Chopping-type sugarcane combined harvester with middle fans

A combine harvester and section-cutting technology, which is applied to harvesters, agricultural machinery and implements, and applications, can solve the problems of low efficiency of waste removal operations, high damage rate of sugarcane heads, and unclean leaf stripping, etc., to reduce the overall High center of gravity, good harvesting quality, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below.

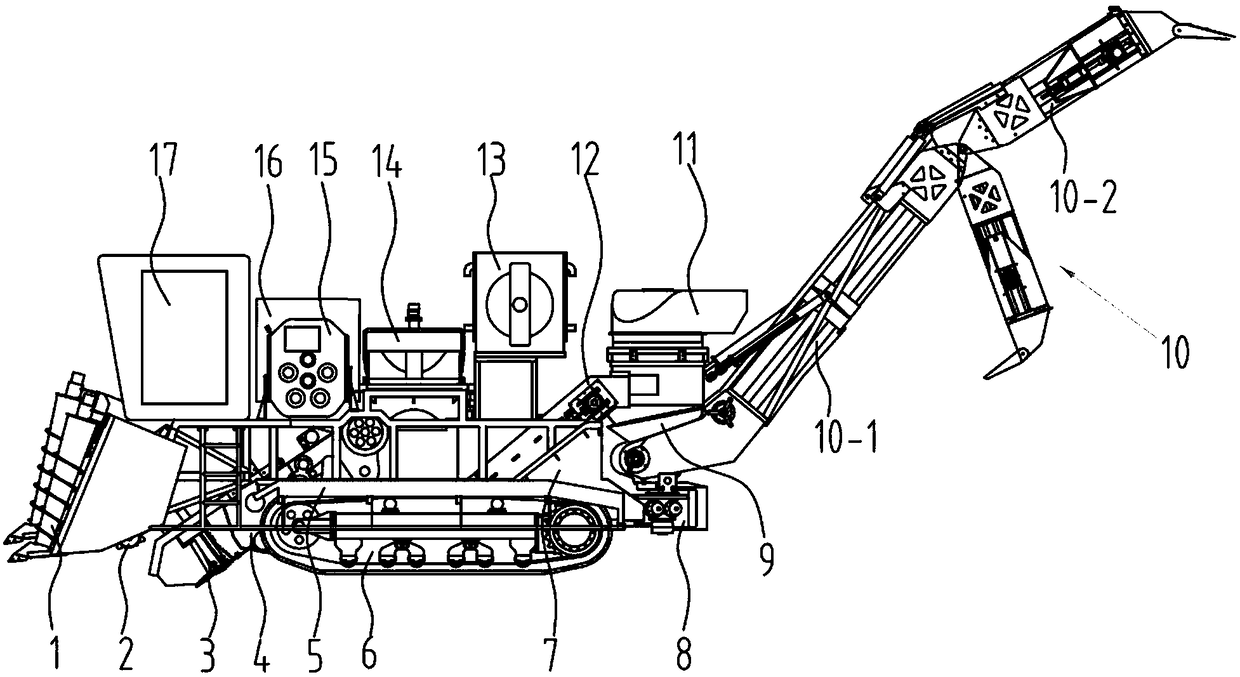

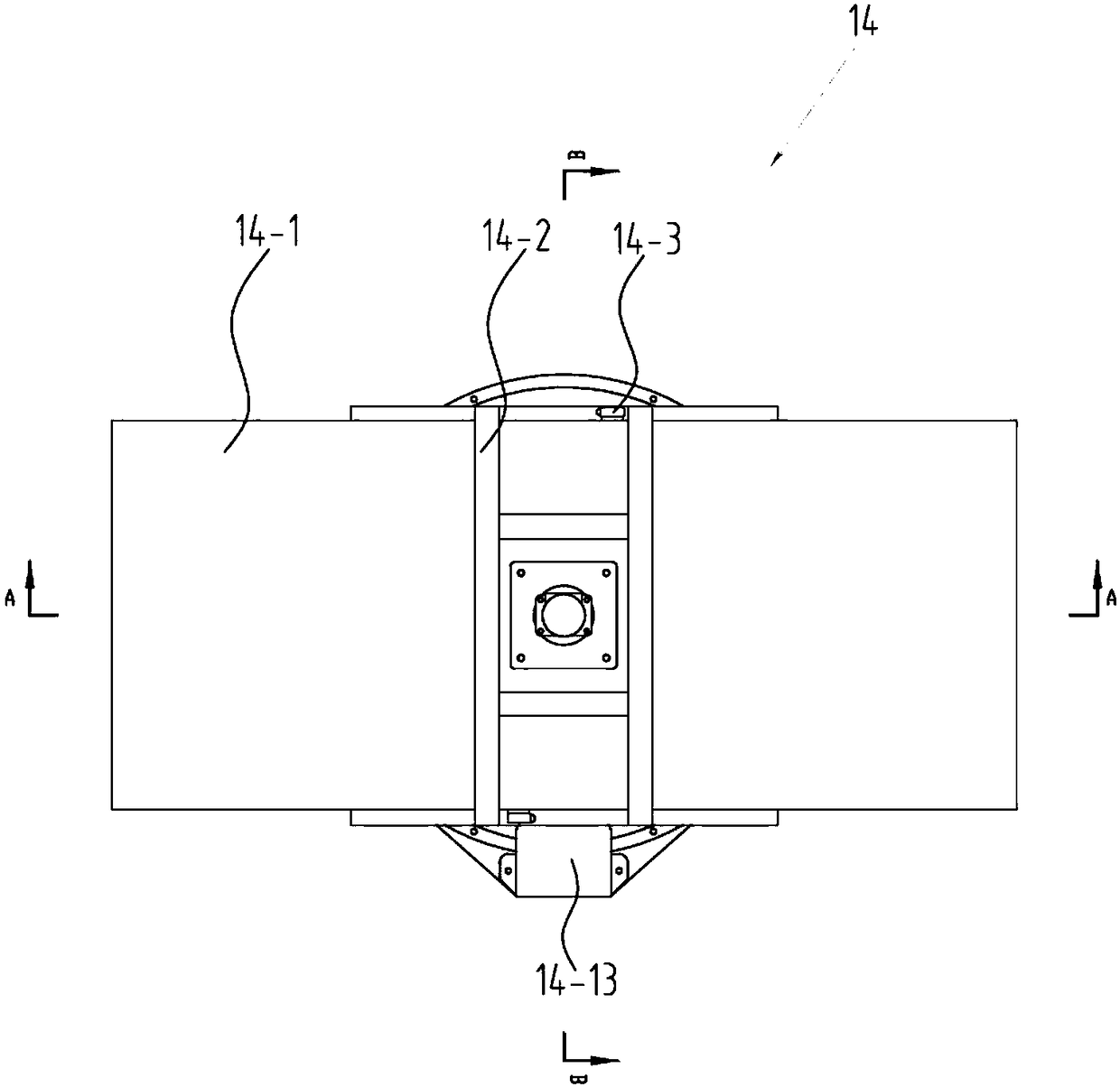

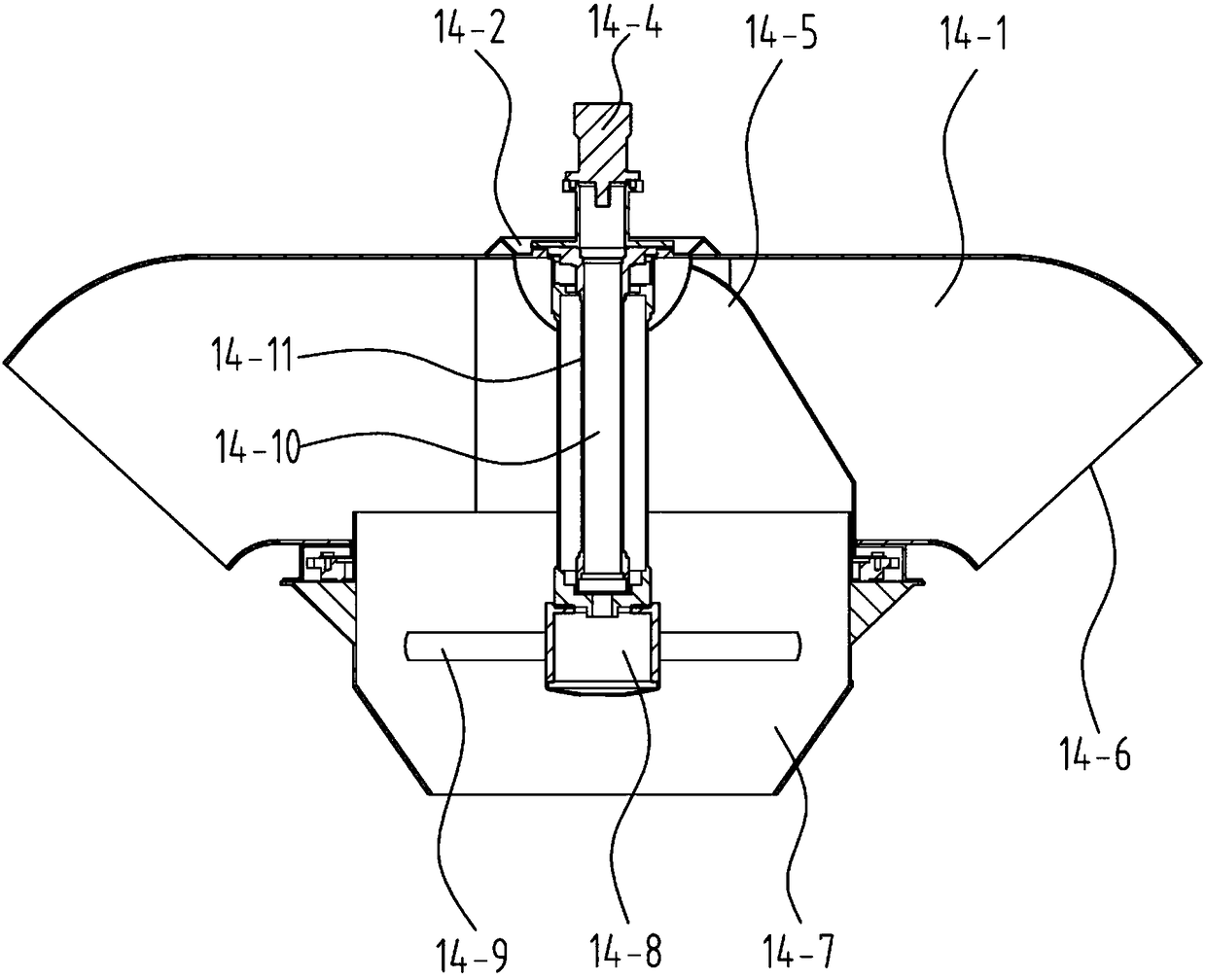

[0032] see figure 1 , a section-cutting sugarcane combine harvester with a fan in the middle, including a spiral divider 1, a push-down roller 2, a header 3, a first-stage conveying channel 4, a central winnowing and miscellaneous removal fan 14, and a second-stage screen type Conveyor channel 12, secondary winnowing submachine 11, conveying arm 10, frame 5, walking device composed of crawler wheels 6, driver's cab 17, fuel tank 7 and supporting power system.

[0033]The driver's cab 17 is installed on the frame 5. A spiral distributor 1 is arranged on the front and lower side of the driver's cab 17. A push-down roller 2 is installed under the spiral distributor 1. A header 3 is arranged below the push-down roller 2. The platform 3 is connected with a primary conveying channel 4 for feeding, conveying and sectioning. The primary conveying channel 4 contains a pair of feeding rollers, a pair of conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com