Plastic coloured glaze decorating tile forming machines

A tile forming machine and glazed technology, which is applied in the field of forming machines for plastic glazed decorative tiles, can solve the problems of high labor intensity, high cost and complicated process of production workers, and achieve the improvement of installation speed and installation quality, reduction of labor intensity, and product quality. Stable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

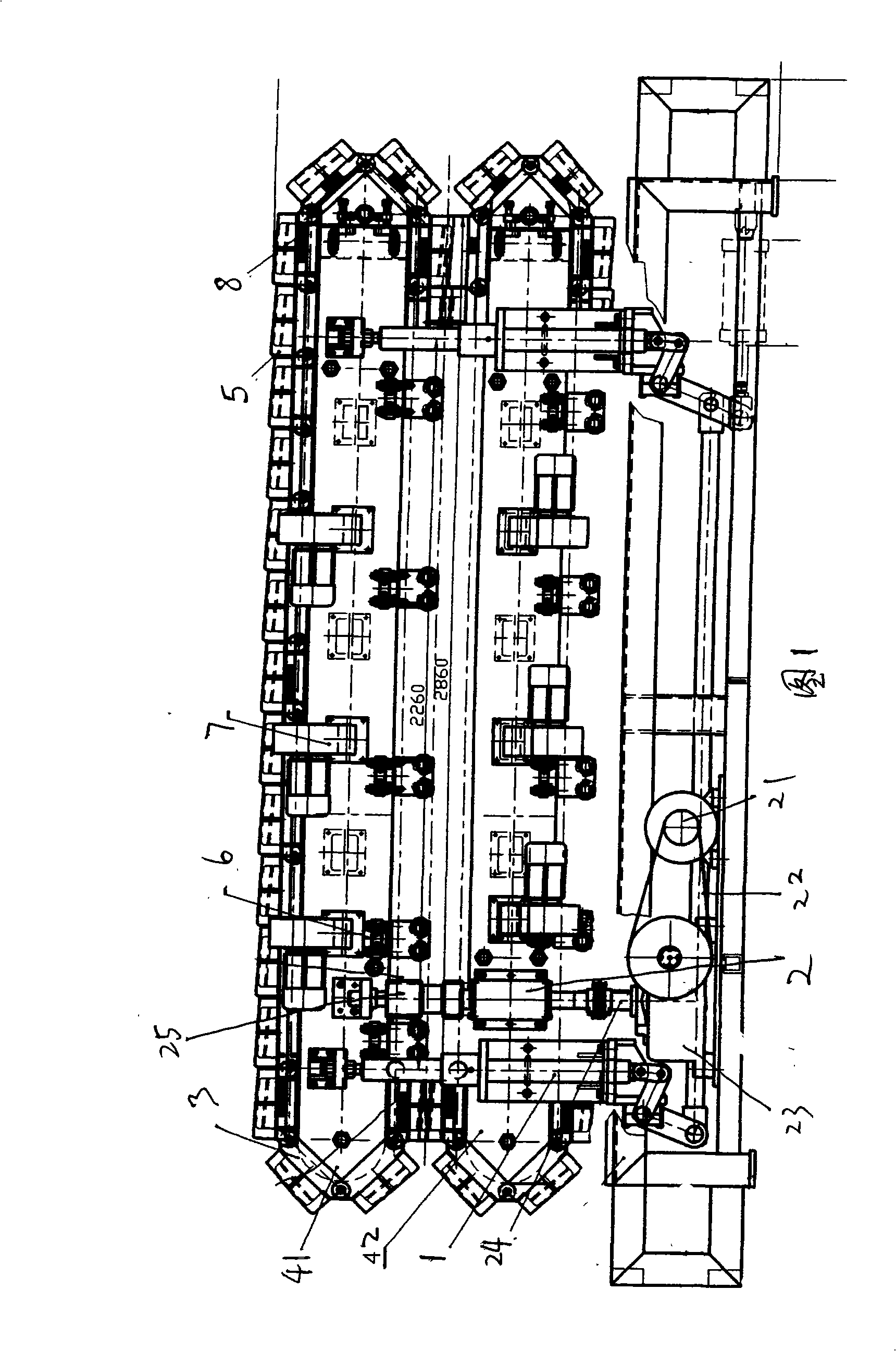

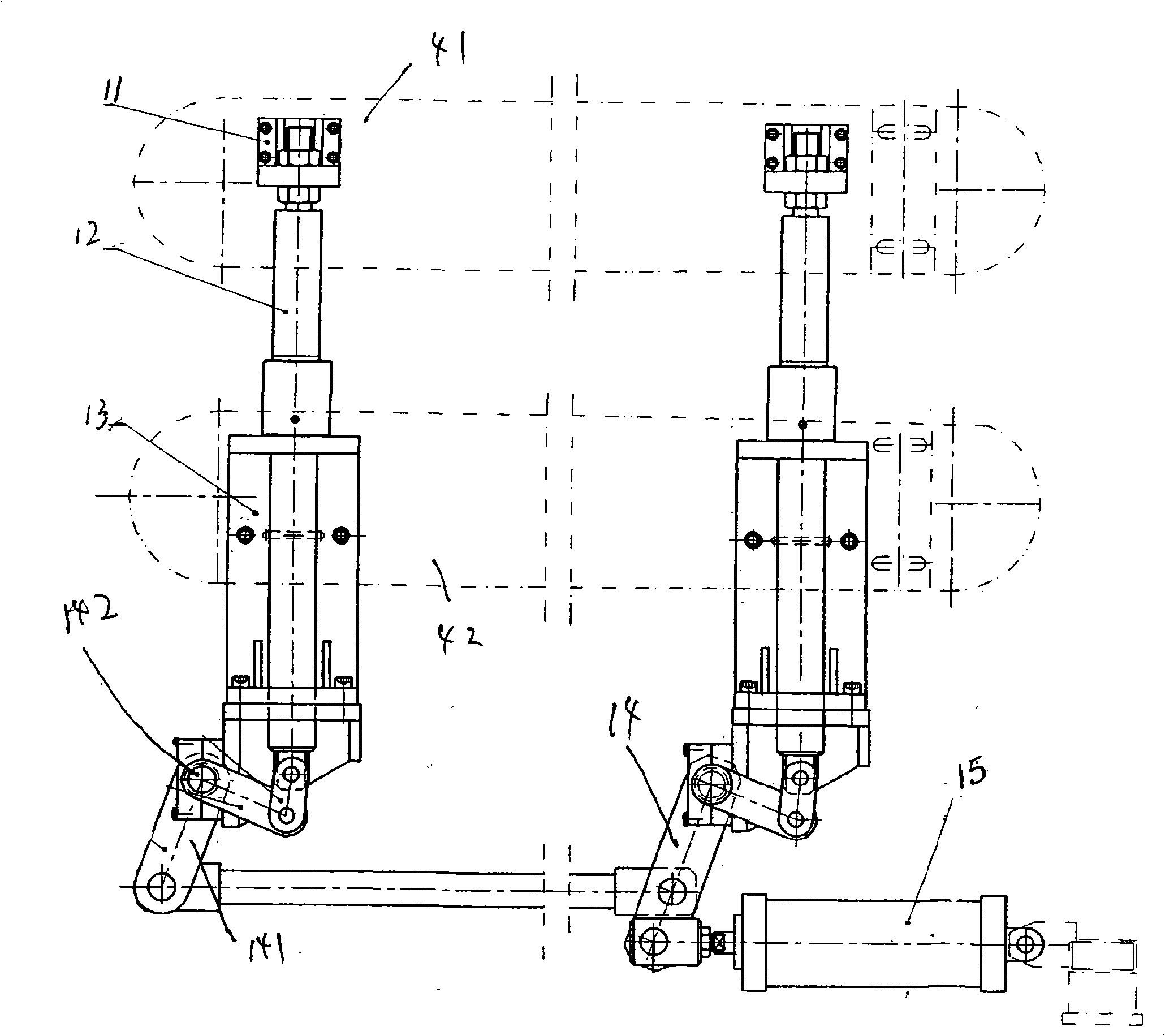

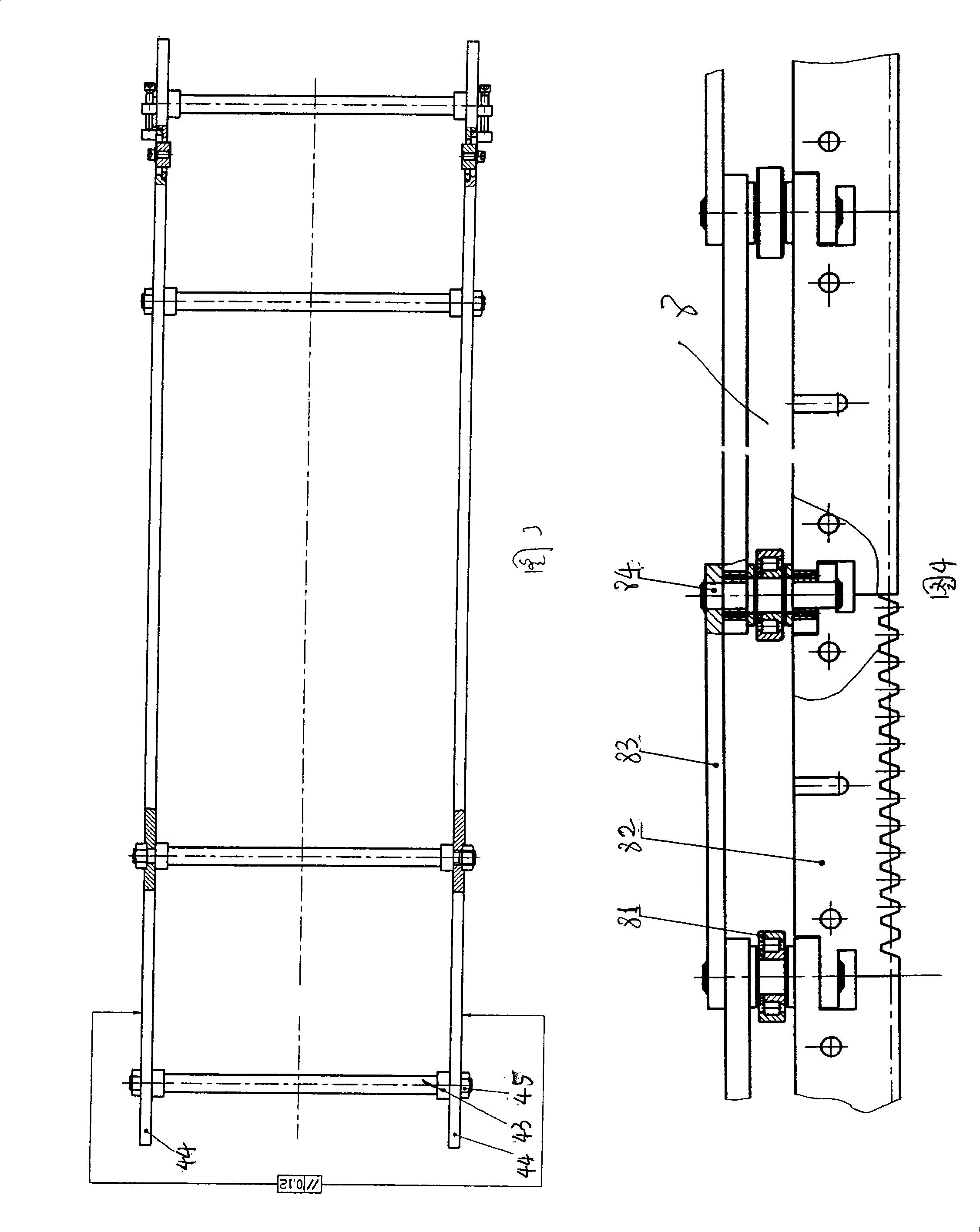

[0018] The present invention will be described in detail below in conjunction with accompanying drawing: shown in accompanying drawing 1, the present invention mainly consists of elevating type frame mechanism 1, transmission mechanism 2, formwork mechanism 3, traction upper beam 41 and traction lower beam 42, qualitative formwork up and down 5. Composed of chain lifting mechanism 6, air cooling mechanism 7, hinge mechanism 8, pulley adjustment mechanism, electrical control box, etc. The present invention adopts advanced frequency conversion stepless speed regulation, connects the input pulley of the reducer 23 through the motor 21 and the pulley drive 22, and then connects the transmission shaft 24 through the output shaft of the reducer 23, and the traction gear 25 on the transmission shaft 24 drives the sleeve On the traction upper beam 41 and the traction lower beam 42, there is a rack of rollers 81, i.e. a hinge plate 82, so that the upper and lower sizing templates 5 fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com