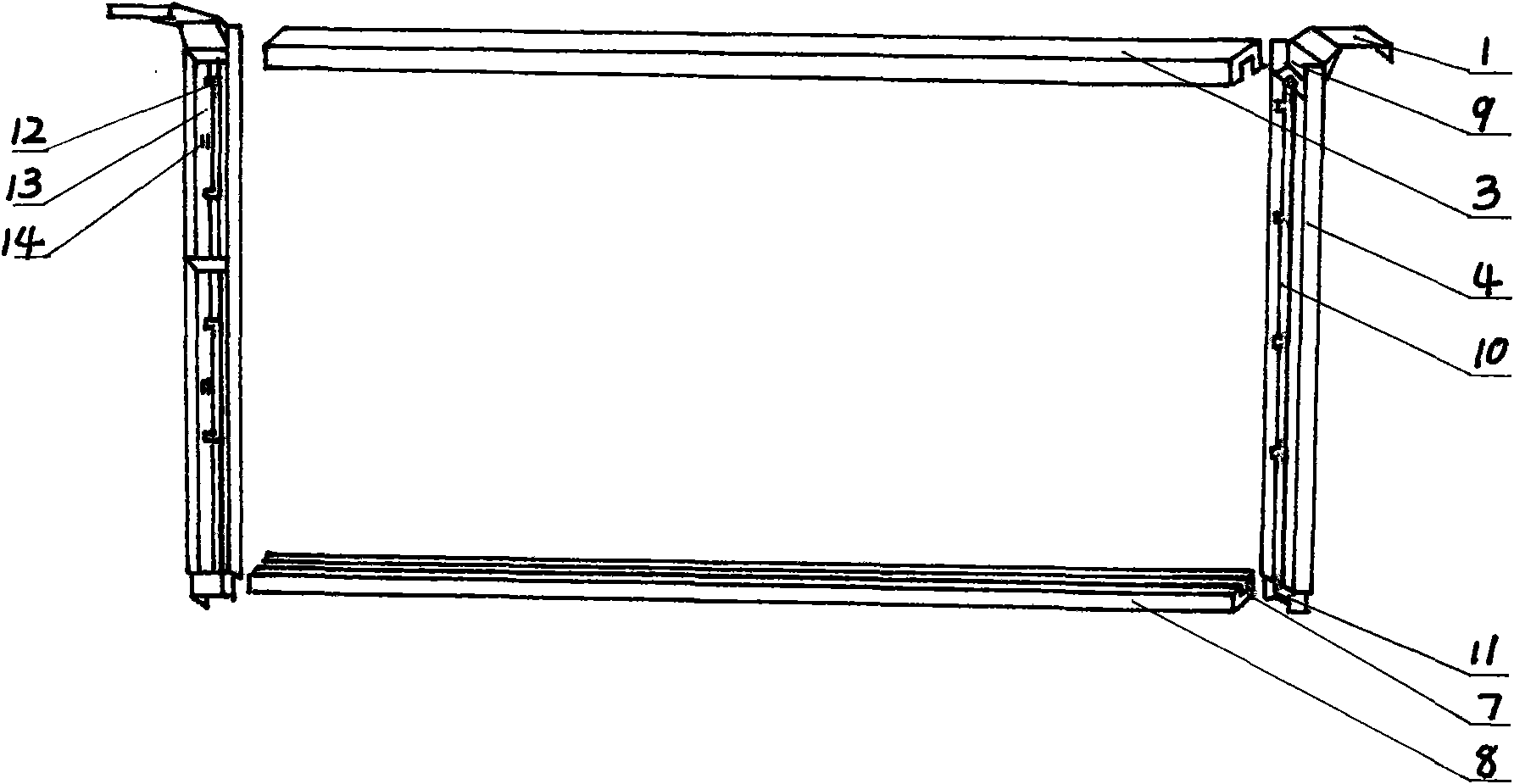

Horizontal and super combined beehive

InactiveCN101897300AImprove work efficiencyIncrease productionBeehivesHoney collectionWaxEngineering

A horizontal and super combined beehive comprises a wide-comb box, a frame support, a powder-releasing cover, a pollen box, a connector, a degummed drape, an inserted frame, an integrated frame and a wax comb foundation with suspension loops. The wide-comb box is characterized in that the both ends of the box are used as the breeding areas for two swarms of bees, a super is supported above the middle production area, frame queen excluders are used to form a working bee centralized production area, the areas are covered; the powder-releasing cover is bottomless, pollens and honey on a powder-leaking railing pedal with anti-theft gantry boxes on both sides directly leak in the pollen box at the bottom; the connected box is coarsely adjusted by a multi-teeth hook and finely adjusted and connected firmly by a screw crow bar through screws; the laps and edgings of the inserted frame are integrated, an upper beam and a lower beam are inserted in the upper and lower grooves of two edgings to integrate, the upper beam is thin, the lower beam and the edgings are provided with grooves to be inserted in the comb foundation; a wide hook with the same width and an adjuster are hung on the wax comb foundation for tightening; the laps are integrated with a frame-distance clip and connected with the upper beam through a downward slope, the tops of comb-forming frame supports are butted to each other and are tightly pressed by the degummed drape and the inner frame of the box cover, the distance of the frames is standard so that people can not stung by bees; and the top of each lap is provided with a handle, thus the laps can be fast gripped outside the box. The wide-comb box can be used to multiply the efficiency, thus being suitable to be used for beekeeping around the world.

Owner:汪修建

Convenient beehive

The invention comprises a convenient beehive consisting of a nest frame support, degummed covering cloth, a powder-removing cover, a pollen box, a connector, a plug-in nest frame, an integrated nest frame and a wax nest foundation with hanging rings, and is characterized in that the powder-removing cover is erected on a box leak powder grate pedal, and pollen and honey water are leaked into the pollen box at the bottom part via a powder grate; the beehive is connected in a multi-tooth hook group for rough adjustment, and a thread of a spiral crowbar is used for fine adjustment and tight prying; the nest frame is integrally formed, laps of the plug-in nest frame are integrated with edge strips, the upper and the lower hanging rings at two ends of the was nest foundation are hung on wide hanging hooks in two edge strip bare cover type mouths, an upper beam and a lower beam are also tightened when being inserted in an upper groove and a lower groove of two edge strips, and a regulating buckle which is not tightened is buckled in the group; the upper beam is thin, the grooves are formed on the edge strips and the lower beam for mounting a plastic nest foundation; the laps are integrated with a frame distance clamp, a lower slope is connected with the upper beam, a frame and the top part of the nest frame support push against each other and compressed by a bee separating plate and a cover frame without gaps, and the frame distance is standard and difficult to kill bees due to extrusion and avoid the bees from stinging people; pull handles are arranged at the top ends of the laps, thereby being convenient to grab outside the beehive; and the degummed covering cloth with holes is used for covering the bees, thereby collecting more gum and realizing fast degumming. The convenient beehive can improve the effectiveness by a plurality of times and is applicable to world beekeeping.

Owner:汪修建

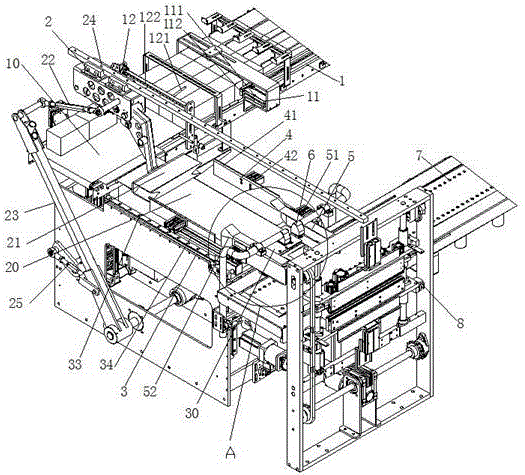

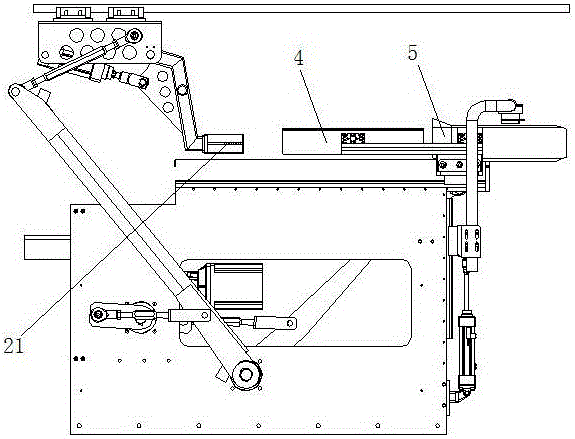

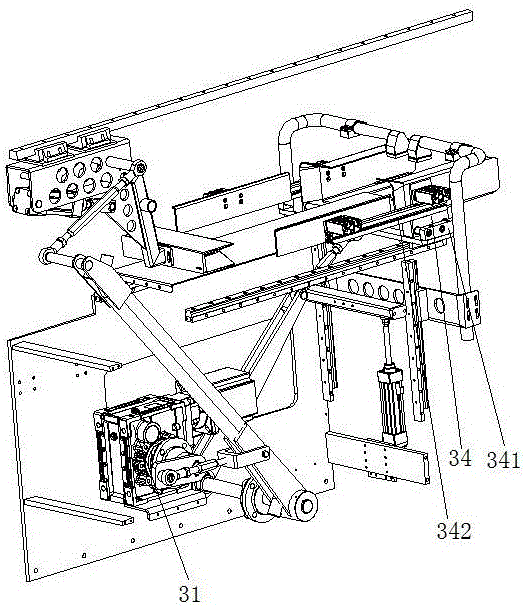

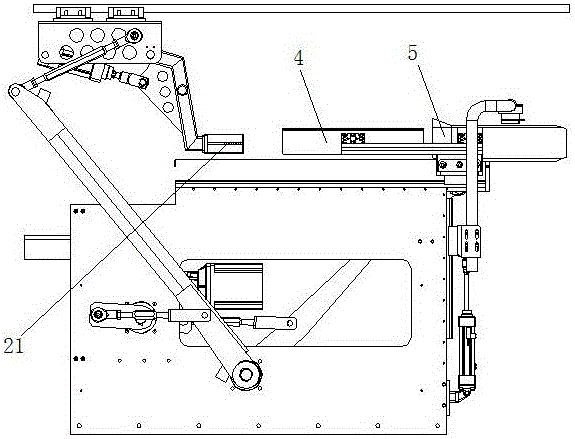

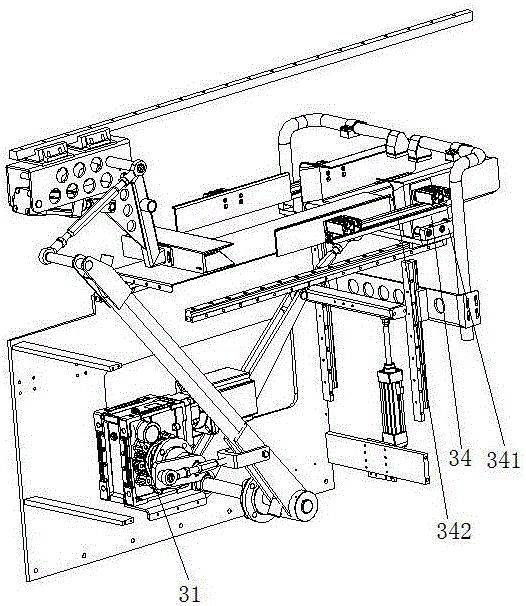

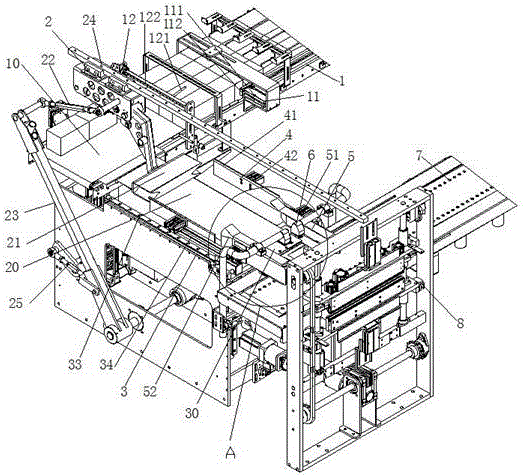

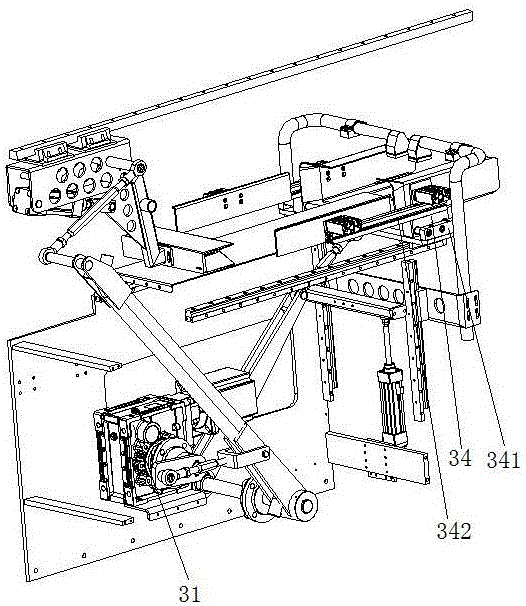

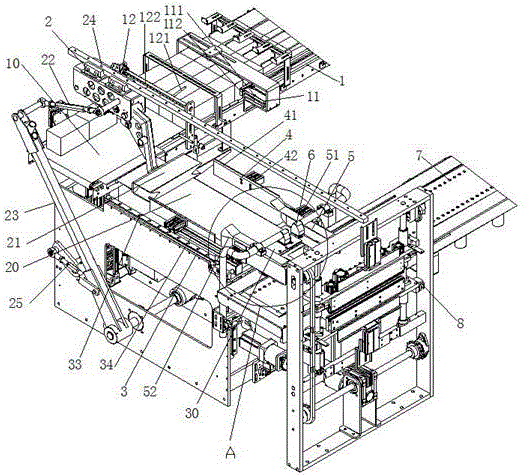

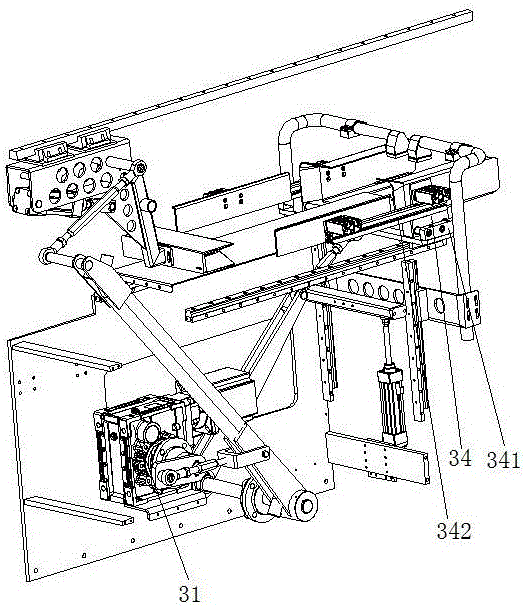

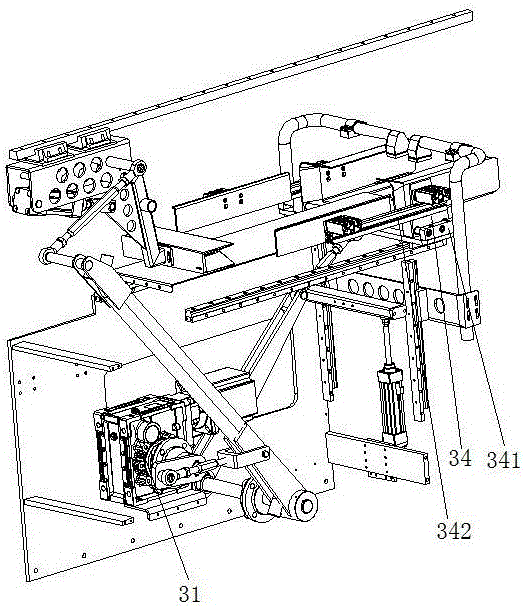

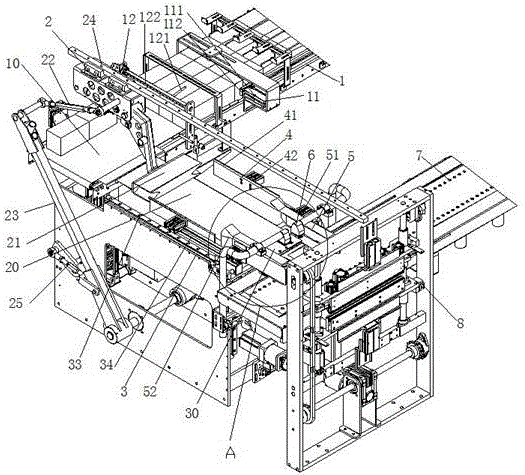

Control system of prefabricated bag packing machine

ActiveCN105857649AShort tripPrevent the situation of dumpingSolid materialRolling paperControl system

The invention discloses a control system of a prefabricated bag packing machine and relates to the technical field of mechanical control of packing machines. The control system of the prefabricated bag packing machine comprises a feeding mechanism, a pushing mechanism, a bag stretching mechanism, a bag opening mechanism and a bag conveying mechanism and is characterized by further comprising a clamping mechanism and a translation mechanism. The control system of the prefabricated bag packing machine is applicable to packing machines for packing via prefabricated bags such as small packing machines, medium packing machines and large packing machines and the like; meanwhile, the control system of the prefabricated bag packing machine is also suitable for packing materials such as facial tissues, flat paper, paper towels, blocky foods, drugs, roll paper, unpackaged foods and the like. Through the control system of the prefabricated bag packing machine, the problems that processes in single station of the prefabricated bag packing machine are complex, various packing actions are needed, the travel distance among the stations is long, the equipment occupied area is large, the material is irregular and is easy to pour, the prefabricated bags are easy to break, the material-pushing travel distance is long, the packing effect is poor, and the packaging efficiency is low in the prior art can be solved.

Owner:上海松川峰冠包装自动化有限公司

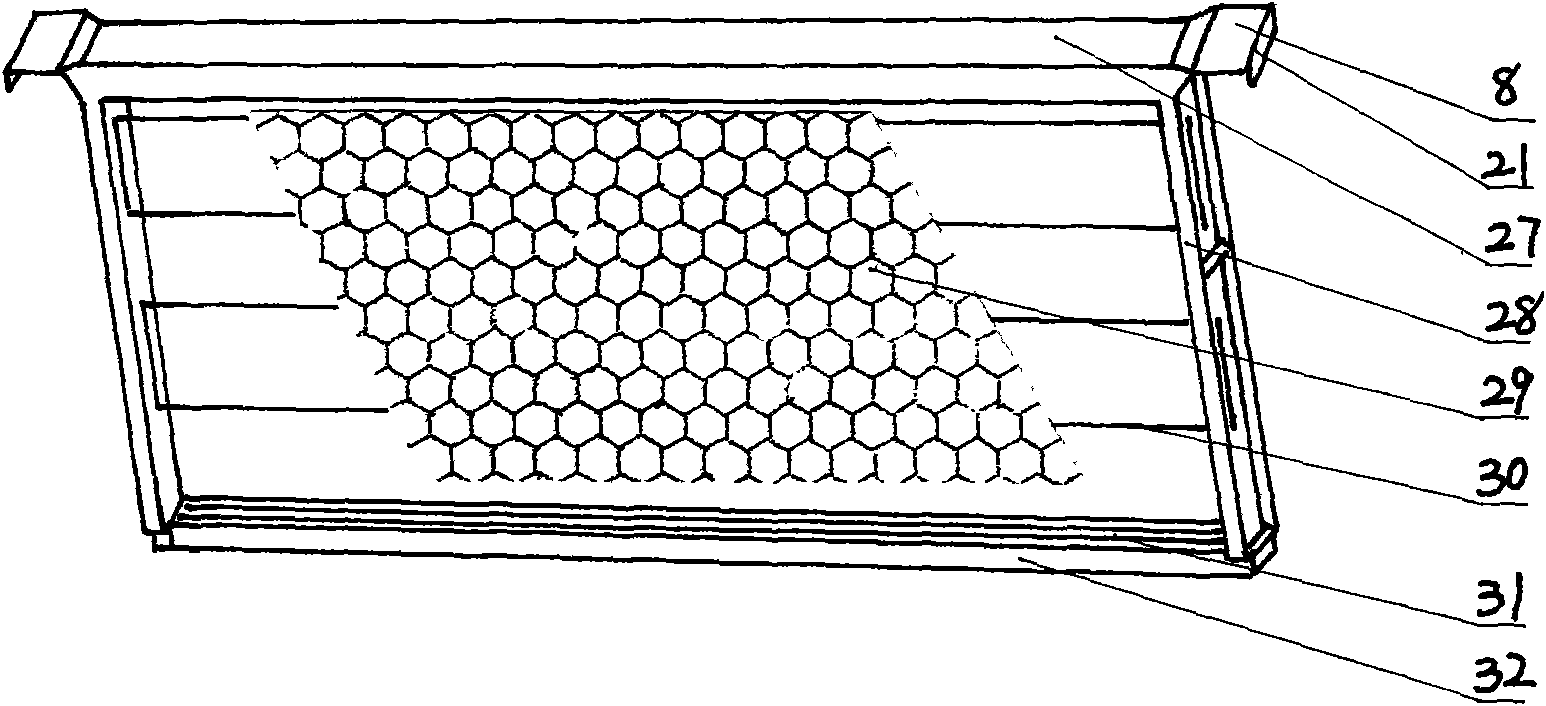

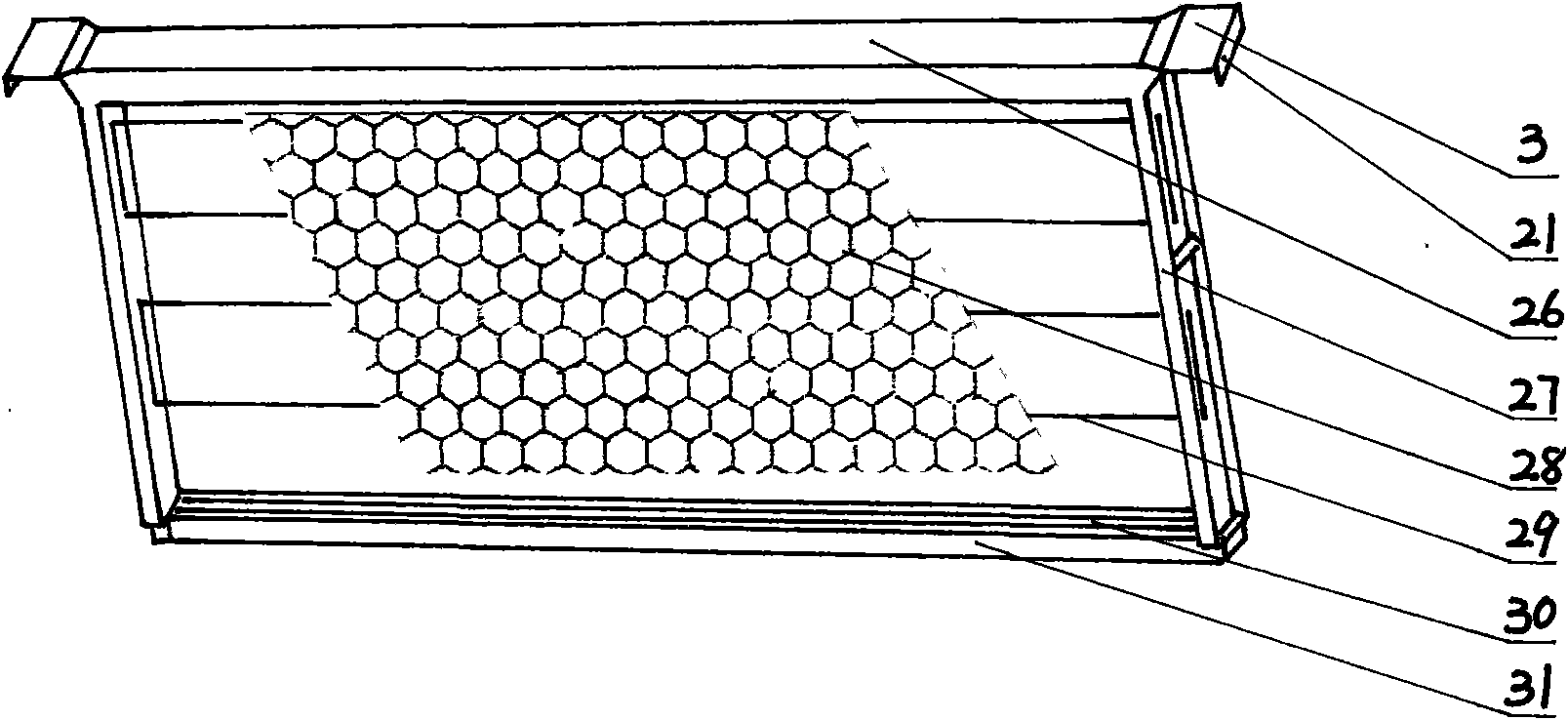

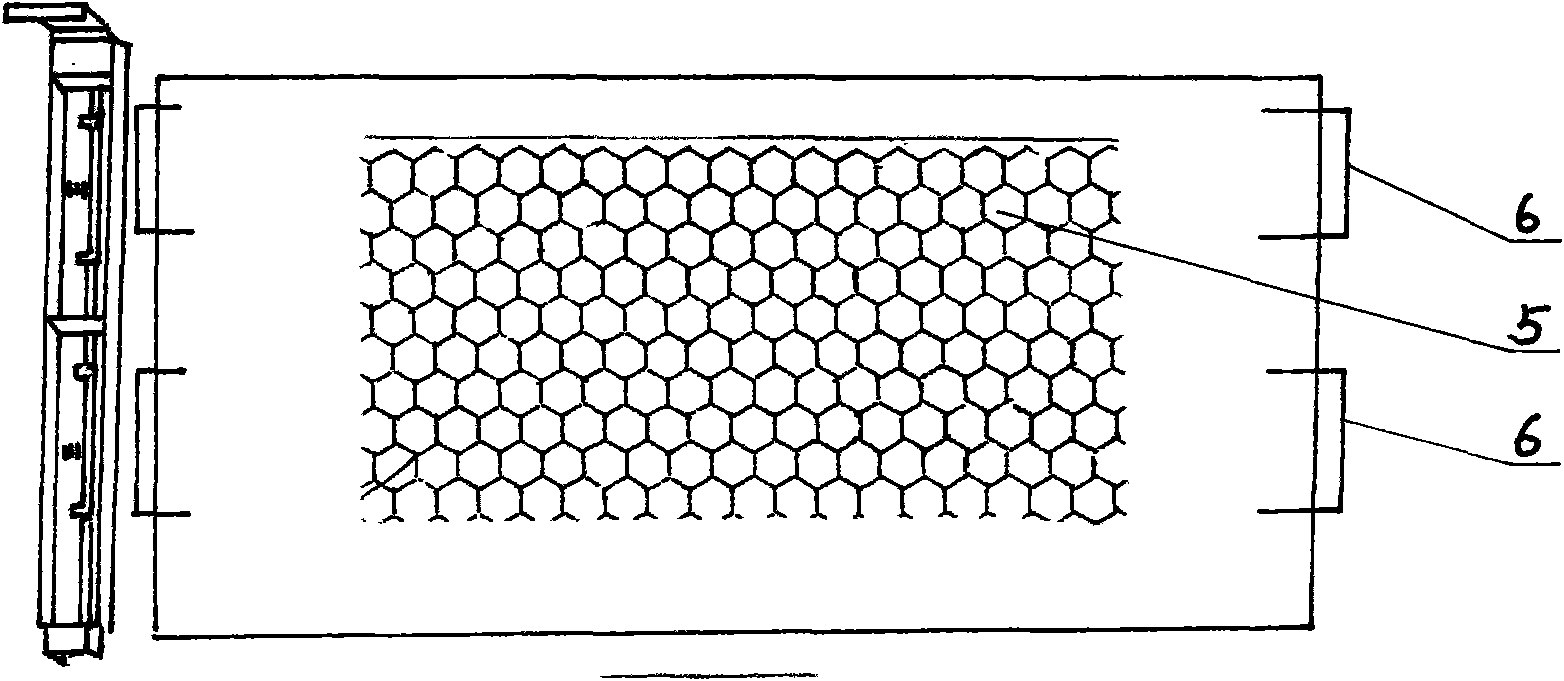

Comb frame and comb foundation sheet

InactiveCN101897302AQuick assemblyNo technical content requiredBeehivesStructural engineeringMechanical engineering

The invention discloses an inserting comb frame and an integrated comb frame, wherein a wax comb foundation sheet with hanging rings at two ends is provided. The comb frame is characterized in that an upper frame beam is thin and the number of cells in the frame is increased; a lower beam and side bars are notched to hold a plastic comb foundation; a lap plane is integrated with a frame distance card a whole, connected with the tops of the side bars by a lower inclined plane and triangular reinforcing planes at two side and higher and wider than the plane of the upper beam in a sopiler shape; the tops of the comb frame brackets are abutted closely against each other and compacted by a queen excluder and a gauze cover frame without gaps, so that honeybees are difficultly to extrud to death and the occurrence of stinging people is prevented; a lower handle on the top end of each lap is convenient to grasp, so that the overlapping of the laps is prevented, the frame distance is standard and the laps are extended out of the box for grasping; the upper and lower bands of the side bars are connected with a transverse ]-shaped opening of the wax comb foundation, a wide hanger and an adjusting buckle set for adjusting the length error of the hanging rings of the comb foundation; the laps of the inserting comb frame is integrated with the side bars into a whole; the wax comb foundation sheet is hung in the upper and lower wide hangers of two side bars; when two ends of the upper beam and two ends of the lower beam are inserted to the upper and lower slots of two side bars to combine the comb frame, the hanging rings are tightened; and the non-tightened hanging rings are pulled into the adjusting buckle set and then buckled. The invention improves the efficacy by more than 20 times and is suitable for keeping bees around the world.

Owner:汪修建

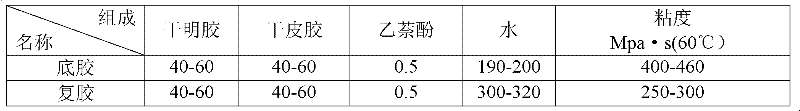

Mirror polishing method for complex ceramic surface

The invention belongs to the field of precision finishing of structural or functional ceramic, particularly relating to a mirror polishing method for a complex ceramic surface. The method comprises the following steps of: adhering a grinding agent to abrasive cloth or abrasive paper and performing a plurality of polishing processes on the mirror surface from coarse to fine to improve degree of finish step by step. The method is characterized in that: the grinding agents adopted in the processes are micron-sized grinding agents with same granularity; and the abrasive cloth adopted in the polishing processes gradually changes from coarse to fine according to the granularity.

Owner:WUHAN FEIMIS SCI & TECH

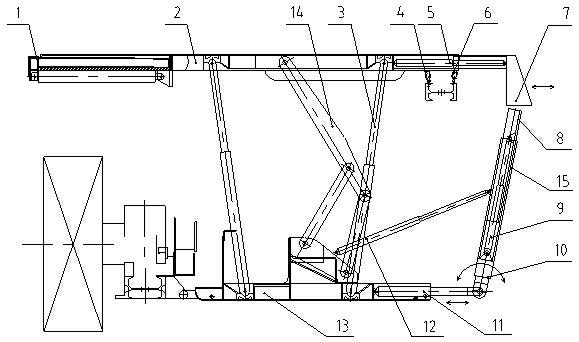

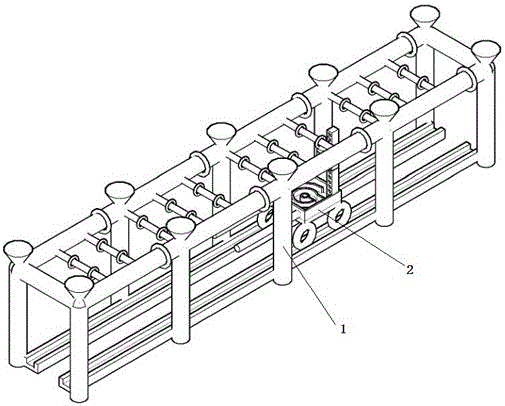

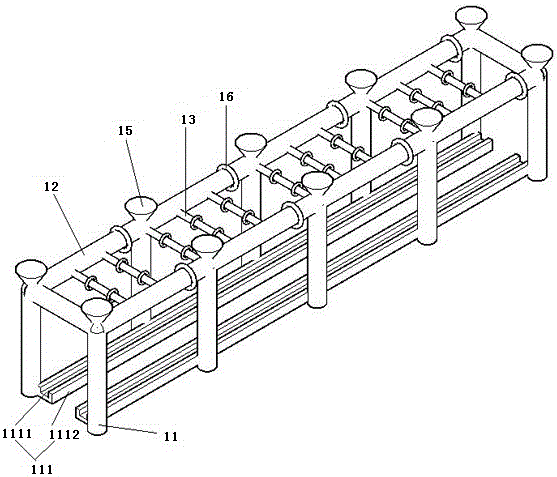

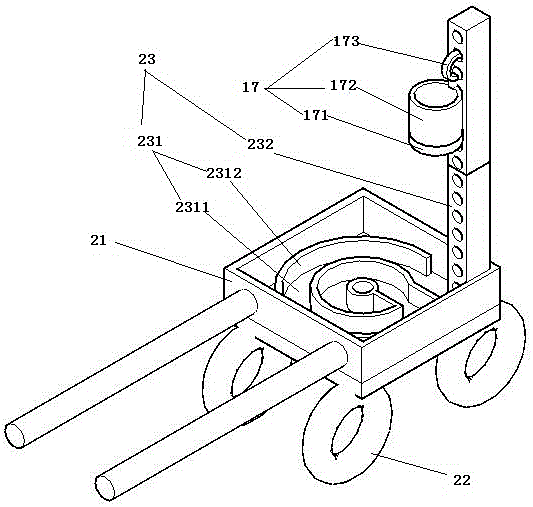

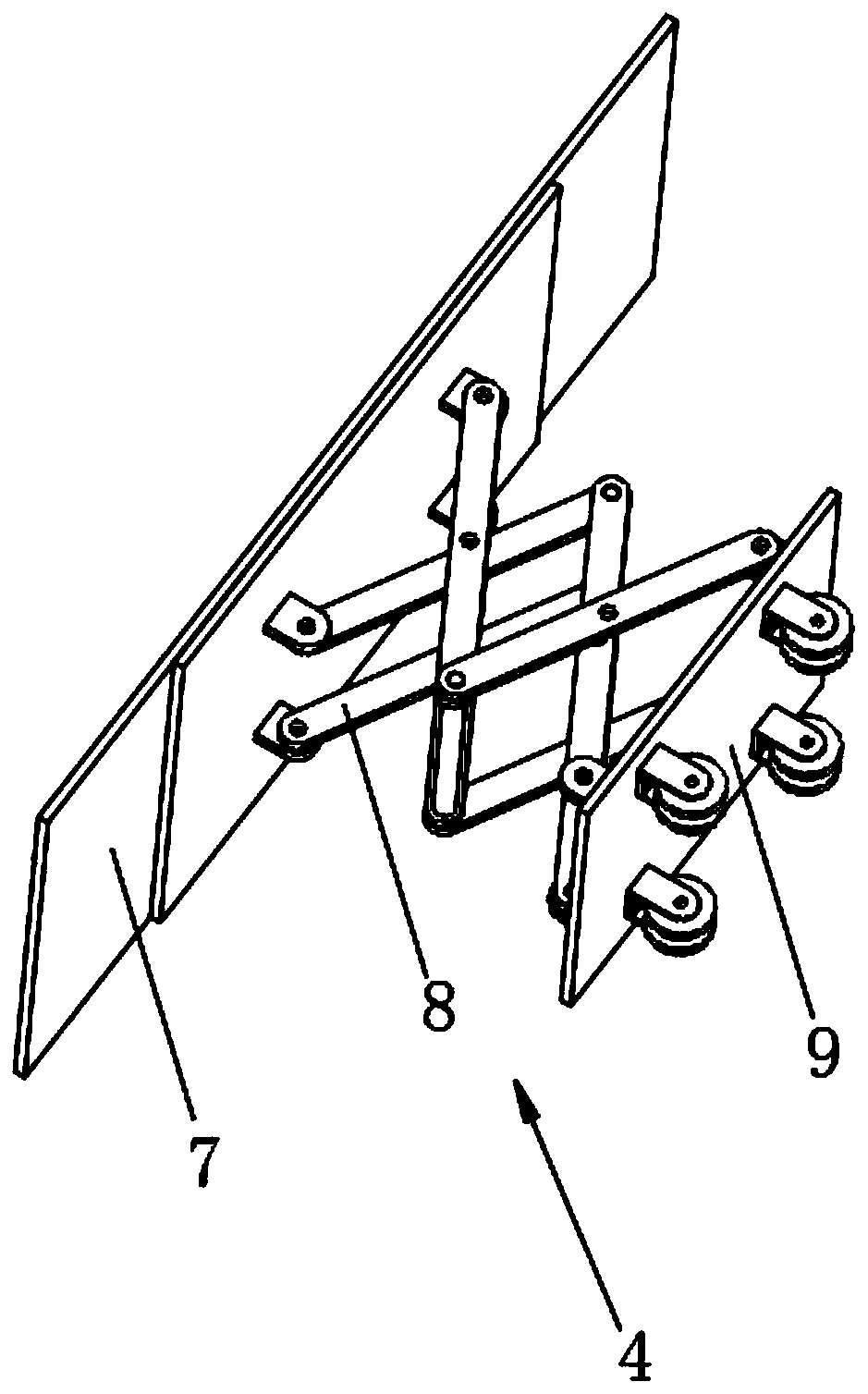

Picking-and-transporting-convenient grape planting method

ActiveCN106069569AProtection result rateIncrease productionClimate change adaptationGreenhouse cultivationGreenhouseTurning frames

The invention relates to a picking-and-transporting-convenient grape planting method. The picking-and-transporting-convenient grape planting method comprises the steps that a greenhouse is built in a grapery and grapes are picked and transported in the later period. The greenhouse comprises supporting pillars, main supporting frames, auxiliary supporting frames and a water pipeline arranged in the supporting pillars, the main supporting frames and the auxiliary supporting frames. The main supporting frames are arranged at the top ends of the supporting pillars and used for connecting and fixing the adjacent supporting pillars, and the auxiliary supporting frames are arranged on the main supporting frames and connected with the main supporting frames. A trailer for transportation is adopted in grape picking and transporting. The trailer comprises a trailer frame, wheels and a harvesting part, wherein the wheels are arranged below the trailer frame and used for moving the trailer frame forwards, and the harvesting part is arranged in the trailer frame and used for containing the grapes. By means of the picking-and-transporting-convenient grape planting method, the survival rate of grape seedlings can be increased, the setting percentage of the grapes is increased, the labor intensity of picking and transporting the grapes of workers is lowered, the final yield of the grapes can be increased, and the freshness degree and the integrity degree of the grapes are guaranteed.

Owner:GUANGDE YUANYE FRUIT GROWING FAMILY FARM

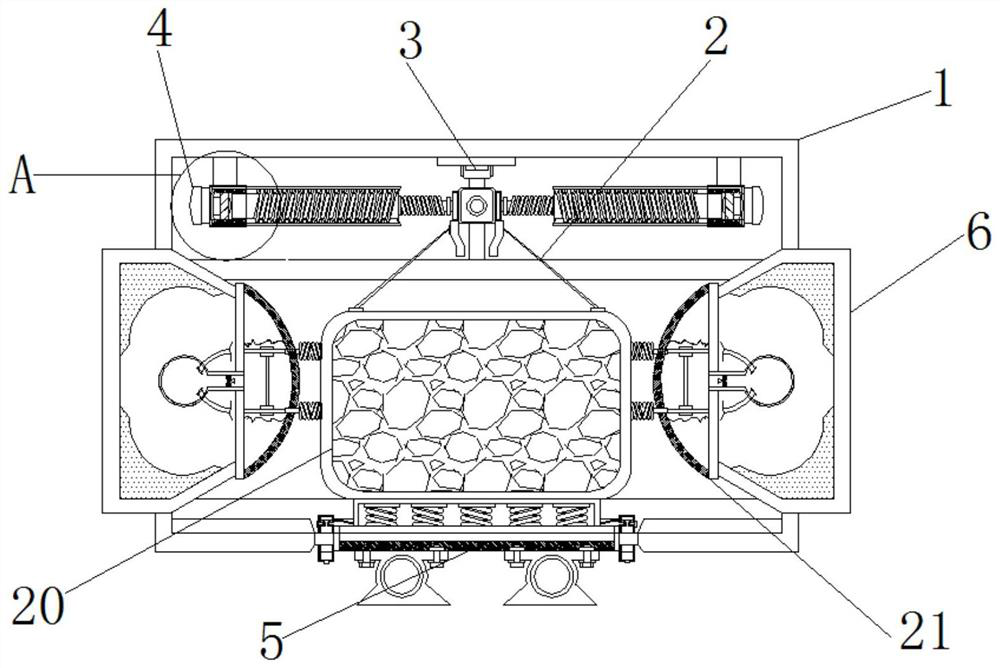

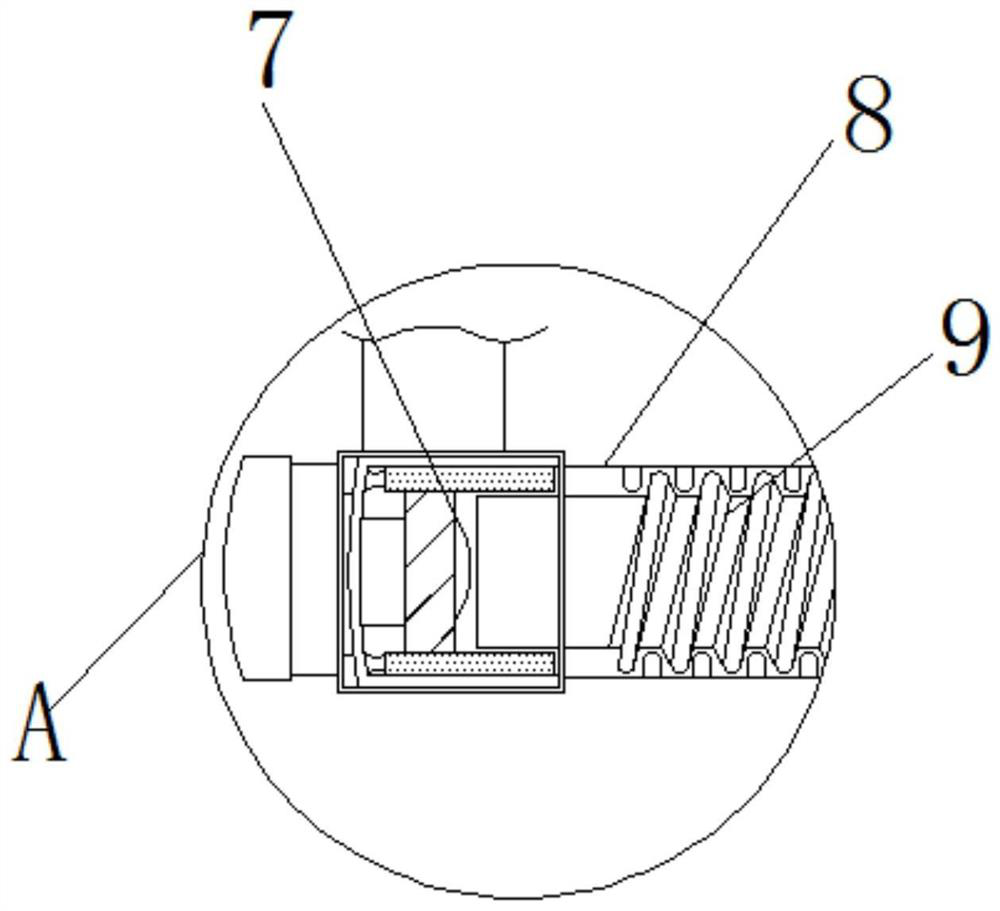

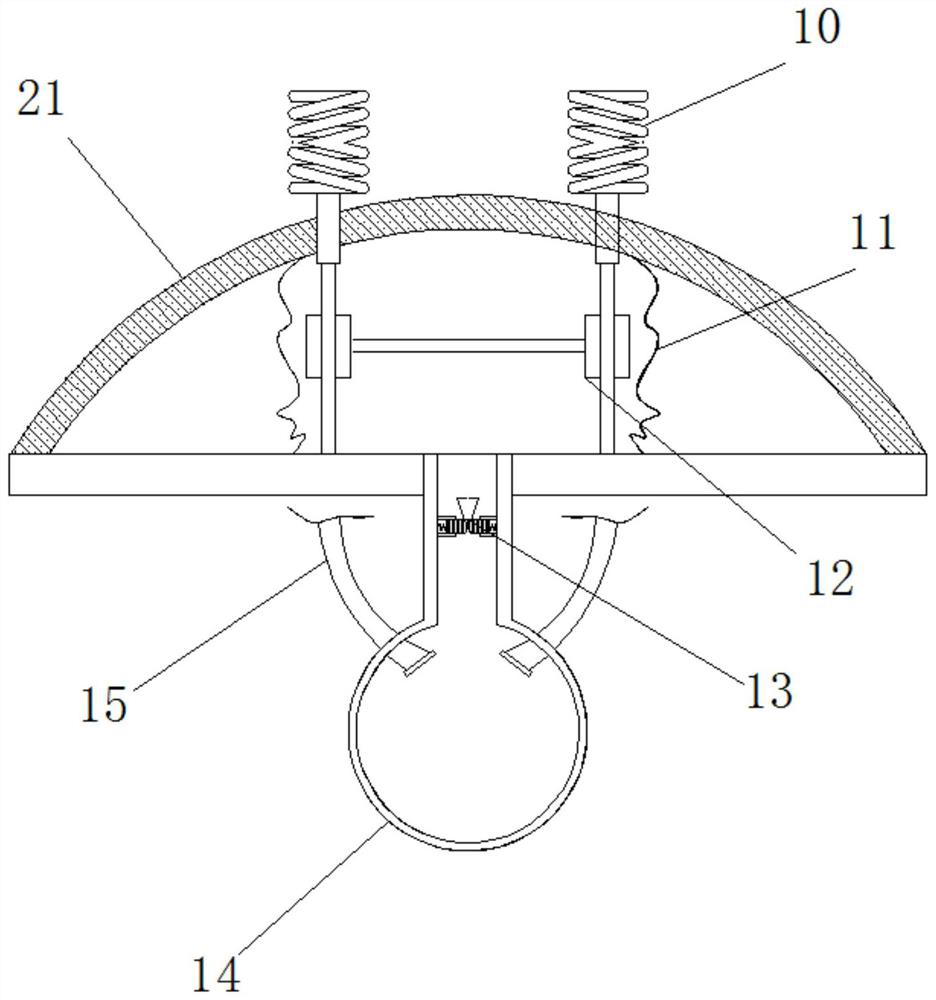

Express transportation box for protecting commodities by utilizing airbag structure

InactiveCN111907894AHas a buffering effectImprove picking efficiencyContainers to prevent mechanical damageRigid containersEngineeringTransportation technology

The invention relates to the technical field of internet commodity transportation, and provides an express transportation box for protecting commodities by utilizing an air bag structure. When the position of a loading tank is stabilized in the middle, internal expresses collide with one another and the internal collided expresses swing outwards, pressure is generated on first springs, the first springs drive fixing plates to press downwards, the fixing plates introduce pistons into airflow tanks through air pipes, so that the pressure intensity in the connection of the airflow tanks and air bags are changed, the airflow tanks introduce compressed air into the air bags, the air bags begin to expand, the air bags drive the rubber layers to deform to be attached to the outer wall of the loading tank to protrude out of the express, and the rubber layers are the rubber layers externally provided with sponge layers, so that the loading tank is not prone to being extruded, the loading tank is stabilized, moreover, a flow limiting net limits the flow of compressed gas, then the situation that the loading tank is impacted by the rubber layers due to the fact that the flow is too large andtoo high is avoided, thus products can not be damaged, and therefore express packages in a container cannot continuously shake in the cabinet.

Owner:广州清辉电子商务有限公司

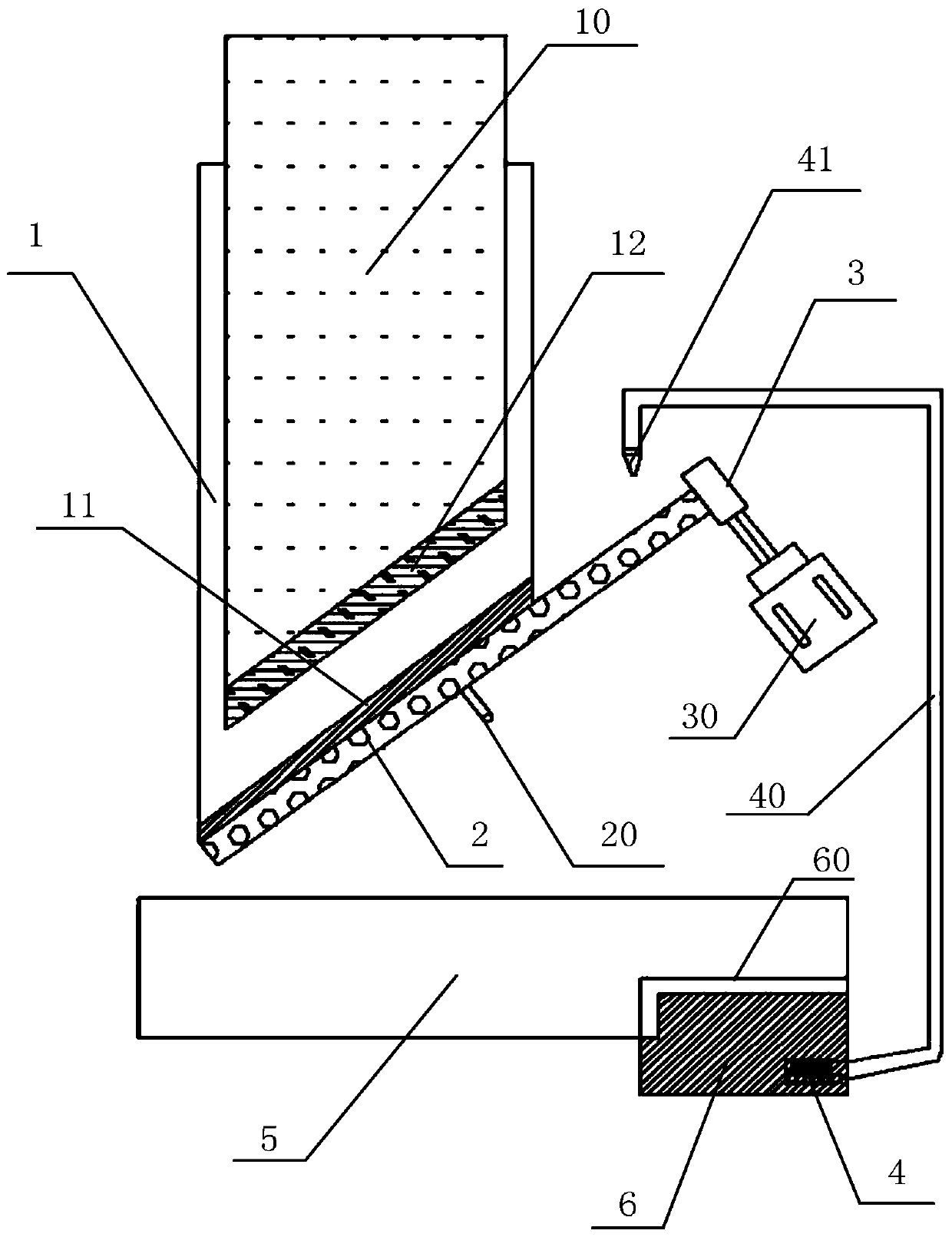

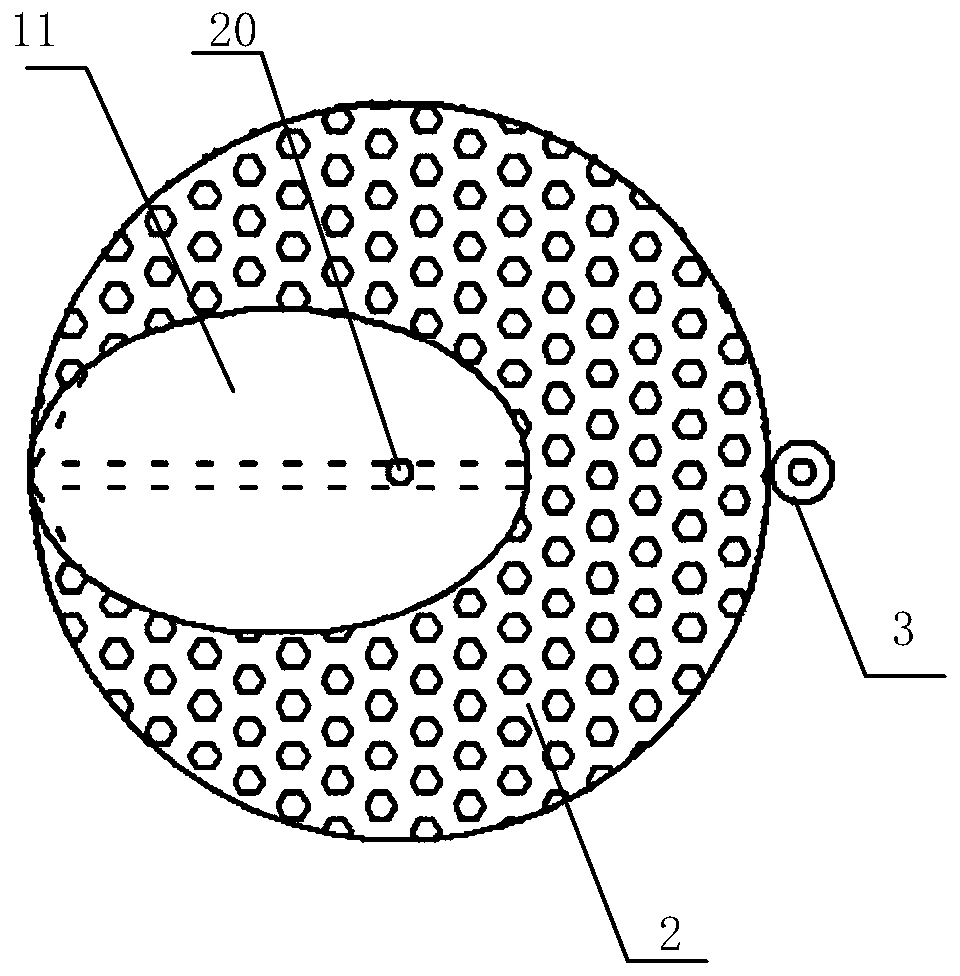

Anti-clogging extruder for wet garbage

The invention provides an anti-clogging extruder for wet garbage and belongs to the field of manufacturing of waste recovery equipment. The anti-clogging extruder comprises an extrusion barrel, a piston and a grid plate. The extrusion barrel is of a tubular structure opened in two ends, and a filter plate for sealing the bottom opening of the extrusion barrel is arranged at the bottom of the extrusion barrel; the piston is inserted into the extrusion barrel from the top opening of the extrusion barrel and is sleeved in the extrusion barrel; the grid plate is arranged close to the filter and isrotatably mounted on the extrusion barrel; and the area of the grid plate is larger than that of the filter plate. By arranging the filter plate at an outlet of the extrusion barrel and arranging therotatable grid plate close to the filter plate, the grid plate can be rotated continuously in an extruding and liquid draining process, so that clogging of the grid plate is avoided, and the wet garbage in the extrusion barrel can be extruded continuously and is hard to clog.

Owner:NANNING UNIV

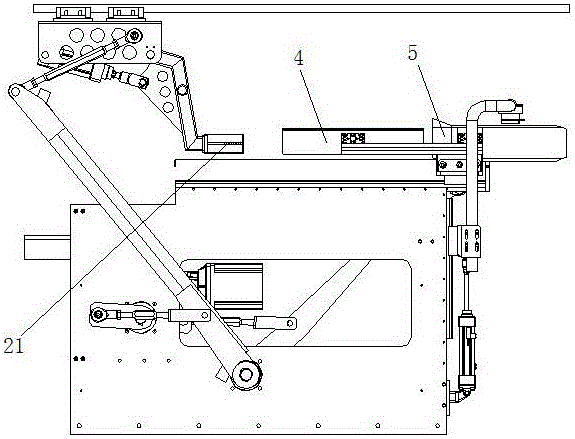

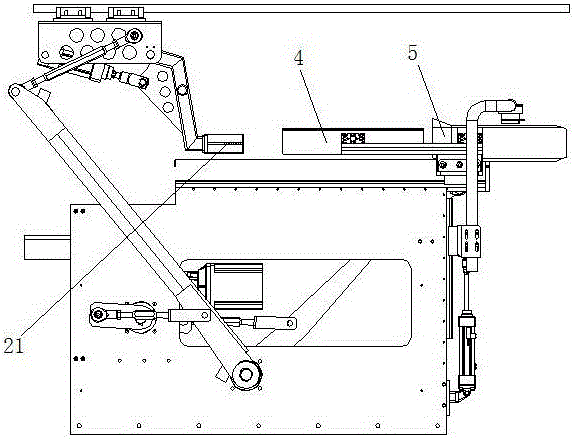

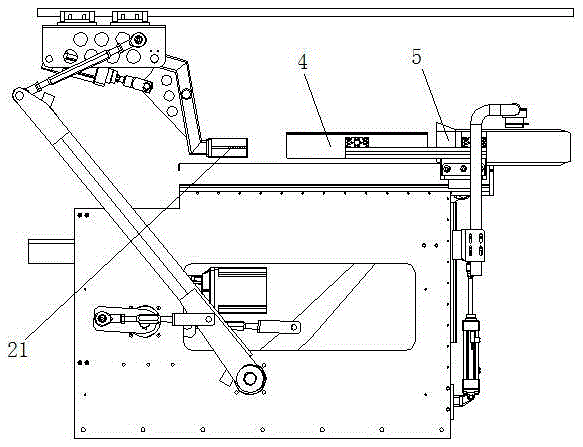

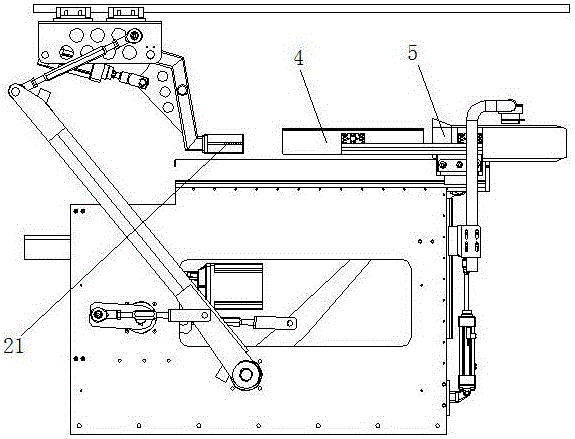

Material conveying and pushing method for prefabricated bag packaging machine

ActiveCN105691676ARealize the action of opening and opening bagsReduce processIndividual articlesRisk strokeSingle station

The invention discloses a material conveying and pushing method for a prefabricated bag packaging machine and relates to the technical field of packaging machine packaging processes. The material conveying and pushing method includes the steps that materials are conveyed to a to-be-clamped station; the materials conveyed to the to-be-clamped station are conveyed to a to-be-pushed station in a clamped manner; in the process of conveying the materials to the to-be-clamped station or the to-be-pushed station, prefabricated bags are conveyed to a bag opening station and opened on the bag opening station; the prefabricated bags are opened while the materials on the to-be-clamped station are conveyed to the to-be-pushed station in the clamped manner; in the material pushing process, the prefabricated bags and the materials move in the opposite directions; and the materials are pushed into the prefabricated bags moving in the direction opposite to the material pushing direction, and the prefabricated bags containing the materials in a wrapping manner are pushed to the assigned positions in the original material pushing direction. The material conveying and pushing method for the prefabricated bag packaging machine can solve the problems that by means of a prefabricated bag packaging machine in the prior art, the working procedures of a single station are complex, the number of the packaging actions is large, the stroke among different stations is long, the area occupied by equipment is large, material dumping occurs easily and the prefabricated bags are broken easily due to the fact that materials are irregular, the material pushing stroke is long, the packaging effect is poor, and the packaging efficiency is low.

Owner:上海松川峰冠包装自动化有限公司

Pumpkin seed meal nutrition breakfast snack food and preparing method thereof

InactiveCN105961496AAlso has therapeutic effectHigh in proteinDough treatmentBakery productsFood additiveAutomatic control

The invention discloses a pumpkin seed meal nutrition breakfast snack food and a preparing method thereof. The pumpkin seed meal nutrition breakfast snack food is prepared from, by weight, 45-55% of pumpkin seeds, 25-35% of flour and 15-25% of corn flour. Under the premise of maintaining the natural characteristics of the raw materials to the maximum and adding no food additive, the novel breakfast food which is green, nutritive and capable of achieving a food therapy effect is studied and developed, and belongs to high-protein and high dietary fiber nutrition food. The food is prepared under the premise that the nutritive ingredients of pumpkin seed meal are not damaged, stability and reliability of the content of dietary fibers in food are ensured, and the product taste is improved. Through automatic control, stability of the temperature, pressure and the like is ensured, stability and reliability of the content of dietary fibers are ensured, and controllability of key points is achieved; meanwhile, the processing time is shortened, and the production efficiency is improved.

Owner:URUMQI FENGYUAN TIANYE AGRI SCI & TECH

Efficient wear-resistant micro-powder graphite lubricating grease for vehicle steel plate spring and preparation method of wear-resistant micro-powder graphite lubricating grease

InactiveCN103275791AExtend your lifeImprove pressure resistanceAdditivesMechanical stabilityGraphite

The invention discloses efficient wear-resistant micro-powder graphite lubricating grease for a vehicle steel plate spring and a preparation method of the wear-resistant micro-powder graphite lubricating grease. The efficient wear-resistant micro-powder graphite lubricating grease is formed by refining lithium-based grease, base oil and an oiliness agent, super-micro and fine graphite powder, an antioxidant and corrosion inhibitor; the efficient wear-resistant micro-powder graphite lubricating grease is efficient in extreme pressure wear-resistant performance and adhesiveness, low in friction coefficient, strong in bearing capability, and excellent in mechanical stability and chemical stability; and the lubricating grease is vapor-resistant, capable of resisting the corrosion of weak acid-base, and excellent in water resistance and water washing. The aims of providing lubricating, wear-resisting, rust-preventing and corrosion-resisting performances for the large lorry steel plate spring are realized in sever rugged environment.

Owner:刘方旭

Hoisting slider device for insulating layer in greenhouse

ActiveCN102356738AGuaranteed uptimeNot easy to come outClimate change adaptationGreenhouse cultivationGreenhouseManufacturing engineering

The invention discloses a hoisting slide device for an insulating layer in a greenhouse. The device provided by the invention comprises a frame, wherein a tackle capable of hoisting the insulating layer in the greenhouse is arranged below the frame; and the tackle is in slip connection with the frame. According the invention, a material steel angle which is never used in a greenhouse heat insulating object operation track design is utilized, so that products can be standardized more easily; the tackle is easy to develop and realize large-scale production; and the overall system is stable in operation, small in resistance, large in bearing, less possibility of digression and less possibilities of squeezing and torsion failure. Compared with the prior art, according to the invention, the cost for each common greenhouse can be saved about ** yuan, thus due to the change, a hanging-type inner heat insulating greenhouse has great popularization and application prospects.

Owner:南通顺天农业发展有限公司

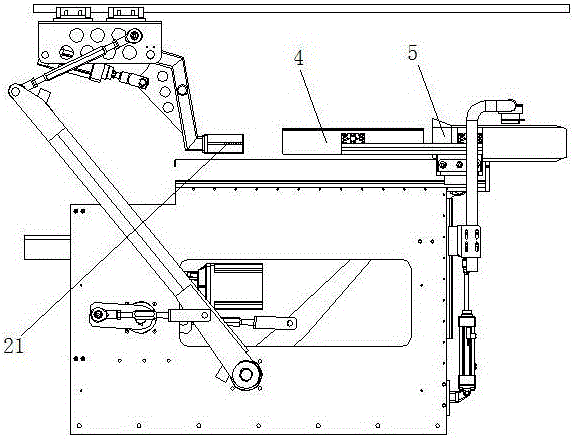

Material clamping and conveying method for prefabricated bag packaging machine

The invention discloses a material clamping and conveying method for a prefabricated bag packaging machine, and belongs to the field of material packaging. The material clamping and conveying method is characterized by comprising the following steps: a, a material is fed by a material feeding mechanism to a to-be-clamped station, and clamped by the two sides in the horizontal material conveying direction of a clamping mechanism; b, the clamped material is conveyed to a to-be-pushed station, and a prefabricated bag is expanded by a bag expanding mechanism; and c, the material conveyed to the to-be-pushed station is pushed by a material pushing mechanism, and meanwhile the prefabricated bag is driven by the bag expanding mechanism to move opposite to the pushed material. By adoption of the material clamping and conveying method, the material can be pushed by the material pushing mechanism into the prefabricated bag continuously, and the continuous degree of material conveying and pushing is high. Besides, the material clamping and conveying method has the characteristics that the conveying and packaging stroke is short, and the packaging efficiency is high.

Owner:上海松川峰冠包装自动化有限公司

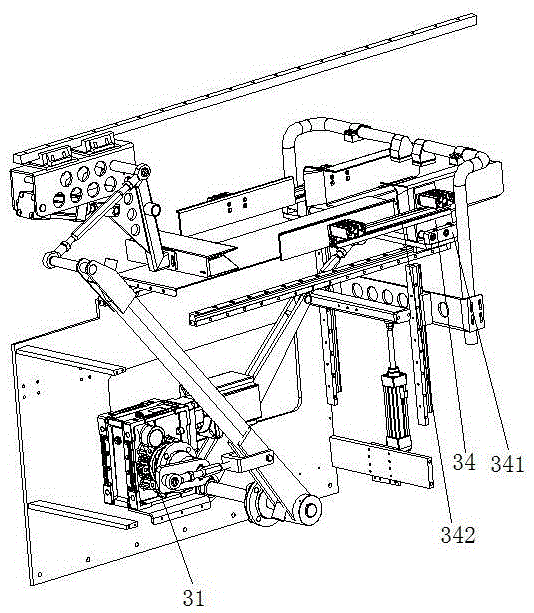

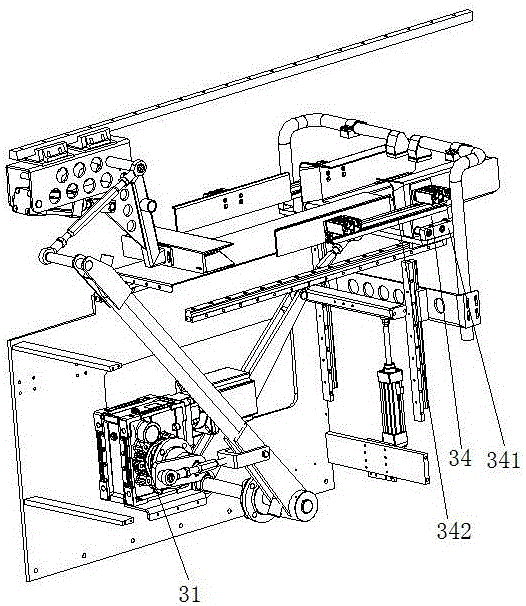

Material packaging method for prefabricated bag packaging machine

ActiveCN105691677AHigh degree of continuityImprove packaging efficiencyIndividual articlesEngineeringPacking method

The invention discloses a material packaging method for a prefabricated bag packaging machine, and belongs to the technical field of material packaging. The material packaging method comprises the following steps: material clamping or holding, prefabricated bag expanding, material pushing and prefabricated bag removing, wherein in the material clamping or holding process, a material is clamped or held under the action of a clamping mechanism or a holding mechanism, and conveyed to a to-be-pushed station; in the prefabricated bag expanding process; the left and right sides of the bag mouth of the prefabricated bag are expanded under the action of a bag expanding mechanism; in the material pushing process, the material moves under the action of a material pushing mechanism in the direction of the bag mouth of the prefabricated bag to the bottom of the prefabricated bag, and continues being pushed along with the prefabricated bag; and in the prefabricated bag removing process, after moving to the bottom of the prefabricated bag, the material continues being pushed by the material pushing mechanism, and then is removed from the bag expanding mechanism. By adoption of the material packaging method, the material can be pushed by a material pushing head into the prefabricated bag continuously, and the continuous degree of material conveying and pushing is high. Compared with a conventional packaging method, the material packaging method provided by the invention has the advantages that the conveying and packaging stroke is shorter, and the packaging efficiency is higher.

Owner:上海松川峰冠包装自动化有限公司

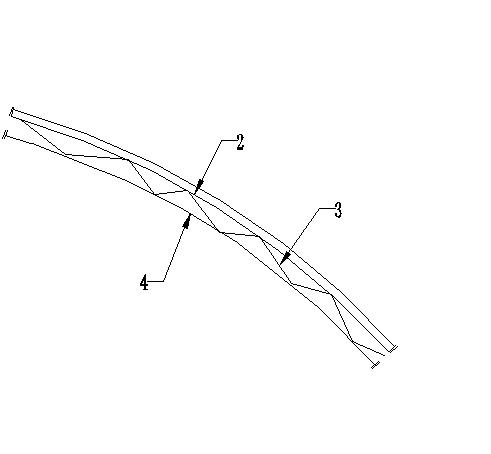

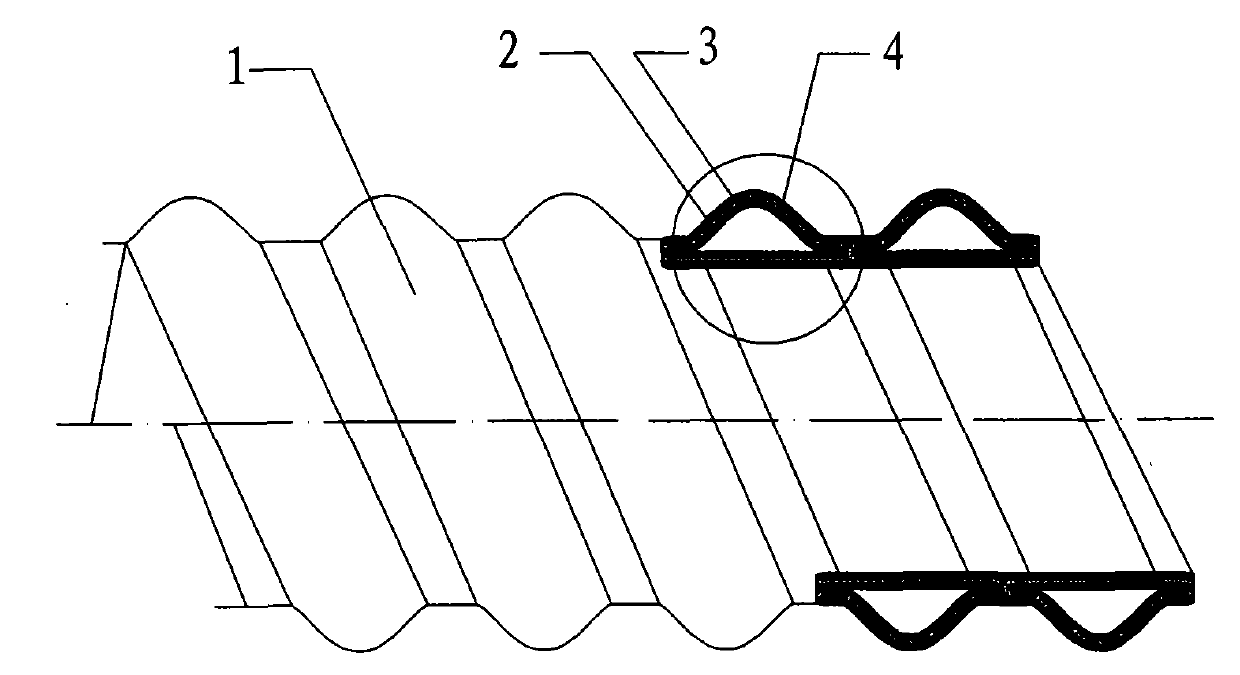

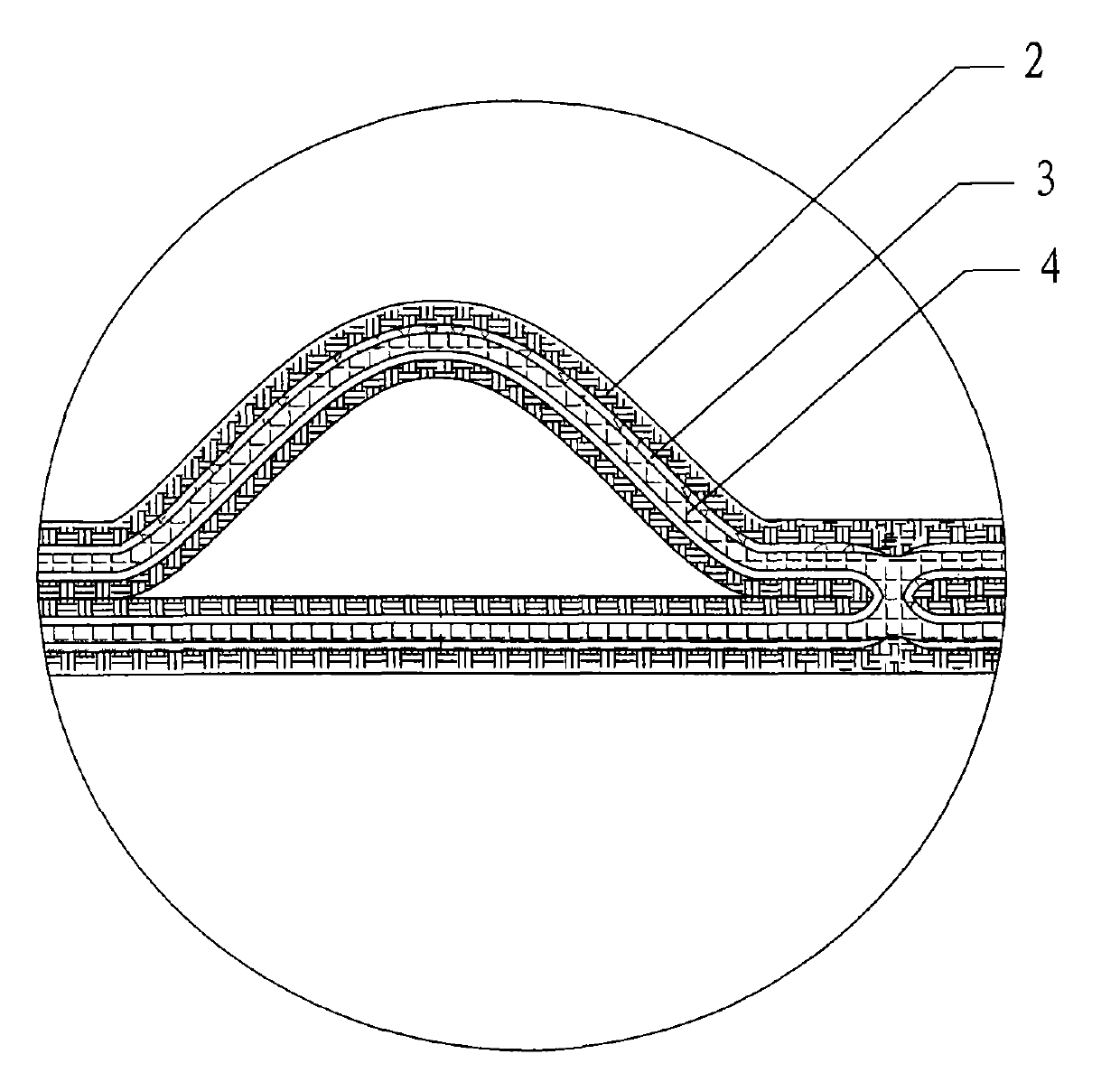

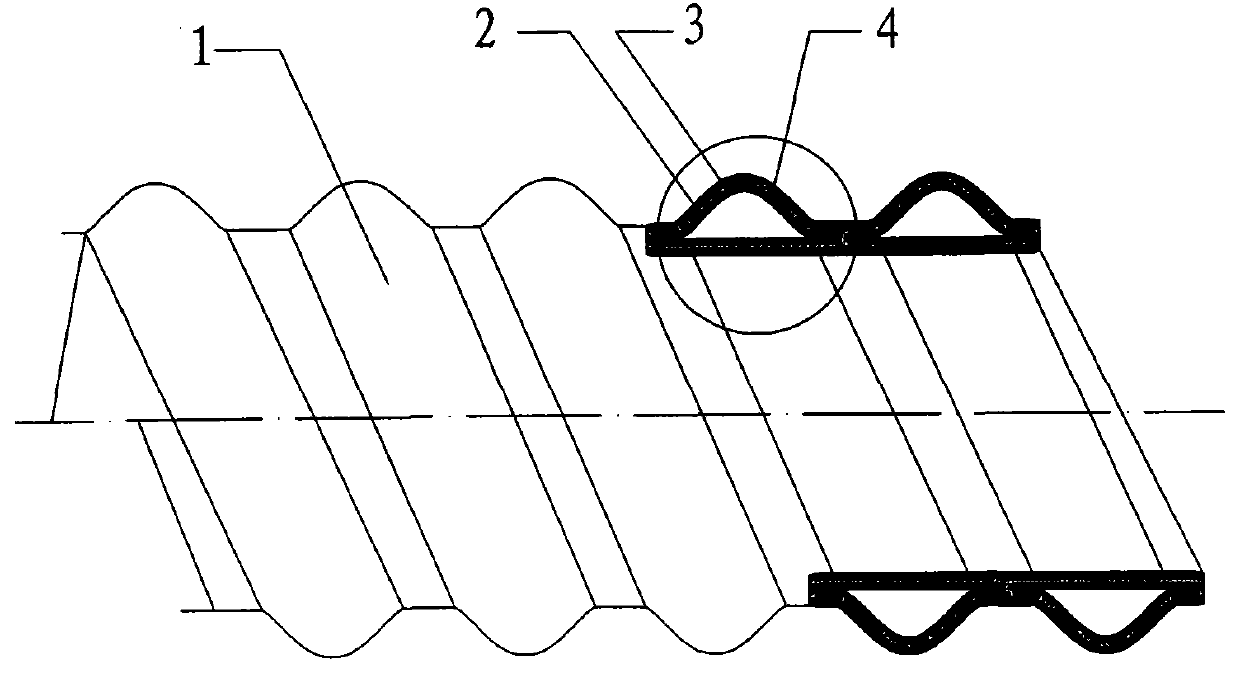

Steel-plastic composite pipe

InactiveCN102086954AIncreased ring stiffnessNot easy to break awayRigid pipesHigh pressureMetallurgy

The invention discloses a steel-plastic composite pipe. The steel-plastic composite pipe comprises a steel strip (4) with a specially-shaped cross section and plastic coatings (2), and is characterized in that: the specially-shaped cross section of the steel strip is hollow and closed; the steel strip is spirally wound to form a tubular body (1); adjacent edges of the steel strip are fixedly welded; and both inner layer and outer layer of the tubular body are provided with the plastic coatings. Since the specially-shaped steel strip has a hollow and closed structure and is wound and welded to form the tubular body, the ring stiffness of a pipeline is obviously improved, high-strength pressure can be born, the pipe is difficultly degummed and squeezed to be broken, and the aims of high strength, high pressure bearing capacity, firm steel-plastic adhesion, difficulty in separating steel from plastic and continuous integral steel strips are fulfilled.

Owner:SICHUAN JINYI PLASTIC PIPE IND

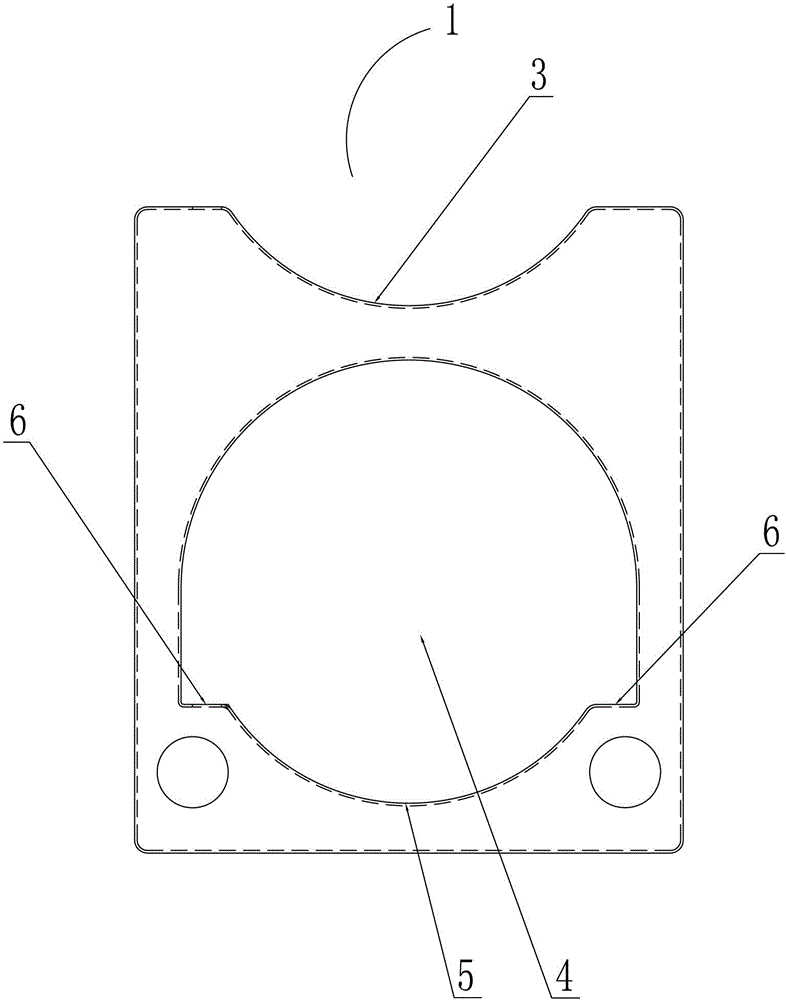

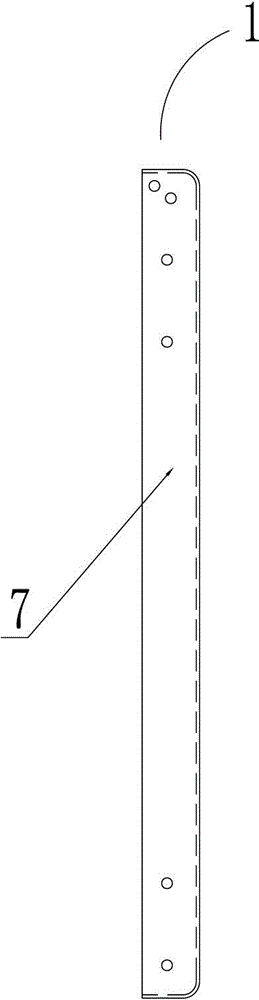

Integrated supporting saddle for mounting upper-down double-gas bottles

InactiveCN104786830AEasy installation and maintenanceImprove the safety of useFuel supplyLiquefied natural gasChemical engineering

The invention discloses an integrated supporting saddle for mounting upper-down double-gas bottles. The integrated supporting saddle comprises an upper-down double-gas bottle supporting template frame integrally formed, the top of the upper-down double-gas bottle supporting template frame is provided with upper arc-shaped gas bottle bases matched with bottle bodies of liquefied natural gas bottles. The portion, below the upper arc-shaped gas bottle bases, of the upper-down double-gas bottle supporting template frame is internally provided with mounting holes allowing the liquefied natural gas bottles to penetrate through. The side edges of the bottoms of the mounting holes are provided with lower arc-shaped gas bases matched with the bottle bodies of the liquefied natural gas bottles. The integrated supporting saddle has the advantages of being convenient to mount and maintain, high in use safety, lighter in weight and not prone to extruding the bottle bodies of the liquefied natural gas bottles.

Owner:ZHANGJIAGANG HUADI MACHINERY EQUIP

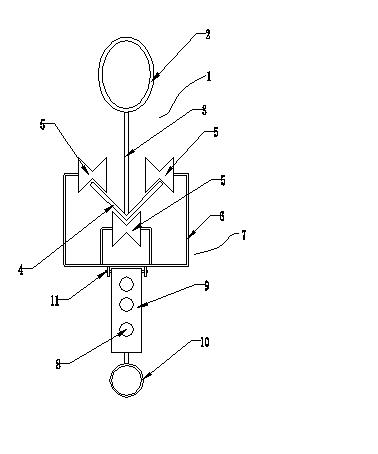

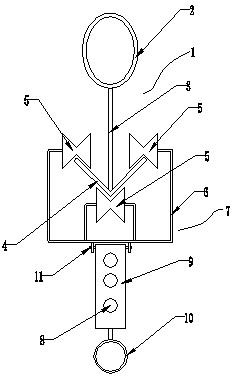

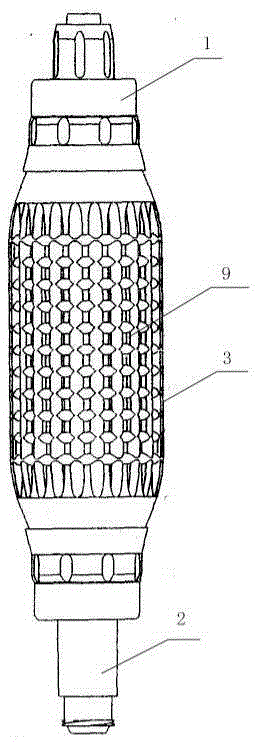

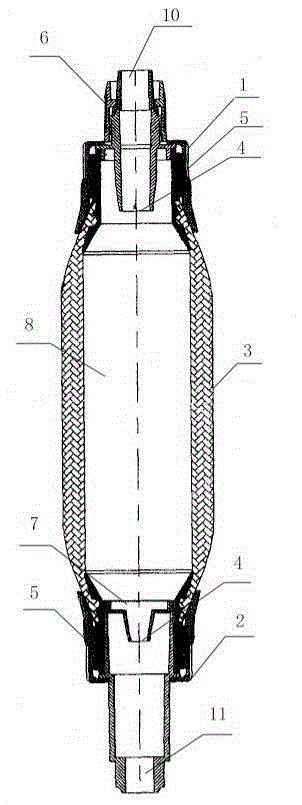

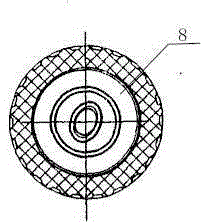

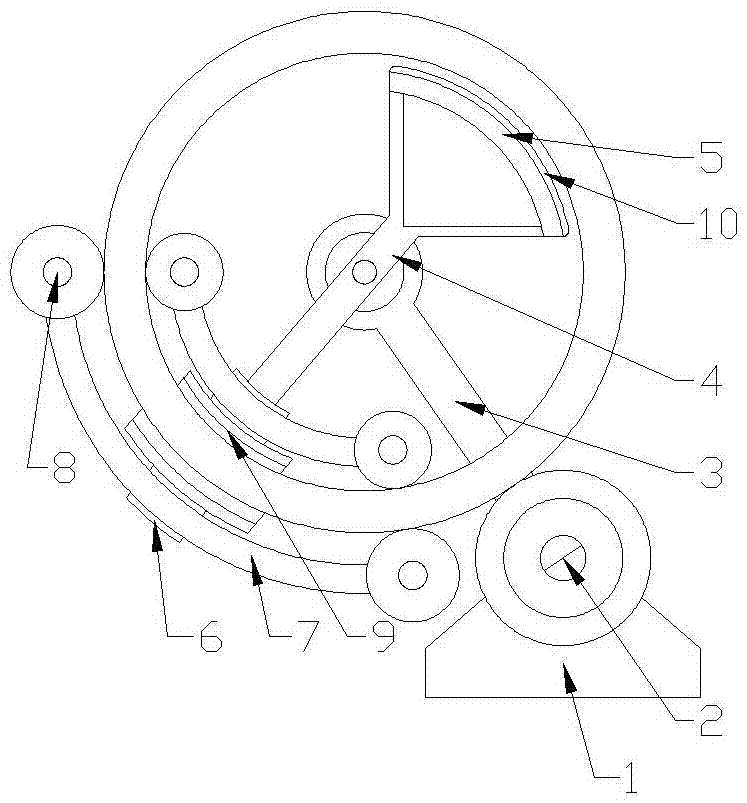

Fusiform scale-like positive and negative pressure biphase hand pump

ActiveCN105412999AImprove adaptabilityRealize different intensity operationsEnemata/irrigatorsWound drainsOperabilityAutologous blood

The invention relates to medical aid equipment, in particular to a fusiform scale-like positive and negative pressure biphase hand pump. The fusiform scale-like positive and negative pressure biphase hand pump is suitable for high-negative-pressure rapid suction and has the high-viscosity rapid phlegm suction function, the low-negative-pressure gastrointestinal decompression function, the low-negative-pressure intrathoracic blood recovery function and the high-pressure debridement wash function. The size of the a fusiform scale-like positive and negative pressure biphase hand pump is obtained after the applicant conducts a lot of experiments, and can be adapt to the shapes of the hands of most medical workers; as coordination and unification between the pump body wall tension and the pump body wall compliance, coordination and unification between the pump body power and the speed per hour and coordination and unification between the pressure capacity and the suction and displacement quantity are achieved, the application range is wider, practicability and operability are improved, forceful manual operation is achieved, the rhythm can be fast or slow, the pressure can be high or low, the flow can be large or small, energy can be released according to the needs of injury, and the large-flow and high-viscosity negative-pressure phlegm suction function, the low-negative-pressure gastrointestinal decompression function, the autologous blood recovery function, the high-displacement spray debridement wash function and the like are achieved.

Owner:张世范

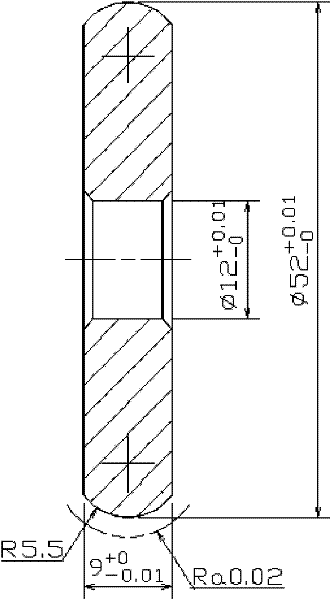

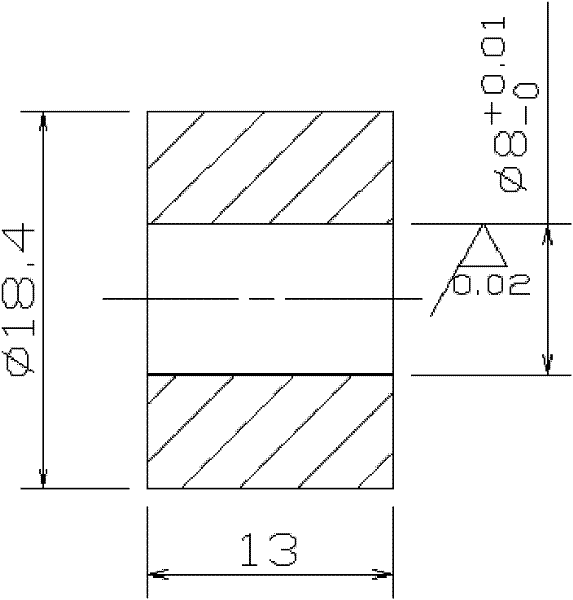

Simple bearing accessory polisher

InactiveCN107538289ASimple structureLow costRevolution surface grinding machinesGrinding work supportsSanderEngineering

The invention relates to a simple bearing accessory grinder, which comprises a base, a support arm is arranged on the base, a sliding arm is arranged on the supporting arm; two groups of pressing members are sequentially arranged on one axial end of the sliding arm , the pressing member includes a sliding sleeve that is slidably connected with the sliding arm, and an arc-shaped pressing piece is fixed on the sliding sleeve. The pressing piece is made of elastic material. wheel; a grinder is provided between the sliding sleeves of the aforementioned two groups of pressing members, the grinder includes a grinding block slidingly connected with the sliding arm, an arc-shaped grinding groove is arranged on the grinding block, and a grinding groove is arranged on the inner wall of the grinding groove. layer; the other end of the sliding arm is fixedly connected with a support frame, the support frame includes two support arms and an arc-shaped support surface fixed between the support arms, and an expansion angle greater than 90° is arranged between the support arms. A sliding surface made of nylon is provided on the surface of the supporting surface.

Owner:WUXI SIBORUI ELECTROMECHANICAL CO LTD

Material conveying method for prefabricated bag packing machine

The invention discloses a material conveying method for a prefabricated bag packing machine, and belongs to the technical field of material packing. The material conveying method is characterized by comprising the following steps that (a), material after being held or clamped is conveyed to a station to be pushed in the opening direction of a prefabricated bag; (b), the left side and the right side of the prefabricated bag are opened; (c), the material is pushed on the station to be pushed, the precast bag is moved, the material and the prefabricated bag perform opposite motion, and the material is pushed into the prefabricated bag; (d), the material is pushed to the bottom of the prefabricated bag, and the material continues moves along with the prefabricated bag in the pushed direction; (e), next material is cyclically conveyed according to the steps. The material conveying method disclosed by the invention has the characteristics that the material pushing serialization degree is high, the conveying and packing distance is short, the materials cannot fall, and the conveying and packing efficiency is high.

Owner:上海松川峰冠包装自动化有限公司

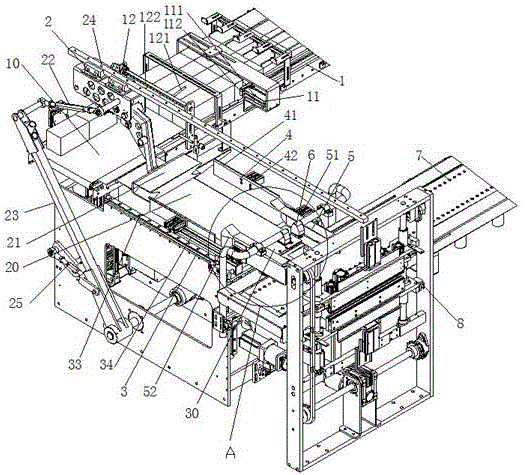

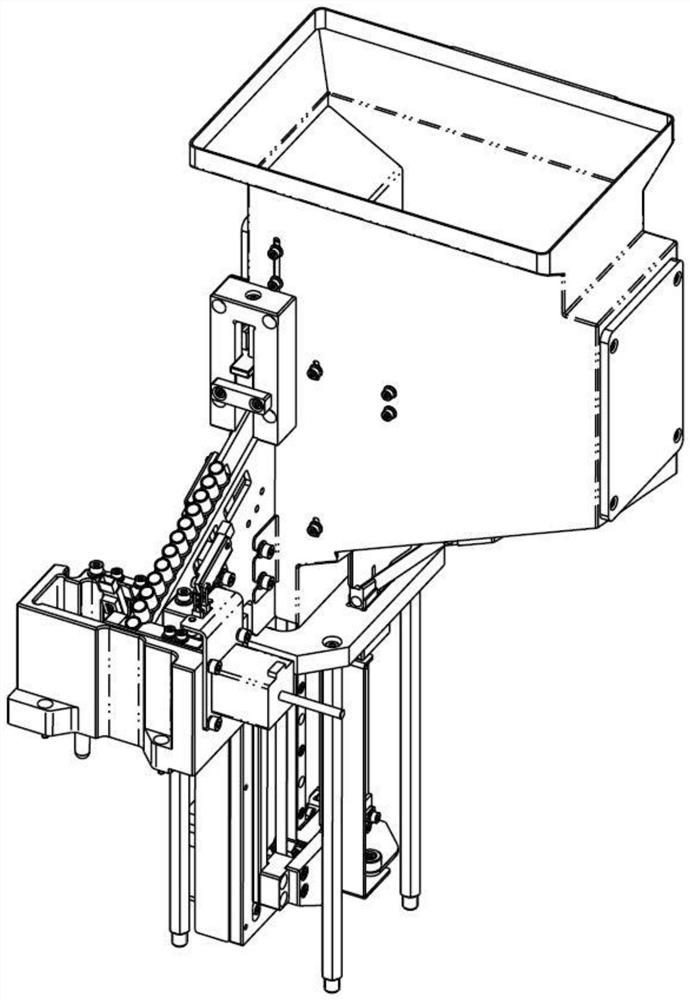

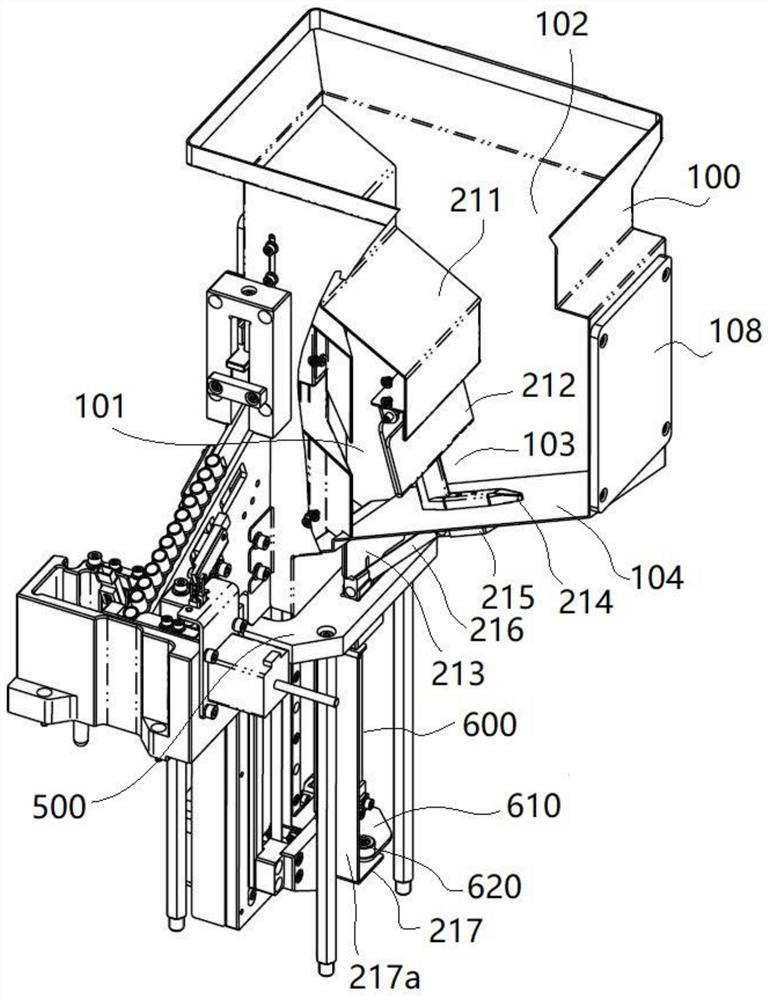

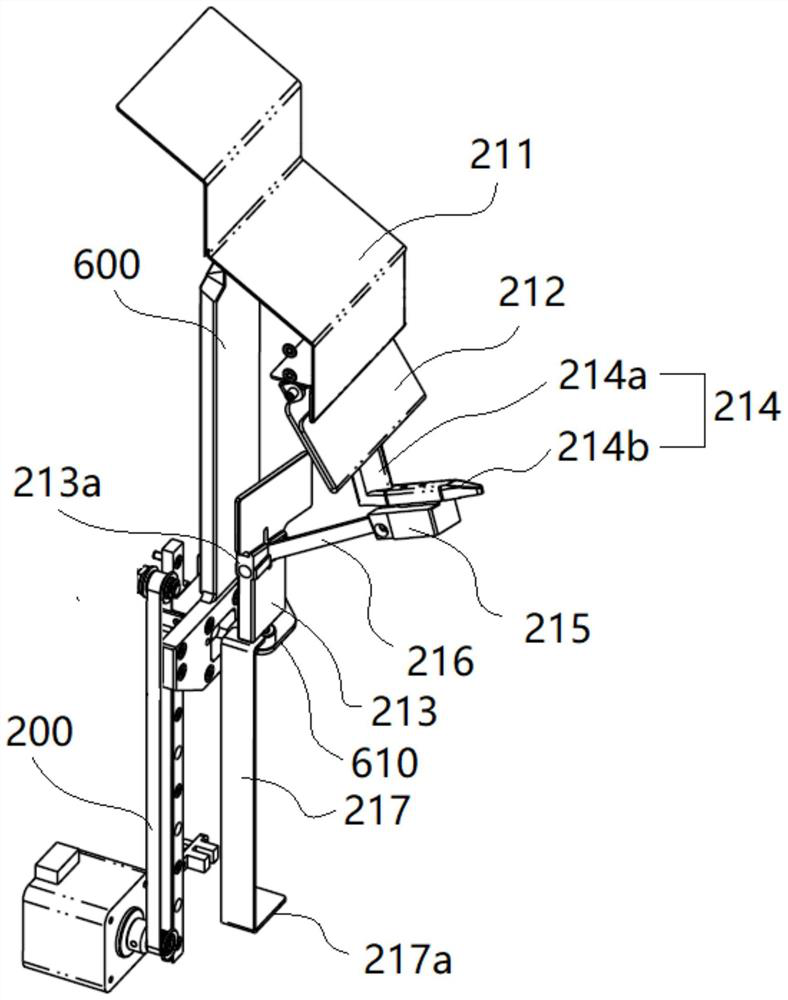

Flow rate control mechanism, flow rate control method and automatic loading and sequencing device

PendingCN112340478ANot easy to squeezeGuaranteed uptimeLoading/unloadingConveyor partsReciprocating motionControl engineering

The invention discloses a flow rate control mechanism, a flow rate control method and an automatic loading and sequencing device. The flow rate control mechanism and the flow rate control method divide the space in a stock bin into a buffer area and an isolation area, and a stroke between the buffer area and the isolation area allows articles to enter a channel of the buffer area from the isolation area. A reciprocating moving part changes the boundary position of the isolation area through periodic reciprocating motion, repeatedly reduces or expands the volume of the isolation area, and pushes, squeezes and disturbs articles in the isolation area when the volume of the isolation area is reduced. According to the flow rate control mechanism, the number of articles in the buffer area is relatively small, so that smooth operation of a material ejecting piece is facilitated, and the articles are not easily damaged by extrusion; and through the reciprocating motion of the reciprocating moving part, the boundary position of the isolation area is changed, articles in the isolation area are pushed, squeezed and disturbed, the phenomenon that a reaction cup is stuck or hollow in a bin canbe avoided, and the reaction cup can enter the buffer area at the periodically-changed flow speed, the reaction cup flows into the bottommost part of the bin at a constant speed equivalently.

Owner:ZYBIO INC

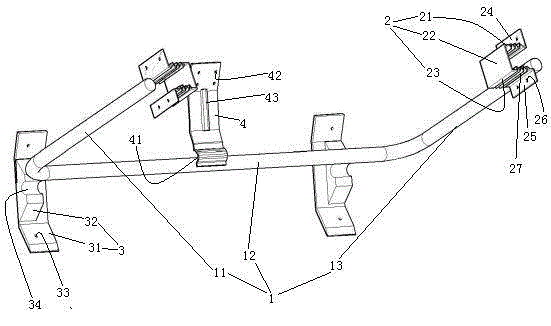

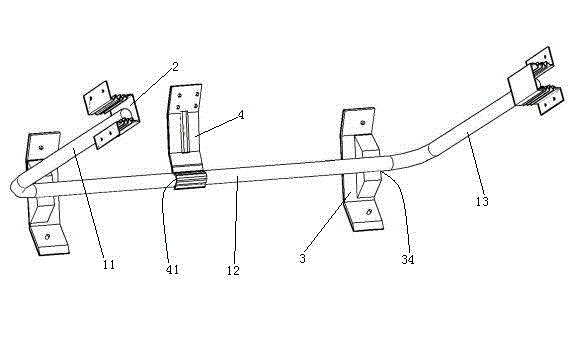

Strengthening beam structure for automobile front wall

ActiveCN102745248ANot easy to cause sheddingImprove securitySuperstructure subunitsStructural engineeringUltimate tensile strength

The invention relates to an automobile strengthening beam. The strengthening beam structure for an automobile front wall comprises a cross beam which is in a tubular structure and comprises a left supporting section, a front wall supporting section and a right supporting section, wherein the three sections are connected in a U shape, the left supporting section is detachably connected onto a left panel of the automobile, the right supporting section is detachably connected onto a right panel of the automobile, and the front wall supporting section is detachably connected onto a front panel of the automobile. The strengthening beam structure for the automobile front wall is high in strength, convenient to mount and dismantle, and solves the problems of poor strength and inconvenient mounting and dismounting of the existing front panel strengthening beam structure for strengthening the front panel.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Hardware tool storage device with large storage capacity and easy to find

ActiveCN110722525AEasy to installQuick installation and removalWork tools storageComputer hardwareDrive shaft

The invention discloses a hardware tool storage device with large storage capacity and easy to find. The hardware tool storage device comprises supporting frames, a rotating mechanism and a storage mechanism, wherein the rotating mechanism comprises a driving shaft in the middle part, and the two ends of the driving shaft are connected with first rotating rods; the outer parts of the two ends of the driving shaft are connected with driven gear rings, and a plurality of bearing plates are connected between the inner wall of each driven gear ring and the outer part of the driving shaft; the rotating mechanism is rotationally arranged between the tops of the two supporting frames; and the first rotating rods of the two ends of the driving shaft are rotationally connected with the supporting frames. The storage mechanism can be assembled and disassembled through a buckling plate and a clamping groove conveniently and quickly and is more convenient and faster in use. A plurality of fixing rings are arranged at the outer part of a connecting shaft through threads, and the fixing rings are twisted to move up and down on the outer part of the connecting shaft. The position of the fixing rings on the connecting shaft can be adjusted according to the actual demand for placing hardware tools of different sizes.

Owner:安徽群升建筑工程有限公司

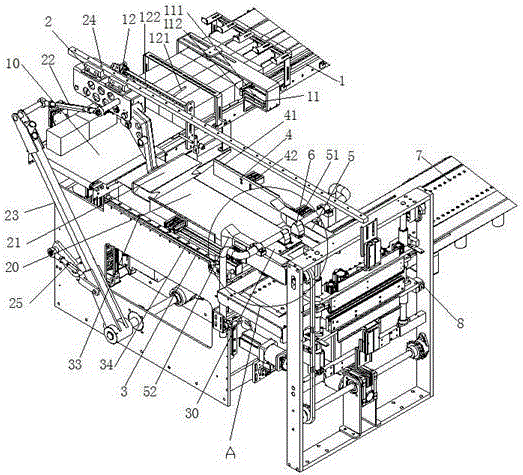

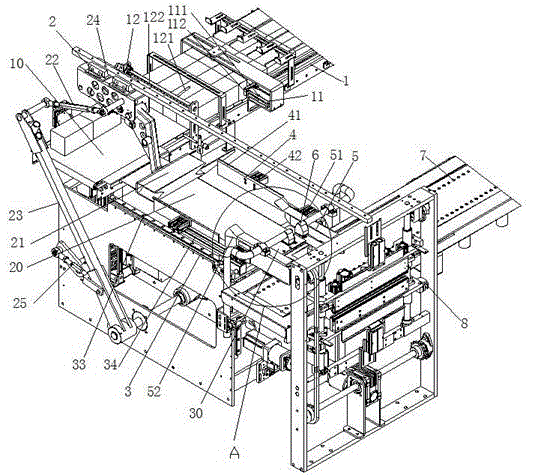

Packaging machine for packaging by adopting prefabricated bags

ActiveCN105620826ARealize the clamping effectRealize hugging and conveyingPackagingEngineeringSingle station

The invention discloses a packaging machine for packaging by adopting prefabricated bags, and relates to the technical field of packaging machinery. The packaging machine comprises a bag opening mechanism and further comprises a translation mechanism and a conveying device for moving in a material clamping or holding-conveying direction, wherein the conveying device is arranged behind the bag opening mechanism; the conveying device is connected to the translation mechanism, and is driven by the translation mechanism to move back and forth in the material clamping or holding-conveying direction. The packaging machine can solve the problems such as complex processes, many packaging actions, relatively long stroke between stations, great equipment floor space, easy material pouring due to irregular materials, easy prefabricated bag breaking, a long material pushing stroke, poor packaging effect, low packaging efficiency and the like on single station of prefabricated bag packaging machinery in the prior art.

Owner:上海松川峰冠包装自动化有限公司

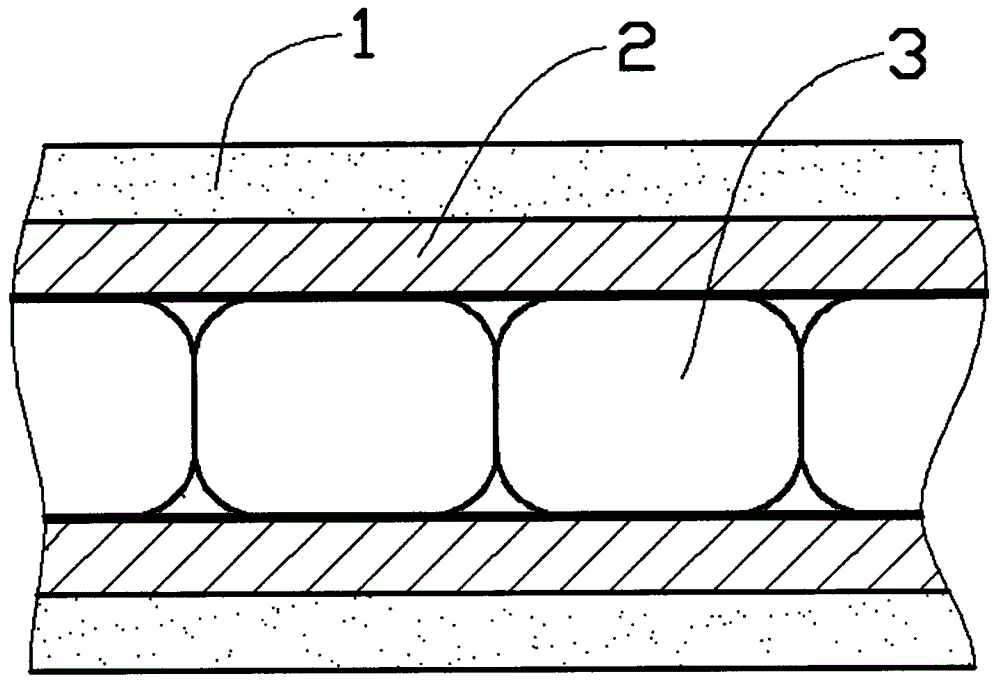

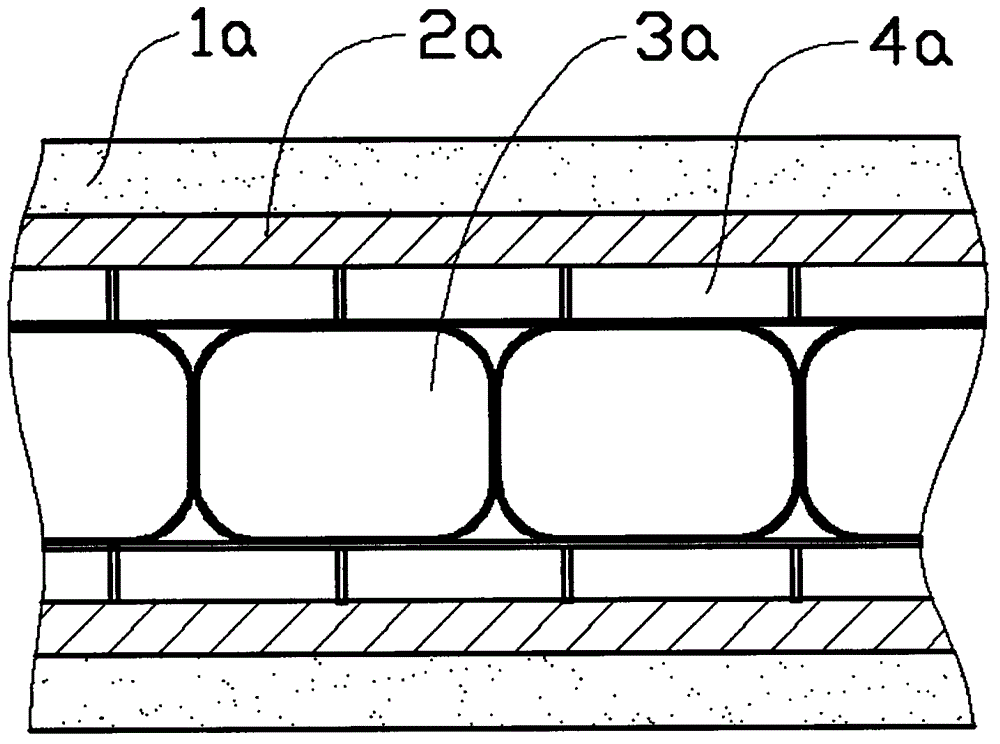

Environment-friendly isolating material and production method thereof

InactiveCN104416981AWith waterproof and moisture-proof functionImprove tensile propertiesSynthetic resin layered productsLaminationPolyesterEnvironmental resistance

The invention provides an environment-friendly isolating material and a production method thereof. The material comprises a polyester layer, an aluminum foil layer and a polyethylene foamed layer, wherein the polyester layer is made from a transparent film material, the polyethylene foamed layer is an up-down dual-plane foam film which is made from high-pressure polyethylene, the aluminum foil layer is respectively attached to two sides of the polyethylene foamed layer by using a binder, and the upper and lower outer layers of the environment-friendly isolating material are the polyester layers which are respectively attached by using the binder. The environment-friendly isolating material can be used as a product packaging material and further can be used as a middle interlayer of a wallspace, a floor, a roof or a decorative wallboard. The environment-friendly isolating material is light, anti-shock and convenient to use and meanwhile has various functions of being moistureproof, insulative, flame-retardant, radiationproof and the like.

Owner:SUZHOU HUNDRED LINTE PACKAGING MATERIAL

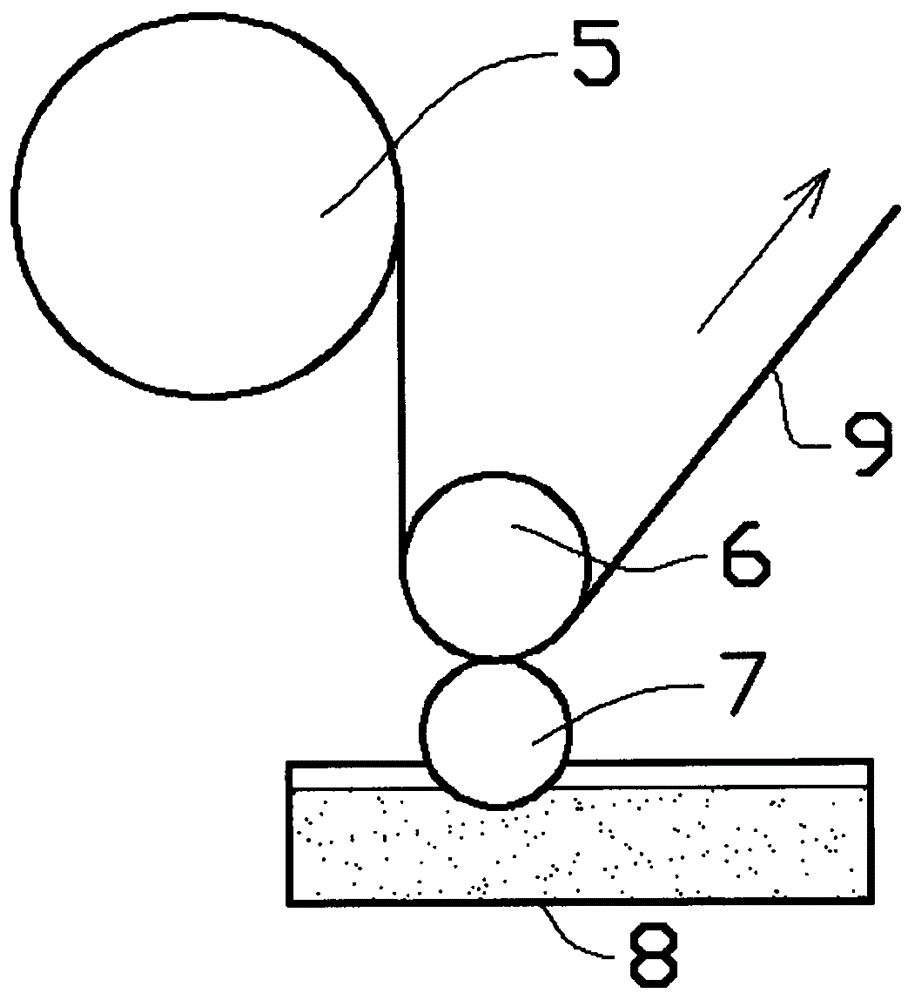

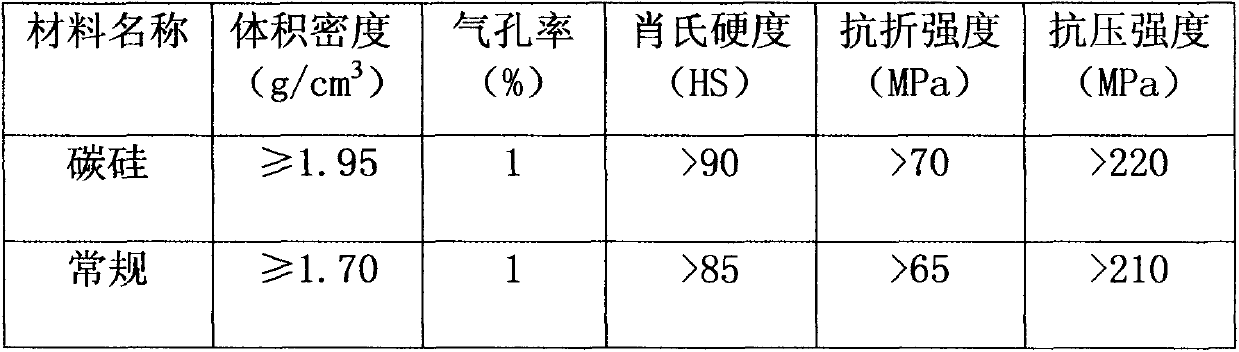

Preparation method for carbon-silicon composite material

InactiveCN103964438AImprove wear resistanceNot easy to squeezeCarbon compoundsIndependent motionCompression molding

A preparation method for a carbon-silicon composite material is characterized by comprising: taking silicon powder, silicon sol, molybdenum disulfide and biphenyl, adding into a stirred kettle, stirring, heating, and adding melt coal tar pitch, so as to prepare a silicon-powder additive mixed solution; adding carbon black powder, graphite powder, pitch coke powder and petroleum coke powder into a kneading kettle for kneading, heating, adding the silicon-powder additive mixed solution, stirring and mixing to prepare a clinker; and performing hot rolling on the mixed clinker to obtain thin sheets, cooling, grinding into a powder, performing compression molding, roasting, performing coal tar pitch dipping, rough turning, performing resin dipping, turning, performing secondary resin dipping, and curing to obtain a finished product. Through the combination of carbon and silicon, the silicon powder has good wear resistance; a grinding kettle end and carbon graphite have auxiliary motion or relative independent motion, carbon graphite is not easy to grind and extrude, is relatively easy to extrude on the end surface of the grinding kettle, so that relatively slide between materials is formed; and the prepared carbon-silicon composite material has a service life being 2-3 times of the service life of a conventional material.

Owner:无锡市前洲电碳厂

Prefabricated bag packaging machine

ActiveCN105691713ASolve complexitySolve problems with more motionPackagingReciprocating motionEngineering

The invention discloses a prefabricated bag packaging machine, and relates to the technical field of packaging machinery. The prefabricated bag packaging machine adopts the structure that a clamping and conveying device is arranged between a to-be-clamped station and a bag opening station; the clamping and conveying device comprises a clamping mechanism and a translation mechanism; and the translation mechanism drives the clamping mechanism to perform reciprocating motion in the material clamping and conveying direction. The prefabricated bag packaging machine provided by the invention solves a plurality of problems in the prior art, for example, the working procedure at a single station of a conventional prefabricated bag packaging machine is complex; the quantity of packaging actions is large; the strokes among various stations are relatively long; the equipment occupied area is large; materials are irregular, and the possibility of material overturning is high; a prefabricated bag is liable to broken; the material pushing stroke is long; the packaging effect is poor; and the packaging efficiency is low.

Owner:上海松川峰冠包装自动化有限公司

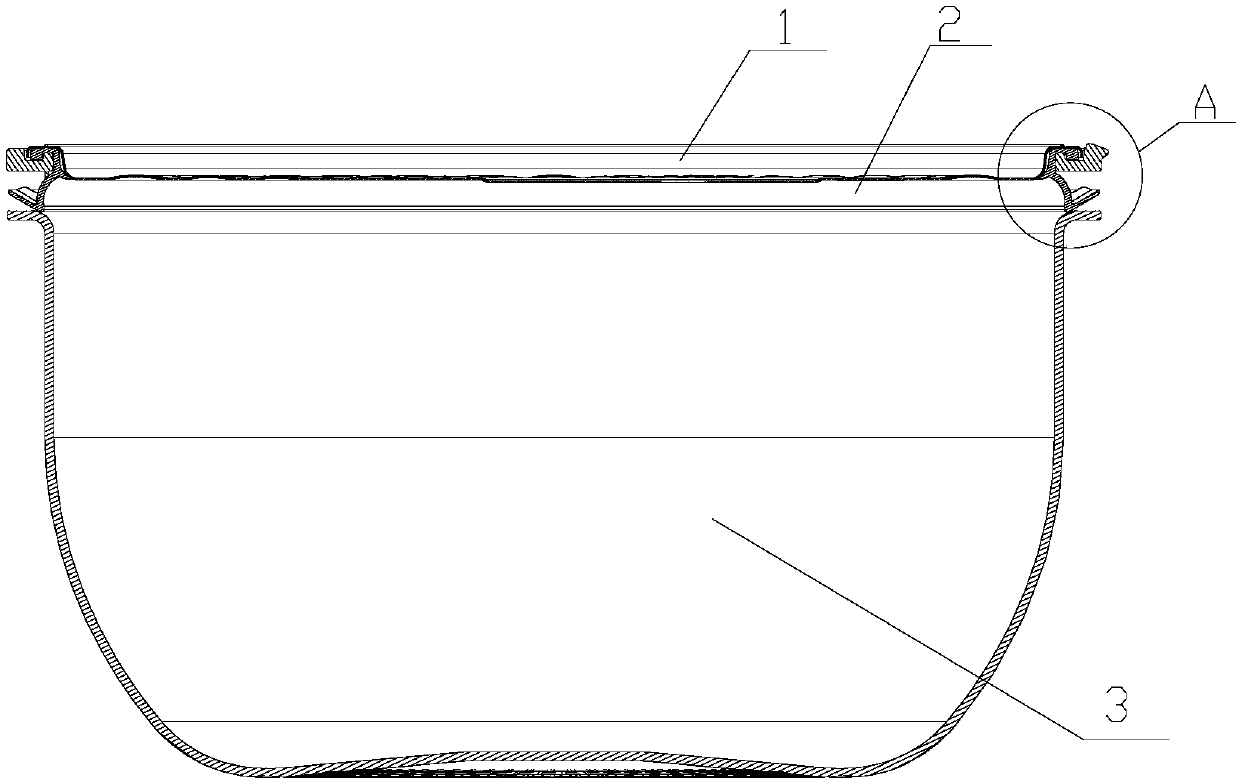

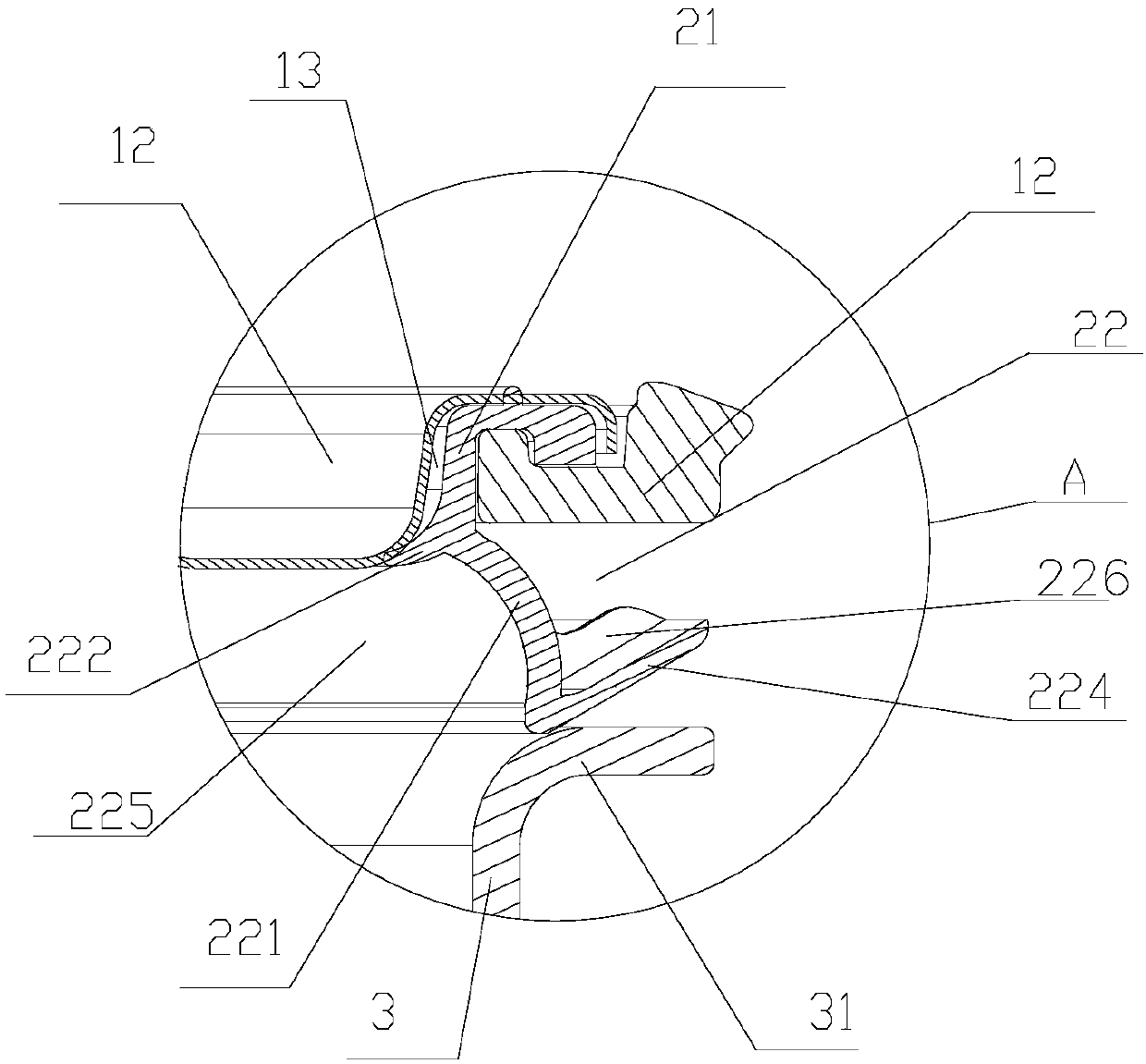

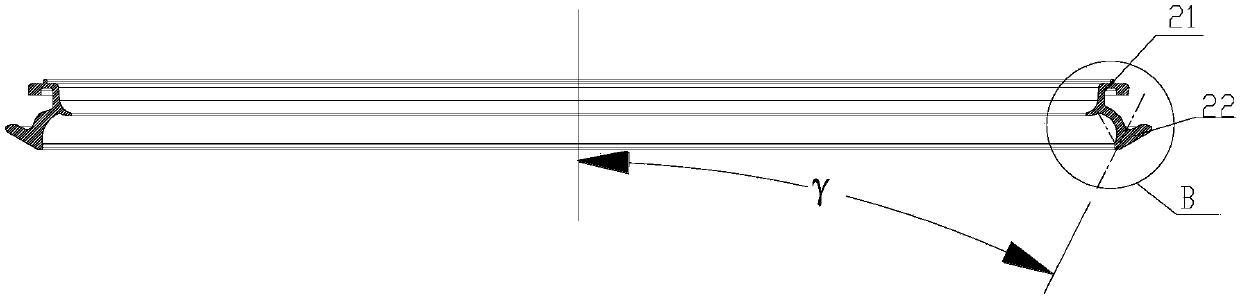

Seal ring on cover plate component, cover plate component, upper cover component and electric appliance

PendingCN107752742AReduce stressEasy to restoreEngine sealsCooking-vessel lids/coversEngineeringExtrusion

The invention relates to a seal ring on a cover plate component, the cover plate component, an upper cover component and an electric appliance. The seal ring comprises an installation part and a sealing part which are integrally connected, the longitudinal cross-section of the installation part is shaped like an upside-down L, the installation part is installed on one side face of the cover platecomponent in a sealed mode, and the sealing part extends out of one side face of the cover plate component in the direction deviating from the cover plate component; when the cover plate component isbuckled on a cooking ware, the sealing part abuts against the edge of an opening of the cooing ware, and an elastic structure used for lowering the extrusion deformation stress of the sealing part isarranged on the side face, located outside the cooking ware, of the sealing part. Accordingly, the sealing part is arranged to be of a V-shaped structure, stiffener is arranged on the inner side of the bending part of the V-shaped structure, the elastic structure is arranged on the stiffener, the rigidity of the seal ring is enhanced, the extrusion deformation stress of the seal ring is lowered, and the seal ring is likely to recover after being extruded.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com