Patents

Literature

49results about How to "Good conveying stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

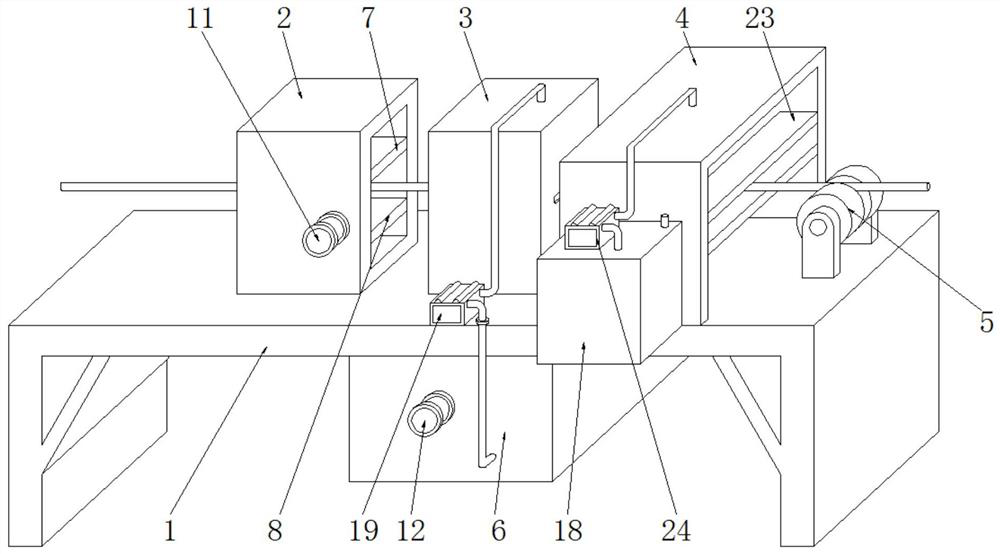

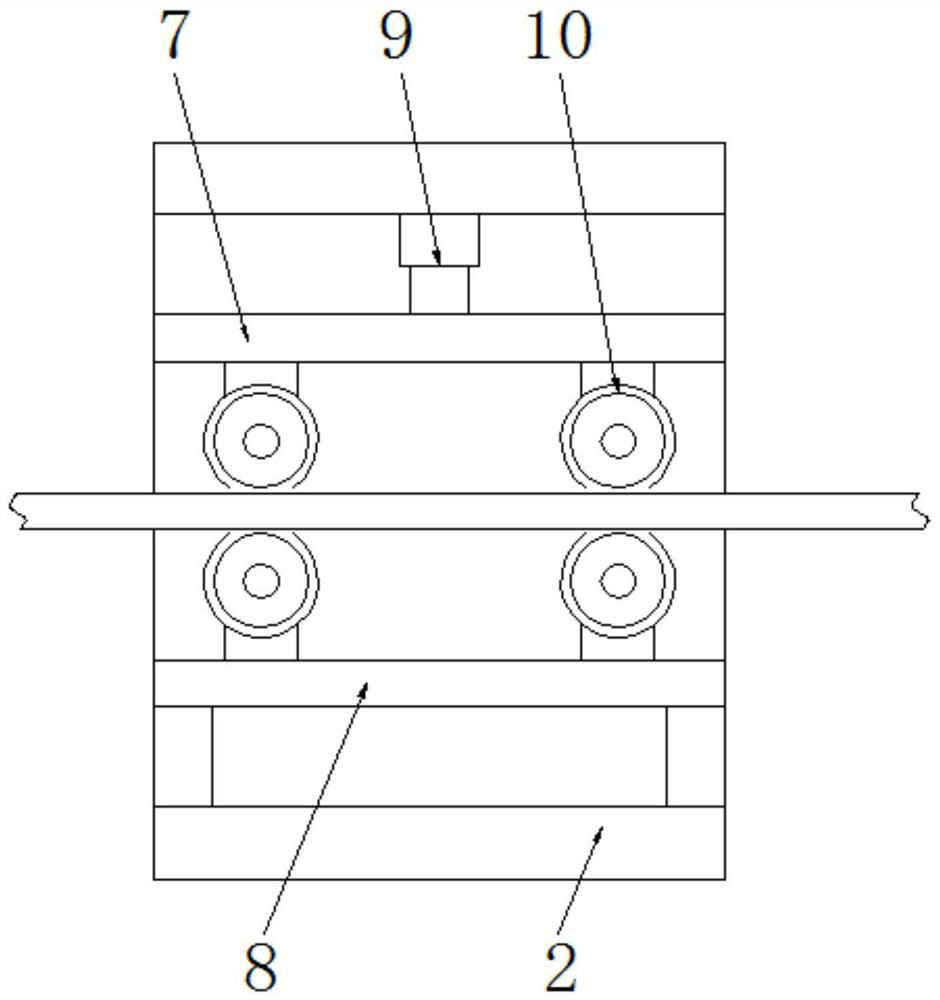

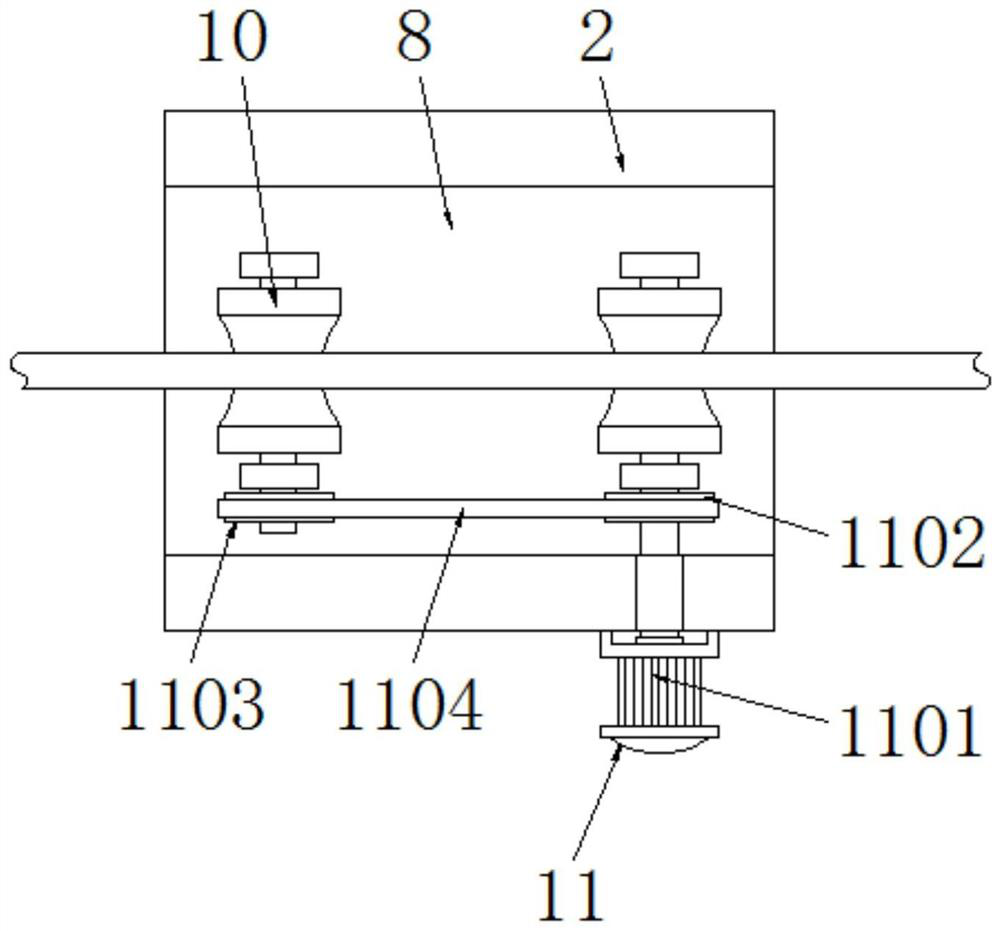

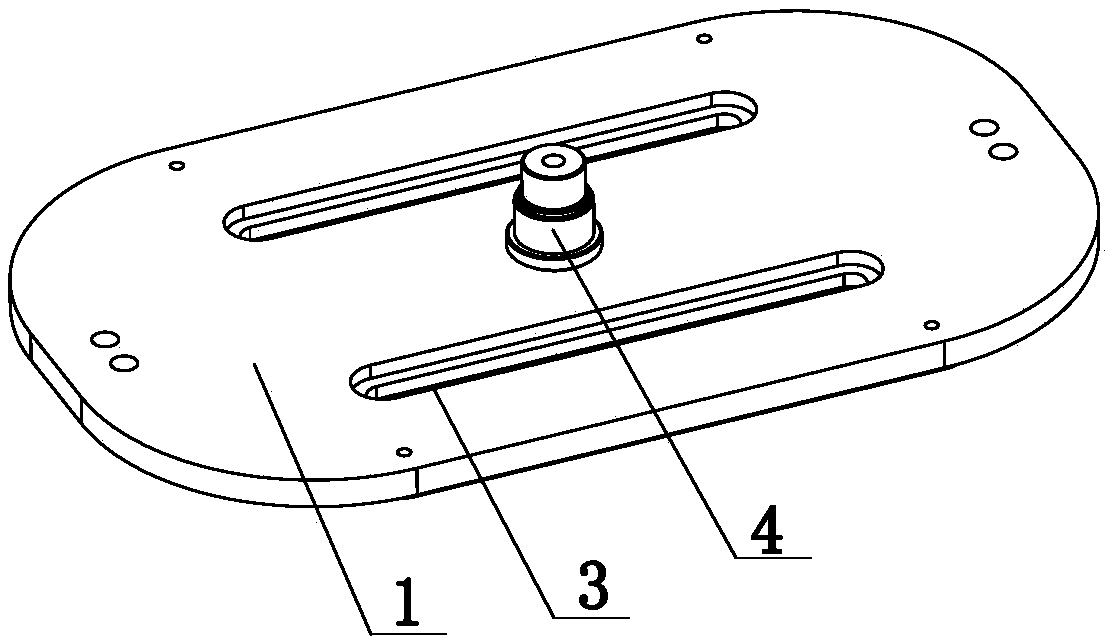

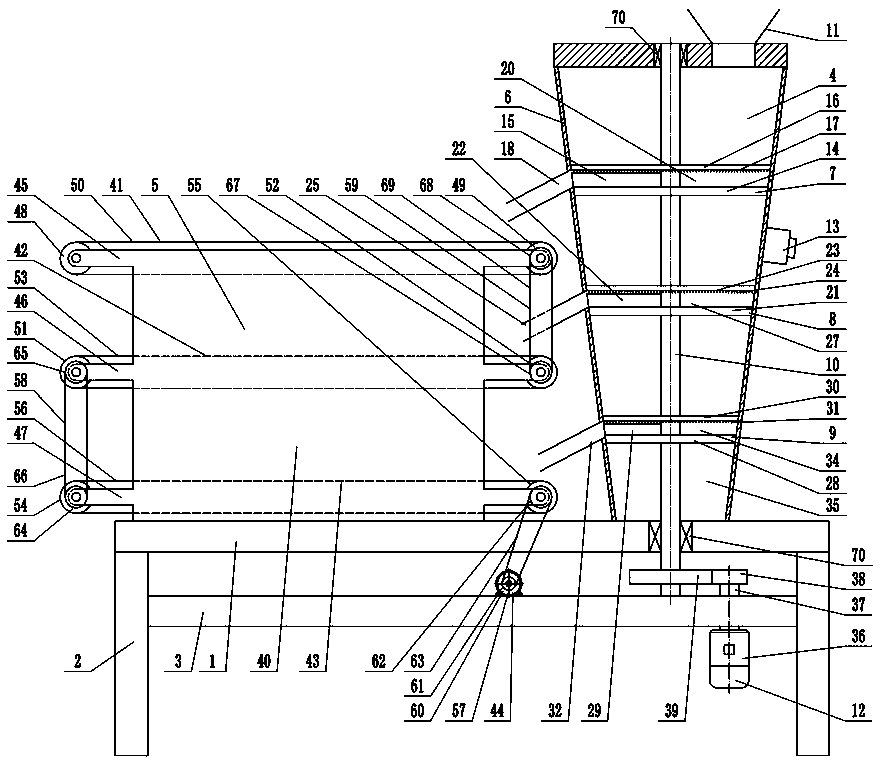

Continuous anti-corrosion treatment equipment and process for rods and wires

PendingCN112427171AGuaranteed water sprayGuaranteed anti-corrosion performancePretreated surfacesLiquid spraying apparatusWire rodReciprocating motion

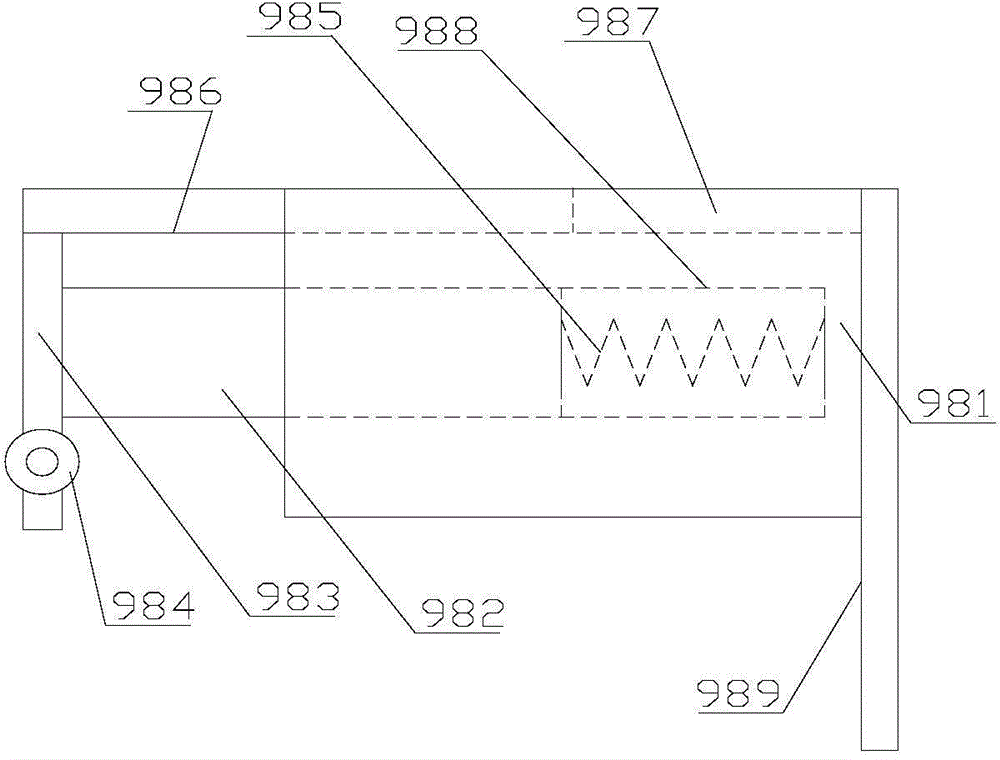

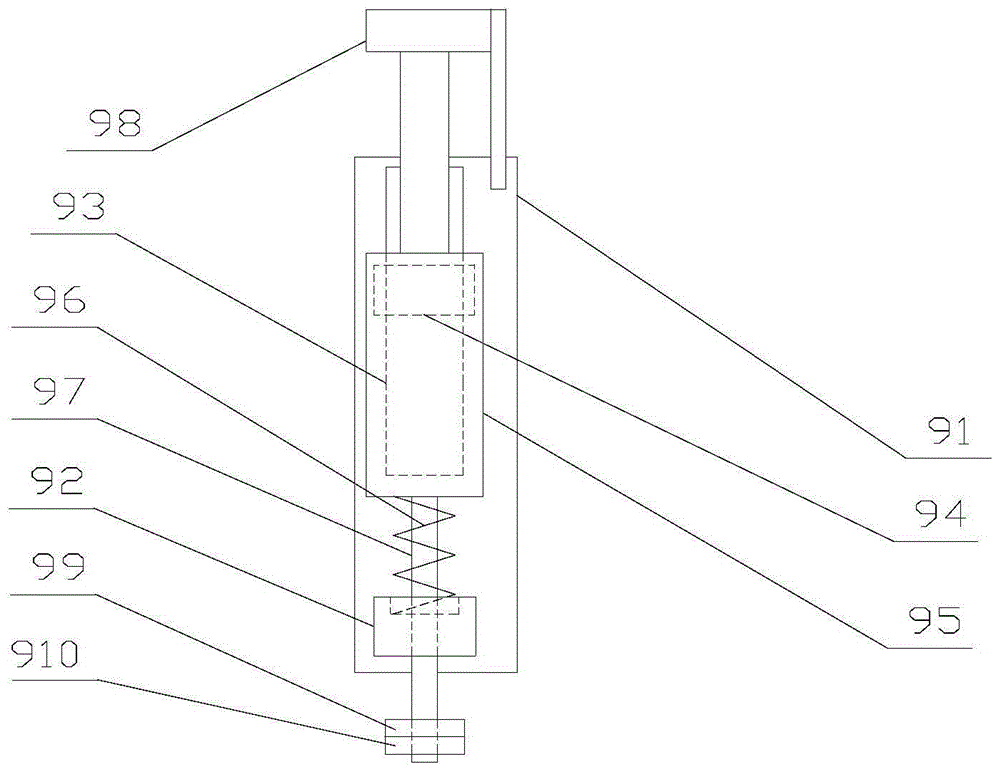

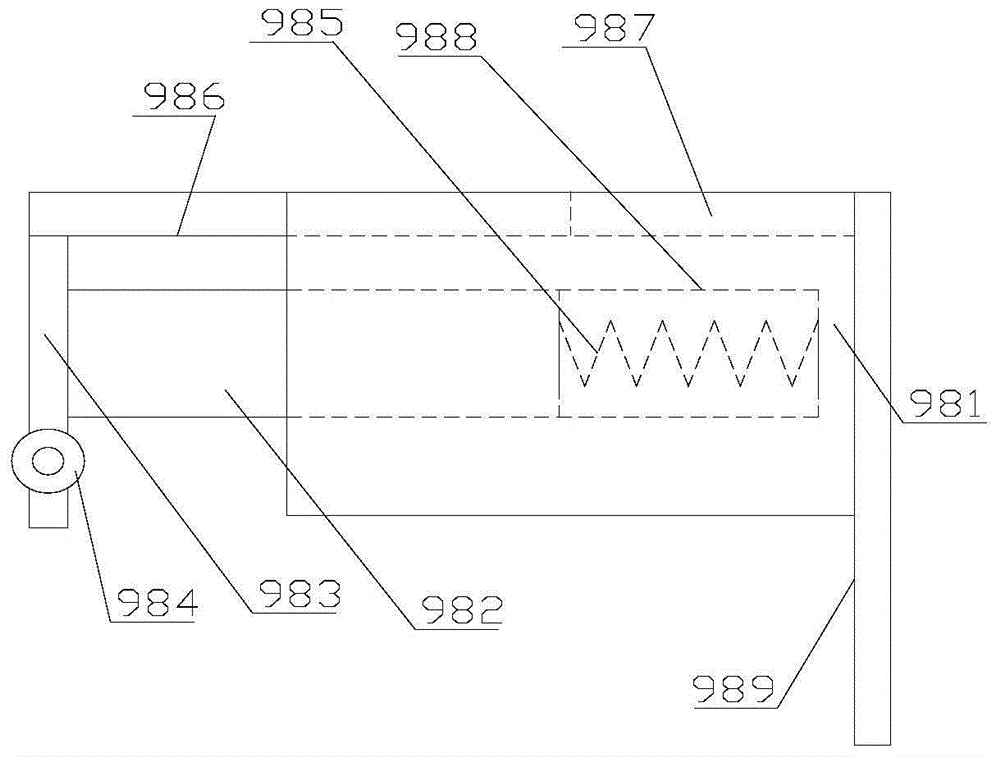

The invention discloses continuous anti-corrosion treatment equipment and a process for rods and wires, and belongs to the technical field of anti-corrosion treatment of rods and wires. The continuousanti-corrosion treatment equipment comprises a workbench, wherein a conveying frame, a cleaning box, an anti-corrosion spraying frame and a supporting roller are sequentially installed on the upper surface of the workbench from left to right, a water tank is installed on the lower surface of the workbench through bolts, and a first supporting plate and a second supporting plate are arranged in the conveying frame. By arranging the conveying frame, rapid conveying of rods and wires is achieved, the structure is simple, and the conveying stability is good; water in the water tank is pumped through a high-pressure water pump and sprayed out through first spraying heads, high-pressure washing can be conducted on the surfaces of the rods and wires to remove rust, the surfaces of the rods and wires can be treated to remove the rust before anticorrosive paint is sprayed, and the anticorrosive effect of the anticorrosive paint sprayed in the later period is guaranteed; and by arranging an adjusting part and a residue filtering net, it is guaranteed that the residue filtering net reciprocates up and down to vibrate through the cooperation of cam rotation and springs to avoid mesh blockage,and therefore smooth proceeding of the residue filtering net is ensured.

Owner:河北敬业钢构科技股份有限公司

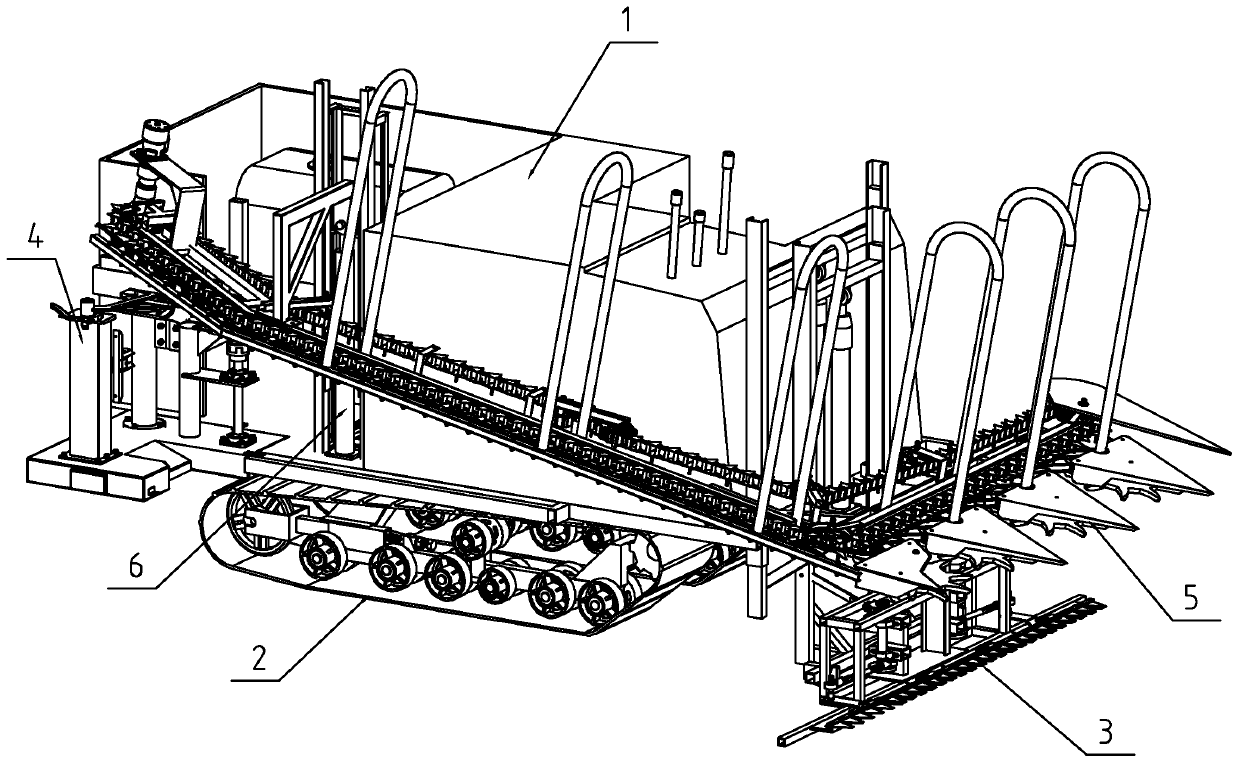

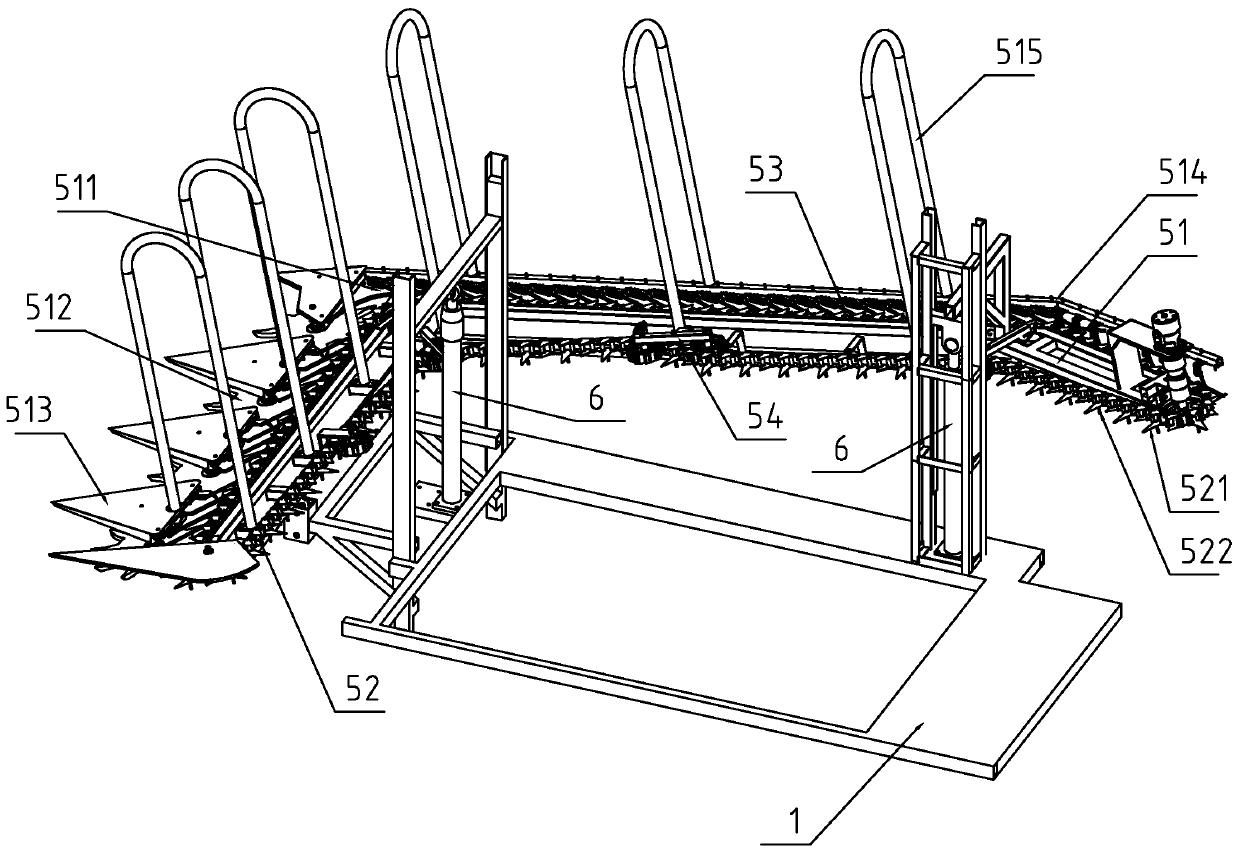

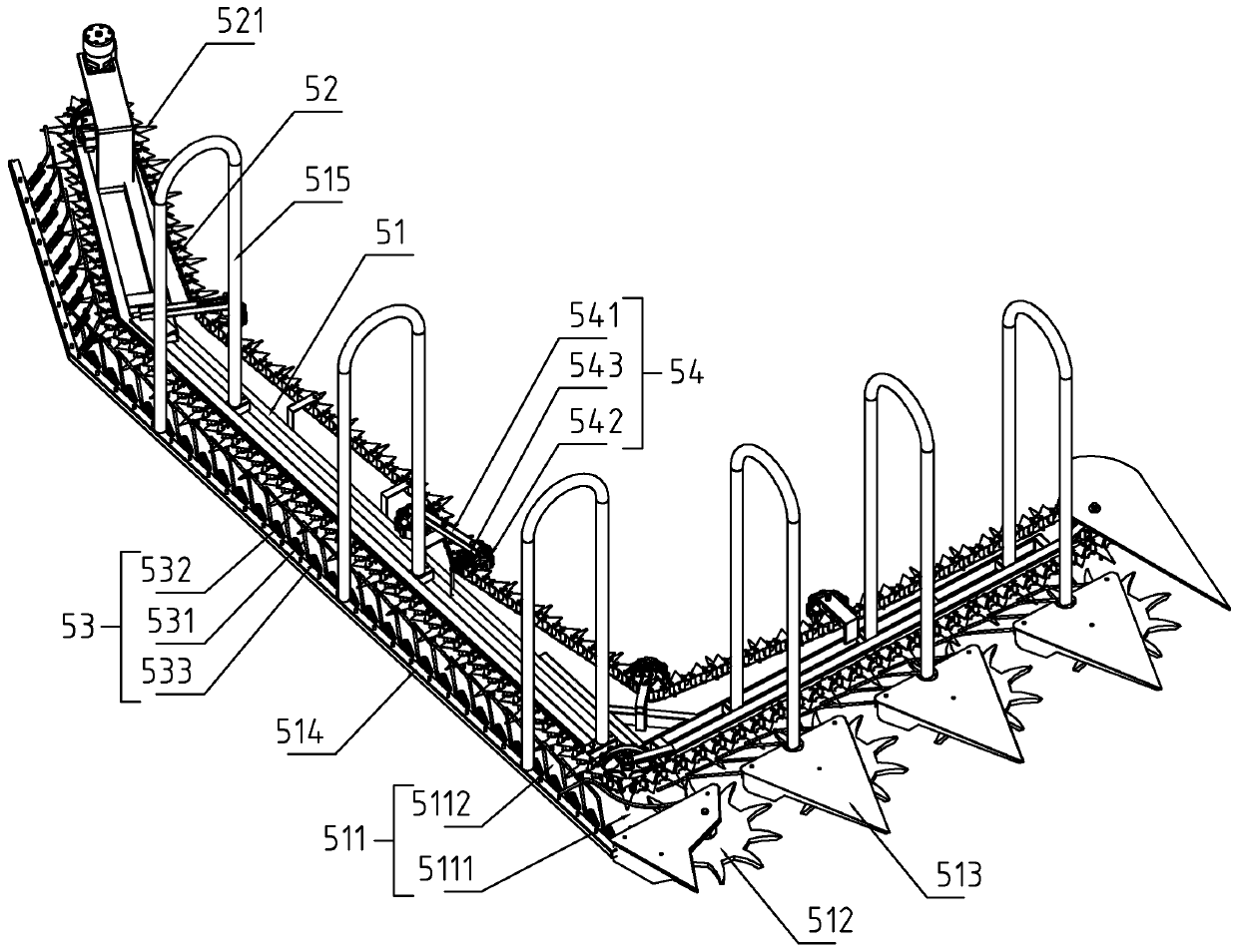

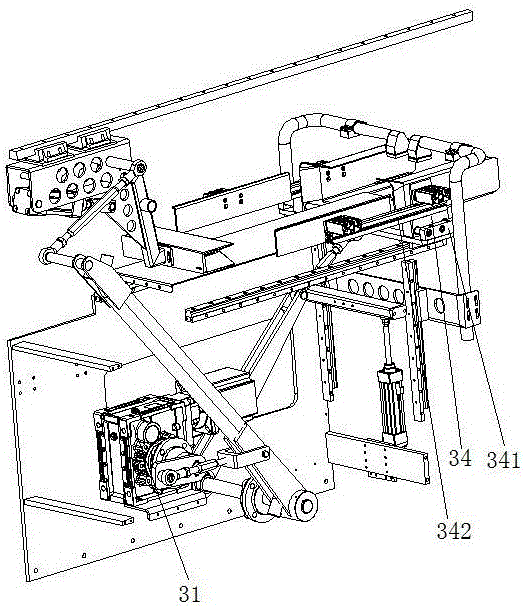

Sheaf-binding reaping machine for ramie

PendingCN110122050AEfficient deliveryRealize deliveryReaper-bindersEngineeringMechanical engineering

The invention discloses a sheaf-binding reaping machine for ramie. The technical scheme is characterized in that the machine comprises a machine body, a power walking mechanism, a cutter mechanism, aclamping and conveying mechanism and a binding mechanism, wherein the feeding end of the clamping and conveying mechanism is located above the cutter mechanism, the binding mechanism is located at thedischarging end of the clamping and conveying mechanism, and the clamping and conveying mechanism comprises a rack and a conveying channel arranged on the rack; a conveying chain is rotationally connected to the rack and located on one side of width of the conveying channel, and stirring pieces are arranged on the conveying chain; a pushing device is arranged on the other side of width of the conveying channel and comprises elastic stirring rods which are arranged in the length direction of the conveying channel, and blocking rods are arranged at the ends of the elastic pulling rods; stirringwheels and blocking plates are rotationally connected with the feeding end of the conveying channel, and are located on two opposite sides of the feeding end of the conveying channel. The sheaf-binding reaping machine can overcome unstable conveying, easy blockage, easy breaking of ramie and the like.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

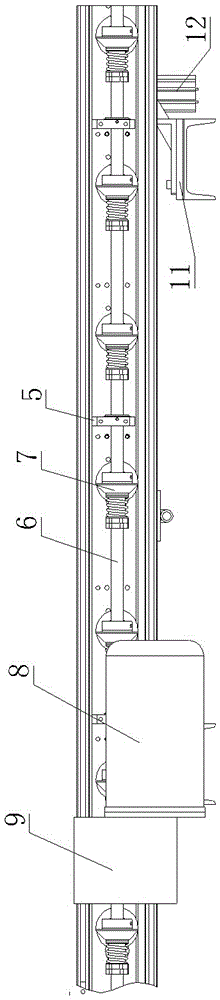

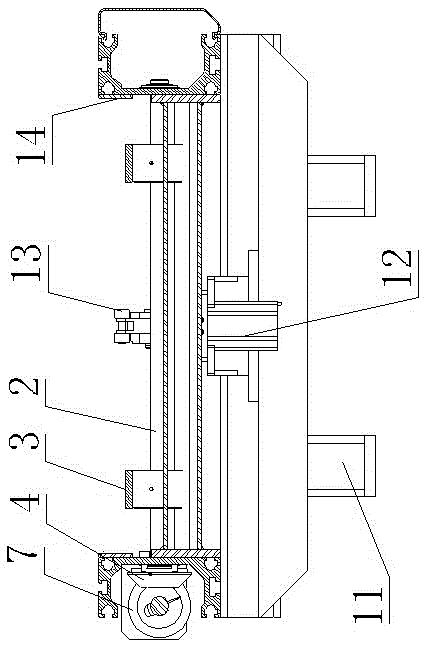

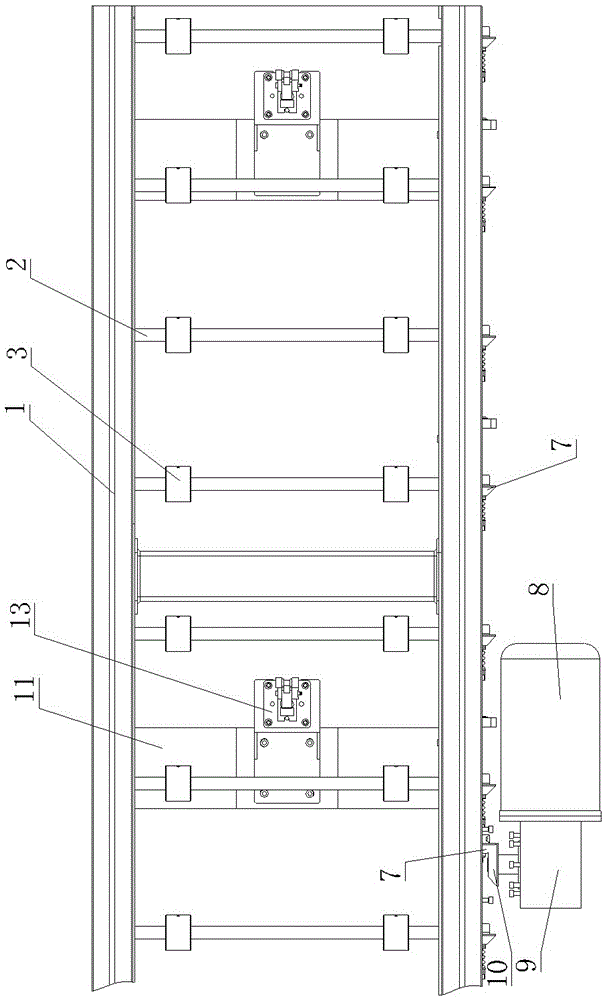

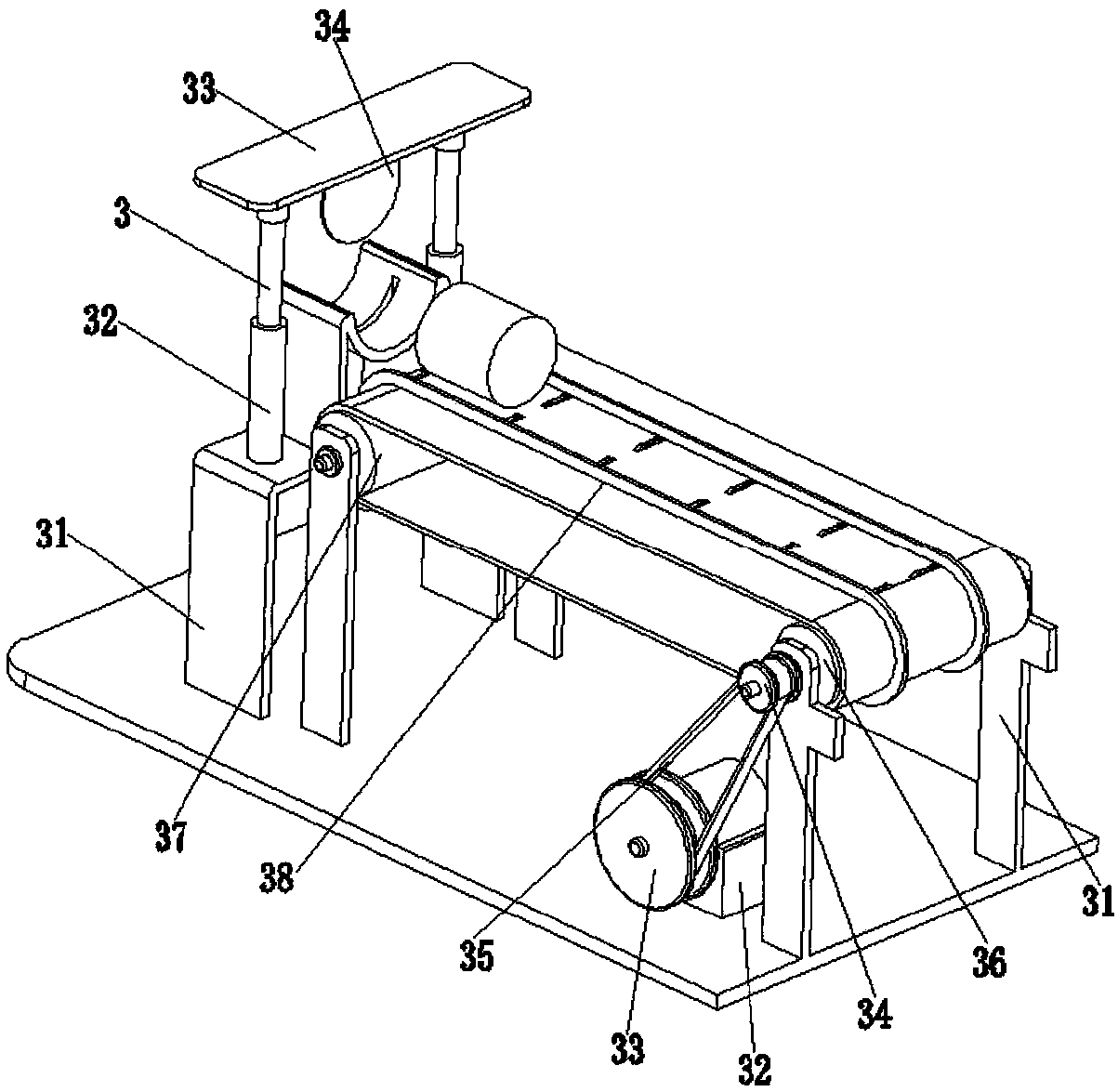

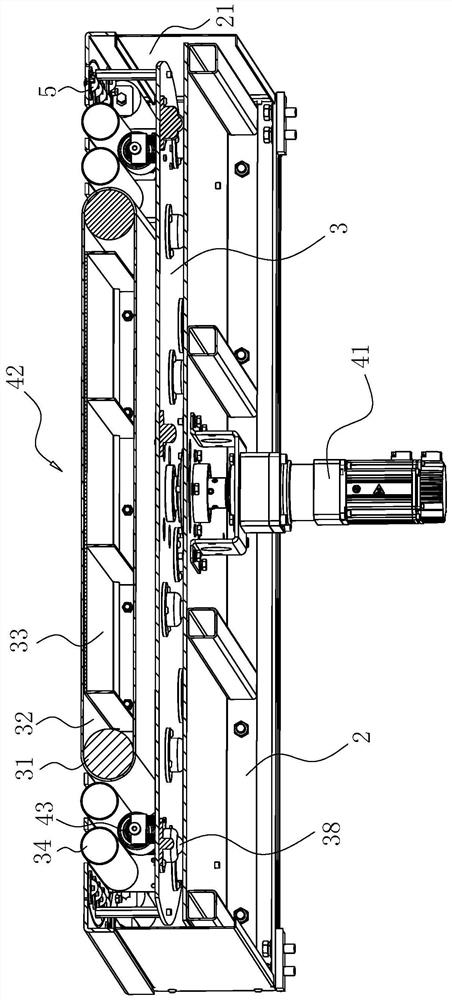

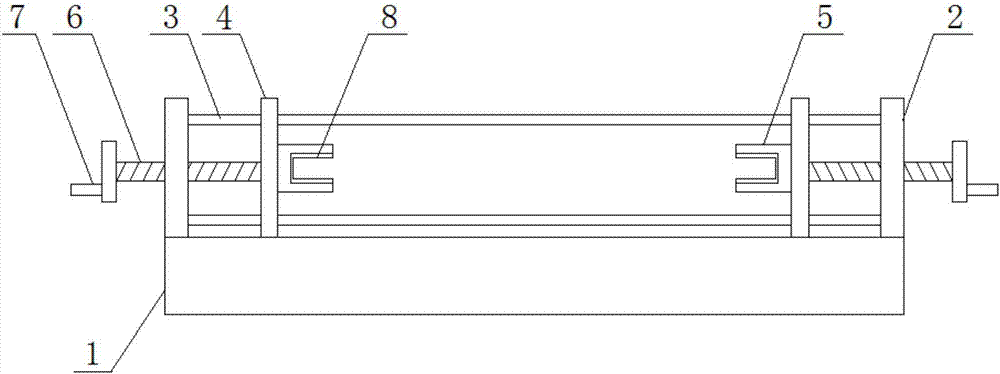

Conveying device of production line

InactiveCN106743073AConstant conveying speedAvoid collisionRollersRoller-waysProduction lineGear wheel

The invention provides a conveying device of a production line. The conveying device is simple in structure, the conveying speed of a conveying rail is constant, conveying can be carried out in cooperation with the production takt of an assembly line, and the conveying stability is good. The conveying device comprises the conveying rail, conveying rollers are distributed on the conveying rail at intervals, the two ends of each conveying roller are installed on the side walls of the two ends of the conveying rail through bearings, and one end of each conveying roller extends into the corresponding side wall of the conveying rail to be provided with a first bevel gear wheel; the outer side of the conveying rail is provided with a driving shaft through a supporting frame in the length direction of the conveying rail, the supporting frame is provided with a bearing to be matched with the driving shaft to rotate, and second bevel gear wheels meshed with the corresponding first bevel gear wheels are arranged on the driving shaft in the manner of corresponding to the first bevel gear wheels; and a conveying motor is arranged on the outer side of the conveying rail and is connected with a conveying reduction box, a third bevel gear wheel is arranged on an output shaft of the conveying reduction box and is meshed on one second bevel gear wheel, and therefore the conveying motor can drive the conveying rollers to rotate.

Owner:WUXI MINGZHU STEEL BALL

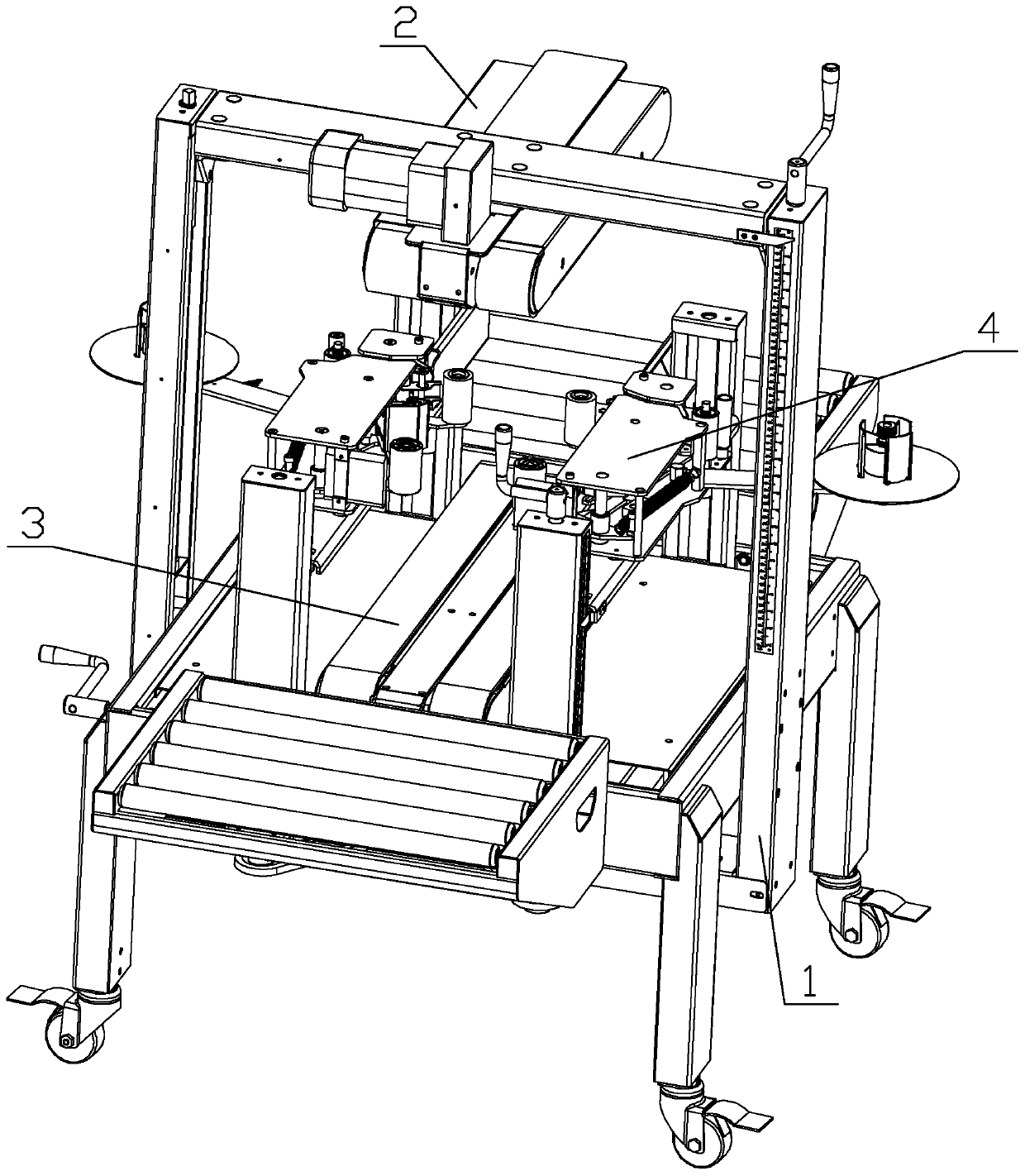

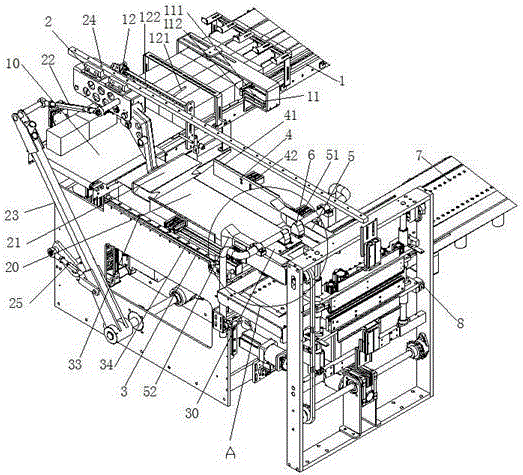

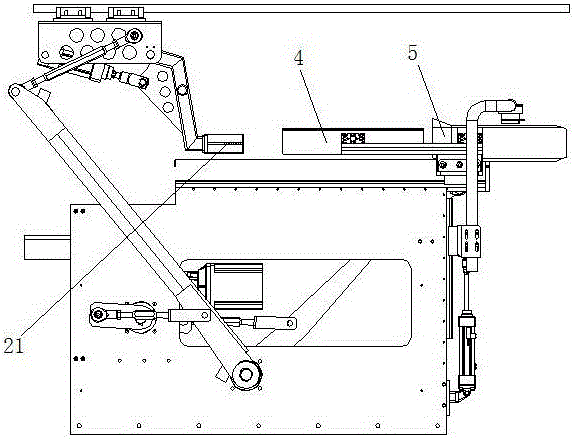

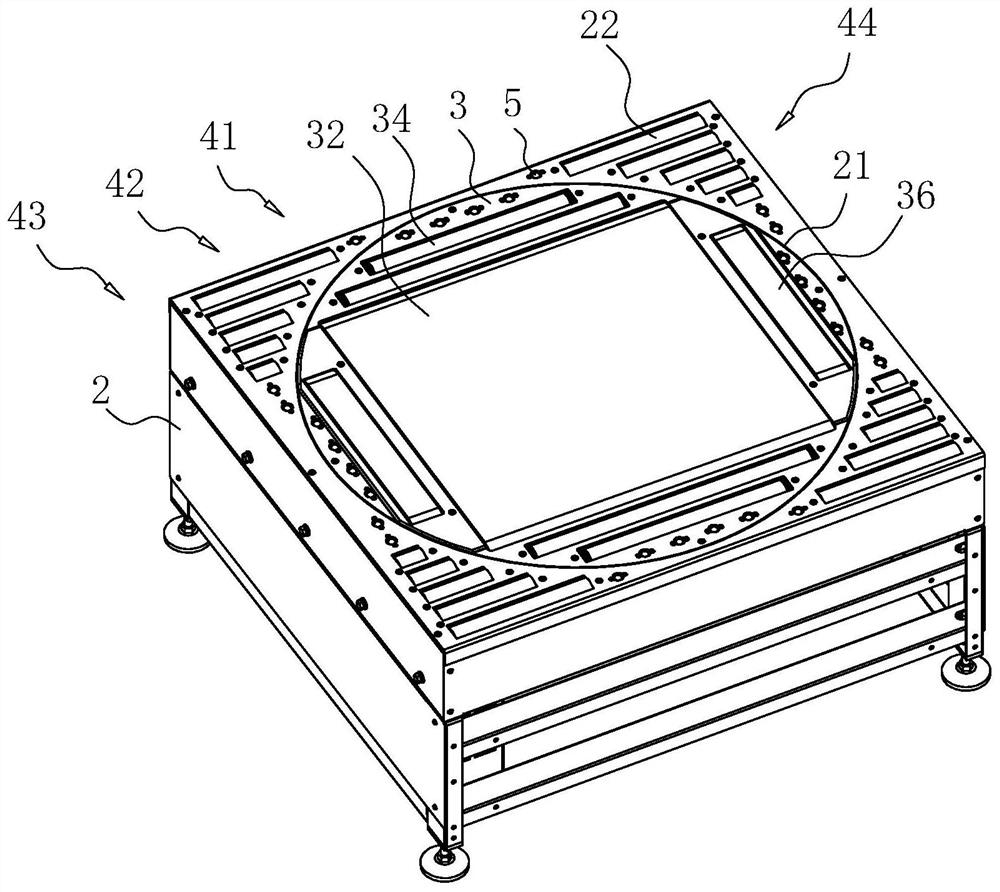

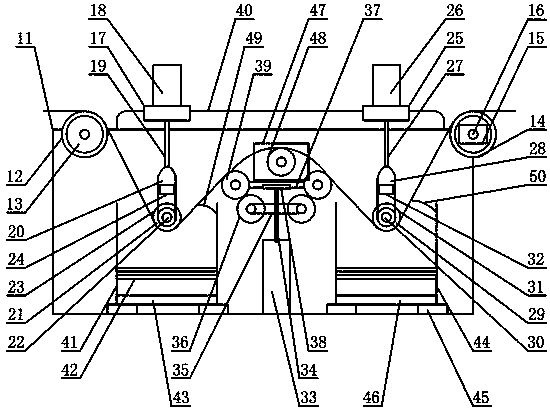

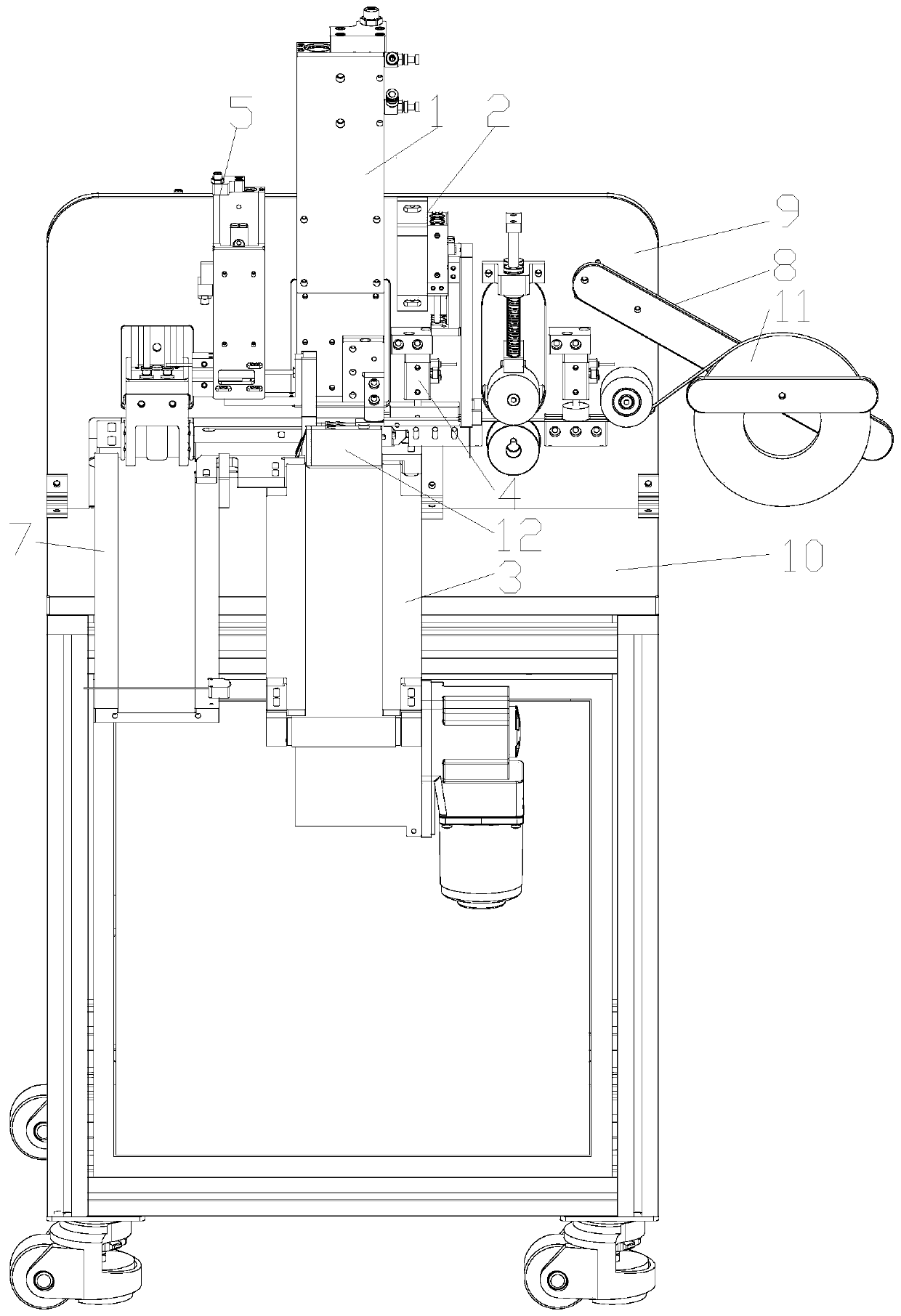

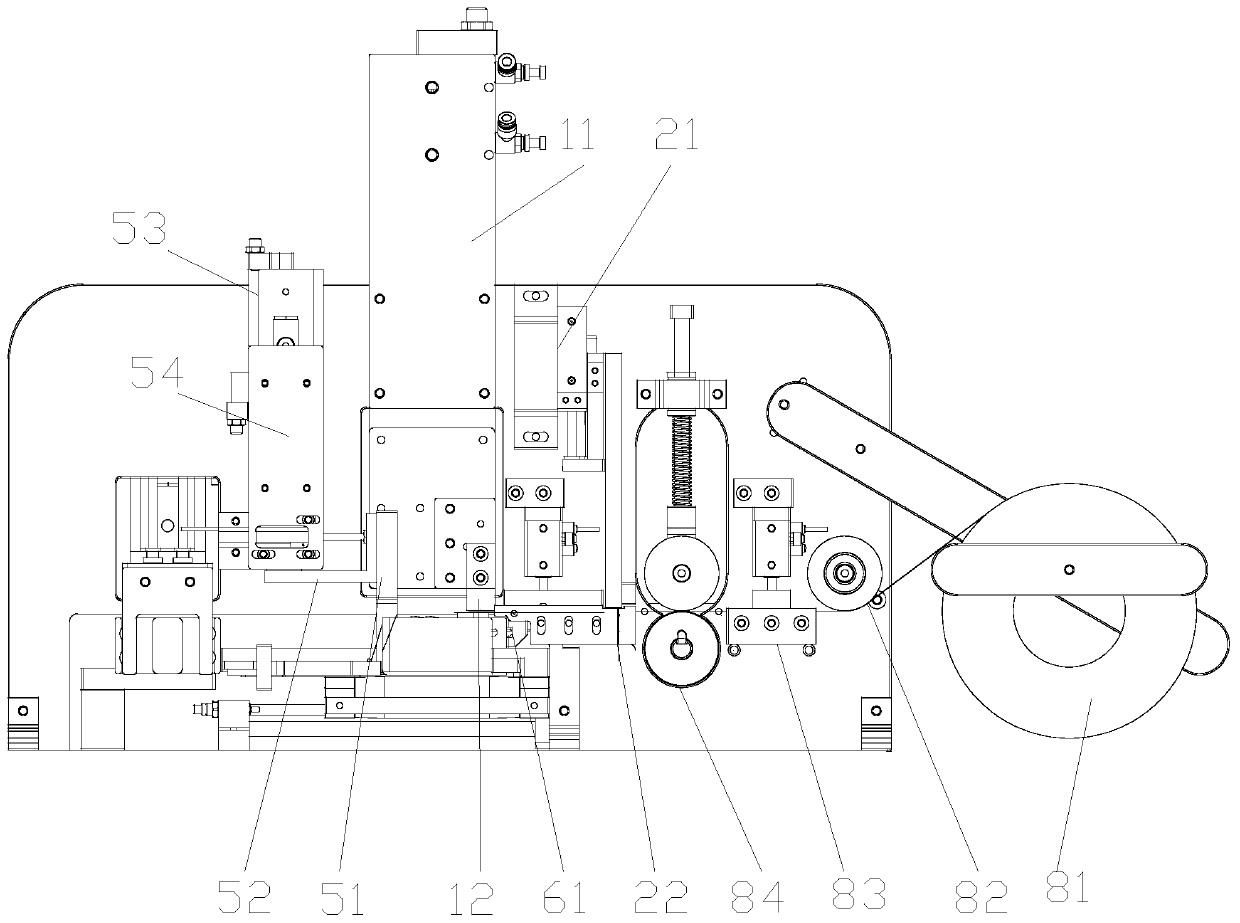

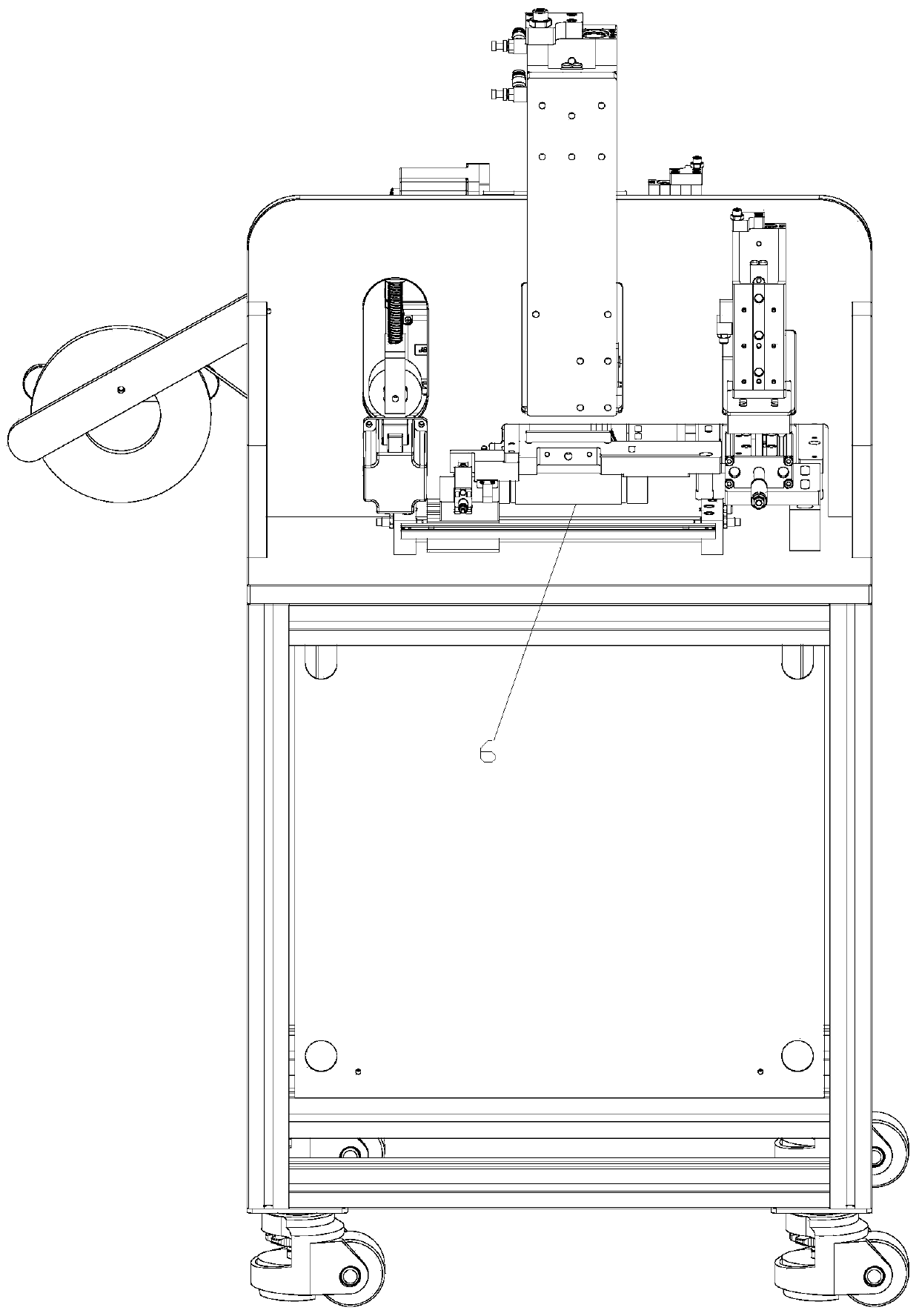

Side sealing box sealing machine

PendingCN110789785AImprove debugging efficiencyImprove support stabilityWrapper twisting/gatheringPhysicsSprocket

The invention discloses a side sealing box sealing machine. A rack of the side sealing box sealing machine comprises an upper frame and a lower frame. The upper frame is arranged on the lower frame ina vertical sliding manner. Upper conveying belts and machine cores are arranged on upper supports, and lower conveying belts are arranged on lower supports. Vertical shafts are arranged on the lowersupports, and the upper supports can be arranged on the vertical shafts in a vertical sliding manner. Chain wheels are arranged on the two sides of the upper frame, a chain is wound around the chain wheels, and an upper section and a lower section of the chain are connected with the upper supports on the two sides. A second driving mechanism drives the upper supports to ascend and descend on the vertical shafts. When a first driving mechanism drives the upper support on one side to move horizontally, the chain moves clockwise or anticlockwise so as to drive the upper supports on the two sidesto synchronously get close to each other or get away from each other on second transverse shafts, and the lower supports horizontally move synchronously. By means of the side sealing box sealing machine, the upper conveying belts and the machine cores on the two sides can ascend and descend synchronously, and the debugging efficiency is improved; and the upper conveying belts and the lower conveying belts are arranged on the two edges, supporting and conveying can be conducted above and below the two sides, and stability is improved.

Owner:ZHEJIANG DINGYE MACHINERY

High concn. solid/water slurry and process for producing same

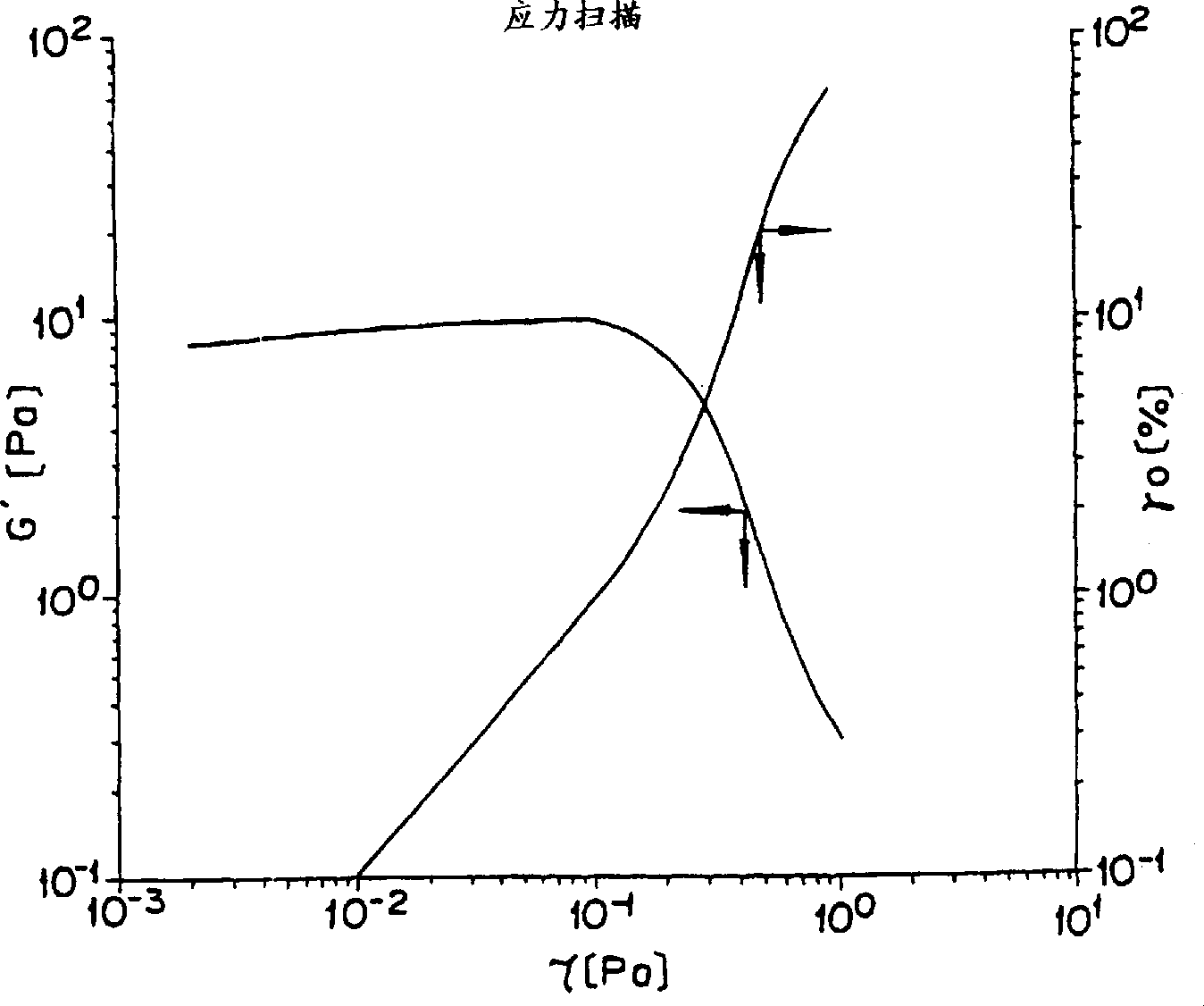

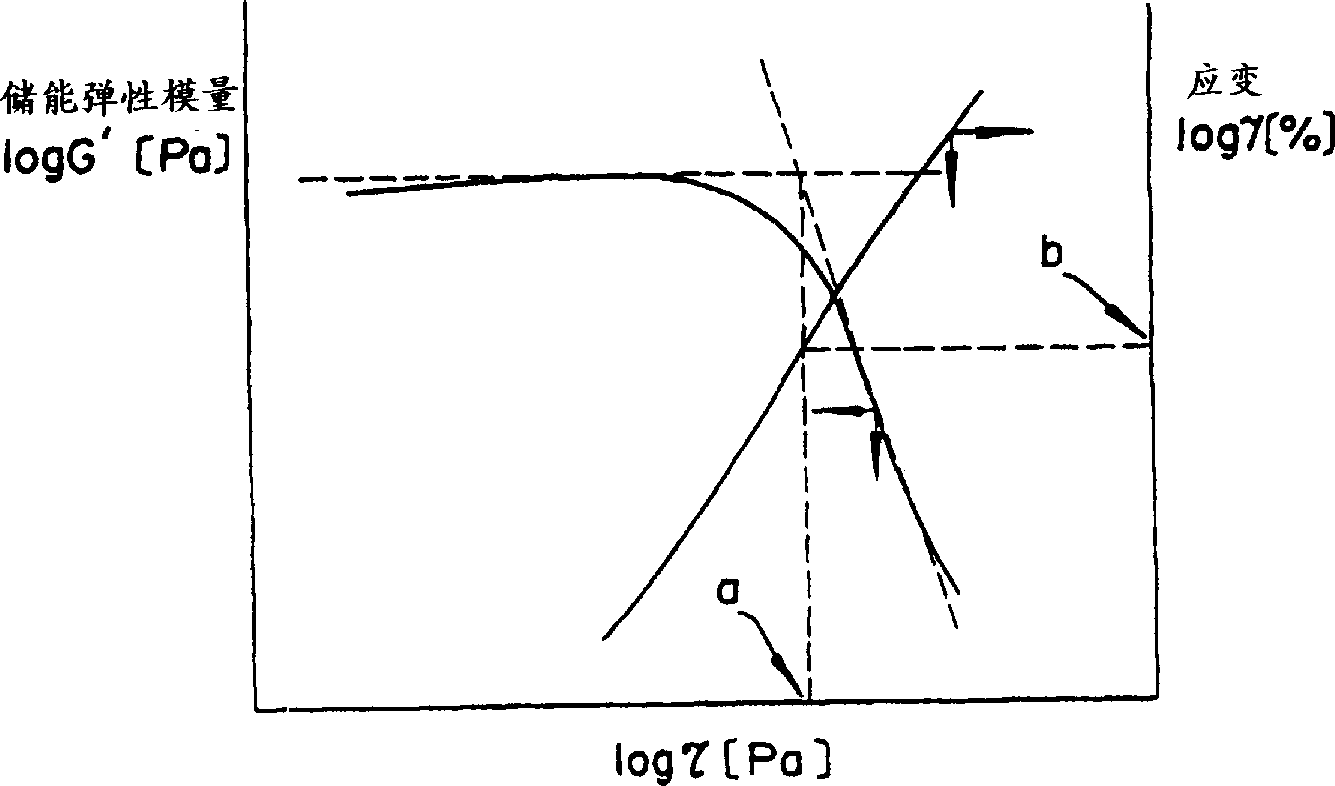

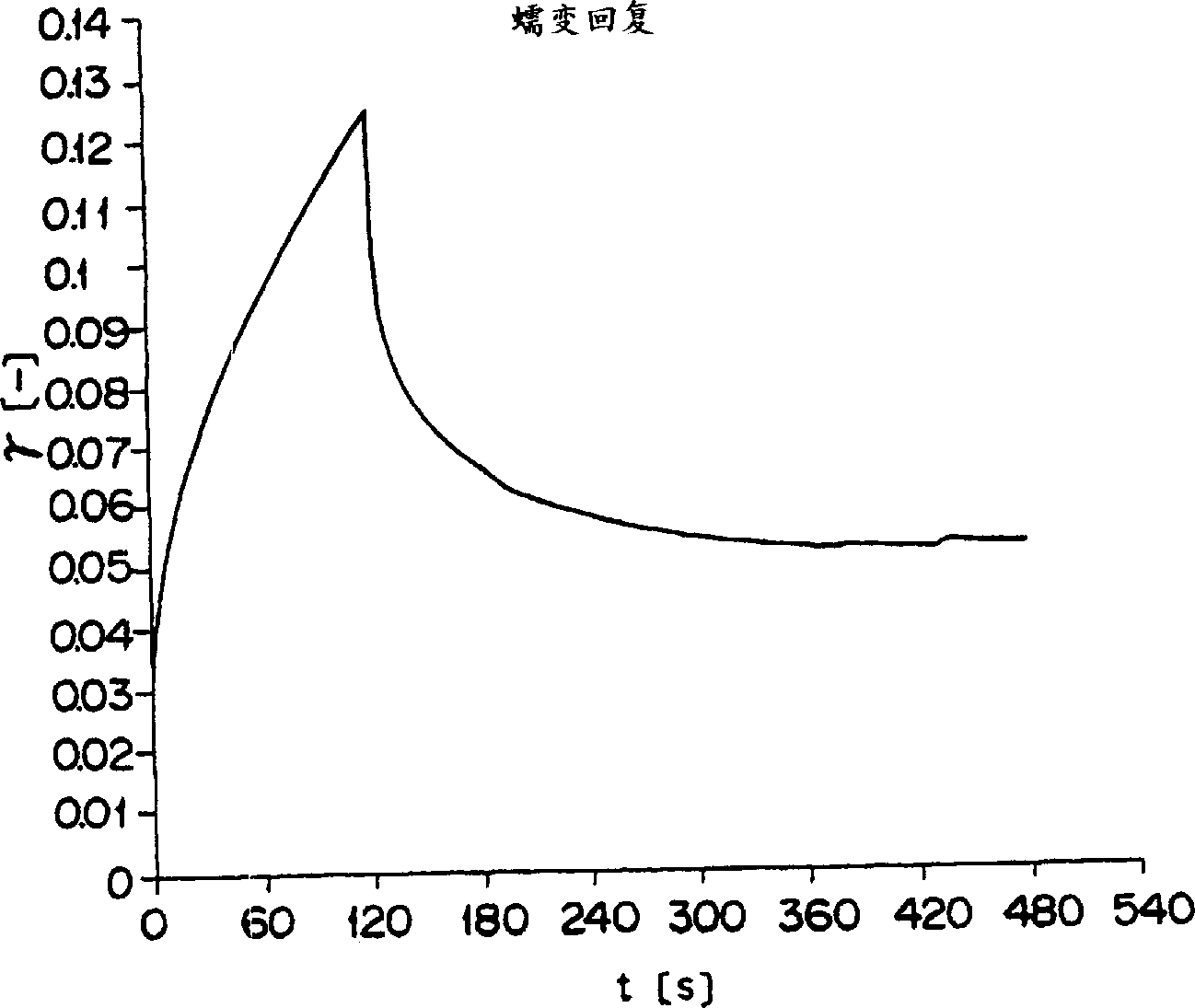

InactiveCN1259985AImprove liquidityGood storage stabilityLiquid carbonaceous fuelsHigh concentrationDynamic viscoelasticity

A high-concentration solid / water slurry which has a high fluidity and excellent storability and transportation stability, and a process for producing the same. In the stress sweeping test for the determination of the dynamic viscoelasticity of this slurry, the maximum stress in a linear-elasticity region as determined at an oscillation frequency of 1 Hz is 0.3 to 10 Pa, and the strain of the slurry yielding the maximum stress in the linear-elasticity region is 2 % or higher. In the creep recovery test value determined in the linear elasticity region for the determination of the static viscoelasticity of the slurry, the elastic modulus of a Maxwell element analyzed by assuming a four-constant mechanical model based on Hookean elasticity and Newtonian viscosity is 8 to 70 Pa, and the elastic modulus of the Voigt element is 3 to 70 Pa.

Owner:NIPPON SHOKUBAI CO LTD

Material conveying method for prefabricated bag packing machine

The invention discloses a material conveying method for a prefabricated bag packing machine, and belongs to the technical field of material packing. The material conveying method is characterized by comprising the following steps that (a), material after being held or clamped is conveyed to a station to be pushed in the opening direction of a prefabricated bag; (b), the left side and the right side of the prefabricated bag are opened; (c), the material is pushed on the station to be pushed, the precast bag is moved, the material and the prefabricated bag perform opposite motion, and the material is pushed into the prefabricated bag; (d), the material is pushed to the bottom of the prefabricated bag, and the material continues moves along with the prefabricated bag in the pushed direction; (e), next material is cyclically conveyed according to the steps. The material conveying method disclosed by the invention has the characteristics that the material pushing serialization degree is high, the conveying and packing distance is short, the materials cannot fall, and the conveying and packing efficiency is high.

Owner:上海松川峰冠包装自动化有限公司

Conveying rail for feeding device of bearing marking machine

ActiveCN104589808AAvoid damageReduce workloadTypewritersOther printing apparatusDrive shaftAgricultural engineering

The invention discloses a conveying rail for a feeding device of a bearing marking machine. The conveying rail comprises a frame, a motor, a longitudinal adjusting plate, a fixing plate, a transverse adjusting plate, a transmission shaft, a first gear, a second gear, a push mechanism, a first connecting frame and a second connecting frame, the fixing plate is arranged on a platform of the frame, the motor and the transmission shaft are arranged below the platform of the frame, the first connecting frame and the first gear are arranged on a rotating shaft of the motor, the first gear is arranged in the rear of the first connecting frame, the first connecting frame penetrates the platform of the frame, the longitudinal adjusting plate is arranged above the platform of the frame, the second gear and the second connecting frame are arranged on the transmission shaft, the second gear is meshed with the first gear, the second connecting frame penetrates the platform of the frame, and the transverse adjusting plate and the push mechanism are arranged above the platform of the frame. Compared with the prior art, the conveying rail can be conveniently adjusted, time is saved, workload of workers is decreased, damage of a bearing is avoided, product quality is kept, and conveying stability is fine.

Owner:XINCHANG JINTAO BEARING

Ash-slag water stable transportation control system and control device thereof

InactiveCN106701207AStable deliveryEasy to transportGasification processes detailsCombustible gas productionFailure rateSlag

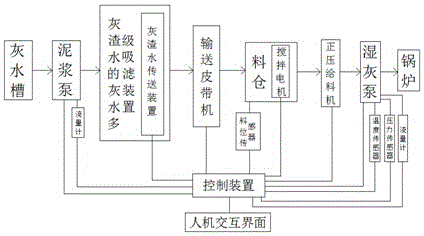

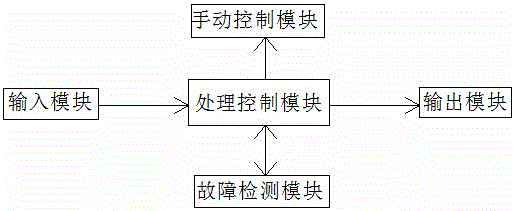

The invention discloses an ash-slag water stable transportation control system and a control device thereof, and relates to the technical field of chemical coal ash treatment. The ash-slag water stable transportation control system is mainly formed by a transportation system, the control device and a human-computer interaction interface. In the ash-slag water stable transportation control system disclosed by the invention, all components of the transportation system are tightly connected, the continuous transportation performance is strong, the running states of all the components of a transportation pump, a conveyor belt machine, a stirring motor and the like in the transportation system can be mastered by the control device in time, in-time processing can be done when failure occurs, comprehensive treatment of ash-slag water of a space gasifier is ensured, the operating stability of the system is ensured by utilizing stable transportation of the ash-slag water in the system, the whole ash-slag water stable transportation control system is low in failure rate and good in ash-slag water transportation stability, and the requirements of comprehensive treatment of the ash-slag water and the utilization of the system are met.

Owner:安徽恒宇环保设备制造股份有限公司

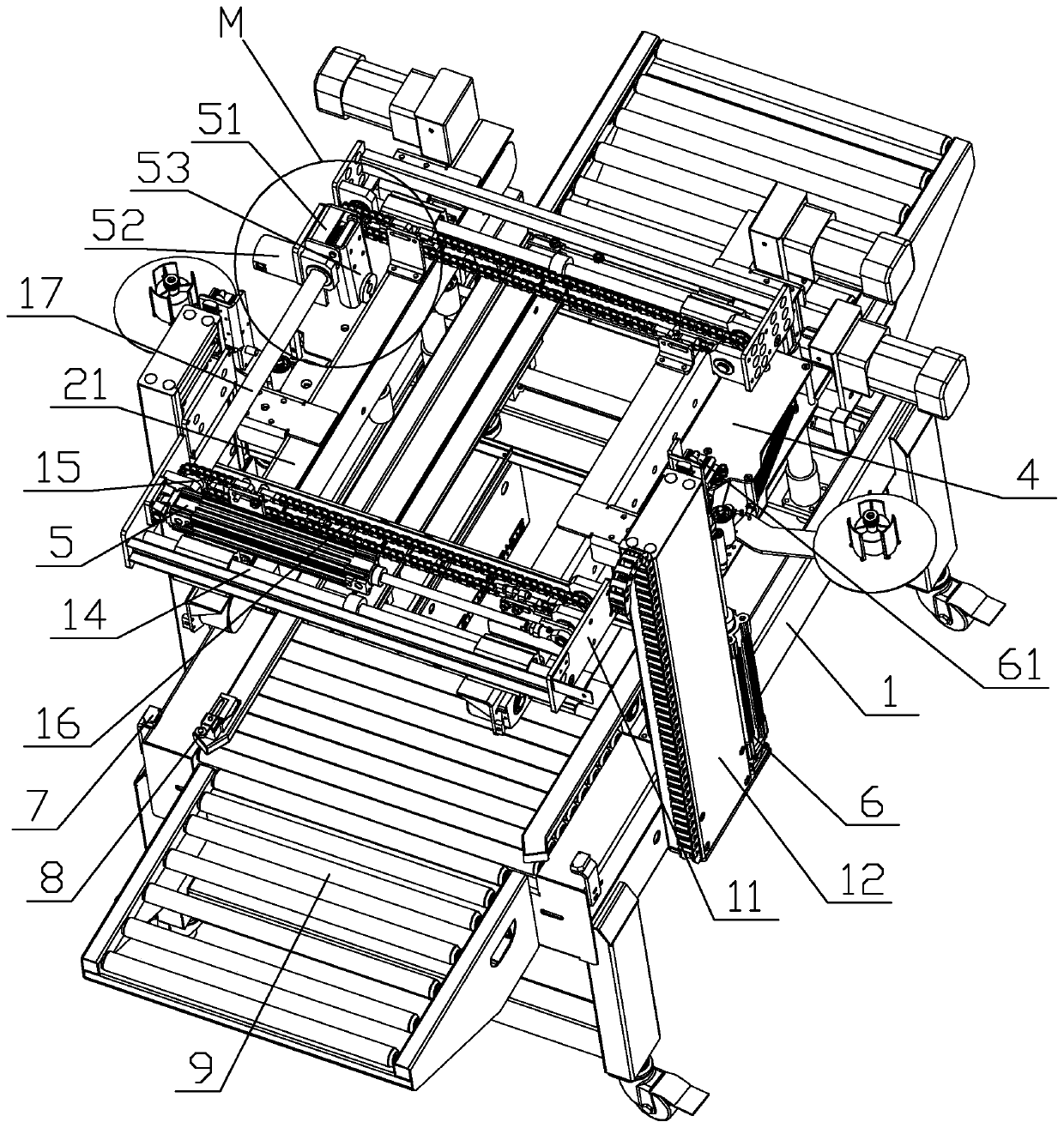

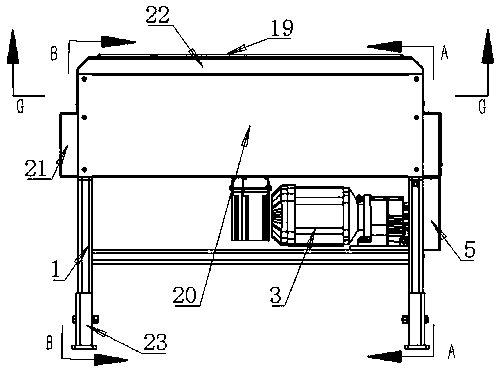

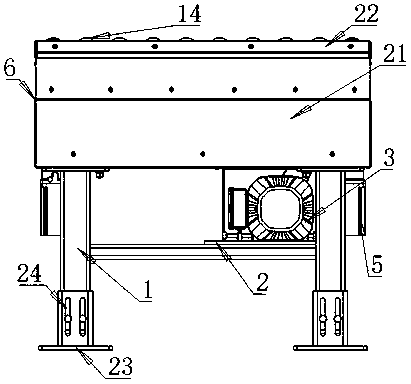

Efficient swing wheel sorting machine

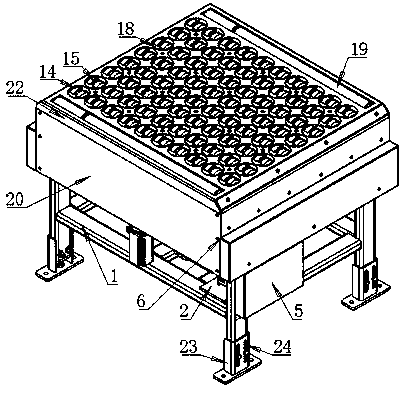

InactiveCN108674917AImprove efficiencyGood conveying stabilityRollersRoller-waysAutomotive engineeringSpeed reduction

The invention relates to the technical field of sorting equipment, in particular to an efficient swing wheel sorting machine. According to the technical scheme, the efficient swing wheel sorting machine comprises a main body supporting connection frame, the main body supporting connection frame is provided with a motor supporting placement rack, and the motor supporting placement rack is connectedwith a speed reduction motor. The center of the right side of the speed reduction motor is provided with a motor main power connection wheel, the motor main power connection wheel exceeds the right side end face of the main body supporting connection frame, and the right side of the motor main power connection wheel is provided with a motor main power protection cover. The upper end of the main body supporting connection frame is provided with an efficient swing wheel sorting function structural main body, and the lower end of the efficient swing wheel sorting function structural main body isprovided with a cylindrical efficient roller control shaft with the axis being in the leftwards and rightwards direction. The efficient swing wheel sorting machine has the advantages that sorting control is performed in a swing wheel structure manner, sorting efficiency can be greatly improved, the stability of the sorting process is better, and the sorting process is smoother.

Owner:江苏豹翔智能科技有限公司

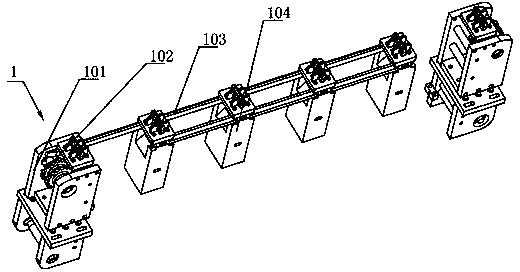

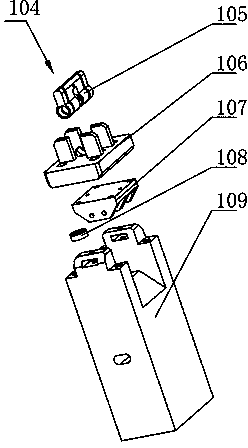

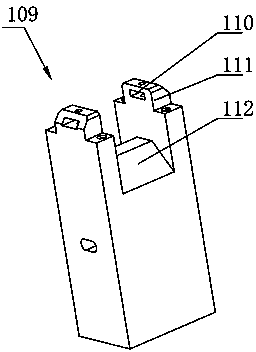

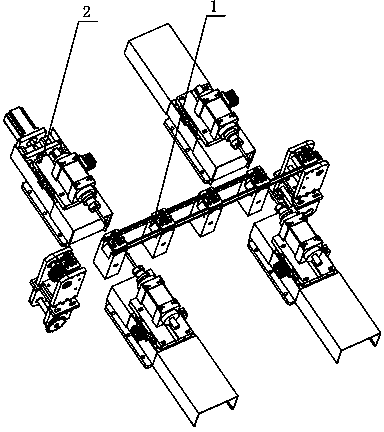

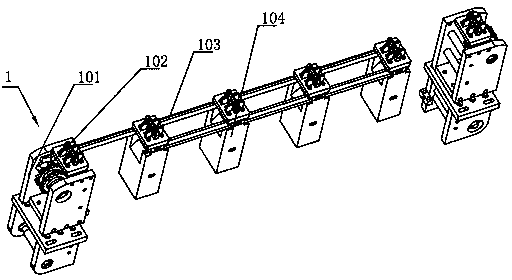

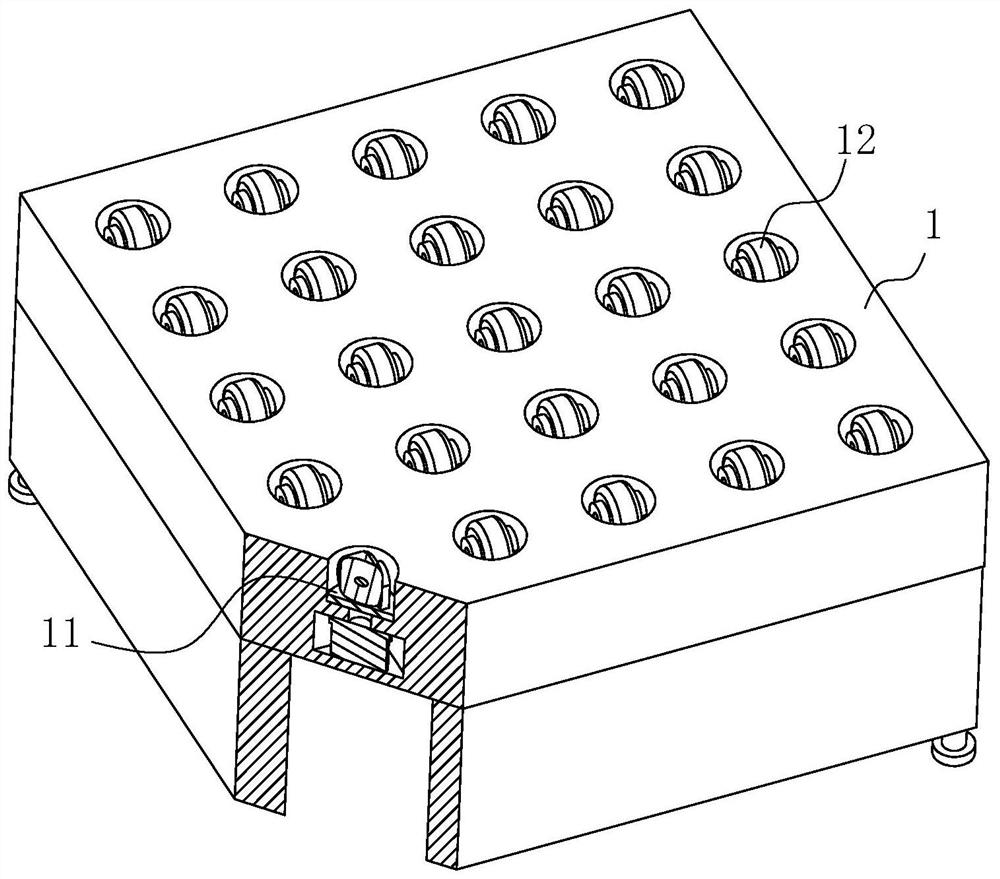

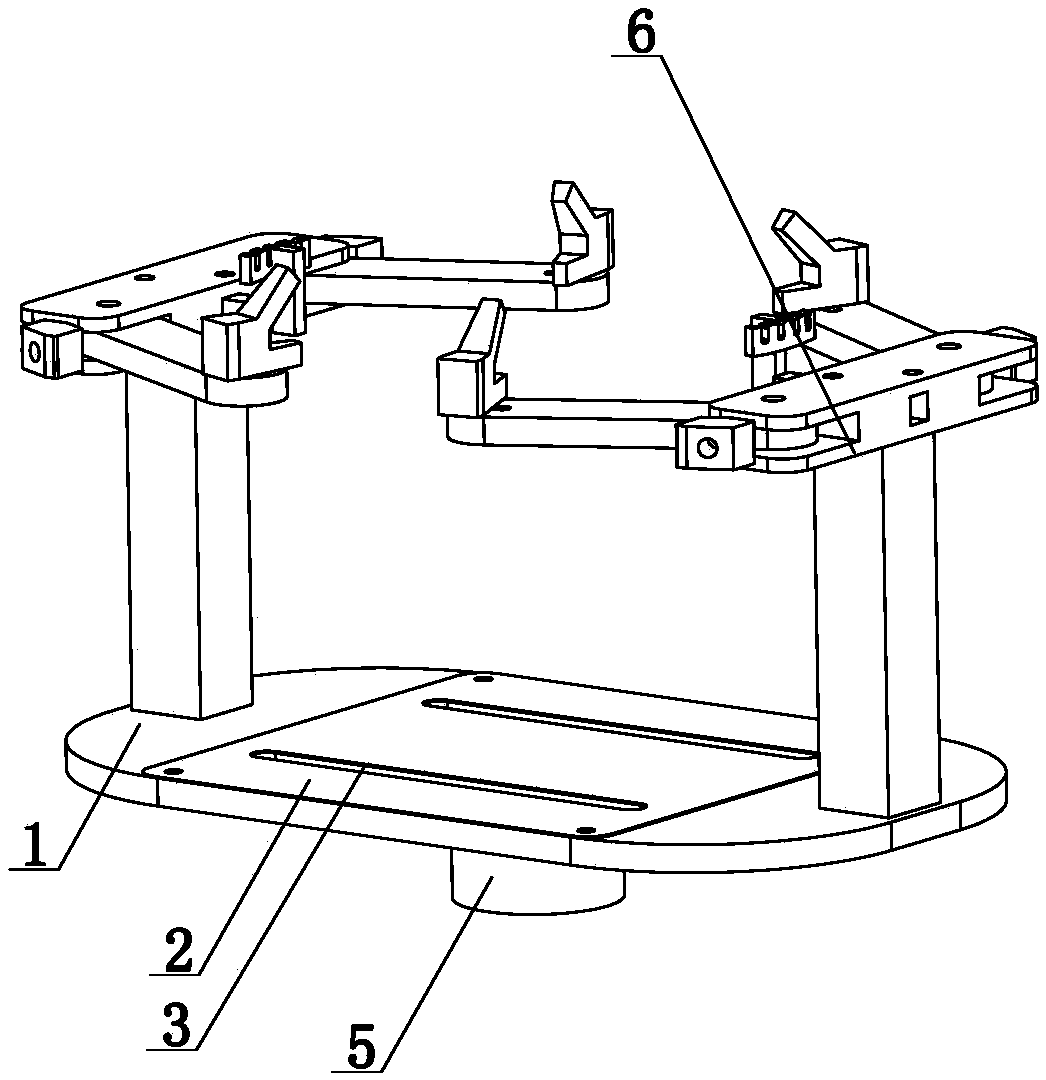

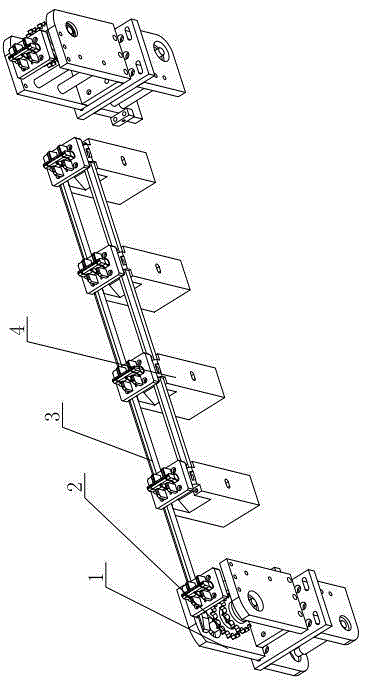

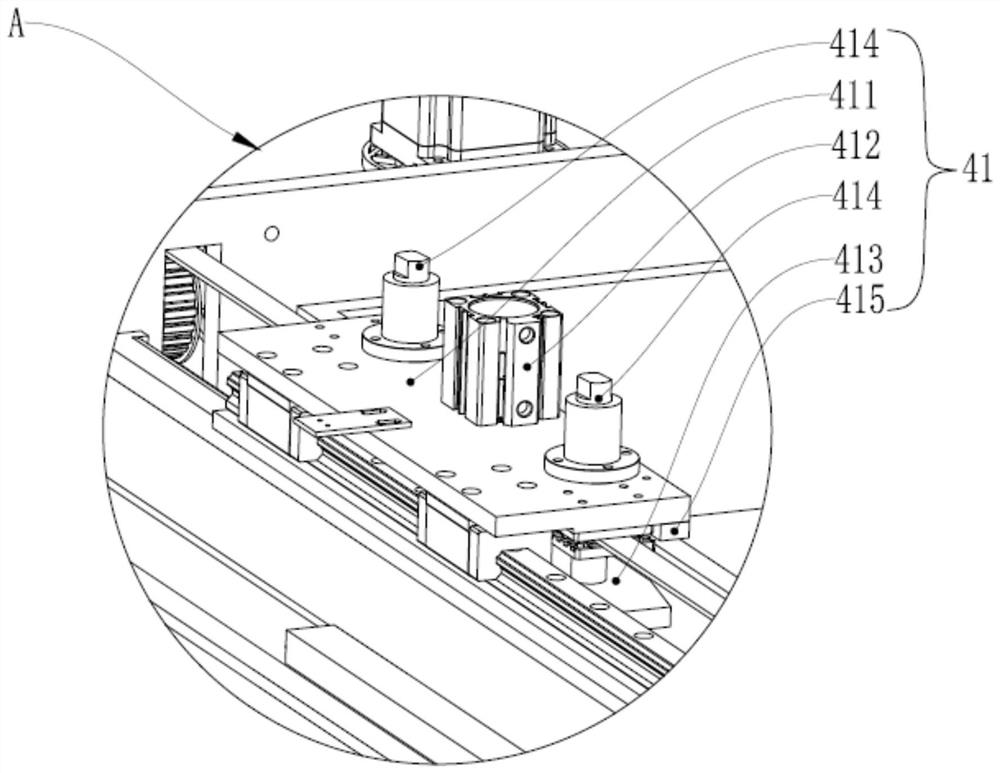

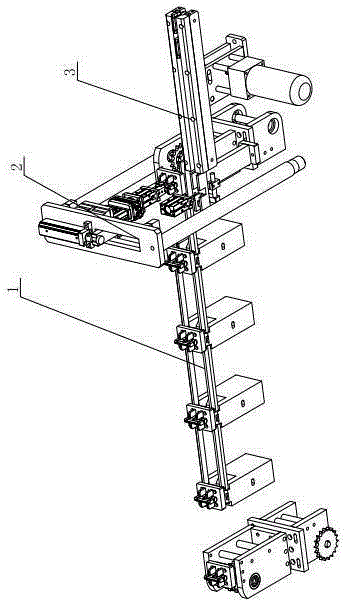

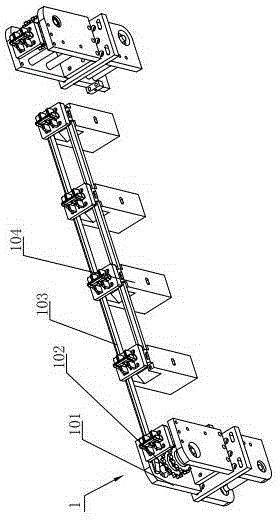

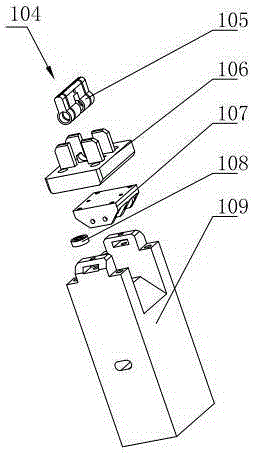

Conveying and transferring mechanism special for lock cylinders

ActiveCN104176483AEasy to pick upCompact structureConveyor partsMechanical conveyorsEngineeringTransfer mechanism

Owner:刘婷婷

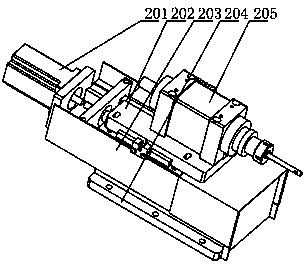

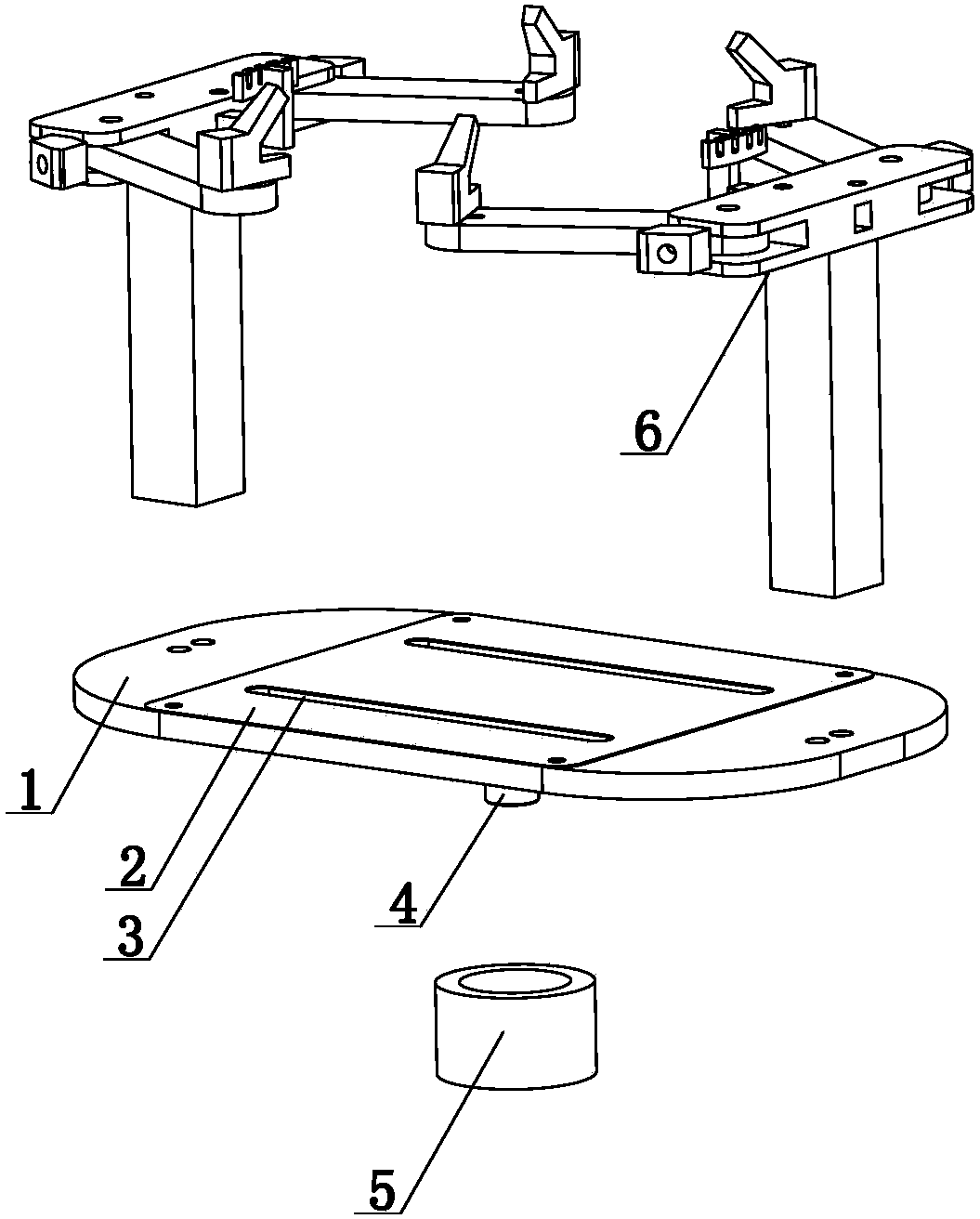

Conveying and punching device special for lock cylinders

ActiveCN104190988ACompact structureReasonable structureWork clamping meansPositioning apparatusPunchingEngineering

The invention relates to a conveying and punching device special for lock cylinders. The conveying and punching device comprises a conveying device, and the two sides of the conveying device are symmetrically provided with punching mechanisms. The structure of each punching mechanism is that a bottom plate is included, the bottom plate is provided with a mounting frame, a sliding plate is mounted through a sliding mechanism on the bottom plate placed on the frame, the sliding plate is fixedly provided with a fixed speed reducer, the output end of the speed reducer is provided with a drill bit, a push cylinder is further fixedly arranged at one end of the frame, and the output end of the push cylinder is connected with the sliding plate. The conveying and punching device special for the lock cylinders is compact and reasonable in structure and convenient to operate, the conveying device drives a clamping seat for conveying under the effect of a conveying chain, namely a fixed seat on the top of the clamping seat drives the lock cylinders to be conveyed forwards and stops when the lock cylinders are conveyed to the needed position. At the time, the operation process of punching is conducted on the lock cylinders, the conveying stability is good, and the working efficiency is high.

Owner:潘焱

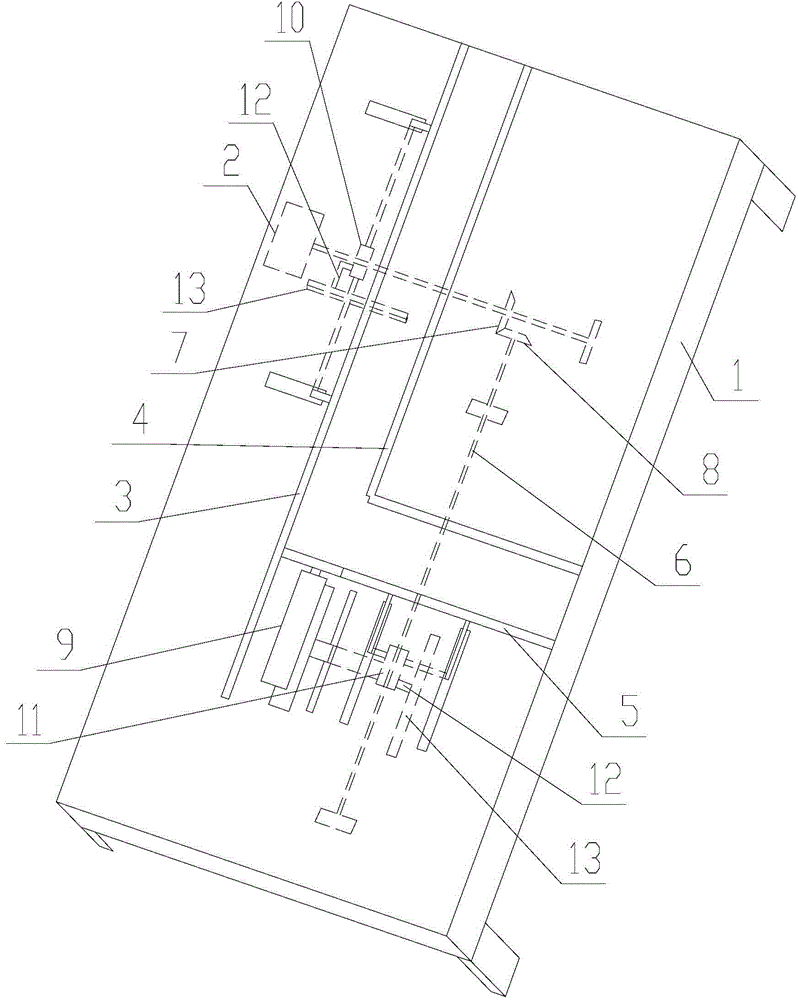

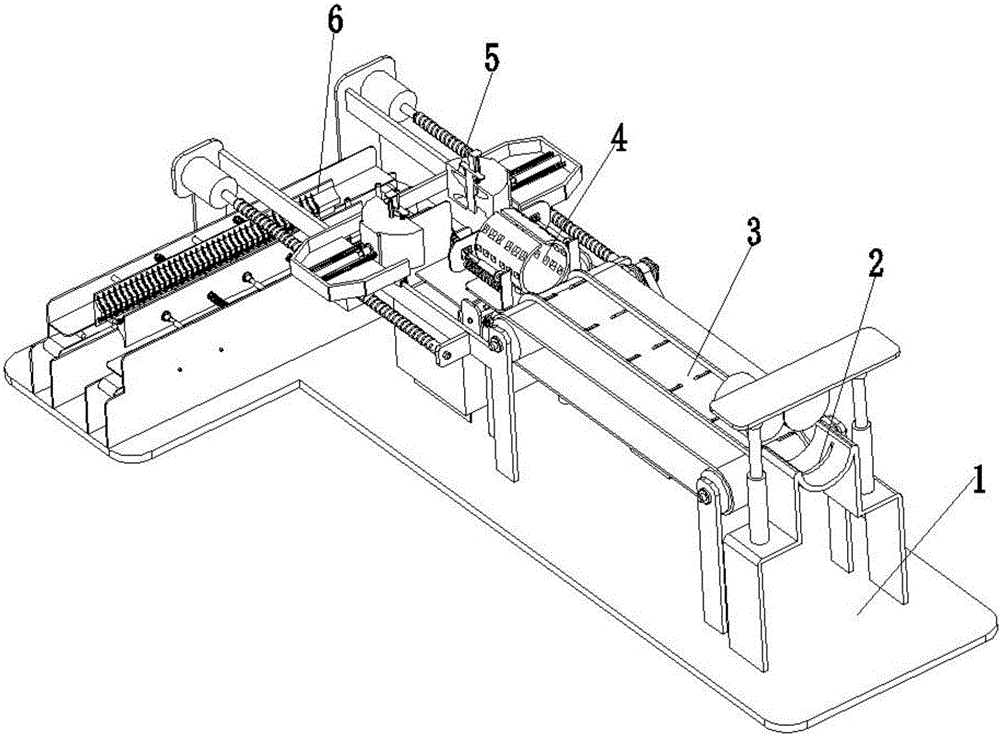

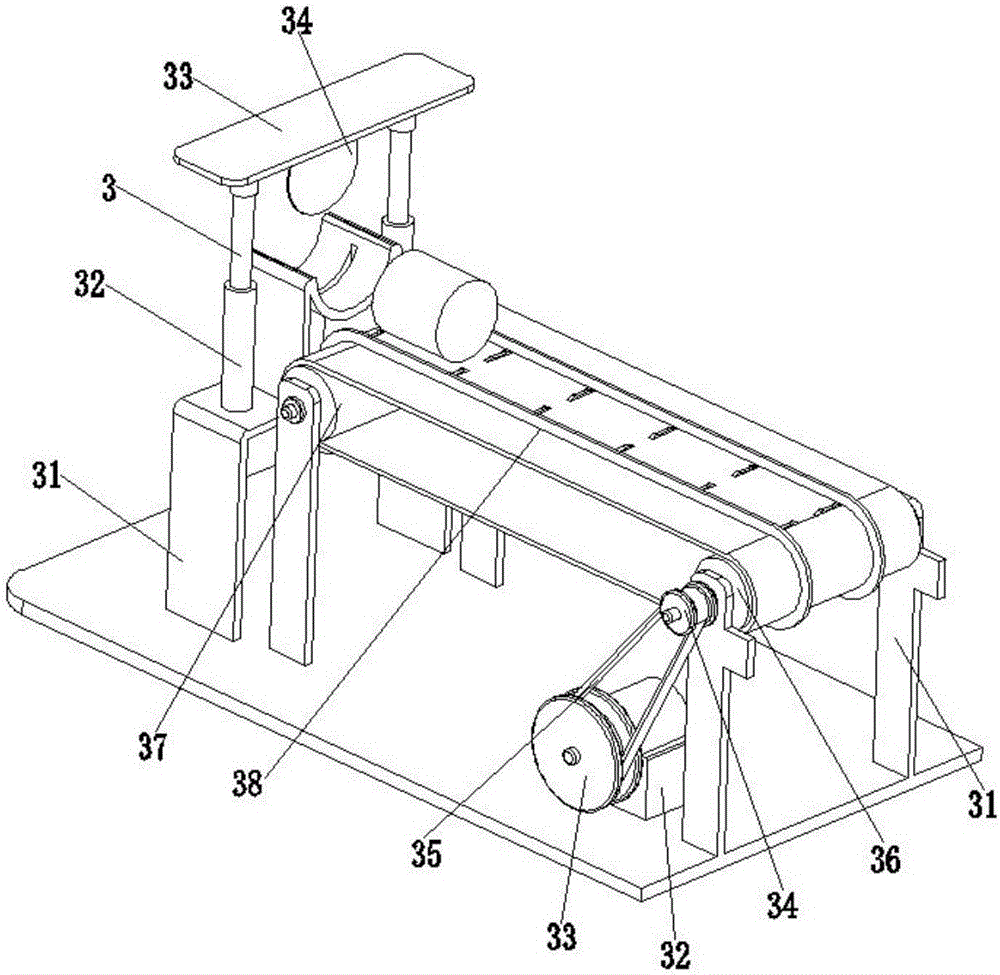

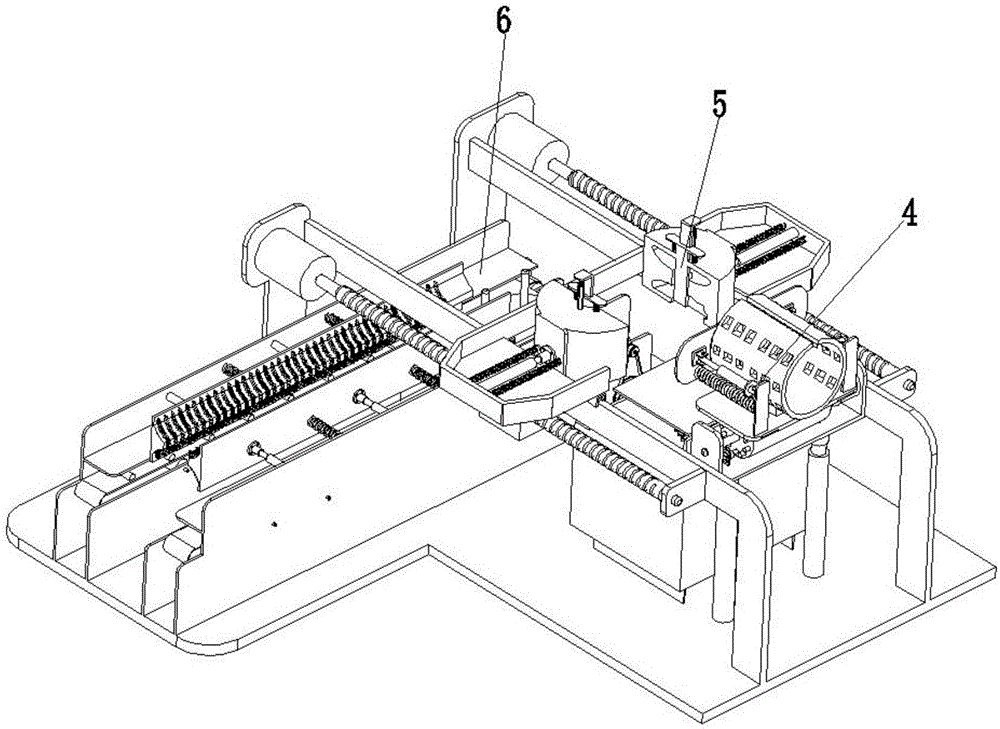

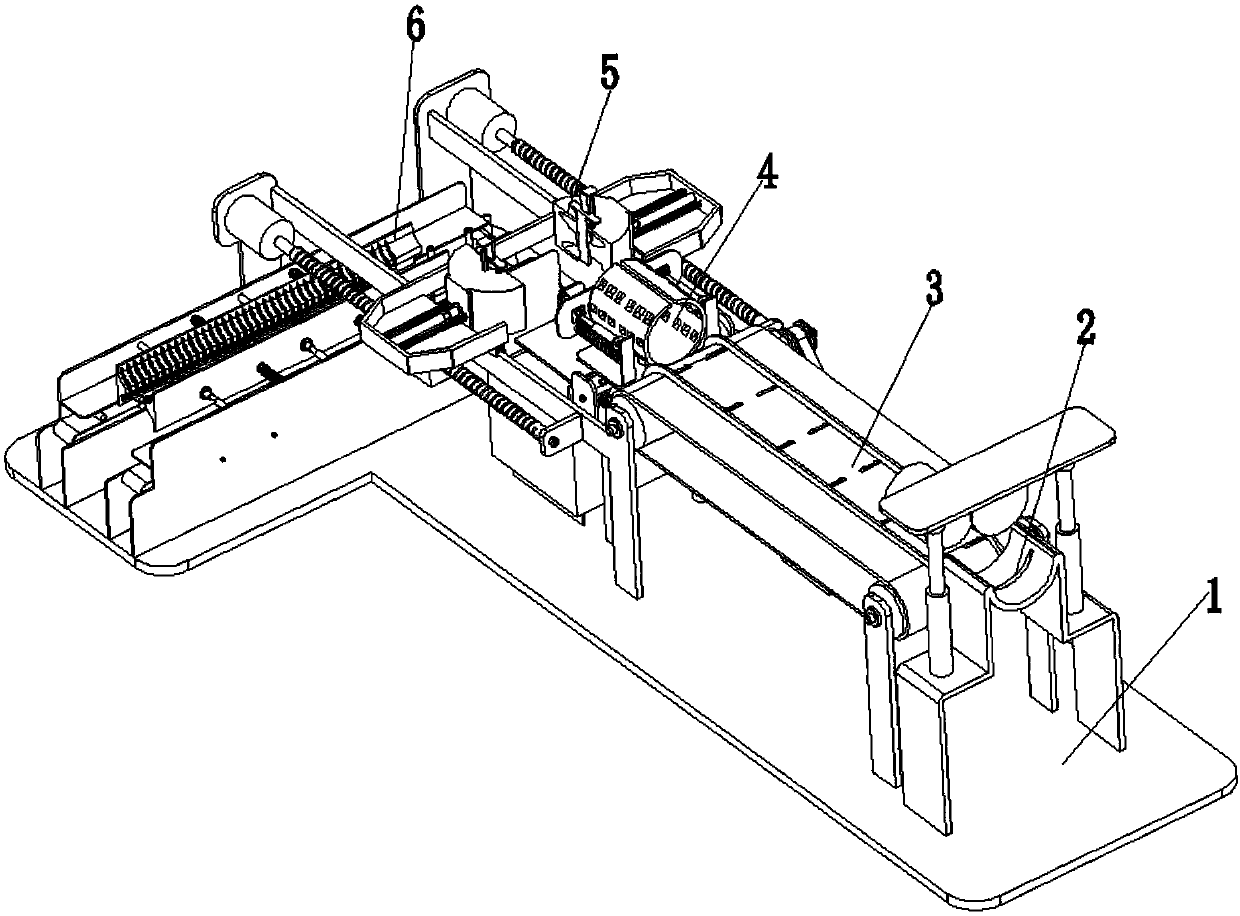

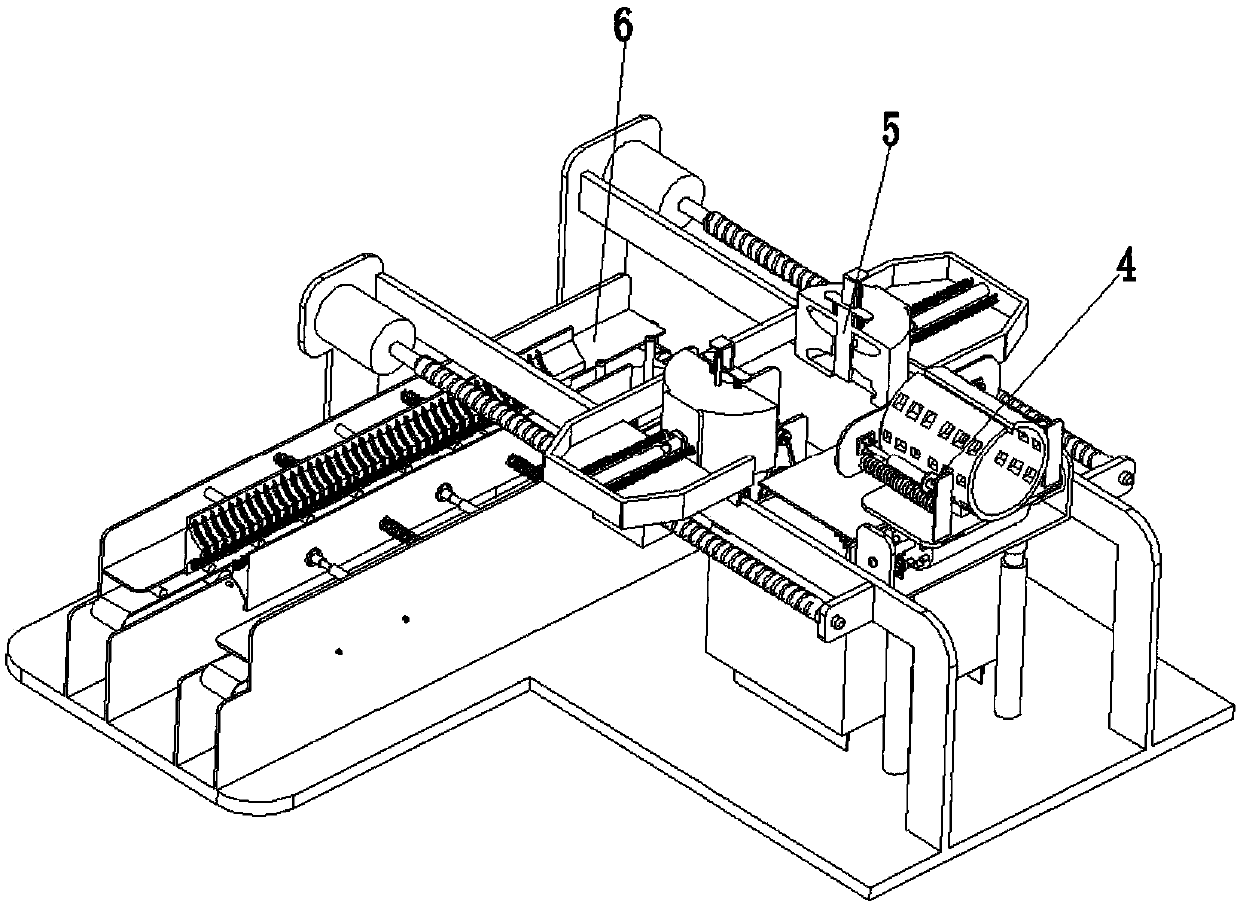

Automatic production equipment of electric insulator

ActiveCN106710755AIncrease productivityImprove product qualityInsulatorsEngineeringProduction quality

The invention relates to automatic production equipment of an electric insulator. The automatic production equipment comprises a bottom plate, a cutting-off device, a conveying device, a position changing device, a molding device and a trimming device, wherein the bottom plate is of an L-shaped structure; the conveying device is located between the cutting-off device and the position changing device; the molding device is located just behind the position changing device; the cutting-off device, the conveying device, the position changing device and the molding device are located on the same straight line; the trimming device is located below the molding device; the bottom end of the trimming device is fixed on the bottom plate; and the trimming device is vertical to the molding device. The automatic production equipment of the electric insulator has many functions of cutting off an insulator blank, conveying the blank, moving and feeding materials, extruding and molding, removing burrs of an embryonic form and trimming and the like; the automatic production equipment has a high mechanical automation degree; the function of automatically producing the insulator is realized, and occupation of manpower resources is reduced; and the production efficiency of the insulator is improved, and the production quality of the insulator is also improved.

Owner:武汉哈工潮江产业发展有限公司

Automatic production equipment for power insulator

InactiveCN107845458AIncrease productivityImprove product qualityInsulatorsEngineeringMaterial resources

The invention relates to automatic production equipment for a power insulator, and the equipment comprises a bottom plate, a cutting device, a conveying device, a transposition device, a forming device, and a trimming deflashing device. The bottom plate is of an L-shaped structure, and the conveying device is located between the cutting device and the transposition device. The forming device is located exactly behind the transposition device, and the cutting device, the conveying device, the transposition device and the forming device are located on the same line. The trimming deflashing device is located below the forming device, and the bottom end of the trimming deflashing device is fixed on the bottom plate, and the trimming deflashing device is perpendicular to the forming device. Theequipment has the functions of insulator blank material cutting, blank material conveying, material carrying and feeding, extruding and forming, and blank deburring and trimming. The equipment is high in mechanical automation degree, achieves the automatic production of insulators, reduces the occupied material resources, improves the production efficiency of insulators, and also improves the production quality of insulators.

Owner:李倍

Universal sorting equipment

InactiveCN113042381AEasy to sort and transportImprove versatilitySortingLogistics managementSoftware engineering

Owner:江苏沃德智能装备有限公司

Waste pressure sensitive adhesive tape recycling device

InactiveCN109264469AGood conveying stabilityEasy melt handlingPlastic recyclingWebs handlingAdhesive beltDrive shaft

The invention discloses a waste pressure sensitive adhesive tape recycling device, which comprises a frame, wherein a primary adhesive removing mechanism, a secondary adhesive removing mechanism and atraction mechanism are arranged on the frame; the traction mechanism is mounted between the primary adhesive removing mechanism and the secondary adhesive removing mechanism; an unwinding rotary drumis arranged on one side of the frame; a winding rotary drum is arranged on the other side of the frame; a driving motor is arranged on the other side of the frame; a driving shaft is arranged at thefront part of the driving motor; the winding rotary drum is mounted on the outer peripheral surface of the driving shaft in a sleeved manner; and the primary adhesive removing mechanism, the secondaryadhesive removing mechanism and the traction mechanism are mounted between the unwinding rotary drum and the winding rotary drum. The device can be convenient to pull and control a sensitive adhesivetape in the conveying process, so that the conveying stability of the sensitive adhesive tape is better; and the device is convenient to remelt an adhesive layer on the waste pressure sensitive adhesive tape, so that the efficiency of melting the adhesive layer on the pressure sensitive adhesive tape is greatly improved.

Owner:杭州浩知科技有限公司

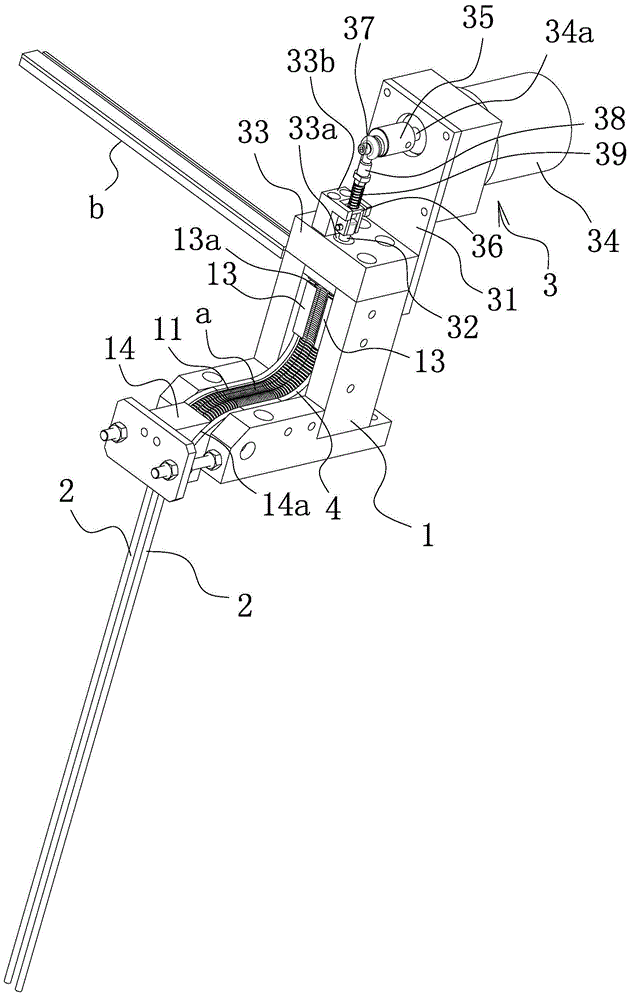

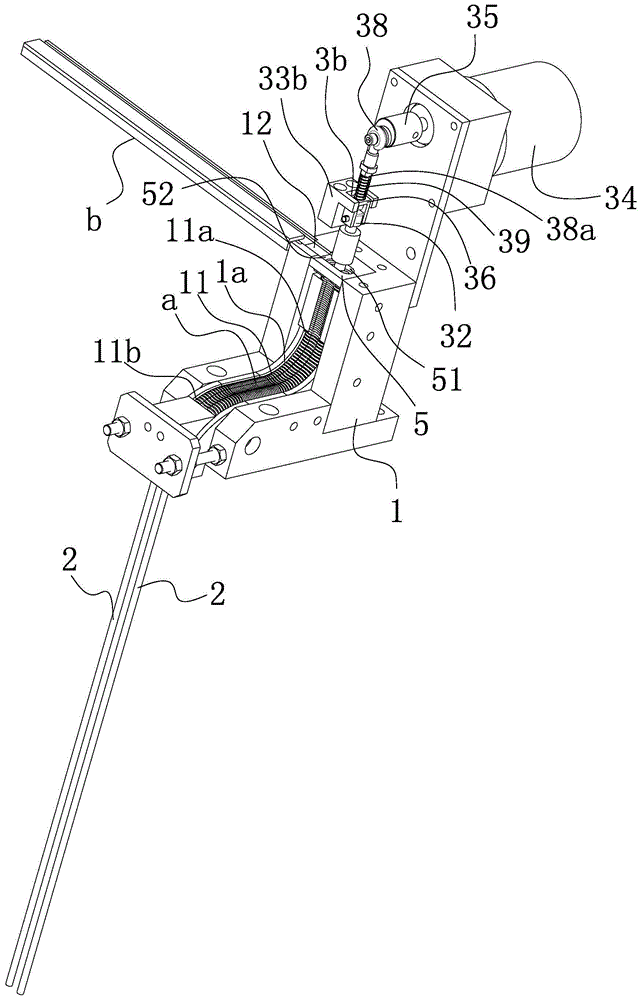

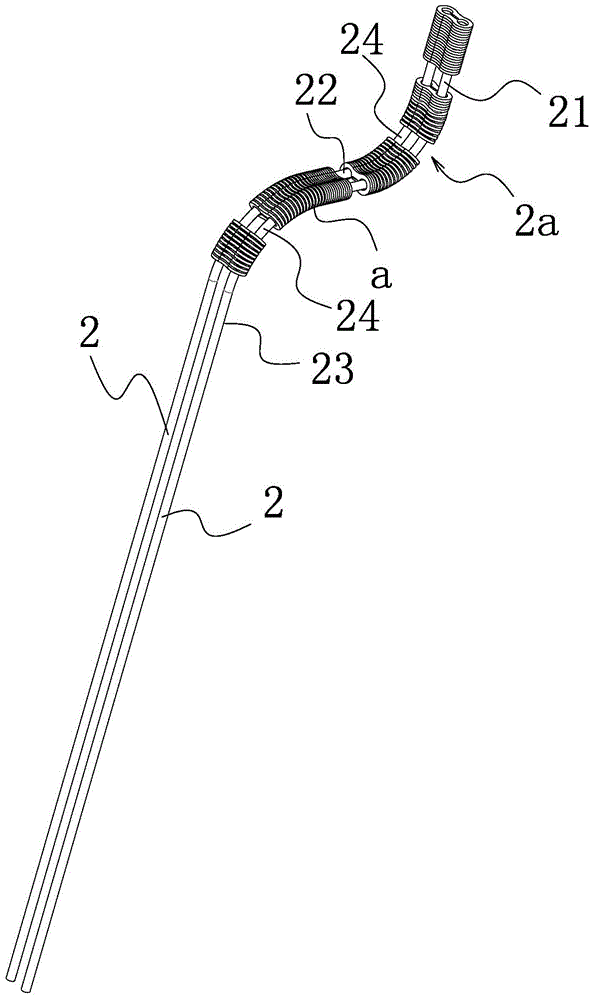

Aluminum tape clamping guide device for die-cutting machine

InactiveCN108372548AGood conveying stabilityEasy die-cut handlingMetal working apparatusMechanical engineeringEngineering

The invention discloses an aluminum tape clamping guide device for a die-cutting machine. The aluminum tape clamping guide device comprises a rotatable adjusting disk, guide mechanisms are arranged ontwo sides of the rotatable adjusting disk and comprise fixed pipelines, positioning shells are arranged at the ends of the fixed pipelines, positioning grooves are formed in the side walls of the middles of the positioning shells, inserting connection pipes are inserted into the positioning grooves, fixed blocks are arranged at the front ends of the inserting connection pipes, supporting blocks are arranged at the ends of the fixed blocks, a plurality of grooves are formed in the tops of the supporting blocks, clamping grooves are formed in two ends of each positioning shell, adjusting arms are inserted into the clamping grooves, one end of each adjusting arm is connected with the outer end of the corresponding positioning shell, a guide seat is arranged at the other end of each adjustingarm, guide grooves are formed in the front of the guide seats, and limit portions arranged on the front upper sides of the guide seats and mounted on the upper portions of the guide grooves. According to the device, two sides of an aluminum tape are limited and controlled through the guide grooves of the guide seats, so that conveying stability of the aluminum tape is better, and die-cutting processing of the aluminum tape is facilitated by the die-cutting machine.

Owner:范科晨

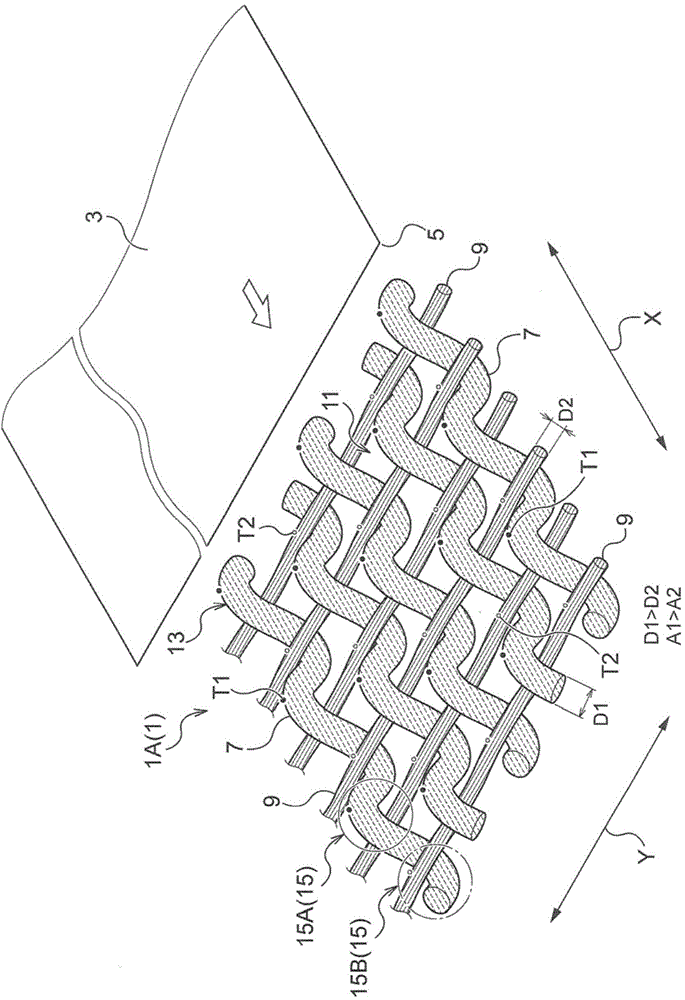

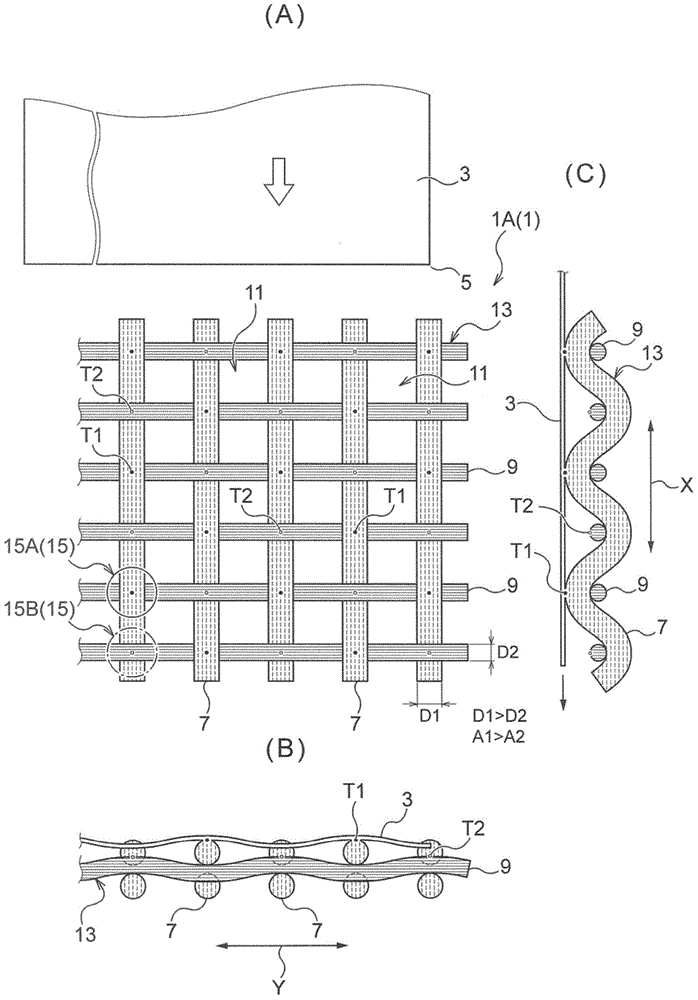

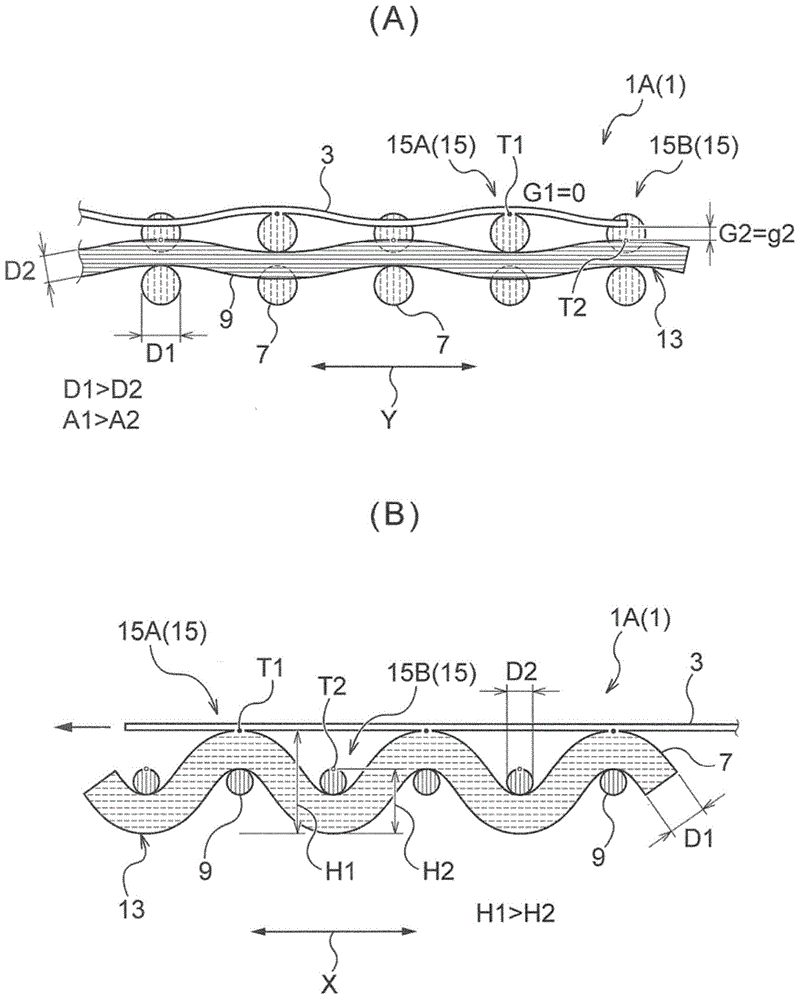

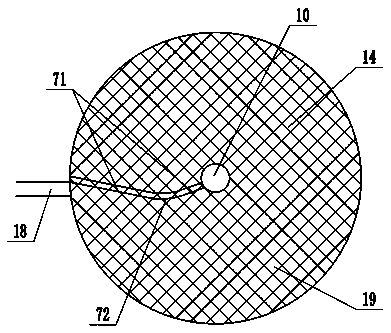

Mesh member, method of producing mesh member, and liquid discharging apparatus

InactiveCN104875501AGood conveying stabilityImprove ventilationLiquid surface applicatorsLoomsStructural engineeringMechanical engineering

A mesh member includes first strands extending in a first direction and second strands extending in a second direction intersecting the first direction. The first strands and the second strands are woven together to cross over and under each other and form a mesh structure. The first strands each have a larger cross-sectional area than the second strands at intersections where the first strands and the second strands cross each other.

Owner:SEIKO EPSON CORP

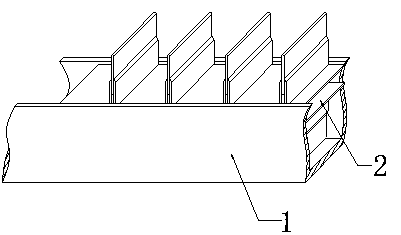

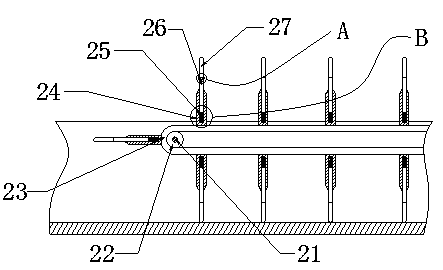

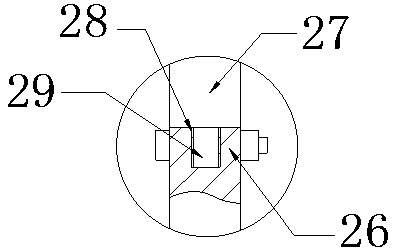

Conveying mechanism of inflaming retarding high-resistance composite membrane cutting and perforating machine

InactiveCN107972111AEasy to useGood conveying stabilityMetal working apparatusHigh resistanceEngineering

The invention discloses a conveying mechanism of an inflaming retarding high-resistance composite membrane cutting and perforating machine. The conveying mechanism comprises a workbench. The left endand the right end of the upper surface of the workbench are vertically and fixedly provided with vertical plates correspondingly. Two smooth rods are horizontally and fixedly arranged between the twovertical plates. The two ends of the two smooth rods are fixedly connected with the vertical plates on the two sides. The two smooth rods are distributed up and down. Two compressing plates are vertically arranged between the two vertical plates. The upper ends and the lower ends of the compressing plates are movably sleeved by the upper smooth rod and the lower smooth rod. The compressing platescan horizontally slide relative to the smooth rods in a friction manner. The opposite faces of the two compressing plates are horizontally and fixedly provided with slide grooves. Openings of the twoslide grooves are oppositely arranged. The left vertical plate and the right vertical plate are each horizontally provided with a lead screw in a thread connection manner. The left compressing plate and the right compressing plate are connected with the left lead screw and the right lead screw through bearings. The lead screws are provided with hand wheels. The conveying mechanism of the inflamingretarding high-resistance composite membrane cutting and perforating machine has the beneficial effects of being good in conveying stability, high in cutting and perforating precision and the like.

Owner:安徽火峰电气有限公司

Feeding device capable of effectively preventing mechanical damage

InactiveCN108674894AAvoid damageImprove product qualityConveyorsMechanical engineeringRubberized sheet

The invention provides a feeding device capable of effectively preventing mechanical damage. The feeding device comprises a rotating shaft, a roller, a conveying belt, hollow plates, springs, solid plates, rubber plates, clamping grooves and convex strips, wherein the rotating shaft is arranged in a support, the roller is assembled on the annular side surface of the rotating shaft, and the conveying belt is assembled inside the support through the roller; and the hollow plates are fixed on the outer surface of the conveying belt, the spring is arranged on the lower side surface of the inside of each hollow plate, the upper ends of the springs are connected with the solid plates, the lower ends of the solid plates are assembled inside the hollow plates, the clamping grooves are formed in the upper side surfaces of the solid plates, the convex strips are fixed on the lower side surfaces of the rubber plates, and the convex strips are assembled in the clamping grooves. According to the design of the feeding device, the materials can be effectively prevented from being damaged in the conveying process; and the feeding device has the advantages that the use is convenient, the structureis simple, the operation is convenient, the protection performance to the materials is good in the conveying process, and the reliability is high.

Owner:王秀丽

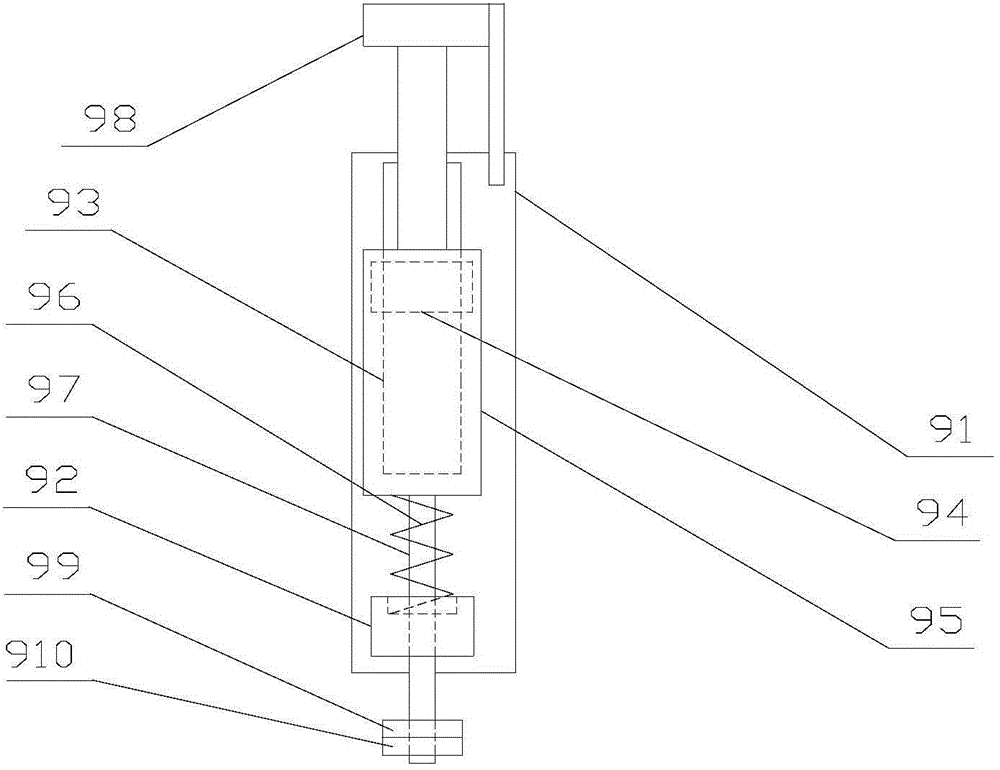

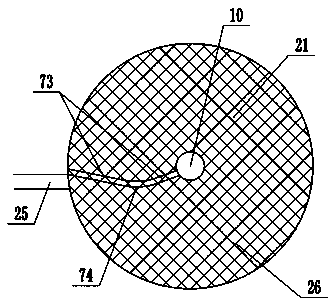

Cocoon stripper with screening function

PendingCN109881263AReduce wearHigh degree of engagementSilk cocoons cleaning/classifyingEngineeringControl theory

The invention provides a cocoon stripper with a screening function and belongs to the technical field of cocoon processing equipment. The cocoon stripper comprises a screening and cocoon stripping device and a screening and conveying device, wherein a first screening and cocoon stripping mechanism, a second screening and cocoon stripping mechanism and a third screening and cocoon stripping mechanism of the screening and cocoon stripping device are sequentially arranged in a cocoon feeding hopper from top to bottom; a first screening and cocoon stripping cavity is formed between a first cross-shaped cocoon stripping frame and a first screening disc of the first screening and cocoon stripping mechanism, a second screening and cocoon stripping cavity is formed between a second cross-shaped cocoon stripping frame and a first screening disc of the first screening and cocoon stripping mechanism, and a third screening and cocoon stripping cavity is formed between a third cross-shaped cocoon stripping frame and a third screening disc of the third screening and cocoon stripping mechanism, a collecting cavity is formed below the third screening disc, and the screening and conveying device comprises a first screening and conveying mechanism, a second screening and conveying mechanism, a third screening and conveying mechanism and a screening and conveying driving mechanism. The cocoon stripper not only can screen silkworm cocoons, but also can strip cocoon coats on the silkworm cocoons.

Owner:桐乡市腾飞家纺股份有限公司

A conveying track for a feeding device of a bearing marking machine

ActiveCN104589808BAvoid damageReduce workloadTypewritersOther printing apparatusGear wheelDrive shaft

The invention discloses a conveying rail for a feeding device of a bearing marking machine. The conveying rail comprises a frame, a motor, a longitudinal adjusting plate, a fixing plate, a transverse adjusting plate, a transmission shaft, a first gear, a second gear, a push mechanism, a first connecting frame and a second connecting frame, the fixing plate is arranged on a platform of the frame, the motor and the transmission shaft are arranged below the platform of the frame, the first connecting frame and the first gear are arranged on a rotating shaft of the motor, the first gear is arranged in the rear of the first connecting frame, the first connecting frame penetrates the platform of the frame, the longitudinal adjusting plate is arranged above the platform of the frame, the second gear and the second connecting frame are arranged on the transmission shaft, the second gear is meshed with the first gear, the second connecting frame penetrates the platform of the frame, and the transverse adjusting plate and the push mechanism are arranged above the platform of the frame. Compared with the prior art, the conveying rail can be conveniently adjusted, time is saved, workload of workers is decreased, damage of a bearing is avoided, product quality is kept, and conveying stability is fine.

Owner:XINCHANG JINTAO BEARING

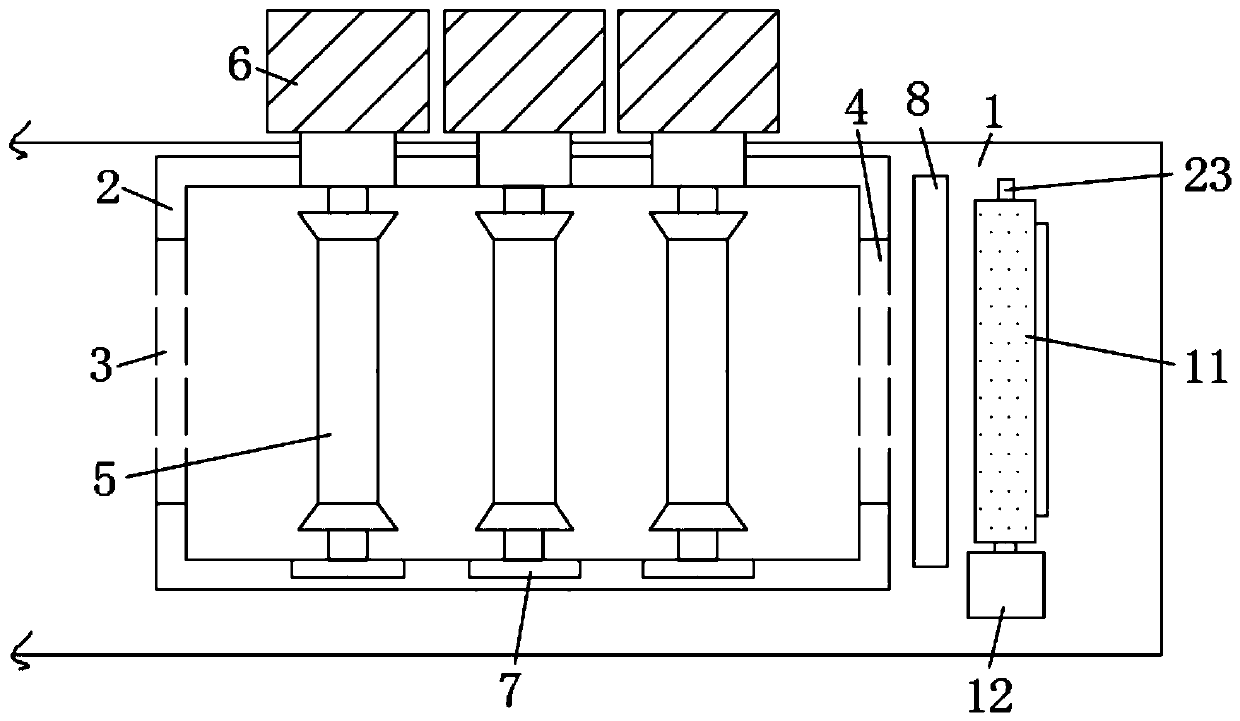

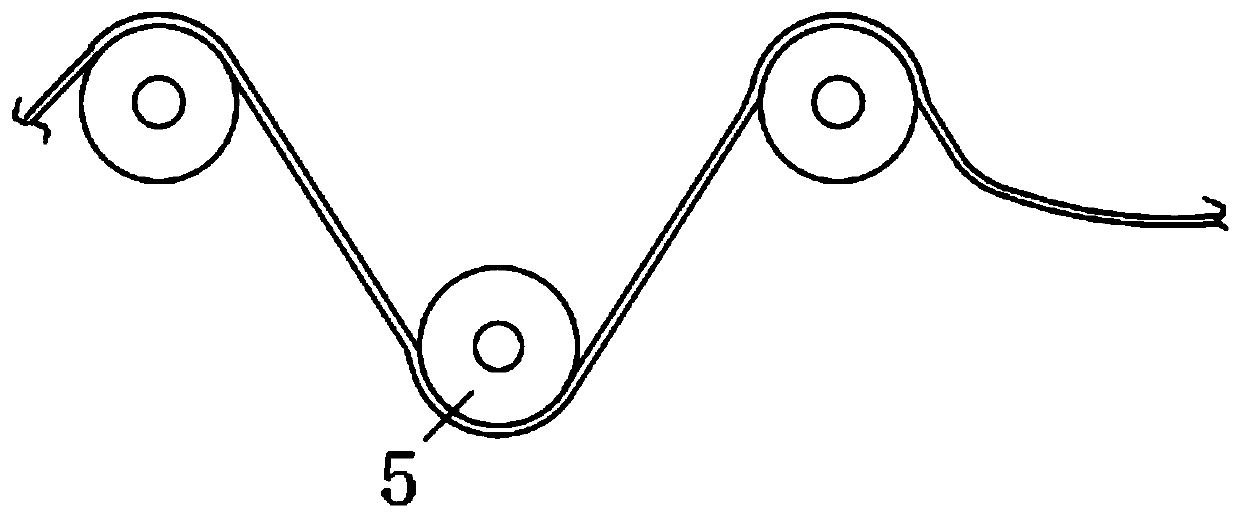

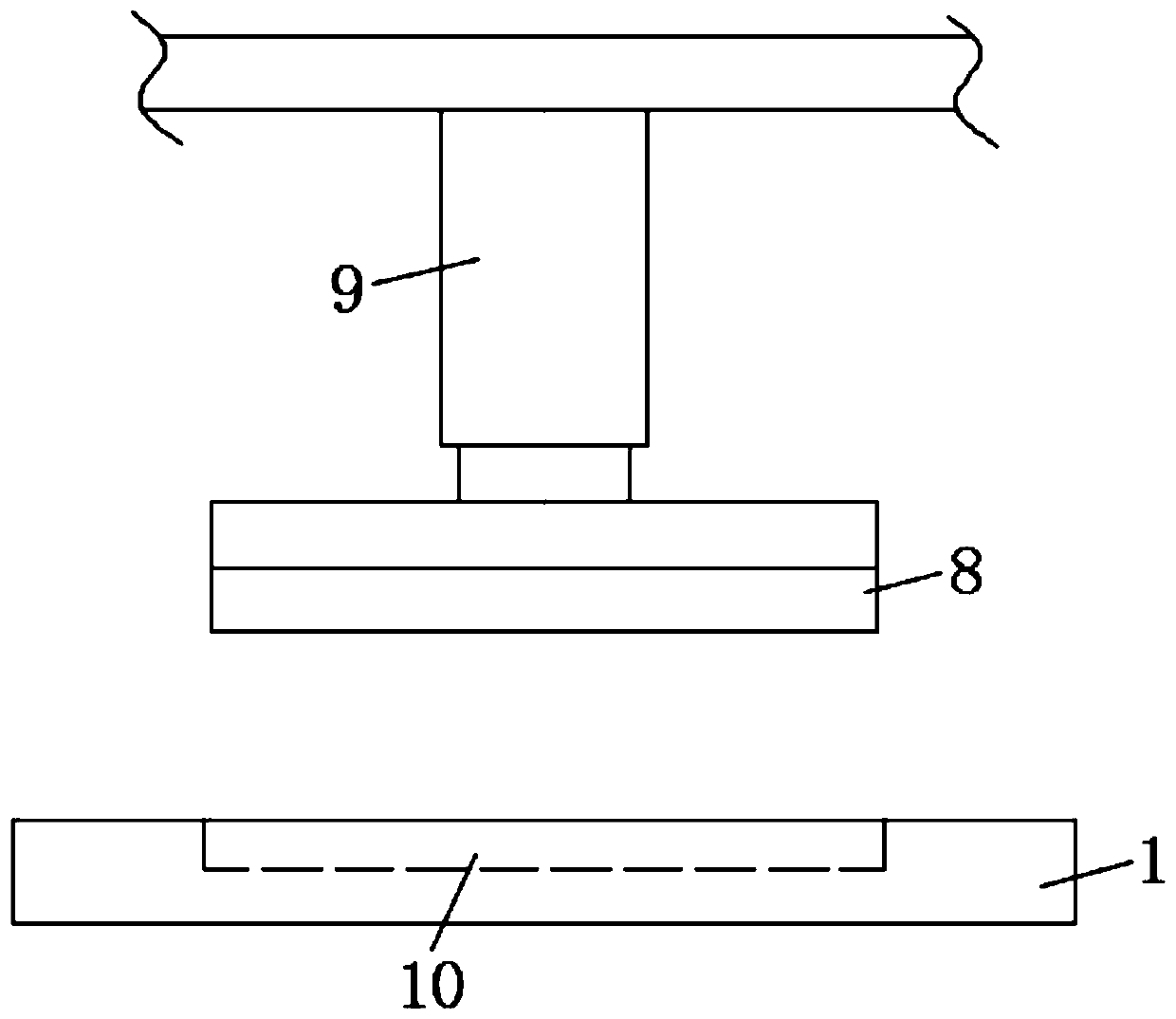

Electric car lithium battery pole piece dryer adopting V-shaped tensioning mode

InactiveCN106784631ASpeed up dryingImprove work efficiencyElectrode thermal treatmentEngineeringSlurry

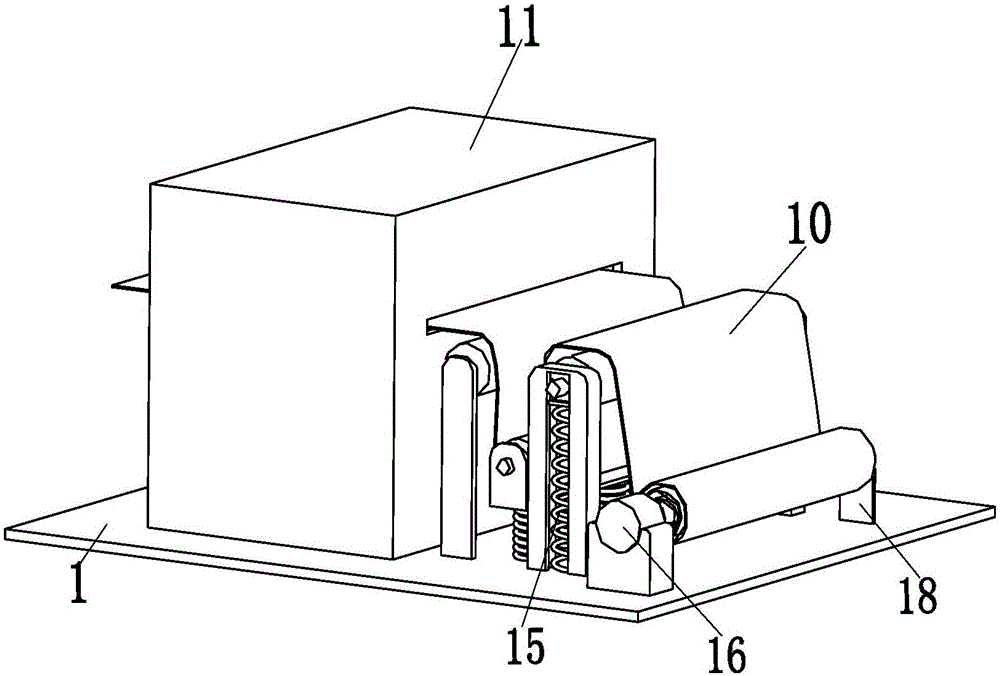

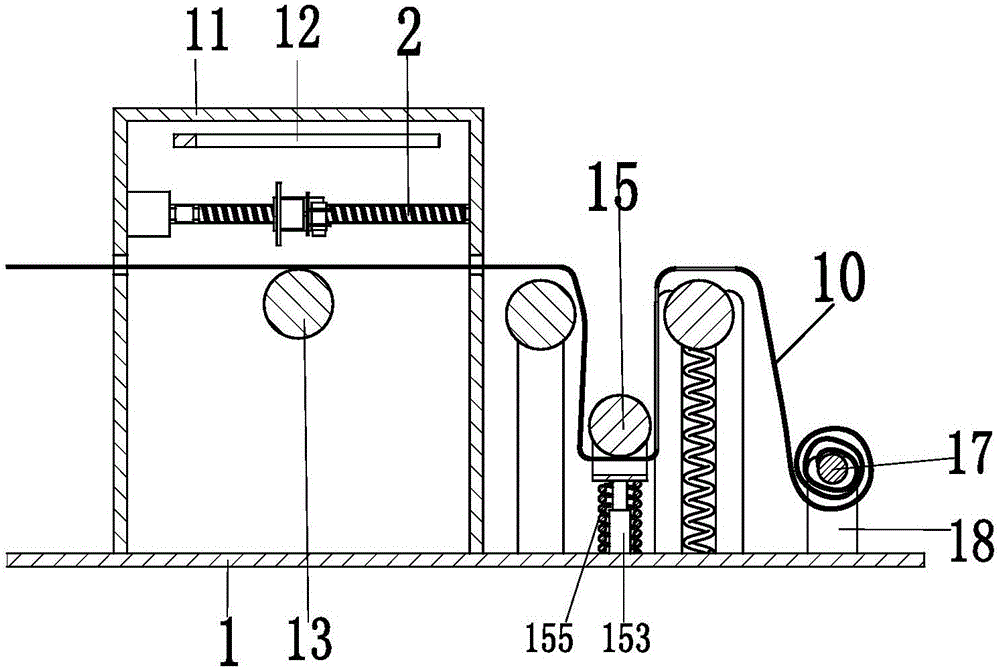

The invention relates to an electric car lithium battery pole piece dryer adopting a V-shaped tensioning mode. The electric car lithium battery pole piece dryer comprises a bottom plate and a pole piece, wherein a drying box is installed at the left end of the bottom plate, the drying box is used for drying slurry uniformly covering the pole piece, both the left end and the right end of the drying box are respectively provided with an opening structure, the pole piece can enter from the left opening structure of the drying box and is output from the right opening structure of the drying box, a corrugated heating pipe is arranged on the top inner wall of the drying box, and the heating pipe heats the slurry on the pole piece entering the drying box, so that the drying speed of the slurry is increased, and the drying effect is good. The electric lithium battery pole piece dryer can realize a high-efficiency drying function and an automatic tension adjusting function of the pole piece in a coating process and has the advantages of good tensioning effect, good conveying stability, short drying time, good drying effect, high working efficiency and the like.

Owner:汪成立

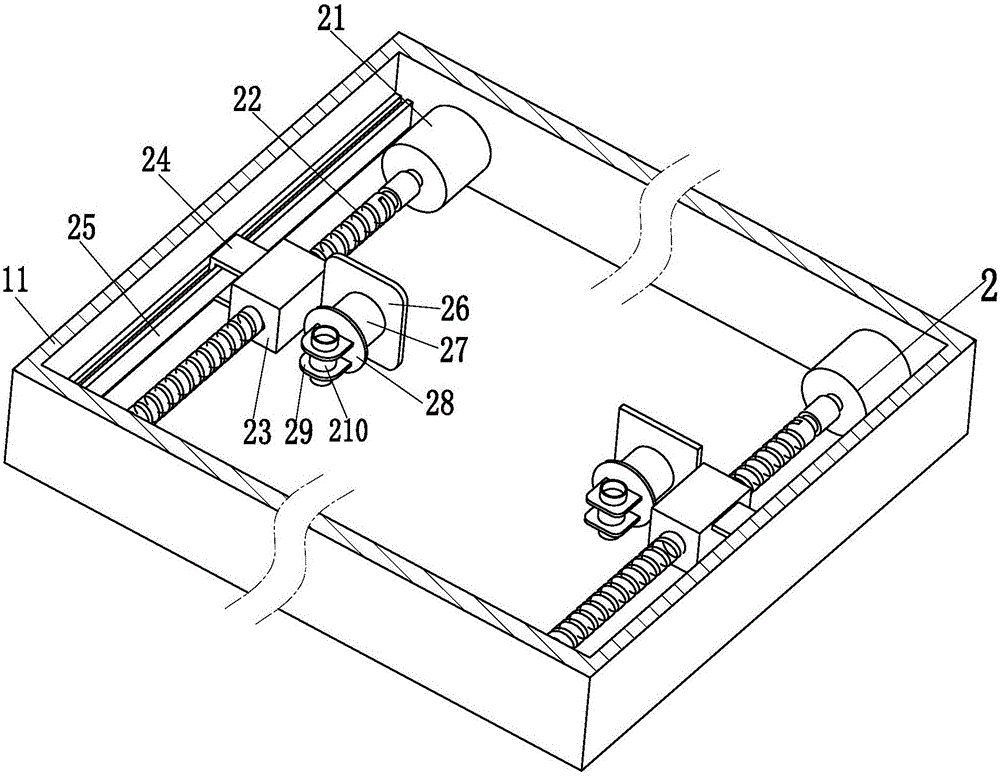

Automatic winding machine for braids

ActiveCN111071829AGood conveying stabilityImprove conveying smoothnessWebs handlingWinding machineElectric machinery

The invention discloses an automatic winding machine for braids and relates to the technical field of winding machines. The automatic winding machine for the braids comprises a support plate and a conveying frame, wherein the conveying frame is fixedly mounted at the top of the support plate, an inlet is formed in one side of the conveying frame, an outlet is formed in the other side of the conveying frame, a plurality of conveying rollers are movably mounted in the conveying frame, the back ends of the multiple conveying rollers penetrate through the back surface of the conveying frame and are fixedly connected with a first motor, and a plurality of bearings are fixedly mounted at the front end of the interior of the conveying frame. According to the automatic winding machine for the braids, the braids enter the conveying frame from the inlet, the conveying stability of the braids is higher by the conveying rollers, the conveying flatness of the braids is improved, the braids passingthrough one end of the outlet can penetrate through a press groove, then, a press plate presses inwards, when a second clamping head is clamped with a first clamping head, one end of the braids is clamped, then, the braids are automatically wound by a second motor, the operation is convenient, and the winding efficiency of the braids is improved.

Owner:中山市冠一织带有限公司

Automatic ink box sealing device

PendingCN110092021AGood stability and reliabilityThe conveying process is stableWrapper twisting/gatheringEngineeringMaterial resources

The invention relates to an automatic ink box sealing device. The automatic ink box sealing device comprises a rack, a machine table, a first guide mechanism, a second guide mechanism, an ironing mechanism, an unrolling mechanism, a pressing mechanism and a first conveying mechanism, wherein the first guide mechanism comprises a first pushing plate and a first guide part; the first guide part is used for pushing the first pushing plate to move in a length direction of the machine table; the second guide mechanism comprises a second pushing plate and a second guide part; the second guide part is used for pushing the second pushing plate to move in a width direction of the machine table; the ironing mechanism is positioned between the first pushing plate and the second pushing plate; the cutting mechanism comprises a cutting part and a cutting guide part; the cutting guide part is used for pushing the cutting part to move in the horizontal direction; and the unrolling mechanism is used for mounting an aluminum film roll; and the unrolling mechanism, the pressing mechanism, the cutting part and the ironing mechanism are sequentially arranged. The automatic ink box sealing device is high in working efficiency, is good in sealing effect, can save a great seal of manpower and material resources, and is high in popularization value.

Owner:北海绩迅科技股份有限公司

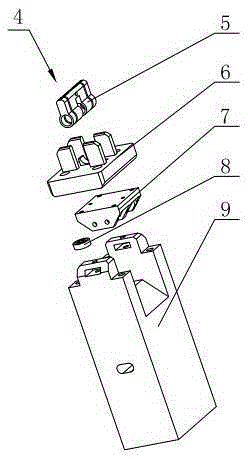

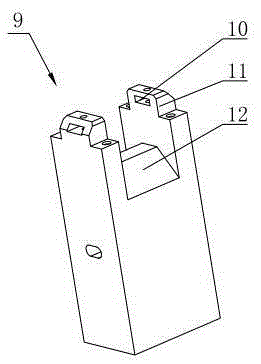

Special delivery device for lock cylinder

The invention relates to a conveying device special for lock cylinders. The conveying device comprises supporting seats which are arranged at intervals. Double-row chain wheels are mounted in the supporting seats, and a double-row chain is mounted between the two double-row-chain wheels. A plurality of conveying blocks are mounted on the double-row chain at intervals. The structure of the conveying blocks is that fixed bottom columns are included, the tops of the bottom columns are provided with clamping seats through idler wheels, the clamping seats are fastened with the chain links of the double-row chain through pin shafts, fixed seats are mounted on the tops of the clamping seats, and the lock cylinders are placed on the fixed seats. Two adjacent bottom columns are connected through one supporting column. The conveying device special for the lock cylinders is compact and reasonable in structure and convenient to use. The clamping seats are driven for conveying under the effect of the conveying chain, namely the fixed seats on the tops of the clamping seats drive the lock cylinders to be conveyed forwards, and the fixed seats stop when the lock cylinders are conveyed to the needed position. At the time, operation work processes such as punching are conducted on the lock cylinders, the conveying stability is good, and the working efficiency is high.

Owner:广西庚源香料有限责任公司

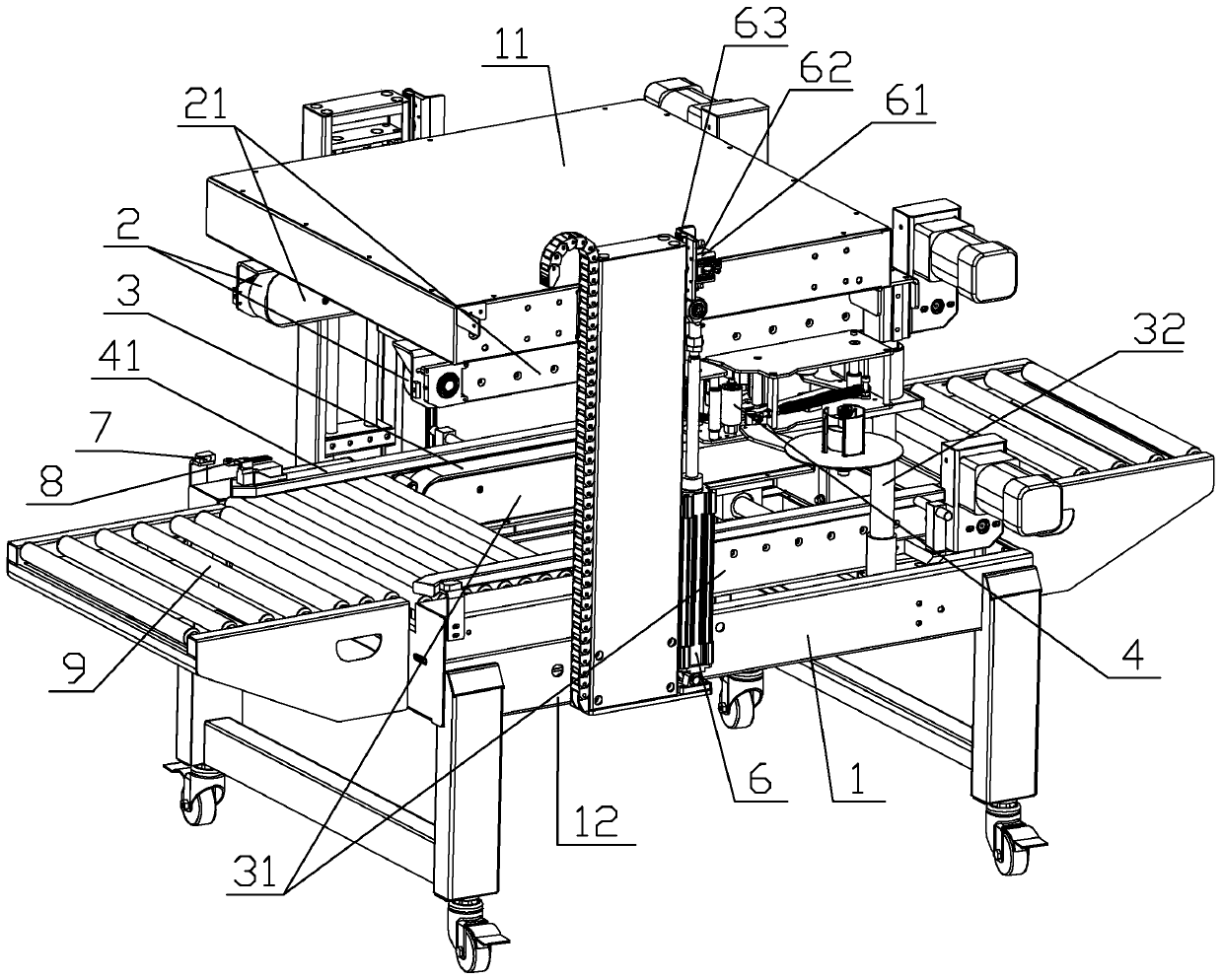

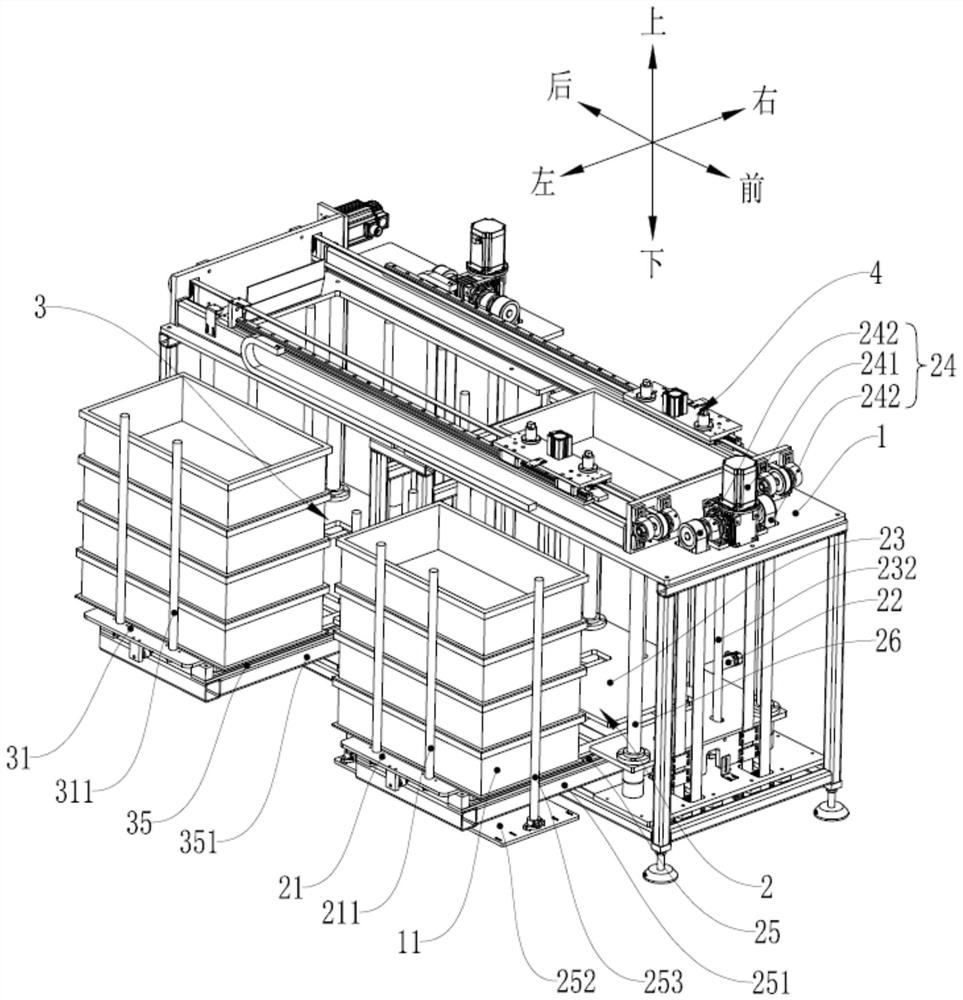

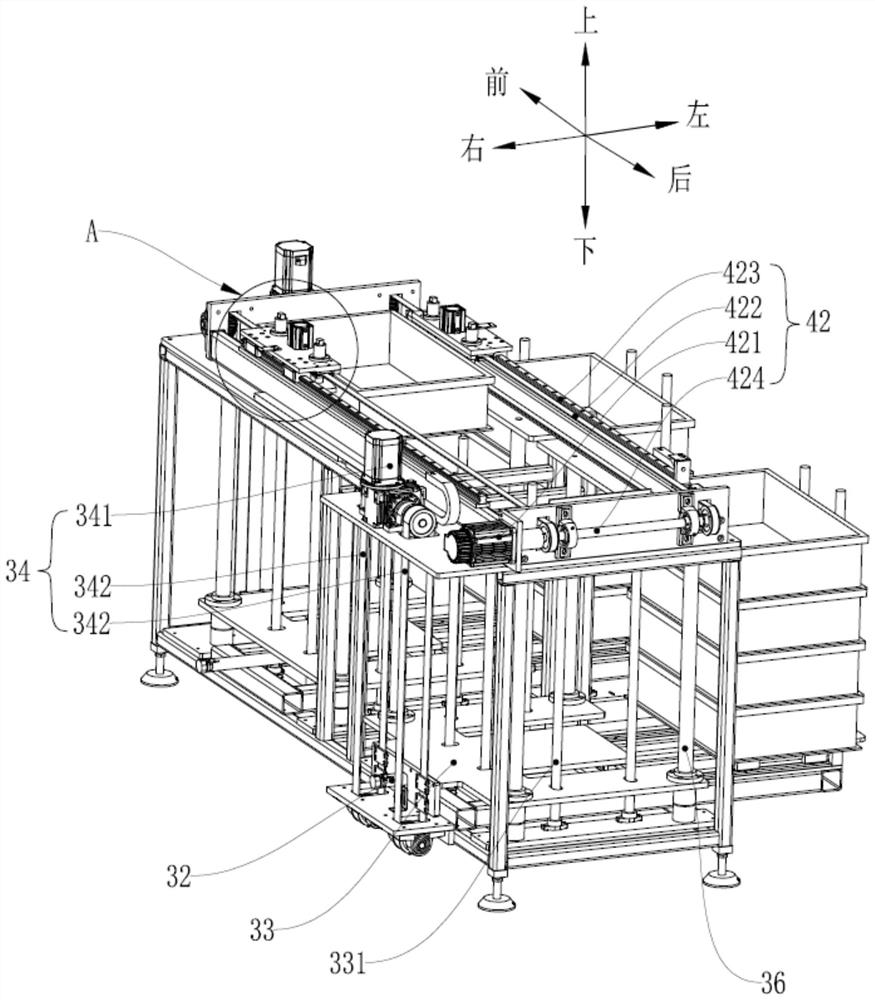

Material collecting device

PendingCN112938438AImprove charging efficiencyGood conveying stabilityConveyor partsEngineeringMechanical engineering

The invention discloses a material collecting device. The material collecting device comprises a rack, wherein a box supplying mechanism is arranged on the front portion of the rack, a box receiving mechanism is arranged on the rear portion of the rack, and a conveying mechanism is arranged on the top of the rack; and the box supplying mechanism comprises a first material box platform, a first driving device, a first lifting platform and a first driving assembly, the first driving device drives the first material box platform to move close to or away from the first lifting platform, the first material box platform conveys a material box to the first lifting platform, the first driving assembly drives the first lifting platform to move in the up-down direction, and the first lifting platform conveys the material box to the conveying mechanism. The material collecting device is high in charging efficiency and good in material box conveying stability, the working efficiency is effectively improved, the labor cost is effectively reduced, and the problems that an existing material collecting device is low in working efficiency and high in dependence degree on manpower are solved.

Owner:智鑫隆科技(广东)有限公司

Special conveying and transferring mechanism for lock cylinder

ActiveCN104176483BEasy to pick upCompact structureConveyor partsMechanical conveyorsEngineeringTransfer mechanism

Owner:刘婷婷

chain chain mechanism

ActiveCN103978150BGuaranteed stabilityGood conveying stabilityMetal chainsEngineeringMechanical engineering

Owner:ZHEJIANG HENGJIU MACHINERY GROUP ZHUJI SPECIAL CHAIN

Automatic ball feeder

The invention provides an automatic ball feeder. The automatic ball feeder comprises a conveying assembly and a driving assembly. The conveying assembly is composed of a ball storage tank of which thebottom is provided with slideways inclined by a certain angle, a movable baffle mounted on the lower portion of the slideways and a transmission mechanism arranged in the movable baffle and used forconveying steel balls to a ball receiving hopper. The end, facing the ball receiving hopper, of the bottom of the movable baffle is provided with a ball outlet. A blocking part is mounted on the jointbetween the sideway and the transmission mechanism. The driving assembly is composed of a motor connected with the transmission mechanism through a transmission shaft and a coupling arranged betweenthe motor and the transmission shaft. The automatic ball feeder is high in conveying efficiency, high in running stability, capable of effectively preventing bridging and preventing the balls from getting jammed and also capable of saving motor power, has the overload protection effect, ensures the quite high filling rate, reduces loss of equipment, substantially reduces the cost and meanwhile, further improves the working efficiency.

Owner:BENGANG STEEL PLATES

Caterpillar band occlusion conveying device used for spraying and painting machine

The invention discloses a caterpillar band occlusion conveying device used for a spraying and painting machine. The device comprises a driving motor, a driving shaft is arranged on the front of the driving motor, the periphery face of the end of the driving shaft is sleeved with a rotating disc and a grinding wheel, an occlusion block is arranged on one side of the periphery face of the grinding block, a conveying belt is arranged under the grinding wheel, a side base is arranged on the top of the driving motor, a top base is arranged on the top of the side base, a fixed base is arranged on the front of the top base, an adjusting shell is arranged on the fixed base, an operation arm is arranged on the upper portion of the adjusting shell, an operation handle is arranged on the outer end ofthe operation arm, a push tube is arranged on the front of the top base, the upper end of the push tube penetrates through the top base and the fixed base, the upper end of the push tube is connectedwith the adjusting shell, the lower end of the push tube is a free end, a guide rail is arranged on the front of a sliding base, a moving shell is arranged on the guide rail, a push base is arrangedon the upper portion of the moving shell, a fastening adjusting wheel is arranged on the lower portion of the push base, and the fastening adjusting wheel is arranged above the conveying belt. The grinding wheel can carry out occlusion and conveying on a caterpillar band on the conveying belt through the occlusion block.

Owner:浙江兰思教育科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com