Patents

Literature

32results about How to "Strong profiling ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

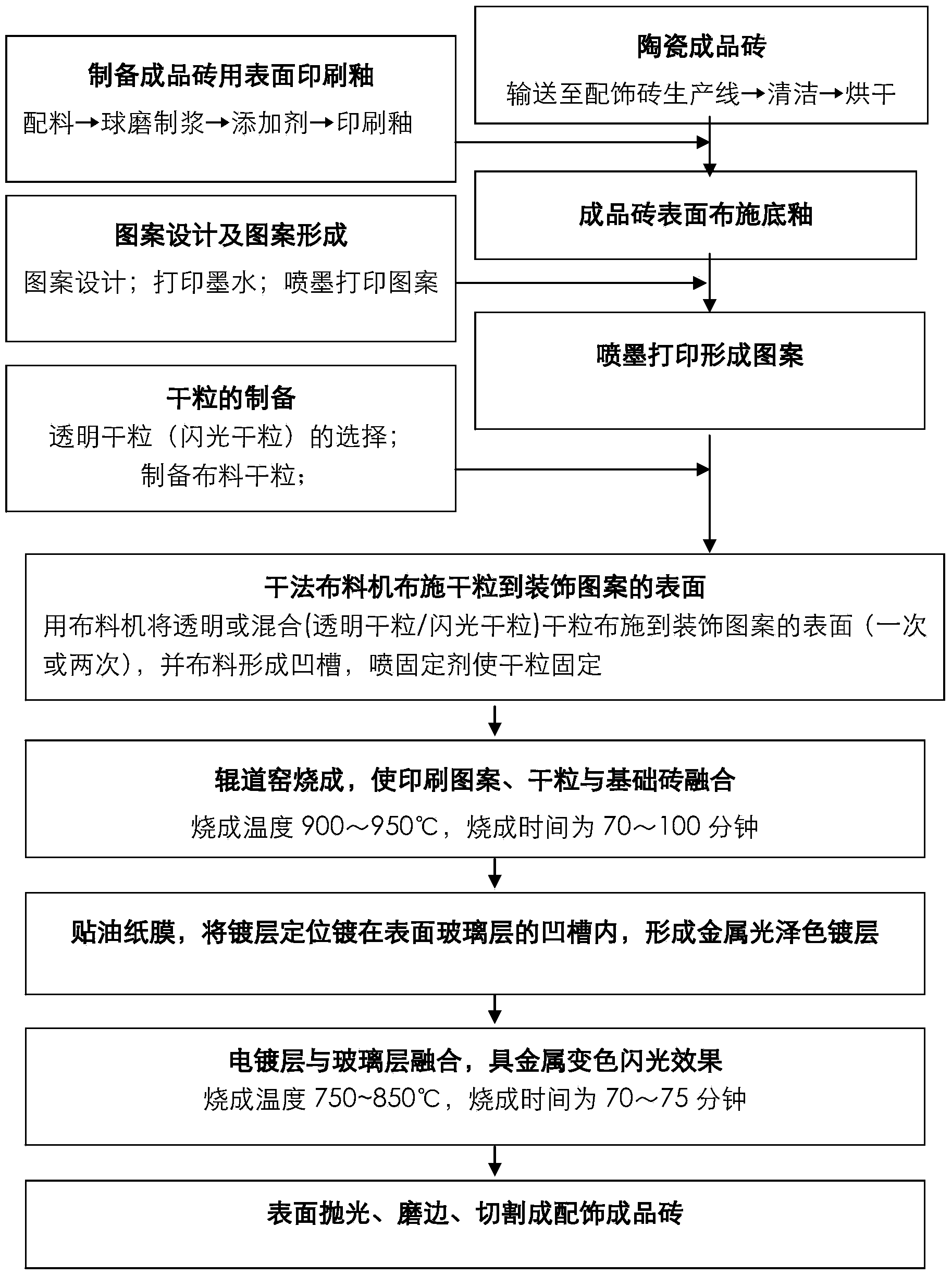

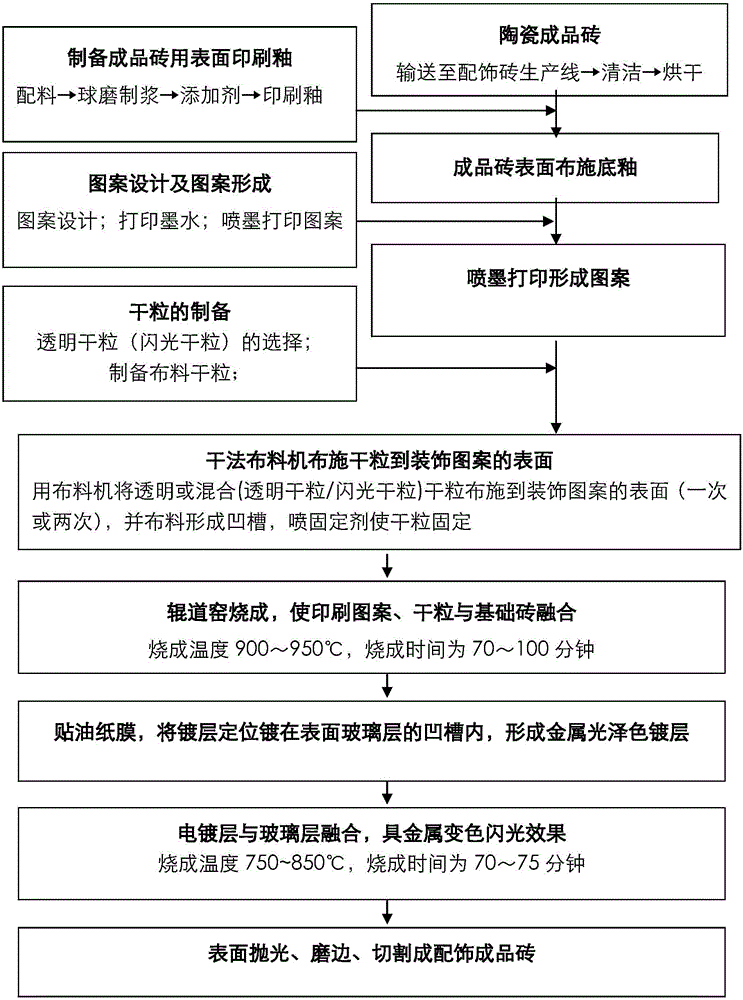

Manufacturing process of ceramic accessory tile and ceramic accessory tile manufactured by the process

The invention relates to a manufacturing process of a ceramic accessory tile and the ceramic accessory tile. The manufacturing process comprises the steps of: (1) printing a ground coat on the surface glass layer of sintered ceramic tile; (2) conducting ink-jet printing on the printing ground coat to form patterns; (3) applying transparent dry grains on the surface of the pattern layer for two times, and sintering; (4) electroplating metal color on a groove of the surface glass layer by adopting a lamination positioning electroplating method, and sintering; (5) polishing the surface of the sintered product; and (6) cutting the sintered accessory tile blank to prepare the accessory tile. The ceramic accessory tile comprises a base tile, ground coat applied on the surface of the base tile, the pattern layer attached on the ground coat, and the first dry grain layer and the second dry grain layer applied on the pattern layer. Irregular pits, grooves or concave curves, wherein the irregular pits, the grooves or the concave curves are hollowed towards the inside and are arranged on the layer surface of the second dry grain distribution layer. The accessory tile varieties include ground flowers, ground line, waist line and corner, and is used for supporting the ceramic wall and floor tiles.

Owner:JIANGXI HEMEI CERAMICS

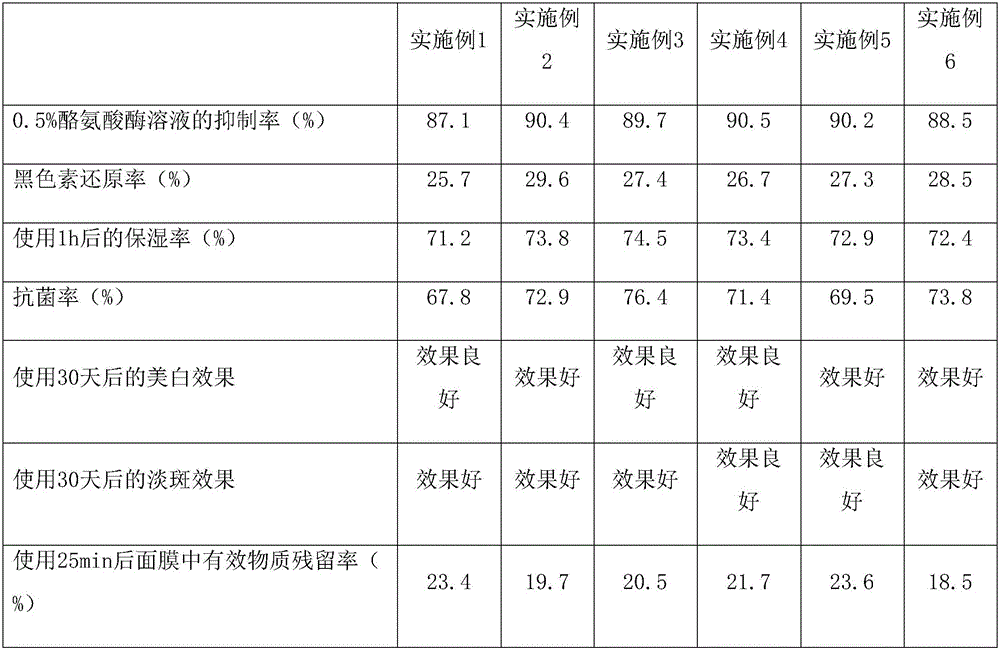

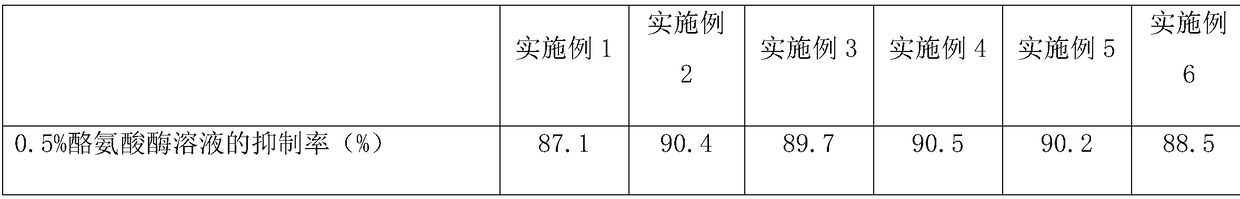

Apple facial mask based on traditional Chinese medicine formula

ActiveCN105769652AImprove antioxidant capacityStop chain reactionCosmetic preparationsToilet preparationsBetaineTremella

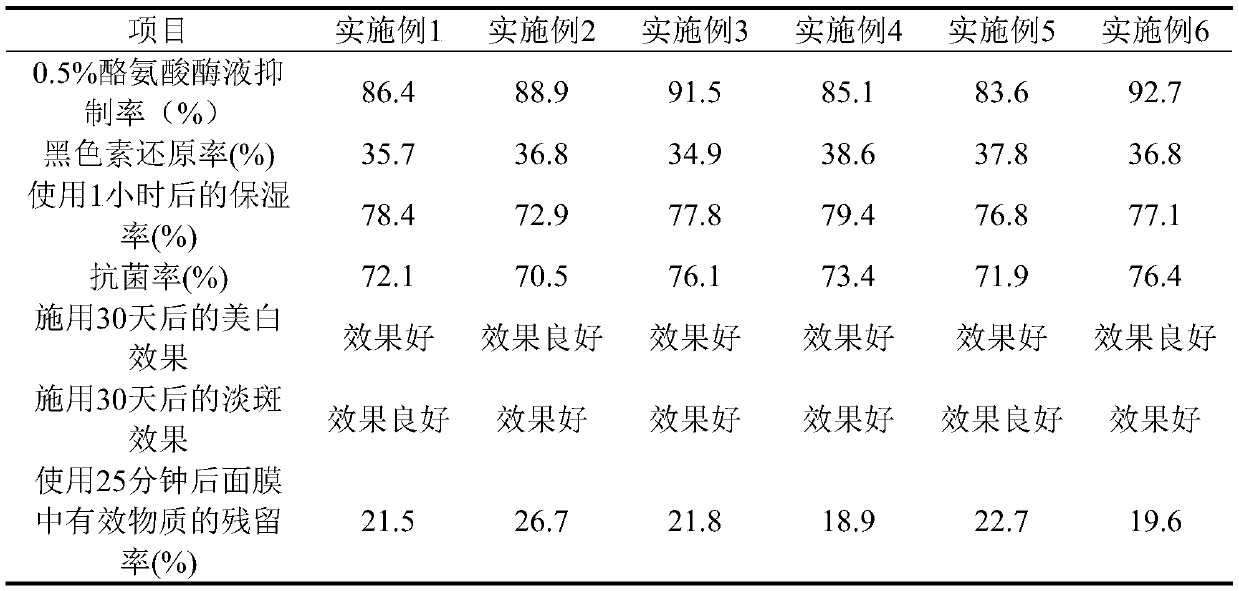

The invention provides an apple facial mask based on a traditional Chinese medicine formula.The apple mask comprises a silk matrix and a water-soluble substance.The water-soluble substance comprises apple extract, traditional Chinese medicine extract, seaweed extract, sodium hyaluronate, beta-glucan and assistant.The traditional Chinese medicine extract comprises tremella extract, centella asiatica extract, polygonum cuspidatum root extract, scutellaria root extract, tea extract, glycyrrhiza glabra root extract, chamomilla recutita flower extract, rosmarinus officinalis leaf extract and purslane herb extract.The seaweed extract contains chondrus crispus and bio-saccharide gum-1.The assistant comprises butanediol, propylene glycol, diglycerol, polyethylene glycol-400, Carbomer, hydroxyethyl cellulose, urea, allantoin, glycine betaine, nicotinamide, sodium glutamate, triethanolamine, 1,2-hexanediol, decoyl hydroximic acid, 1,3-propylene glycol, hexanediol and deionized water.The apple mask has the effects that stability is good, dispersibility is high, nutrients are proper in quantity and balanced, antibiosis and anticorrosion effects are achieved, and moisturizing, skin whitening and stain lightening are achieved.

Owner:珠海市雅莎医疗器械有限公司

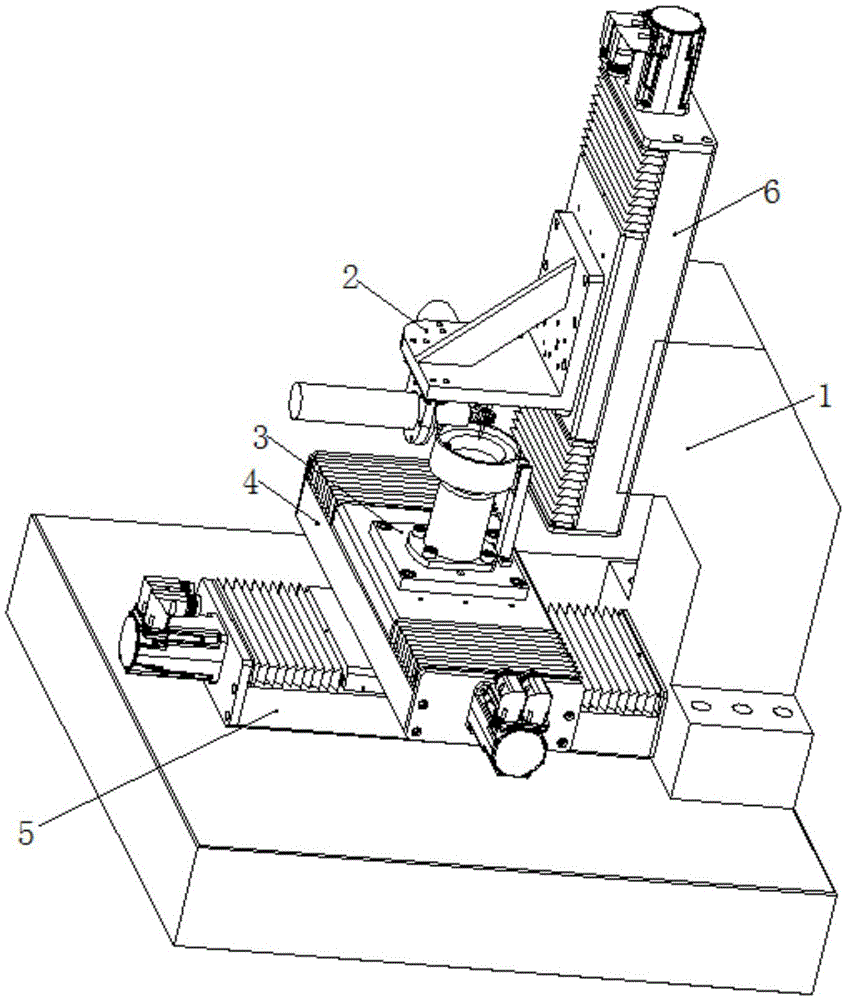

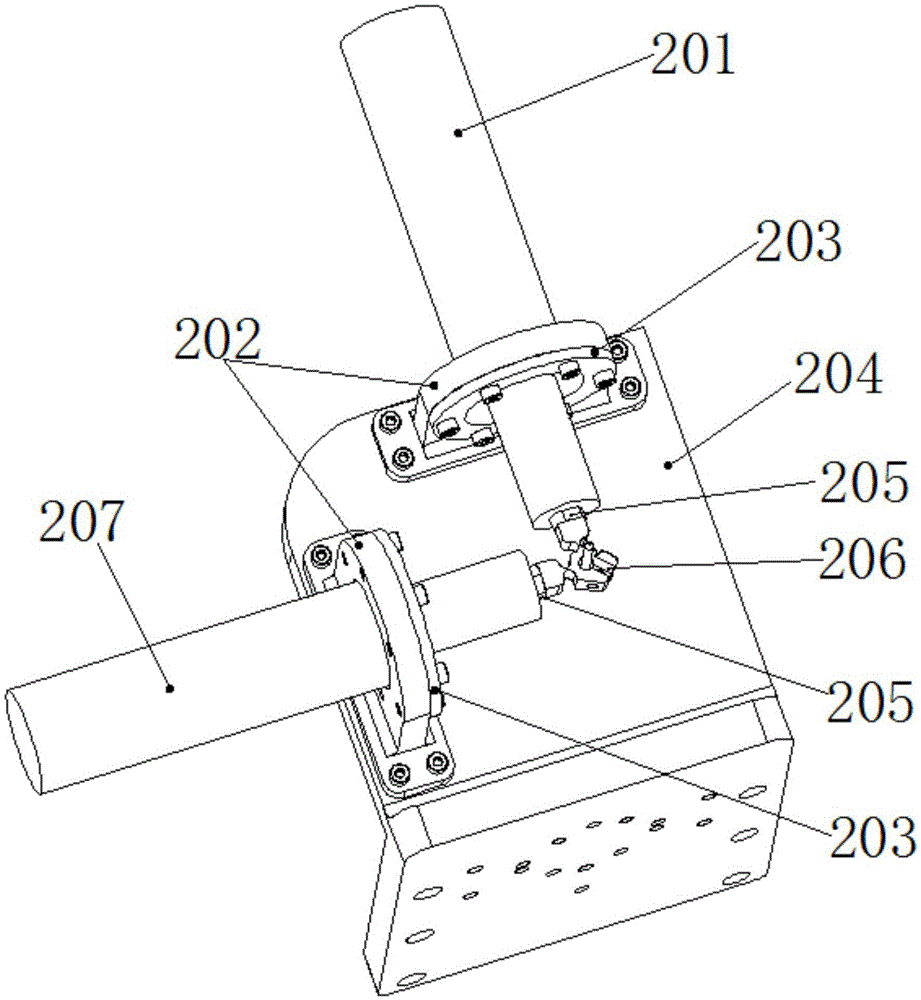

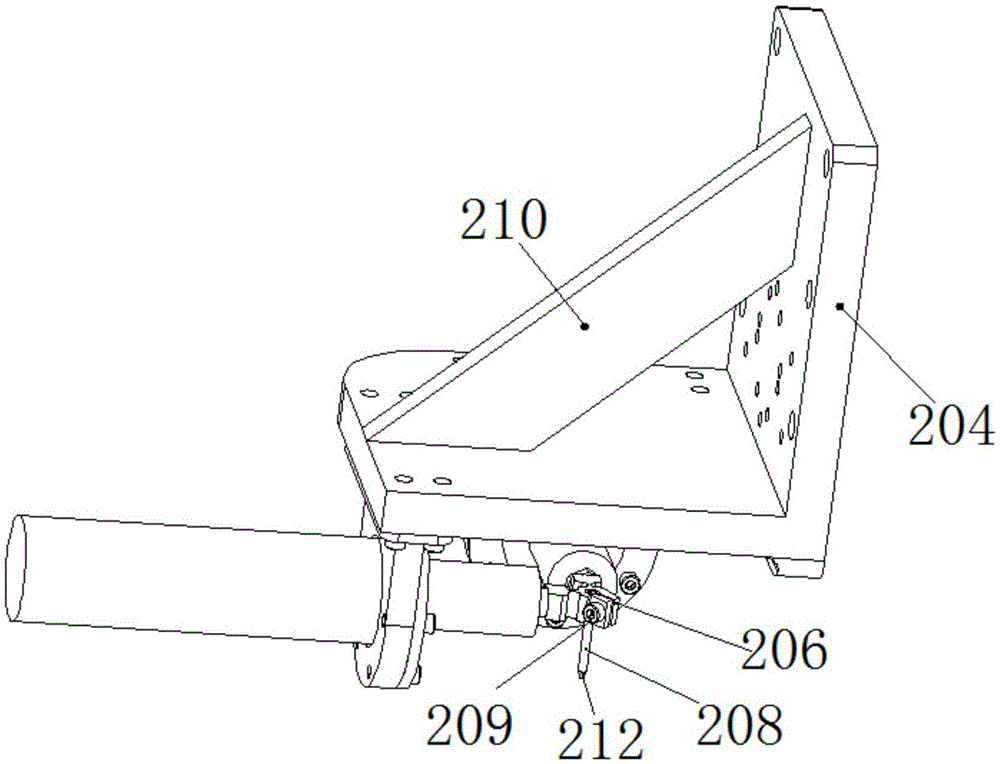

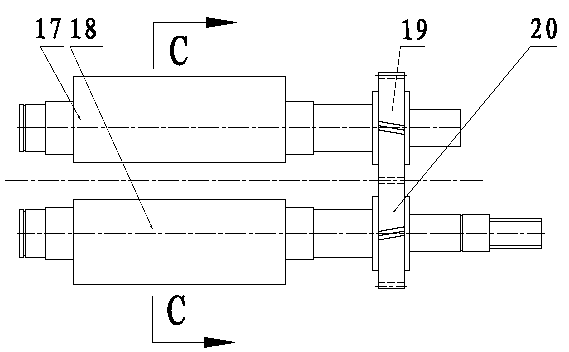

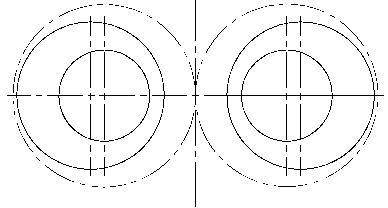

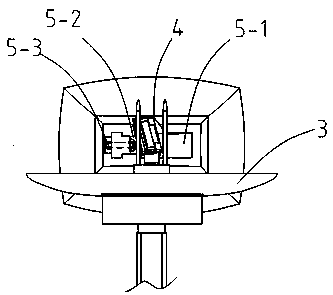

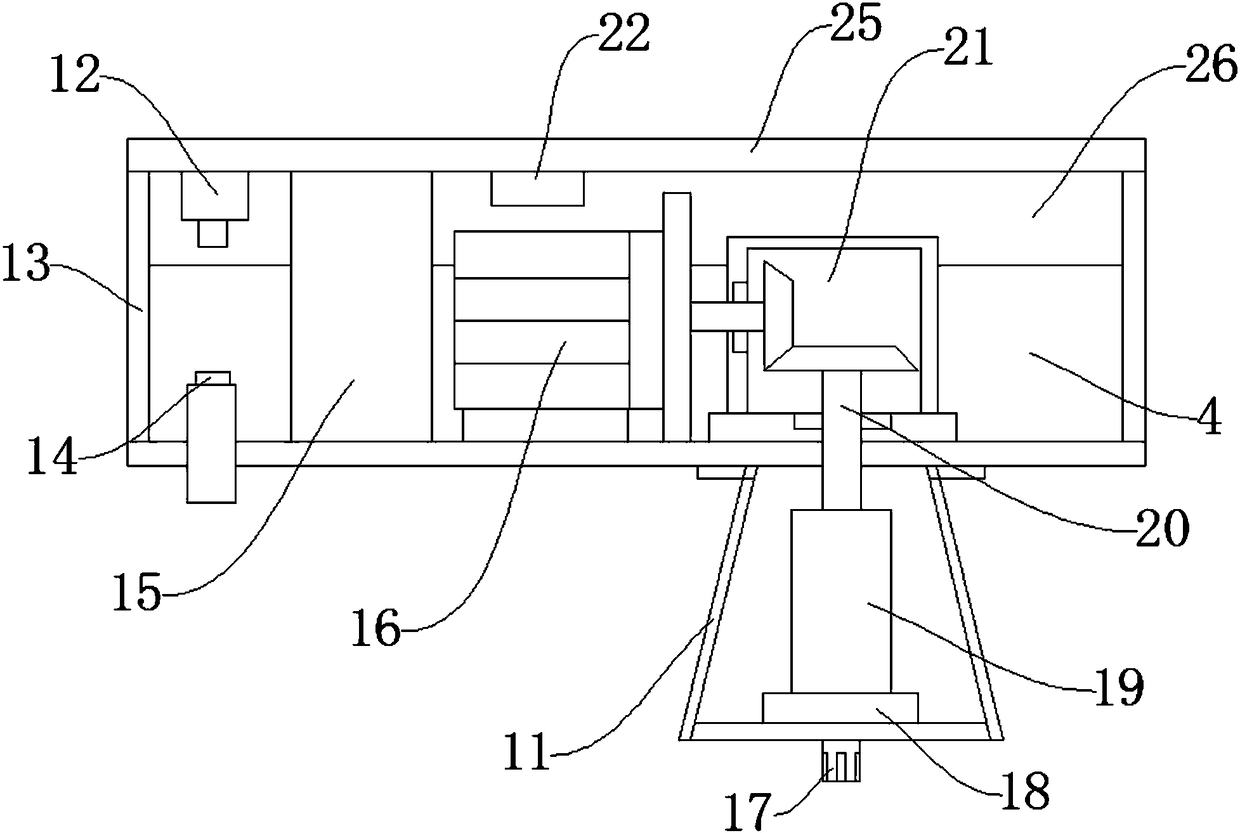

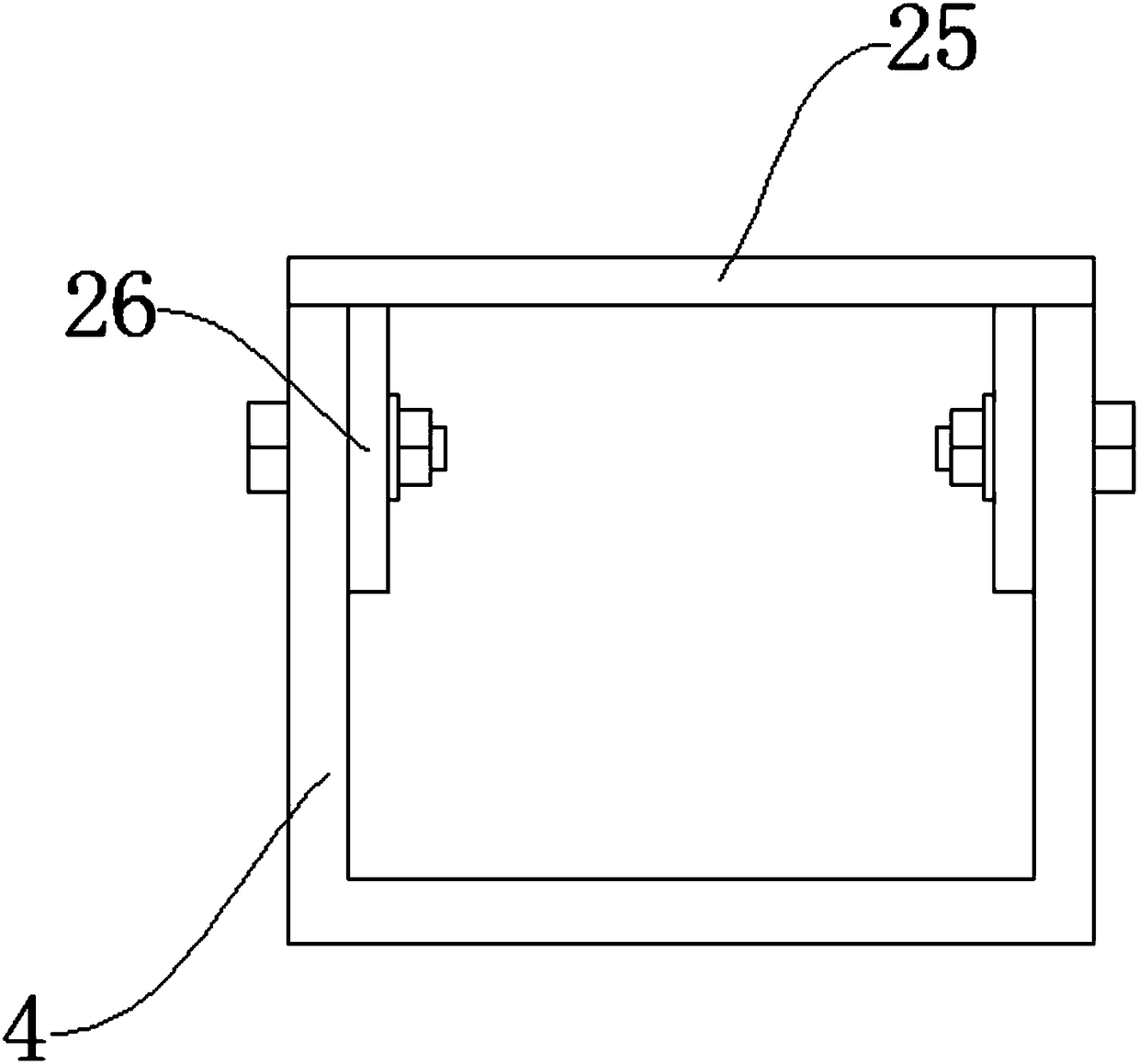

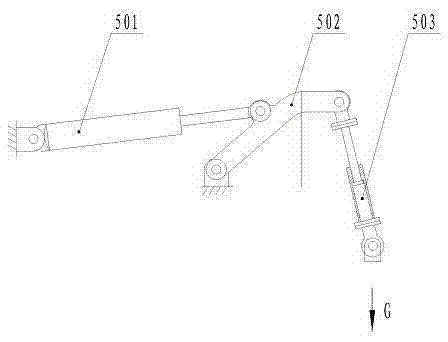

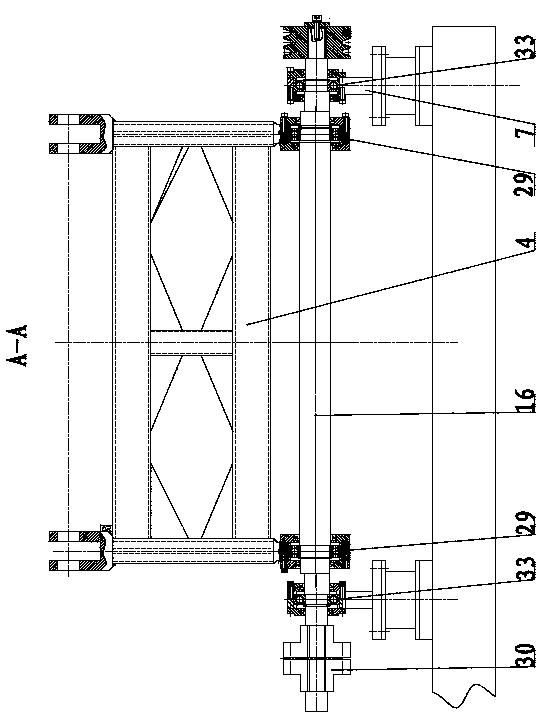

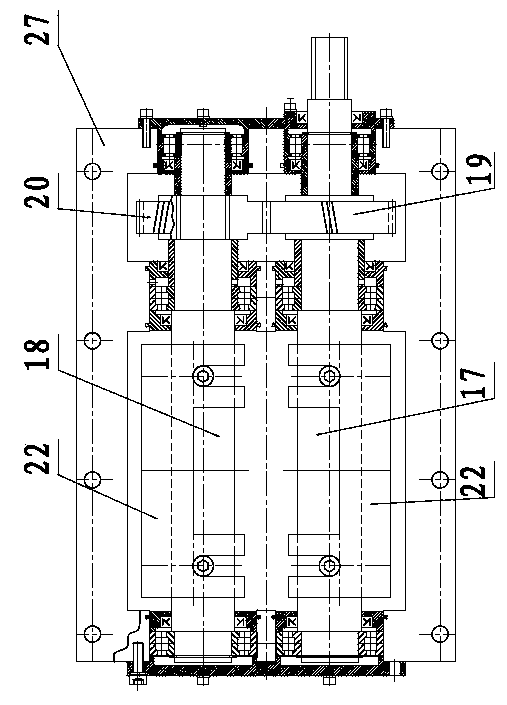

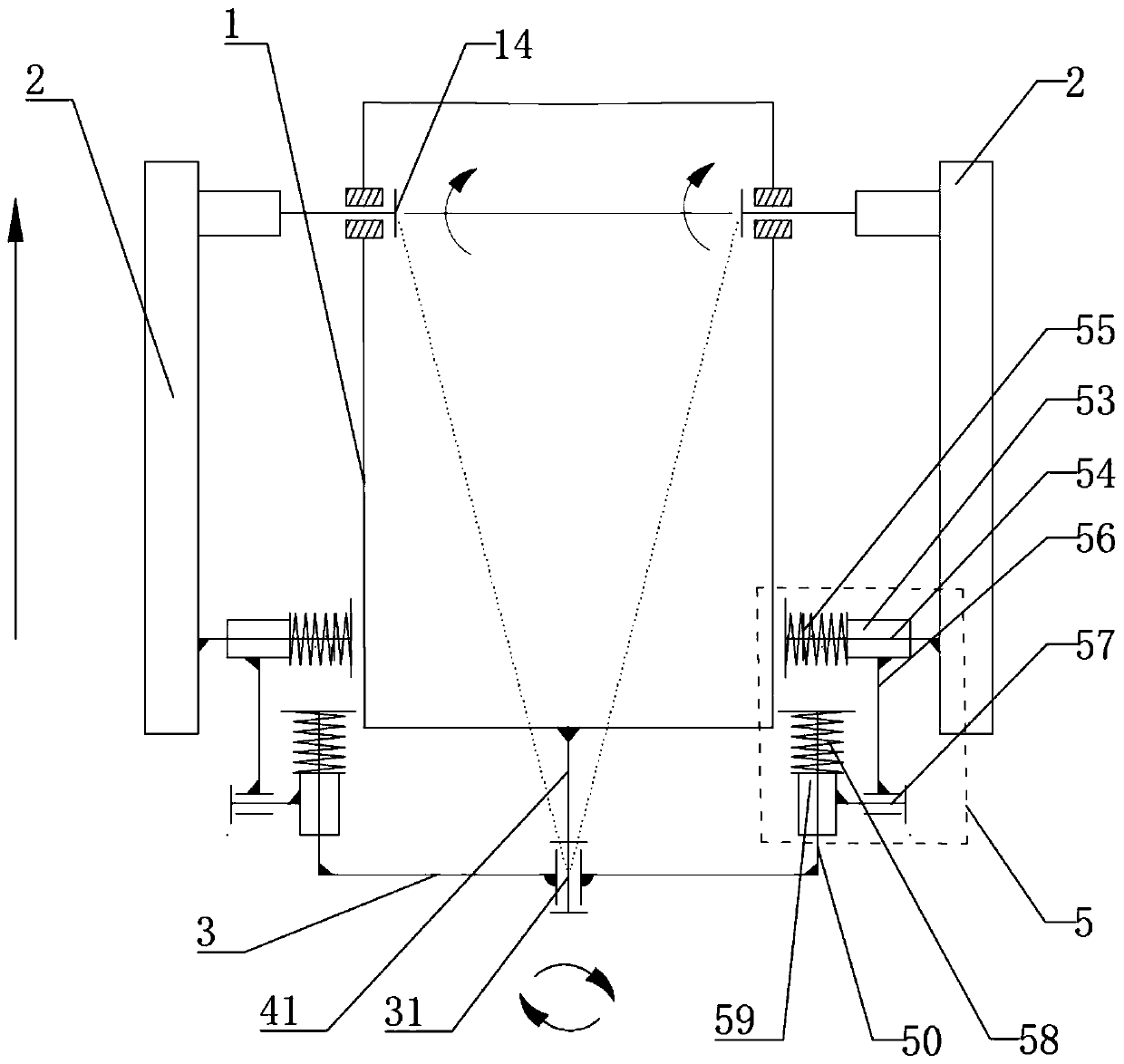

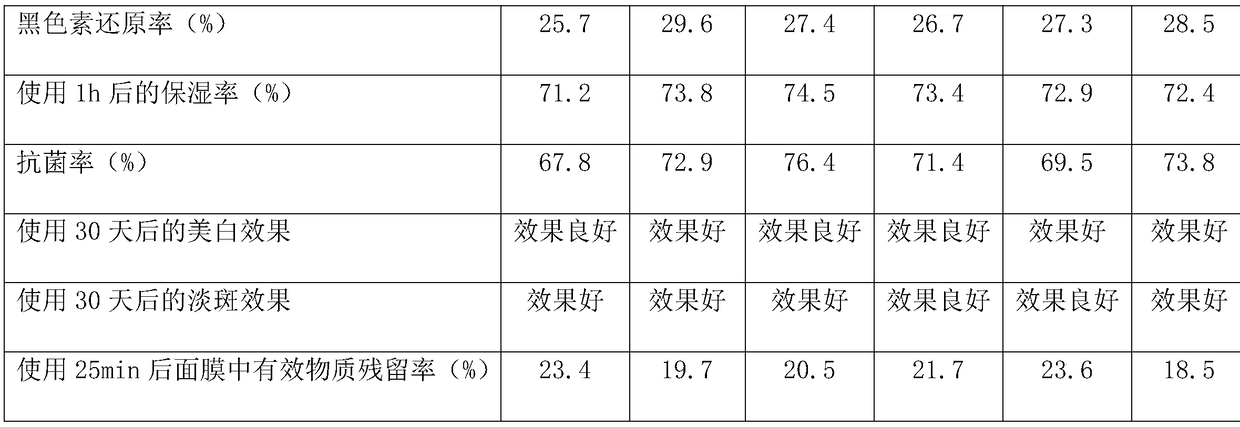

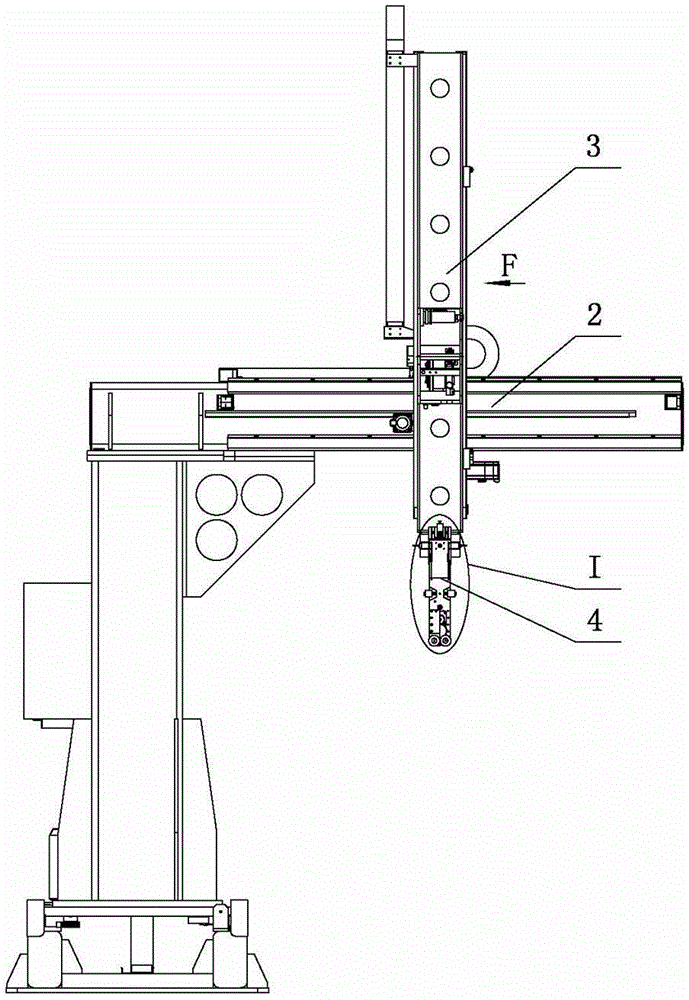

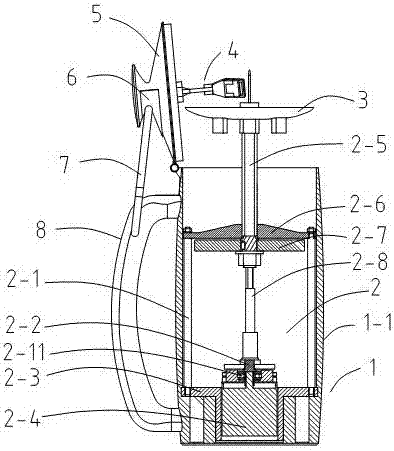

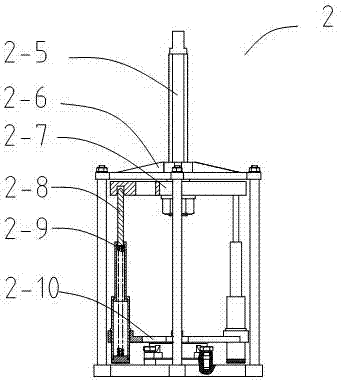

Two-dimensional ultrasonic vibration polishing device and method

InactiveCN105619187AIdeal Instantaneous Random Motion TrajectoryStrong profiling abilityVibratory signalEngineering

The invention relates to a two-dimensional ultrasonic vibration polishing device and a two-dimensional ultrasonic vibration polishing method, and belongs to the technical field of machine manufacturing. A two-dimensional ultrasonic vibration polishing tool is fastened to the z-axis of a machine tool by screws; a workpiece fixture is fastened to the x-axis of the machine tool by the screws; and the x-axis, the y-axis and the z-axis of the machine tool are fixedly connected with a machine tool main body after debugging. The two-dimensional ultrasonic vibration polishing device provides elliptical vibration in a polishing tangent plane, vibration signals of an x-direction ultrasonic vibrator and a y-direction ultrasonic vibrator are coupled to form two-dimensional vibration at a pivoting joint, and are output to a polishing head, the polishing head acquires a perfect instantaneous random motion track in a processing area, and motion composited by the vibration is polishing primary motion, so that a polishing force can be controlled to be stable on the premise that no polishing head rotates; the polishing head has high profile modeling capability, so that various complicated curved surfaces can be processed; deterministic polishing is realized; stable and uniform removal of a polishing material is realized; and high-efficiency and high-quality polishing can be realized simply by controlling the polishing force.

Owner:JILIN UNIV

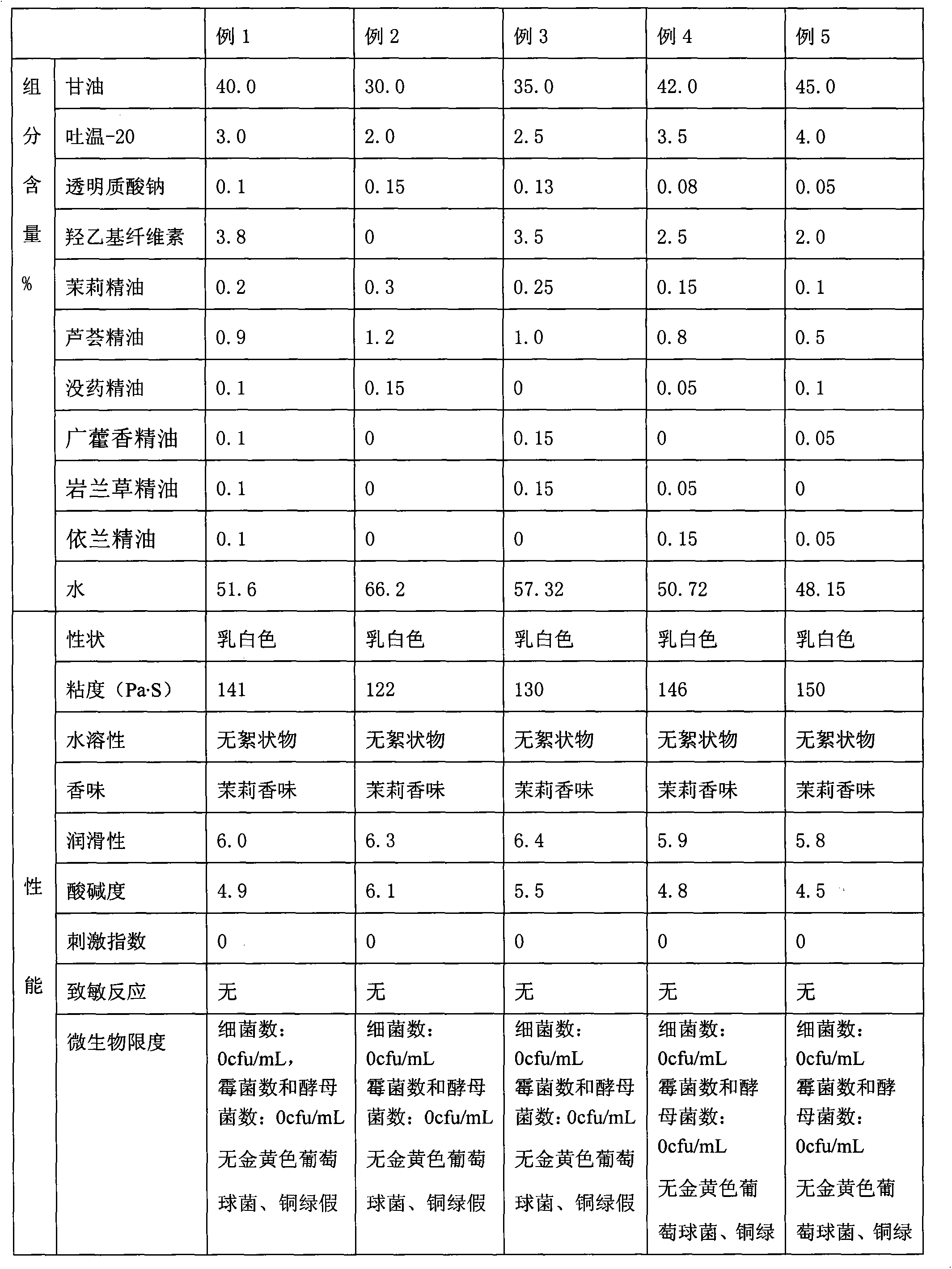

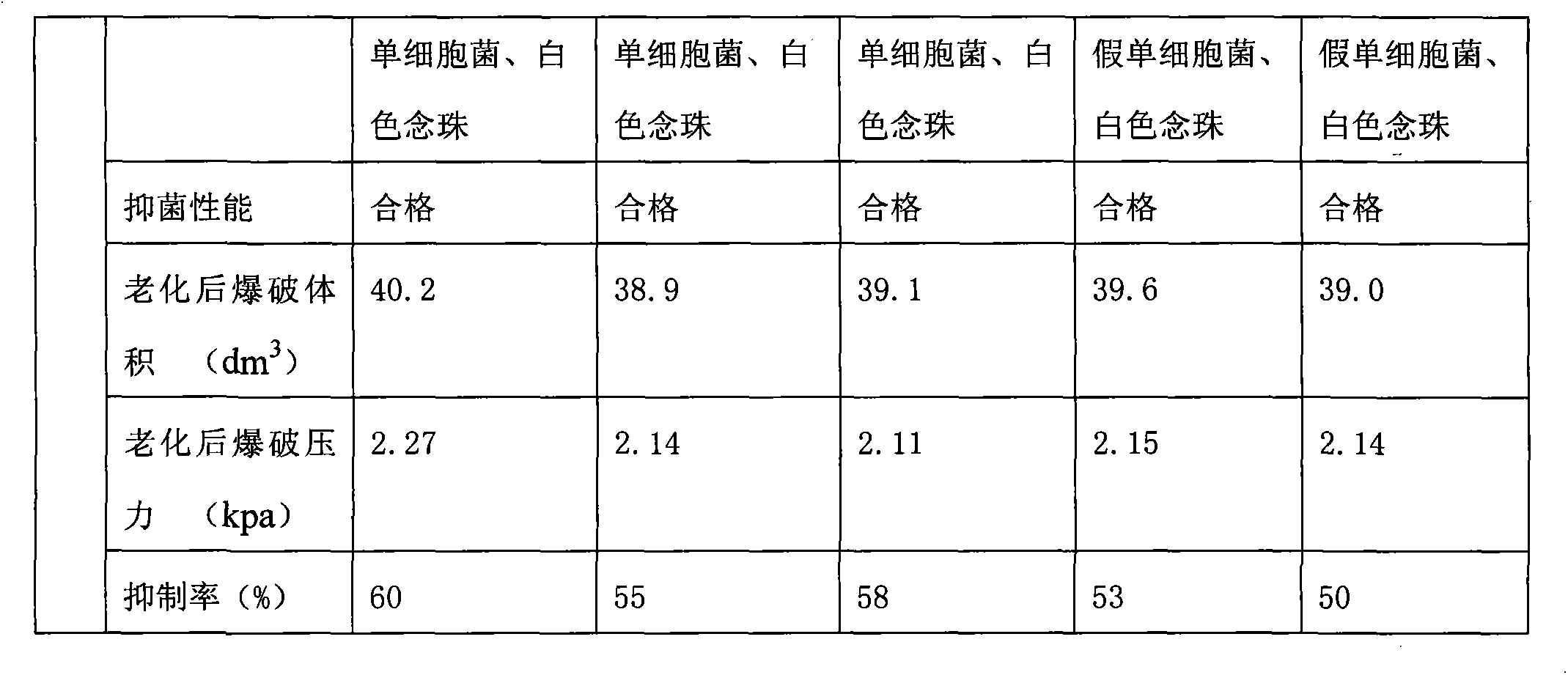

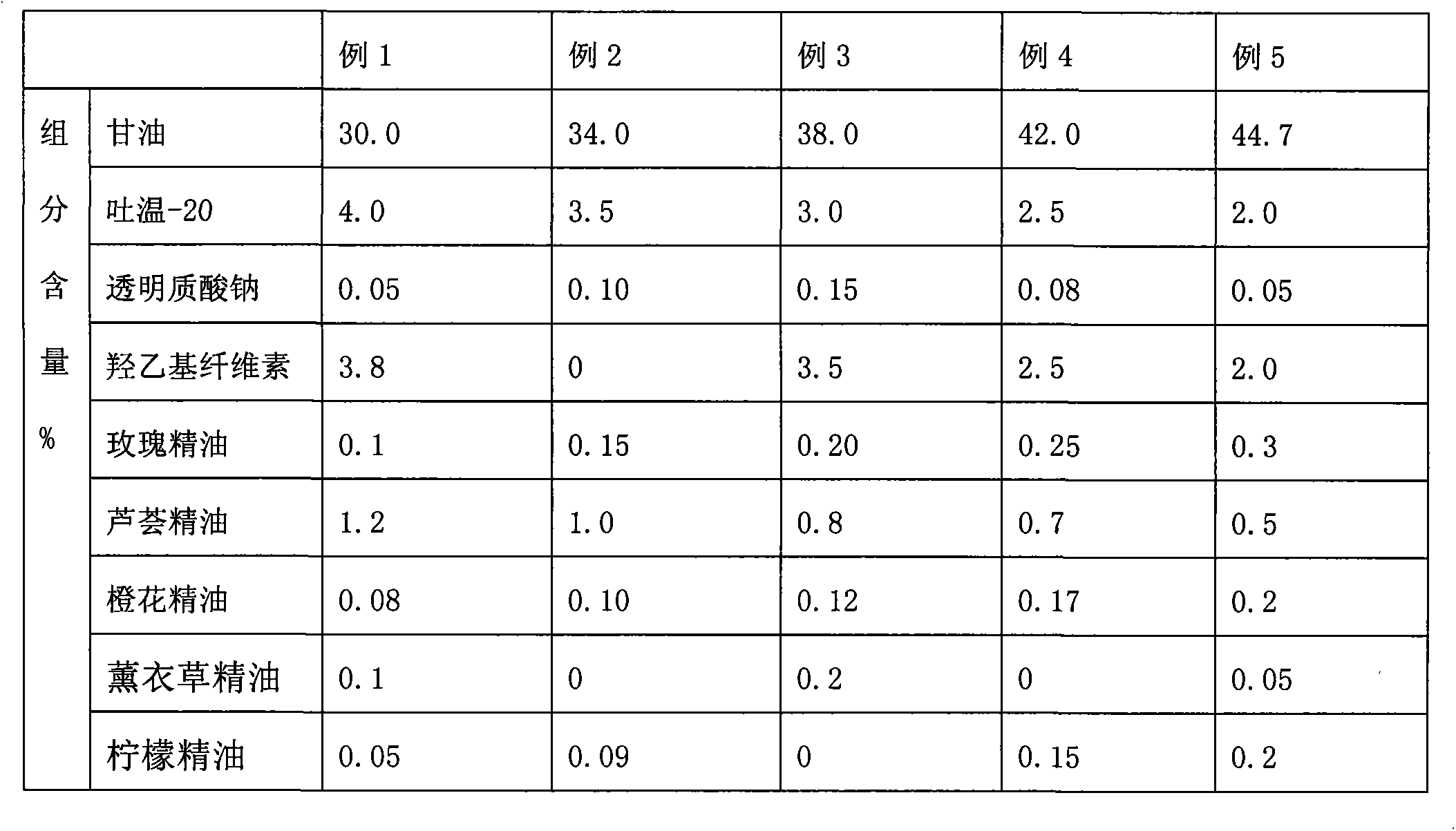

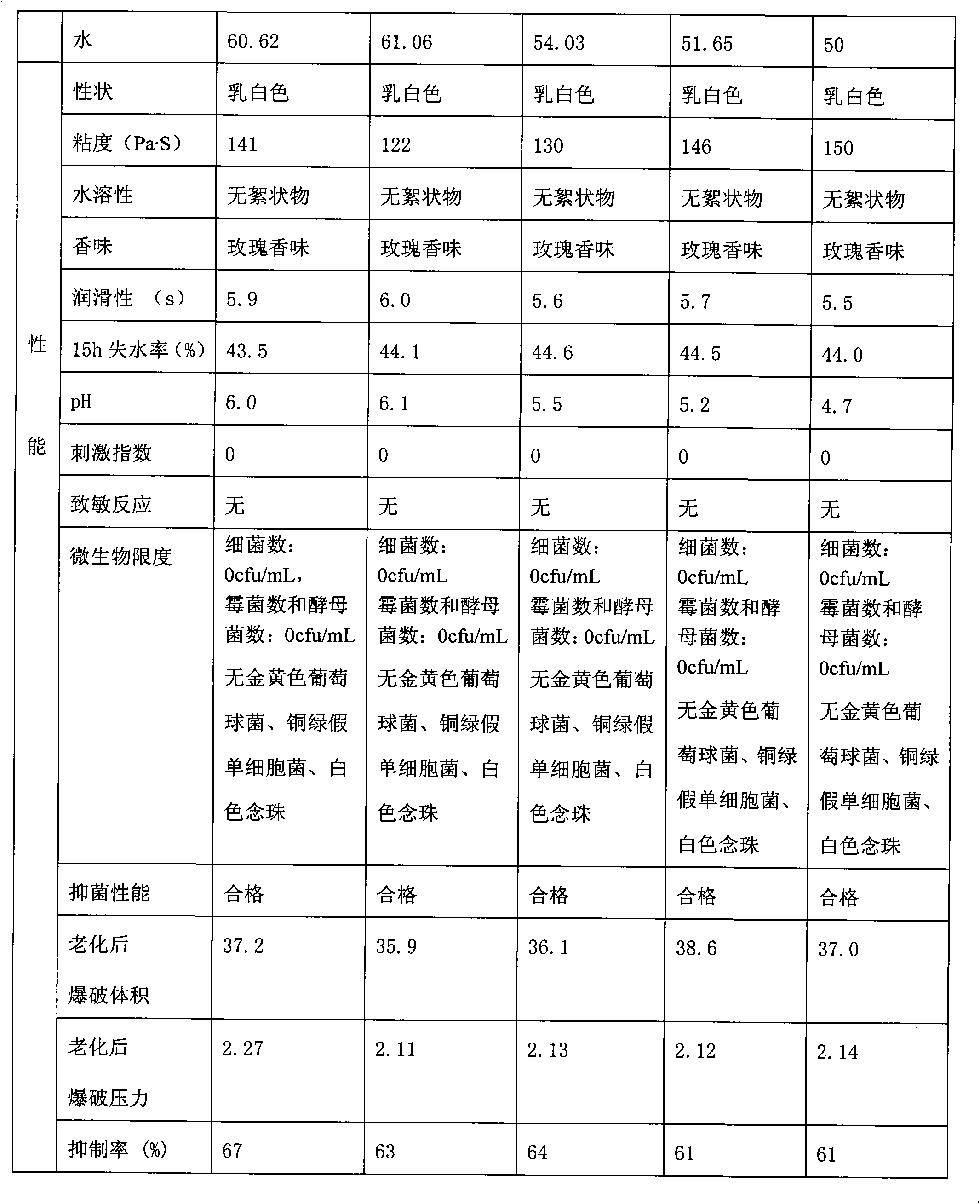

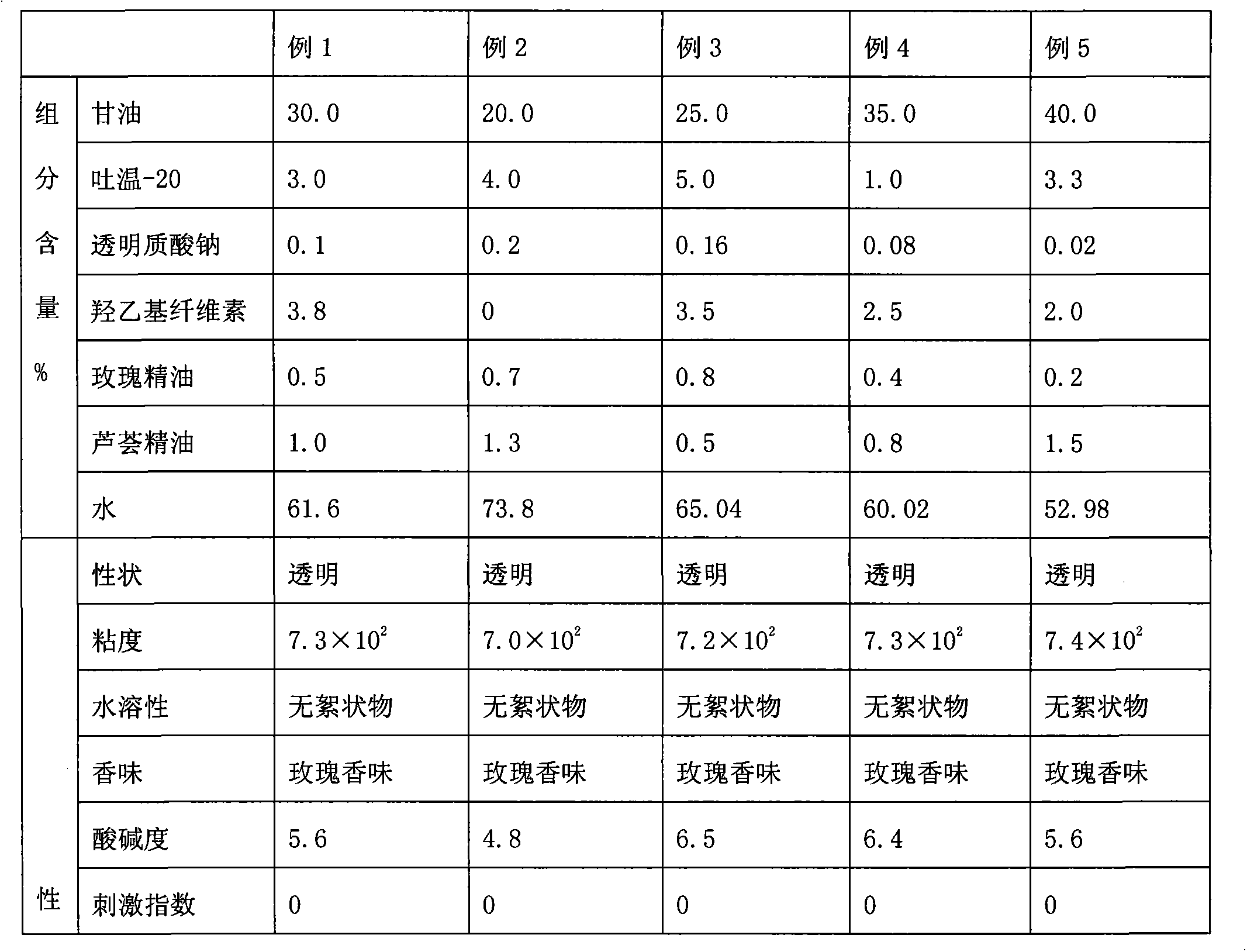

Compact-type water-soluble human lubricant, preparation method of lubricant and condom

InactiveCN103405610ANo greasy feelingEasy to cleanOrganic active ingredientsSurgeryGlycerolVaginal tissue

The invention discloses a compact-type water-soluble human lubricant, a preparation method of the lubricant, and a condom using the lubricant. The compact-type water-soluble human lubricant comprises the following components in percentage by weight: 30-47% of glycerol, 2-4% of tween-20, 0.05-0.15% of sodium hyaluronate, 0.1-0.3% of jasminum essential oil, 0.5-1.2% of aloe essential oil, and 48-66% of water. The compact-type water-soluble human lubricant has good compatibility with the naturally-selected body fluid of human body, is not greasy, has a pH value as same as the pH value of the normal physiological environment of female vagina, and has the effects of nourishing vaginal tissues, promoting cell growth, increasing muscle elasticity, and improving vaginal relaxation.

Owner:明业有限公司

Nourishing type water-soluble personal lubricant and preparation method thereof, and condom

InactiveCN103405591AMaintain acid-base balanceAvoid allergiesSurgeryPharmaceutical non-active ingredientsGlycerolSodium hyaluronate

The invention discloses a type water-soluble personal lubricant and a preparation method thereof, and a condom adopting the lubricant. A compact type water-soluble personal lubricant contains the following components in percentage by weight of 30-45 percent of glycerol, 2-4 percent of tween-20, 0.05-0.15 percent of sodium hyaluronate, 0.5-1.2 percent of aloes essential oil, 0.08-0.2 percent of flores aurantii essential oil, 0.1-0.3 percent of rose essential oil and 50-61.15 percent of water. The compact type water-soluble personal lubricant is good in compatibility with a personal natural secretion body fluid without greasiness, is consistent in pH value of a normal physiological environment of the vagina of a woman, and has the advantages of nourishing the vagina tissue, promoting the cell growth, and increasing the muscle elasticity.

Owner:闫一粼

Compound vibrating type ice/snow removing shovel

The invention relates to a compound vibrating type ice / snow removing shovel and especially relates to a snow shovel capable of generating a complex excitation force along vertical and horizontal directions. A vibrator is fixed on a shovel plate; an adjustable vertical excitation force is generated by the vibrator; a horizontal vibrating mechanism is arranged and is used for driving a horizontal eccentric vibrating shaft to rotate by a motor, so as to cause a shovel blade to reciprocate along the horizontal direction; a certain point on a road surface is repeatedly impacted by the shovel blade; and meanwhile the shovel blade has a certain impact force along the horizontal direction and has a certain function of removing ice and snow along the horizontal direction. The snow shovel mainly comprises the components, such as a shovel blade, a shovel plate, a rear turning obstacle avoidance mechanism, a four-connecting-rod combined mechanism, a vibrator, a horizontal vibrating shaft, a bias rotating shaft type road surface profiling mechanism, and the like. The snow shovel has the characteristics of removing the ice and snow under various states without damaging the road surface.

Owner:张铁民

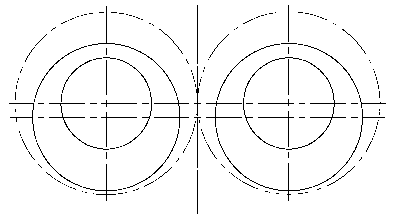

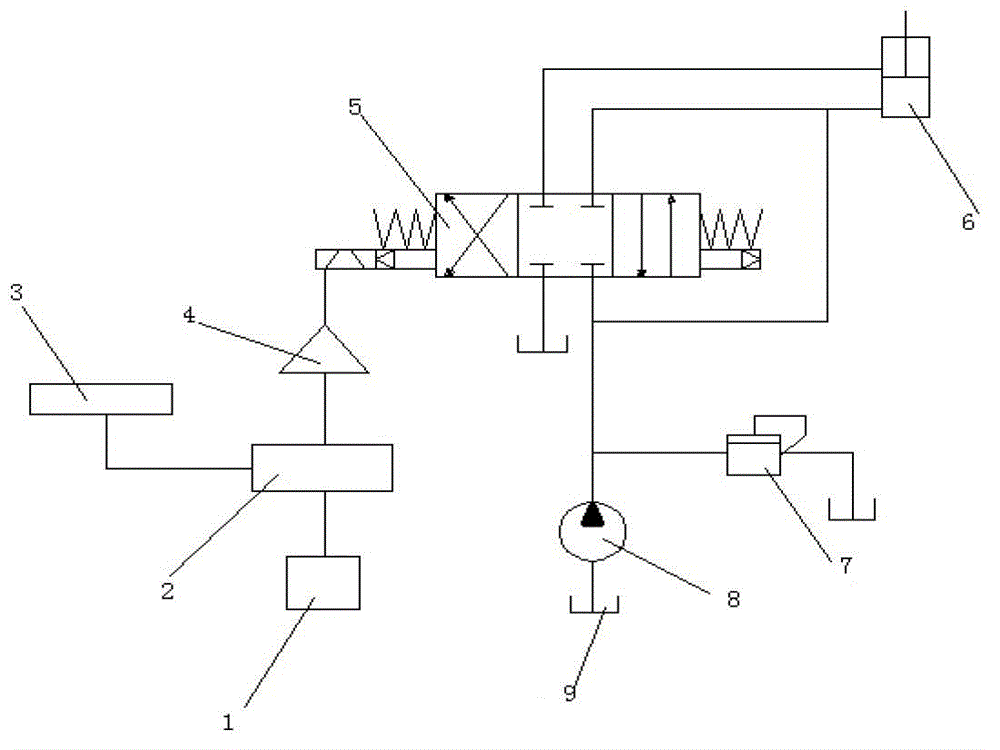

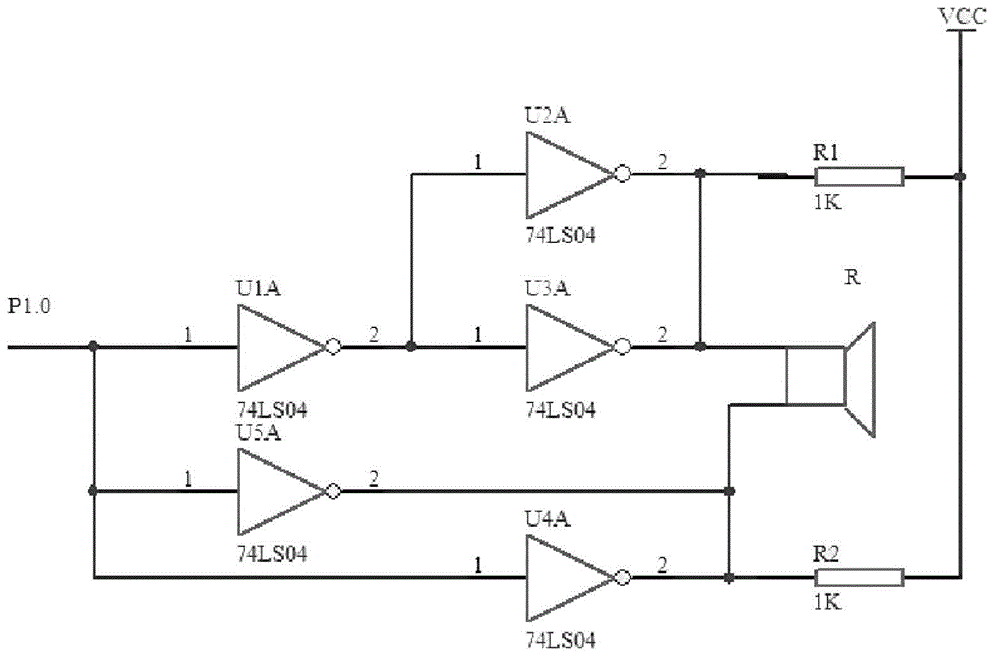

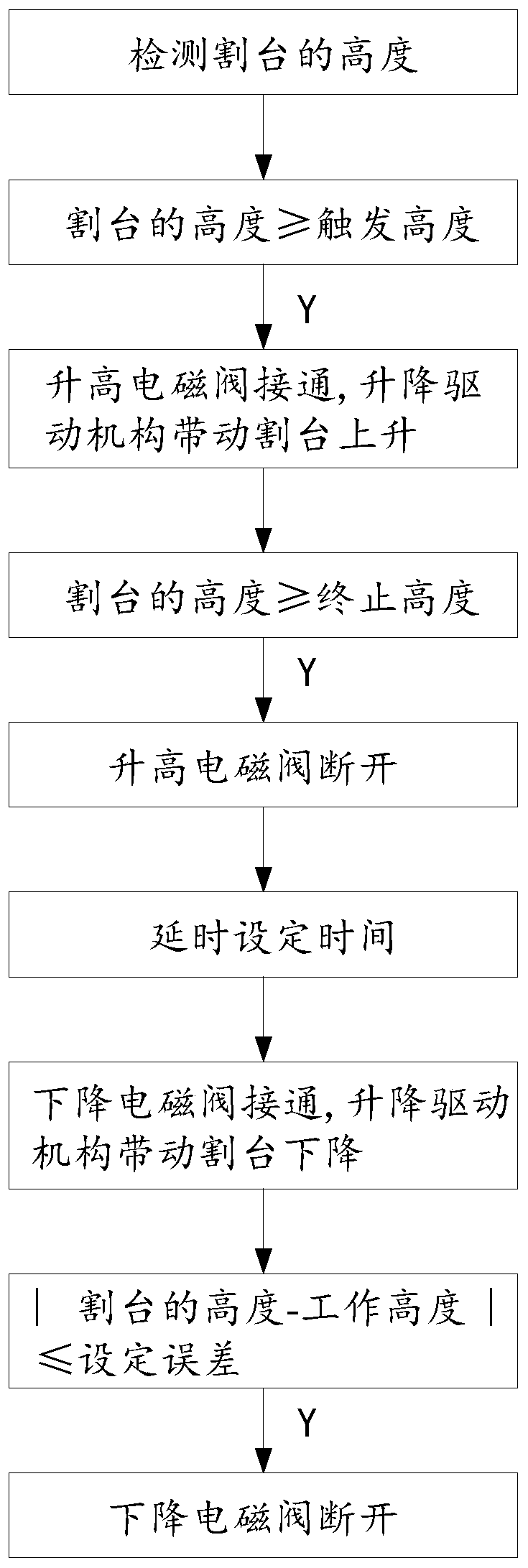

System and method for mechanical waking control based on ground profiling

InactiveCN102714972AImprove profiling abilityImprove Harvest QualityProgramme controlComputer controlTraffic volumeEngineering

The invention provides a system and a method for mechanical waking control based on ground profiling. The system comprises an ultrasonic sensor, a single chip microcomputer, a display and a three-position four-way electromagnetic valve, wherein the ultrasonic sensor is used for monitoring height of a mechanical chassis of a harvester and transmitting signal to the single chip microcomputer and the display, the single chip microcomputer analyzes the signal and transmits the processed signal to the three-position four-way electromagnetic valve, and control of carrying current or pressure in different directions is achieved by controlling current of the electromagnetic valve.

Owner:CHINA AGRI UNIV

Water-soluble personal lubricant, preparation method thereof, and condom employing lubricant

The invention relates to a water-soluble personal lubricant, a preparation method thereof, and a condom employing the lubricant. The water-soluble personal lubricant is prepared from the following components by weight percent: 20-40% of glycerol, 1-5% of tween-20, 0.02-0.2% of sodium hyaluronate, 0.2-0.8% of rose essential oil, 0.5-1.5% of aloe essential oil, 0.5-2% of pharmaceutical-grade water-soluble azone and the balance of water. The personal lubricant can be mutually dissolved with normal secretion of a human body, and is free of greasy feeling, and consistent with a pH value of a normal physiological environment of a female vagina; improvement of sex joy is also facilitated besides a good lubricating effect; nutrient substances required by the skin are supplied; woman health is also facilitated.

Owner:石杰克

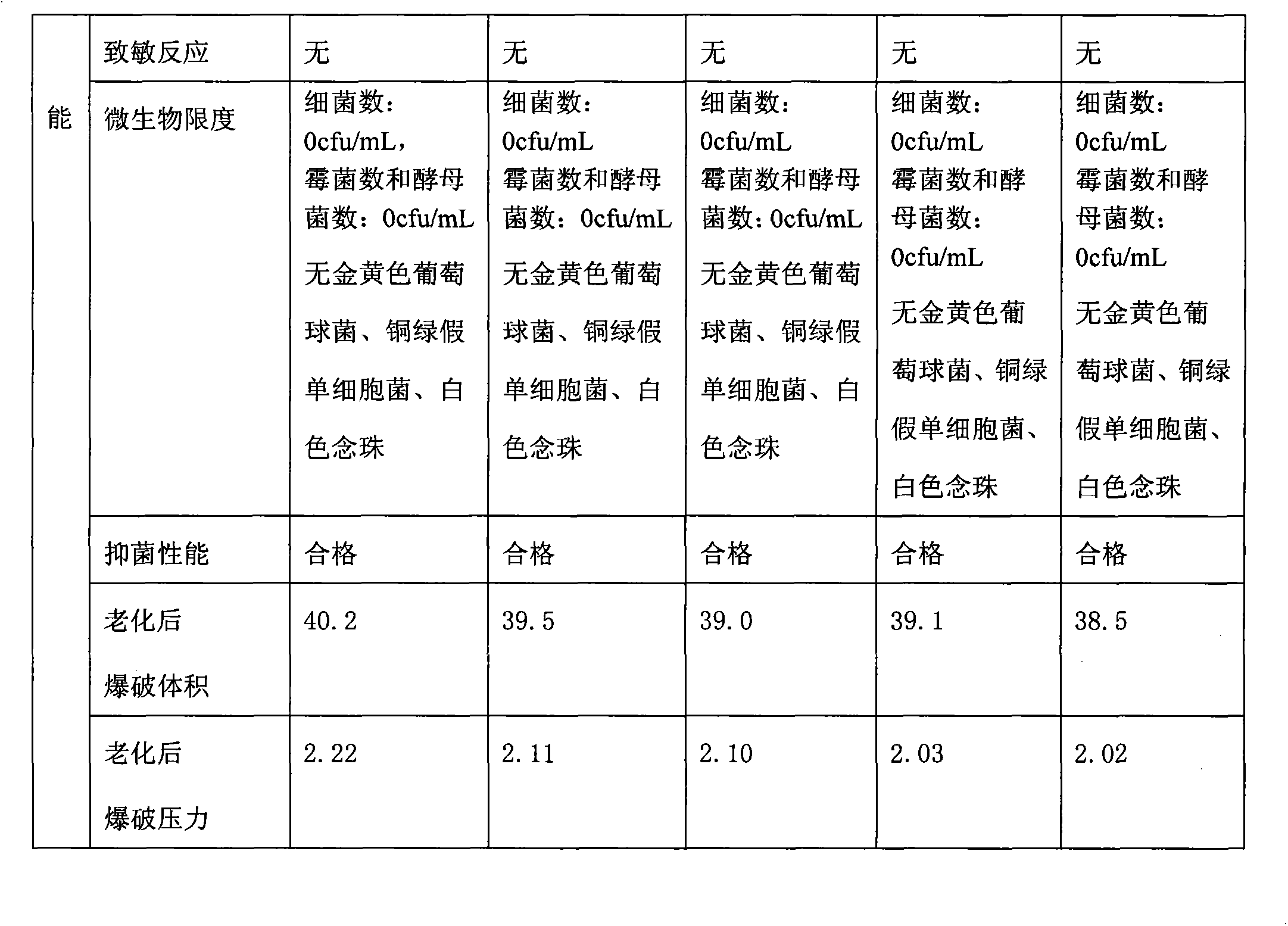

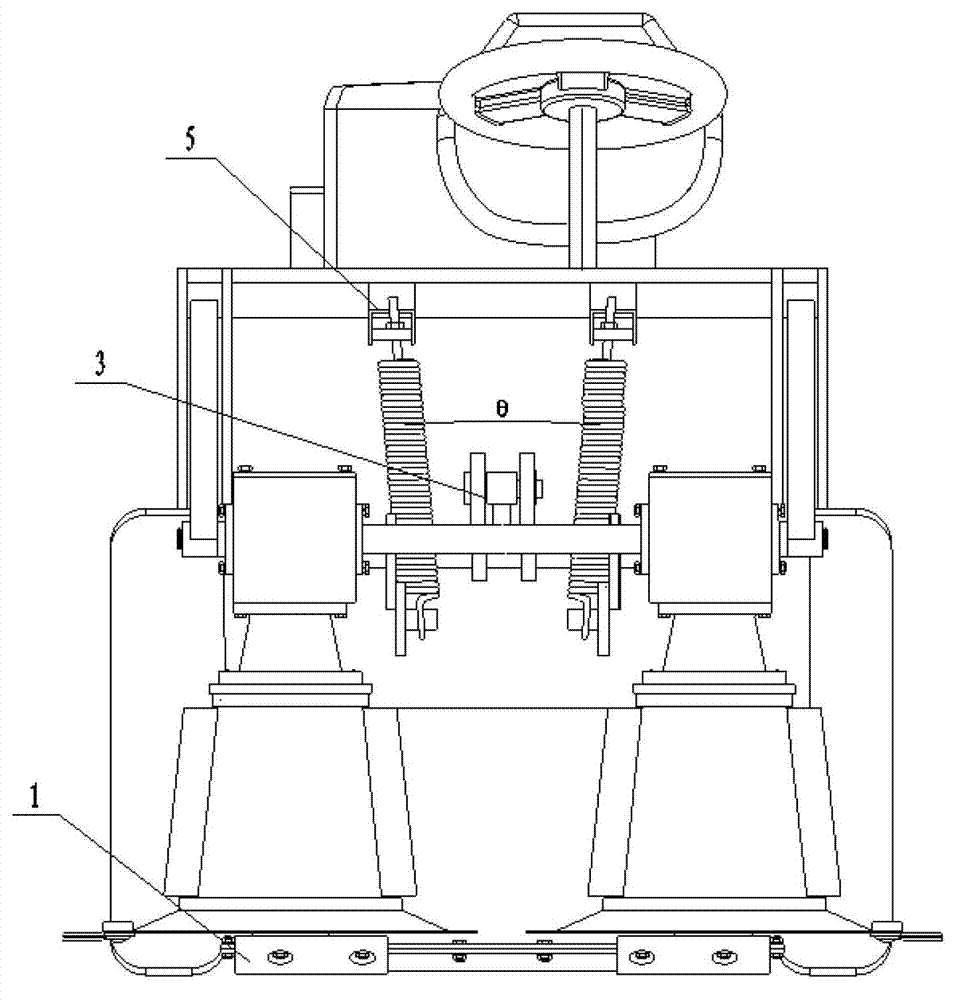

Soft ground vehicle walking mechanism

InactiveCN105539417AReduce contact pressureStrong profiling abilityAir-cushionContact pressureGround vehicles

The invention relates to a soft ground vehicle walking mechanism. The soft ground vehicle walking mechanism comprises a control motor, a high pressure air chamber, an electromagnetic valve, airways, driving mechanisms, springs, an inflating air cushion shoe and a deflating air cushion shoe, wherein the inflating air cushion shoe and the deflating air cushion shoe are symmetrically arranged on the left and right sides under the walking mechanism in a longitudinal direction; the closed high pressure air chamber is formed in the walking mechanism; the control motor for controlling the pressure of the high pressure air chamber is arranged at the upper end of the high pressure air chamber; the longitudinally adjustable driving mechanisms are arranged between the high pressure air chamber and the inflating air cushion shoe and between the high pressure air chamber and the deflating air cushion shoe; the inflating air cushion shoe and the deflating air cushion shoe are connected with the high pressure air chamber through airways; solenoid valves for regulating air switches are mounted on the air ways; and the springs in a stretched state are arranged in the inflating air cushion shoe and the deflating air cushion shoe. The invention is advantaged in that the soft ground vehicle walking mechanism is simply structured, the copying passing capacity of a vehicle is improved while the contact pressure of the vehicle on the soft ground is effectively reduced, the soft ground vehicle walking mechanism realizes excellent slope climbing capacity, a problem that slip, drifting and the like are easily caused due to sensitivity to wind is eliminated, the vehicle runs stably and consumes less energy.

Owner:合肥仲农生物科技有限公司

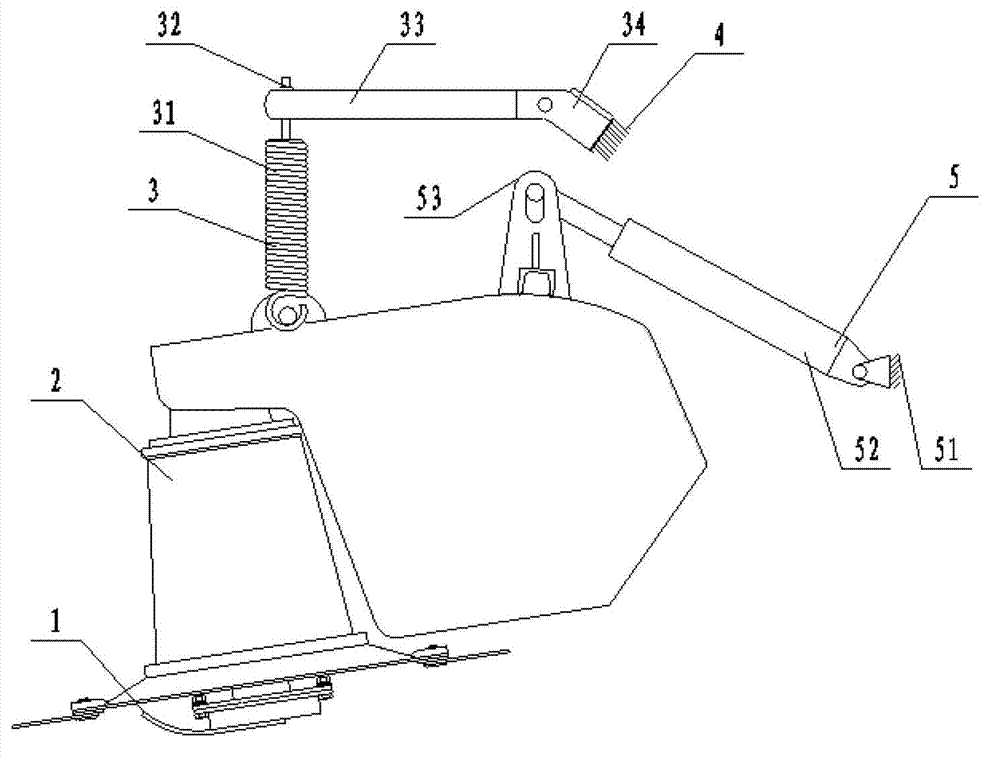

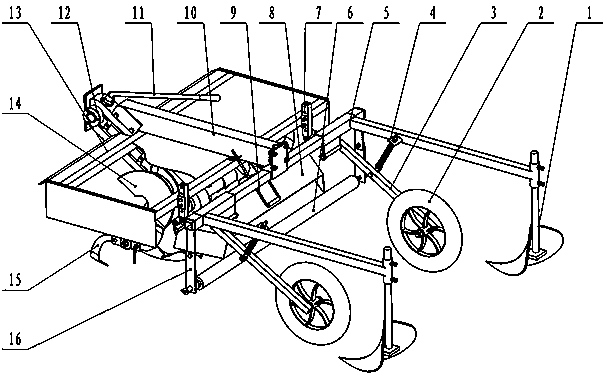

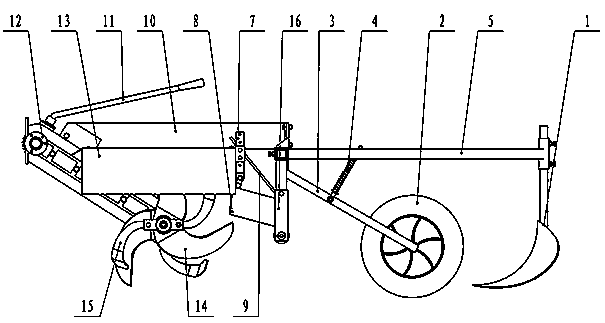

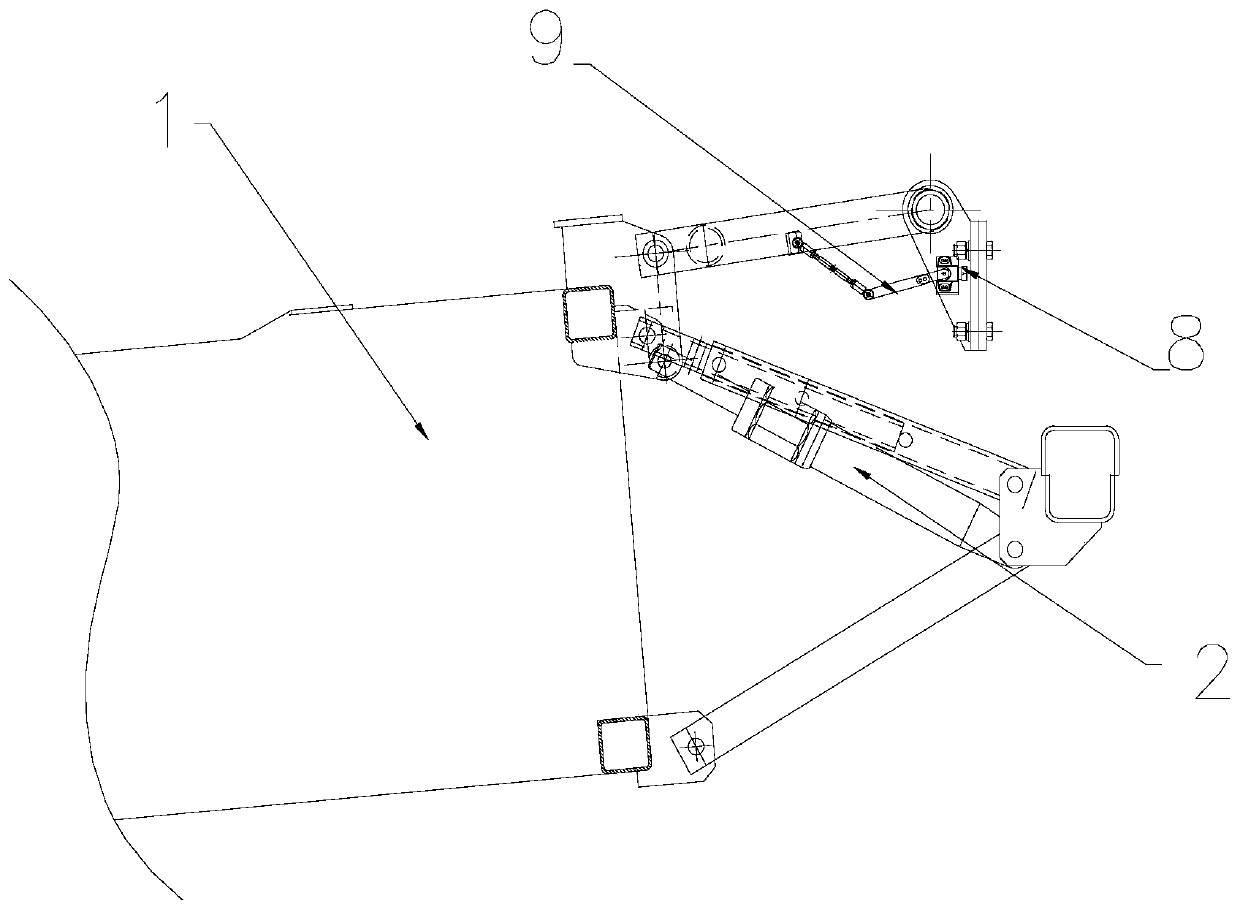

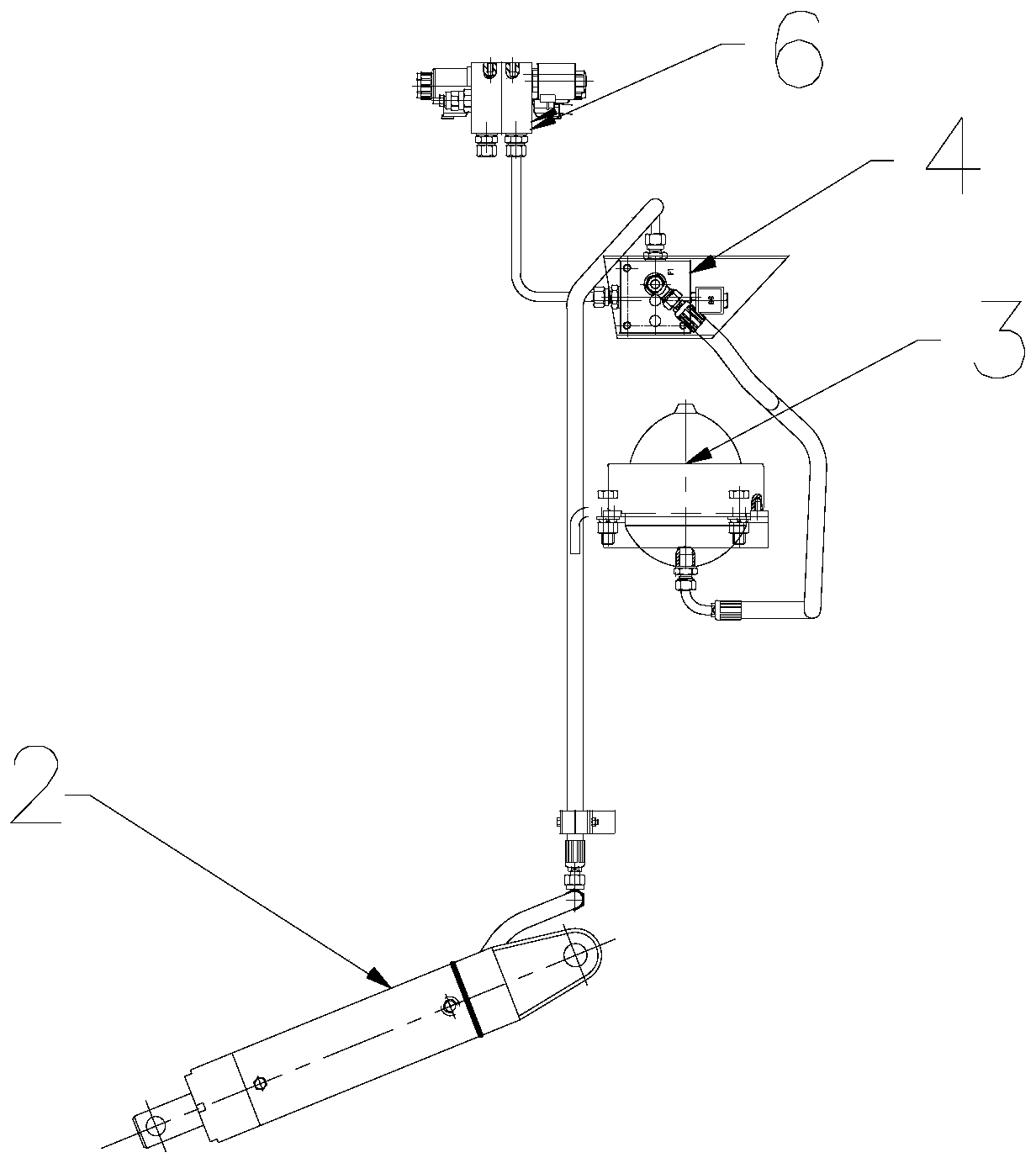

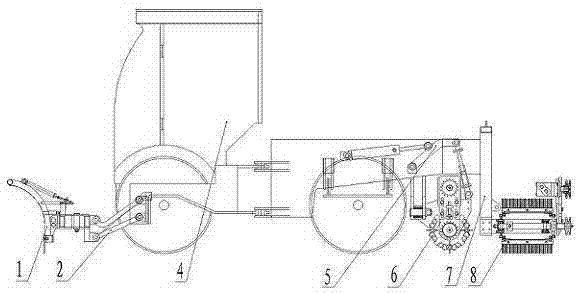

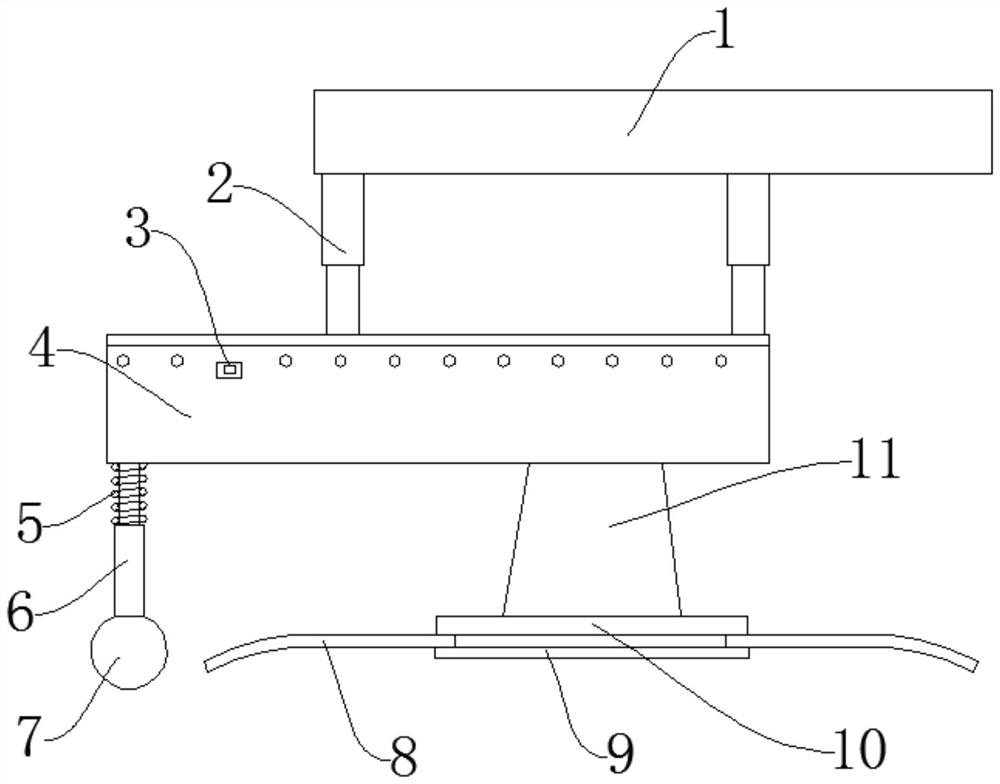

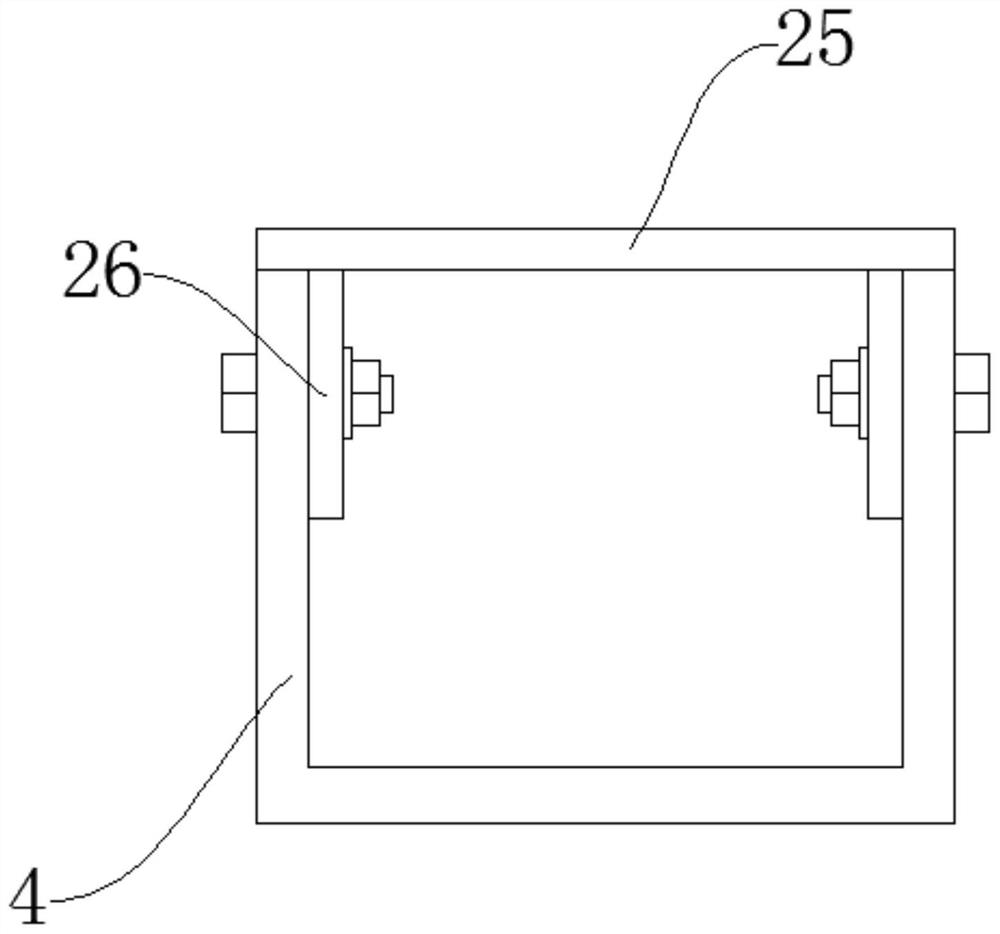

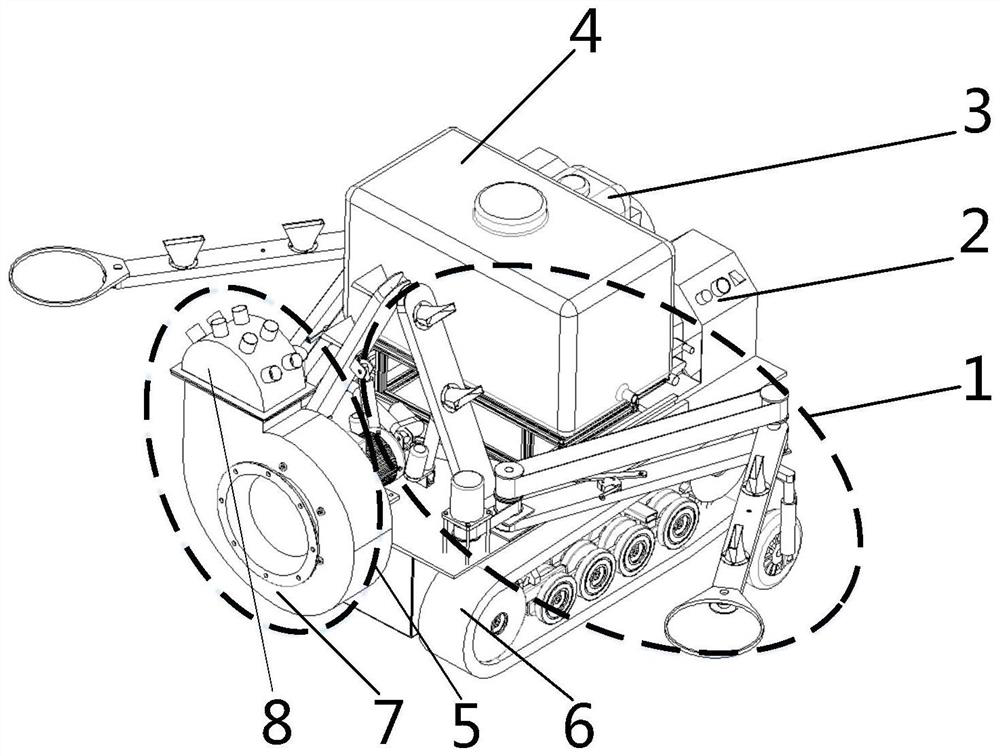

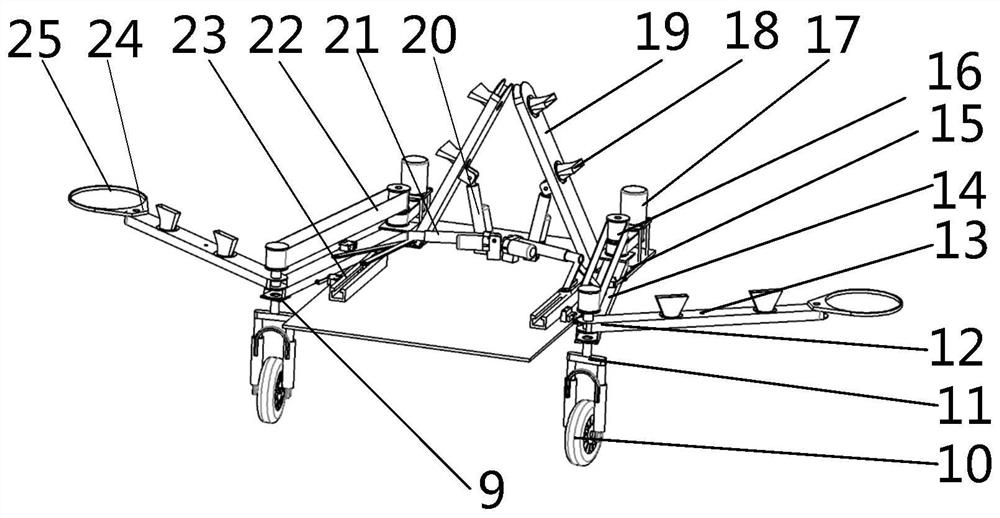

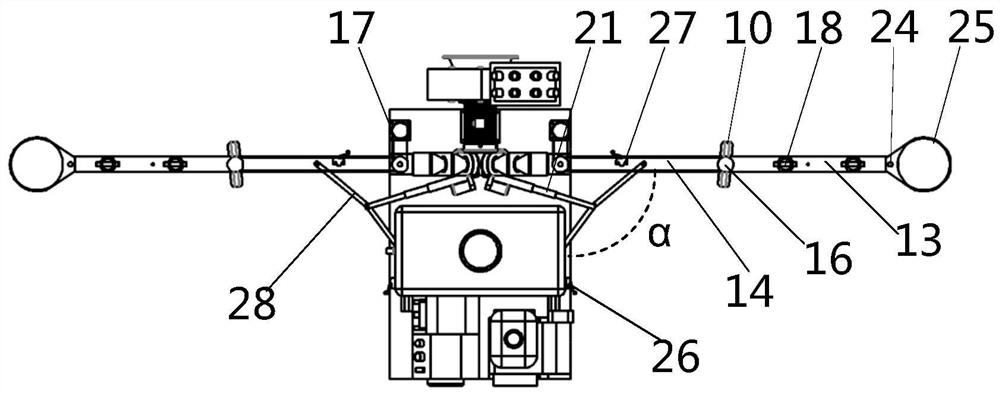

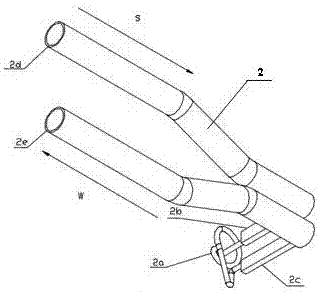

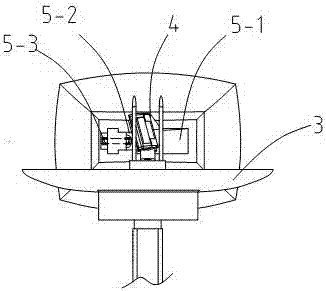

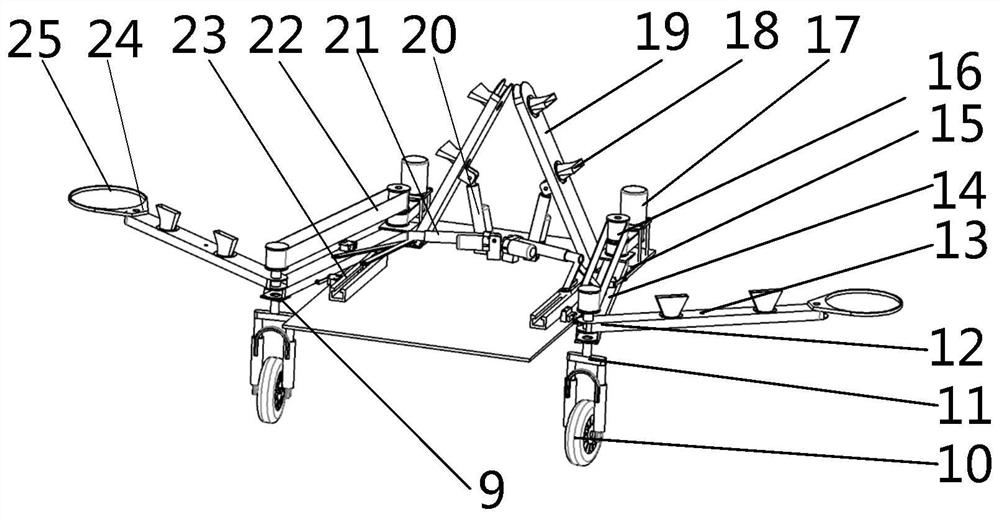

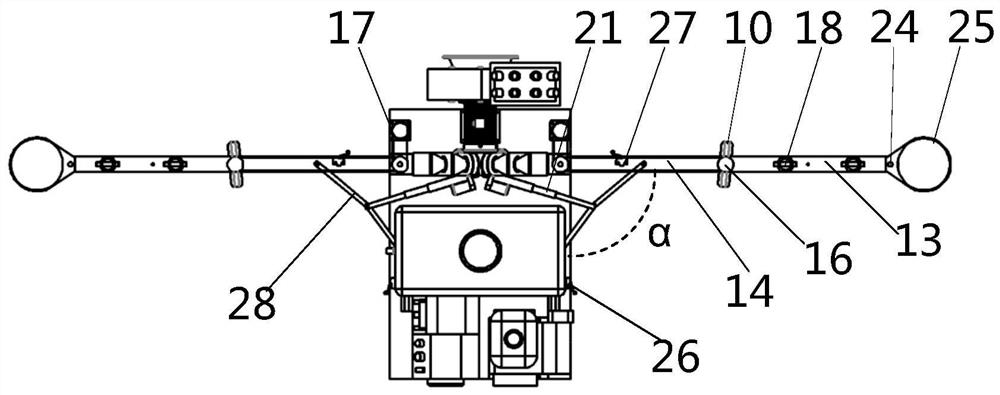

Grass harvesting machine profiling method and device

The invention belongs to the stockbreeding machine technical field, and particularly relates to a grass harvesting machine profiling method and a device. The grass harvesting machine profiling method is characterized in that according to technology characteristics of alfalfa, integrating floating devices, sliding palm devices and a hoisting device, achieving system profiling of a grass harvesting machine, improving profiling performance of the grass harvesting machine, and improving machine operating efficiency. The grass harvesting machine profiling device is mainly composed of the sliding palm devices 1, the floating devices 3 and the hoisting device 5, wherein one ends of the floating devices 3 are connected with a rack 4, and the other ends of the floating devices 3 are connected with a working device 2 in a hooking manner; the sliding palm devices 1 are installed on two sides of ground connection part of the working device 2; two ends of the hoisting device 5 are respectively connected with the rack 4 and the working device 2 in a hooking mode, and the floating devices can enable the working device to float with ground surface in working. Balance of the working device can be achieved by respectively adjusting the floating devices; included angles are arranged on the floating devices placed on both sides of the working device, the working device can be ensured to be stable and reliable in operation, and machine operating efficiency is improved.

Owner:CHINA AGRI UNIV

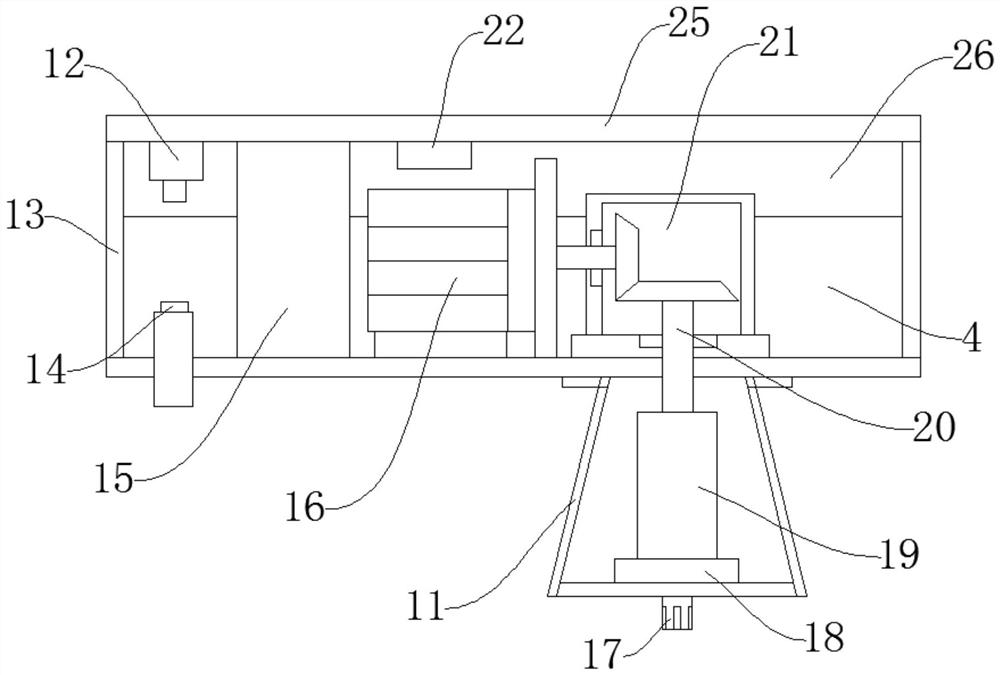

Full-automatic fruit peeling machine

InactiveCN105496165ASolve operational troublesSolve the low safety performancePeelersAgricultural engineering

The invention discloses a full-automatic fruit peeling machine and relates to the technical field of peeling devices. The full-automatic fruit peeling machine comprises a shell mechanism, a transmission mechanism and a knife mechanism, the shell mechanism comprises a barrel, a cover is arranged at the upper edge of the barrel in a hinged manner, the knife mechanism is mounted on the inner side of the cover, a barrel transmission mechanism is arranged in the barrel, and a fruit tray matched with the knife mechanism in use is arranged on the transmission mechanism. The full-automatic fruit peeling machine is suitable for peeling fruits different in type and shape and has the advantages of feasible structure, high practicability and easiness in popularization.

Owner:CHENGDU UNIV

Ridging shaping environment-friendly mulching film laying machine

PendingCN108811554ASimple structureEasy size adjustmentSpadesPloughsFailure rateAgricultural engineering

The invention discloses a ridging shaping environment-friendly mulching film laying machine. The machine comprises a machine frame, a rotary tillage device is arranged at the front lower part of the machine frame, a gearbox is installed at the part, located behind the rotary tillage device, of the machine frame, the rotary tillage device is installed below the gearbox through a rotary tillage shaft, and a clutch handle is arranged at the upper part of the gearbox; and a film laying device is installed at the part, located behind a shaping device, of the machine frame, earthing shovels are installed at the part, located behind the film laying device, of the machine frame, and the earthing shovels are located on the outer side of the film laying device. According to the ridging shaping environment-friendly mulching film laying machine disclosed by the invention, rotary tillage knives, spiral ridging knives and ditching knives are all installed on the rotary tillage shaft, so that combined operation of rotary tillage and soil loosening at the bottom of ridges, taking and pushing of ridge type soil to the middle part by the spiral ridging knives, and ditching of film edge small ditchesby the ditching knives can be completed once, the structure of the machine tool is greatly simplified, and difficulty of manufacturing and processing and a failure rate of operation are reduced.

Owner:GANSU TAOHE TRACTOR MFG

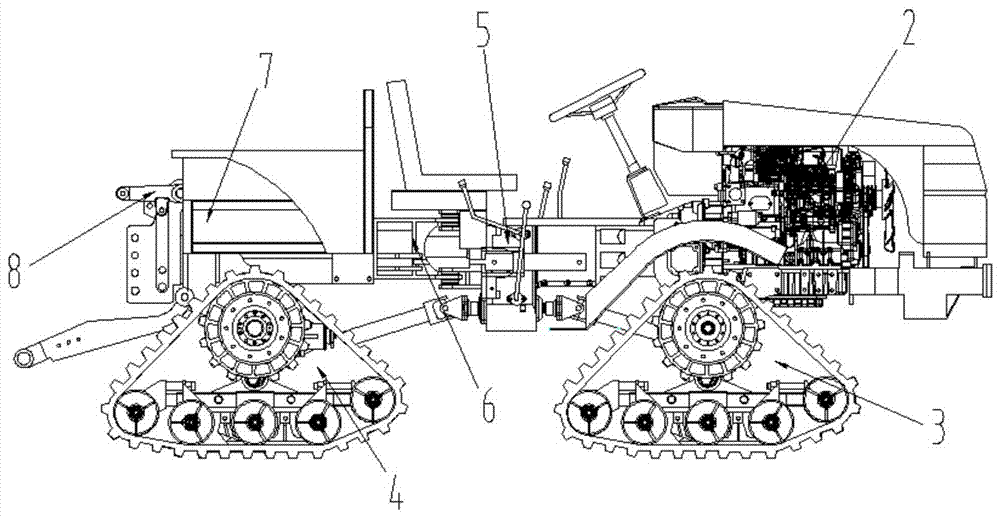

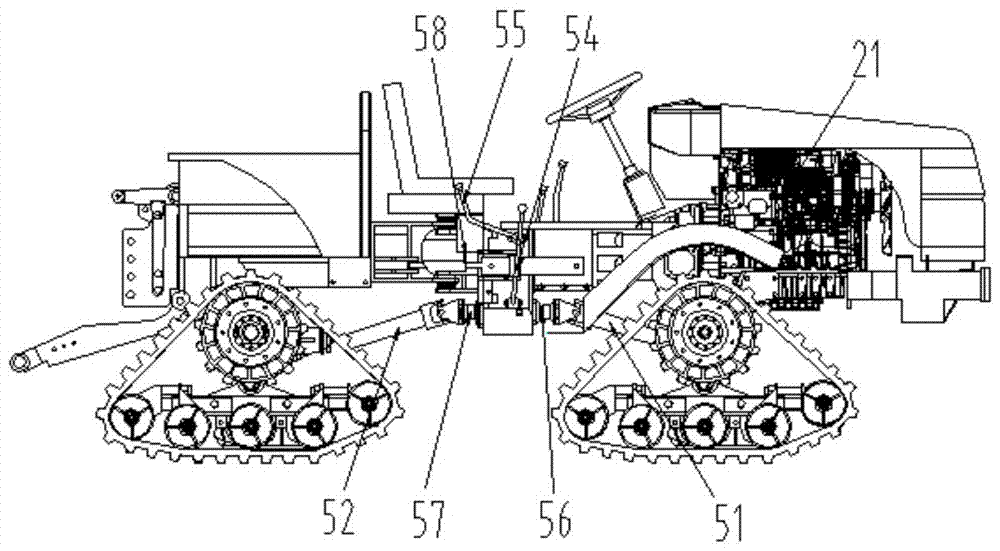

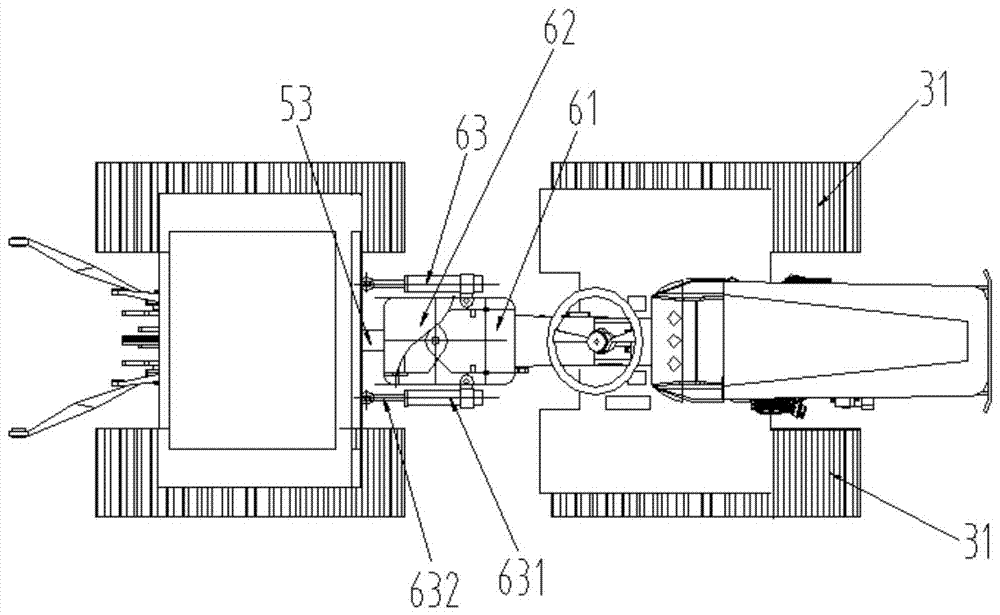

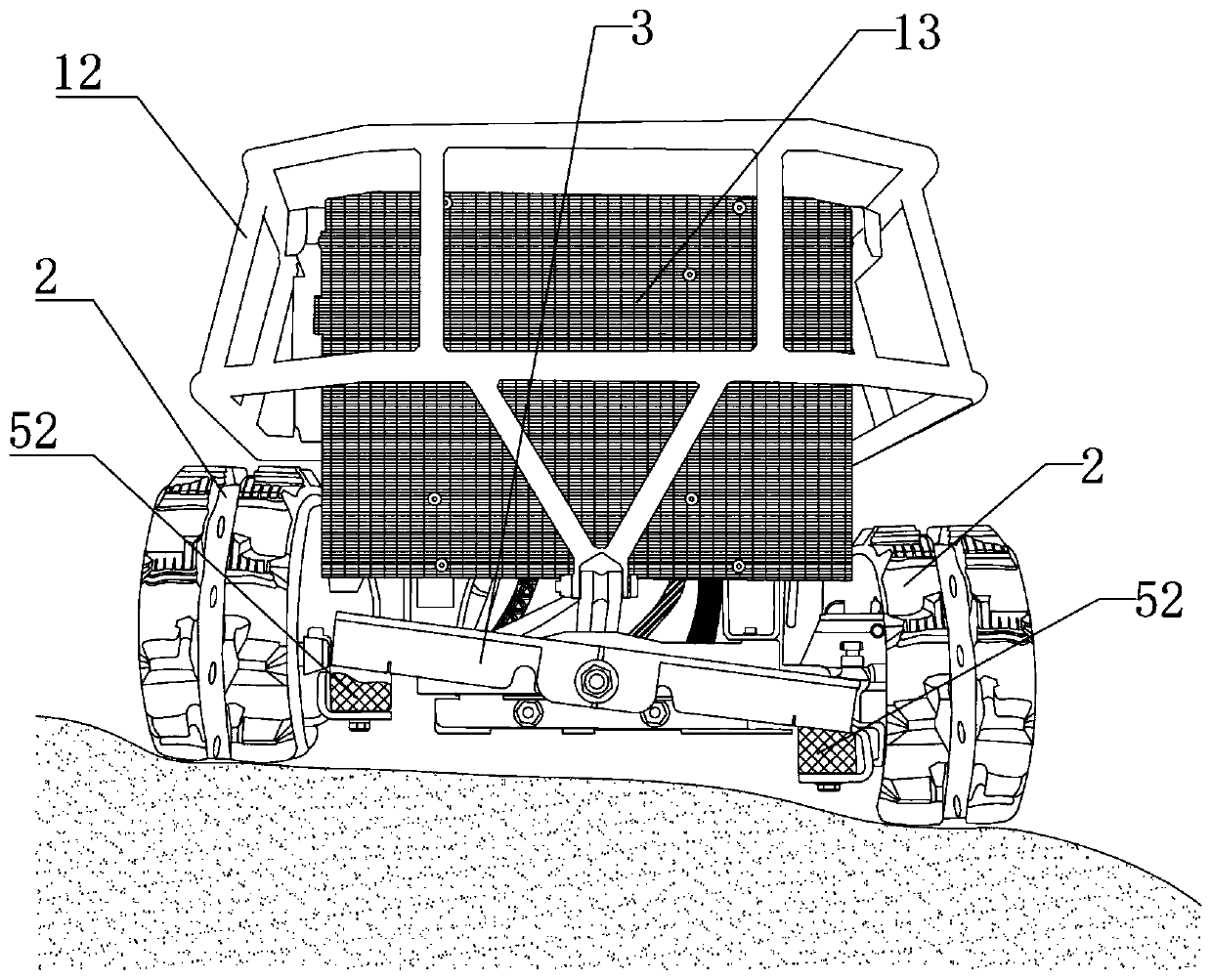

Four-drive four-track hinged type profile modeling tractor

PendingCN107161001ATilt stableOvercoming mud problemsEndless track vehiclesSteering for vehicles in tandemTransfer caseTractor

The invention discloses a four-drive four-track hinged type profile modeling tractor. The tractor comprises a power system, a speed change system, an articulated steering system, a stand-by output transfer case, a hydraulic lifting system, a front drive track wheel set system and a rear drive track wheel set system. The power system is arranged at the front end of the profile modeling tractor and fixedly connected to the front drive track wheel set system, one end of the speed change system is connected with the output end of the power system, and the articulated steering system is fixedly connected to the other end of the speed change system; and the stand-by output transfer case is fixedly connected to the rear drive track wheel set system, and the hydraulic lifting system is located at the rear end of the profile modeling tractor and fixedly connected with the stand-by output transfer case. According to the four-drive four-track hinged type profile modeling tractor, the drive modes such as front-rear axle synchronous drive, front-axle separate drive and rear-axle separate drive can be achieved through a clutch operating lever correspondingly; the middle of a tractor body is connected by a multi-degree-of-freedom hinging body, and the articulated steering function can be achieved through hydraulic drive; and profile modeling rotary shaft mechanisms are arranged in the track wheel set systems, and thus profile modeling movement of the tractor on a complex road surface can be ensured.

Owner:耒阳市伏羲现代农业装备制造有限公司 +1

Manufacturing process of ceramic accessory brick and ceramic accessory brick made by the process

The invention relates to a manufacturing process of a ceramic accessory tile and the ceramic accessory tile. The manufacturing process comprises the steps of: (1) printing a ground coat on the surface glass layer of sintered ceramic tile; (2) conducting ink-jet printing on the printing ground coat to form patterns; (3) applying transparent dry grains on the surface of the pattern layer for two times, and sintering; (4) electroplating metal color on a groove of the surface glass layer by adopting a lamination positioning electroplating method, and sintering; (5) polishing the surface of the sintered product; and (6) cutting the sintered accessory tile blank to prepare the accessory tile. The ceramic accessory tile comprises a base tile, ground coat applied on the surface of the base tile, the pattern layer attached on the ground coat, and the first dry grain layer and the second dry grain layer applied on the pattern layer. Irregular pits, grooves or concave curves, wherein the irregular pits, the grooves or the concave curves are hollowed towards the inside and are arranged on the layer surface of the second dry grain distribution layer. The accessory tile varieties include ground flowers, ground line, waist line and corner, and is used for supporting the ceramic wall and floor tiles.

Owner:JIANGXI HEMEI CERAMICS

Profiling system of cutting table and control method of system

The invention discloses a profiling system of a cutting table and a control method of the system, and relates to the technical field of agricultural machinery. The control method of the profiling system for the cutting table comprises the steps that an automatic control unit is started; in a moving process of the cutting table, the cutting table floats up and down under the action of a hydraulic energy accumulator; the height of the cutting table is detected; when the height of the cutting table is increased to the trigger height, a lifting driving mechanism is started, and the lifting drivingmechanism drives the cutting platform to ascend to the termination height; and after a set time T1 is delayed, the lifting driving mechanism drives the cutting table to descend to the working height,wherein the working height is lower than the trigger height. The cutting table profiling system uses the control method. According to the profiling system of the cutting table and the control methodof the system, an automatic lifting mechanism assists the hydraulic energy accumulator control in controlling the cutting table to ascend and descend, so that the profiling capability of the cutting table is better and the cutting table still can return to the working height after avoiding a relatively large barrier.

Owner:新疆牧神机械有限责任公司 +1

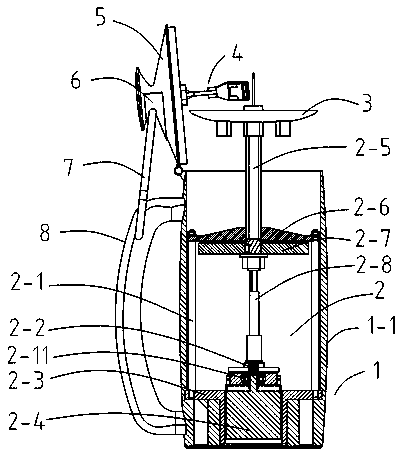

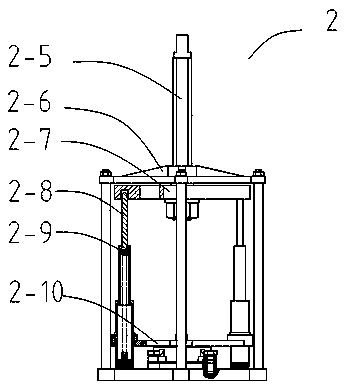

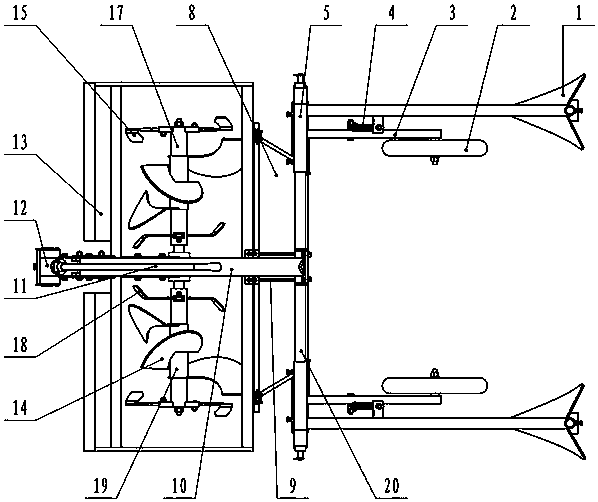

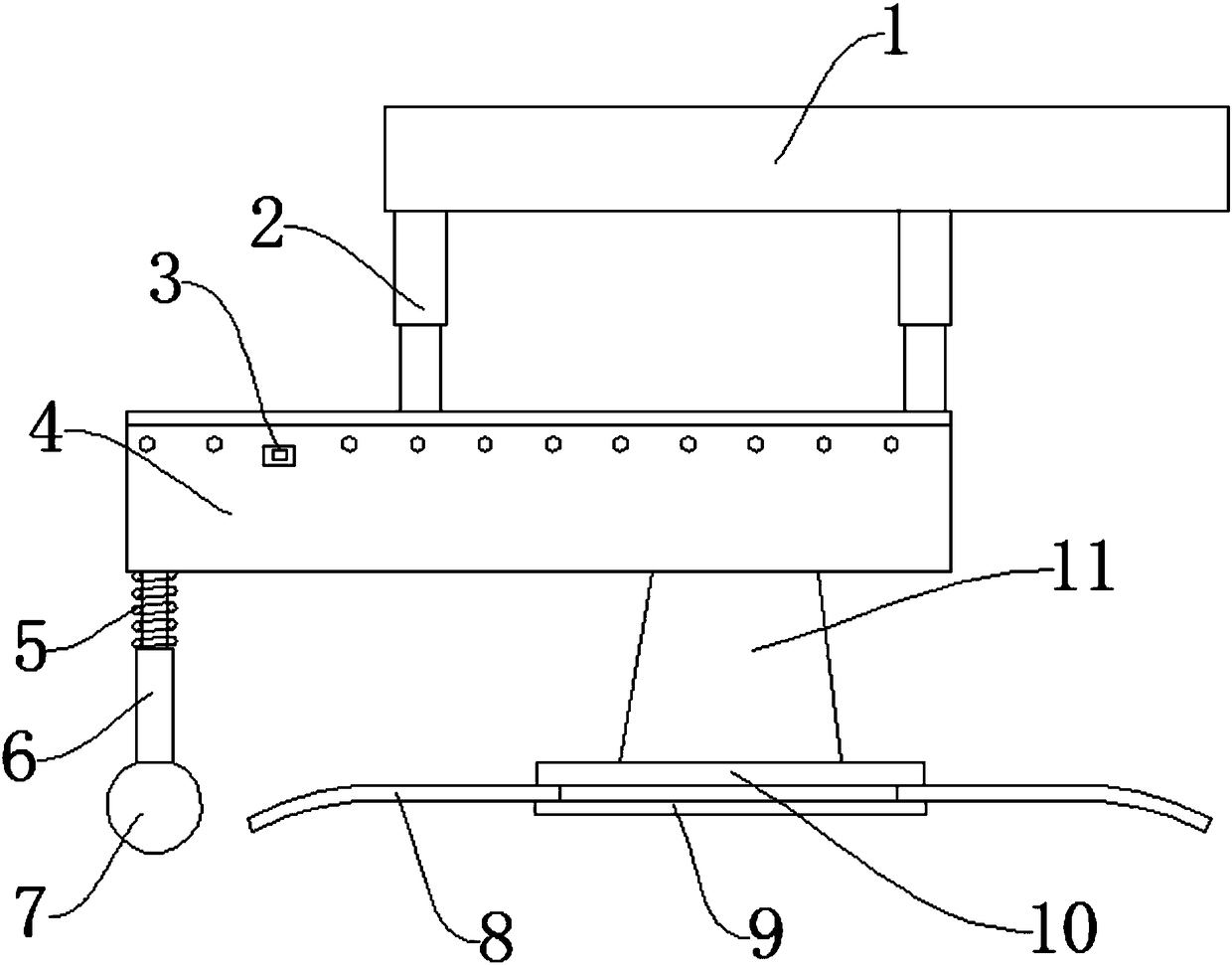

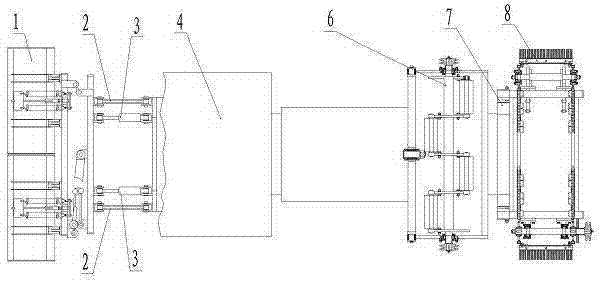

Forage grass harvesting machinery profile modeling method and device

ActiveCN108064541AStrong profiling abilityAvoid accidental damageMowersAnimal ForagingAgricultural engineering

The invention discloses a forage grass harvesting machinery profile modeling method and device. The device includes a rack and a folding net, a hydraulic rod is arranged below the rack, a fixing girder is arranged below the hydraulic rod, an upper sealing cover is arranged above the fixing girder, a connecting plate is arranged on the lower surface of the upper sealing cover, and lateral sealing plates are arranged at both ends of the fixing girder; charging jacks are formed in the side wall of the fixing girder, a connection base is arranged below one end of the fixing girder, a reduction gear box is arranged in the connection base, a power output shaft is arranged below the reduction gear box, a turntable is arranged below the power output shaft, and a central mounting groove is formed in the center of the turntable; a mounting and clamping slot is formed in the lower surface of the turntable, the folding net is arranged in the mounting and clamping slot, and a pressing plate is arranged below the folding net. The device has the advantages that by adopting a mechanical and electronic control cooperation mode for controlling profile modeling motion, the profile modeling effect isimproved, accidental damage is avoided, and the device is convenient to use.

Owner:广西汇创牧业有限公司

Special snow plow for road sidewalk and residential area

The invention relates to a special snow remover for road pavements and residential districts, and is particularly suitable for narrow areas, such as the road pavements, and the residential districts. The snow remover comprises a mini-sized motor vehicle as a walking and power body, a snow shovel arranged at the front end of the vehicle, as well as a rolling impact roller and a row brush arranged at the back part of the vehicle, wherein a fixed beam of the snow shovel is hinged and connected to the front end of a vehicle body through a double-connecting rod mechanism and a front shovel oil cylinder, and is driven by the front shovel oil cylinder to perform parallel lifting movement; the rolling impact roller is arranged at the back part of the vehicle body through a roller lifting mechanism, and is driven by the lifting mechanism to perform lifting movement; and the row brush is arranged at the back end of the vehicle body through a vertical lifting mechanism. The snow remover can remove floating snow and treaded ice and snow, and has strong road surface profiling capability and obstacle crossing ability.

Owner:JILIN NORDIC HEAVY MACHINERY CO LTD

Compound vibrating type ice/snow removing shovel

The invention relates to a compound vibrating type ice / snow removing shovel and especially relates to a snow shovel capable of generating a complex excitation force along vertical and horizontal directions. A vibrator is fixed on a shovel plate; an adjustable vertical excitation force is generated by the vibrator; a horizontal vibrating mechanism is arranged and is used for driving a horizontal eccentric vibrating shaft to rotate by a motor, so as to cause a shovel blade to reciprocate along the horizontal direction; a certain point on a road surface is repeatedly impacted by the shovel blade; and meanwhile the shovel blade has a certain impact force along the horizontal direction and has a certain function of removing ice and snow along the horizontal direction. The snow shovel mainly comprises the components, such as a shovel blade, a shovel plate, a rear turning obstacle avoidance mechanism, a four-connecting-rod combined mechanism, a vibrator, a horizontal vibrating shaft, a bias rotating shaft type road surface profiling mechanism, and the like. The snow shovel has the characteristics of removing the ice and snow under various states without damaging the road surface.

Owner:张铁民

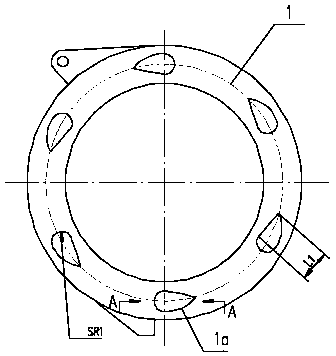

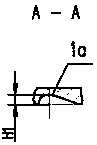

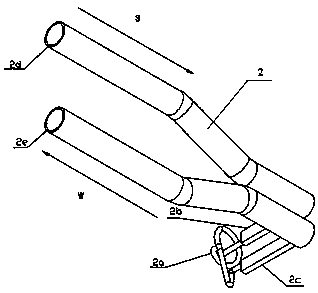

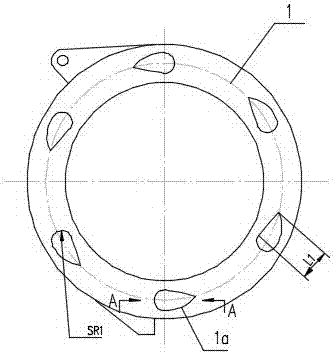

Quenching Inductor Used in Cone Dimple of Brake Pressure Plate and Method for Determining the Matching Dimensions

ActiveCN107164611BSolve the problem that heating efficiency is difficult to improveIncrease the effective sensing areaFurnace typesIncreasing energy efficiencySize determinationInductor

The invention discloses a quenching inductor for a conical pit of a brake disc and a matched application size determining method. The quenching inductor comprises a heating coil of the quenching inductor, a left square pipe, a right square pipe, a left round pipe and a right round pipe; the heating coil, the left square pipe, the right square pipe, the left round pipe and the right round pipe are hollow pipes; the water inlet end of the left square pipe is vertically welded with the water outlet end of the left round pipe, and the water outlet end of the left square pipe is horizontally welded with a water inlet pipe orifice of the heating coil; the water outlet end of the right square pipe is vertically welded with the water inlet end of the right round pipe, and the water inlet end of the right square pipe is horizontally welded with the water outlet pipe orifice of the heating coil; and one end of each of the left square pipe and the right square pipe communicates with the inside of the heating coil, and the other ends of the left square pipe and the right square pipe communicate with the insides of the left round pipe and the right round pipe respectively. The effective induction area is increased, and the problem that it is difficult to increase the induction heating efficiency is solved; the heating coil of the inductor is effectively coincided with the conical pit, and a gap is retained; and the heating efficiency and the depth of a hardened zone are guaranteed, and no fusing and ignition phenomena can be caused. The quenching inductor is reasonable in structure and reliable in application; and a matched application method is simple and feasible as well as easy to implement.

Owner:FIRST TRACTOR

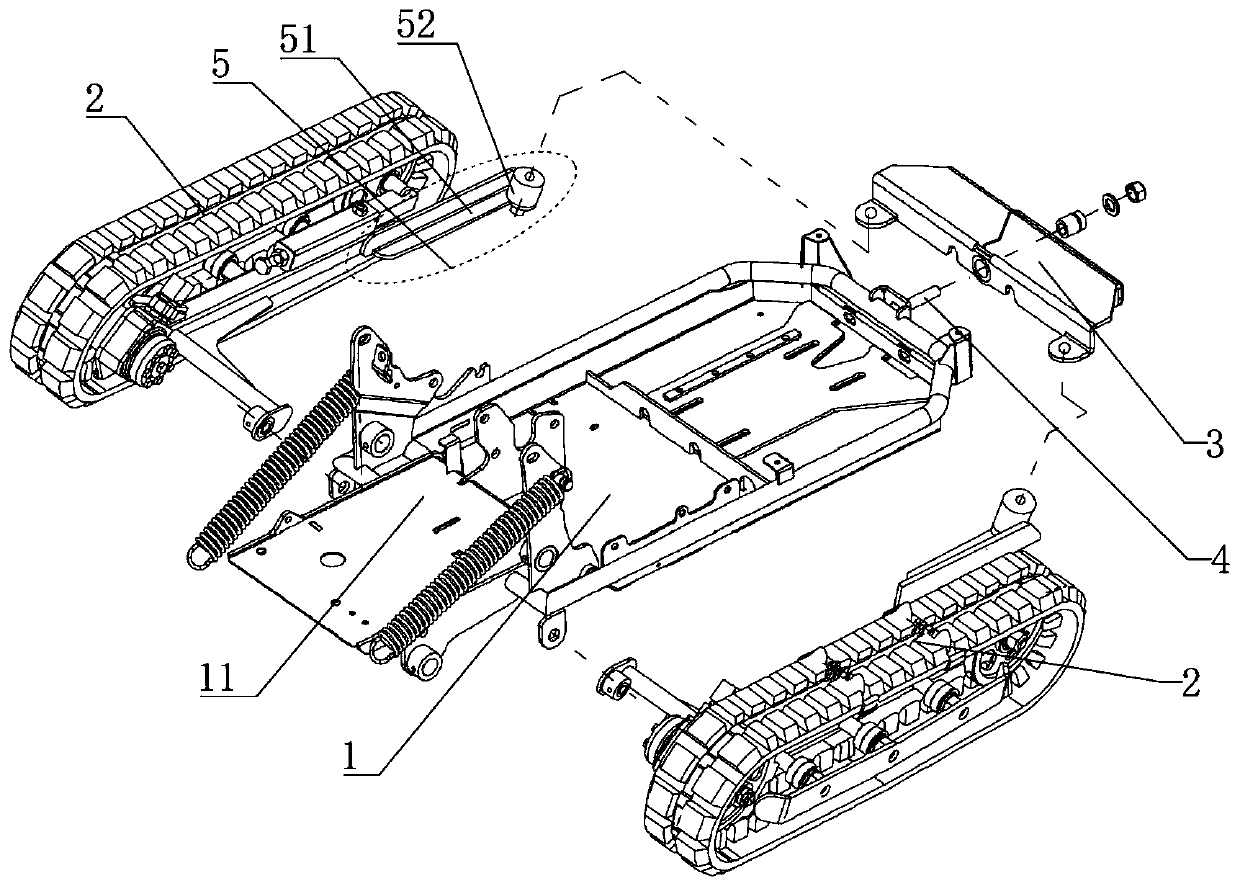

Rotary-point type double-side floating travelling chassis

PendingCN110654469AStrong profiling abilityImprove passabilityEndless track vehiclesEngineeringControl theory

The invention discloses a rotary-point type double-side floating travelling chassis. According to the rotary-point type double-side floating travelling chassis, a balanced tail plate is arranged, thebalance tail plate is rotatably connected with a chassis frame through a balance rotary point connecting device, then the two ends of the balance tail plate are connected and supported to a travellingdevice through an elastic compensation connecting device, in a complex terrain environment, the travelling device swings up and down to drive the two ends of the balance tail plate to float up and down, due to the fact that the chassis frame is connected with the balance tail plate through a rotation connecting center, the up-down swing of the travelling device during travelling in the complex terrain environment can be compensated through the balance tail plate, so that too large vibration is not brought to the chassis frame; and the profiling capability of travelling in irregular hilly andmountainous areas of the chassis is improved, the passing performance is enhanced, and the travelling chassis is more suitable for the complex terrain environment.

Owner:GUANGDONG PROVINCE MODERN AGRI EQUIP RES INST +1

A kind of apple facial mask based on traditional Chinese medicine formula

ActiveCN105769652BImprove antioxidant capacityStop chain reactionCosmetic preparationsToilet preparationsBetaineApple extract

The invention provides an apple facial mask based on a traditional Chinese medicine formula.The apple mask comprises a silk matrix and a water-soluble substance.The water-soluble substance comprises apple extract, traditional Chinese medicine extract, seaweed extract, sodium hyaluronate, beta-glucan and assistant.The traditional Chinese medicine extract comprises tremella extract, centella asiatica extract, polygonum cuspidatum root extract, scutellaria root extract, tea extract, glycyrrhiza glabra root extract, chamomilla recutita flower extract, rosmarinus officinalis leaf extract and purslane herb extract.The seaweed extract contains chondrus crispus and bio-saccharide gum-1.The assistant comprises butanediol, propylene glycol, diglycerol, polyethylene glycol-400, Carbomer, hydroxyethyl cellulose, urea, allantoin, glycine betaine, nicotinamide, sodium glutamate, triethanolamine, 1,2-hexanediol, decoyl hydroximic acid, 1,3-propylene glycol, hexanediol and deionized water.The apple mask has the effects that stability is good, dispersibility is high, nutrients are proper in quantity and balanced, antibiosis and anticorrosion effects are achieved, and moisturizing, skin whitening and stain lightening are achieved.

Owner:珠海市雅莎医疗器械有限公司

A profiling method and device for forage harvesting machinery

ActiveCN108064541BStrong profiling abilityAvoid accidental damageMowersAgricultural engineeringStructural engineering

The invention discloses a profiling method and device for pasture harvesting machinery, comprising a frame and a gathering net. A hydraulic rod is arranged under the frame, a fixed beam is arranged under the hydraulic rod, and an upper rod is arranged above the fixed beam. The cover, the lower surface of the upper cover is provided with a connecting plate, the two ends of the fixed beam are provided with side sealing plates, the side wall of the fixed beam is provided with a charging jack, and the bottom of one end of the fixed beam is provided with a connecting seat , the connecting seat is provided with a reduction gear box, a power output shaft is provided under the reduction gear box, a rotating disc is provided under the power output shaft, a central installation groove is provided in the center of the rotating disc, and the rotating disc The lower surface is provided with an installation card slot, and the gathering net is arranged in the installation card slot, and a pressing plate is arranged under the gathering net. The beneficial effect lies in that the profiling movement is controlled by means of mechanical and electronic control cooperation, the profiling effect is improved, accidental damage is avoided, and the use is convenient.

Owner:广西汇创牧业有限公司

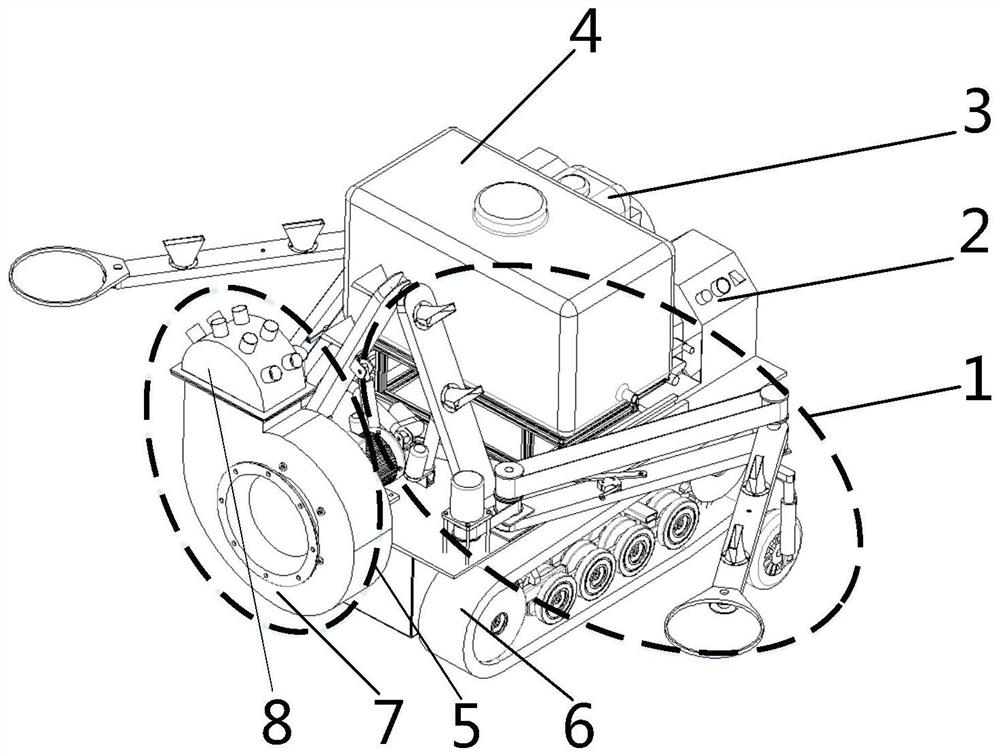

Mobile spraying machine with folding arm type spraying device

ActiveCN112400836AImprove drug acceptance uniformityReduce job jitterInsect catchers and killersAgricultural engineeringStructural engineering

The invention belongs to the technical field of plant protection mechanical equipment, and relates to a mobile spraying machine with a folding arm type spraying device. The mobile spraying machine comprises a vertical spraying mechanism, a horizontal spraying mechanism, a support wheel, a buffer mechanism and an anti-collision mechanism. The vertical spraying mechanism and the horizontal sprayingmechanism are matched for operation, the spraying requirement of the middle-lower portion of a crown layer can be met, the horizontal spraying mechanism can send nozzles to the lower portion of the crown layer, and the pesticide receiving uniformity inside the crown layer and on the back faces of leaves is improved; supporting wheels can support the horizontal spraying mechanism, operation shakingof the horizontal spraying mechanism can be reduced, and the supporting wheels are matched with the buffer mechanism to enable the mobile spraying machine to have certain ground imitating capacity soas to meet the adaptability to different terrains; the anti-collision mechanism is matched with an anti-collision sensor to guarantee the operation safety to the maximum extent; and in addition, theoperation space can be effectively improved through the folding arm type structures of the vertical spraying mechanism and the horizontal spraying mechanism, and meanwhile the inter-row passing capacity and the transition capacity are not affected.

Owner:CHINA AGRI UNIV +1

Quenching inductor for conical pit of brake disc and matched application size determining method

ActiveCN107164611ASolve the problem that heating efficiency is difficult to improveIncrease the effective sensing areaIncreasing energy efficiencyFurnace typesInductorQuenching

The invention discloses a quenching inductor for a conical pit of a brake disc and a matched application size determining method. The quenching inductor comprises a heating coil of the quenching inductor, a left square pipe, a right square pipe, a left round pipe and a right round pipe; the heating coil, the left square pipe, the right square pipe, the left round pipe and the right round pipe are hollow pipes; the water inlet end of the left square pipe is vertically welded with the water outlet end of the left round pipe, and the water outlet end of the left square pipe is horizontally welded with a water inlet pipe orifice of the heating coil; the water outlet end of the right square pipe is vertically welded with the water inlet end of the right round pipe, and the water inlet end of the right square pipe is horizontally welded with the water outlet pipe orifice of the heating coil; and one end of each of the left square pipe and the right square pipe communicates with the inside of the heating coil, and the other ends of the left square pipe and the right square pipe communicate with the insides of the left round pipe and the right round pipe respectively. The effective induction area is increased, and the problem that it is difficult to increase the induction heating efficiency is solved; the heating coil of the inductor is effectively coincided with the conical pit, and a gap is retained; and the heating efficiency and the depth of a hardened zone are guaranteed, and no fusing and ignition phenomena can be caused. The quenching inductor is reasonable in structure and reliable in application; and a matched application method is simple and feasible as well as easy to implement.

Owner:FIRST TRACTOR

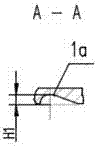

Special safety binding cable

InactiveCN103085707AReasonable structureStrong profiling abilityLoad securingCargo supporting/securing componentsPear shapedMechanical engineering

Disclosed is a special safety binding cable. Bolt seats are arranged at two ends of a fastening ring, a bent bolt is arranged on the left bolt seat of the fastening ring, a connecting ring, a movable turn and a locking ring are mounted on the bent bolt, a right-handed thread is arranged on the bent bolt, a straight bolt is arranged on the right bolt seat of the fastening ring, another connecting ring and a pear-shaped ring are mounted on the straight bolt, and a left-handed thread is arranged on the straight bolt. The special safety binding cable is capable of binding goods in simulation, timesaving and laborsaving, and compact and firm in binding.

Owner:ZHAOYUAN YUNFAN HARDWARE MACHINERY

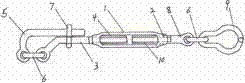

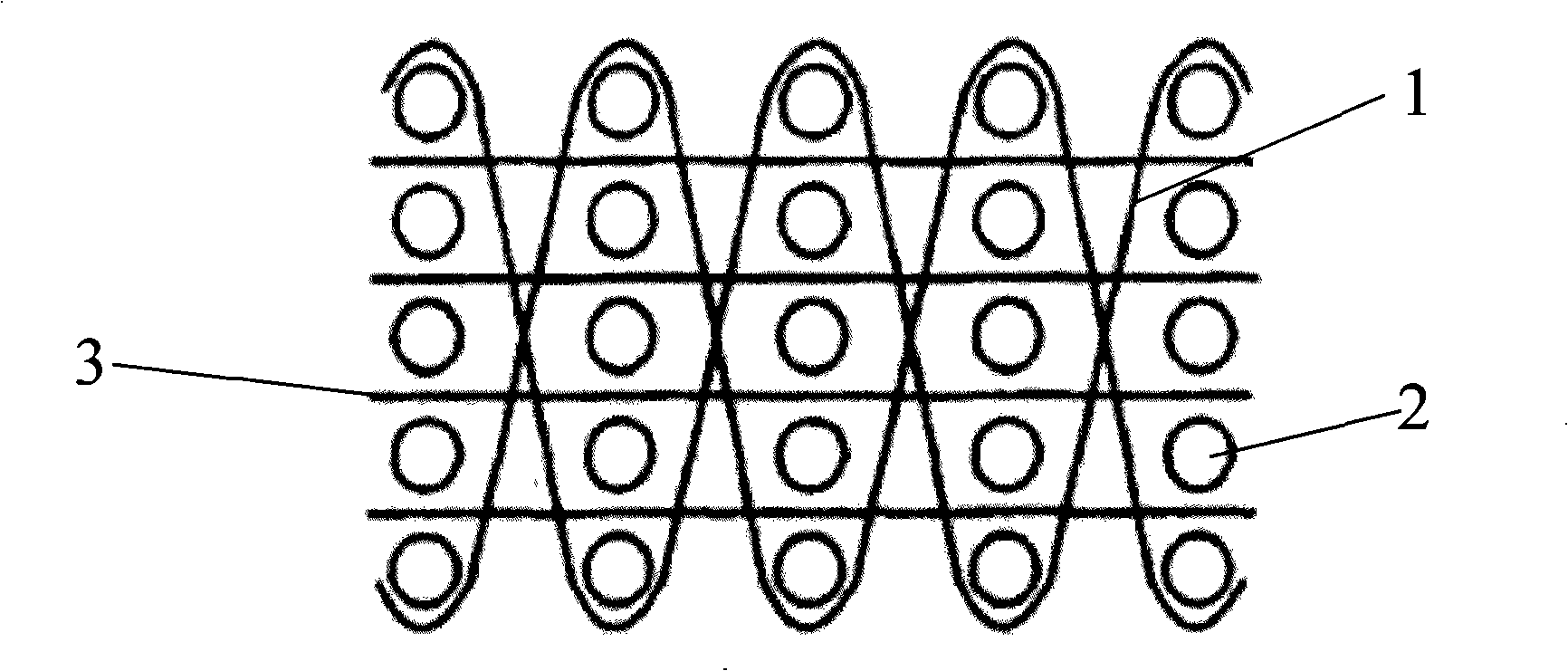

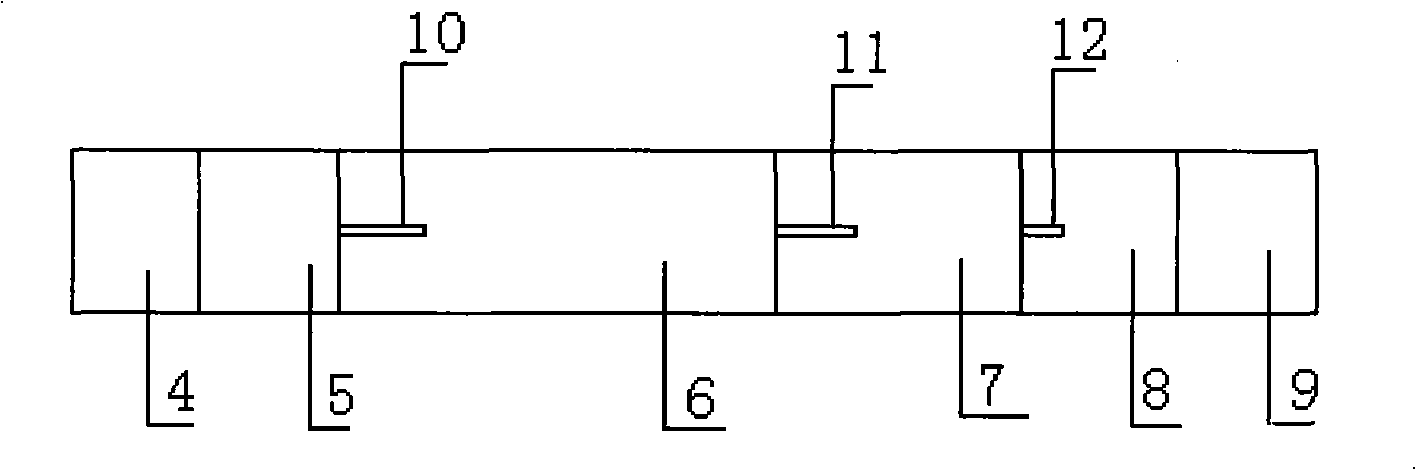

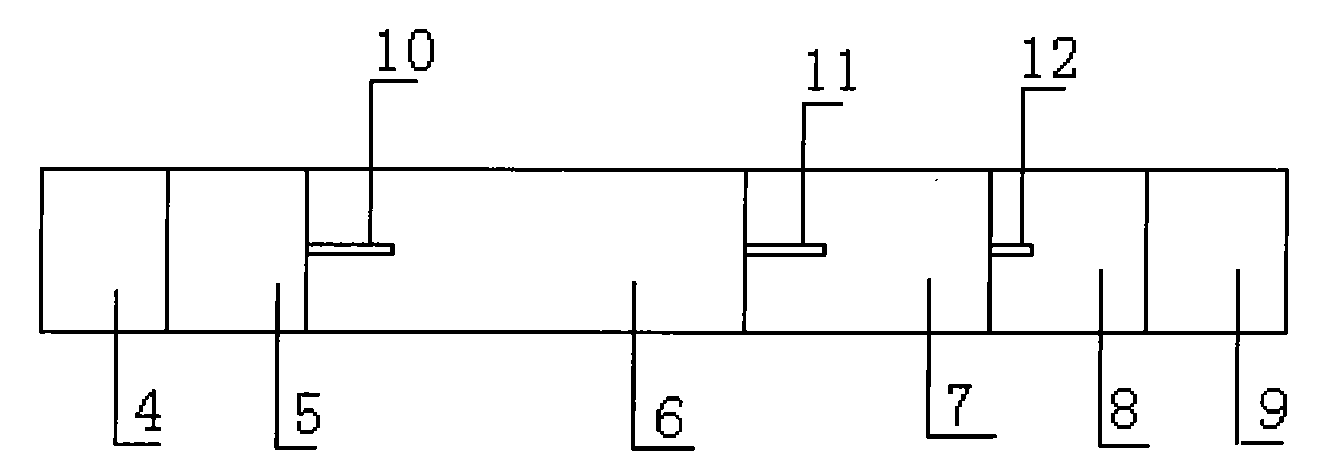

Method for weaving inclusive ring of gas compressor of engine

InactiveCN101532506BIncreased interlaminar shear strengthStrong profiling abilityPump componentsPumpsFiberAxial compressor

The invention provides a method for weaving a containing ring of a gas compressor of an engine. The method is characterized by comprising the following steps: weaving a three-dimensional orthogonal intertexture by a three-dimensional weaving machine as a main part of the containing ring; weaving holes on the three-dimensional orthogonal intertexture by a double side weft insertion method; weavingthe edge part of the containing ring of the three-dimensional orthogonal intertexture through manual hemming; and seaming the containing ring by a step shaped lapping method. The method uses the three-dimensional weaving machine to weave the three-dimensional orthogonal intertexture of the containing ring, uses the double side weft intersection method to directly weave part interface reserved holes, and is simple and practical. The containing ring is woven by high performance fibers, has compact structure and high impact resistance, can effectively prevent severe threat on other parts of a plane because high-speed splinters generated by an unexpectedly damaged vane puncture the shell of the engine under a condition of high speed operation of the engine.

Owner:DONGHUA UNIV

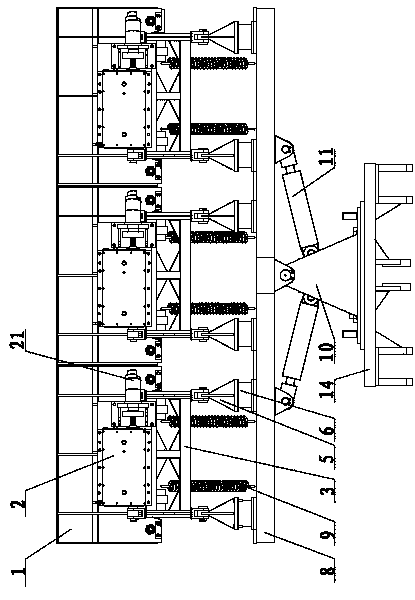

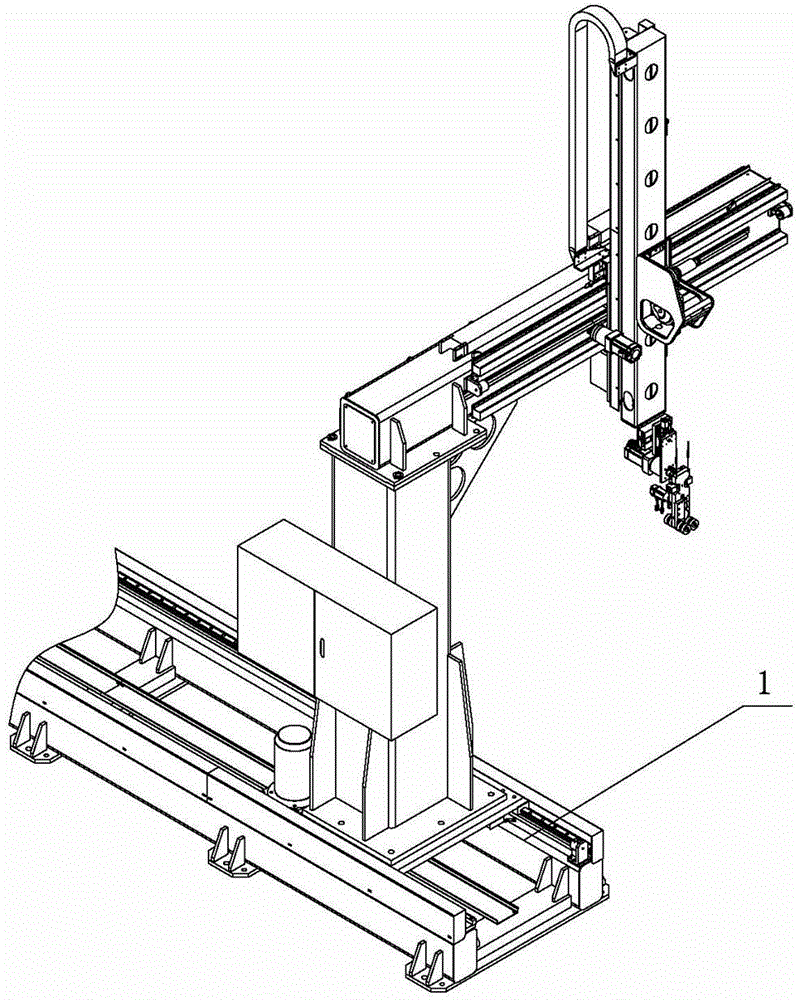

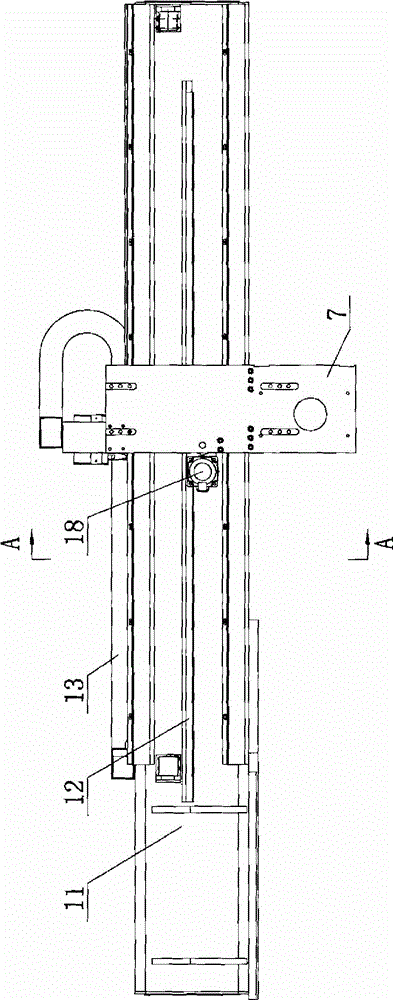

Internal u welding automatic welding machine

ActiveCN103273234BQuality assuranceQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding joint

Owner:SHANDONG SHUIBO WELDING & CUTTING EQUIP MFG CO LTD

Automatic Fruit Peeling Machine

The invention discloses a full-automatic fruit peeling machine and relates to the technical field of peeling devices. The full-automatic fruit peeling machine comprises a shell mechanism, a transmission mechanism and a knife mechanism, the shell mechanism comprises a barrel, a cover is arranged at the upper edge of the barrel in a hinged manner, the knife mechanism is mounted on the inner side of the cover, a barrel transmission mechanism is arranged in the barrel, and a fruit tray matched with the knife mechanism in use is arranged on the transmission mechanism. The full-automatic fruit peeling machine is suitable for peeling fruits different in type and shape and has the advantages of feasible structure, high practicability and easiness in popularization.

Owner:CHENGDU UNIV

A mobile sprayer with a folding arm spray device

ActiveCN112400836BImprove drug acceptance uniformityReduce job jitterInsect catchers and killersSprayerStructural engineering

Owner:CHINA AGRI UNIV +1

Common bletilla tuber mask and preparation method thereof

InactiveCN110013458AEnhance cell viabilityReduce scarCosmetic preparationsToilet preparationsBiologyTraditional Chinese medicine

The present invention discloses a common bletilla tuber mask and relates to the field of daily cosmetics. The common bletilla tuber mask comprises a matrix and mask liquid; and the mask liquid is mainly prepared from the following raw materials in parts by weight: 25-45 parts of vegetable and fruit extracts, 15-25 parts of traditional Chinese medicine extracts and 30-40 parts of auxiliaries; the vegetable and fruit extracts are mainly prepared from a herba portulacae extract, a cucumber extract and a tomato extract; and the traditional Chinese medicine extracts are mainly prepared from a common bletilla tuber extract, a white poria cocos extract, a radix angelicae extract, a radix salviae miltiorrhizae extract, a radix codcnopsitis pilosulas extract, an artificially planted ginseng extract, a mulberry bark extract, a cortex moutan extract and a cortex dictamni extract. The present invention also discloses a preparation method of the common bletilla tuber mask. Beneficial effects are asfollows: the prepared common bletilla tuber mask contains a plurality of the traditional Chinese medicine extracts, efficacies of each of the raw materials are utilized and the raw materials complement each other.

Owner:WEST ANHUI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com