Hoisting slider device for insulating layer in greenhouse

A technology of sliding device and insulation layer, which is applied in the field of hoisting sliding device and insulation layer hoisting sliding device, which can solve the problems that channel steel and I-beam are difficult to participate in the production of arch skeleton, easy to derail, and the internal torsion of the pulley, etc., so as to achieve easy development And large-scale production, not easy to squeeze and twist, not easy to derail the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

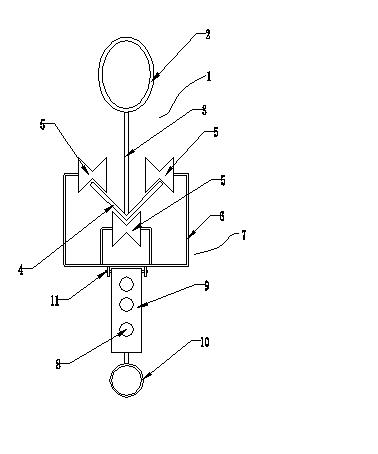

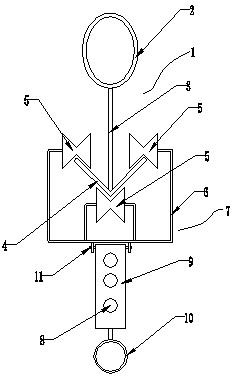

[0021] Examples such as figure 1 , figure 2 As shown, a hoisting and sliding device for the inner heat preservation layer in a greenhouse includes a skeleton 1, a pulley 7 capable of hoisting the inner heat preservation layer in the greenhouse is provided below the skeleton 1, and the pulley 7 is slidably connected with the skeleton 1 .

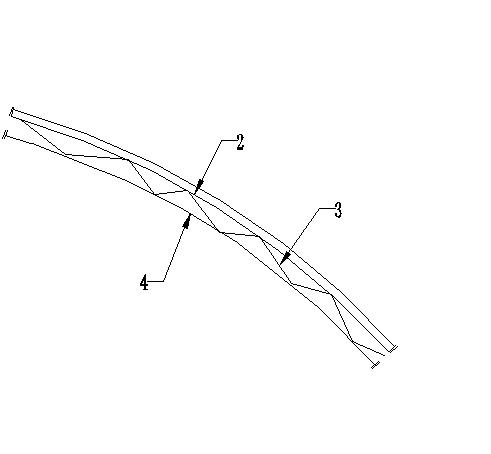

[0022] The frame 1 includes an arc-shaped frame upper chord 2 made of steel pipe with a diameter of 20mm and a frame lower chord 4 made of angle steel of 20mm*20mm*3mm. The 10mm connecting rod 3 is fixedly connected.

[0023] The lower chord 4 of the skeleton is arranged in a V shape, and the connecting rod 3 is fixedly connected to the inner bottom of the lower chord 4 of the skeleton.

[0024] The tackle 7 includes a boom 9, the upper end of the boom 9 is connected with a roller frame 6, and three rollers 5 are installed on the roller frame 6, and the three rollers 5 are arranged in a triangle and are connected to the lower chord 4 sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com