System and method for mechanical waking control based on ground profiling

A walking control and harvester technology, applied in the general control system, control/regulation system, computer control, etc., can solve the problems of inability to acquire and analyze header height data, poor control accuracy and real-time performance, and solve serious cutting losses , improve the ability of profiling, and solve the effect of high head breaking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The walking control system and method based on ground profiling machinery provided by the present invention improve the ground profiling of harvesting machinery and the height control of the harvesting chassis. Ultrasonic sensors are used to measure the distance between the header and the ground, and then the hydraulic system is controlled by a single-chip microcomputer. Control the rise and fall of the header so that the header can reach the optimal distance from the ground.

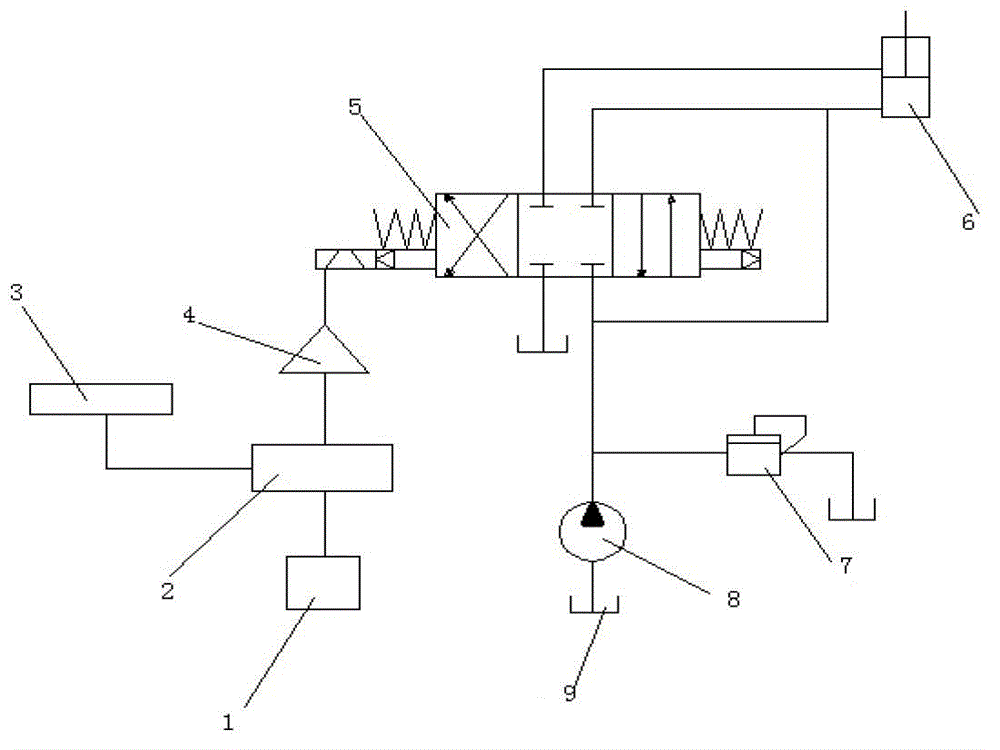

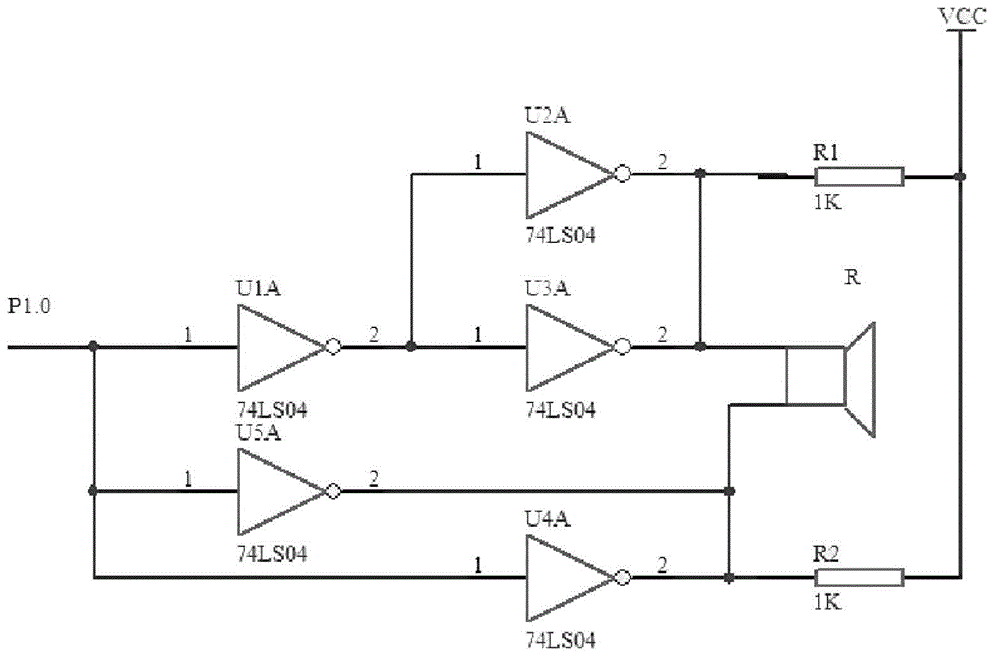

[0036] Use (1) ultrasonic sensor to monitor the height of the harvesting chassis of the harvesting machine, and send the signal to (2) AT89S52 single-chip microcomputer, and display the height value on the LDC1602 display at the same time, the single-chip microcomputer analyzes and processes the signal according to the built-in PID algorithm, and then The reflected signal is transmitted to the three-position four-way solenoid valve through the D / A converter and (4) proportional amplifier, and the ...

Embodiment 2

[0039] The invention provides a walking control system for sugarcane harvesting machinery based on ground profiling, the system includes: ultrasonic sensors, single-chip microcomputers, displays, proportional amplifiers, three-position four-way solenoid valves, hydraulic cylinders and other hydraulic accessories (7, 8, 9 ).

[0040] The ultrasonic sensor is a UNAM 50 ultrasonic sensor produced by Shanghai Pengcheng Electronics Co., Ltd., with a sensing range of 400-2500 mm, and a cylindrical shell with brass nickel plating. And make it into a kind of detection head and place it at a certain position above the harvesting chassis, and make it able to monitor the height to the ground.

[0041] Described single-chip microcomputer is the AT89S52 type that Atmel Company produces, and this single-chip microcomputer is a kind of low power consumption, high-performance, adopts the 8-bit single-chip microcomputer that CMOS technology makes, and is fully compatible with the instruction s...

Embodiment 3

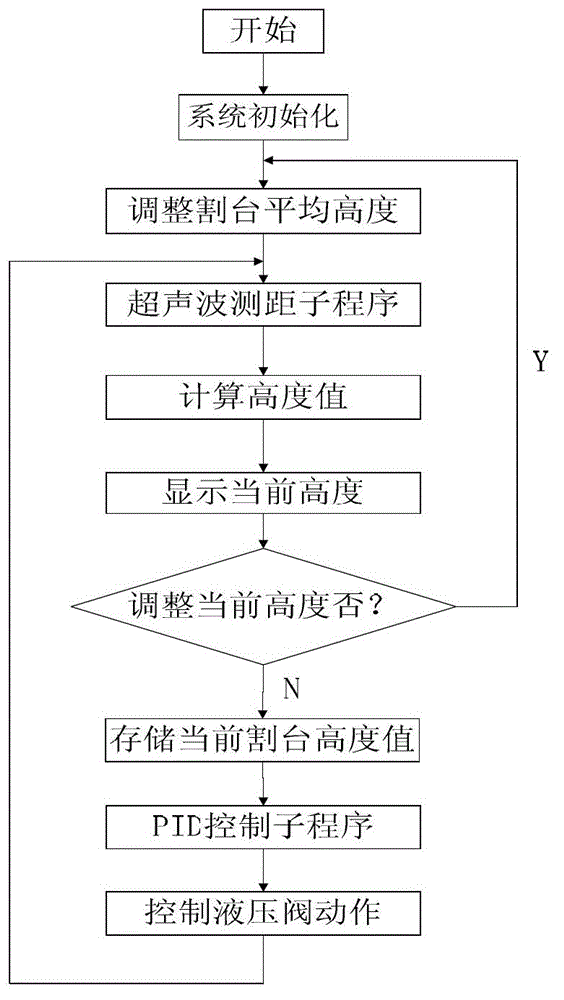

[0047] In addition to the same content as Embodiment 2, the system also includes software features. The software programming of the system is mainly based on C language and assembly language through Keil uVision2 software, and the program is burned into the single-chip microcomputer through the burning software. The program algorithm mainly includes: ultrasonic ranging algorithm, LCD display algorithm and PID algorithm. When the ultrasonic sensor transmits the signal, the single-chip microcomputer can respond to the signal. On the one hand, it sends a response signal to the solenoid valve according to the built-in PID algorithm, and on the other hand, it displays the signal of the sensor on the LCD.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com