Steel-plastic composite pipe

A technology of steel-plastic composite pipe and steel belt, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., and can solve problems such as uneven structural strength of pipes, inability to withstand internal pressure, peeling and fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

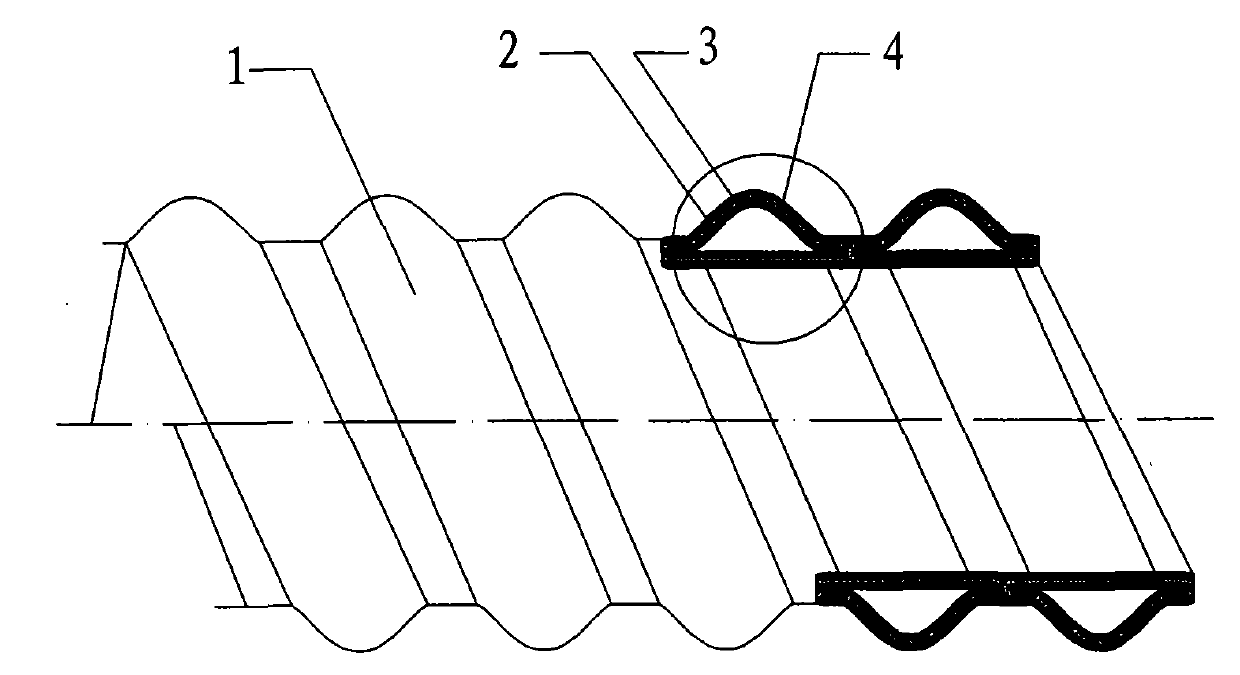

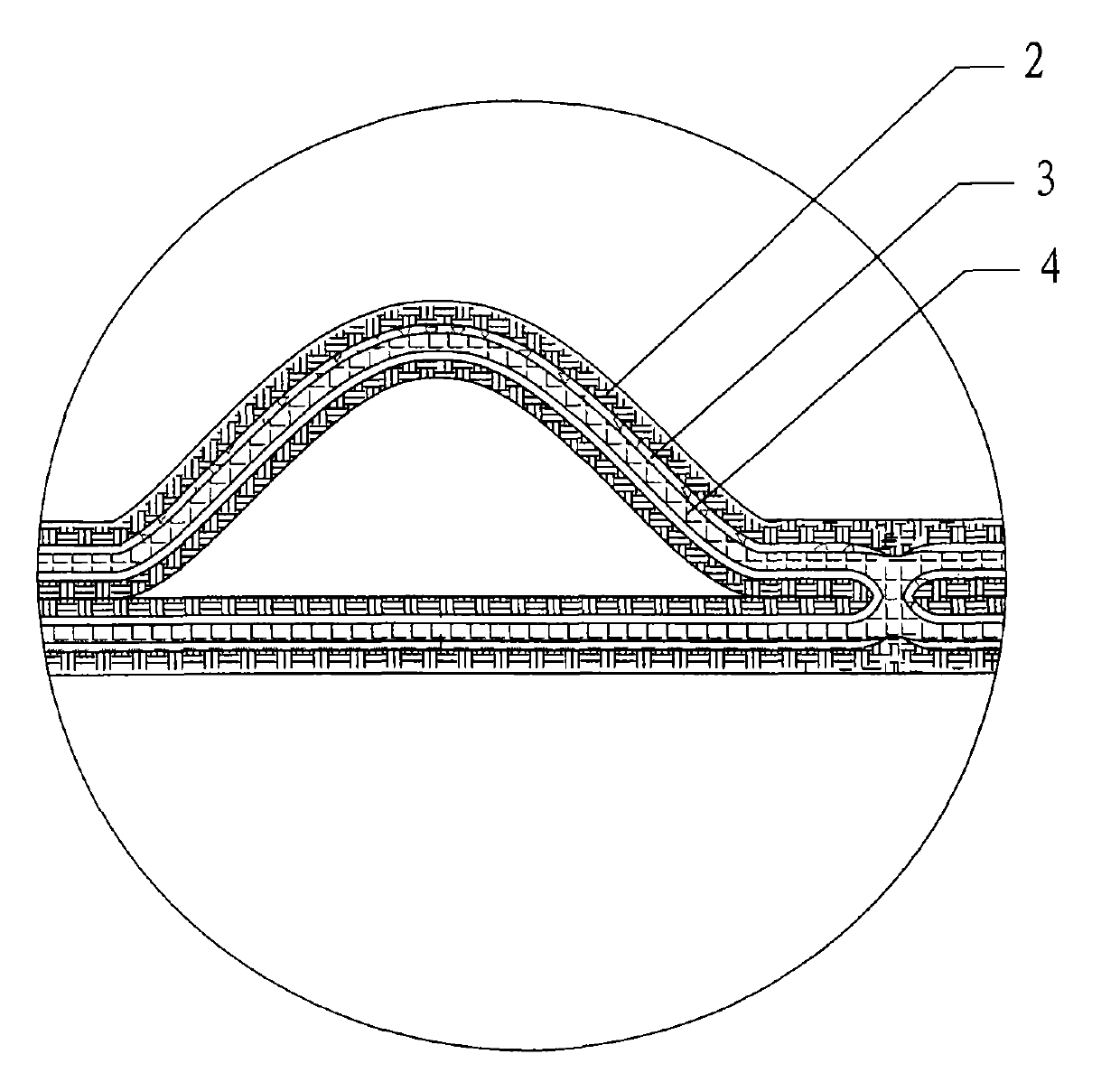

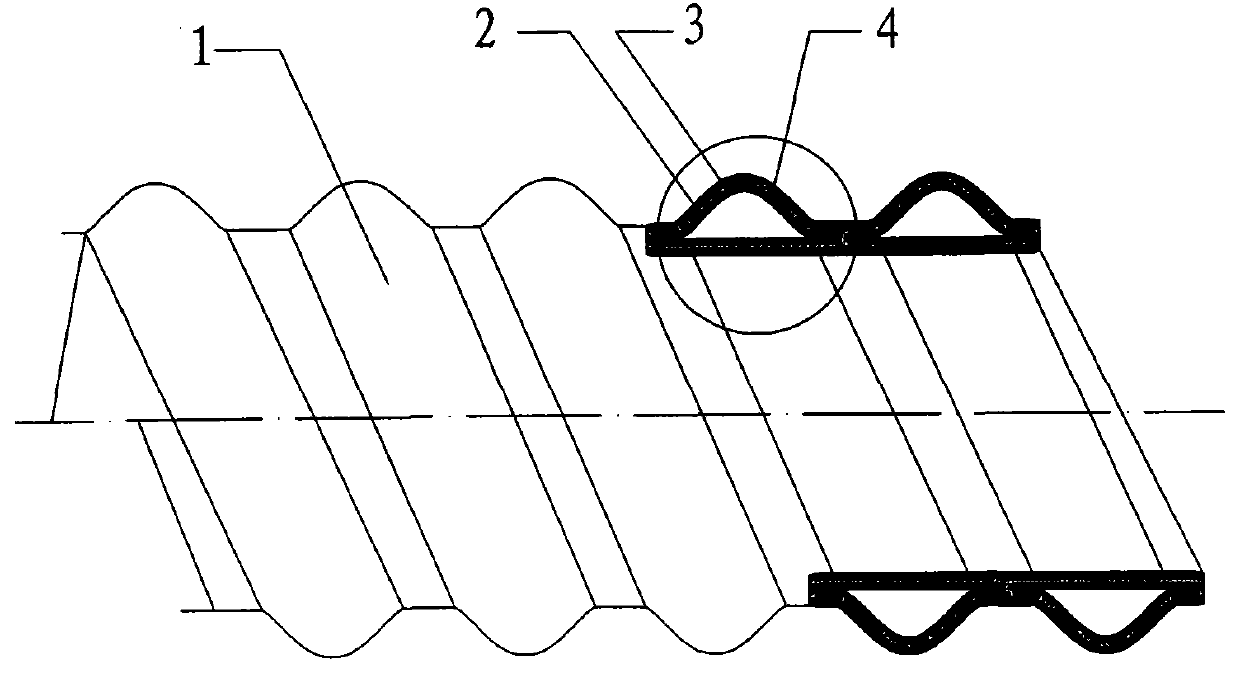

[0011] Example 1, see figure 1 , figure 2 The steel-plastic composite pipe includes a steel strip 4 with a special-shaped section and a plastic coating 2. The special-shaped section of the steel strip is hollow and closed, and then spirally wound into a tubular body 1. The adjacent edges of the steel strip are fixed by welding. The inner and outer layers of the body are provided with a plastic coating. The special-shaped section of the steel strip is hollow and closed, with one side being flat and the other protruding outward. In order to ensure the tight combination of the plastic coating and the steel strip, an adhesive resin layer 3 is added between the steel strip and the plastic coating. In order to prevent the hollow interior of the steel strip from corroding, the inner surface of the hollow steel strip is also provided with an adhesive resin layer and a plastic coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com