Patents

Literature

320 results about "Rubberized sheet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

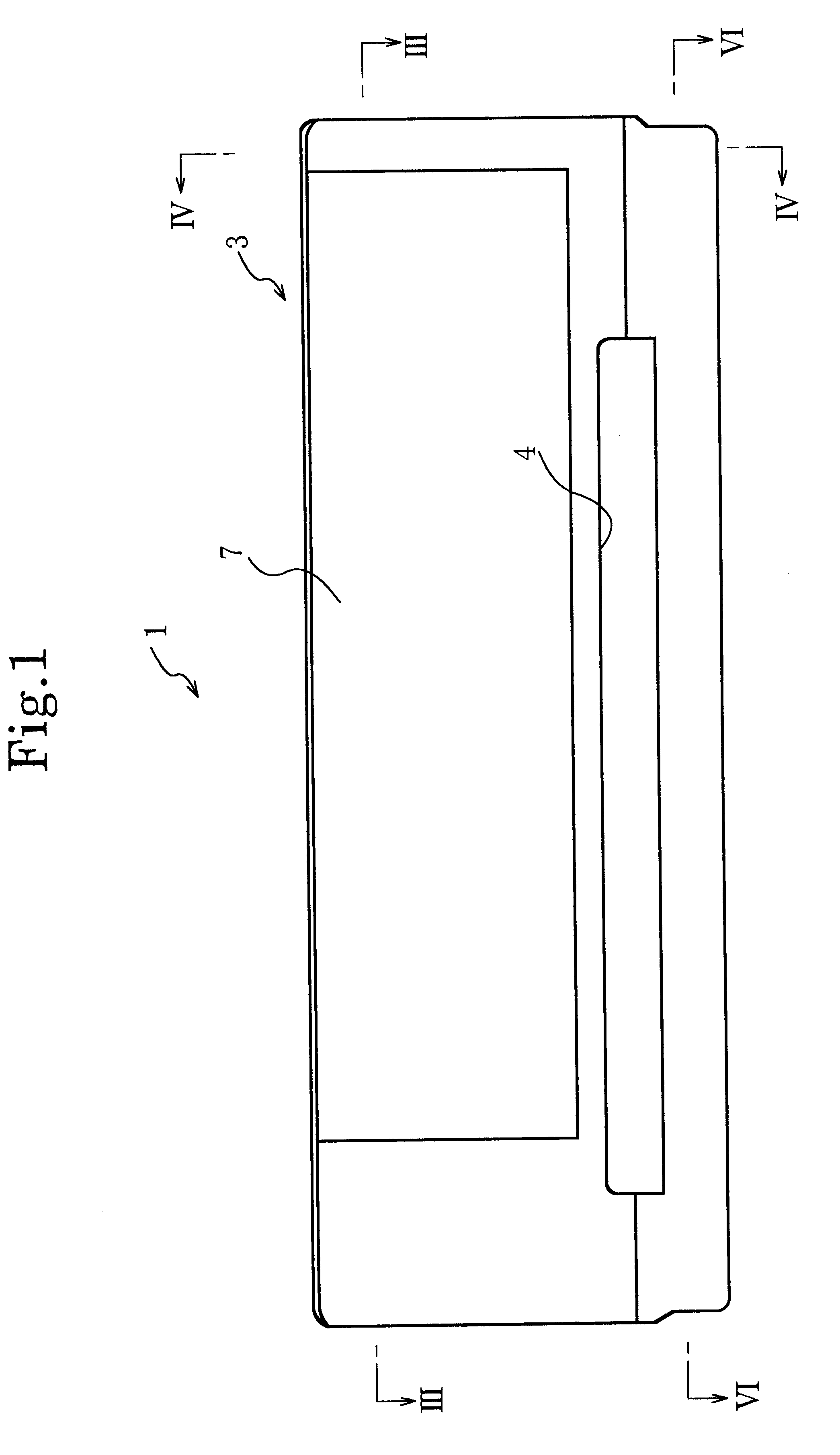

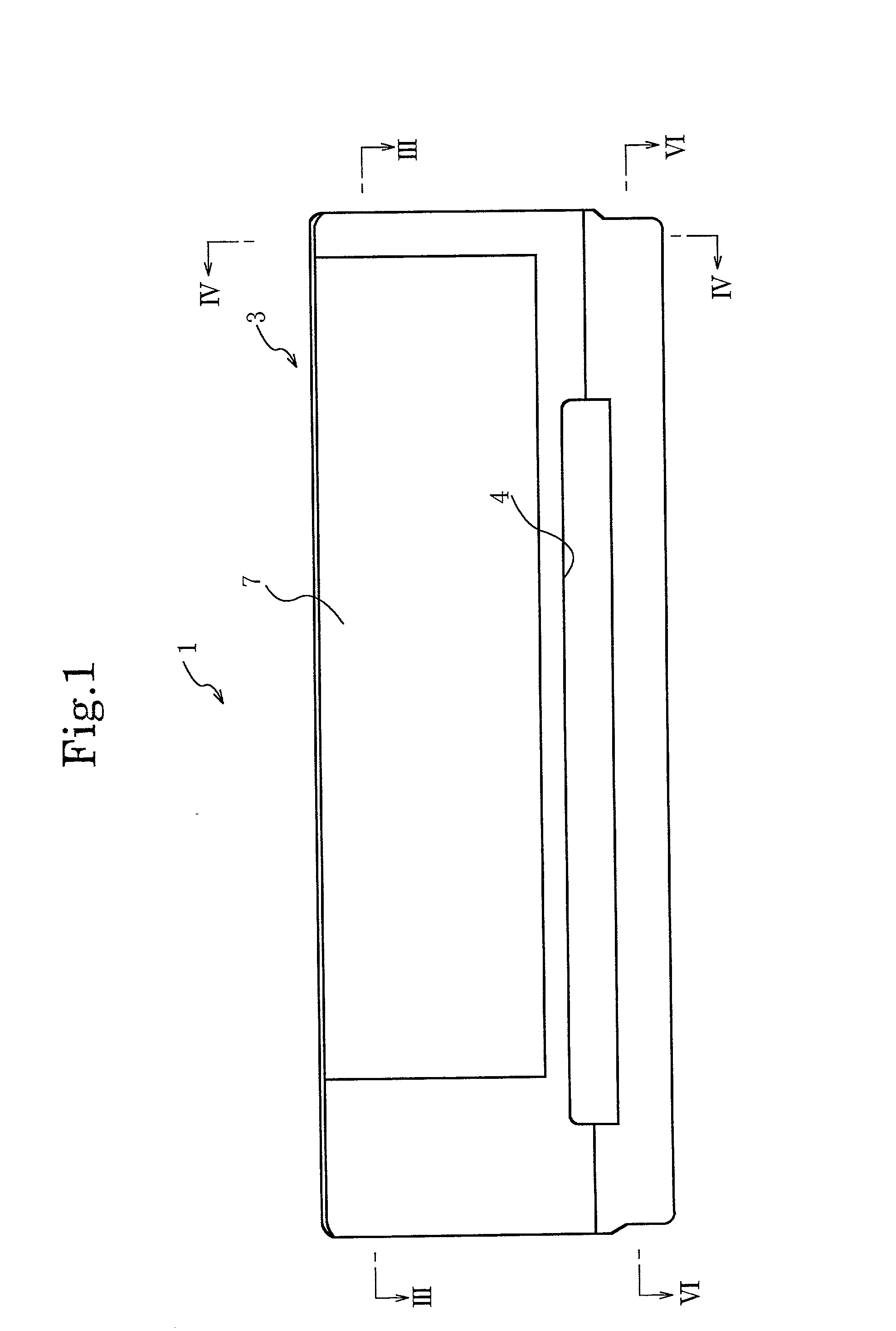

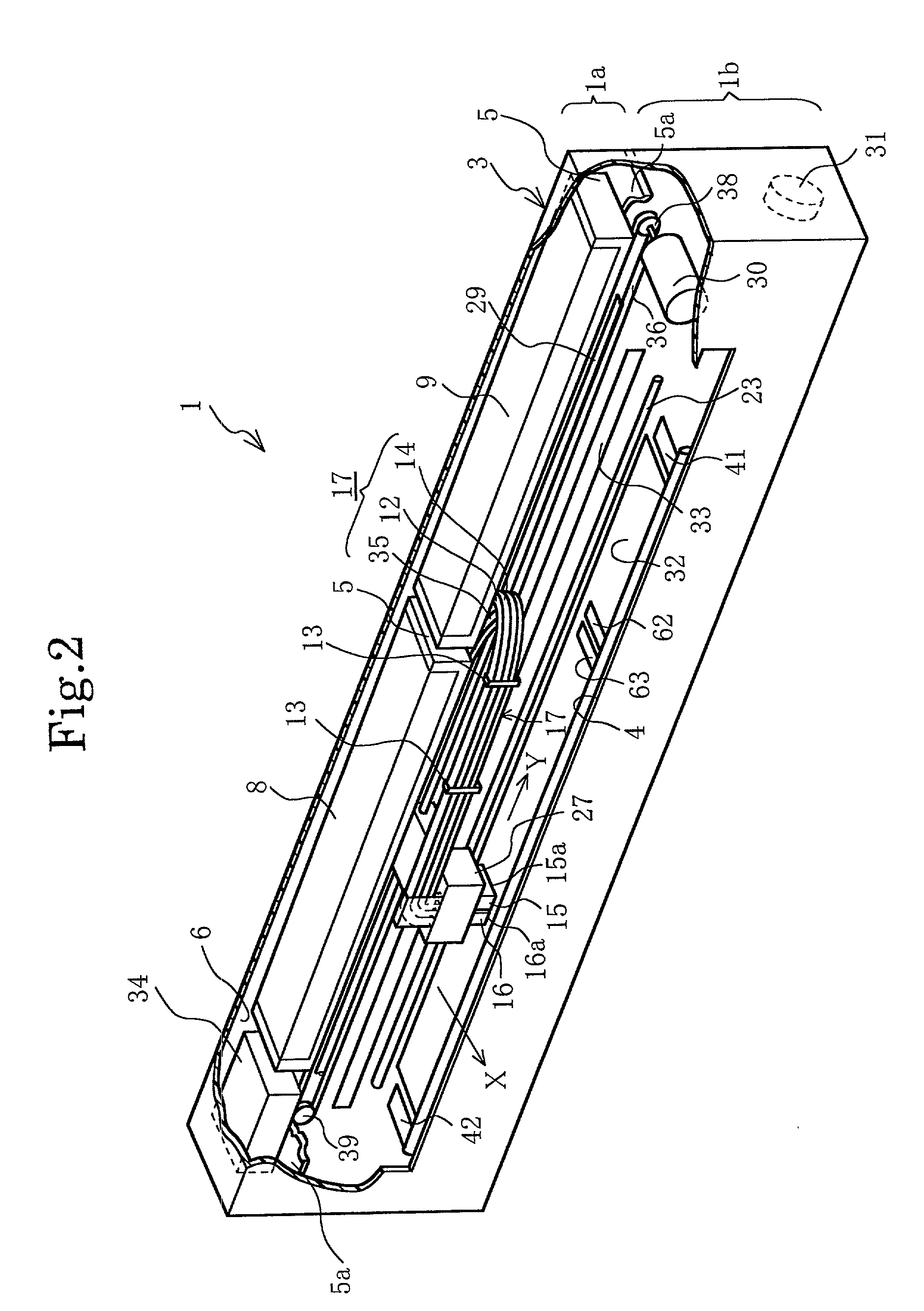

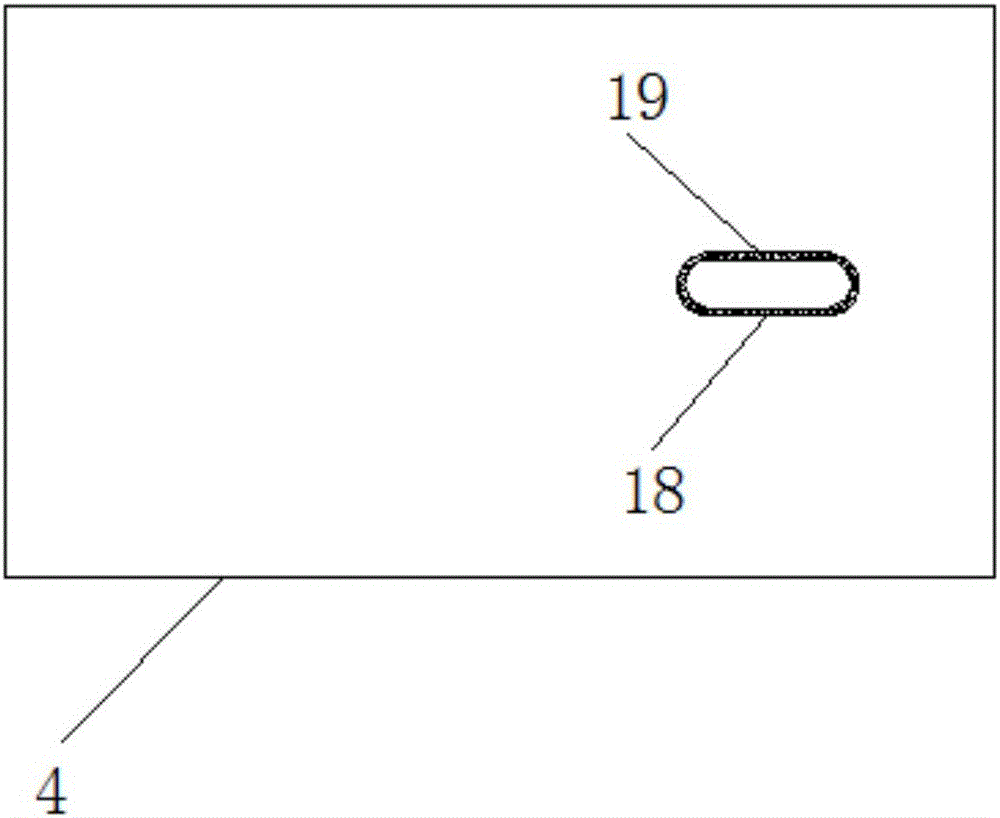

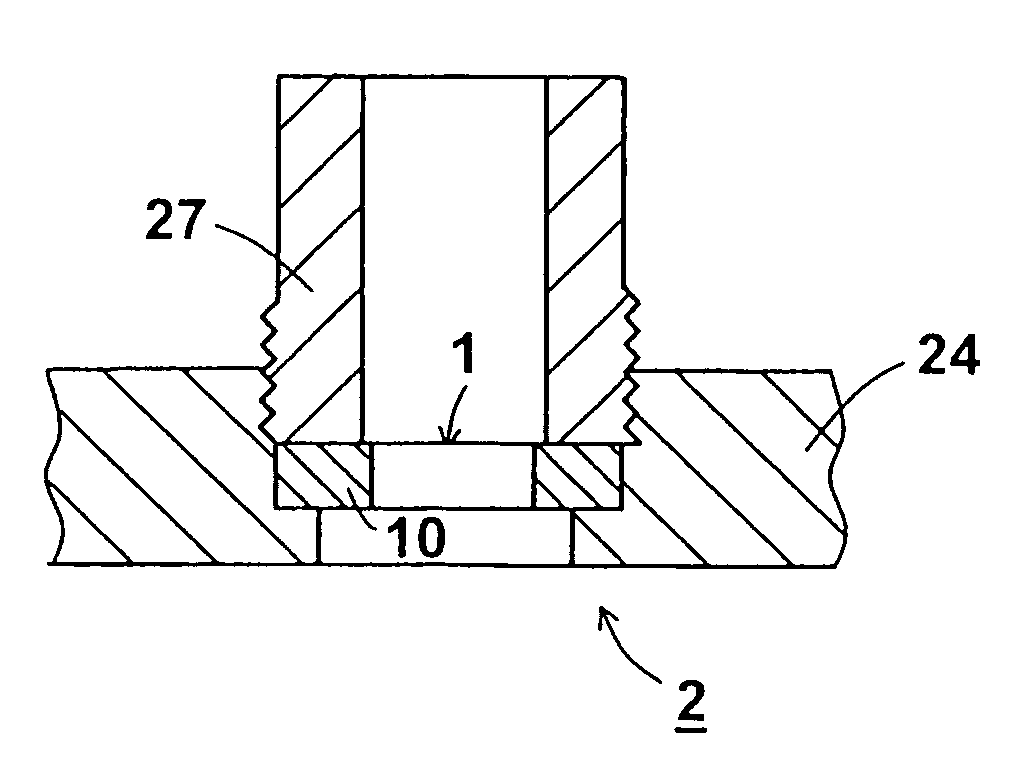

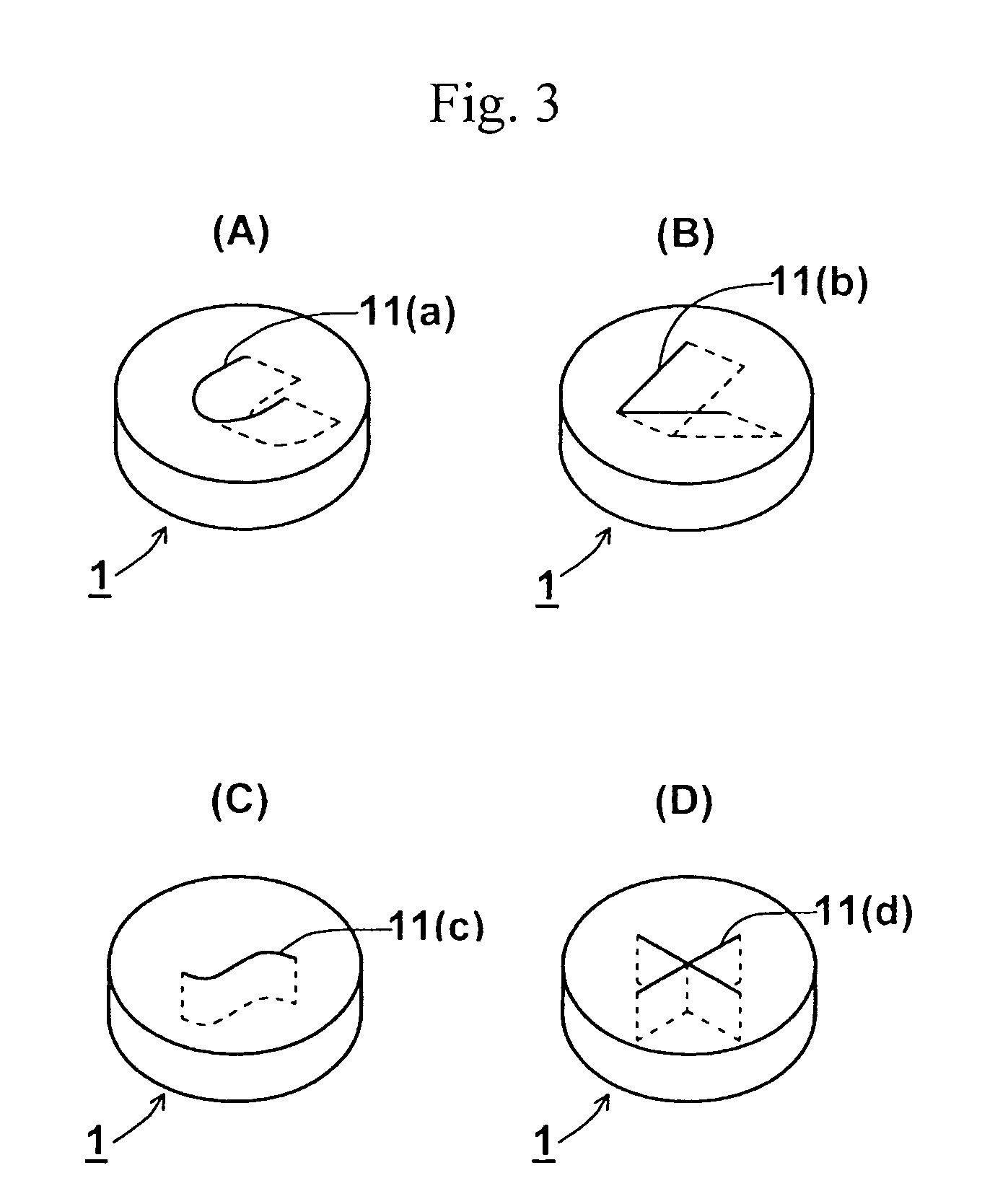

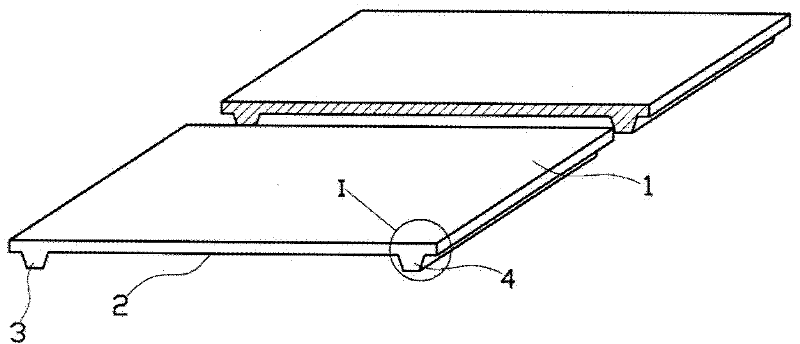

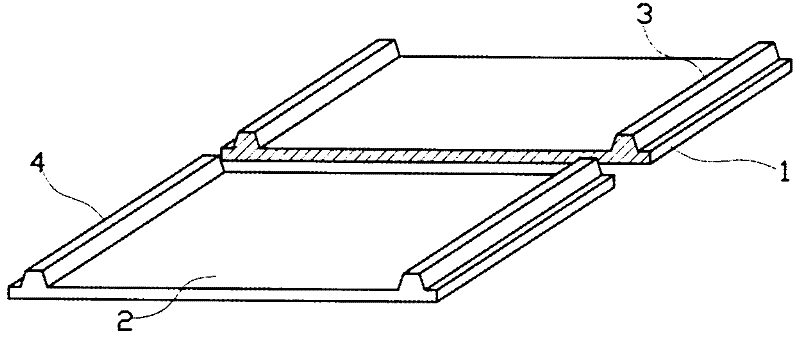

Mounting structure of re-peelable protective panel and mounting sheet using the same

InactiveUS20090087655A1Improve buffering effectAvoid elevationDetails for portable computersElectrical equipmentDisplay deviceEngineering

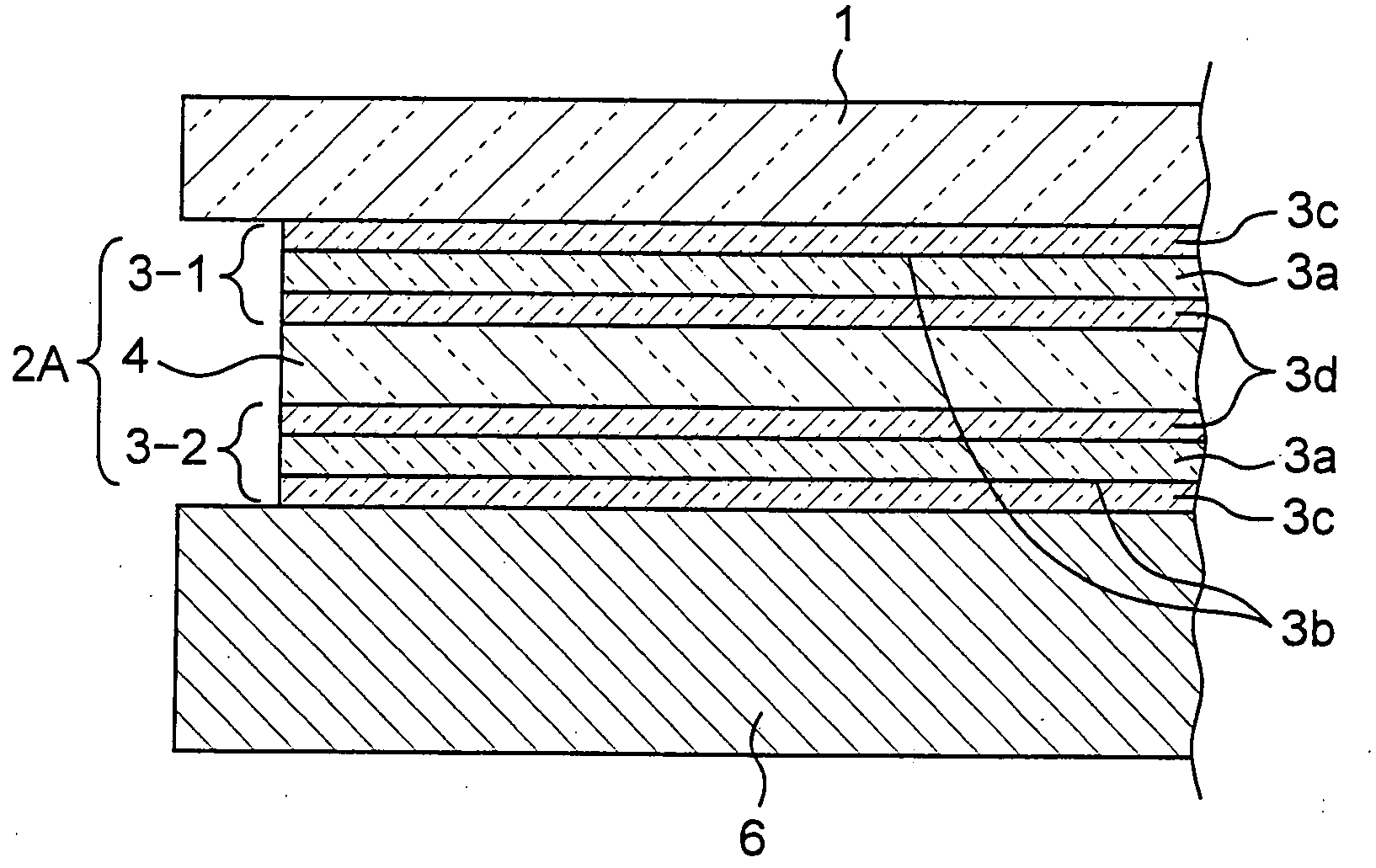

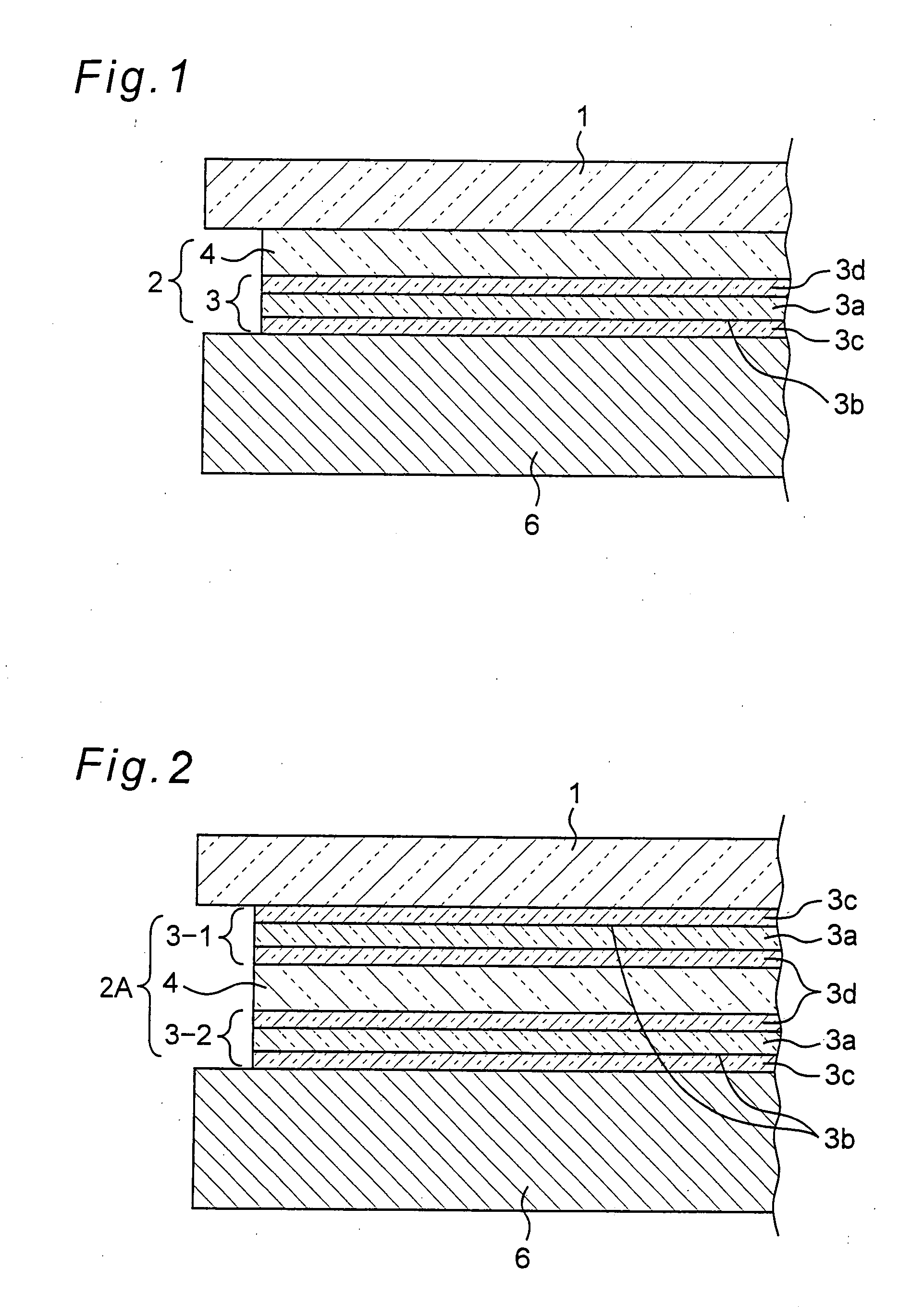

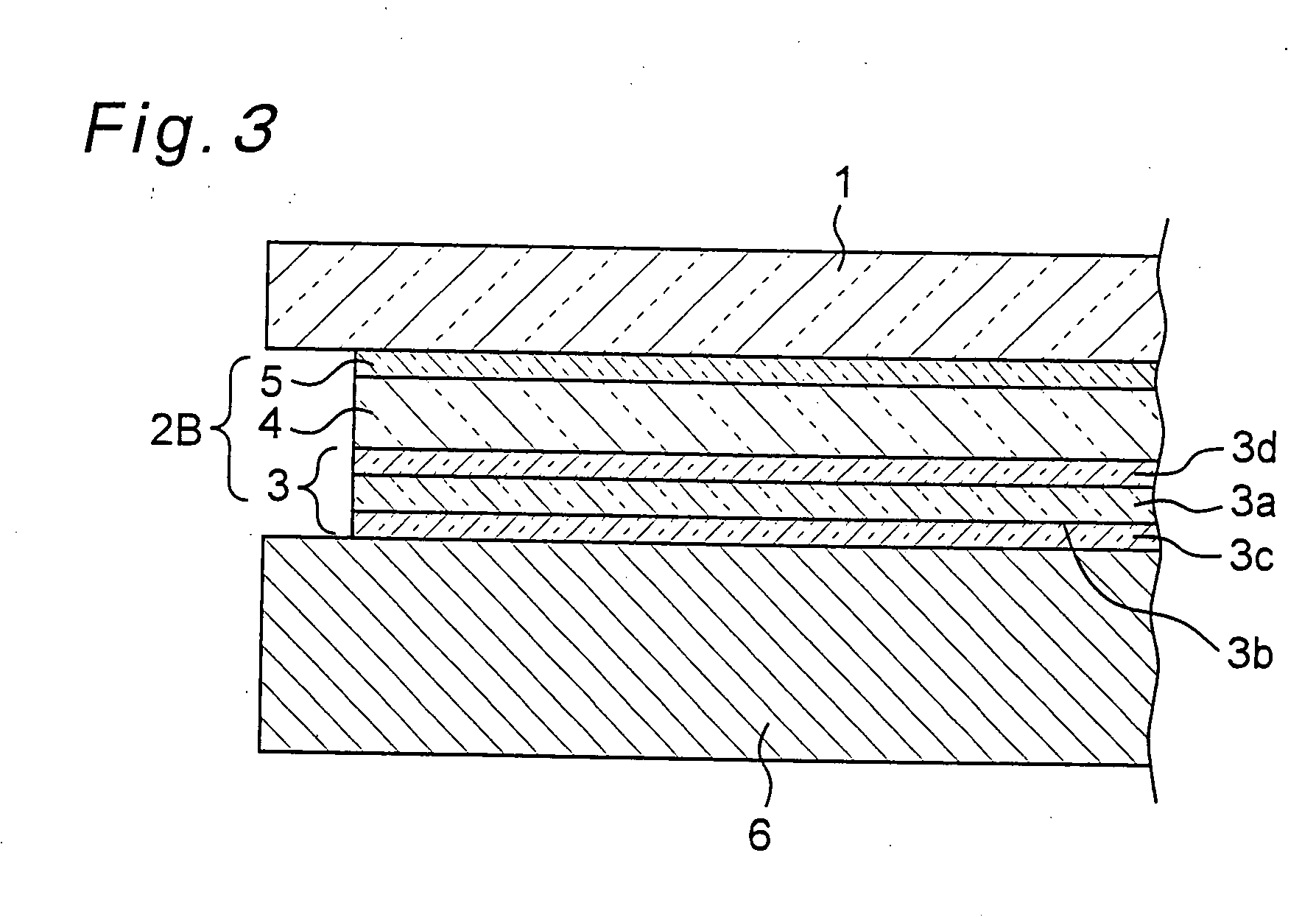

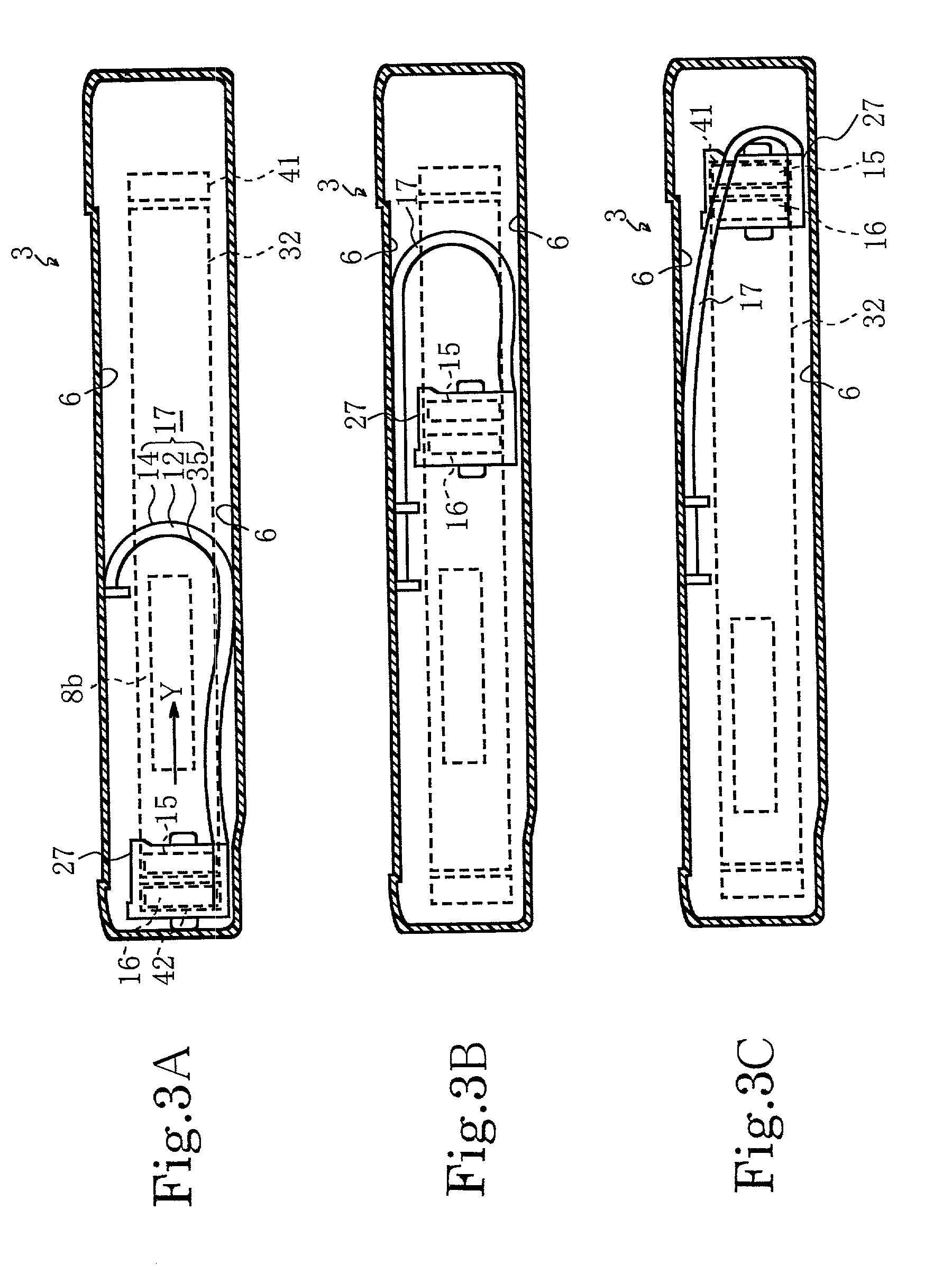

A transparent mounting sheet has a structure in which a one-sided re-peelable sheet, provided with a core member of a plastic film, a silicone rubber sheet that is laminated on a primer treated surface formed by one surface of the core member having been subjected to a primer treatment, and an acrylic adhesive agent layer that is laminated on the other surface of the core member, is bonded to at least one of surfaces of a gel sheet by the acrylic adhesive agent layer, and this transparent mounting sheet is used so that a protective panel for an electronic apparatus display window is mounted on a surface of a display in a manner so as to be re-peelable.

Owner:NISSHA PRINTING COMPANY

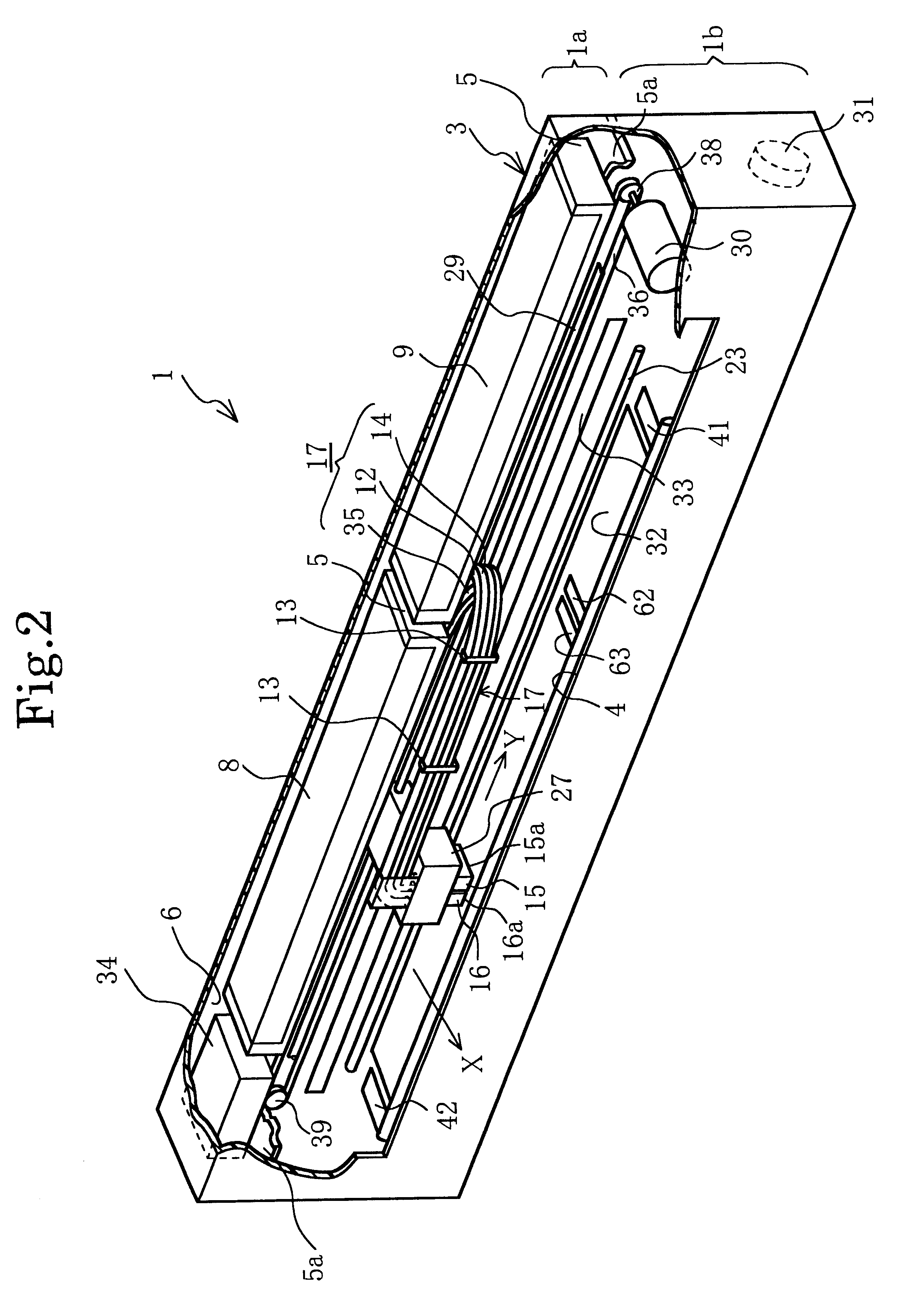

Ink cartridge

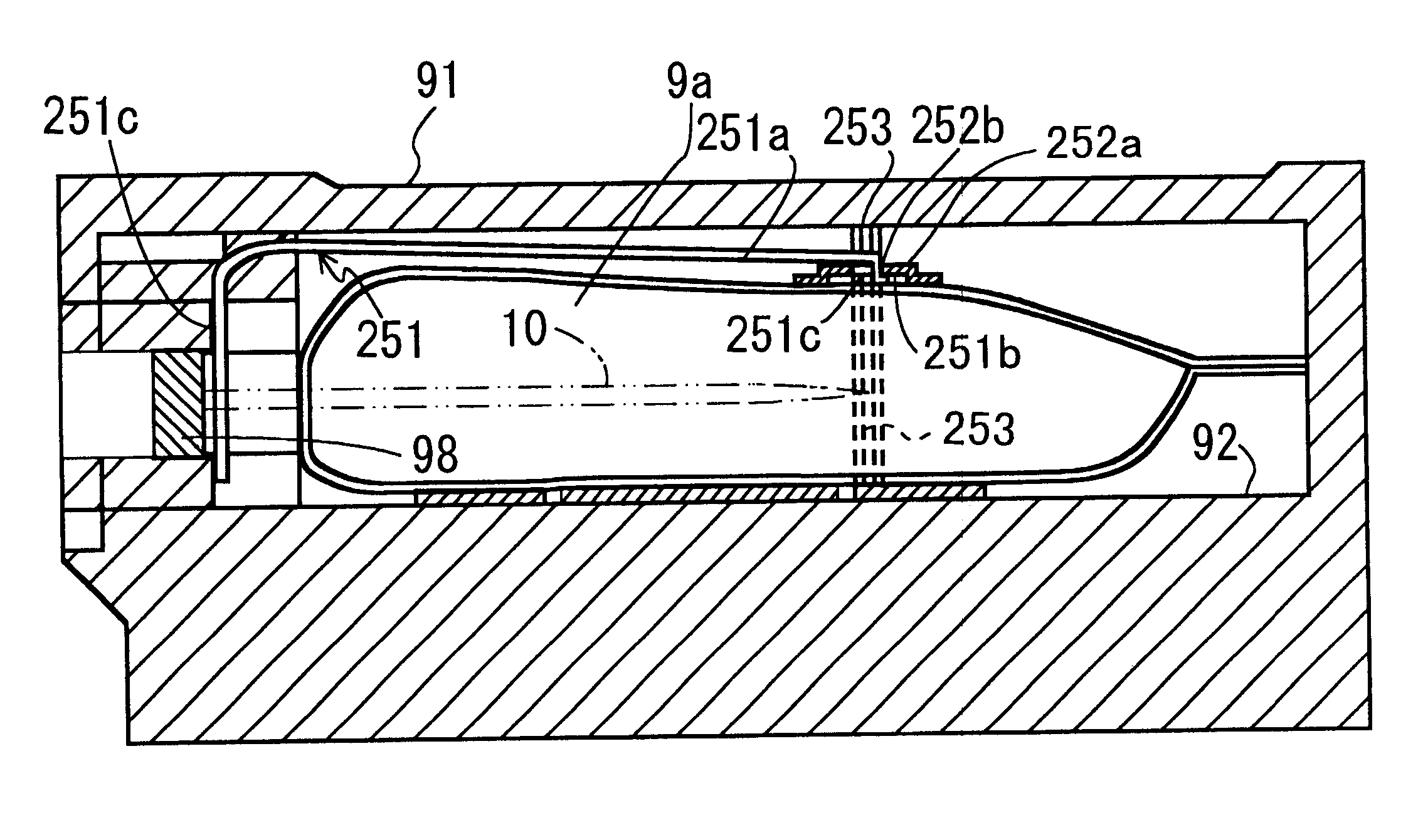

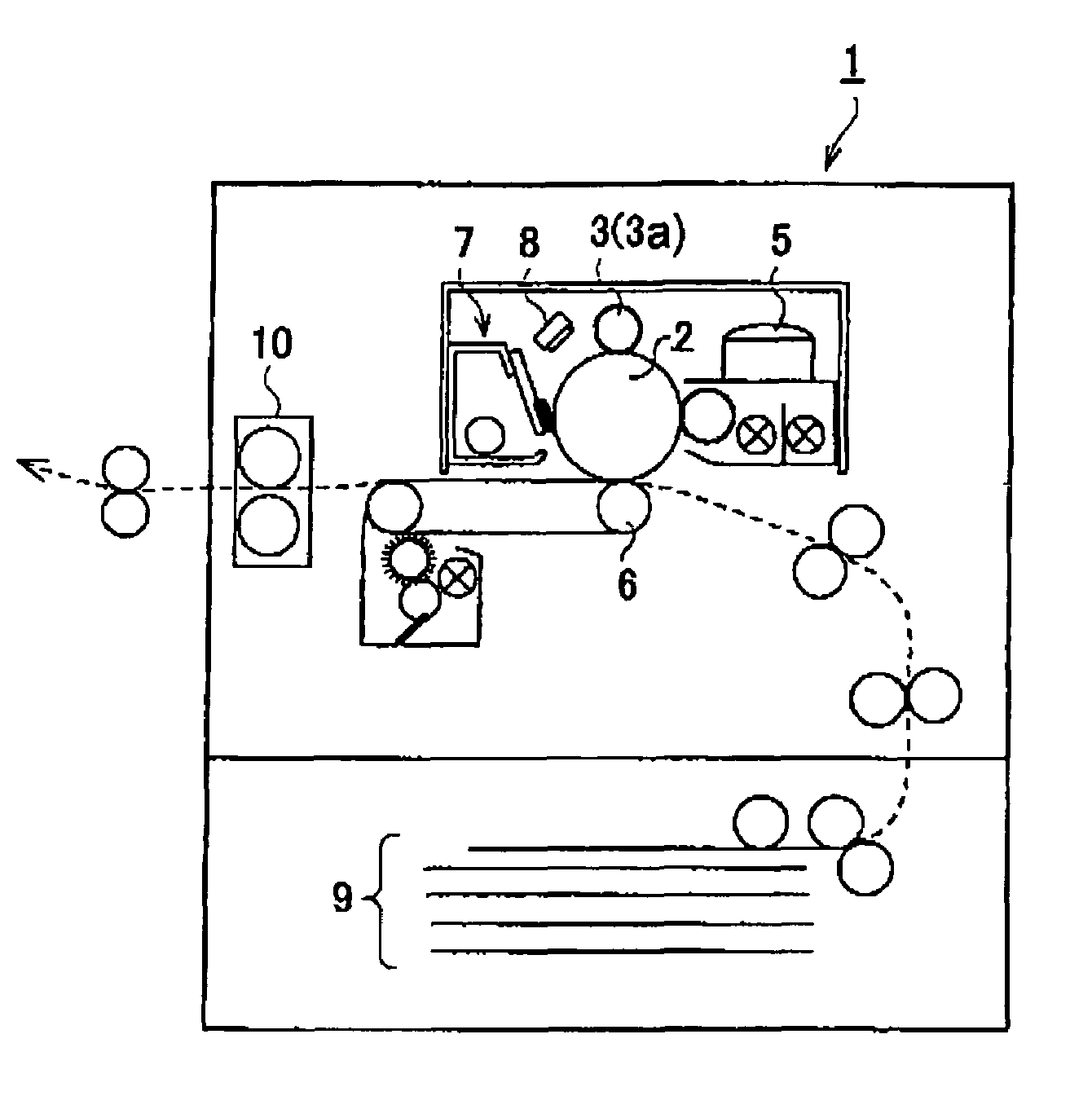

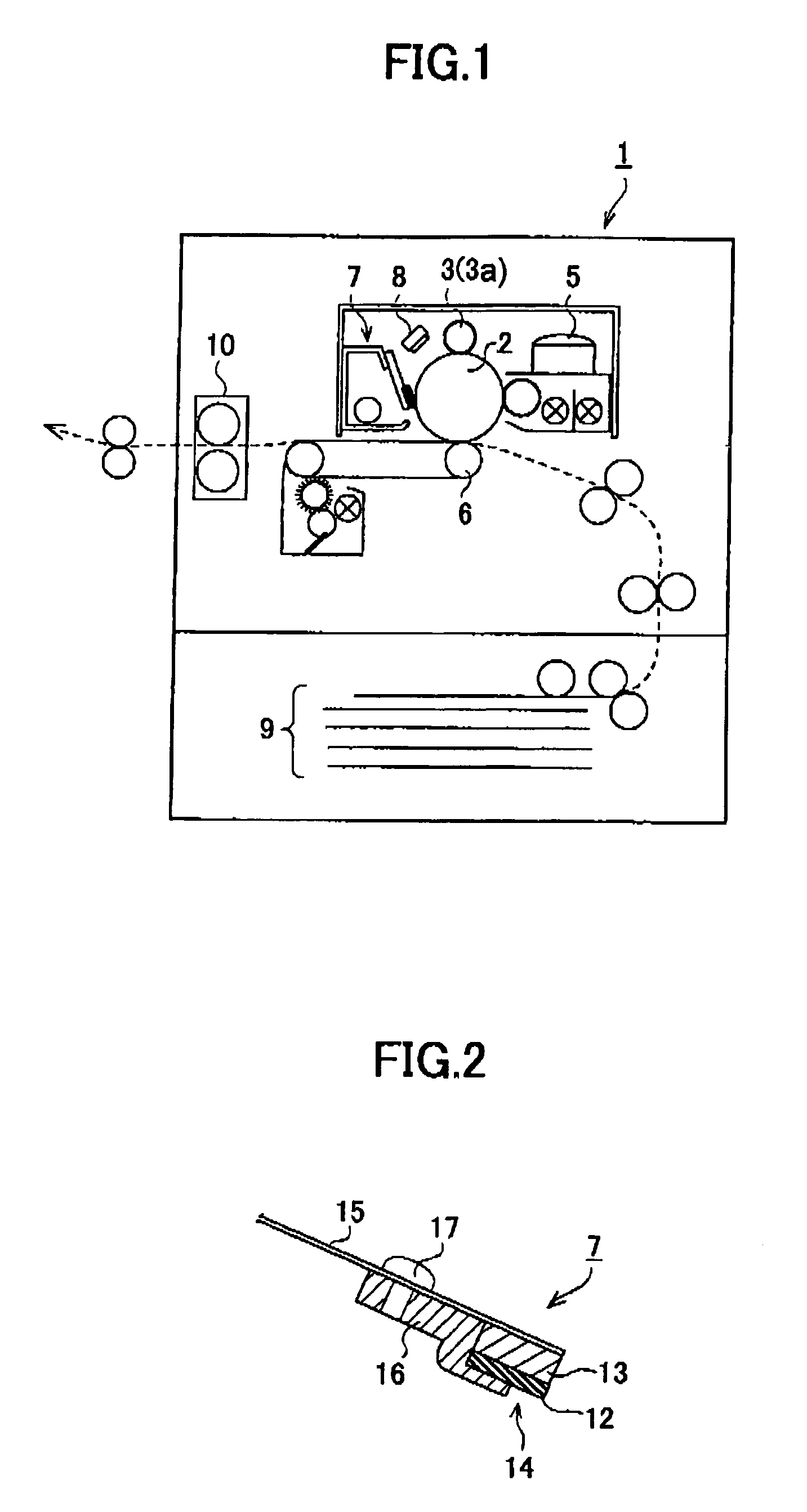

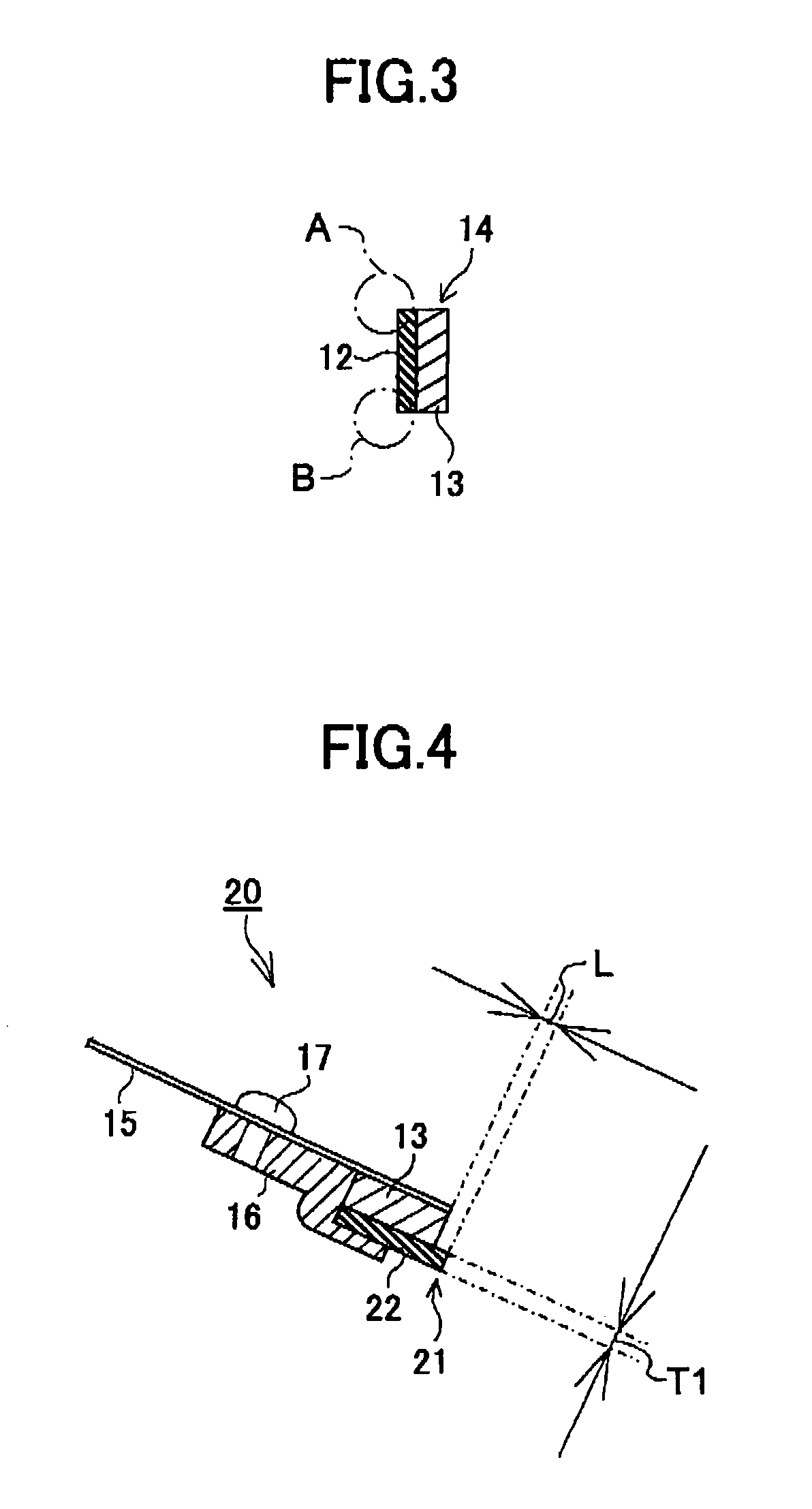

The invention provides a ink cartridge for supplying ink, including an ink pack formed from a flexible bag to seal liquid ink therein, a cartridge body having an ink pack housing therein, an extraction opening having a rubber plate into which a hollow ink extracting needle is inserted, an upper supporting spring movably supported with one end thereof by the cartridge body and affixed to the upper surface of the ink pack, and a lower supporting plate affixed to the lower surface of the ink pack and the lower surface of the cartridge body. A pair of the upper supporting spring and the lower supporting spring urges / pulls so that the volume of the bag of the ink pack is enlarged.

Owner:BROTHER KOGYO KK

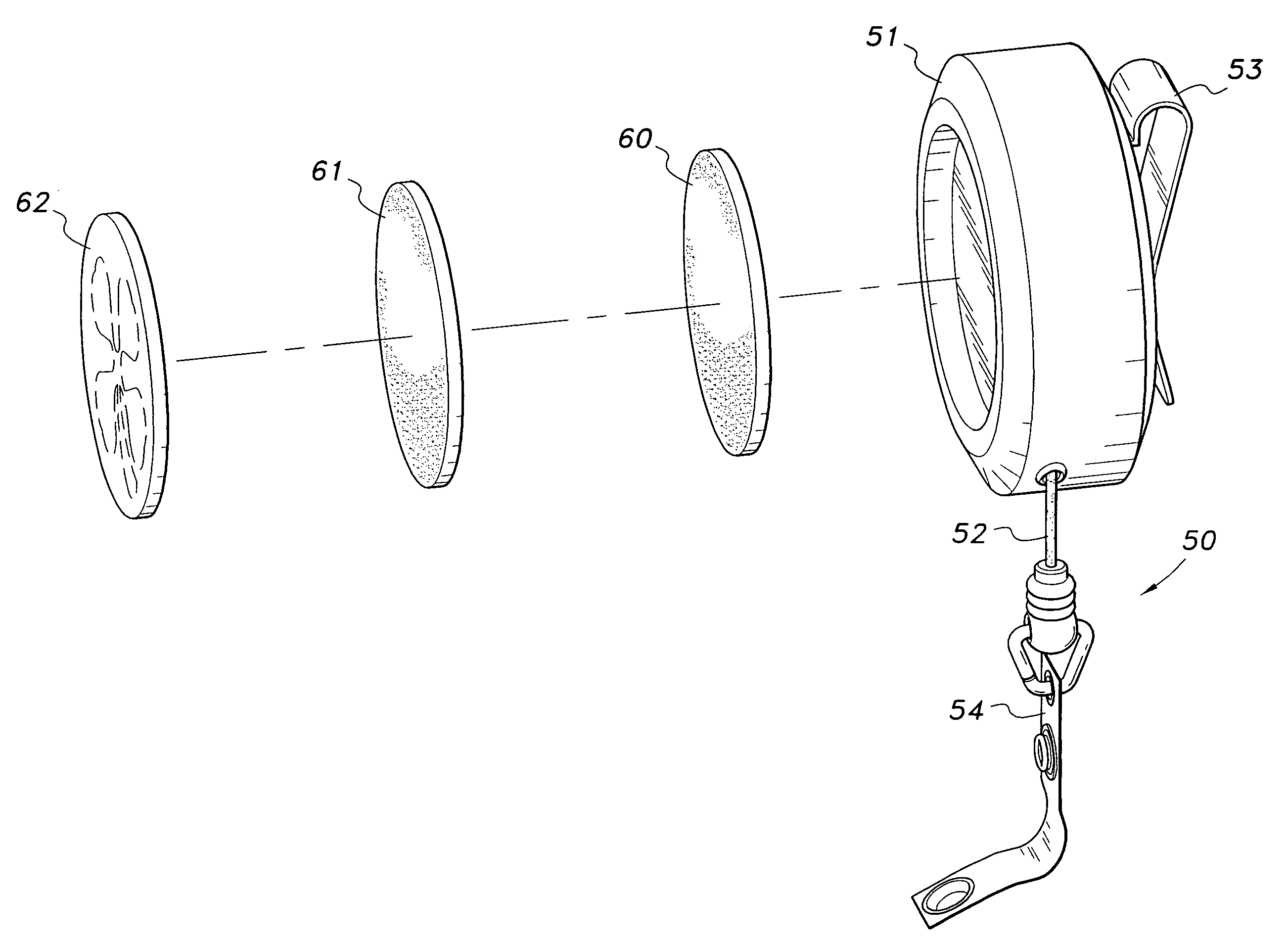

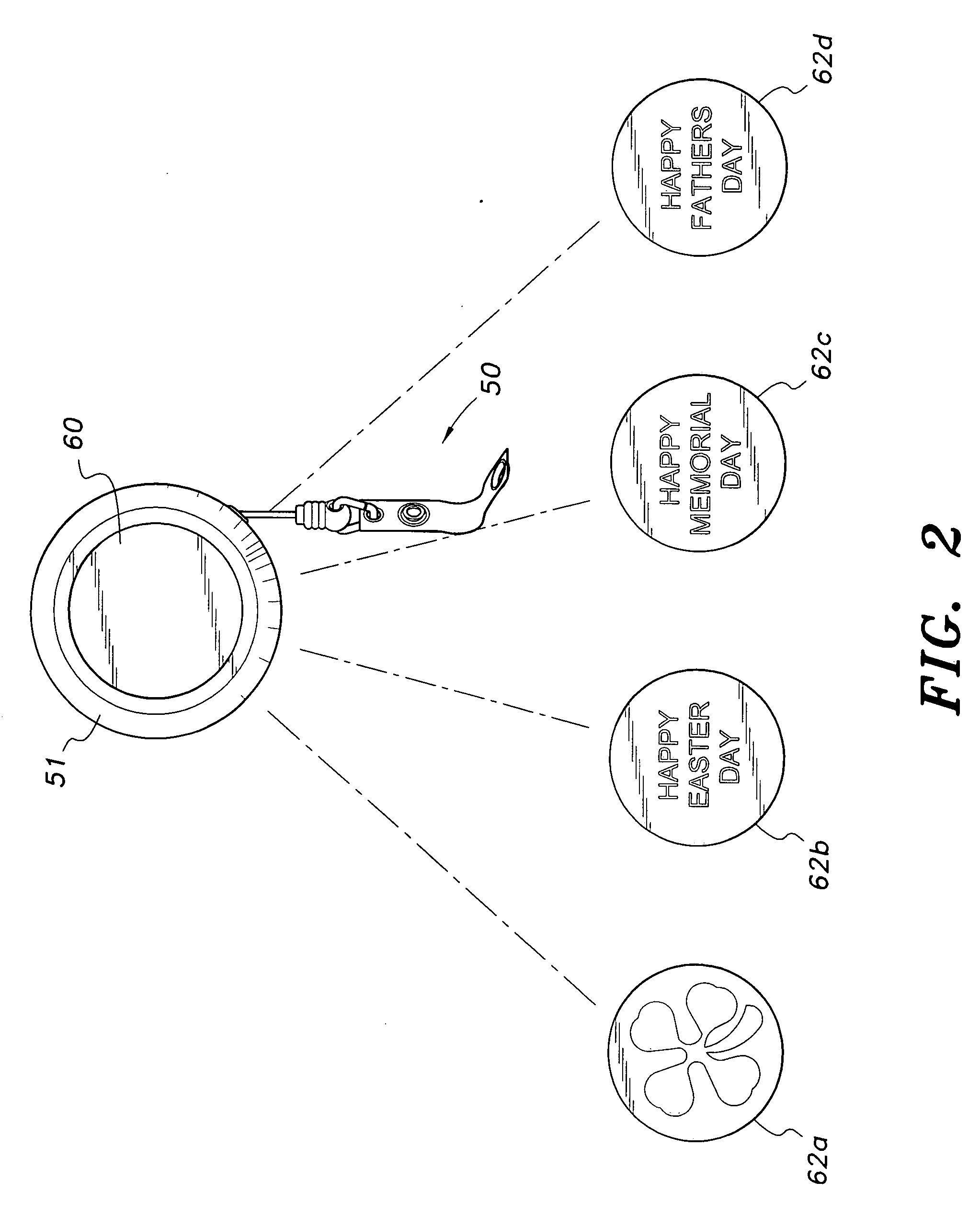

Retractable ID badge holder kit

The retractable ID badge holder kit provides removable and replaceable indicia on a retractable reel housing to celebrate a promotional event, special occasion or holiday. The kit contains a retractable reel supporting an ID badge holder at the end of the retractable cord or tether, a ferromagnetic plate to be glued to one side of the reel housing, an assortment of promotional pictures symbolic of special events, special occasions and holidays, and a rubberized sheet magnet attached or attachable to the rear surface of the pictures.

Owner:ANGIULI JOSEPH

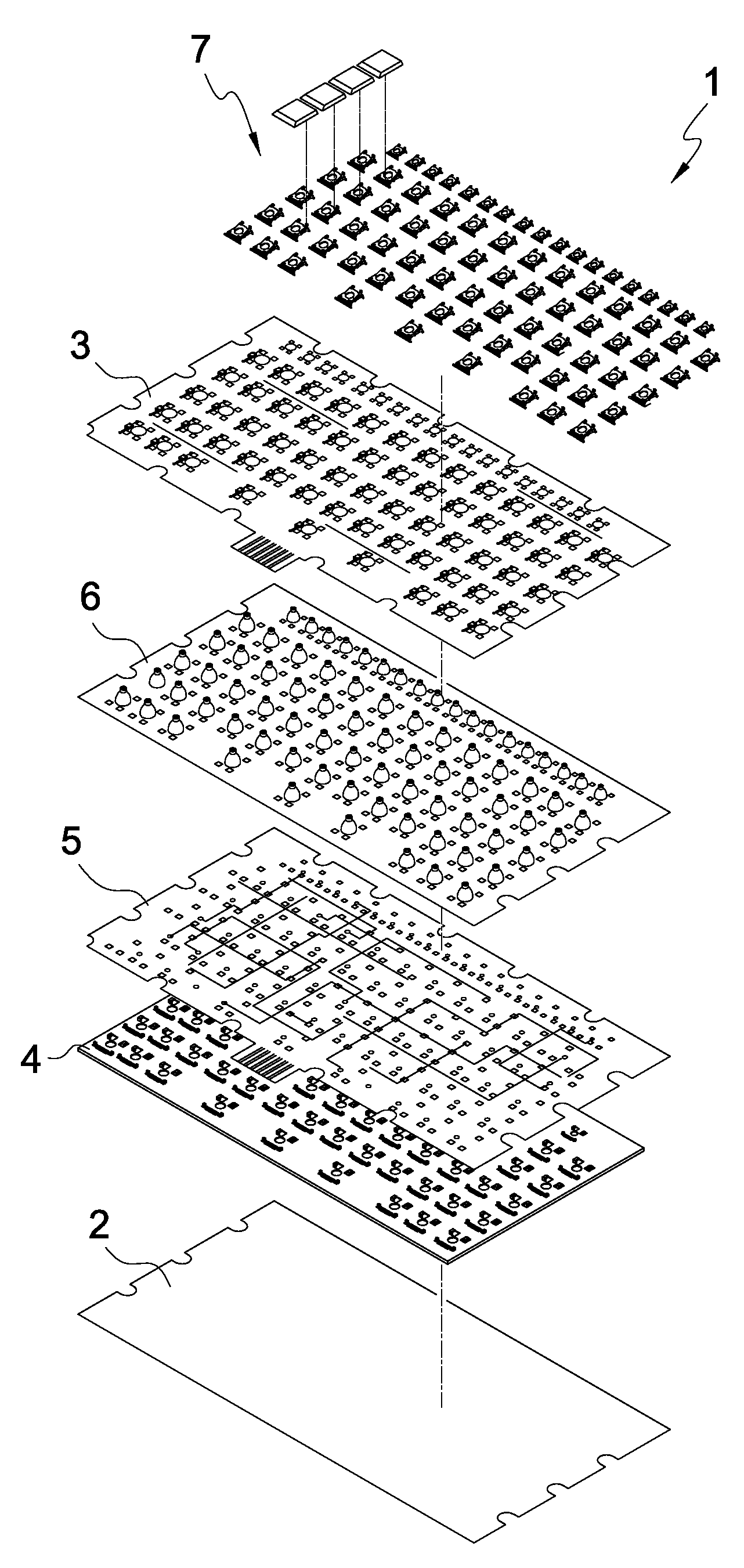

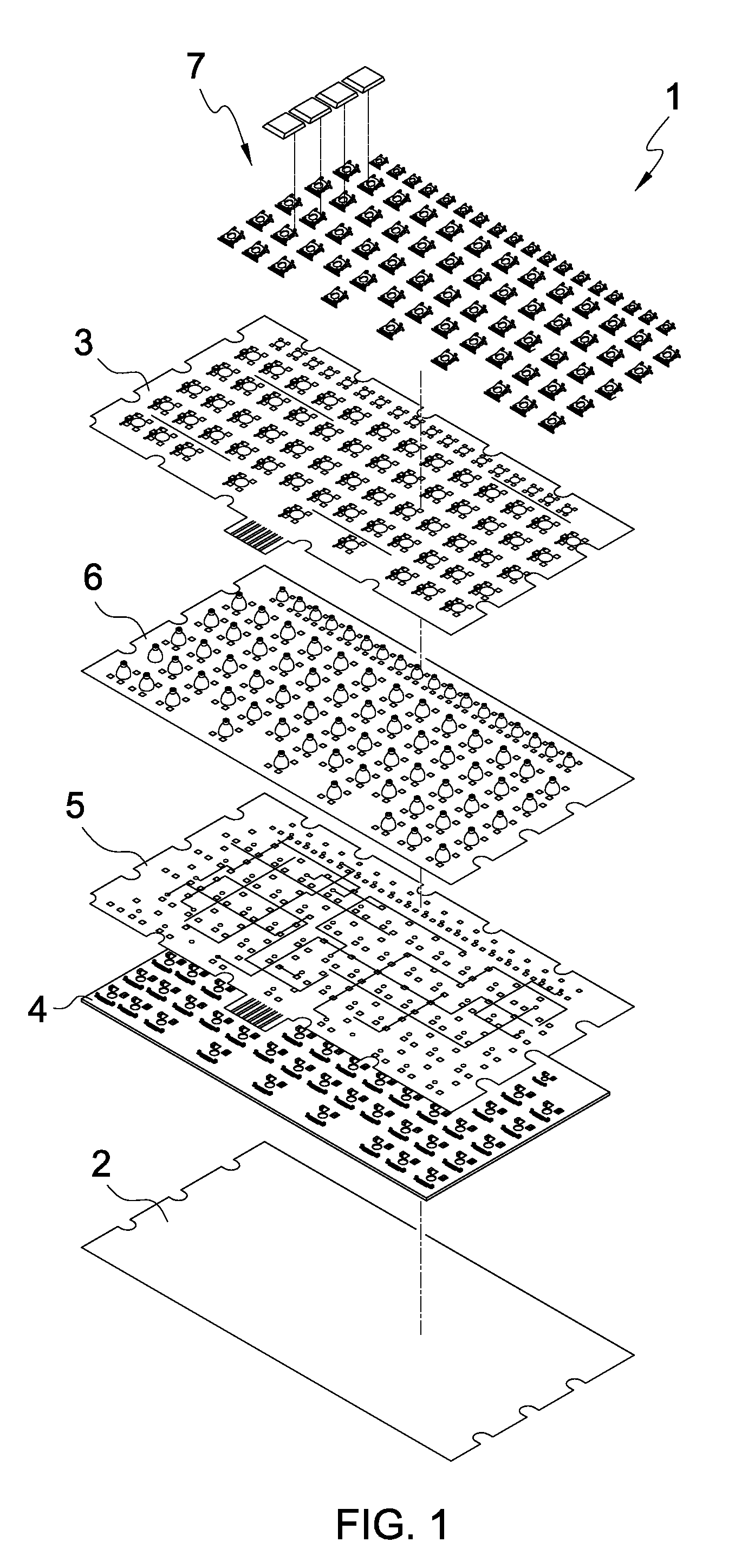

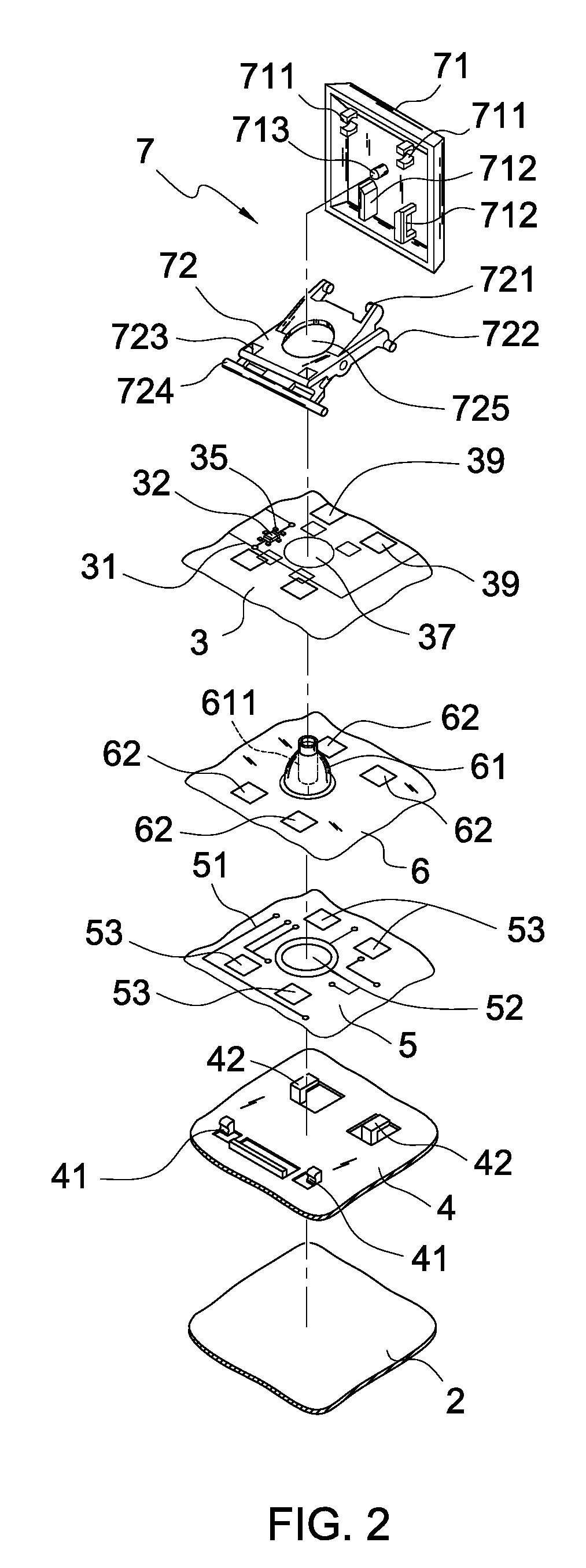

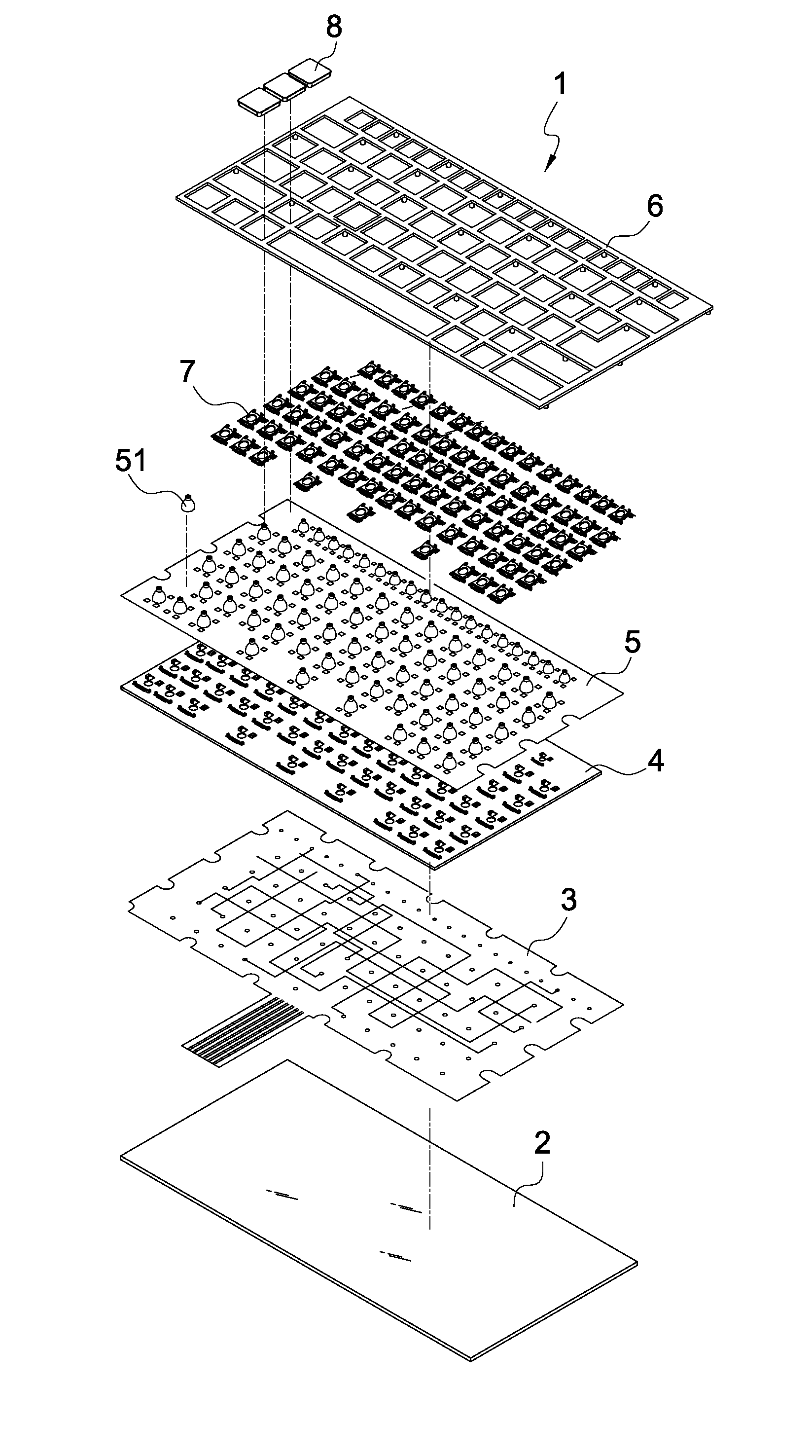

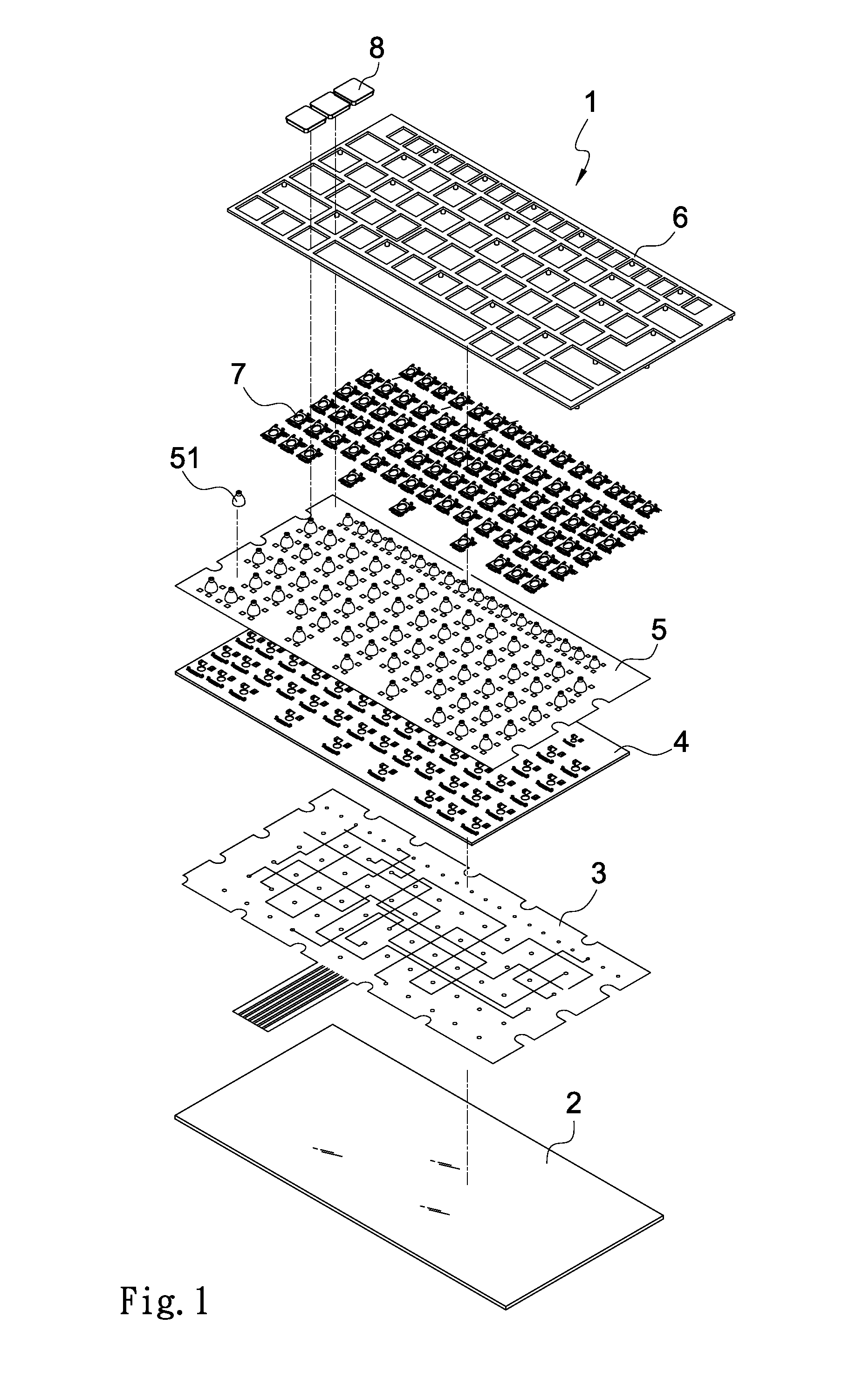

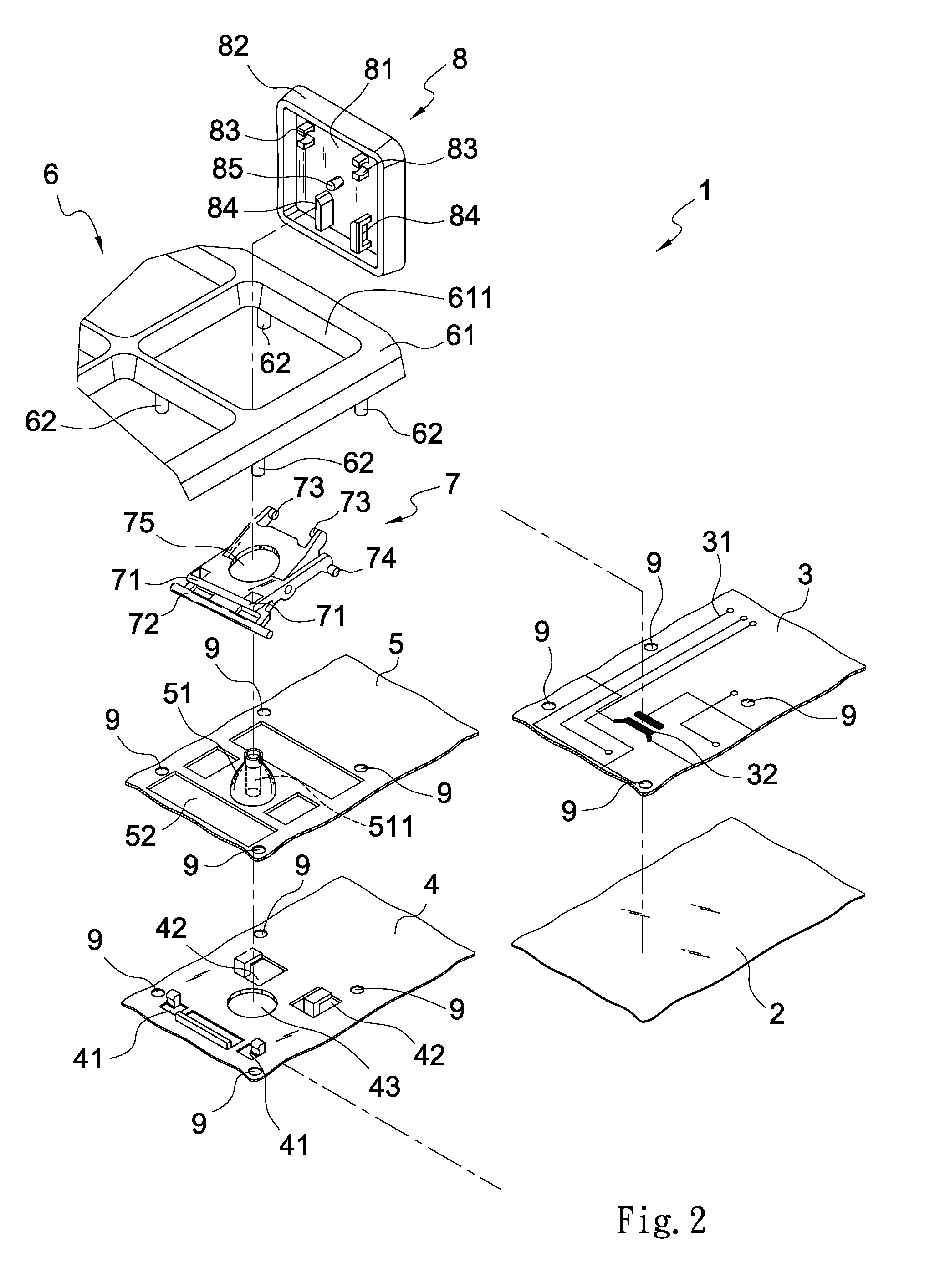

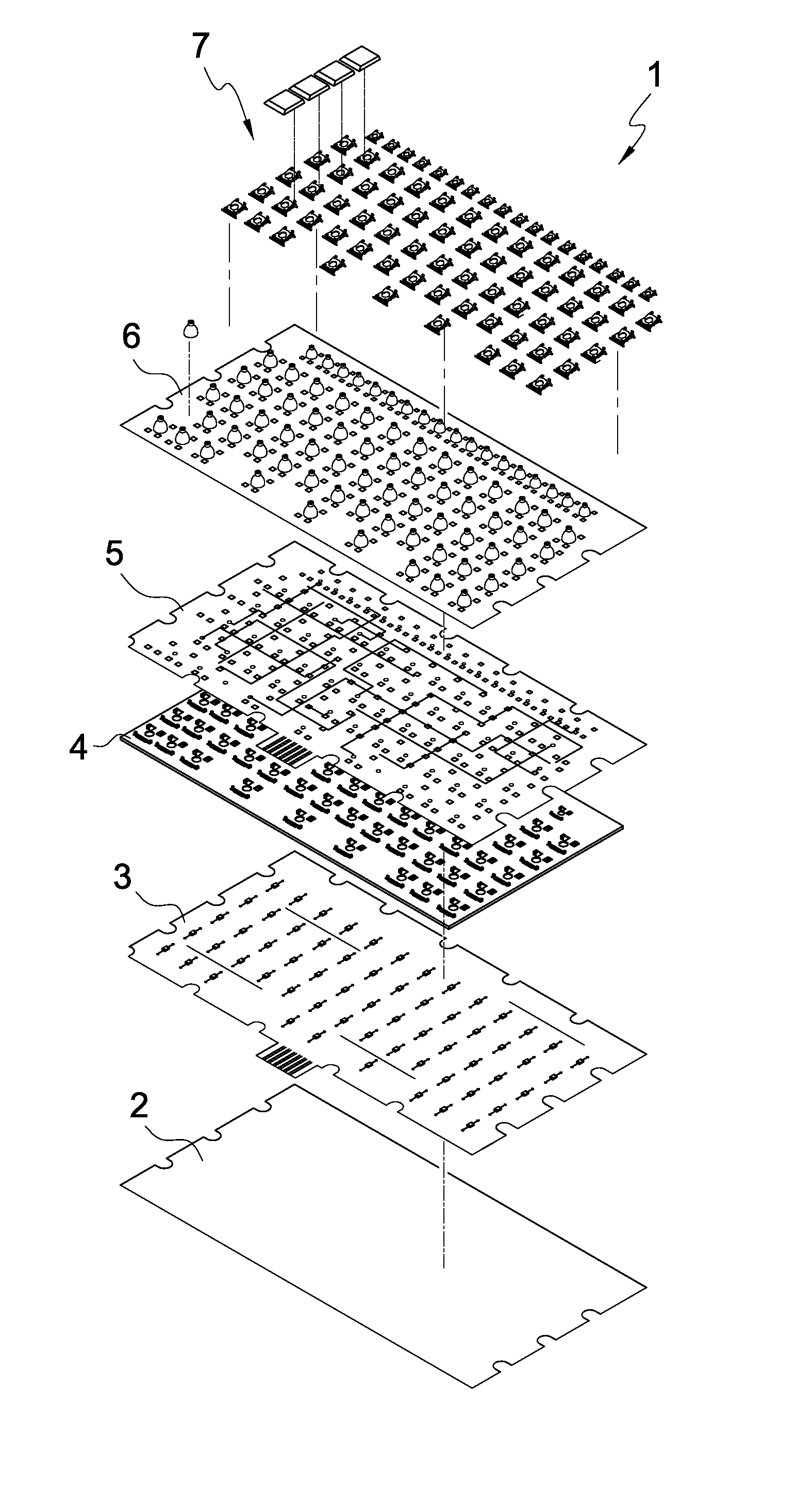

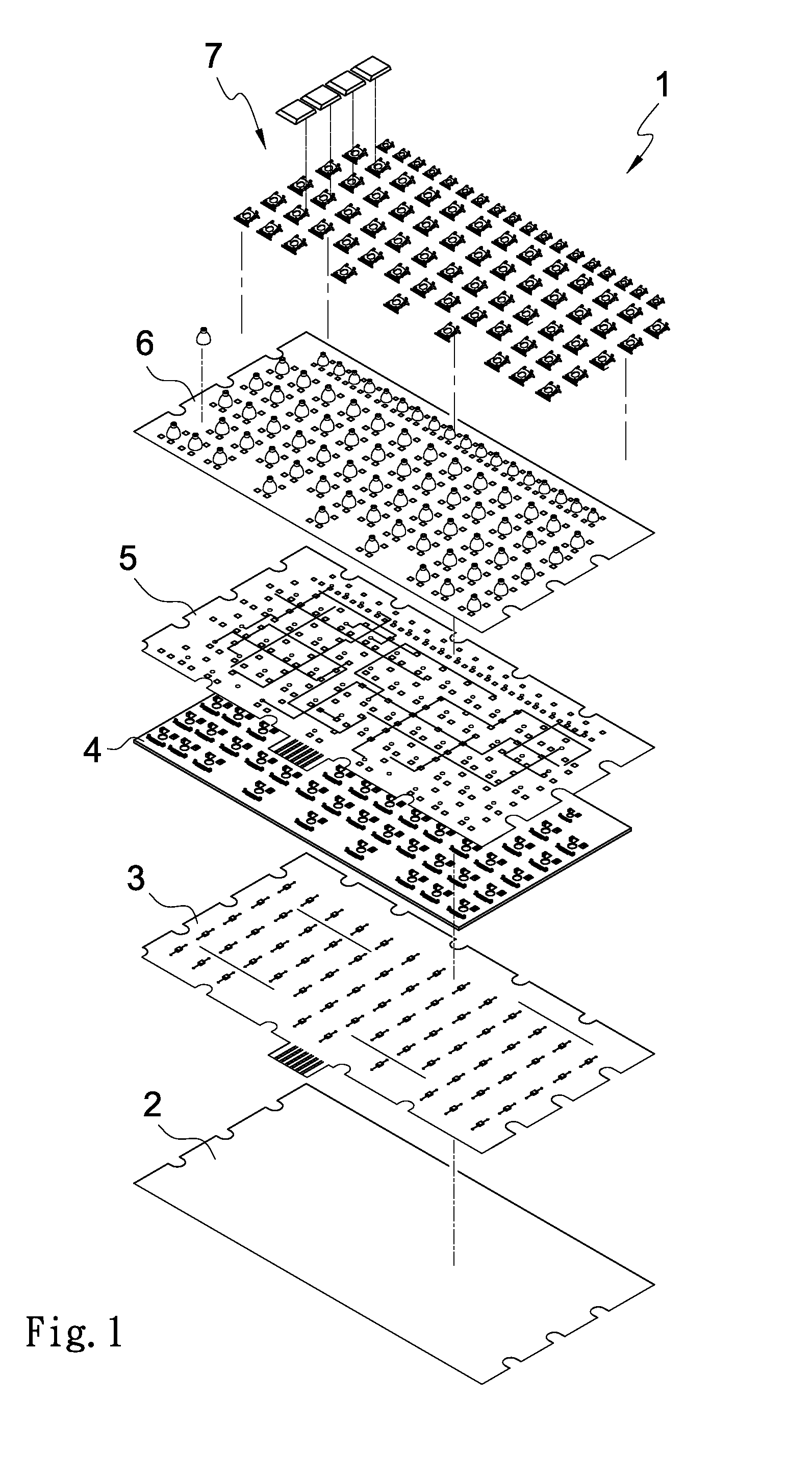

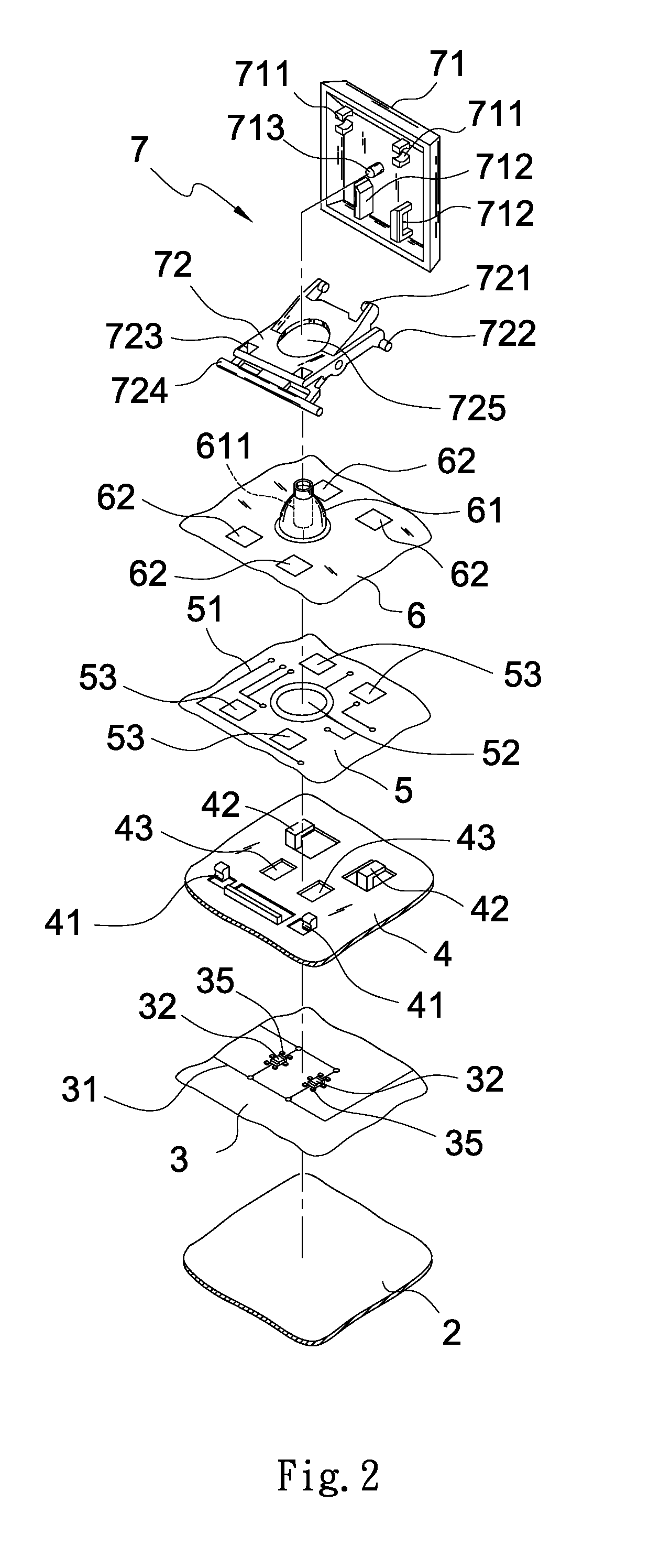

Illuminated keyboard

An illuminated keyboard includes keys; a spacer board on a base plate and comprising units each including two first groove connectors and two second groove connectors; an optically transmissive film circuit board on the spacer board and comprising a second circuitry, switch contacts, and first holes each with the first or second groove connector passing; a rubber plate of optically transmissive plastic and on the film circuit board, the rubber plate comprising resilient domes having a recessed top for retaining the key, a conductive bottom stem above the switch contact, and second holes grouped as groups each formed as four corners around the dome, the first or second groove connectors adapted to pass through the second holes; and an LED circuit board on the rubber plate and comprising a first circuitry and LEDs electrically connected to the first circuitry to be powered therefrom.

Owner:SUNREX TECH

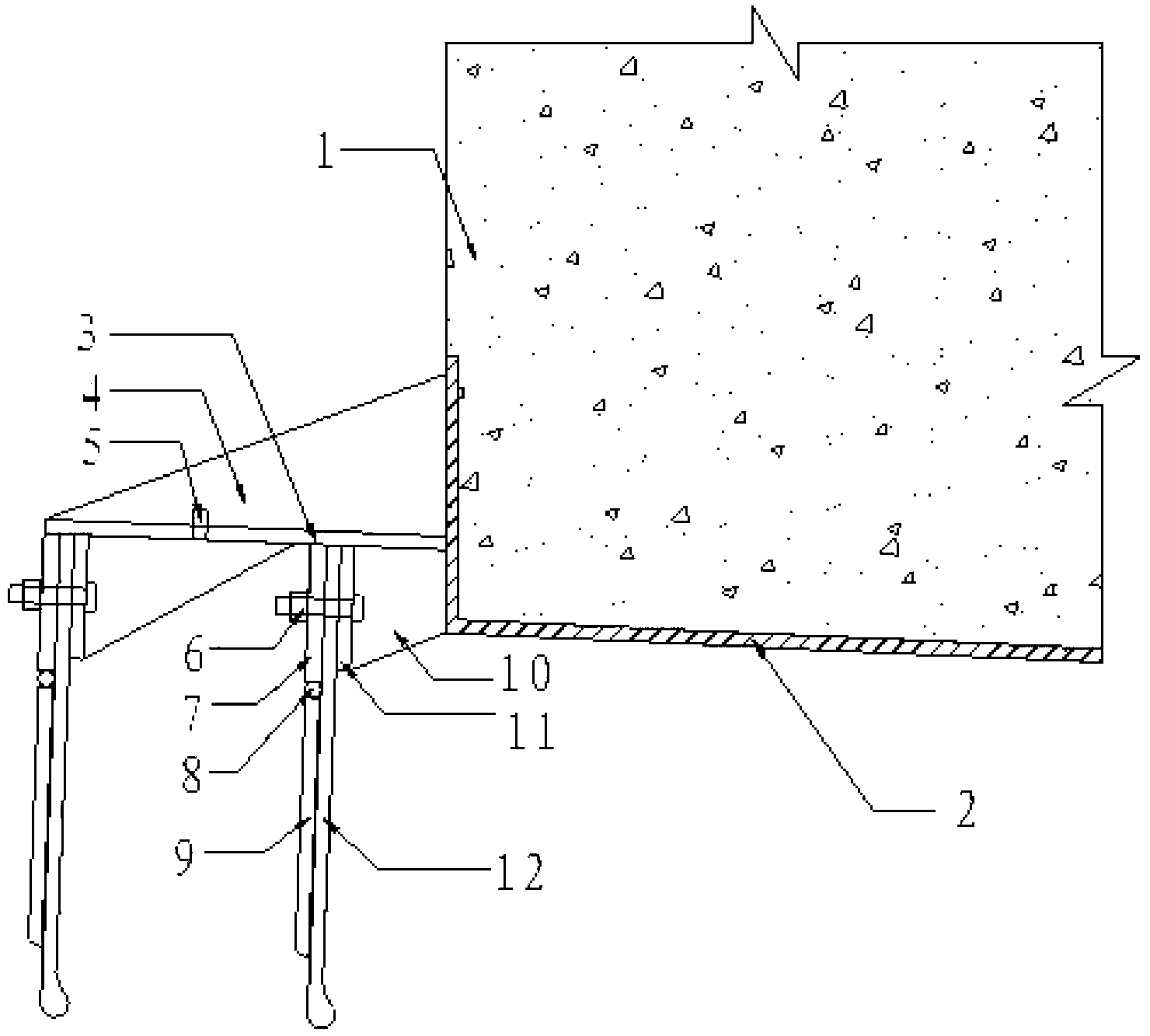

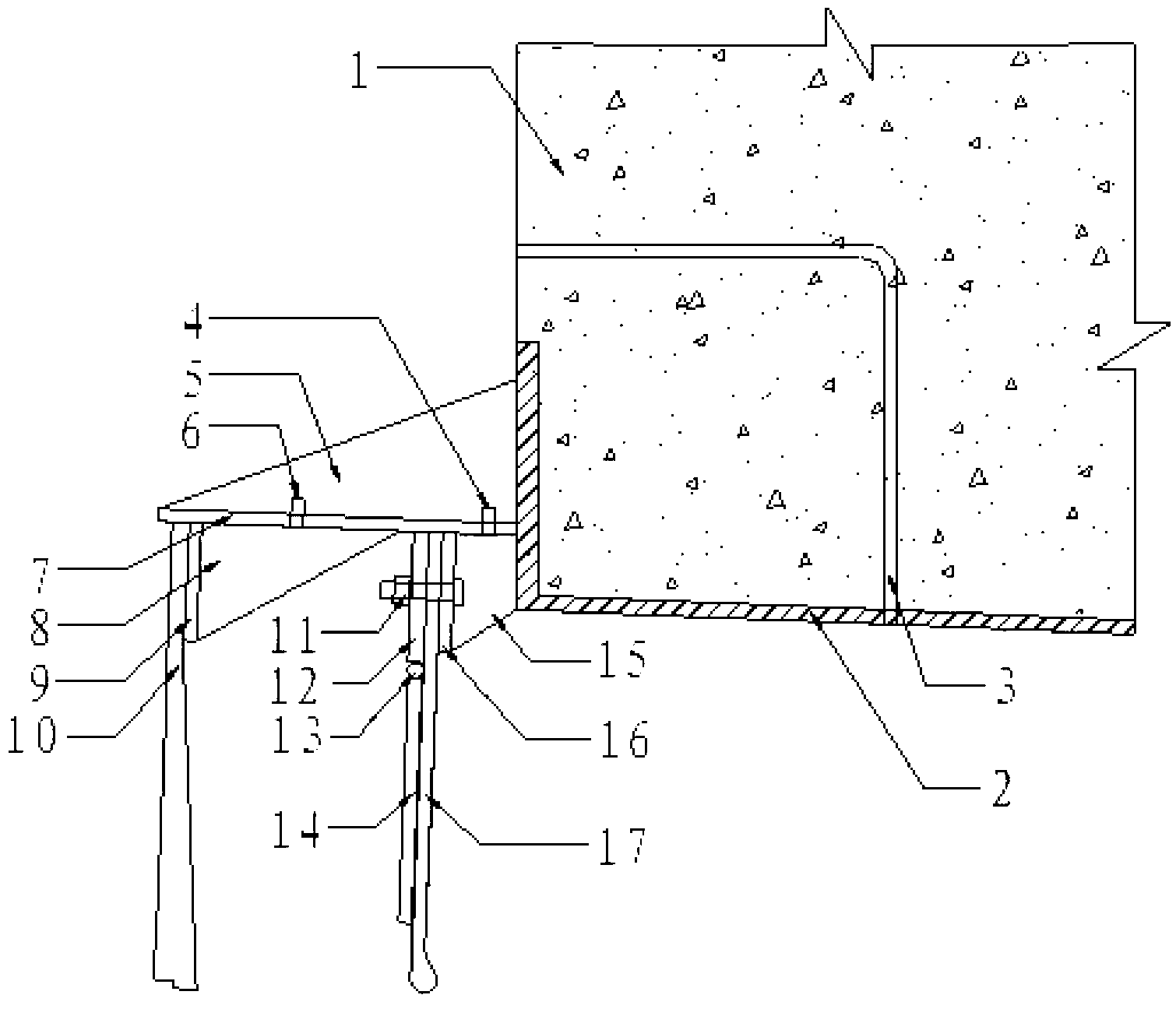

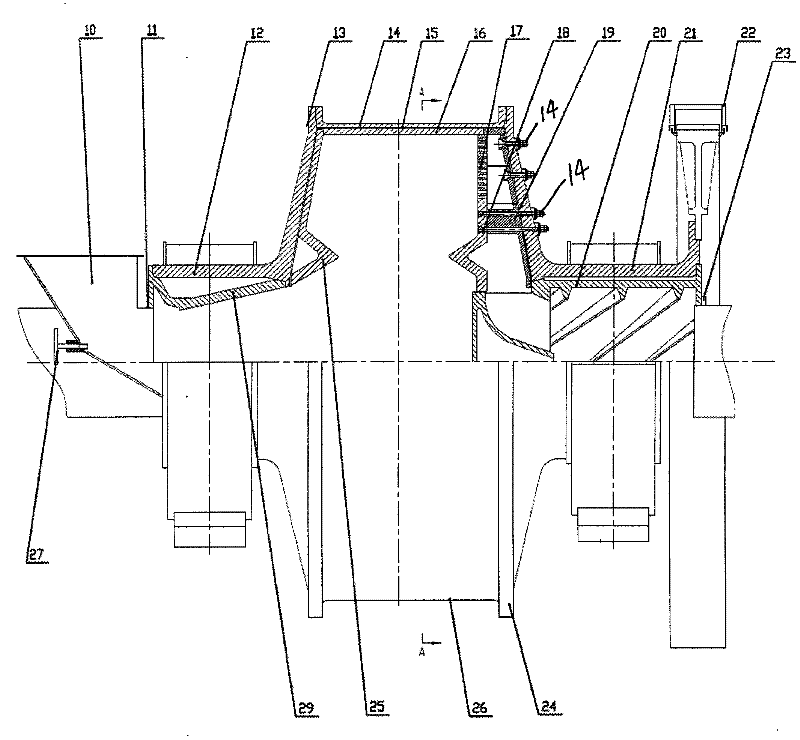

Shield tunnel portal sealing device and shield tunnel portal sealing method

InactiveCN103266898APrevent gushingPrevent water seepageUnderground chambersTunnel liningEngineeringShield tunneling

The invention belongs to the technical field of shield tunnel engineering and particularly relates to a shield tunnel portal sealing device and a shield tunnel portal sealing method. The shield tunnel portal sealing device comprises a lined wall, an embedded steel ring is arranged on the lined wall, a sealing box is arranged on the embedded steel ring and comprises a sealing steel ring, a fixing plate, a fold type support plate and two waterproof structures, a plurality of grease injecting holes are evenly circumferentially reserved in the sealing steel ring between the two waterproof structures, each waterproof structure comprises a steel wire brush and a cord fabric rubber plate, the cord fabric rubber plates are arranged on one side close to the embedded steel ring, and grouting holes are reserved in the lined wall and in the sealing steel ring on the inner sides of the cord fabric rubber plates. The shield tunnel portal sealing device has the advantages that the cord fabric rubber plates are primarily used for sealing to prevent a major part of water and soil from pouring out, so that 'pouring prevention' is achieved; water penetration is prevented as the steel wire brushes secondarily achieve seamless contact with a shield tunneling machine shell or duct pieces; and the grouting holes reserved in the lined wall and the sealing steel ring can achieve grouting sealing timely in emergencies.

Owner:CCCC SECOND HARBOR ENG

Ink cartridge

The invention provides a ink cartridge for supplying ink, including an ink pack formed from a flexible bag to seal liquid ink therein, a cartridge body having an ink pack housing therein, an extraction opening having a rubber plate into which a hollow ink extracting needle is inserted, an upper supporting spring movably supported with one end thereof by the cartridge body and affixed to the upper surface of the ink pack, and a lower supporting plate affixed to the lower surface of the ink pack and the lower surface of the cartridge body. A pair of the upper supporting spring and the lower supporting spring urges / pulls so that the volume of the bag of the ink pack is enlarged.

Owner:BROTHER KOGYO KK

Computer keys with inwardly tapered bottom

A computer keyboard includes a base plate; a film circuit board; a spacer plate; a rubber plate; a key housing; a plurality of pivotal scissor shaped structures; and a plurality of keys each comprising a key cap and a periphery depending downward from the key cap to inwardly taper toward bottom. The keyboard has the following advantages: Increased key cap surface for printing or engraving additional characters or Braille characters on the key cap. Debris or other foreign objects are not easy to enter the keyboard through gaps between keys. The keyboard can be made low-profile.

Owner:SUNREX TECH

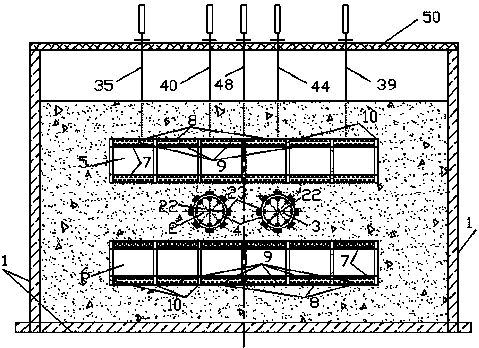

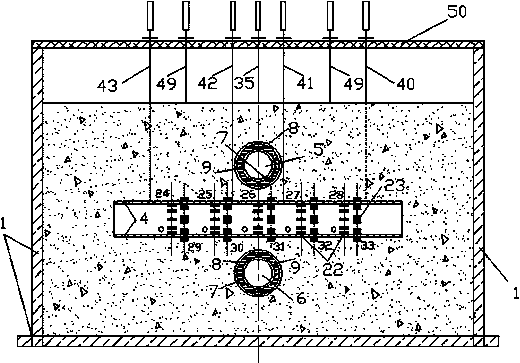

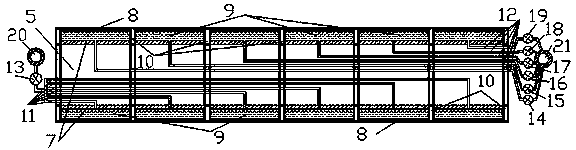

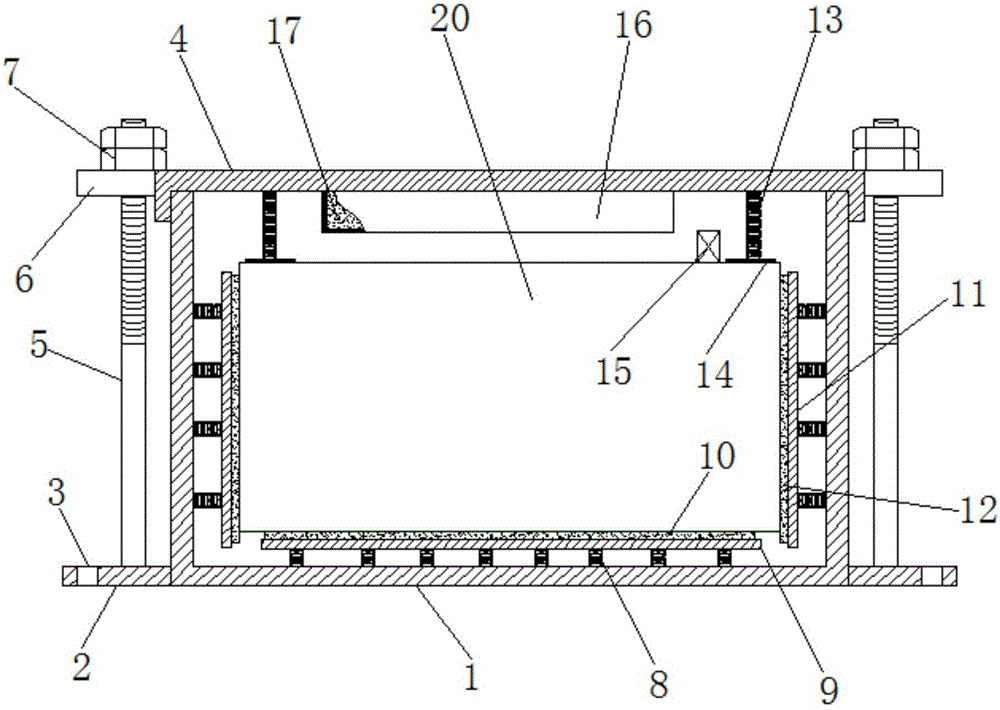

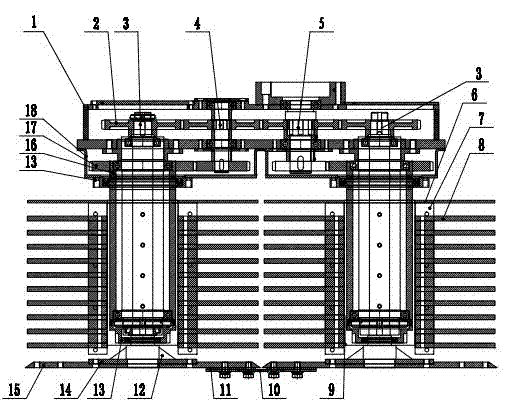

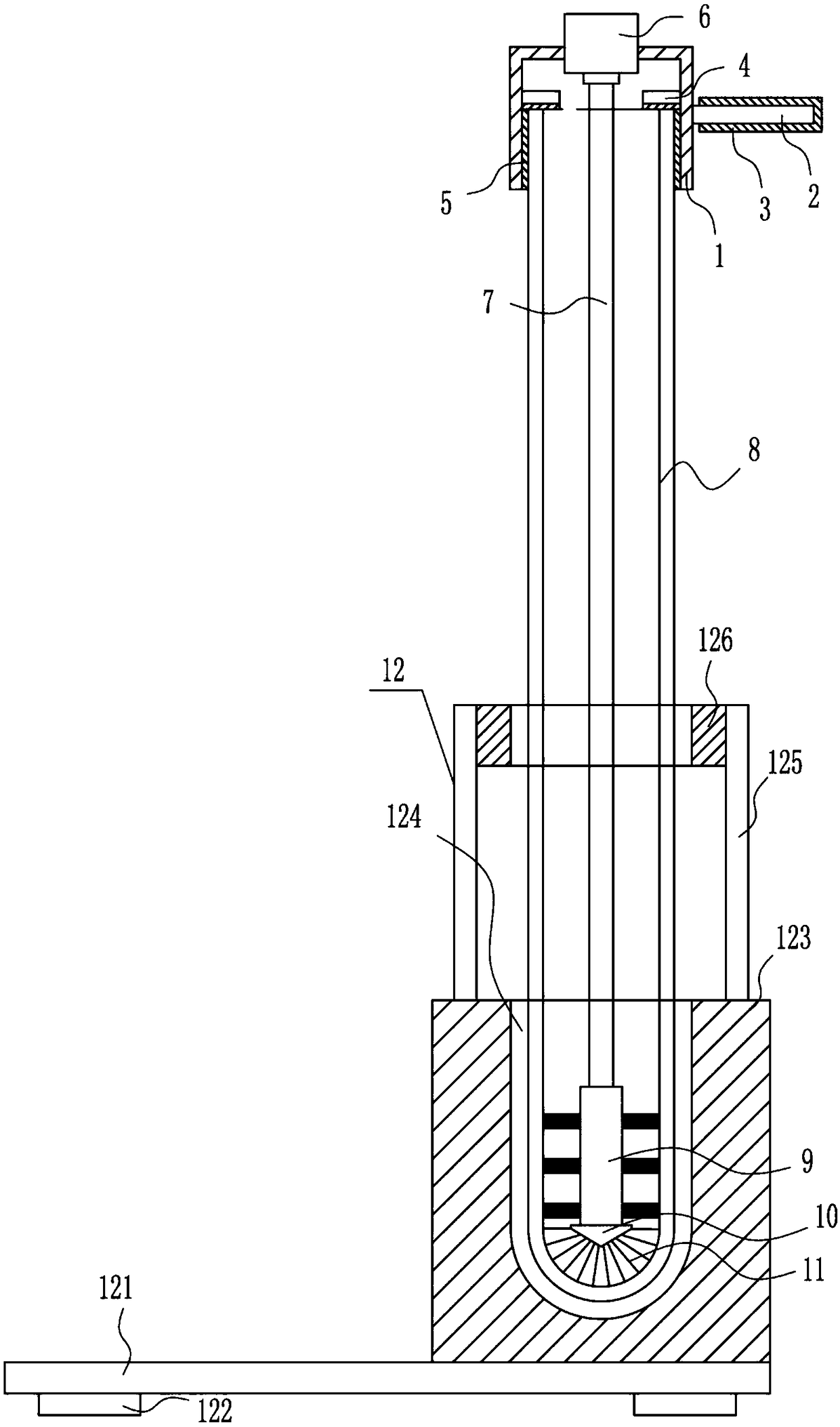

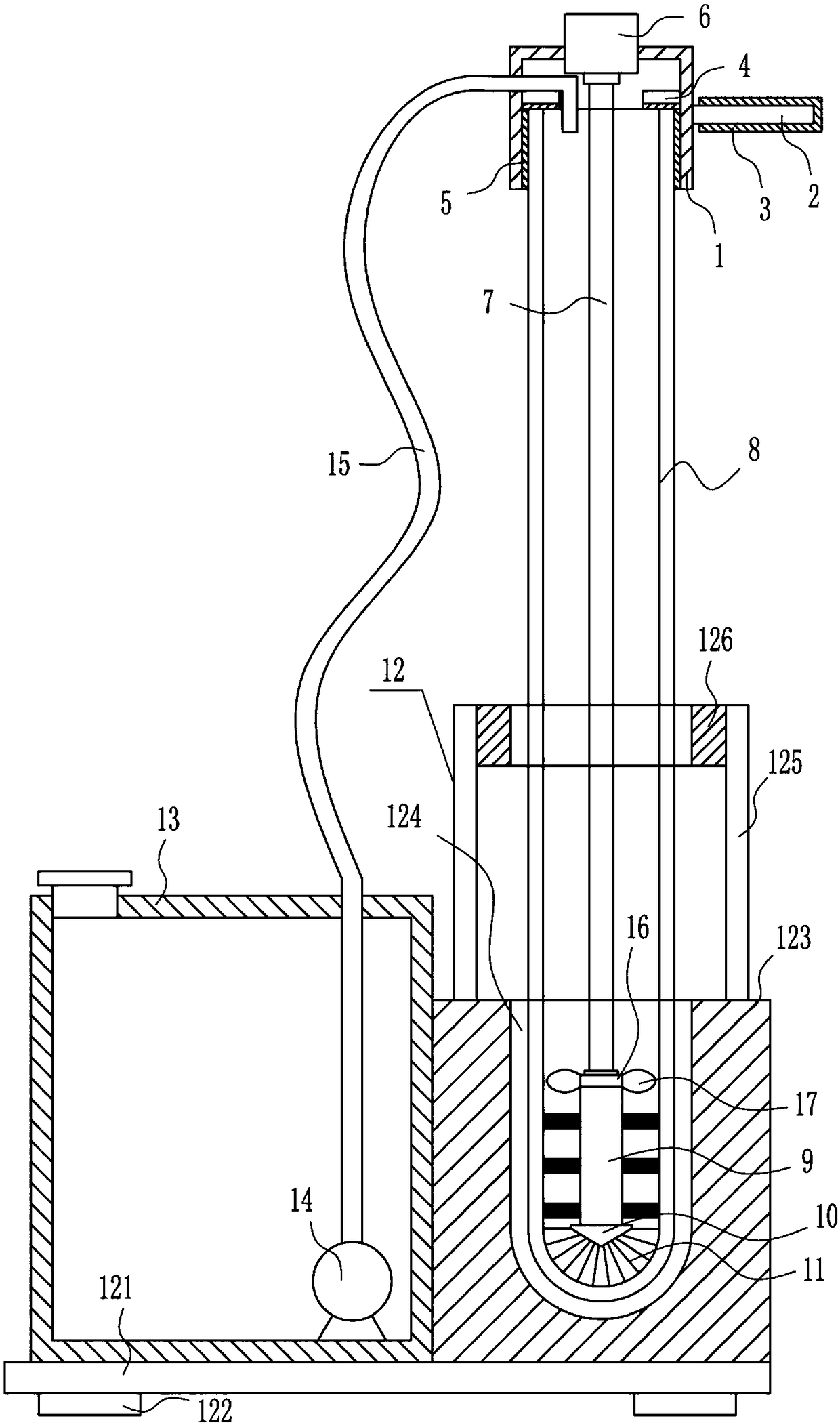

Laboratory model test device for testing influence on operating tunnel from vertically-overlapped tunnel construction

ActiveCN103996348AImprove scalabilityConvenient consultationEducational modelsPressure cellEngineering

The invention relates to a laboratory model test device for testing the influence on an operating tunnel from vertically-overlapped tunnel construction. An uplink lining model and a downlink lining model of an existing tunnel are longitudinally and symmetrically placed in parallel inside a model box. An uplink lining model and a downlink lining model of an excavated tunnel are transversely and symmetrically placed in parallel above and below the uplink lining model and the downlink lining model of the existing tunnel. Strain meters adhere to the inner walls of the uplink lining model and the downlink lining model of the existing tunnel and pressure cells adhere to the outer walls of the uplink lining model and the downlink lining model of the existing tunnel. The uplink lining model and the downlink lining model of the excavated tunnel are divided into multiple lining sections. The lining sections are separated through thin rubber boards. Displacement meter supports are fixed to the top face of the model box and multiple displacement meters are fixed to the uplink lining model and the downlink lining model of the existing tunnel, the uplink lining model and the downlink lining model of the excavated tunnel and the stratum soil mass surface through the corresponding displacement meter supports respectively. An excavation construction simulation device comprises a latex film surrounding the lining models of the excavated tunnel and an annular liquid cavity formed between the lining models of the excavated tunnel and the latex film. One end of the annular liquid cavity is provided with a liquid injection guide pipe and the other end of the annular liquid cavity is provided with a liquid drainage guide pipe.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

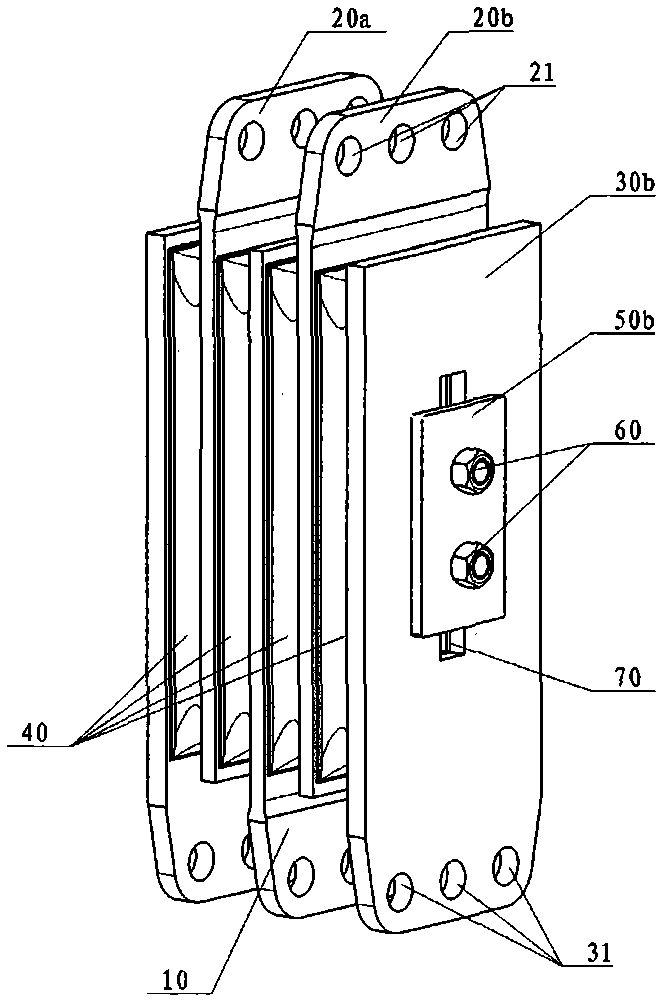

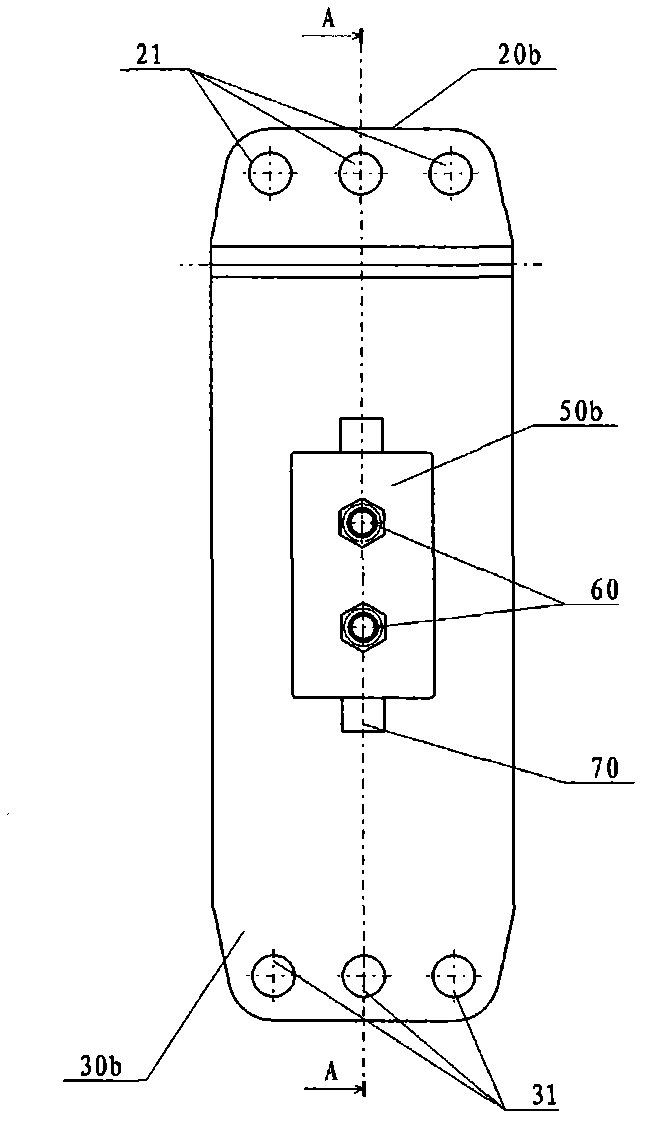

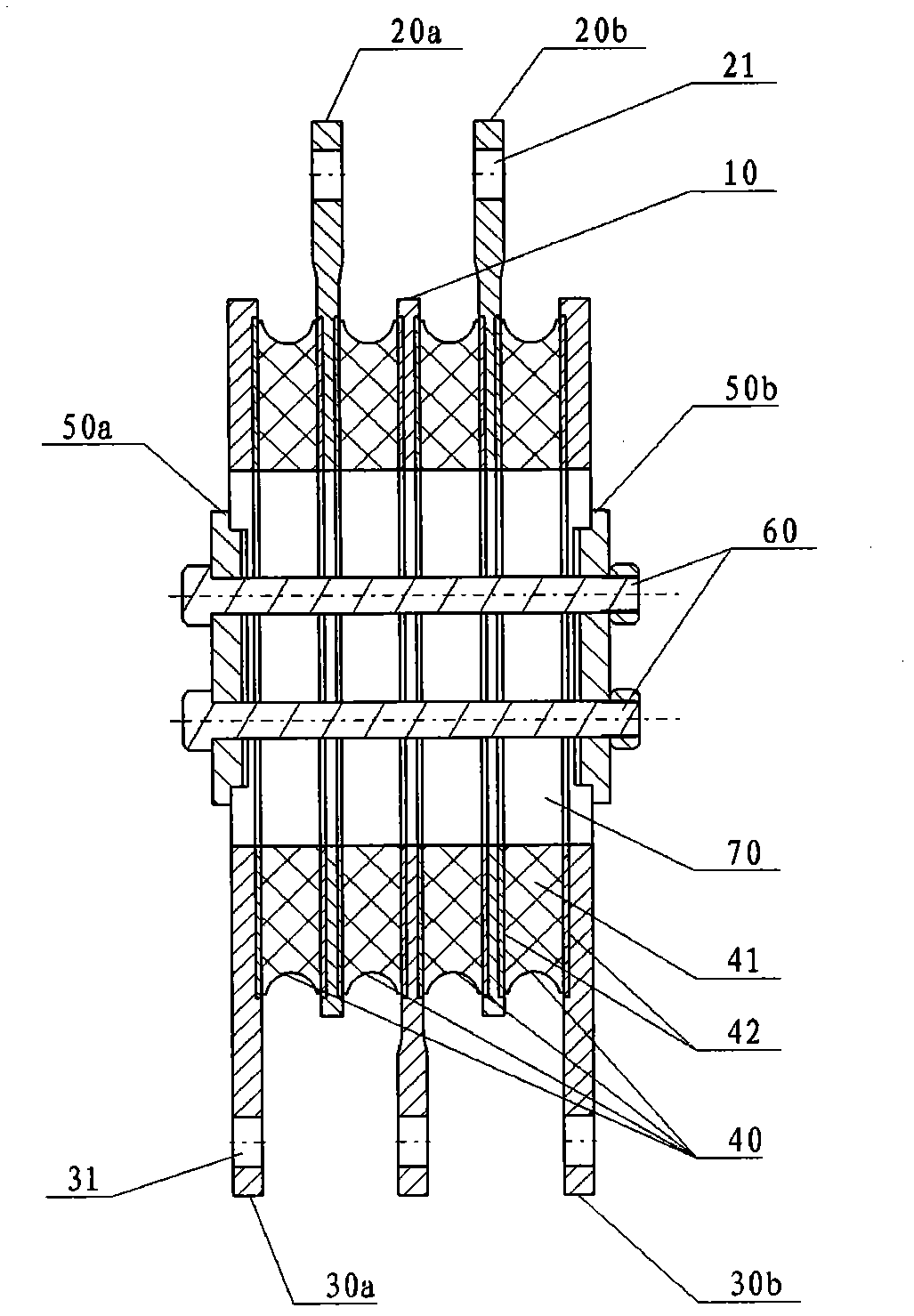

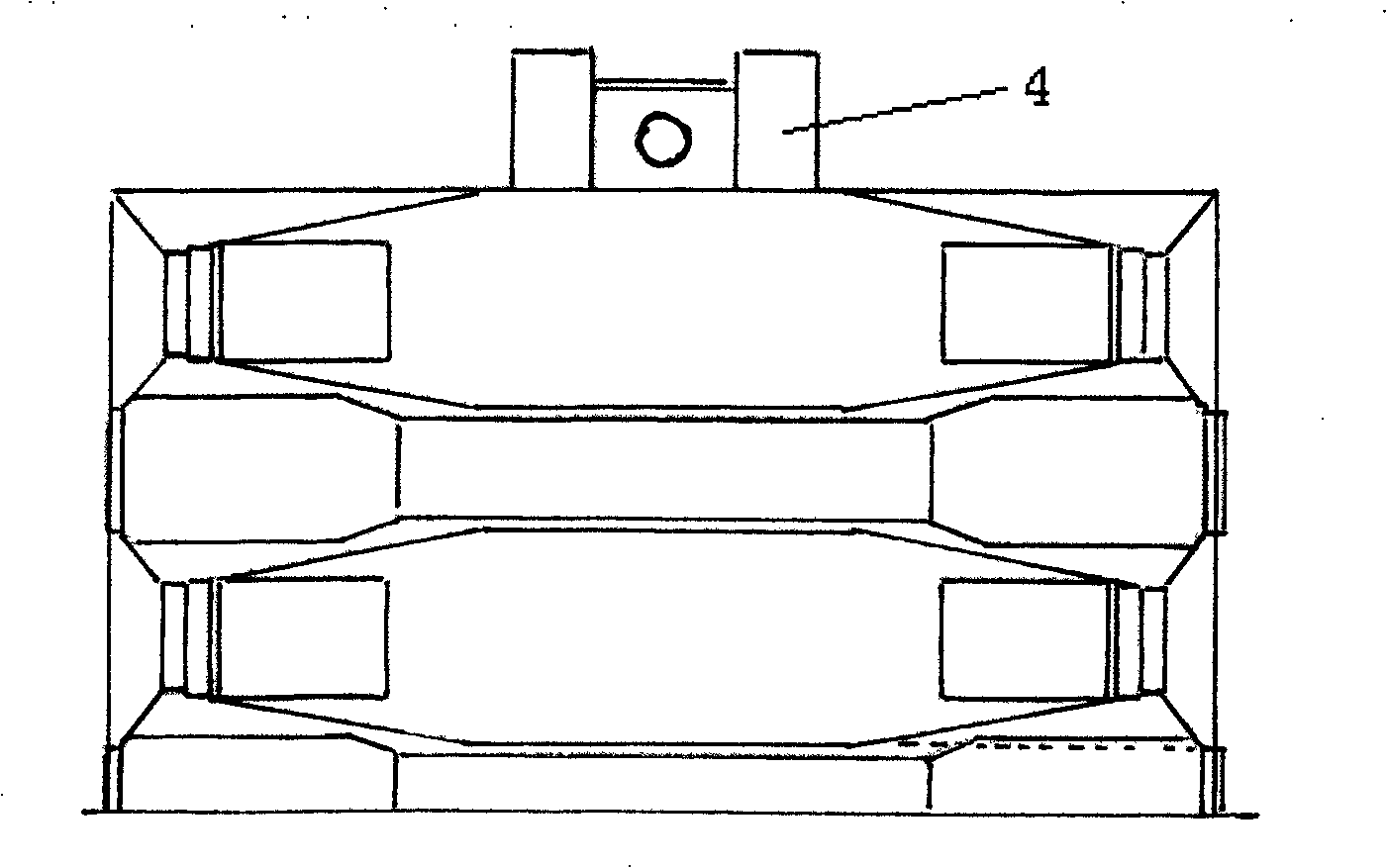

Band type damper and preparation method thereof

The invention belongs to the technical field of multilayer shearing viscoelastic dampers, and relates to an improvement on a band type damper of a helicopter rotor wing. The band type damper comprises five rigid slabs and four sandwich plates, wherein, the four sandwich plates are positioned between the five rigid slabs. A preparation method of the band type damper comprises the steps as follows: the sandwich plates of the band type damper are prepared firstly, and then the five rigid slabs and the four sandwich plates are assembled so as to form the band type damper. The band type damper can be used for adjusting the thickness of rubber plates of the sandwich plates or the number of the sandwich plates so as to satisfy the rigidity and damping requirements of different helicopter rotor wing systems; the band type damper is easy to form, convenient to process and easy to assemble, and has the advantages of low cost, small installation space and overload limiting capability; the band type damper is convenient to maintain, the sandwich plates can be checked visually, the sandwich plates out of operation are convenient to replace, the rigid slabs can be used for a long time without replacement, and maintenance cost is saved; and the band type damper is easy to dissipate heat, and prolongs the service life.

Owner:BAIMTEC MATERIAL CO LTD

Protection device for electric automobile accumulator

InactiveCN106515414AAvoid driftingAvoid fireElectric propulsion mountingElectric-vehicle batteryEngineering

The invention discloses a protection device for an electric automobile accumulator. The protection device comprises an accumulator placing box; a mounting plate is arranged on each of the left side and the right side of the bottom of the accumulator placing box; a plurality of shock absorbing springs are arranged at the bottom inside the accumulator placing box; a lower supporting plate is arranged at the top of the shock absorbing springs; and a lower rubber plate is arranged at the top of the lower supporting plate. The left side wall and the right side wall inside the accumulator placing box are also provided with shock absorbing springs; a side supporting plate is arranged at one end of the shock absorbing springs on the side walls; and a side rubber plate is arranged on one side of the side supporting plate. An accumulator body is placed between the lower rubber plate and the side rubber plate; a dry powder extinguishing agent box is arranged at the bottom of an upper cover and between upward pressing springs. A dry powder extinguishing agent is arranged in the dry powder extinguishing agent box. When a major collision accident happens, the dry powder extinguishing agent box can be broken so that the accumulator placing box can be filled with the dry powder extinguishing agent, thereby preventing liquid in the accumulator from flowing around and effectively avoiding the occurrence of fire.

Owner:CHENGDU UNIV OF INFORMATION TECH

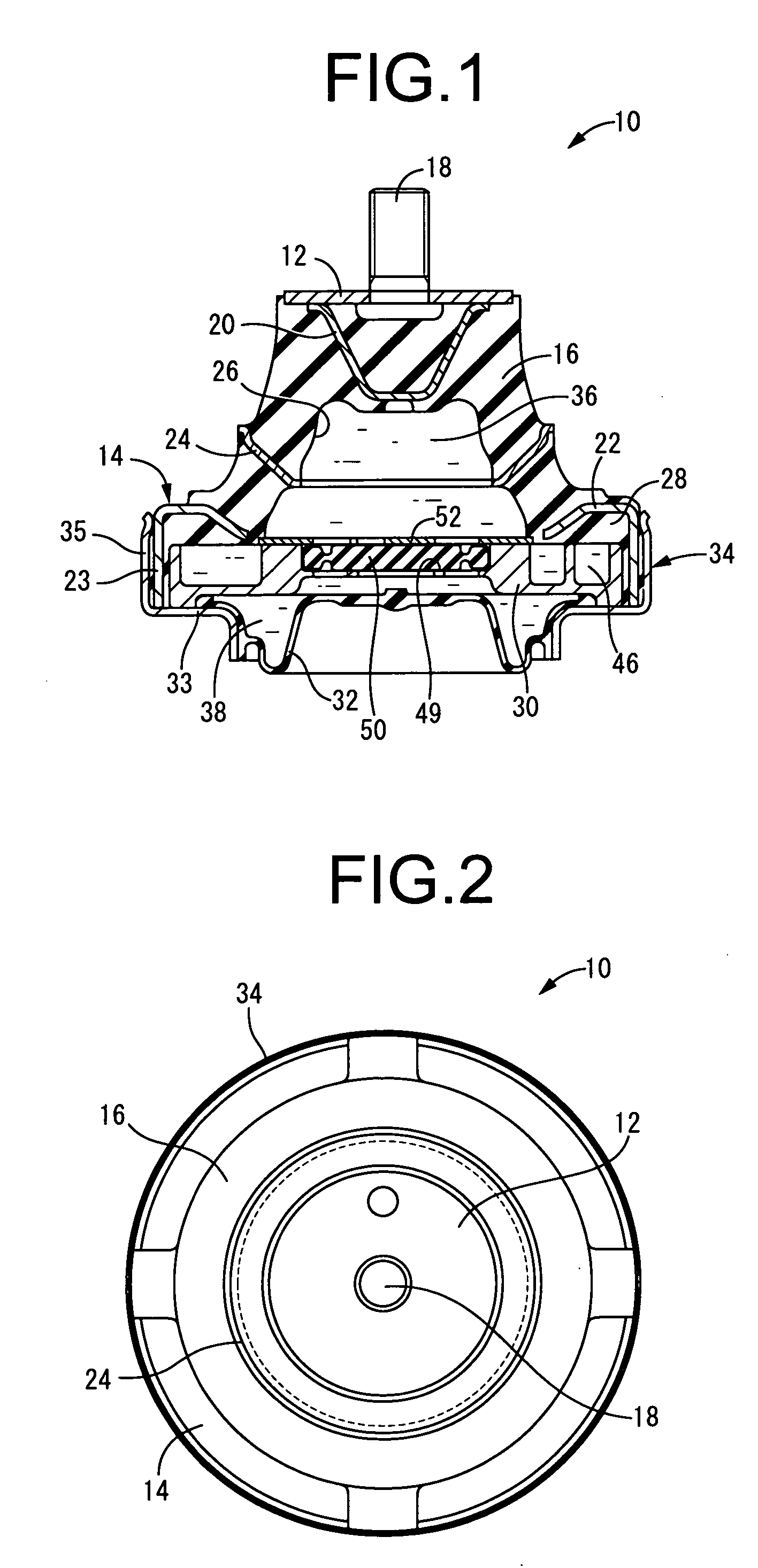

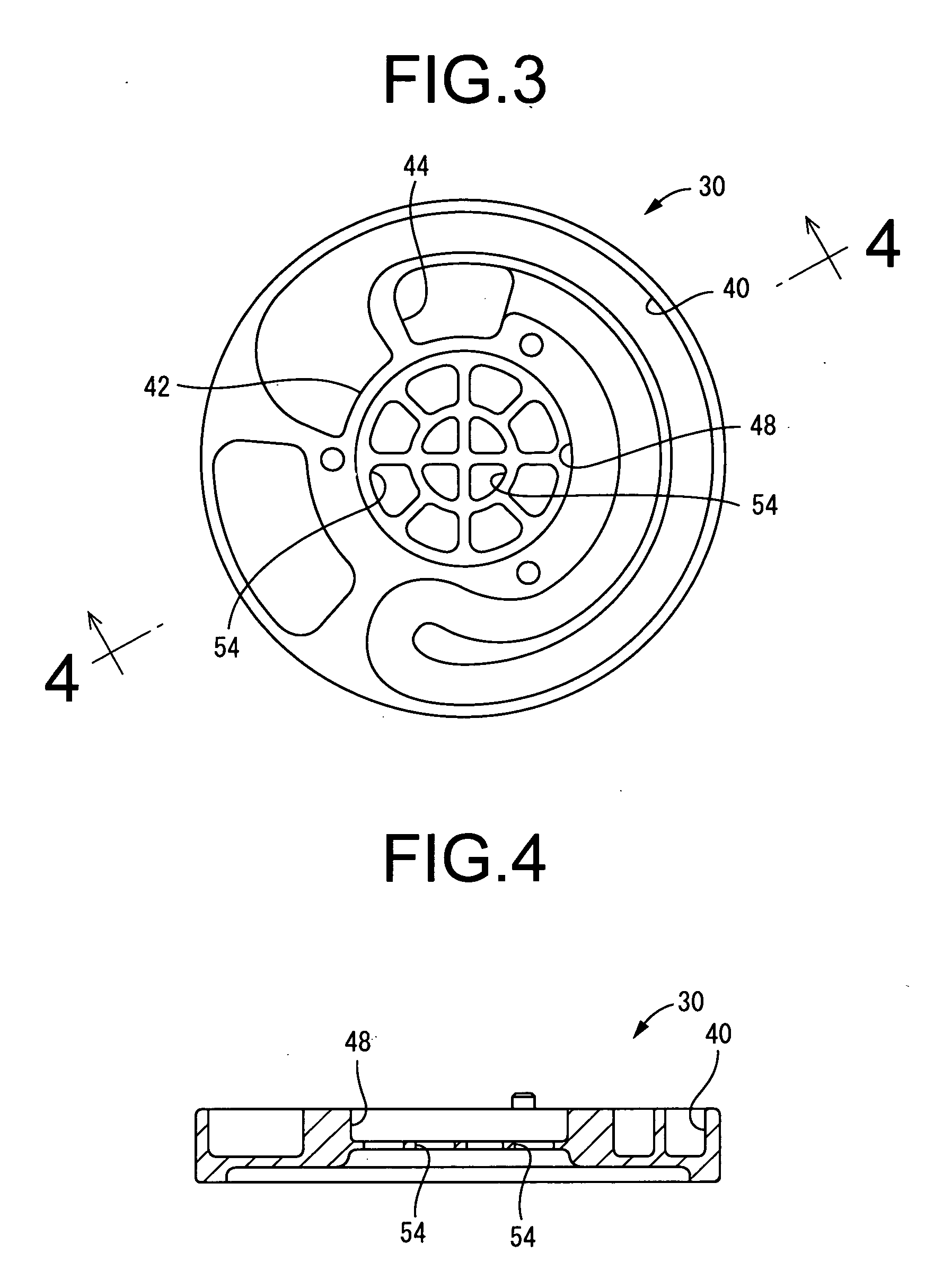

Fluid filled vibration damping device

Owner:SUMITOMO RIKO CO LTD

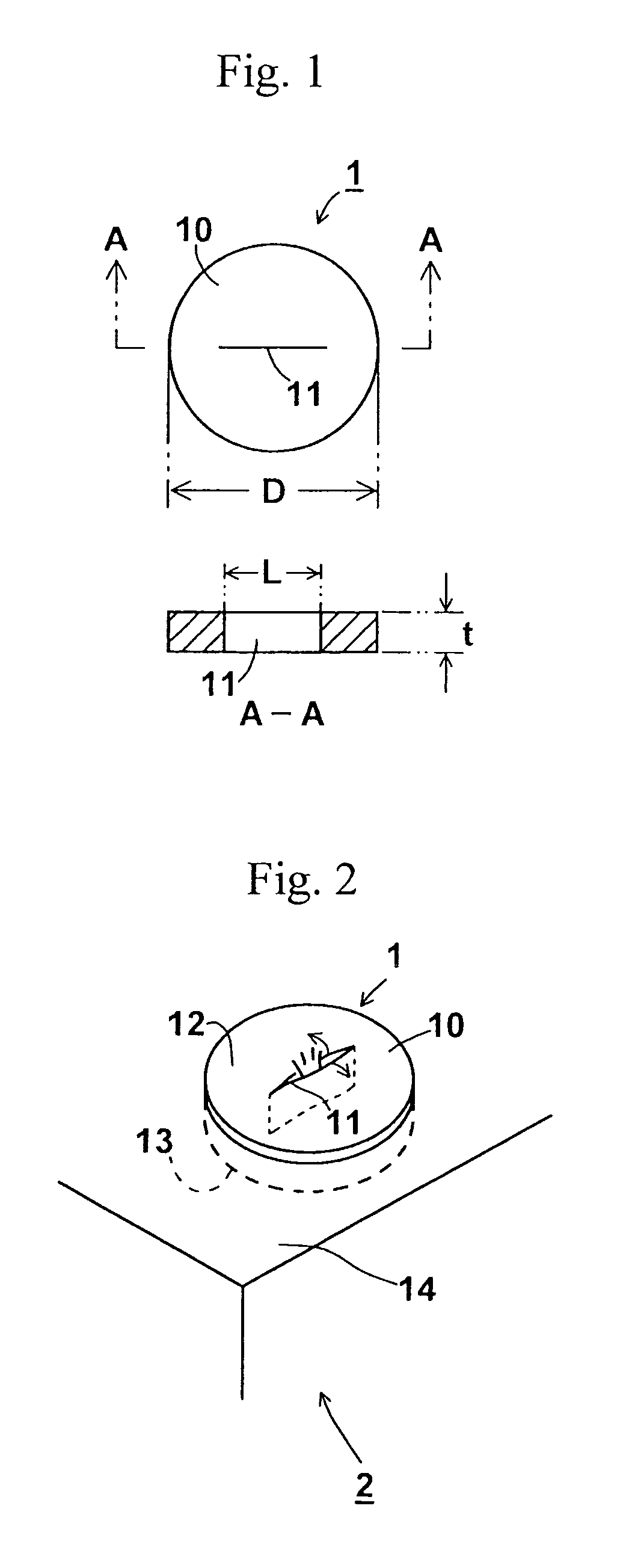

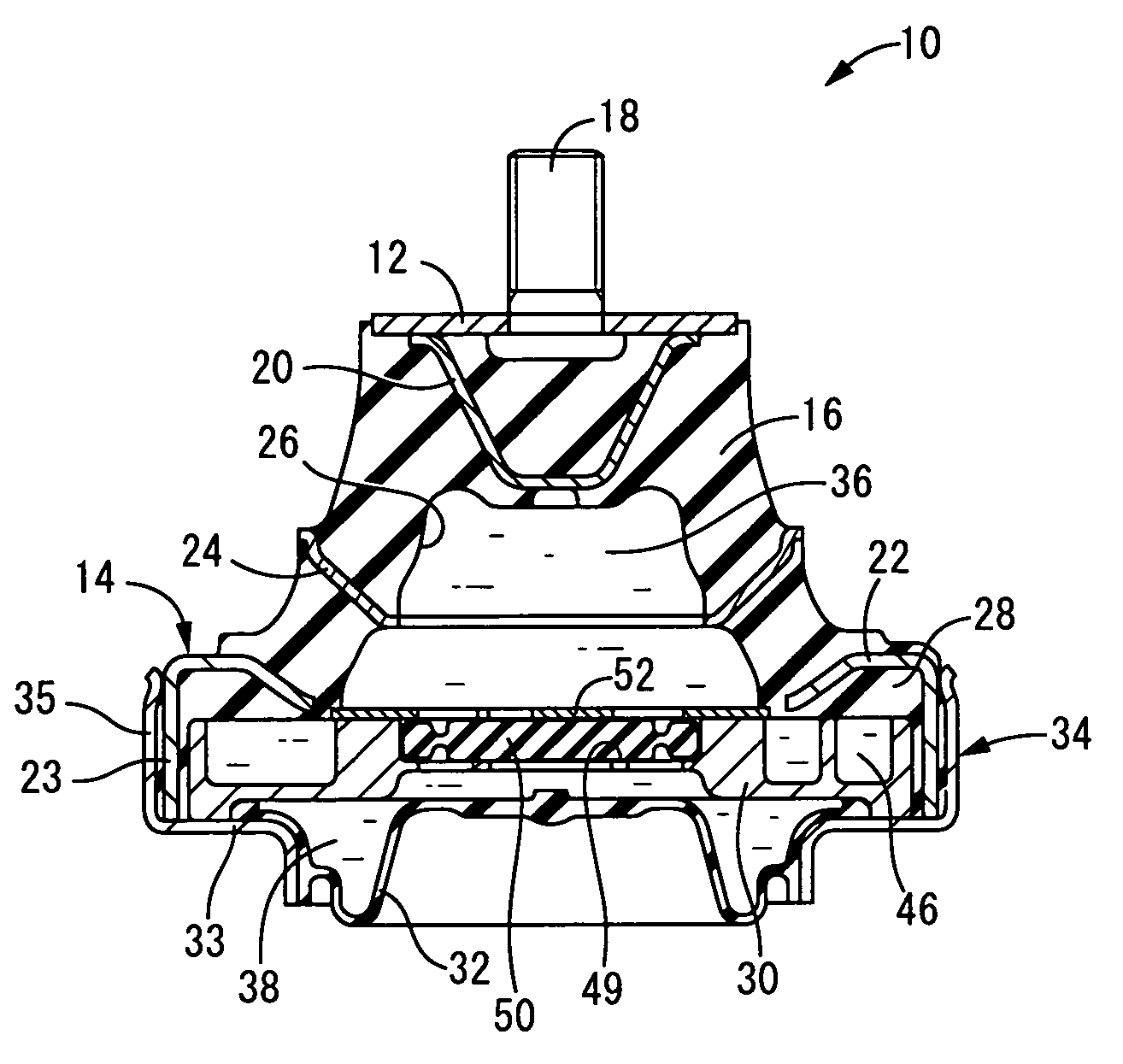

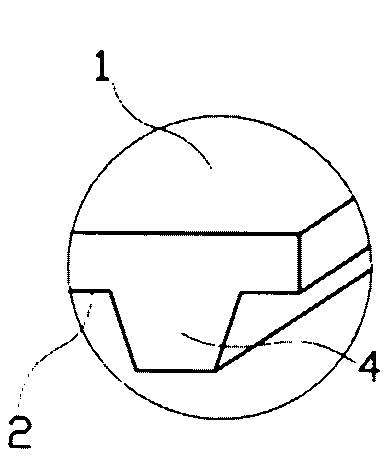

Excessive Pressure Release Valve And Release Valve Unit Having The Release Valve

InactiveUS20100032039A1Improve performanceSmall and simple structureReactant parameters controlCheck valvesMedicineSilicone oil

Provided is a small, simple-structured, homogeneous and mass-producible excessive pressure release valve which works even at a relatively low excessive pressure to surely and safely release the pressure to the external world. The excessive pressure release valve has an elastic rubber plate and a reversibly openable slit that passes through the upper and the lower surfaces and release the pressure to the external world when the internal excessive pressure stressing on the lower side surface, pushes and opens the slit toward upper surface side. The elastic rubber plate is made of silicone rubber containing 1-20% by mass of silicone oil.

Owner:ASAHI RUBBER

Caked cement barrel cleaning device for building

The invention relates to a caked cement barrel cleaning device, in particular to a caked cement barrel cleaning device for building. According to the caked cement barrel cleaning device for building, the time and labor are saved, working efficiency is high, and cloths cannot be spotted by caked cement in the cleaning process. For achieving the technical effects, the caked cement barrel cleaning device for building comprises a first box body and the like, a fixing device body is arranged in middle of the bottom in the first box body, and knocking device bodies are arranged on the left side and the right side in the first box body. According to the caked cement barrel cleaning device for building, through knocking balls on the left side and the right side of the caked cement barrel cleaning device, a cement barrel is knocked, cleaning of the caked cement in the cement barrel is accelerated, and rubber plates can enable the cement barrel to be more stable.

Owner:孔佳佳

Fluid filled vibration damping device

Owner:SUMITOMO RIKO CO LTD

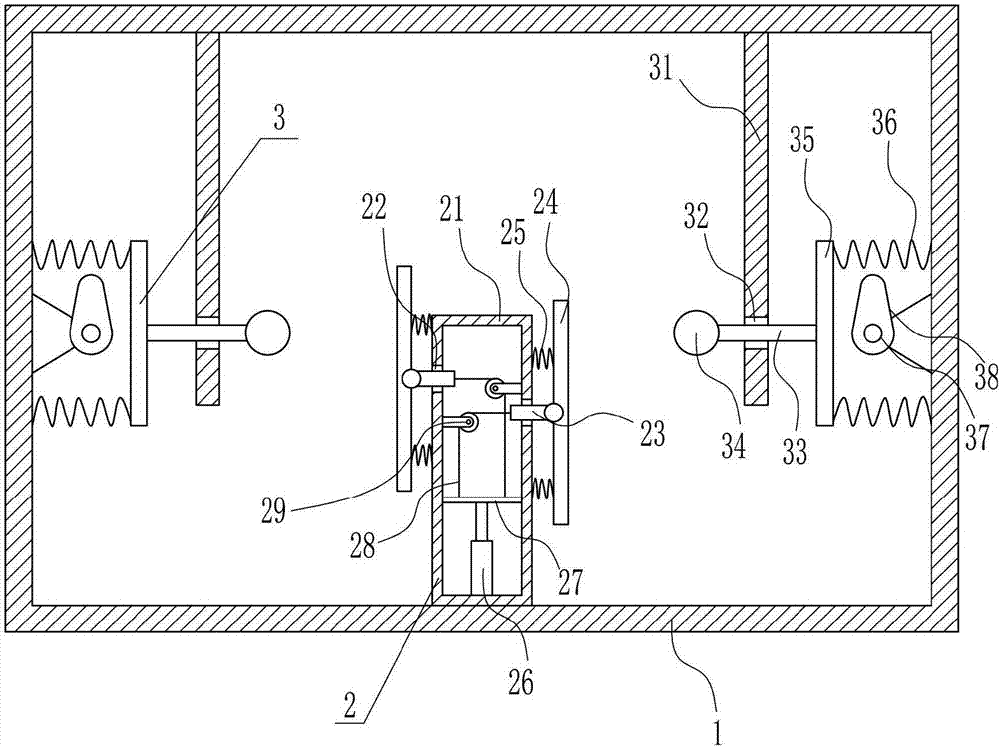

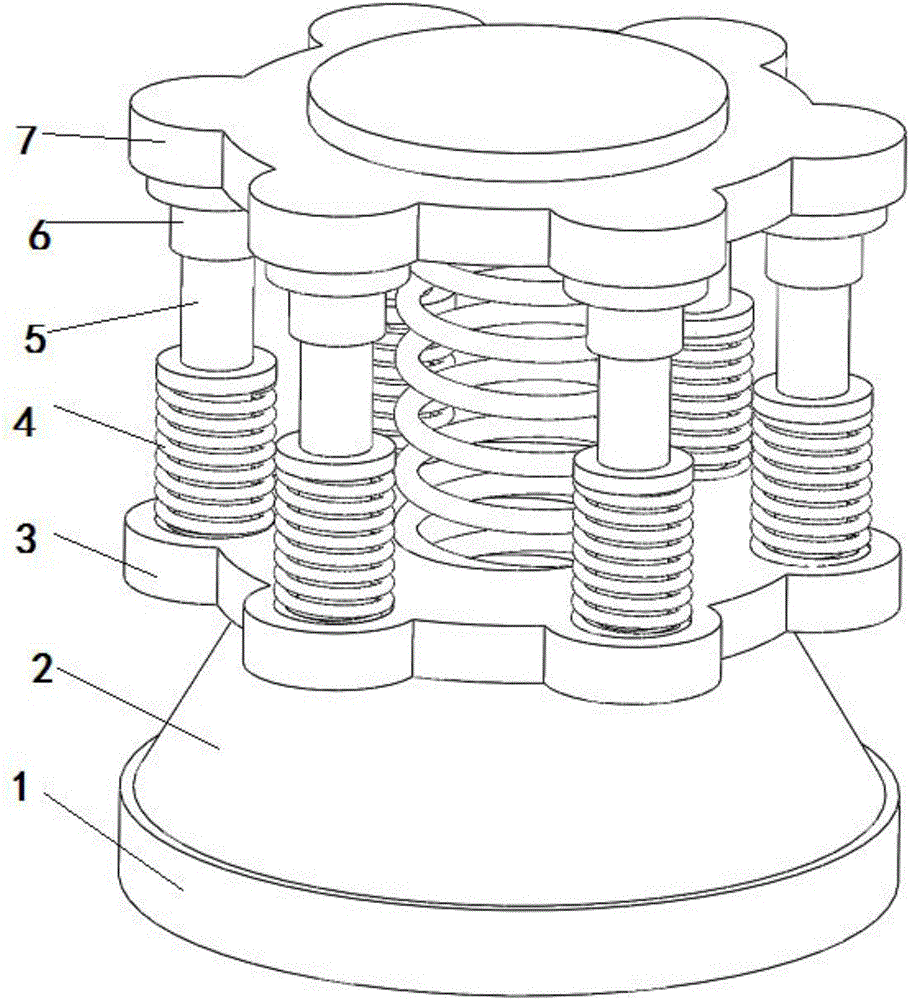

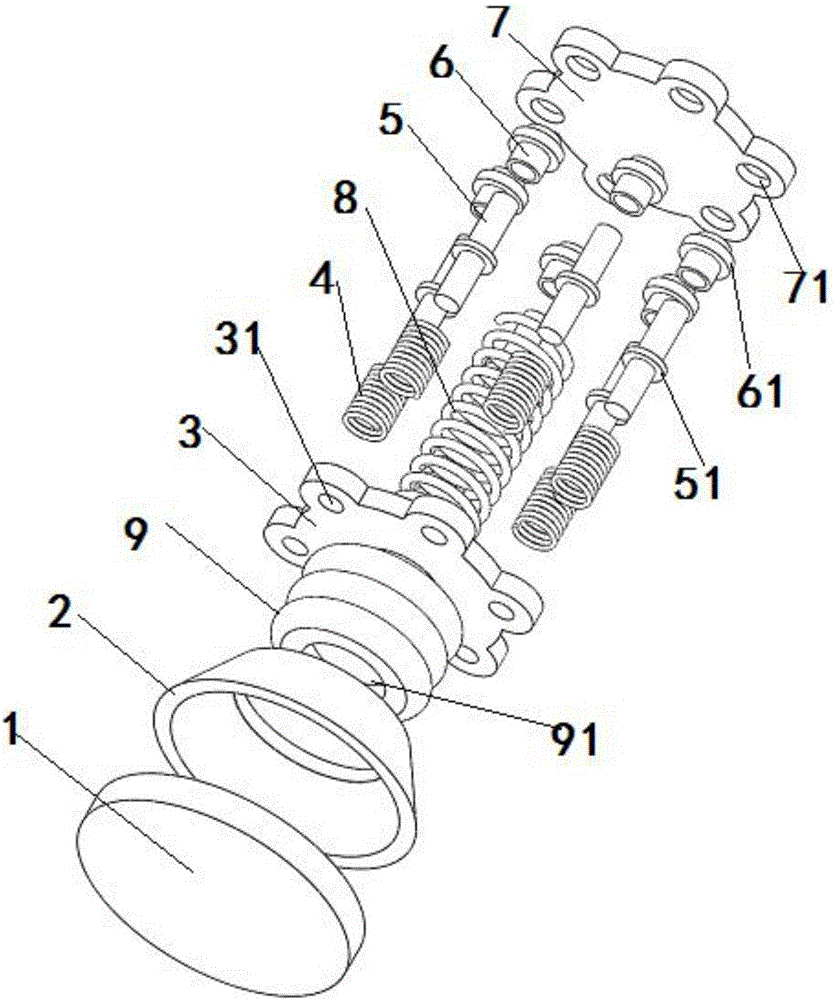

Buffer support device for sterilizing machine

PendingCN106763479AStable supportImprove shock absorptionNon-rotating vibration suppressionEconomic benefitsEngineering

The invention discloses a buffer support device for a sterilizing machine. The buffer support device comprises a base, a rubber cover, a middle plate, a first spring, a screw rod, a threaded cylinder, and a top cover which are sequentially installed and connected, wherein the center of the surface of the base is provided with a circular groove, the rubber plate is stacked in the circular groove, and an installation hole is formed in the rubber plate; the rubber cover is in a horn shape, and the highest point of the rubber cover and the highest point of the rubber plate are positioned on the same horizontal surface; six guide holes are uniformly distributed in the edge of the middle plate; a first limiting block is arranged in the middle part of the screw rod, and the first spring is arranged between the first limiting block and the middle plate. The buffer support device has the advantages that by sequentially installing and connecting the base, the rubber cover, the middle plate, the first spring, the screw rod, the threaded cylinder and the top cover, the direct impact action of the sterilizing machine on the ground is effectively reduced, the function of an internal structure of the sterilizing machine is greatly protected, the working property and reliability of the sterilizing machine are improved, and the practical value and economic benefit are good.

Owner:江四胜

Integrated cutting and conveying device of sugarcane harvester

The invention discloses an integrated cutting and conveying device of a sugarcane harvester. The integrated cutting and conveying device comprises a cutting mechanism and a conveying mechanism fixed to each other. The conveying mechanism comprises a feeding fixed plate and a rubber plate. The feeding fixed plate is fixed on a roller. The rubber plate penetrates through the feeding fixed plate and is then fixedly connected to the outside of the roller. Cut canes are effectively conveyed back by the feeding fixed plate and the rubber plate disposed on the roller. Gears in a gear bank have different tooth numbers, so that rotation speed of the rubber plate is smaller than that of a disc cutter, the cut canes can be timely, stably and orderly conveyed to subsequent procedures through the feeding fixed plate and the rubber plate, multi-breakage of the canes is avoided, cane harvesting quality is improved, and damage of sugar content of the canes is avoided.

Owner:LINHAI HENGFENG MACHINERY

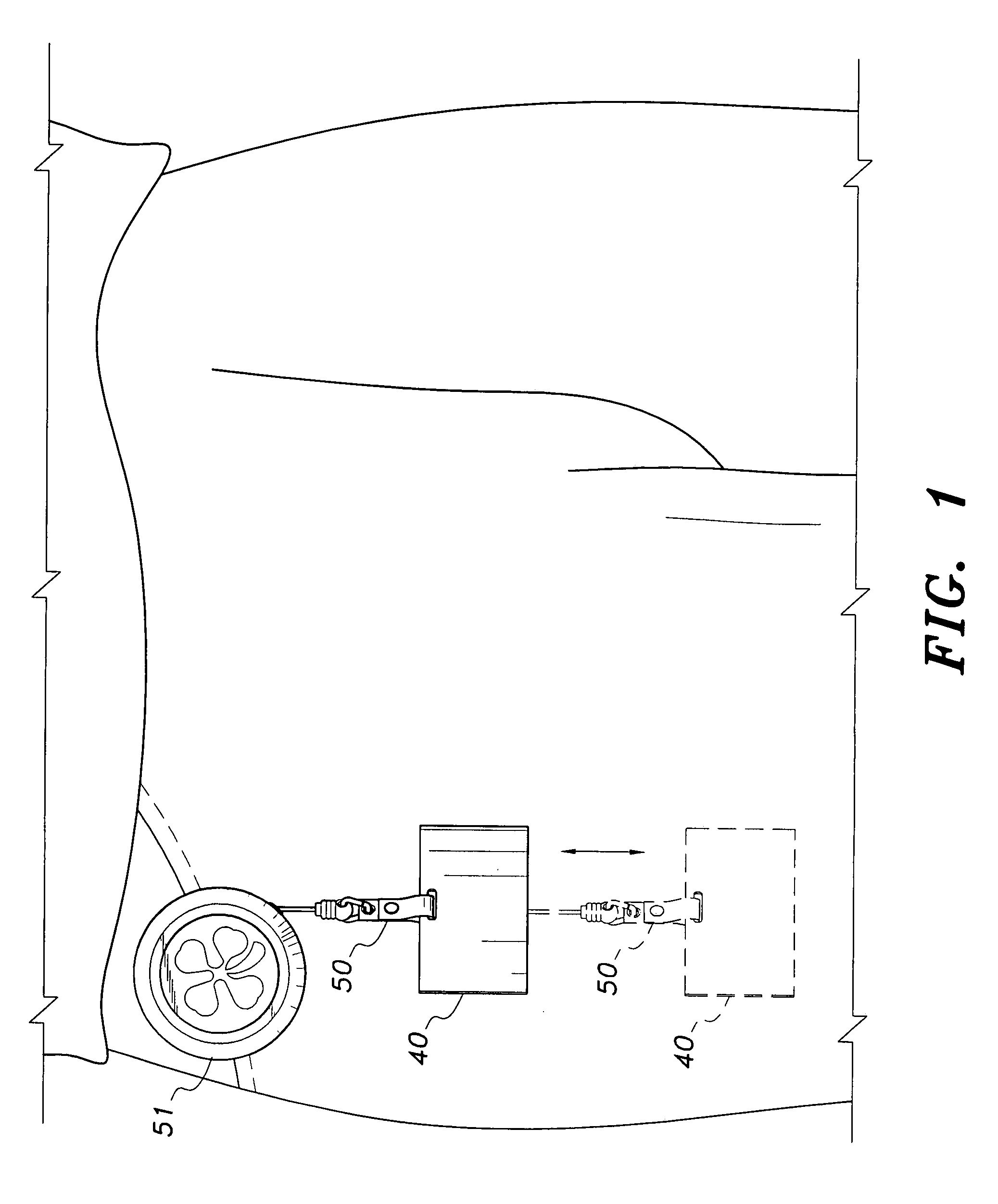

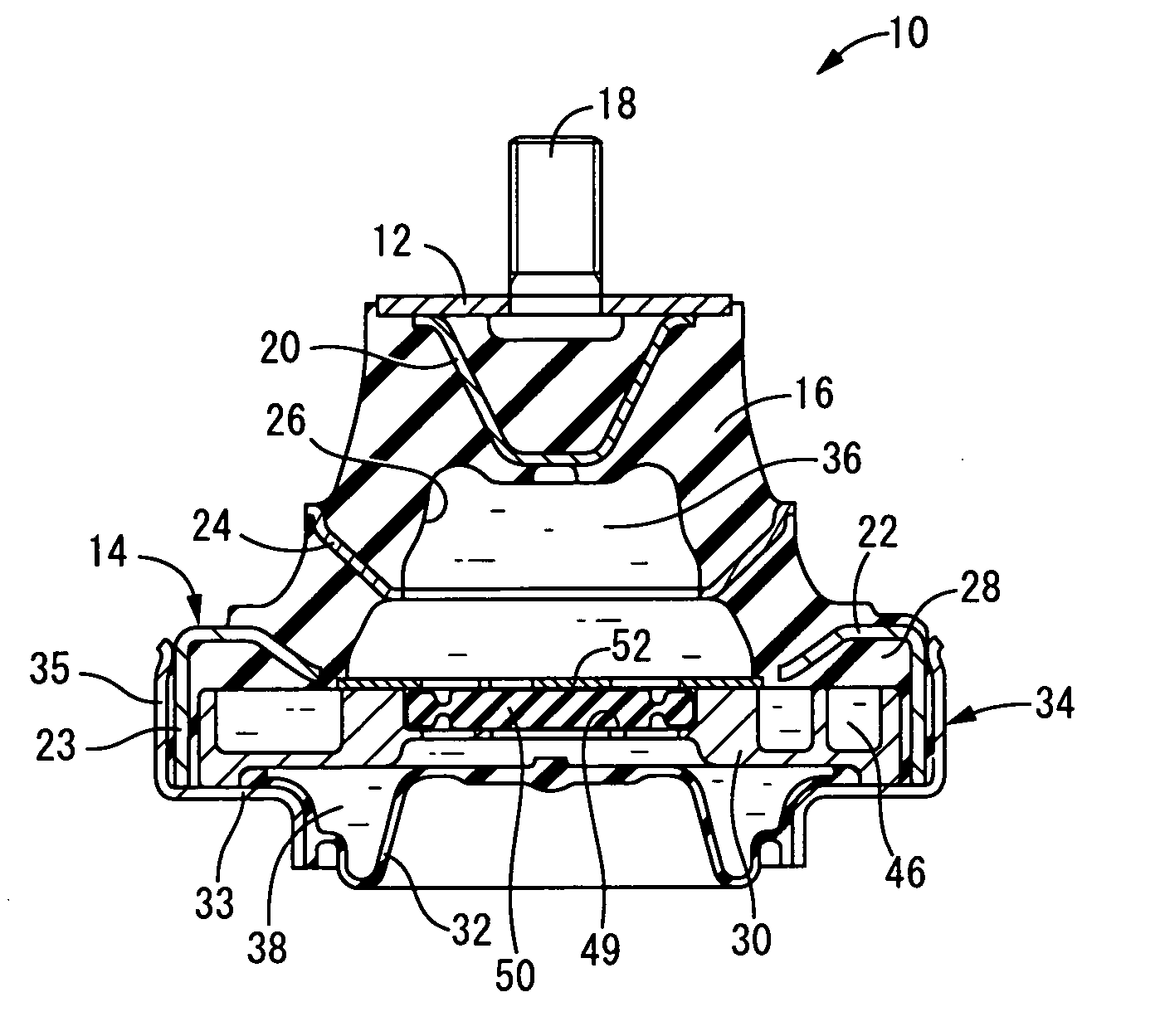

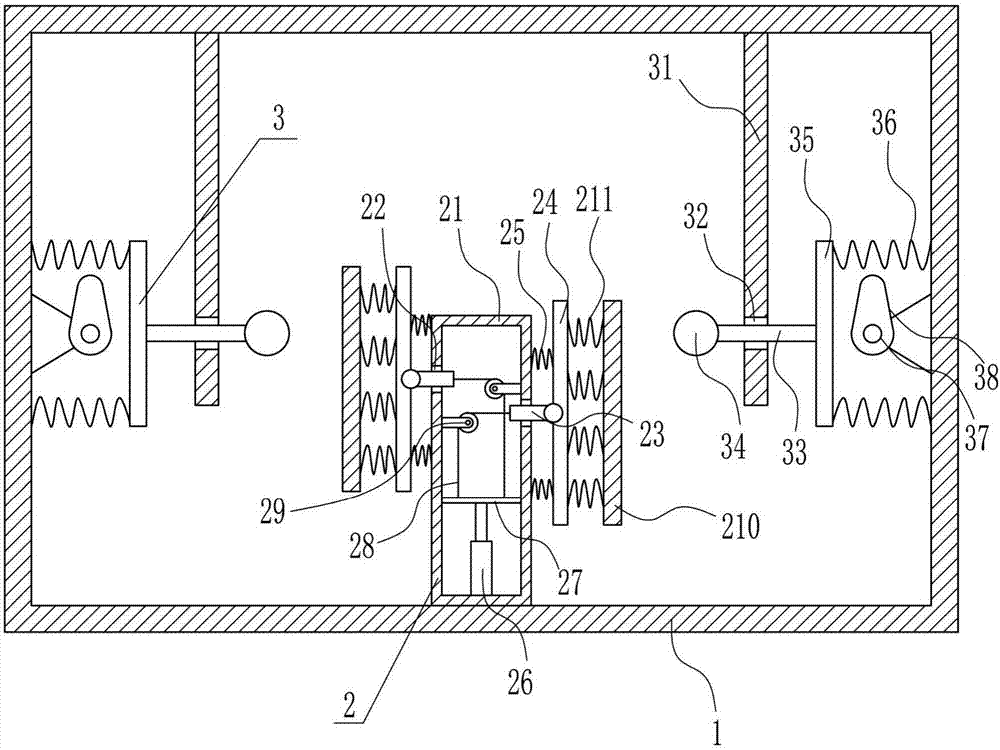

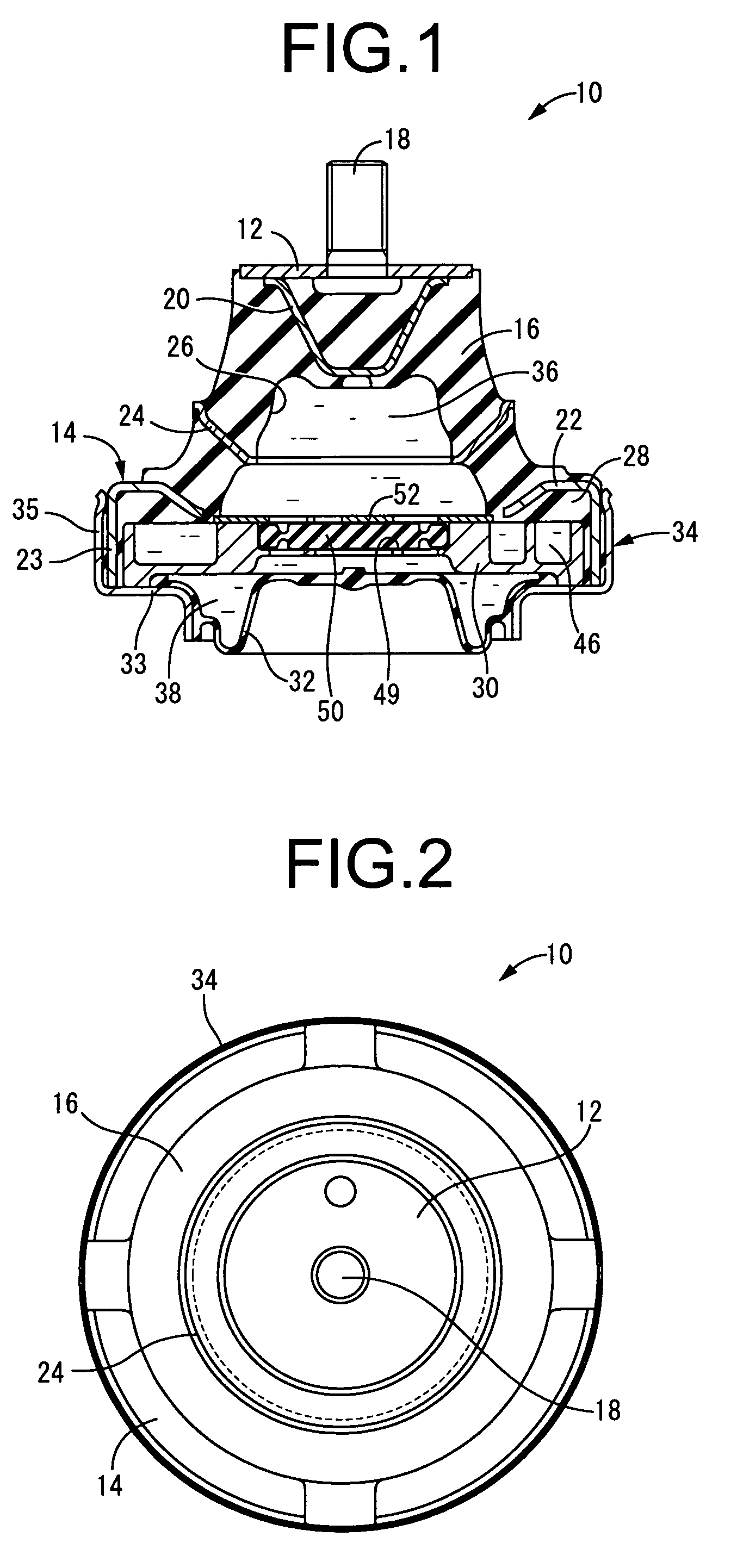

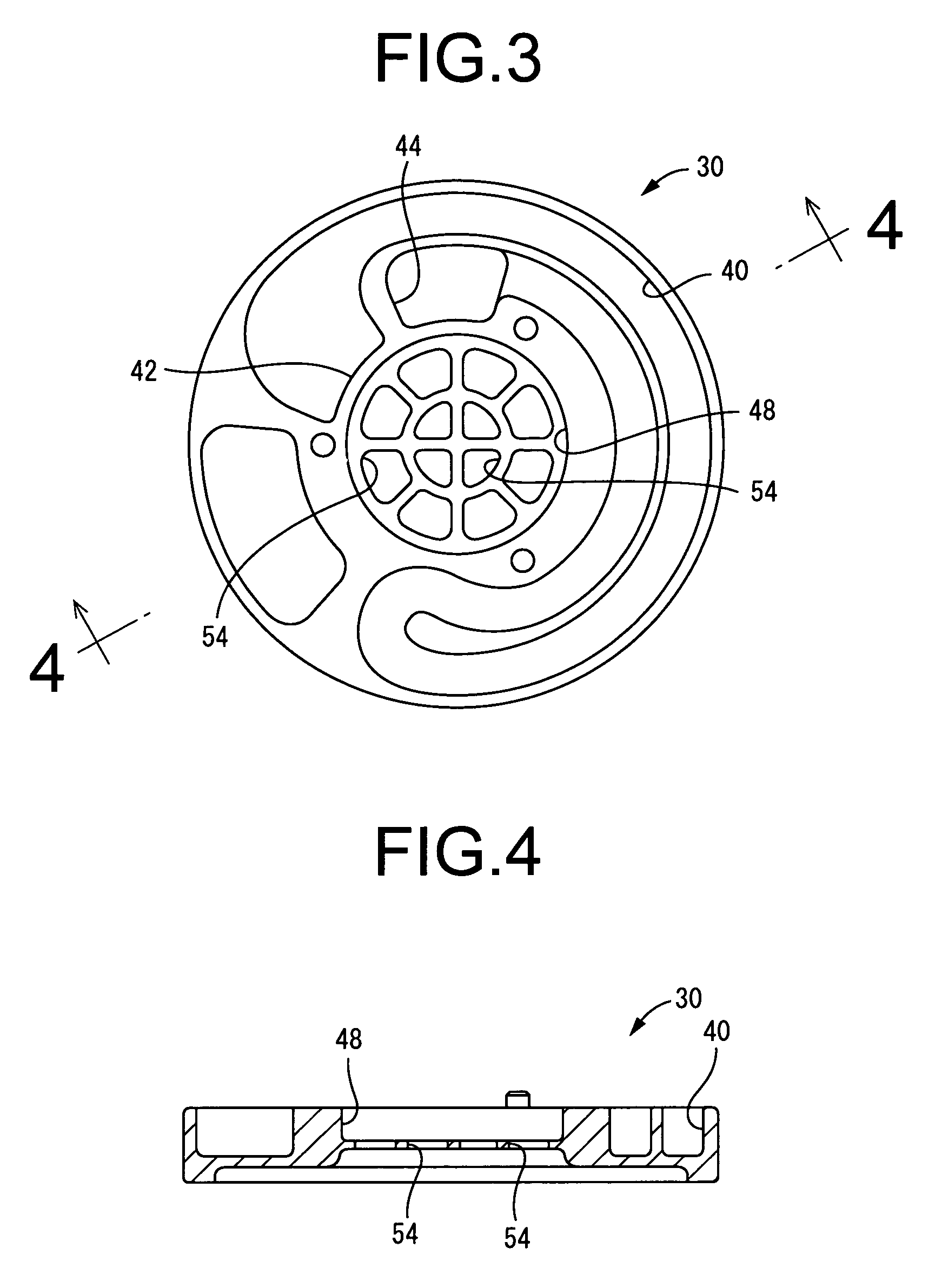

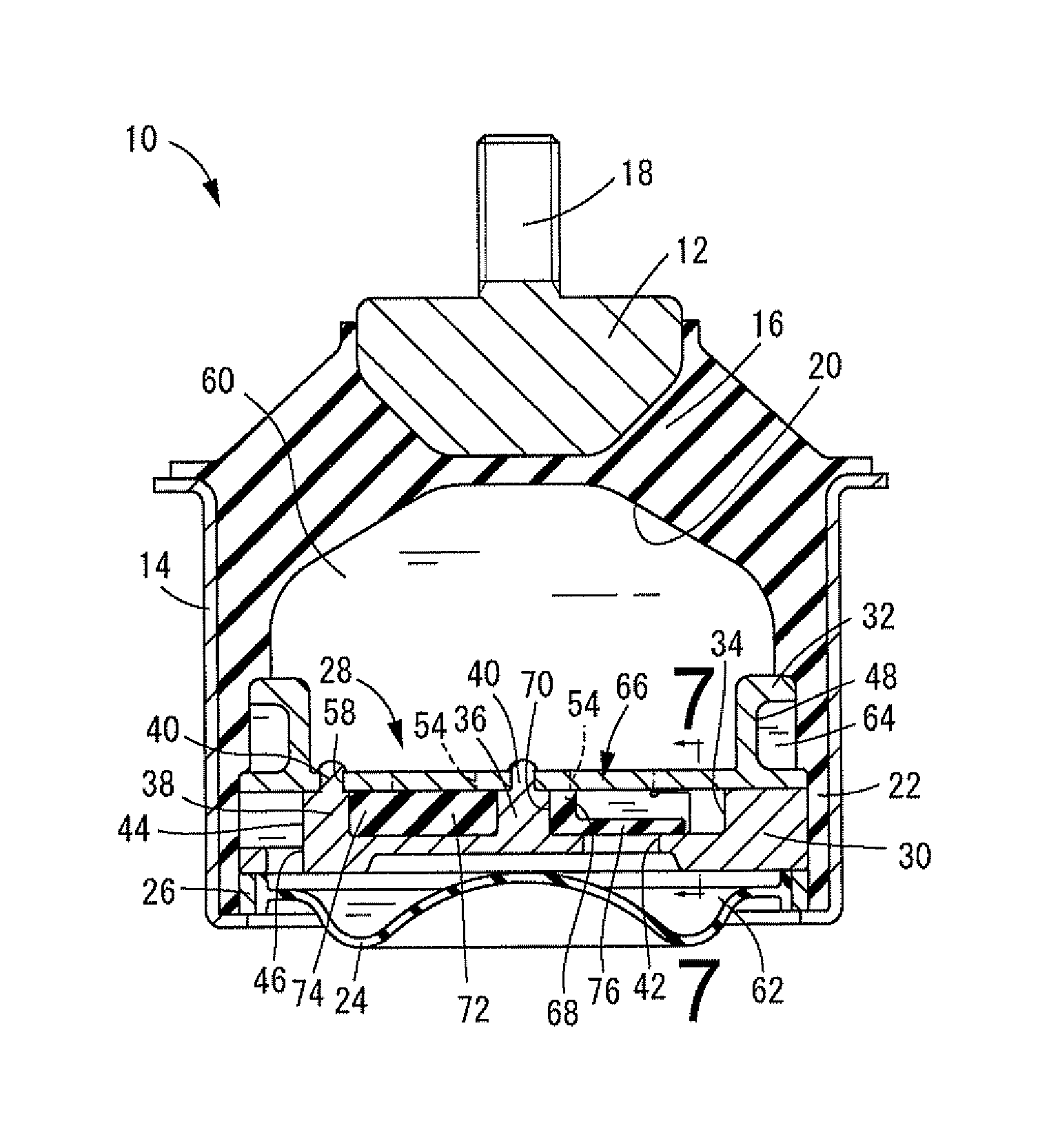

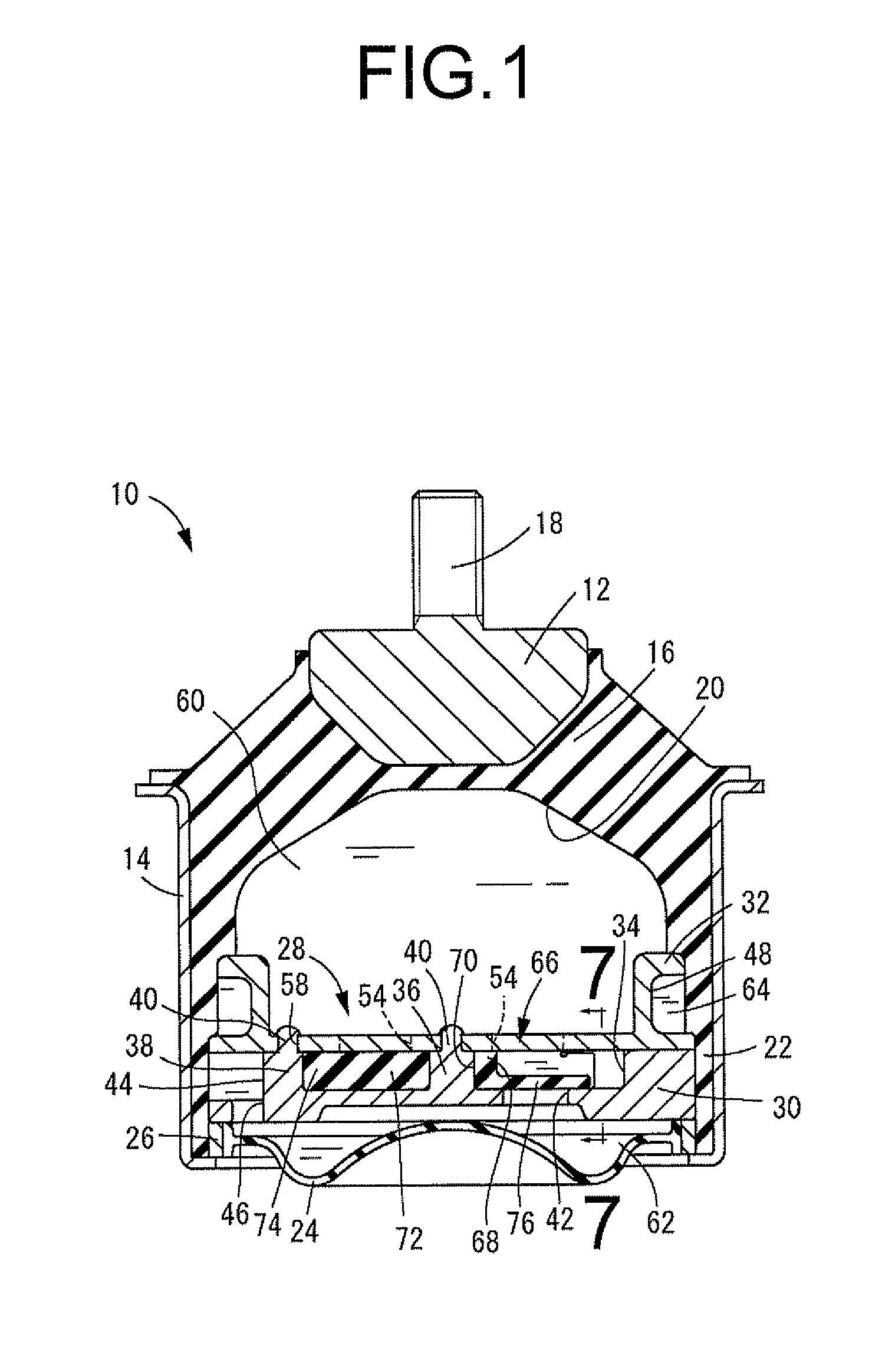

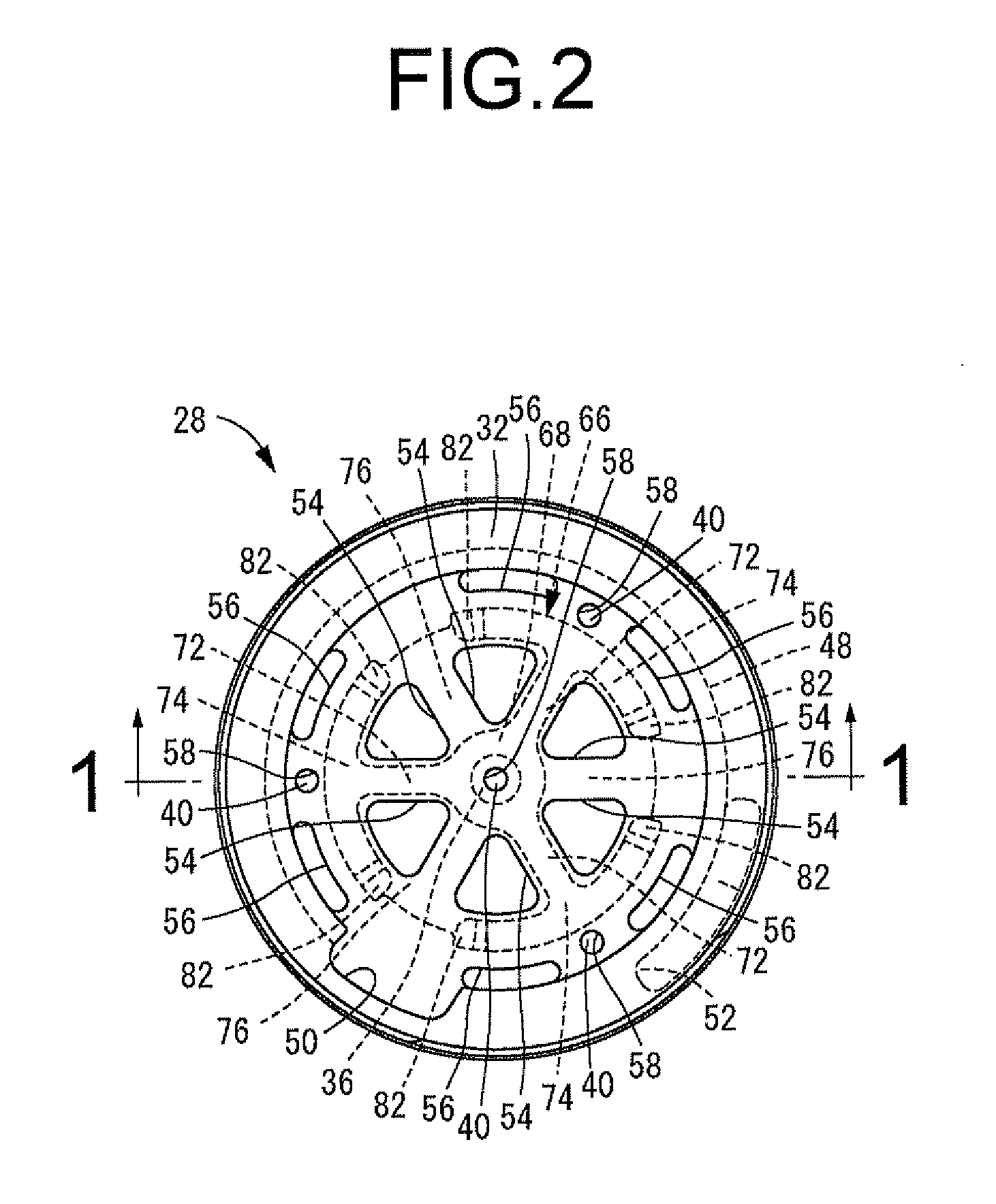

Fluid filled type vibration damping device

ActiveUS8556239B2Rapid short-circuitAvoid impactMachine framesLiquid springsDifferential pressureMechanical engineering

A fluid filled type vibration damping device including: an obstructing rubber elastic plate disposed so as to obstruct a communication aperture that connects a pressure receiving chamber and an equilibrium chamber; contact retaining portions arranged on an outer peripheral edge of the rubber plate and held in contact against a partition member; an elastic deformation zone arranged circumferentially between the contact retaining portions of the rubber plate so as to undergo elastic deformation on a basis of pressure differential between the pressure receiving chamber and the equilibrium chamber to be spaced away from the partition member to cause the aperture to open up; and a non-linearizing member provided such that the elastic characteristics of the elastic deformation zone become more rigid in a non-linear manner in association with increase in an amount of its deformation.

Owner:SUMITOMO RIKO CO LTD

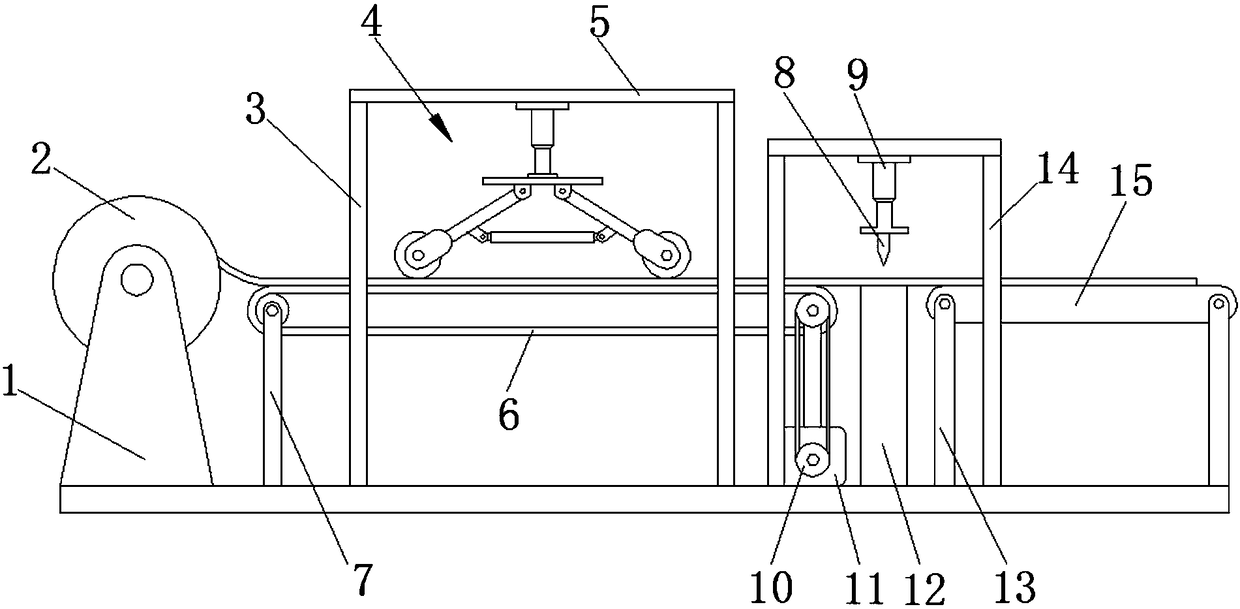

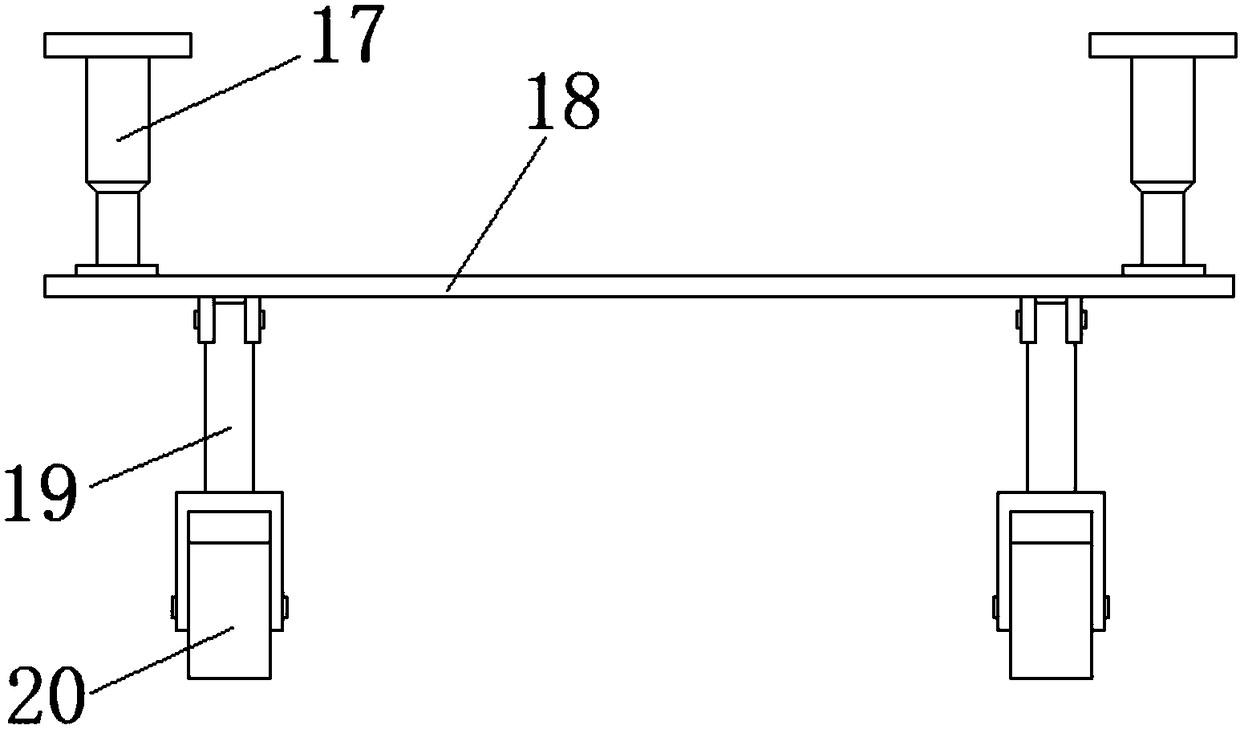

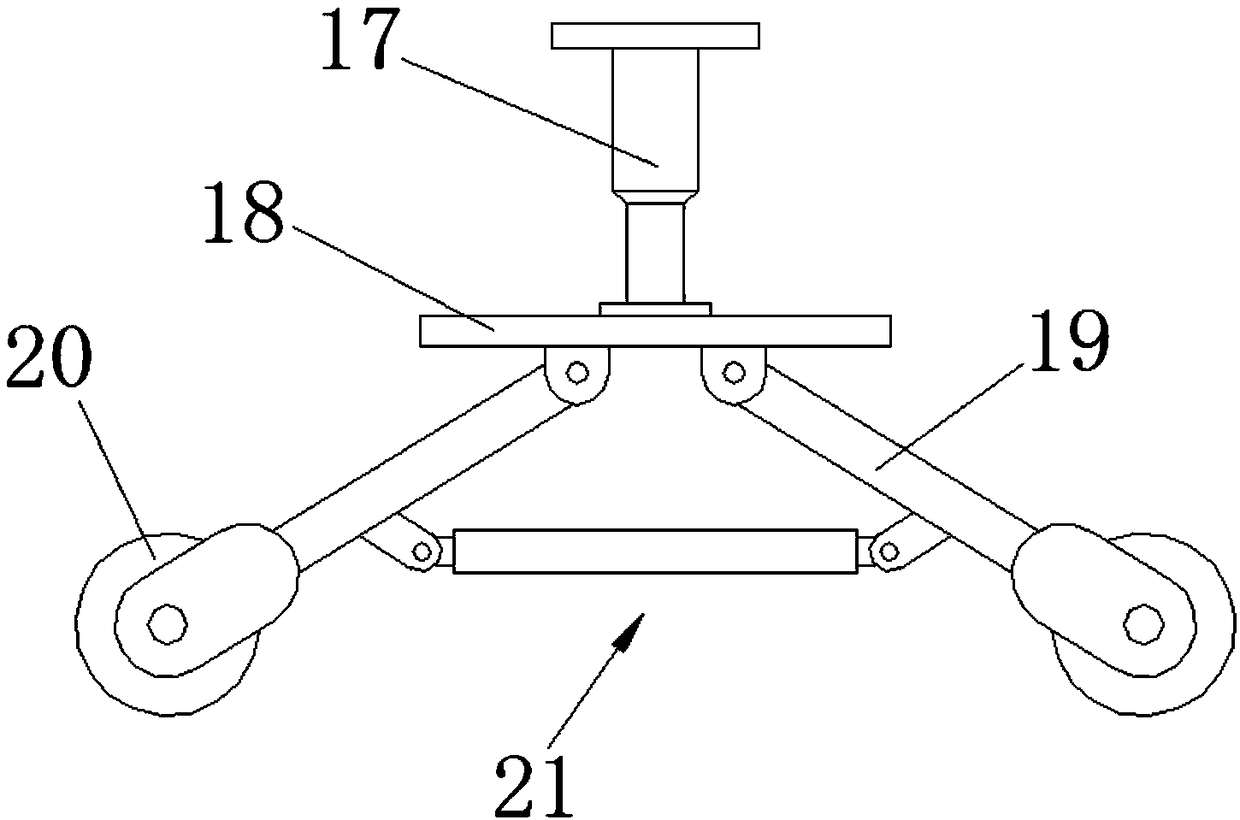

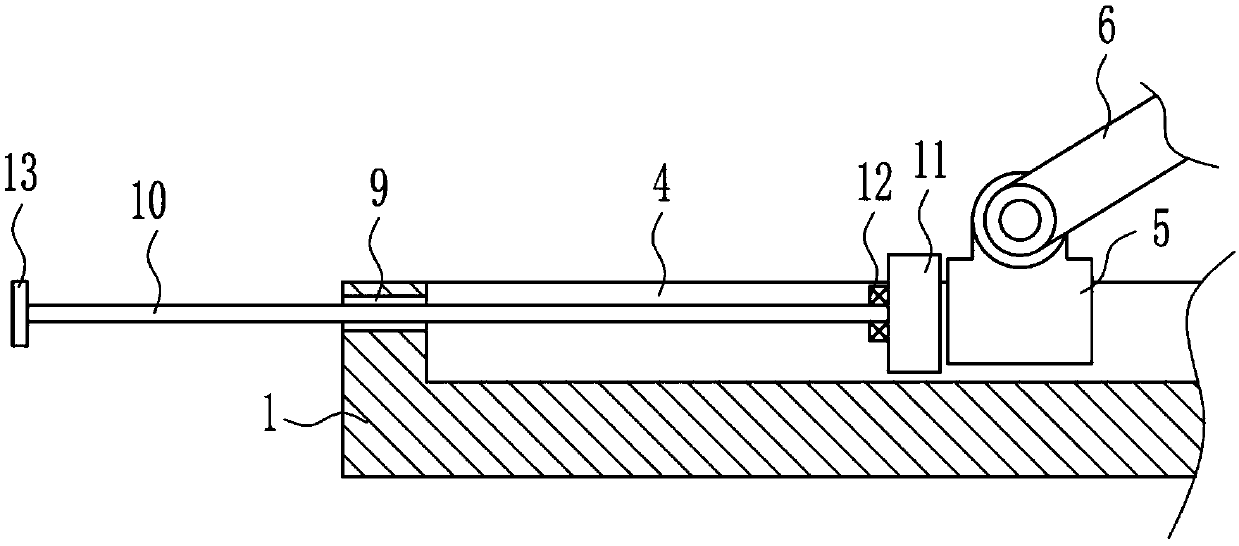

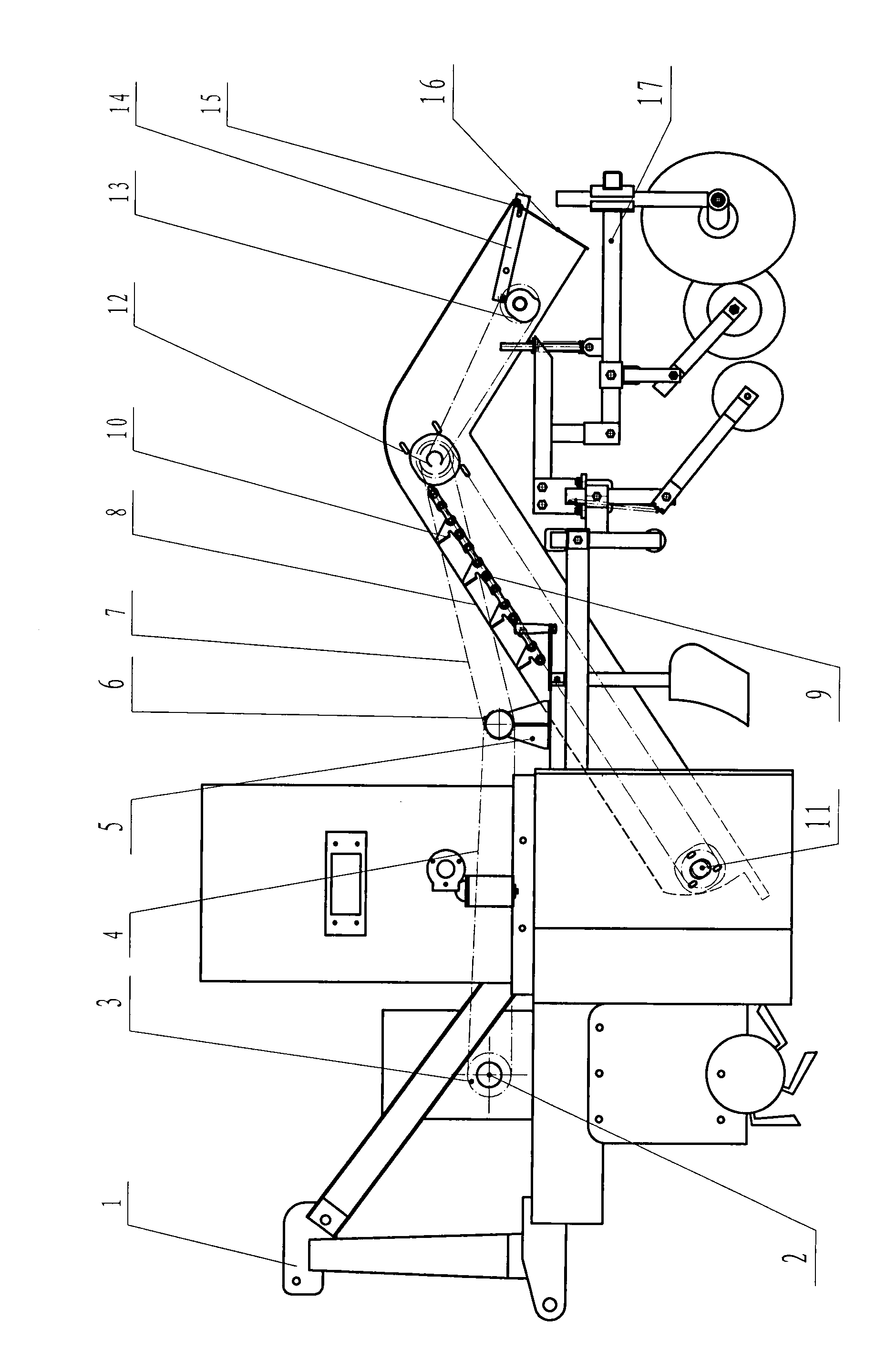

Rubber automatic plate-cutting machine

InactiveCN108162034AImprove cutting efficiencyImprove cutting accuracyNon-rotating vibration suppressionMetal working apparatusEngineeringConveyor belt

The invention discloses a rubber automatic plate-cutting machine. The rubber automatic plate-cutting machine includes a discharge roller, a conveyor belt, a material-pressing mechanism and material-delivery rollers, two ends of the discharge roller are rotatably installed on a fixing table through a revolving shaft, and the right side of the discharge roller is horizontally provided with the conveyor belt for supporting a first support of the conveyor belt to be vertically installed below two ends of the conveyor belt; the upper part of the conveyor belt is provided with the material-pressingmechanism which is fixedly installed on a top beam above a first fixing frame, the right end of the conveyor belt is horizontally provided with the material-delivery rollers, and a plurality of groupsof material-delivery rollers are arranged in parallel; and two ends of the multiple groups of material-delivery rollers are horizontally provided with two groups of fixing plates, and two ends of themultiple groups of material-delivery rollers are rotatably installed on the fixing plates through the revolving shaft to support second supports of the fixing plates to be vertically installed belowtwo ends of the fixing plates. According to the rubber automatic plate-cutting machine, the cutting efficiency of a rubber plate can be improved, the production cost is reduced, the cutting precisionof the rubber plate can be greatly improved at the same time, and the defective rate is decreased.

Owner:JINGDONG RUBBER

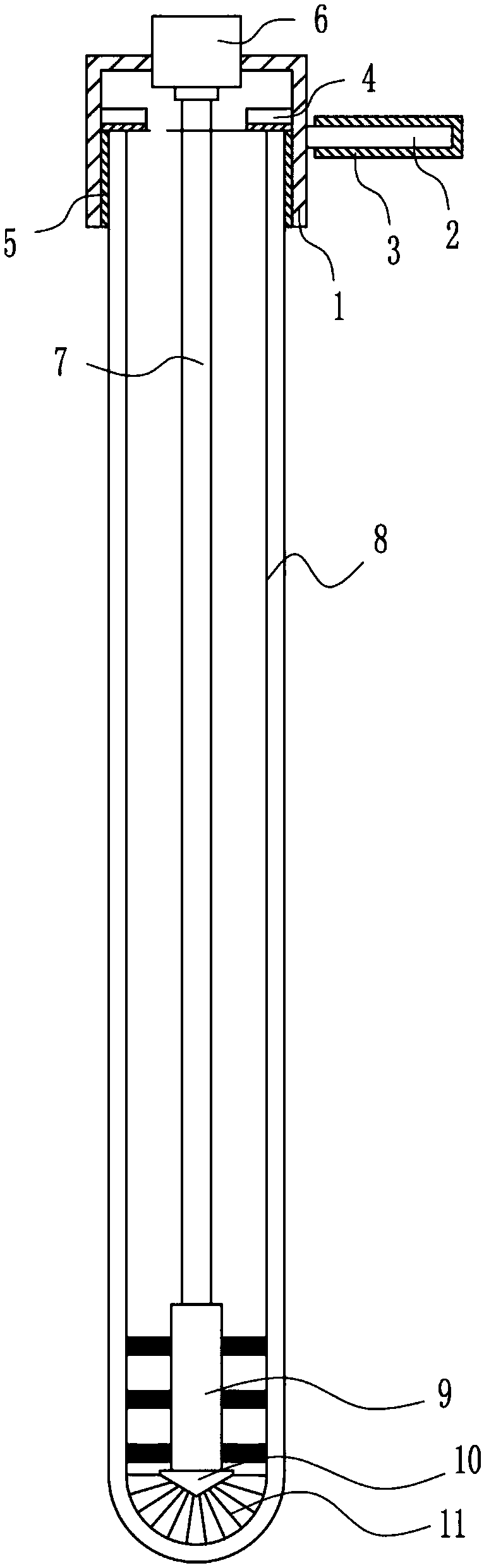

Cleaning device inside solar energy heat collection pipe

The invention relates to a cleaning derive, in particular to a cleaning device inside a solar energy heat collection pipe. The cleaning device inside the solar energy heat collection pipe is comprehensive in cleaning, can place the heat collection pipe well without affecting cleaning. According to the technical scheme, the cleaning device inside the solar energy heat collection pipe comprises a frame body, a handle, a rubber sleeve, limiting blocks, rubber plates, a motor, a rubber rotating rod and the like. The handle is installed on the middle part of the right side face outside the frame body, the rubber sleeve is arranged on the handle, the limiting blocks are installed on the upper portions of the left and right side faces in the frame body, and the rubber plates are installed on thebottom portions of the limiting blocks and the left and right side faces in the frame body. According to the cleaning device inside the solar energy heat collection pipe, the heat collection pipe canbe placed steadily through a support device without affecting cleaning; water is not needed to be continuously poured into the heat collection pipe for cleaning by people through a water injection device, convenience and swiftness are achieved, comprehensive cleaning is achieved, the heat collection pipe can be placed well, and the effect of cleaning is not affected.

Owner:杭州全要素科技服务有限公司

Anti-deviation conveyer belt for belt conveyer

Owner:铁岭陆平粮油仓储设备有限公司

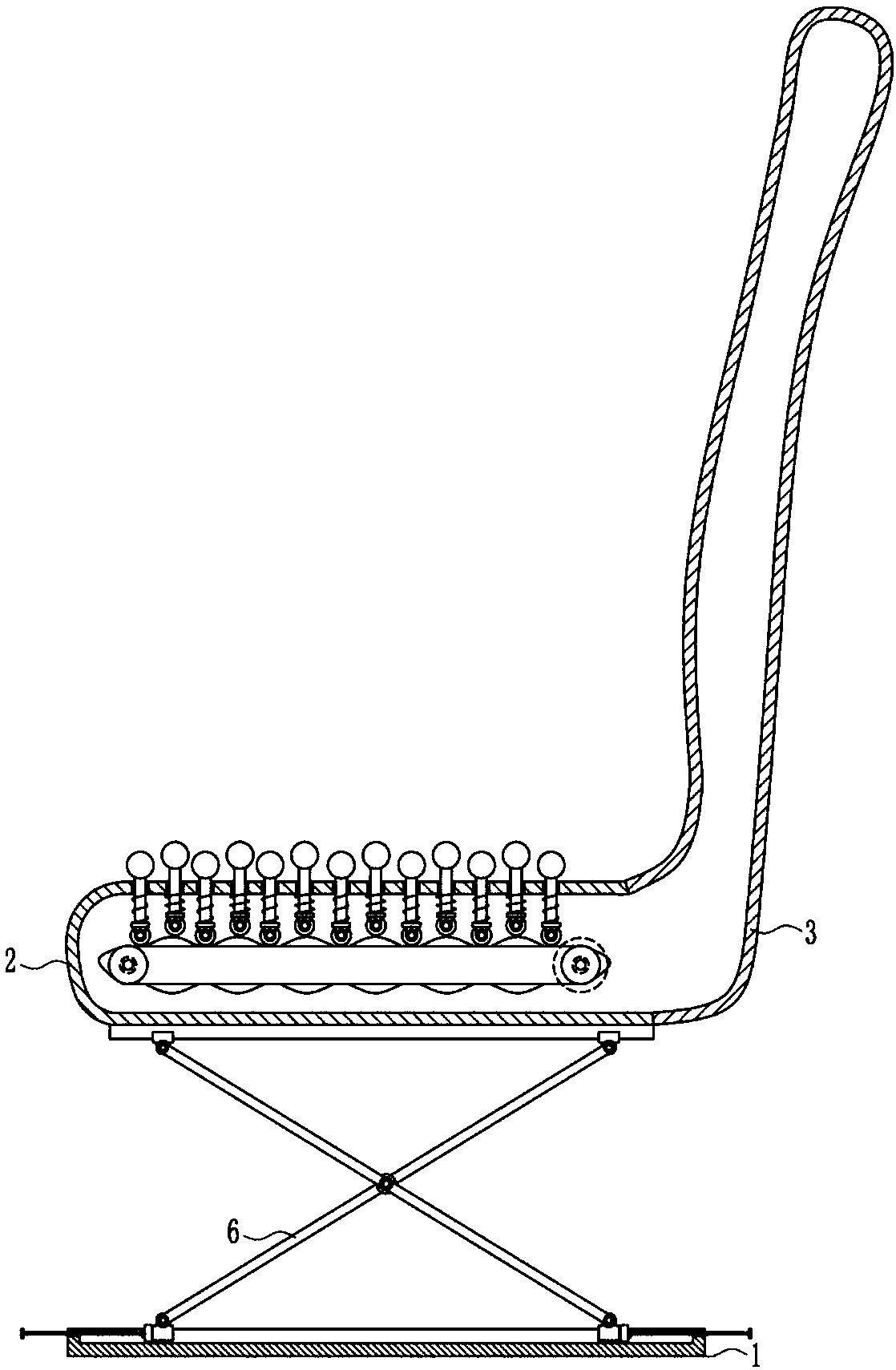

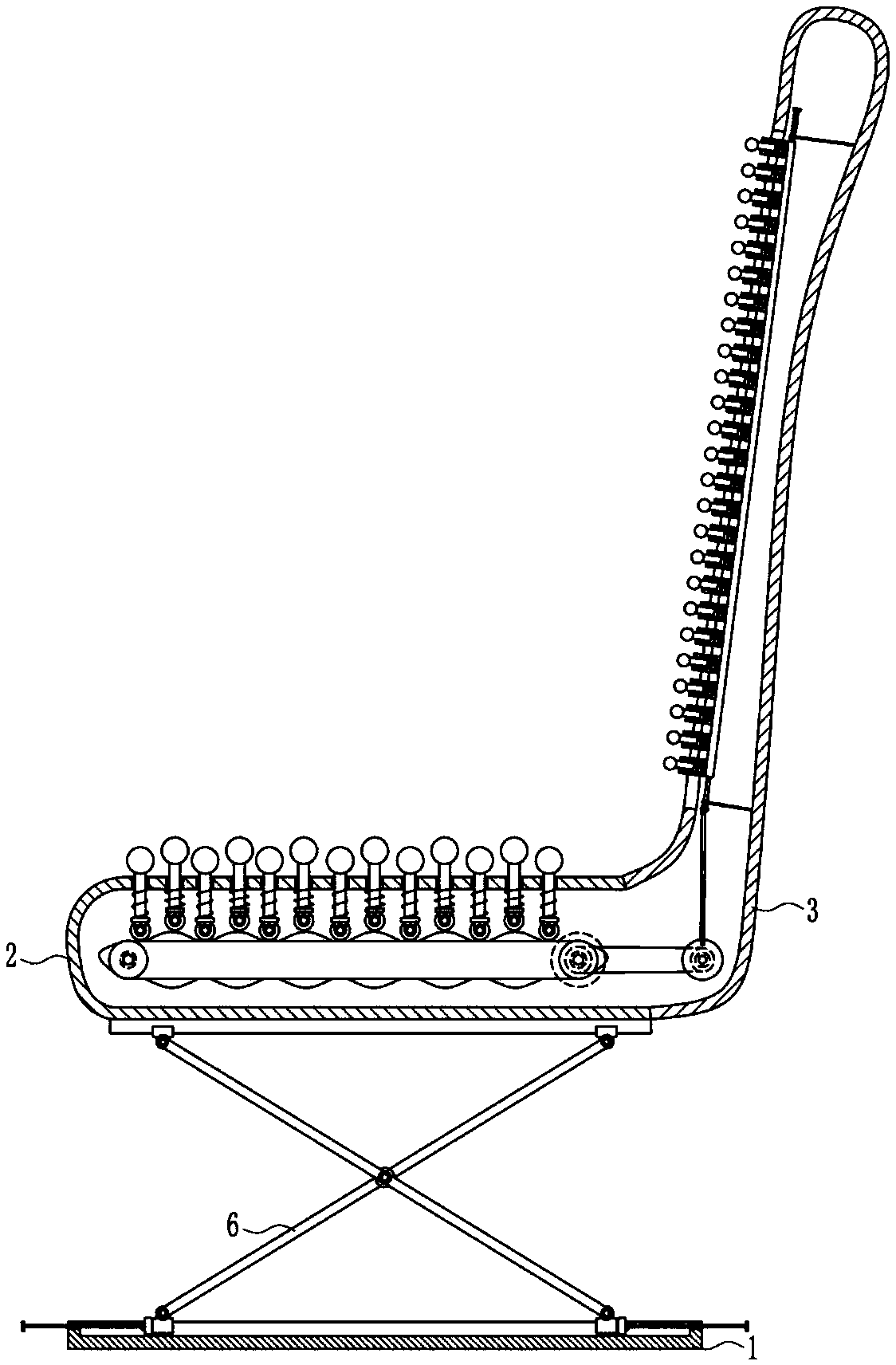

Massage chair for office

The invention relates to a massage chair, in particular to a massage chair for office. The invention provides a massage chair for office with more uniform massage force. According to the technical scheme: the massage chair for office comprises a bottom plate, a hollow seat cushion, a hollow backrest, first sliding blocks, connecting rods, a second sliding rail, a second sliding block, a threaded rod, a first rubber plate, a first bearing seat and the like; the upper part of the bottom plate is provided with the hollow seat cushion, the right side of the hollow seat cushion is provided with thehollow backrest, the hollow seat cushion is communicated with the hollow backrest, the top of the bottom plate is provided with the first sliding groove, two first sliding blocks are slidably arranged in the first sliding groove, and the tops of the two first sliding blocks are hinged with the connecting rod respectively. According to the invention, the first rubber plate is driven to move left and right through the threaded rod, so that the first sliding blocks are driven to move left and right, the height of the hollow seat cushion is adjusted through the connecting rods, the first massageball is driven by the first motor to massage the buttock of an operator, so that the effect of more uniform massage is achieved.

Owner:肖建平

Illuminated keyboard

An illuminated keyboard includes keys; a base plate; an LED circuit board on the base plate and comprising a first circuitry and LEDs; a spacer plate on the LED circuit board and comprising units each corresponding to the key, each unit including two first groove connectors, two second groove connectors, and at least one opening each for receiving the LED; an optically transmissive film circuit board on the spacer plate and comprising a second circuitry, switch contacts, and holes, the first or second groove connector passing through the hole; and a rubber plate on the film circuit board and comprising resilient domes each disposed between the key and the switch contact, the dome having a recessed top for retaining the key, a bottom stem, and through holes grouped as groups each around the dome. The first or second groove connectors are adapted to pass through the holes.

Owner:SUNREX TECH

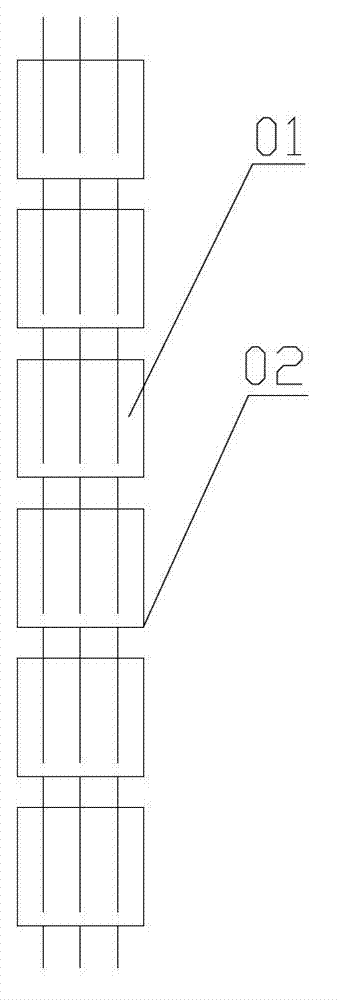

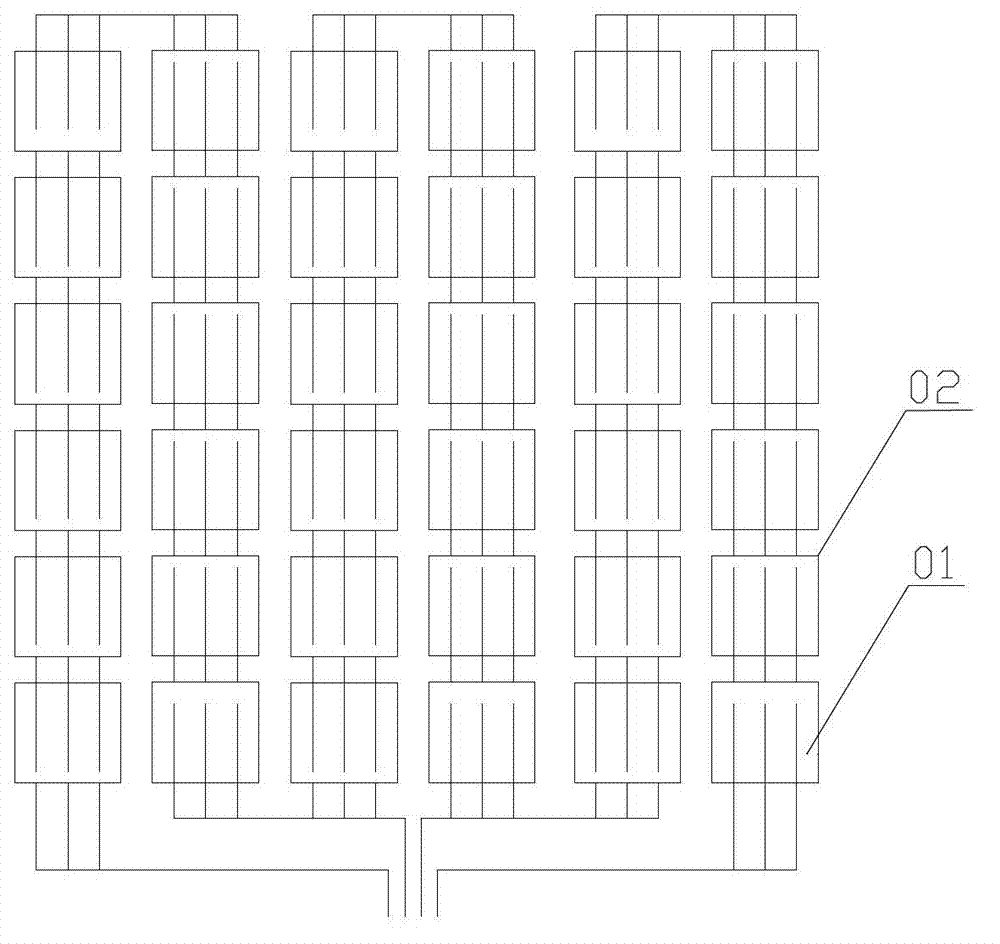

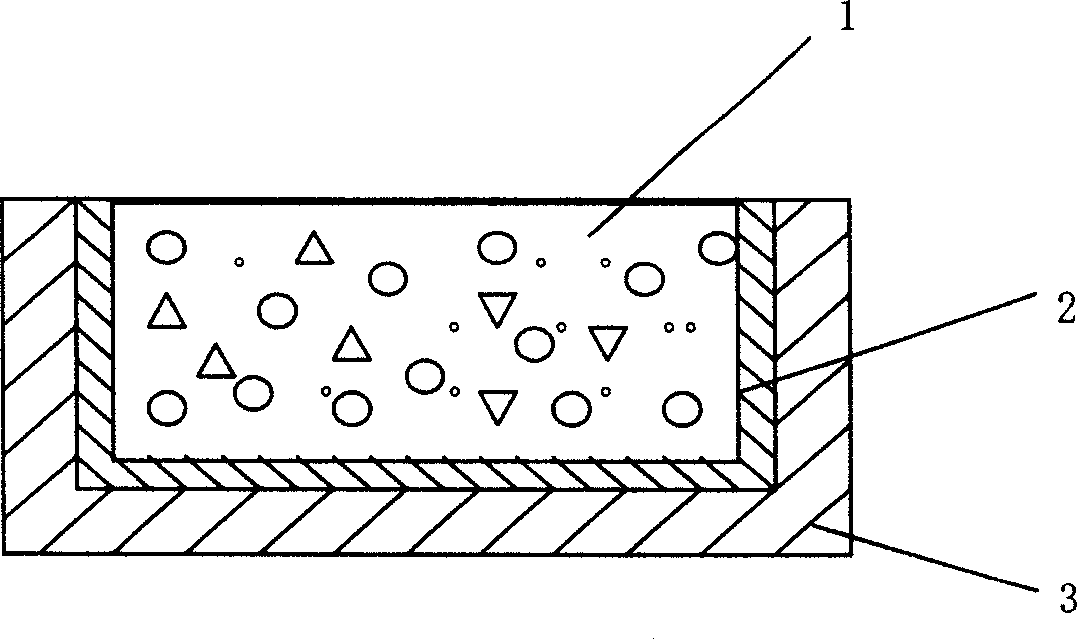

Photovoltaic module and packaging process thereof

ActiveCN102856411AHigh light transmittanceExtended service lifeFinal product manufacturePhotovoltaic energy generationEngineeringNitrogen gas

The invention provides a photovoltaic module and a packaging process thereof. The photovoltaic module and the packaging process thereof have high production efficiency and low cost and breakage rate; and the light transmittance of the photovoltaic module can be improved. The photovoltaic module comprises solar slices; a plurality of solar slices are connected in series to form cell strings; the cell strings are connected in parallel and are arranged at intervals to form a cell panel; the photovoltaic module comprises a first glass plate, the cell panel, a rubber plate and a second glass plate which are sequentially laminated; the rubber plate is in sealed connection with the first glass plate; a cavity body surrounded by the rubber plate and the first glass plate is a vacuum cavity body in which the cell panel is arranged; and a space between the rubber plate and the second glass plate is sealed and is full filled with nitrogen. The packaging process disclosed by the invention comprises the following steps of: firstly, completing laying of each part of the photovoltaic module; then forming two sealed chambers by adopting an adhering mode; and finally, implementing the connection of the cell panel and the first glass plate by utilizing a vacuumizing mode and simultaneously full filling the nitrogen between the rubber plate and the second glass plate, so that the rubber plate is prevented from being oxidized.

Owner:TIANJIN YINGLI NEW ENERGY RESOURCES

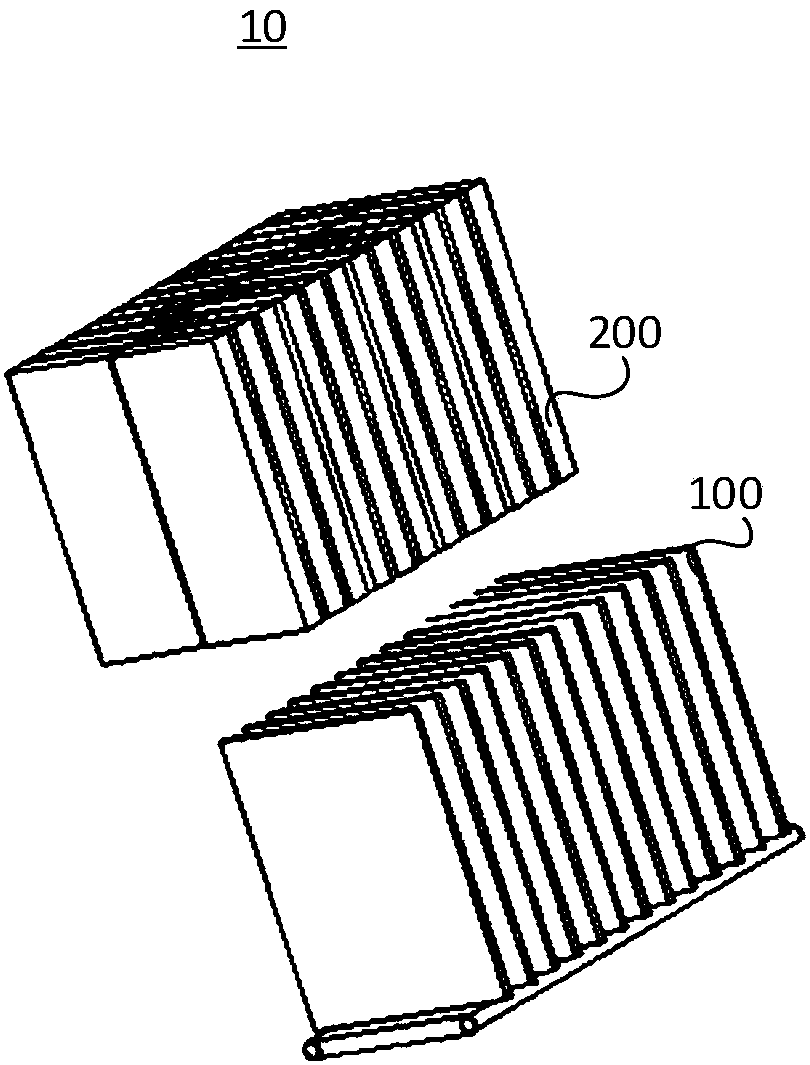

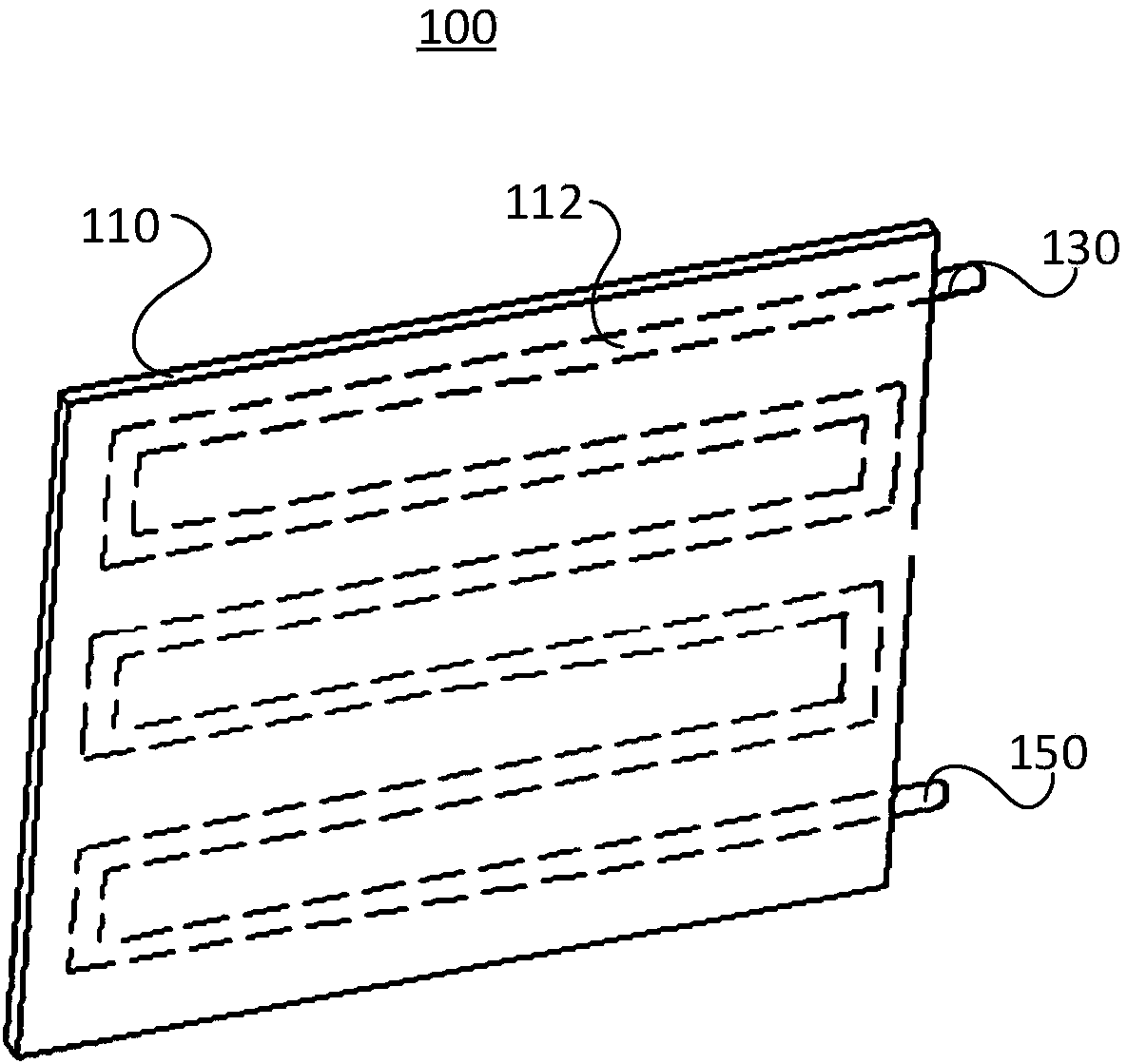

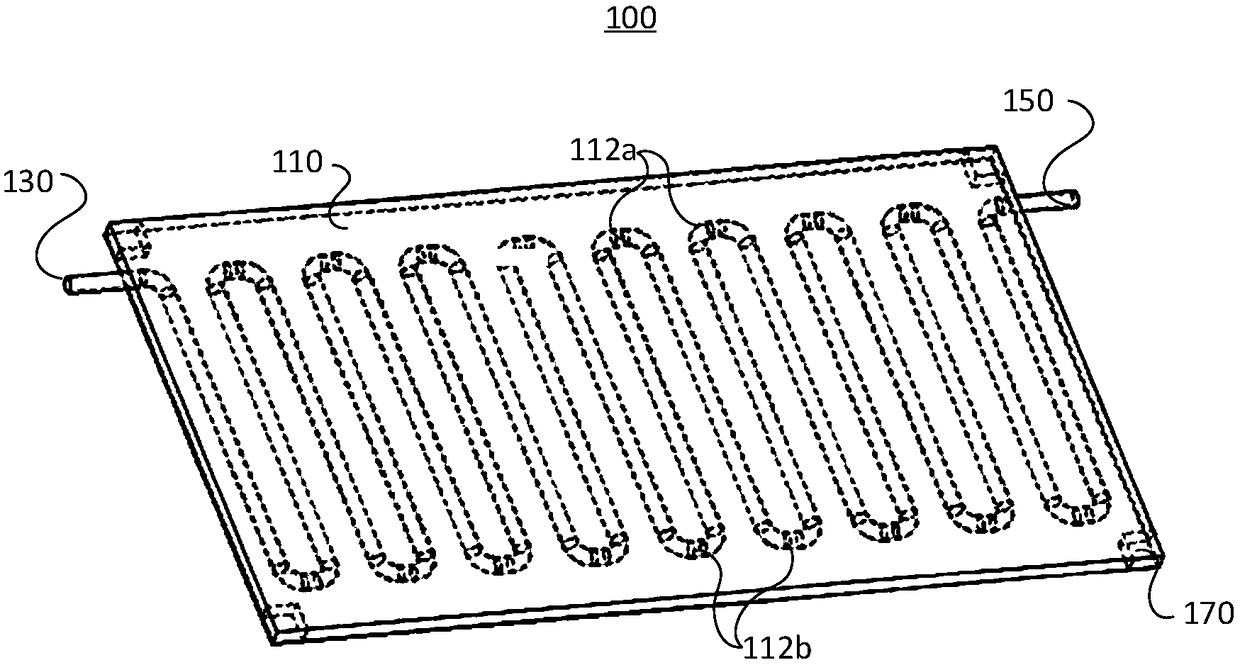

Liquid cooling device and battery module

PendingCN108199119AAvoid explosive situationsEffective cushioningSecondary cellsCooling fluidBattery pack

Owner:HUATING HEFEI POWER TECH

Soil-feeding and film-pressing device of rotary-tillage, ridging, fertilizing and film-mulching machine

InactiveCN103262685AOvercome the problem that it cannot be completed and can only be done manuallySolve the problem of not being able to press the soil and cover the filmSpadesPloughsAgricultural engineeringSprocket

The invention discloses a soil-feeding and film-pressing device of a rotary-tillage, ridging, fertilizing and film-mulching machine. The soil-feeding and film-pressing device comprises a rotary-tillage, ridging and fertilizing machine, wherein a film-mulching device is arranged behind the rotary-tillage, ridging and fertilizing machine, a soil-feeding cylinder is installed in the middle of the rear end of the rotary-tillage, ridging and fertilizing machine and is bent towards the ground on the outer side of a transmission chain wheel shaft, a transmission chain which is driven by a transmission chain wheel and the transmission chain wheel shaft is arranged inside the soil-feeding cylinder, rubber plates are fixed on the transmission chain, and the transmission chain wheel is matched with an intermediate chain wheel on an intermediate bearing block through a chain and is in transmission connection with a power output chain wheel through a power output chain. The soil-feeding and film-pressing device has the advantages that when the rotary-tillage, ridging and fertilizing machine advances for ridging, a certain amount of soil is taken by the soil-feeding cylinder from the middle of a broad ridge at the back and conveyed by the chain and the rubber plates on the chain to the position of the rear film-mulching device to press a film, so that the problem that soil laying and film mulching can not be conducted in the middle of large ridge broad films can be solved, and the problem that the operation can only be completed through manual operation instead of machines previously is solved. The production efficiency is greatly improved, and the operation cost is reduced. The agricultural requirement for soil-feeding and film-pressing in the middle of the large ridge broad films is met.

Owner:张桂荣

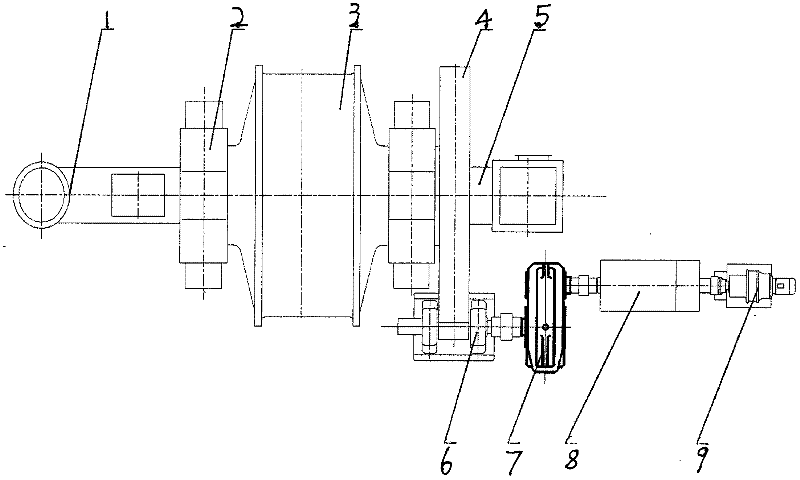

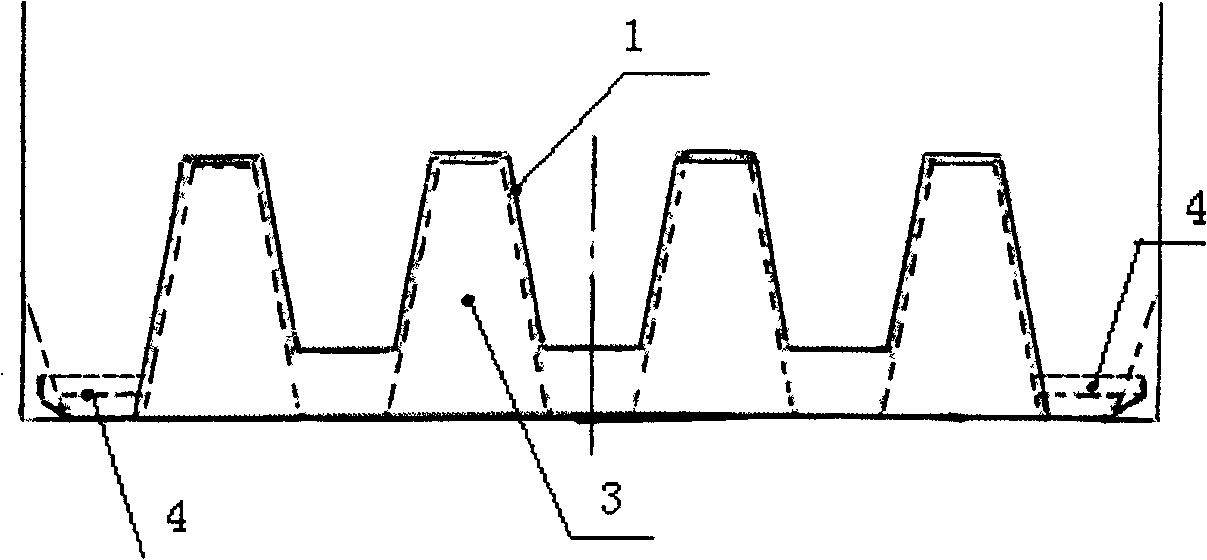

Forced discharge pulverizing mill for crushed materials

The invention discloses a forced discharge pulverizing mill for crushed materials. In the invention, no pulverizing medium is needed, the product purity is increased, materials blocks which are 300 millimeters in diameter can be pulverized into particles of which the particle sizes are less than 0.074 millimeter at one time, and the material crushing flow is simplified; by replacing a lining plate, the requirements of different particle sizes and yield are met, the equipment is utilized to the maximum extent simultaneously, and the investment cost is saved; and the service life of a barrel is prolonged, and the maintenance cost of the equipment is lowered. The forced discharge pulverizing mill consists of a feeding part, a main bearing, a revolving part, a driven gear, a discharging part, a driving gear, a speed reducer, a main motor, a low-speed driving device, a feeding hole, a feeding end cover gland, a feeding end cover, a bolt, a lining plate connecting bolt, a rubber plate, a barrel lining plate, a shifting board, a discharging end cover corrugated plate, a trough plate, a discharging screw, a discharging end cover, a gear cover, a discharging end cover gland, a barrel flange, a feeding end cover corrugated plate, a barrel, a pushing device, a pressure strip and a feeding spiral port. The forced discharge pulverizing mill has a simple and compact structure, and the production efficiency is increased.

Owner:洛阳宇航重工科技股份有限公司

Special-purpose loading reinforcing device for coiled steel transportation

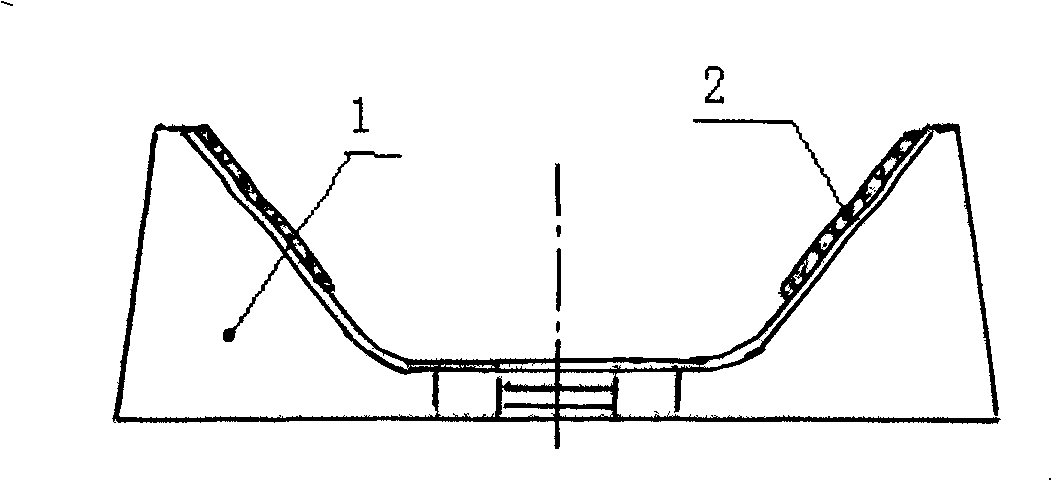

InactiveCN101264764APrevent tippingReduce in quantityReel unit transportationCargo supporting/securing componentsEngineeringLateral movement

The invention relates to a special purpose loading fastening device for transporting coil steel and designed as saddle type loading and fastening device with trench type hollow structure, comprising a steel saddle, a rubber plate and a fixed arm for fixing the loading and fastening device, which is characterized in that the loading and fastening device is ''V'' type and can stop the rolling of coil steel; the rubber plate is arranged on the inclined plane of the steel saddle and stop the lateral movement of the coil steel; the fixed arm is arranged on the front end of the saddle bottom plate, the fixed arm can be snapped in the side post of the car body to reinforce the fixed saddle, which can position longitudinally and laterally and prevent the turning over of the saddle. The invention has the advantages that the saddle is hollow structured, can be embedded mutually, can be used repeatedly with simple loading, convenient fastening, need not the auxiliary fastening, can enhance the loading efficiency and reduce the costs of loading and fastening.

Owner:CRRC YANGTZE CO LTD

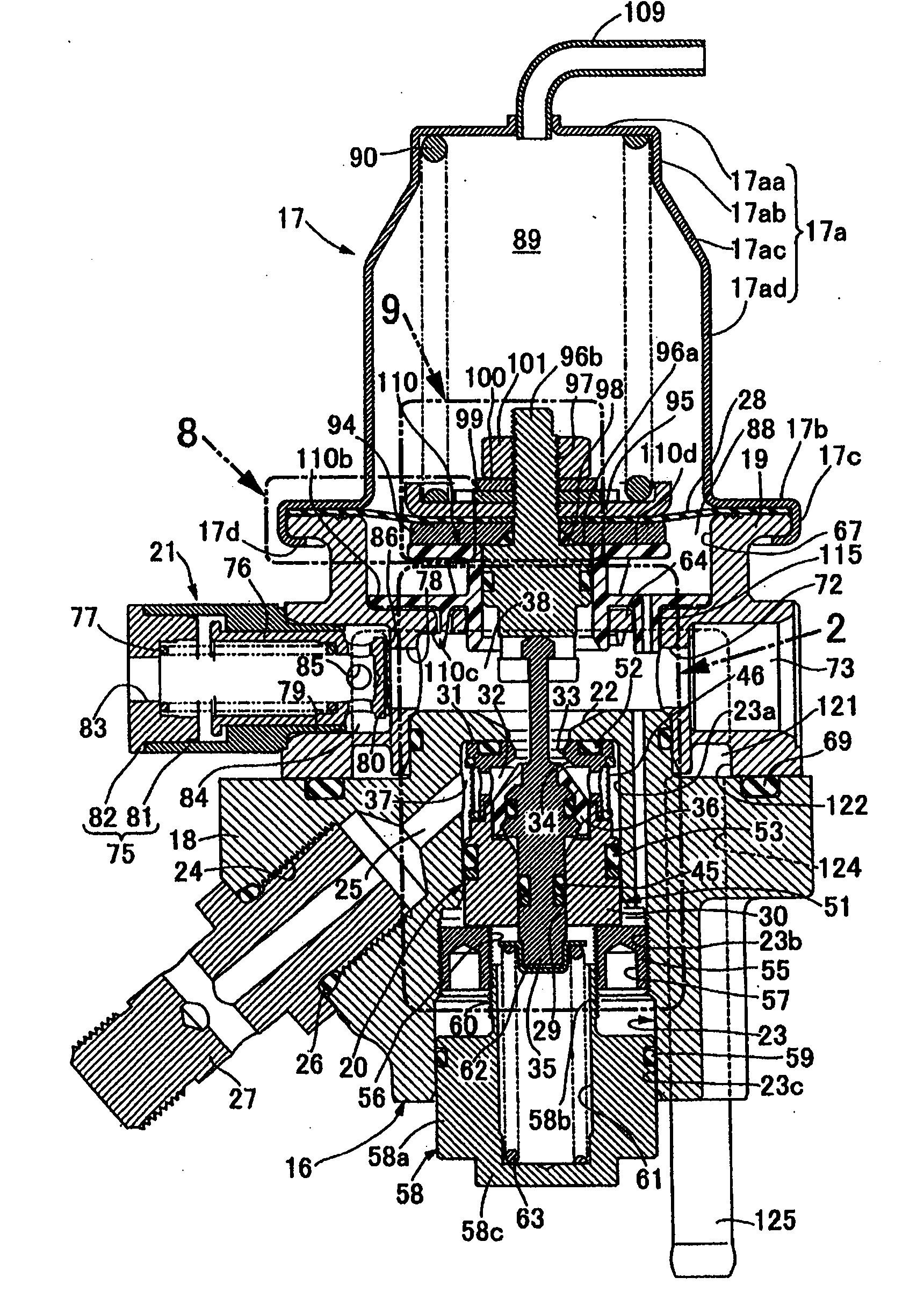

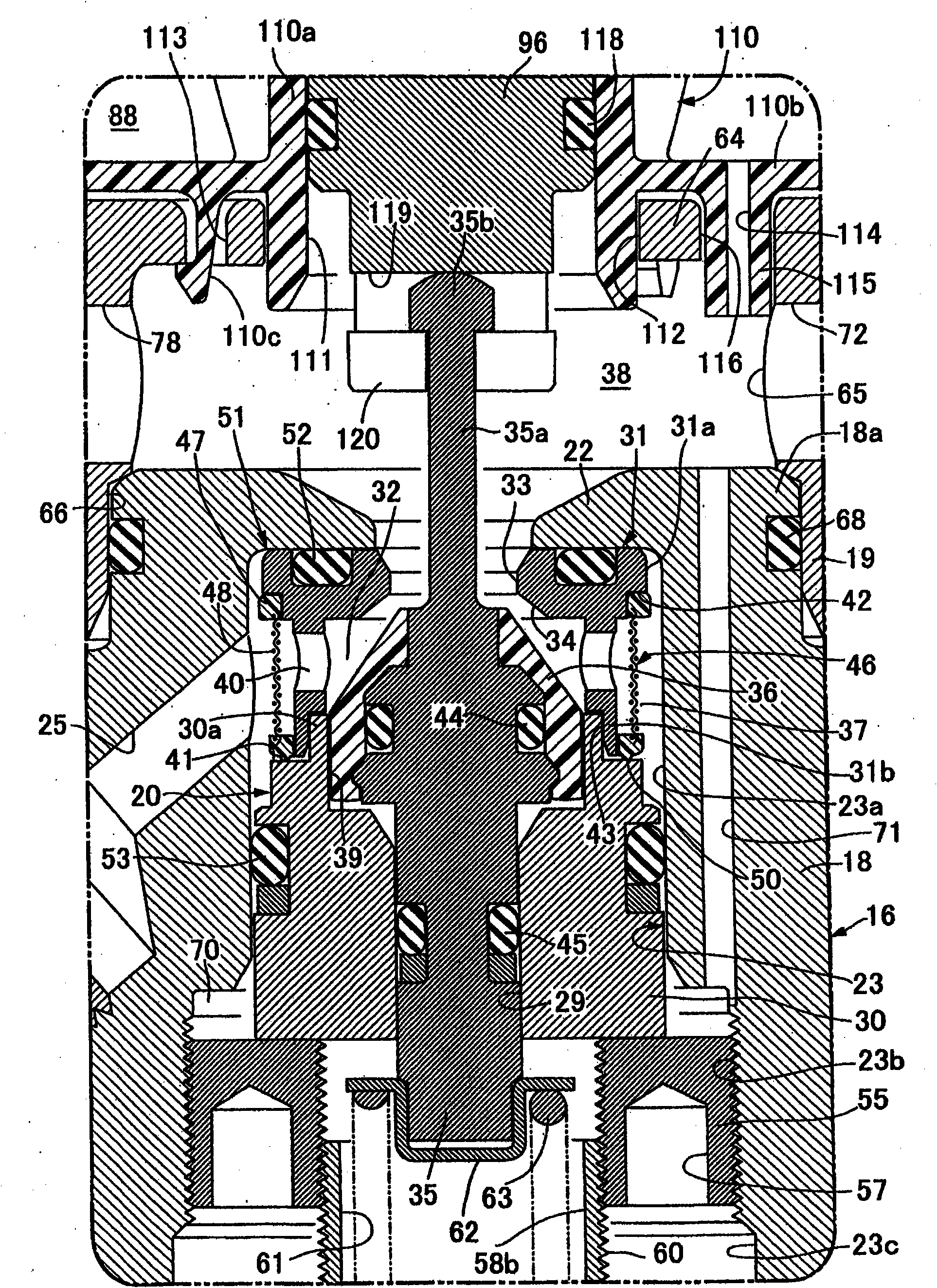

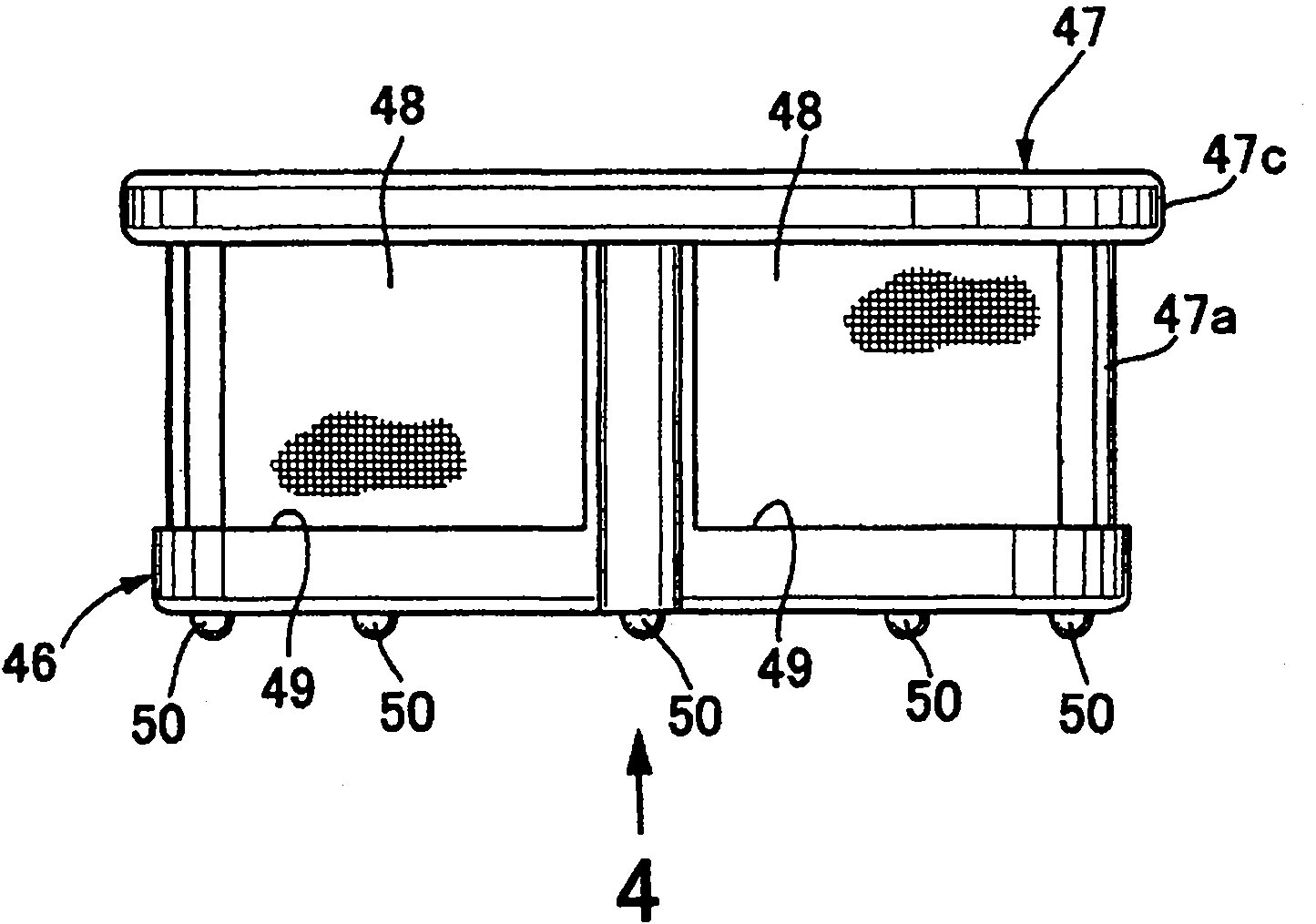

Pressure reducing valve

InactiveCN101790657AIncreased resistance to shedding loadsImprove sealingOperating means/releasing devices for valvesFluid pressure controlComing outNatural state

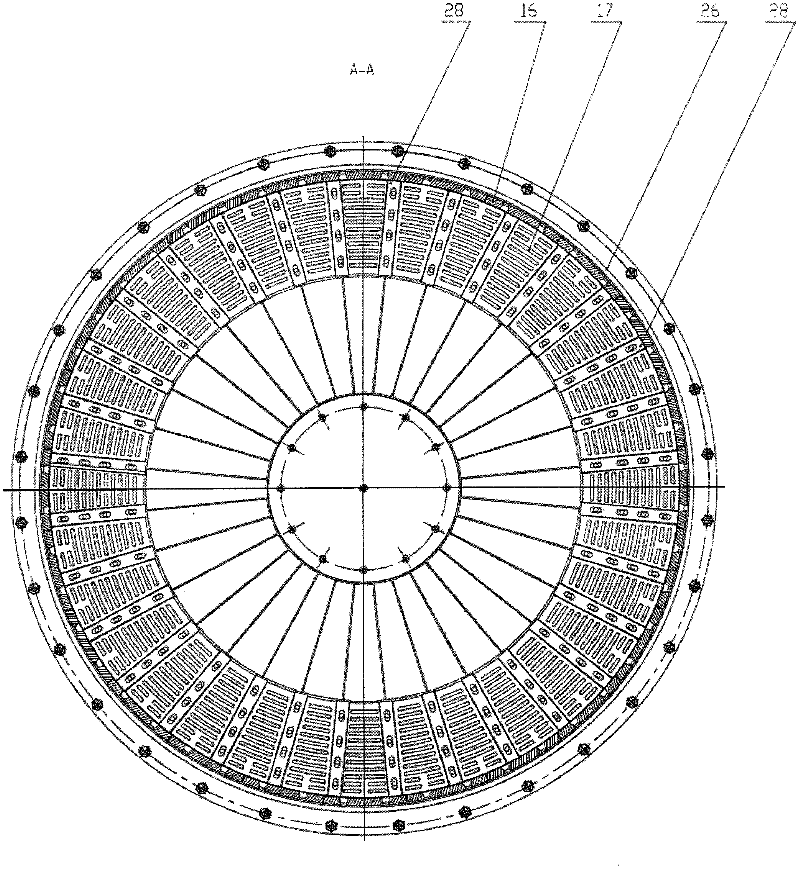

A pressure reducing valve in which a diaphragm rod interconnected with a valve body of a valve mechanism is connected to the center of a diaphragm whose peripheral edge is held between a body and a diaphragm cover. The diaphragm (28) is constructed from a disc-shaped rubber plate whose thickness at least at its peripheral edge is uniform in a natural state. The peripheral edge of the diaphragm (28) is compressed and held between a flange (17b) of the diaphragm cover (17) and a holding surface (91) of the body (16), and thus the diaphragm cover (17) is fixed to the body (16). In this state, that portion of the diaphragm (28) which is located between the flange (17b) and the holding surface (91) and at which the gap between them is the smallest is located on the inside radially of that portion of the diaphragm (28) at which the gap is the largest. The construction reduces the weight and cost of the pressure reducing valve, improves sealing ability of the diaphragm, and prevents the diaphragm from coming out of place.

Owner:KEIHIN CORP

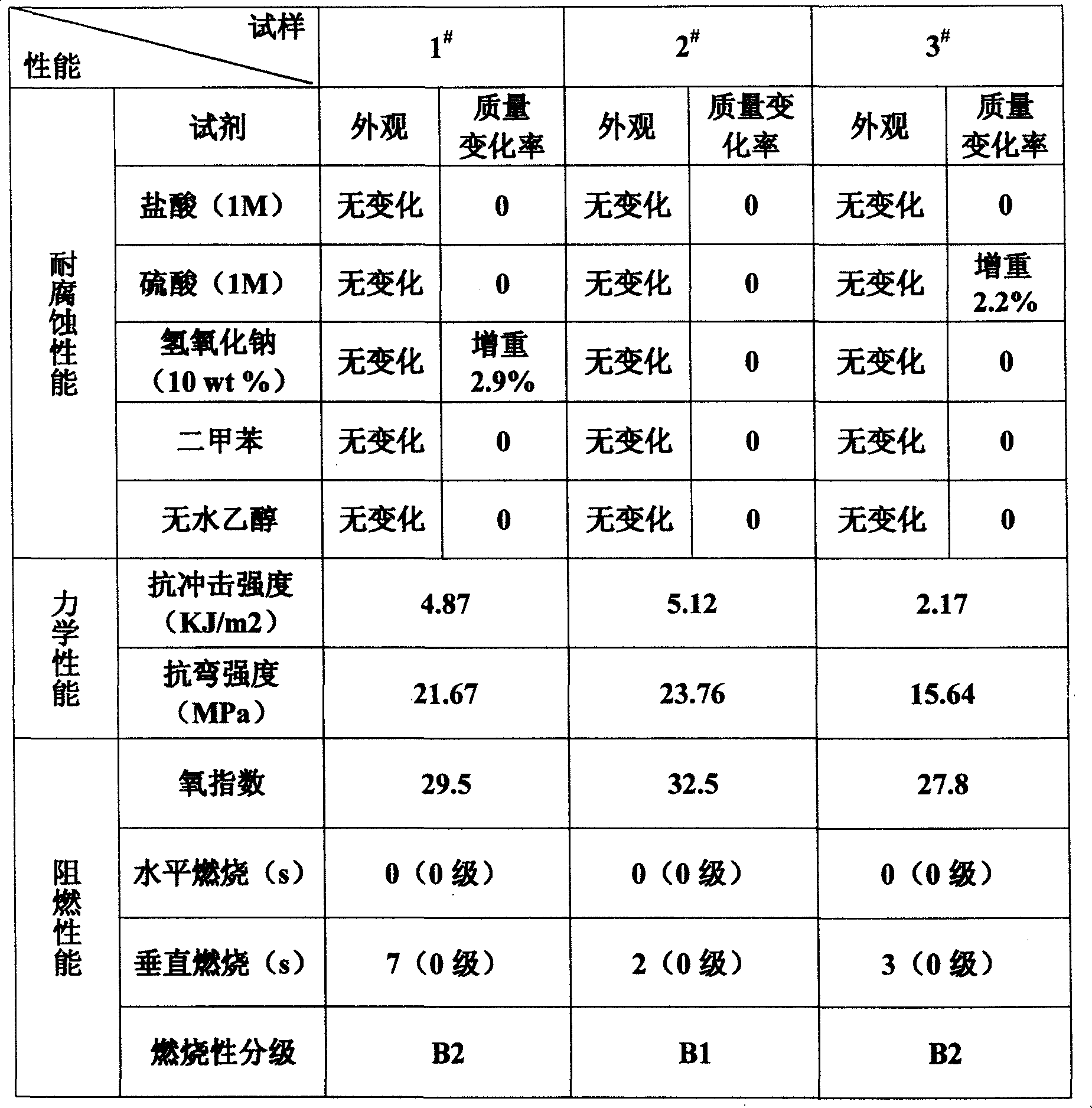

Corrosion resistant clad plate with flame resisting construction and preparation method thereof

InactiveCN1654202AWith fire performanceWith mechanical propertiesSynthetic resin layered productsPolymer sciencePolymer concrete

The present invention relates to composite structural board, and is especially one kind of composite anticorrosive fireproof structural board comprising facing layer of polymer material and base layer of water hardened gel material and its preparation process. The composite anticorrosive fireproof structural board has excellent mechanical performance, fireproof performance and anticorrosive performance. During its preparation, polymer concrete is used as the transition layer to optimize the adhesion between two kinds of base material, and the water hardened gel material is in-situ cast onto the facing polymer layer for close and firm combination. The present invention may be used to replace ceramic tile, rubber plate and other facing material widely used in chemical, pharmaceutical, electronic, computer and other industrial fields.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com