Strengthening beam structure for automobile front wall

A technology for strengthening beams and automobiles, applied in the direction of upper structure, upper structure sub-assembly, vehicle parts, etc., which can solve the problems of inconvenient installation and disassembly, poor strength, etc., and achieve the effect of low maintenance cost, good rigidity, and favorable occupant safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

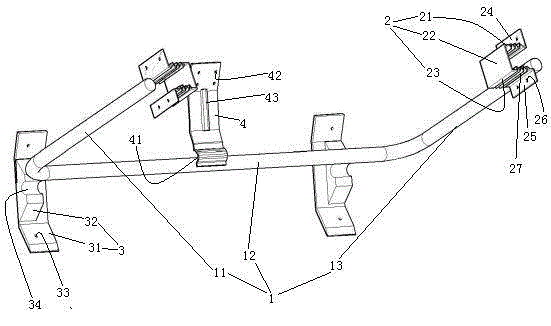

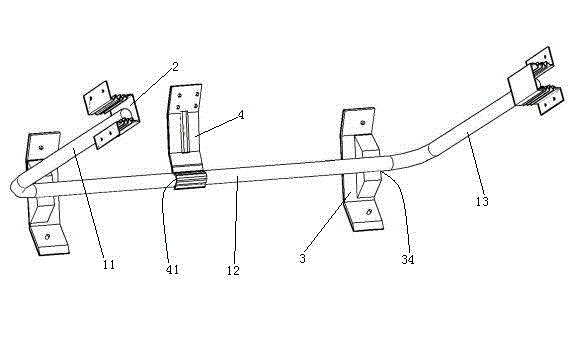

[0030] see figure 1 , an automobile front wall reinforcement beam structure, including a cross beam 1, two side panel connecting bodies 2, two dash panel connecting bodies 3 and a cross beam suspension body 4.

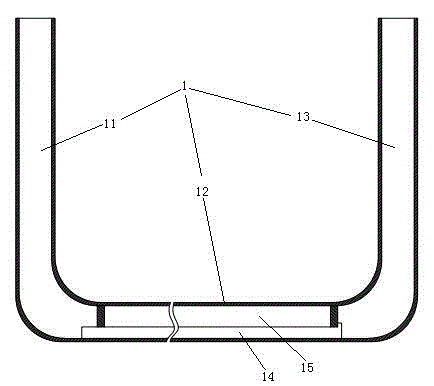

[0031] The beam 1 includes a left support section 11 , a cowl support section 12 and a right support section 13 . The left support section 11, the front wall support section 12 and the right support section 13 are connected together in a "U" shape.

[0032]The side wall connecting body 2 is provided with an upper wall 21 , an inner wall 22 and a lower wall 23 in sequence. The upper wall 21 , the inner wall 22 and the lower wall 23 are connected together in a "U" shape. The upper wall 21 is bent outward to form an upper wall supporting edge 24 . The lower wall 23 is bent outward to form a lower wall supporting edge 25 . Both the upper wall s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com