A wear-resistant ring piston

A wear-resistant insert ring and piston technology, which is applied to piston rings, engine components, machines/engines, etc., can solve problems such as oil seal wear and aging, complex processing technology content, piston body deformation, etc., to ensure working fastness, The application effect is good and the effect of increasing the mechanical bonding fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

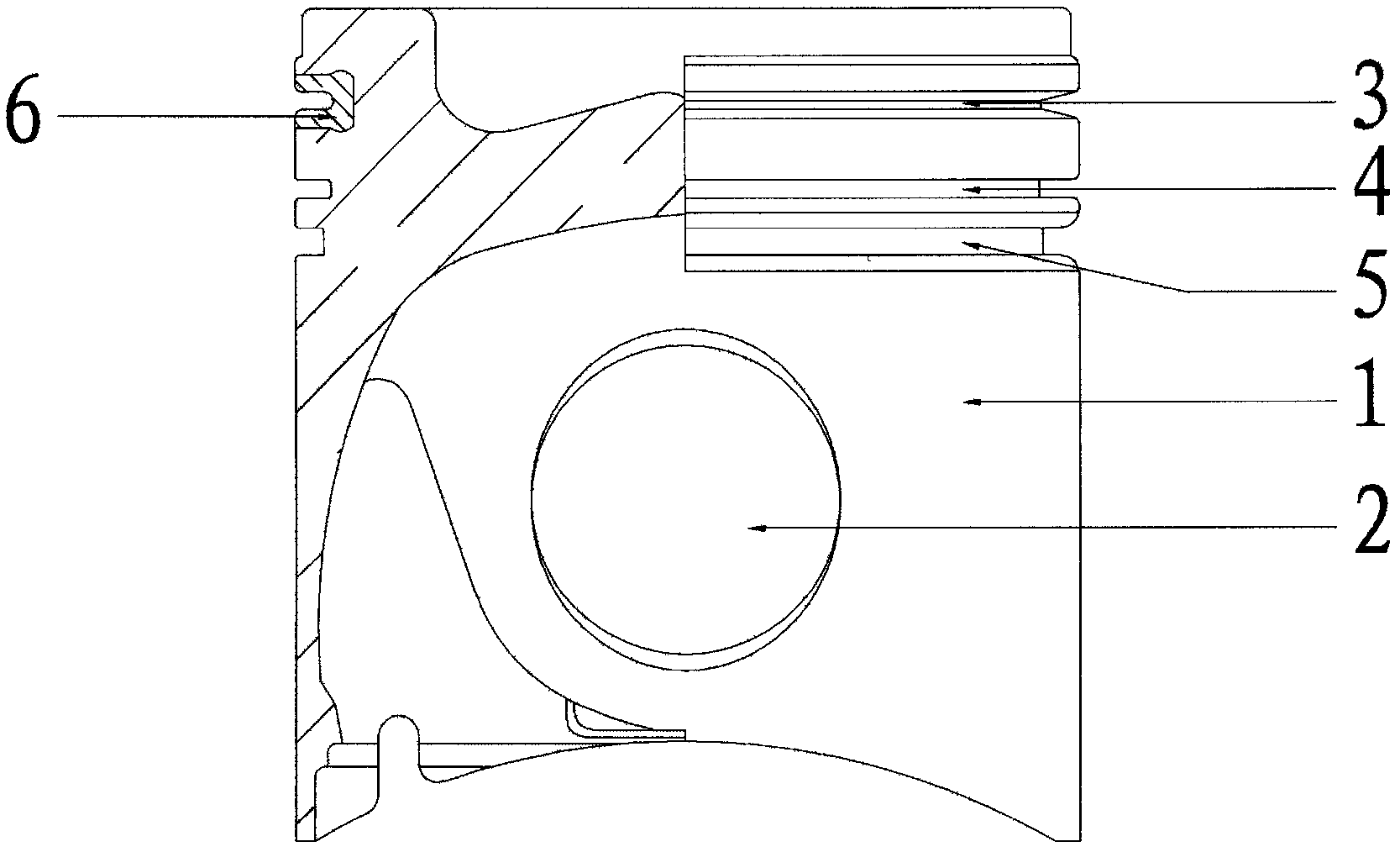

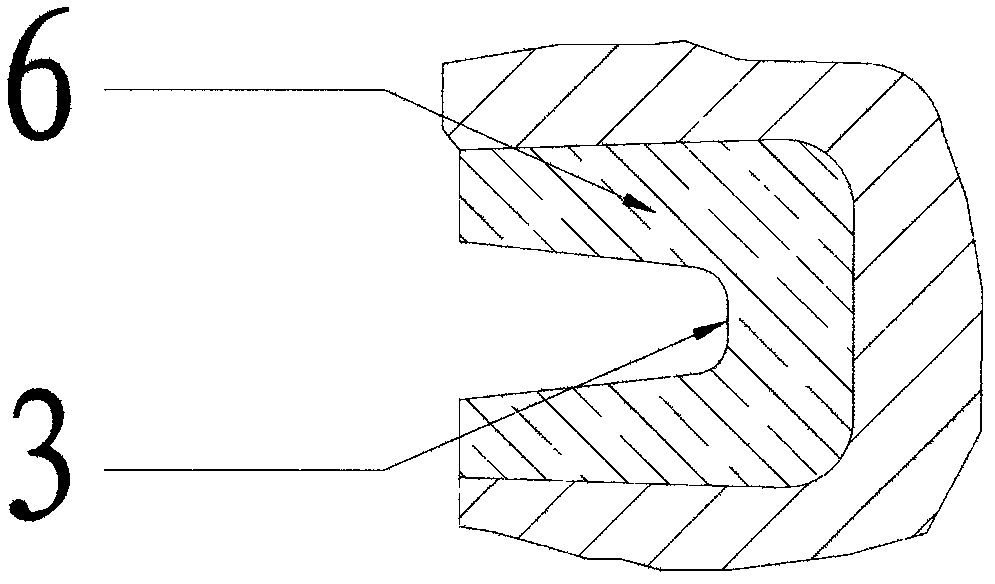

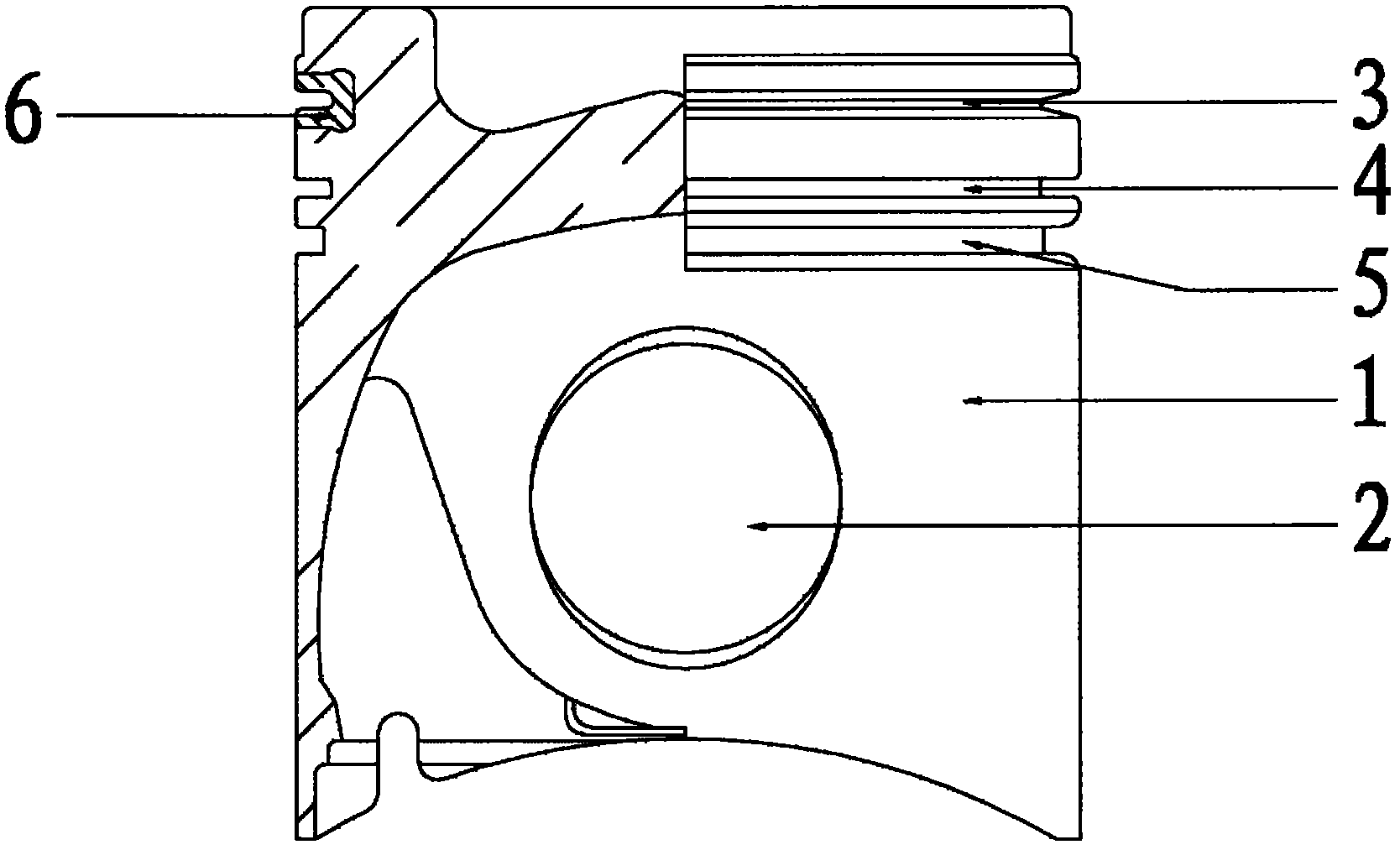

[0013] A wear-resistant ring-mounted piston according to the present invention, as shown in the accompanying drawings, mainly consists of a piston body 1, a pin hole 2, a ring groove 3, a second ring groove 4, three ring grooves 5 and a wear-resistant insert Circle body 6 etc. are formed. The overall structure of the piston body 1 is the same as that of the traditional piston. The upper end is the head, that is, the contact part with the combustion chamber, the lower end is the skirt, that is, the guiding part of the piston, and the middle end is the piston pin seat, which is provided for the connection between the piston and the connecting rod. The pin hole 2. In the present invention, three ring grooves are arranged on the upper end of the piston body 1, one ring groove 3 and two ring grooves 4 are used as placement grooves for sealing air rings, and the three ring grooves are used for placing sealing oil rings. Considering the cast iron material of the sealing air ring pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com