Ultra-soft temperature-resistant bulletproof optical cable and production method thereof

A fiber optic cable and temperature-resistant technology, which is applied in the field of super-flexible, temperature-resistant and bulletproof optical cables, can solve the problems that the stress of the optical cable cannot be released, affect the transmission performance of the optical fiber, and reduce the service life of the optical cable, so as to reduce performance changes and improve the overall structural design. Ingenious, shock-absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

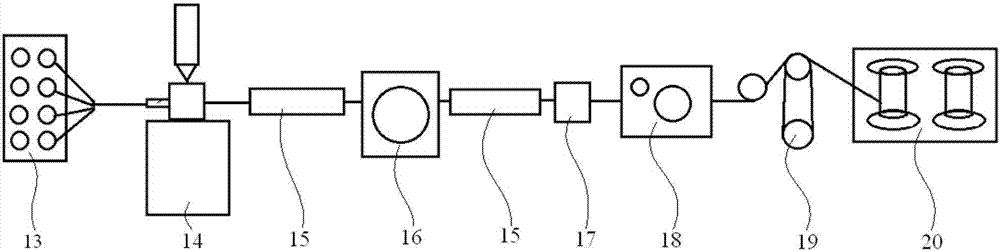

[0028] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

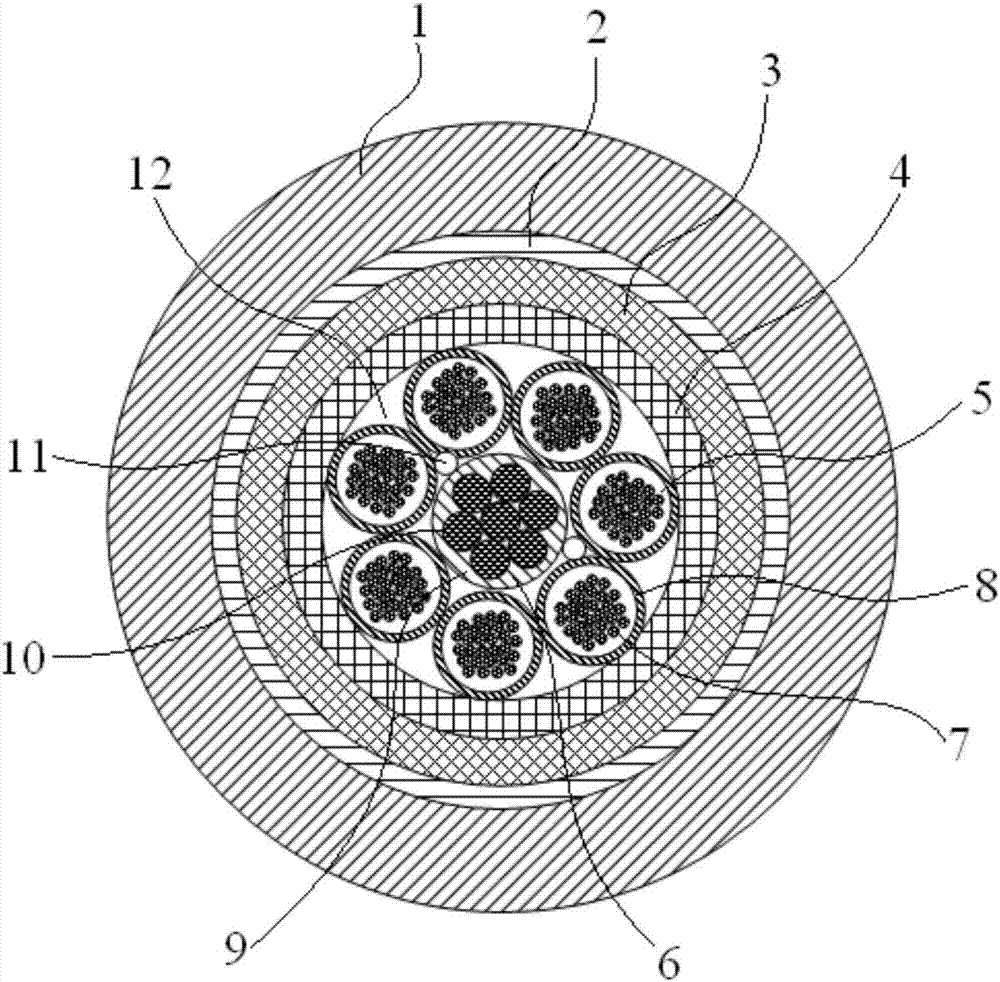

[0029] Such as figure 1 and 2 As shown, a kind of ultra-flexible temperature-resistant bulletproof optical cable includes a cable core 12, a plastic foam layer 4, a bulletproof armor layer 3 and an outer sheath layer 1 arranged sequentially from the inside to the outside, that is, the surface of the cable core 12 is arranged There is a layer of plastic foam layer 4, and the outside of the plastic foam layer 4 is provided with a layer of bulletproof armor layer 3, and the outside of the bulletproof armor layer 3 is provided with an outer sheath layer 1.

[0030] Wherein, the plastic foam layer 4 adopts a plastic foam tape, and the plastic foam tape is longitudinally wrapped on the surface of the cable core 12 . The plastic foam tape has flexibility, light weight, high elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com