Patents

Literature

54results about How to "Fusion firm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-sensor information fusion-based method for measuring height of small unmanned gyroplane

ActiveCN104567799AImprove reliabilityHigh precisionHeight/levelling measurementAccelerometerMulti sensor

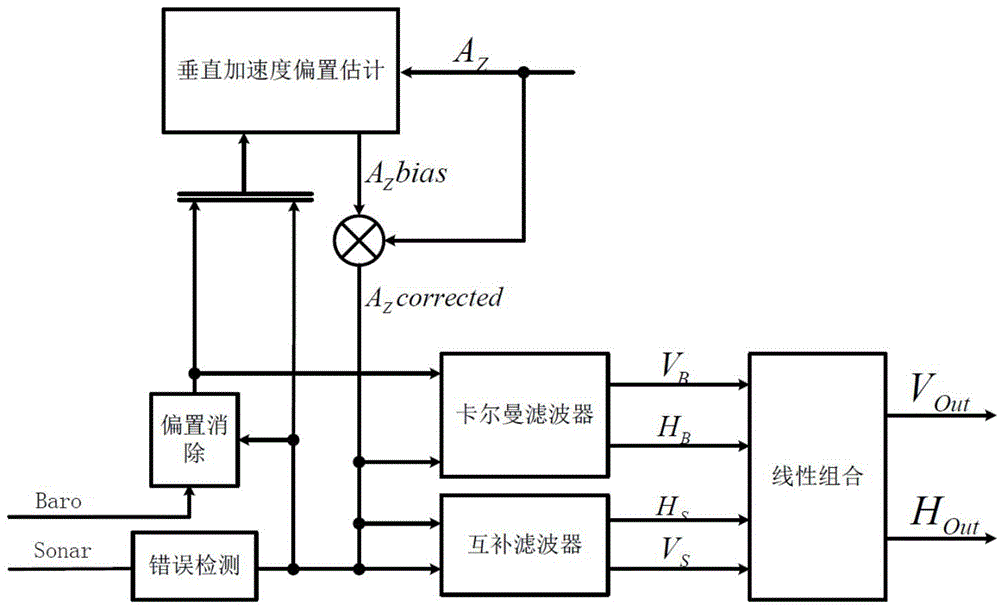

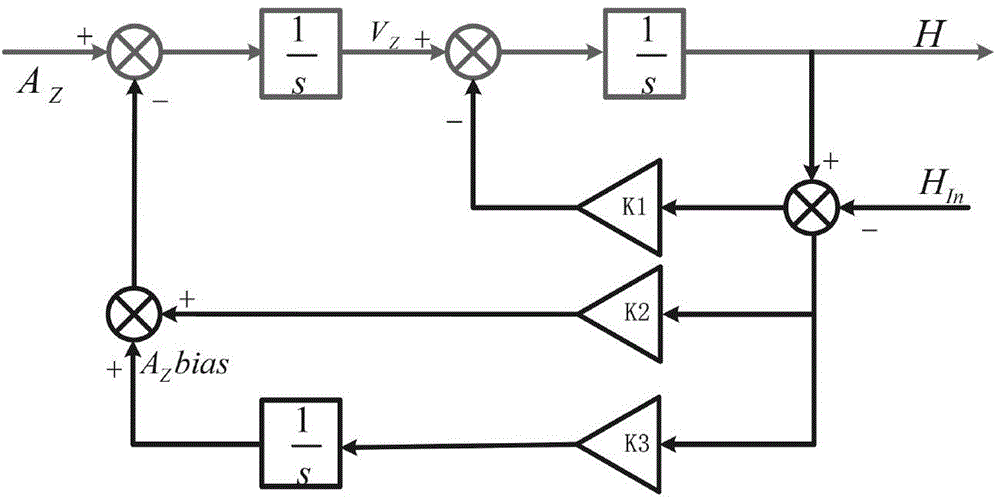

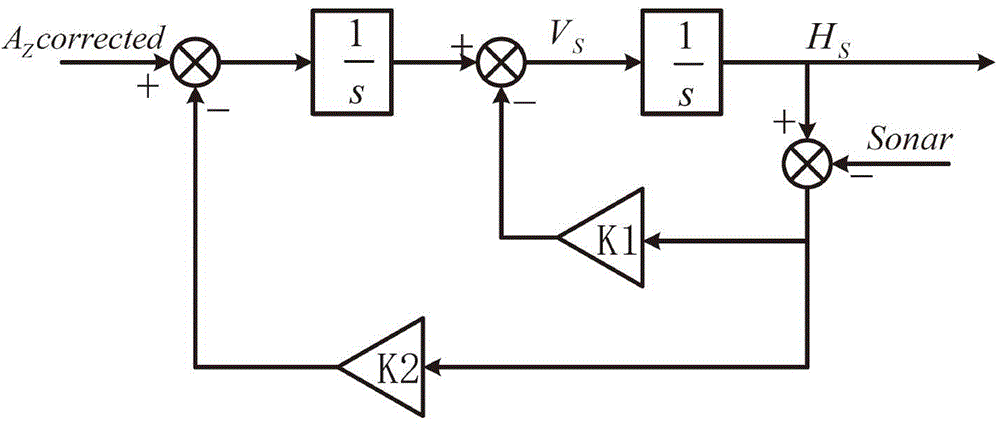

The invention belongs to the field of small unmanned gyroplane autonomous flight control research, provides a multi-sensor information fusion-based method for measuring the height of a small unmanned gyroplane, and aims at providing real-time, precise and reliable height information for the small unmanned gyroplane. The adopted technical scheme is as follows: a sonar arranged at the bottom of the unmanned gyroplane is used for acquiring the distance from the sonar to the ground, and the distance is used as a sonar measurement height; an accelerometer is utilized for acquiring the triaxial accelerated speed of the unmanned gyroplane under an object coordinate system, thereby acquiring the vertical acceleration in a geodetic reference system; a barometer is used for measuring barometric pressure information of the unmanned gyroplane at certain height, comparing the barometric pressure information of the unmanned gyroplane at certain height with ground barometric pressure information, substituting a comparing result into a standard atmosphere model to obtain the height measurement information based on the barometric pressure measurement; and the multi-sensor information fusion height measurement method is adopted for obtaining the high-frequency real-time height and vertical velocity information by use of the inputs. The method is mainly applied to the unmanned gyroplane autonomous flight control.

Owner:TIANJIN UNIV

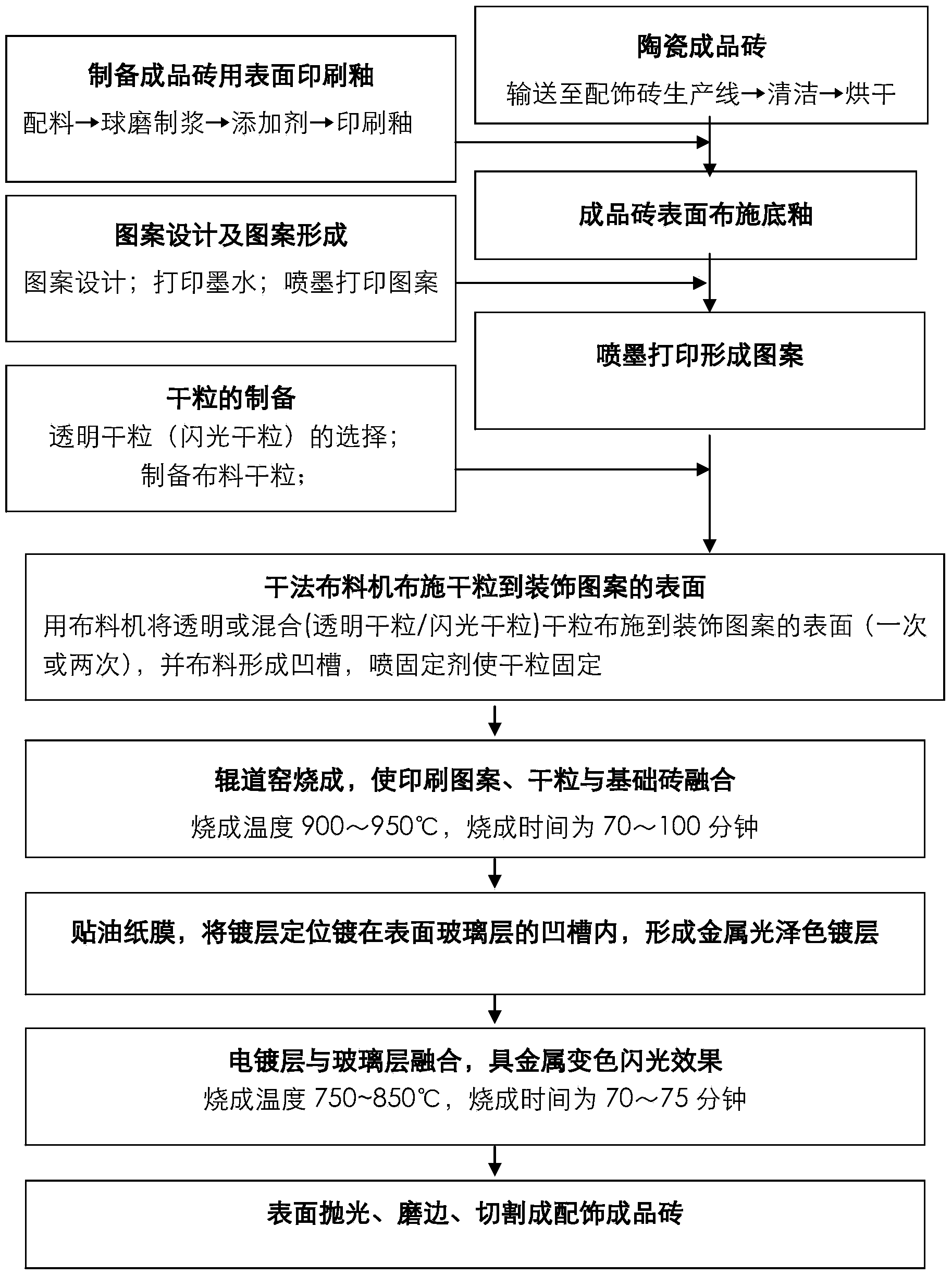

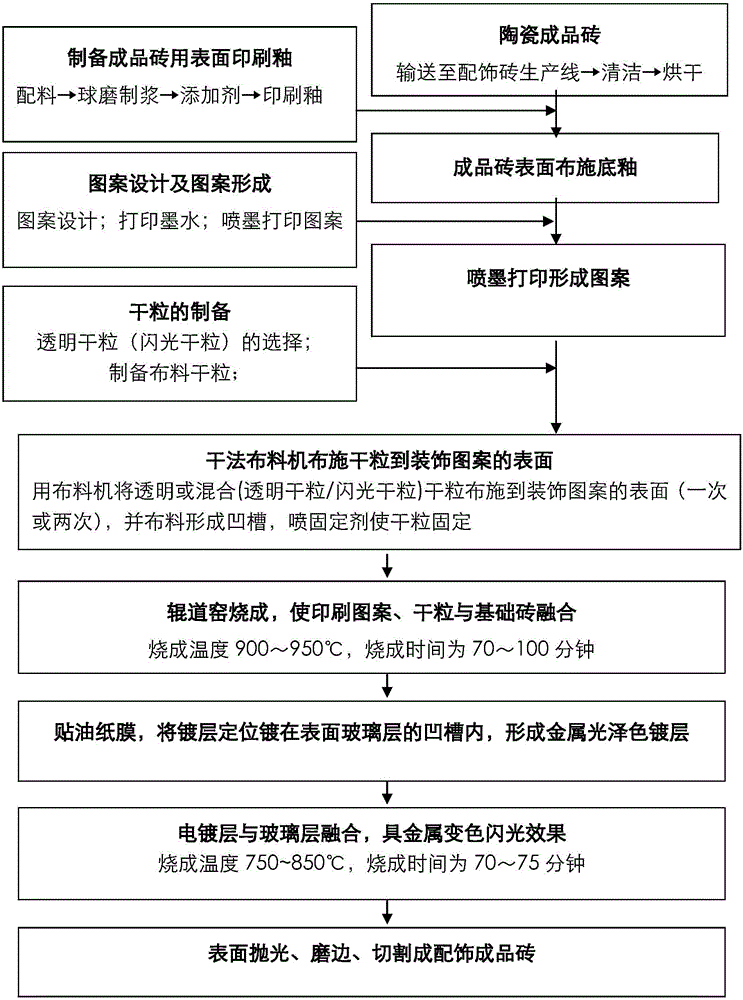

Manufacturing process of ceramic accessory tile and ceramic accessory tile manufactured by the process

The invention relates to a manufacturing process of a ceramic accessory tile and the ceramic accessory tile. The manufacturing process comprises the steps of: (1) printing a ground coat on the surface glass layer of sintered ceramic tile; (2) conducting ink-jet printing on the printing ground coat to form patterns; (3) applying transparent dry grains on the surface of the pattern layer for two times, and sintering; (4) electroplating metal color on a groove of the surface glass layer by adopting a lamination positioning electroplating method, and sintering; (5) polishing the surface of the sintered product; and (6) cutting the sintered accessory tile blank to prepare the accessory tile. The ceramic accessory tile comprises a base tile, ground coat applied on the surface of the base tile, the pattern layer attached on the ground coat, and the first dry grain layer and the second dry grain layer applied on the pattern layer. Irregular pits, grooves or concave curves, wherein the irregular pits, the grooves or the concave curves are hollowed towards the inside and are arranged on the layer surface of the second dry grain distribution layer. The accessory tile varieties include ground flowers, ground line, waist line and corner, and is used for supporting the ceramic wall and floor tiles.

Owner:JIANGXI HEMEI CERAMICS

Method for engraving (three-dimensional) bionic artificial bones in compound bioactive material microdomains

The invention provides a method for engraving (three-dimensional) bionic artificial bones in compound bioactive material microdomains. The method comprises the following steps: selecting orthopedics department hard biological materials and active cell tissues for growing support materials, carrying out bionics matching, and carrying out 3DMAX creation and 3D printing by adopting computer three-dimensional design, thus realizing the simulation of artificial bone materials and structures; establishing an artificial bone microcirculation structure and a blood perfusion condition; establishing osteogenesis stem cells growing environments, namely a capillary bed and a biological activity support. The capillary bed and the biological activity support manufactured by adopting the method have the advantages that the initiative response of hard materials (transplanted bones) and host bones is established, the problem of the initiative fusion between currently various biological materials comprising artificial bone materials of allogeneic bones and the host bones is solved, the clinical indication range of bone transplantation is widened, the secondary replacement of artificial joints can be avoided, and the application ranges of the artificial bones and the artificial joints can be widened.

Owner:BEIJING JIYUAN UNITED BIOLOGICAL TECH

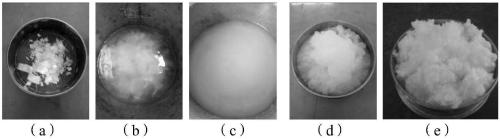

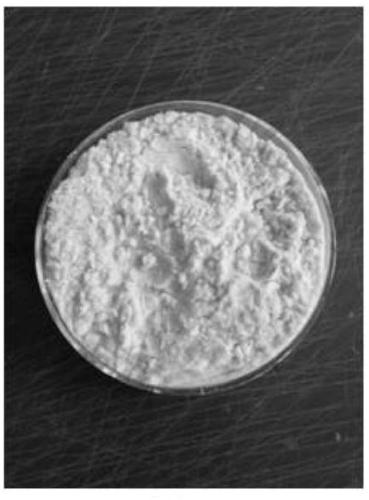

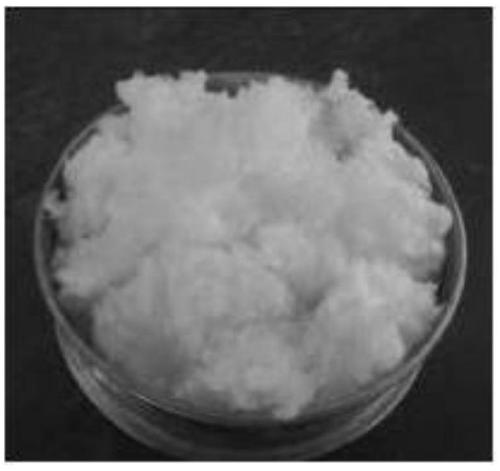

Material for heat insulating nano-material, mixing method of material, heat insulating nano-material and preparation method of heat insulating nano-material

ActiveCN109400011AImprove mixing dispersibilityImprove the effect of mechanical fusionFiberMixed materials

The invention relates to a material for a heat insulating nano-material, a mixing method of the material, the heat insulating nano-material and a preparation method of the heat insulating nano-material. The mixing method includes the steps: uniformly dispersing ceramic fibers by water, drying the uniformly dispersed ceramic fibers to obtain pre-dispersed ceramic fibers; mechanically fusing nano-powder, the pre-dispersed ceramic fibers and auxiliary dispersing agents selected from groups formed by sodium dodecyl benzene sulfonate, methylcellulose, carboxymethylcellulose and polyoxyethylene to obtain nano-heat insulating material. The preparation method of the heat insulating nano-material includes the steps: uniformly mixing 85-100% of materials and 0-15% of additives to obtain a mixed material; performing mold pressing on the mixed material to prepare the nano-heat insulating material. The material is uniformly mixed by the mixing method without destroying fiber shapes and a microstructure of the nano-powder. According to the method, the heat insulating nano-material with low density, low heat conductivity coefficient and excellent mechanical property can be prepared.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

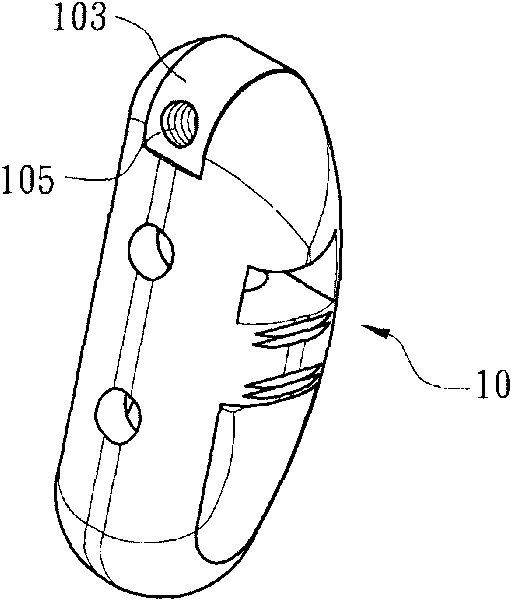

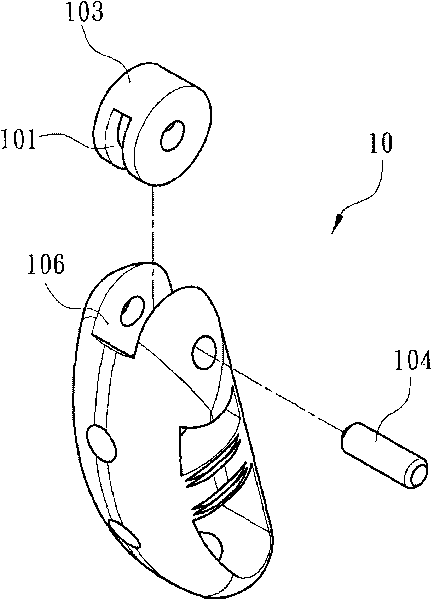

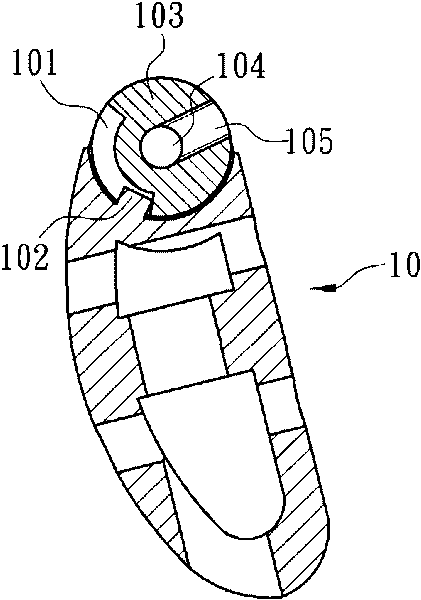

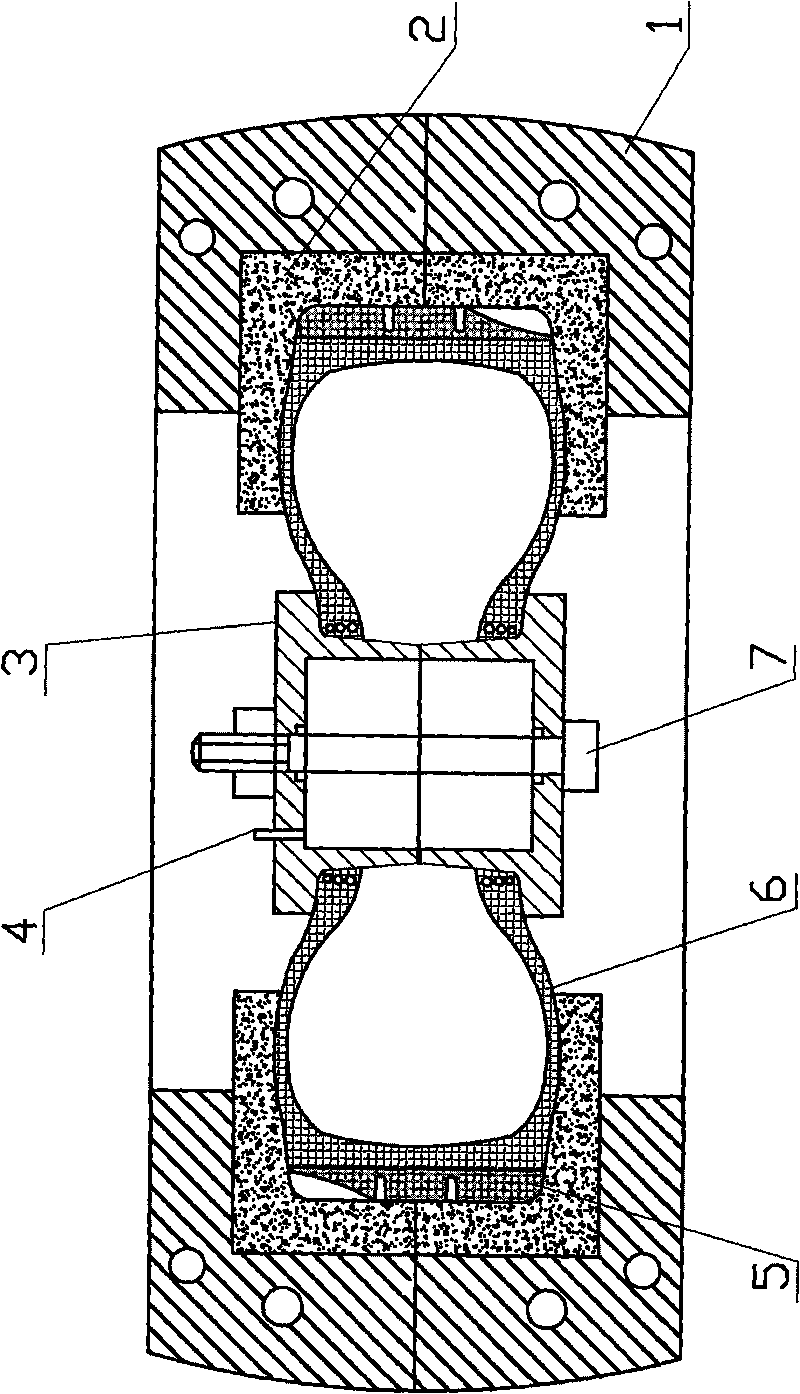

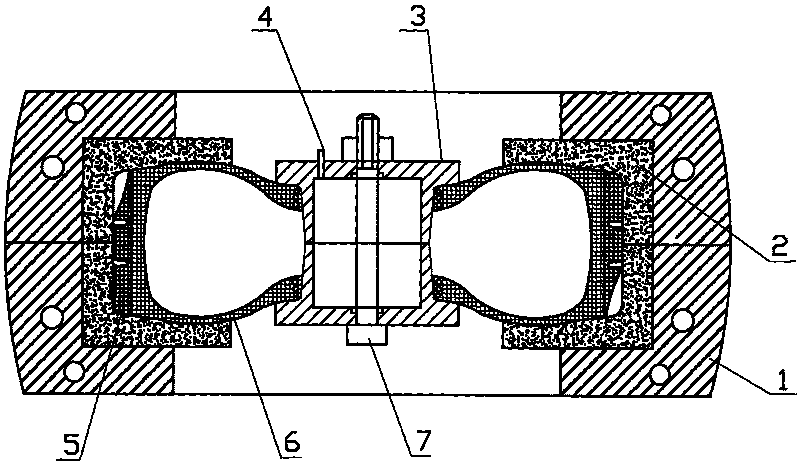

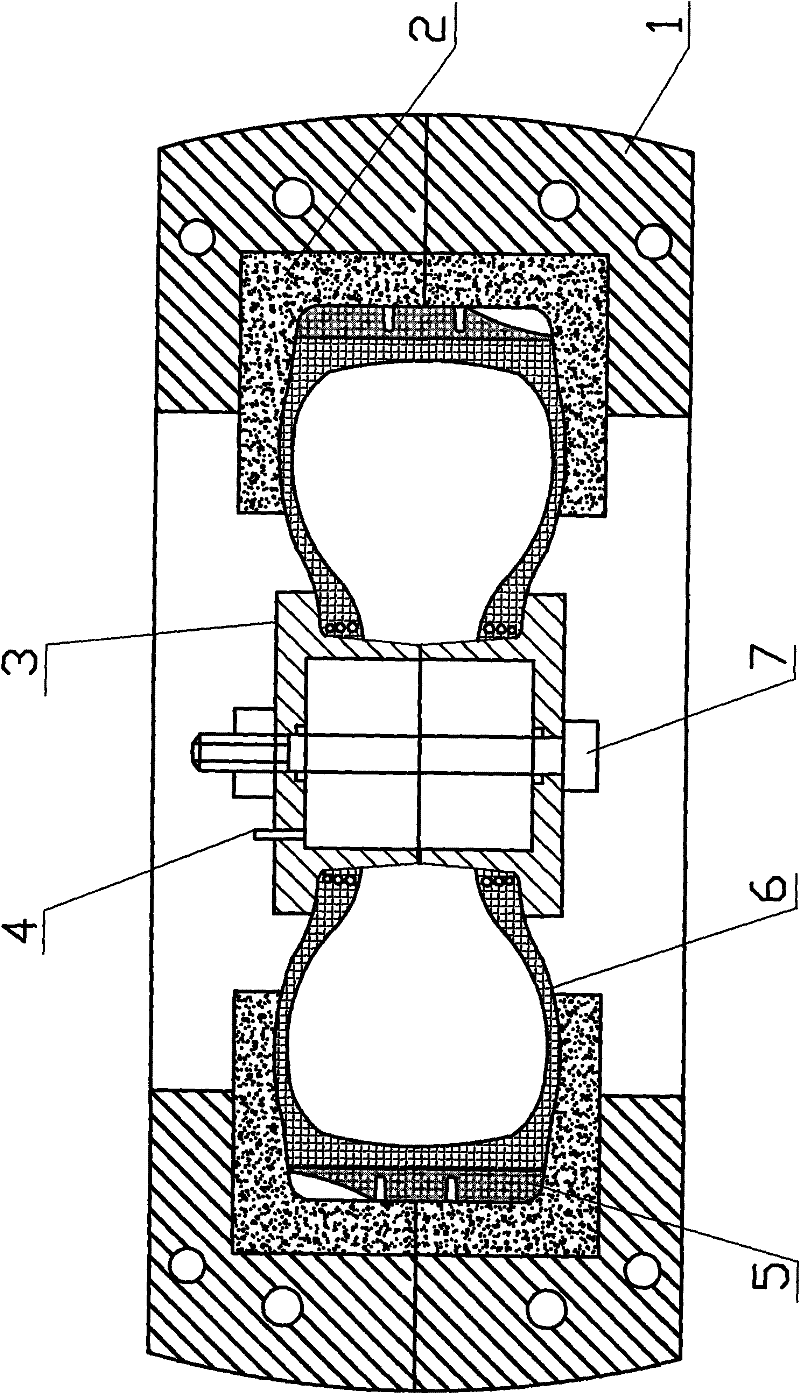

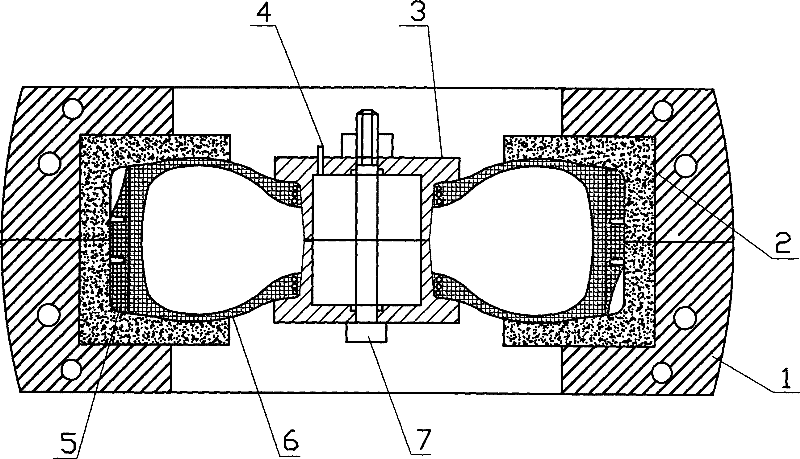

Minimally invasive intervertebral fusion cage and implanting device

InactiveCN101732084AEven by forceImprove stabilityInternal osteosythesisLess invasive surgeryImplanted device

The invention relates to a minimally invasive intervertebral fusion cage and an implanting device. The implanting device comprises a chambering instrument set, a fusion case, a guide rail tube and a guiding instrument set, wherein the chambering instrument set expands an intervertebral space; the fusion case is implanted between vertebras; the guide rail tube guides the fusion cage; the guiding instrument set pushes the fusion cage from the guide rail tube to the intervertebral space; a pivoting groove for accommodating a rotating ring is arranged on one side of the fusion cage; a pivoting pin inserts into the axes of the rotating ring so that the rotating ring is connected with the pivoting groove, and the rotating ring is annularly provided with a first limiting part and a first pivoting part which is connected with the guiding instrument set; and when the rotating ring forms a rotation relationship relative to the pivoting groove, the first limiting part is clamped with a second limiting part which is formed in the pivoting groove. The minimally invasive intervertebral fusion cage and the implanting device ensure that the fusion cage can be arranged between the vertebras at an ideal angle by the spinal fusion instrument, so the intervertebral pressure is uniformly distributed and only a small wound is left at the wounded part. The minimally invasive intervertebral fusion cage and the implanting device realize the aim of minimally invasive surgery and overcome the shortcomings of the current intervertebral fusion cage instrument and the implanting device.

Owner:FARMAR LICENSING

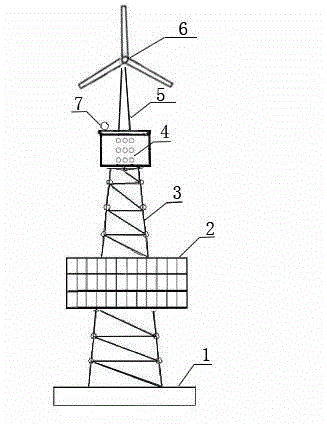

LED (light emitting diode) beacon light based on wind and solar complementation integral power supply mode

InactiveCN102980124AStable and reliable powerMeet power requirementsLighthousePoint-like light sourceEngineeringSolar cell

The invention discloses an LED (light emitting diode) beacon light based on a wind and solar complementation integral power supply mode. The LED beacon light comprises an LED beacon light main body and an LED beacon light tool. The LED beacon light is characterized in that a power supply circuit of the LED beacon light is provided with a wind and solar hybrid power supply system, and the LED beacon light supplies power in the wind and solar hybrid integral power supply mode. Then, a wind power generator and a solar cell panel are arranged on the top or all sides of the LED beacon light main body by a bracket. The LED beacon light has the advantages that the solar energy and the wind energy are sufficiently utilized, and are combined to supply power in the hybrid way, so the stable and reliable power is supplied for the LED beacon light, the power supplying requirements of the LED beacon lights in different areas are met, and the running cost is reduced; in addition, the LED beacon light is provided with a lightning arrestor and an optical control switch, so the starting and the closing of the LED beacon light can be automatically controlled according to the brightness of the environment light rays; and the low-carbon and environment-friendly effects are realized, the running is stable, the noise is low, and the easy popularization is realized.

Owner:倪晓旺

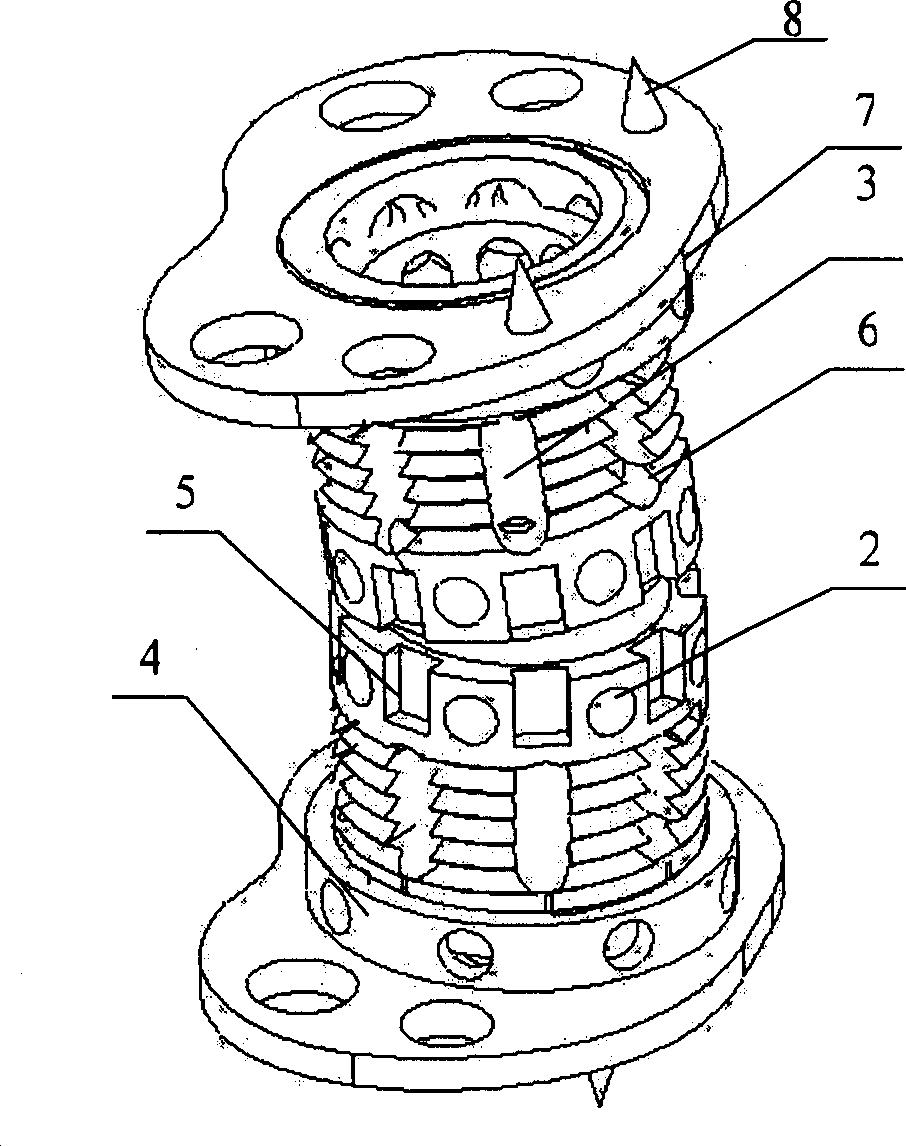

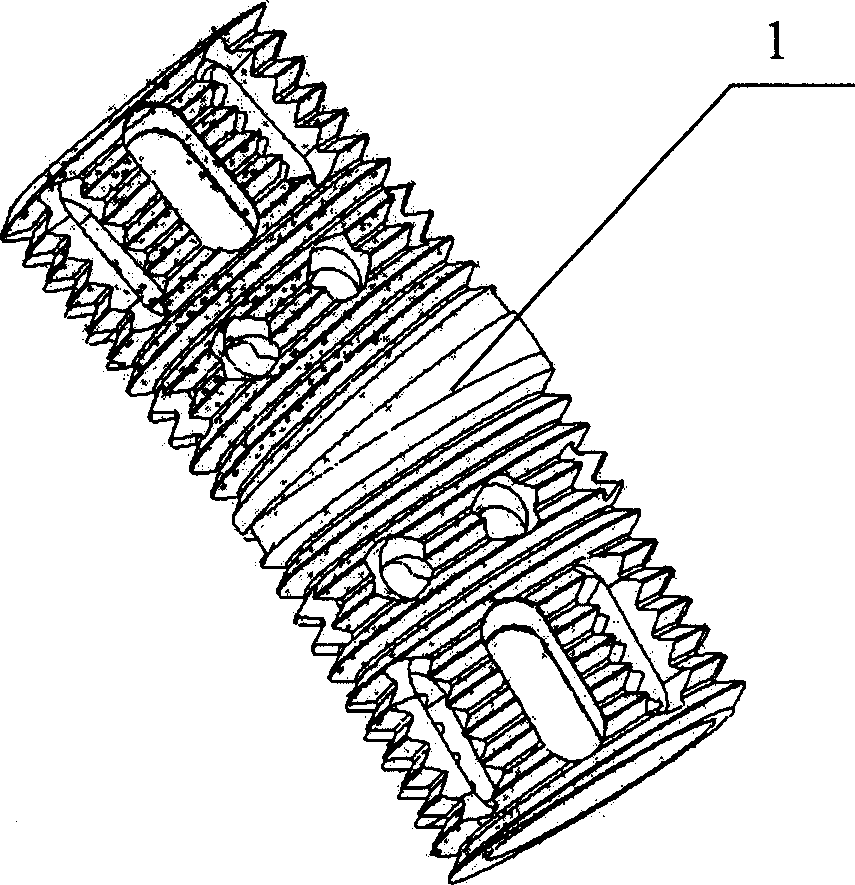

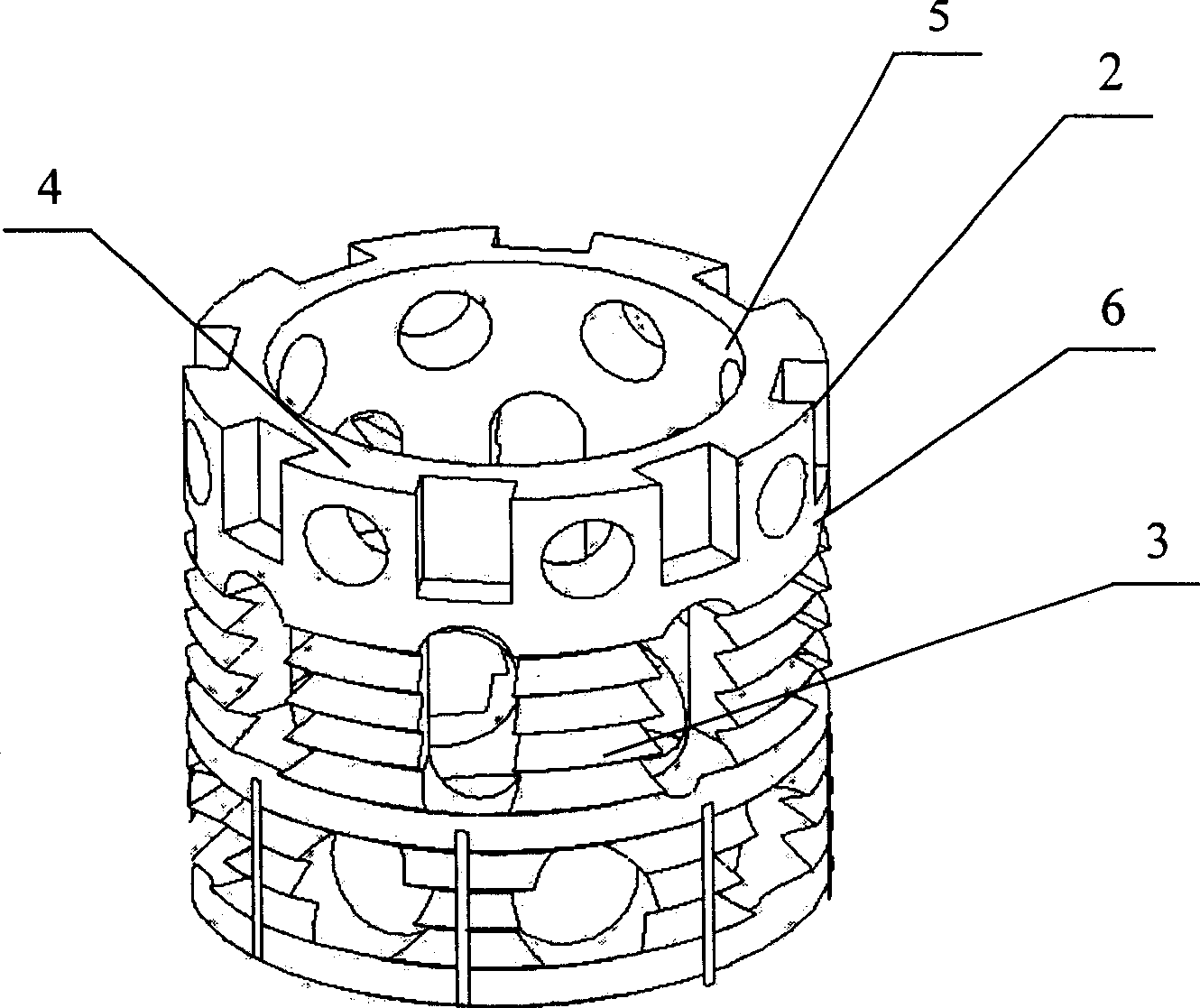

Self -fixing type artificial vertebral body and mounting tool thereof

InactiveCN1483389ARestore physiological curveEasy to implantSurgeryJoint implantsLamina terminalisEngineering

The present invention relates to a self-fixed artificial vertebral body and its mounting tool. It is formed from an intermediate cover, two side covers and two end cover terminal laminas which are assembled together. Its whole structure is up-down symmetrical, its interior is hollow, its length is adjustable, and its middle portion can be bent at a certain angle so as to ensure spinal physiological curve. Its mounting tool includer manual ring drill, curved wrench and sighting device. Said invention also provides its mounting method and steps.

Owner:XI AN JIAOTONG UNIV

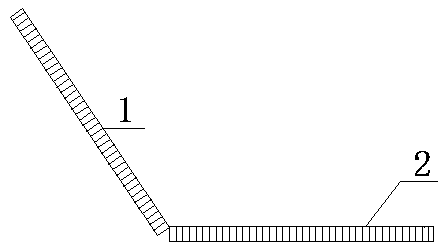

Workpiece surface processing method for self-propagating reaction synthetic process

The invention discloses a workpiece surface processing method for a self-propagating reaction synthetic process, relates to a workpiece surface processing method, and in particular to a processing method for achieving the self-propagating reaction synthetic process on an opening-shaped object. According to the workpiece surface processing method for the self-propagating reaction synthetic process, the structure is simple, the cost is low, operation is easy and convenient, the control capacity on the self-propagating reaction synthetic process is high, and the self-propagating reaction synthetic process can be reliably applied to the opening-shaped object. The workpiece surface processing method for the self-propagating reaction synthetic process includes the following steps: A, a to-be-machined surface (2) of the opening-shaped object (1) is carved; B, the to-be-machined surface (2) is coated with a well-mixed self-propagating reaction coating material; C, the coating material is ignited to motivate a self-propagating reaction; and D, pressurization and heat preservation are carried out on a resultant of the reaction and the workpiece (1).

Owner:宋冠弘

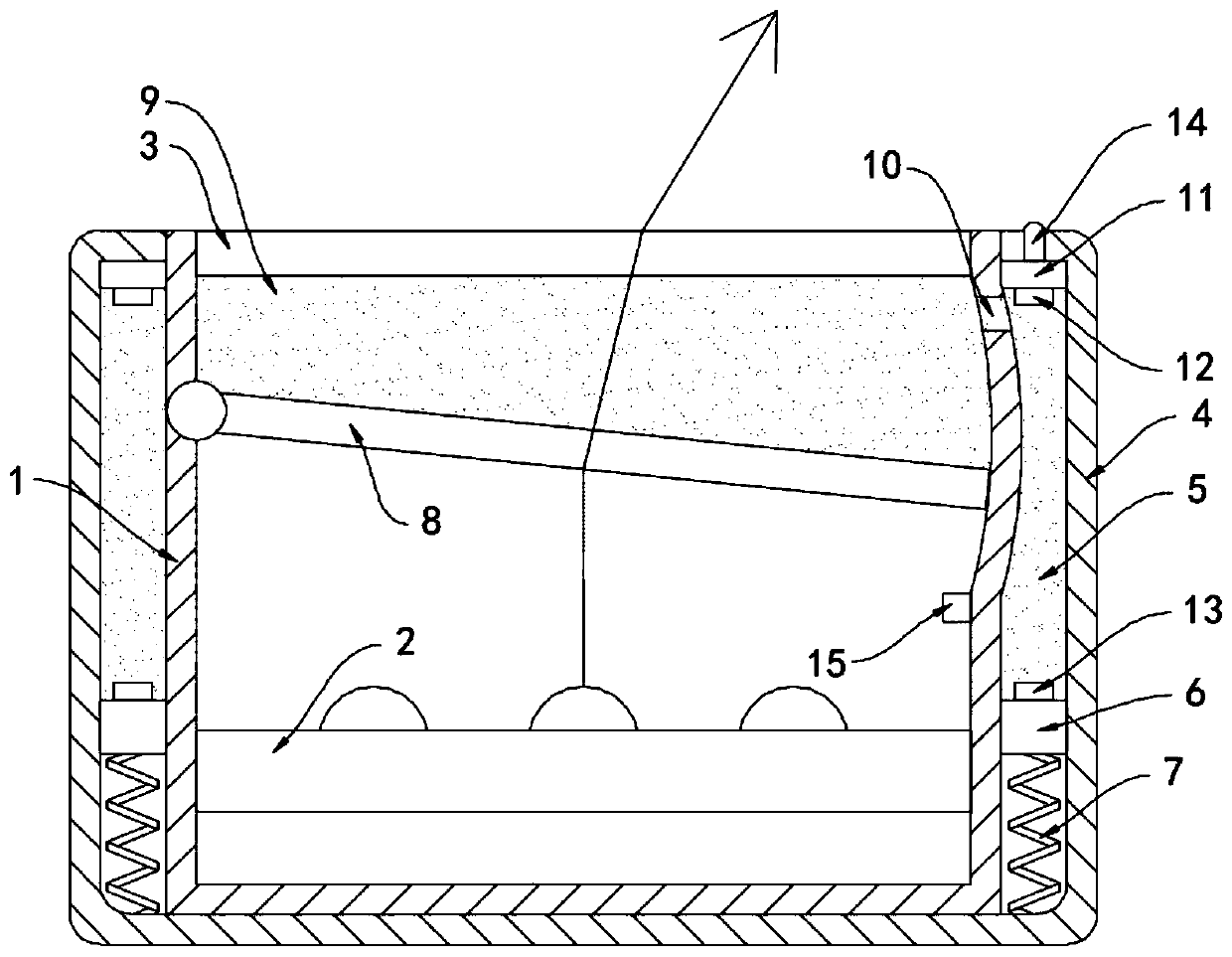

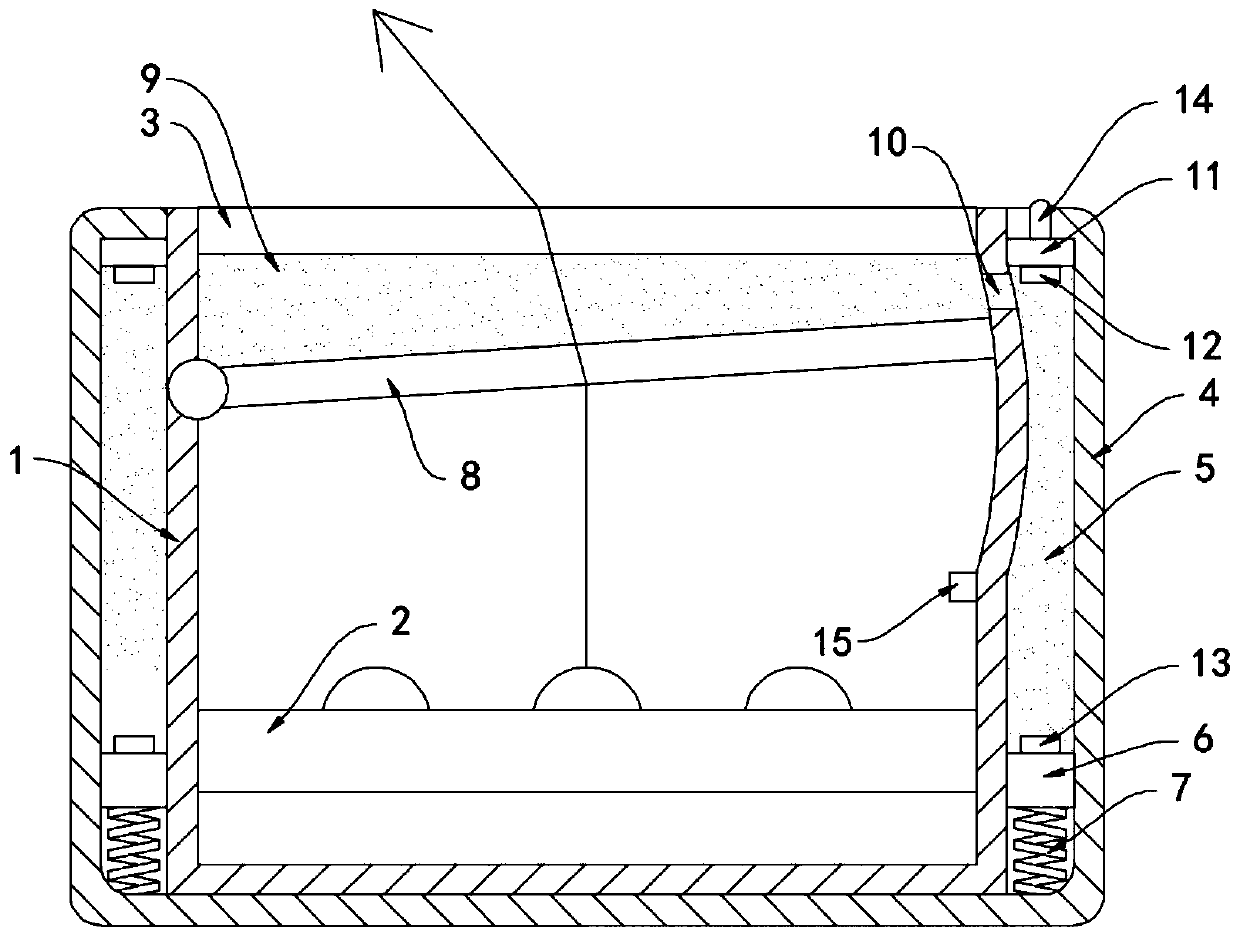

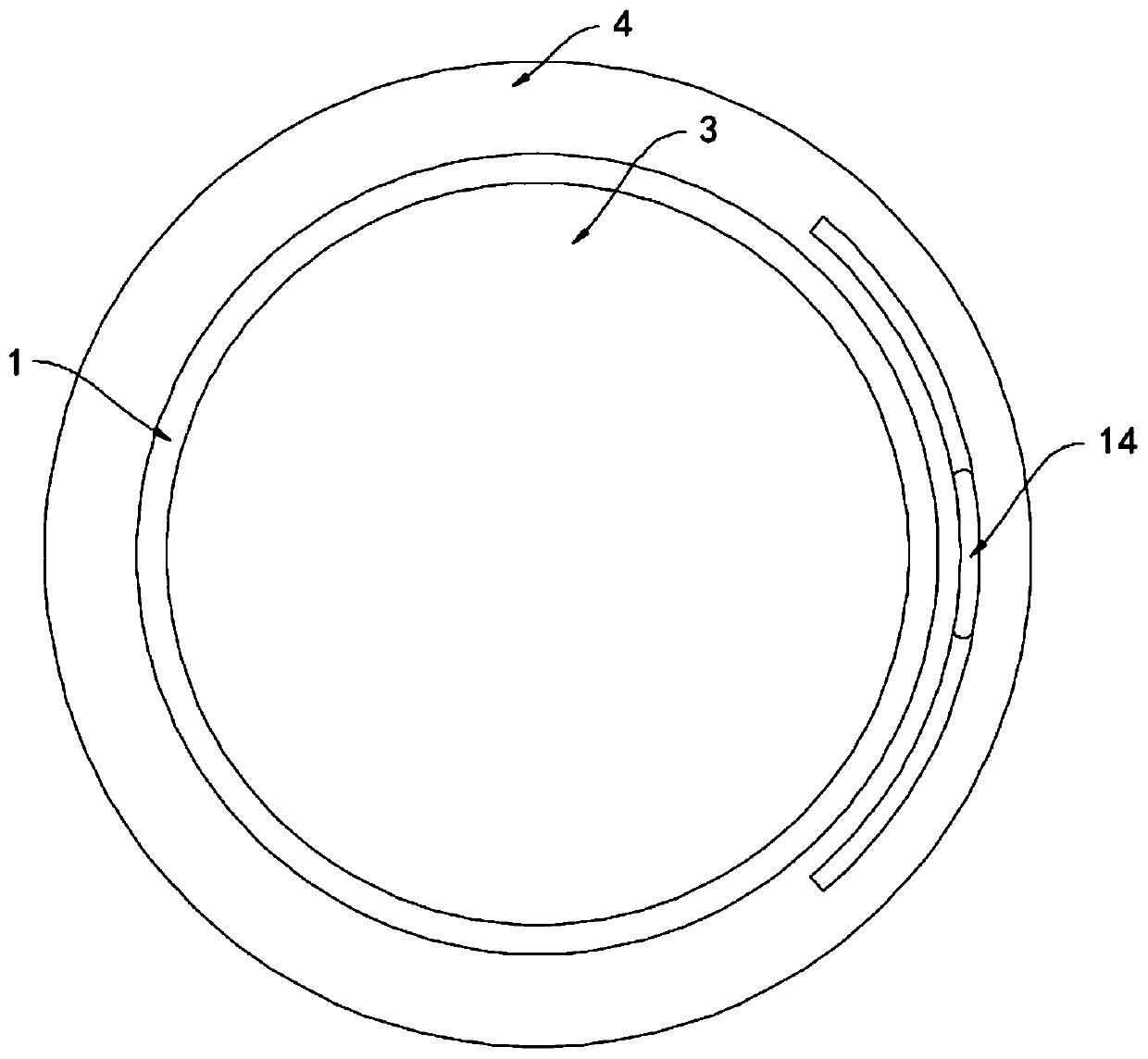

LED underground lamp with adjustable irradiation angle

ActiveCN110939895ANo need to disassembleReduce repulsionLighting heating/cooling arrangementsGas-tight/water-tight arrangementsLED lampMechanical engineering

The invention belongs to the field of LED lamps, in particular to an LED underground lamp with an adjustable irradiation angle. The LED underground lamp comprises an inner shell and an LED lamp set installed in the inner shell. A transparent cover plate is fixedly mounted at the upper end of the inner shell; the inner shell is fixedly sleeved with an outer shell. An annular heat dissipation cavityis formed between the inner shell and the outer shell; the side wall of the annular heat dissipation cavity is connected with a sealing ring in a sealed and sliding mode. The sealing ring is fixedlyconnected with the bottom face of the outer shell through a supporting spring, a refraction plate is rotatably connected to the inner side wall of the inner shell through a hinge, the side wall of theother end of the refraction plate is connected with the inner side wall of the inner shell in a sealed and sliding mode, and a refraction cavity is formed between the refraction plate and the transparent cover plate. According to the underground lamp, the repulsive force of the arc-shaped magnet to the permanent magnet can be adjusted by rotating the adjusting ring, then the position of the refraction plate is adjusted, the refraction direction of refraction liquid to lamplight is changed, and the illumination angle of the underground lamp can be adjusted without disassembling the undergroundlamp.

Owner:SHENZHEN TIAN YU HARDWARE & ELECTRICAL

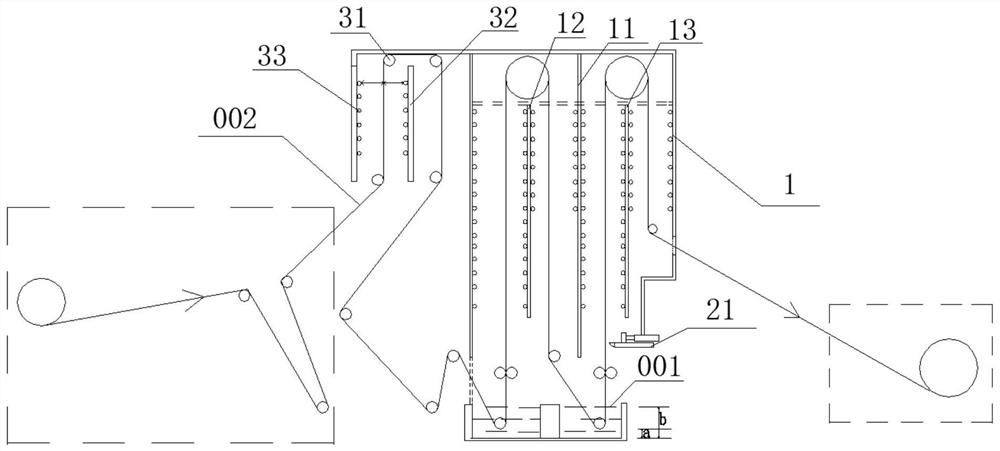

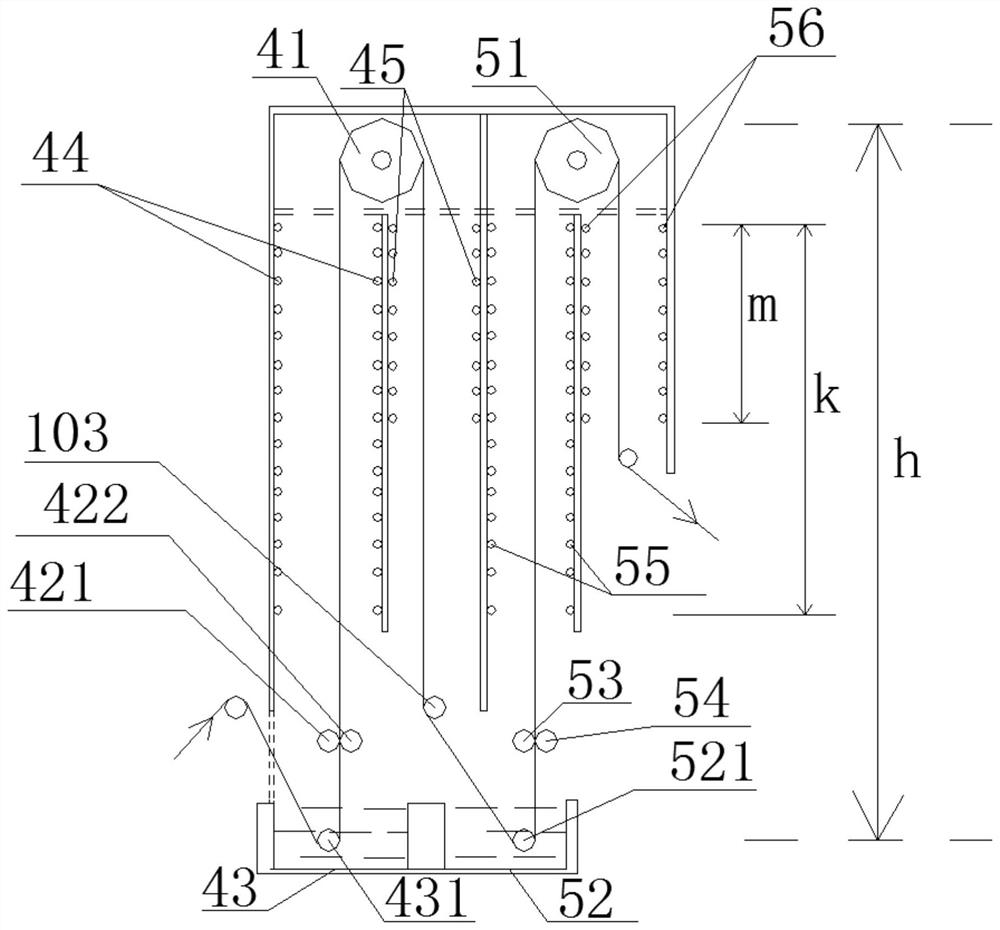

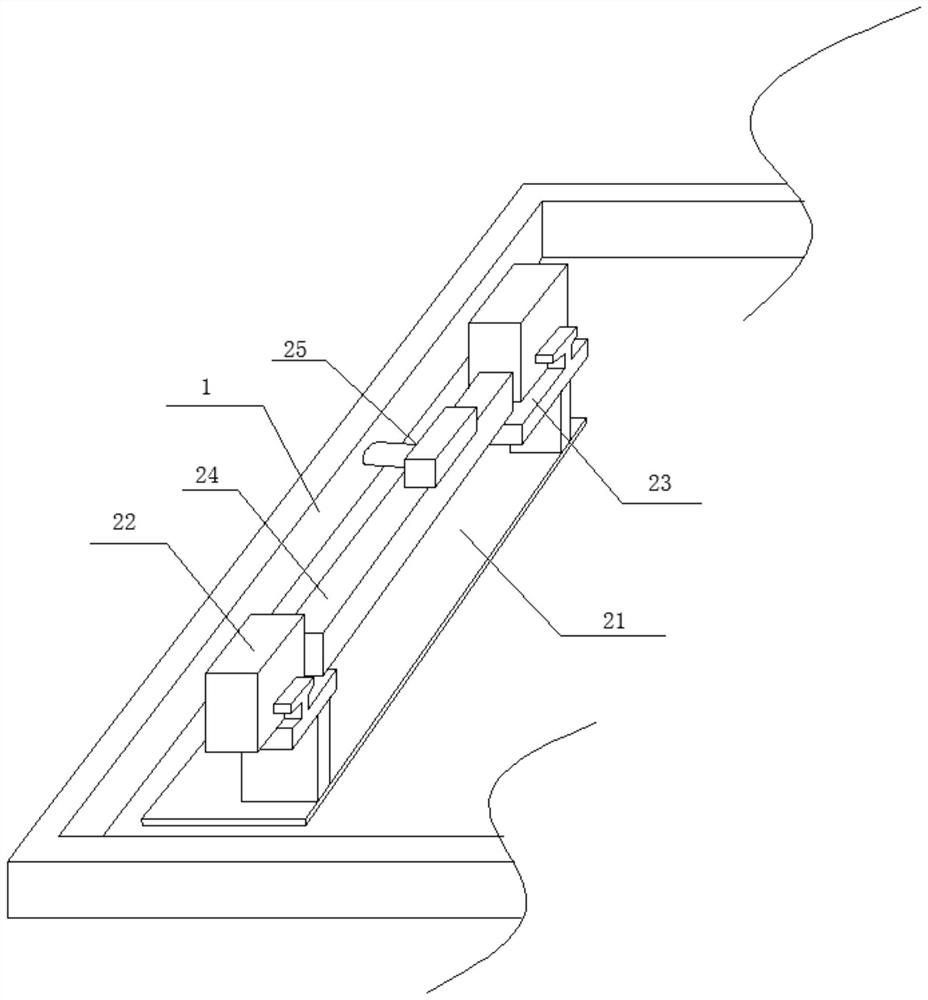

Vertical two-impregnation one-scraping polyester-mixed cotton cloth impregnator

PendingCN111790566AConvenient for advertisingImprove satisfactionLiquid surface applicatorsCoatingsPolyesterPolymer science

The invention discloses a vertical two-impregnation one-scraping polyester-mixed cotton cloth impregnator, belongs to the technical field of impregnation, and particularly relates to the vertical two-impregnation one-scraping polyester-mixed cotton cloth impregnator. The impregnator comprises a machine base, wherein a first impregnation mechanism used for impregnating polyester-mixed cotton cloth,a second impregnation mechanism used for adding rubber to the polyester-mixed cotton cloth and a rubber scraping mechanism used for scraping rubber cement on one side of the polyester-mixed cotton cloth are arranged on the machine base, the impregnator further comprises a traction mechanism used for conveying the polyester-mixed cotton cloth to the first impregnation mechanism and a winding device used for collecting the polyester-mixed cotton cloth discharged from the second impregnation mechanism, and the rubber scraping mechanism comprises a scraper fixed to the machine base through a moving device. The impregnator is simple in structure and high in practicability.

Owner:台州捷豹橡胶有限公司

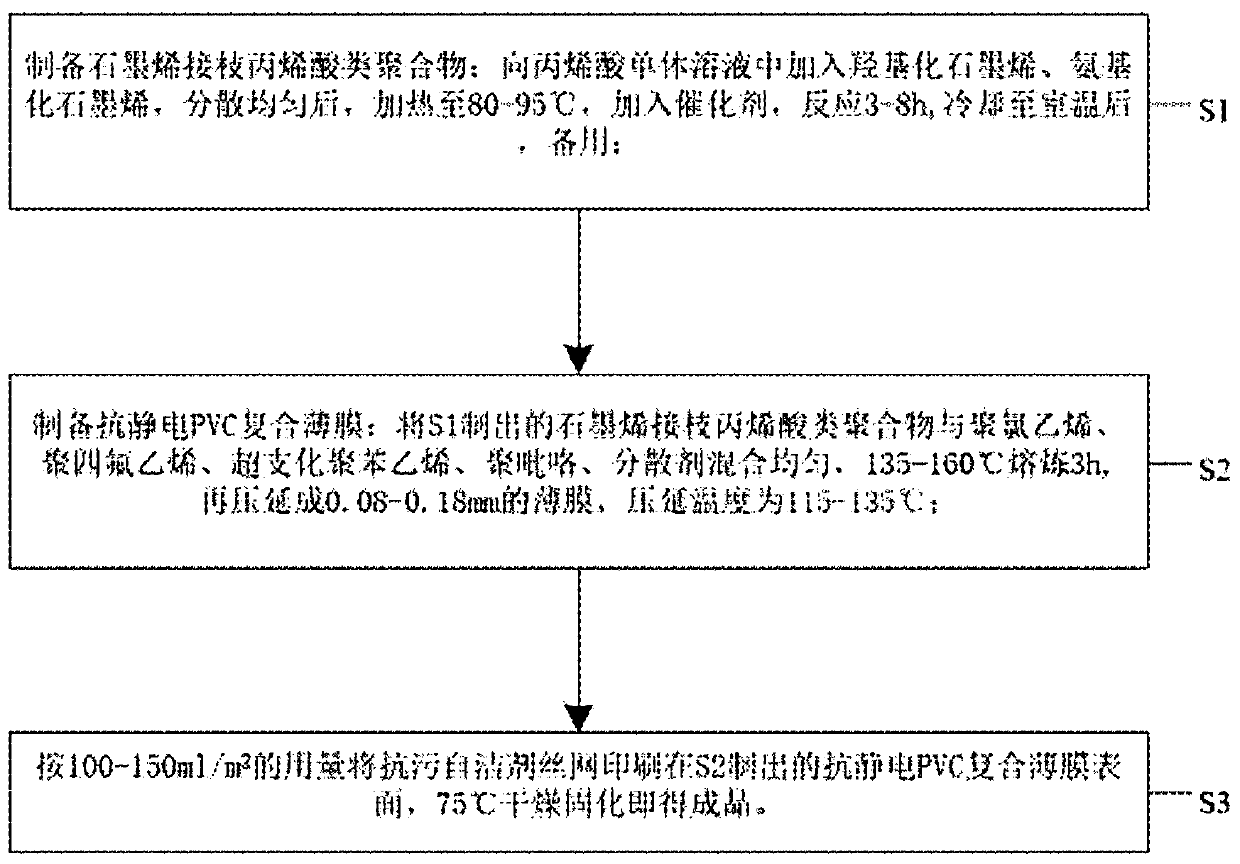

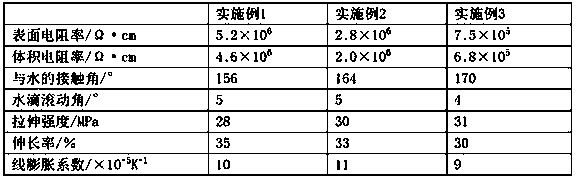

Hydrophobic and oleophobic antistatic PVC composite film

ActiveCN111349264AHas permanent antistatic abilityImprove bindingAntifouling/underwater paintsPaints with biocidesPolymer scienceAcrylic resin

The invention discloses a stain-resistant antistatic PVC composite film. According to the stain-resistant antistatic PVC composite film, an antistatic PVC composite film is used as a substrate, and astain-resistant self-cleaning agent is printed on the surface of the substrate in a silk-screen mode; the antistatic PVC composite film comprises the following components in percentage by weight: 45-65% of polyvinyl chloride, 10-14% of polytetrafluoroethylene, 12-18% of an acrylic monomer, 6-10% of hydroxylated graphene, 4-6% of aminated graphene, 0.1-0.5% of a catalyst, 1.8-4% of hyperbranched polystyrene, 1-2% of polypyrrole and 0.1-0.5% of a dispersing agent. The stain-resistant self-cleaning agent is prepared from the following components in percentage by weight: 30 to 55 percent of nano TiO2 sol, 5 to 10 percent of nano silver powder, 10 to 15 percent of a lotus leaf hydrophobic agent, 10 to 15 percent of perfluorooctyltriethoxysilane and 20 to 30 percent of perfluoroalkyl ethyl acrylate. According to the invention, graphene is introduced into an acrylic polymer molecular chain under the chemical cross-linking action of graphene with a special functional group structure and acrylic resin, and the modified graphene conductive particles are stably compatible with PVC resin by utilizing the principle of similarity and compatibility among media, so that the PVC composite film haspermanent antistatic capacity.

Owner:SUZHOU ZIJIN PLASTIC

Automotive polyvinyl chloride interior trimming panel and preparation method thereof

InactiveCN109161132AHigh hardnessHigh bending strengthChemical industryFlexural strengthPolyvinyl chloride

The invention discloses an automotive polyvinyl chloride interior trimming panel and a preparation method thereof, belongs to the technical field of polyvinyl chloride panels, and solves the problemsthat the thickness, the hardness, the bending strength and the like of existing wood-plastic panels cannot meet the requirements of automotive interior trimming panels. The polyvinyl chloride interiortrimming panel is prepared from 80-100 parts of polyvinyl chloride SG8-type resin, 40-50 parts of heavy calcium carbonate, 10-20 parts of a wood-plastic reclaimed material, a foaming regulator as well as ingredients including a calcium-zinc stabilizer, an interior lubricant, an exterior lubricant, a foaming agent, wood flour and the like. The preparation method of the panel comprises steps as follows: the polyvinyl chloride SG8-type resin and the ingredients are put into a hot-mixing pot for hot-mixing, then the foaming regulator and calcium powder are put sequentially for hot-mixing, the wood-plastic reclaimed material is put finally, the mixture is put into a cold-mixing pot for cooling after hot-mixing, is sent to a mold for extrusion finally after being plasticized by seven sections of double screws of a barrel, is subjected to cooling press-fitting shaping by a shaping platform and is pulled out by a pulling machine for cutting forming, and a finished product is obtained. The invention is applicable to the automotive interior trimming panel.

Owner:SHANDONG HUIFENG NEW MATERIAL TECH CO LTD

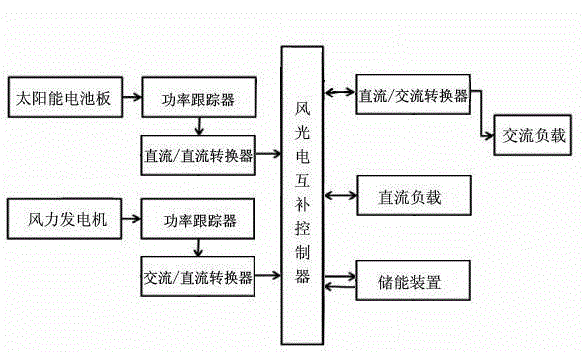

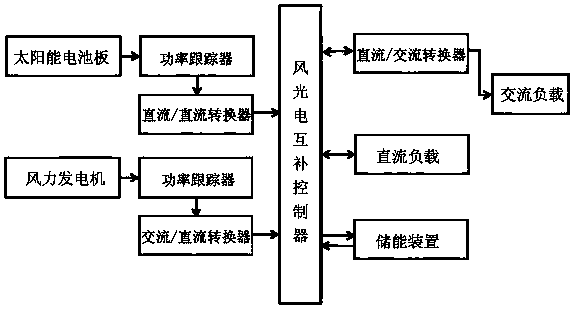

Wind, light and power integrated power supply system and apparatus

InactiveCN108616138AEffective distributionStable and reliable powerBatteries circuit arrangementsPV power plantsWind drivenAlternating current

Owner:DALIAN XINCHENG CREDIT MANAGEMENT CONSULTING

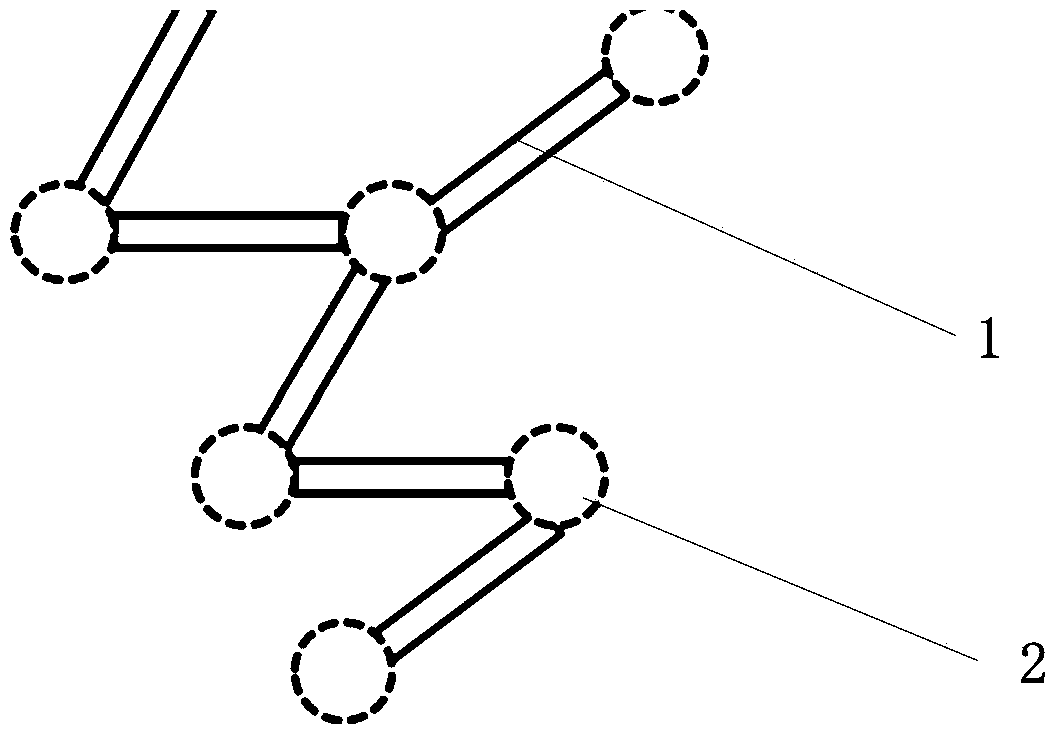

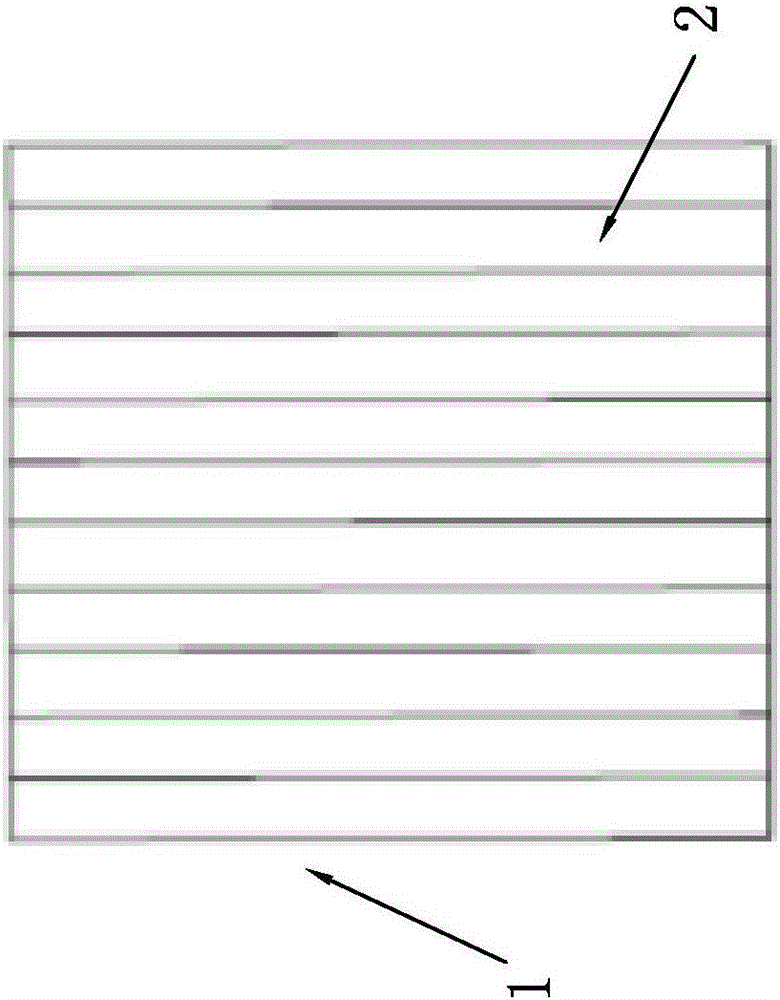

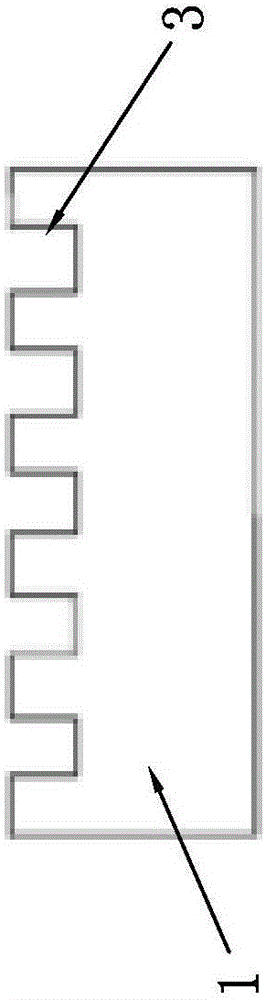

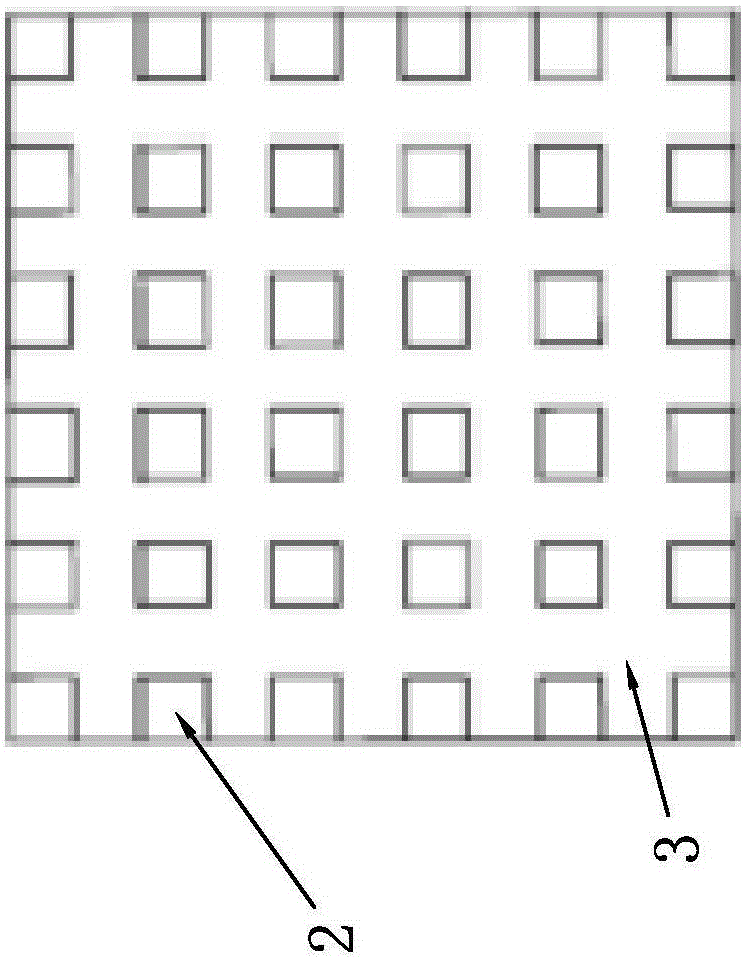

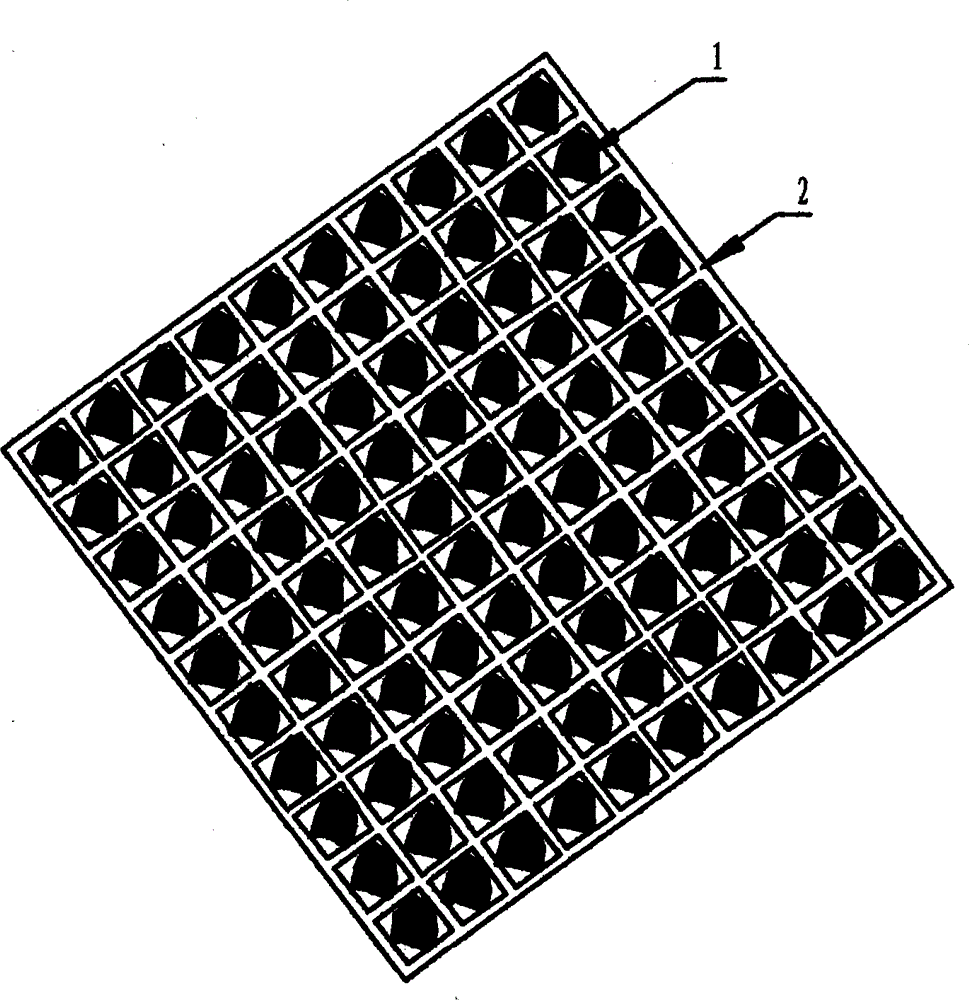

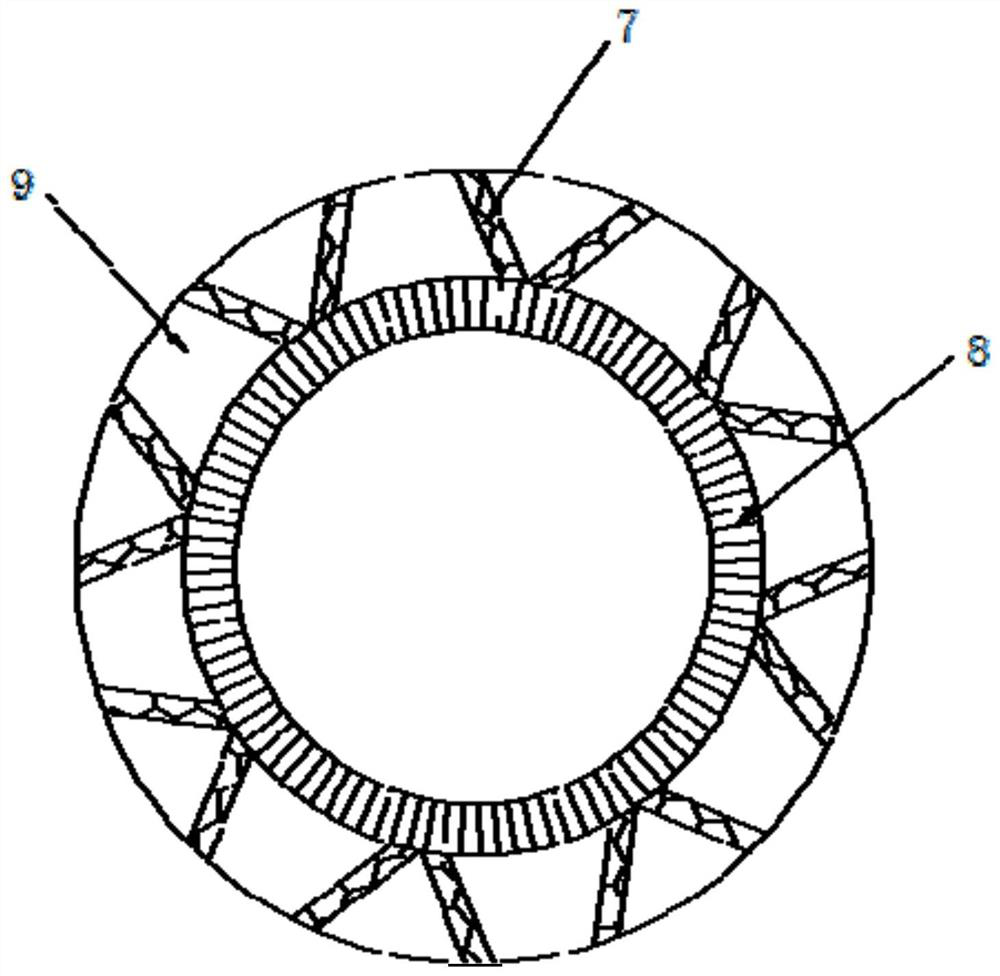

Casting method for fusing metal gridding reinforcing body and a metal matrix

The invention provides a casting method for fusing a metal gridding reinforcing body and a metal matrix. The casting method comprises the following steps of fixing reinforcing bodies (1) by using metal grids (2); mounting the reinforcing bodies (1) in corresponding positions of a foam mould; injecting pre-foamed foam beads in the foam mould to obtain a bright and clean foam mould with reinforcing body metal grids; accurately positioning the reinforcing bodies (1); uniformly coating foam mould clusters by using foam mold casting coatings; performing vibratory modeling on the foam mould clusters in a casting sand box; connecting a vacuumizing system to the casting sand box; pouring qualified smelted liquid metal on the foam mould; performing vacuumizing while pouring; and taking out the foam mould after cooling down the foam mold so as to obtain a casting on which the reinforcing bodies (1) are fused at accurate surface positions of the metal matrix. By the casting method, the reinforcing bodies (1) can be accurately positioned and uniformly distributed on the casting of the metal matrix; after the metal grids (2) and the metal matrix are fused, a transitional layer is formed; the reinforcing bodies (1) can be firmly fused with the metal matrix; the yield of products is improved; the cost is effectively reduced; and the quality of products is guaranteed.

Owner:吴建化

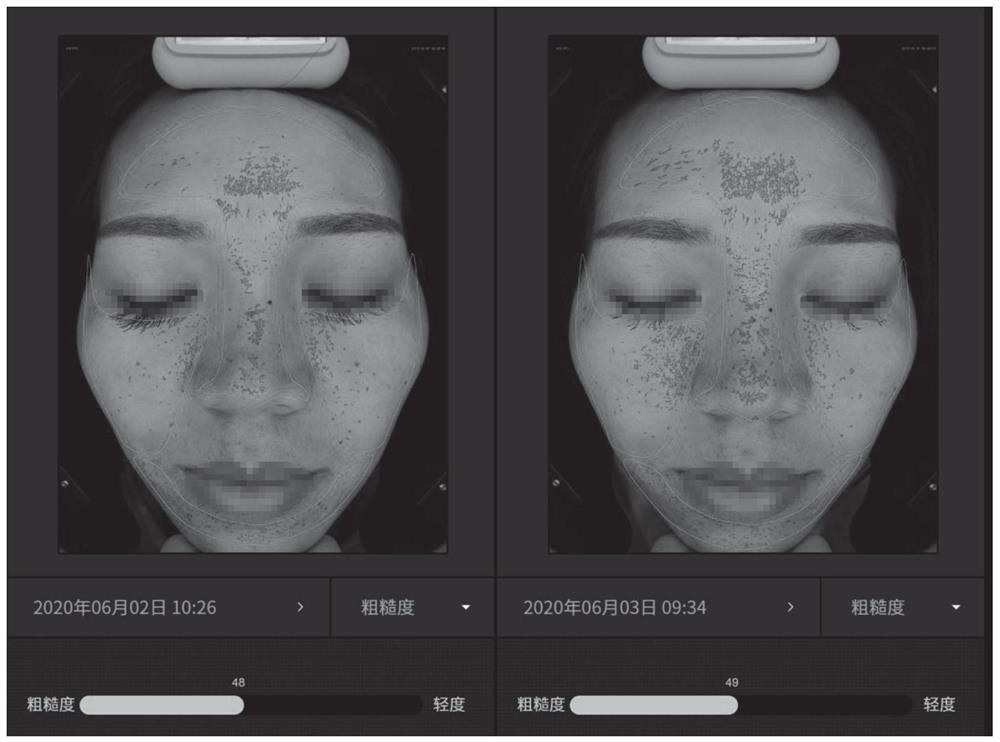

Cosmetic composition containing nanocarbon material

PendingCN112006927AFusion firmLarge specific surface areaCosmetic preparationsToilet preparationsNanostructured carbonNanotechnology

The invention relates to a cosmetic composition containing a nano carbon material. The nano carbon material comprises one or more of nano diamond, carbon onion and carbon nanohorn, the particle size of the nano carbon material is 2 nm to 100 nm, and the weight percentage of the nano carbon material in the cosmetic composition is 0.1% to 0.5%. According to the invention, the nano carbon material isinnovatively applied to cosmetics. By utilizing the characteristics of micro-nano scale, hydrophilicity, high specific surface area and high porosity, the deep cleaning function of cleaning cosmeticcompositions such as cleaning masks and facial cleansing products is realized, the purpose of adsorbing dirt, grease and blackheads in pores is achieved, and meanwhile, all raw material components inthe cosmetic composition are fused stably and are not easy to separate.

Owner:河南英能新材料科技有限公司

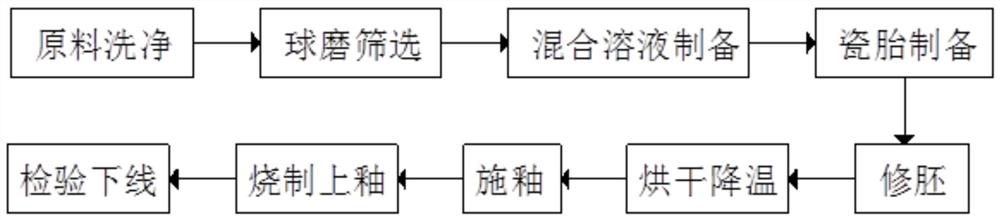

Preparation method of multi-layer glaze daily-use porcelain

The invention provides a preparation method of multi-glaze daily-use porcelain. The multi-glaze daily-use porcelain is prepared from the following raw materials of: aluminum oxide, silicon dioxide, ferric oxide, calcium oxide, magnesium oxide, potassium oxide, sodium oxide, titanium dioxide, chromium carbonate, diboron trioxide, barium oxide, pigment and deionized water. Through reasonable matching of the raw materials, the selection of the ceramic materials is changed, the chemical reaction sufficiency of the ceramic materials is improved, the reaction among the chemical components of the ceramic materials is more stable. The preparation method comprises the following steps of: raw material washing, ball-milling and screening, mixed solution preparation, porcelain body preparation, blanktrimming, drying and cooling, glazing, firing and glazing, and inspecting and discharging. Clean and standard raw materials are used, meanwhile, the manufacturing precision of each link is guaranteed;the thermal stability of a ceramic product is improved; the ceramic product is not prone to cracking in a high-temperature or low-temperature environment; the ceramic is sintered at the medium temperature, the sintering cost of the ceramic is greatly reduced, and the energy-saving and consumption-reducing functions are achieved.

Owner:GUANGDONG SITONG GROUP

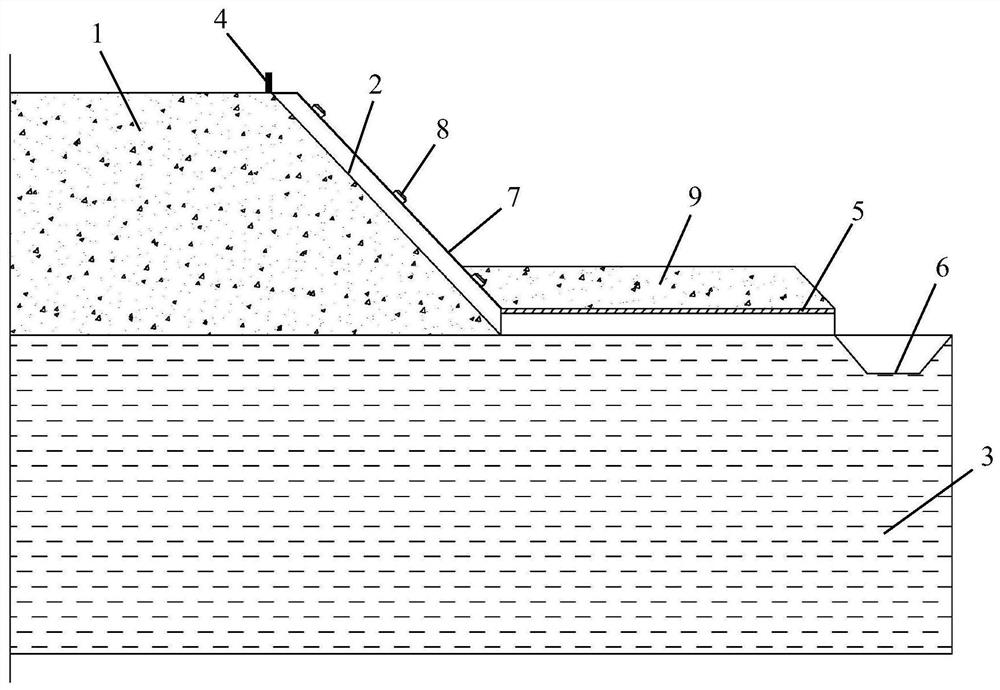

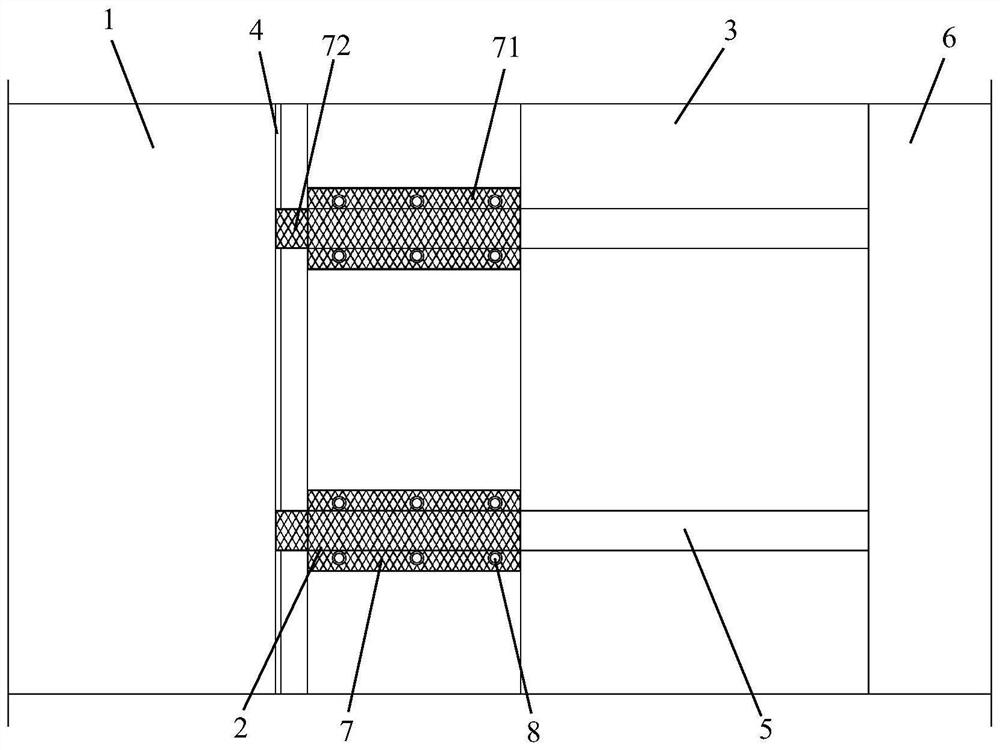

A drainage system and drainage method for expressway reconstruction and expansion construction

ActiveCN111894104BEnsure the construction quality of renovation and expansionEasy to implementExcavationsSewer pipelinesArchitectural engineeringStructural engineering

The invention discloses a drainage system and a drainage method for expressway reconstruction and expansion construction. A torrent trough is set up on the old highway, a temporary water blocking ridge is set, and a diversion pipeline is laid at the same time; the rainwater is made to flow along the top notch of the torrent trough. Flow down into the rush trough, and flow to the drainage ditch through the diversion pipeline; use the anchor rod to fix the steel wire mesh on the slope of the old road, and make the steel mesh cover the top notch and the opening of the trough of the rush trough; A new road will be built on the top surface of the road. After the new road is built, foam light soil will be filled in the rush flow tank and diversion pipeline. The invention avoids roadbed erosion, water damage and other diseases caused by poor drainage during the highway reconstruction and expansion project construction period, ensures the construction quality of highway reconstruction and expansion, and adopts a steel wire mesh covering structure, which can ensure the stable fusion of old and new highways The foaming light soil with high fluidity is filled in the diversion pipeline and the drainage system is saved, and the implementation is simple, the structure is stable, and the cost is low.

Owner:河北交通职业技术学院

Regenerated wrought aluminum alloy melt

The invention discloses a regenerated wrought aluminum alloy melt. The regenerated wrought aluminum alloy melt comprises the following components: 95%-98% of 6xxx series waste aluminum, 0.8%-1.4% of metal Mg, 0.6%-1.2% of metal Cu, 0.1%-0.25% of metal Mn, 0.2%-0.7% of metal Cr, 0.3%-0.7% of an Al-Ti series refiner, 0.2%-0.6% of an Al-10Sr alterant and 0.1%-0.4% of a stabilizer. According to the regenerated wrought aluminum alloy melt, metal aluminum liquid is subjected to residue filtering treatment, and meanwhile, added metal is subjected to refining purification treatment, the purity of the mixed solution is guaranteed, and in addition, the stabilizer is added into the mixed solution, fusion stability between the solutions is guaranteed, and the quality and comprehensive performance of the prepared aluminum alloy are effectively guaranteed.

Owner:QINGYUAN ZHENGTONG METAL PROD CO LTD

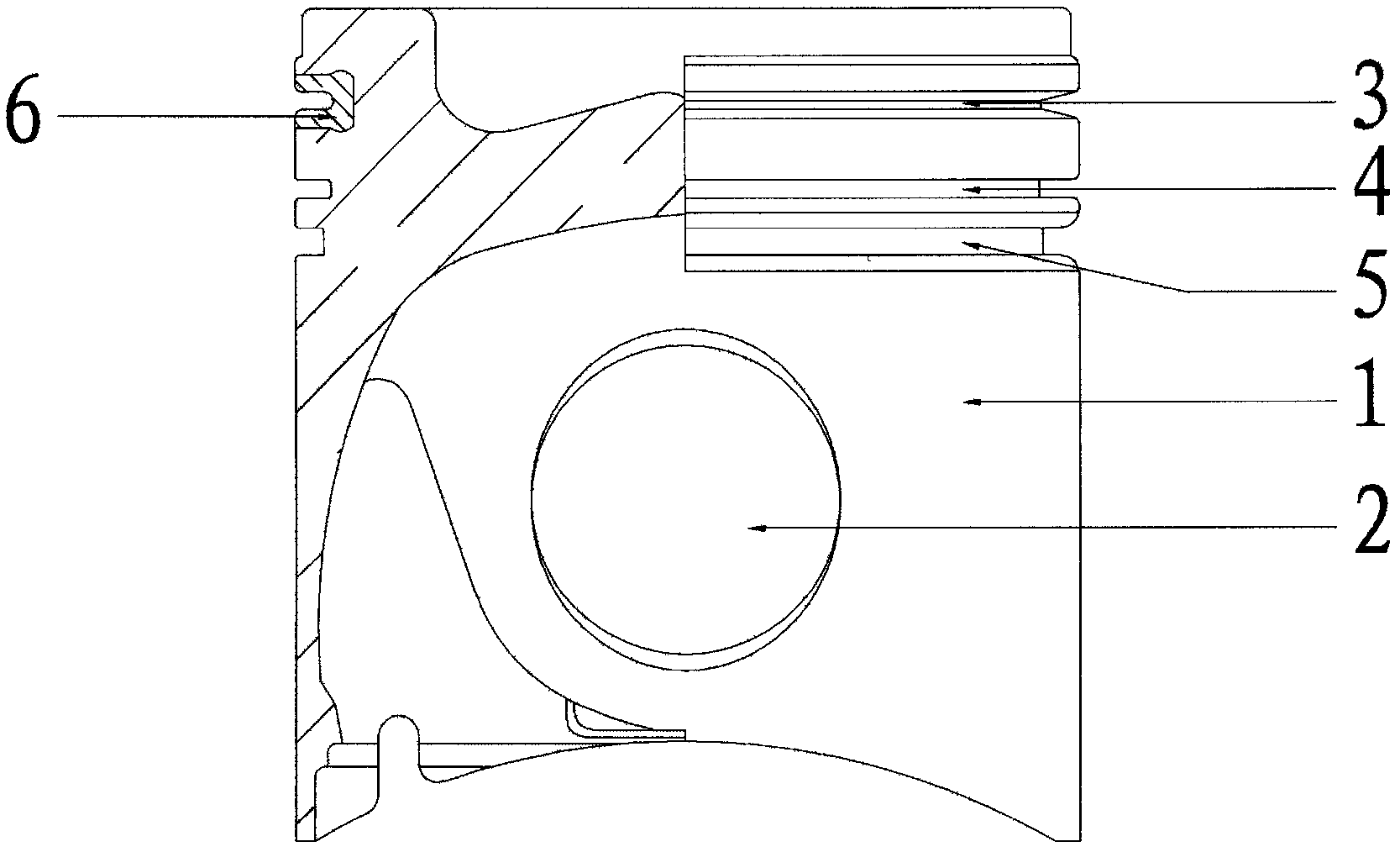

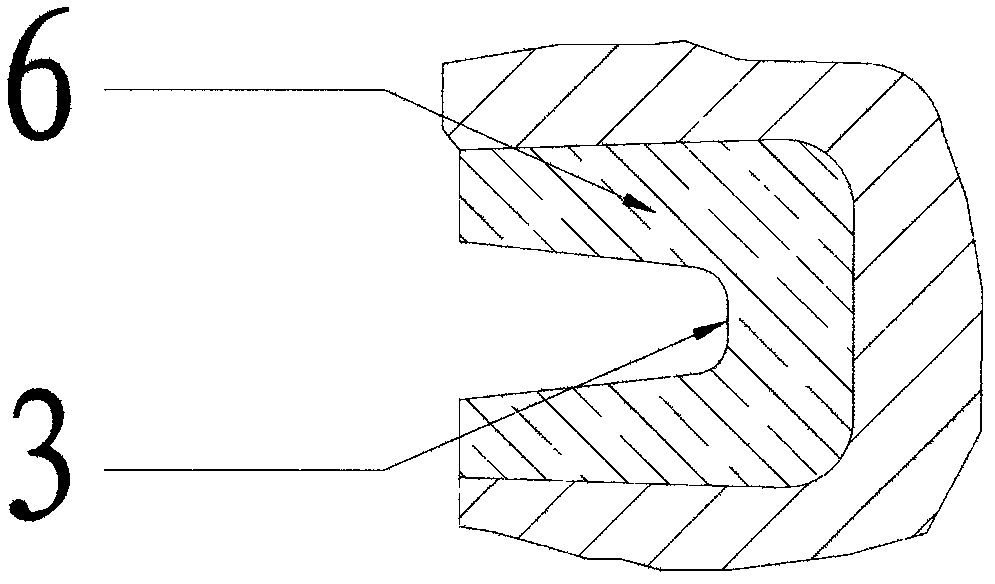

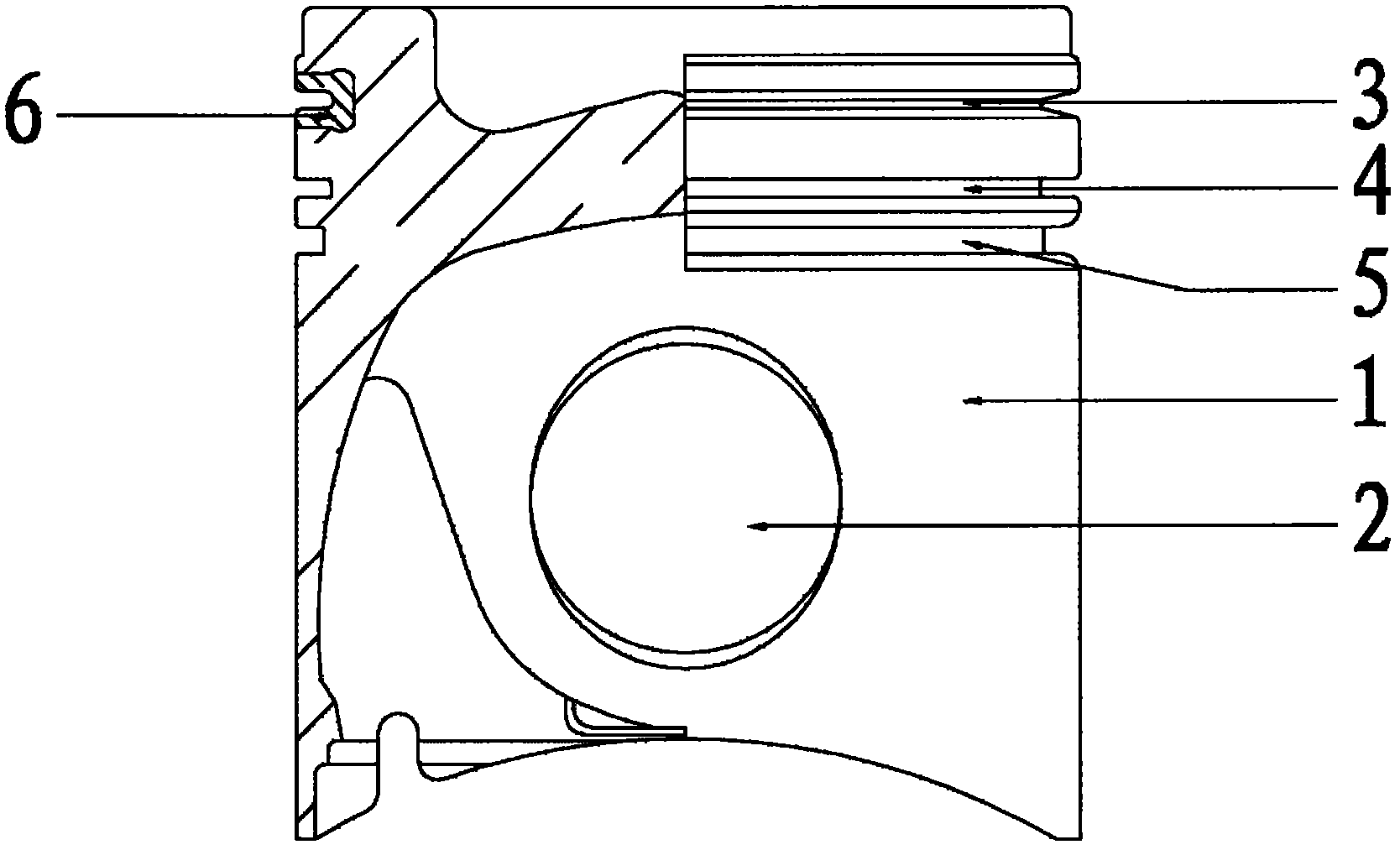

A wear-resistant ring piston

InactiveCN102278227AGood mounting fastnessGood diffusion layerPiston ringsMachines/enginesPiston ringWear resistant

The invention discloses a wear-resistant ring-inlaid piston, which mainly consists of a piston body, a pin shaft hole, one ring groove, two ring grooves, three ring grooves, a wear-resistant ring ring body and the like. The overall structure of the piston body is the same as that of the traditional piston. The upper end is the head, the lower end is the skirt, and the middle end is the piston pin seat. There is a pin hole for connecting the piston and the connecting rod. In the present invention, a ring groove is wear-resistant inlaid. Compared with the prior art, the present invention has certain changes in the selection of the material of the wear-resistant insert body, the determination of the insert process, and the shape design of the insert body. The high-nickel austenitic cast iron is selected as the insert body The material adopts the aluminizing process in the temperature range of 650°C-700°C, and adopts a trapezoidal design for the cross-section of the wear-resistant insert body, which ensures the working fastness of the piston and the entire insert ring structure. works well.

Owner:ZHEJIANG YIBANG MACHINERY

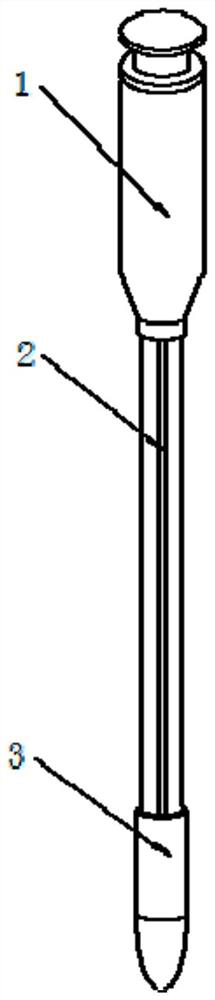

Novel PTCA balloon catheter

InactiveCN112007215AImprove fusion effectGood compatibilityBalloon catheterPharmaceutical delivery mechanismHydrophilic coatingPharmaceutical drug

The invention provides a novel PTCA balloon catheter. The catheter comprises a far-end tube, a near-end tube and a balloon, a near-end tube is arranged at the bottom end of the far-end tube, the balloon sleeves the outside of the near-end tube, the balloon is provided with three layers and comprises a hydrophilic coating, a compatibility layer and an anti-proliferative drug layer, an inner flow layer and an outer flow layer are arranged on the inner wall of the balloon, the inner flow layer is attached to the outer flow layer, the inner flow layer is formed by staggered limiting slim tubes, and the outer flow layer is formed by a fine hair structure. The PTCA balloon catheter adopts the hydrophilic coating, the compatibility layer and the anti-proliferative drug layer to improved the intermiscibility of organisms; and during the flow process, a liquid flows into the inner flow layer from the outer flow layer, the fusion of the liquid is improved by a plurality of groups of the limitingslim tubes, so that the biocompatibility of organisms can be greatly improved; the biological liquid flows to the outer flow layer after being dissolved, and the liquid tends to be stable after beingfused due to the action of a plurality of fine hairs; and in addition, the compatibility of the liquid can be further improved due to the action of the fine hairs.

Owner:浙江桐轩医疗科技有限公司

Manufacturing process of ceramic accessory brick and ceramic accessory brick made by the process

The invention relates to a manufacturing process of a ceramic accessory tile and the ceramic accessory tile. The manufacturing process comprises the steps of: (1) printing a ground coat on the surface glass layer of sintered ceramic tile; (2) conducting ink-jet printing on the printing ground coat to form patterns; (3) applying transparent dry grains on the surface of the pattern layer for two times, and sintering; (4) electroplating metal color on a groove of the surface glass layer by adopting a lamination positioning electroplating method, and sintering; (5) polishing the surface of the sintered product; and (6) cutting the sintered accessory tile blank to prepare the accessory tile. The ceramic accessory tile comprises a base tile, ground coat applied on the surface of the base tile, the pattern layer attached on the ground coat, and the first dry grain layer and the second dry grain layer applied on the pattern layer. Irregular pits, grooves or concave curves, wherein the irregular pits, the grooves or the concave curves are hollowed towards the inside and are arranged on the layer surface of the second dry grain distribution layer. The accessory tile varieties include ground flowers, ground line, waist line and corner, and is used for supporting the ceramic wall and floor tiles.

Owner:JIANGXI HEMEI CERAMICS

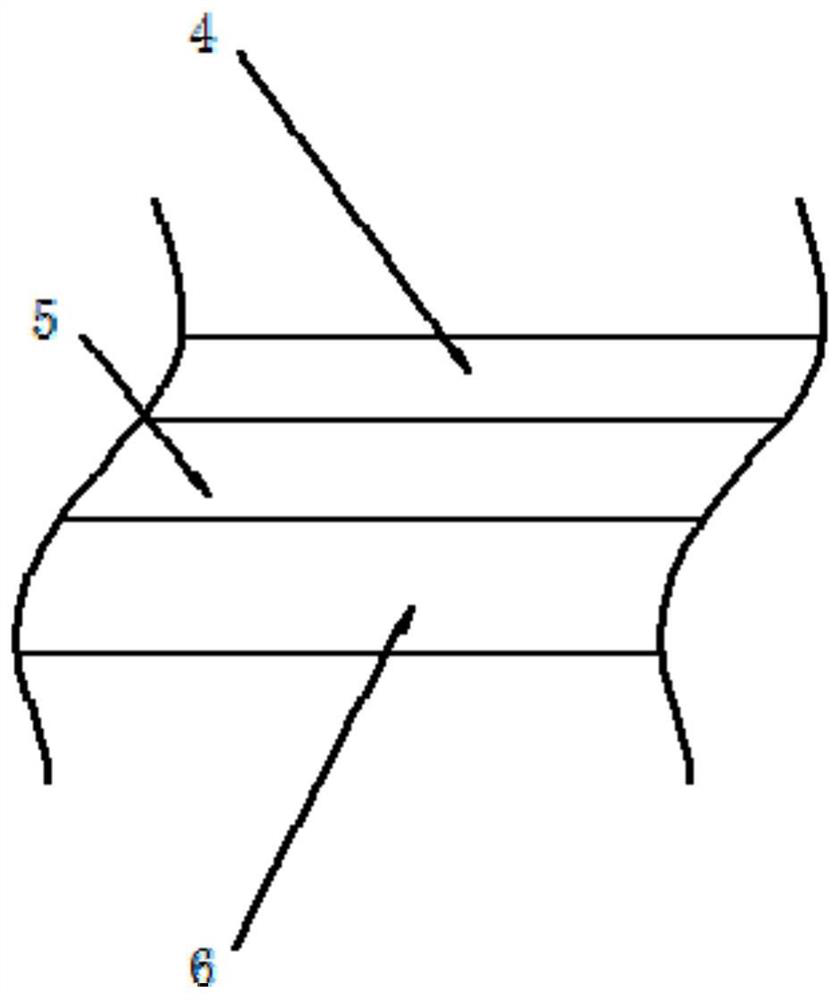

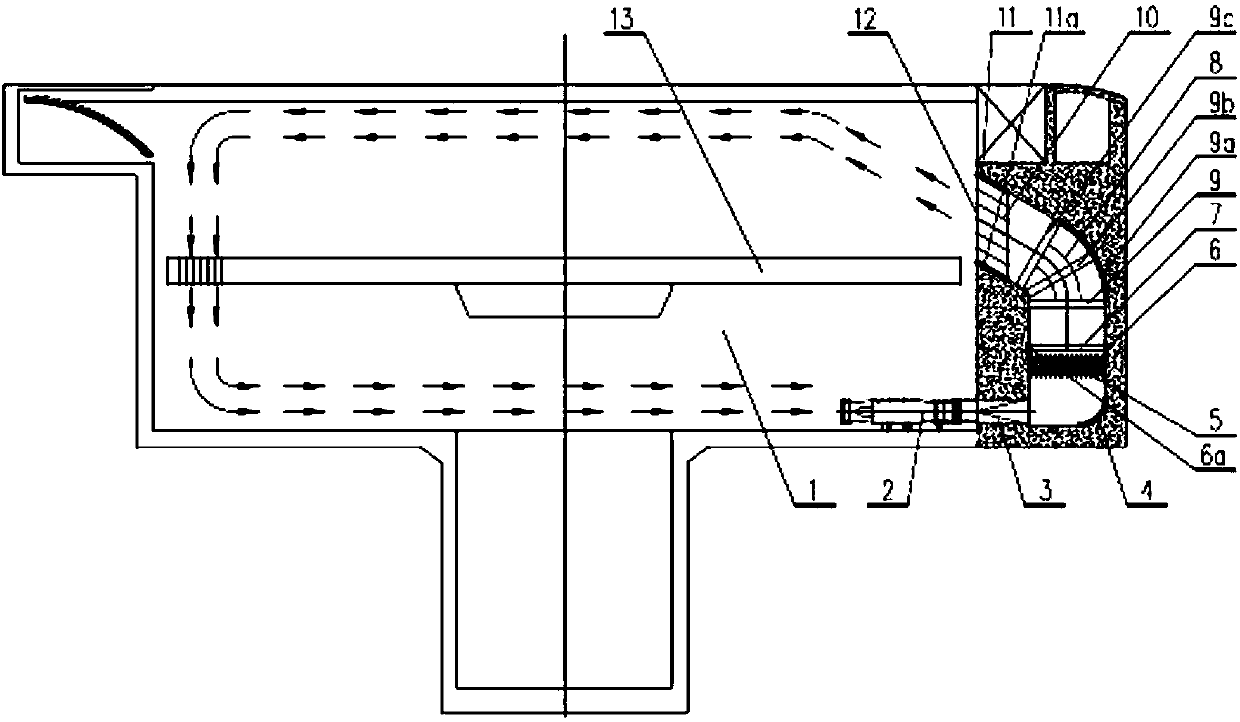

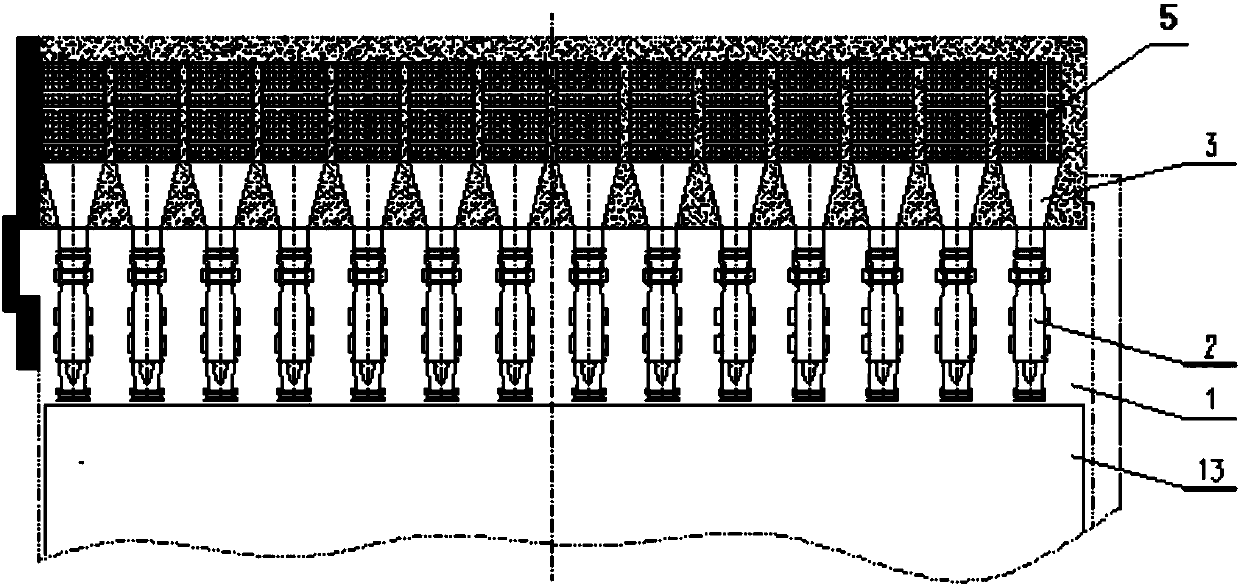

Large off-the-road (OTR) tire prevulcanization retreading equipment and use method

The invention relates to large off-the-road (OTR) tire prevulcanization retreading equipment and a use method. A ring with a hollow inner cavity is formed in a folded die of the equipment; and the inner cavity is matched with the tire tread and the tire shoulder of a tire and has a smooth cure surface without tread blocks. Two clamping disks comprise platens and central cylinders fixedly connected with the two platens which are provided with opposite through holes; the two central cylinders are respectively inserted in a rim-mounting hole in the center of the tire from upside to downside; the two platens are respectively pressed and covered on an upper tire bead and a lower tire bead of the tire; clamping bolts penetrate through the two platens and are fastened by nuts; and gas nozzles of the clamping disks are connected with an air compressor. The use method comprises the following steps of: pasting a prevulcanization tread adhesive on the tire; mounting the clamping disks to seal the inner cavity of the tire; mounting the tire; folding the die; and heating the vulcanization die while pressing the tire by the gas nozzles to finish retreading and vulcanizing. The invention only heats the top and the shoulder of a tire, avoids damaging the tread, enables the retrodden tire to resist abrasion, piercing and cutting and have stable appearance quality, does not need a rim, a package envelope and a tire tube and reduces consumption.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

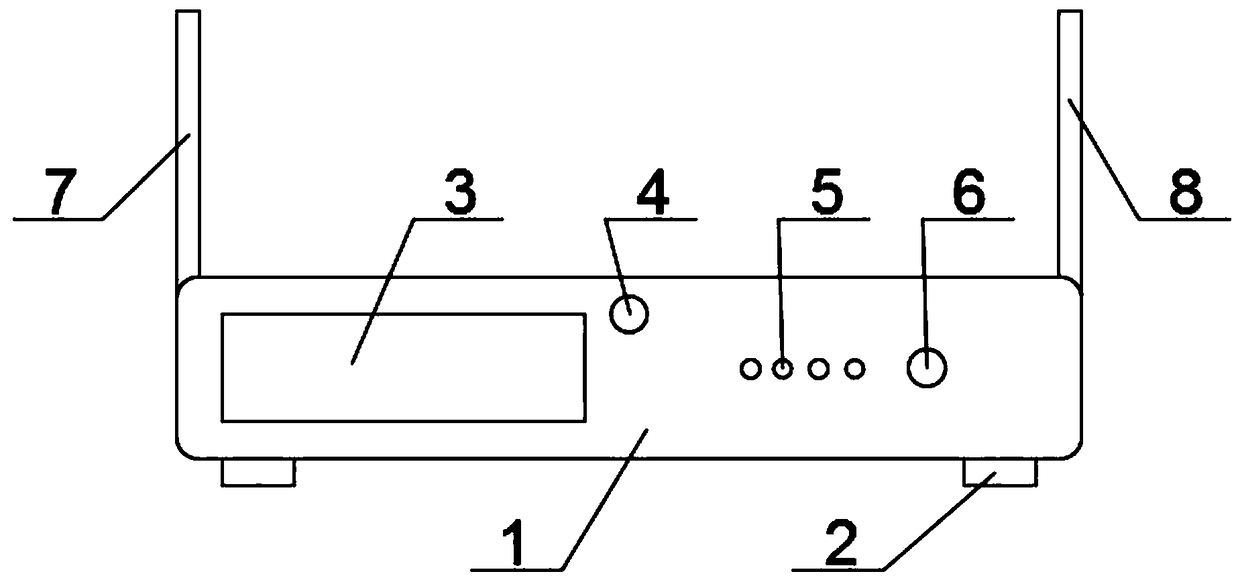

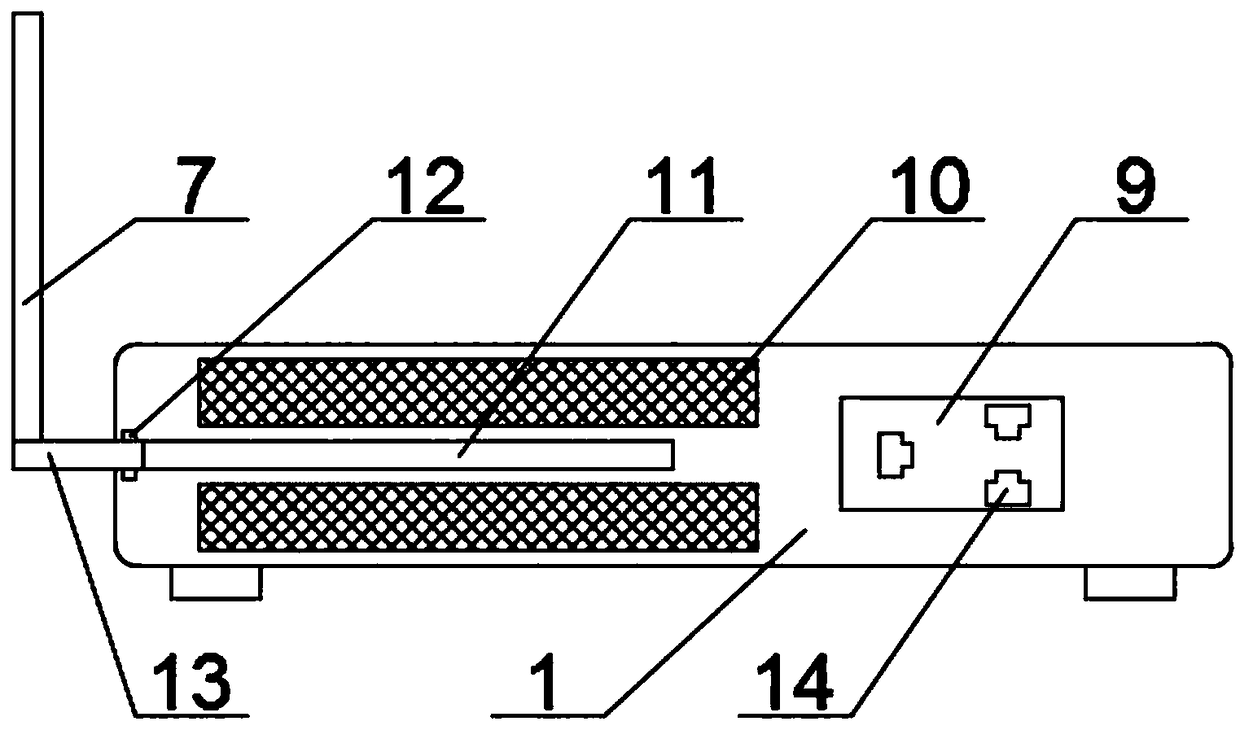

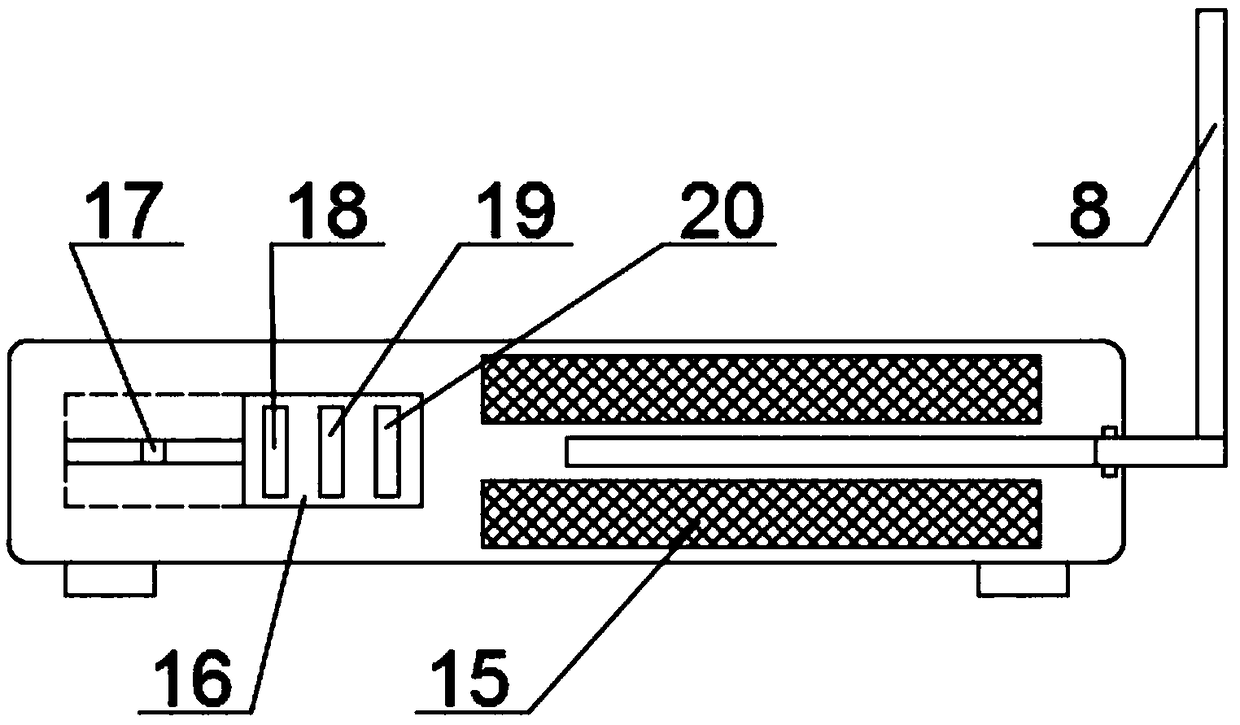

Three-network integrated set top box

InactiveCN108965960AEasy to assemble and disassemblePrevent dust from enteringSelective content distributionInformation technologyFingerprint

The invention relates to a three-network integrated set top box and belongs to the field of a new generation of information technology. The three-network integrated set top box comprises a shell, wherein a mainboard is arranged in the shell, a memory, a voice module, a first processor, a buffer and a power connector are arranged on the mainboard, a routing module is arranged at the left side of the mainboard, a reticle interface, a second processor and a power interface are arranged on the routing module, and a first SIM card slot, a second SIM card slot and a third SIM card slot are formed inthe right end of the mainboard. The three-network integrated set top box provided by the invention has the advantages that the routing module is detachably mounted on a set top box, stable and effective integration of a telecommunication network, a broadcast television network and Internet is realized, the routing module is used after being mounted inside the set top box at ordinary times, and only the interfaces need to be pulled out for free connection and use when the routing module needs to be used independently, thereby being convenient in mounting and dismounting and being more practical; by virtue of the three SIM card slots which are formed in a sliding chute, a sliding plate is combined, and dust is effectively prevented from entering; and by virtue of a card swiping module, a fingerprint module and a camera, multiple payment modes such as card swiping payment, fingerprint payment and face swiping payment are realized.

Owner:深圳市鹏朗贸易有限责任公司

Large off-the-road (OTR) tire prevulcanization retreading equipment and use method

The invention relates to large off-the-road (OTR) tire prevulcanization retreading equipment and a use method. A ring with a hollow inner cavity is formed in a folded die of the equipment; and the inner cavity is matched with the tire tread and the tire shoulder of a tire and has a smooth cure surface without tread blocks. Two clamping disks comprise platens and central cylinders fixedly connected with the two platens which are provided with opposite through holes; the two central cylinders are respectively inserted in a rim-mounting hole in the center of the tire from upside to downside; thetwo platens are respectively pressed and covered on an upper tire bead and a lower tire bead of the tire; clamping bolts penetrate through the two platens and are fastened by nuts; and gas nozzles ofthe clamping disks are connected with an air compressor. The use method comprises the following steps of: pasting a prevulcanization tread adhesive on the tire; mounting the clamping disks to seal the inner cavity of the tire; mounting the tire; folding the die; and heating the vulcanization die while pressing the tire by the gas nozzles to finish retreading and vulcanizing. The invention only heats the top and the shoulder of a tire, avoids damaging the tread, enables the retrodden tire to resist abrasion, piercing and cutting and have stable appearance quality, does not need a rim, a package envelope and a tire tube and reduces consumption.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

Partition wallboard of environmental protective lightweight fiber

InactiveCN100460354CThe overall thickness is thinTake advantage ofSolid waste managementBuilding componentsFiberHigh resistance

Owner:陈敏

Preparation method of cotton-feeling softener

PendingCN112323500ASoft touchGood moisture absorption and air permeabilityGrip property fibresVegetal fibresManufacturing engineeringIndustrial engineering

The invention discloses a preparation method of a cotton-feeling softener, and belongs to the technical field of softener preparation. The preparation method comprises the following steps: 1, auxiliary material preparation; 2, raw material weighing; and 3, finished product preparation. The method is simple in overall process and reasonable in step matching, the prepared softener can endow fabric with good softness and cotton texture, and the use quality of the fabric is improved.

Owner:长兴卓恒新材料科技有限公司

A flow-making system for deep-water test pools

The invention relates to the technical field of deep sea engineering and provides a current generating system used in a deep water experiment pool. The current generating system mainly comprises the deep pool, round-to-square connecting sections, rectifying walls and a lifting platform. Current generating water pumps are installed in the deep pool. Water outlets of the current generating water pumps are connected with the round-to-square connecting sections. A rectifying baffle is jointed to the position behind the rectifying walls and fixedly connected to rectifying baffle embedded steel plates. A plurality of current passing holes corresponding to the rectifying walls are formed in the rectifying walls. A deflector is arranged behind the rectifying baffle and fixedly connected to deflector embedded steel plates, so that a diversion channel is formed. A diversion rail is arranged behind the deflector and installed on diversion rail embedded steel plates. A steel wire mesh is arranged behind the diversion rail and used for controlling turbulence in a current. According to the current generating system used in the deep water experiment pool, overall current generating in the pool is adopted, and water pump water outlet corridors and water suction pipelines are not needed, so that the space is saved, the cost is reduced, and meanwhile, the overall flow velocity target requirement is met.

Owner:DALIAN UNIV OF TECH

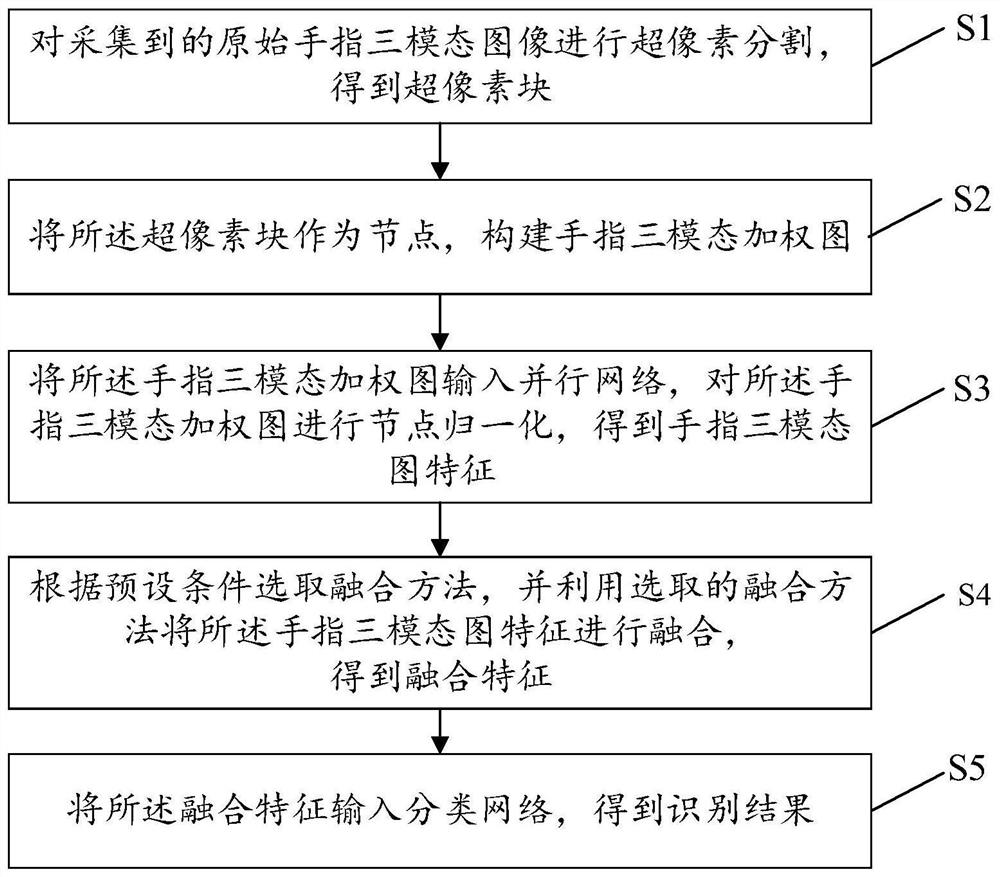

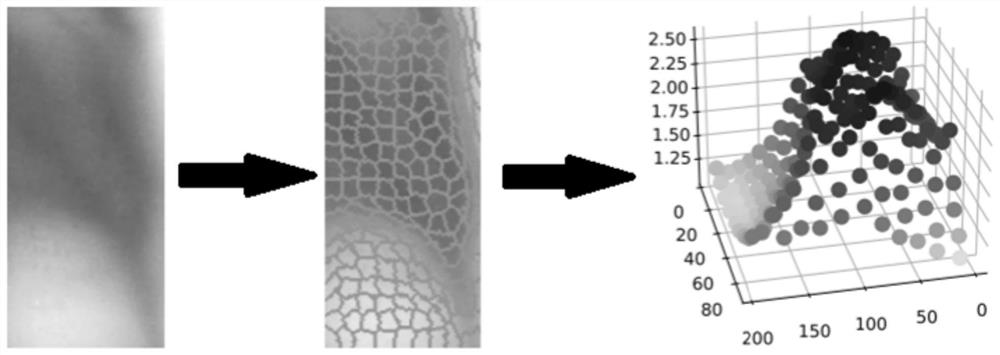

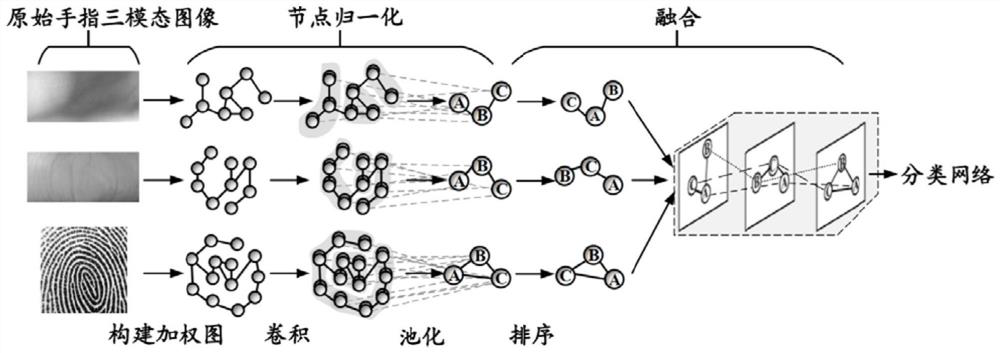

Finger three-mode fusion recognition method, system and device and storage medium

ActiveCN113591629AStable Feature FusionImprove recognition accuracyCharacter and pattern recognitionNeural architecturesFeature vectorEngineering

The invention relates to the technical field of biological feature recognition, in particular to a finger three-mode fusion recognition method, system and device and a storage medium, and the method comprises the steps of carrying out the normalization processing of a finger three-mode weighted graph through a parallel network, and obtaining the features of a finger three-mode graph; and fusing the finger three-mode graph features through a competition fusion method and a feature vector centrality fusion method to obtain fused features. According to the invention, the finger three-modal features are constructed into the graph features with consistent feature space based on the superpixel segmentation method, and meanwhile, the effective fusion of the finger three-modal graph features is realized by utilizing the node feature information and the structure information of the graph, so that the finger three-modal recognition precision is remarkably improved; in addition, the problem that effective fusion of finger three-mode features is affected due to inconsistent sizes of three-mode images is effectively solved through a parallel network.

Owner:SHENZHEN POLYTECHNIC

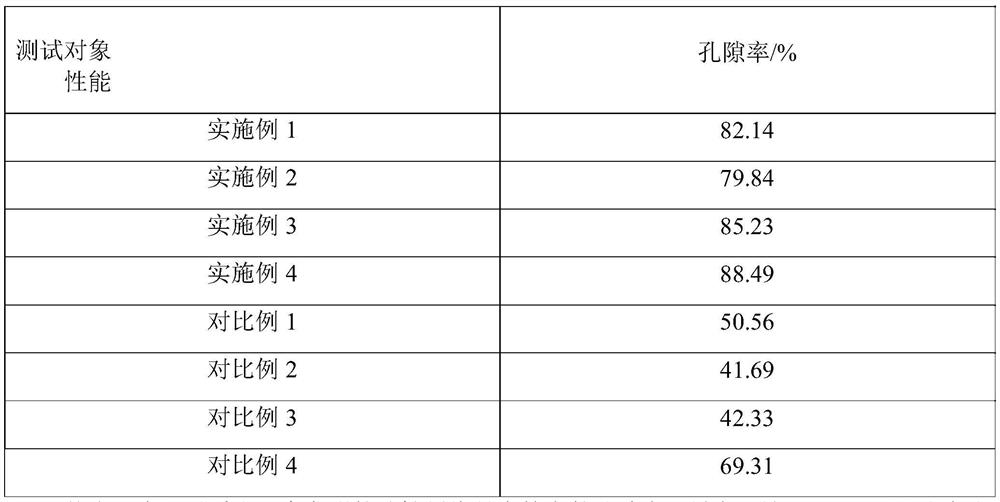

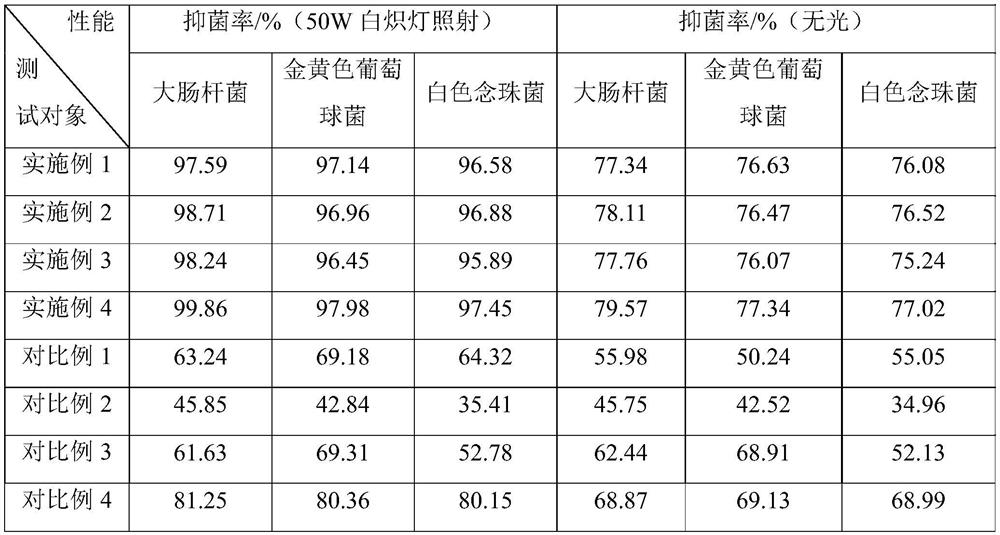

Antibacterial and breathable philodendron-containing modified fiber and preparation method thereof

InactiveCN112746351AImprove stabilityImprove breathabilityConjugated cellulose/protein artificial filamentsArtifical filament manufactureAnti bacterialMilk protein

The invention discloses antibacterial and breathable philodendron-containing modified fiber. The fiber comprises a fiber body and an antibacterial film coating the fiber body, wherein the fiber body is composed of the following components in percentage by weight of 40 to 55 percent of milk protein fiber, 30 to 45 percent of bamboo fiber, 10 to 15 percent of jute fiber and 5 to 10 percent of philodendron fiber; and an active ingredient of the antibacterial film is a mixture of chitosan / metal ion doped nano titanium dioxide. The invention further discloses a preparation method of the antibacterial and breathable philodendron-containing modified fiber. The modified fiber is coated with the antibacterial film, and the antibacterial film is safe, non-toxic, non-irritant to the skin, high in antibacterial capacity, capable of killing bacteria under the visible light condition and even the dark condition, and wide in antibacterial range.

Owner:南京金榜麒麟家居股份有限公司

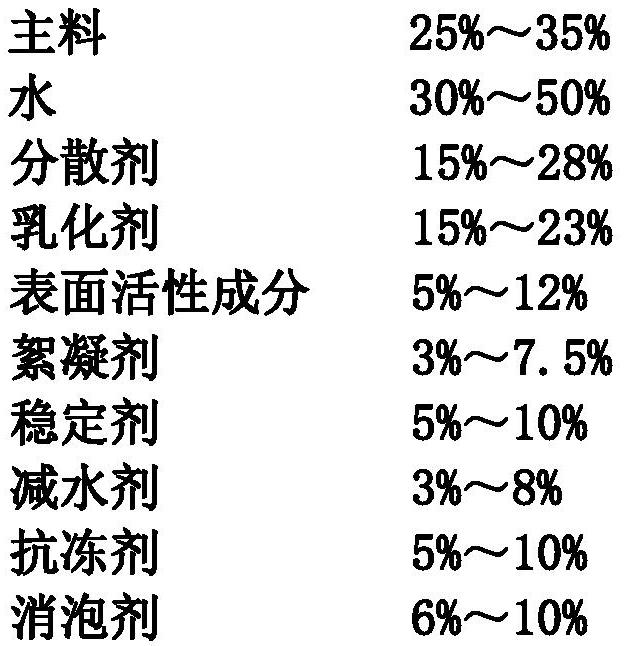

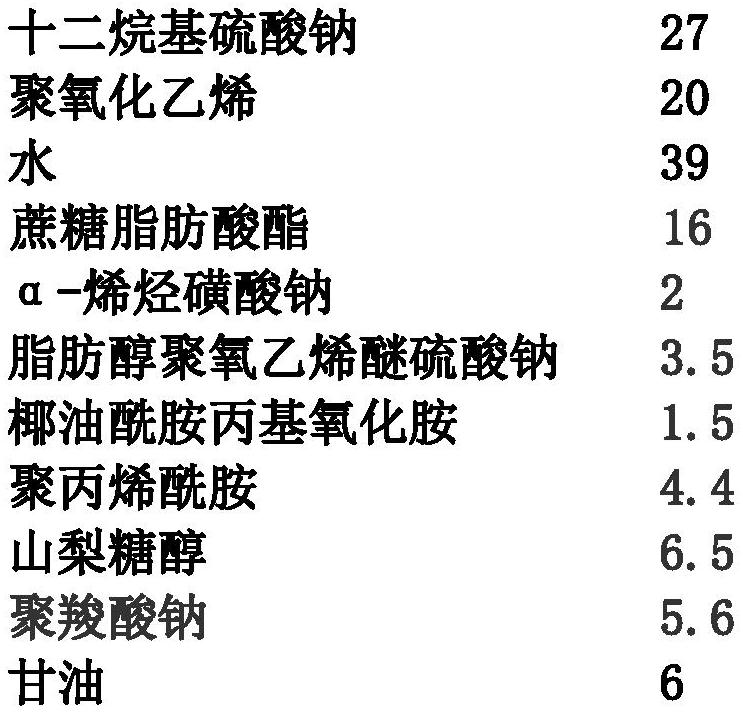

Composite liquid soil stabilizer and preparation method thereof

PendingCN114574211ANo pollution in the processSmall shrinkage deformationSolid waste managementBuilding constructionsSucrosePolyethylene glycol

The invention discloses a composite liquid soil curing agent and a preparation method thereof. The curing agent comprises a main material, a dispersing agent, an emulsifying agent, a surface active component, a flocculating agent, a stabilizing agent, a water reducing agent, an anti-freezing agent, a defoaming agent and water. Wherein the curing agent main material is one or more of lauryl sodium sulfate and diethanolisopropanolamine, the dispersing agent is one or more of polyoxyethylene and polyethylene glycol, and the emulsifying agent is one or more of sucrose fatty acid ester, OP-15, sodium dodecyl sulfate, sodium dodecyl sulfate, sodium dodecyl sulfate and sodium dodecyl sulfate. The surface active component is sodium alpha-olefin sulfonate, sodium alcohol ether sulphate and cocamidopropyl dimethylamine oxide, the flocculating agent is one or more of polyacrylamide, sodium polyacrylate and calcium polyacrylate, the stabilizer is sorbitol, the water reducing agent is sodium polycarboxylate, the antifreeze agent is glycerol, and the dispersant is sodium dodecyl sulfate. The defoaming agent is an organic silicon defoaming agent. The composite liquid soil stabilizer provided by the invention is environment-friendly, pollution-free, small in shrinkage deformation, good in low-temperature stability, high in compressive strength, convenient in construction process, capable of shortening the construction period and suitable for curing treatment of backfill of constructional engineering.

Owner:三智胜祥集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com