Method for forming duct made of elastomer

A pipe and elastic technology, applied in the field of pipes of air pipes and corrugated pipes, can solve the problems of damaged products, lower product quality, insufficient, etc., and achieve the effect of avoiding damage and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

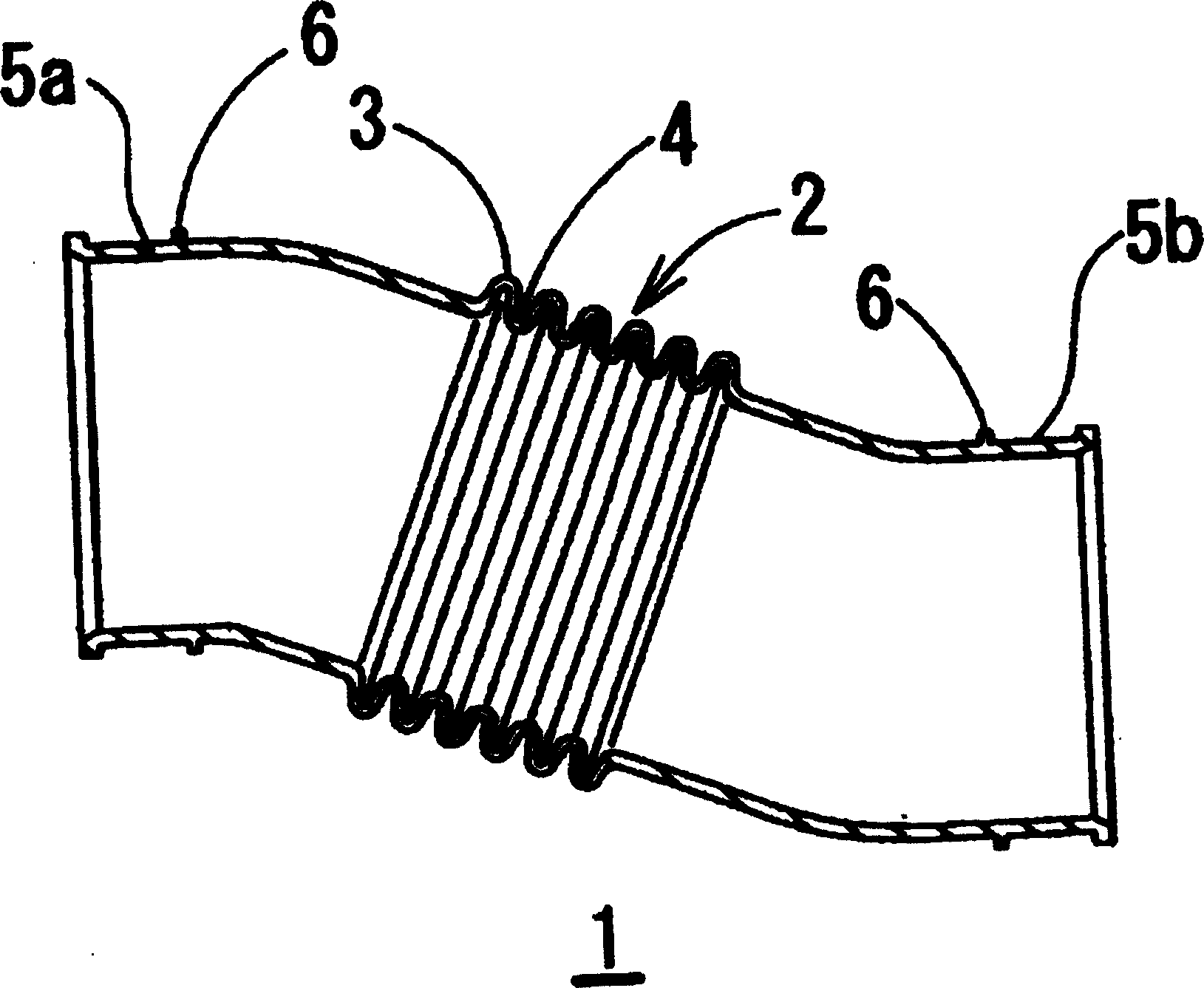

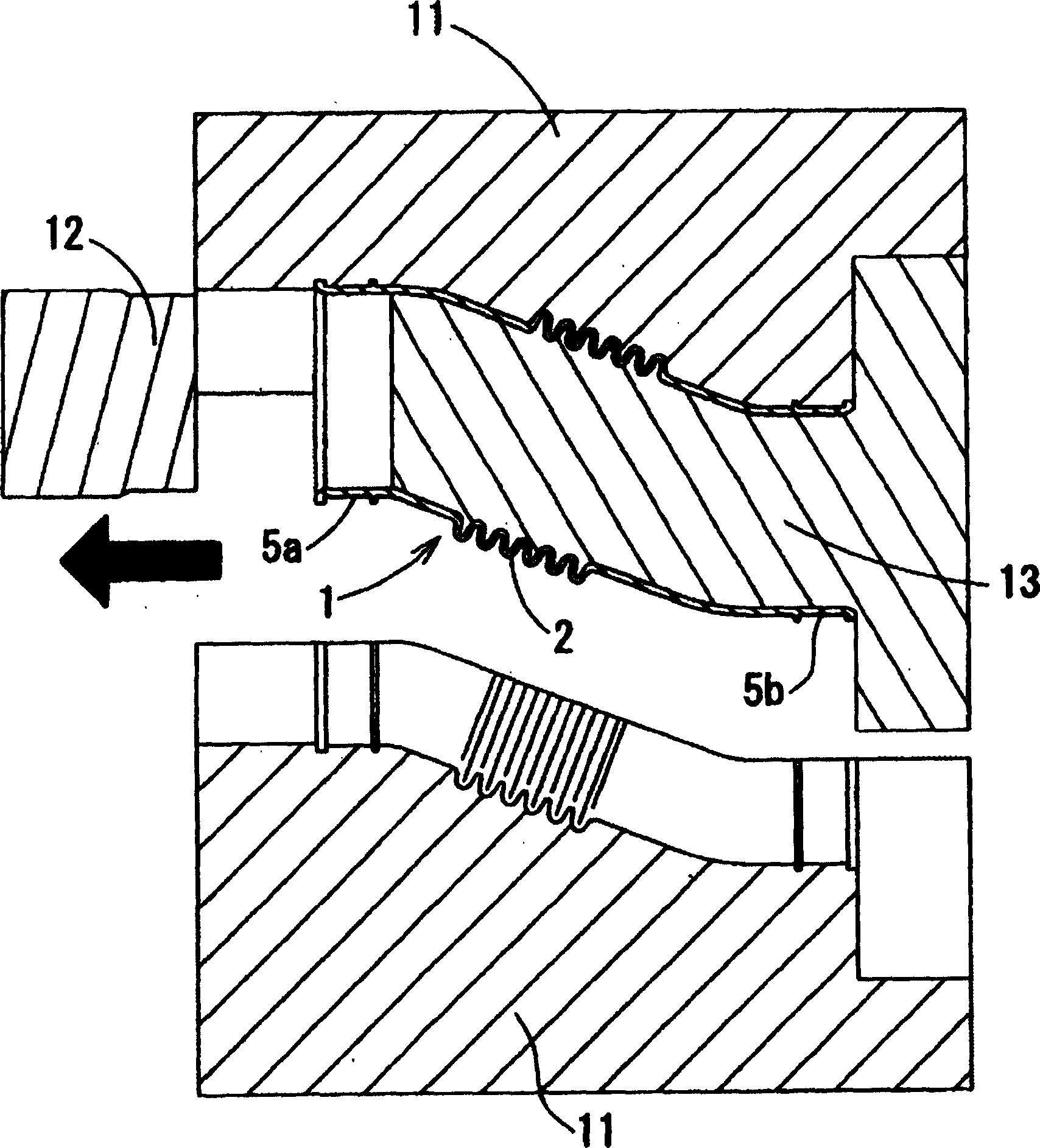

[0030] figure 1 is a cross-sectional side elevational view of the resin pipe 1 injection-molded into a shape bent in a given direction. This duct serves as an air duct connecting the engine body of the automobile to an air cleaner (not shown), and has a corrugated section (or corrugated section) 2 near the middle part of the duct as a part in the longitudinal direction, and the corrugated section 2 A plurality of protrusions or peaks 3 formed with a large diameter and a plurality of depressions or valleys 4 with a small diameter are alternately arranged along the axial center direction of the pipe. Both ends 5a and 5b of the pipe 1 are formed in non-corrugated sections with almost smooth surfaces, and are connected and fixed to the engine body or the air cleaner by clamps (not shown). Incidentally, symbols 6 and 6 show reinforcing ribs formed continuously and integrally along the circumferential direction of the peripheral surface in the vicinity of the end portions 5a and 5b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com