Garlic harvester

A technology of harvesting machine and garlic, which is applied in the field of agricultural machinery and tools, and can solve problems such as affecting the quality of harvesting, incomplete harvesting, and inability to produce garlic when the ground is dry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

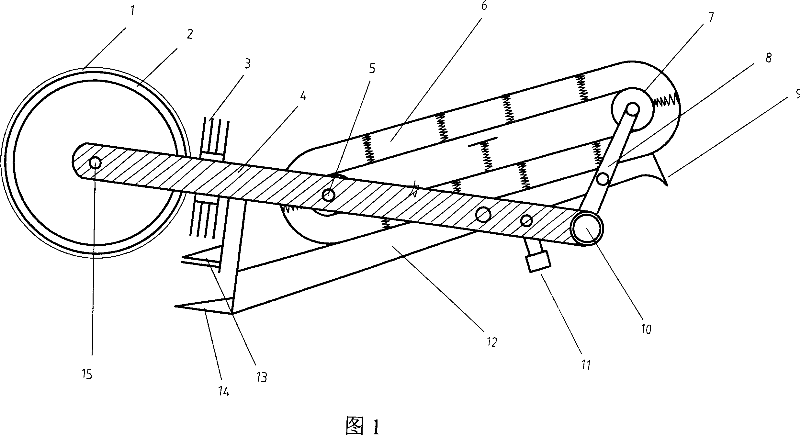

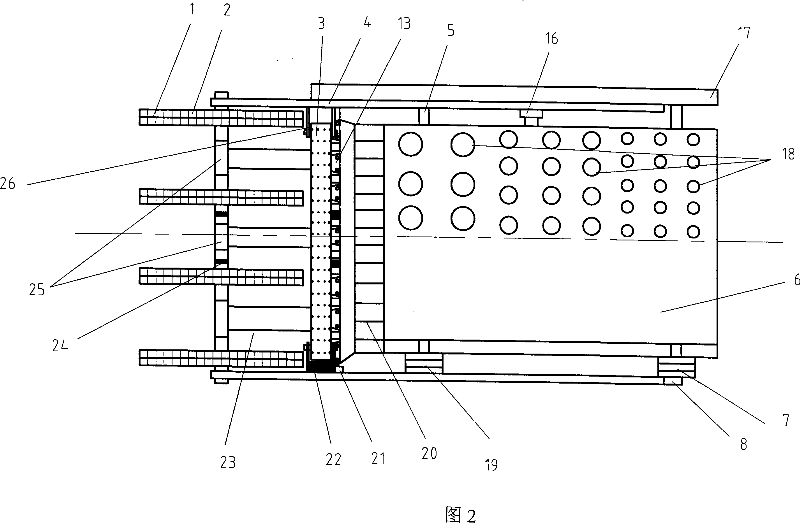

[0010] In Fig. 1, Fig. 2, the present invention is made of advancing wheel (2), telescoping sleeve (25), rotating brush (3), crossbeam (4), connecting shaft 1 (5), cutting root device (6), Drive wheel 1 (7), support (8), garlic outlet (9), connecting shaft 2 (10), hydraulic jack (11), sponge sieve (12), upper blade (13), lower blade (14) , Support shaft (15) is formed. There is a support shaft (15) at the front end of the crossbeam (4), on the support shaft (15) is provided with four advancing wheels (2) that are arranged in equal parts, and the advancing wheel (2) is provided with a blade (1). Telescopic sleeve (25) is installed between four advancing wheels, and operating rod (23) is installed on the telescopic sleeve (25), and upper blade (13) links to each other with operating rod (23). Install a fixed bracket (28) on the beam (4), install a rotary brush (3) on the fixed bracket (28) and drive the rotary brush (3) to work through the transmission steering mechanism (22), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com