Material conveying method for prefabricated bag packing machine

A pre-made bag, packaging machine technology, applied in packaging and other directions, can solve the problems of low post-packaging efficiency, short conveying and packaging strokes, irregularities, etc., to achieve a high degree of continuous pushing, short conveying and packaging strokes, and high packaging efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] A material conveying method for a prefabricated bag packaging machine, comprising the following steps:

[0102] a. After being held or clamped, the material is transported along the opening direction of the prefabricated bag to the station to be pushed;

[0103] b. The left and right sides of the prefabricated bag are opened;

[0104] c. The material is pushed on the station to be pushed, the prefabricated bag moves, the material and the prefabricated bag form a relative movement, and the material is pushed into the prefabricated bag;

[0105] d. The material is pushed to the bottom of the prefabricated bag, and the material continues to move along the direction of being pushed along with the prefabricated bag;

[0106] e. The next material is conveyed circularly according to the above steps.

[0107] After being held or clamped, the material is transported to the station to be pushed along the opening direction of the prefabricated bag; the left and right sides of th...

Embodiment 2

[0109] The material conveying method of the prefabricated bag packaging machine, the specific steps are as follows:

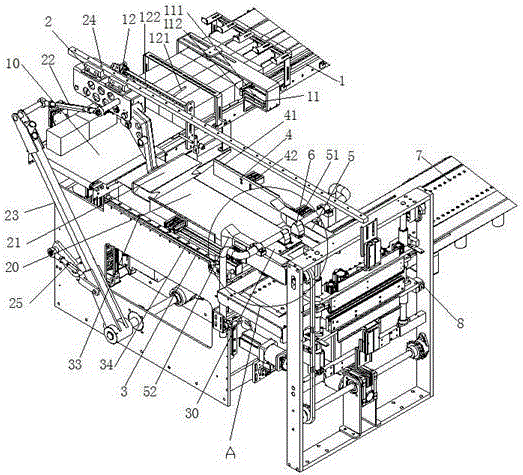

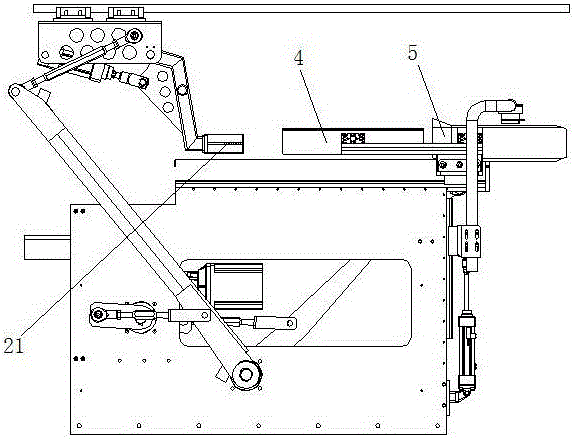

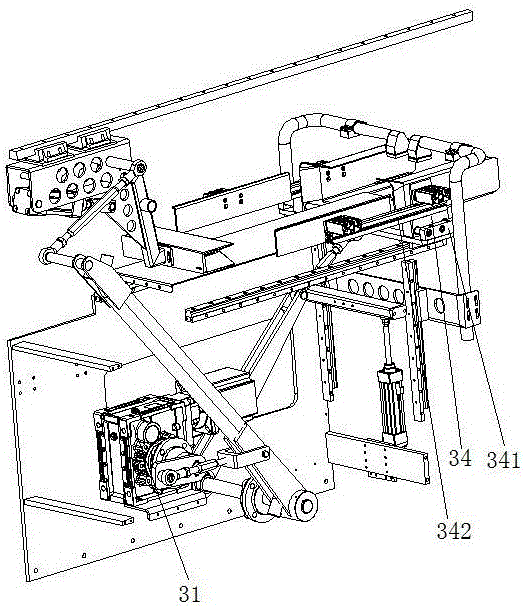

[0110] a. The material is held or clamped along the opening direction of the prefabricated bag and transported to the station to be pushed; the station to be pushed is provided with a pushing mechanism 2;

[0111] b. After the upper and lower sides of the mouth of the prefabricated bag are opened, the bag opening mechanism 5 extends into the prefabricated bag to open the left and right sides of the mouth of the prefabricated bag;

[0112] c. The pushing mechanism 2 pushes the material, and the prefabricated bag moves under the action of the bag opening mechanism 5, and the material and the opened prefabricated bag form a relative movement, and the material is pushed into the prefabricated bag;

[0113] d. When the material reaches the bottom of the prefabricated bag, the pushing mechanism 2 continues to push the prefabricated bag away from the bag stretching me...

Embodiment 3

[0117] The material conveying method of the prefabricated bag packaging machine, the specific steps are as follows:

[0118] a. The material is held or clamped along the opening direction of the prefabricated bag and transported to the station to be pushed; the station to be pushed is provided with a pushing mechanism 2;

[0119] b. After the upper and lower sides of the mouth of the prefabricated bag are opened, the bag opening mechanism 5 extends into the prefabricated bag to open the left and right sides of the mouth of the prefabricated bag;

[0120] c. The pushing mechanism 2 pushes the material, and the prefabricated bag moves under the action of the bag opening mechanism 5, and the material and the opened prefabricated bag form a relative movement, and the material is pushed into the prefabricated bag;

[0121] d. When the material reaches the bottom of the prefabricated bag, the pushing mechanism 2 continues to push the prefabricated bag away from the bag stretching me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com