Standing corn harvest machine cutting bench

A technology for harvesting headers and corn, applied in the direction of headers, harvesters, agricultural machinery and implements, etc., can solve the problems of broken stalks, blocked headers, difficult and easy feeding, etc., to increase the gap and prevent gnawing. Injury, the effect of improving work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

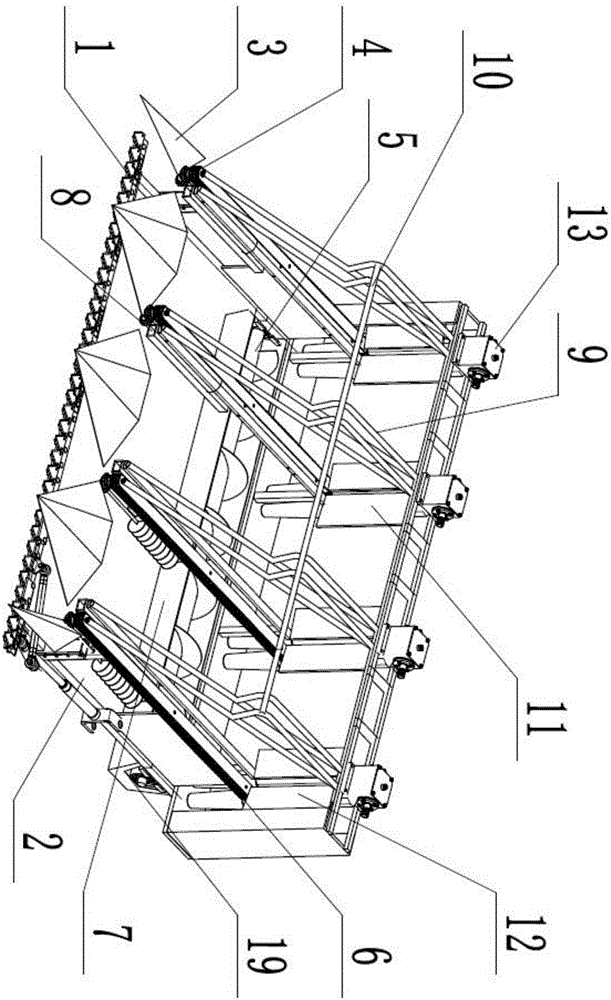

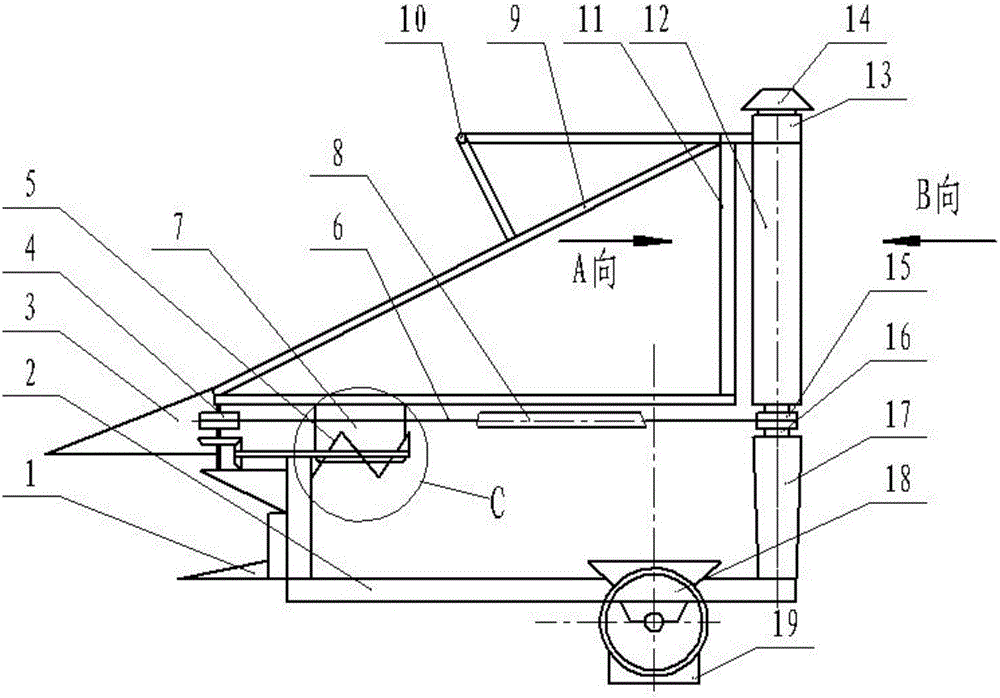

[0035] Such as figure 1 , figure 2 and image 3 , this embodiment makes a detailed description of the structure and principle of a vertical corn harvesting header of the present invention.

[0036] This embodiment provides a vertical corn harvesting header, including a reciprocating cutter 1, a frame 2, a crop divider 3, a sprocket 4, a reel chain 6 with a dial finger 21, and a reel with flexible blades. Auger 5, blade removal plate 7, pressing bar 8, stalk 9, stem pressing bar 10, fringe picking plate 11, long pulling stem roller 12, bevel gear 14, gear box 13, drive sprocket 15, main shaft 16 , short stem pulling roller 17, fruit ear horizontal conveying auger 18, grain recovery box 19 and passive stem pulling roller 20;

[0037] Two described grain dividers 3 of every row symmetrical distribution are installed on the front end of described frame 2, wherein the sprocket wheel 4 is provided under the rear portion of one of the grain dividers, and the rear and lower portio...

Embodiment 2

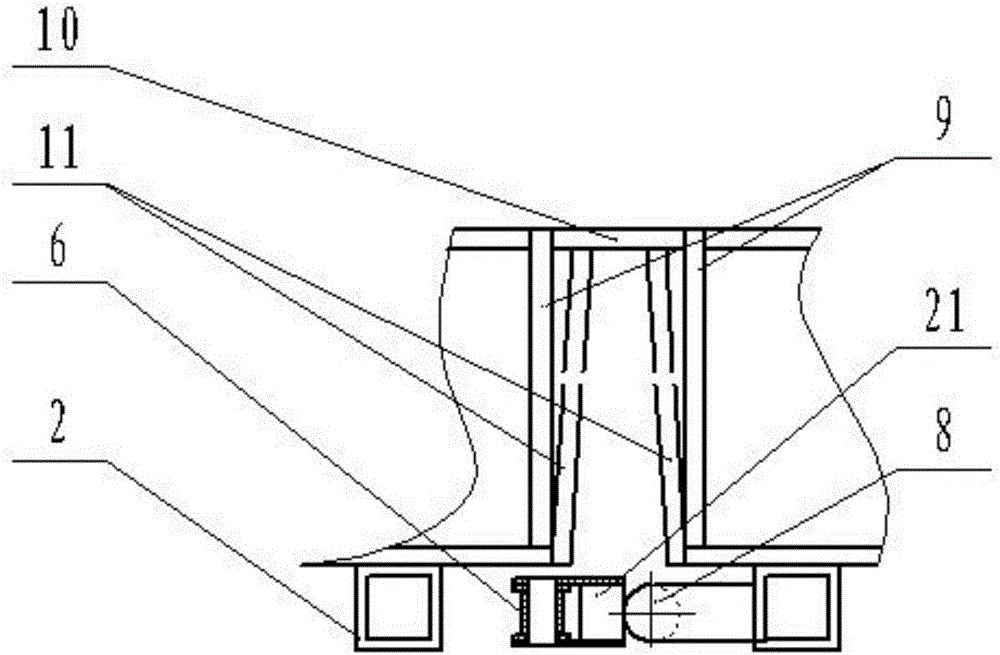

[0041] Such as Figure 4 , Figure 5 and Figure 6 , this embodiment is an embodiment further improved on the basis of Embodiment 1, and at the same time, further details of the present invention are made.

[0042] In this embodiment, the front portion of the blade plate 7 is streamlined and outwardly curved, and the middle part of the blade plate 7 is in close contact with the auger 5 with flexible blades, and the auger 5 with flexible blades The delivery speed of 5 is faster than the speed of said reel chain 6.

[0043] The two parallel straws 9 are located directly above the reel chain 6 and the pressing bar 8, and the gap between the two parallel straws 9 is closely related to the reel chain 6 and the pressing bar. The gap between the poles 8 is facing, and the gap between the two parallel straws 9 can be adjusted by 15 to 20 cm; the two parallel straws 9 can correct the feeding direction of the stalks and prevent the stalks from The horizontal feeding can solve the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com