Patents

Literature

132results about How to "Improve harvest quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

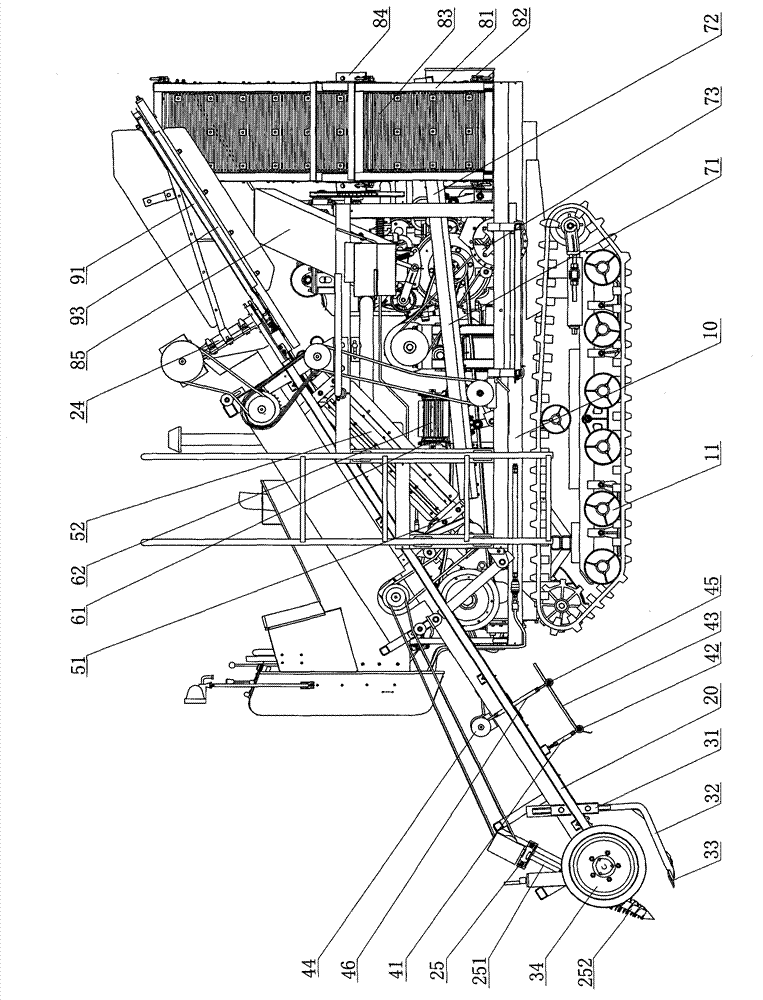

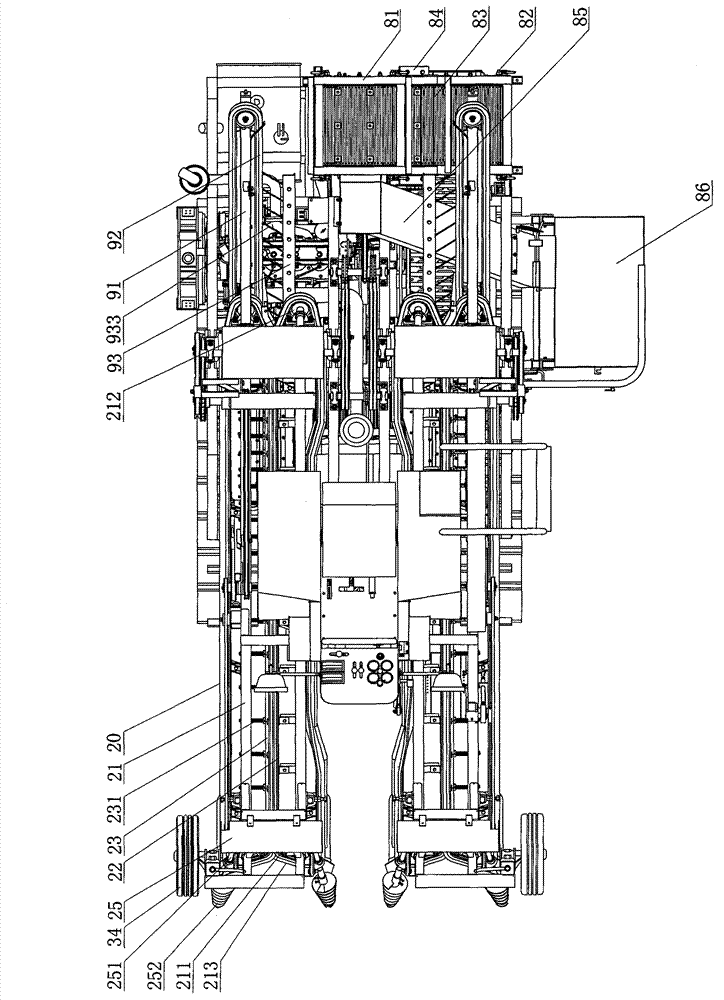

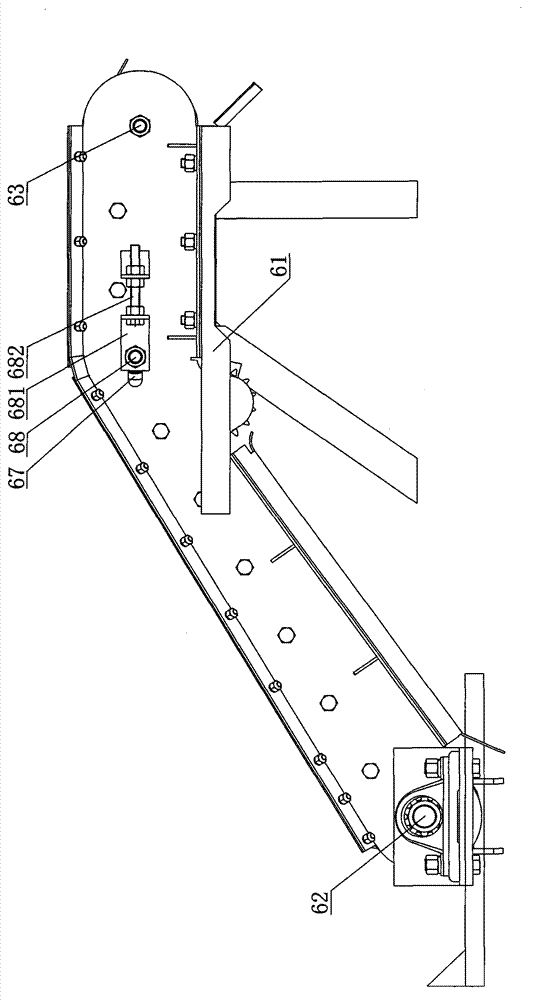

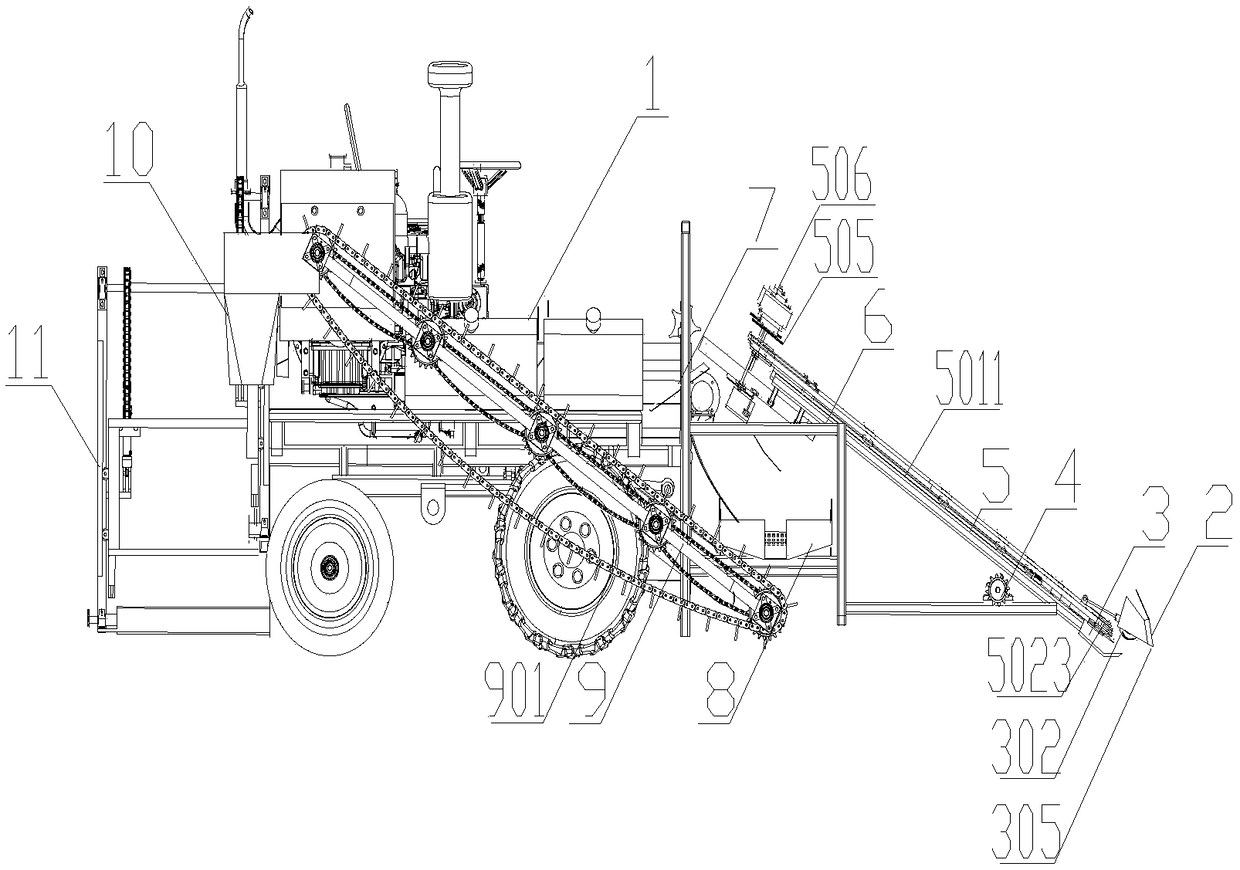

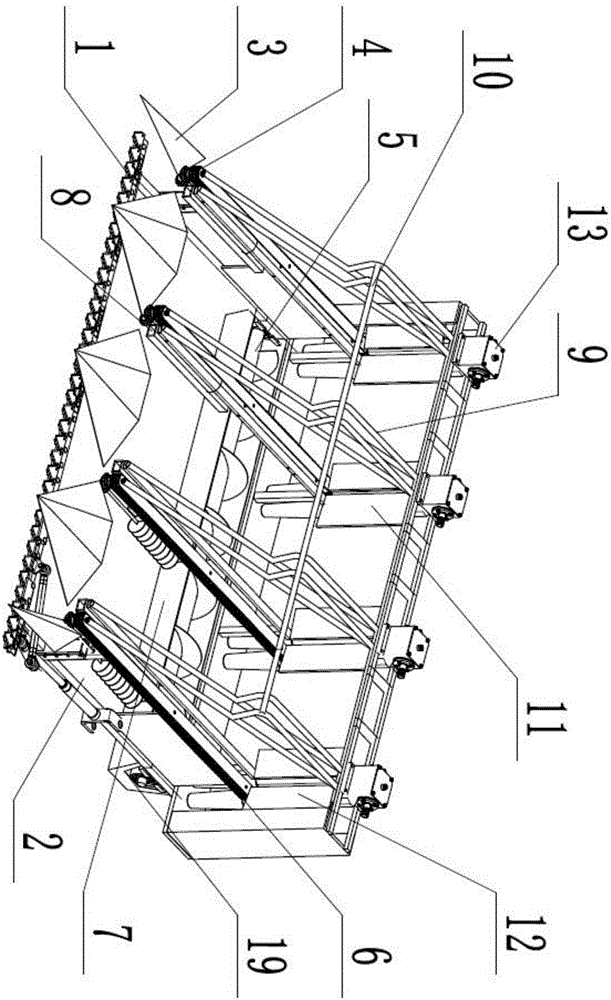

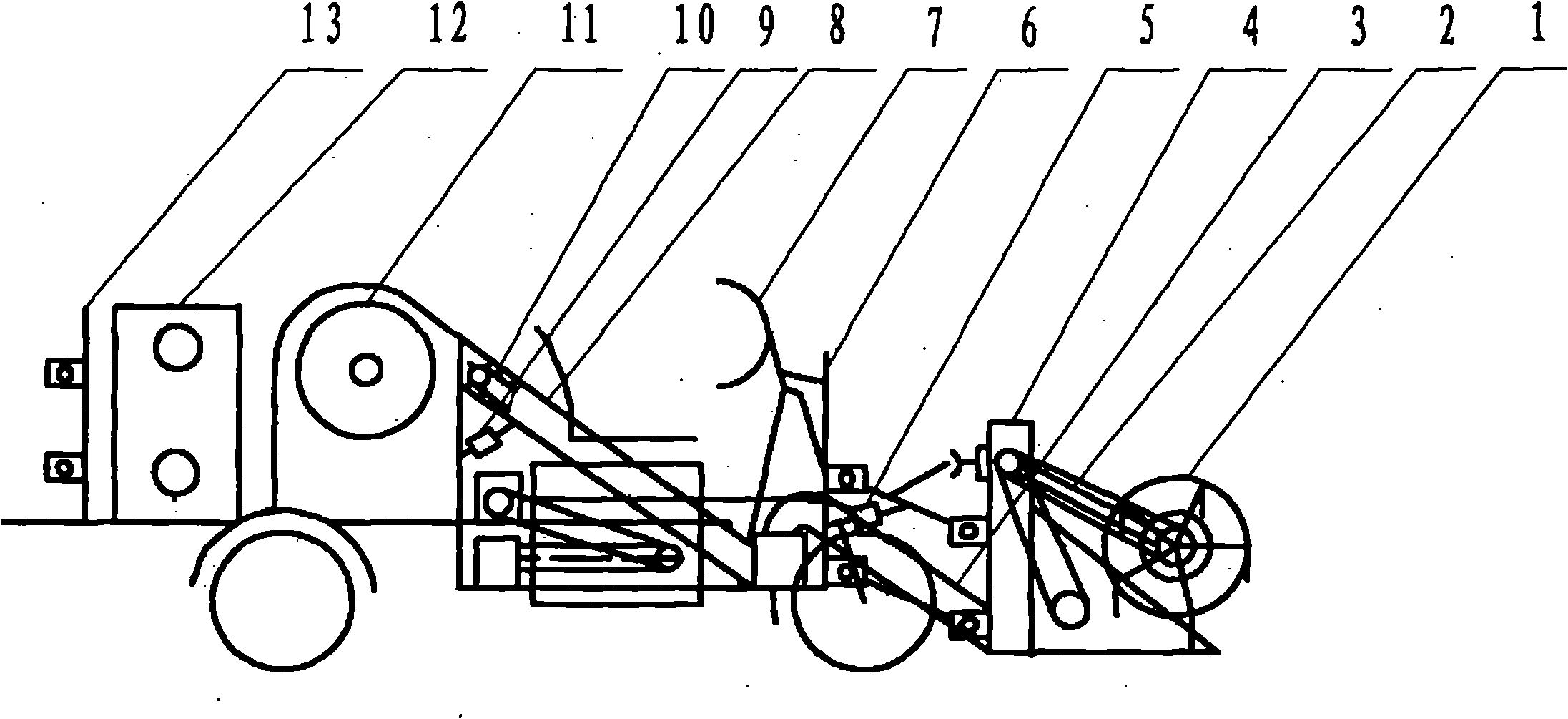

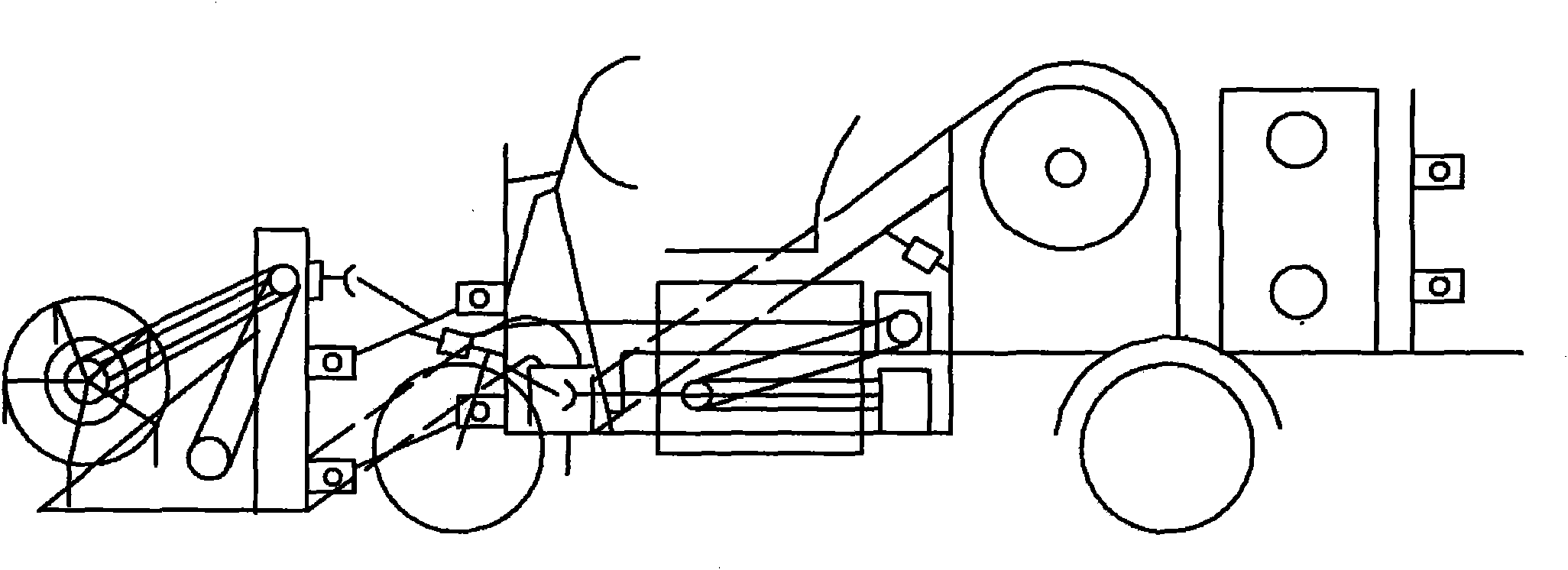

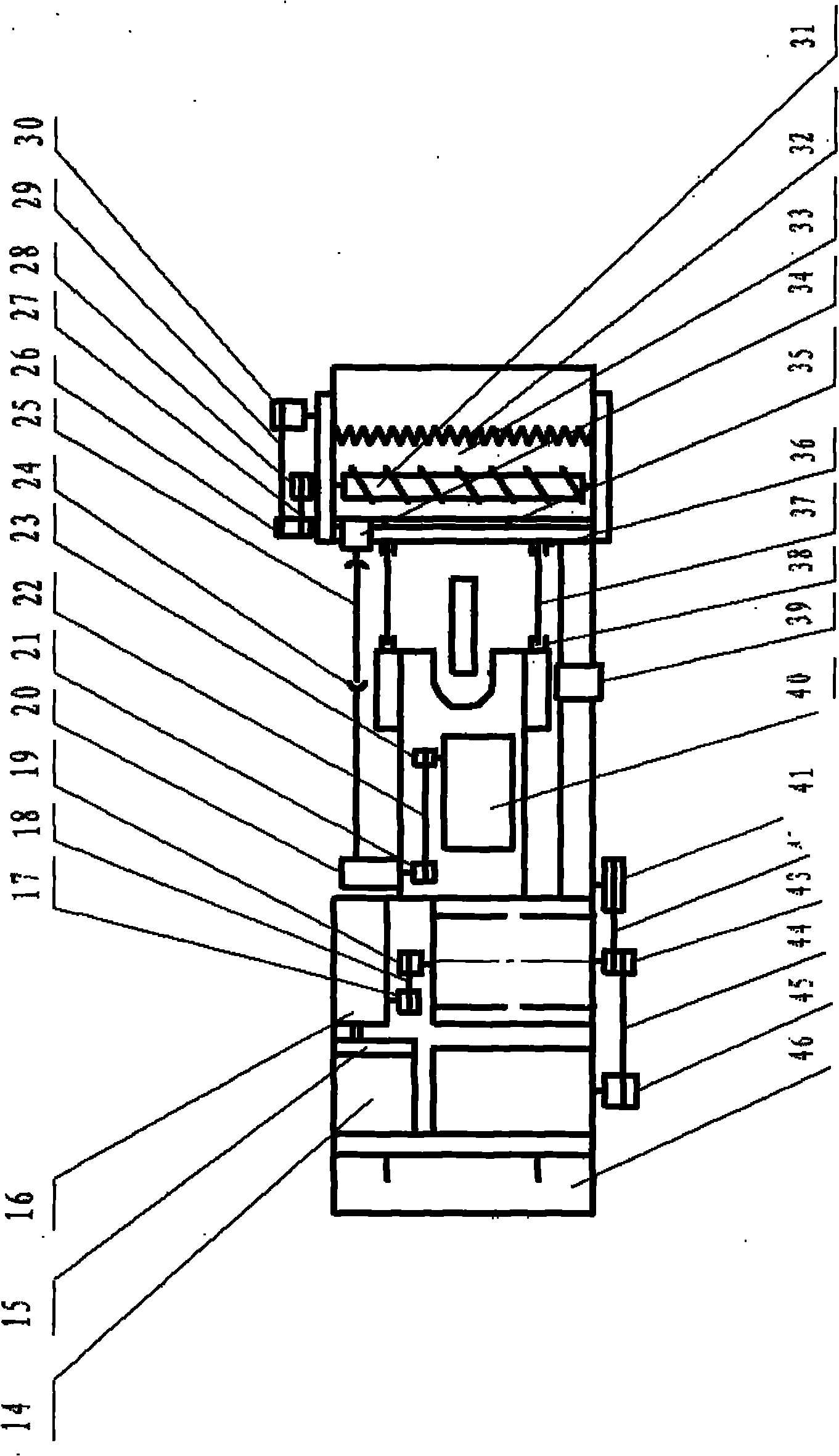

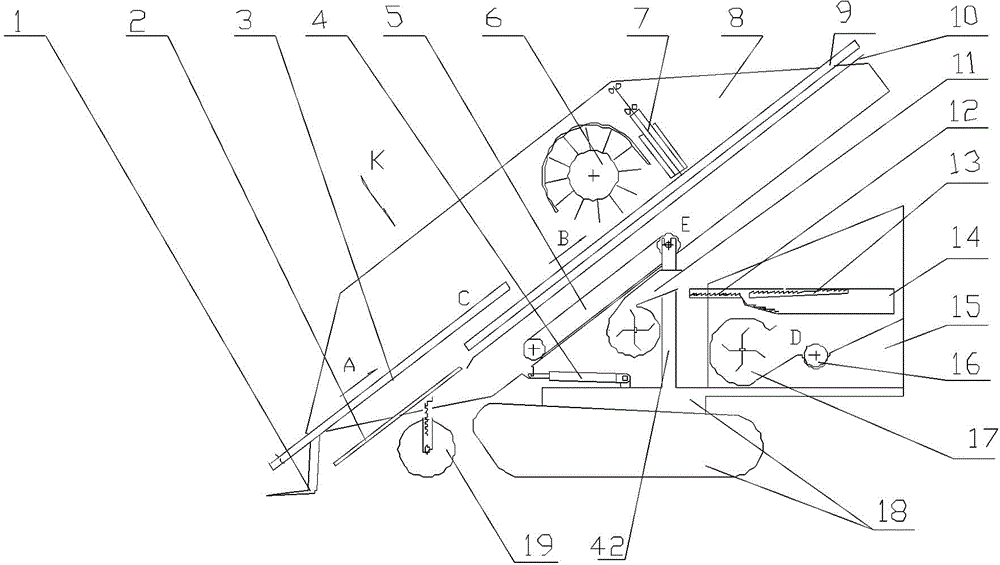

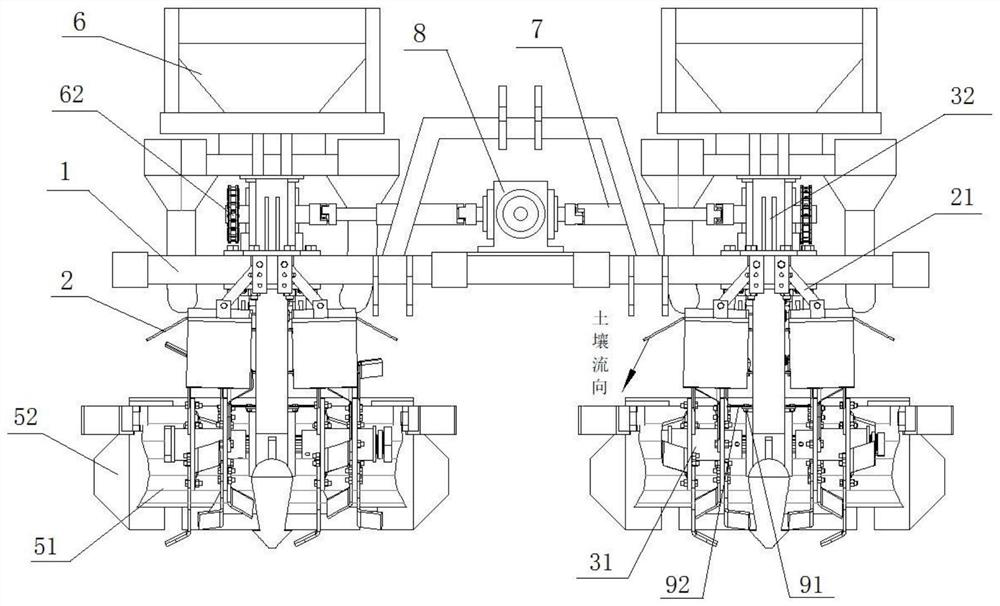

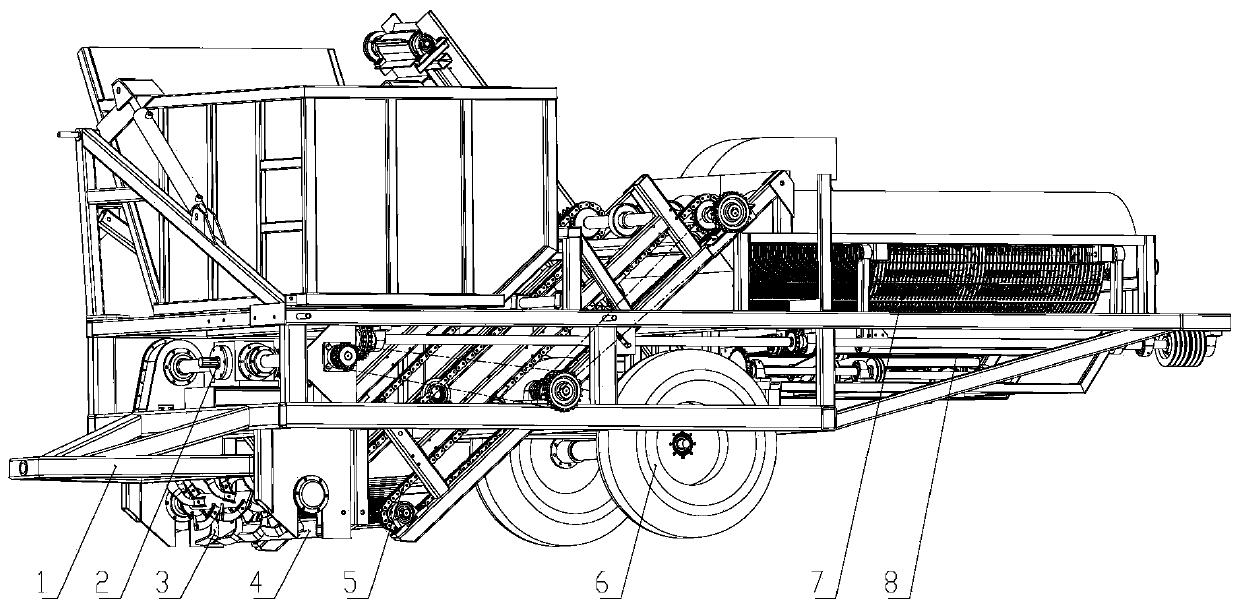

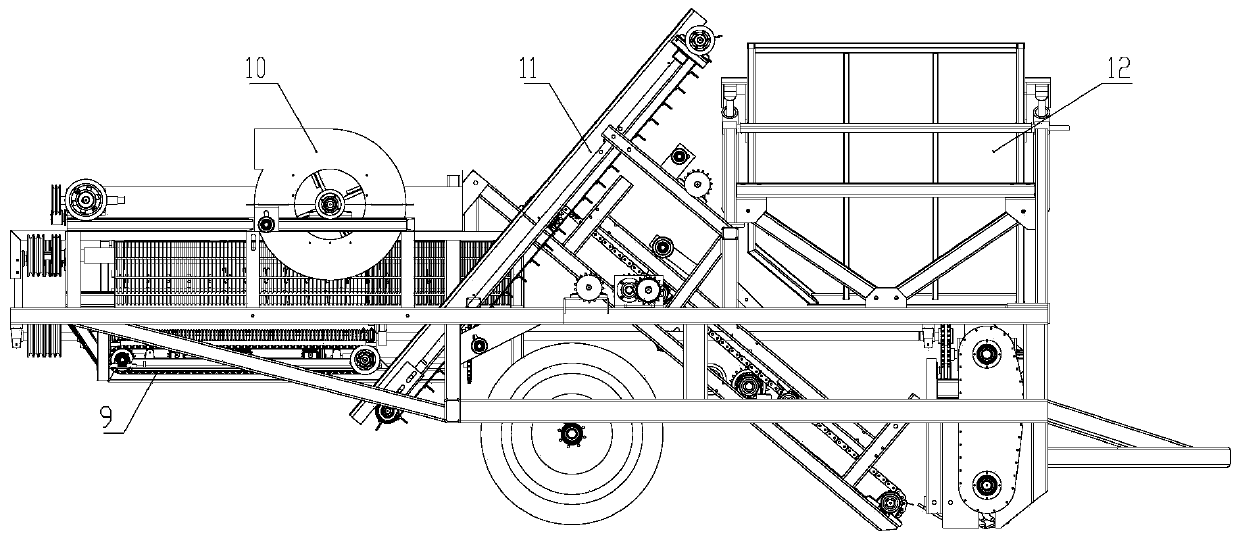

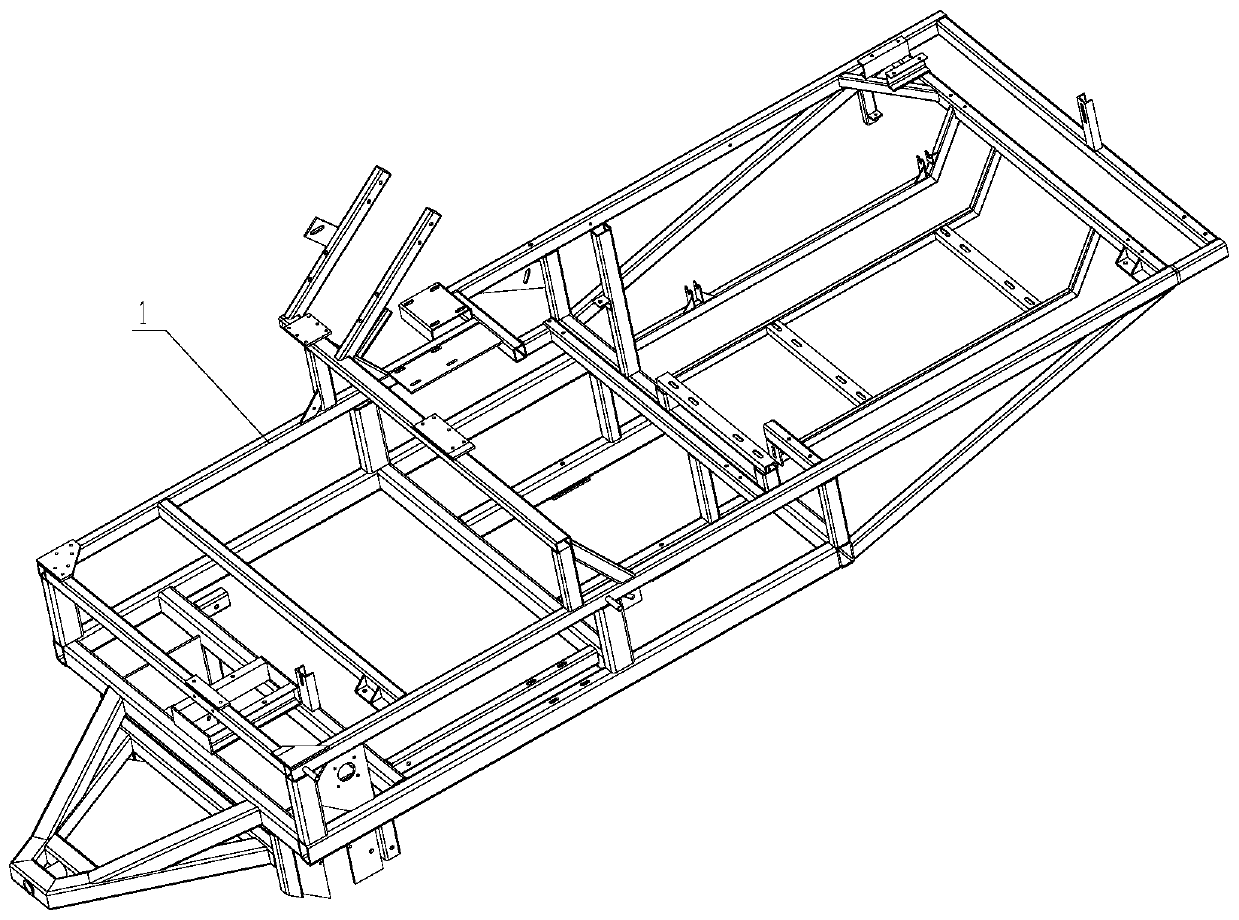

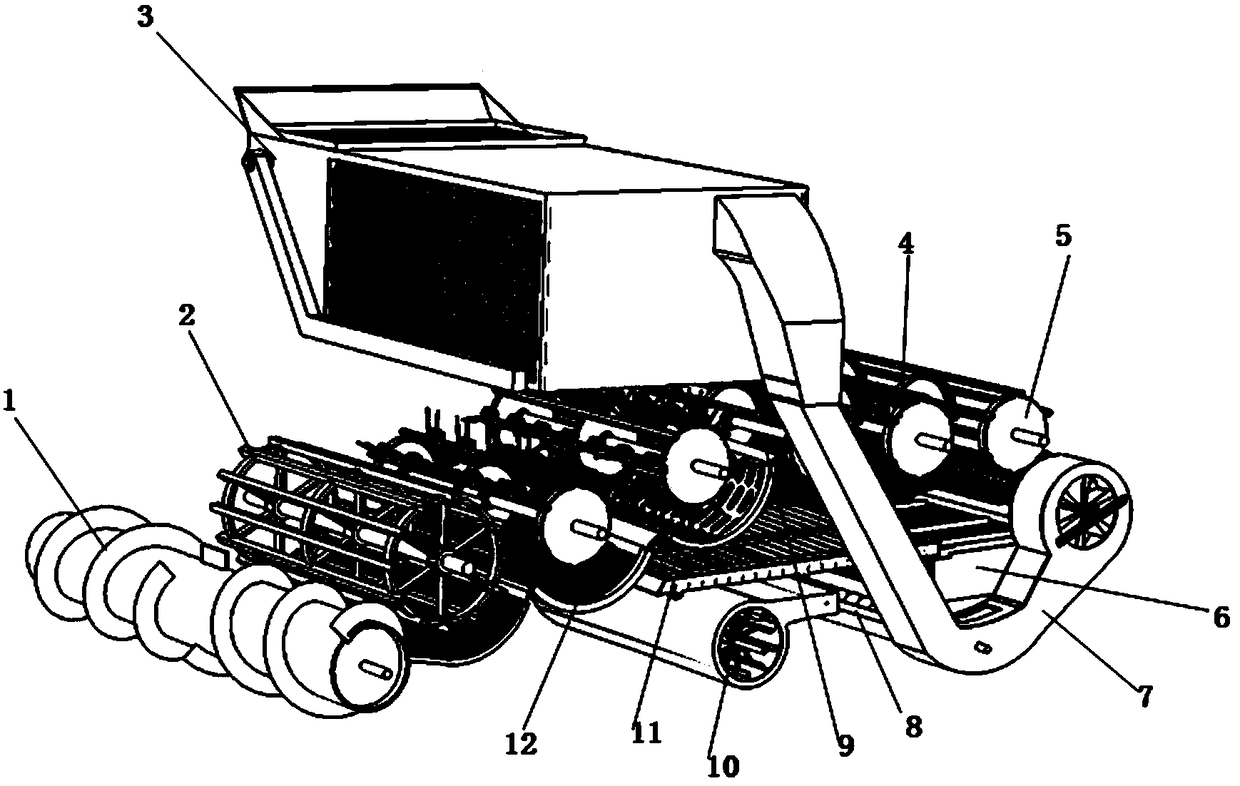

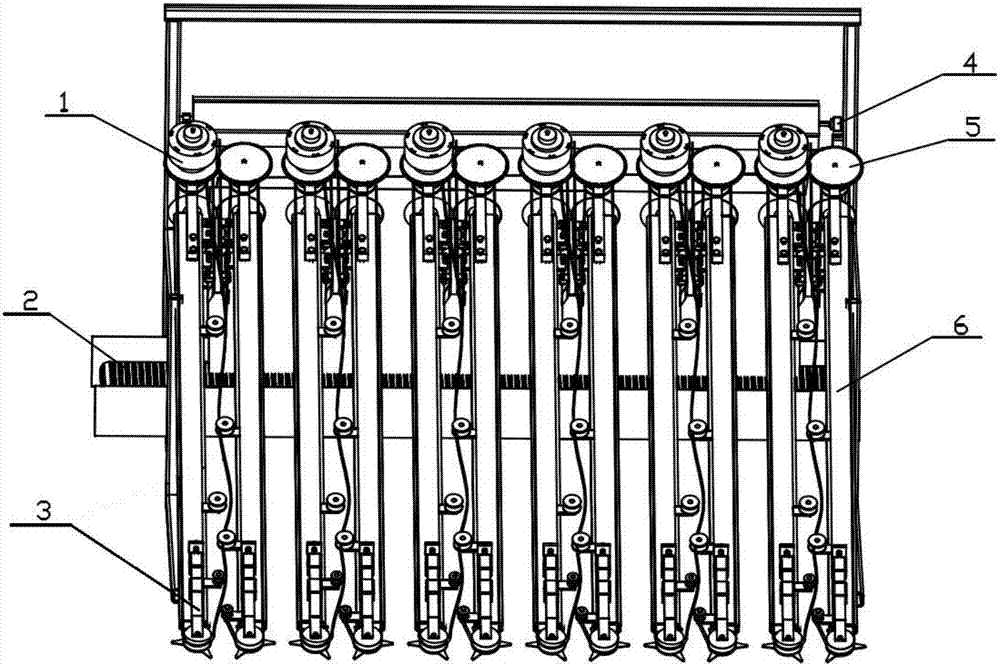

Peanut combine harvester

InactiveCN102812811AEasy to pick fruitEasy to collect and storeDigger harvestersBalingEngineeringCombine harvester

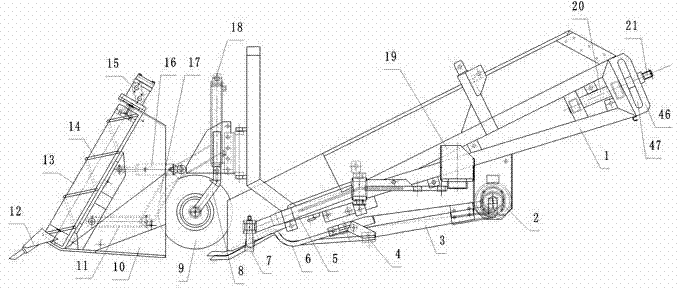

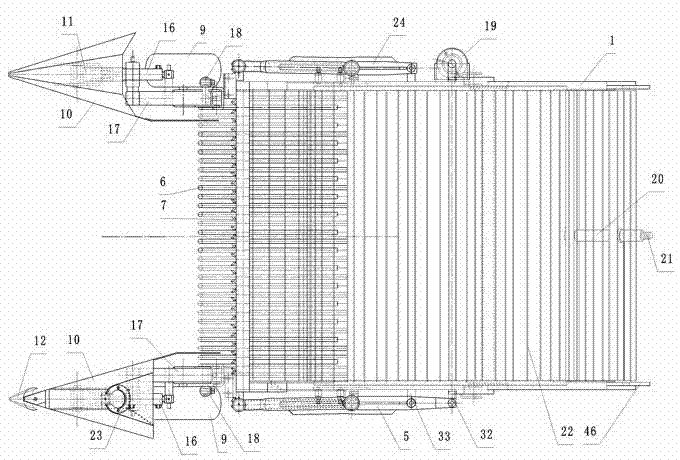

The invention discloses a peanut combine harvester, which comprises a frame, clamping and conveying devices, digging devices, soil removing devices, fruit picking devices, a transverse conveying device, a cleaning device, a lifting and flow guide device, and a peanut plant discharge device, wherein a power walking device is installed at the bottom of the frame; the clamping and conveying devices are obliquely installed on the frame; the digging devices are respectively installed at the front lower ends of the two clamping and conveying devices; the soil removing devices are respectively installed at the rear parts of the two digging devices; the fruit picking devices are respectively installed at the rear parts of the two soil removing devices; the transverse conveying device is installed between the fruit picking devices on two sides; the cleaning device is installed below the outlet end of the transverse conveying device; the lifting and flow guide device is installed at the outlet end of the cleaning device; and the peanut plant discharge device is installed at the rear part of the fruit picking devices and is connected with the clamping and conveying devices. The peanut combine harvester has the advantages that the structure is reasonable, the harvester works stably, the soil adaptability is strong, the fruit crushing rate during operate is low, the fruits are thoroughly picked, the harvesting rate is high, the peanut plants are tidily discharged, the treatment after harvesting is facilitated, the automation level and the operating efficiency are high, and the harvester is suitable for harvesting peanuts planted in large area.

Owner:WUZHENG

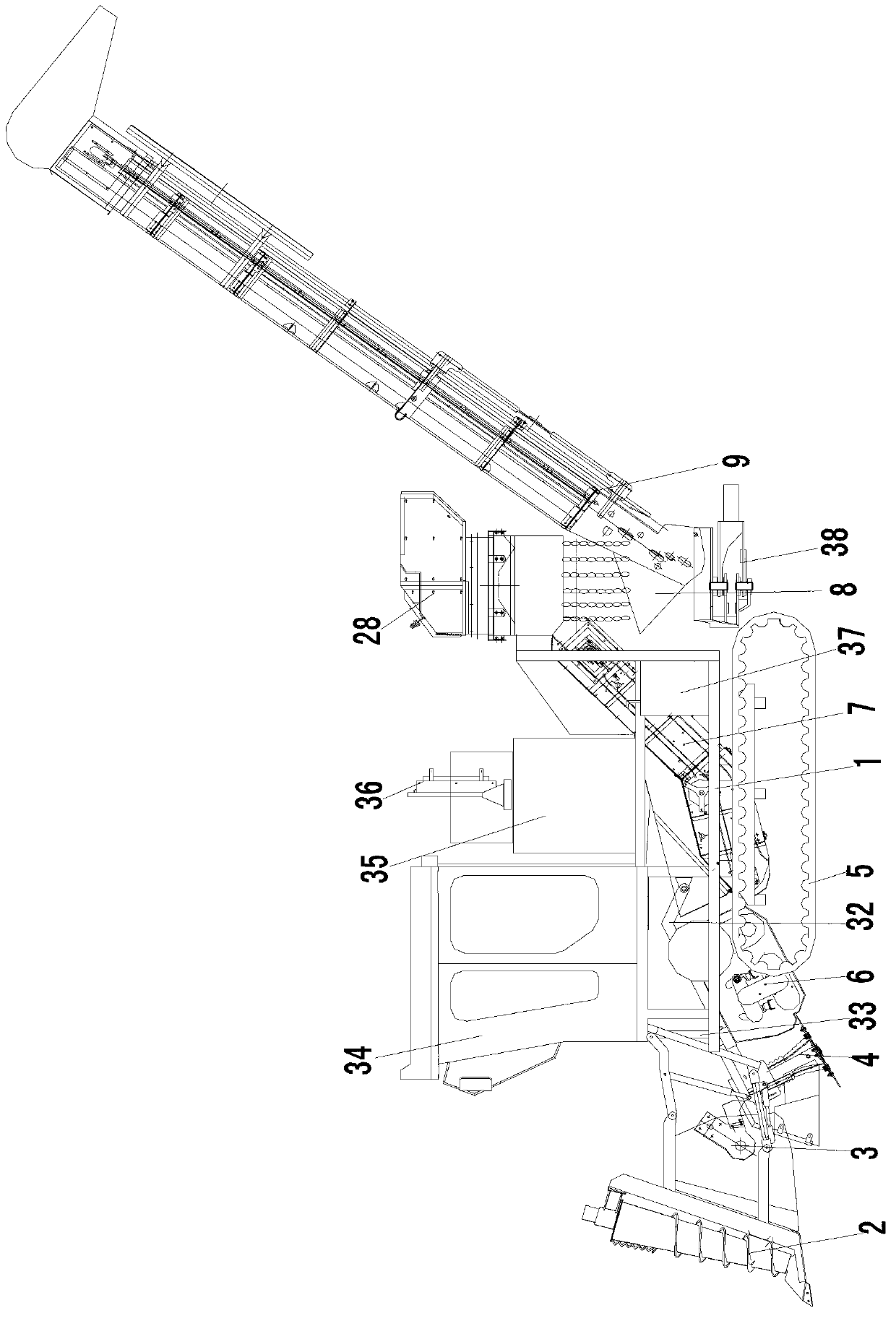

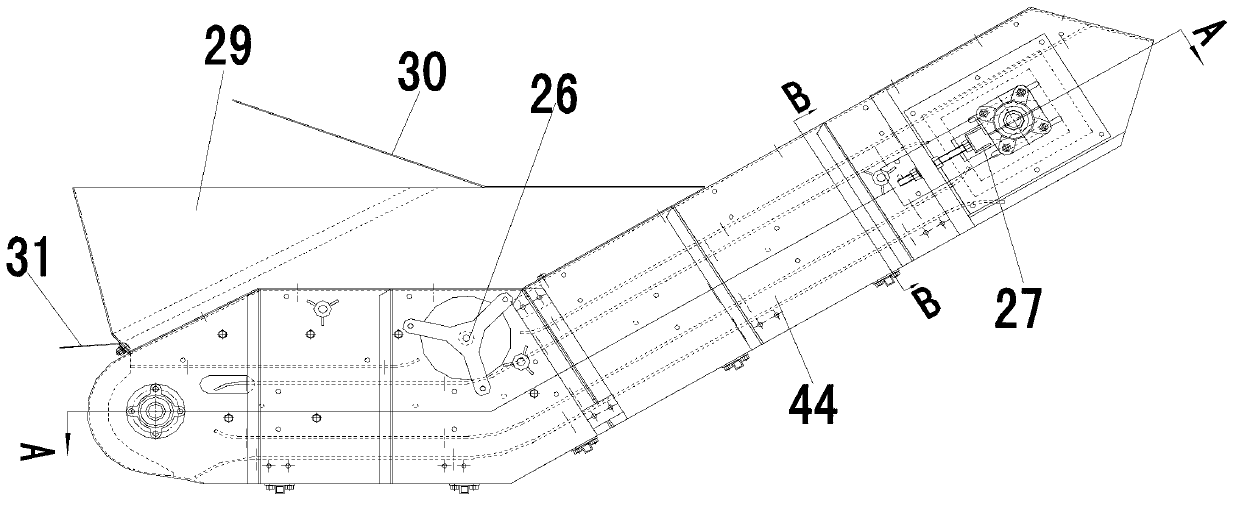

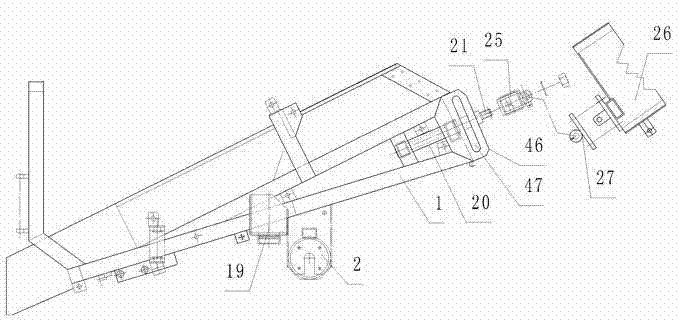

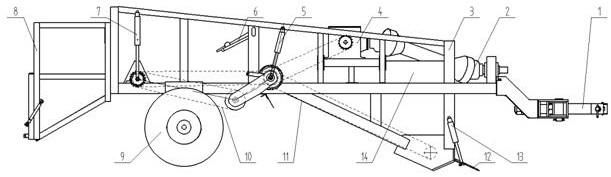

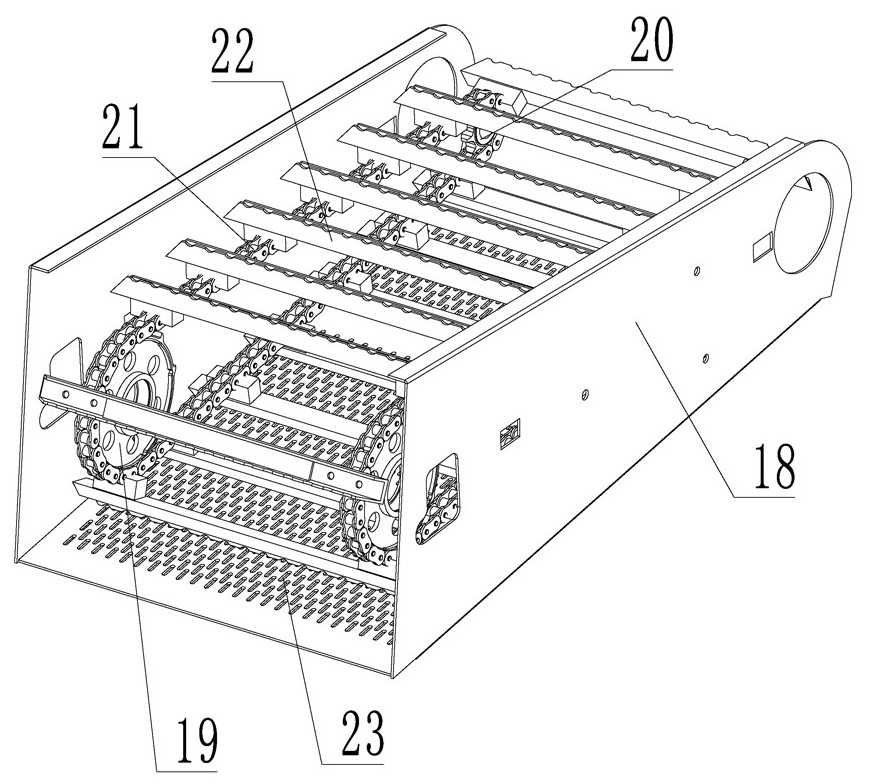

Sugarcane combine-harvester with novel conveying manner

ActiveCN103098615AReduce conveyor path lengthReduce path lengthHarvestersPatch materialCombine harvester

The invention discloses a sugarcane combine-harvester with a novel conveying manner. The sugarcane combine-harvester comprises a machine frame. A spiral branching device, a push-down roller and a cutting table are sequentially arranged at the front end of the machine frame. A walking device is disposed under the machine frame. A level-one roller conveyance and cut-in-section device is mounted at the back of the cutting table. A level-two screen type conveying chain lifting and conveying device is disposed at the back of the level-one roller conveyance and cut-in-section device. A hopper is arranged under the output end of the level-two screen type conveying chain lifting and conveying device. The hopper is connected with a conveying arm. According to the sugarcane combine-harvester with the novel conveying manner, the length of a conveying path on which a whole piece of sugarcane is conveyed in the harvester is reduced, and the problems of blocking in conveying, poor quality, low efficiency and the like caused by the fact that the sugarcane conveying path in the prior art is too long, sugarcane goes out of the path, and sugarcane stems are damaged or broken are resolved. The sugarcane combine-harvester has the advantages of being simple in structure, strong in patch material handling capacity, high in mechanical operation efficiency, good in harvest quality and the like.

Owner:SOUTH CHINA AGRI UNIV

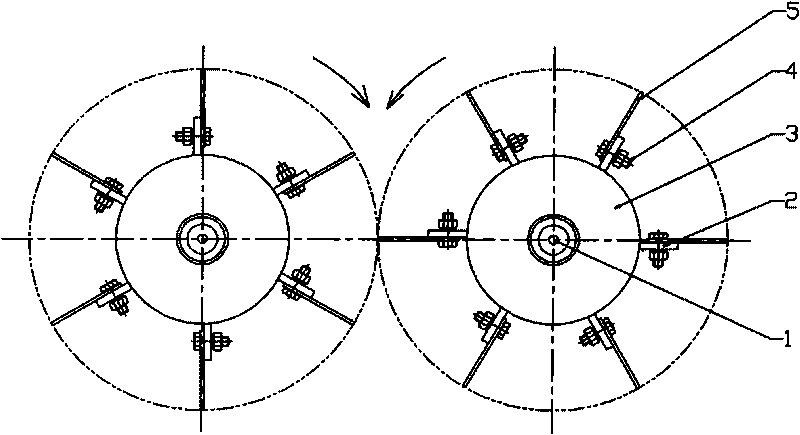

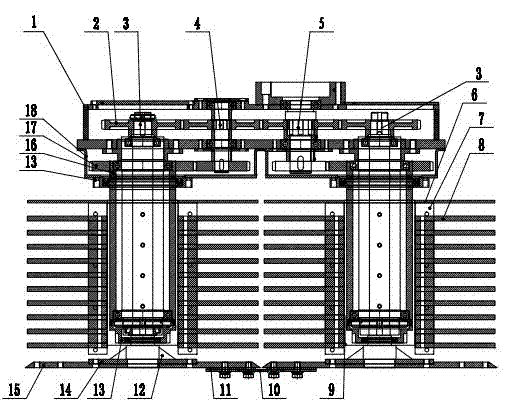

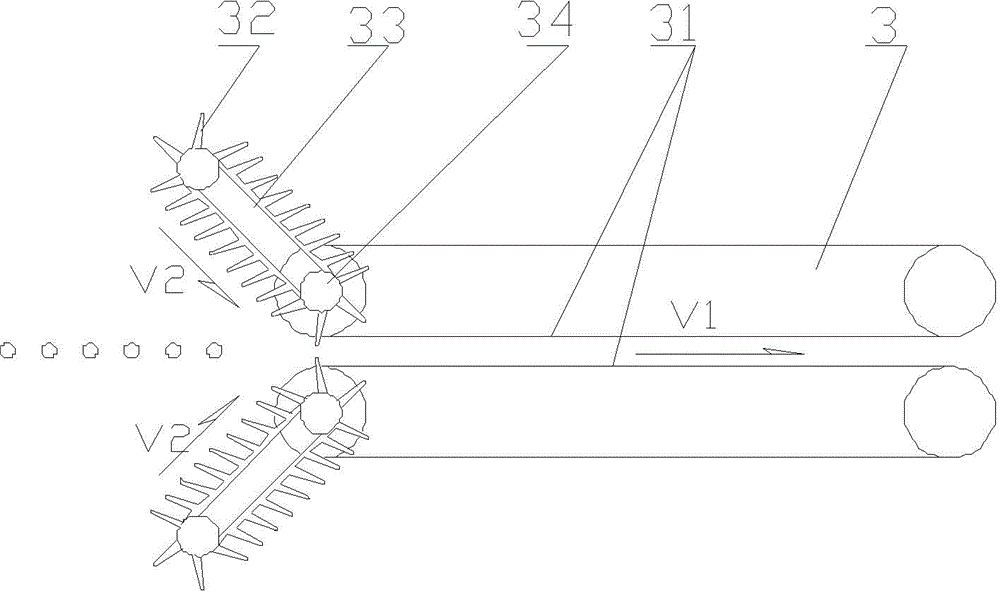

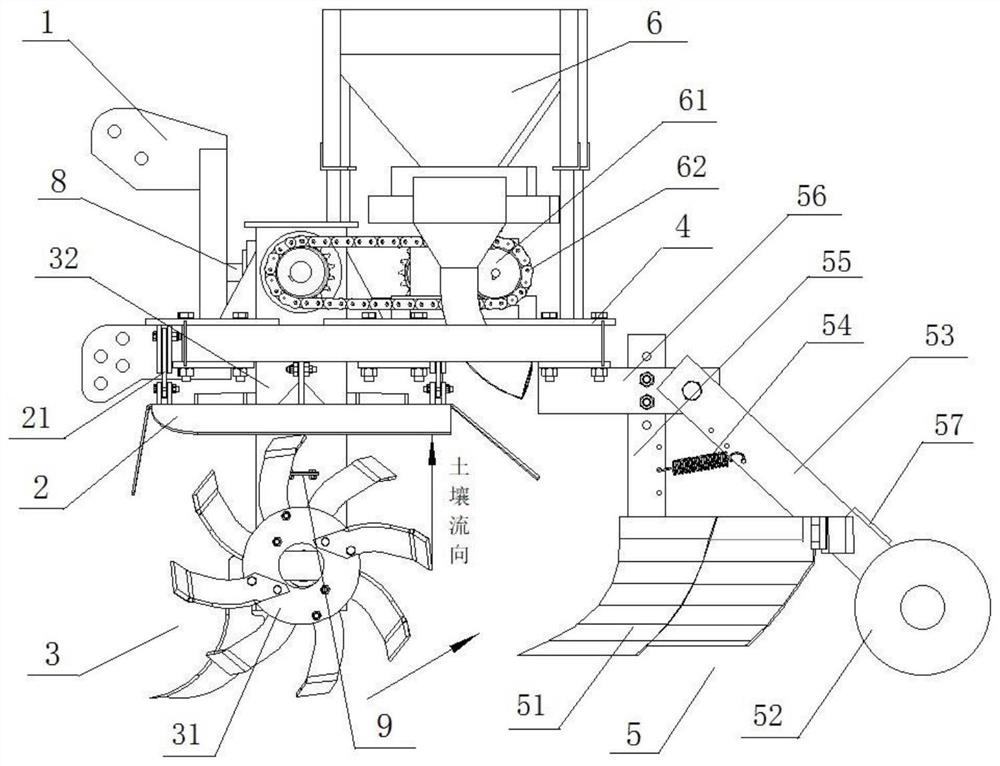

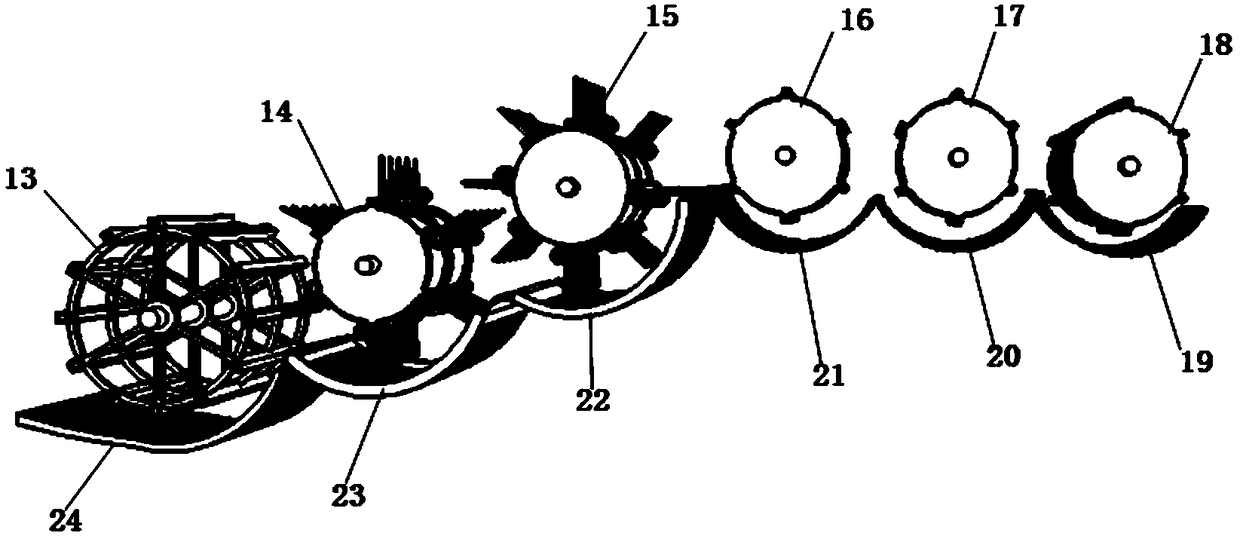

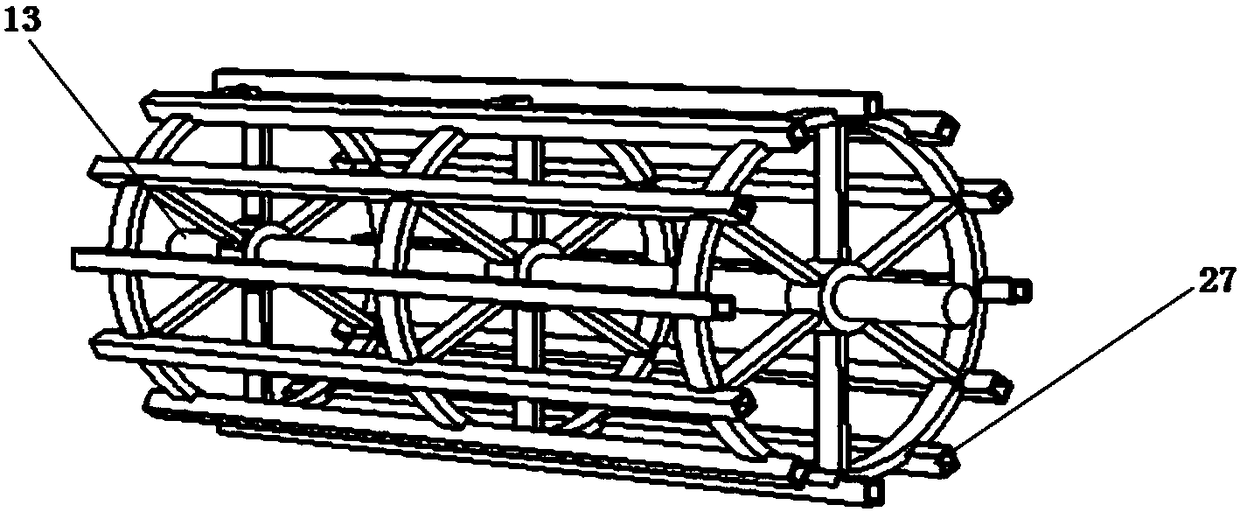

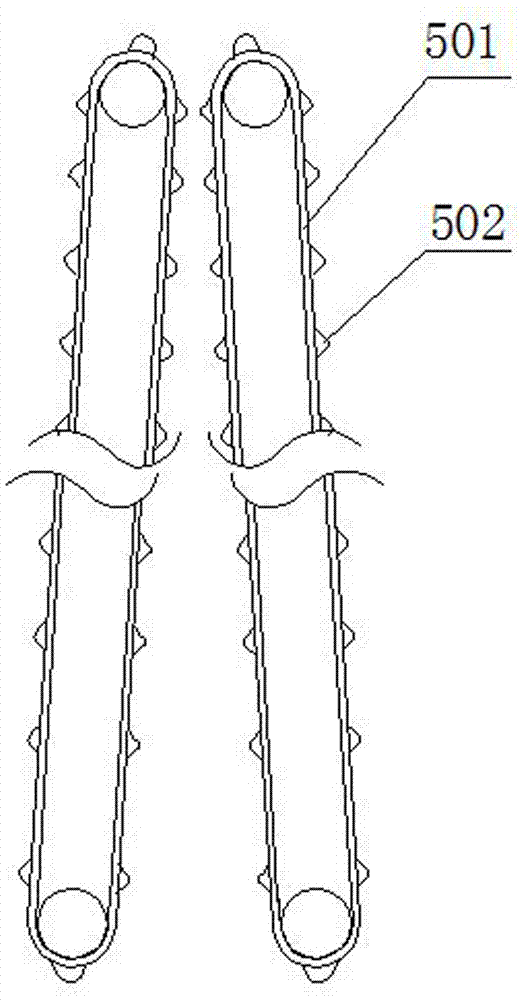

Semi-feeding device for harvesting peanut and picking fruit

InactiveCN101699948AImprove harvest qualityForce softeningDigger harvestersDifferential phaseEngineering

The invention relates to a semi-feeding device for harvesting peanuts and picking fruits, belonging to the technical field of agricultural machinery. The device comprises a pair of rollers racially provided with fruit-picking blades in differential phase distribution at intervals; the fruit-picking blades present continuous curved surfaces which gradually bend deviating from the rotary direction of the roller. For the convenient manufacture, the curved surface is in a circular arc shape. The device of the invention not only keeps high picking rate, but also effectively reduces the stem carrying rate of fruit pods and the rates of seedling breaking and root breaking, thus the harvest quality of a semi-feeding peanut combine harvester can be significantly improved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

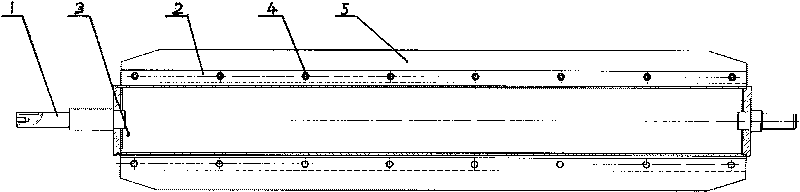

Integrated cutting and conveying device of sugarcane harvester

The invention discloses an integrated cutting and conveying device of a sugarcane harvester. The integrated cutting and conveying device comprises a cutting mechanism and a conveying mechanism fixed to each other. The conveying mechanism comprises a feeding fixed plate and a rubber plate. The feeding fixed plate is fixed on a roller. The rubber plate penetrates through the feeding fixed plate and is then fixedly connected to the outside of the roller. Cut canes are effectively conveyed back by the feeding fixed plate and the rubber plate disposed on the roller. Gears in a gear bank have different tooth numbers, so that rotation speed of the rubber plate is smaller than that of a disc cutter, the cut canes can be timely, stably and orderly conveyed to subsequent procedures through the feeding fixed plate and the rubber plate, multi-breakage of the canes is avoided, cane harvesting quality is improved, and damage of sugar content of the canes is avoided.

Owner:LINHAI HENGFENG MACHINERY

Multi-row garlic combine harvester

ActiveCN108966797AImprove cleanlinessImprove harvest qualityLiftersTopping machinesIntegrated operationsEngineering

The invention relates to a multi-row garlic combine harvester, and especially relates to a harvester which is used for harvesting multiple rows of garlic. The combine harvester comprises a chassis, adigging blade, a grain guiding device, a land purifying device, a flexible clamping device, a switching device, a seedling falling device, a conveying disc, a gathering debris removing device, a collection port, and a garlic collecting device. The combine harvest can achieve the harvesting of multiple rows of garlic, can achieve the integrated operation of garlic at a time: digging-clamping and conveying-soil removing and purifying-stem cutting and seedling slinging-gathering, vibrating and debris removing-automatic collection. Meanwhile, the land purifying device and the gathering debris removing device guarantee the harvesting quality of garlic, and the garlic collecting device with an infrared detector can achieve the automatic loading and unloading, thereby improving the harvesting quality. The combine harvester improves the efficiency, and reduces the operation cost.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

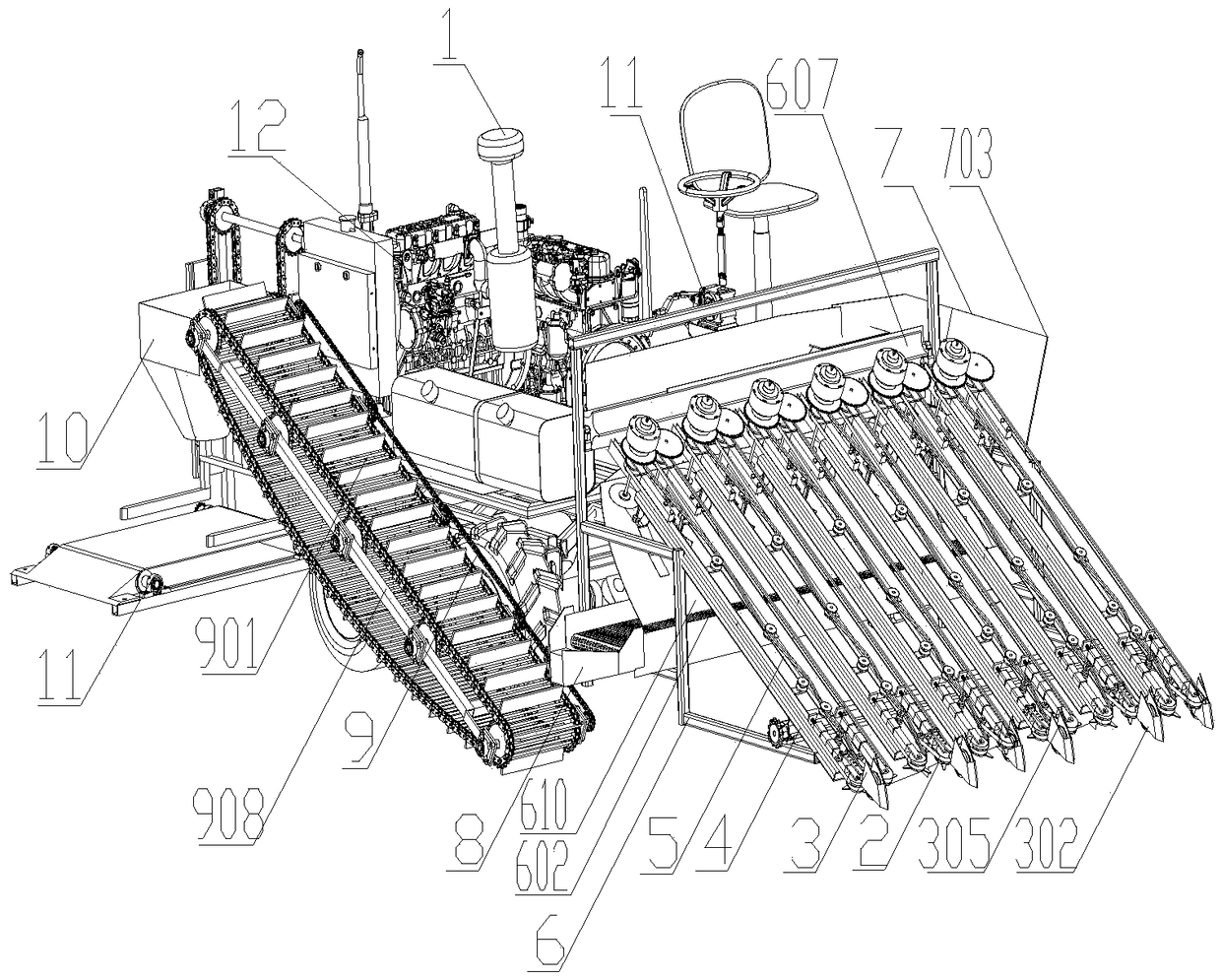

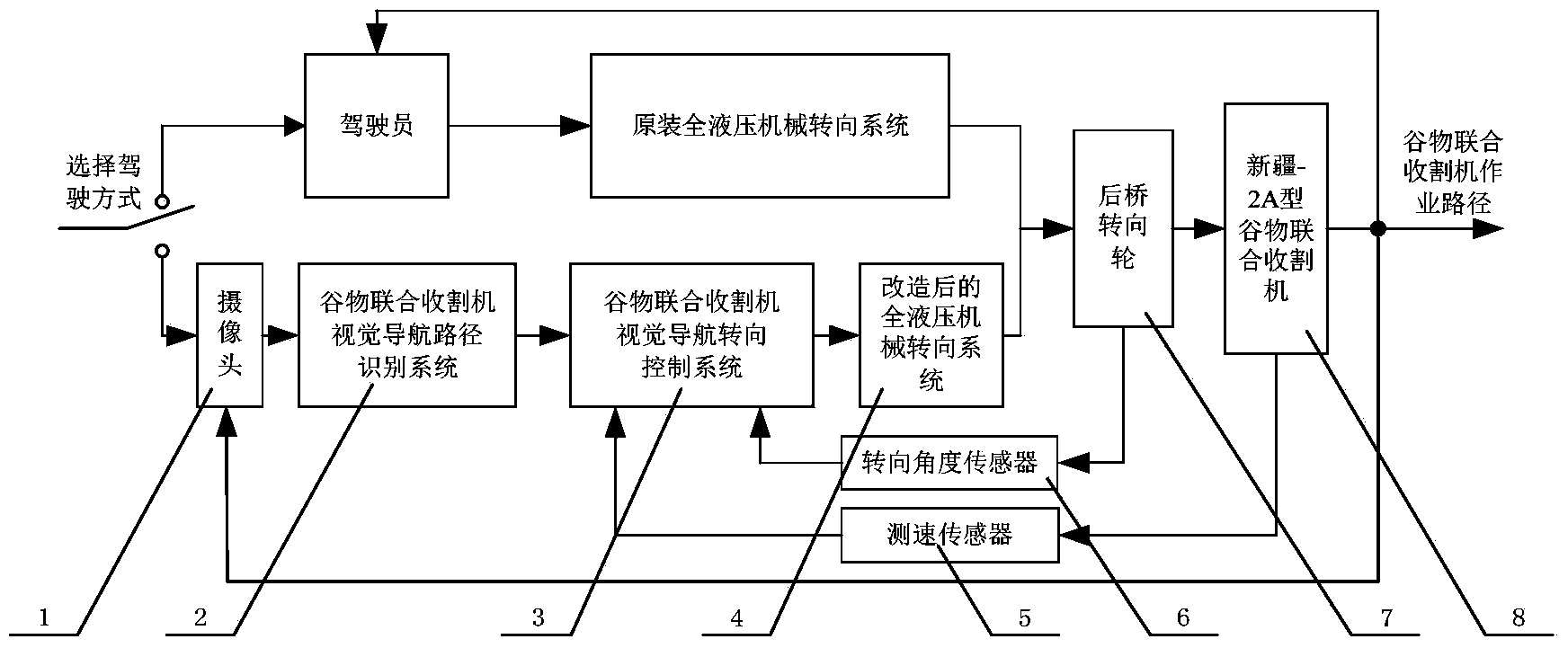

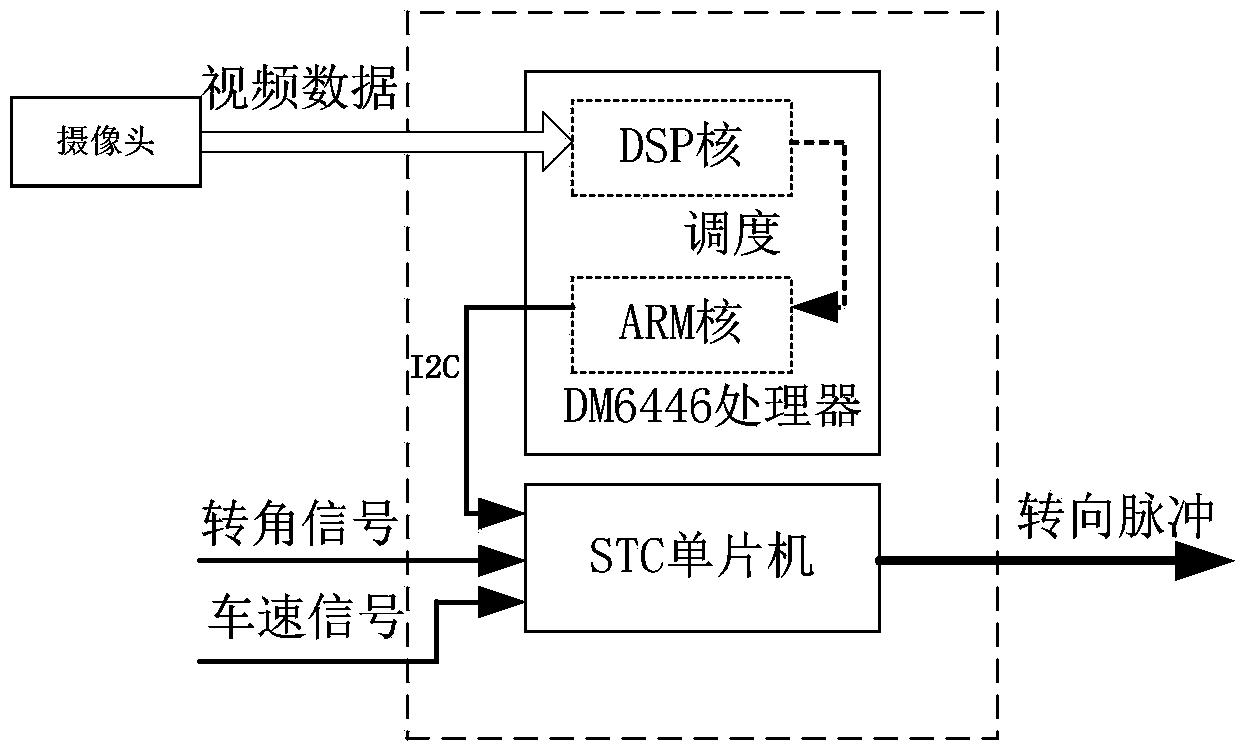

Visual navigation driving assisting system for grain combine harvester

InactiveCN103914070AReduce power consumptionEasy to installPosition/course control in two dimensionsVisual navigationSteering angle

The invention relates to a visual navigation driving assisting system for a grain combine harvester. The visual navigation driving assisting system for the grain combine harvester comprises a camera, a grain combine harvester visual navigation path recognition system, a grain combine harvester visual navigation steering control system and a full-hydraulic mechanical steering system. The grain combine harvester visual navigation path recognition system is used for receiving a farmland scene image collected by the camera and performing calculation to obtain navigation path line parameters. The grain combine harvester visual navigation steering control system integrates the navigation path line parameters, harvester steering angle signals and harvester traveling speed signals and then outputs control instructions to the full-hydraulic mechanical steering system matched with the visual navigation driving assisting system. The full-hydraulic mechanical steering system matched with the visual navigation driving assisting system adjusts the steering angle of a rear axle steering wheel according to the control instructions so as to achieve steering control over the grain combine harvester. The visual navigation driving assisting system for the grain combine harvester combines a DSP and a single-chip microcomputer and is low in power consumption, capable of achieving equipment miniaturization, convenient to install and suitable for being popularized and used.

Owner:CHINA AGRI UNIV

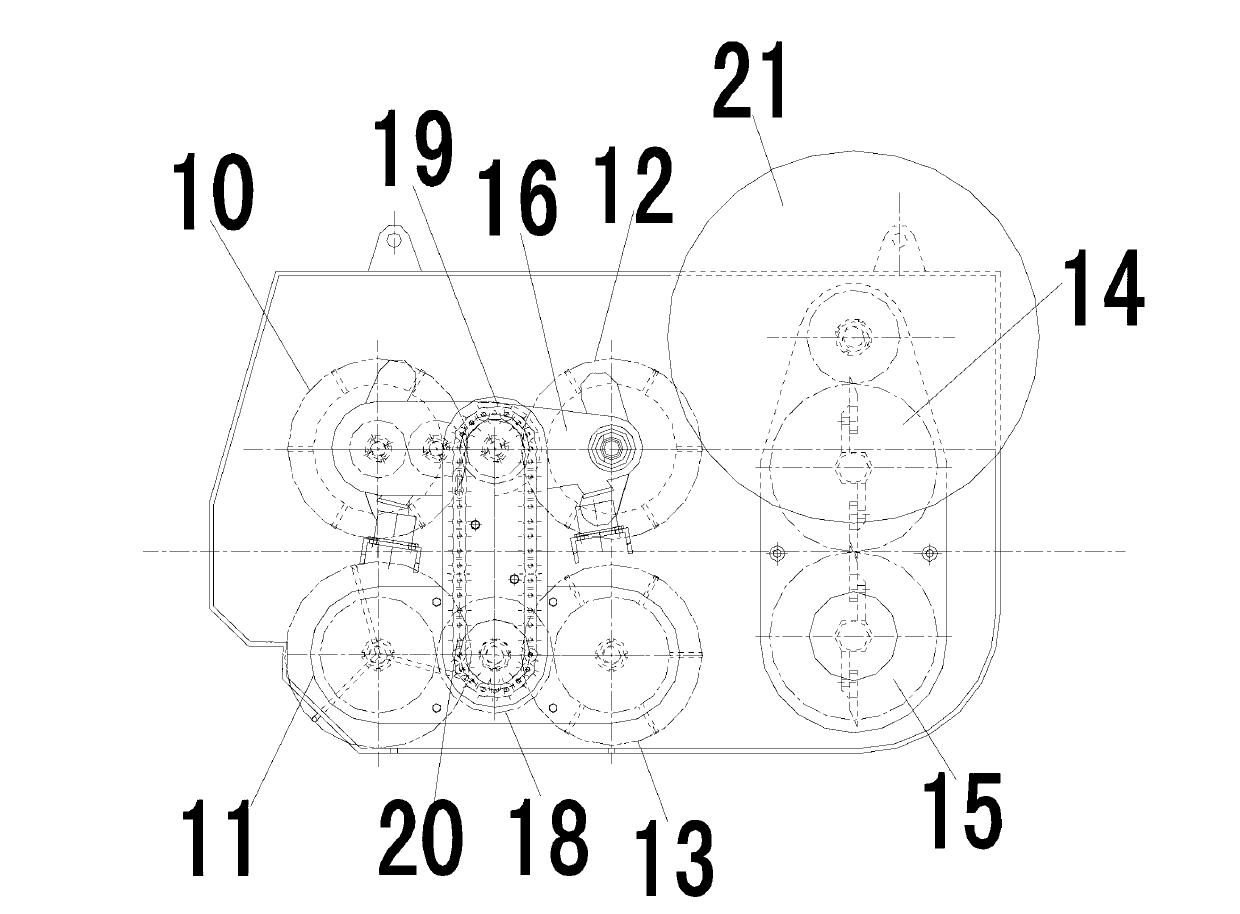

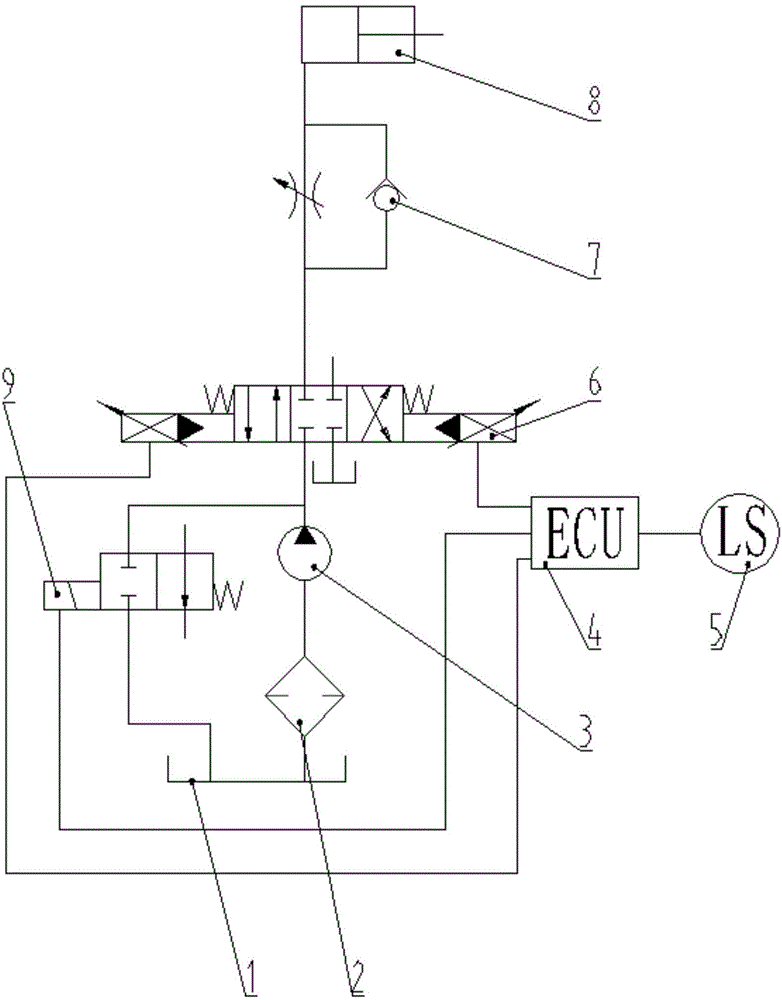

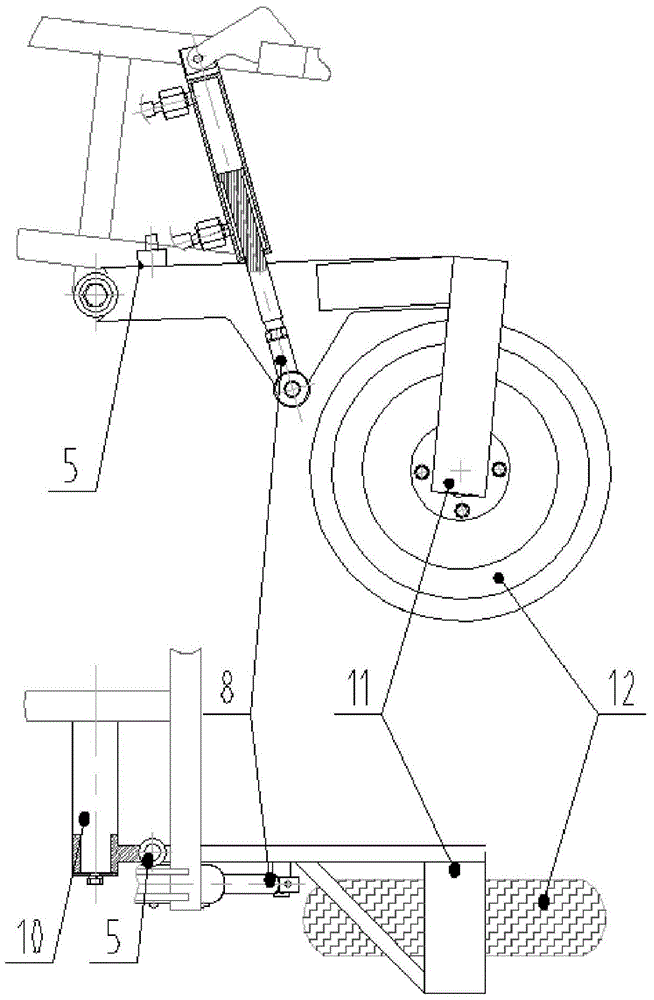

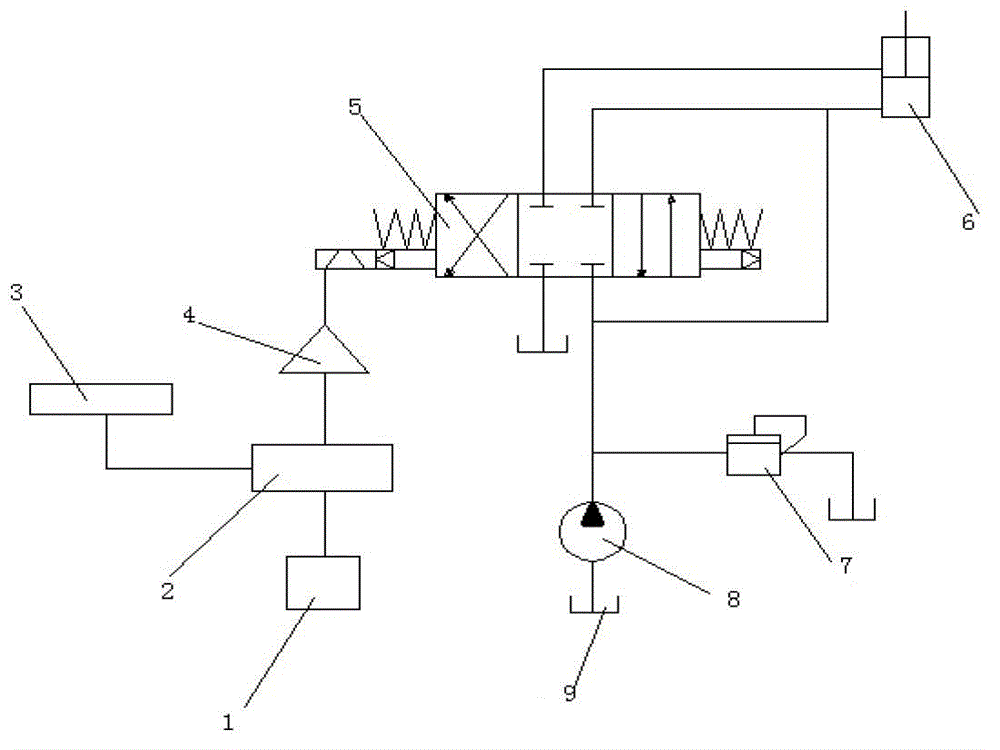

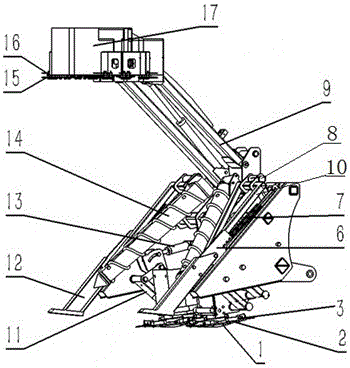

Automatic intelligent deepening controlling system of peanut combine harvester and using method of automatic intelligent deepening controlling system

InactiveCN104919965AConsistent sink depthImprove harvest qualityDigger harvestersAutomatic controlFuel tank

Disclosed is an automatic intelligent deepening controlling system. The automatic intelligent deepening controlling system comprises cantilevers (10), deepening wheel supports (11) sleeving the cantilevers (10), deepening wheels (12) mounted on the deepening wheel supports (11), a control panel, a hydraulic system, an automatic control system and a rotating angle measuring device, wherein the control panel is used for setting preset deepening values of the deepening wheels (12); the hydraulic system comprises a hydraulic oil tank (1), a filter (2), a hydraulic pump (3) and a hydraulic oil cylinder (8); the automatic control system comprises an ECU (electric control unit 4), an electromagnetic proportional directional valve (6), a one-way throttle valve (7) and an electromagnetic reversing valve (9), the electromagnetic proportional directional valve (6) comprises a left-end electromagnet and a right-end electromagnet, and the electromagnetic reversing valve (9) comprises an electromagnet; the rotating angle measuring device is connected with the automatic control system. The automatic intelligent deepening controlling system has the advantages that by means of monitoring the deepening of the deepening wheels in real time, the position of a piston of the hydraulic oil cylinder can be adjusted timely, consistency of the deepening is guaranteed, and high harvesting quality can be obtained.

Owner:临沭县东泰机械有限公司

Cultivation method for konjac used as commercial konjac

The invention discloses a cultivation method for konjakc used as commercial konjakc. The method comprises the steps of preparing soil, fertilizing, sowing, managing and harvesting. The method has the beneficial effects that: the steps of preparing soil, fertilizing, sowing, managing and harvesting can be unitedly implemented through special cultivation of the commercial konjac; by united soil preparation, sterilization and fertilization, a soil environment suitable for seed konjac growth can be created, and the occurrence of diseases and insect pests is reduced; the seed konjacs of a uniform specification are intensively cultivated to ensure that the konjac plants grow at the same time, and the overall yield is improved; and the harvesting quality of the commercial konjacs can be improved through the timely harvesting and a harvesting method.

Owner:重庆天娇农业开发有限公司

Picking head used in tomato harvester

The invention relates to a picking device used in a crop harvester, in particular to a picking head used in a tomato harvester. The picking head comprises a frame, a seedling separator, a contour wheel, a conveying device, a cutting knife mechanism and a shifting fork mechanism. The picking head is characterized in that: the frame is provided with a frame steering mechanism; the frame steering mechanism comprises a rotary sleeve arranged at the rear part of the frame and a rotary shaft; circular connecting plates are arranged at two ends of the rear part of the frame respectively; the frame is connected with a bracket through the rotary sleeve and the rotary shaft; the bracket is a connecting member for connecting the frame and a main truck frame; the middle part of the bracket is hinged with the main truck frame; two ends of the bracket are respectively hinged with the circular connecting plates arranged on the frame; and the two ends of the bracket are respectively connected with the main truck frame through fixed seats. The picking head has the advantages of reasonable structure, few faults, high work efficiency, good harvesting quality, economic efficiency and practicability.

Owner:SHIHEZI AVIC GUIZHOU AGRI MACHINERY EQUIP

Standing corn harvest machine cutting bench

The invention discloses standing corn harvest machine cutting bench, including reciprocating cutting device, machine skeleton, corn stem separator, corn stem prodding chain, flexible leaf stirring auger, leaf removing board, pressing pole, corn stem support pole, stem pressing pole, tassel pick board, long stretch stem roll, short stretch stem roll and more. Two units of corn stem separator is symmetrically installed at machine skeleton front most end, one unit of corn stem separator back lower part is arranged with chain wheel, the other back lower part is provided with pressing pole, chain wheel is joined with head moving chain wheel through corn stem prodding chain, pressing pole faces towards corn stem prodding chain, corn stem prodding chain and pressing pole front lower part is installed with flexible leaf stirring auger and leaf removing board, long, short stretch stem rolls and pull moved stretch stem roll are put at machine skeleton back section, the front of long, short stretch stem rolls and pull moved stretch stem roll is arranged perpendicular tassel pick board, back section of two parallel units of stem support pole is installed above tassel pick board, the front is installed on corn stem separator machine skeleton, 2 / 3 size of which is placed with the stem pressing pole, the device works reliably, bites no tassel, and possesses good flexibility.

Owner:SHANDONG UNIV OF TECH

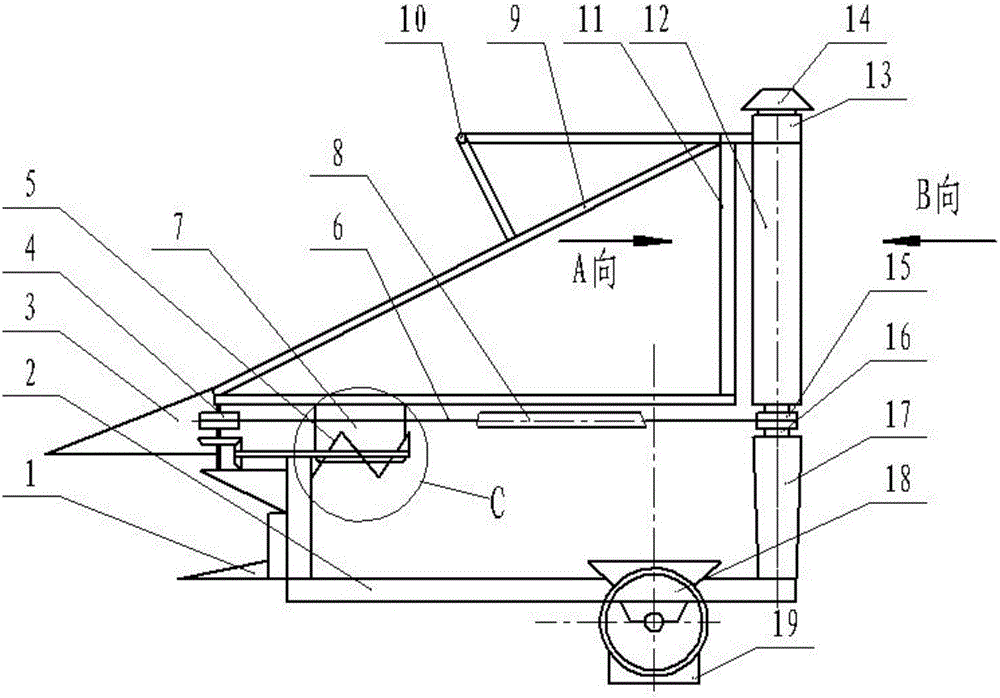

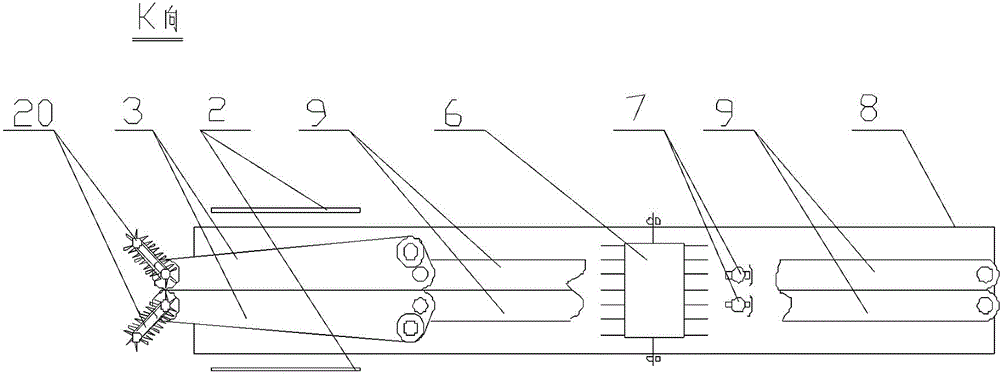

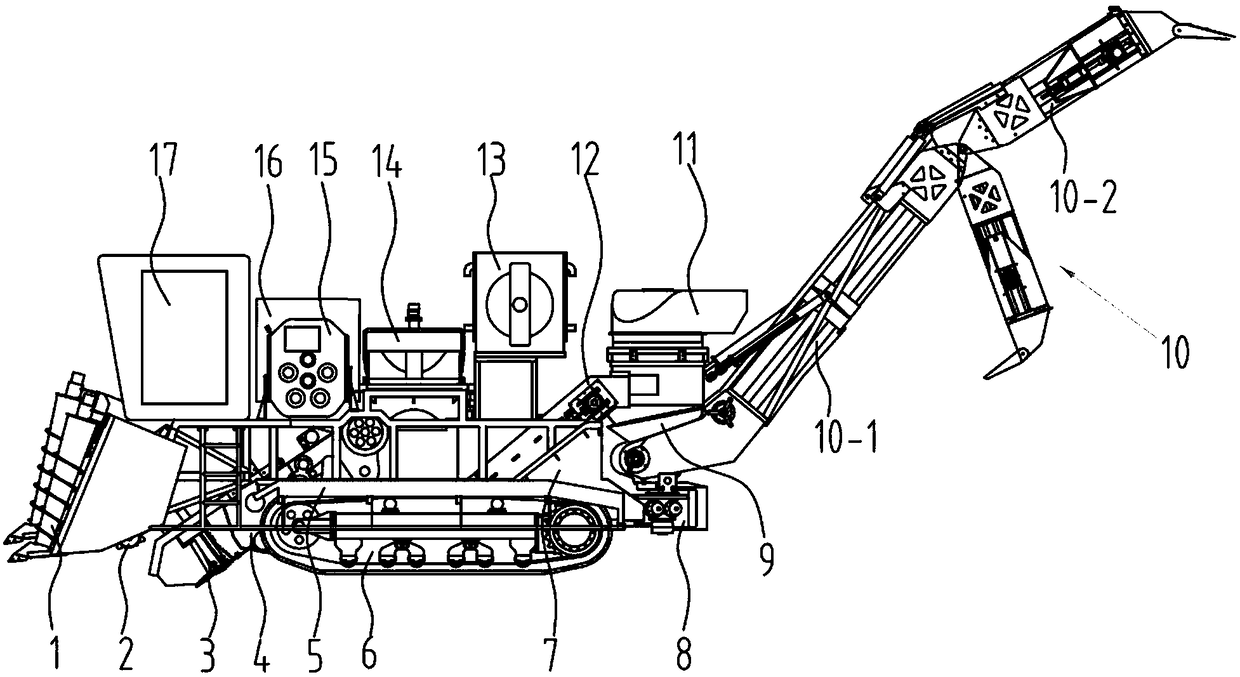

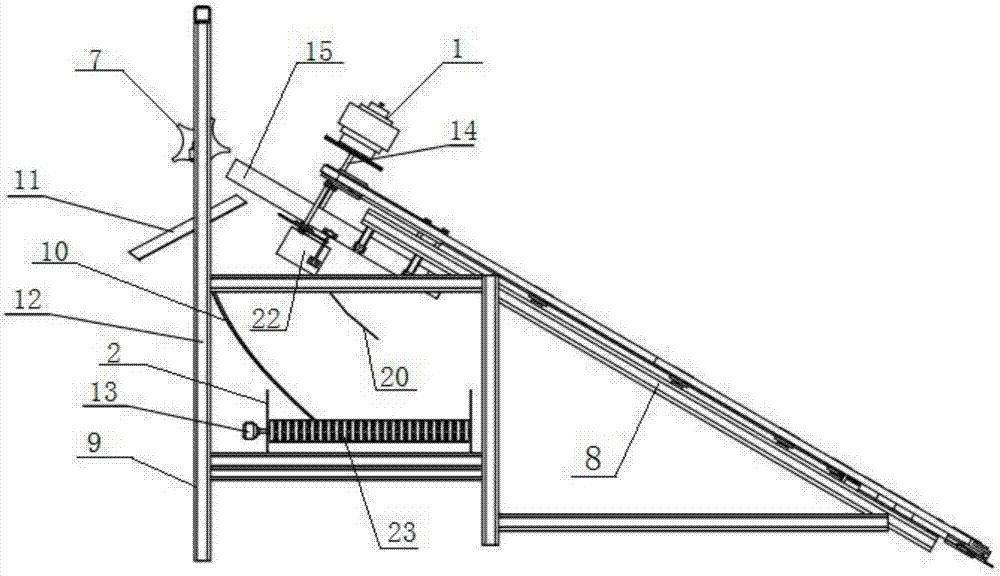

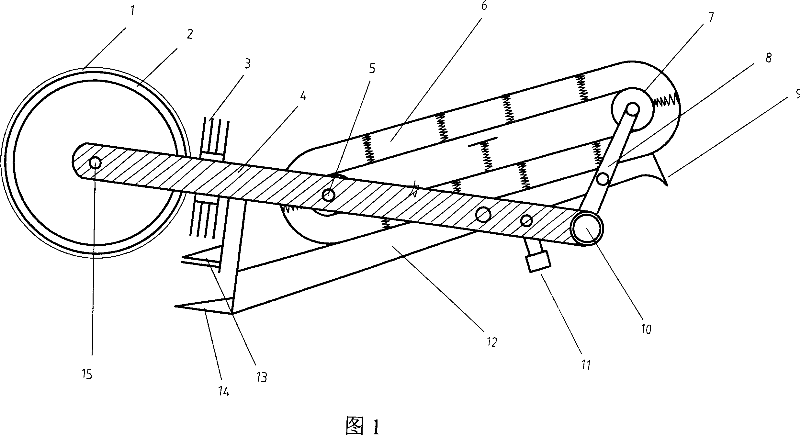

Combine harvester for mountain areas

InactiveCN102027832AAchieve mechanized harvestingLower center of gravityMowersDrive shaftAgricultural engineering

The invention relates to a combine harvester for mountain areas. The front end of an agricultural tricycle (7) is provided with a reel (1), a cutting knife (32), a cutting table (33) and the like; the middle part of the agricultural tricycle (7) is provided with a first-stage conveying groove (3), a second-stage conveying groove (8), a transmission shaft (25) and the like; and the back part of the agricultural tricycle (7) is provided with a thresher drum combination (11), a cleaning and conveying mechanism (12), a grain storage cabin (14), a rear diesel engine (16), a thresher belt pulley, a clutch device (19) and the like. The combine harvester has the advantages of relatively low centre-of-gravity position, high stability, capabilities of walking stably and entirely on tricycle roads of the mountain areas, performing combined harvesting on crops such as wheat and the like on slopes at the angle of less than 20 degrees and realizing mechanical harvesting on the mountain areas and hilly grounds in an ideal way, high harvesting efficiency, good harvesting quality and wide application to intercropping regions and single planting regions on plains.

Owner:郝亮

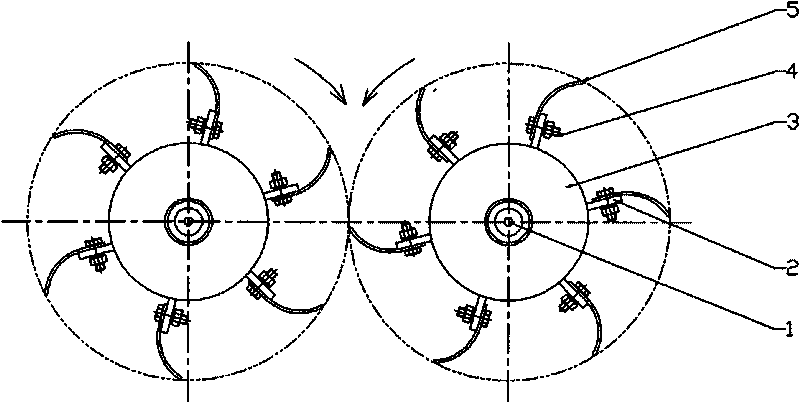

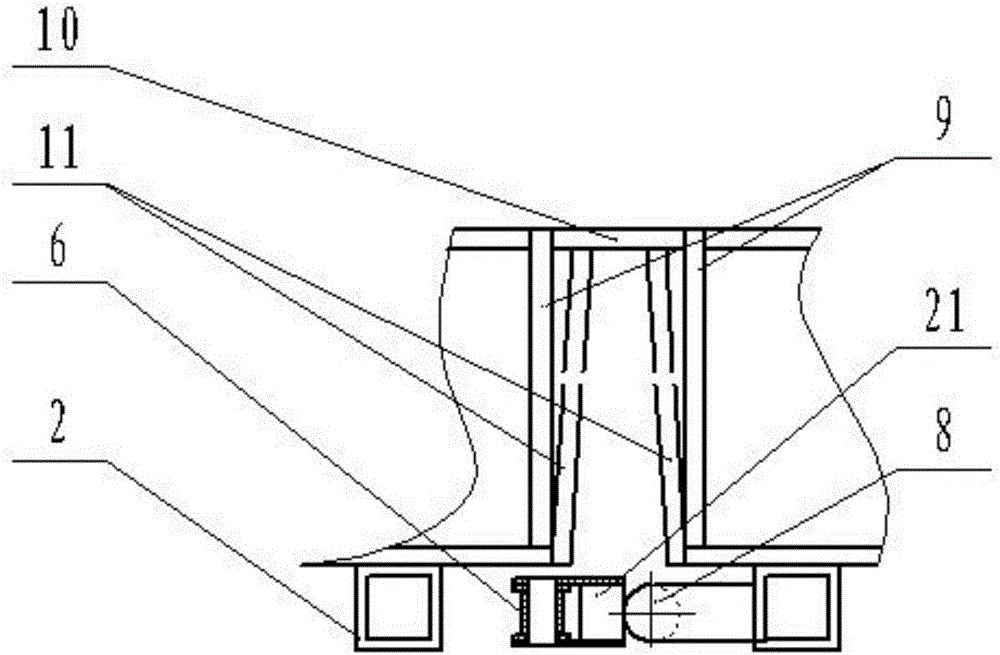

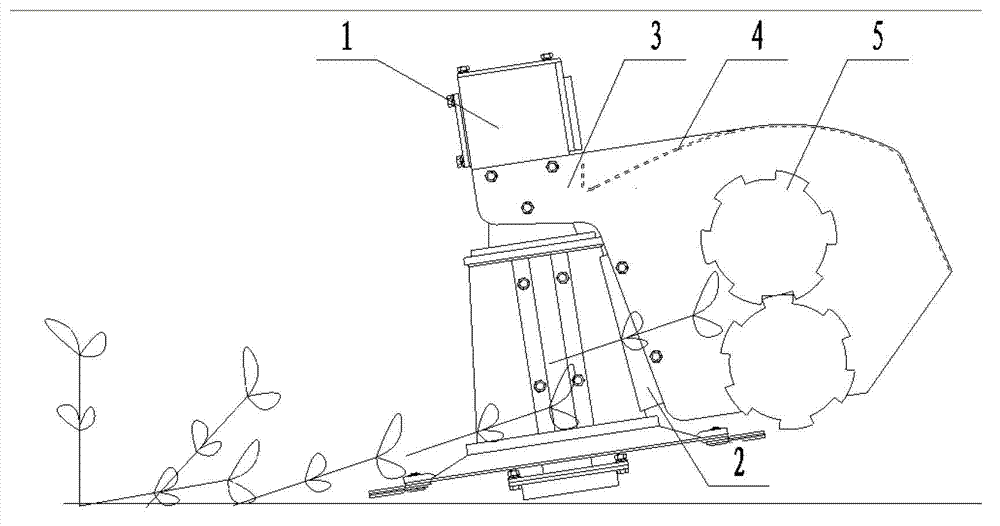

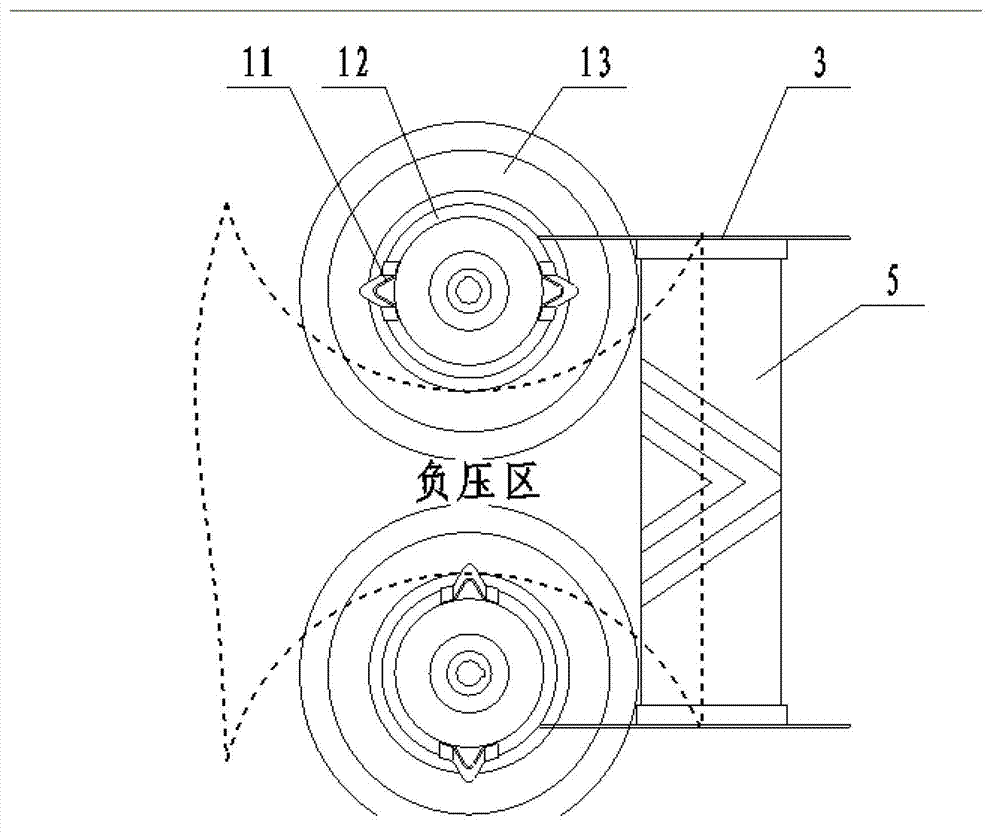

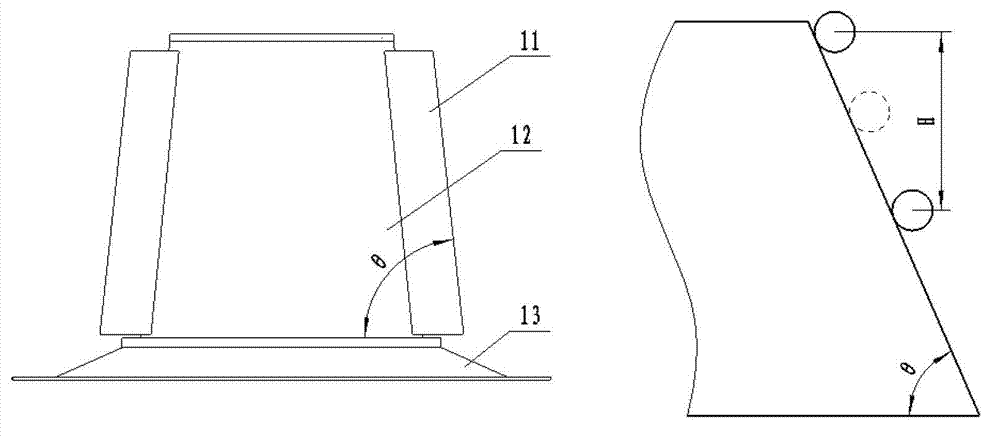

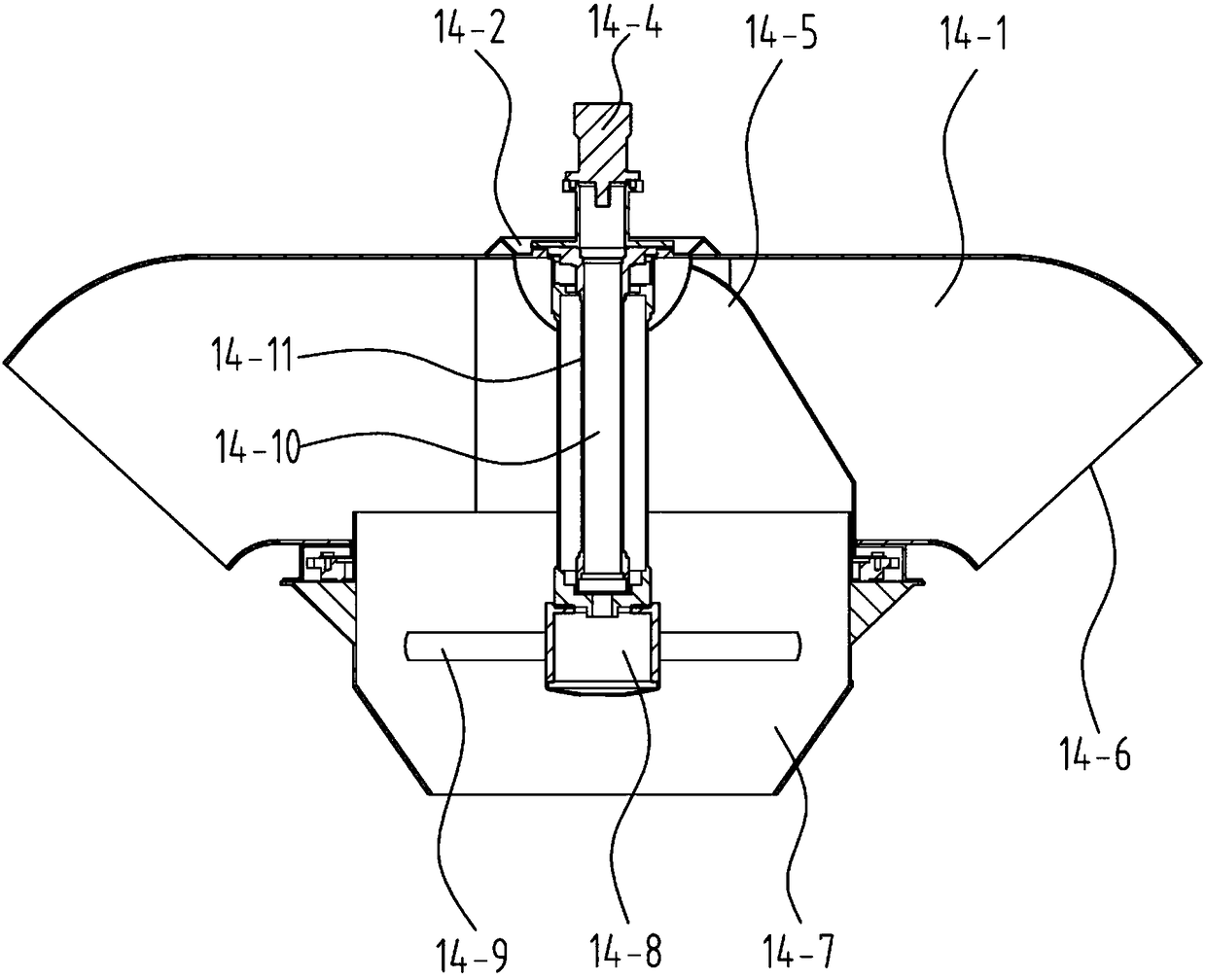

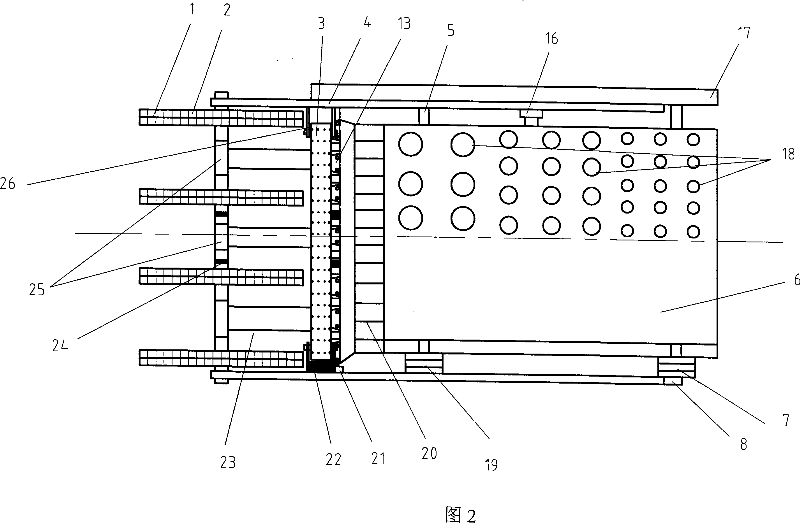

Double disc type rotating cropper cradling feeding mode and device

ActiveCN103109646AAffects modulation qualityImprove harvest qualityHarvestersEngineeringMechanical field

The invention belongs to the stockbreeding mechanical field, and particularly relates to a double disc type rotating cropper cradling feeding mode and a device. An alfalfa cradling feeding method utilizes an airflow field generated in the working process of the double disc type rotating cropper works to suck up lodging alfalfa plants, and then completes cradling. Besides, a sector feeding mode is formed between a cutter and a conditioner roll, the alfalfa plants can enter the conditioner roll in an even and orderly mode, material blockage can be prevented, tempering quality is improved, and alfalfa harvest quality is improved. An alfalfa cutting device mainly comprises a double disc type rotating cutter (1), a seal device (2), a lateral device (3), a top cap device (4) and an inbuilt conditioner roll device (5). A space hyperbolic curve type negative pressure zone, the lodging alfalfa plants can be sucked up, and then cradling can be achieved. Meanwhile, the sector feeding mode in an even and orderly mode is formed between the double disc type rotating cutter (1) and the conditioner roll device (5), material blockage can be prevented, tempering quality is improved, and alfalfa harvest quality is improved.

Owner:CHINA AGRI UNIV

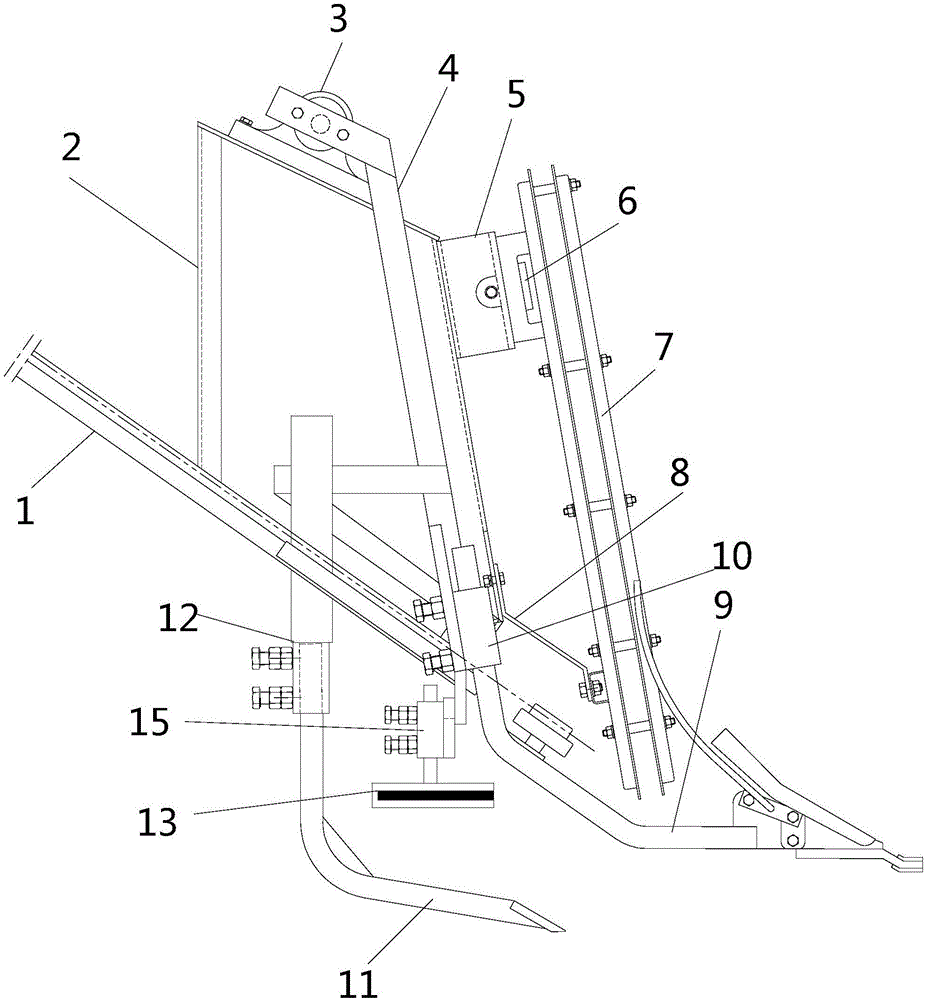

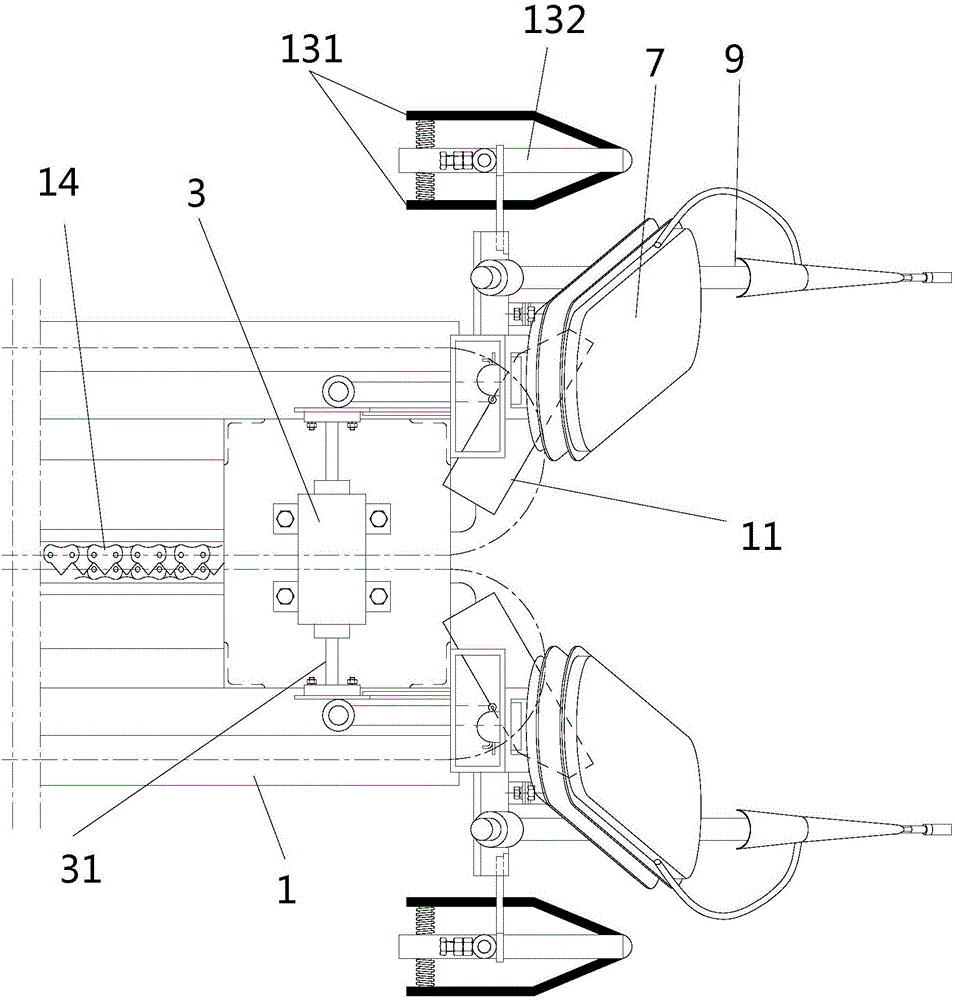

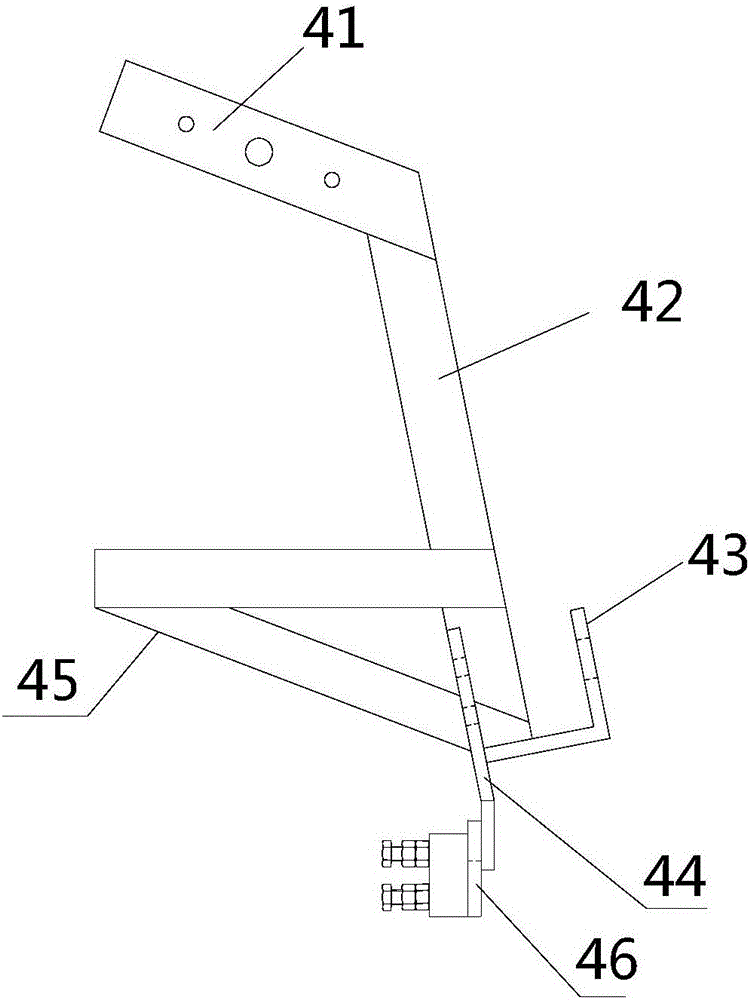

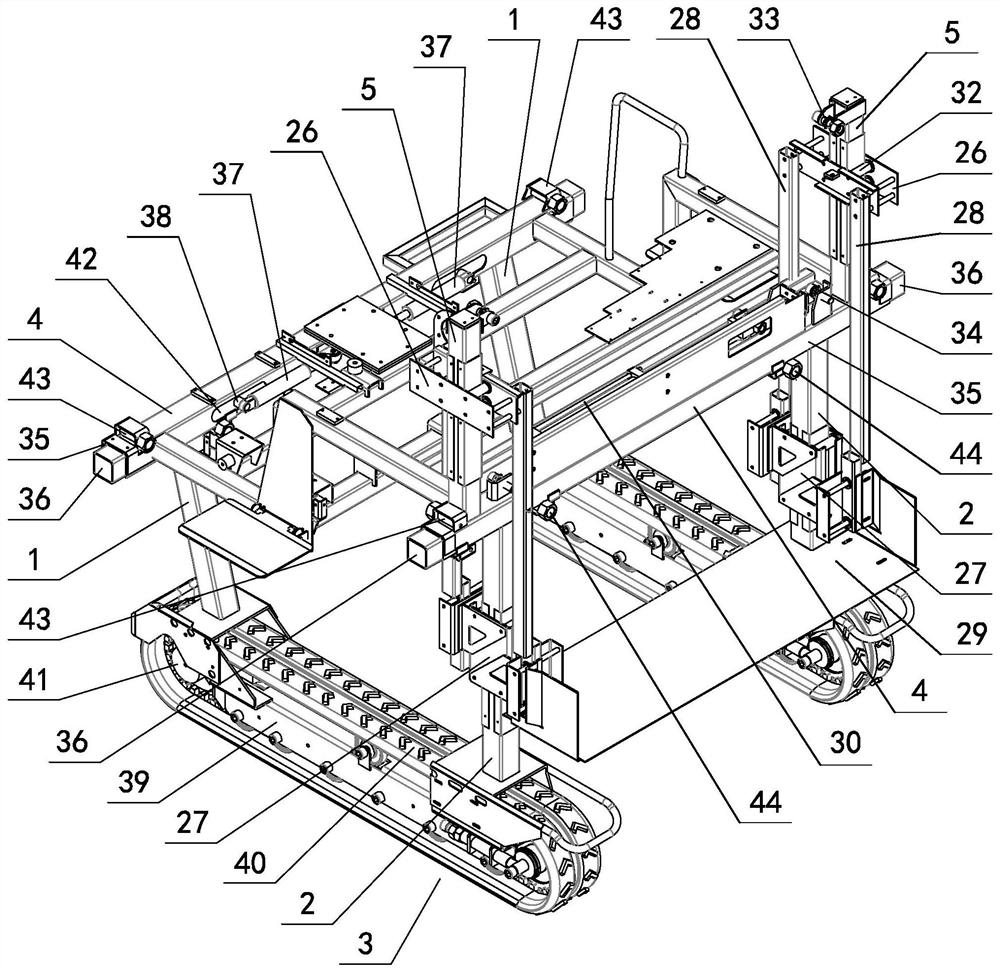

Automatic adjustment row-controlled device of peanut combine

ActiveCN106489411AImprove work efficiencyImprove reliabilityDigger harvestersControl systemEngineering

The invention discloses an automatic adjustment row-controlled device of a peanut combine. The device comprises a supporting frame arranged on a rack. A positioning electric cylinder is arranged on the supporting frame, the positioning electric cylinder is a double-acting electric cylinder, and the left end and the right end of a telescopic rod of the positioning electric cylinder stretch outwards along the left side and the right side respectively and are fixedly connected with corresponding installing frames. Each installing frame is provided with a grain lifter, a divider, a detection device and a digging shovel. The detection devices are used for detecting extrusion force of the two side walls of a furrow between two adjacent ridges and transmitting extrusion force signals to a control system, the control system makes a judgment and controls the positioning electric cylinder to act, and the telescopic rod of the positioning electric cylinder moves left and right to drive the grain lifters, the dividers, the detection devices and the digging shovels on the two installing frames to move left and right synchronously. The device has the advantages that the digging shovels and other working parts on the two installing frames are driven by the positioning electric cylinder to move left and right synchronously, and automatic adjustment row-controlled operation is achieved.

Owner:CHUZHOU UNIV

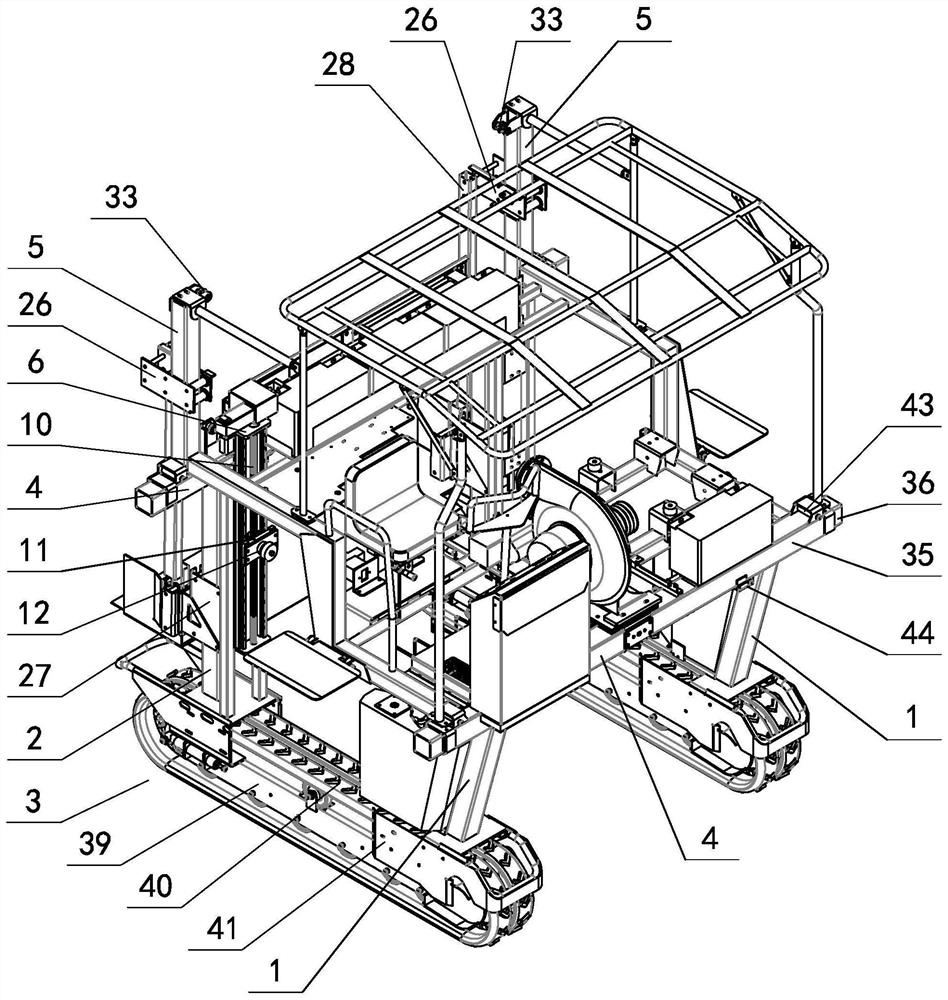

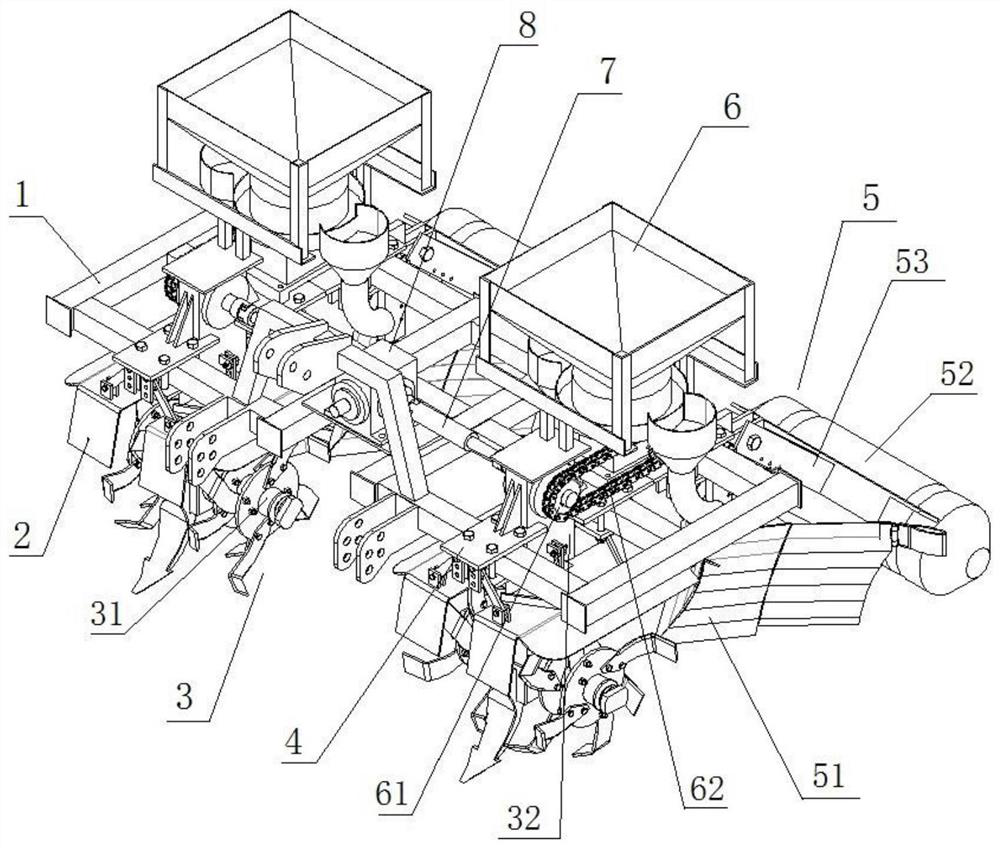

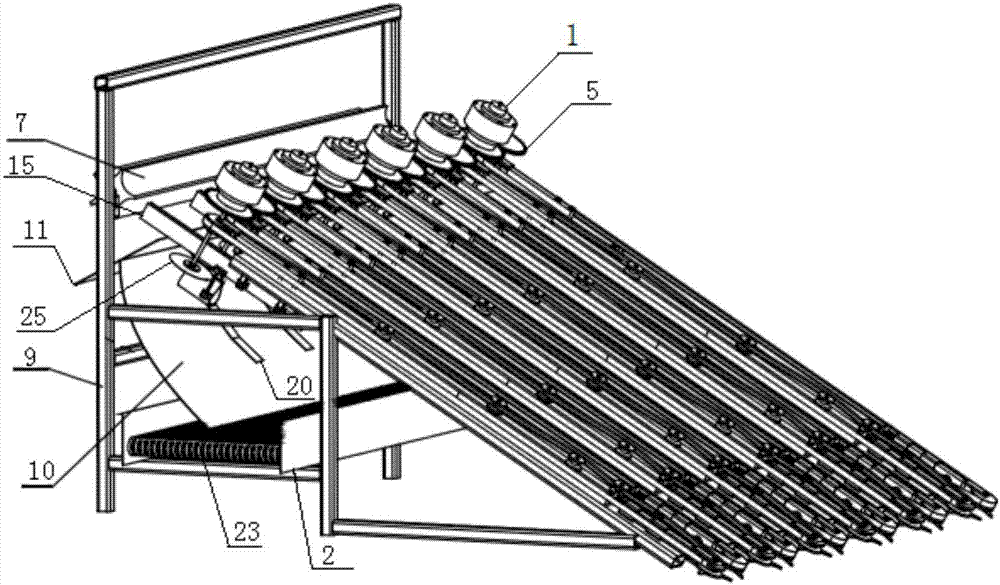

Green soybean combine harvester

The invention discloses a green soybean combine harvester. The green soybean combine harvester comprises a header, a colter, a segment clamping device, a two-time picking mechanism, a beanstalk uprearing mechanism, an oil cylinder and a chassis; the colter is located at the front end of the header, a depth limiting wheel is fixedly connected below the header, the segment clamping device comprises an upper clamp holder and a lower clamp holder, sludge clearing devices are arranged at the two sides of the rear end of the colter, sludge guiding grooves are formed in the rear ends of the sludge clearing devices, and the beanstalk uprearing mechanism is arranged at the front end of the upper clamp holder; the two-time picking mechanism is installed in the harvesting direction on the lower clamp holder and comprises a drum type picker and a roller picker, a brush roller is arranged in front of the drum type picker, green soybeans picked off and branches, leaves and weeds are conveyed to a cleaning box through a conveying belt, and the cleaning box comprises a conveying auger, a vibrating screen, a primary fan and a secondary fan. Soil on beanstalk roots is knocked down by a sludge knocking rod, residual soil is collected by the sludge guiding grooves and returned to a field, which is beneficial for picking the green soybeans, as the drum type picker and the roller picker are arranged, secondary picking can be carried out, and the working efficiency is greatly improved.

Owner:海门市万科保田机械制造有限公司

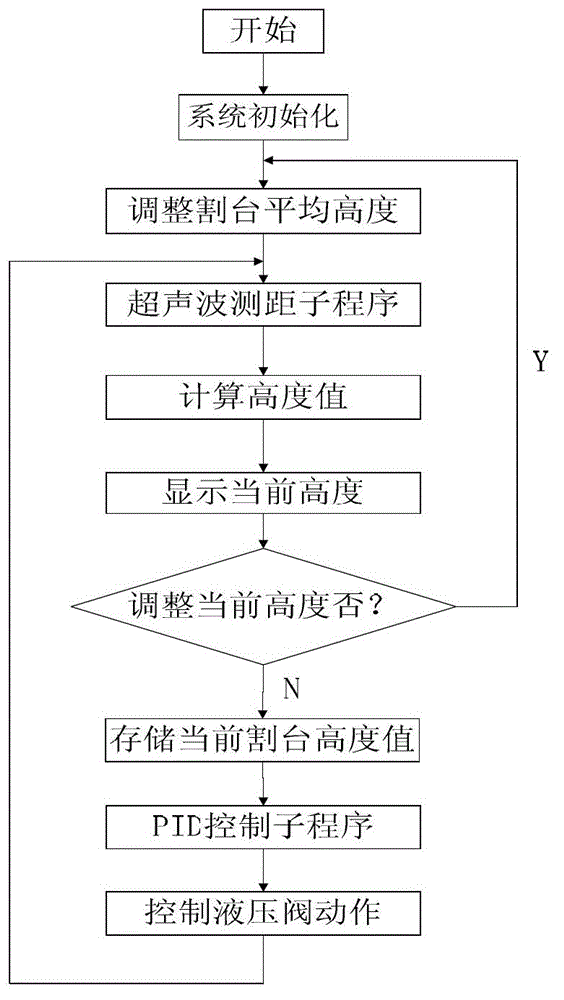

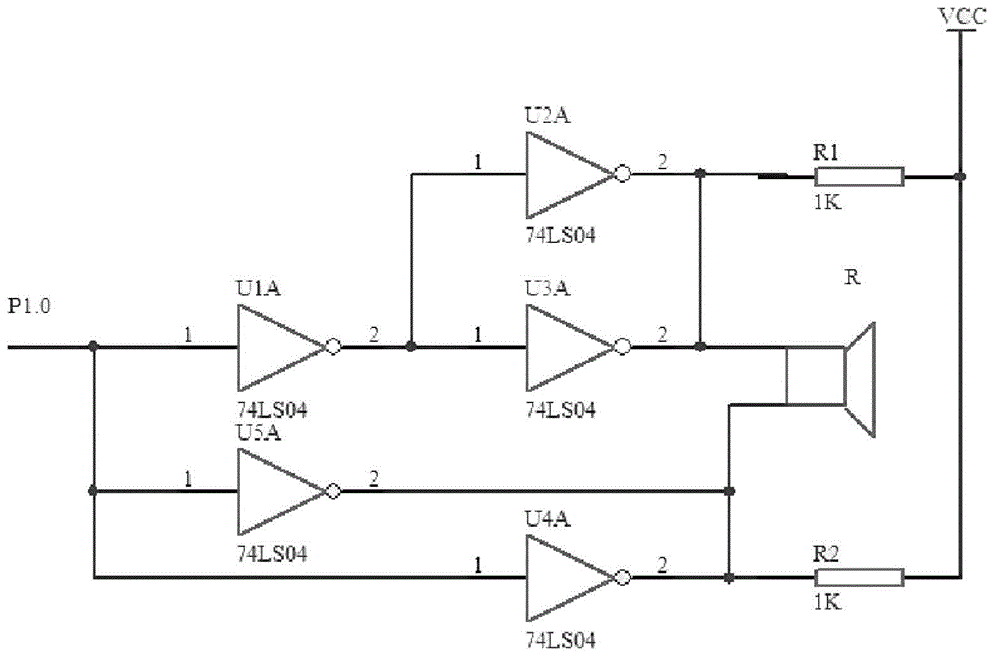

System and method for mechanical waking control based on ground profiling

InactiveCN102714972AImprove profiling abilityImprove Harvest QualityProgramme controlComputer controlTraffic volumeEngineering

The invention provides a system and a method for mechanical waking control based on ground profiling. The system comprises an ultrasonic sensor, a single chip microcomputer, a display and a three-position four-way electromagnetic valve, wherein the ultrasonic sensor is used for monitoring height of a mechanical chassis of a harvester and transmitting signal to the single chip microcomputer and the display, the single chip microcomputer analyzes the signal and transmits the processed signal to the three-position four-way electromagnetic valve, and control of carrying current or pressure in different directions is achieved by controlling current of the electromagnetic valve.

Owner:CHINA AGRI UNIV

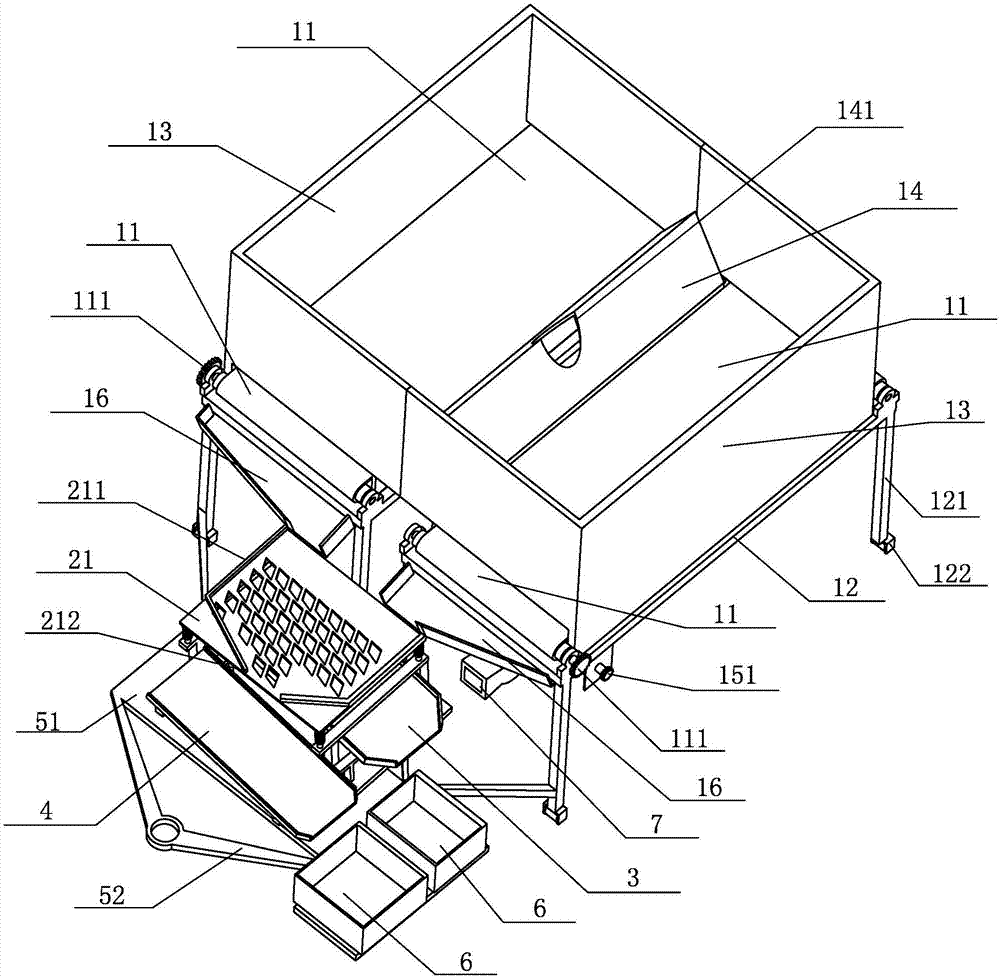

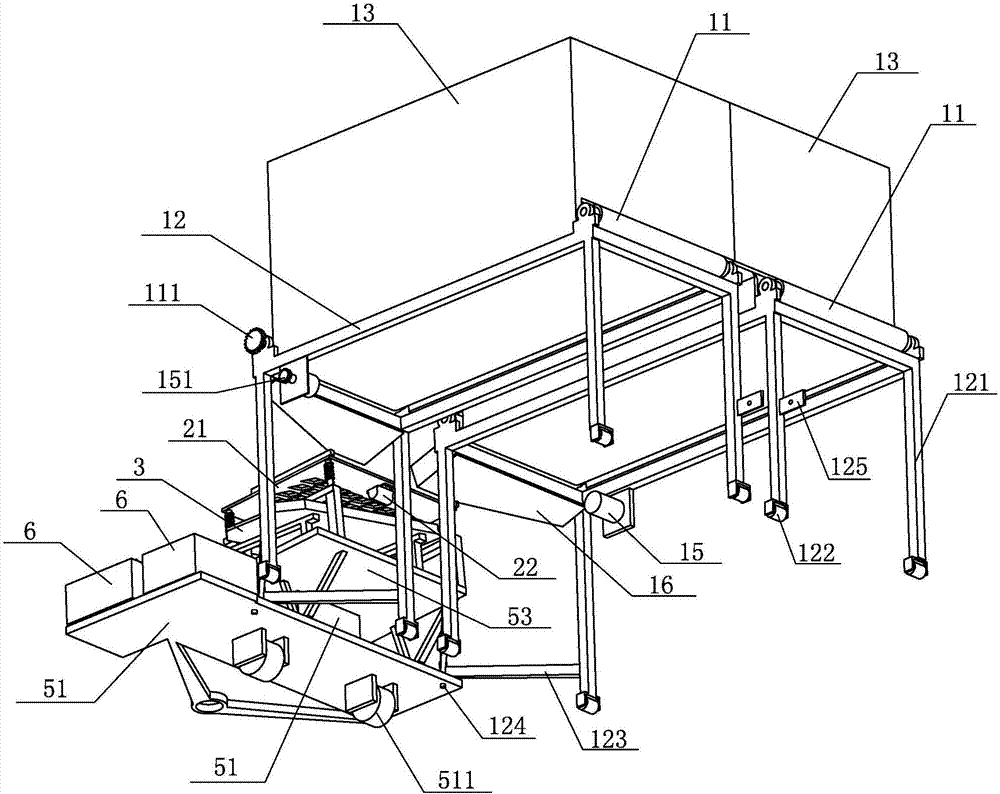

Riding type tea-leaf picker

ActiveCN111937586AMinimal recovery lossImprove harvest qualityAgricultural machinesAdjusting devicesAgricultural engineeringStructural engineering

The invention discloses a riding type tea-leaf picker. A tea-leaf cutting device, a tea-leaf collecting device and a wheel track adjusting device are arranged on a rack, and screw rod mechanisms are vertically arranged on the front sides of two rear stand columns. The tea-leaf cutting device comprises an arc-shaped cutting knife limiting plate and two sawtooth cutting knives which are arranged inan up-down overlapping mode, a cutting knife limiting groove is formed in the front side of the cutting knife limiting plate, the backs of the sawtooth cutting knives are embedded in the cutting knifelimiting groove, elastic baffles are vertically arranged at the two ends of the cutting knife limiting plate of the tea-leaf cutting device, the two ends of the cutting knife limiting plate are arranged on the screw rod mechanisms on the two sides of the rack through the elastic baffles, and the middle of the cutting knife limiting plate is connected with a cutting knife radian adjusting mechanism. By adjusting the shape of the cutting knives, the height of the tea-leaf collecting device and the wheel track, the riding type tea-leaf picker has the advantages of high tea-leaf harvesting quality, small harvesting loss and wide application range, and high practical value is achieved.

Owner:浙江丰凯机械股份有限公司

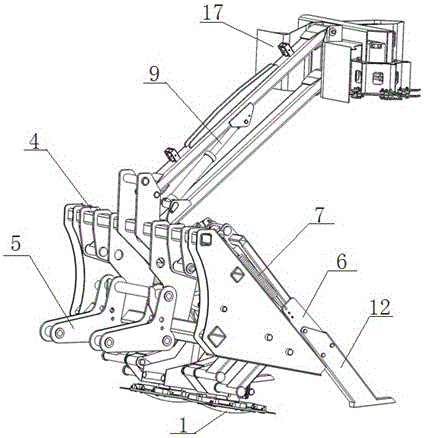

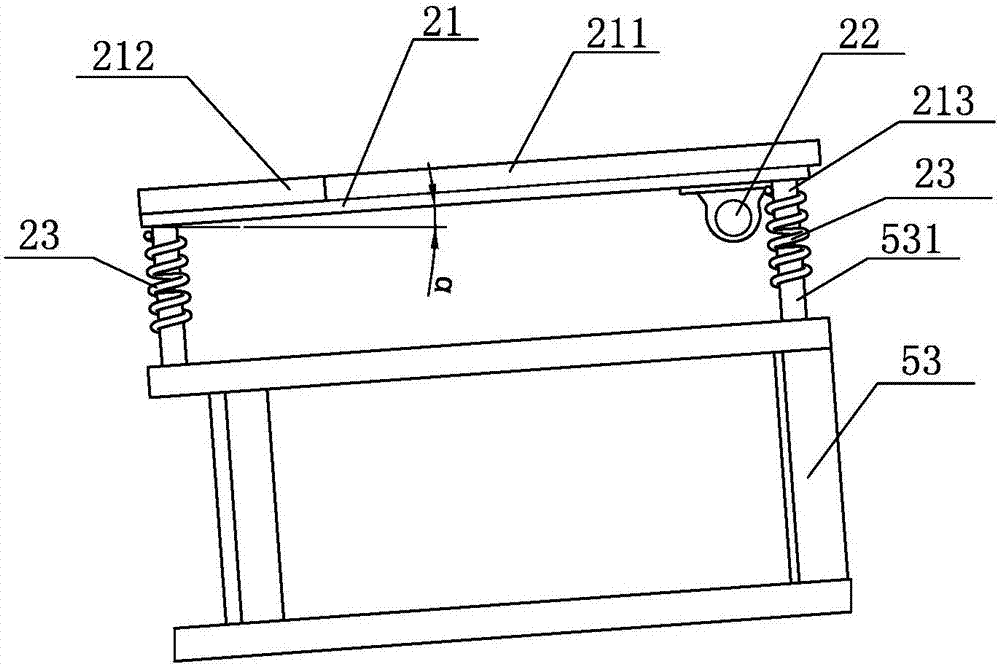

Landform simulation sugarcane harvesting machine

The invention discloses a landform simulation sugarcane harvesting machine. The landform simulation sugarcane harvesting machine comprises a harvesting machine main body and a tractor. The harvesting machine main body comprises a sugarcane-lifer assembly, a cutting table assembly, a topper assembly, a hydraulic power system and a harvesting machine hanger bracket. The harvesting machine is characterized in that the sugarcane-lifer assembly comprises a trigonal bracket and a conical spiral device, the conical spiral device is fixedly connected to one side of the trigonal bracket, a cymbiform base is arranged at the bottom of the trigonal bracket, and a sugarcane-lifer swing arm is arranged at the upper end of the trigonal bracket and connected with the harvesting machine hanger bracket. A spring is arranged at the lower end of the outer side edge of the trigonal bracket, and the other end of the spring is connected with the harvesting machine hanger bracket. The cutting table assembly comprises a cutting table cutter disc, cutting table blades, a cutting table swing arm and an air spring, a hemispherical base is arranged at the bottom of the cutting table cutter disc, one end of the cutting table swing arm is connected with the cutting table cutter disc, the other end of the cutting table swing arm is connected with one end of the air spring, and the other end of the air spring is connected with the harvesting machine hanger bracket.

Owner:王剑

Multifunctional driving type sugarcane intertillage hiller

PendingCN112470571AReduce power consumptionReduce loss rateSpadesMowersAgricultural scienceAgricultural engineering

The invention discloses a multifunctional driving type sugarcane intertillage hiller. The hiller comprises a rack and at least two hilling mechanisms. The two hilling mechanisms are distributed in a bilateral symmetry manner and are connected with the rack in a bilateral movement manner; each hilling mechanism comprises a rotary tillage assembly, a soil control assembly, a fertilizing device and ahilling device. Each rotary tillage assembly comprises a gear box and a rotary tillage cutter set, and the rotary tillage cutter set is connected with the gear box; the upper end of each gear box isconnected with the front end of the rack in a left-right moving manner; each soil control assembly is installed on the corresponding gear box and located above the corresponding rotary tillage cutterset; each fertilizing device is mounted on the corresponding gear box and is positioned at the rear upper part of the corresponding soil control assembly; and each hilling device is connected with therack in a left-right moving manner and is positioned at the rear lower part of the corresponding fertilizing device. The hiller can be suitable for different line spacing of sugarcanes, part loss isreduced, and the hilling effect is improved.

Owner:GUANGXI UNIV +2

Auxiliary device for hang-dried jujube harvest

InactiveCN107321617ARealize deliveryPrevent fallingSievingConveyorsDrive motorUltimate tensile strength

Owner:彭英通

Adjustable potato harvester

PendingCN111903310AImprove harvesting efficiencyImprove harvest qualityDiggersAgricultural scienceAgricultural engineering

The invention discloses an adjustable potato harvester, belongs to the field of agricultural machinery, and overcomes the defects of the prior art through hydraulic control and adjustment. The structure of the adjustable potato harvester mainly consists of a traction device, a rack, comprehensive adjusting oil cylinders, a stalk separating device, a second-stage soil-potato separating adjusting oil cylinder, a second-stage soil-potato separating and conveying device, a first-stage soil-potato separating and conveying device, a digging shovel, a digging shovel adjusting oil cylinder, a hydraulic oil tank and the like, wherein the comprehensive adjusting oil cylinders are located on the two sides of the stalk separating device; the second-stage soil-potato separating adjusting oil cylinder is located at the rear section of the rack, the fixed end of the oil cylinder is located on the oblique beam of the rack, and the movable end is connected with the two ends of a driving part of the second-stage soil-potato separating and conveying device; the digging shovel is located at the lower end of a front beam of the rack and connected with the first-stage soil-potato separating and conveying device; the digging shovel adjusting oil cylinder is located at the angle adjusting end of the digging shovel; and the hydraulic oil tank is located in front of the rack. The adjustable potato harvester is wide in application range and easy to operate, and the harvesting efficiency of the harvester and the product quality are improved.

Owner:LANZHOU LS ENERGY EQUIP ENG RES INST

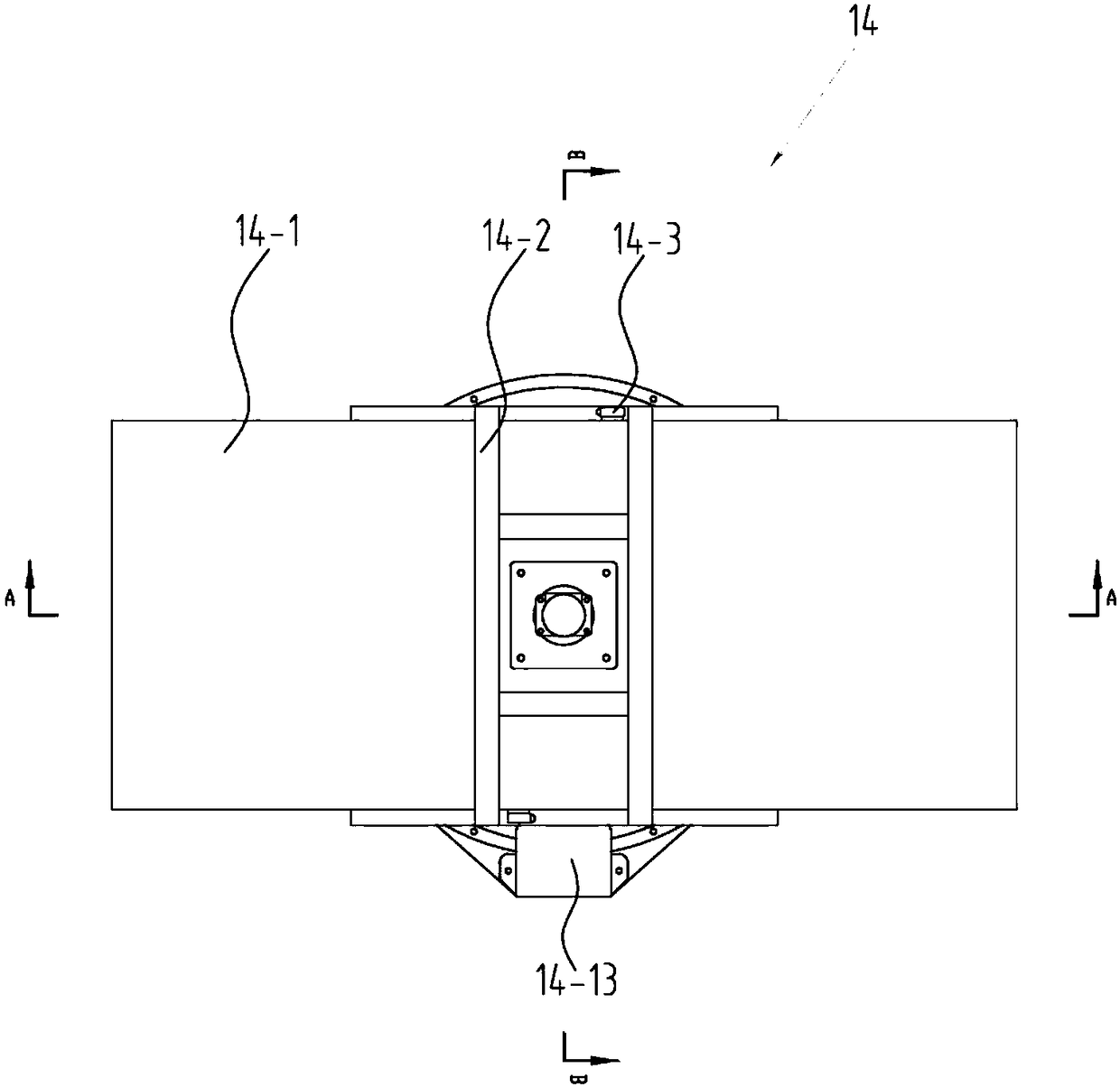

Chopping-type sugarcane combined harvester with middle fans

ActiveCN108575289AImprove efficiencyQuality improvementHarvestersPulp and paper industryAir separation

The invention relates to a chopping-type sugarcane combined harvester with middle fans. The chopping-type sugarcane combined harvester comprises a travelling device, a rack, a spiral line separator, apushover roller, a cutting table, a primary conveying channel, a secondary screen type conveying channel, a sugarcane receiving hopper, a driving cab and a power system and also comprises a middle air separation and impurity removal fan; the rack is mounted on the travelling device; the spiral line separator, the pushover roller, the cutting table, the primary conveying channel, the secondary screen type conveying channel and the sugarcane receiving hopper are sequentially arranged from front to rear on the rack in a material conveying direction; the driving cab and the power system are mounted on the rack; the middle air separation and impurity removal fan is located above a joint of the primary conveying channel and the secondary screen type conveying channel and is used for forwards moving the gravity center of the harvester and reducing the gravity center height of the whole machine; and a secondary air separation and impurity removal fan is arranged at the tail end of the secondary screen type conveying channel and above the sugarcane receiving hopper. The chopping-type sugarcane combined harvester adopts the double air separation and impurity removal fans including the middle air separation and impurity removal fan and the secondary air separation and impurity removal fan, so that the impurity removal efficiency and quality in a sugarcane harvesting operation process arefurther increased, and the impurity content of chopped sugarcanes is reduced; and the chopping-type sugarcane combined harvester belongs to the technical field of agricultural machines.

Owner:SOUTH CHINA AGRI UNIV

Traction type cyperus esculentus harvester

InactiveCN111133877AImprove harvesting efficiencyReduce machine lossThreshersDiggersAgricultural scienceAgricultural engineering

The invention provides a traction type cyperus esculentus harvester, belongs to the technical field of agricultural machinery, and particularly relates to a cyperus esculentus harvester. The tractiontype cyperus esculentus harvester comprises a main machine frame, wherein a transmission system, a rotary digging device, a digging shovel, an elevating net chain assembly, a travelling wheel combination, a dual-drum threshing device, a vibrating screen assembly, a horizontal conveying device, an impurity sucking fan, a belt elevator and a grain tank are arranged on the main machine frame; the digging shovel is mounted at the rear part of the rotary digging device; the elevating net chain assembly is obliquely arranged on the main machine frame, and two ends of the elevating net chain assemblyare adjacent to the digging shovel and the dual-drum threshing device; the vibrating screen assembly is arranged below the dual-drum threshing device; the horizontal conveying device is located outside an outlet of the vibrating screen assembly; the impurity sucking fan is arranged above the horizontal conveying device; and the lower end of the belt elevator is located below the front part of thehorizontal conveying device, and the upper end of the belt elevator extends to the edge of a grain tank. Through the adoption of the traction type cyperus esculentus harvester disclosed by the invention, the harvesting efficiency is notably improved, the machine harvesting loss is reduced, and operating cost is saved.

Owner:JILIN ACAD OF AGRI MACHINERY

Multi-tangential-flow drum corn threshing and cleaning device

The invention relates to a multi-tangential-flow drum corn threshing and cleaning device, and belongs to the field of agricultural machinery. The device comprises a cutting unit, a threshing unit, a cleaning unit and a collecting unit; the cutting unit comprises an auger (1); the threshing unit comprises a pressure feeding device (2), a thumb shifter type feeding device (12), a primary threshing device (9), a main threshing device (4) and a re-threshing device (5) which are successively arranged from front to back; the pressure feeding device (2) is arranged at the rear of the auger (1); and the cleaning unit comprises a shaking sieve (11), a vibrating sieve (6) and a cleaning fan (10). Corns can be peeled, threshed, cleaned, conveyed and collected mechanically in a whole process, the working efficiency is greatly improved, the labor intensity is reduced, meanwhile, the loss ratio, breakage ratio and impurity content are reduced, the corn harvesting quality is improved, and market space is wide.

Owner:CHINA AGRI UNIV

Profiling seedling cutting and flexible speed reduction type conveying device for garlic harvester

PendingCN107360779APracticalSimple structureTopping machinesAgricultural engineeringCollection system

The invention relates to a profiling seedling cutting and flexible speed reduction type conveying device for a garlic harvester. The conveying device comprises a frame, at least one group of profiling seedling cutting systems, a garlic seedling collection system and a flexible speed reduction type garlic bulb conveying system. Each profiling seedling cutting system comprises a clamping conveying device, a garlic seedling supporting guide rail, a garlic bulb profiling guide rail, stem cutting disc cutters, a hydraulic motor I and a transmission gear group, wherein the garlic seedling supporting guide rail is mounted below an output end of the clamping conveying device, and the garlic bulb profiling guide rail is mounted below the garlic seedling supporting guide rail. The garlic seedling collection system is positioned at a position corresponding to a garlic seedling outlet of the garlic seedling supporting guide rail, and the flexible speed reduction type garlic bulb conveying system is positioned below garlic bulb outlets of the garlic bulb profiling guide rails. The conveying device has the advantages that problems of failure in alignment of garlic bulbs, low cut-off rate, cut nonuniformity and high breakage rate in a conveying process are mainly solved, and the conveying device is applied to garlic combine harvesters to complete profiling seedling cutting of conveyed dug garlic seedlings and flexible speed reduction type conveying of the garlic bulbs after seedling cutting.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

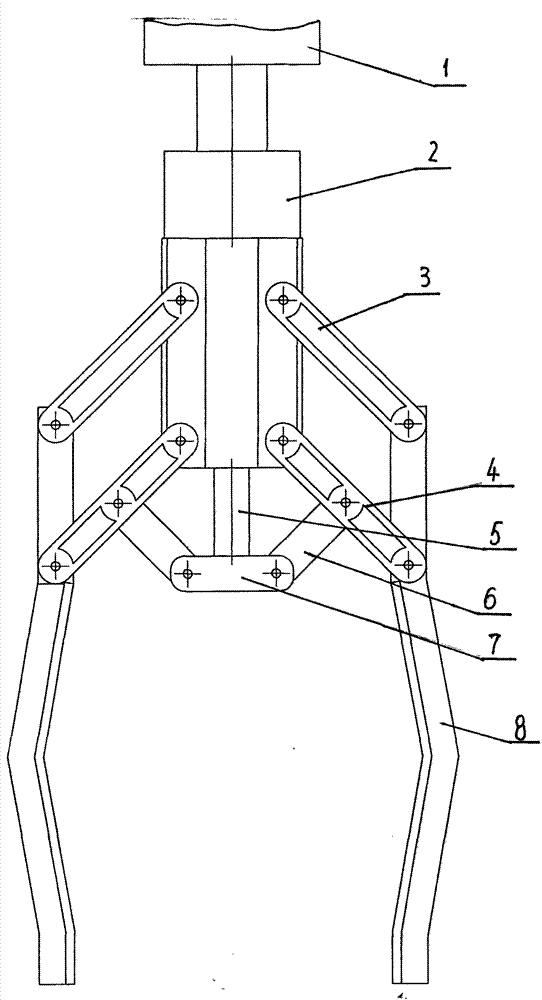

Cole crop pulling and taking jaw assembly

The invention provides a cole crop pulling and taking jaw assembly, and belongs to agricultural machinery. Upper swing arms are symmetrically hinged to the upper side portion of a two-way hydraulic cylinder, lower swing arms are symmetrically hinged to the portions, located below the upper swing arms, on the lower side portion of the two-way hydraulic cylinder, jaw teeth are symmetrically hinged to the upper swing arms which are symmetrically arranged in a hinged mode and the lower swing arms which are symmetrically arranged in a hinged mode, an arm base is arranged on the lower end portion of a cylinder rod of the two-way hydraulic cylinder, and drive arms are symmetrically hinged to the portions between the lower swing arms which are symmetrically arranged in the hinged mode and the arm base respectively. According to the assembly, selective clamping, pulling and harvesting of cole crops are achieved, and the cole crop pulling and taking jaw assembly has the advantages of being simple in structure, convenient and reliable in clamping and pulling operation, good in harvest quality, high in selectivity, wide in application range and beneficial to the improvement of agricultural economic benefits.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

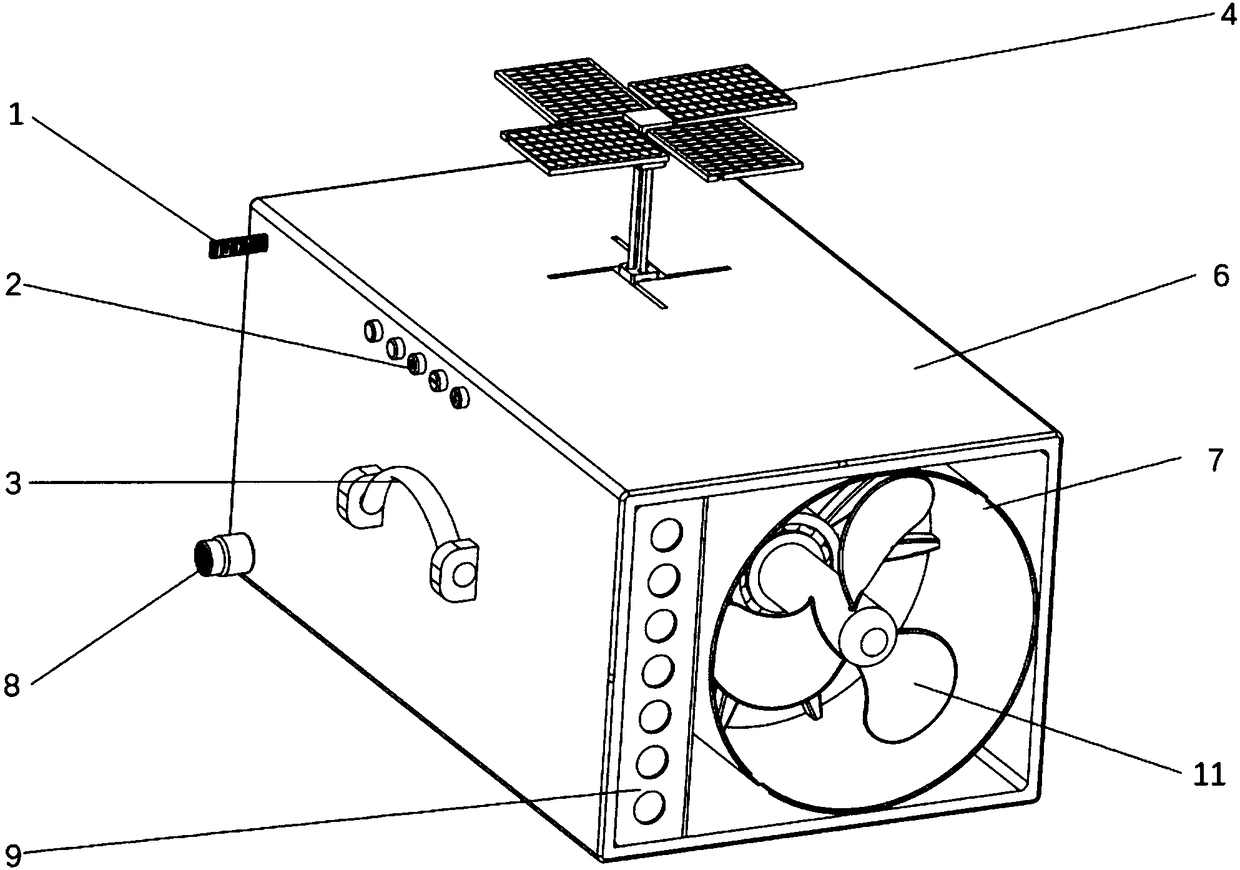

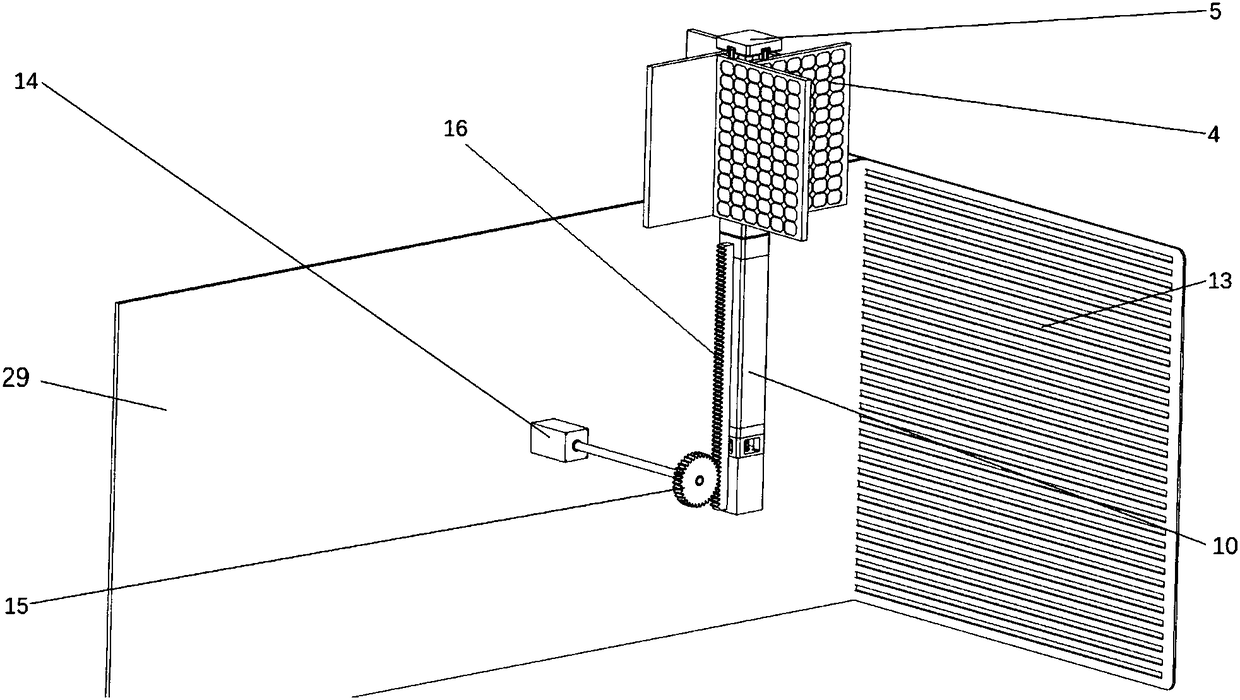

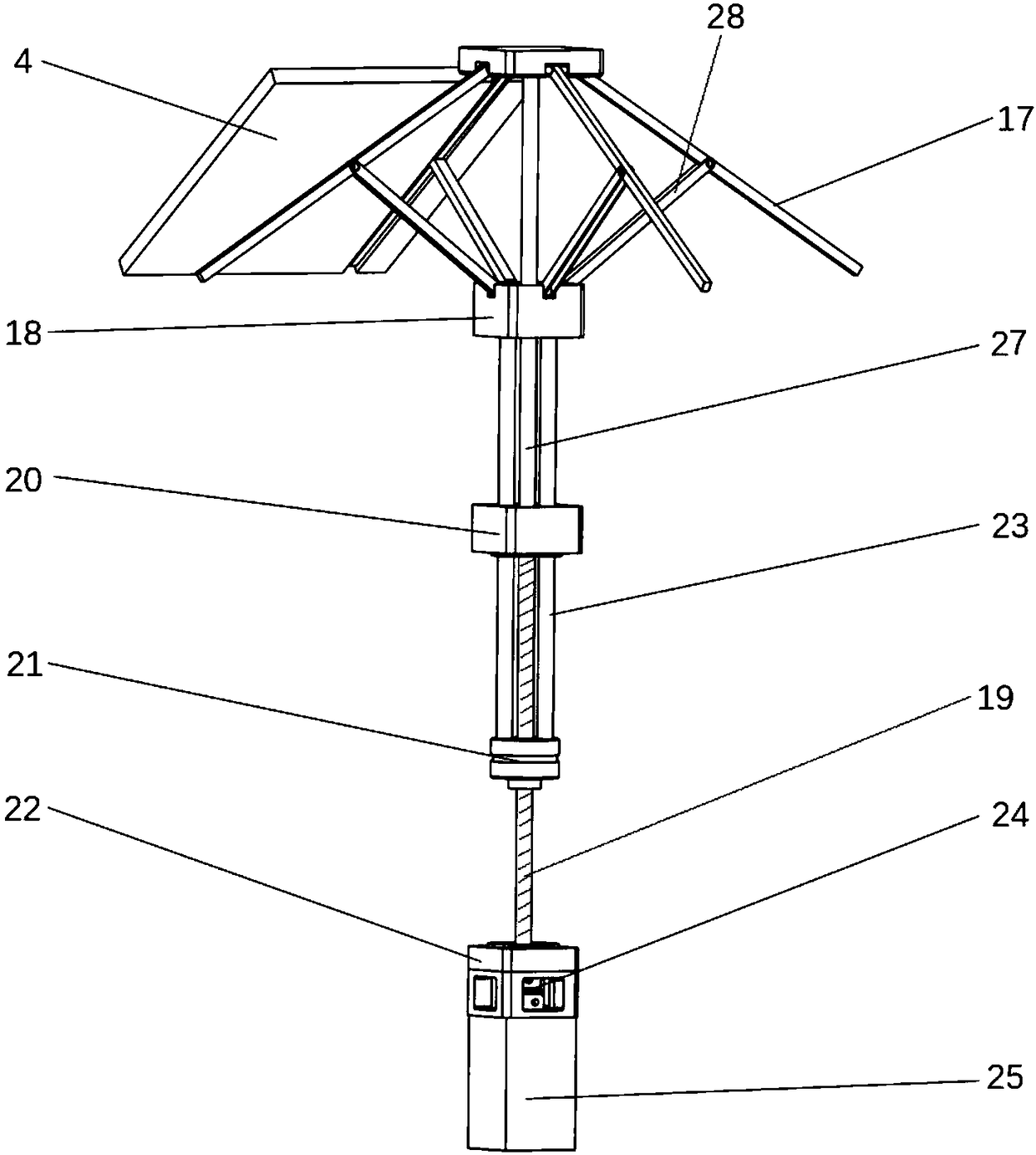

Solar self-powered intelligent exhaust device of greenhouse

PendingCN108575453AImprove the growing environmentImprove harvest qualityClimate change adaptationGreenhouse cultivationDiseaseElectricity

The invention discloses a solar self-powered intelligent exhaust device of a greenhouse. The device comprises a box, wherein the box is through in the front and rear directions; a louver is arranged on the rear end surface of the box; an exhaust fan is arranged on the front part of the interior of the box; solar panels are arranged on the surface of the top of the box; a temperature and humidity sensor and a carbon dioxide sensor are arranged on the side surface of the rear part of the box; a control circuit board and an accumulator are arranged in the box; the exhaust fan, the solar panels, the temperature and humidity sensor, the carbon dioxide sensor and the control circuit board are all electrically connected with the accumulator; the circuit board can control turn-on and turn-off of the exhaust fan according to data detected by the temperature and humidity sensor and the carbon dioxide sensor. According to the device, automatic air exhausting can be conducted according to detectedenvironment parameters in the greenhouse, so that the requirements for manpower are effectively reduced, the device can not only provide a better growing environment for fruits and vegetables to improve the yields and the quality of the fruits and the vegetables, but also provide a better temperature and humidity environment for growers, and diseases brought by the environment can be reduced to acertain extent.

Owner:SOUTHWEST JIAOTONG UNIV

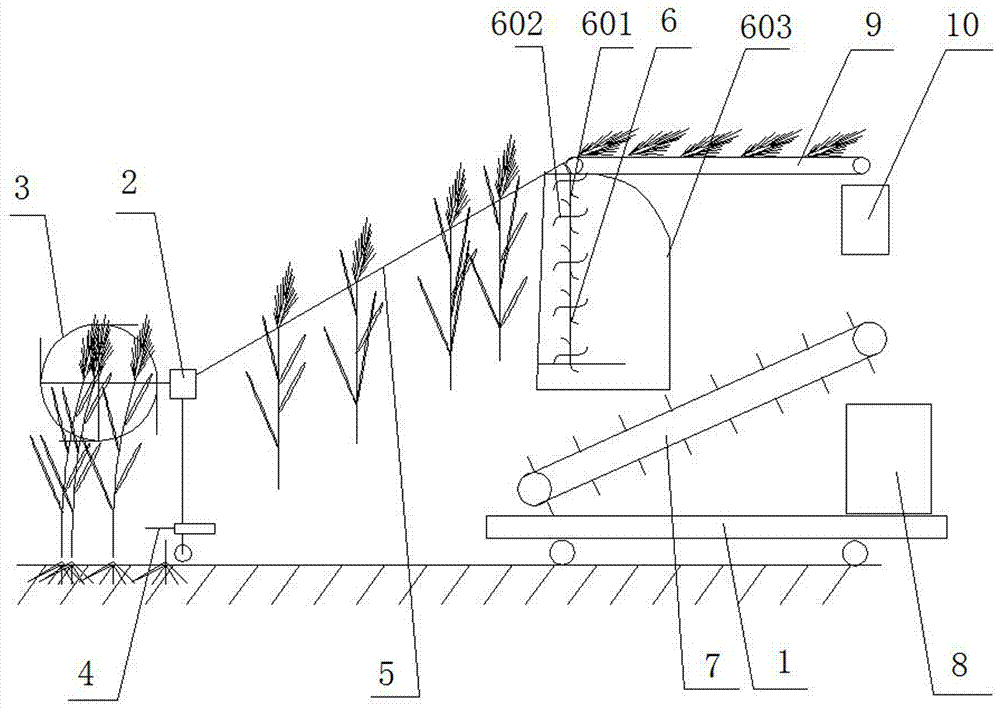

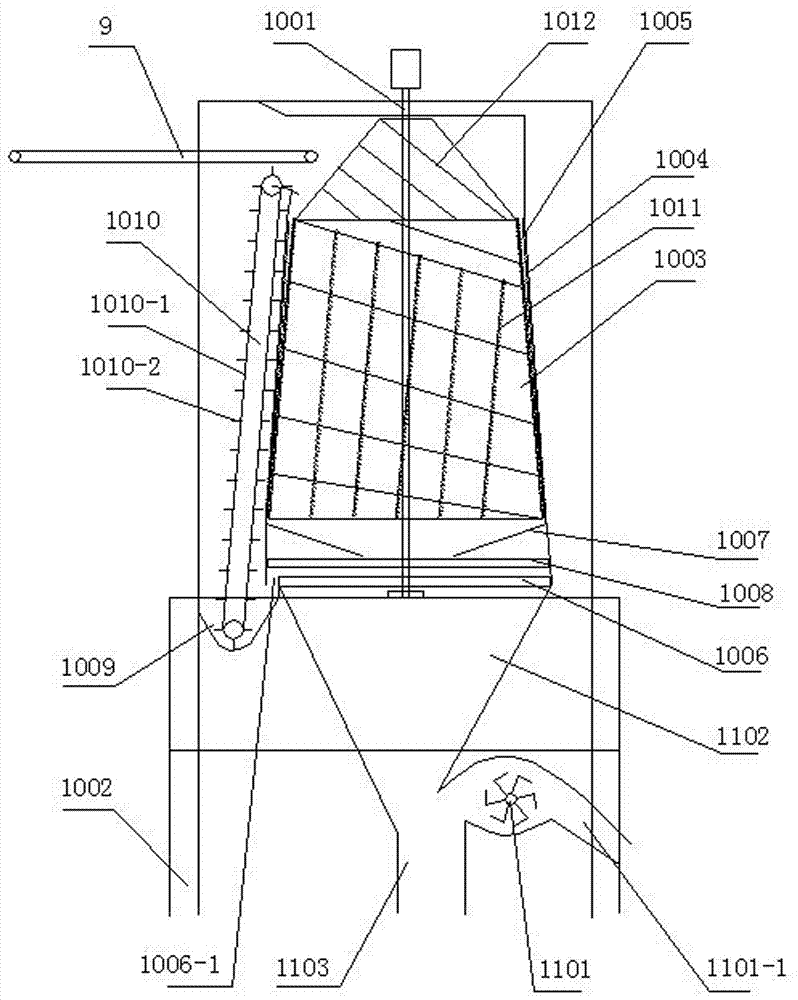

Harvesting device suitable for spike-stalk distributary harvesting of highland barley

PendingCN107493806AImprove harvest qualityMeet the needs of double incomeMowersThreshersEngineeringAgricultural machinery

The invention relates to the field of agricultural machinery, in particular to a harvesting device suitable for spike-stalk distributary harvesting of highland barley. The harvesting device comprises a frame and a bracket, wherein a reel and a cutter are arranged on the bracket; chain clamping transport mechanisms are arranged between the bracket and the frame and used for conveying stalks, cut off by the cutter and arranged in rows under the action of the reel, toward the frame; a multi-layered free-swinging cutter mechanism for separating the stalks from spikes and crushing the stalks is arranged at the position, below the tail ends of the chain clamping transport mechanisms, on the frame; a stalk conveying mechanism is arranged below the multi-layered free-swinging cutter mechanism; a grass collecting and bundling mechanism is arranged at the tail end of the stalk conveying mechanism; and a spike conveying mechanism is arranged in the position, at the tail ends of the chain clamping transport mechanism, on the frame, and a highland barley spike threshing mechanism is arranged at the tail end of the spike conveying mechanism. The harvesting device is simple in structure and low in cost, can realize harvesting of both grain and grass, and adapts to the characteristics of highland barley spikes, and the threshing efficiency and quality are improved.

Owner:HENAN UNIV OF SCI & TECH

Garlic harvester

InactiveCN101040582AHarvest garlic fastReduce labor intensityLiftersTopping machinesEngineeringAllium sativum

The invention discloses a toasted garlic collector, formed by a forward wheel, a flexible sheath, a rotary brush, a beam, a root cutter, a transmission wheel 1, a transmission wheel 2, a toasted garlic outlet, a hydraulic jack, a screen, an upper blade and a lower blade. The invention can be operated by a tractor, a hand tractor or a digger, the wheel can adjust depth, collect toasted garlic anywhere with high speed, low labor strength and improved collecting quality.

Owner:李振师

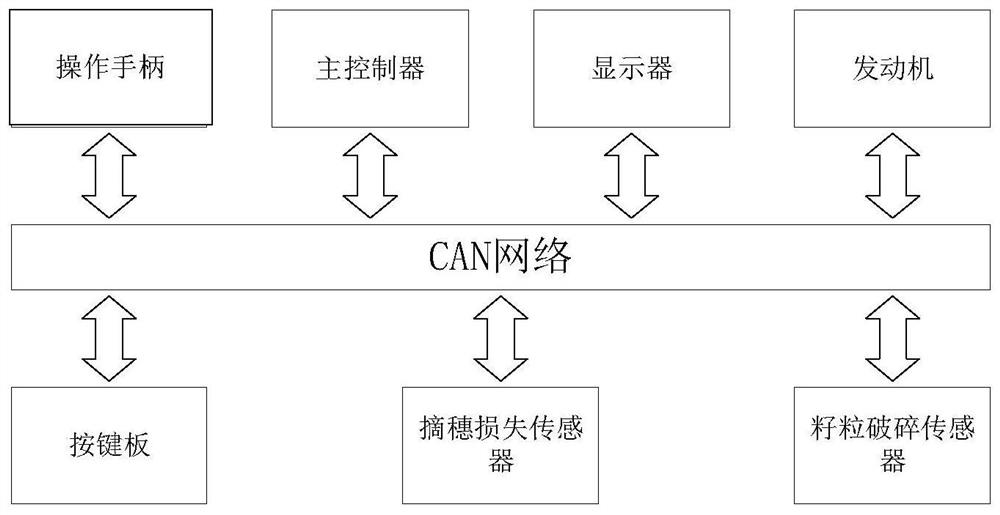

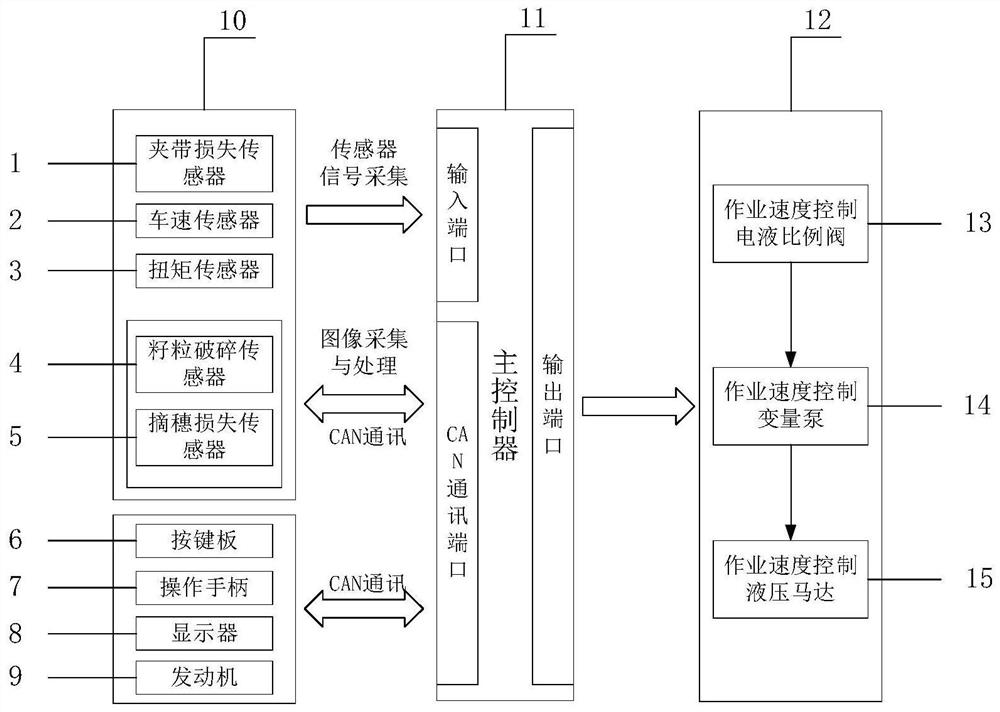

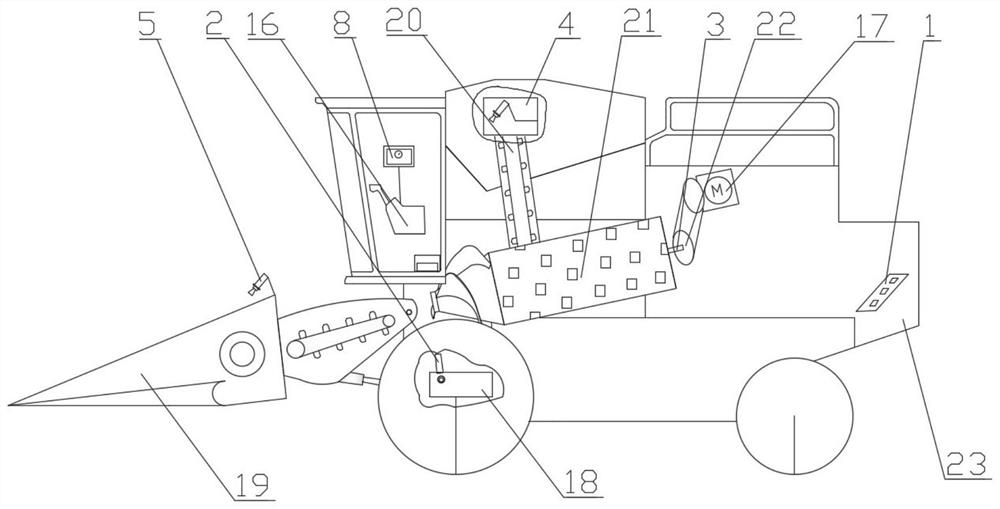

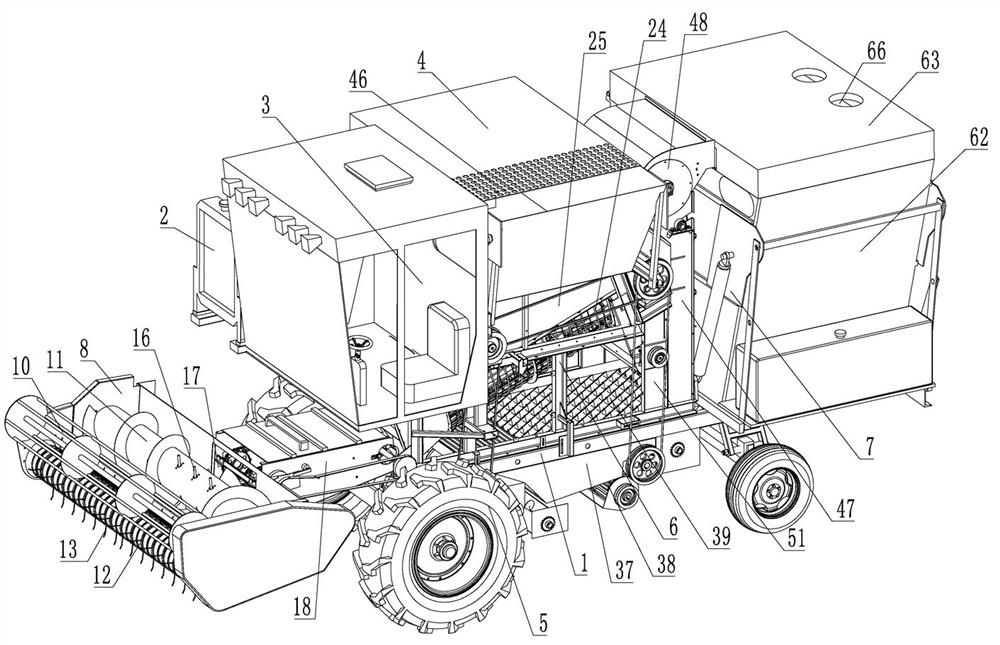

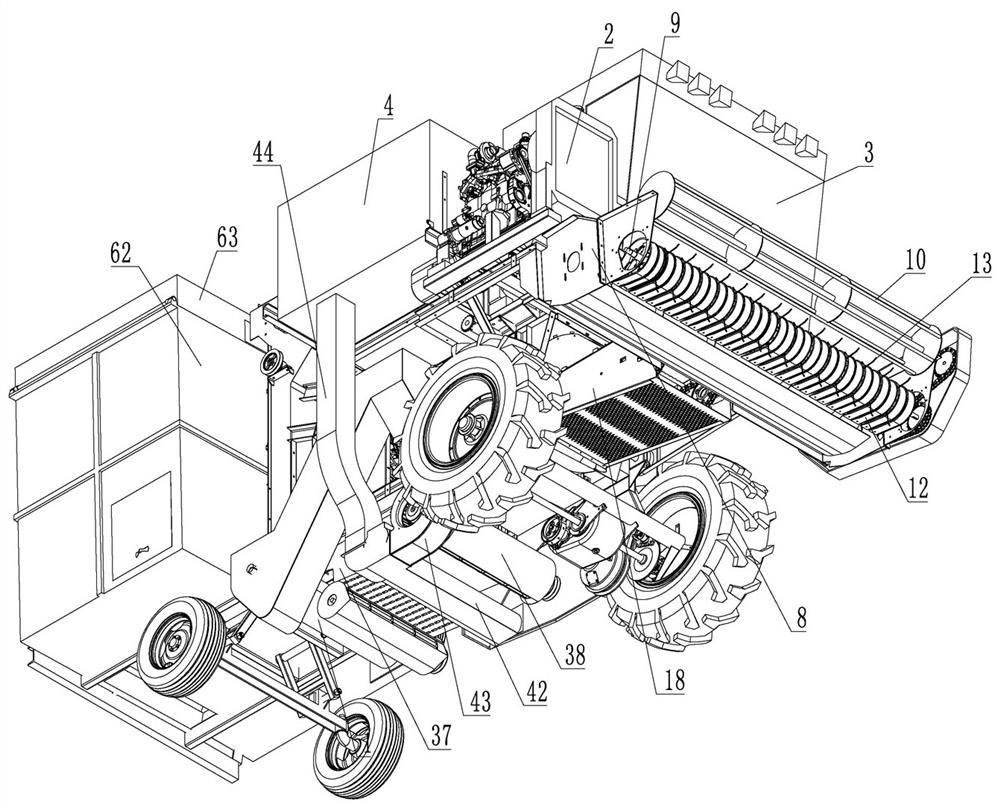

Self-adaptive control system and self-adaptive control method for corn harvesting feeding amount

PendingCN111670681AFunctionalAdjust the working mode at any timeMowersInformation processingAgricultural engineering

The invention relates to a self-adaptive control system and a self-adaptive control method for corn harvesting feeding amount. The control system comprises a CAN bus, a measuring and transmitting device, an armrest box assembly, a displayer, a main controller and a hydraulic executing mechanism. The CAN bus integration technology is adopted, a corn harvesting quality parameter online detection andsensing information processing and fault diagnosis system are integrated on the basis of a CAN bus, and the real-time performance and reliability of information transmission of the control system areguaranteed. The optimal target feeding amount is obtained through real-time calculation according to multiple pieces of feedback information of the grain breakage rate, the entrainment loss rate andthe ear picking loss rate, the current feeding amount is calculated through the torque value, the feeding amount of the corn harvester in the harvesting process is adaptively adjusted by adjusting theoperation speed, and the purpose of improving the working efficiency and the harvesting quality is achieved. Multi-sensor fusion adjustment ensures the reliability and scientificity of adaptive adjustment of the feeding amount, so that the vehicle speed control in the harvesting process is more reasonable and accurate.

Owner:CHINA AGRI UNIV

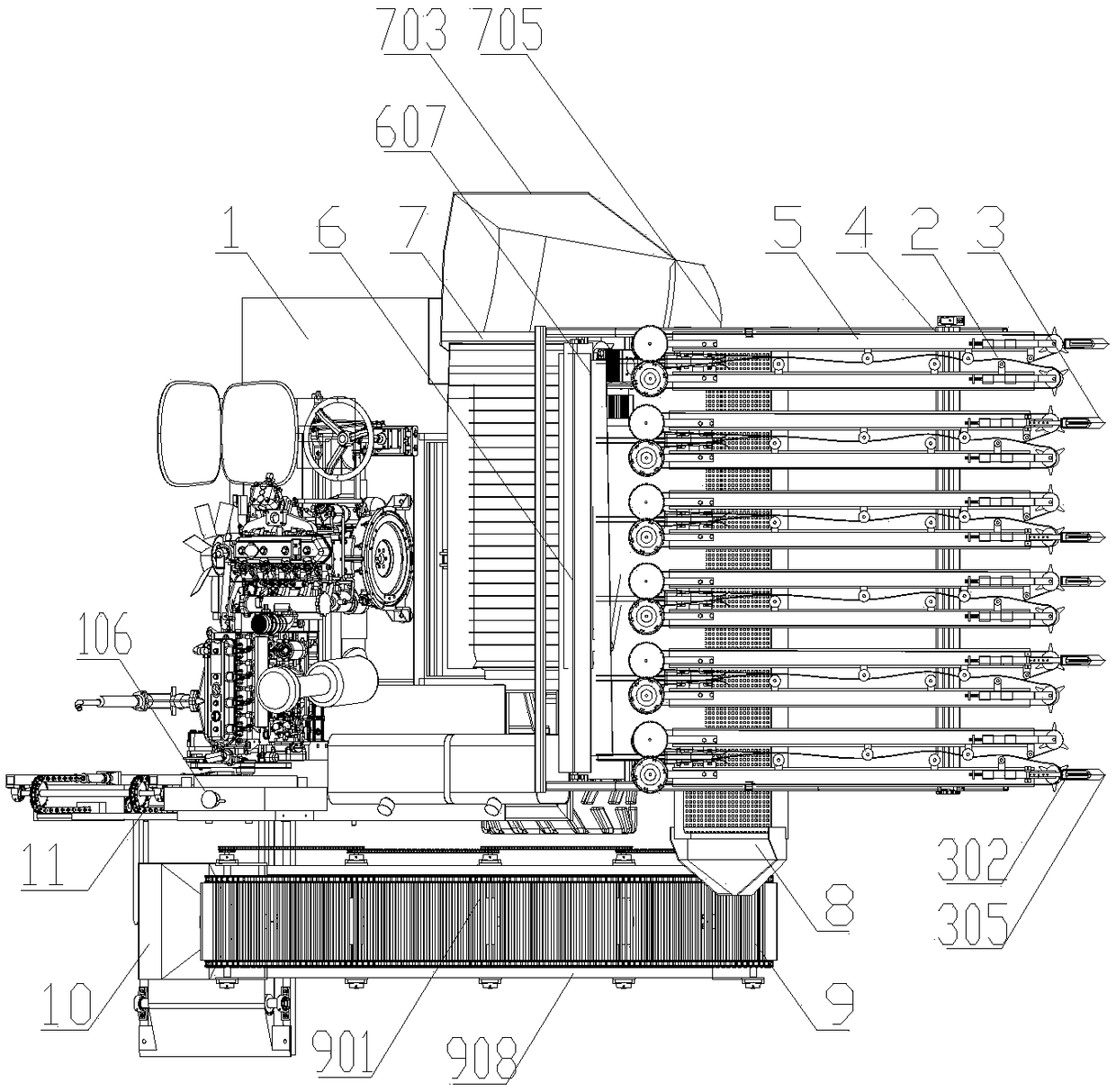

Dust fall type peanut picking harvester

ActiveCN113853922APromote repairExtended service lifeLoadersDiggersAgricultural scienceAgricultural engineering

A dust fall type peanut picking harvester comprises a chassis, an engine, a cab, a peanut picking table system, an inclined peanut conveying system, a peanut threshing system, a screening system, a fruit collecting system, a peanut vine smashing and conveying system, a fruit box and a dust fall grass collecting box. The peanut picking table system is installed on the front side of the chassis, the inclined peanut conveying system is installed on the chassis, the peanut threshing system and the screening system are both fixedly installed in the middle of the chassis, the fruit collecting system is fixedly installed on the lower side of the middle of the chassis, the peanut vine smashing and conveying system is fixedly installed on the rear side of the middle of the chassis, and a peanut recycling system is fixedly arranged on the lower portion of the rear side of the middle of the chassis. The engine provides power for the peanut picking table system, the inclined peanut conveying system, the peanut threshing system, the fruit collecting system, the peanut vine smashing and conveying system and the peanut recycling system. The peanut picking harvester is scientific in design, smooth in the whole working process, high in efficiency, high in peanut harvesting quality and environmentally friendly in dust falling.

Owner:HENAN AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com