Sisal harvester

A harvester and sisal technology, applied in the field of tropical crop harvesting machinery, can solve problems such as unsatisfactory sisal harvesters, and achieve the effects of reducing sisal harvesting costs, simple operation and high harvesting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

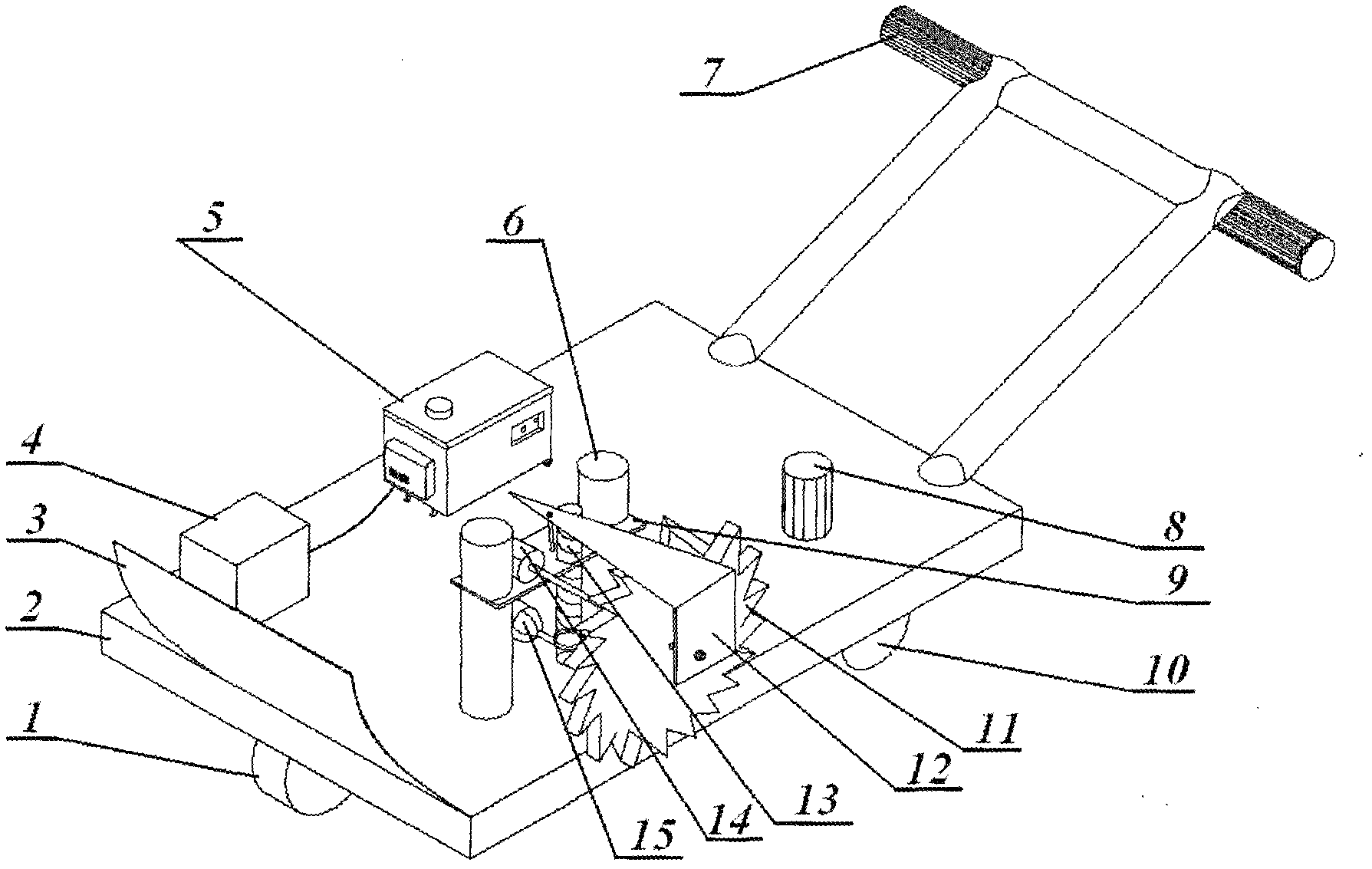

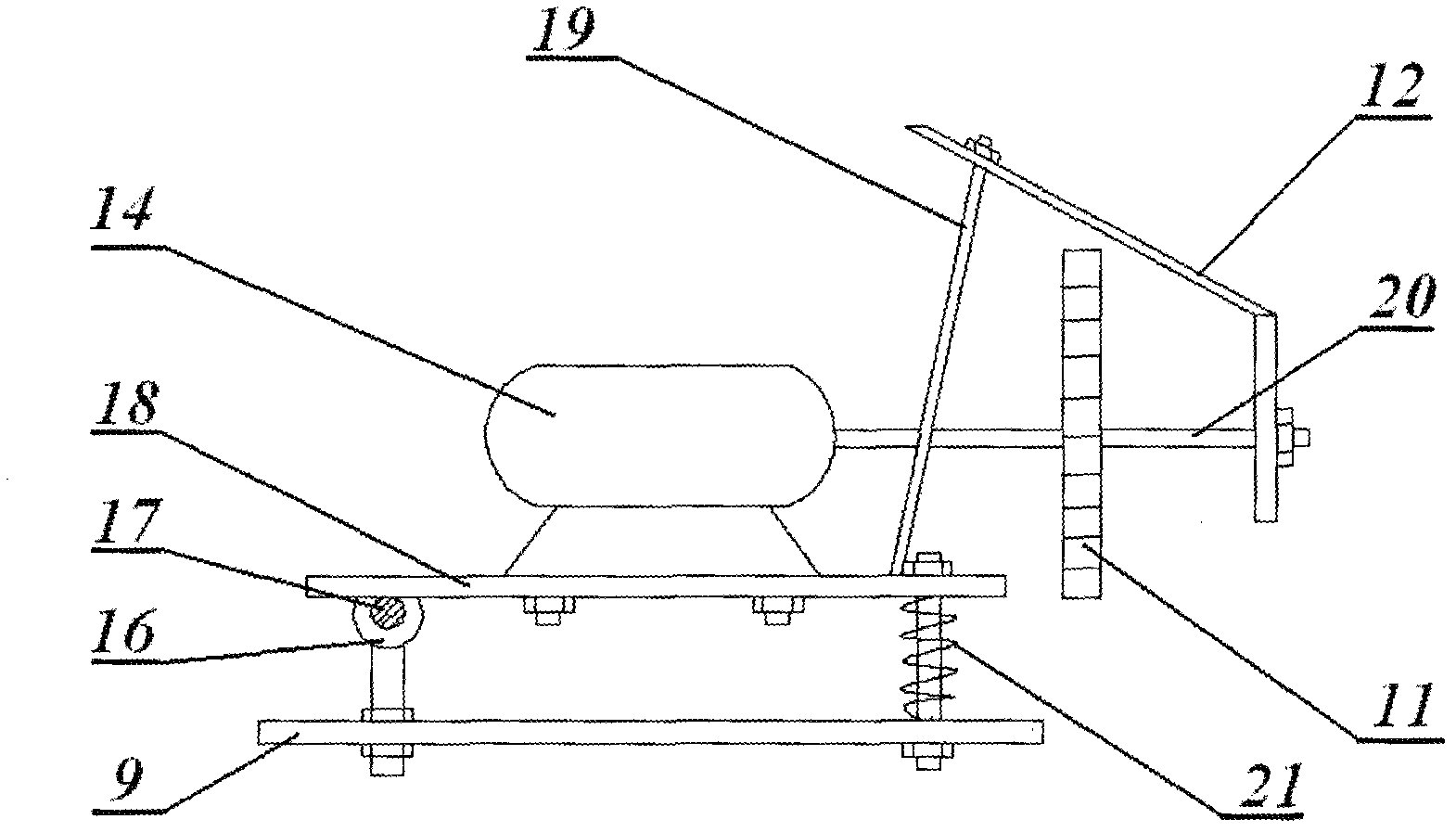

[0011] A small flatbed truck is equipped with a small diesel generator 5 to provide power for the whole machine. It is equipped with a cutting saw blade 11, which is driven by the main servo motor 14 to rotate. The main servo motor 14 is installed in a height adjustable On the lifting base plate 9, the main servo motor 14 and the lifting base plate 9 adopt a flexible connection, that is, the main servo motor 14 is installed on the motor support plate 18, and the rear of the motor support plate 18 is provided with a fixed shaft 17 which passes through joint bearings. 16 is connected to the lifting bottom plate 9, and the front part of the motor support plate 18 is connected to the lifting bottom plate 9 through a spring 21. The cutting saw blade 11 is provided with a guide guard 12, and one end of the guide guard 12 is connected to the guide guard support rod 19 The motor support plate 18 is connected, and the other end is connected to the saw blade shaft 20 through a bearing. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com