PVC modular high-ring stiffness spiral winding pipe and production method thereof

A spiral winding pipe and spiral winding technology, applied in the field of PVC modular high ring stiffness winding pipe, can solve the problems of high corrosion, easy corrosion of metal, and no consideration of long-term pipe life, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

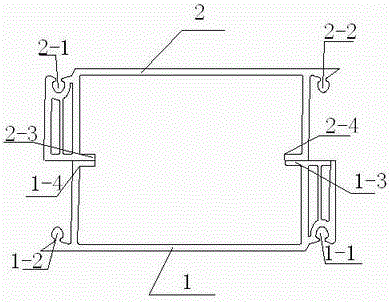

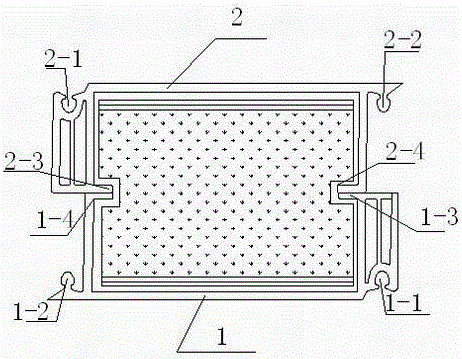

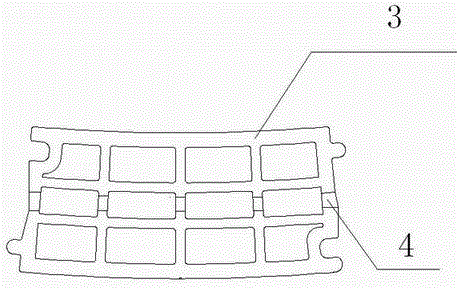

[0024] The technical solutions in the embodiments of the present invention will be described clearly and in detail below with reference to the drawings in the embodiments of the present invention. The described embodiments are only some of the embodiments of the invention.

[0025] Technical scheme of the present invention is as follows:

[0026] This device mainly imitates the traditional Chinese "bucket hoop" mode. The principle is that the force on the ring is uniform and the ring rigidity is high. Our innovation is to turn the ring into a fan shape piece by piece. The ring stiffness strengthening module is added to the frame profile, and then combined into a ring, which is more rigid than the original overall ring ring; and the original technology has no way to put the overall ring into it, and there is no way to become infinite For long pipes, rotate the fan-shaped module 90 degrees and put it into the first profile to suspend the fan-shaped module. After rotating 180 de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com