Material packaging method for prefabricated bag packaging machine

A packaging method and technology of prefabricated bags, which are applied in the directions of packaging, transportation and packaging, and single objects, can solve the problems of many packaging actions, short packaging strokes, and complex procedures, and achieve a high degree of continuous pushing and short conveying and packaging strokes. , the effect of high degree of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

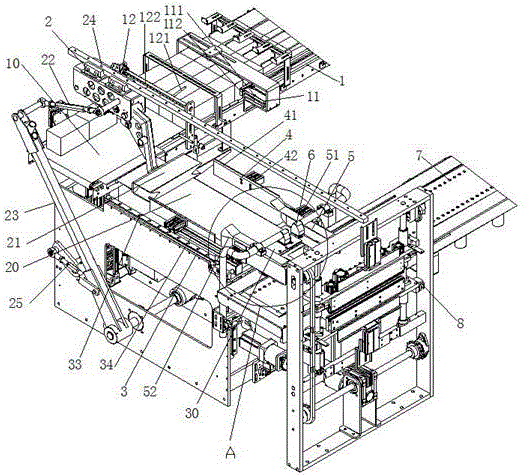

[0118] The material packaging method of the prefabricated bag packaging machine includes the following steps:

[0119] Material clamping or holding, prefabricated bag opening, material pushing and prefabricated bag unloading, among which:

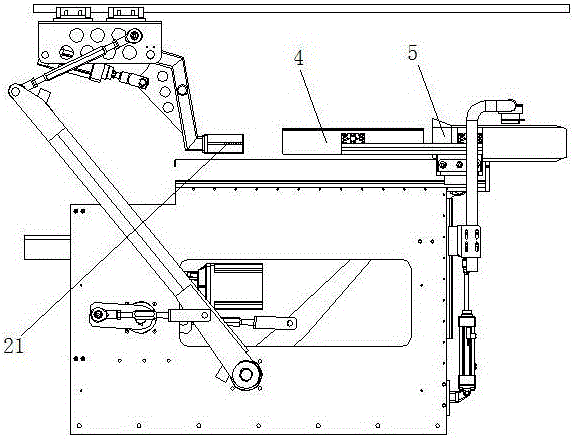

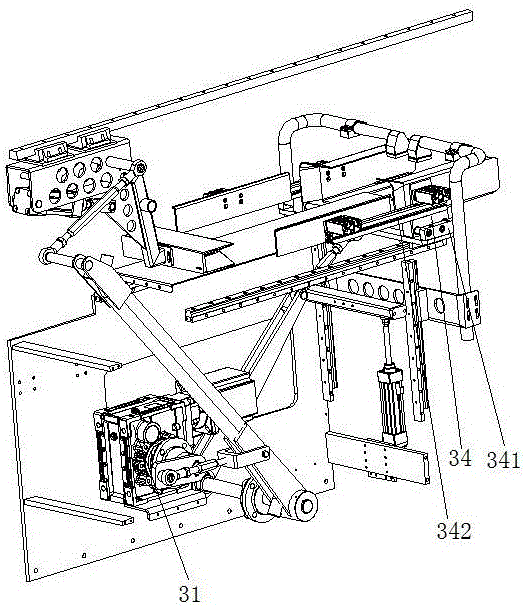

[0120] The material clamping or holding means that the material is clamped or held to the position to be pushed under the action of the clamping mechanism 4 or the holding mechanism 9;

[0121] The prefabricated bag stretching bag: refers to that the prefabricated bag opens the left and right sides of the bag opening under the action of the bag stretching mechanism 5;

[0122] The material pushing means that under the action of the material pushing mechanism 2, the material moves towards the opening of the prefabricated bag, and reaches the bottom of the prefabricated bag, and the material continues to be pushed along with the prefabricated bag;

[0123] Prefabricated bag debagging: after the material reaches the bottom of the prefabricate...

Embodiment 2

[0126] The material packaging method of the prefabricated bag packaging machine includes the following steps:

[0127] Material clamping or holding, prefabricated bag opening, material pushing and prefabricated bag unloading, among which:

[0128] The material clamping or holding means that the material is clamped or held to the position to be pushed under the action of the clamping mechanism 4 or the holding mechanism 9;

[0129] The prefabricated bag stretching bag: refers to that the prefabricated bag opens the left and right sides of the bag opening under the action of the bag stretching mechanism 5;

[0130] The material pushing means that under the action of the material pushing mechanism 2, the material moves towards the opening of the prefabricated bag, and reaches the bottom of the prefabricated bag, and the material continues to be pushed along with the prefabricated bag;

[0131] Prefabricated bag de-bagging: after the material reaches the bottom of the prefabricat...

Embodiment 3

[0135] The material packaging method of the prefabricated bag packaging machine includes the following steps:

[0136] Material clamping or holding, prefabricated bag opening, material pushing and prefabricated bag unloading, among which:

[0137] The material clamping or holding means that the material is clamped or held to the position to be pushed under the action of the clamping mechanism 4 or the holding mechanism 9;

[0138] The prefabricated bag stretching bag: refers to that the prefabricated bag opens the left and right sides of the bag opening under the action of the bag stretching mechanism 5;

[0139] The material pushing means that under the action of the material pushing mechanism 2, the material moves towards the opening of the prefabricated bag, and reaches the bottom of the prefabricated bag, and the material continues to be pushed along with the prefabricated bag;

[0140] Prefabricated bag de-bagging: after the material reaches the bottom of the prefabricat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com