Composite liquid soil stabilizer and preparation method thereof

A soil curing agent and composite technology, applied in chemical instruments and methods, soil conditioning materials, fertilizer mixtures, etc., can solve the problems of low strength, easy generation of dust, material cracking, etc., and achieve good low temperature stability and convenient construction technology. , the effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

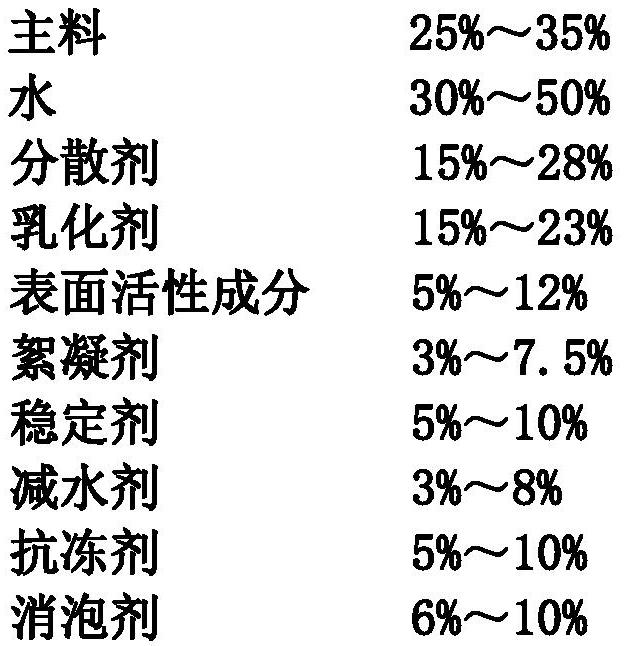

[0026] A composite liquid soil curing agent made of the following materials and raw materials with weight percentage content:

[0027]

[0028]

[0029] Preparation method of a composite liquid soil curing agent, the method comprising the following steps:

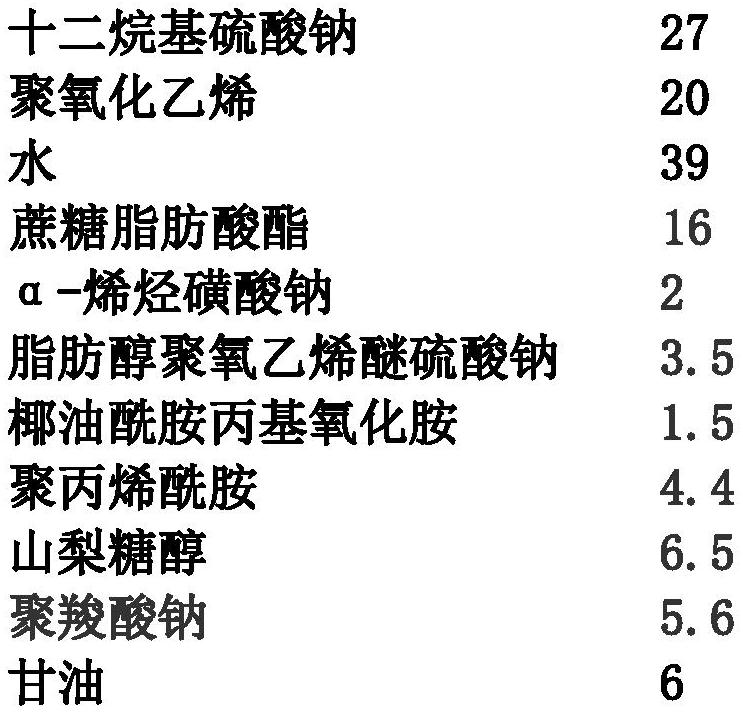

[0030](1) Preparation: According to the following materials and weight percentage content: sodium lauryl sulfate 27, polyethylene oxide 20, water 39, sucrose fatty acid ester 16, sodium α-olefin sulfonate 2, fatty alcohol polyoxyethylene ether sodium sulfate 3.5, cocamidopropyl amine oxide 1.5, polyacrylamide 4.4, sorbitol 6.5, sodium polycarboxylate 5.6, glycerin 6, silicone defoamer 6.5;

[0031] (2) Premix: under the temperature of 42 °C, under sealing conditions, sodium lauryl sulfate, polyethylene oxide, sucrose fatty acid ester and water are mixed and stirred in accordance with step (1) weight ratio for 47min to prepare the premix;

[0032] (3) Mixing: the premix prepared in step (2) and α- sodium olefin sulfonate, fa...

Embodiment 2

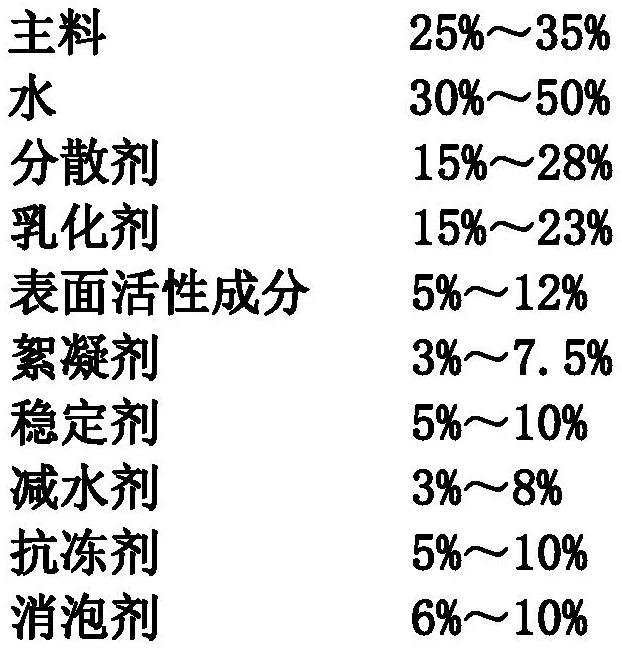

[0035] A composite liquid soil curing agent made of the following materials and raw materials with weight percentage content:

[0036]

[0037] Preparation method of a composite liquid soil curing agent, the method comprising the following steps:

[0038] (1) Preparation: According to the following materials and weight percentage content: diethanol monoisopropanol amine 32, polyethylene glycol 17, water 43, 0P-1518.5, α-olefin sulfonate 3, fatty alcohol polyoxyethylene ether sodium sulfate 3.5, cocamidopropyl amine oxide 1.5, sodium polyacrylate 6.2, sorbitol 5.2, sodium polycarboxylate 5.6, glycerin 4.2, silicone defoamer 7.2;

[0039] (2) Premix: Under the temperature of 37 °C, under sealing conditions, the diethanol monoisopropanolamine, polyethylene glycol, 0P-15 and water are mixed and stirred in accordance with the weight ratio of step (1) for 30min to obtain the premix;

[0040](3) Mixing: the premix prepared in step (2) and sodium α-olefin sulfonate, fatty alcohol polyox...

Embodiment 3

[0043] A composite liquid soil curing agent made of the following materials and raw materials with weight percentage content:

[0044]

[0045]

[0046] (1) Preparation: According to the following materials and weight percentage content: sodium lauryl sulfate 27, polyethylene oxide 8, polyethylene glycol 11, water 39, 0P-1520, sodium α-olefin sulfonate 3, fatty alcohol polyoxyethylene ether sodium sulfate 3.5, cocamidopropyl amine oxide 2.5, calcium polyacrylate 4.2, sorbitol 6.4, sodium polycarboxylate, glycerin 6, silicone defoamer 6.8;

[0047] (2) Premix: under the temperature of 39 °C, under the sealing conditions, the diethanol monoisopropanolamine, polyethylene glycol, 0P-15 and water are mixed and stirred in accordance with the weight ratio of step (1) to prepare the premix for 36 minutes;

[0048] (3) Mixing: the premix prepared in step (2) and α- sodium olefin sulfonate, fat alcohol polyoxyethylene ether sodium sulfate, cocamidopropyl amine oxide, sodium polyacrylate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com