Preparation method of coating containing TiB2 metal ceramic composite powder for thermal spraying piston ring

A metal-ceramic composite and composite powder technology, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problems of high brittleness, low density, small particle size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

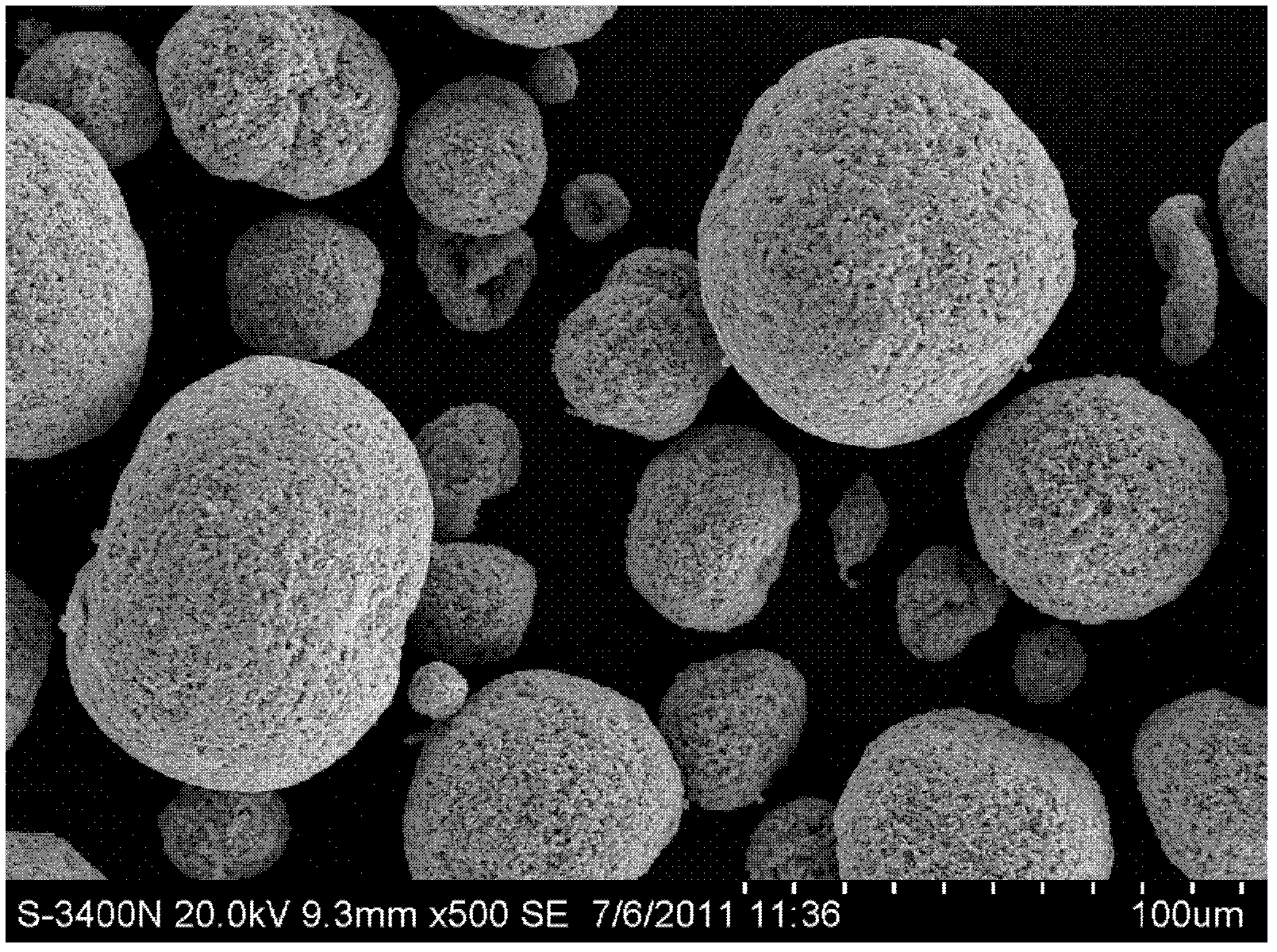

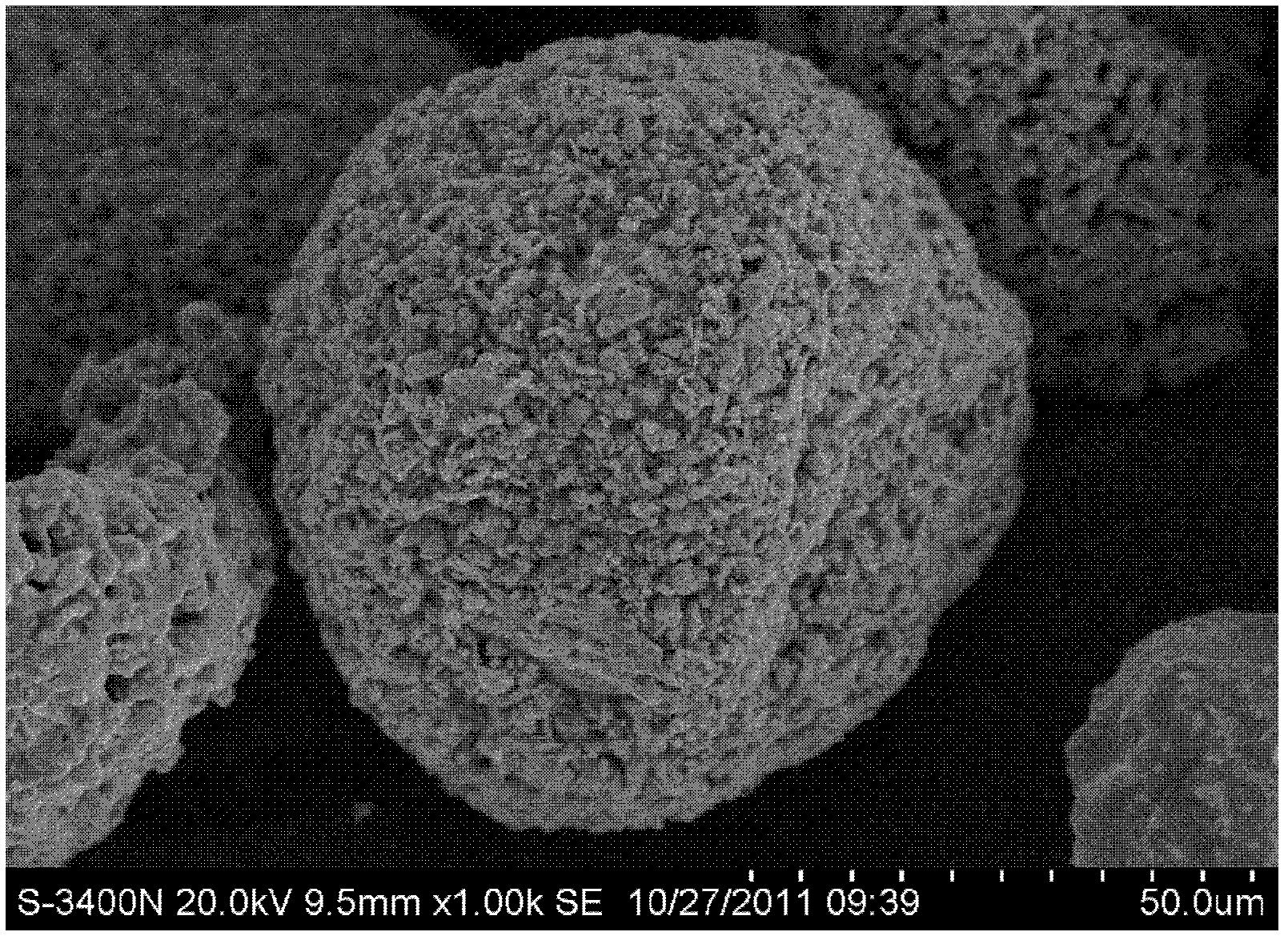

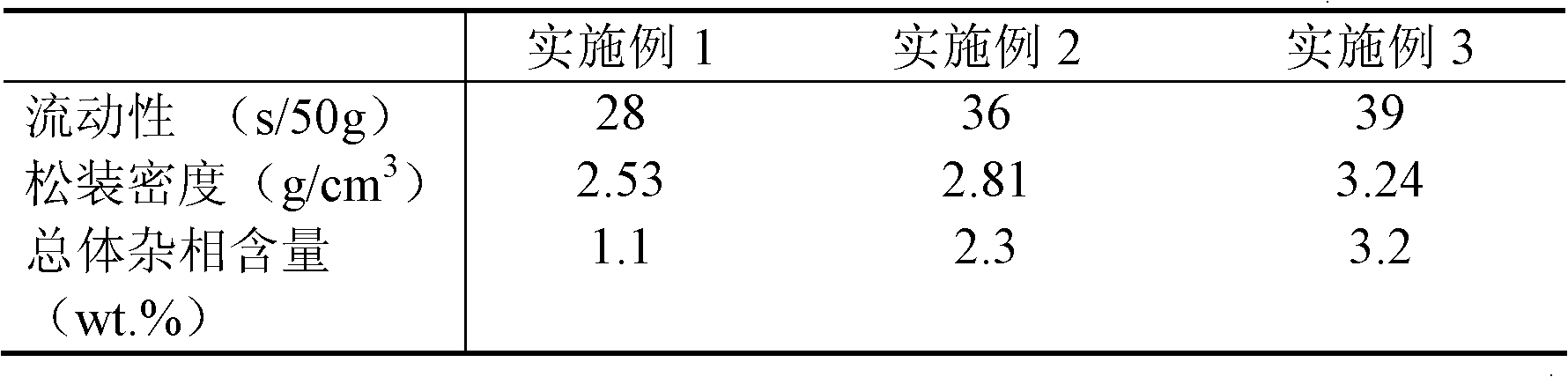

[0025] Take TiB with a particle size of 1 to 3 microns 2 Add 128.1g of powder, 25.6g of NiCr powder with a particle size of 20 to 30 microns and 46.3g of Mo powder with a particle size of 1 to 2 microns into the ball mill tank, then add 250g of absolute ethanol for mixed ball milling for 15 hours, and put the wet-milled powder at 60°C Dry, sieve and disperse, add the mixed powder less than 3 microns into 300g deionized water, stir well and heat it with an electric furnace, add 0.4g ammonium citrate and 0.7g polyethylene glycol after heating to 80°C, and then keep At 80°C, continue stirring for 10 minutes, then add the dissolved PVA solution with a content of 3.2g, and finally adjust the pH value to 9.5 while maintaining the temperature at 80°C, and continue stirring for 60 minutes to obtain a TiB-containing solution. 2 Metal-ceramic composite powder slurry. If bubbles are generated, add n-butanol defoamer dropwise. After the slurry is prepared, the slurry is spray-dried and ...

Embodiment 2

[0028] Take TiB with a particle size of 1 to 3 microns 2Add 108.1g of powder, 35.6g of NiCr powder with a particle size of 20 to 30 microns and 56.3g of Mo powder with a particle size of 1 to 2 microns into the ball mill tank, then add 250g of absolute ethanol for mixed ball milling for 13 hours, and put the wet-milled powder at 60°C Dry, sieve and disperse, add the mixed powder less than 3 microns into 250g deionized water, stir well and heat with electric furnace, after heating to 80°C, add 0.2g ammonium citrate, 0.3g ammonium polyacrylate and 1g polyethylene glycol, Then, at a temperature of 75°C, continue stirring for 10 minutes, then add an aqueous solution with a dissolved PVA content of 2.6 g, and finally, at a temperature of 75°C, adjust the pH value to 10.3 and continue stirring for 60 minutes to obtain a TiB-containing solution. 2 Metal-ceramic composite powder slurry. If bubbles are generated, add n-butanol defoamer dropwise. After the slurry is prepared, the slur...

Embodiment 3

[0031] Take TiB with a particle size of 1 to 3 microns 2 Add 88.1g of powder, 45.6g of NiCr powder with a particle size of 20 to 30 microns and 66.3g of Mo powder with a particle size of 1 to 2 microns into the ball mill tank, then add 250g of absolute ethanol for mixed ball milling for 11 hours, and put the wet-milled powder at 60°C Dry, sieve and disperse, add the mixed powder less than 3 microns into 200g deionized water, stir well and heat it with an electric furnace, add 0.4g ammonium polyacrylate and 0.8g polyethylene glycol after heating to 80°C, and then keep At 85°C, continue stirring for 10 minutes, then add the dissolved PVA solution with a content of 2.2g, and finally adjust the pH value to 8.6 while maintaining the temperature at 85°C, and continue stirring for 60 minutes to obtain a TiB-containing solution. 2 Metal-ceramic composite powder slurry. If bubbles are generated, add n-butanol defoamer dropwise. After the slurry is prepared, the slurry is spray-dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com