Anti-deviation conveyer belt for belt conveyer

A technology of belt conveyors and conveyor belts, which is applied in the direction of conveyors, transportation, and packaging, and can solve problems such as time-consuming, laborious, and difficult to adjust conveyor belts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

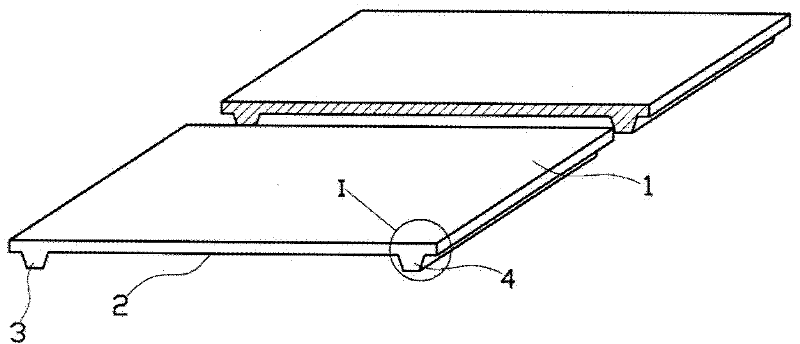

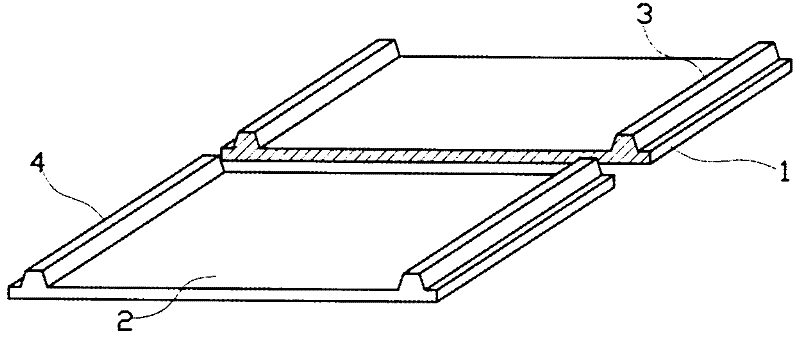

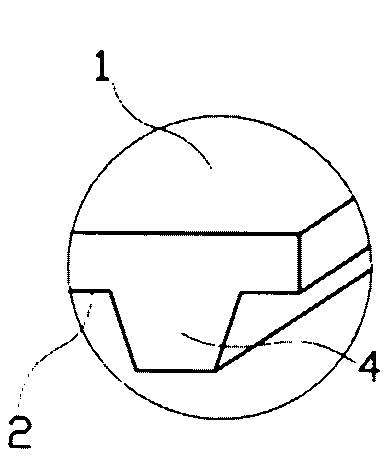

[0015] Figure 1~Figure 3 Among them, the anti-deviation belt conveyor is equipped with a strip-shaped rubber plate 1 with a reinforced skeleton. The bottom 2 of the strip-shaped rubber plate is a plane. The ribs 3 and 4 are trapezoidal in section along the length direction of the elongated rubber sheet.

[0016] The cross-section of the protruding ribs along the length direction of the strip-shaped rubber sheet is trapezoidal at the bottom of the above-mentioned strip-shaped rubber sheet. The cross-section of the protruding ribs along the length direction of the strip-shaped rubber sheet under the strip-shaped rubber sheet can also be rectangular or dovetail-shaped.

[0017] image 3 Among them, the cross-section of the rib under the strip-shaped rubber plate is rectangle 5.

[0018] Figure 4 Among them, the cross-section of the protruding rib below the elongated rubber plate is dovetail 6.

[0019] When in use, corresponding to the rectangular cross-section ribs or dov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com