Brush roll type picking table

A picking table and brush-roller type technology, which is applied in the direction of picking machines, agricultural machinery and implements, etc., can solve the problems of long cotton boll opening period, not easy to be entangled, easy to fall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

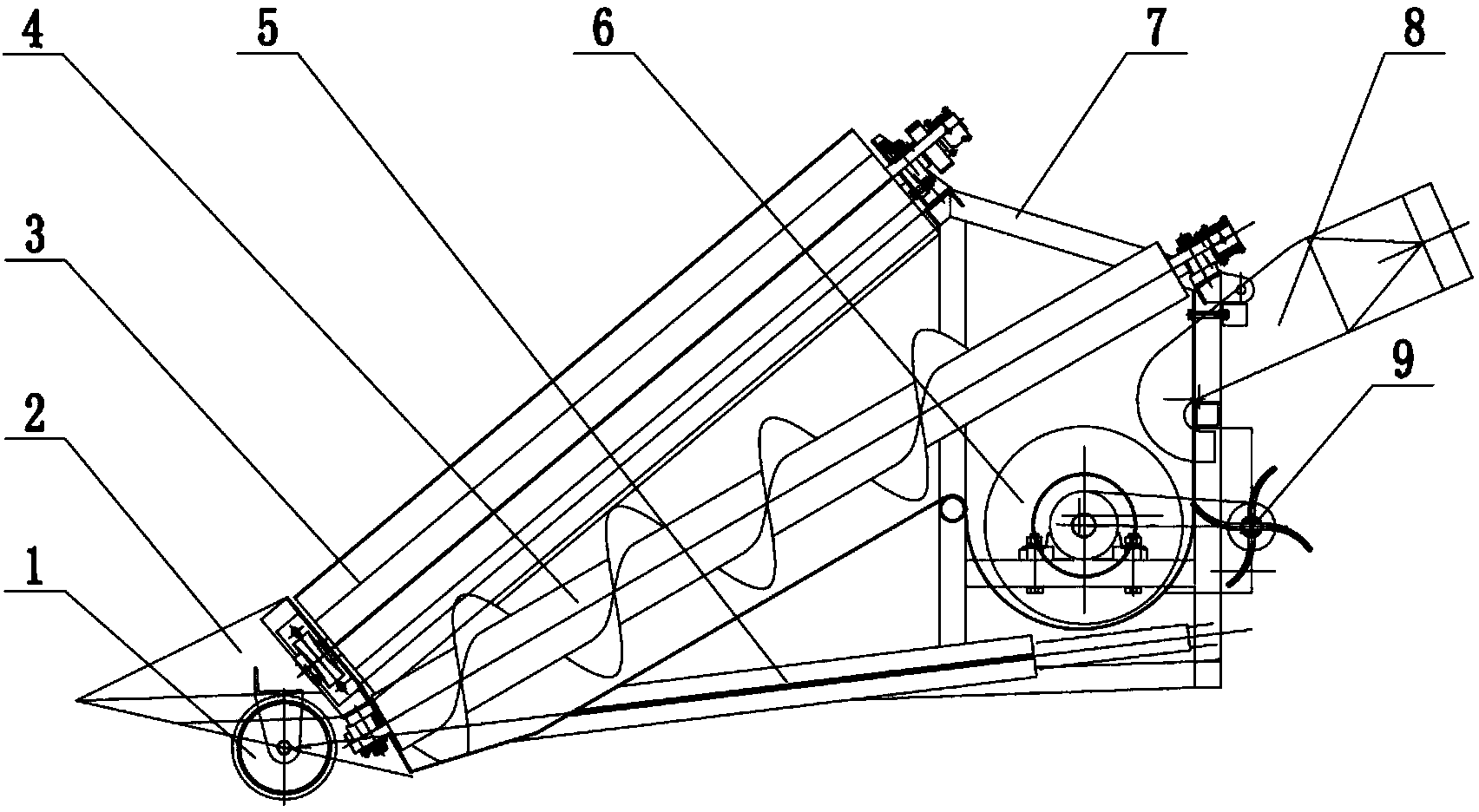

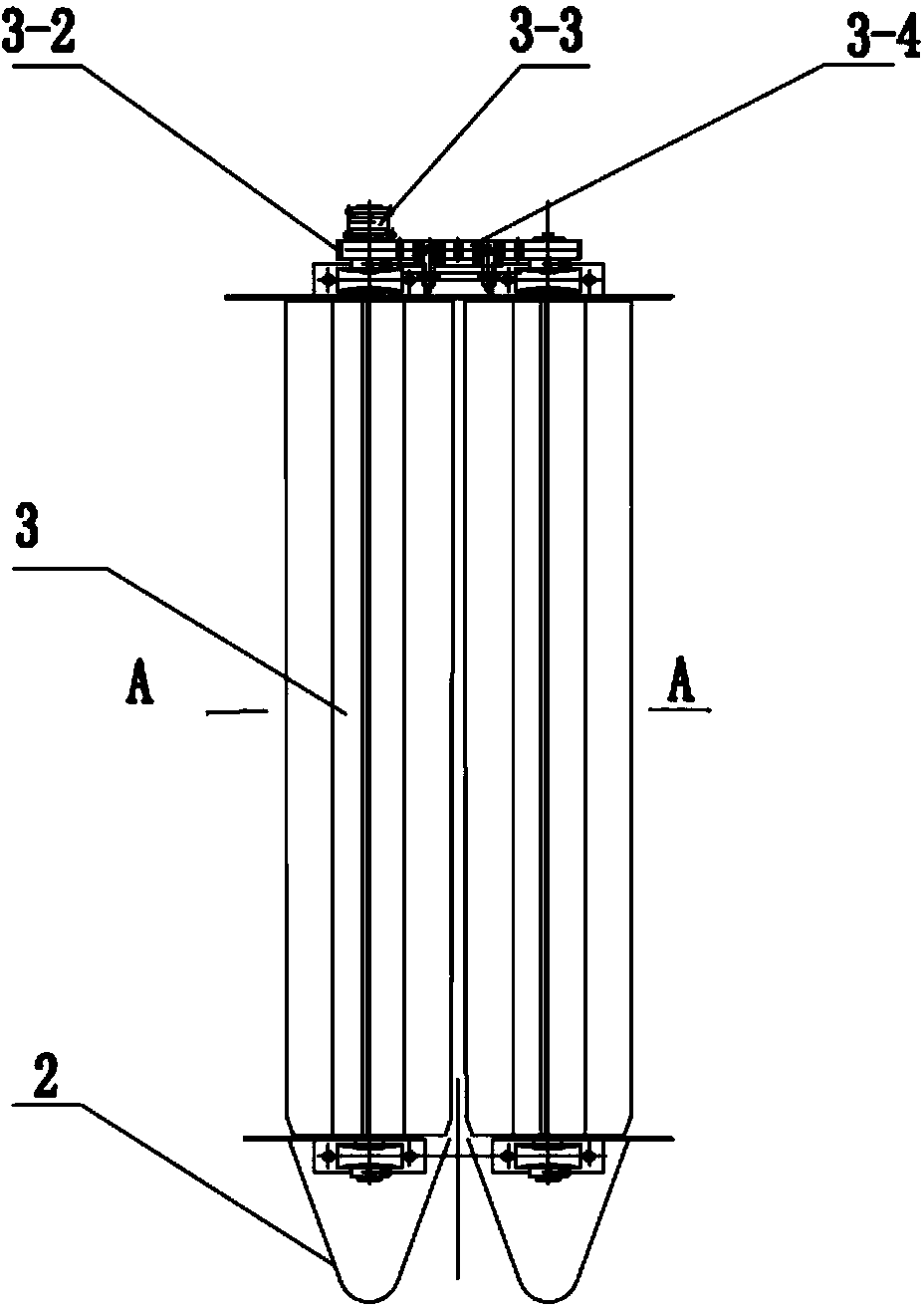

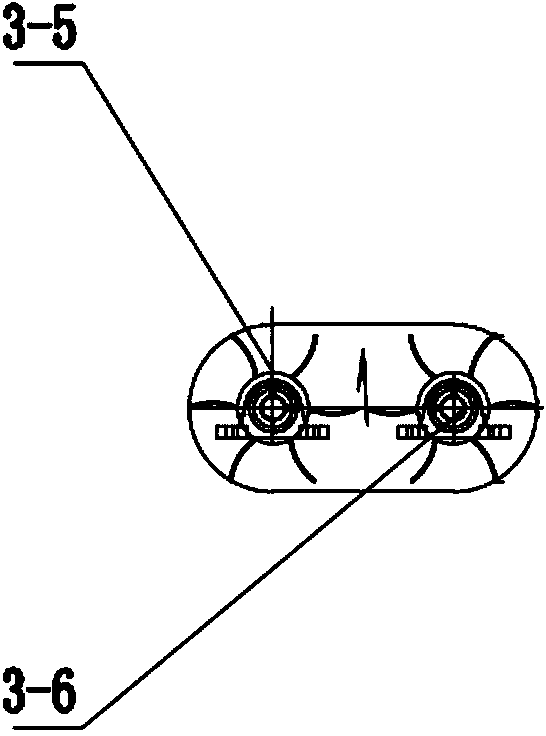

[0016] The basic structure of the picking platform of the present embodiment is as follows: Figure 1 to Figure 4 As shown, three pairs of grain dividers 2 with conical heads are installed at the front end of the picking stand 7, and the bottom of the grain divider 2 is supported on the depth-limiting wheel 1, and three parallel picking heads 3 are housed thereafter. For the specific structure of picking head 3, see Figure 2 to Figure 4 , Contain a pair of left and right brush rollers 3-5,3-6 that are supported on the picking stand 7 with a low front and a high rear, forming an angle of 30-40° with the ground. Left, the rear end of brush roller 3-5 is coaxial with drive gear 3-3, and realizes the same speed reverse rotation transmission with right brush roller 3-6 through transmission gear 3-2 and two transition gears 3-3. The left and right brush rollers 3-5 and 3-6 are respectively circumferentially evenly distributed with six brush plates extending radially. The circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com