A flow-making system for deep-water test pools

A deep-water test and pool technology, applied in the field of deep-sea engineering, can solve problems such as poor economy, lack of rectifiers, and inability to simulate high-quality flow fields, saving space and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the drawings.

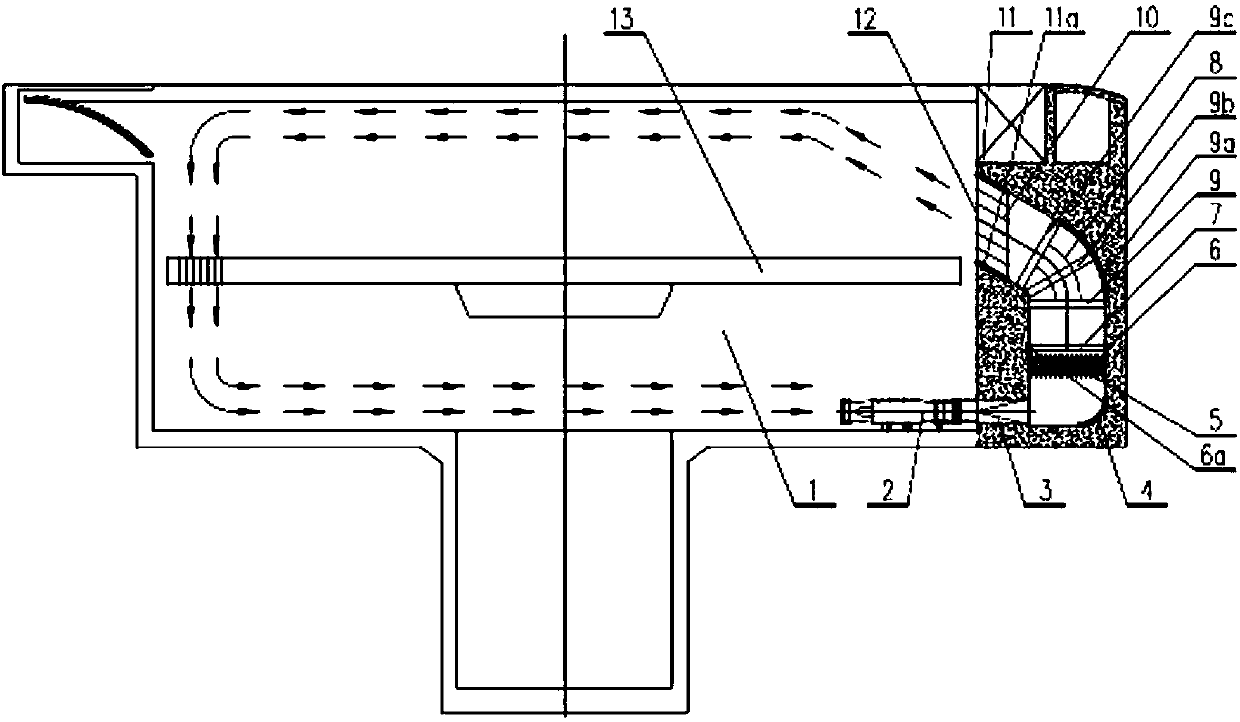

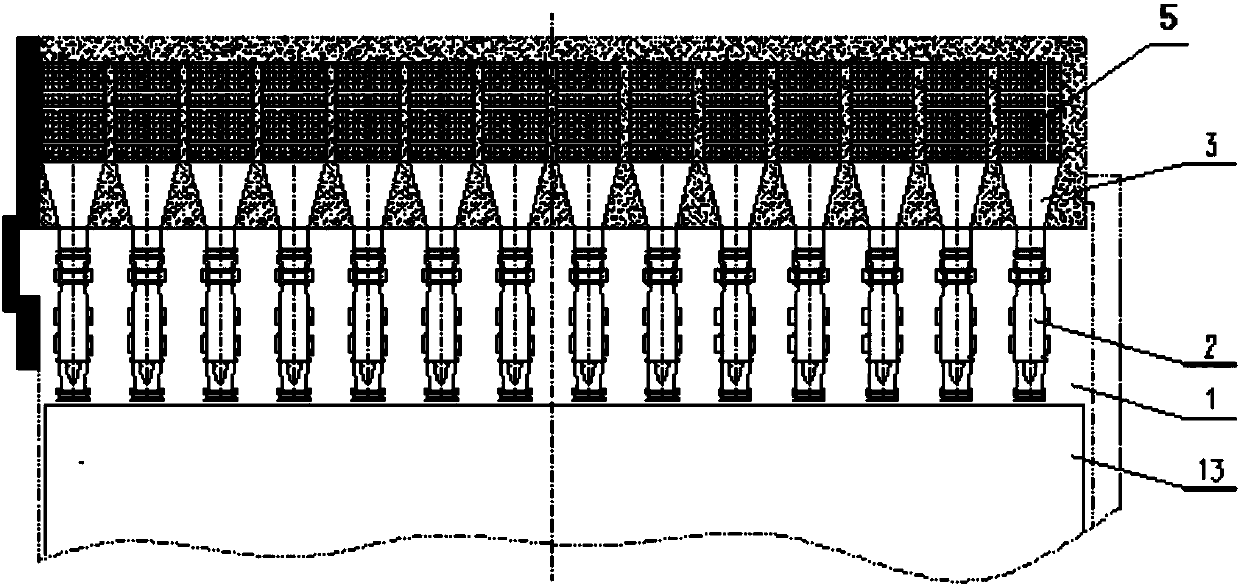

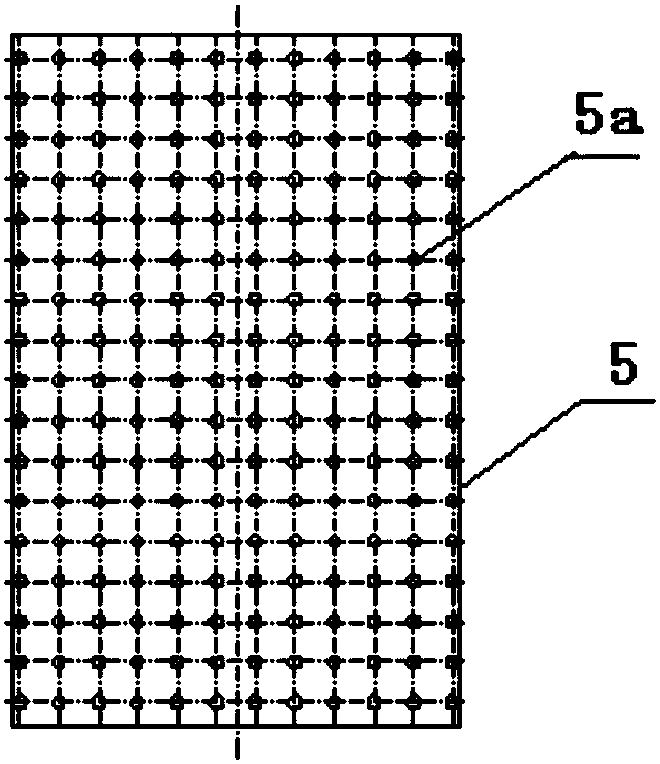

[0014] Such as figure 1 , 2 , 3, a flow generation system used in the deep water test pool, mainly including deep water pool 1, first, second, ... N-1, N round variable square connecting section 3, first, second, ... N- 1. N rectifying wall 5 and lifting platform 13, said deep water pool 1 is equipped with first, second, ... N-1, N flow pumps 2, and said first, second, ... N-1, N flow The water outlets of the water pump 2 are respectively connected to the first, second,...N-1, N round variable square connection section 3, and a rectifying baffle 7 is connected behind the first, second,...N-1, N rectifying wall 5, The rectifying baffle 7 is fixedly connected to the first and second embedded steel plates 6, 6a of the rectifying baffle, and the rectifying baffle 7 is provided with a number of flow-through holes, and is connected to the first, second,... The N-1 and N rectification walls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com