A quantitative packaging scale for functional color masterbatch packaging

A technology of quantitative packaging and color masterbatch, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items, can solve the problems of cross-contamination, falling off, and adhesion of color masterbatch, affecting the normal processing of color masterbatch, and achieves uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

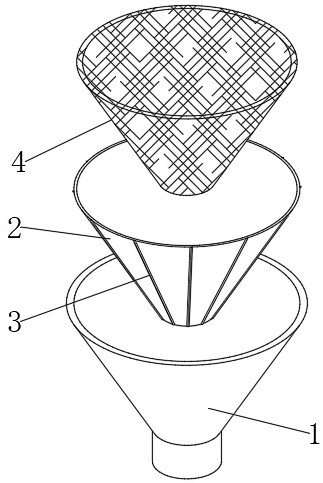

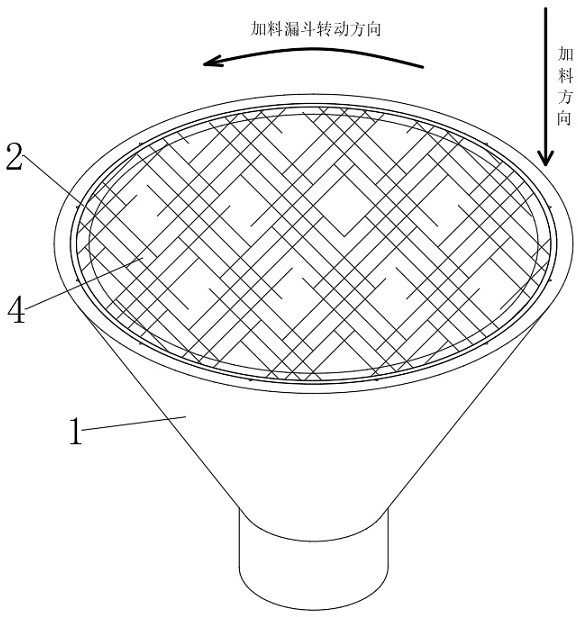

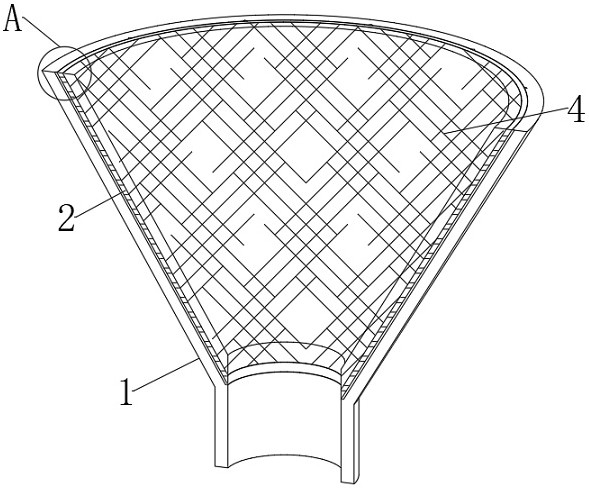

[0038] see Figure 1-7, a quantitative packaging scale for functional color masterbatch packaging, including a feeding funnel 1, an adhesive pad 2 matching itself is placed in the feeding funnel 1, the adhesive pad 2 includes a rubber pad main body 201, and a rubber pad main body 201 An expansion net 202 is embedded inside, and the expansion net 202 always has a tendency to expand outward. The inner wall of the attached rubber pad 2 is fixedly connected with a protective hose blanket 4, and the protective hose blanket 4 includes multiple protective hoses. The fixed end 401, the end of the hard fixed end 401 close to the rubber pad body 201 penetrates the surface of the rubber pad body 201 and extends into the rubber pad body 201 to be fixedly connected with the expansion net 202, and the adjacent hard fixed end 401 is far away from the rubber pad body 201 One ends are intertwined with each other to form a stable three-dimensional space structure. The end of the hard fixed end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com