Laboratory model test device for testing influence on operating tunnel from vertically-overlapped tunnel construction

An indoor model and test device technology, applied in teaching models, educational appliances, instruments, etc., can solve the problems of erroneous monitoring information, large amount of calculation, difficult to obtain soil physical and mechanical parameters, etc., and achieves good extensiveness and strong scalability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail through a preferred example below in conjunction with the accompanying drawings.

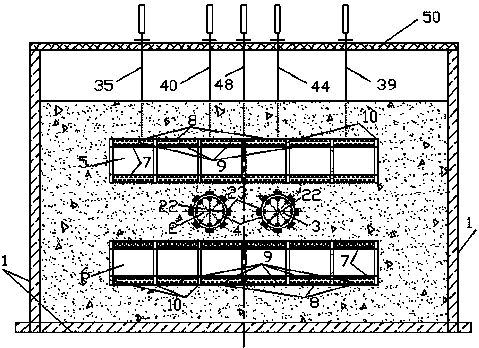

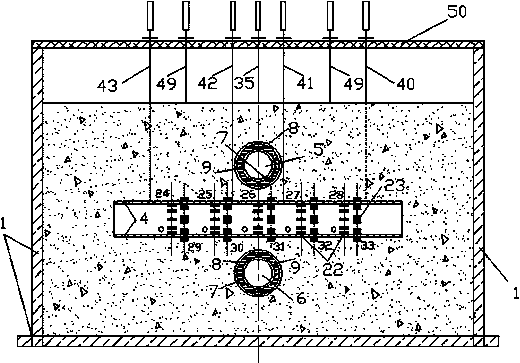

[0023] First, make a model box, two existing tunnel lining models, two excavated tunnel lining models and two excavation construction simulation devices.

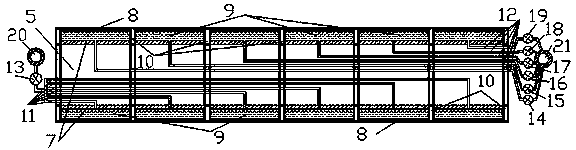

[0024] Such as figure 1 , 2 As shown, the shape of the model box 1 is a cuboid, and the internal space size is 1200 mm × 1200 mm × 800 mm (length × width × height), which is composed of five aluminum alloy plates with a thickness of 30 mm. The existing lining models 2 and 3 for the upper and lower lines of the tunnel are respectively composed of hollow aluminum alloy tubes 4 with an outer diameter of 100 mm, an inner diameter of 84 mm, a wall thickness of 8 mm, and a longitudinal length of 800 mm. The upper and lower line lining models 5 and 6 of the excavated tunnel are six-section hollow aluminum alloy tubes 7 with an outer diameter of 100 mm, an inner diameter of 84 mm, a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com