Large off-the-road (OTR) tire prevulcanization retreading equipment and use method

A large-scale engineering, pre-vulcanization technology, applied in the direction of tires, applications, household appliances, etc., can solve the problems of the difficulty of wrapping large tires, the wear resistance, cutting resistance and puncture resistance of retreaded tires, and the loss of the wrapping sleeve, etc. Insufficient tread pressure, stable appearance quality, and the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

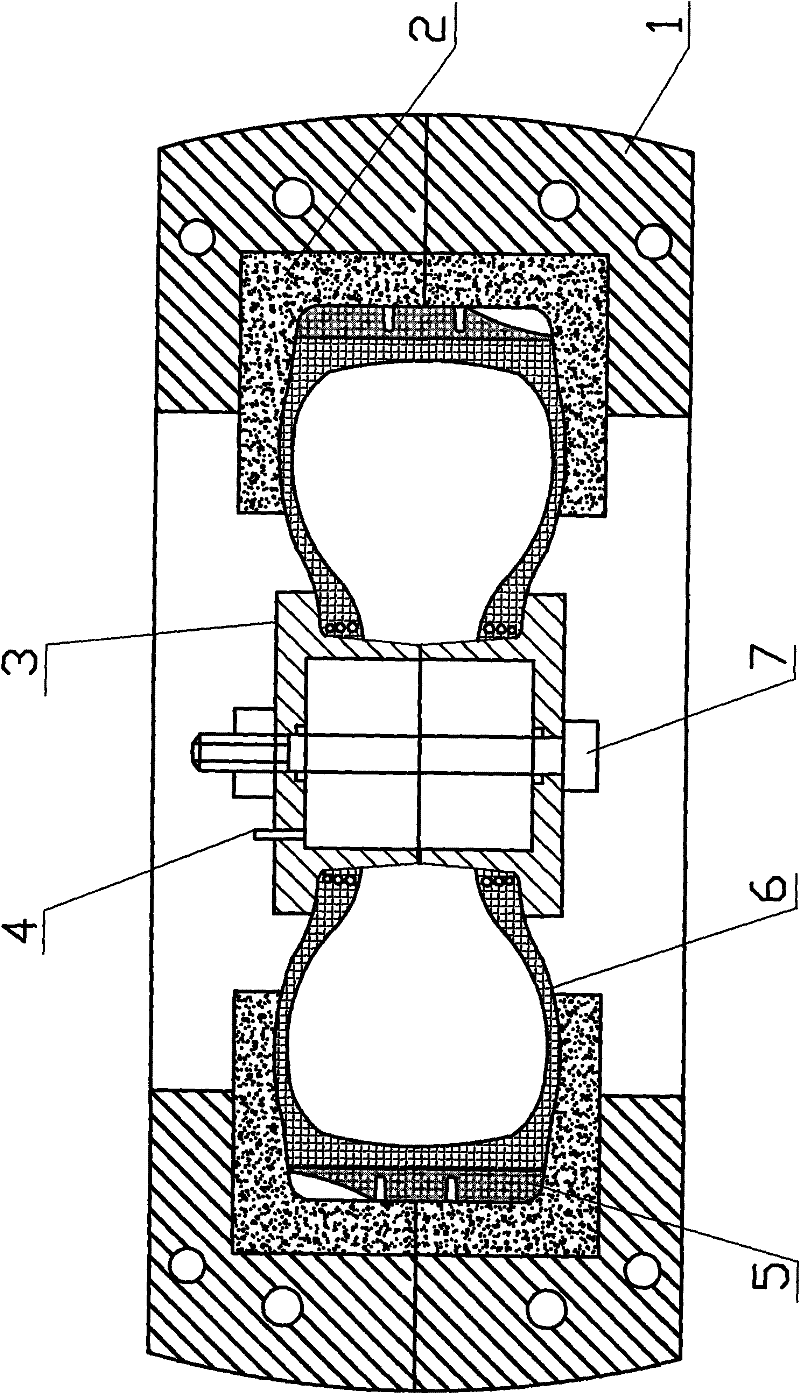

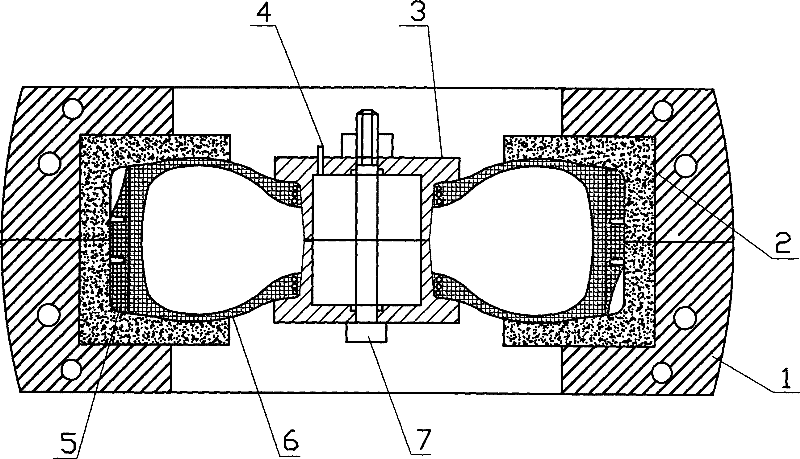

[0018] The embodiment of this large-scale engineering machinery tire pre-vulcanization retreading equipment includes a vulcanizer 1 as a main body, a vulcanization mold 2 divided into upper and lower molds, and a clamping disc 3, such as figure 1 As shown, the vulcanization mold 2 is divided into upper and lower molds, which become a ring with a hollow cavity after mold closing, and the cavity matches the tire crown and shoulder part of the tire 6, and the maximum inner diameter of the bottom of the cavity is slightly larger than that of the tire 6 to be retreaded. diameter, the width of the inner cavity is slightly larger than the width of the tire 6 to be retreaded, the depth of the inner cavity is slightly larger than the distance between the top of the tread of the tire 6 to be retreaded and the sidewall, and the surface of the inner cavity that is in contact with the top of the tire 6 tread to be retreaded is a smooth curved surface. Tread blocks. The clamping disc 3 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com