A kind of melamine composite fiber and its manufacturing method

A melamine, composite fiber technology, applied in the direction of single-component synthetic polymer rayon, rayon manufacturing, fiber chemical characteristics, etc., can solve problems such as poor strength and toughness, eliminate air bubbles, improve compatibility and stability , the effect of more operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

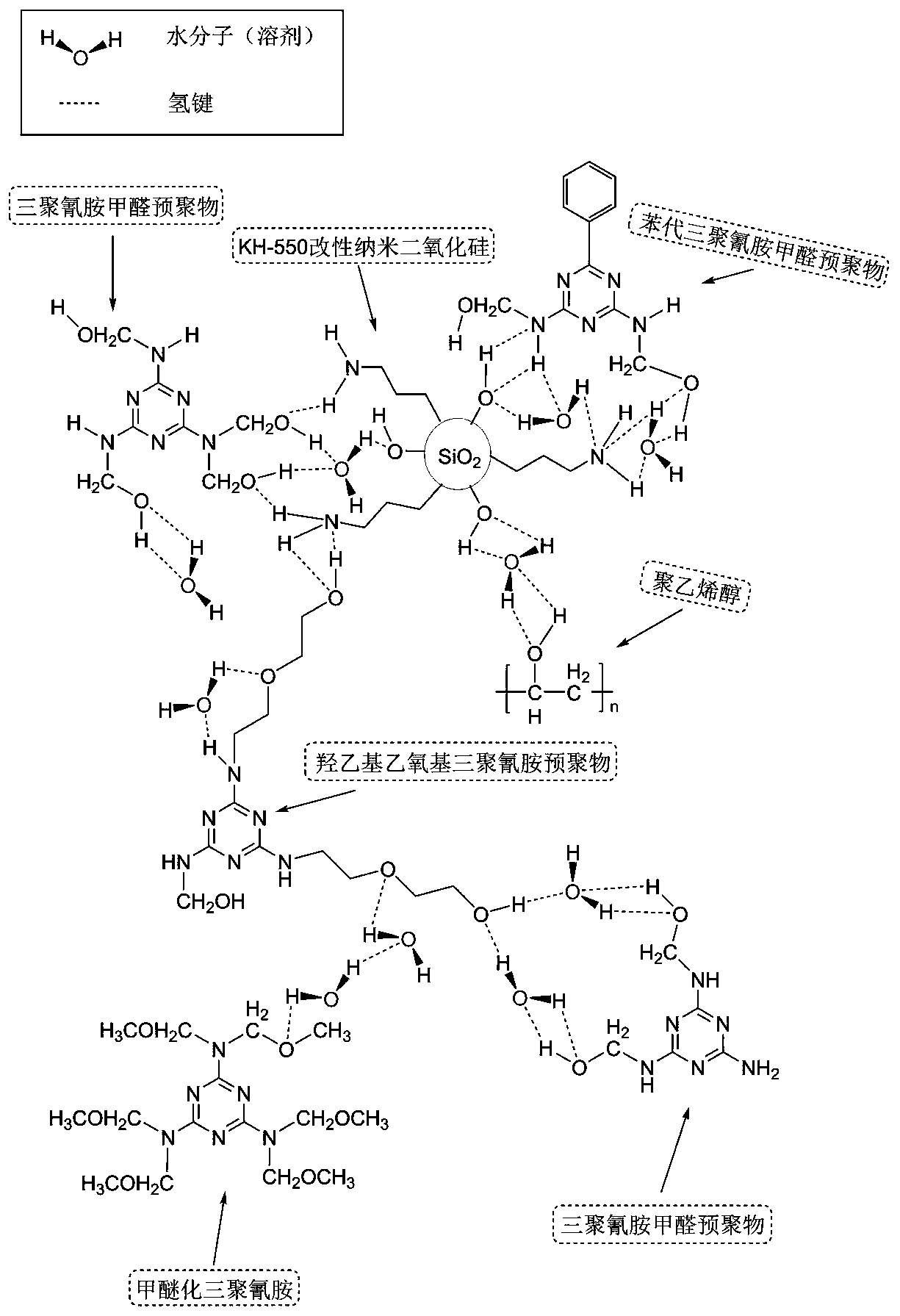

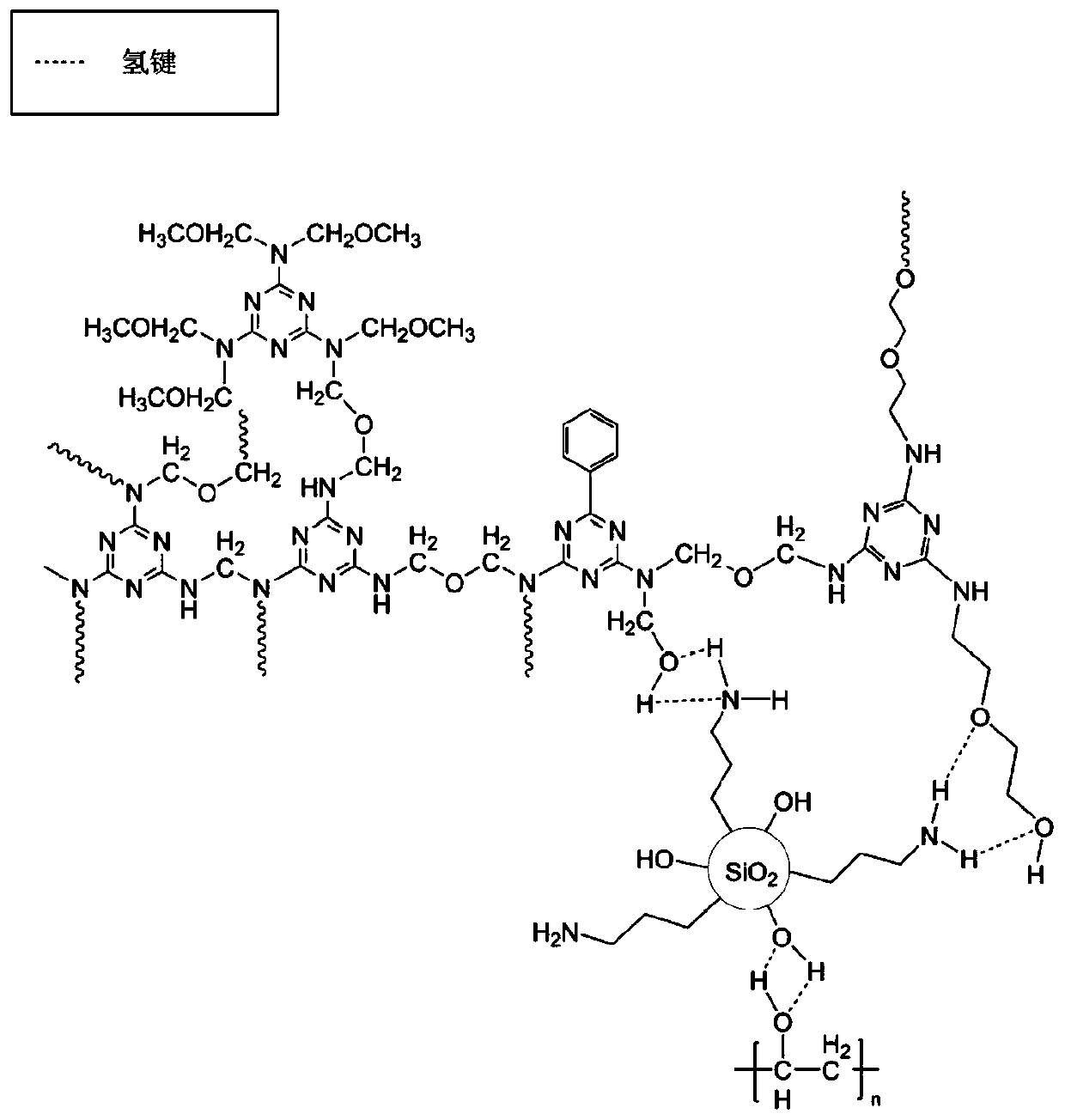

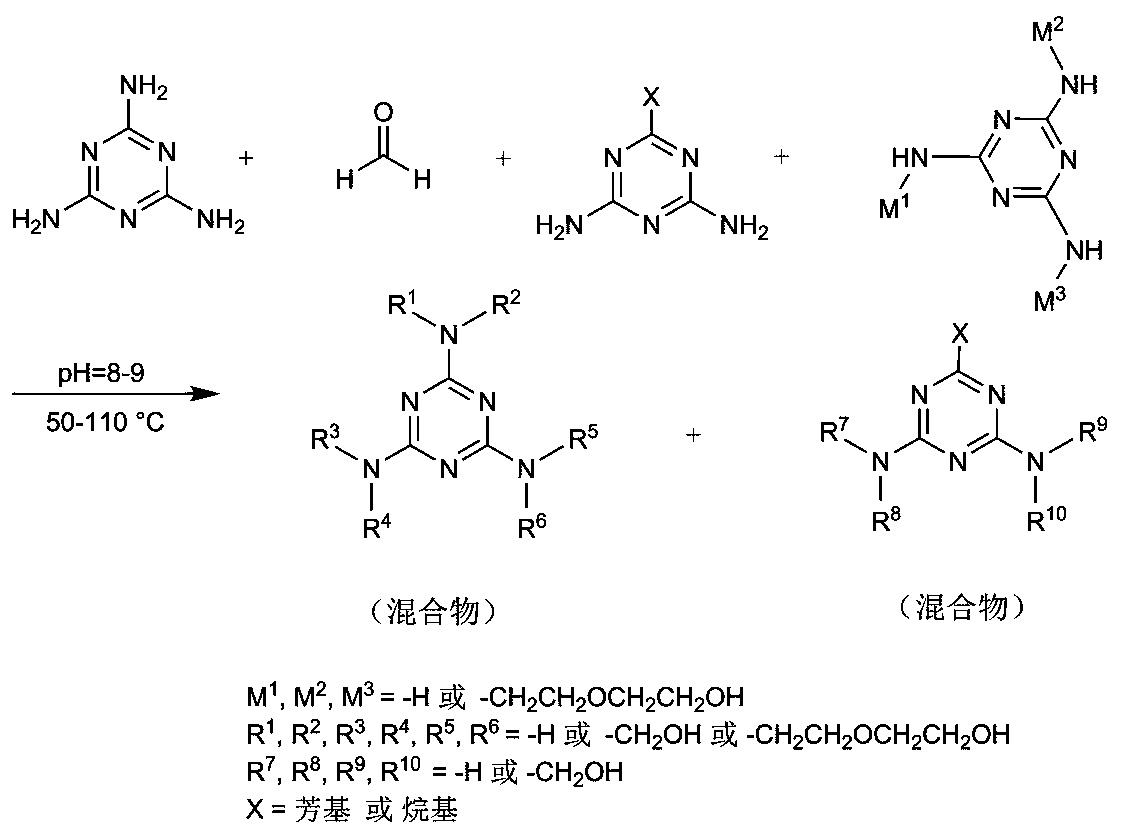

Method used

Image

Examples

Embodiment 1

[0066] Melamine 504.5g, benzomelamine 74.9g, 37wt% formaldehyde solution 792.8g, paraformaldehyde 43.2g, polyvinyl alcohol 11g, methyl etherified melamine 10g, hydroxyethyl melamine 20g, demineralized water 25g, modified by KH-550 Add 2g of nano-silica to a reaction kettle equipped with a thermometer, a pressure gauge, a mechanical stirrer, a reflux condenser, and an ultrasonic probe, add 4g of sodium hydroxide, adjust the pH to about 9, oscillate ultrasonically for 3 hours, and stir at 90°C After 6 hours, a spinning dope with a solid content of 66% was obtained. The storage time can reach 35 days, the fiber forming property is still good, and the viscosity is 2600Pa·s. The spinning stock solution is sent to the spinning process, pumped into the filter device by the metering pump, passed through the spinneret (the diameter of the spinneret hole is 0.12mm, the pressure is 3.5Mpa, and the temperature is about 40°C), and it is continuously formed into filaments, and then enters t...

Embodiment 2

[0068] Melamine 403.6g, methylguanamine 50.1g, 37wt% formaldehyde solution 642.2g, polyethylene oxide 10g, KH-550 modified nano silicon dioxide 1g, butylated melamine 10g, hydroxyethyl ethoxylate Base melamine 30g, demineralized water 50g, add in the reactor that is equipped with thermometer, pressure gauge, mechanical stirrer, reflux condenser, ultrasonic probe, add potassium hydroxide 3g, adjust pH to be 8-9, ultrasonic vibration 3 hours, 80 °C and stirred for 8 hours to obtain a spinning dope with a solid content of 62%. The storage time can reach 37 days, the fiber forming property is still good, and the viscosity is 3100Pa·s. The spinning stock solution is sent to the spinning process, pumped into the filter device by the metering pump, passed through the spinneret (the diameter of the spinneret hole is 0.06mm, the pressure is 6Mpa, and the temperature is about 40°C), and it is continuously formed into filaments, and enters the spinning chamber filled with acid gas. The tu...

Embodiment 3

[0070] Melamine 504.5g, methylguanamine 50.1g, 37wt% formaldehyde aqueous solution 648.6g, paraformaldehyde 91.2g, sodium carboxymethyl cellulose 20g, nano-silica 7.5g modified by KH-570, methylated Melamine 5g, hydroxyethyl ethoxy melamine 25g, demineralized water 100g, add in the reactor that is equipped with thermometer, pressure gauge, mechanical stirrer, reflux condenser, ultrasonic probe, add potassium hydroxide 4g, adjust pH to be about 9 , ultrasonically oscillated for 4 hours, and stirred at 90° C. for 7 hours to obtain a spinning dope with a solid content of 65%. The storage time can reach 33 days, the fiber forming property is still good, and the viscosity is 4200Pa·s. The spinning stock solution is sent to the spinning process, pumped into the filter device by the metering pump, passed through the spinneret (the diameter of the spinneret hole is 0.12mm, the pressure is 8.7Mpa, and the temperature is about 40°C), and it is continuously formed into filaments, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com