Adjustable potato harvester

A potato and harvester technology, which is applied to excavator harvesters, harvesters, excavators, etc., can solve the problems of inability to adapt to different geological soil conditions, increased excavation resistance of potato harvesters, and inability to achieve efficient harvesting of potato pieces. , to achieve the effect of improving harvest efficiency and product quality, reducing skin damage rate and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

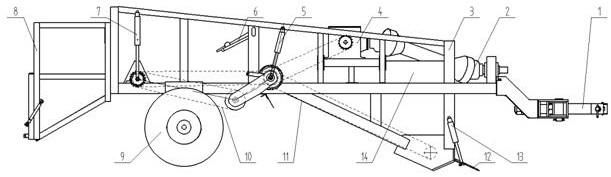

[0016] In conjunction with the accompanying drawings, the present invention will be described in further detail.

[0017] As shown in the figure, the adjustable potato harvester is mainly composed of traction device 1, universal drive shaft 2, frame 3, gearbox 4, comprehensive adjustment cylinder 5, stem separation device 6, and secondary soil and potato separation adjustment cylinder 7 , Potato collecting box 8, walking device 9, secondary soil and potato separation and conveying device 10, primary soil and potato separation and conveying device 11, digging shovel 12, digging shovel adjusting oil cylinder 13, hydraulic oil tank 14 and other components; the traction device 1 is located on the machine The front end of the frame is connected with the frame beam through U-shaped bolts. The device has two degrees of freedom to rotate freely to achieve traction, which are two degrees of freedom parallel to the ground and perpendicular to the ground; The key component of tractor pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com