Harvesting device suitable for spike-stalk distributary harvesting of highland barley

A harvesting device and highland barley technology, applied in applications, harvesters, threshing equipment, etc., can solve the problems of bulky rice and wheat threshing equipment, restrictions on highland barley planting and production, and low efficiency, so as to benefit economic development, increase forage sources, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

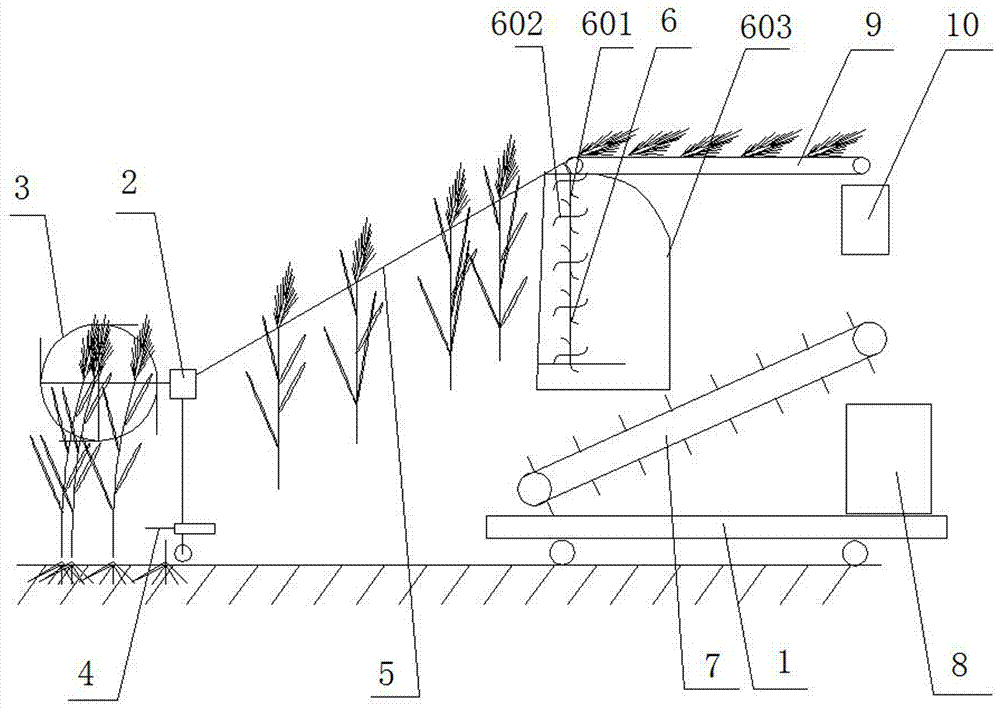

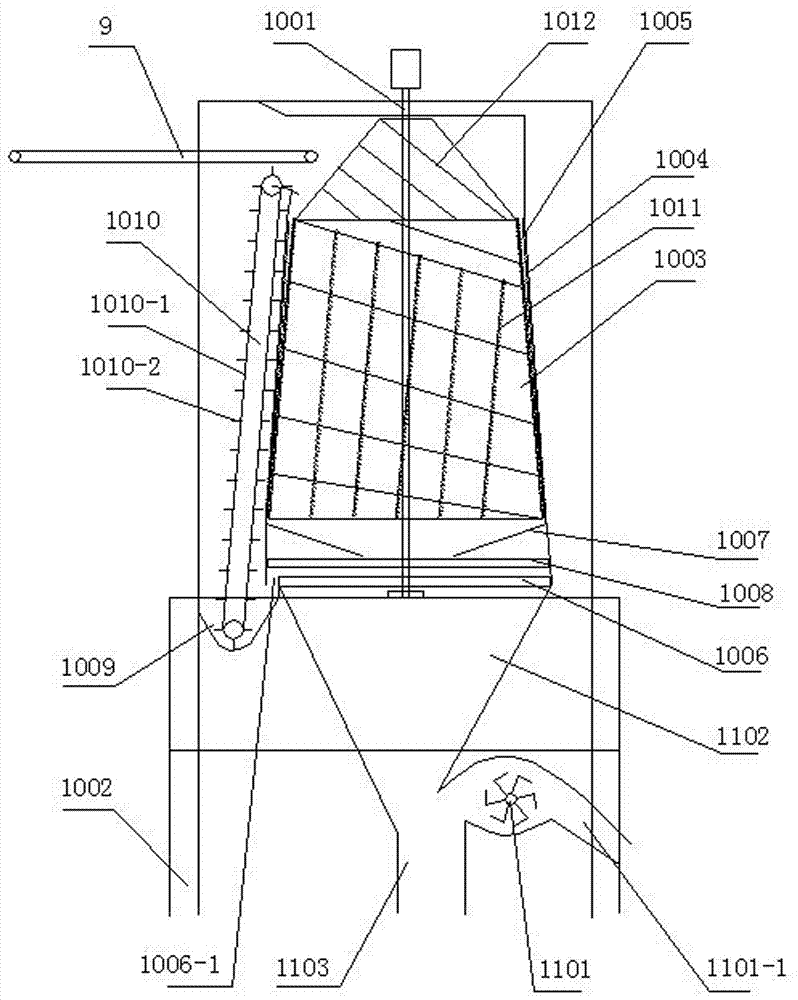

[0023] Such as Figure 1 to Figure 3 As shown, a harvesting device suitable for split harvesting of highland barley ears and stalks of the present invention includes a vehicle frame 1 and a bracket 2 arranged at the front end of the vehicle frame 1 in the direction of travel. The reel 3 that moves in the direction of the frame 1 and the cutter 4 that is used to cut off the stalk from the bottom. The depth gauge wheel for adjusting the height of the bracket 2 is also provided on the bracket 2 .

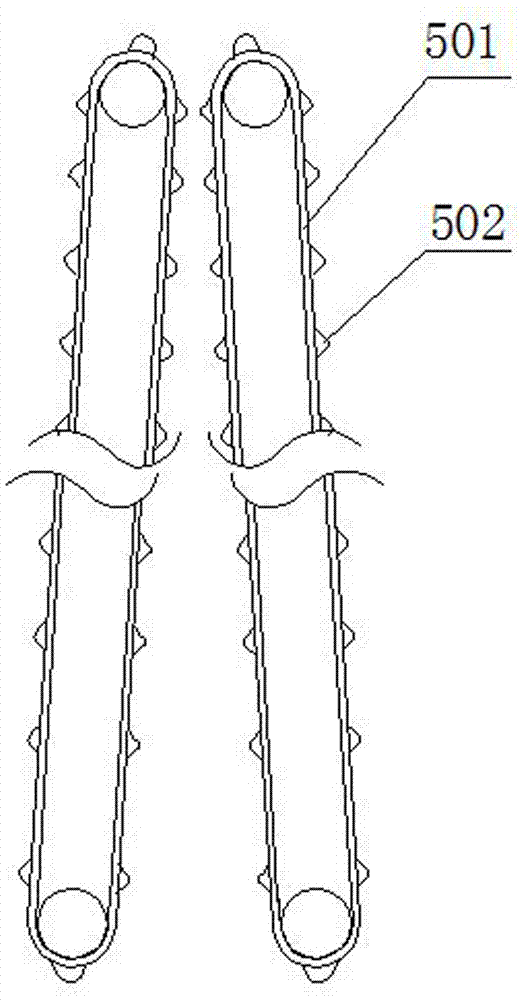

[0024] Between the bracket 2 and the vehicle frame 1, a plurality of chain clamping and conveying mechanisms 5 inclined towards the vehicle frame 1 are arranged side by side. The stalks arranged in rows are conveyed towards the vehicle frame 1 direction. Any one of the chain clamping conveying mechanisms 5 includes two closed loop chains 501 arranged side by side, the gap between the two closed loop chains 501 forms a delivery channel for the stalk, and the outer circumference of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com