Preparation process of composite material corrugated sandwich plates

A composite material and preparation technology, applied to corrugated products, applications, household appliances, etc., can solve the problems of low specific strength and specific stiffness, high production cost, long processing cycle, etc., and achieve high specific strength and specific stiffness , Low production cost and short processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

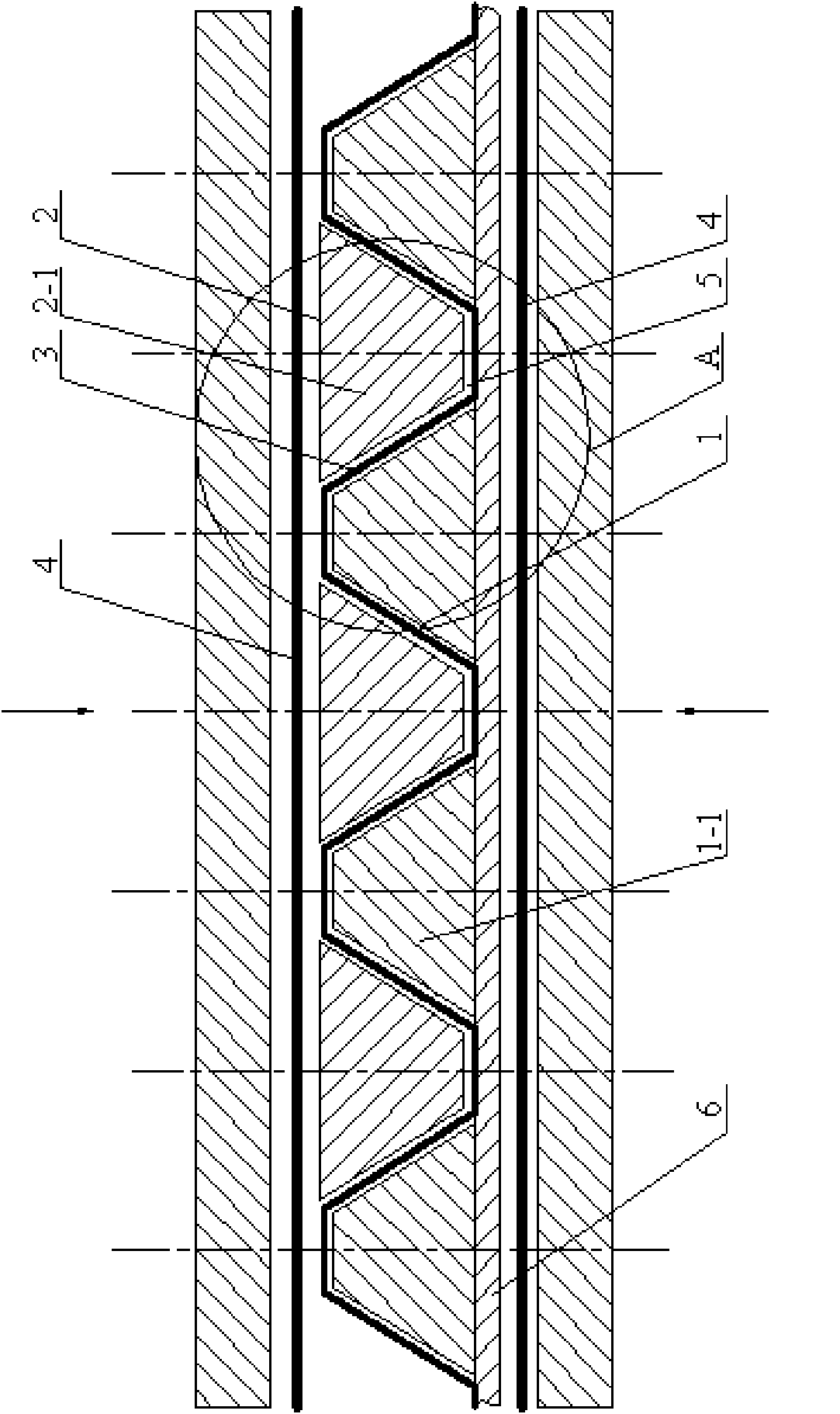

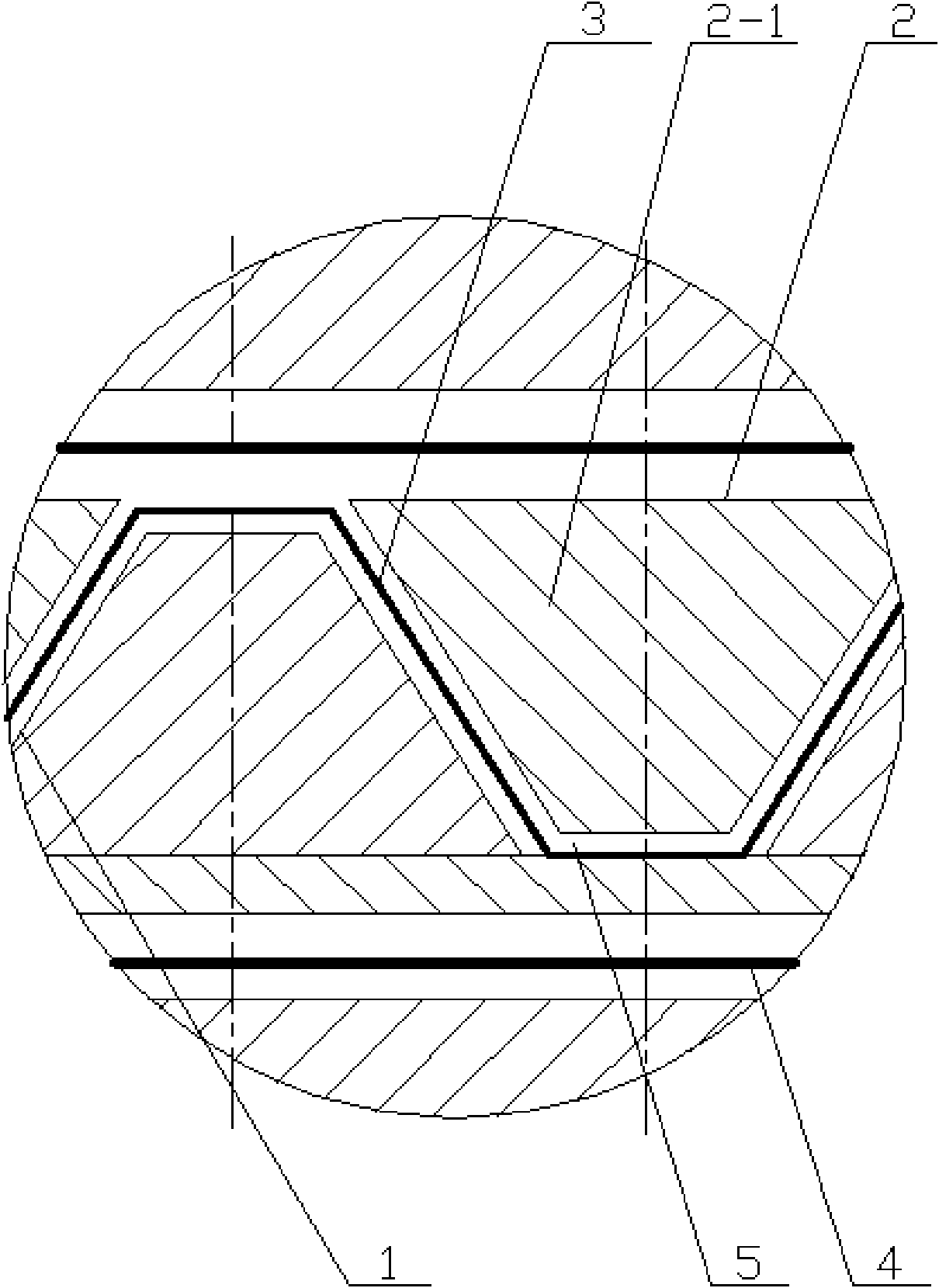

[0007] Specific implementation mode one: combine figure 1 and figure 2 Illustrate this embodiment, the preparation process of this embodiment is finished like this: one, coat release agent; The surface of core mold is cleaned up, and is coated with release agent on core mold surface; Two, core mold positioning; The lower mold 1 of the core mold is fixed on a flat steel plate 6, and the upper mold 2 of the core mold is removed; 3. Lay the full composite material core 3; Lay the full composite material core 3 to the core mold The outer surface of the upper mold 2, and matches the shape of the upper mold 2 of the core mould; four, the full composite material core 3 is finalized; the upper mold 2 of the core mold is installed in the lower mold 1 of the core mold , that is, mold closing, so that the full composite material core 3 is finalized, and a layer of panels 4 are respectively laid on the upper surface and the lower surface of the core mold, and then heated and pressurized...

specific Embodiment approach 2

[0009] Embodiment 2: The mold in step 1 of this embodiment is a silicone rubber mold, which is beneficial for demoulding. Other method steps are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 and figure 2 To illustrate this embodiment, the all-composite material core 3 in Step 3 of this embodiment is made of 55-80 parts of reinforcing phase material and 45-20 parts of matrix material according to the weight ratio. The strength and rigidity of the all-composite material corrugated board can be guaranteed. Other method steps are the same as those in the first embodiment.

[0011] Specific implementation mode four: combination figure 1 and figure 2 To illustrate this embodiment, the all-composite material core 3 in Step 3 of this embodiment is made of 60 parts of reinforcing phase material and 40 parts of matrix material according to the ratio of parts by weight. The strength and rigidity of the all-composite material corrugated board can be guaranteed. Other method steps are the same as in the third embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com