Semi-feeding device for harvesting peanut and picking fruit

A peanut harvesting and semi-feeding technology, which is applied in the direction of digging harvesters, harvesters, agricultural machinery and implements, etc., can solve the problem of many broken seedlings and broken branches, increase the separation of peanuts from seedlings, and the rate of fruit pods with stalks advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

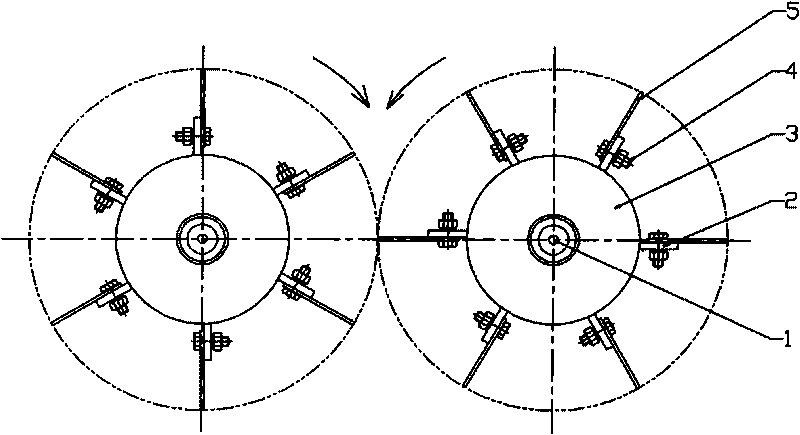

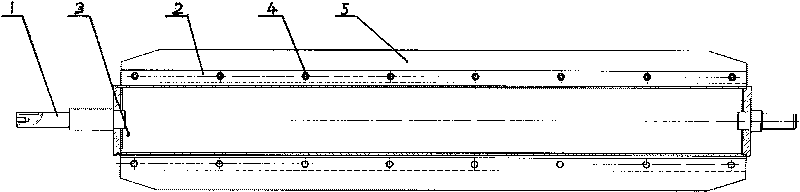

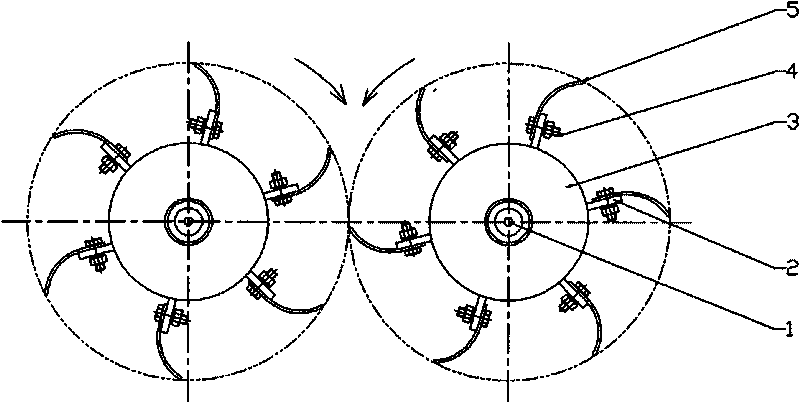

[0016] The half-feeding peanut harvesting device of the present embodiment is as image 3 As shown, it is made of a pair of rollers 3, and the two rollers are radially equipped with fruit-picking blades 5 that are distributed in different phases at intervals, that is, the fruit-picking blades 5 of the two rollers are mutually staggered. The two ends of the roller 3 are supported on the roller shaft 1, and the blade fixing seats 2 distributed at intervals extend radially from the outer circle, and each blade fixing seat is equipped with a fruit-picking blade 5 through a fixing bolt 4, and the fruit-picking blade 5 faces away from the roller 3 A circular arc surface that is gradually curved in the direction of rotation, with chamfers at both ends (see figure 2 ).

[0017] When working, the arc-shaped fruit-picking blades have a beating effect on the peanut pods instead of a brushing effect, thus avoiding the shearing effect. Moreover, since the arc-shaped fruit-picking blades...

Embodiment 2

[0019] The half-feed peanut picking device of the present embodiment is as image 3 As shown, the basic structure is the same as that of Embodiment 1, the difference is that the blade fixing seat 2 extending radially from the outer circle of the roller 3 is inclined towards the direction away from the rotation of the roller 3, and the included angle with the radial direction is 30±5° Preferably, the bending direction of the outermost edge of the circular arc fruit picking blade 5 is tangentially coincident with the enveloping circle of the outermost edge of the arc fruit picking blade 5 . Like this, when fruit-picking blade 5 is in contact with branch-shaped seedlings, rhizomes, and fruit stalks, its slapping effect will only cause it to deform, and will not make rhizomes and fruit stalks be cut off. Only then will it produce a more obvious hitting force and "take it off".

[0020] Practice has proved that, after this embodiment is applied to improve the semi-feeding peanut c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com