Patents

Literature

176results about "Corrugation articles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

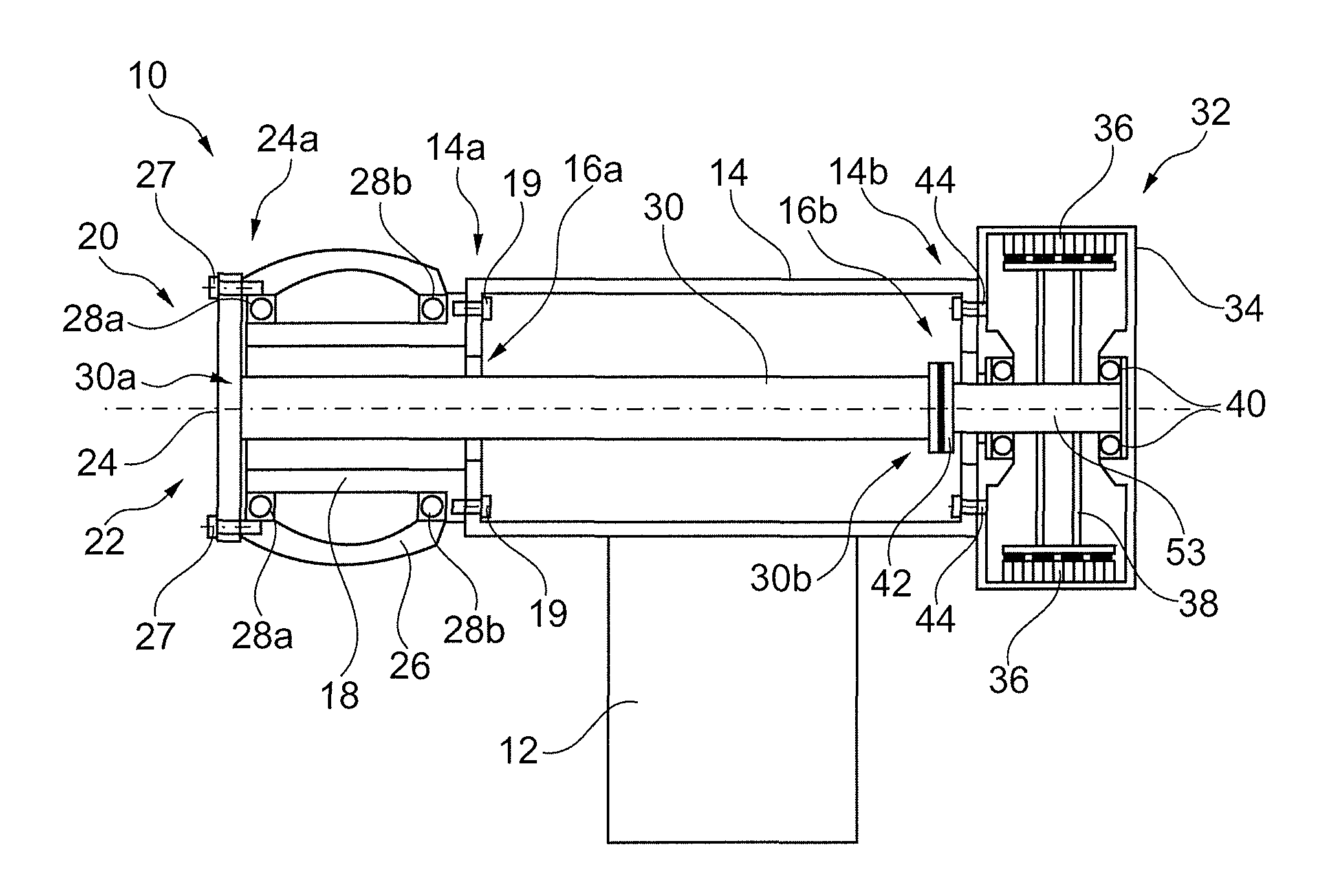

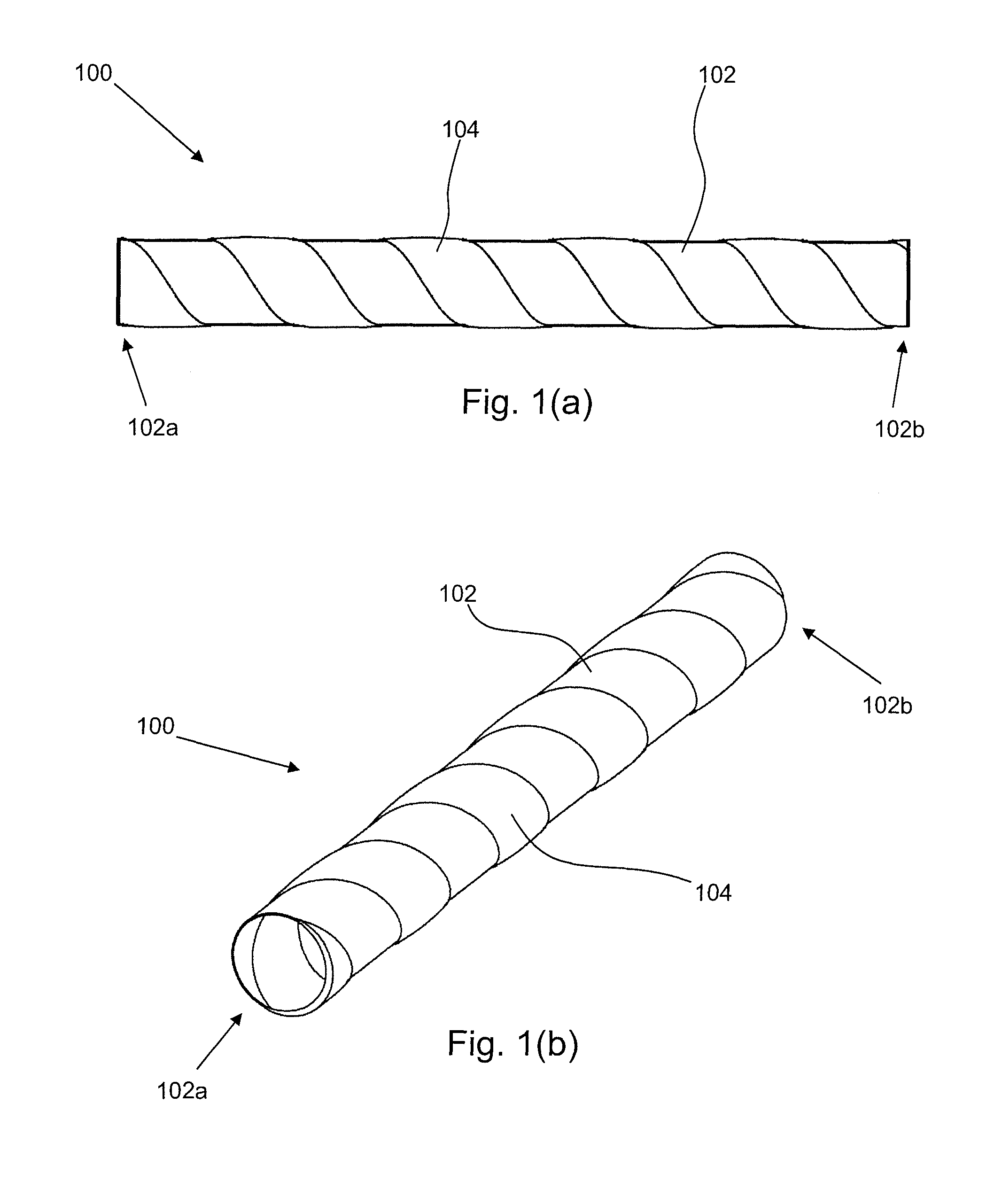

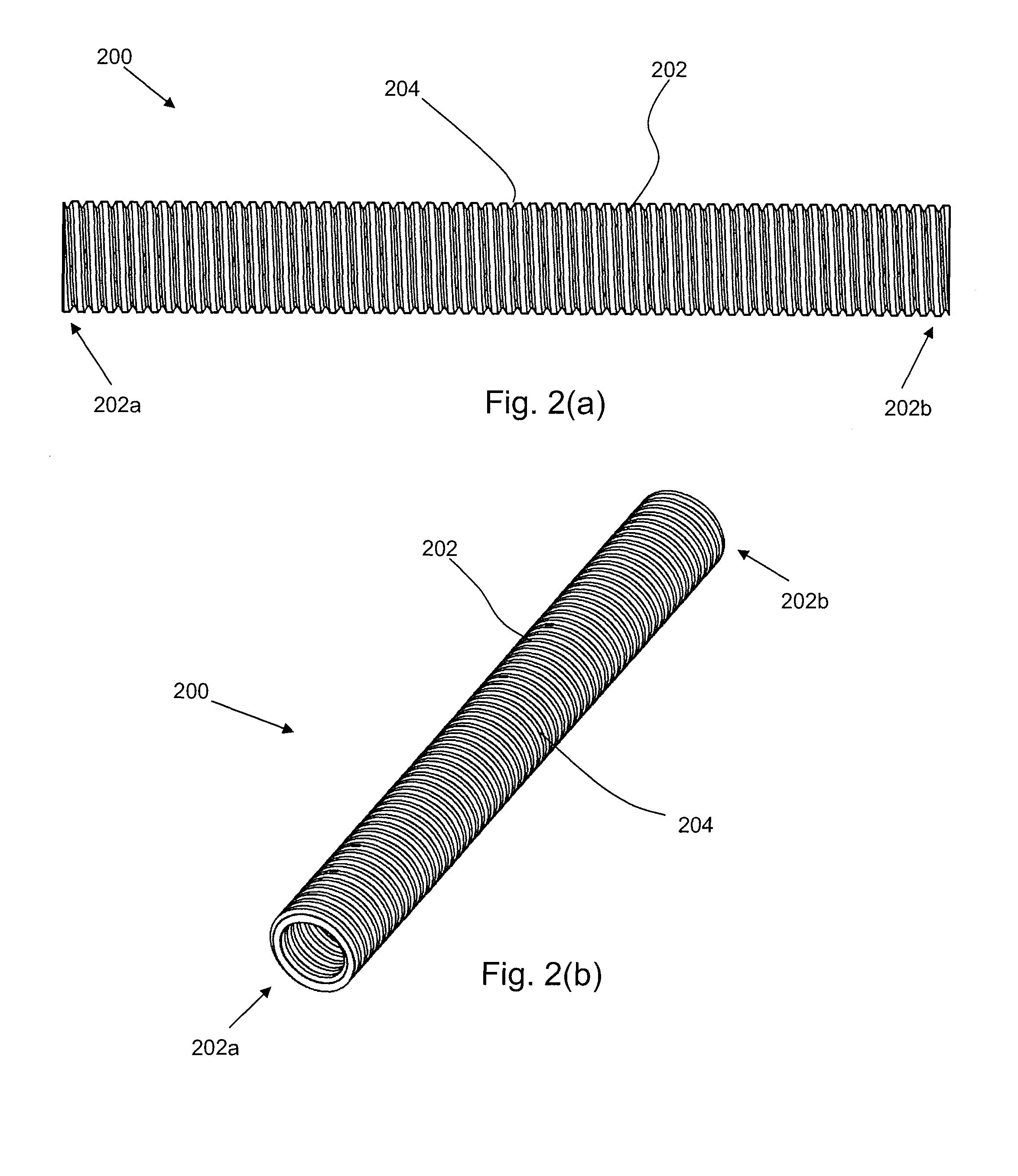

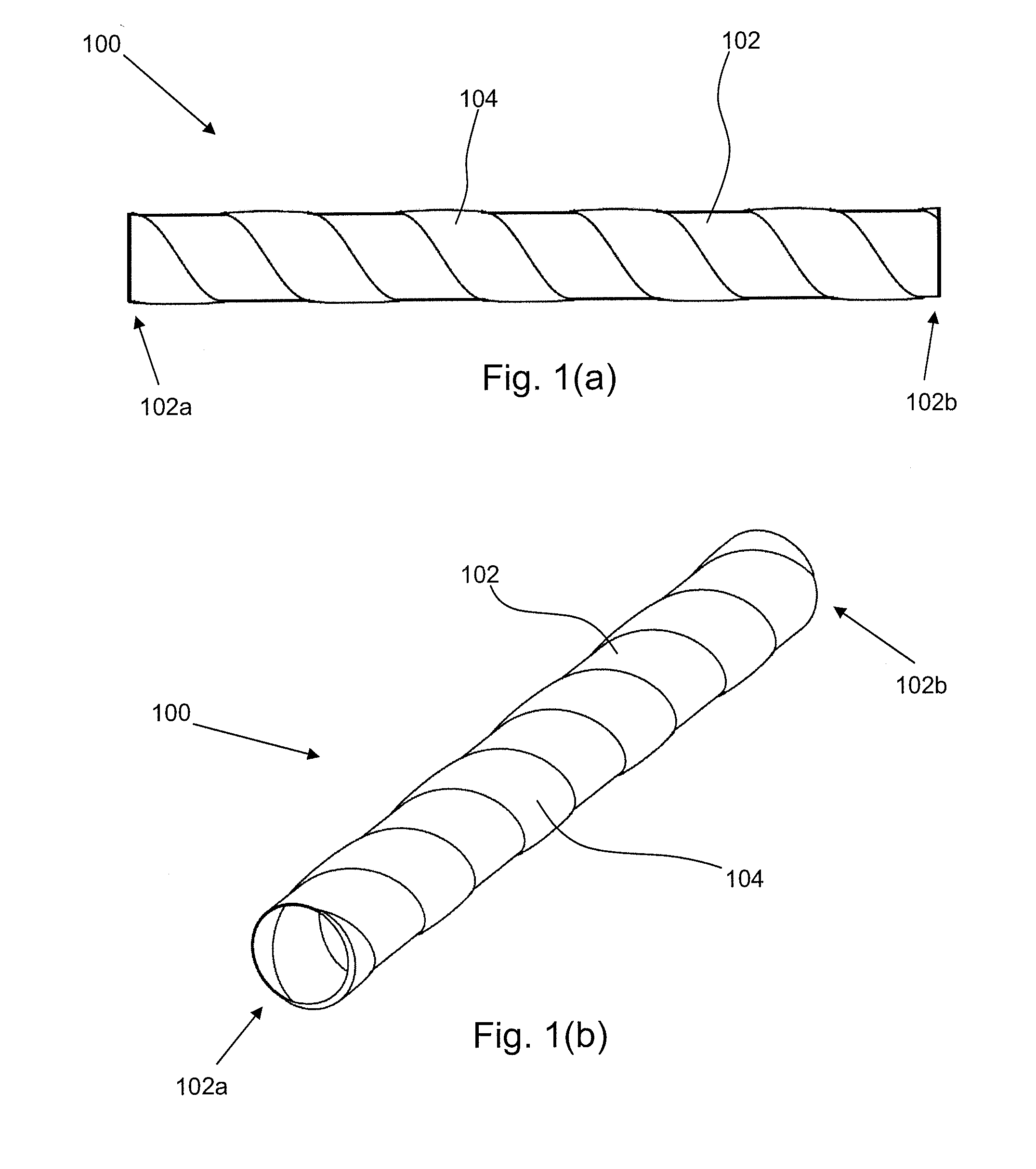

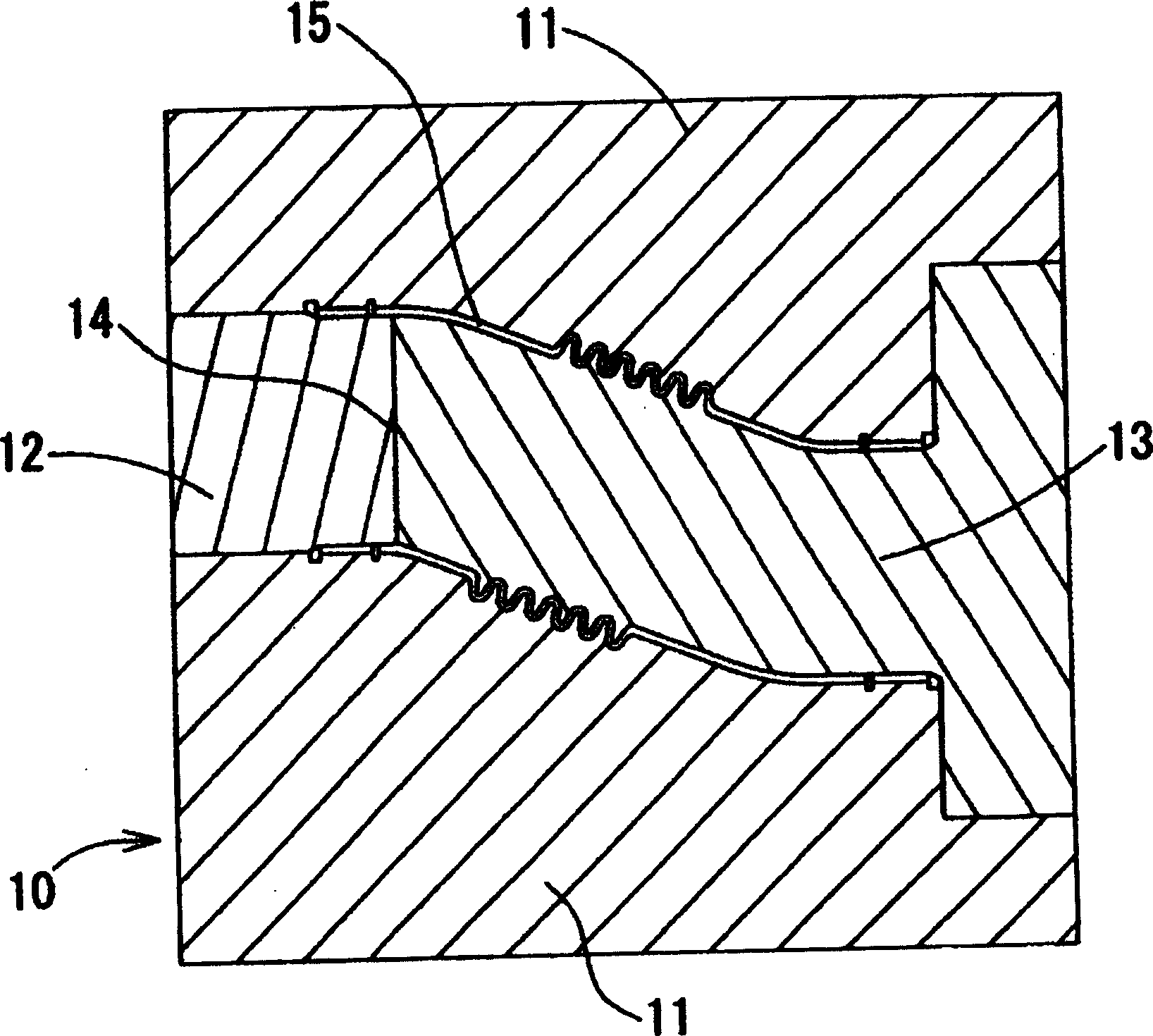

Wind turbine and a shaft for a wind turbine

InactiveUS8664792B2Little strengthImproves buckling stabilityEngine fuctionsFinal product manufactureDrive shaftTurbine

A drive shaft for a wind turbine is shaped so as to allow for increased bending of the shaft, while being suitable for transferring torque in a wind turbine system. An example of such a shaping is a drive shaft having a helical rib defined on the surface of the shaft. A wind turbine incorporating such a shaft, and a method of manufacture of such a shaft are also described.

Owner:ENVISION ENERGY DENMARK

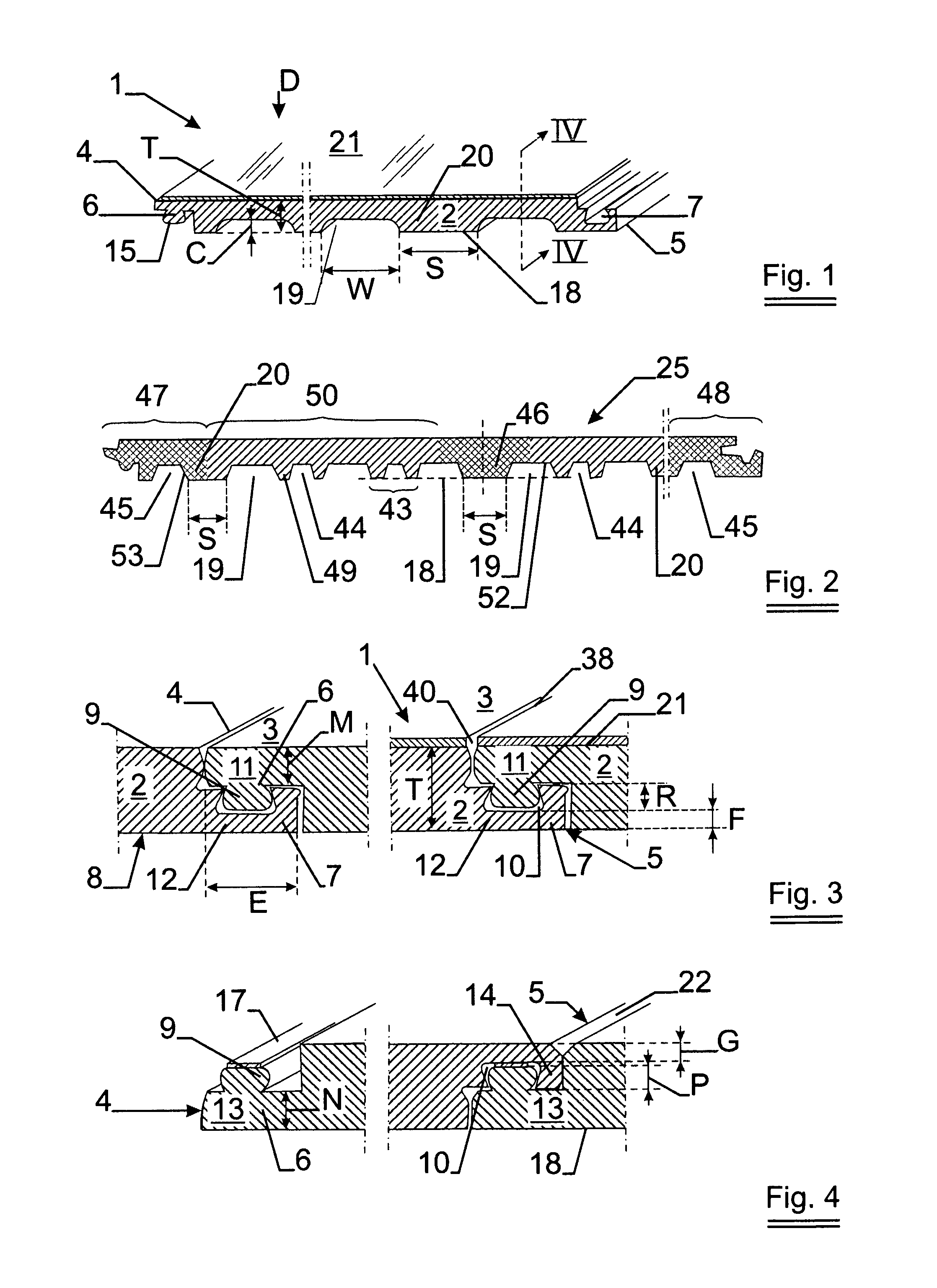

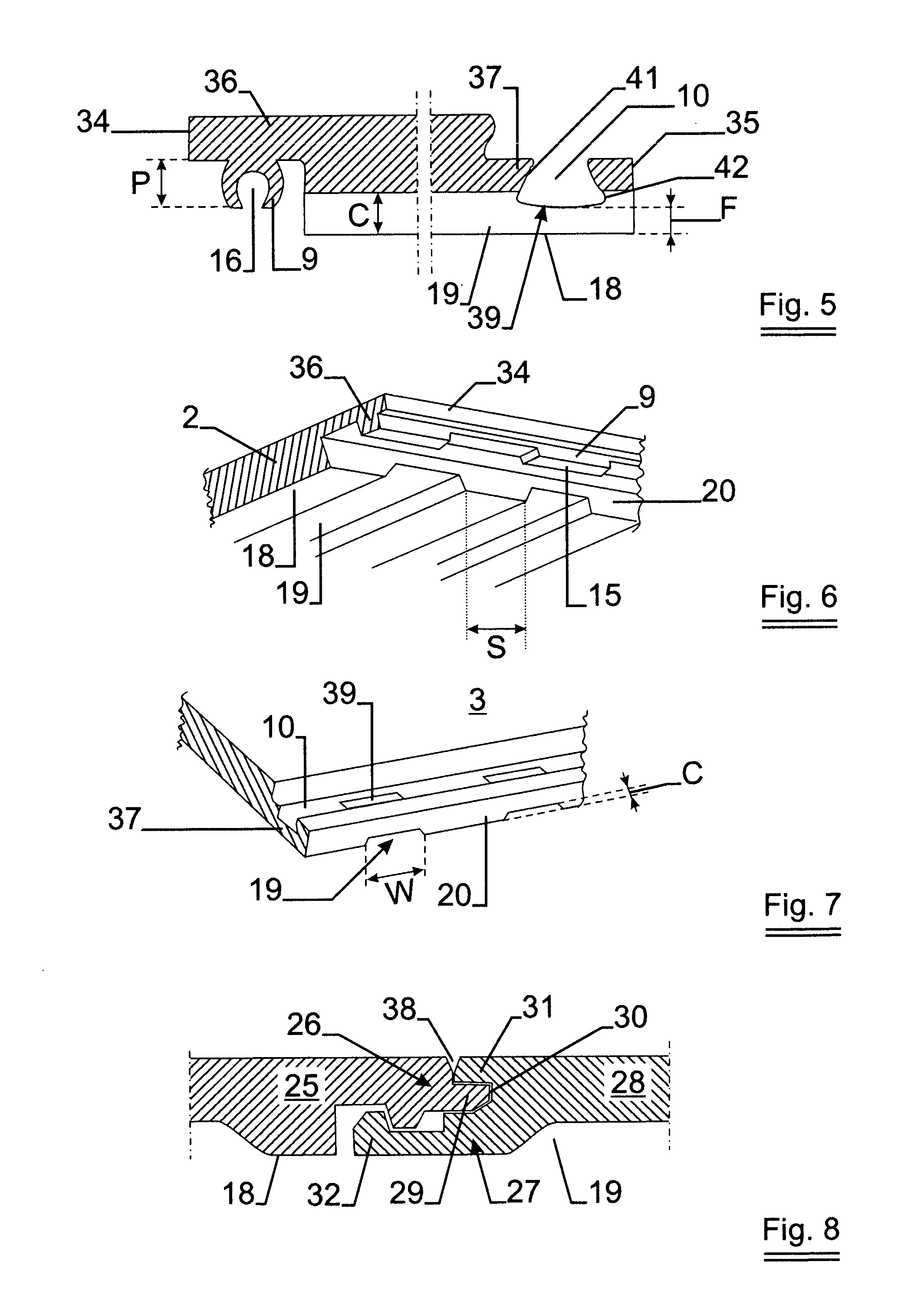

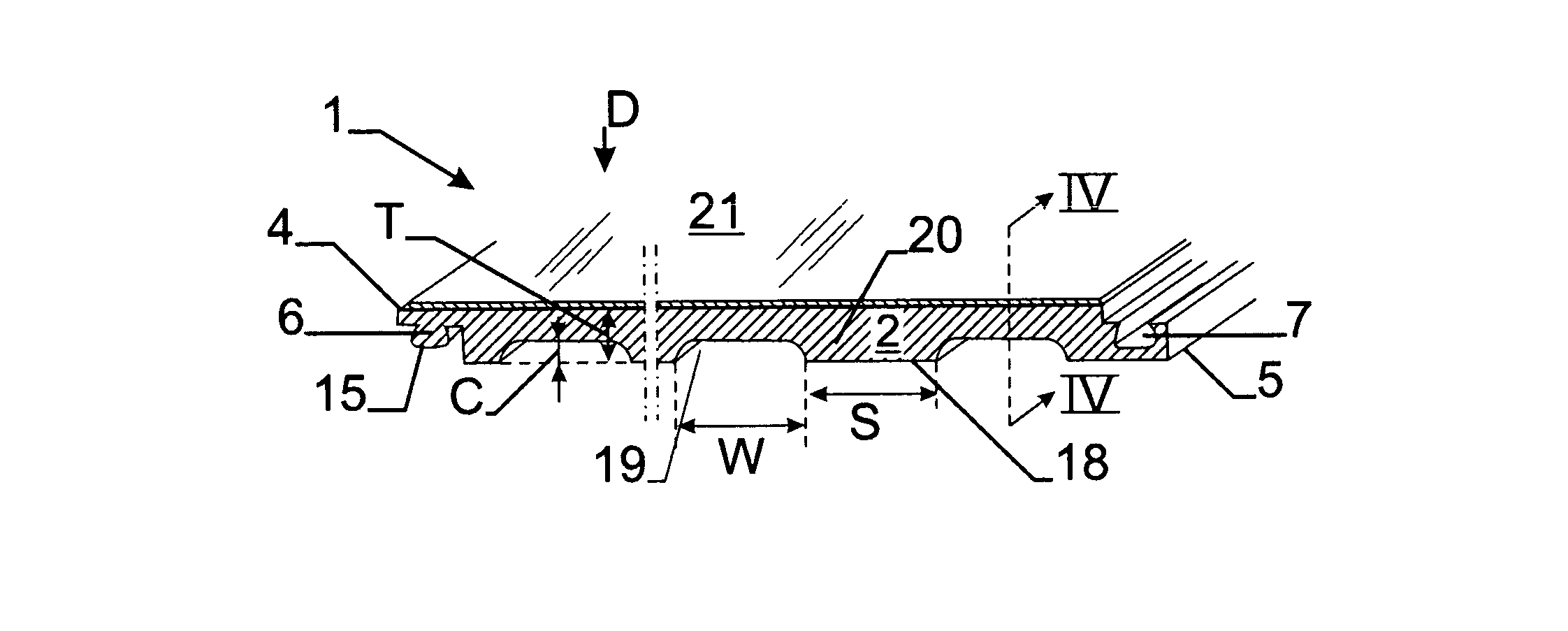

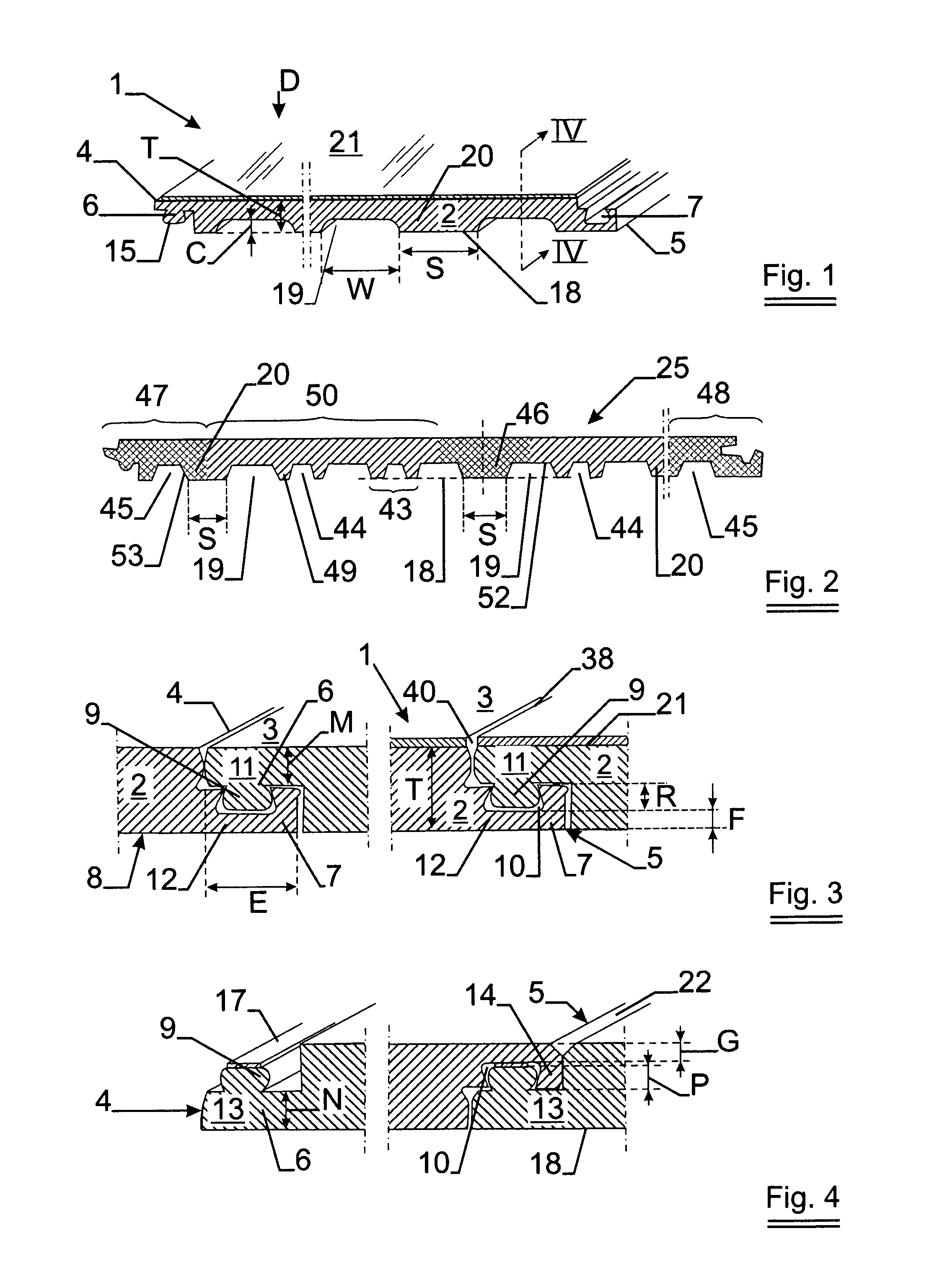

Covering panel

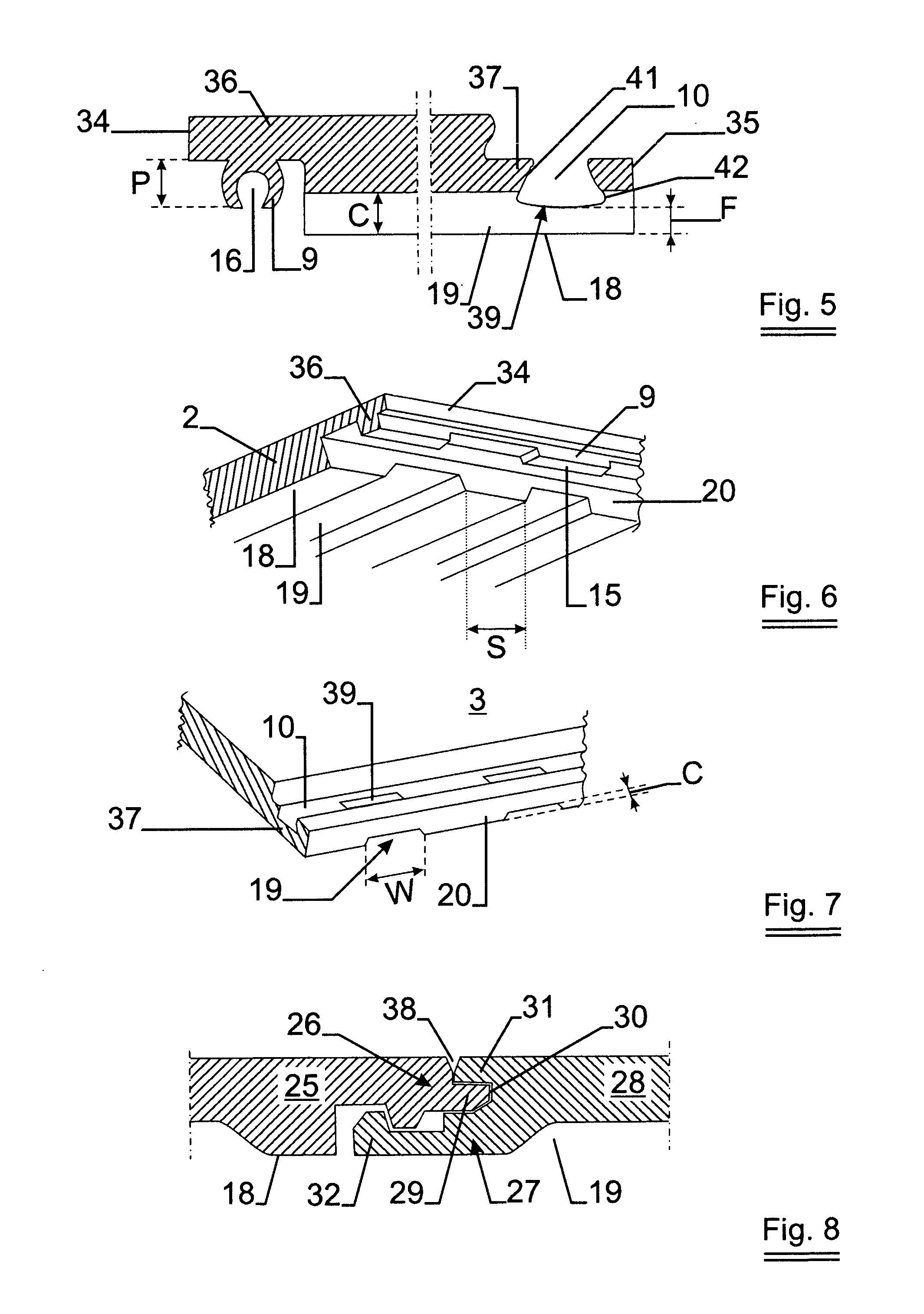

A covering panel has a support plate, made from synthetic plastic material, with a flat and even top surface, a bottom face and pairs of opposite sides provided with complementary profile edges in the form of a male profile edge on one side and a female profile edge on the other, where said male profiled edge can be connected to a female edge of an equal adjacent covering panel, preferably according to a direction that runs perpendicular to said top surface. In their bottom face there are strip-shaped recesses that run according to the direction of extrusion and alternate with a number of support strips, of which at least a part has a width S along that bottom face that complies with 1.5 T<S<10 T, and whereby 0.4 T<C<0.7 T applies, in which C is the average depth of these recesses. A process extrudes a synthetic plastic plate.

Owner:I4F LICENSING NV

Covering panel

Owner:I4F LICENSING NV

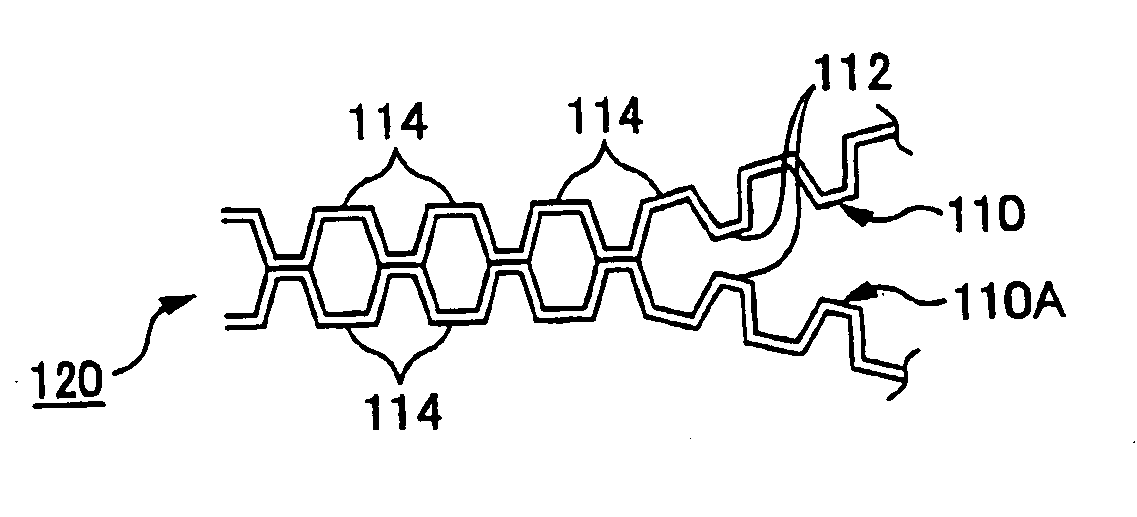

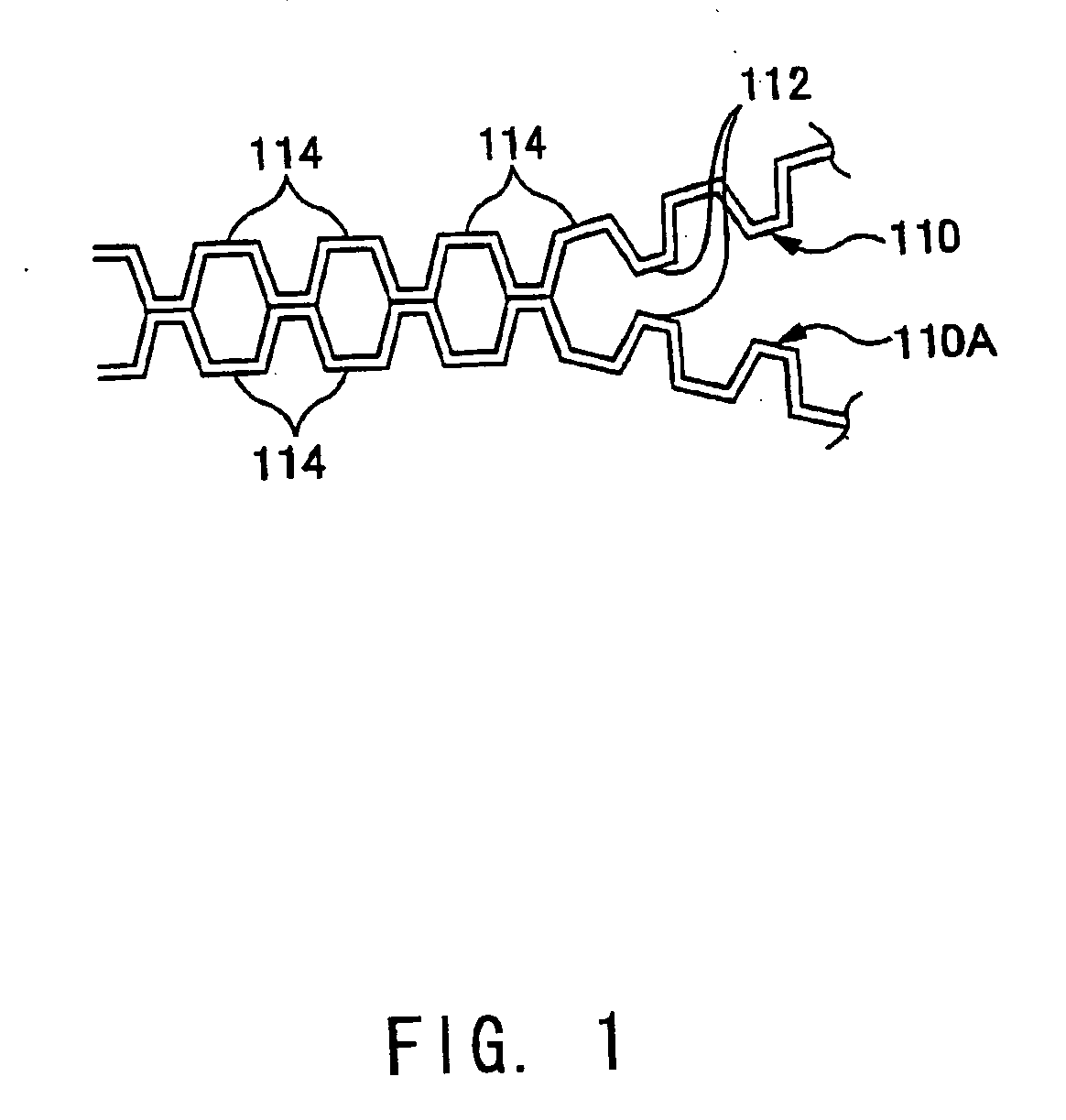

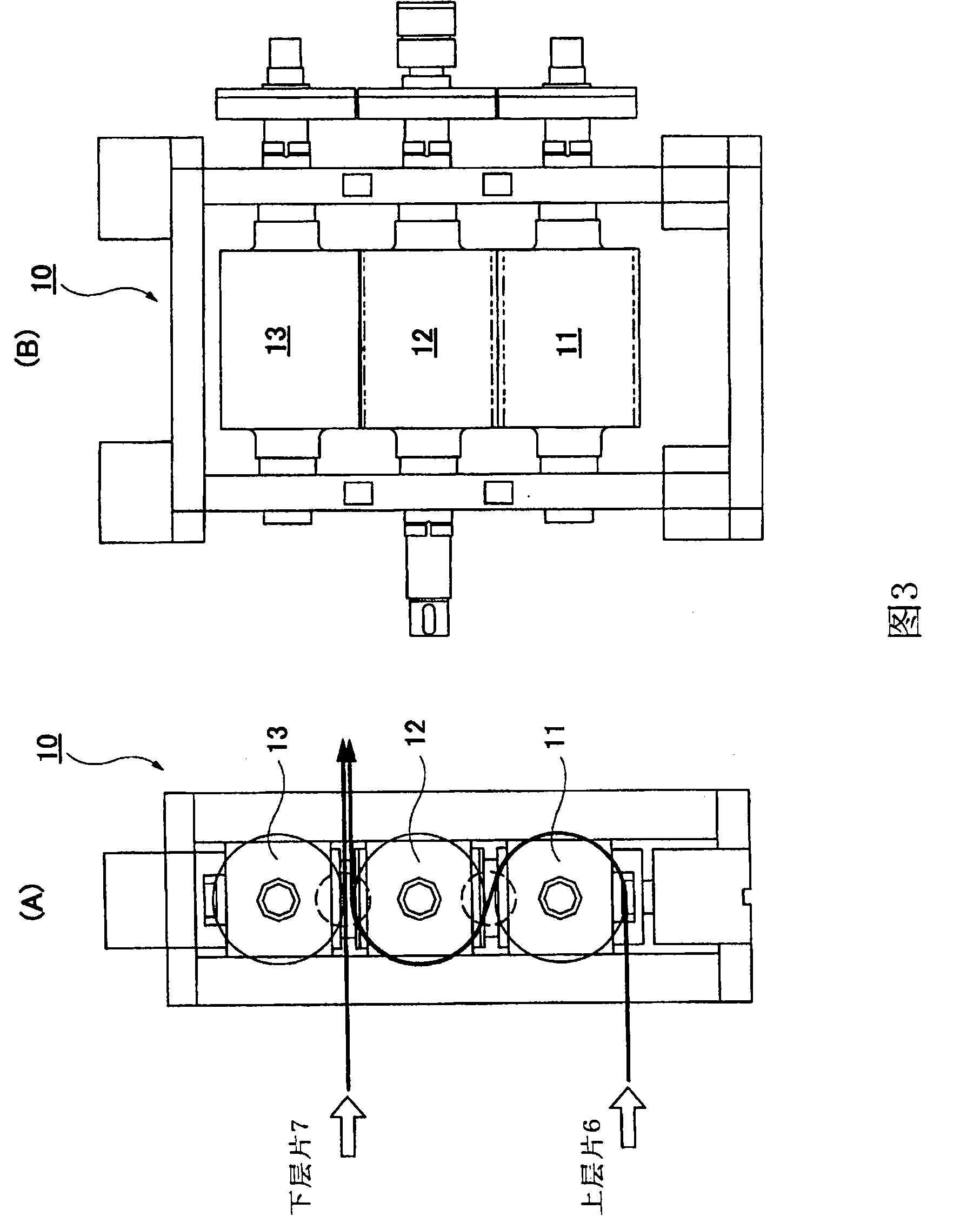

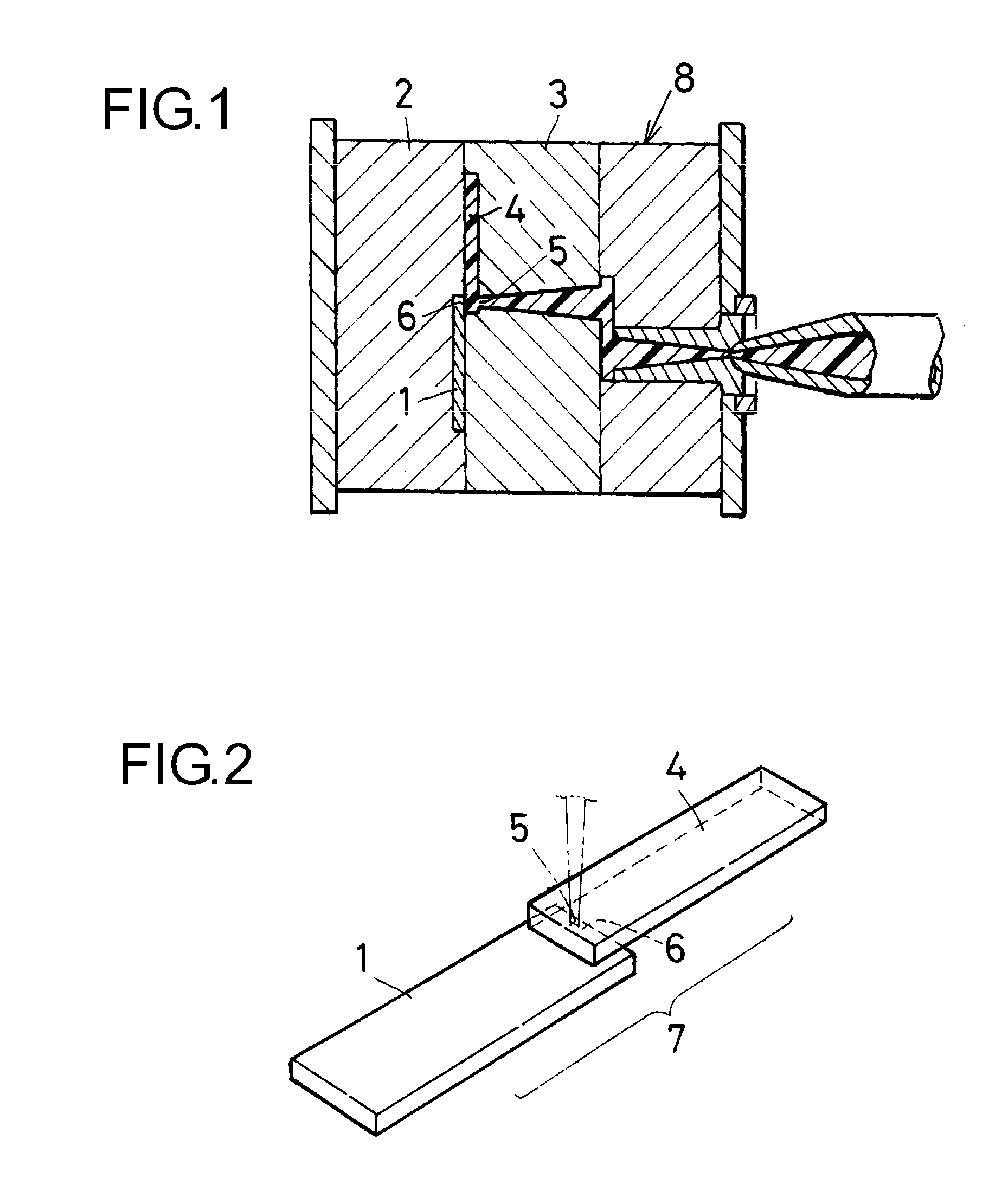

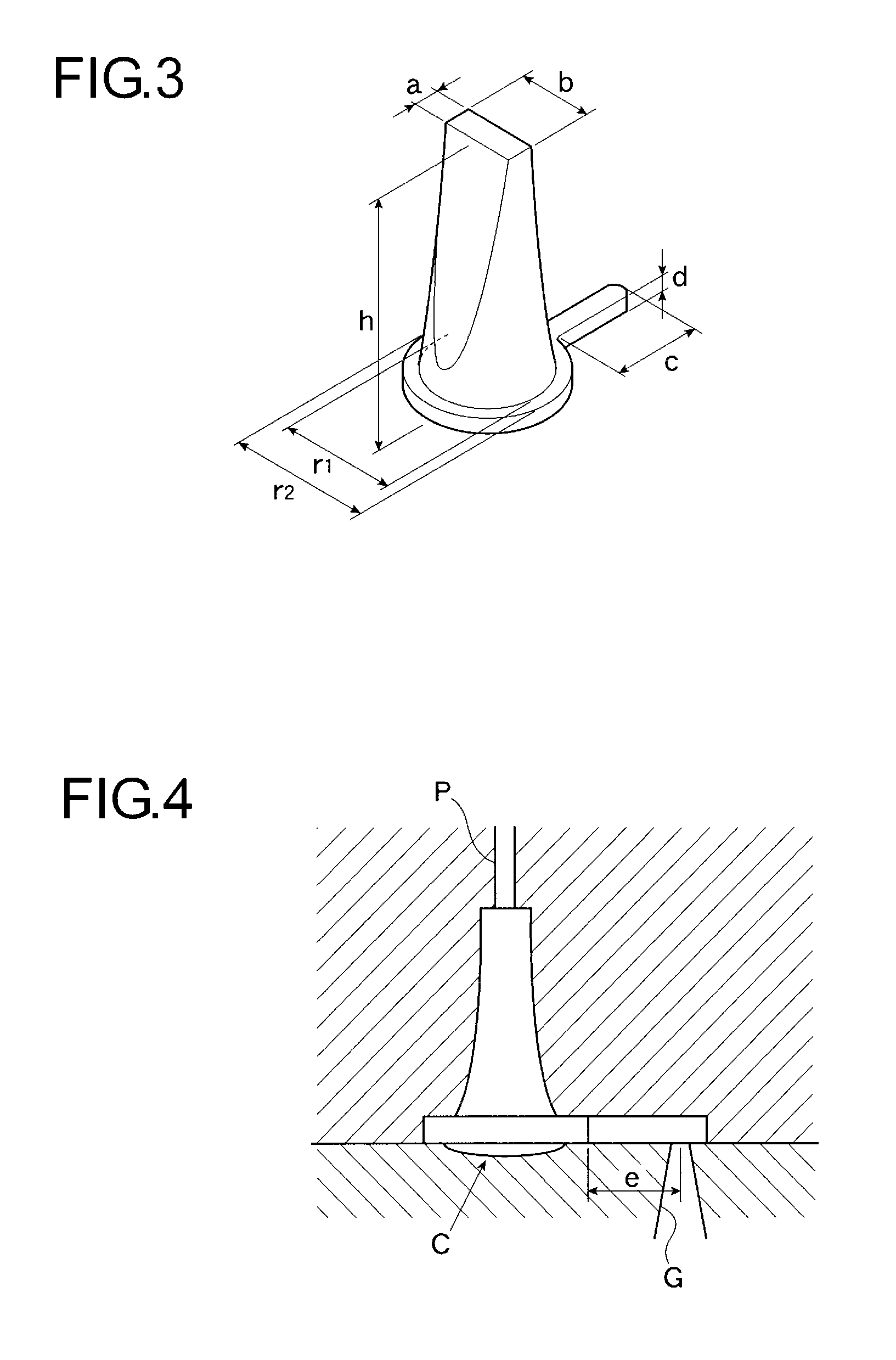

Hollow structure plate, manufacturing method thereof, manufacturing device thereof, and sound absorbing structure plate

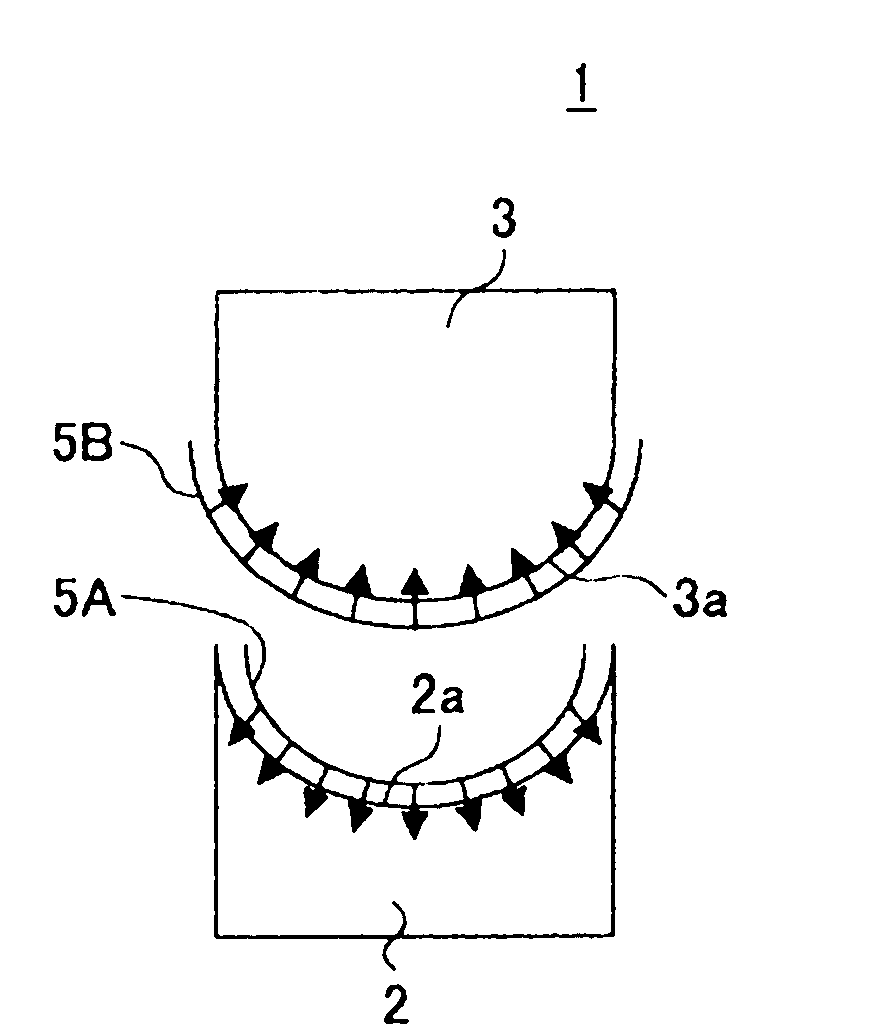

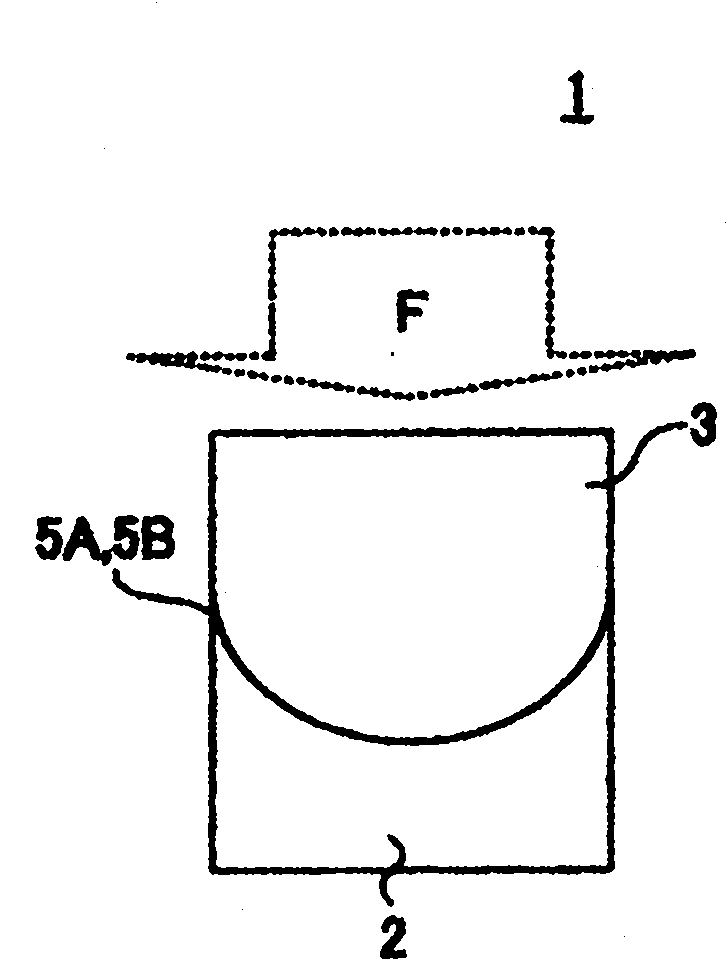

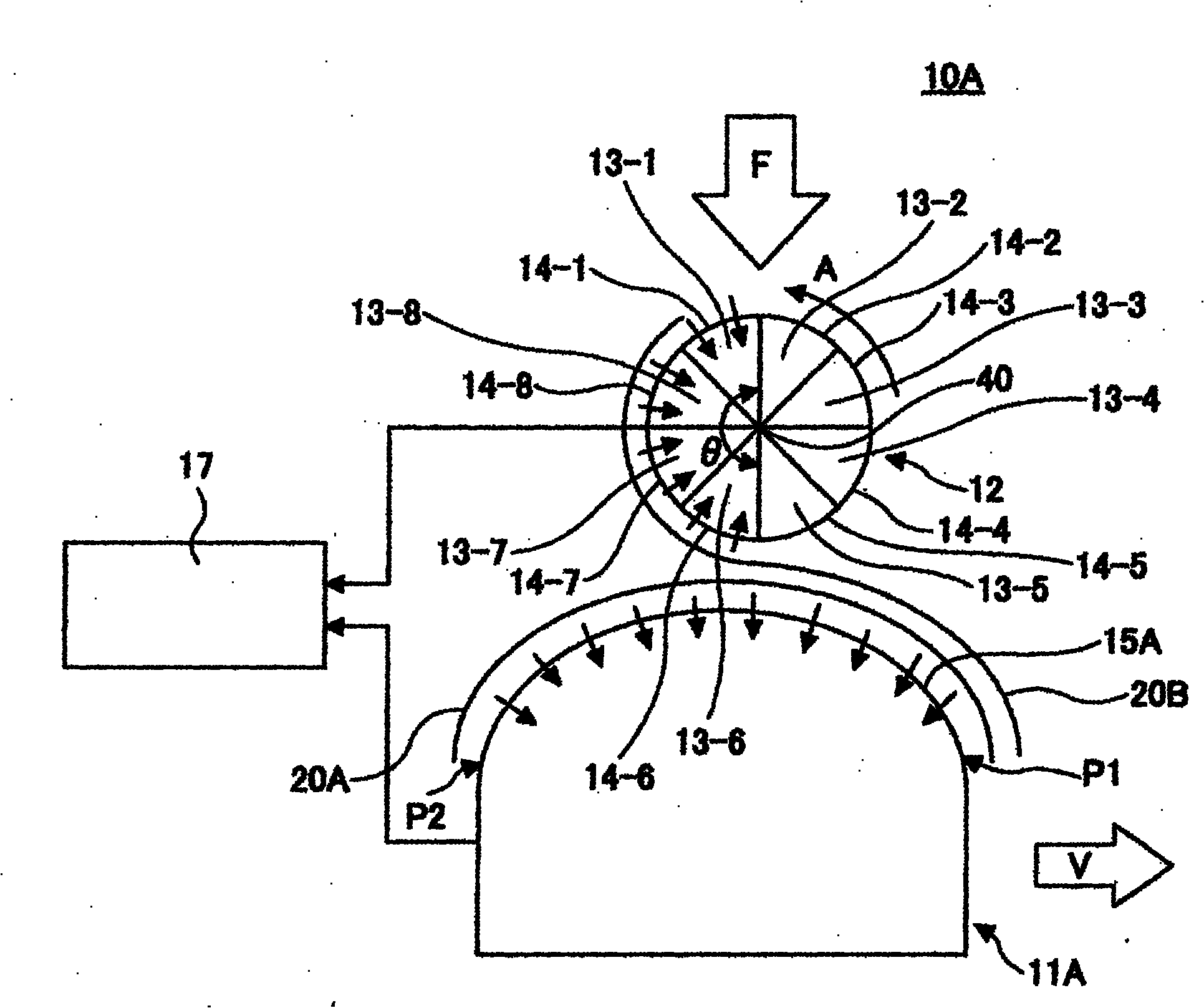

Introduction guides 12 are provided above and below a sheet-introduction opening portion of a pressure-reduced chamber 10, and heating means 17 is provided between the introduction guides. Each resin sheet 3 is attracted and attached respectively to the circumferential surface of a corresponding emboss roller 11 by reducing pressure. Pins 112 of the emboss roller 11 are truncated cone-shaped. The ratio of the total area of the lower bases of the pins 112 to the area of the circumferential surface of the emboss roller is 0.5 or more. The rising angle θ of the pin side face, in the vertical plane including the central axis of the pins 112, is in the range from 50 degrees to 70 degrees. Furthermore, a multilayered hollow structure plate 140 is formed by attaching non-air-permeable sheets 130 onto both the front and back of a core member obtained by fusing together hollow protrusions 112 in two thermoplastic resin sheets. A sound absorbing material 150 is provided on at least one of the front and back side thereof, and small holes 114a opened in the multilayered hollow structure plate are formed in liner portions 114 and the non-air permeable sheet 130 only in the positions that matches the liner portions 114.

Owner:UBE NITTO KASEI CO LTD

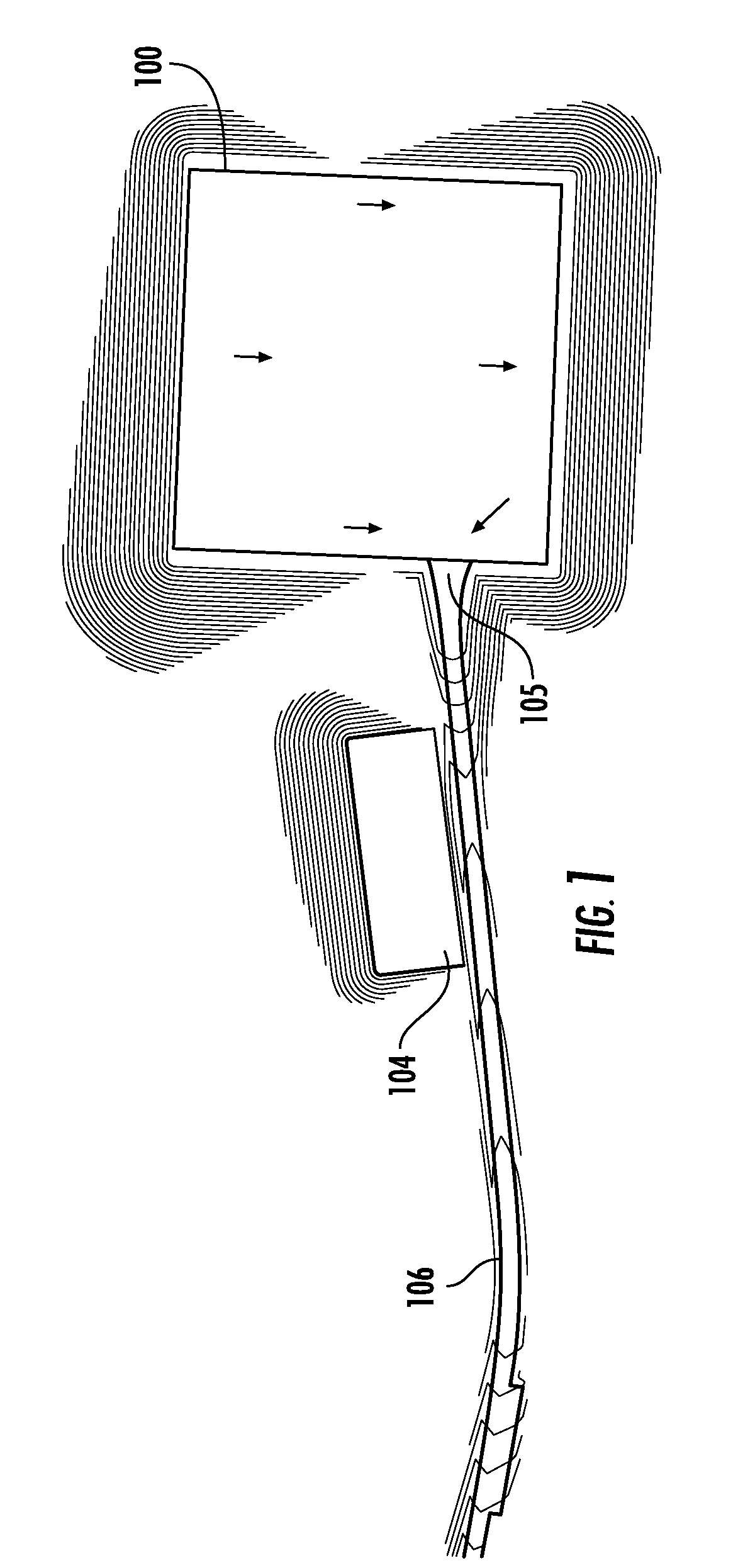

Film sticking device, film sticking method, and electronic paper manufacturing method

InactiveCN102119077AReduce manufacturing costLamination ancillary operationsLaminationEngineeringVacuum chamber

A film sticking device, a film sticking method, and an electronic paper manufacturing method for curving and sticking a plurality of film substrates. The film sticking device has a mold which has a curved surface adsorption surface having a desired shape, an adsorption drum which is constituted to be movable relatively on the curved surface adsorption surface and has a plurality of vacuum chambers for holding the film substrates, and a suction device which is capable of performing sucking processing of the vacuum chambers individually. Then, at a facing position where the adsorption drum faces a film substrate, the suction processing of a vacuum chamber corresponding to the facing position is started and the sucking processing of the vacuum chamber corresponding to a stuck film substrate is stopped in order.

Owner:FUJITSU LTD

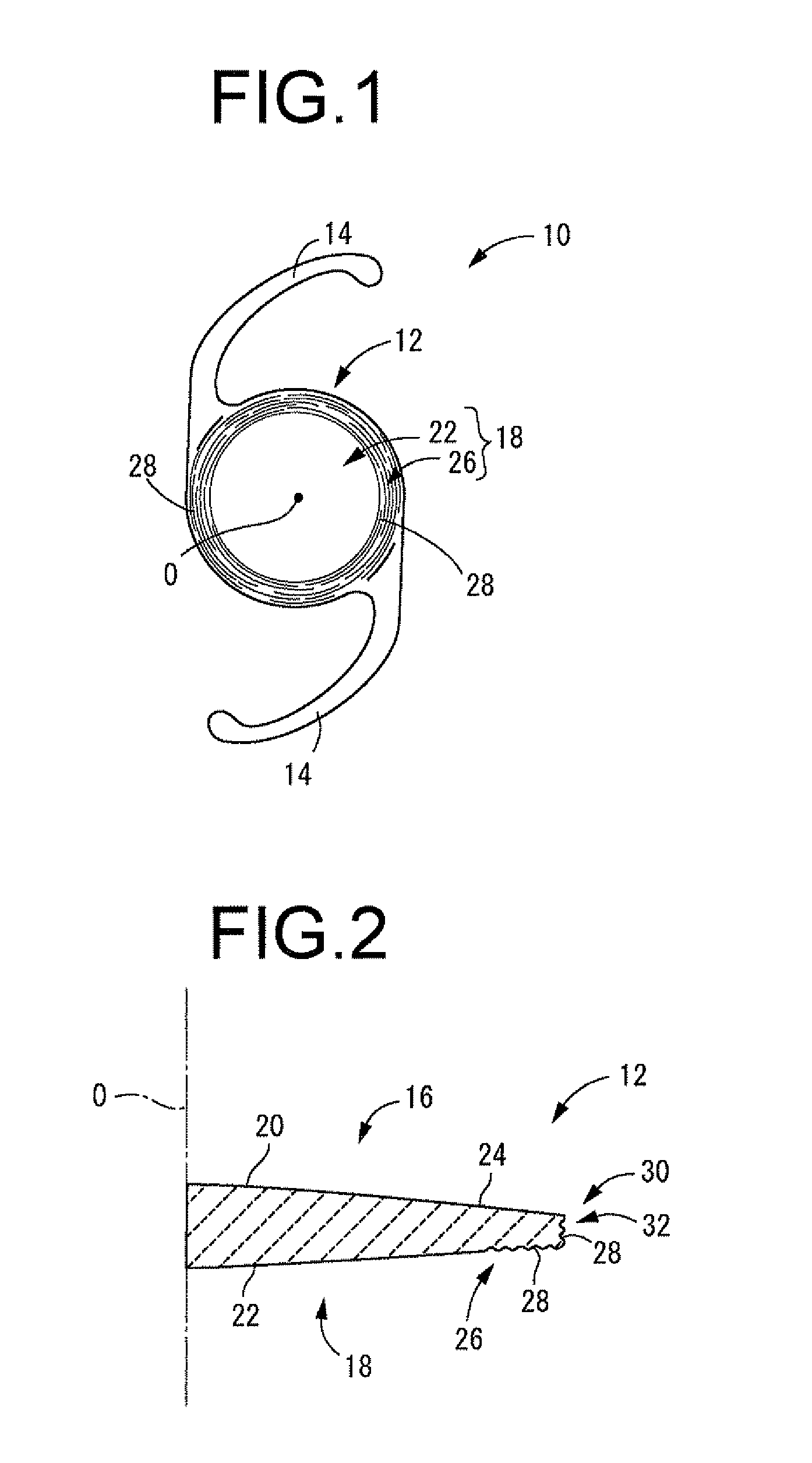

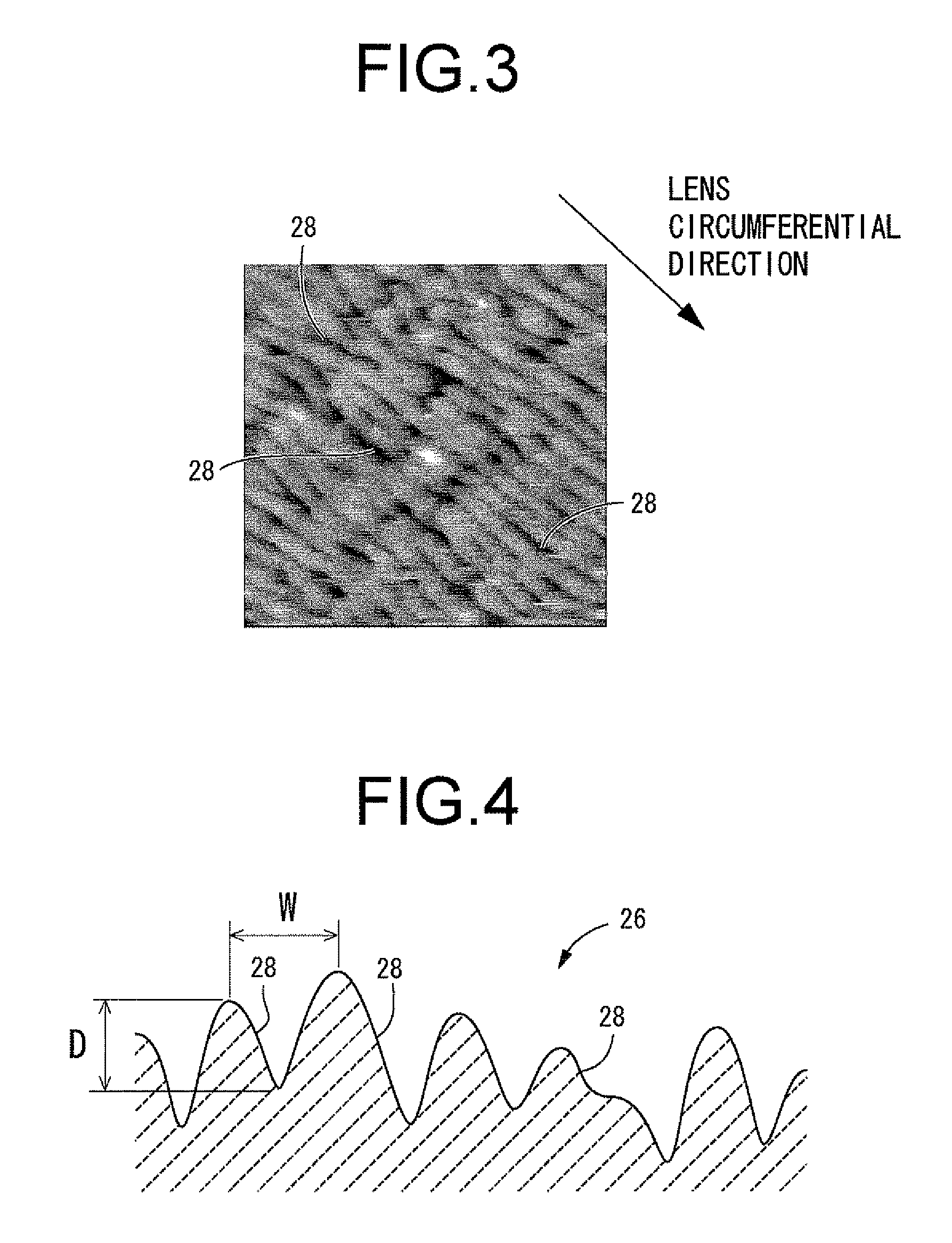

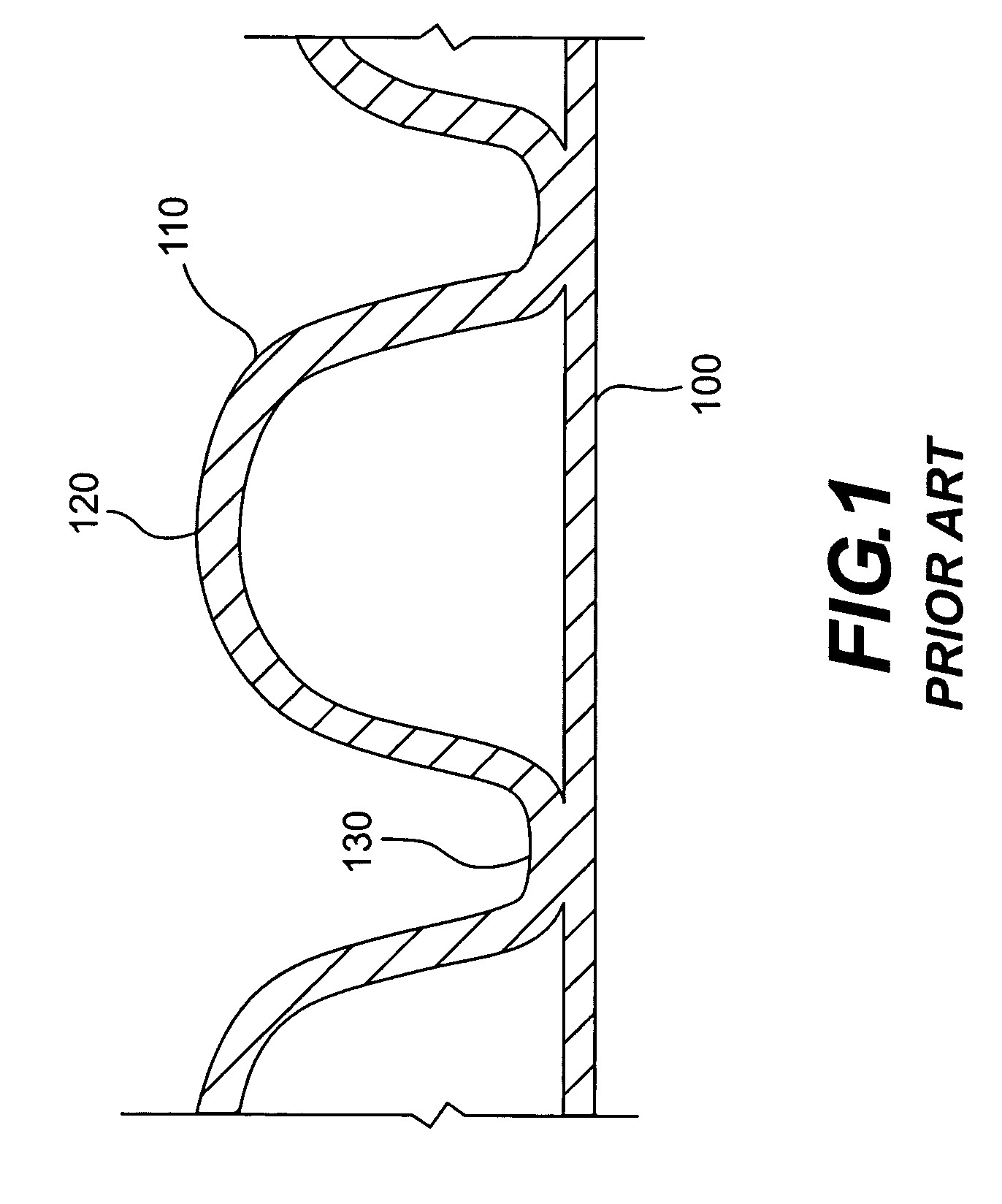

Intraocular lens and manufacturing method thereof

InactiveUS20110098808A1Ability of to developSmall sizeOptical articlesCorrugation articlesIntraocular lensEntire cell

An intraocular lens adapted for deployment within a lens capsule. At least part of a lens surface of the intraocular lens constitutes a cell inducing region in which are directly formed a multitude of microgrooves. The microgrooves take a form of minute linear grooves and lands of depth dimension between 0.01 and 1.0 μm and width dimension between 0.1 and 2.0 μm extending with prescribed length in a circumferential direction on the lens surface. The minute linear grooves and lands are formed with a chained pattern connected in the circumferential direction of the lens surface and with a periodic pattern arrayed periodically in a diametrical direction so that the minute linear grooves and lands are formed without intervening spaces throughout the entire cell inducing region and impart visible light transmittance of 60% or above to the cell inducing region.

Owner:KOWA CO LTD

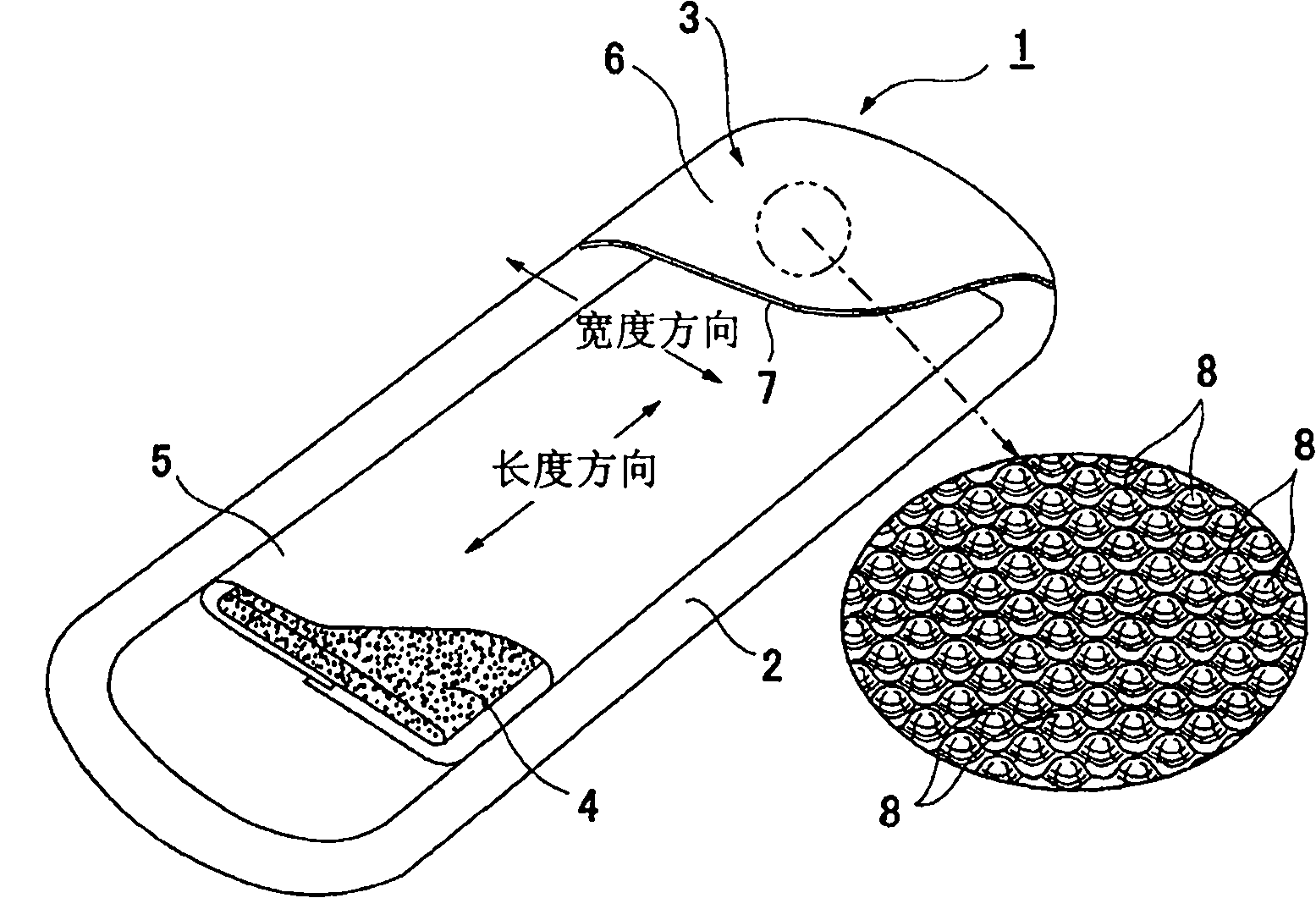

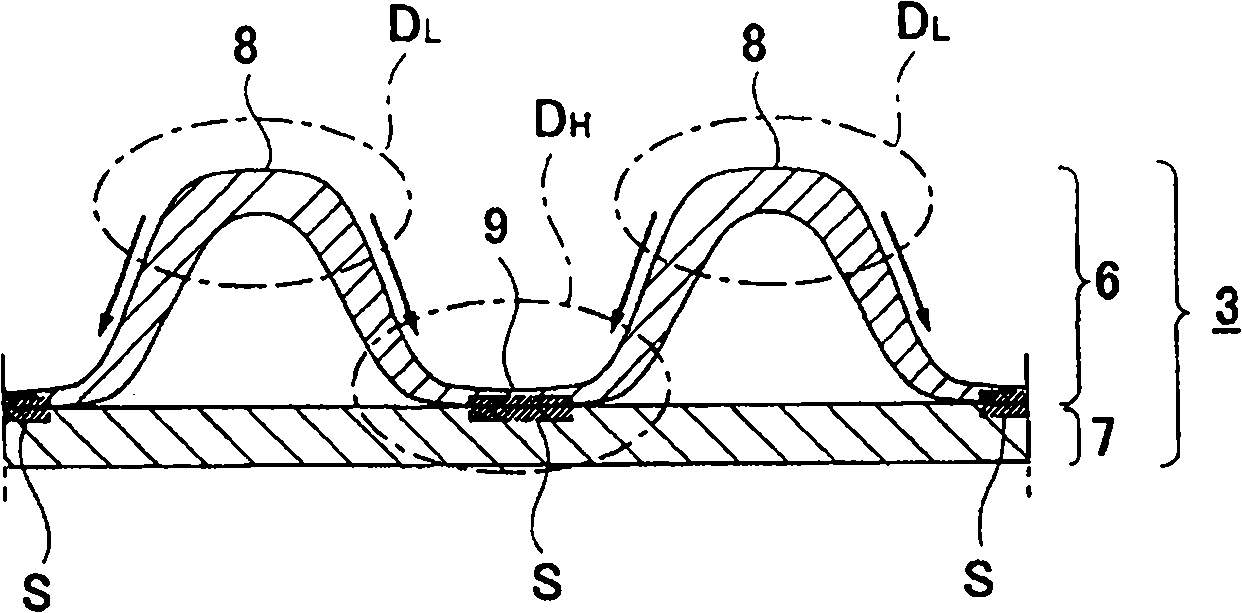

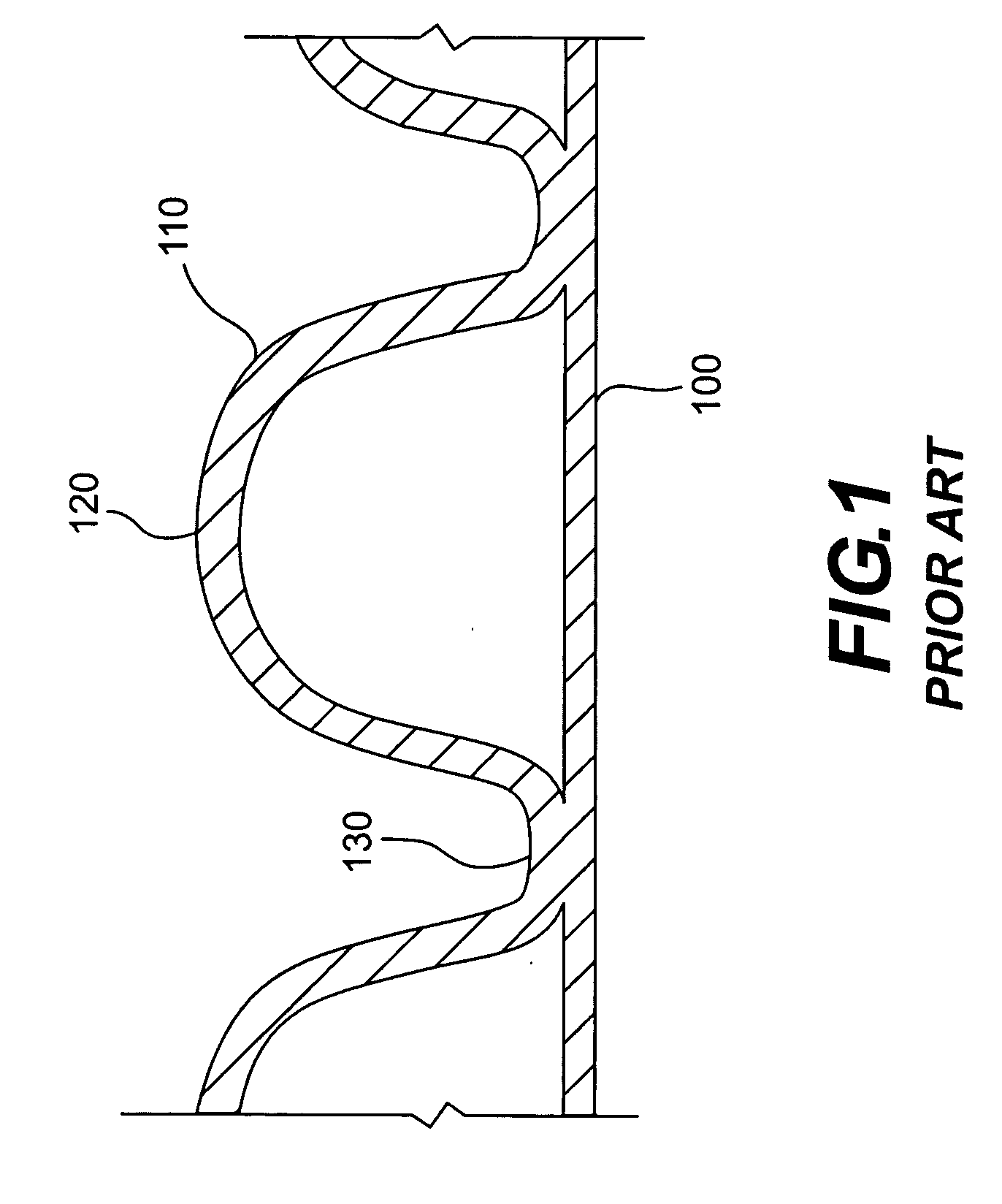

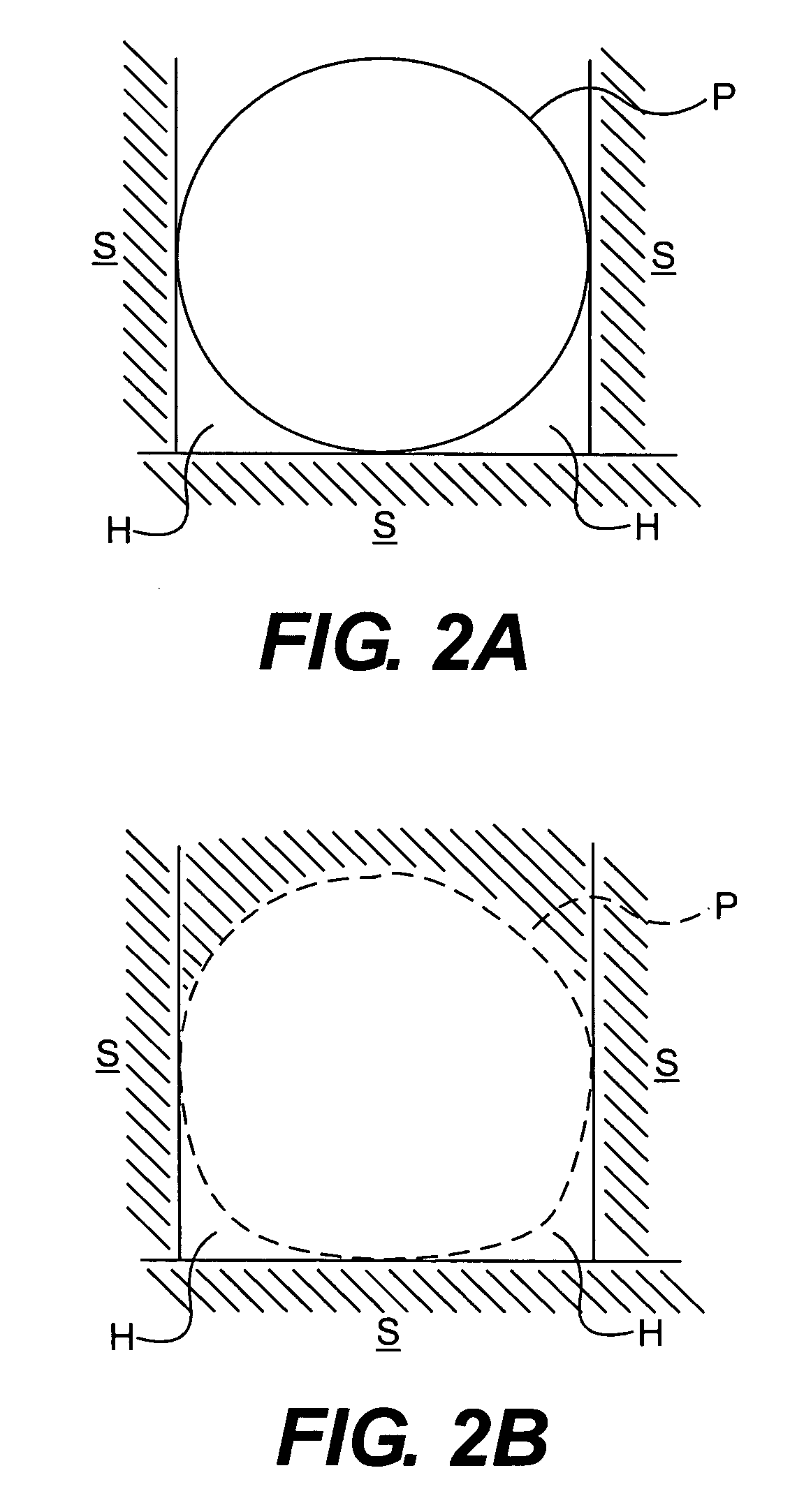

Emboss roller and method for producing surface sheet using emboss roller and absorbent article employing surface sheet

ActiveCN101970211AEliminate stiffnessGood touchLamination ancillary operationsLaminationFiberMechanical engineering

Disclosed is an emboss roller comprising a set of a first emboss roll (11) and a second emboss roll (12) and imparting an irregularly embossed shape onto a surface sheet, wherein a reference surface (14), which has a protrusion (15) protruding outward from the reference surface (14) and a recess (16) recessed from the reference surface (14), the reference surface (14) serving as the boundary, and is smooth to the peripheries of the protrusion (15) and the recess (16), exists on the surface of the first emboss roll (11), and a reference surface (17), which has a protrusion (18) protruding outward from the reference surface (17) to mesh the recess (16) in the first emboss roll (11) and a recess (19) recessed from the reference surface (17) to mesh the protrusion (15) of the first emboss roll (11), the reference surface (17) serving as the boundary, and is smooth to the peripheries of the protrusion (18) and the recess (19), exists on the surface of the second emboss roll (12).

Owner:DAIO PAPER CORP

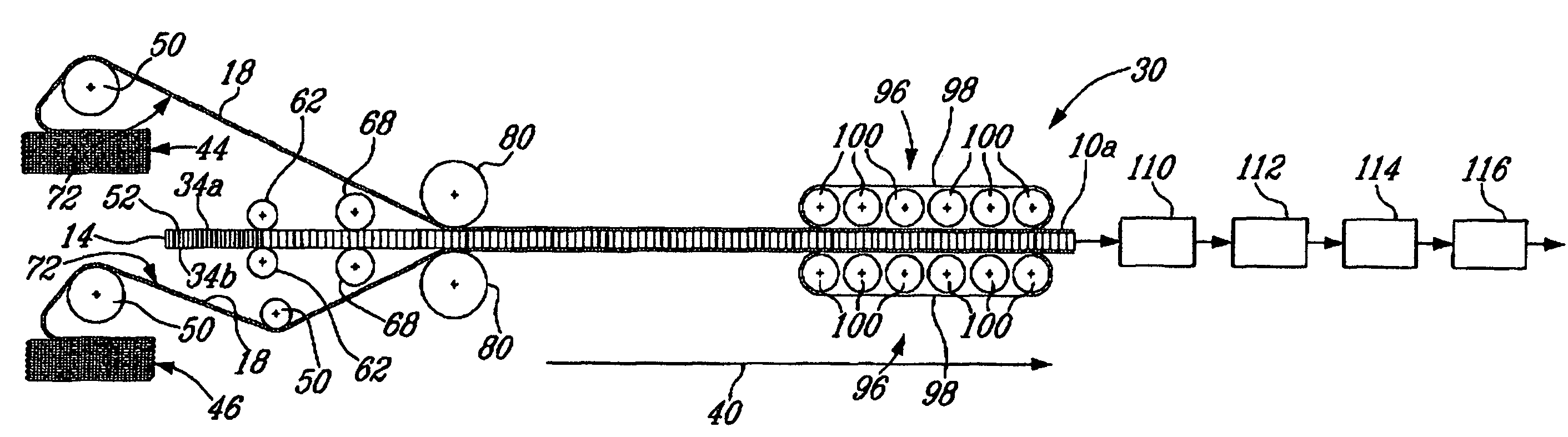

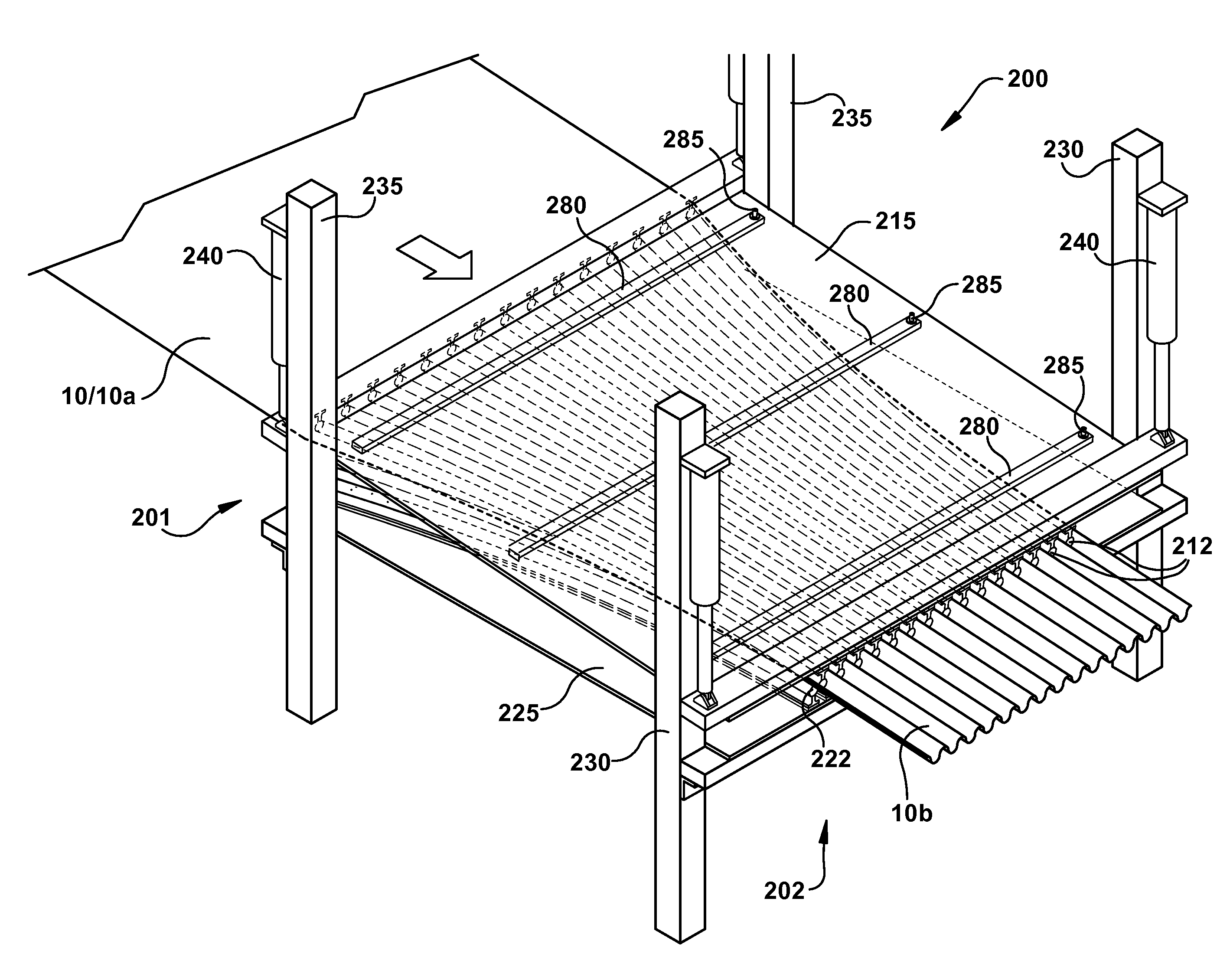

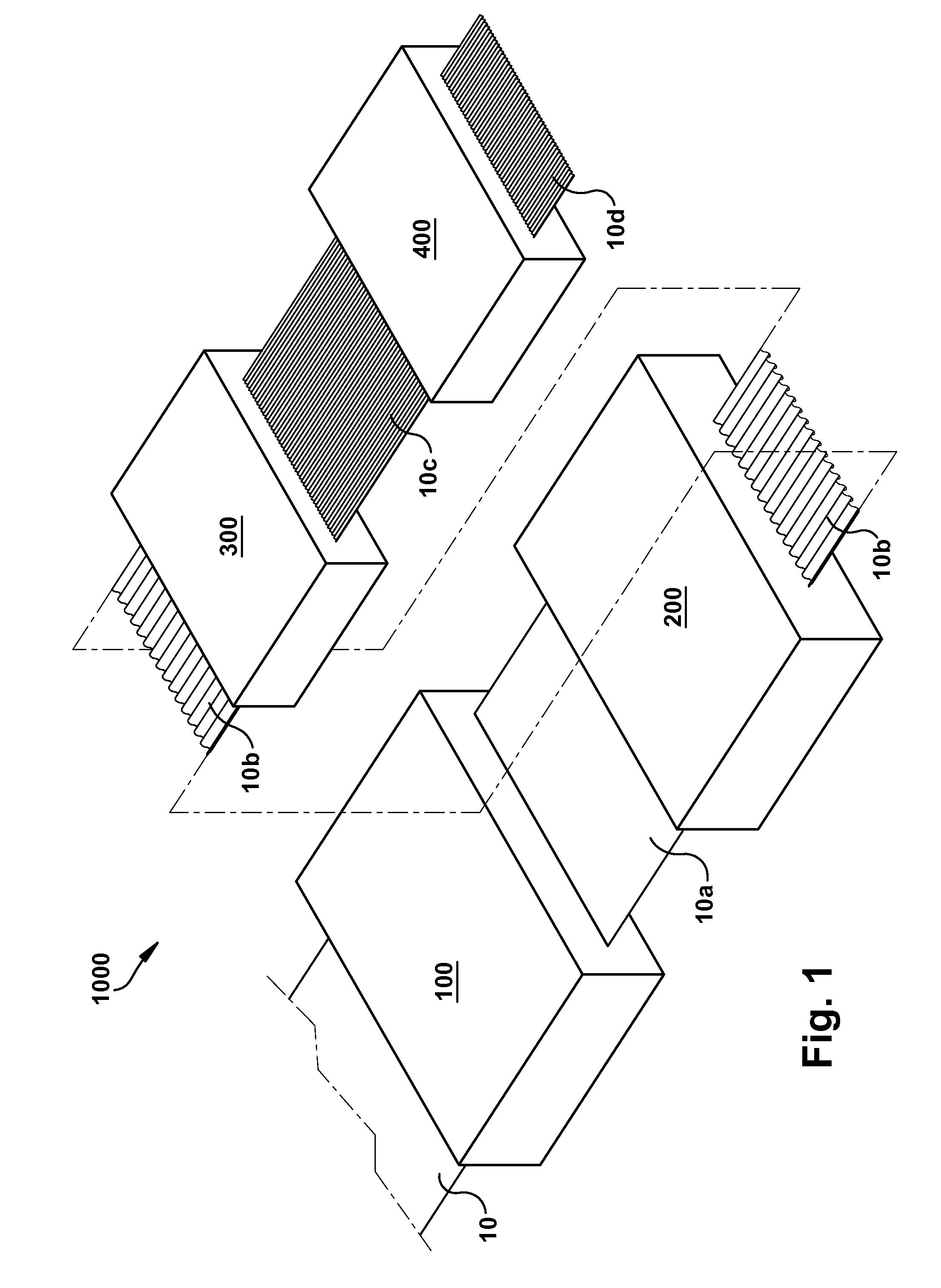

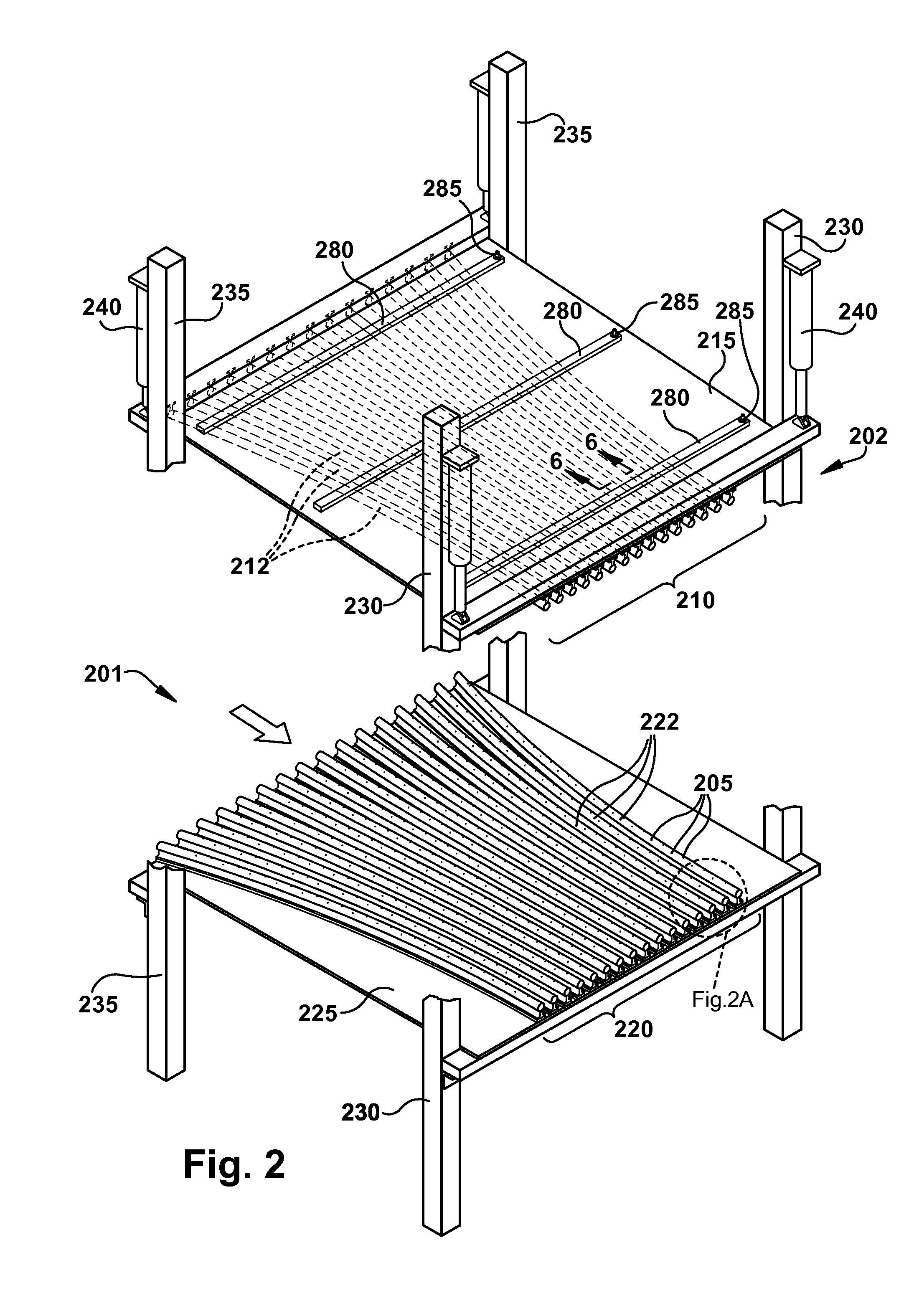

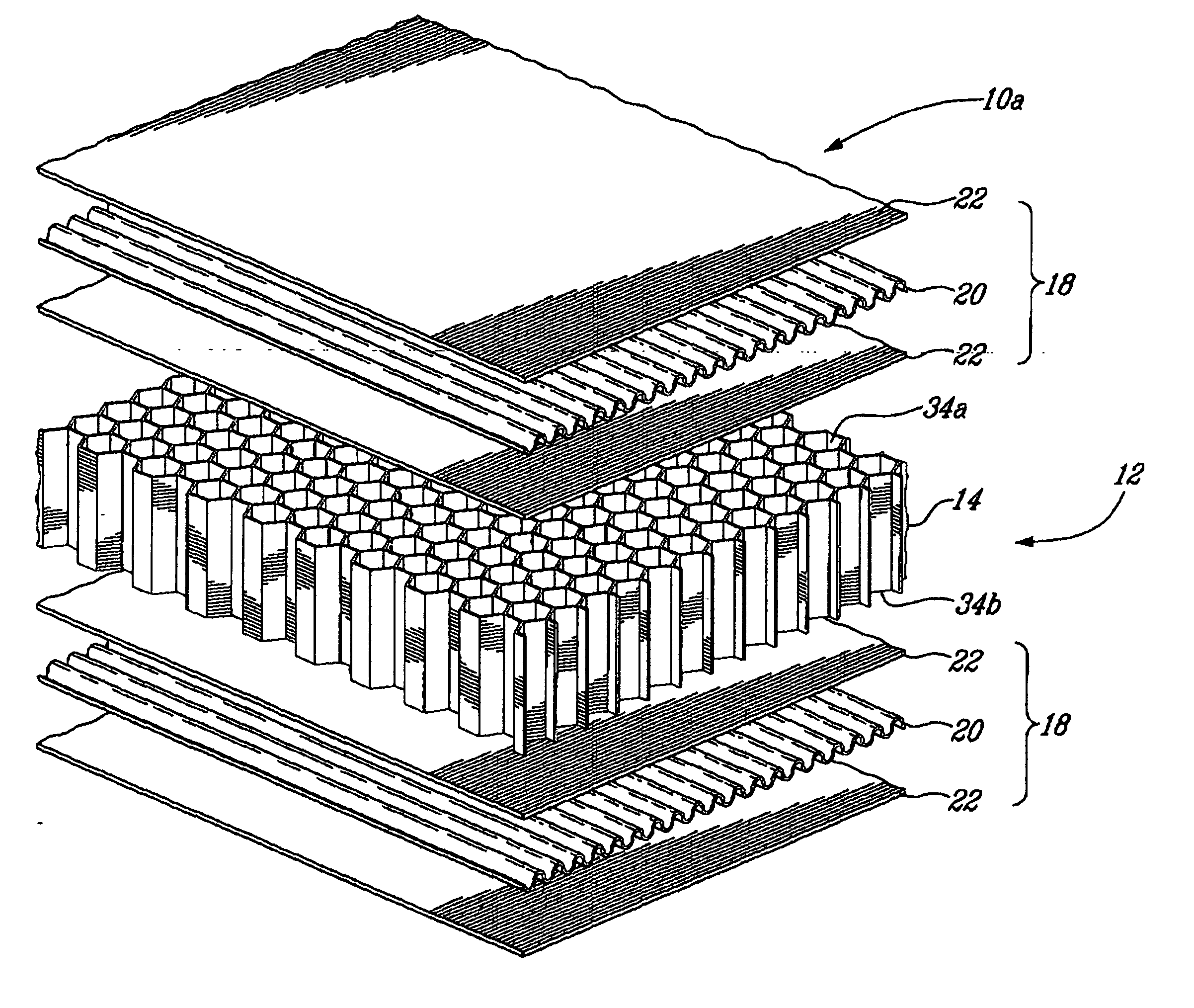

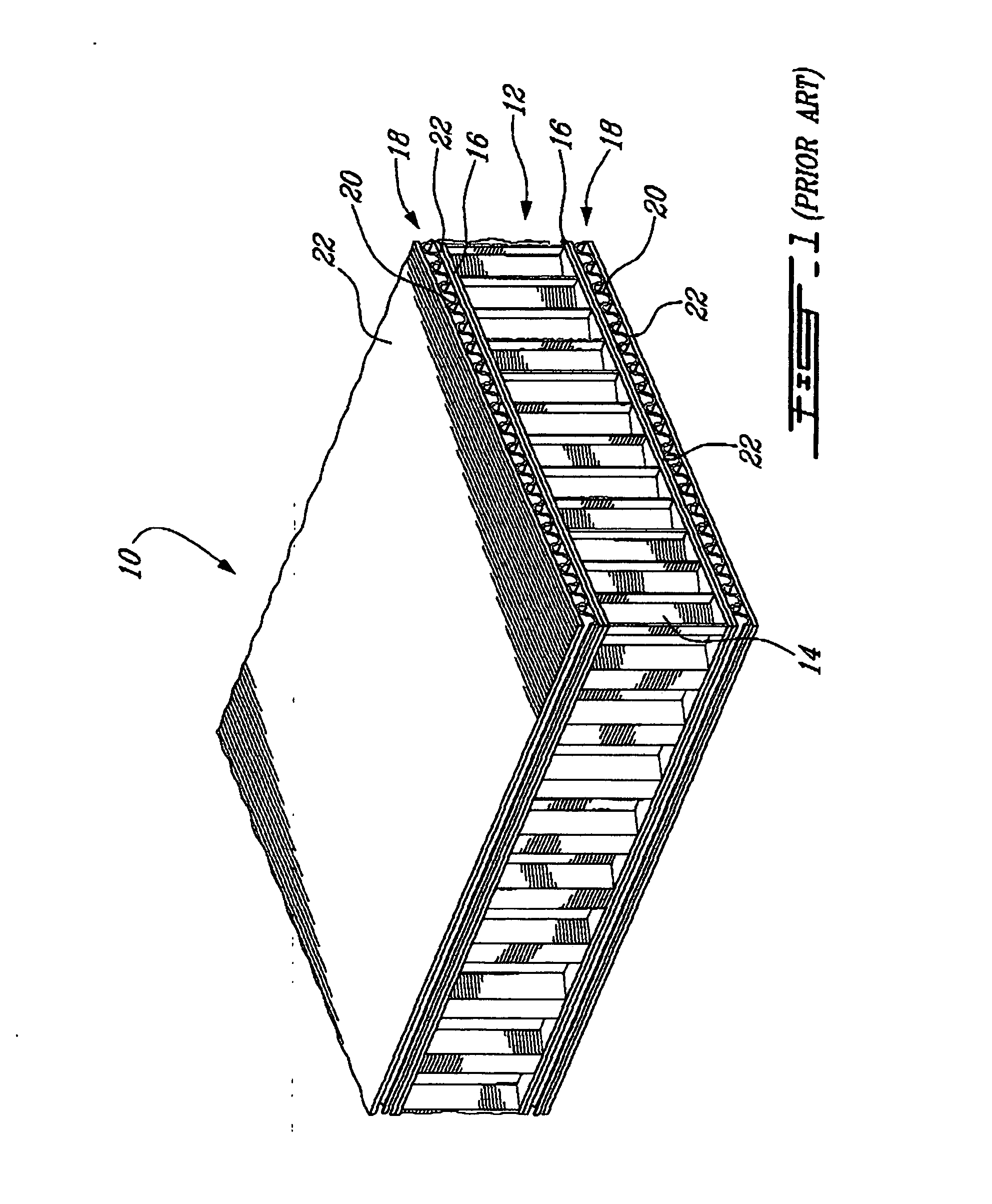

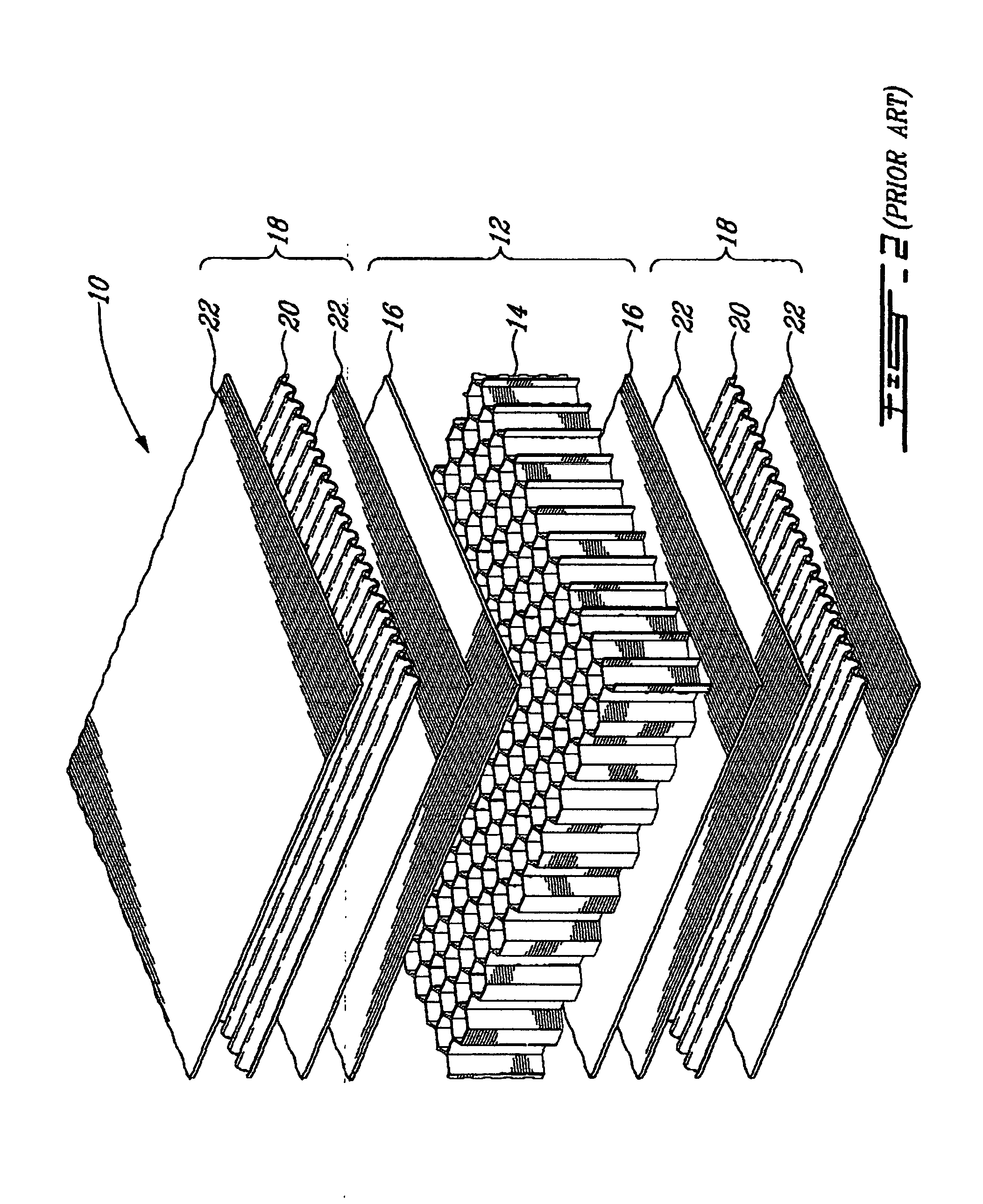

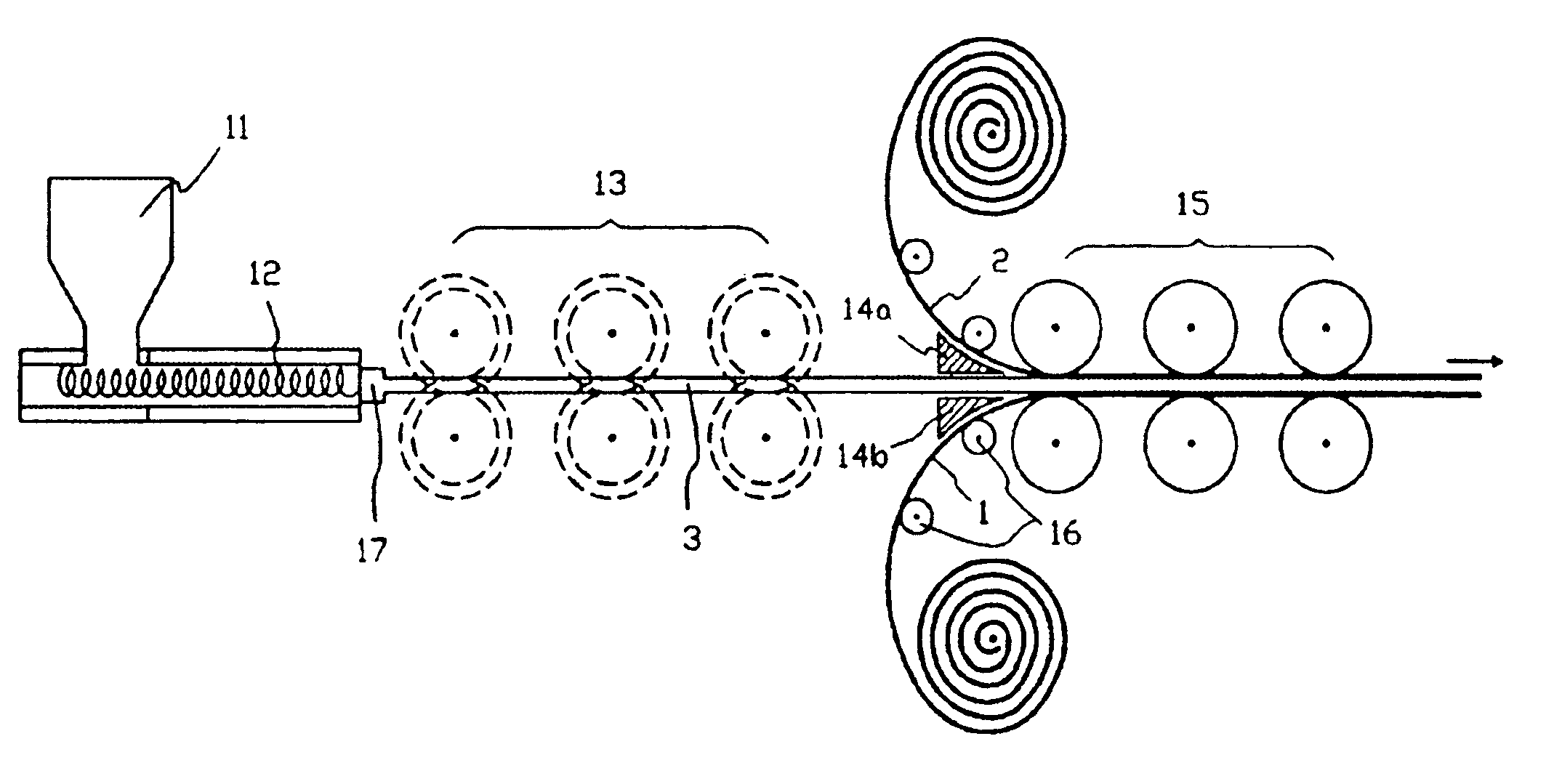

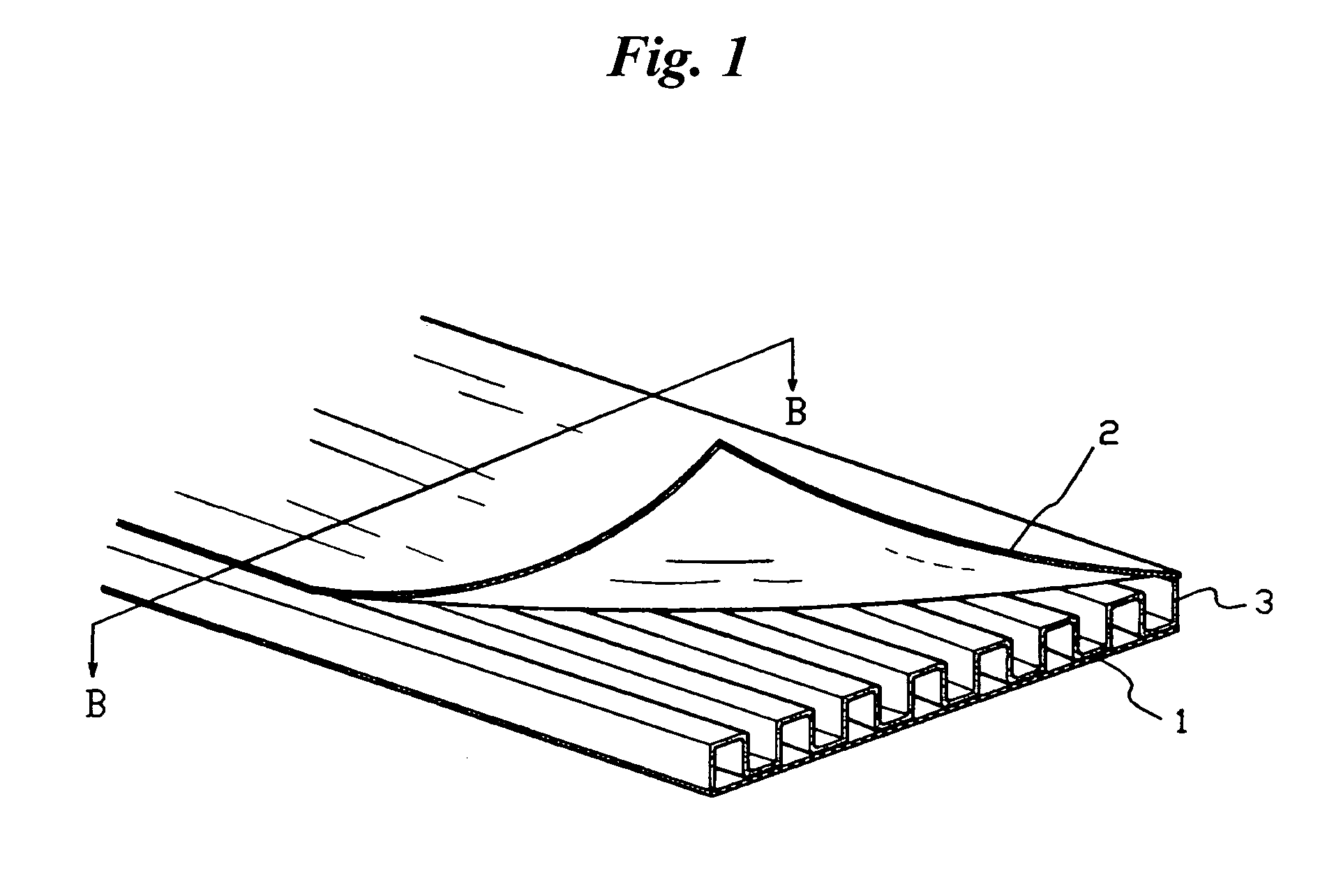

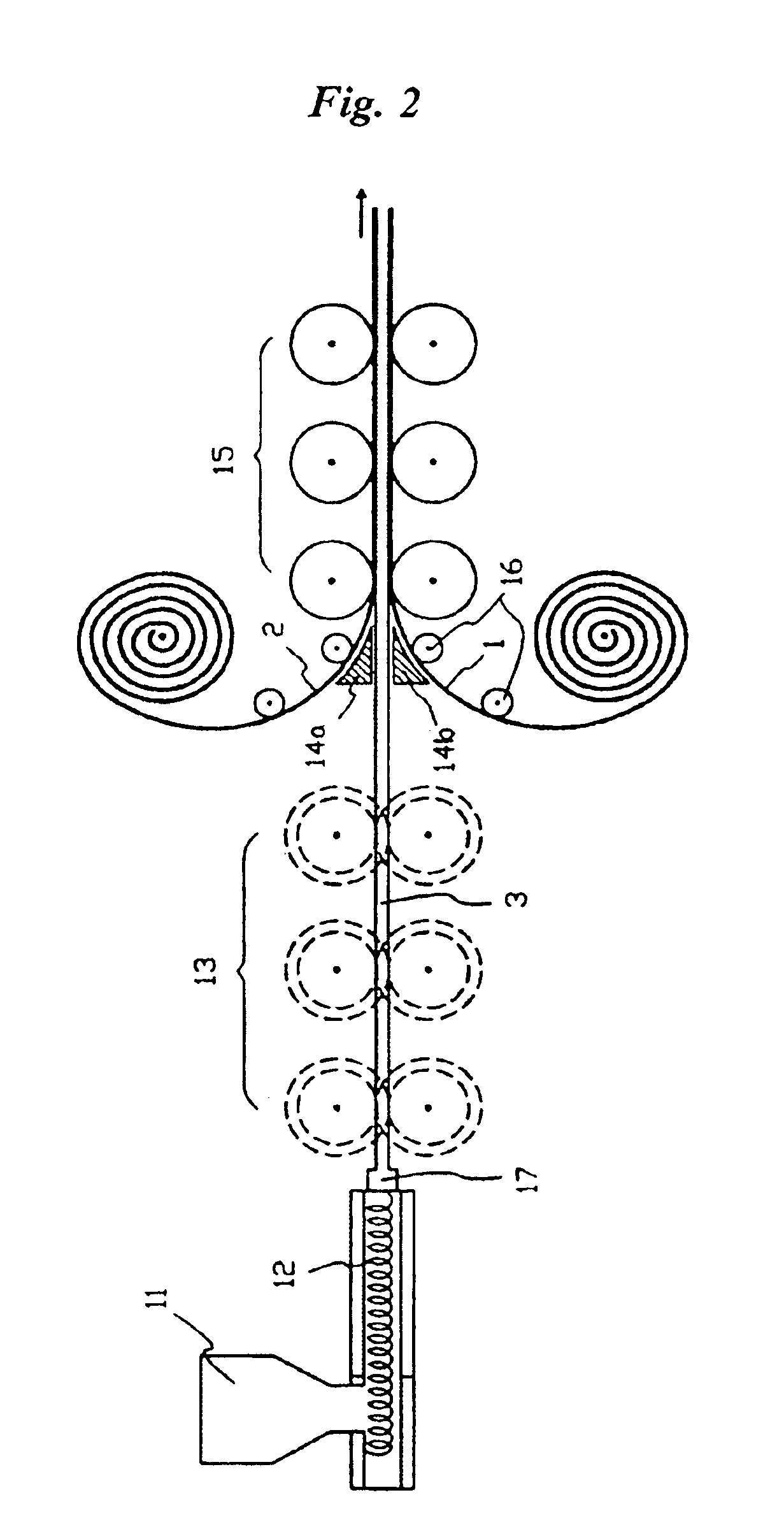

Process and apparatus for manufacturing a honeycomb composite material

ActiveUS7288164B2Improve mechanical propertiesReduce manufacturing costAdhesive processesLamination ancillary operationsCardboardProduction line

The present invention relates to for a continuous production of a web of a composite material. The process comprises the steps of: providing a web of honeycomb material; providing at least one web of face sheet material having a corrugated medium with at least one linerboard on at least one face thereof; carrying the web of honeycomb material and the at least one web of face sheet material along a production line; and adhesively applying the at least one web of face sheet material to one face of the honeycomb material while the honeycomb material is being conveyed through the production line and maintained in an expanded state. The present invention also relates to a packaging material manufactured with a process described hereinabove and an apparatus to manufacture same.

Owner:CASCADES CANADA INC

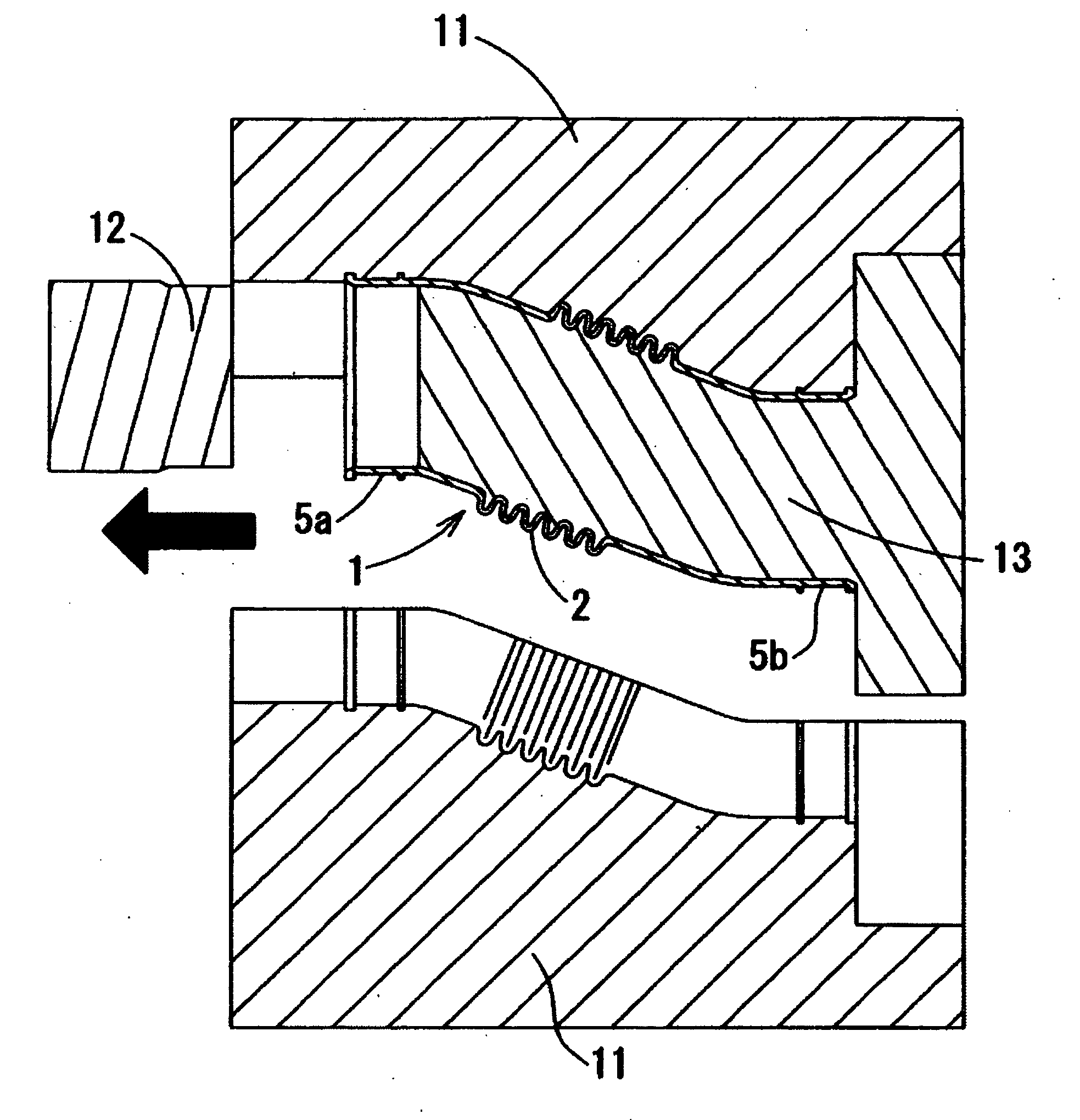

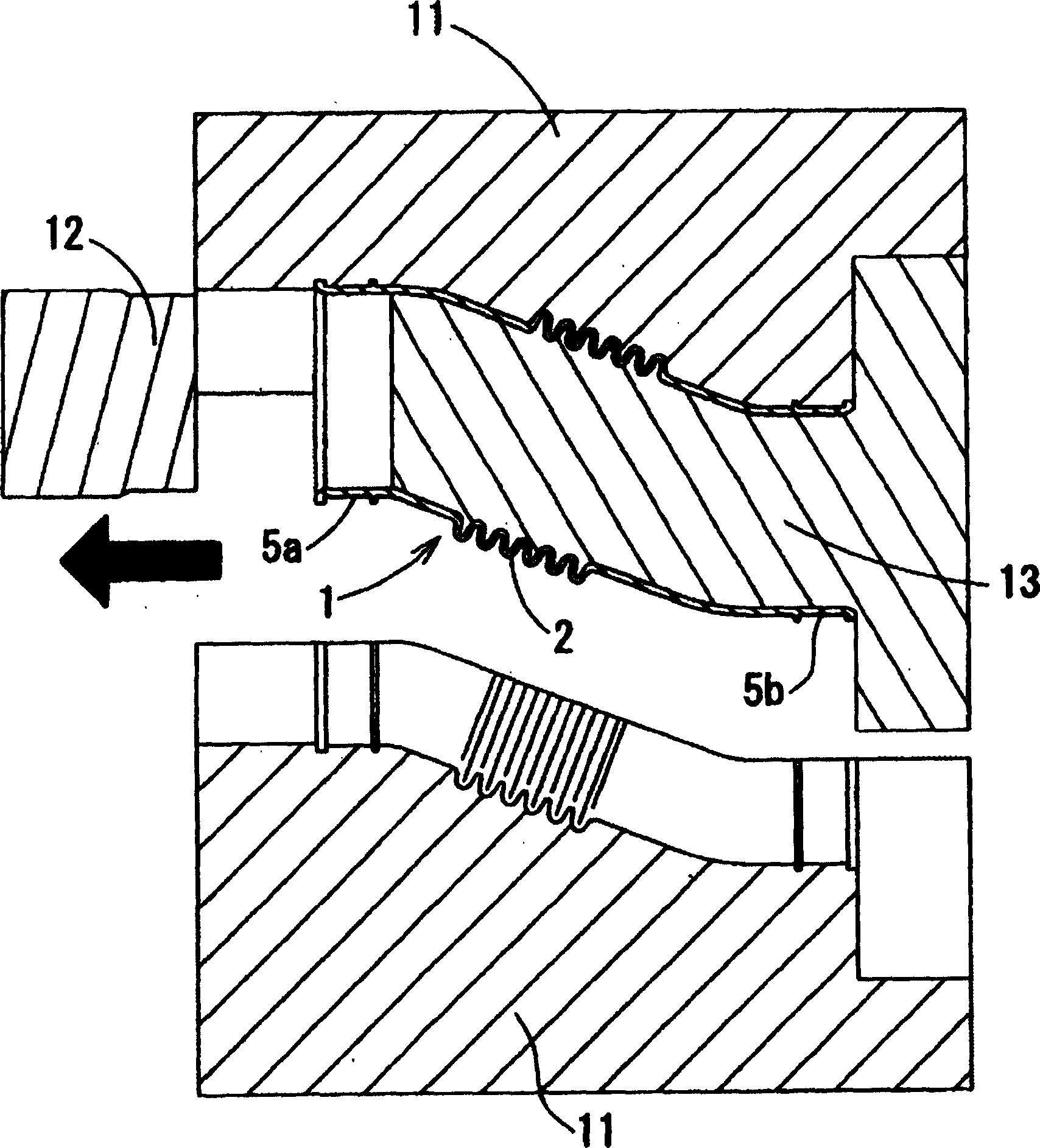

Method for forming duct made of elastomer

InactiveUS20060125149A1Low elastic modulusEasy to disassembleMouldsConfectioneryElastomerEngineering

[Objects] In a method for forming a duct used as, e.g., an air duct for an automobile engine, and provided with a corrugated section as an undercut part in a part of the longitudinal direction of the duct, an elastomeric duct is formed with ensuring easy removal of a duct molded by injection from a core die even when the duct is made of a resin poor in elasticity. [Means to Solve the Problems] A method for forming an elastomeric duct having a corrugated section in a longitudinal direction thereof as a part of the duct by injection molding, which comprises injecting an elastomer material into a cavity formed with a cavity die for forming an external surface of the duct, and a core die for forming an internal surface of the duct, wherein the core die is a splittable core die which is axially splittable into two parts, one is a core die A for forming a duct area at least containing the corrugated section, and the other is a core die B for forming a duct area free from the corrugated section, and removing the duct area containing the corrugated section from the core die A with expanding at least the corrugated section in the radius direction by air injection after opening the cavity die.

Owner:TAIGAASU HORIMAA

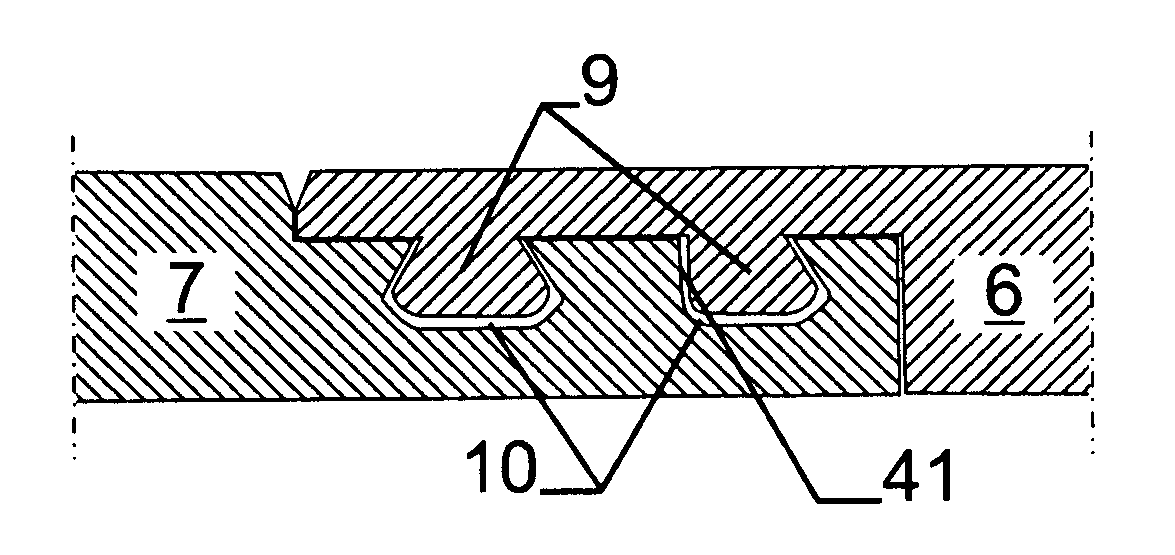

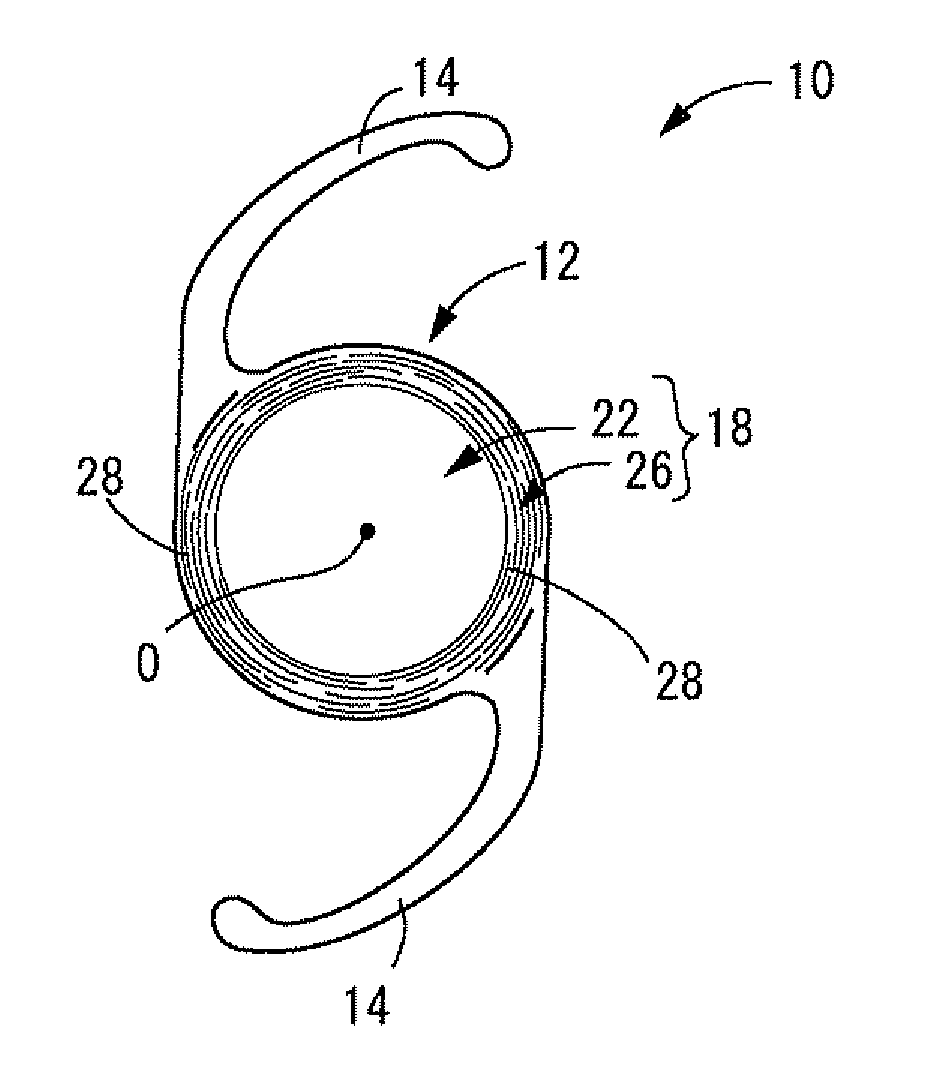

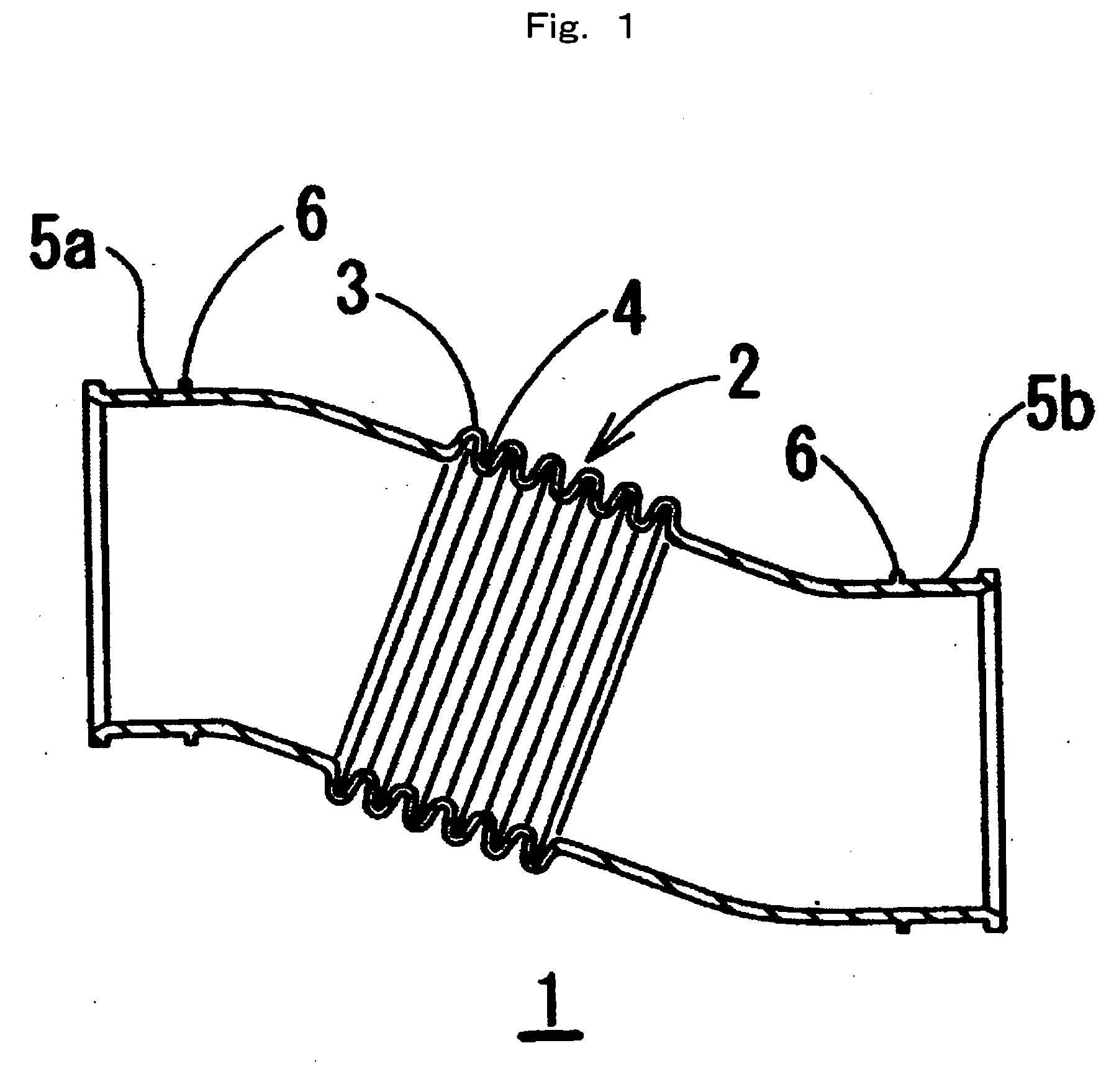

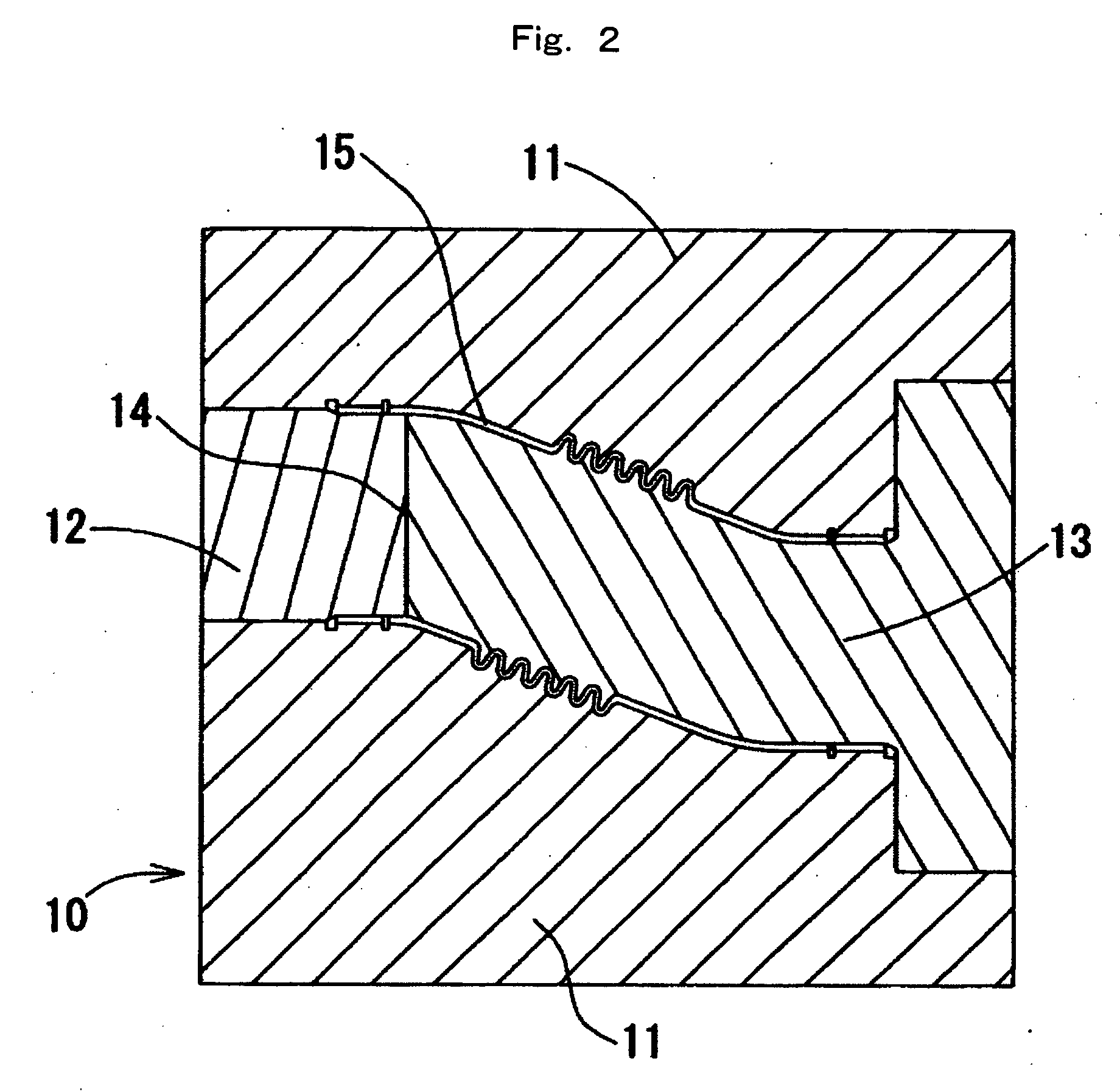

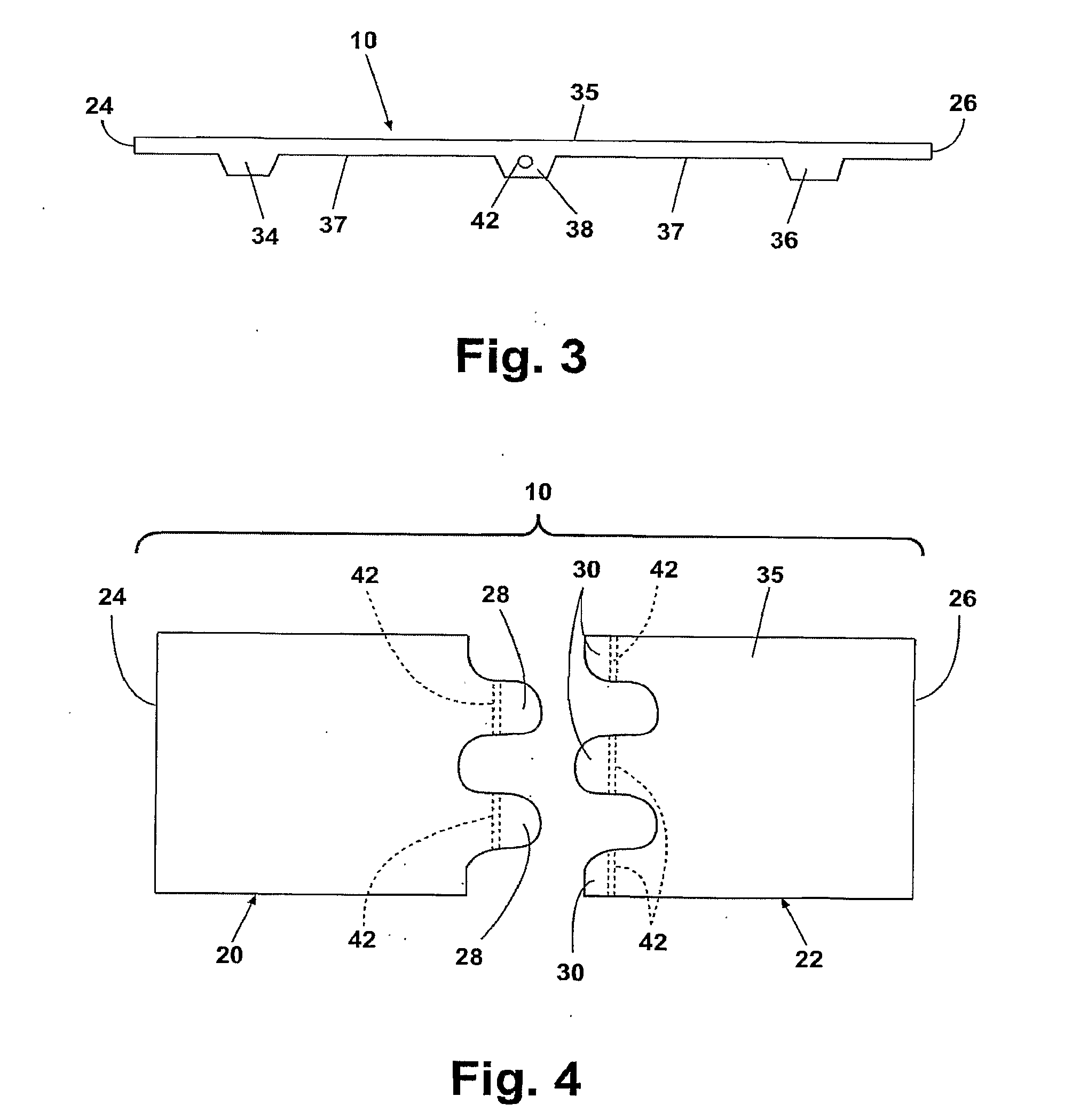

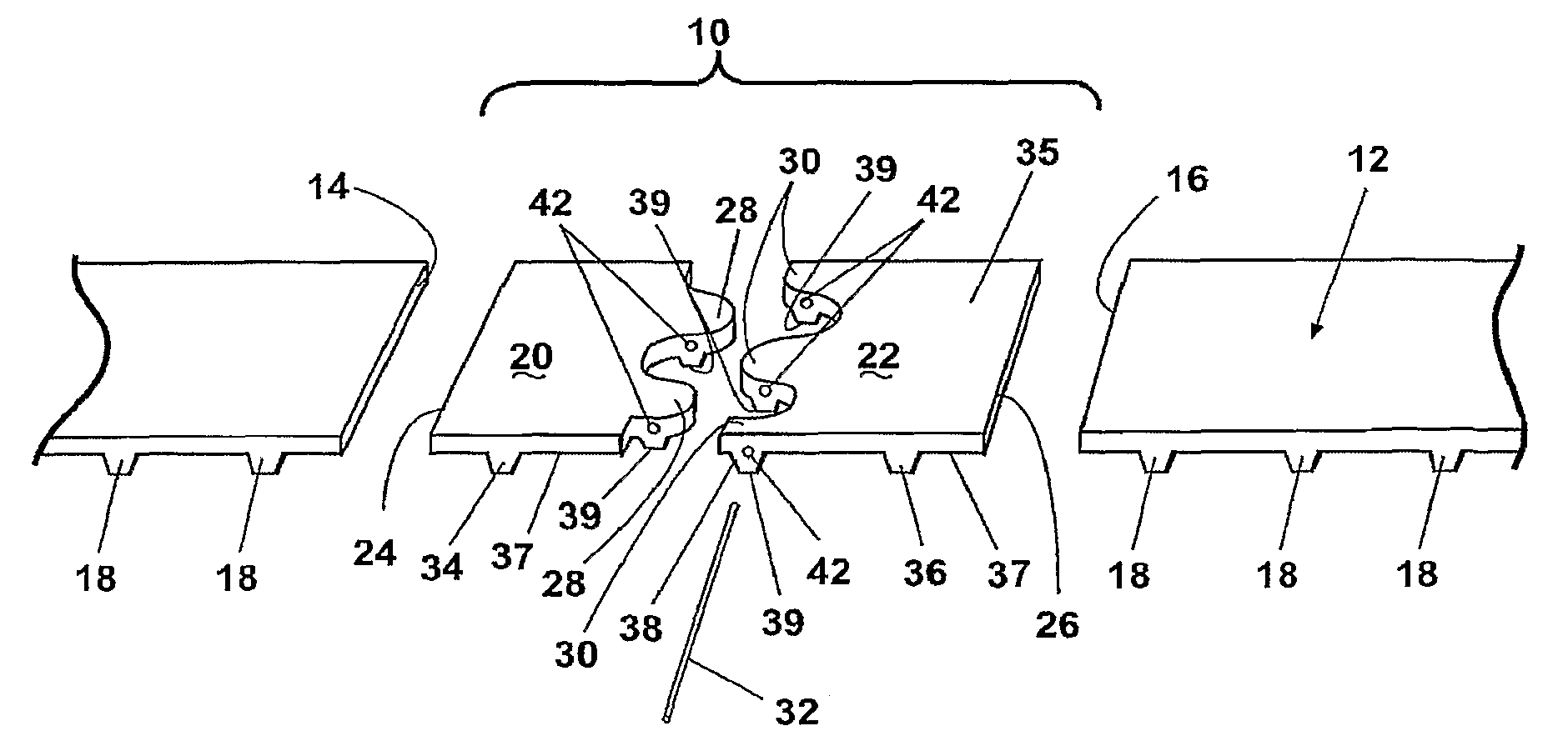

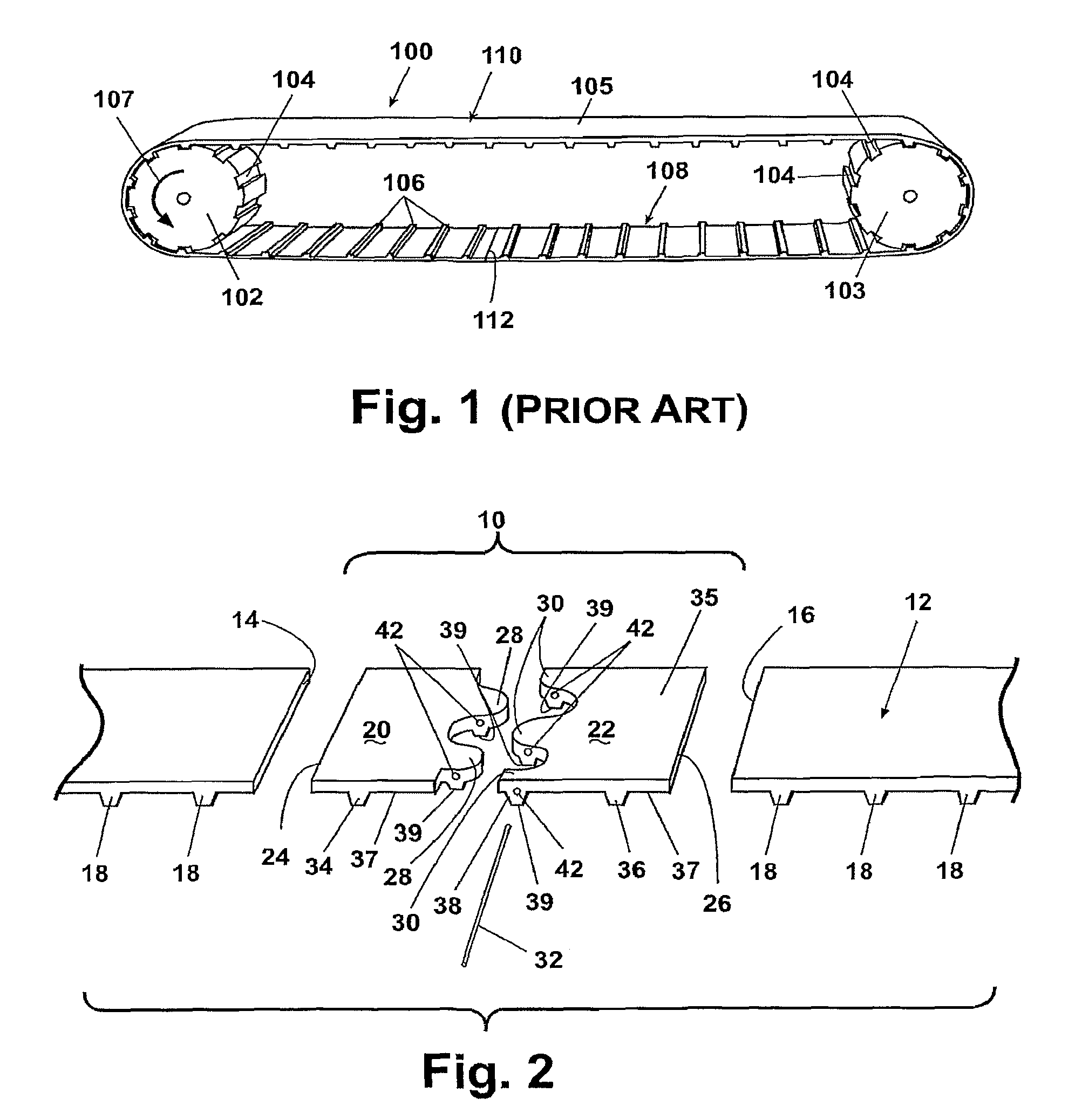

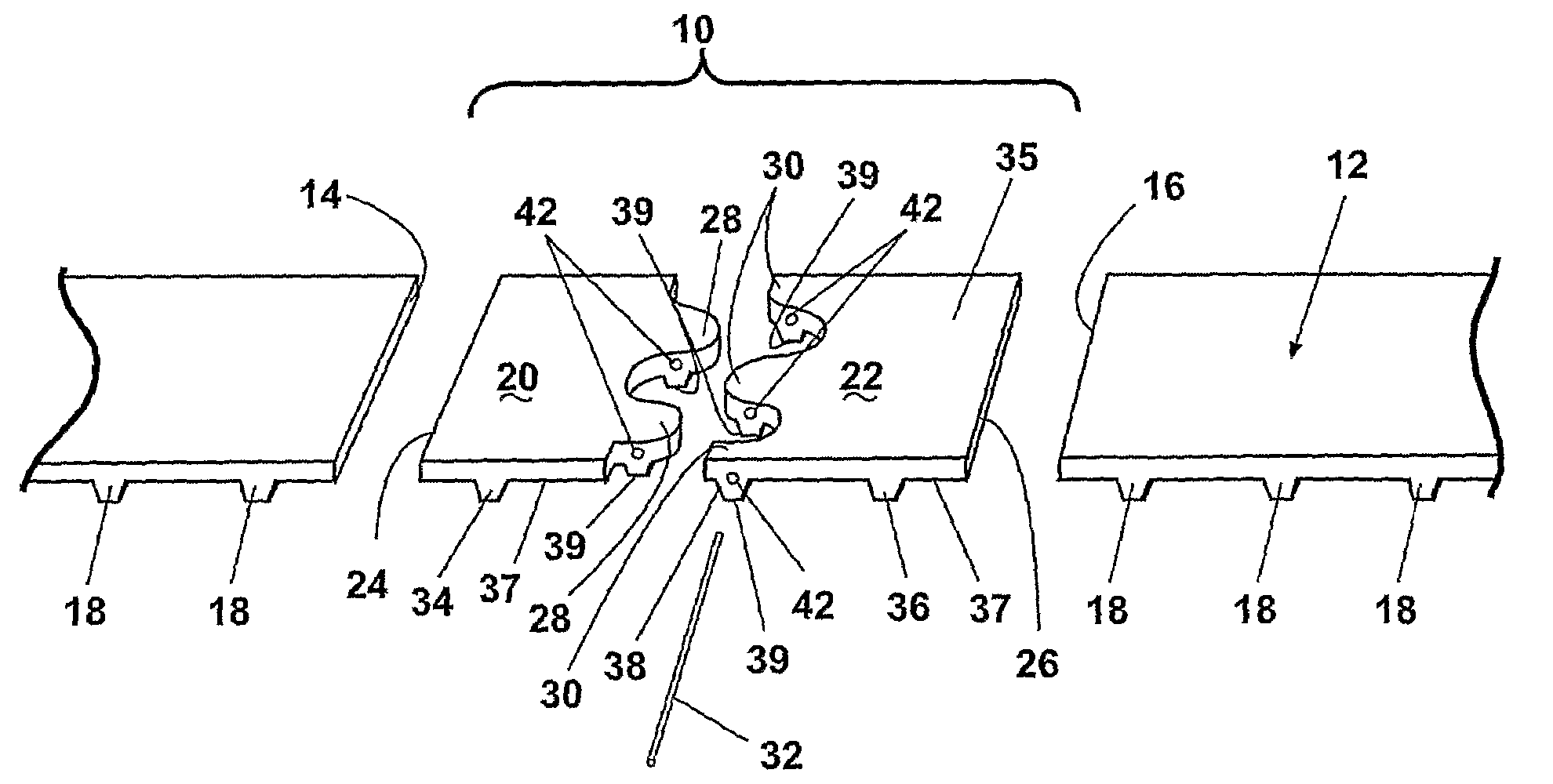

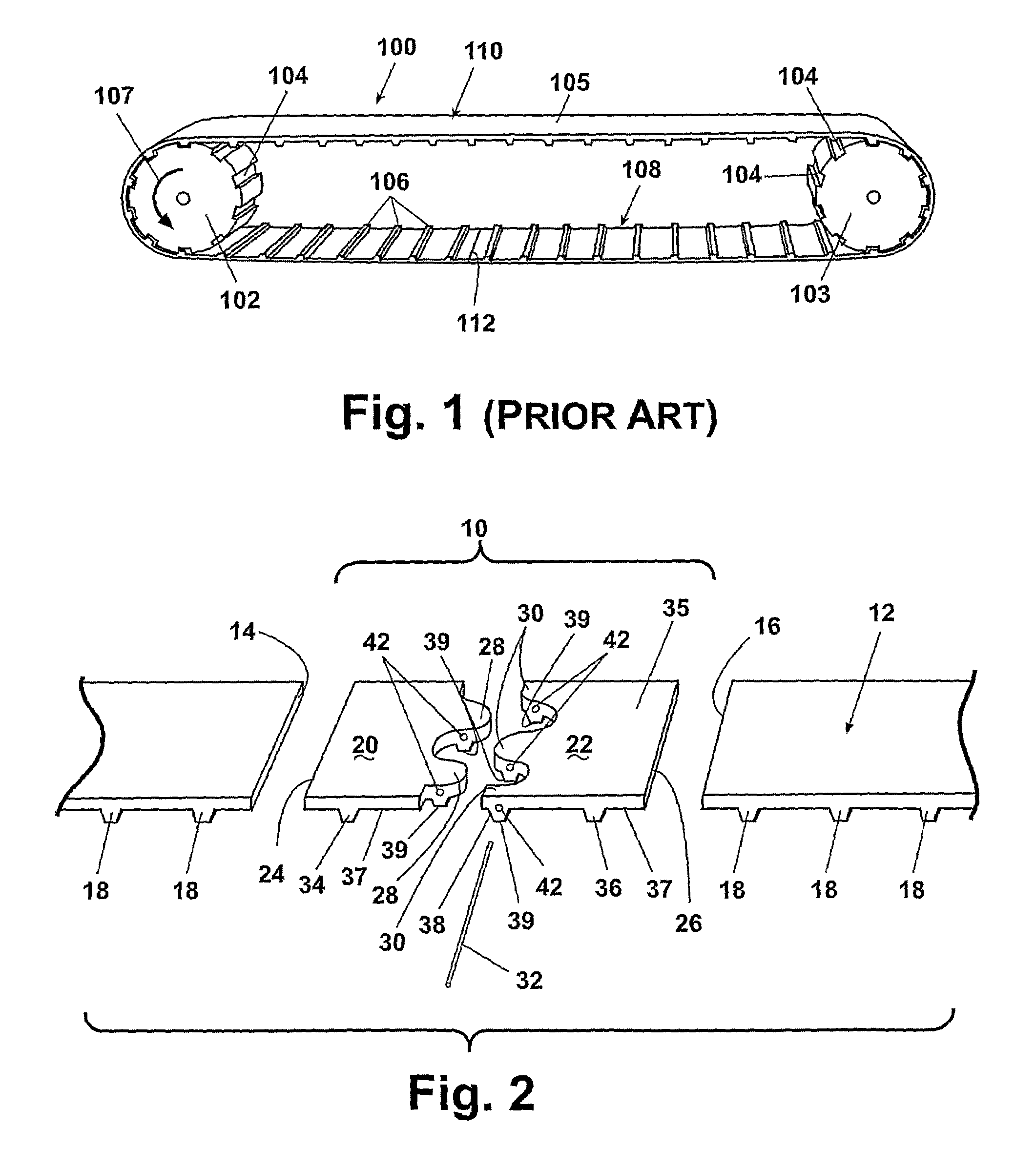

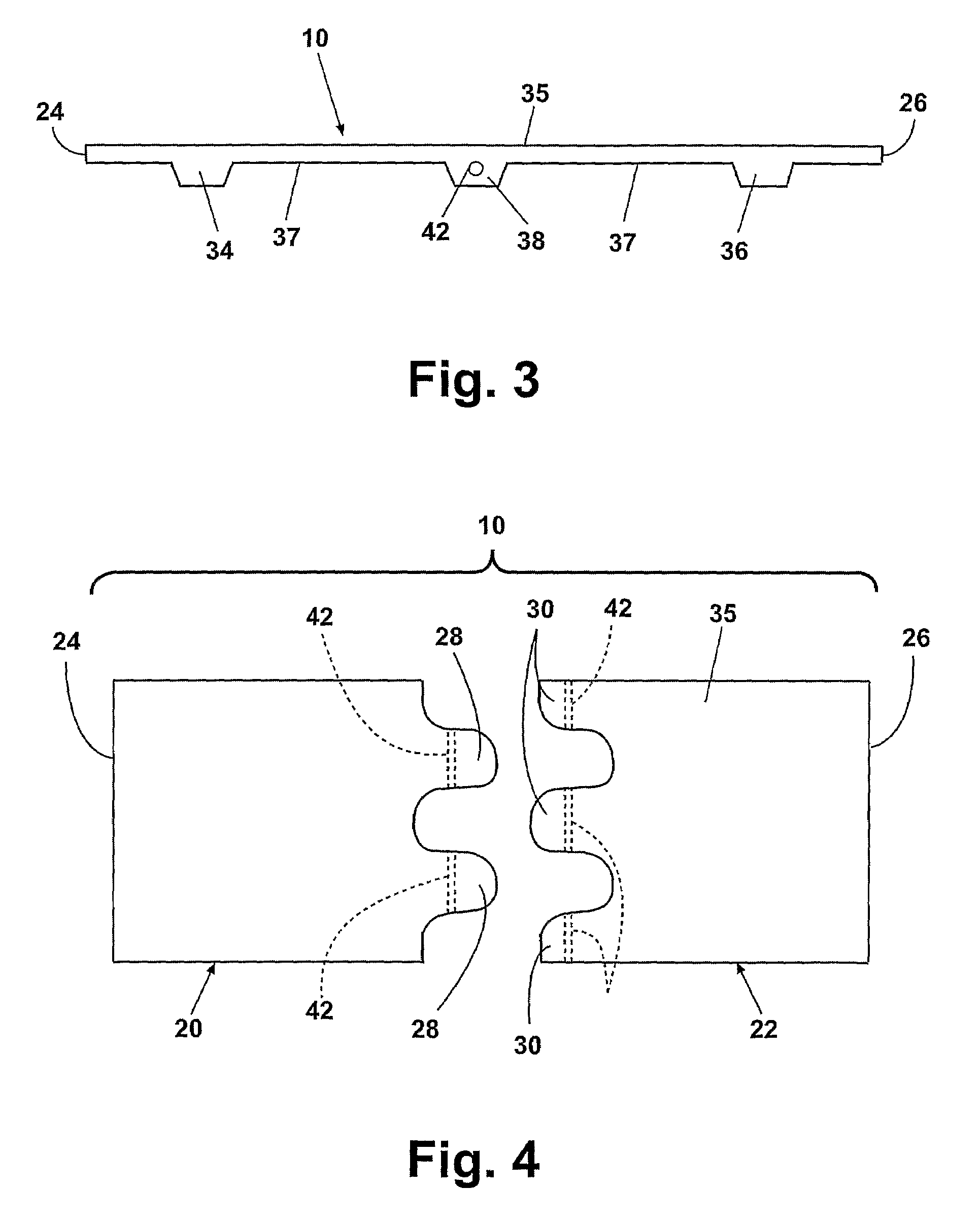

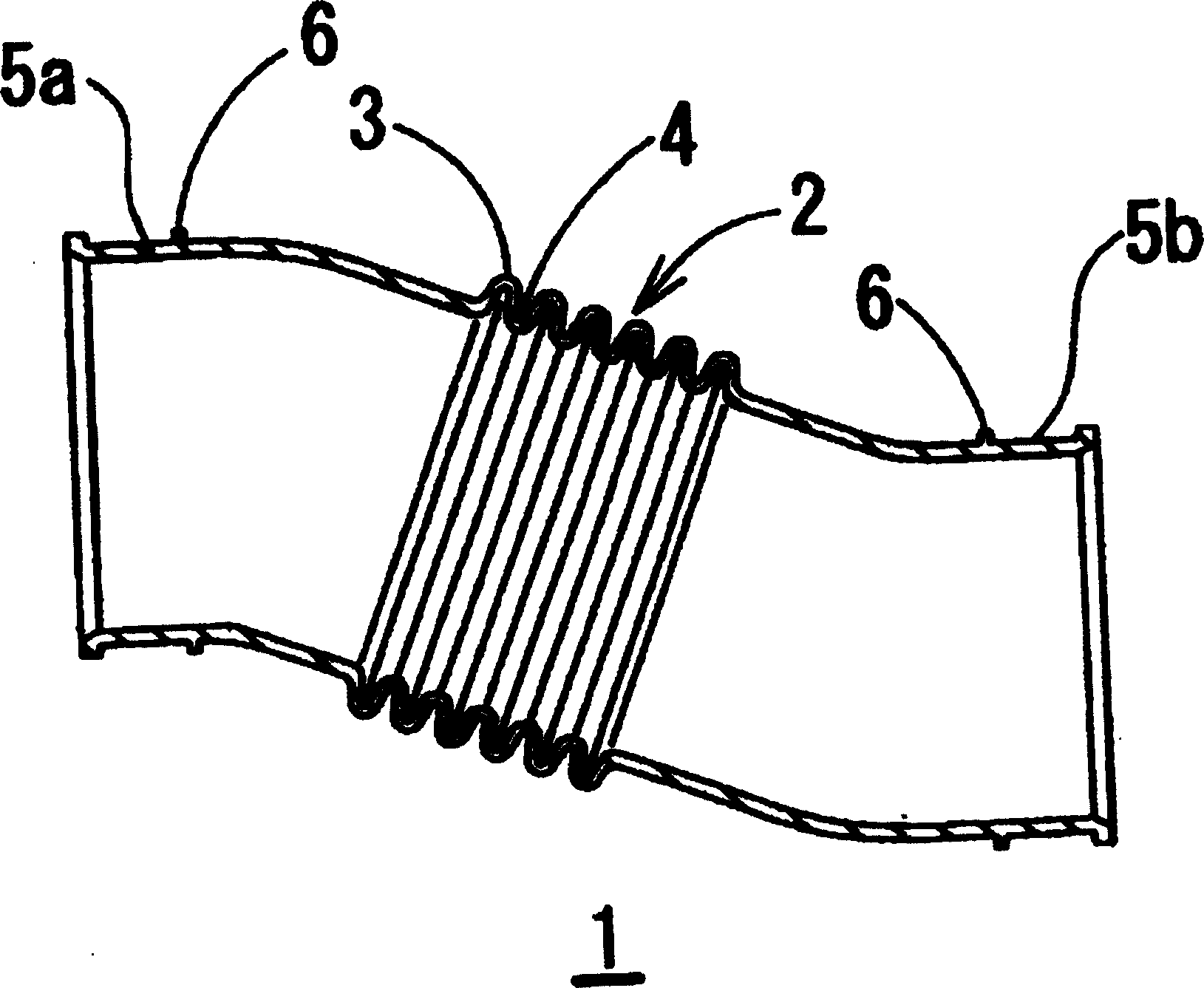

Thermoplastic belt connector with fingers

A toothed belt connector for making an endless belt has two leaves, adapted to be connected to each other by knuckles along one or more teeth. Each knuckle has at least one hole extending through tooth portions so that when the holes are in registry, a pin can be extended through the holes to connect the leaves at the teeth. The leaves can be adjoined to the ends of a belt to make the belt endless. The tip end of each knuckle can be beveled or it can have a stepped finger that fits into a cutout on the opposite leaf to keep the end of the knuckle from protruding as the belt wraps around a sprocket.

Owner:LAITRAM LLC

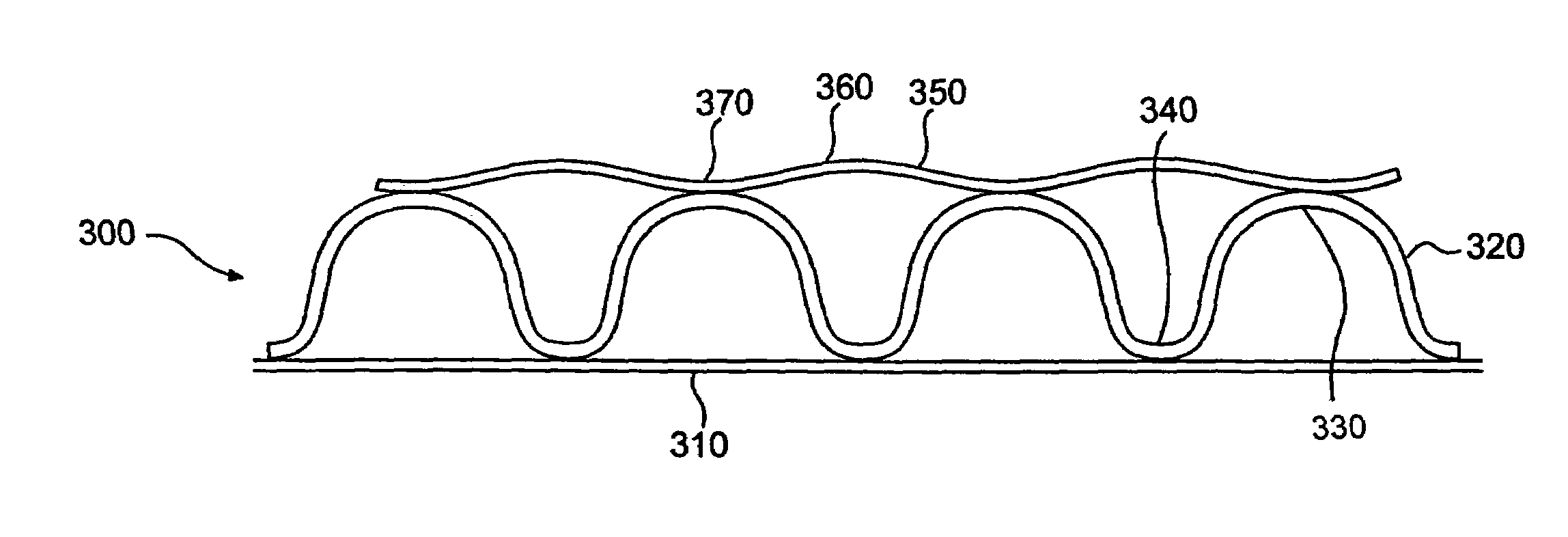

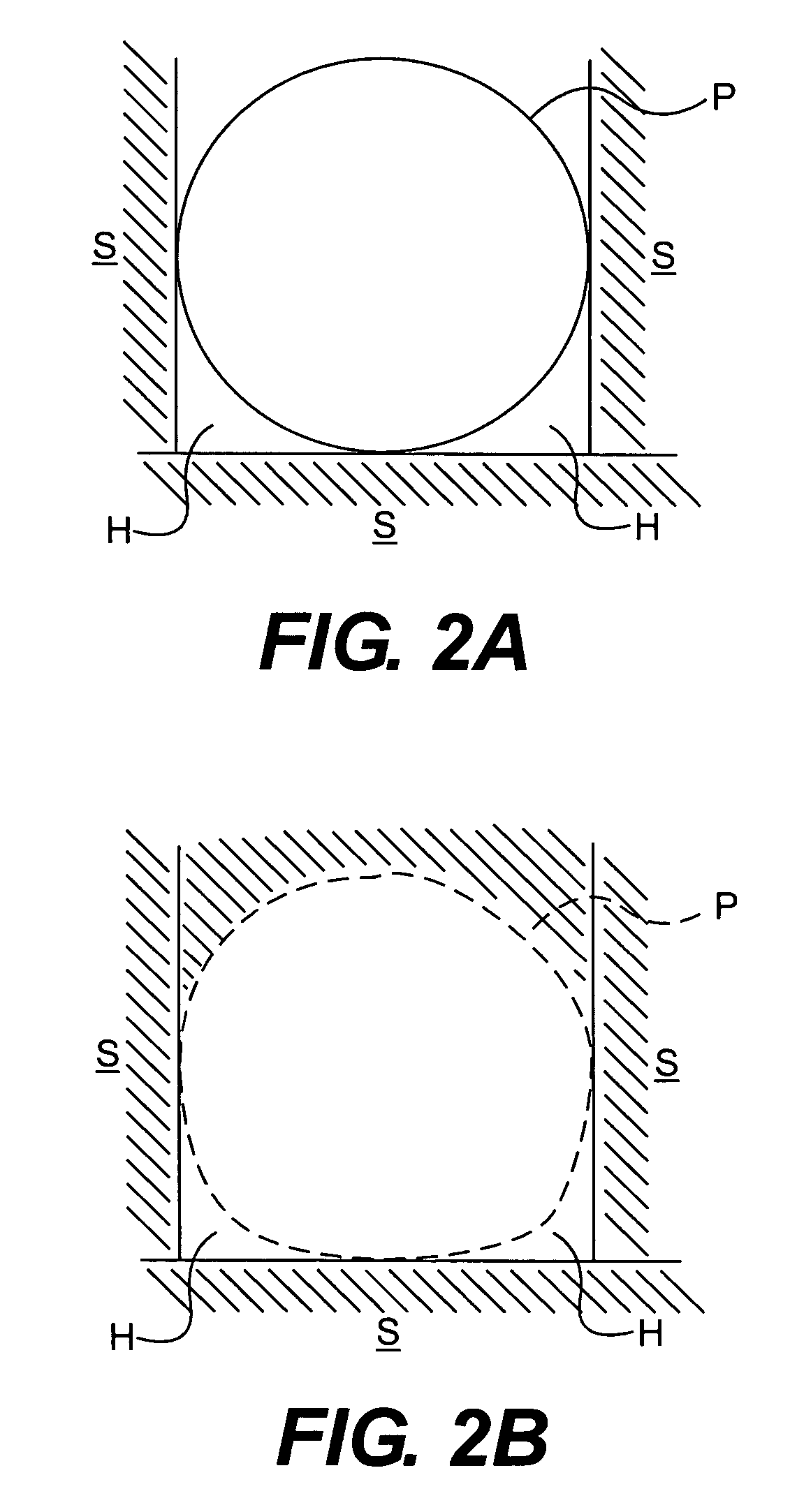

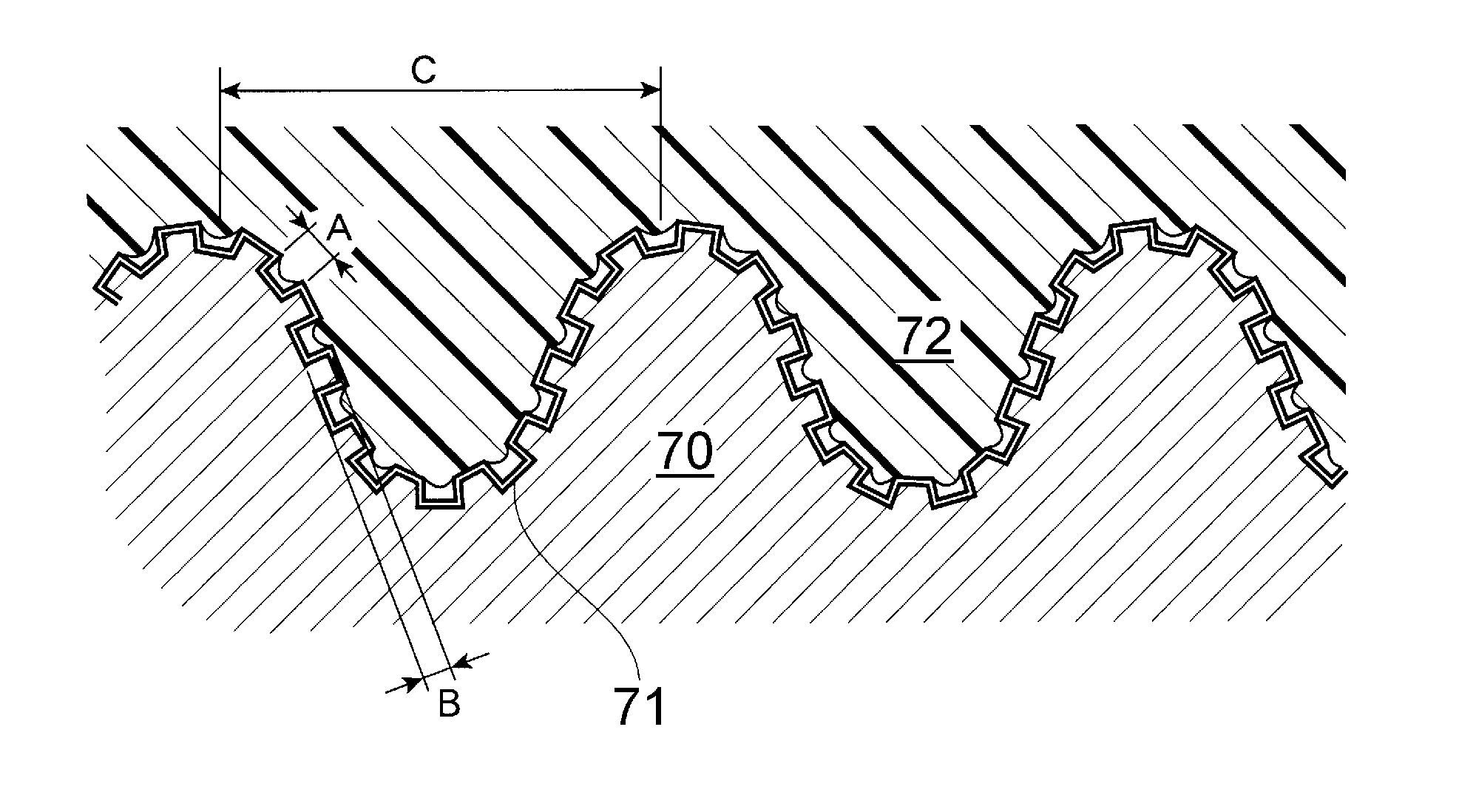

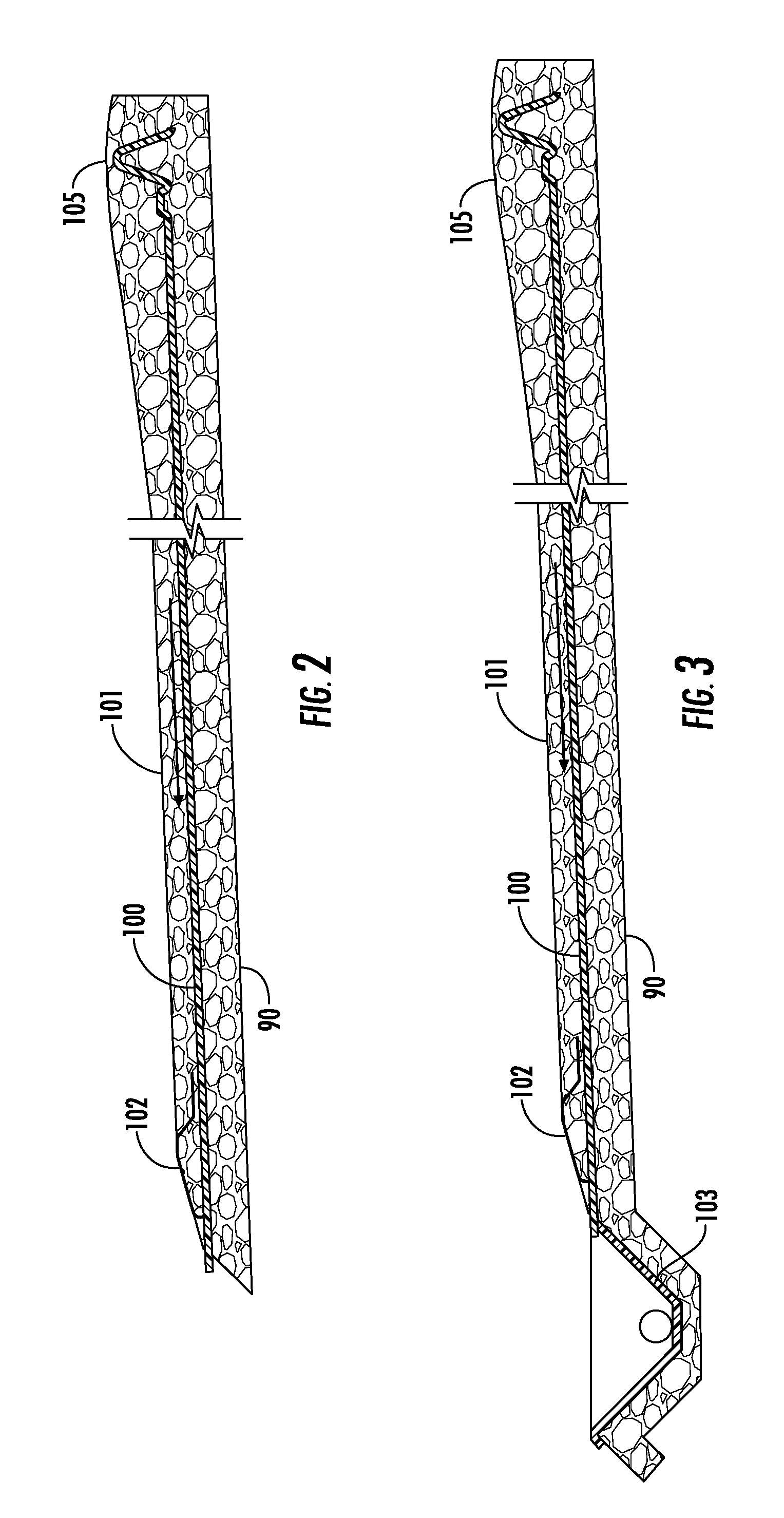

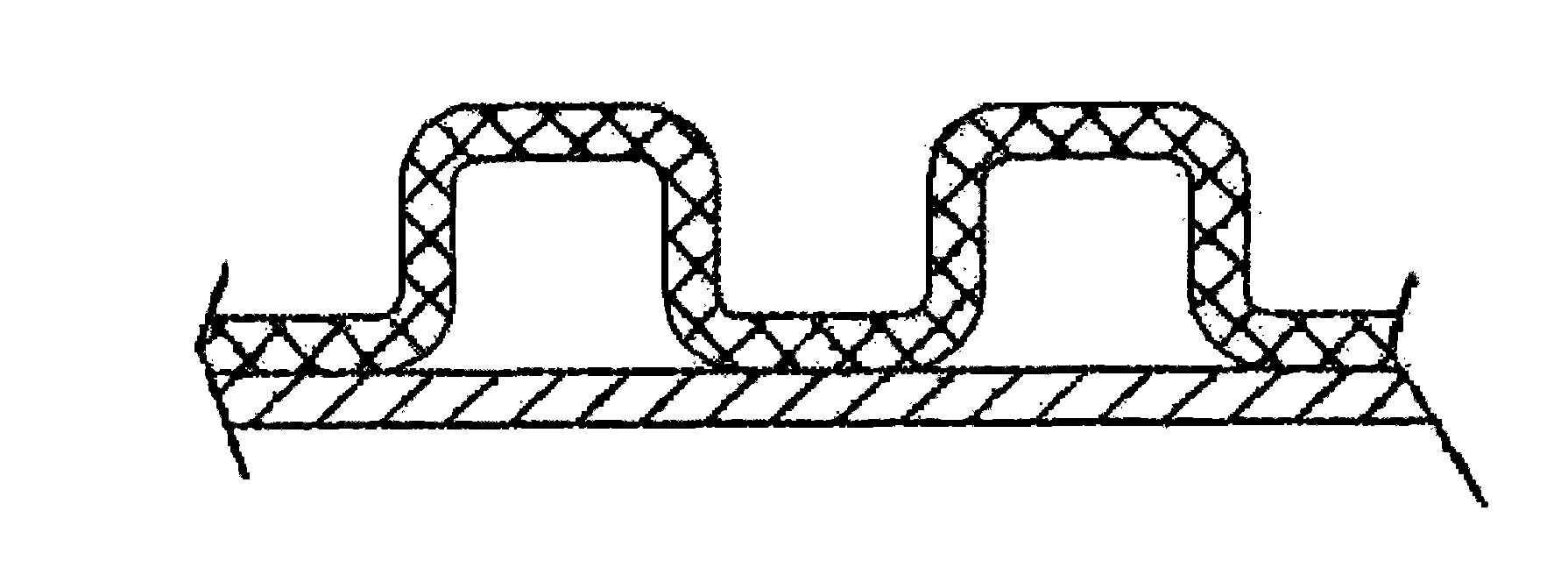

Corrugated pipe with outer layer

ActiveUS7484535B2Improve the immunityCorrugation articlesFlexible pipesEngineeringMechanical engineering

A pipe having an axially extending bore is defined by a pipe wall including a corrugated outer wall having axially adjacent annular outwardly-extending crests separated by valleys. The pipe wall also includes a non-linear outer layer having adjacent concave portions and convex portions. The concave portions are aligned with the corrugation crests of the outer wall so that the convex portion of the outer layer extends outwardly between at least two corrugation crests to provide improved resistance to deformation.

Owner:ADVANCED DRAINAGE SYST

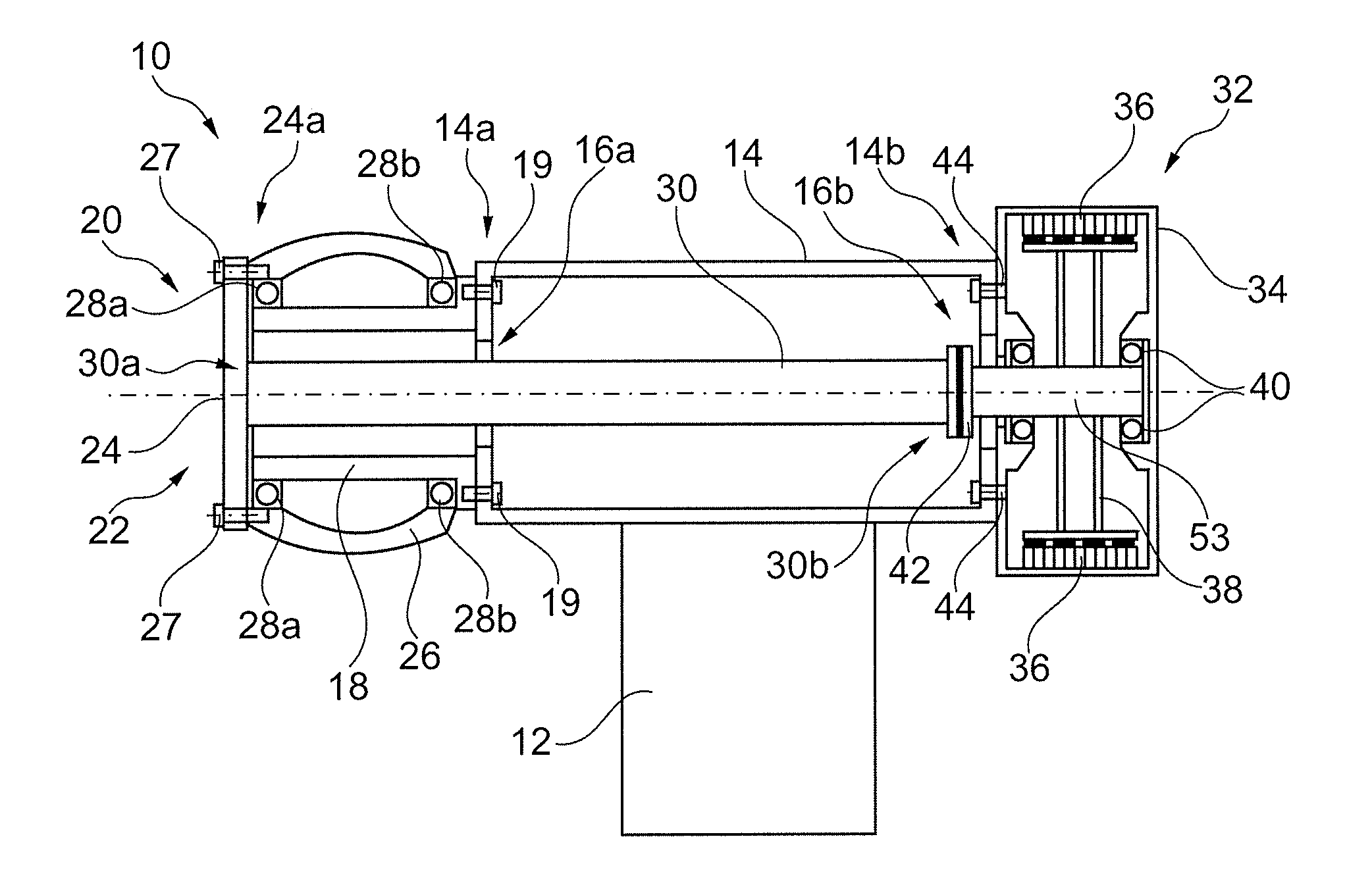

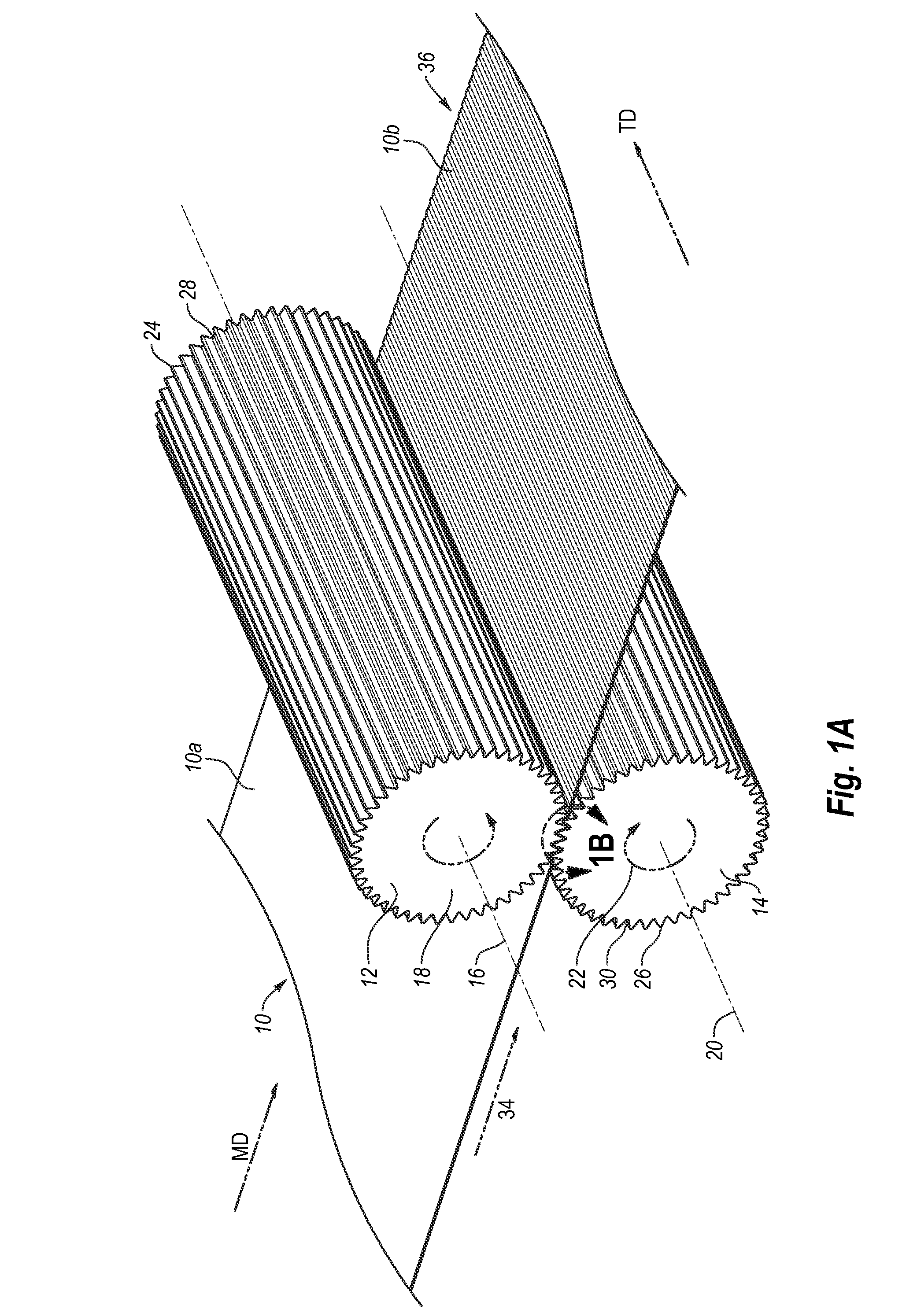

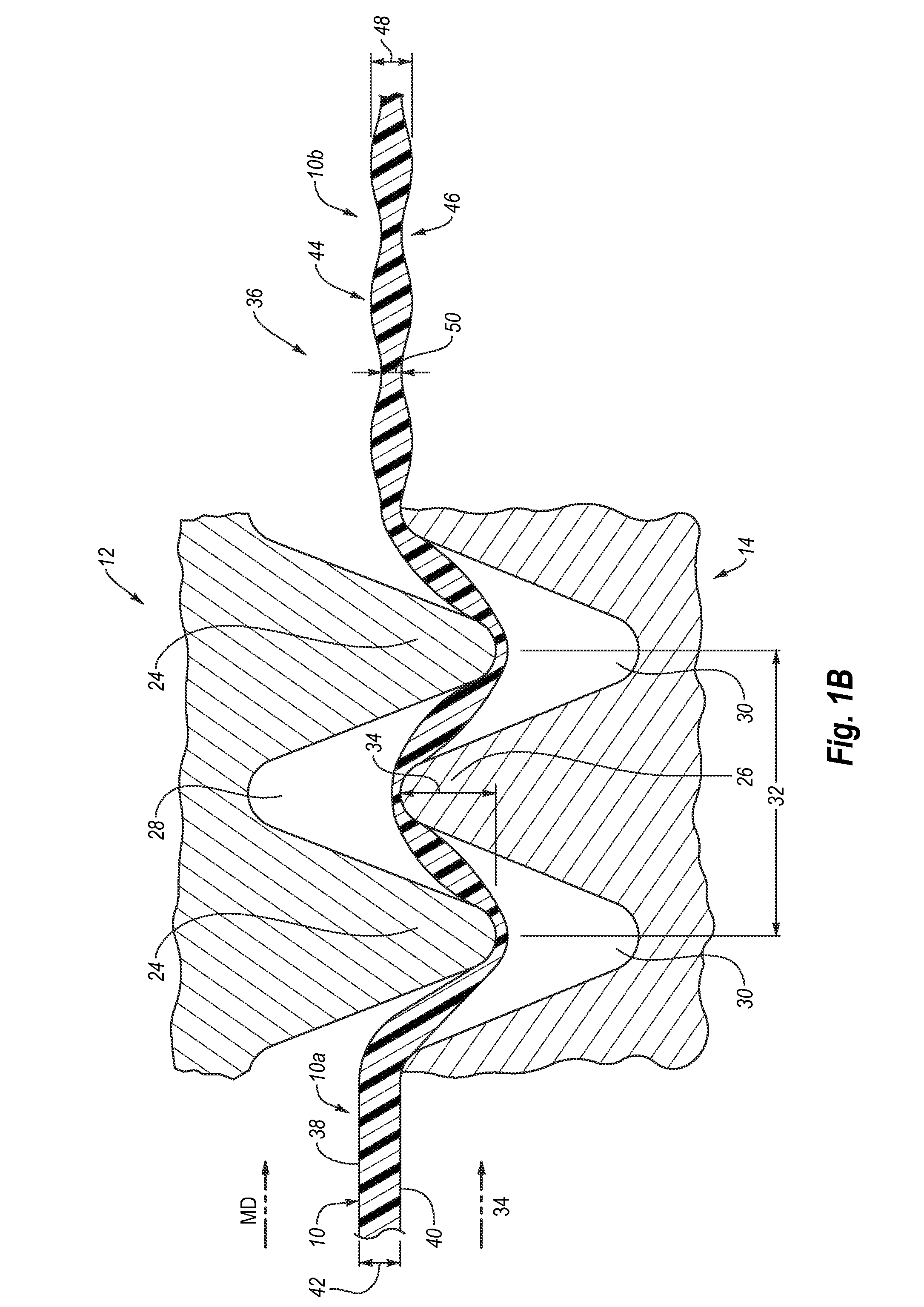

Method and apparatus for fluting a web in the machine direction

Owner:INT PAPER CO

Thermoplastic belt connector with fingers

Owner:LAITRAM LLC

Composite of steel and resin and method for manufacturing same

ActiveUS20100279120A1Improve corrosion resistanceImprove performanceMetal rolling stand detailsSynthetic resin layered productsSheet steelAdhesive

Disclosed is a composite in which an aluminum-plated steel sheet and a resin are securely and integrally joined together, as well as a corrosion resistant steel sheet. Through chemical etching the aluminum-plated steel sheet is caused to have a surface configuration, in which three-dimensional protrusions having pebble-like shapes with a diameter of at least about 0.3 μm or having irregular shapes with a minor diameter of at least 0.3 μm and a major diameter of at least several microns are scattered over a plain-like part, where 30 to 50% of the surface area of the plain-like part is accounted for by a portion covered with shallow recesses having a diameter of 20 to 50 nm in a state of being distributed adjacent to each other. The surface of the three-dimensional protrusions is mainly ceramic containing silicon and the flat part is mainly a ceramic containing aluminum. The steel is heated and welded under pressure to a resin composition, injection joining is performed or adhesion joining with another adherend is performed with a resin-based adhesive. Coating with a corrosion resistant material can also be performed.

Owner:TAISEI PLAS CO LTD

Process and apparatus for manufacturing a honeycomb composite material

ActiveUS20060000547A1Improve mechanical propertiesReduce manufacturing costAdhesive processesLamination ancillary operationsCardboardProduction line

The present invention relates to for a continuous production of a web of a composite material. The process comprises the steps of: providing a web of honeycomb material; providing at least one web of face sheet material having a corrugated medium with at least one linerboard on at least one face thereof; carrying the web of honeycomb material and the at least one web of face sheet material along a production line; and adhesively applying the at least one web of face sheet material to one face of the honeycomb material while the honeycomb material is being conveyed through the production line and maintained in an expanded state. The present invention also relates to a packaging material manufactured with a process described hereinabove and an apparatus to manufacture same.

Owner:CASCADES CANADA INC

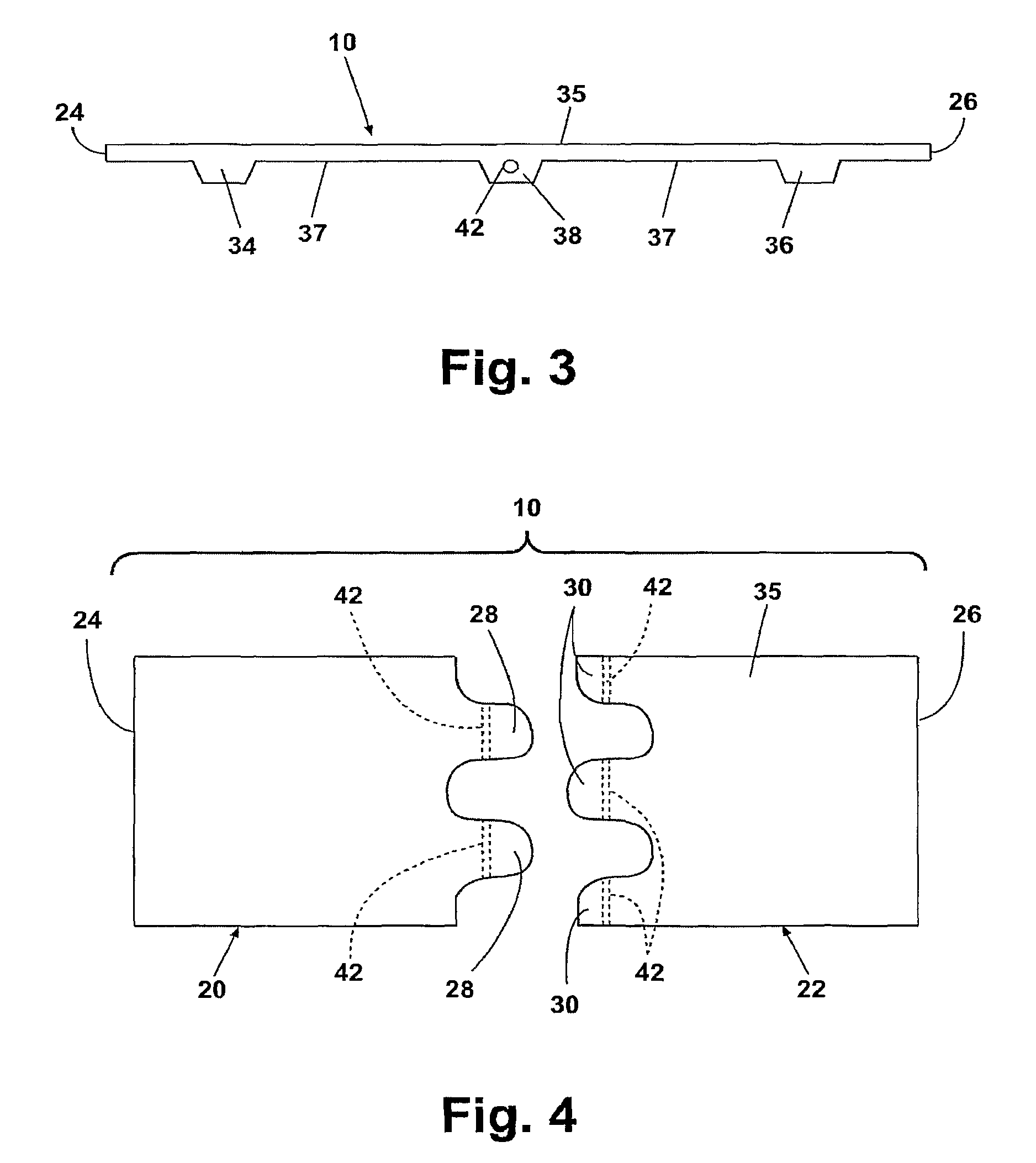

Thermoplastic belt connector

A thermoplastic toothed belt connector (10, 50) for making an endless belt (12) has two leaves (20, 22, 58, 60), adapted to be hingedly connected to each other by knuckles (28, 30, 60, 62) along one or more teeth (38, 52, 54). Each knuckle (28, 30, 60, 62) has a hole (42, 72) extending through tooth portions (39) so that when the holes (42, 72) are in the registry, a pin (32, 74) can be extended through the holes (42, 72) to form the hinge at the teeth (38, 52, 54). The leaves (20, 22, 58, 60) can be adjoined to the ends of a thermoplastic belt (12) to make the belt endless.

Owner:LAITRAM LLC

Preparation process of composite material corrugated sandwich plates

InactiveCN101665001ALow densityReduce manufacturing costCorrugation articlesHigh densityMetallic materials

The invention discloses a preparation process of composite material corrugated sandwich plates, relating to a preparation process of corrugated sandwich plates. The invention aims at the problems thatthe current preparation process of the corrugated sandwich plates has long process period and high manufacturing cost and the problems that the current corrugated sandwich plate is made of metal materials and has high density, low specific strength and specific stiffness, and poor designability. The technology is that the surface of a core die is coated with a release agent; the upper die of thecore die is removed; a composite material core is paved on the outer surface of the upper die of the core die and matched with the outer surface of the upper die in shape; the die is closed to lead the composite material core to be formed, and the upper surface and the lower surface of the core die are respectively paved with a layer of panel, and then heated and pressurized and solidified with the heating temperature of being 160 DEG C-180 DEG C, the solidifying pressure being 0.5MPa-1.5MPa, and the solidifying time being 2.5h-3.5h; and demoulding is conducted to prepare the composite material corrugated sandwich plate. The invention has the advantages of short process period, low manufacturing cost, low density, and high specific strength and specific stiffness, and is mainly applied tothe super-light multifunctional structures in the fields of space flight and aviation and the like.

Owner:HARBIN INST OF TECH

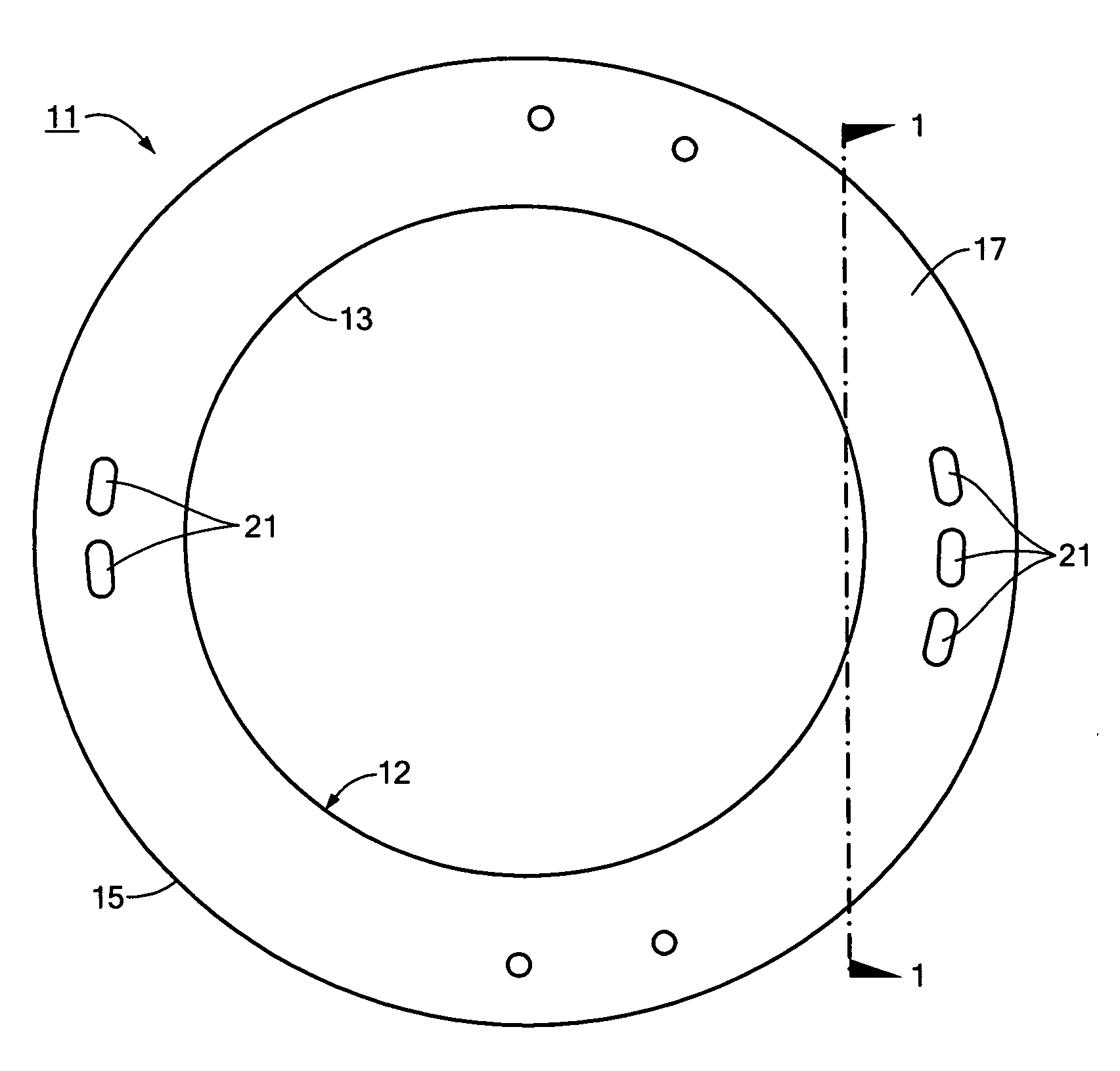

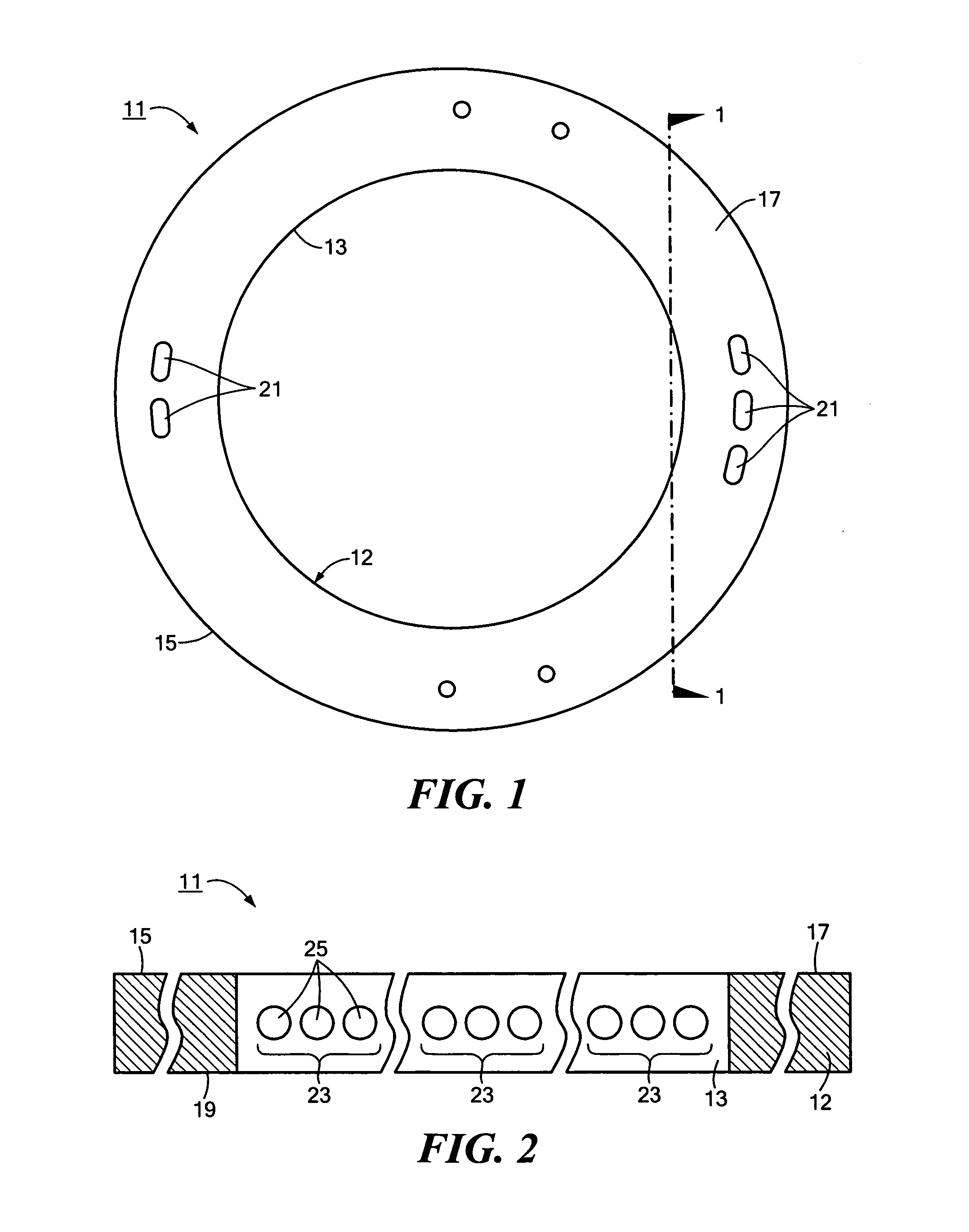

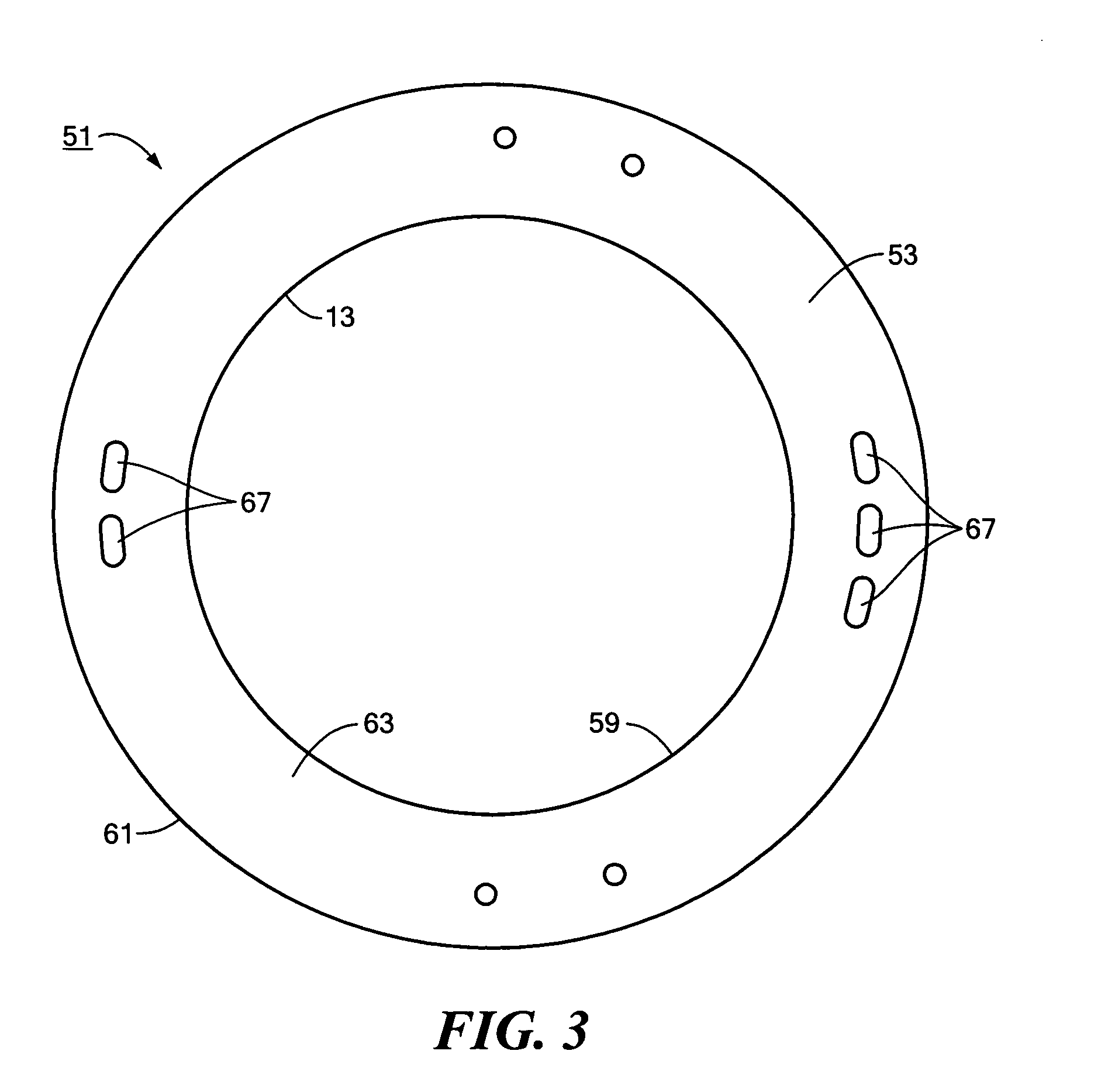

Cell frame for high-pressure water electrolyzer and method for manufacturing the same

Cell frame for high-pressure water electrolyzer and method of manufacturing the same. According to one embodiment, radial openings in a water electrolyzer frame are provided by laminating half-frames, one or both of which contains grooves that may be formed by molding, machining or die-cutting. Another to another embodiment, radial openings are provided by laminating three or more thin frame portions, the center piece of which may include transverse slots that may be made by molding, machining or die-cutting. According to yet another embodiment, two or more frame portions are provided, at least one of which includes a recess for receiving a porous structure. The frames of the present invention can be additionally laminated to the membrane and electrode assembly, as well as the bipolar separator plate in the perimeter or seal area, comprised of the same or similar material as the frame, to form unitized electrolyzer stack subassemblies or full assemblies.

Owner:GINER ELECTROCHEMICAL SYST LLC

Wind turbine and a shaft for a wind turbine

InactiveUS20110309632A1Easy to optimizeLittle strengthFinal product manufactureEngine fuctionsDrive shaftTurbine

A drive shaft for a wind turbine is shaped so as to allow for increased bending of the shaft, while being suitable for transferring torque in a wind turbine system. An example of such a shaping is a drive shaft having a helical rib defined on the surface of the shaft. A wind turbine incorporating such a shaft, and a method of manufacture of such a shaft are also described.

Owner:ENVISION ENERGY DENMARK

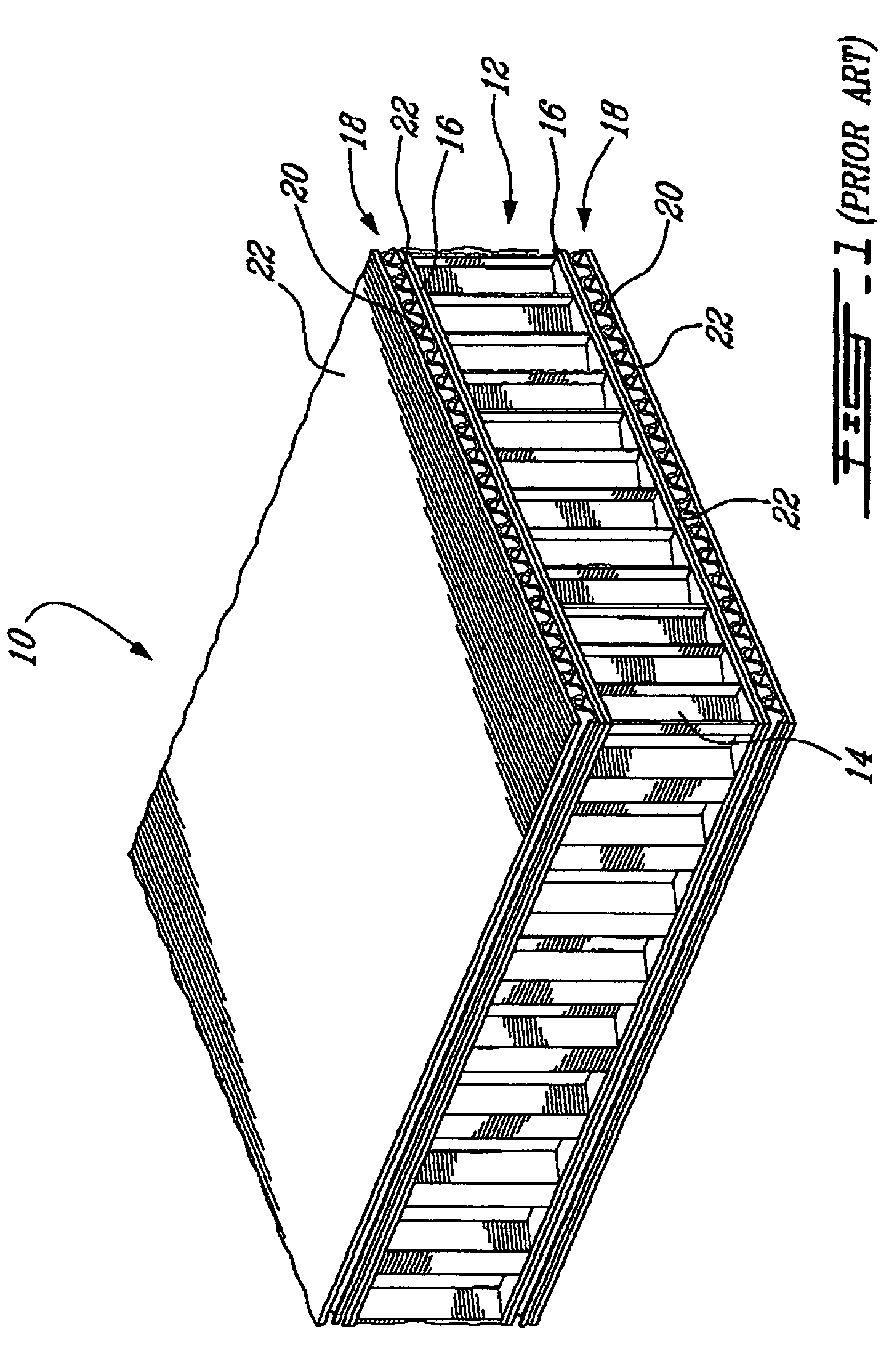

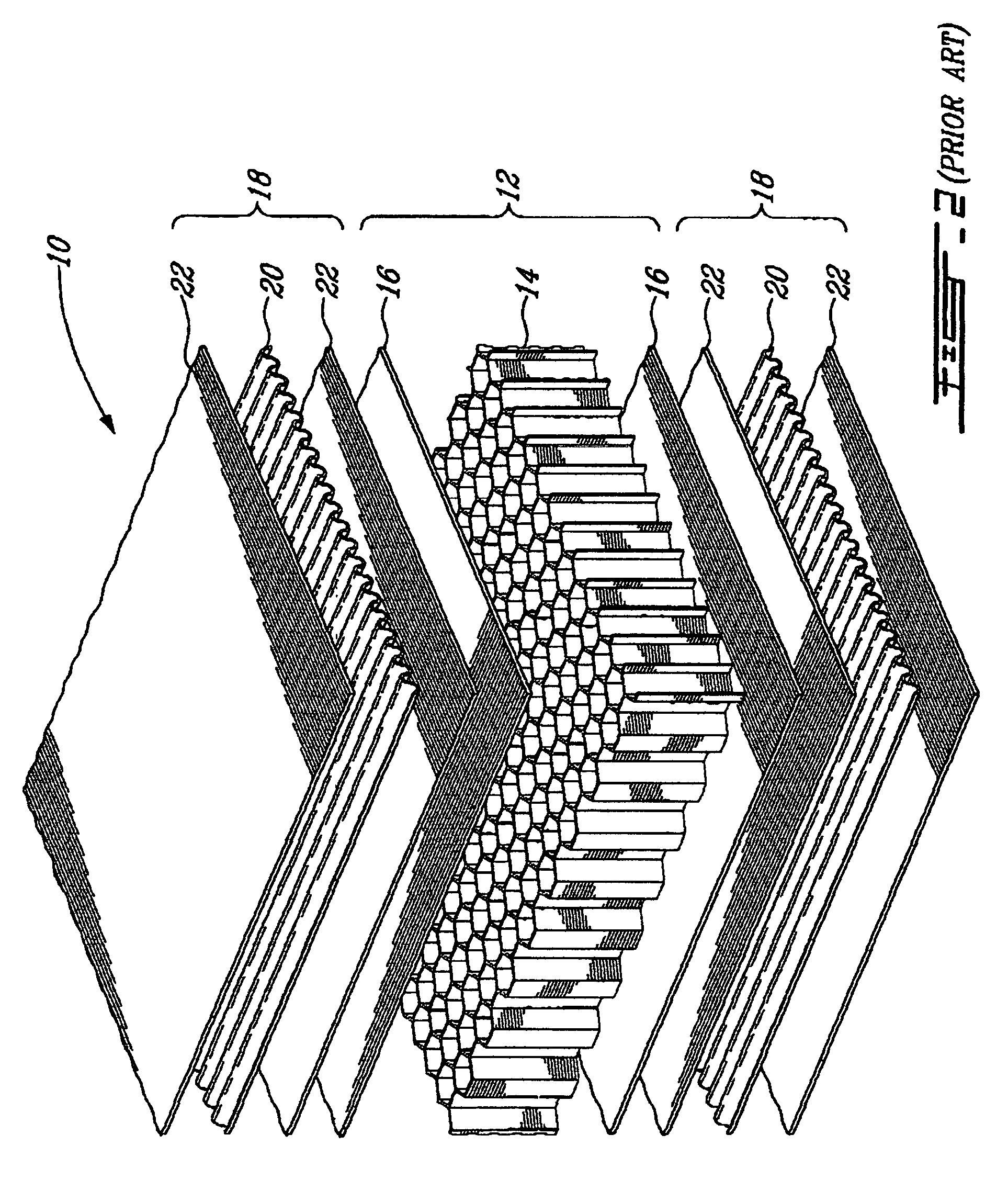

Corrugated sandwich panel and method for manufacturing the same

InactiveUS7041187B2Improve bindingHigh mechanical strengthMechanical working/deformationWood working apparatusSandwich panelPolyethylene

Owner:ENG CORP

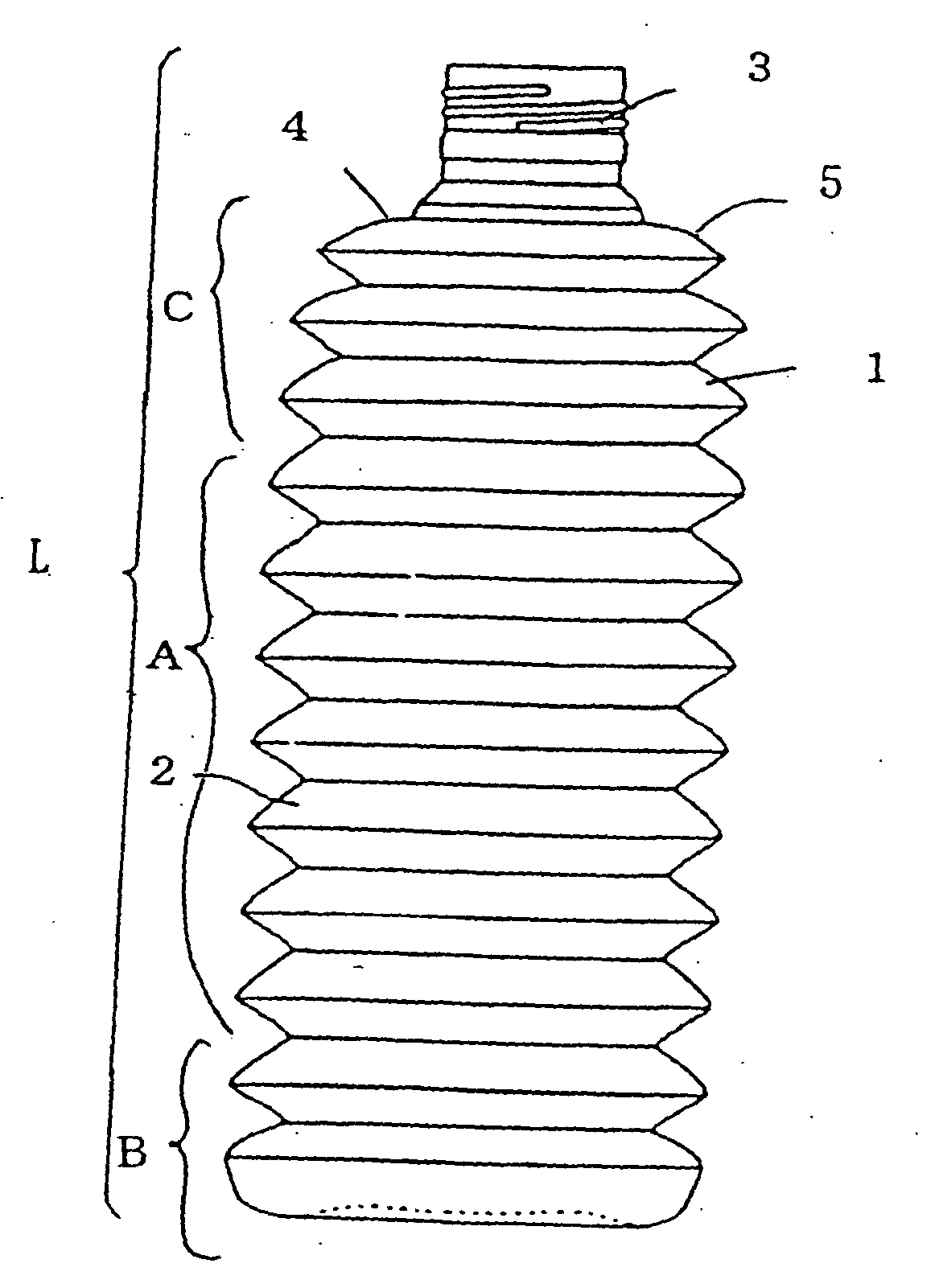

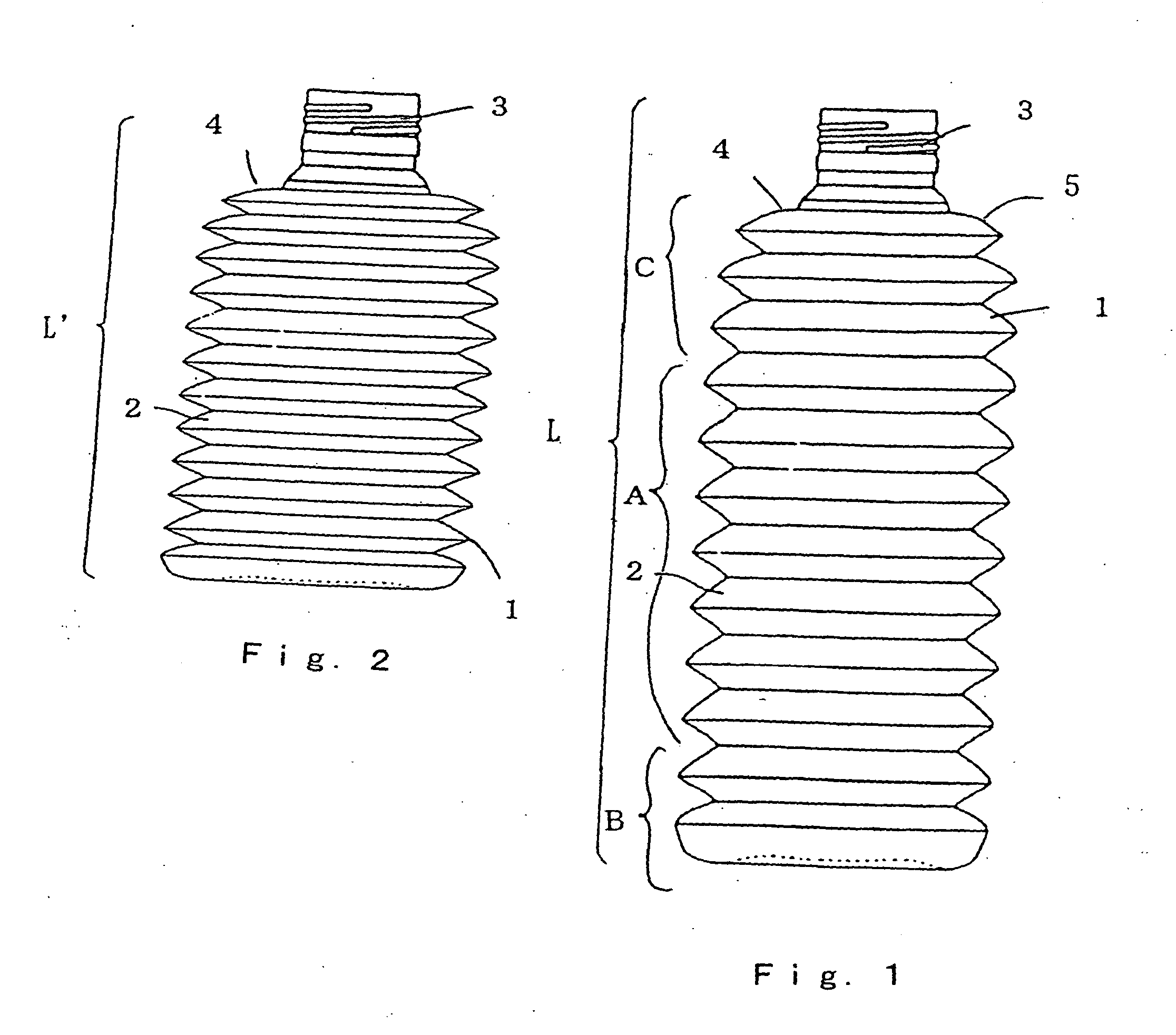

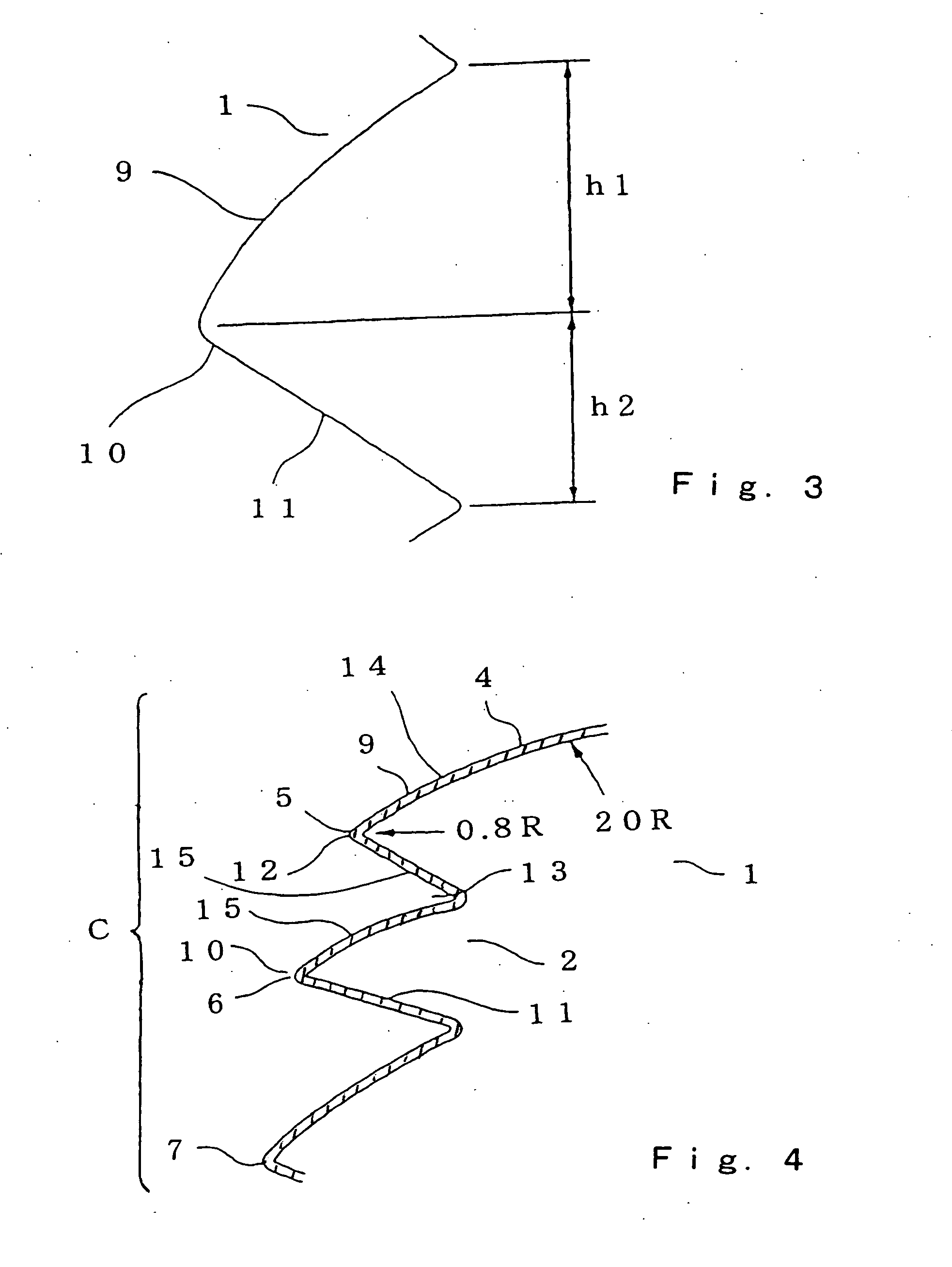

Longitudinally expandable plastic bottle, and method and apparatus for manufacturing the same

There is proposed and provided a plastic bottle the longitudinal dimension (height) of which is decreased substantially when the bottle is manufactured, as compared with the time when the bottle is filled with contents, a method for manufacturing the plastic bottle, and an apparatus for manufacturing the plastic bottle. When the bottle is manufactured, the bottle being constructed so that a longitudinal part or the whole of the bottle, except a mouth portion at the upper end, has a bellows shape in the horizontal direction, the bottle is molded in a state of having substantially smaller volume and height than the volume and height at the time when the bottle is filled with contents, and when an empty portion is formed in the bottle by an operation of drinking up the contents, the bottle can be made again in a state of having substantially smaller volume and height than the volume and height at the time when the bottle has been filled with contents.

Owner:GOHSHO CO LTD

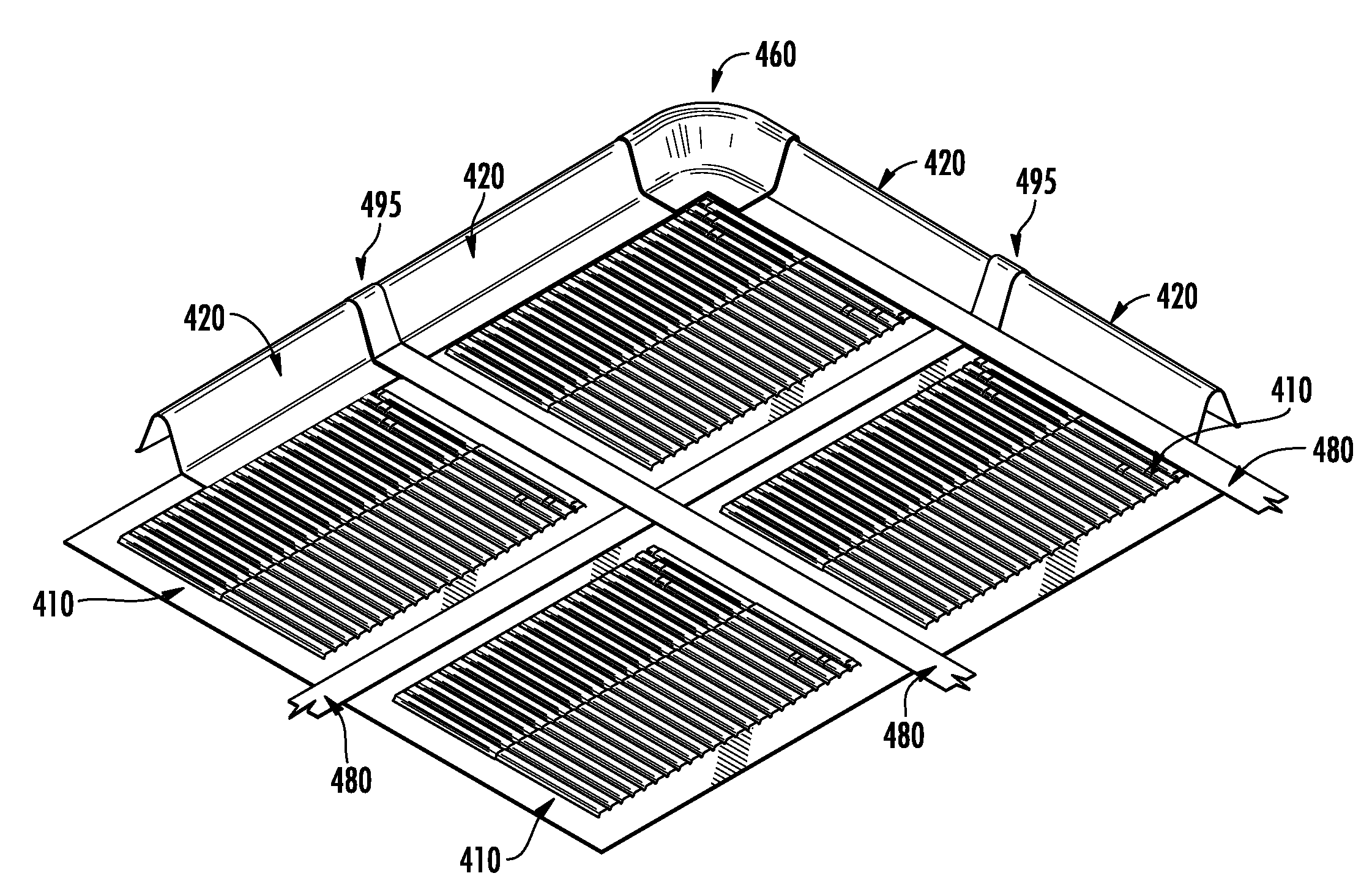

Modular, scalable spill containment lining system

An exemplary embodiment relates to a containment lining system comprising a plurality of connectable thermoplastic body panels, perimeter panels, and corner panels. The panels are adapted for substantially liquid-tight end-to-end connection and side-to-side connection. The perimeter and corner panels are equipped with raised perimeter ribs adapted to provide containment on at least a portion of the perimeter of the lining. The system may be used for containing industrial site waste and leaked fluids, as well as natural precipitation, to provide for controlled recovery or disposal for liquids in the contained lining system and to facilitate removal and transfer of such liquids to a selected destination.

Owner:PENDA

Corrugated pipe with outer layer

ActiveUS20060201567A1Improve the immunityCorrugation articlesFlexible pipesMechanical engineeringEngineering

A pipe having an axially extending bore is defined by a pipe wall including a corrugated outer wall having axially adjacent annular outwardly-extending crests separated by valleys. The pipe wall also includes a non-linear outer layer having adjacent concave portions and convex portions. The concave portions are aligned with the corrugation crests of the outer wall so that the convex portion of the outer layer extends outwardly between at least two corrugation crests to provide improved resistance to deformation.

Owner:ADVANCED DRAINAGE SYST

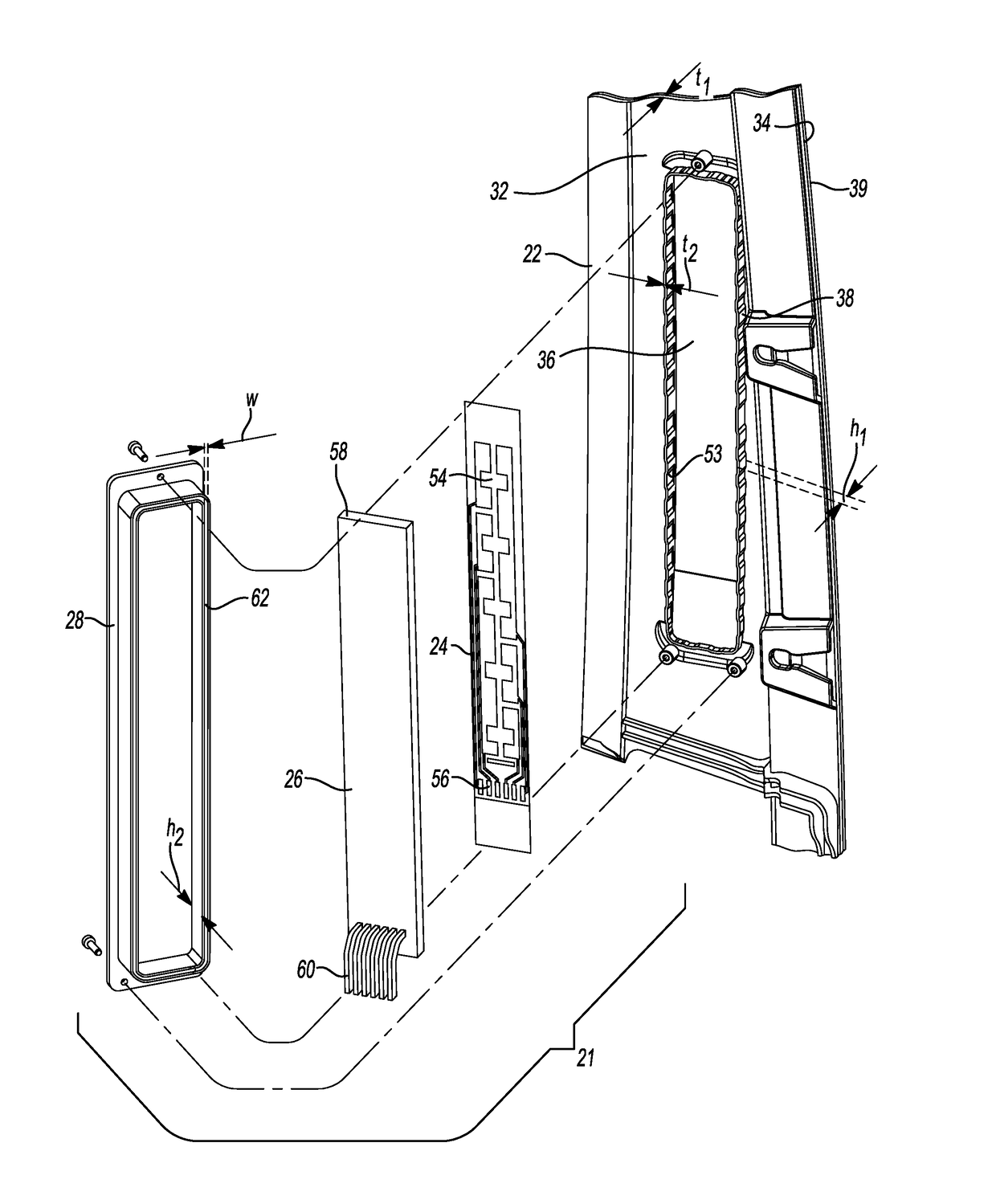

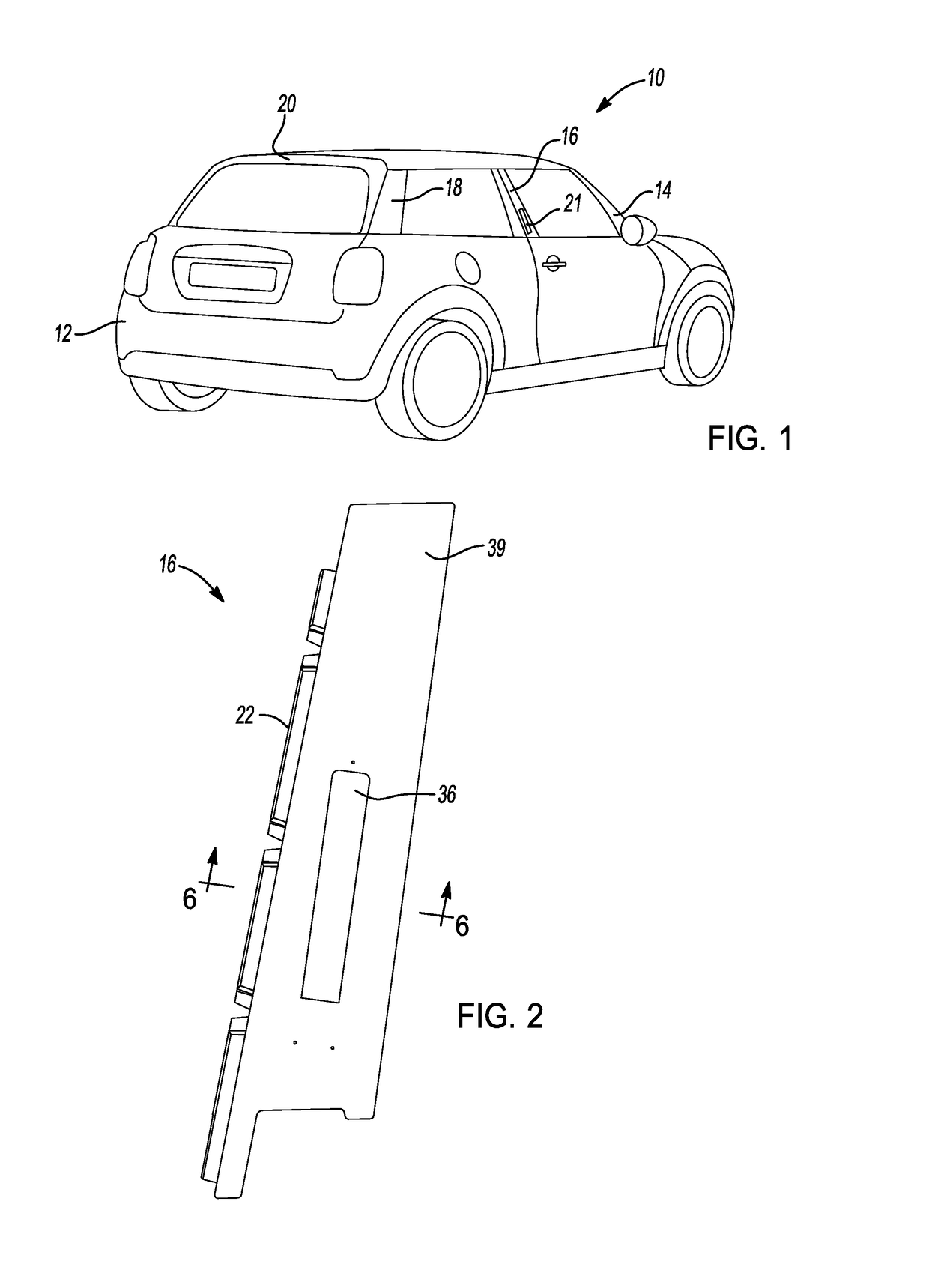

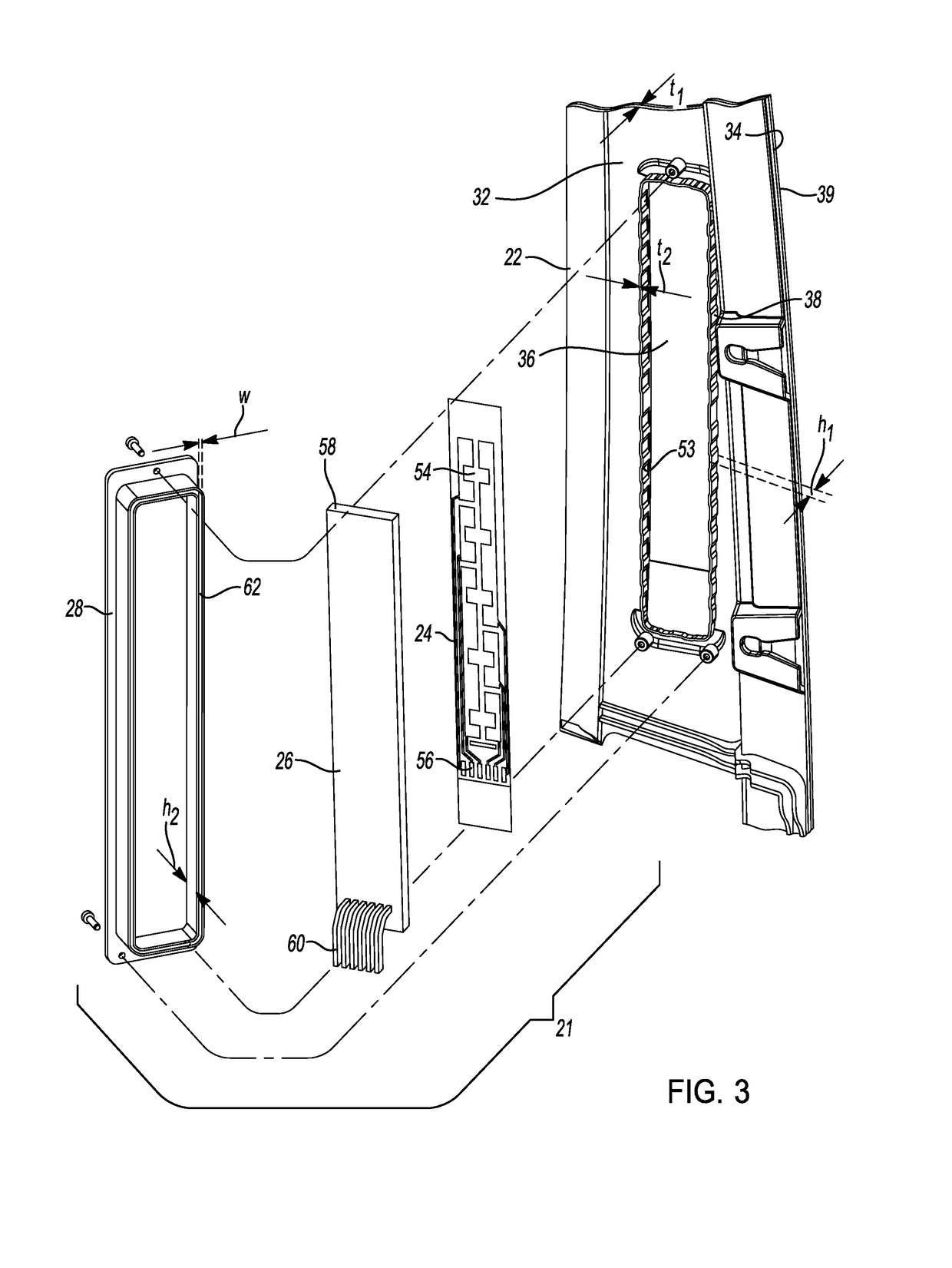

Exterior trim for a motor vehicle

Owner:PLASMAN US HOLDCO LLC

Method for forming duct made of elastomer

InactiveCN1835834AGood removal effectAvoid damageCorrugation articlesMachines/enginesElastomerEngineering

In a method for forming a duct used as, e.g., an air duct for an automobile engine, and provided with a corrugated section as an undercut part in a part of the longitudinal direction of the duct, an elastomeric duct is formed with ensuring easy removal of a duct molded by injection from a core die even when the duct is made of a resin poor in elasticity. [Means to Solve the Problems] A method for forming an elastomeric duct having a corrugated section in a longitudinal direction thereof as a part of the duct by injection molding, which comprises injecting an elastomer material into a cavity formed with a cavity die for forming an external surface of the duct, and a core die for forming an internal surface of the duct, wherein the core die is a splittable core die which is axially splittable into two parts, one is a core die A for forming a duct area at least containing the corrugated section, and the other is a core die B for forming a duct area free from the corrugated section, and removing the duct area containing the corrugated section from the core die A with expanding at least the corrugated section in the radius direction by air injection after opening the cavity die.

Owner:TAIGAASU HORIMAA

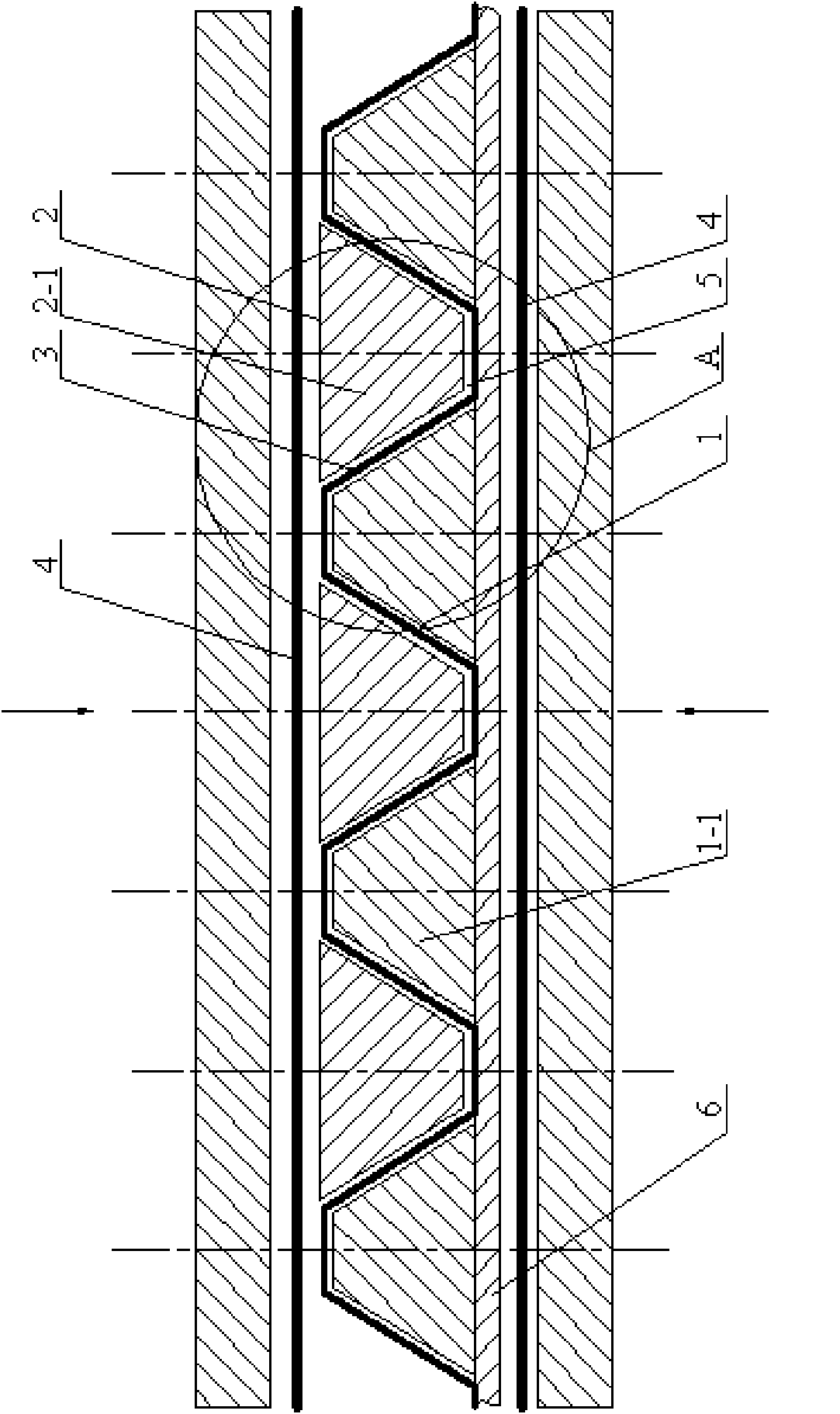

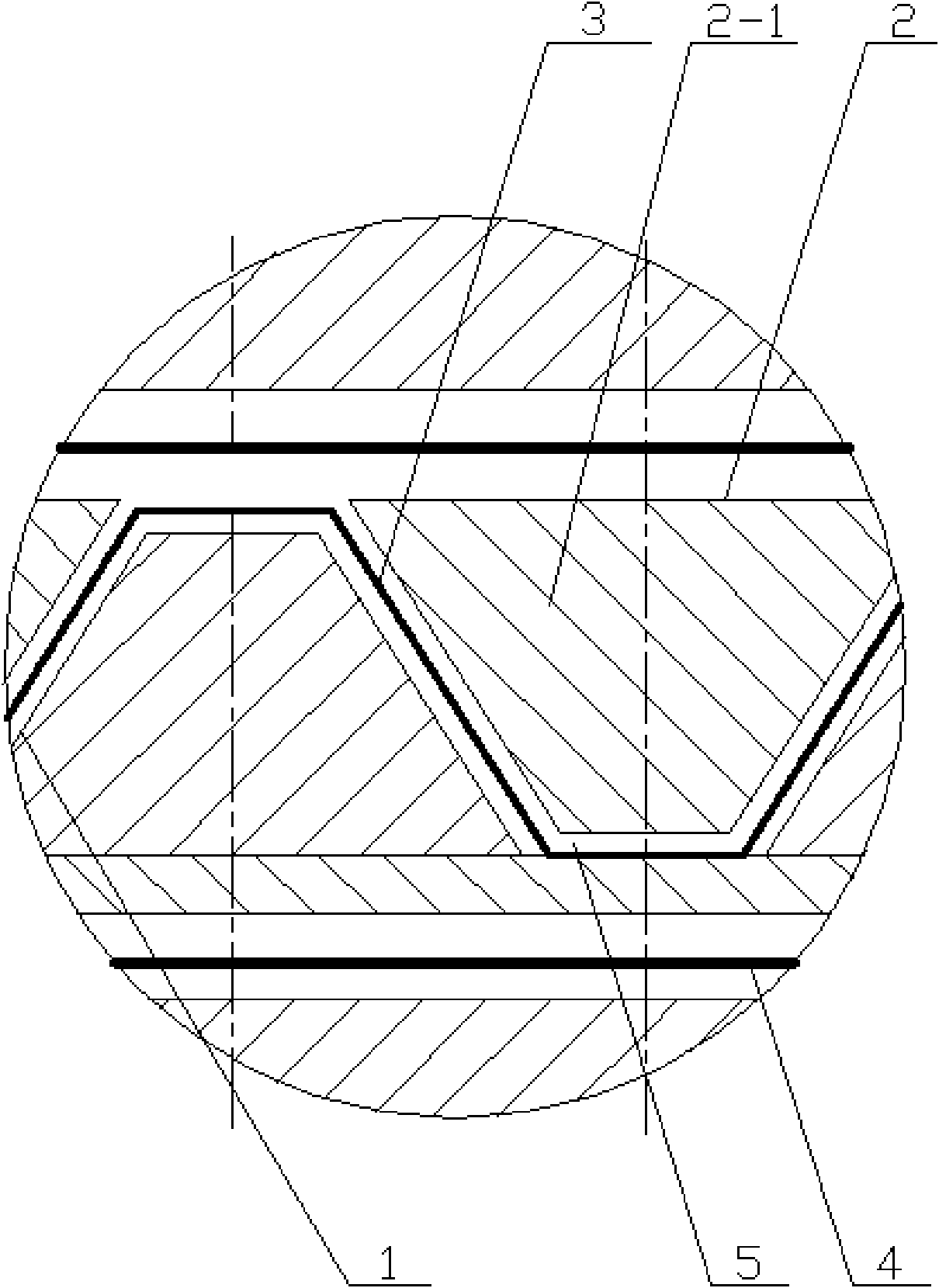

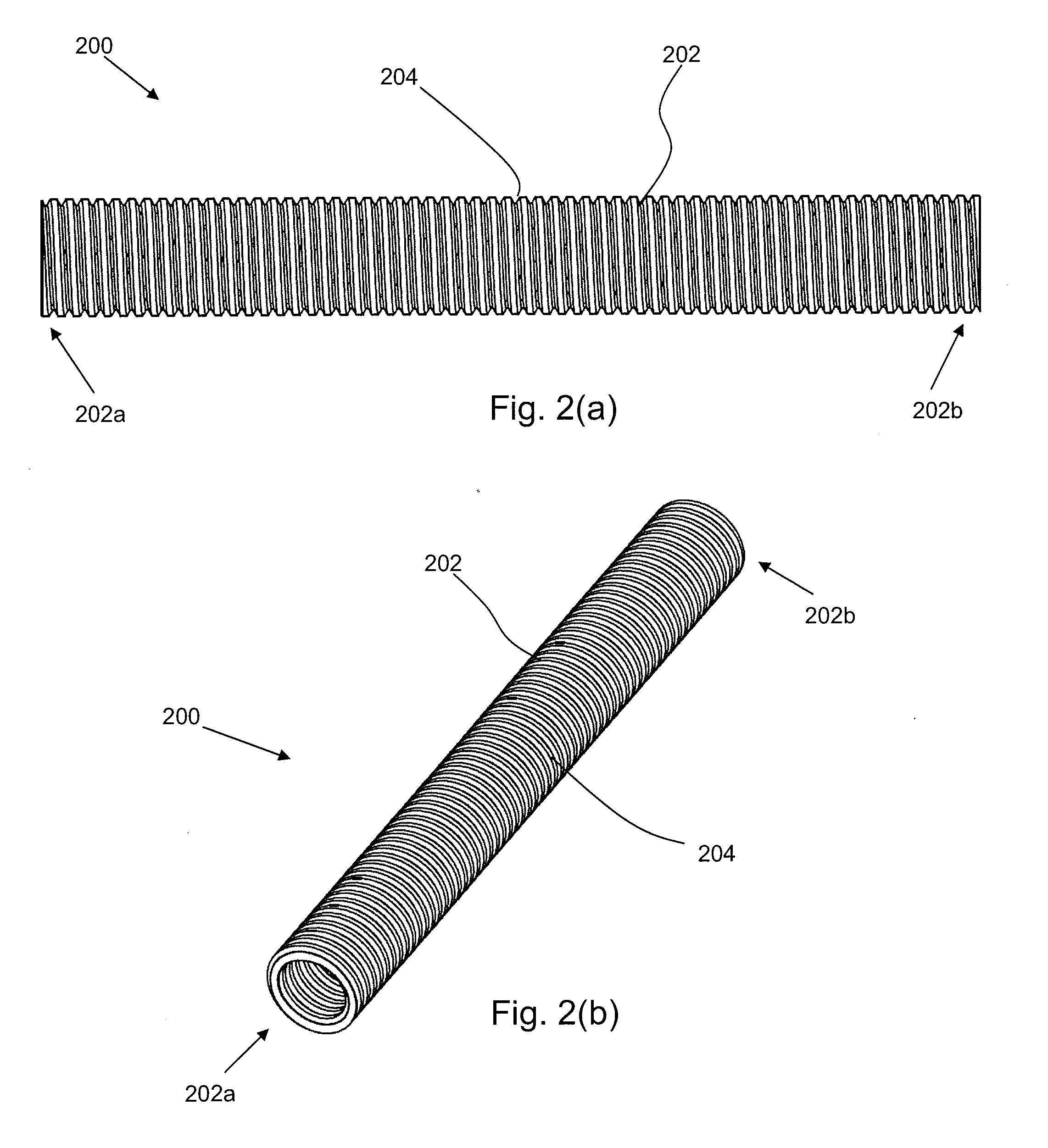

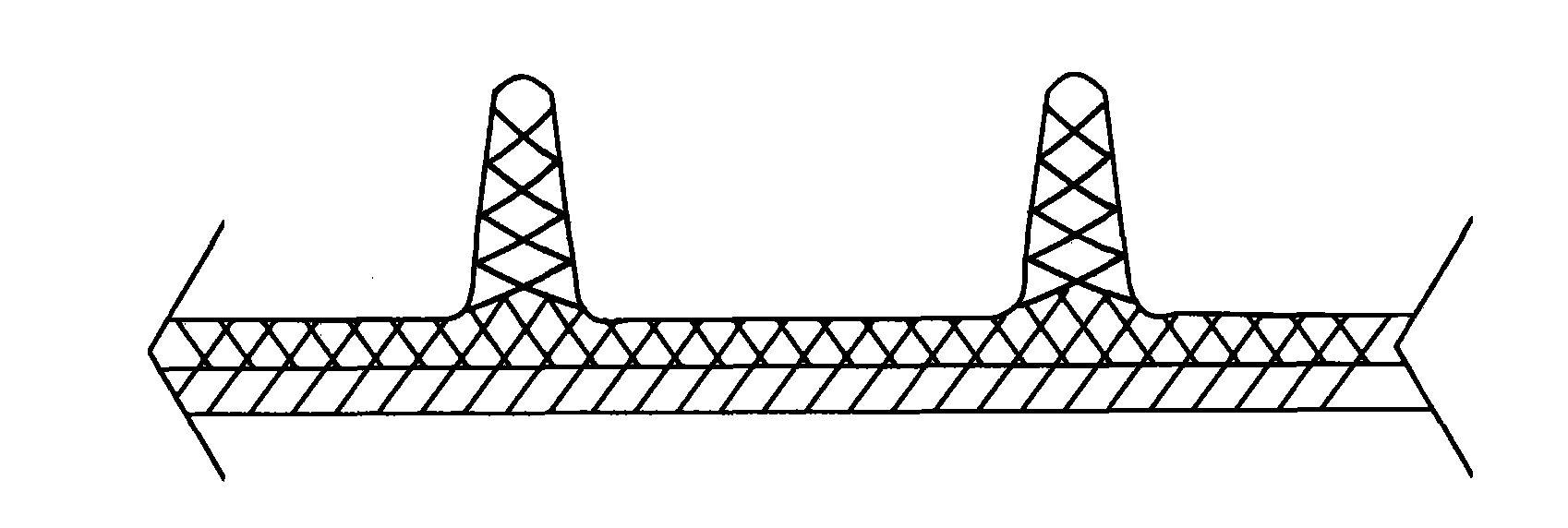

Continuously wound reinforced corrugated pipe and manufacturing method thereof

ActiveCN104279379AIncrease the outer surface areaIncreased structural wall thicknessCorrugation articlesFlexible pipesSolid wallAdhesive

The invention discloses a continuously wound reinforced corrugated pipe and a preparation method thereof. The pipe comprises a continuous solid-wall cylindrical pipe body formed by lapping and fusing a plurality of spirally wound special rods of which the two sides are provided with butting wings through the wings; a plurality of hollow reinforcing ribs are spirally wound on the pipe wall of the cylindrical pipe body; each hollow reinforcing rib comprises at least one special single-wall corrugated reinforcement pipe which is spirally wound on the pipe wall of the cylindrical pipe body through a reinforcement adhesive layer, and an outer reinforcement layer which is spirally wound, spans and presses on the special single-wall corrugated reinforcement pipe and of which two ends are adhered to the pipe wall of the cylindrical pipe body; the center line of each hollow reinforcing rib is overlapped with the center line of a lapping and fusing part of wings of an adjacent special rod. The pipe is high in stability and welding effect, the crest height of the pipe is higher than that of a double-wall corrugated pipe, the continuously wound reinforced corrugated pipe can be produced by matching common wound pipe production equipment with a suitable die, and equipment investment is small.

Owner:戴爱清 +1

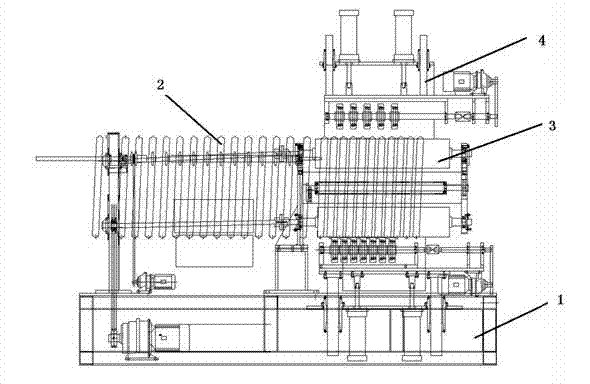

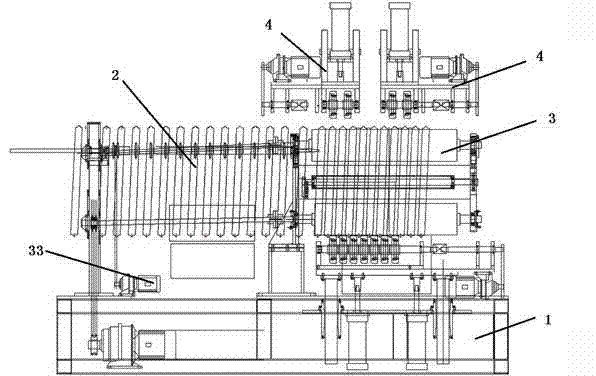

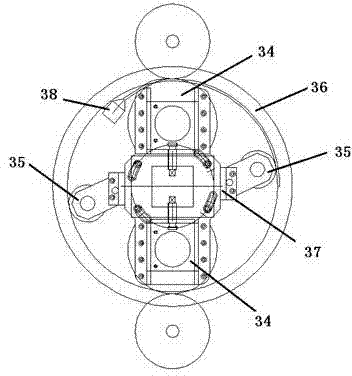

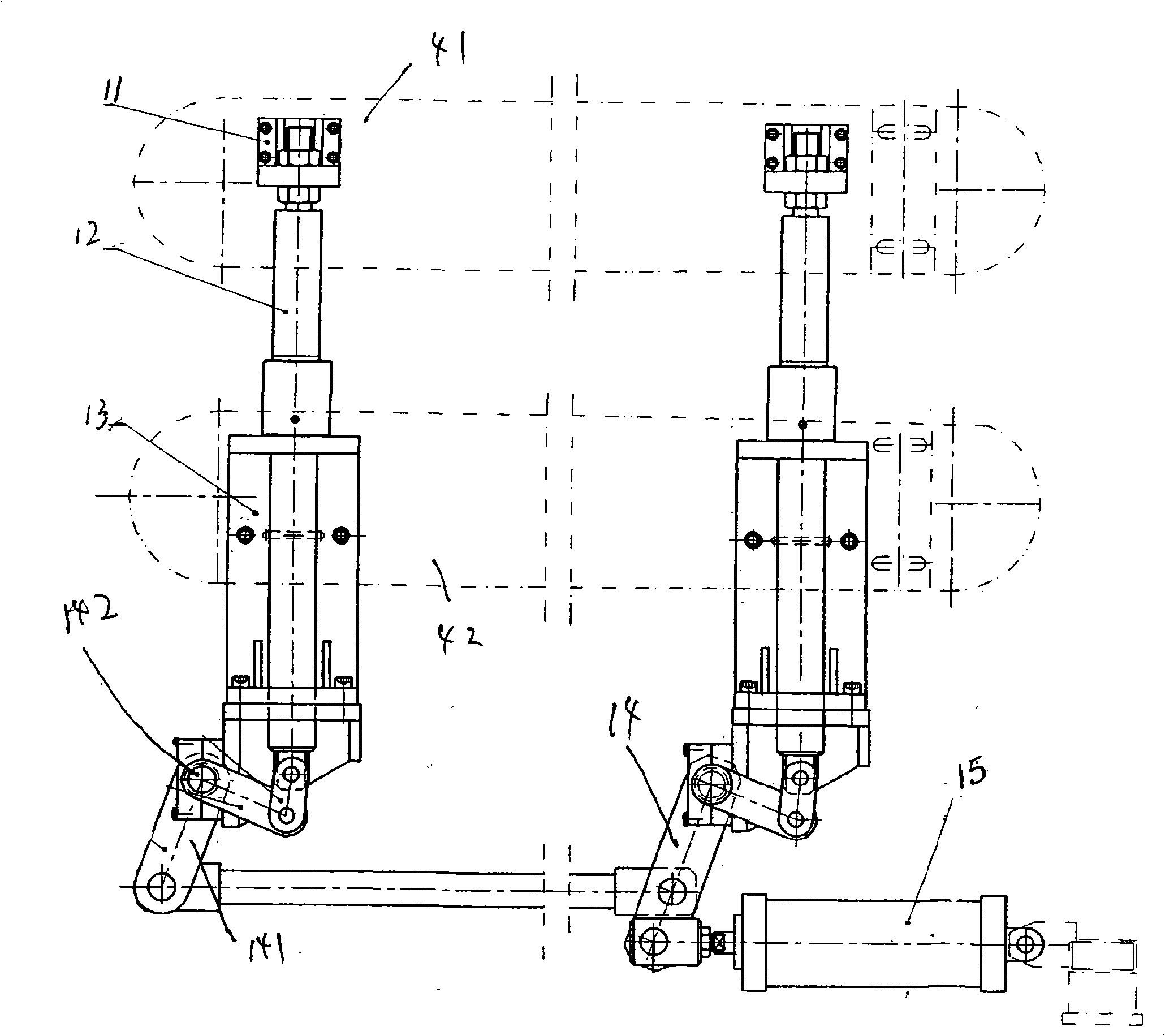

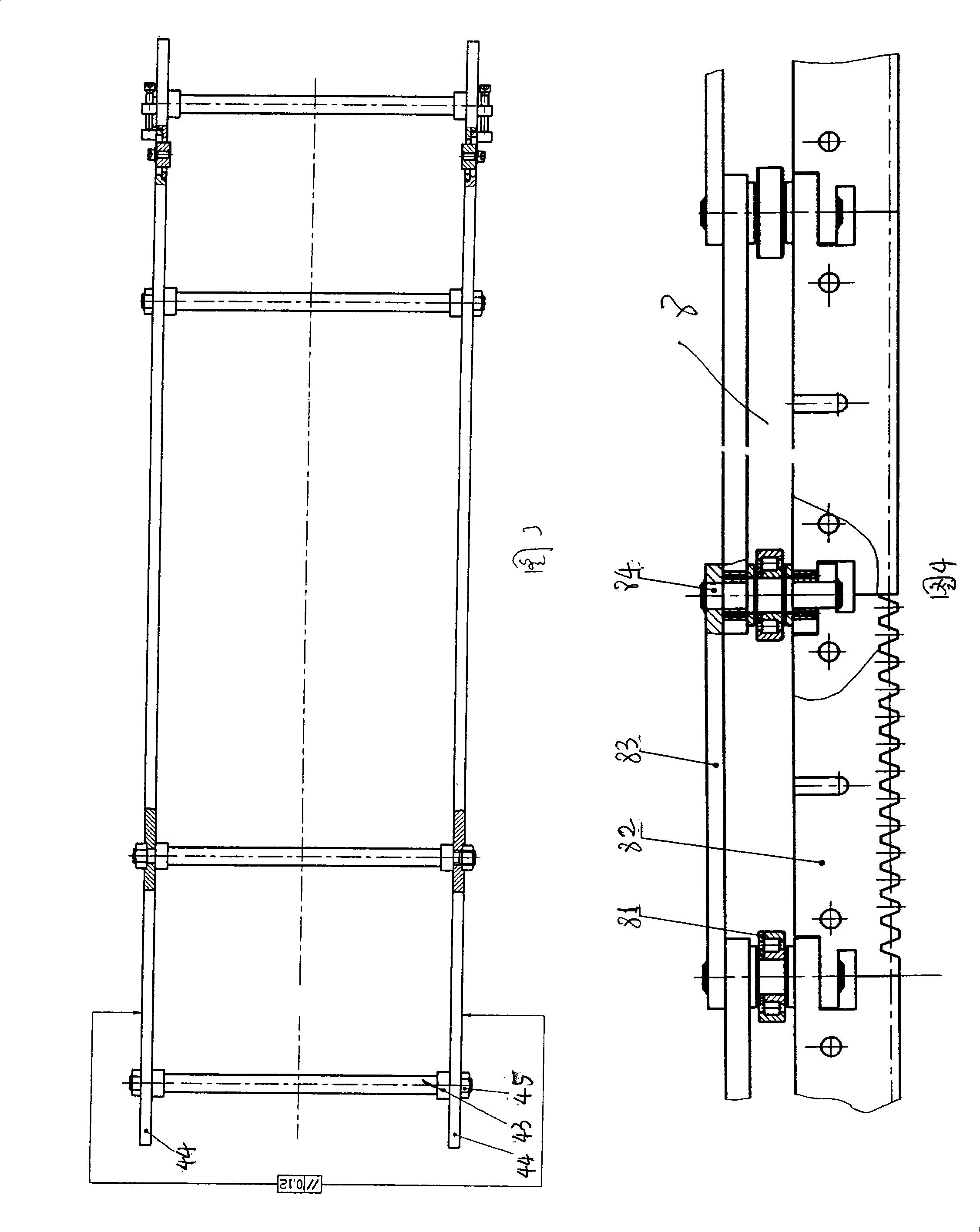

Manufacturing device of enhanced metal spiral corrugated pipe

ActiveCN104325649AReduce distanceMeet production needsCorrugation articlesTubular articlesThreaded pipeEngineering

The invention discloses a manufacturing device of an enhanced metal spiral corrugated pipe. The manufacturing device comprises a thread pipe wall molding unit; at least two main support rollers are arranged at the internally tangent part of a ring-shaped support surface; the main support rollers are movably arranged on a support frame by an adjusting mechanism, so that the ring-shaped support surface can be adjusted along the radial direction; the axial directions of the main support rollers are located by an axial support locating rod; the main support rollers are driven to rotate by a main support roller driving mechanism. According to the manufacturing device, all the main support rollers are movably connected, so that the production demands of various corrugated pipes with different diameters can be met to the utmost extent; devices with different models do not needed to be added within a certain range, so that the manufacturing device is good in universality.

Owner:昆山通塑挤出机械制造有限公司

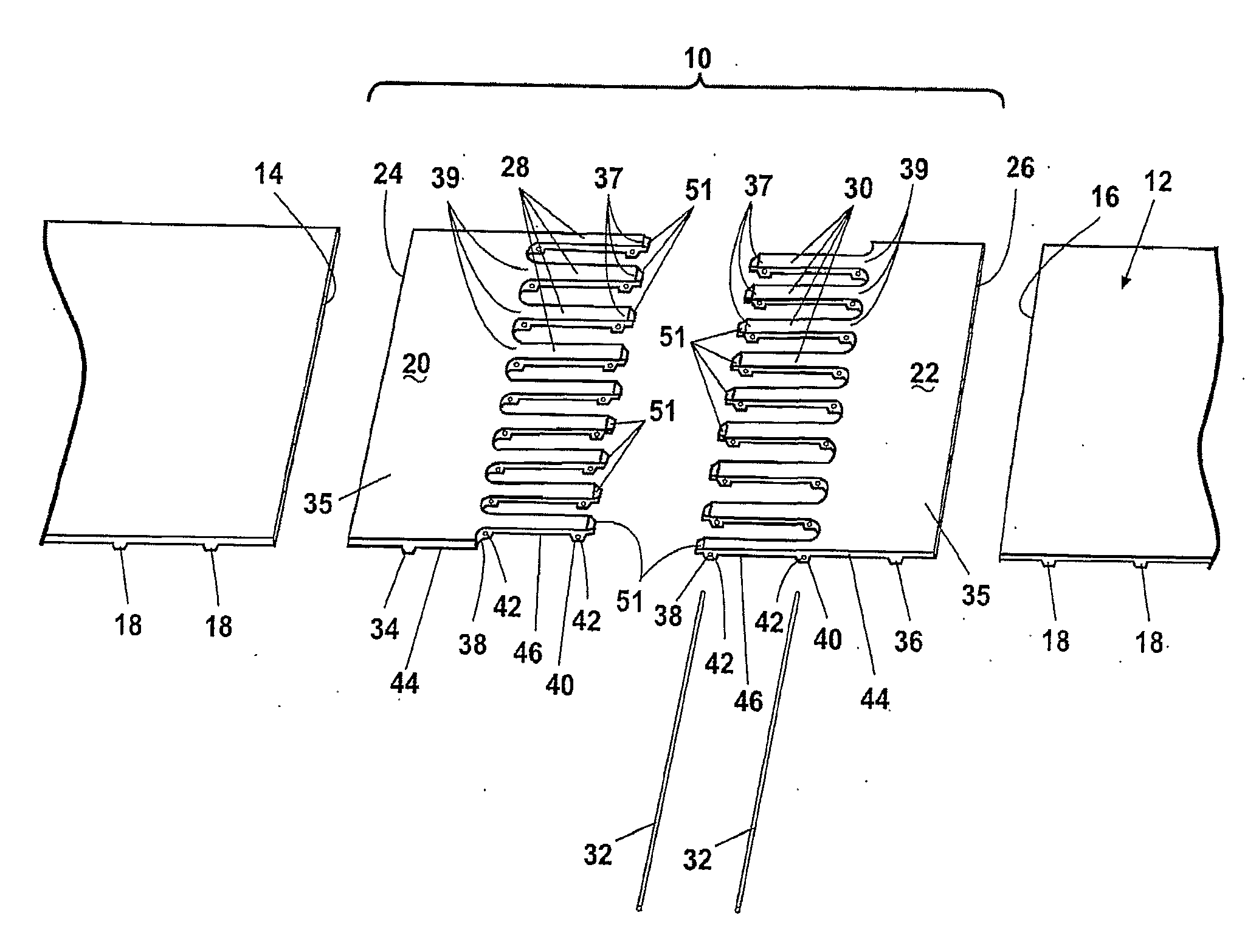

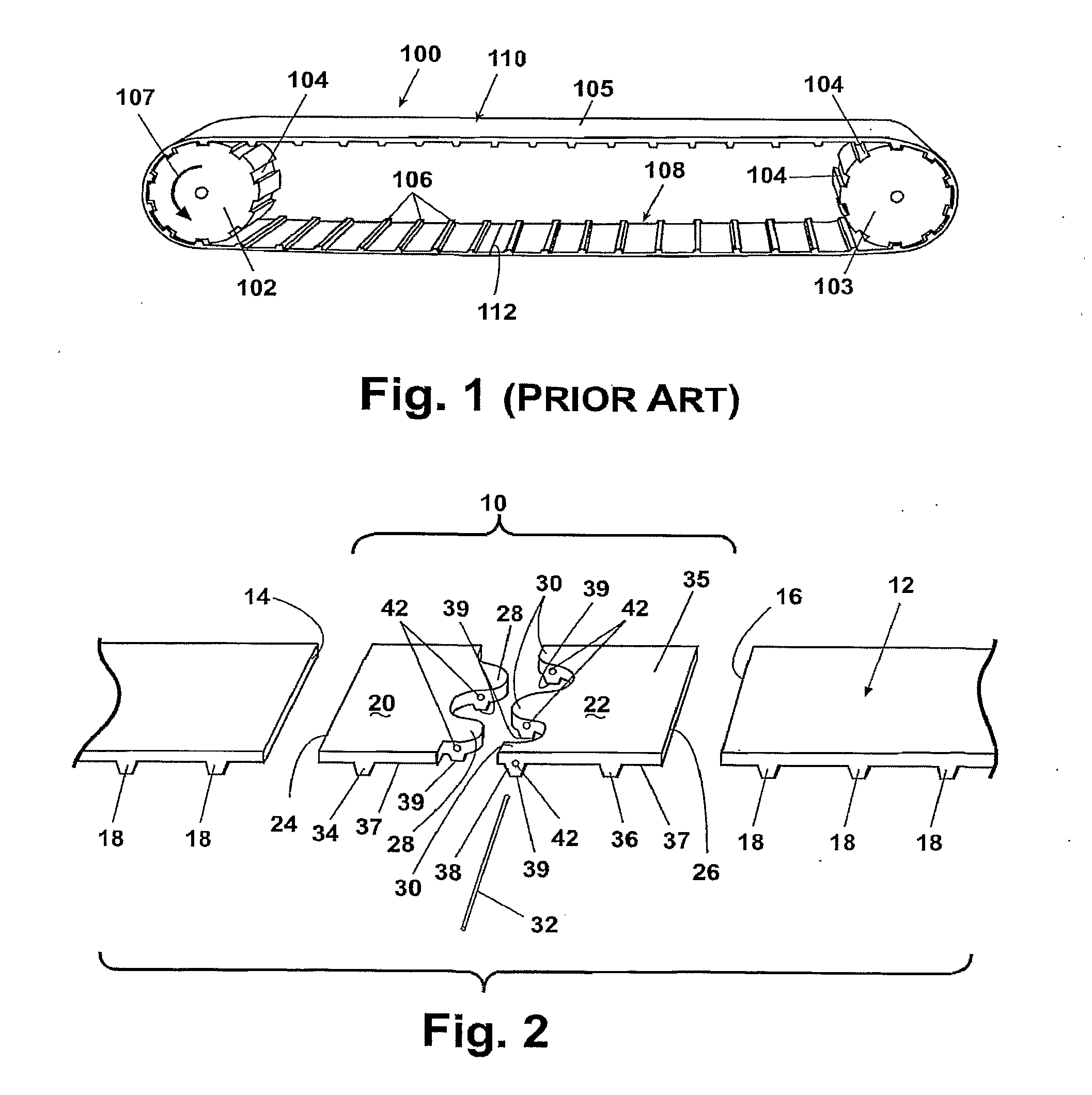

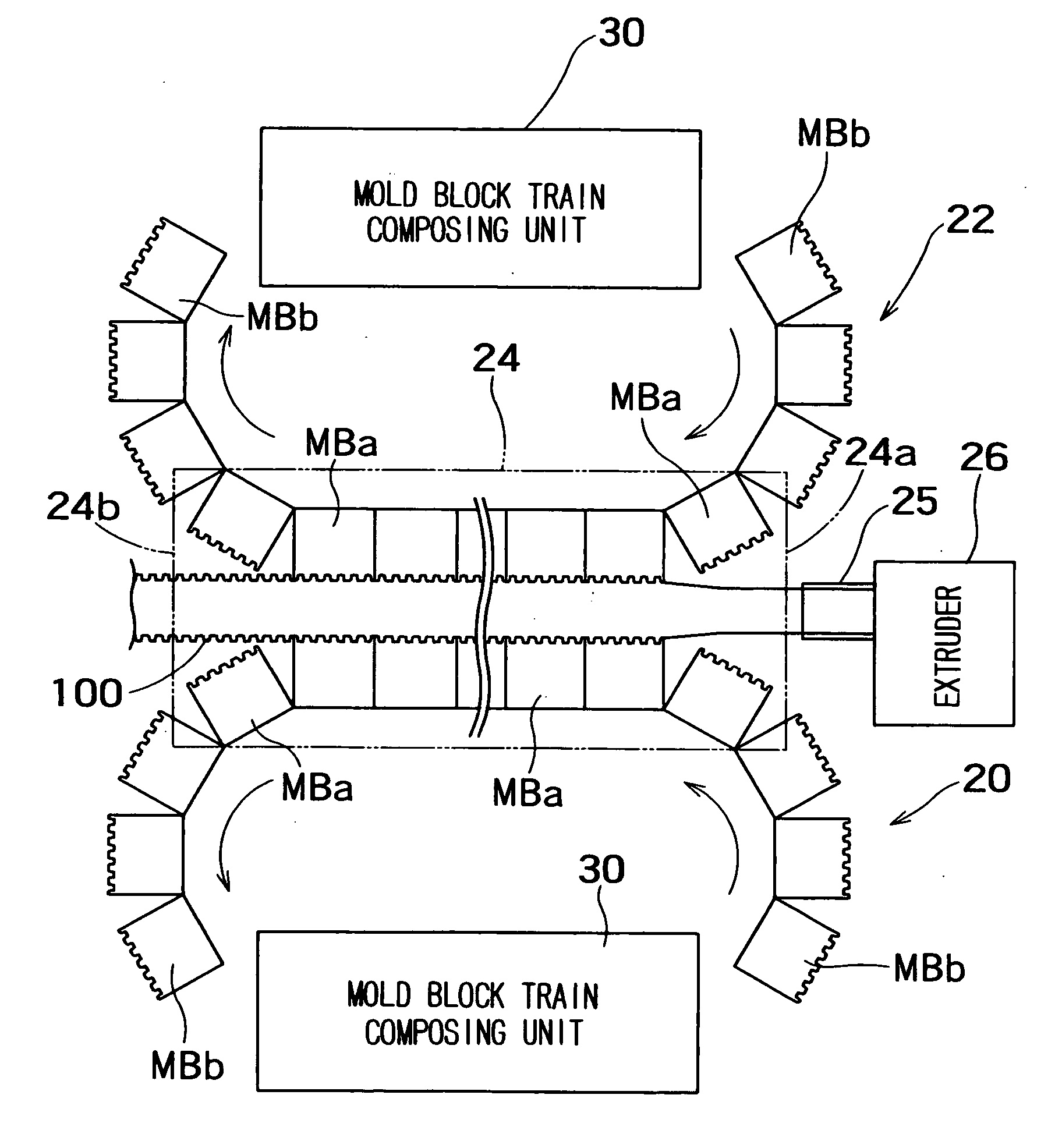

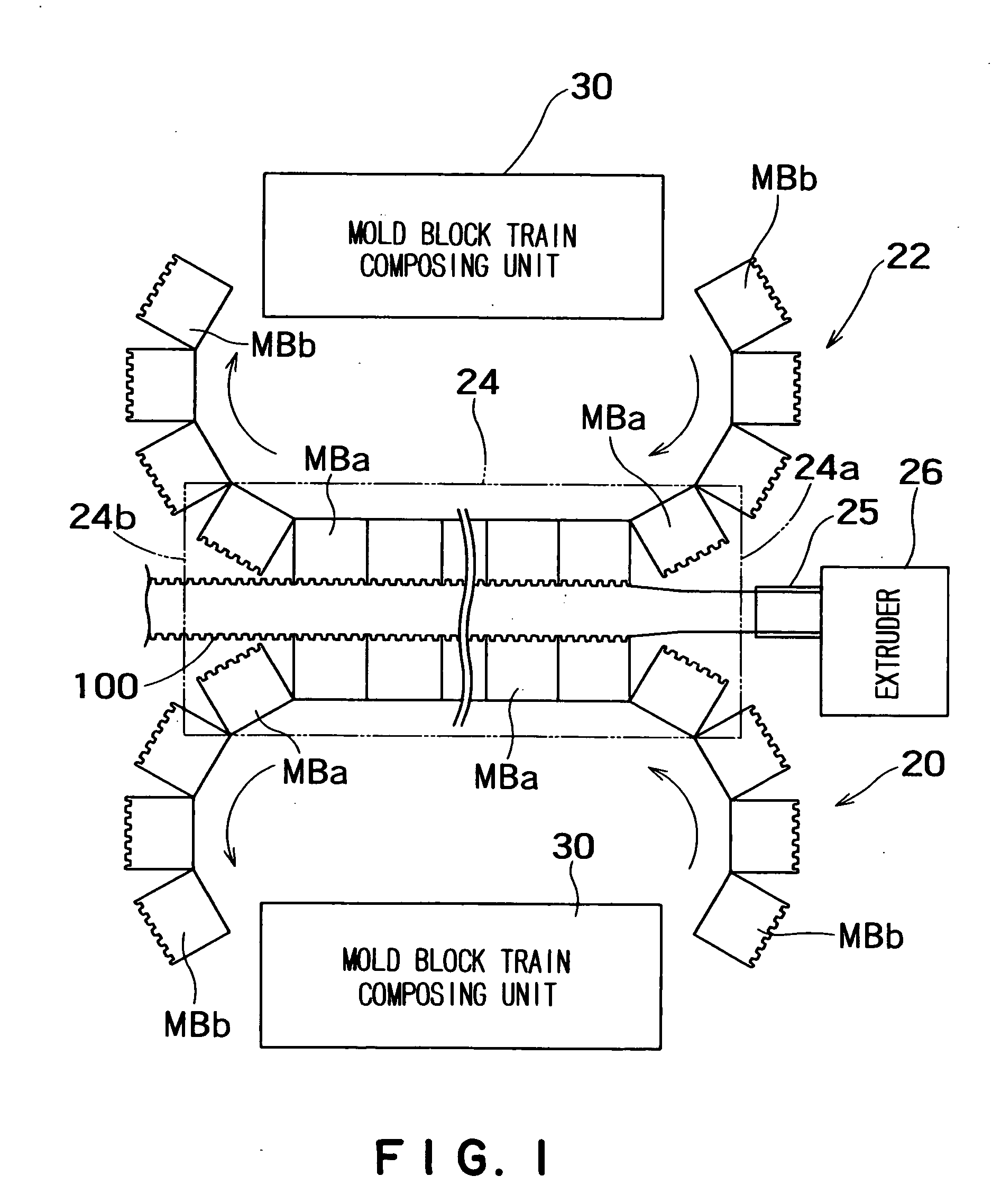

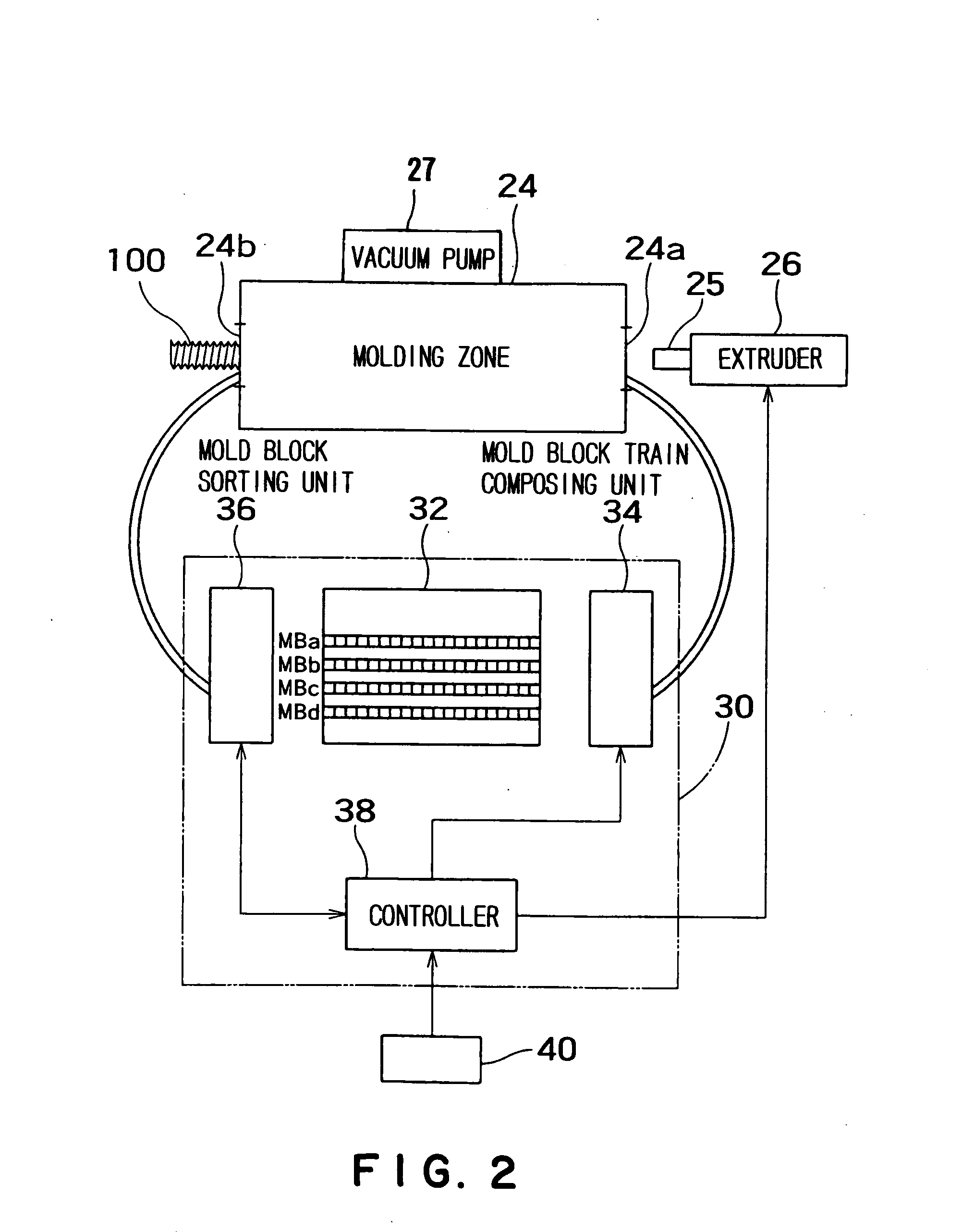

Method and device for manufacturing bellows tube

InactiveUS20050012249A1Efficient preparationDough-sheeters/rolling-machines/rolling-pinsConfectioneryProduction rateShell molding

A bellows tube manufacturing method and a system for manufacturing bellows tubes enables composing new mold block trains for molding a bellows tube of a new pattern and sending the new mold block trains into a molding zone without requiring any preparatory operation and without stopping the bellows tube manufacturing system, and manufacturing bellows tubes at high productivity. Elemental mold blocks MBa, MBb, MBc and MBd necessary for composing a first mold block train 20 and a second mold block train 22 for forming elemental molds having molding surfaces conforming to the shape of a bellows tube to be manufactured are selected and arranged according to composition data specifying the numbers, types and order of arrangement of the elemental mold blocks MBa, MBb, MBc and MBd to compose the first mold block train 20 and the second mold block train 22, and the mold block trains 20 and 22 are moved into a molding zone 24. A molten resin is extruded into a space between the mold block trains 20 and 22 moving in the molding zone 24 through an extrusion die 25 by an extruder 26. The corresponding elemental mold blocks MB of the mold block trains 20 and 22 are clamped to form the elemental molds having cavities as the mold block trains 20 and 22 move in the same direction, and a negative pressure is produced in the cavities to mold a bellows tube. The elemental mold blocks MB of the mold block trains 20 and 22 returned from the molding zone 24 are sorted according to type.

Owner:SANOH KOGYO KK

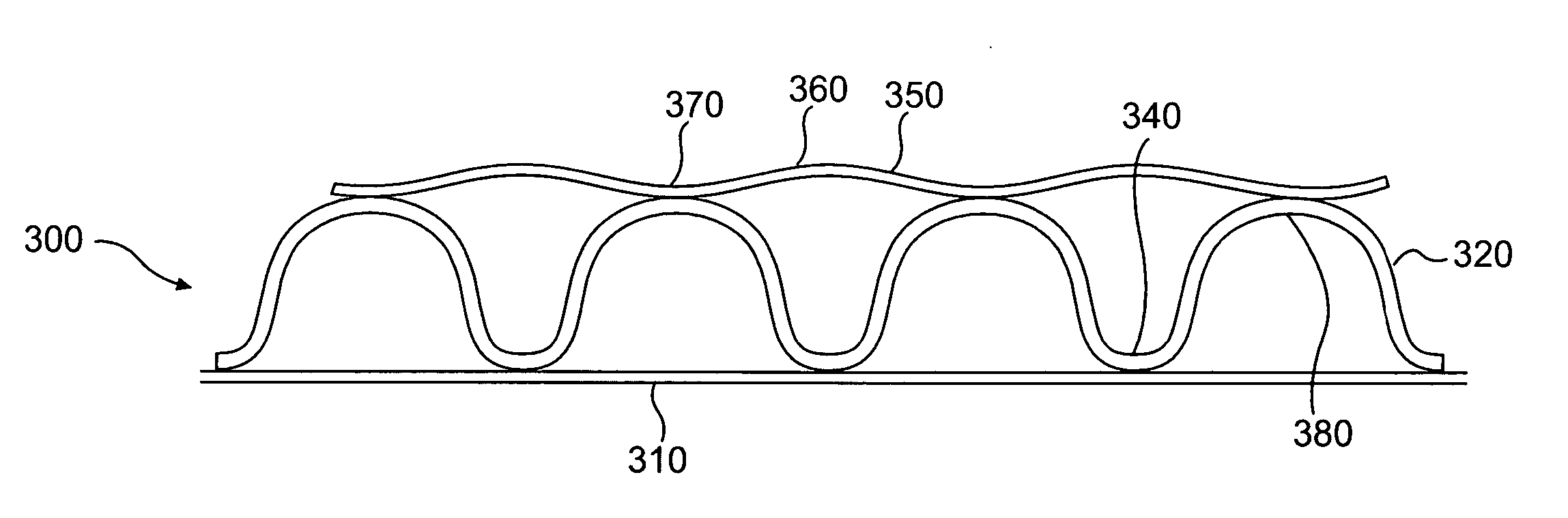

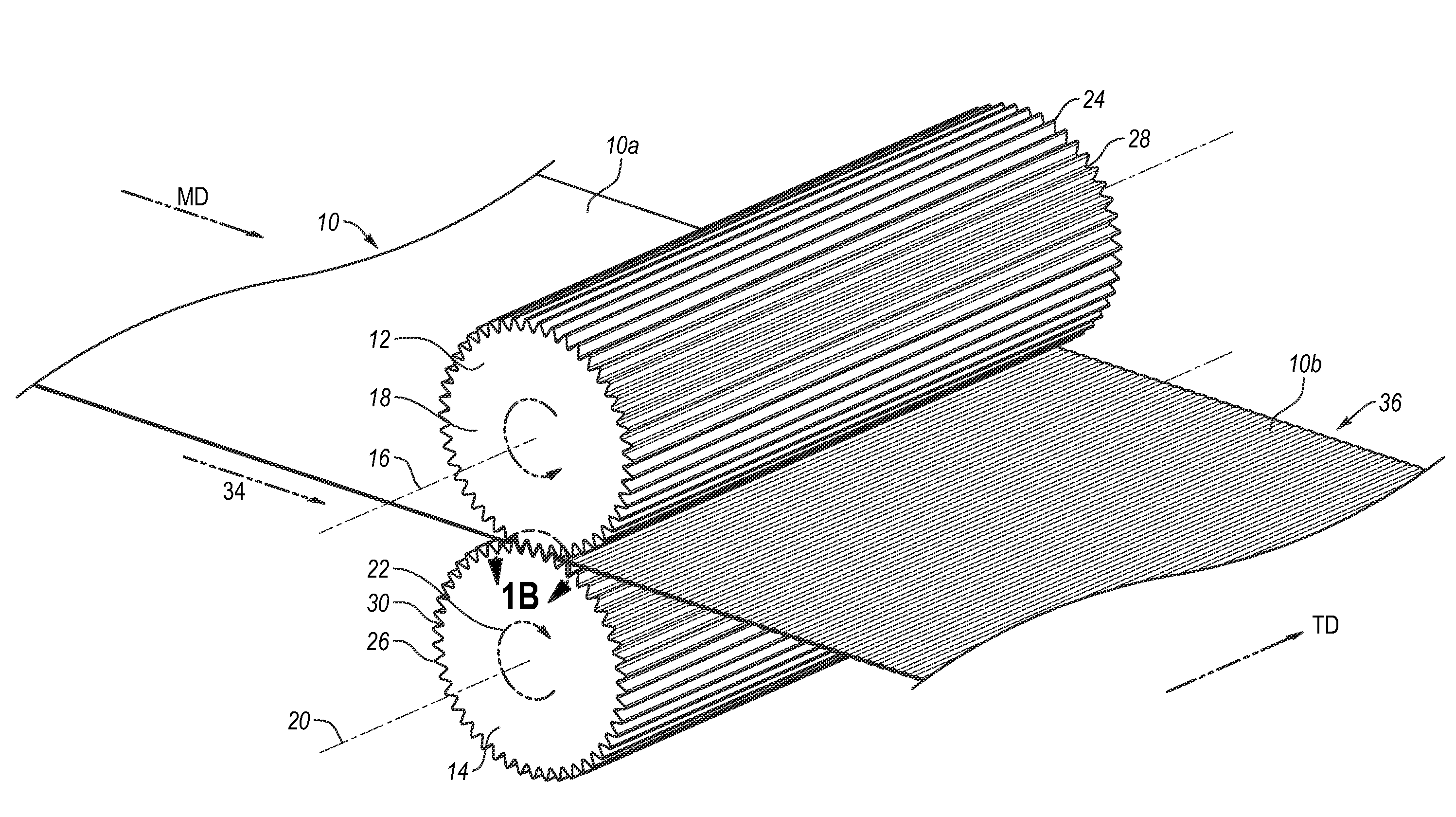

Incrementally Stretched Films with Increased Tear Resistance and Methods For Making The Same

ActiveUS20130029066A1Maintained and increased MD tear resistanceMaintaining and increasing film ' MD tear resistanceMechanical working/deformationBag making operationsTear resistanceEngineering

Methods of incrementally stretching thermoplastic films in the machine direction include elongating the films in the machine direction without reducing the films' machine-direction tear resistance. In one or more implementations, methods of incrementally stretching thermoplastic films include reducing the gauge of the films without reducing the films' machine-direction tear resistance. The methods can involve cold stretching the films and imparting transverse-direction extending linear rib pattern into the film. The linear ribs can have alternating thick and thin gauges. Incrementally stretched thermoplastic films can have a machine-direction tear resistance that is approximately equal to or greater than the machine-direction tear resistance of the film prior to stretching.

Owner:THE GLAD PROD CO

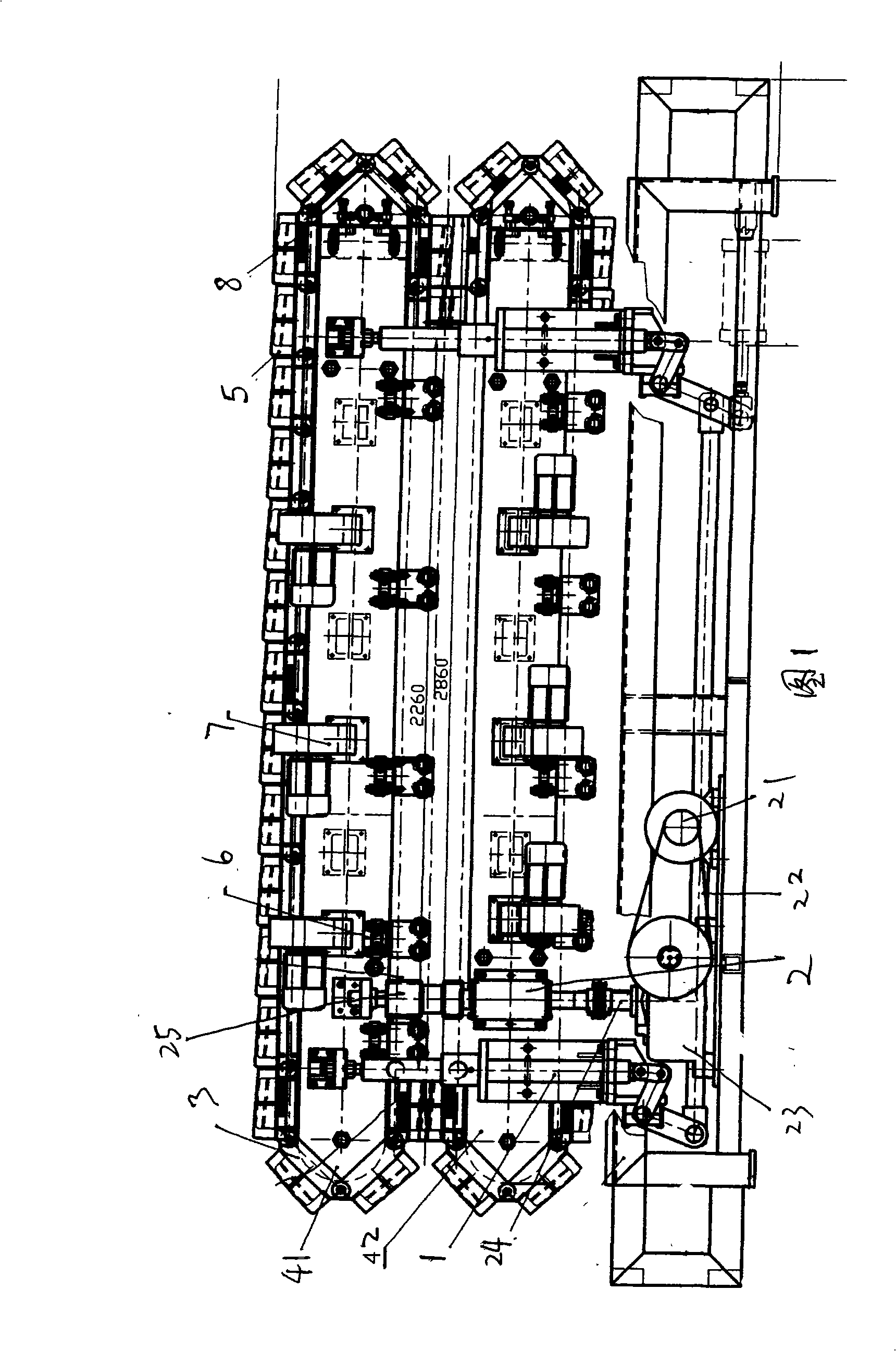

Plastic coloured glaze decorating tile forming machines

ActiveCN101289001ALow costIncrease productivityCorrugation articlesContinuous/uninterruptedFixed frame

A plastic glazed decorative tile shaping machine mainly comprises a frame mechanism, a transmission mechanism and a template mechanism. The frame mechanism comprises four pieces of vertically fixed upright rods, the upper ends of which are provided with top blocks and a fixed lower beam fixing frame; the corresponding top blocks on the front and the back pieces of the upright rods are respectively and fixedly provided with an upper draught beam; while the corresponding front and the back lower beam fixing frames are respectively and fixedly provided with a lower draught beam; the upper draught beam and the lower draught beam are respectively surrounded by a closed ring which is driven by the transmission mechanism, wherein the closed ring consists of a gemel plate, a strengthening plate, a gemel shaft and a cylinder roller bearing; furthermore, an upper location template and a lower location template are fixedly arranged on the gemel plate so as to form the template mechanism. The shaping machine of the invention has the advantages of simple manufacturing technique, high manufacturing efficiency, being capable of lightening the working intensity, reducing the cost, being capable of realizing continuous and ceaseless manufacturing and shaping of the glazed tile, improving the mounting speed and mounting quality of a construction spot and stabilizing the product quality, etc.

Owner:杭州泰能塑料机械厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com